Toro 71140, 71180, 71181, 71182, 71184 Service Manual

...

TORO XL LAWN TRACTOR SERVICE MANUAL

Table of Contents – Page 1 of 3

SPECIFICATIONS

DIMENSIONS

HYDRO-GEAR HYDROSTATIC TRANSAXLE USAGE

TURNING RADIUS

ELECTRICAL SYSTEM

TECUMSEH PEERLESS TRANSAXLES

1993 - 1995

1996 - PRESENT

TORQUE SPECIFICATIONS

FASTENER IDENTIFICATION

STANDARD TORQUE FOR DRY, ZINC PLATED, AND STEEL FASTENERS (INCH SERIES)

STANDARD TORQUE FOR DRY, ZINC, AND STEEL FASTENERS (METRIC FASTENERS)

OTHER TORQUE SPECIFICATIONS

SAE GRADE 8 STEEL SET SCREWS

THREAD CUTTING SCREWS (ZINC PLATED STEEL)

CONVERSION FACTORS

WHEEL BOLTS AND LUG NUTS

THREAD CUTTING SCREWS (ZINC PLATED STEEL)

EQUIVALENTS AND CONVERSIONS

DECIMAL AND MILLIMETER EQUIVALENTS

U.S. TO METRIC CONVERSIONS

XL GEAR DRIVE

XL GEAR DRIVE TRANSAXLE REMOVAL - 915 TRANSAXLE

XL GEAR DRIVE TRANSAXLE INSTALLATION - 915 TRANSAXLE

XL GEAR DRIVE TRACTION DRIVE BELT REPLACEMENT PROCEDURE - 915 TRANSAXLE

XL GEAR DRIVE SHIFT LEVER ADJUSTMENT - 915 TRANSAXLE

XL GEAR DRIVE BRAKE ADJUST MENT -915 TRANSAXLE

XL GEAR DRIVE MST-205 TRANSAXLE REMOVAL

XL GEAR DRIVE MST-205 TRANSAXLE INSTALLATION

XL GEAR DRIVE SHIFT LEVER ADJUSTMENTS, MST-205 TRANSAXLE

XL GEAR DRIVE BRAKE ADJUST MENT, MST-205 TRANSAXLE

CHECKING THE BRAK E

ADJUSTING THE BRAKE

XL GEAR DRIVE TRACTION DRIVE BELT REPLACEMENT PROCEDURE, MST-205 TRANSAXLE

CABLE ADJUSTMENT, SHIFT-ON-THE-GO, 915 AND MST-205 TRANSAXLE

XL HYDROSTATIC TRANSAXLES

IDENTIFICATION

HYDRO-GEAR 0500/0750 TRANSAXLE

HYDRO-GEAR 0510 TRANSAXLE

INTERNAL SERVICE

TROUBLESHOOTING CHART

PURGING PROCEDURES

FLUID CHANGE

HXL HYDRO TRANSAXLE REMOVAL - 2000 AND PRIOR

NEUTRAL ADJUSTMENT - HXL HYDRO- 2000 AND PRIOR

BRAKE ADJUSTMENT - HXL HYDRO - 2000 AND PRIOR

TRACTION DRIVE BELT REPLACEMENT ON HXL HYDRO - 2000 AND PRIOR

HXL HYDRO TRANSAXLE REMOVAL - 2001 AND LATER

HXL HYDRO TRANSAXLE INSTALLATION - 2001 AND LATER

TORO XL LAWN TRACTOR SERVICE MANUAL

Table of Contents – Page 2 of 3

XL HYDROSTATIC TRANSAXLES -CONTINUED

NEUTRAL ADJUSTMENT - HXL HYDRO - 2001 AND LATER

BRAKE ADJUSTMENT - HXL HYDRO - 2001 AND LATER

TRACTION DRIVE BELT REPLACEMENT - HXL HYDRO - 2001 AND LATER

CHASSIS

FRONT AXLE REMOVAL

UPPER STEERING SHAFT REMOVAL (NO TILT STEERING)

STEERING RACK REMOVAL

STEERING ASSEMBL Y

TILT STEERING

STEERING SHAFT REMOVAL (TILT STEERING)

STEERING TOWER REMOVAL

STEERING TOWER INSTALLATION

REAR BODY/FENDER ASSEMBLY REMOVAL

INSTALLATION OF THE REAR BODY

ELECTRICAL SYSTEM

RELAY

PURPOSE

LOCATION

HOW IT WORKS

TESTING

SOLENOID

PURPOSE

HOW IT WORKS

TESTING

LOCATION

NEUTRAL SWITCH (USED ON 1999 AND PRIOR LAW N TRACTORS)

PURPOSE

LOCATION

HOW IT WORKS

TESTING

PTO SWITCH

PURPOSE

LOCATION

HOW IT WORKS

TESTING

NEUTRAL SWITCH (USED ON 2000 AND LATER LAWN TRACTORS)

PURPOSE

LOCATION

HOW IT WORKS

TESTING

SEAT SWITCH

PURPOSE

LOCATION

HOW IT WORKS

TEST

KEYCHOICE™ REVERSE OPERATING SYSTEM – USED ON 1999 AND LATER XL LAWN TRACTORS

TESTING THE KEY CHOICE™ REVERSE OPERATING SYSTEM

CHECKING THE KEYCHOICE™ SYSTEM

TORO XL LAWN TRACTOR SERVICE MANUAL

Table of Contents – Page 3 of 3

ELECTRICAL SYSTEM - CONTINUED

KEYCHOICE™ REVERSE OPERATING SYSTEM SWITCH

PURPOSE

HOW IT WORKS

TESTING

REVERSE SWITCH

PURPOSE

LOCATION

HOW IT WORKS

TESTING

KEYCHOICE™ REVERSE OPERATING SYSTEM MODULE

PURPOSE

LOCATION

HOW IT WORKS

TESTING

MOWER

32" MOWER

REMOVING 32" MOWER

INSTALLING 32" MOW ER

BLADE DRIVE BELT

REMOVING THE BLADE DRIVE BELT

INSTALLING THE BLADE DRIVE BELT

SIDE-TO-SIDE MOWER LEVELING

FRONT-TO-REAR BLA DE SLOPE

38" MOWER

REMOVING 38" MOWER

INSTALLING 38" MOW ER

BLADE DRIVE BELT

REMOVING THE BLADE DRIVE BELT

INSTALLING THE BLADE DRIVE BELT

SIDE-TO-SIDE MOWER LEVELING

FRONT-TO-REAR BLA DE SLOPE

44" MOWER

REMOVING 44" MOWER

INSTALLING 44" MOW ER

INSTALLING 44" RECYCLER BAFFLE

REMOVING 44" RECYCLER BAFFLE

BLADE DRIVE BELT

REMOVING THE BLADE DRIVE BELT

INSTALLING THE BLADE DRIVE BELT

ADJUSTING BLADE BRAKES

SIDE-TO-SIDE MOWER LEVELING

FRONT-TO-REAR BLA DE SLOPE

XL Lawn Tractor

PREFACE

This service manual was written expressly for Toro service technicians. The Toro Company has made every effort

to make the information in this manual complete and correct.

Basic mechanical/electrical skills are assumed. The Table of Contents lists the systems and the related topics

covered in this manual.

For additional information on the electrical system, please refer to the Toro Electrical Demystification Guide (492-

4404). For information specific to the engines used on this unit, refer to the appropriate engine manufacturer’s

service and repair instructions.

We are hopeful that you will find this manual a valuable addition to your service shop. If you have any questions or

comments regarding this manual, please contact us at the following address:

The Toro Company

Consumer Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

The Toro Company reserves the right to change product specifications or this manual without notice.

The hydrostatic transaxle is a sophisticated piece of machinery. Maintain strict cleanliness control during all stages

of service and repair. Cover or cap all hose ends and fittings whenever they are exposed. Even a small amount of

dirt or other contamination can severely damage the system.

Copyright© All Rights Reserved

©2001 The Toro Company

TABLE OF CONTENTS

SPECIFICATIONS

Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydro-Gear Hydrostatic Transaxle Usage . . . . . . . . . . . . . . . . . . . . . . . . .

Turning Radius . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tecumseh Peerless Transaxles . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1993 - 1995 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1996 - Present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Identifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series) . . . . . . . . . . . . .

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners) . . . . . . . . . . . . . .

Other Torque Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAE Grade 8 Steel Set Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thread Cutting Screws (Zinc Plated Steel) . . . . . . . . . . . . . . . . . . . . . . .

Wheel Bolts and Lug Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thread Cutting Screws (Zinc Plated Steel) . . . . . . . . . . . . . . . . . . . . . . .

Equivalents and Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decimal and Millimeter Equivalents . . . . . . . . . . . . . . . . . . . . . . . . . .

U.S. to Metric Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-1

1-1

1-2

1-2

1-2

1-2

1-2

1-3

1-3

1-4

1-5

1-6

1-6

1-6

1-6

1-6

1-7

1-7

1-7

XL GEAR DRIVE

XL Gear Drive Transaxle Removal - 915 Transaxle . . . . . . . . . . . . . . . . . . . . .

XL Gear Drive Transaxle Installation - 915 Transaxle . . . . . . . . . . . . . . . . . . . . .

XL Gear Drive Traction Drive Belt Replacement Procedure - 915 Transaxle . . . . . . . . . . . .

XL Gear Drive Shift Lever Adjustment - 915 Transaxle . . . . . . . . . . . . . . . . . . . .

XL Gear Drive Brake Adjustment - 915 Transaxle . . . . . . . . . . . . . . . . . . . . . .

XL Gear Drive MST-205 Transaxle Removal . . . . . . . . . . . . . . . . . . . . . . . .

XL Gear Drive MST-205 Transaxle Installation . . . . . . . . . . . . . . . . . . . . . . .

XL Gear Drive Shift Lever Adjustment, MST-205 Transaxle . . . . . . . . . . . . . . . . . .

XL Gear Drive Brake Adjustment, MST-205 Transaxle . . . . . . . . . . . . . . . . . . . .

Checking the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XL Gear Drive Traction Drive Belt Replacement Procedure, MST-205 Transaxle . . . . . . . . . .

Cable Adjustment, Shift-On-The-Go, 915 and MST-205 Transaxle . . . . . . . . . . . . . . . .

XL HYDROSTATIC TRANSAXLES

Identifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydro-Gear 0500/0750 Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydro-Gear 0510 Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purging Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-4

2-6

2-9

2-11

2-12

2-13

2-14

2-15

2-15

2-15

2-16

2-19

3-1

3-1

3-1

3-2

3-2

3-3

3-3

iXL Lawn Tractor Service Manual

TABLE OF CONTENTS

XL HYDROSTATIC TRANSAXLES cont.

HXL Hydro Transaxle Removal - 2000 and Prior . . . . . . . . . . . . . . . . . . . . . .

Neutral Adjustmnet - HXL Hydro - 2000 and Prior . . . . . . . . . . . . . . . . . . . . . .

Brake Adjustment - HXL Hydro - 2000 and Prior . . . . . . . . . . . . . . . . . . . . . .

Traction Drive Belt Replacement on HXL Hydro - 2000 and Prior . . . . . . . . . . . . . . . .

HXL Hydro Transaxle Removal - 2001 and Later . . . . . . . . . . . . . . . . . . . . . .

HXL Hydro Transaxle Installation - 2001 and Later . . . . . . . . . . . . . . . . . . . . . .

Neutral Adjustment - HXL Hydro - 2001 and Later . . . . . . . . . . . . . . . . . . . . . .

Brake Adjustment - HXL Hydro - 2001 and Later . . . . . . . . . . . . . . . . . . . . . . .

Traction Drive Belt Replacement - HXL Hydro - 2001 and Later . . . . . . . . . . . . . . . . .

CHASSIS

Front Axle Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper Steering Shaft Removal (No Tilt Steering) . . . . . . . . . . . . . . . . . . . . . .

Steering Rack Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tilt Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Shaft Removal (Tilt Steering) . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Tower Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Tower Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Body/Fender Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation of the Rear Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric PTO Clutch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric PTO Clutch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3

3-10

3-11

3-13

3-16

3-18

3-20

3-21

3-22

4-1

4-1

4-1

4-2

4-3

4-4

4-4

4-5

4-6

4-8

A4-1

A4-2

ELECTRICAL SYSTEM

Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Neutral Switch (Used on 1999 and Prior Lawn Tractors) . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTO Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1

5-1

5-1

5-1

5-2

5-2

5-2

5-3

5-3

5-3

5-4

5-4

5-4

5-4

5-4

5-4

5-4

5-5

5-5

5-5

ii XL Lawn Tractor Service Manual

TABLE OF CONTENTS

ELECTRICAL SYSTEM cont.

Neutral Switch (Used on 2000 and Later Lawn Tractors) . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seat Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KeyChoice™ Reverse Operating System - Used on 1999 and Later XL Lawn Tractors . . . . . . . .

Testing The KeyChoice™ Reverse Operating System . . . . . . . . . . . . . . . . . . . .

Checking the KeyChoice™ System . . . . . . . . . . . . . . . . . . . . . . . . . .

KeyChoice™ Reverse Operating System Switch . . . . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reverse Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KeyChoice™ Reverse Operating System Module . . . . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric PTO Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric PTO Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coil Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Clutch Current Draw . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5

5-5

5-5

5-6

5-6

5-6

5-6

5-6

5-6

5-6

5-7

5-7

5-7

5-8

5-8

5-8

5-8

5-8

5-8

5-9

5-9

5-9

5-9

5-9

5-10

5-10

5-10

A5-1

A5-1

A5-1

A5-1

A5-1

A5-2

A5-2

A5-2

A5-2

A5-2

A5-2

A5-3

MOWER

32” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing 32” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing 32” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side-to-Side Mower Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front-to-Rear Blade Slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

6-1

6-2

6-4

6-4

6-4

6-5

6-5

iiiXL Lawn Tractor Service Manual

TABLE OF CONTENTS

MOWER cont.

38” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing 38” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing 38” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side-to-Side Mower Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front-to-Rear Blade Slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing 44” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing 44” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing 44” Recycler Baffl e . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing 44” Recycler Baffl e . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Blade Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side-to-Side Mower Levleing . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front-to-Rear Blade Slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32” Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32” Mower Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38” Mower with Manual PTO Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . .

38” Mower Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44” Mower with Manual PTO Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . .

44” Mower Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38” Mower with Electric PTO Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing 38” Mower with Electric PTO Clutch . . . . . . . . . . . . . . . . . . . . .

Installing 38” Mower with Electric PTO Clutch . . . . . . . . . . . . . . . . . . . . . .

Replacing the Blade Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Blade Drive Belt, 38” Mower with Electric PTO Clutch . . . . . . . . . . . . .

Installing the Blade Drive Belt, 38” Mower with Electric PTO Clutch . . . . . . . . . . . . . .

Leveling 38” Mower from Side-to-Side . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting 38” Mower Front-to-Rear Blade Slope . . . . . . . . . . . . . . . . . . . . . . .

44” Mower with Electric PTO Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing 44” Mower with Electric PTO Clutch . . . . . . . . . . . . . . . . . . . . .

Installing 44” Mower with Electric PTO Clutch . . . . . . . . . . . . . . . . . . . . . .

Replacing the Blade Drive Belt, 44” Mower with Electric PTO Clutch . . . . . . . . . . . . . . .

Removing the Blade Drive Belt, 44” Mower with Electric PTO Clutch . . . . . . . . . . . . .

Installing the Blade Drive Belt, 44” Mower with Electric PTO Clutch . . . . . . . . . . . . . .

Leveling 44” Mower from Side-to-Side . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting 44” Mower Front-to-Rear Blade Slope . . . . . . . . . . . . . . . . . . . . . . .

6-7

6-7

6-10

6-12

6-12

6-12

6-12

6-13

6-15

6-15

6-17

6-20

6-21

6-21

6-21

6-21

6-22

6-22

6-23

A6-1

A6-1

A6-1

A6-1

A6-2

A6-2

A6-2

A6-2

A6-4

A6-7

A6-7

A6-7

A6-7

A6-9

A6-10

A6-10

A6-12

A6-15

A6-15

A6-16

A6-16

A6-17

iv XL Lawn Tractor Service Manual

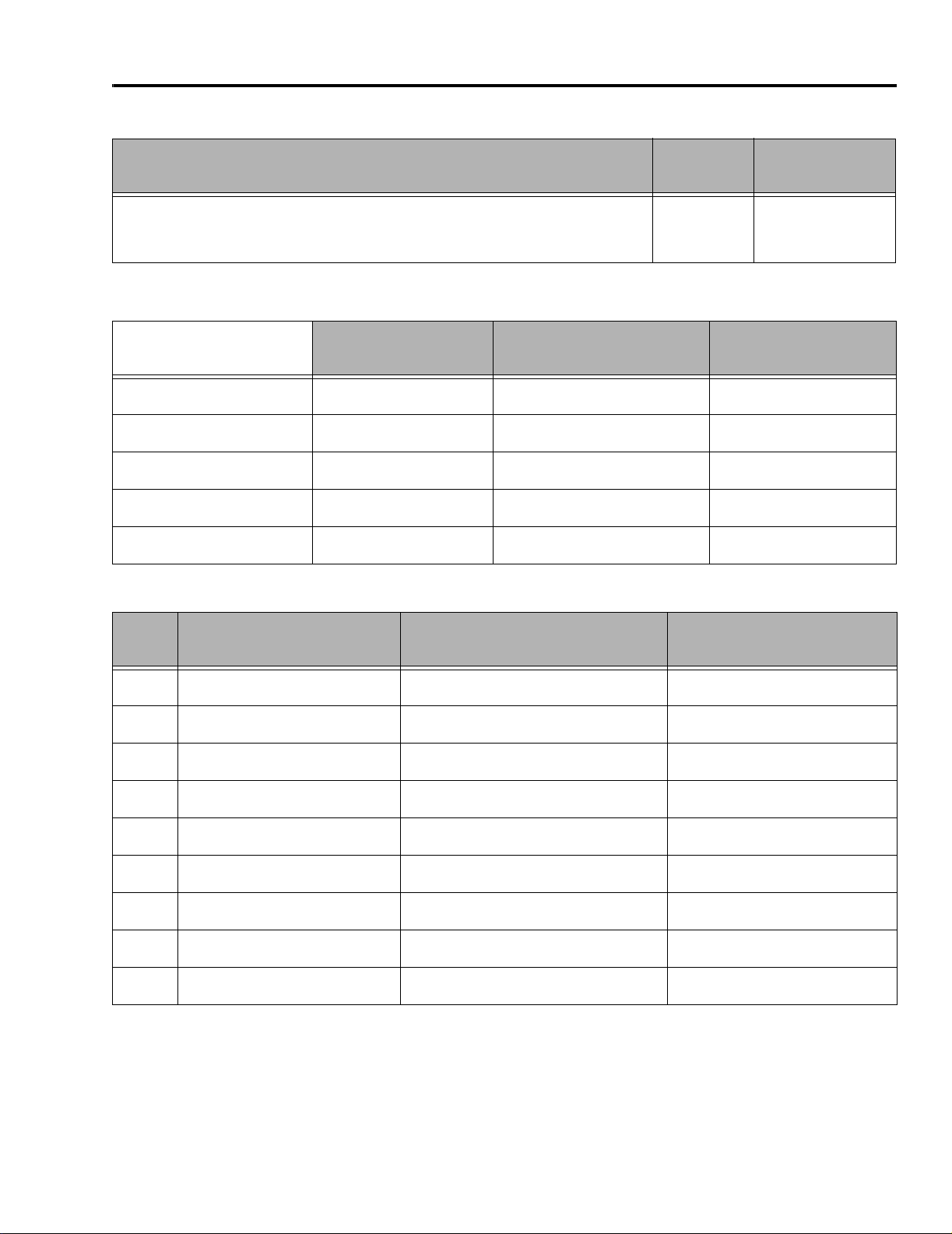

Specifications

SPECIFICATIONS

Engines

All tractors since 1993 were manufactured with Briggs & Stratton engines

ranging from 10 to 17 Horsepower. For more information on servicing the

engines, please contact Briggs & Stratton.

Dimensions

32” (81.3cm) XL

Lawn Tractors

Wheel Base:

Length:

Height:

Width (includes mower):

Weight:

48.5” (123.2cm) 47” (119.4cm) 47.5” (120.7cm)

66.5” (168.9cm) 66.5” (168.9cm) 68” (172.7cm)

39.3” (99.8cm) 40” (101.6cm) 42” (106.7cm)

39.3” (99.8cm) 45” (114.3cm) 55” (139.7cm)

375 lbs. Net (168.9kg) 412 lbs. Net (185.6kg) 468 lbs. Net (210.8kg)

Hydro-Gear Hydrostatic Transaxle

38” (96.5cm) XL and HXL

Lawn Tractors

Usage

Fuel

Capacity

7 qts (6.65l) Sector and Pinion

44” (111.8c m) HXL

Steering

Lawn Tractors

Year 12-38 XHL - 16-38 HXL

1993

1994

1995

1996

1997

1998

1999

2000

2001

316-0500

316-0500

321-0500 316-0750

323-0500 316-0750

323-0500 326-0750

323-0500 326-0750

323-0500 326-0750

323-0500 326-0750

15-44 XHL, 16-44HXL,

and 17-44 HXL

16-38 HXL and 17-44 HXL

318-0510

XL Lawn Tractor Service Manual 1 - 1

SPECIFICATIONS

Turning Radius

Model Turning Radius

32” (81.3cm) XL 21.5” (54.6cm) - Left

22” (55.8cm) - Right

38” (96.5cm) HXL and XL 20” (50.8cm) - Left

22” (55.8cm)- Right

44” (111.8cm) HXL 20” (50.8cm) - Left

22” (55.8cm) - Right

Electrical System

Engine Battery

3 amp unregulated / 80 watt A.C. Alternator 12 volt - 160 CCA

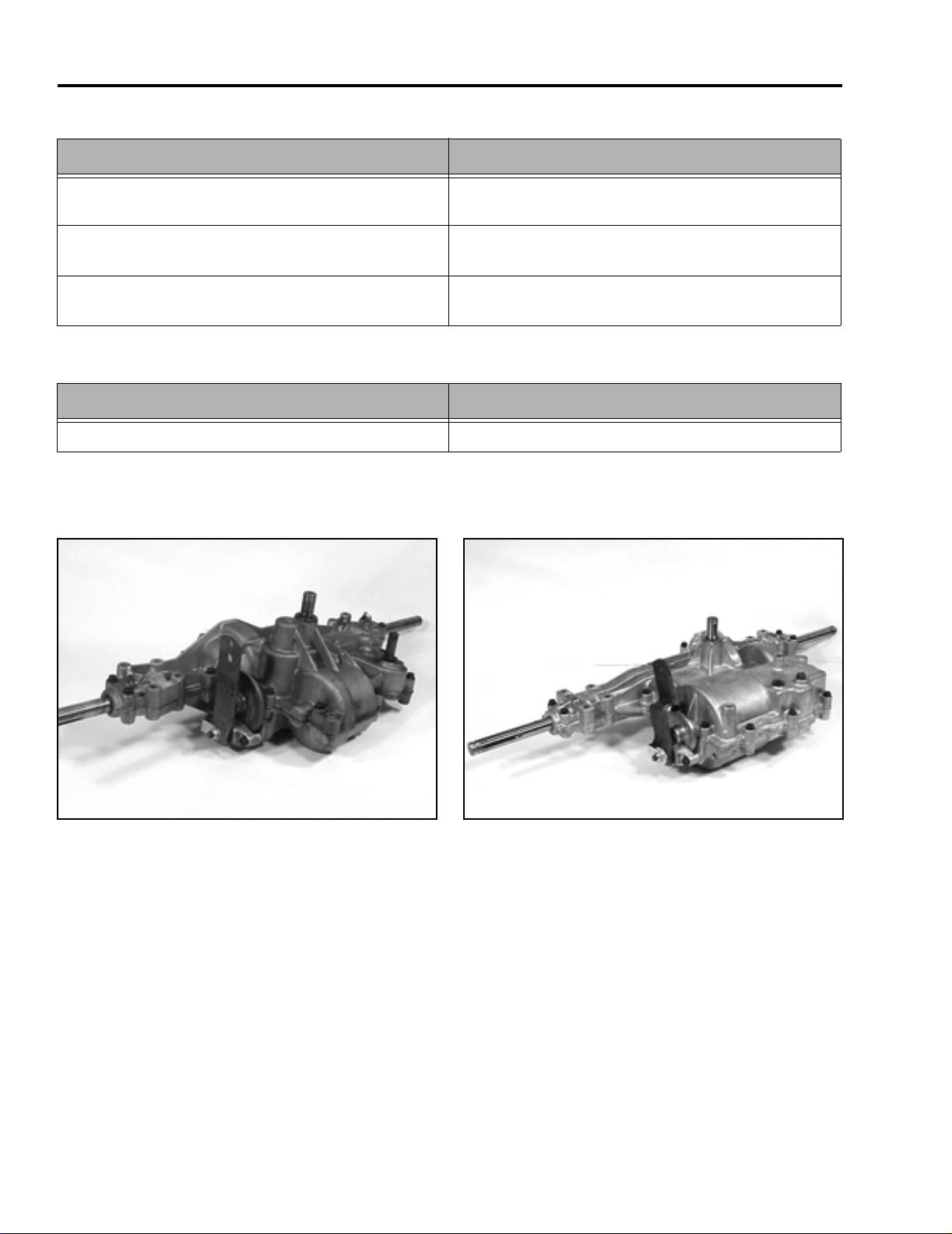

Tecumseh Peerless Transaxles

1993 - 1995

mvc-667

Tecumseh Peerless

Model: 915-020

Lubrication: Bentonite grease (available through

Tecumseh)

NOTE: Tractor may have been converted to current MST-205 transaxle.

Tecumseh Peerless

Model: MST-205

Lubrication: 80W90 gear lube

1996 - Present

mvc-668

For further information on servicing Peerless transaxles, contact Tecumseh Products.

1 - 2 XL Lawn Tractor Service Manual

SPECIFICATIONS

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as

determined by Toro, either the recommended torque or

a torque that is unique to the application is clearly

identified and specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific

torque value should be determined based on the

aluminum or brass material strength, fastener size,

length of thread engagement, etc.

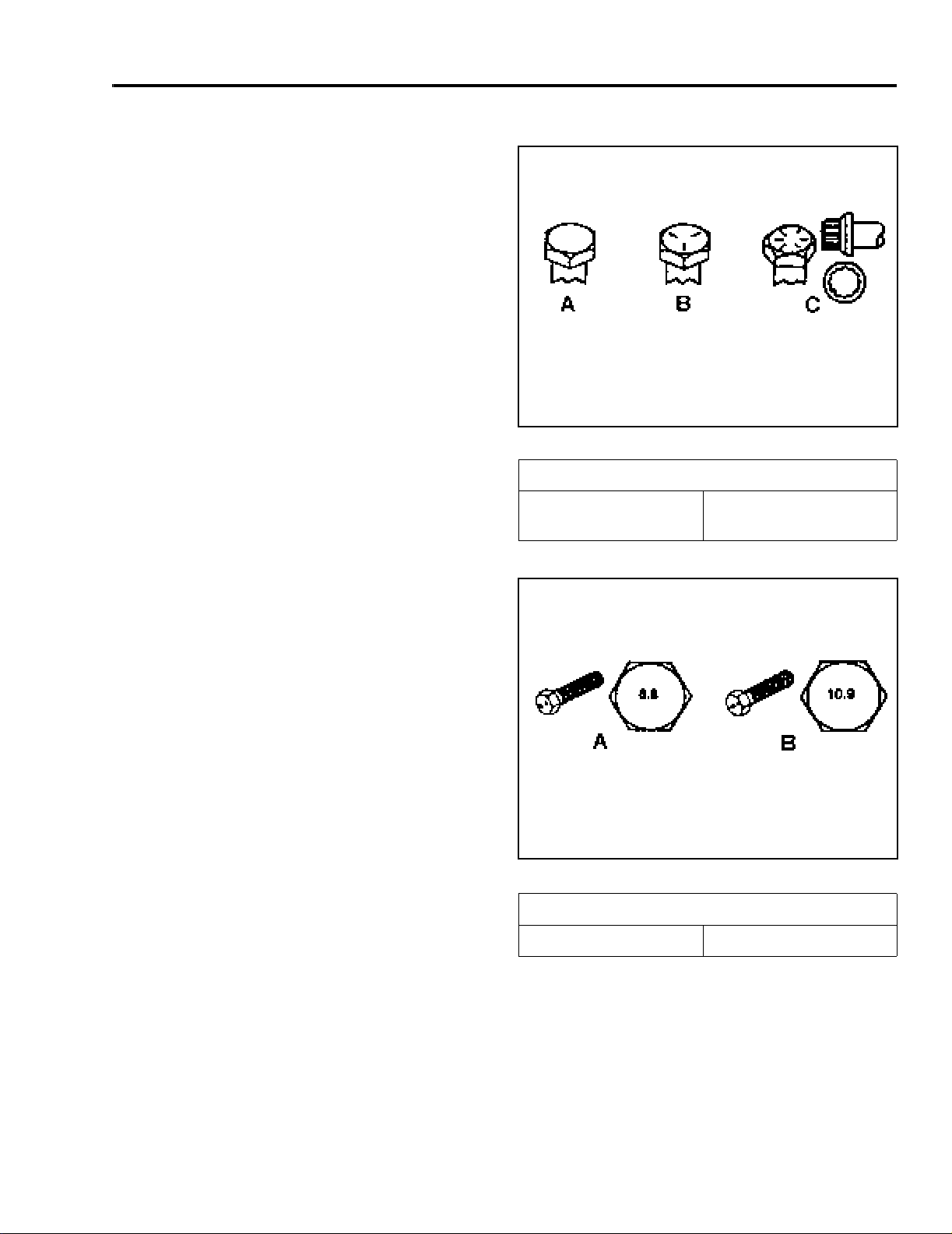

Fastener Identification

Inch Series Bolts and Screws

(A) Grade 1

(B) Grade 5

Figure 1

(C) Grade 8

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

Figure 2

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

XL Lawn Tractor Service Manual 1 - 3

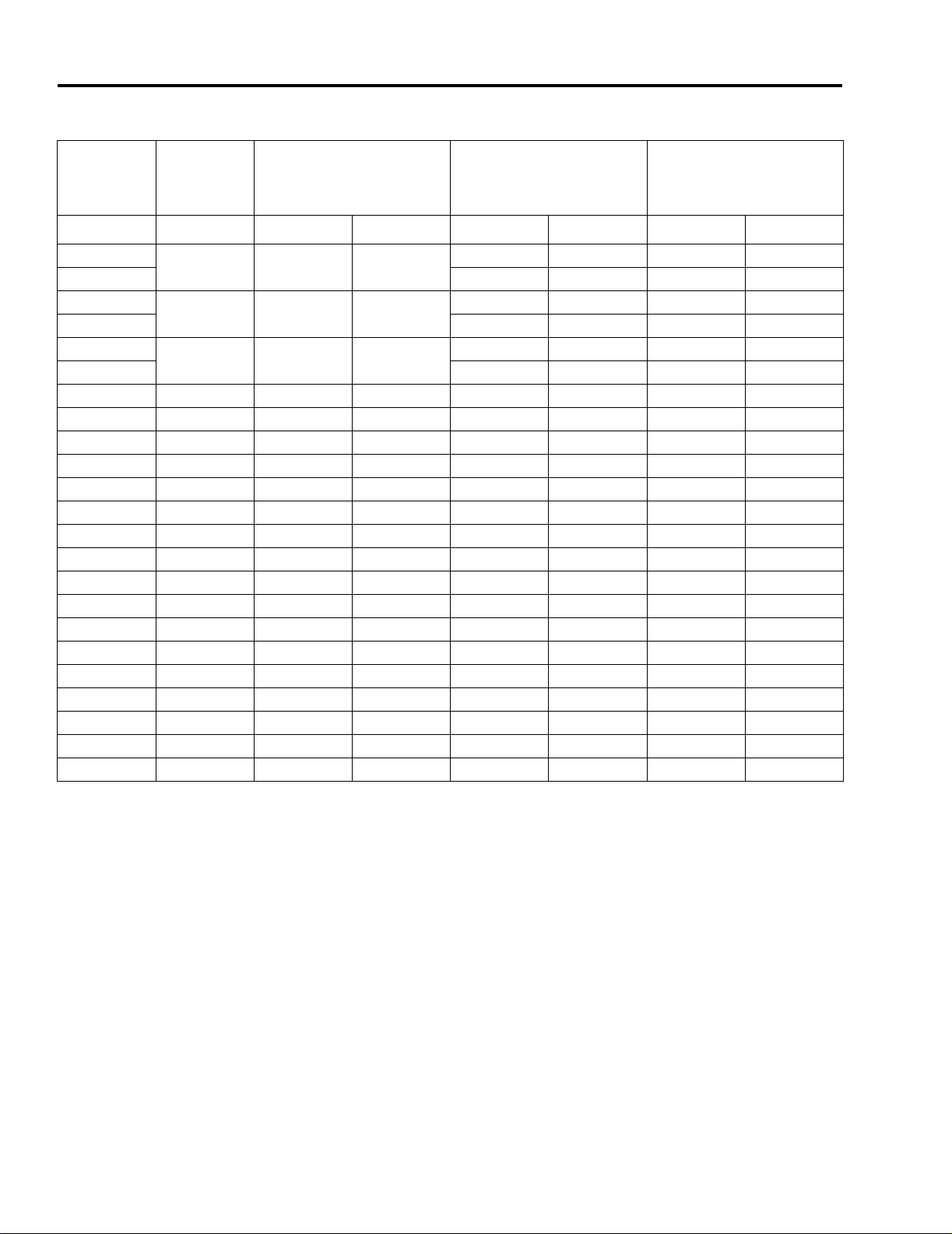

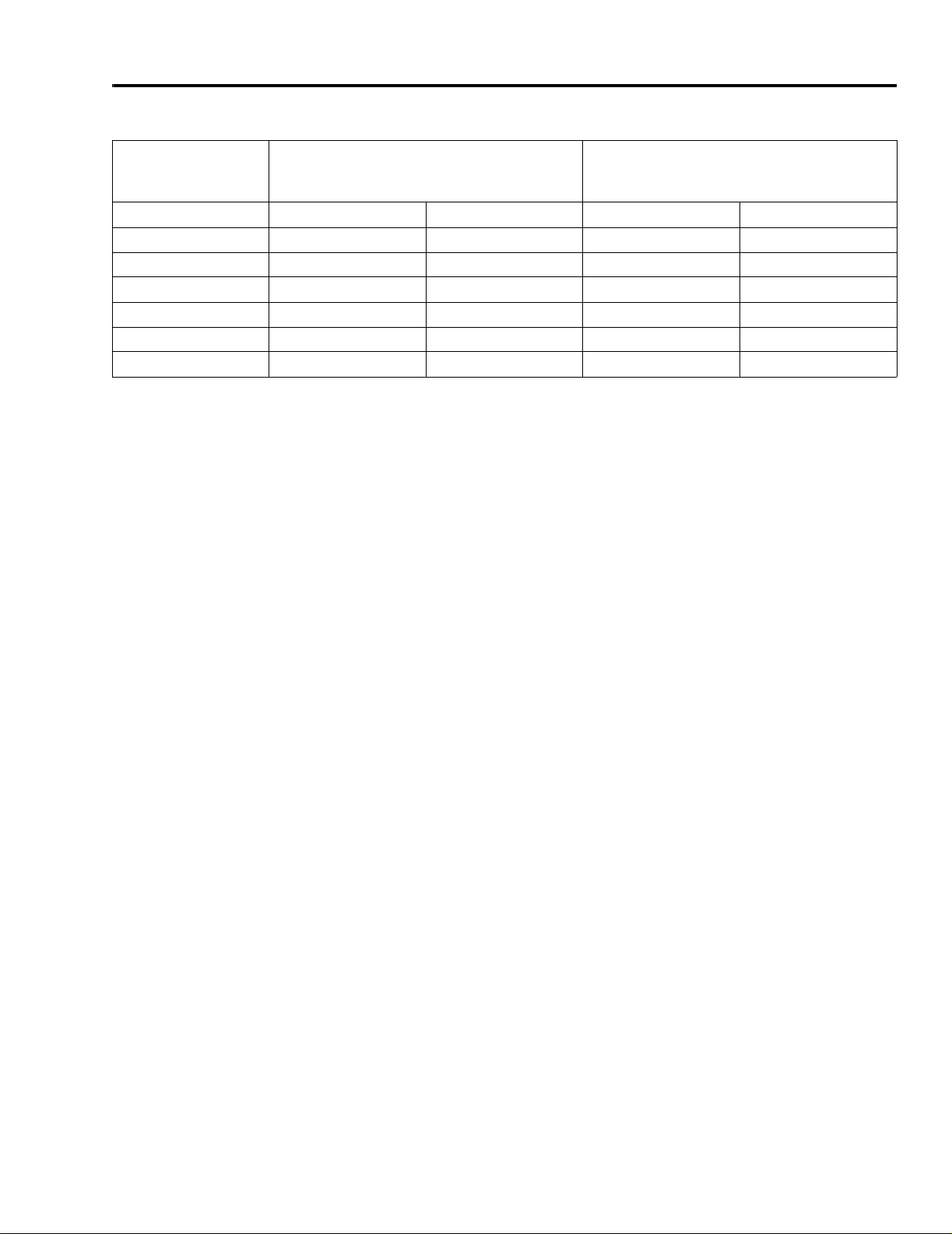

SPECIFICATIONS

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

Grade 1, 5, &

Thread Size

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 17 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995 Grade

2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995 Grade

2 or Stronger Nuts)

15 ± 2 170 ± 20 23 ± 2 260 ± 20

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995 Grade

2 or Stronger Nuts)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately

value. Thin height nuts include jam nuts.

± 10% of the nominal torque

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

1 - 4 XL Lawn Tractor Service Manual

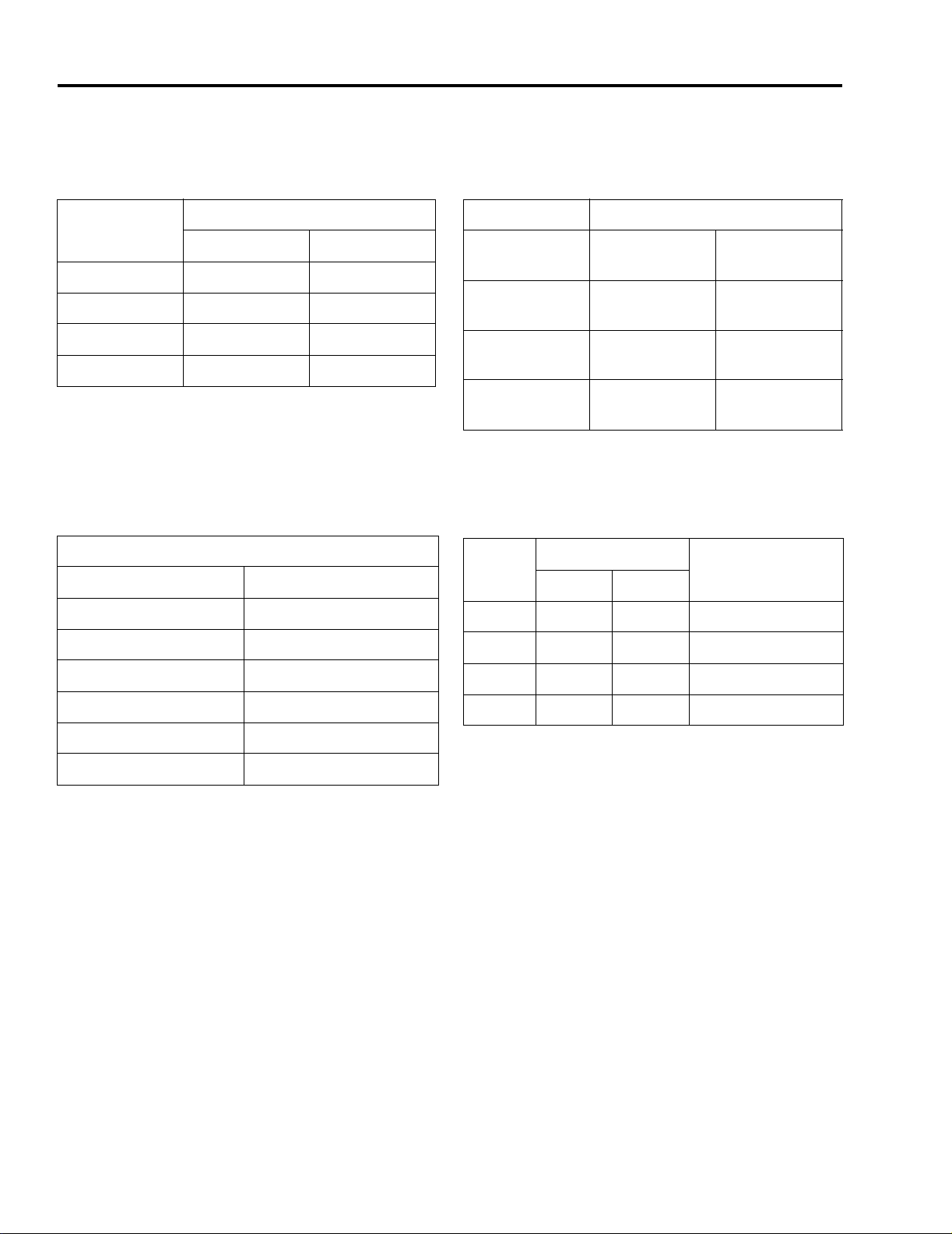

SPECIFICATIONS

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 640 ± 60 N-cm 78 ± 7 in-lb 885 ± 80 N-cm

M6 X 1.0 96 ± 9 in-lb 1018 ± 100 N-cm 133 ± 13 in-lb 1500 ± 150 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 27 ± 2 ft-lb 36 ± 3 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 53 ± 5 ft-lb 72 ± 7 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 92 ± 9 ft-lb 125 ± 12 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 20 N-m 229 ± 22 ft-lb 310 ± 30 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 37 ft-lb 610 ± 50 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately

the nominal torque value. Thin height nuts include jam nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

± 10% of

XL Lawn Tractor Service Manual 1 - 5

SPECIFICATIONS

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non-lubricated fasteners.

Thread

Size

No. 6 18 20 20 ± 5 in-lb

Threads per Inch

Type A Type B

65 ± 10 ft-lb 88 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

Thread Cutting Screws

(Zinc Plated Steel)

Baseline Torque*

No. 8 - 32 UNC 30 ± 5 in-lb

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Conversion Factors

in-lb X 11.2985 - N-cm

ft-lb X 1.3558 = N-m

No. 8 15 18 30 ± 5 in-lb

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on nonlubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 - ft-lb

1 - 6 XL Lawn Tractor Service Manual

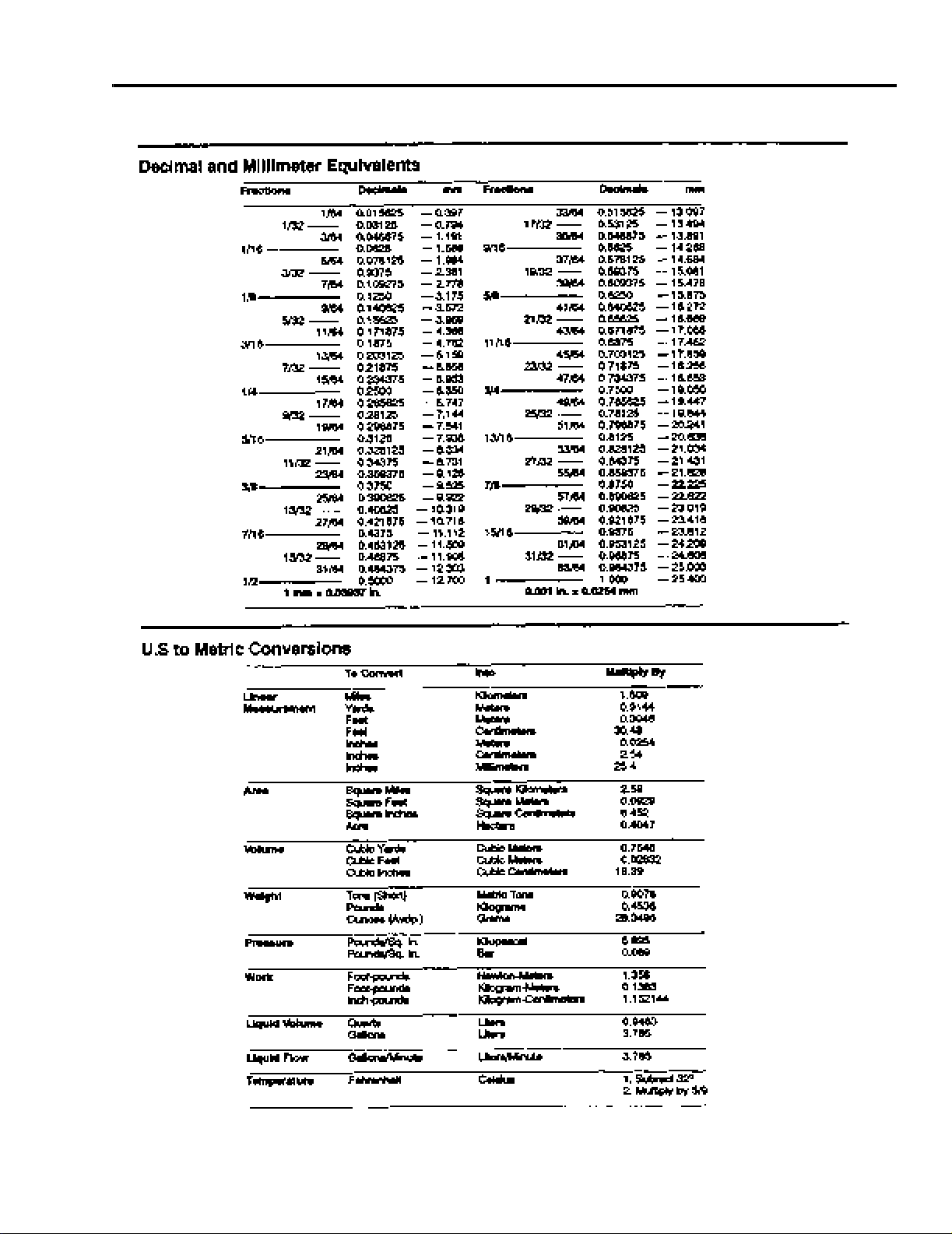

Equivalents and Conversions

SPECIFICATIONS

XL Lawn Tractor Service Manual 1 - 7

THIS PAGE INTENTIONALLY LEFT BLANK

1 - 8 XL Lawn Tractor Service Manual

XL GEAR DRIVE

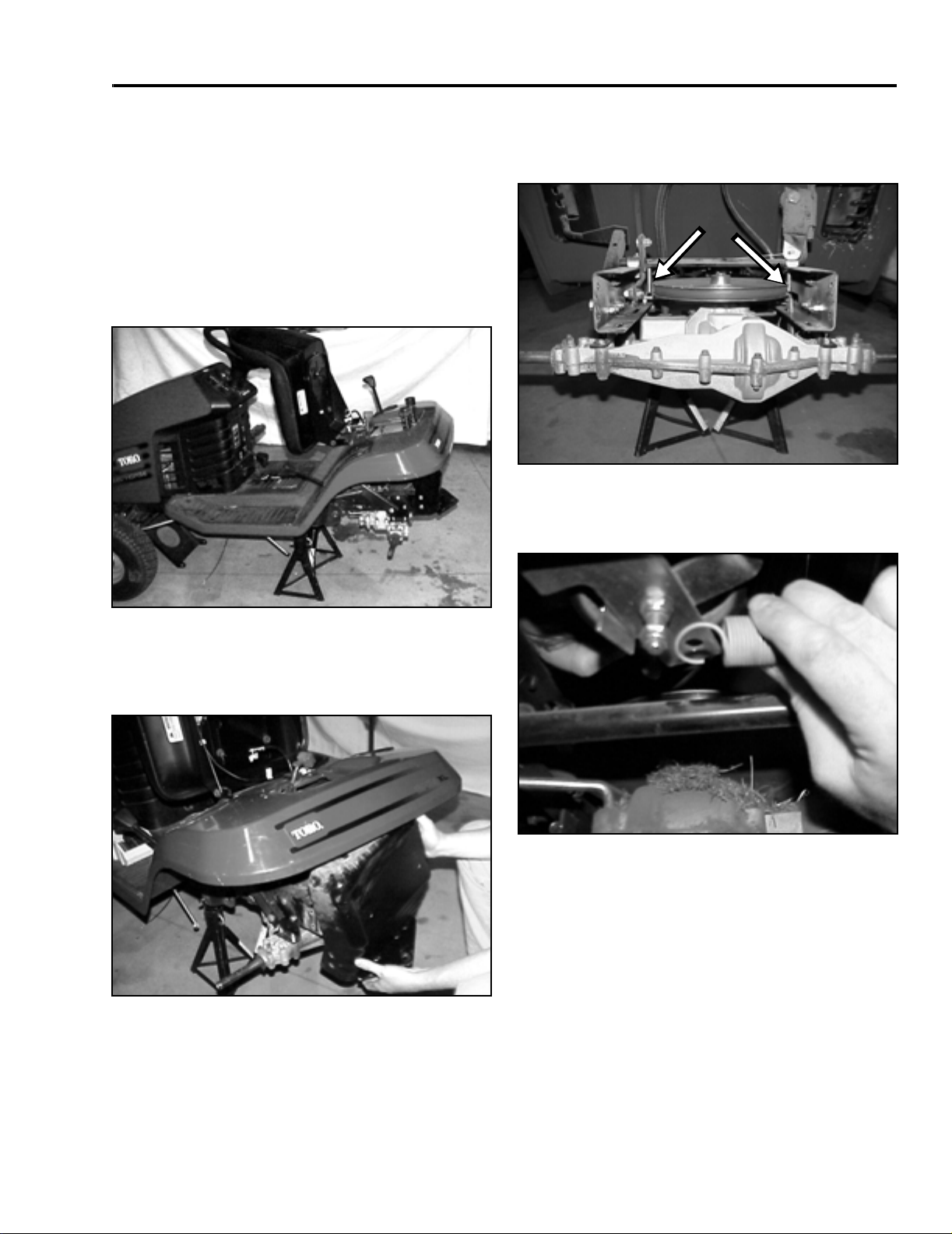

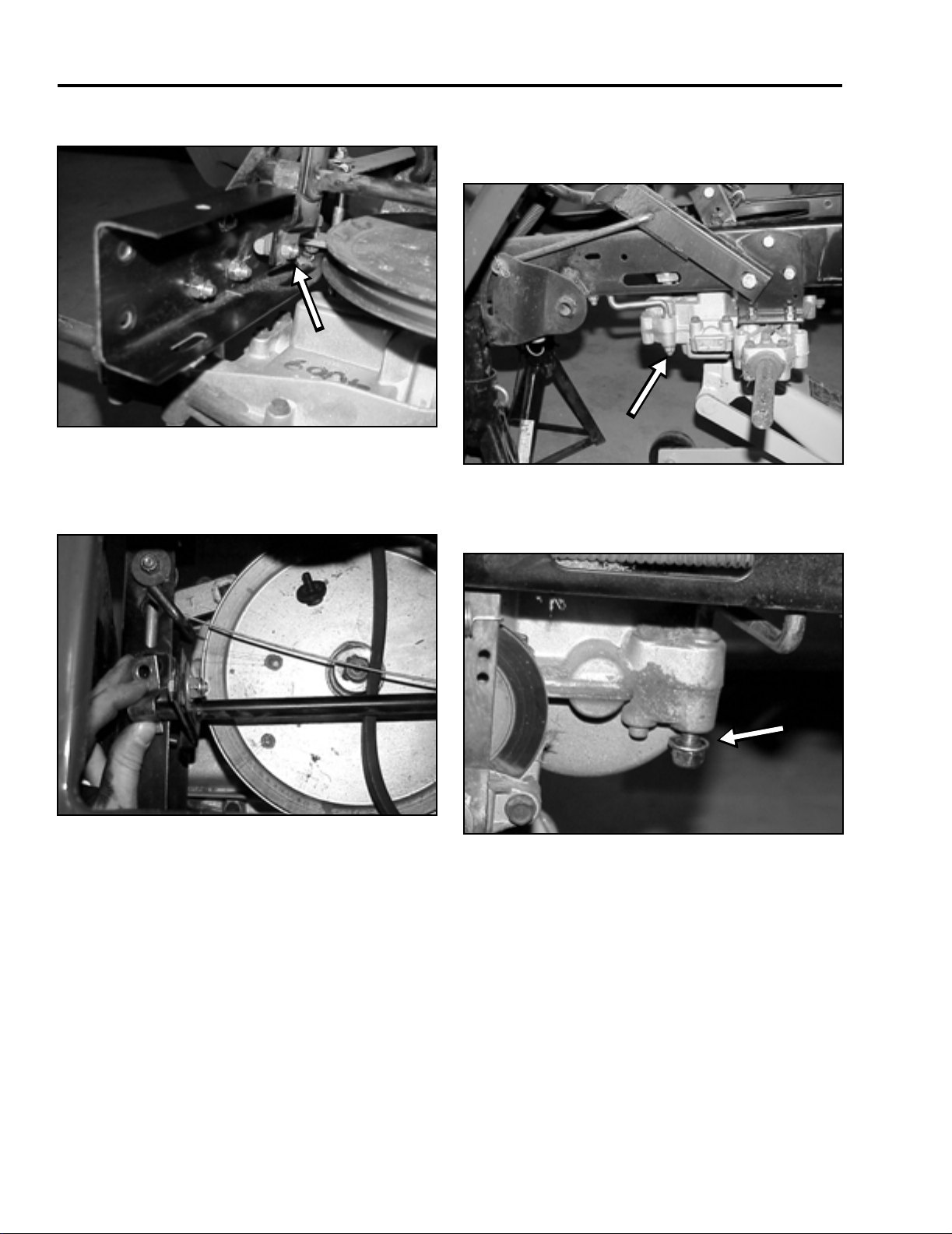

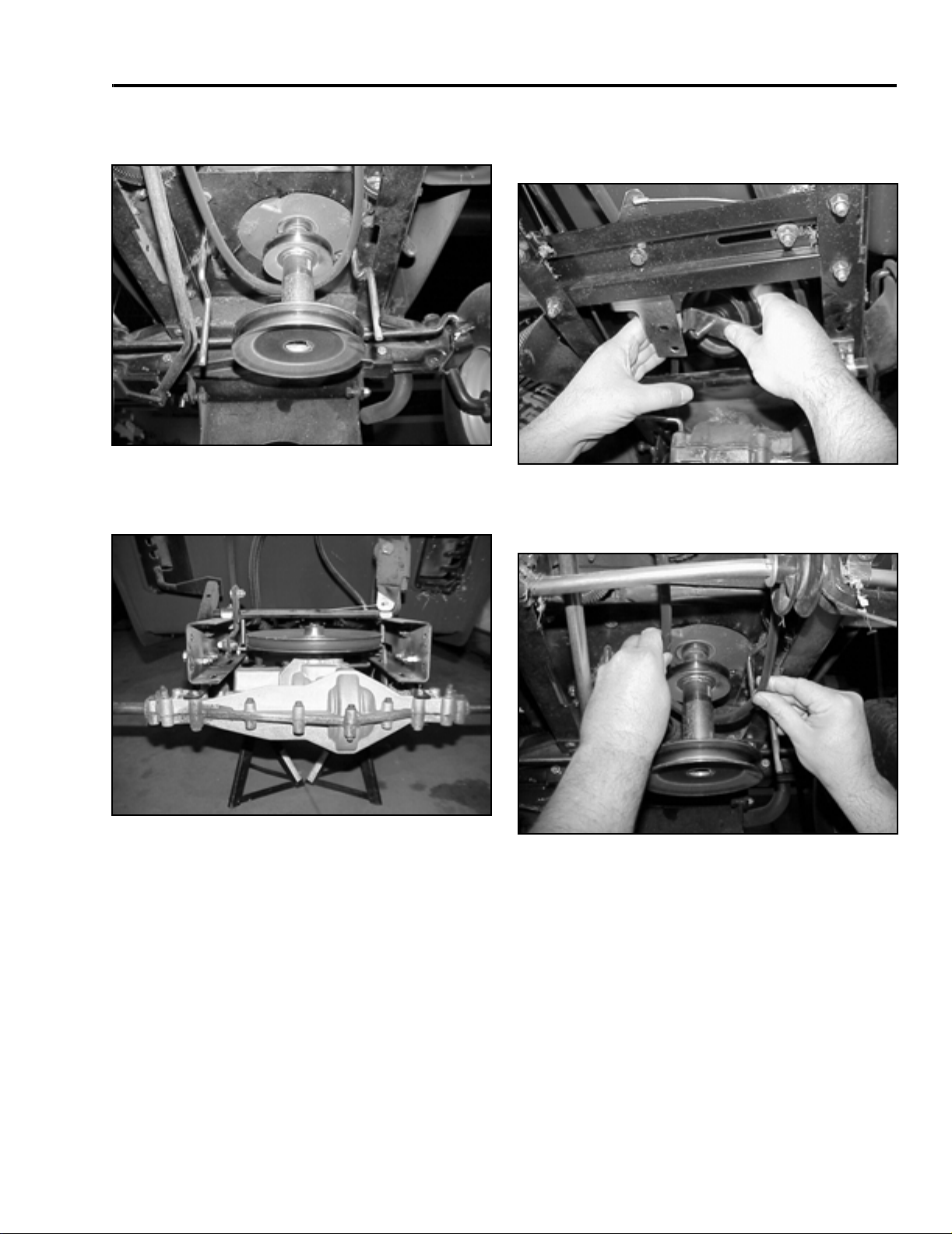

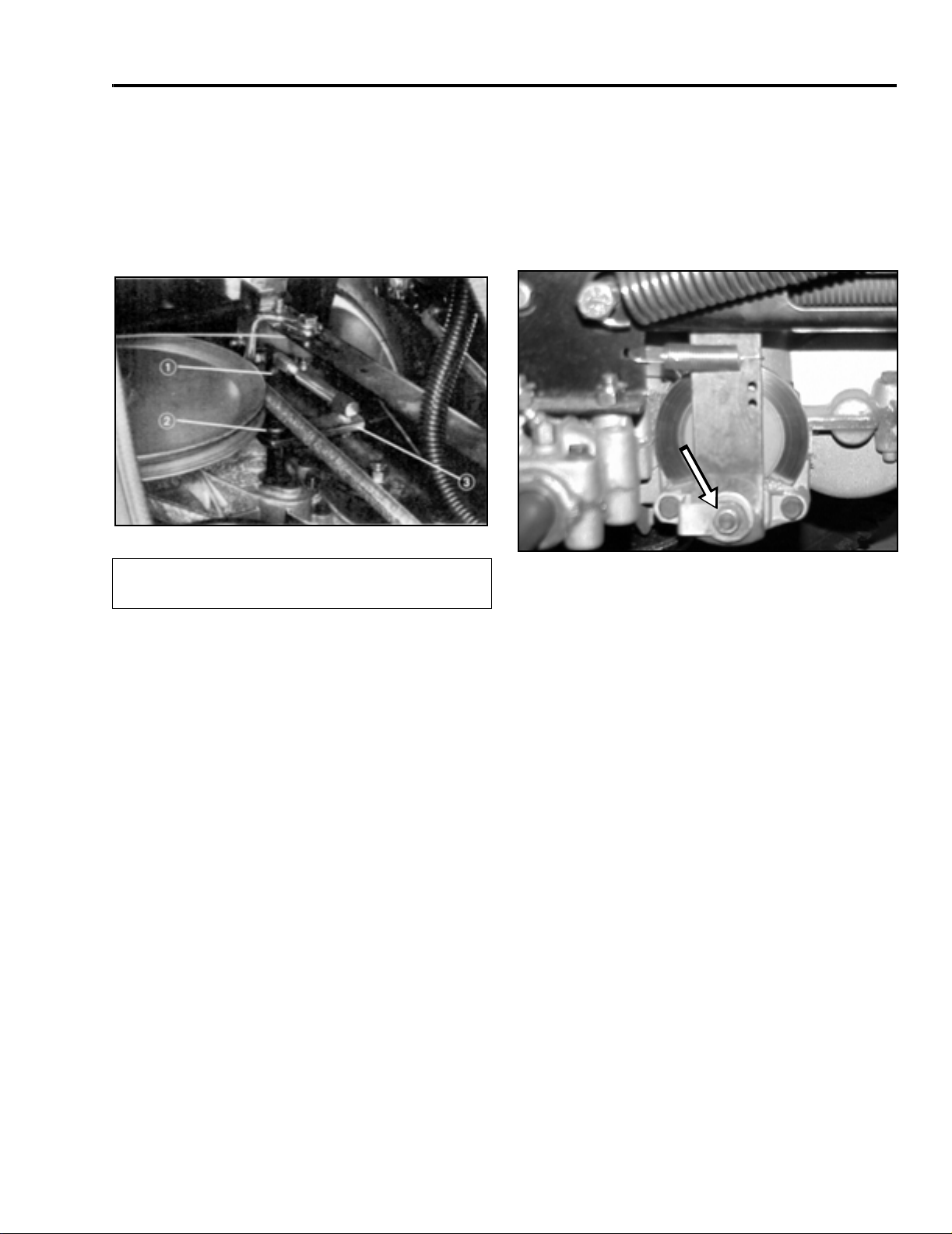

XL Gear Drive Transaxle Removal -

915 Transaxle

1. Disconnect battery cables and remove the battery

and battery tray. Remove the mower deck (refer

to “Mower” section on page 6 - 1).

2. Raise the rear of the tractor and remove the right

and left rear tires. Put jack-stands under the

frame, just in front of the transaxle (Figure 3).

4. Loosen the left transaxle belt guide and move it

away from the belt. The right transaxle belt guide

needs to be removed (Figure 5).

Figure 5

5. Unhook the idler spring from the idler assembly

(Figure 6).

mvc-796

Figure 3

3. Remove the rear hitch panel. There are 2 bolts

and nuts holding the seat springs and 2 bolts and

nuts on each side of the rear panel (Figure 4).

Figure 4

mvc-794

mvc-795

Figure 6

mvc-798

XL Lawn Tractor Service Manual 2 - 1

XL GEAR DRIVE

6. Remove the nut on the shift tie rod (Figure 7).

Figure 7

mvc-800

7. Remove the bolt and nut on the left side shift pivot

clamp and slide the shift pivot rod so you can

remove the shift tie rod (Figure 8).

8. Remove the nut and washer holding the left side

torque strap leaving the torque strap bolted to the

frame (Figure 9).

Figure 9

mvc-803

9. Remove both the top and bottom washer and nut

from the right side torque strap (Figure 10).

Figure 8

mvc-802

Figure 10

mvc-806

2 - 2 XL Lawn Tractor Service Manual

XL GEAR DRIVE

10. Remove the brake return spring (Figure 11).

Figure 11

11. Unhook the brake spring from the clutch/brake rod

(Figure 12).

mvc-808

A

12. Before removing the 4 transaxle bolts, put a floor

jack under the transaxle so you can lower it from

the frame. Remove the 4 bolts, washers, and nuts

(Figure 13).

Figure 13

13. Lower the transaxle slightly so you can free it from

the two front torque straps. Unhook the brake

spring from the transaxle brake arm (Figure 14).

mvc-810

B

Figure 12

(A) Spring (B) Clutch/brake rod

XL Lawn Tractor Service Manual 2 - 3

iso3

Figure 14

mvc-811

XL GEAR DRIVE

14. The transaxle should be free from the frame now

(Figure 15).

Figure 15

mvc-813

XL Gear Drive Transaxle Installation

- 915 Transaxle

1. Raise the transaxle to the frame making sure the

brake lever fits through the slot in the frame.

Reinstall the brake spring on the brake lever

(Figure 14 and Figure 16).

2. Install the right and left torque straps to the frame

and the transaxle, do not tighten. Install the 4 axle

bolts, washers, and nuts and tighten first. Then

tighten the torque straps (Figure 17).

Figure 17

3. Install the left side shift pivot clamp on the shift

pivot rod before securing the clamp to the frame.

Make sure the shift tie rod is reinstalled in the hole

in the shift pivot rod. Tighten the shift pivot clamp

and the shift tie rod (Figure 18).

mvc-816

Figure 18

Figure 16

2 - 4 XL Lawn Tractor Service Manual

mvc-814

mvc-817

XL GEAR DRIVE

4. Install brake spring to the clutch/brake rod (Figure

19).

A

B

Figure 19

(A) Spring (B) Clutch/brake rod

5. Install belt around the transaxle pulley. Reinstall

the idler spring to the idler assembly (Figure 20).

iso3

6. Install the right and left belt guides and adjust so

they are within 1/8” (3mm) of the transaxle pulley

and drive belt (Figure 21). Note direction of belt

guide installation, right hand points forward, left

hand points rearward.

1/8” (3mm)

1/8” (3mm)

Figure 21

7. Connect the brake return spring to the brake lever

(Figure 22).

mvc-818

Figure 20

XL Lawn Tractor Service Manual 2 - 5

mvc-798

Figure 22

mvc-819

XL GEAR DRIVE

8. Install the rear hitch panel. There are two bolts,

washers, and nuts on each side of the plate and 2

bolts, washers, and nuts for the seat springs

(Figure 23).

Figure 23

9. Install the right and left rear tires. Install the

battery and battery box. Note: Make sure the

battery drain tube is installed through the rear hole

of the frame (Figure 24; rear hitch panel removed

for clarity).

mvc-795

10. Check the following items:

A. The Shift-On-The-Go for proper adjustment. If

adjustment is needed, (refer to “Cable

Adjustment, Shift-On-The-Go, 915 and MST205 Transaxle” on page 2 - 19).

B. Brake Adjustment. If adjustment is needed,

(refer to “XL Gear Drive Brake Adjustment -915

Transaxle” on page 2 - 11).

C. Shift Lever Adjustment. If adjustment is

needed, (Refer to “XL Gear Drive Shift Lever

Adjustment - 915 Transaxle” on page 2 - 9).

11. Install mower deck; see instructions in the Mower

section.

12. Check all safety switches to make sure they are

operating properly.

XL Gear Drive Traction Drive Belt

Replacement Procedure - 915

Transaxle

1. Disconnect battery and remove battery and

battery tray. Remove mower deck. (Refer to

Mower section.)

Figure 24

mvc-639

2. Remove the rear hitch panel. There are 2 bolts

and nuts holding the seat springs and 2 bolts and

nuts on each side of the rear panel (Figure 25).

Figure 25

mvc-795

2 - 6 XL Lawn Tractor Service Manual

XL GEAR DRIVE

3. Loosen and move the right and left engine belt

guides (Figure 26).

Figure 26

mvc-821

4. Loosen the left side transaxle belt guide. Remove

the right side transaxle belt guide (Figure 27).

5. Remove the idler spring on the idler assembly.

Remove the idler pulley and belt guide (Figure

28). Remove the drive belt.

Figure 28

mvc-824

6. Install new belt around the engine drive pulley

(Figure 29).

Figure 27

mvc-796

Figure 29

mvc-825

XL Lawn Tractor Service Manual 2 - 7

XL GEAR DRIVE

7. Route belt back over the pedal pivot rod, the idler

pivot bracket, and around the transaxle pulley

(Figure 30).

Figure 30

8. Install the idler pulley to the idler bracket. Note

the correct hole location of the bolt and nut

retaining the pulley and belt guide bracket (Figure

31).

mvc-826

9. Hook the idler spring to the idler bracket (Figure

32).

Figure 32

10. Install the right side belt guide and adjust to within

1/8” (3mm) of the transaxle pulley and belt. Adjust

and tighten the left belt guide so it is within 1/8”

(3mm) of the transaxle pulley and belt (Figure 21

and Figure 33).

mvc-829

1/8” (3mm)

Figure 31

2 - 8 XL Lawn Tractor Service Manual

mvc-828

Figure 33

mvc-796

XL GEAR DRIVE

11. Recheck the routing of the belt (Figure 34).

Figure 34

12. Install the mower deck. (Refer to Mower Deck

section). Make sure the engine belt guides are

adjusted so they are within 1/8” (3mm) of both the

engine and mower drive pulley.

13. Install battery and battery tray making sure the

battery drain tube is installed in the rear hole of

the frame (Figure 35). Install the rear hitch panel

(Figure 25).

mvc-833

14. Check the following:

A. The Shift-On-The-Go for proper adjustment. If

adjustment is needed, (refer to “Cable

Adjustment, Shift-On-The-Go, 915 and MST205 Transaxle” on page 2 - 19).

B. Brake Adjustment. If adjustment is needed,

(refer to “XL Gear Drive Brake Adjustment -915

Transaxle” on page 2 - 11).

C. Shift Lever Adjustment. If adjustment is

needed, (refer to “XL Gear Drive Shift Lever

Adjustment - 915 Transaxle” on page 2 - 9).

15. Check all safety switches to make sure they are

operating properly.

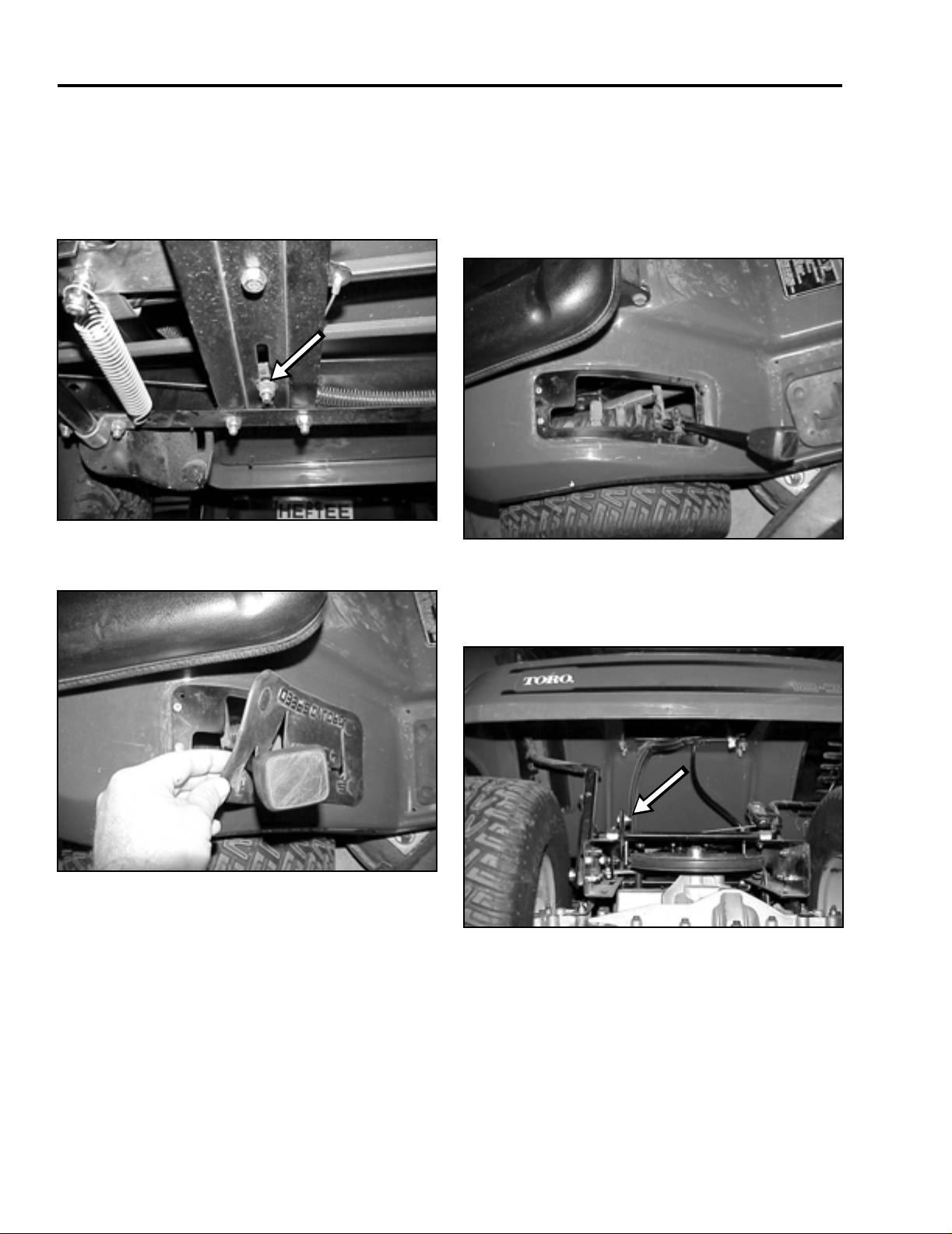

XL Gear Drive Shift Lever

Adjustment - 915 Transaxle

It is VERY important the shift lever is properly aligned

with the shift gates.

If the gear shift lever and shift gates do not properly

align, you may encounter the following symptoms:

1. No reverse.

2. No fifth gear.

3. Jumping out of gear.

Figure 35

If the misalignment is ignored for a period of time,

severe transaxle damage will result.

Adjust using the following procedure:

1. Disconnect the battery cables and remove the

battery and battery tray.

mvc-639

XL Lawn Tractor Service Manual 2 - 9

XL GEAR DRIVE

2. Remove the rear hitch panel by removing the two

bolts and nuts holding the seat springs and two

bolts and nuts located on each side of the hitch

panel. Loosen the fastener securing the front

cable guide to remove tension from the shift cable

(Figure 36).

Figure 36

mvc-834

3. Remove the rubber shift gate cover (Figure 37).

4. Shift the transaxle through each gear to verify the

gear shift lever centers in each gate as the internal

transaxle detents are felt. The lever should also

“detent” into 5th gear and reverse (Figure 38).

That is, the shift lever should not contact the side

of the metal “fingers” of each gate as the lever

enters the gate.

Figure 38

mvc-836

5. If the shifter does not align with the gates, loosen

the bolt and nut between the shift pivot and the

shift pivot lever and adjust (Figure 39).

Figure 37

mvc-835

Figure 39

mvc-840

2 - 10 XL Lawn Tractor Service Manual

XL GEAR DRIVE

6. If the shifter still does not go into 5th gear, loosen

the jam nut on the tie rod end of the shift arm and

remove the nut. Rotate the tie rod end until the

gear shift lever is centered in the 5th gear gate.

Place the shift arm on the gear selector shaft and

verify that neutral, reverse, and fifth gears properly

align. Reinstall the shift arm fastener and tighten

the jam nut (Figure 40).

Figure 40

(1) Jam Nut

(2) Fastener

7. Reassembly:

A. Ensure the transaxle and engine pulley belt

guides are positioned 1/8” (3mm) away from

the drive belt.

B. Adjust the transaxle shift cable (refer to “Cable

Adjustment, Shift-On-The-Go, 915 and MST205 Transaxle” on page 2 - 19.)

C. Reinstall the shift gate cover, rear hitch panel,

battery, and battery tray. Note: Make sure the

battery drain tube is installed in rear hole of the

frame (Figure 35). Reconnect the battery

cables.

D. Test drive the tractor and verify all adjustments

and safety switches are operating properly.

(3) Shift Arm

HL11014

XL Gear Drive Brake Adjustment 915 Transaxle

The brake is located on the right side of the rear axle,

inside the rear tire. If the brake does not hold securely

or stopping power is insufficient, an adjustment is

required (Figure 41).

Figure 41

1. Park the machine on a level surface, disengage

the blade control (PTO), shift into neutral, set the

parking brake, and turn the ignition key to “OFF” to

stop the engine.

2. If the rear wheels lock and skid when you push the

tractor forward, no adjustment is required. An

adjustment is required if the wheels turn and do

not lock.

3. To increase braking resistance, tighten the brake

adjusting nut (Figure 41) 1/8 turn clockwise; then

check the brake again. Continue this adjusting

and checking process until the brake is set

properly.

If the brake system does not respond to

adjustment, the brake pads and possibly the brake

disc, require replacement.

mvc-847

4. Push down on the clutch/brake pedal to release

the parking brake.

IMPORTANT: With the parking brake released,

the rear wheels must rotate freely when you push

the tractor. If the brake seems to “drag”, loosen

the adjusting nut slightly until the wheels rotate

freely.

XL Lawn Tractor Service Manual 2 - 11

XL GEAR DRIVE

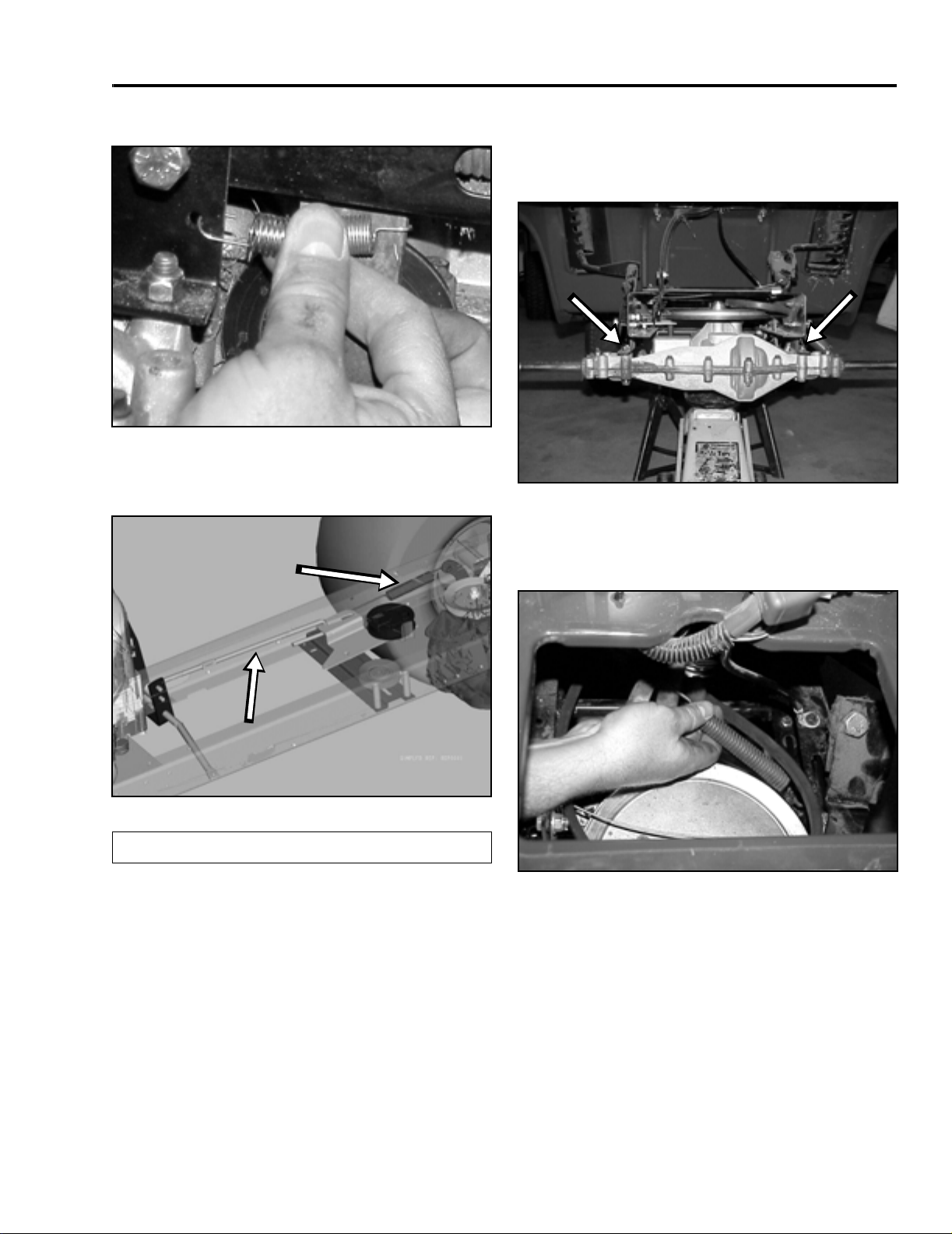

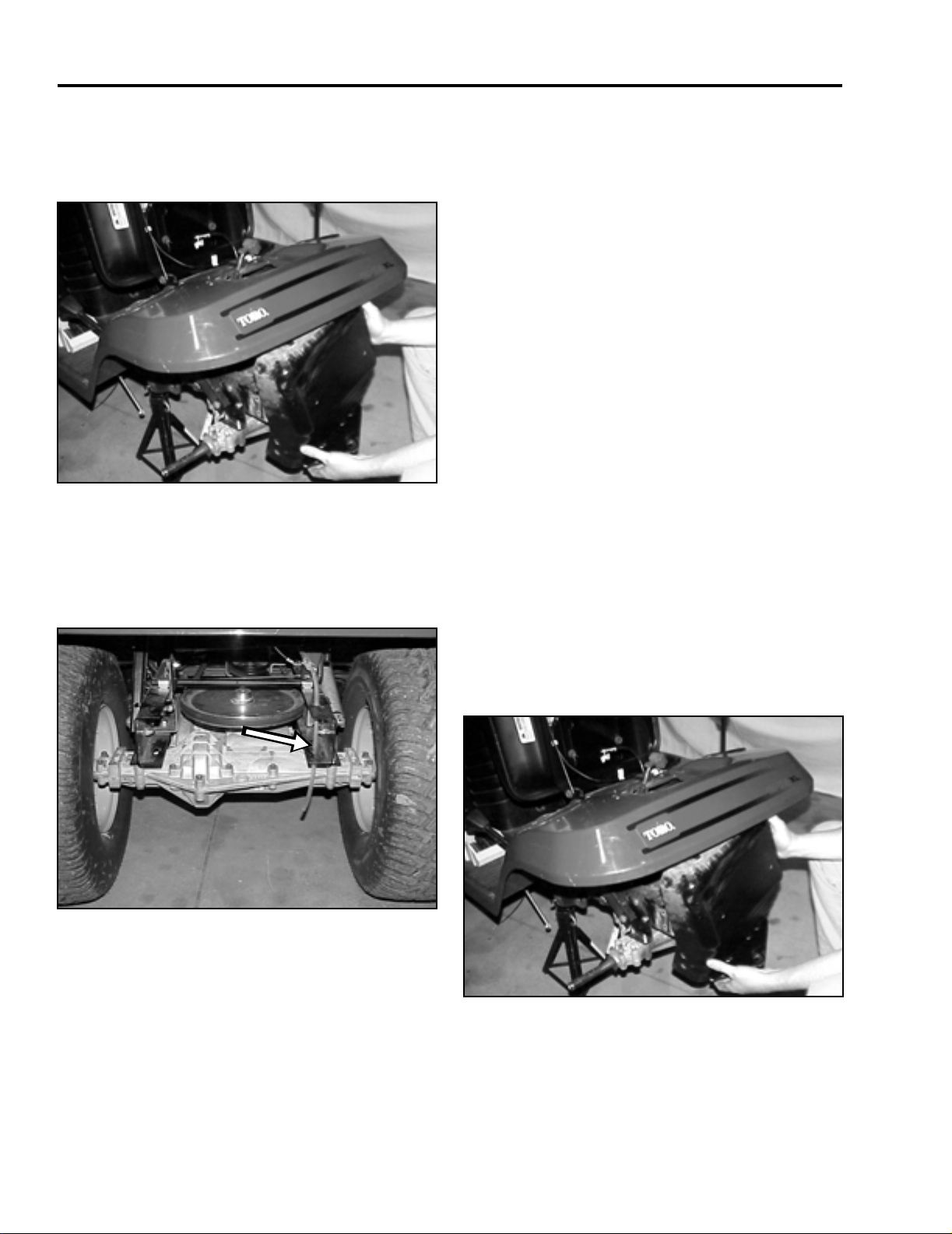

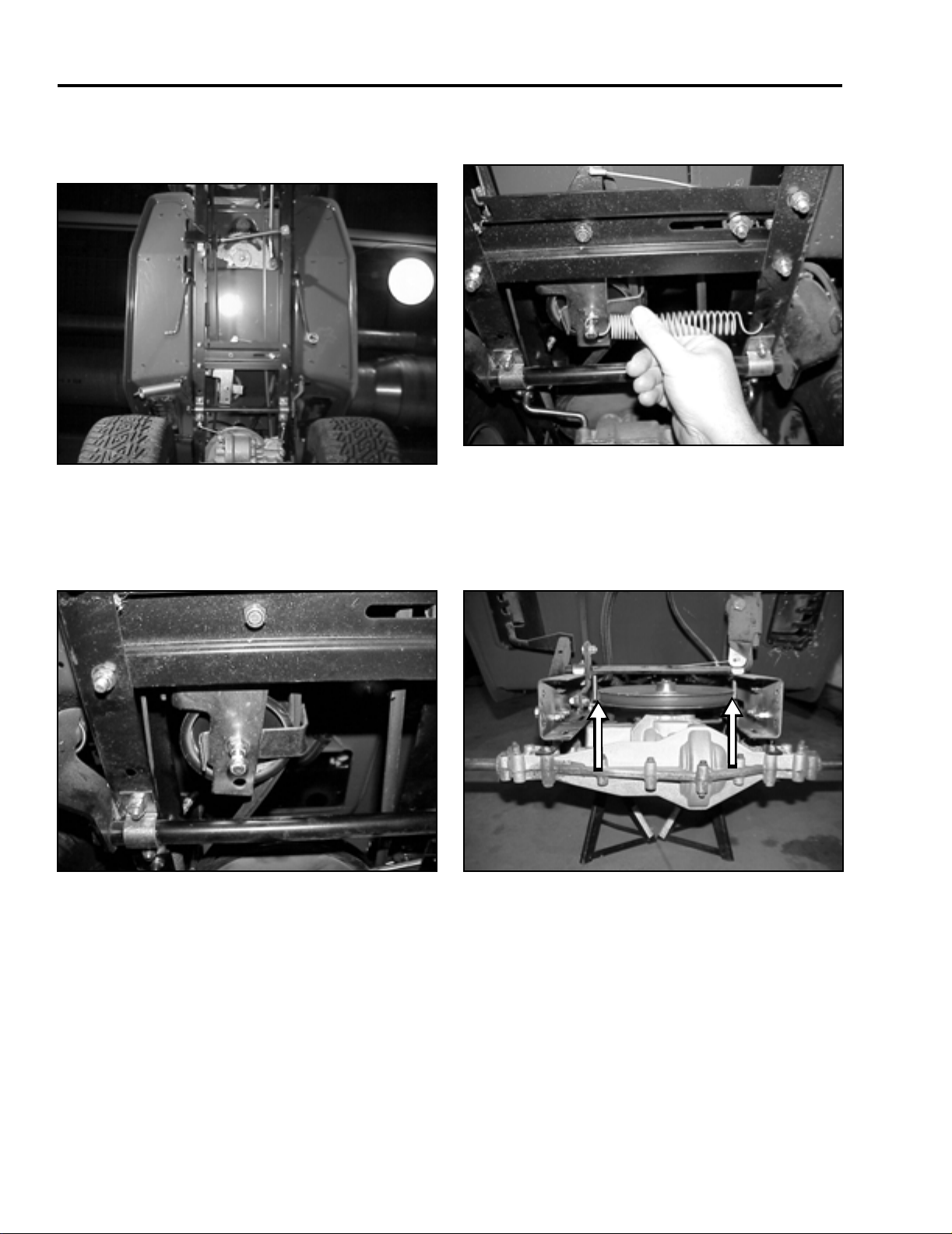

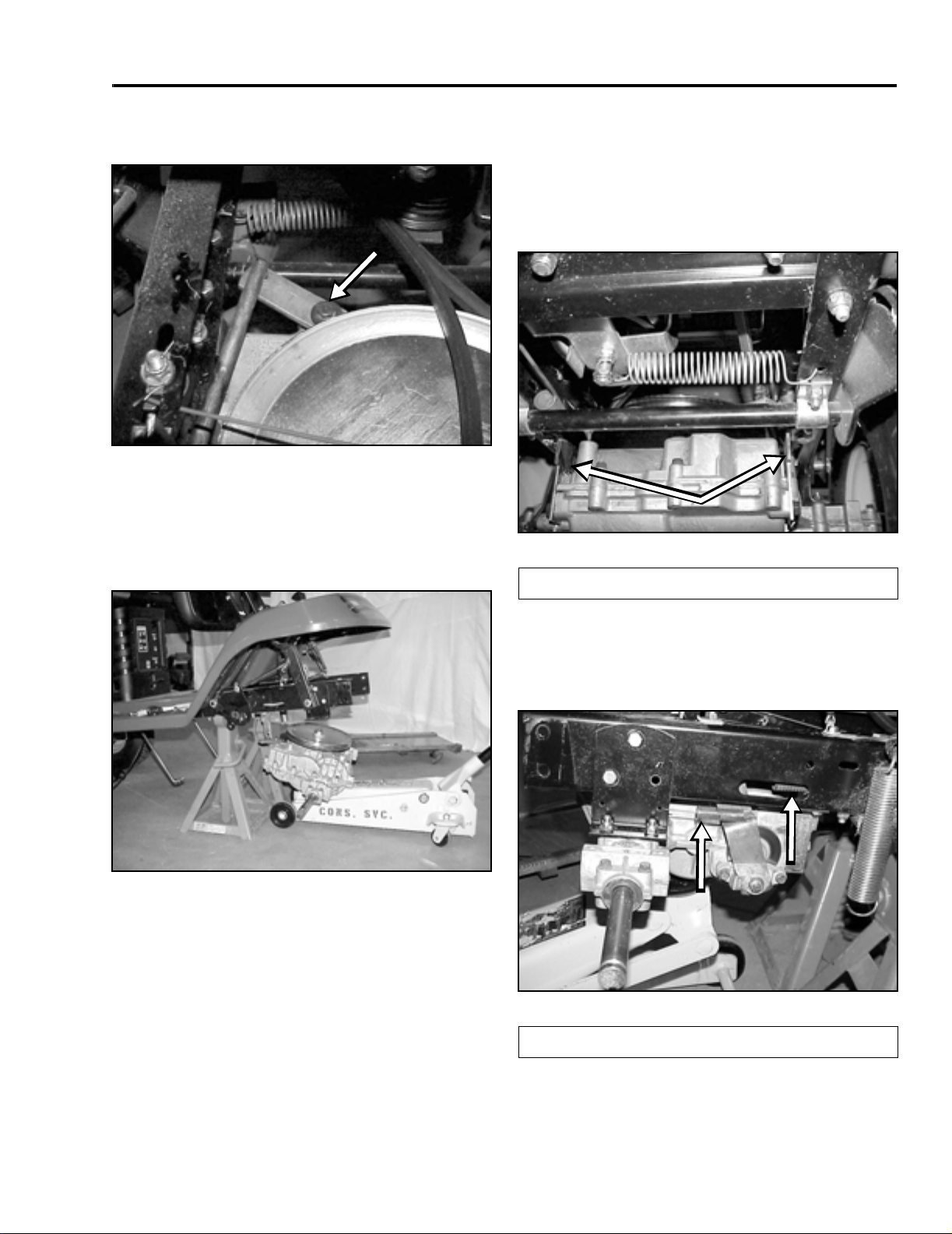

XL Gear Drive MST-205 Transaxle

Removal

1. Disconnect battery cables and remove battery and

battery tray. Remove mower deck (refer to

“Mower” section on page 6 - 1). Lift the rear of the

tractor and remove both the right and left rear tires

(Figure 42).

Figure 42

2. Remove the rear hitch panel, removing the two

bolts and nuts holding the seat springs and two

bolts and nuts located on each side of the hitch

panel (Figure 43).

mvc-0001

3. Remove the right and left transaxle belt guides.

Put the park brake on and then slip the traction

drive belt off the transaxle pulley (Figure 44).

A

Figure 44

(A) Belt Guides

4. Release the park brake and disconnect the brake

spring (A) at the idler arm assembly. Remove the

brake return spring (B) (Figure 45).

mvc-0002

A

B

Figure 45

(A) Brake Spring (B) Brake Return Spring

Figure 43

2 - 12 XL Lawn Tractor Service Manual

mvc-0037

mvc-0005

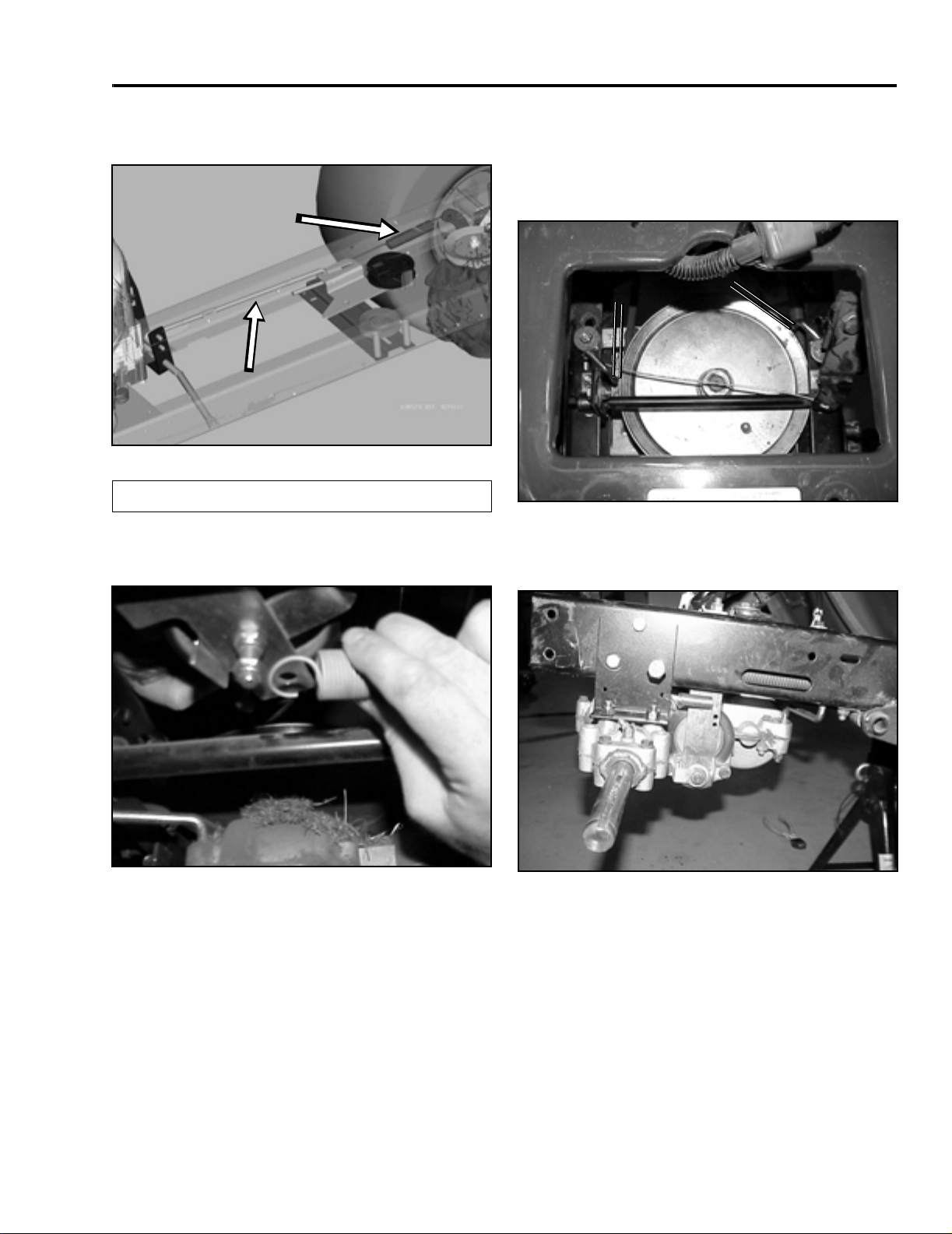

XL GEAR DRIVE

5. Disconnect the shift link at the transaxle shift lever

(Figure 46).

Figure 46

6. Use a floor jack to support and lower the transaxle

from the frame. Unbolt and remove the two torque

strap bolts located in the front of the transaxle.

Remove the 4 axle bolts holding the transaxle to

the frame (Figure 47).

mvc-0003

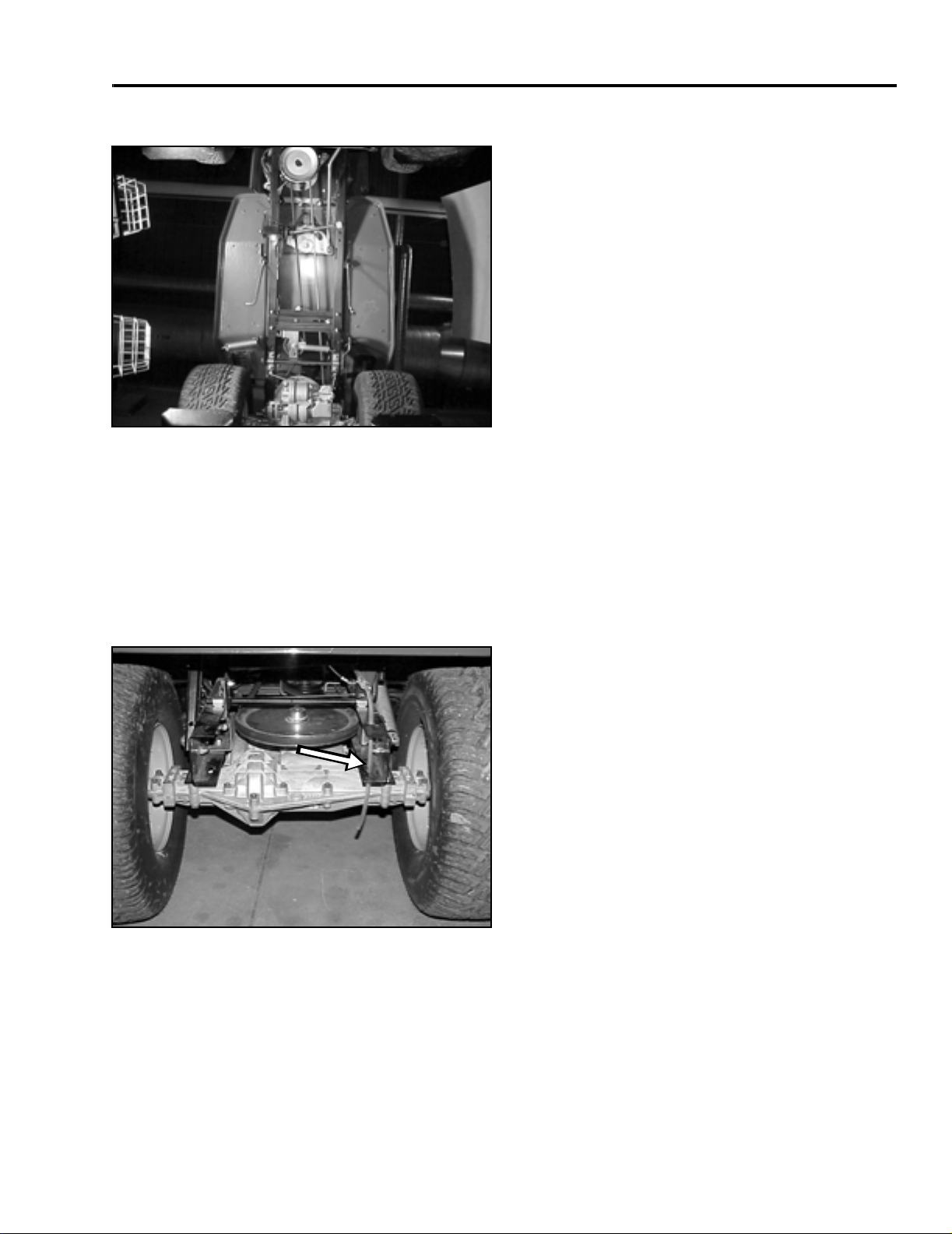

XL Gear Drive MST-205 Transaxle

Installation

1. Raise the transaxle up to the frame and install the

4 axle bolts and 2 torque strap bolts. Tighten all 6

bolts (Figure 48).

A

Figure 48

(A) Torque Straps

mvc-0011

Figure 47

mvc-0004

2. Connect the brake spring between the clutch/

brake rod and the transaxle brake lever. Install

the brake return spring, located between the

transaxle brake lever and the axle frame bracket.

A

B

Figure 49

(A) Brake Spring (B) Brake Return Spring

mvc-0005

XL Lawn Tractor Service Manual 2 - 13

Loading...

Loading...