Toro 70-8090, 70-8100, 70-7010 Operator's Manual

Form No. 3318–282

Counterbalance Kit

For Groundsmaster 200 Series Decks

Part No. 70–7010

Part No. 70–8090

Part No. 70–8100

Installation Instructions

Safety and Instruction Decals

The following decal is installed on the spring cover in two

locations. If they become damaged or illegible, replace

them. The decal part number is listed below and in your

parts catalog. Replacements can be ordered from your

Authorized Toro Distributor.

Loose Part Chart

Description Qty. 52” Qty. 62”, 72” Use

Adapter bar* 0 1* Adapts bracket to 217–D and 220 models.

Mounting bracket 1 2 Spring cover mount.

Lock pin assembly 2 4 Install on bracket.

55-4300

Self-tapping screw 2 4 To secure lock pins to bracket.

Spring cover assembly 1 2 Install in bracket.

Clevis pin 1 2 Insert in spring cover & top of spring.

Hairpin cotter 1 2 Use to secure clevis pin.

Spring end—top 1 2 Install on clevis pin & top of extension spring.

Heavy extension spring 1 2

Light extension spring 0 1

Lower spring end 1 2

Knee link 1 2

Capscrew, 3/8 x 2-1/4 in. 2 4

Capscrew, 3/8 x 1 in. 2 4

Shoulder bolt 2 4

Flat washer 2 4 Use with shoulder bolt and locknut.

Install between top & bottom of spring ends

(Use one only on 62”, L.H. side).

62” only. Mount between top & bottom spring ends;

R.H. side.

Install on bottom of extension spring. Assemble

knee link to lower hole.

Attach top hole to lower spring end, bottom hole to

deck bracket.

To mount adapter bar (62”, 72”) and mounting

bracket to 217–D & 220 traction unit frames (52”).

Secures mounting brackets to adapter bar (62”, 72”)

and mounting bracket to 224 & 220–D traction unit

frames.

Attaches knee link to deck bracket and lower spring

end.

Locknut, 3/8 in. 4 12 Use with all fasteners, where necessary.

Decal–caution 2 4 Apply over decals for CE compliance

* Not included with kit; Order Part No. 66–8210 from your Authorized Toro Distributor.

2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

1

All Rights Reserved

Printed in the USA

Installation

Note: The cutting deck and carrier frame must be installed

on traction unit before installing the counterbalance kit.

Fully raise the cutting deck, set the parking brake, stop the

engine, and remove the ignition key. Place blocks under the

cutting deck to prevent it from falling during assembly.

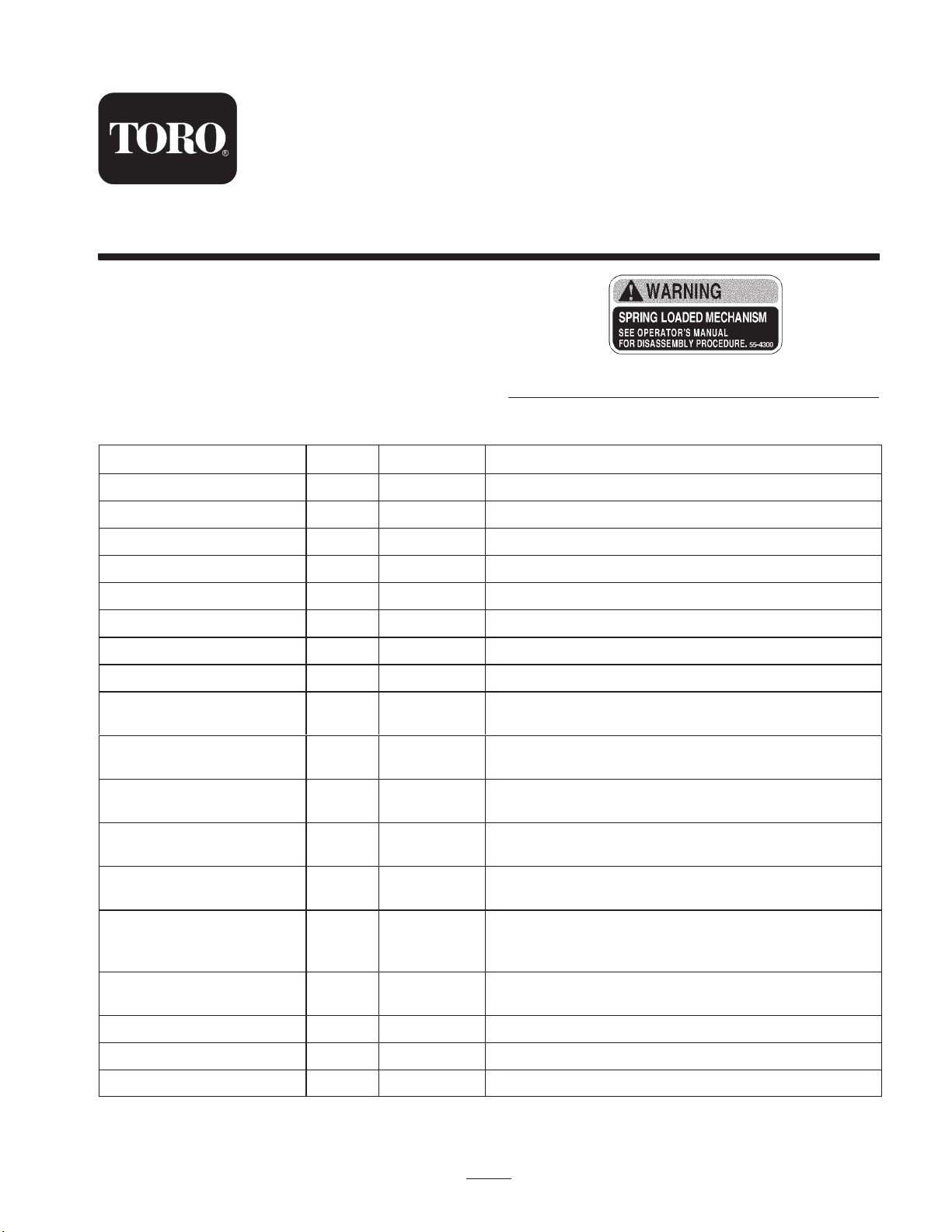

Note: Mounting brackets must be installed in different

configurations (Fig. 1) and, depending on the cutter deck,

in different locations on 220–D and 223–D, 228–D, 225,

224 and 1000L models than on the 217–D and 220 model

machines (Fig. 2, 3).

52” Cutting Decks

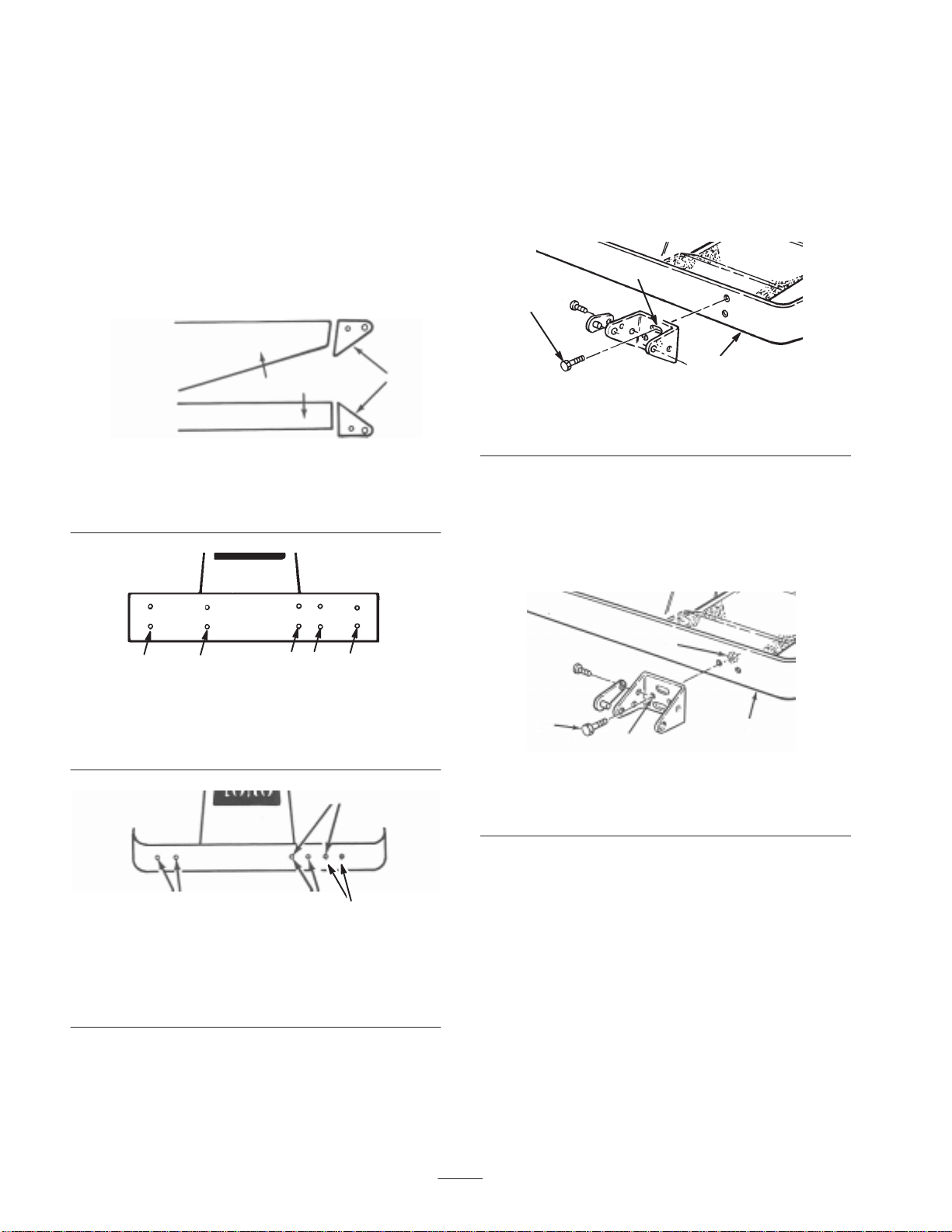

1. To install the mounting brackets,

• Groundsmaster 220–D, 223–D, 228–D, 225, 224

and 1000L – Insert 2 flange head capscrews (3/8 x

1 in.) through the slotted bracket holes. Thread the

screws into the captivated frame nuts and torque

them to 45–50 ft.-lb. (61–68 N⋅m) (Fig. 4).

2

1

1

Figure 1

1. 220–D, 223–D, 228–D,

225, 224 & 1000L traction

unit frame

3

GM 220–D, 223–D, 228–D, 225, 224 & 1000L

2

2. 217–D, 220 traction unit

frame

1

Figure 2

1. 52″ side discharge deck

2. 52″ deck w/bagger

3. 62″ and 72″ decks

4. 52″ rear discharge deck

2

3

Figure 4

1. Flange head capscrew

2. Slotted hole

3

3. Frame

• Groundsmaster 217–D and 220 – Align the bracket

with the frame mounting holes. Insert 2 flange head

capscrews (3/8 x 2–1/4 in.) through the non–slotted

bracket holes and frame mounting holes. Install lock

nuts and torque them to 45–50 ft.-lb. (61–68 N⋅m)

(Fig. 5)

3

4

3

1

4

2

Figure 5

1

1. Flange head capscrew

2. Non–slotted hole

3. Locknut

4. Frame

1,3

GM 217–D & 220

1. Adapter bar mount holes

(62” & 72” C.U.)

2. 52” Side discharge deck

Figure 3

4

2

3. 52” Side discharge

w/bagger

4. 52” Rear discharge deck

2. Thread the top extension spring coil into the top spring

end holes and the bottom extension spring coil into the

bottom spring end holes (Fig. 6).

2

Loading...

Loading...