Toro 07052, 7050 Operator's Manual

66” Rake–O–Vac Sweeper

PTO and Engine Driven

Model No. 07050–220000001 and up

Model No. 07052–220000001 and up

Form No. 3329–240

Operator ’s Manual

Domestic English (EN)

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Important The engine in this product is not equipped

with a spark arrester muffler. It is a violation of California

Public Resource Code Section 4442 to use or operate this

engine on any forest-covered, brush-covered, or

grass-covered land as defined in CPRC 4126. Other states

or federal areas may have similar laws.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada.

Contents

Page

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 5. . . . . . . . . . . . . . . .

Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions and Weights (approx.) 7. . . . . . . . . . .

Optional Equipment 7. . . . . . . . . . . . . . . . . . . . . . .

Setup 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove, Activate And Charge Battery 8. . . . . . . .

Install Battery 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mount Sweeper To Prime Mover 9. . . . . . . . . . . . .

Connecting Drive Shaft to Prime Mover PTO Shaft 10

Removing Sweeper From Prime Mover 10. . . . . . . .

Before Operating 11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Engine Oil 11. . . . . . . . . . . . . . . . . . . . . . . . .

Check Clutch Housing Oil 11. . . . . . . . . . . . . . . . . .

Fill Fuel Tank 12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Tire Pressure 12. . . . . . . . . . . . . . . . . . . . . . .

Transport Hooks 13. . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Reel Support Arm 13. . . . . . . . . . . . . . . . . . .

Adjust Rake Depth 13. . . . . . . . . . . . . . . . . . . . . . . .

Adjust Rubber Flap 14. . . . . . . . . . . . . . . . . . . . . . .

Page

Operation 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Instructions (Engine Driven) 15. . . . . . . . .

Stopping Instructions 16. . . . . . . . . . . . . . . . . . . . . .

Starting Instructions (PTO Driven) 16. . . . . . . . . . .

Operating Tips 16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Cleanup After Operation 16. . . . . . .

Maintenance 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Drive Chain 18. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Sweeper Jack 18. . . . . . . . . . . . . . . . . . . . . . . . .

Changing Engine Oil and Filter 18. . . . . . . . . . . . . .

General Air Cleaner Maintenance 19. . . . . . . . . . . .

Servicing Air Cleaner 19. . . . . . . . . . . . . . . . . . . . . .

Replacing Spark Plugs 19. . . . . . . . . . . . . . . . . . . . .

Removing Debris From Engine 20. . . . . . . . . . . . . .

Replace Fuel Filter 20. . . . . . . . . . . . . . . . . . . . . . . .

Changing Clutch Housing Oil 20. . . . . . . . . . . . . . .

Adjusting Clutch 20. . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Rubber Flap 21. . . . . . . . . . . . . . . . . . . . .

Cleaning Blower Housing 21. . . . . . . . . . . . . . . . . .

Adjusting Belts 22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Drive Chain 24. . . . . . . . . . . . . . . . . . . . .

Changing Gear Box Oil 25. . . . . . . . . . . . . . . . . . . .

Gear Box Removal 25. . . . . . . . . . . . . . . . . . . . . . . .

Locking Collar Removal 26. . . . . . . . . . . . . . . . . . .

Pulley Removal 26. . . . . . . . . . . . . . . . . . . . . . . . . .

Flex Tip Reel Removal 26. . . . . . . . . . . . . . . . . . . . .

Thatcher Installation 27. . . . . . . . . . . . . . . . . . . . . . .

Flex Tip Rake Rod Or Finger Plate Replacement 27

Flex Tip Rake Tine Replacement 28. . . . . . . . . . . . .

Brush Half Replacement 28. . . . . . . . . . . . . . . . . . . .

Changing Tires 29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Care 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 32. .

2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Introduction

Safety

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

Figure 1

1. Model & serial number plate

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

The RAKE–O–VAC was designed and tested to offer

safe service when operated and maintained properly.

Although hazard control and accident prevention

partially are dependent upon the design and

configuration of the machine, these factors are also

dependent upon the awareness, concern, and proper

training of the personnel involved in the operation,

transport, maintenance, and storage of the machine.

Improper use or maintenance of the machine can result

in injury or death. To reduce the potential for injury or

death, comply with the following safety instructions.

Since the Rake–O–Vac must be towed to operate, it is

extremely important that the tow tractor be carefully

selected to assure the best performance and safe operation.

The tow tractor must have the proper wheel base and tread

width and equipped with a roll bar and seat belt to operate

safely on hilly terrain. The normal operating speed is 6 mph

but will vary with terrain and debris being picked up. The

maximum transport speed is 20 mph with slower speeds

required on hilly terrain. Refer to tractor Operator’s Manual

for information or tractor service agency if you have any

question on safe operation.

The brakes of the tow tractor must have the capacity to stop

the Rake–O–Vac with hopper fully loaded and traveling at

the maximum recommended transport speed.

The power take–off drive of the Rake–O–Vac requires a

tractor with operating speeds of 540 rpm and output power

of 20 hp or higher. Do not exceed the 540 rpm speed.

The Rake–O–Vac must comply with local road

requirements, if transported on public roads. A

Slow–moving vehicle sign has been provided. Signal lights

and brakes are not provided and may be required in some

areas.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Before Operating

• Operate the machine only after reading and

understanding the contents of this manual. A

replacement manual is available by sending complete

model and serial number to:

The Toro Company

8111 Lyndale Avenue South

Bloomington, Minnesota 55420–1196.

• Never allow children to operate the machine or adults to

operate it without proper instructions.

• Become familiar with the controls and know how to

stop the engine/sweeper quickly.

• Keep all shields, safety devices and decals in place. If a

shield, safety device or decal is malfunctioning,

illegible, or damaged, repair or replace it before

operating the machine.

3

• Always wear substantial shoes. Do not operate machine

while wearing sandals, tennis shoes or sneakers. Do not

wear loose fitting clothing which could get caught in

moving parts and cause personal injury.

– Shut engine off and wait for all movement to stop.

The impeller may momentarily turn after other

components have stopped. Use extreme caution

when removing cover from blower housing.

• Wearing safety glasses, safety shoes, long pants and a

helmet is advisable and required by some local safety

and insurance regulations.

• Keep everyone, especially children and pets away from

the areas of operation.

• Since gasoline is highly flammable, handle it carefully.

– Use an approved gasoline container.

– Do not remove cap from fuel tank when engine is

hot or running.

– Do not smoke while handling gasoline.

– Fill fuel tank outdoors and to about one inch below

top of tank, (bottom of filler neck). Do not overfill.

– Wipe up any spilled gasoline.

While Operating

• Exhaust fumes are hazardous and could be deadly, so do

not run the engine in a confined area without adequate

ventilation.

• This product may exceed noise levels of 85 dB(A) at

the operator position. Ear protectors are recommended,

for prolonged exposure, to reduce the potential of

permanent hearing damage.

• Never carry passengers on prime mover or allow

anyone to ride on sweeper.

• Disengage clutch before starting sweeper engine.

• Using the machine demands attention. To prevent

tipping or loss of control:

– Use extreme caution around ditches, creeks or other

hazards.

– Watch for holes or other hidden hazards.

– Use caution when operating machine on a steep

slope. Reduce speed when making sharp turns or

when turning on hillsides.

– Avoid sudden stops and starts.

– Before backing up, look to the rear and assure no

one is behind the machine.

– Watch out for traffic when near or crossing roads.

Always yield the right of way.

• Before leaving operator position:

– Shift into neutral, stop prime mover and engage

parking brake.

– Disengage and lower sweeper implement.

– Shut sweeper engine off.

– Disengage P.T.O.

– Take precautions to prevent accidental starts, rolling

away, etc.

• Do not step over P.T.O. shaft to get to other side of

machine. Walk around sweeper.

• Never get on or off prime mover with P.T.O. shaft

engaged.

• If prime mover or sweeper ever vibrate abnormally,

stop immediately, turn engine off, wait for all motion to

stop and inspect for damage. Repair all damage before

commencing operation.

• Whenever machine is left unattended, be sure engine is

stopped, implement is lowered and key is removed from

ignition switch.

• Shut sweeper blower off when dumping contents of

hopper. Always stand to extreme right or left side of

hopper when opening tailgate.

• Park on a level surface, empty hopper and block wheels

before removing sweeper from prime mover.

Maintenance

• Disengage power to sweeper implement and stop engine

before servicing or making adjustments.

• Disengage power to sweeper implement and stop engine

when transporting or not in use.

• To make sure entire machine is in good condition, keep

all nuts, bolts and screws properly tightened.

• If major repairs are ever needed or assistance is

required, contact an Authorized TORO Distributor.

• To reduce potential fire hazard, keep the engine area

free of excessive grease, grass, leaves and accumulation

of dirt.

• If the engine must be running to perform a maintenance

adjustment, keep hands, feet, clothing, and any parts of

the body away from the engine and any moving parts.

Keep everyone away.

• Do not overspeed engine by changing governor settings.

To assure safety and accuracy, have an Authorized Toro

Distributor check maximum engine speed with a

tachometer. P.T.O. driven machines must not exceed

540 R.P.M.

4

• Engine must be shut off before checking oil or adding

oil to the crankcase.

• Check prime mover brakes periodically to be sure

brakes, when applied, will hold firmly. Also, check to

make sure all safety equipment is functioning properly.

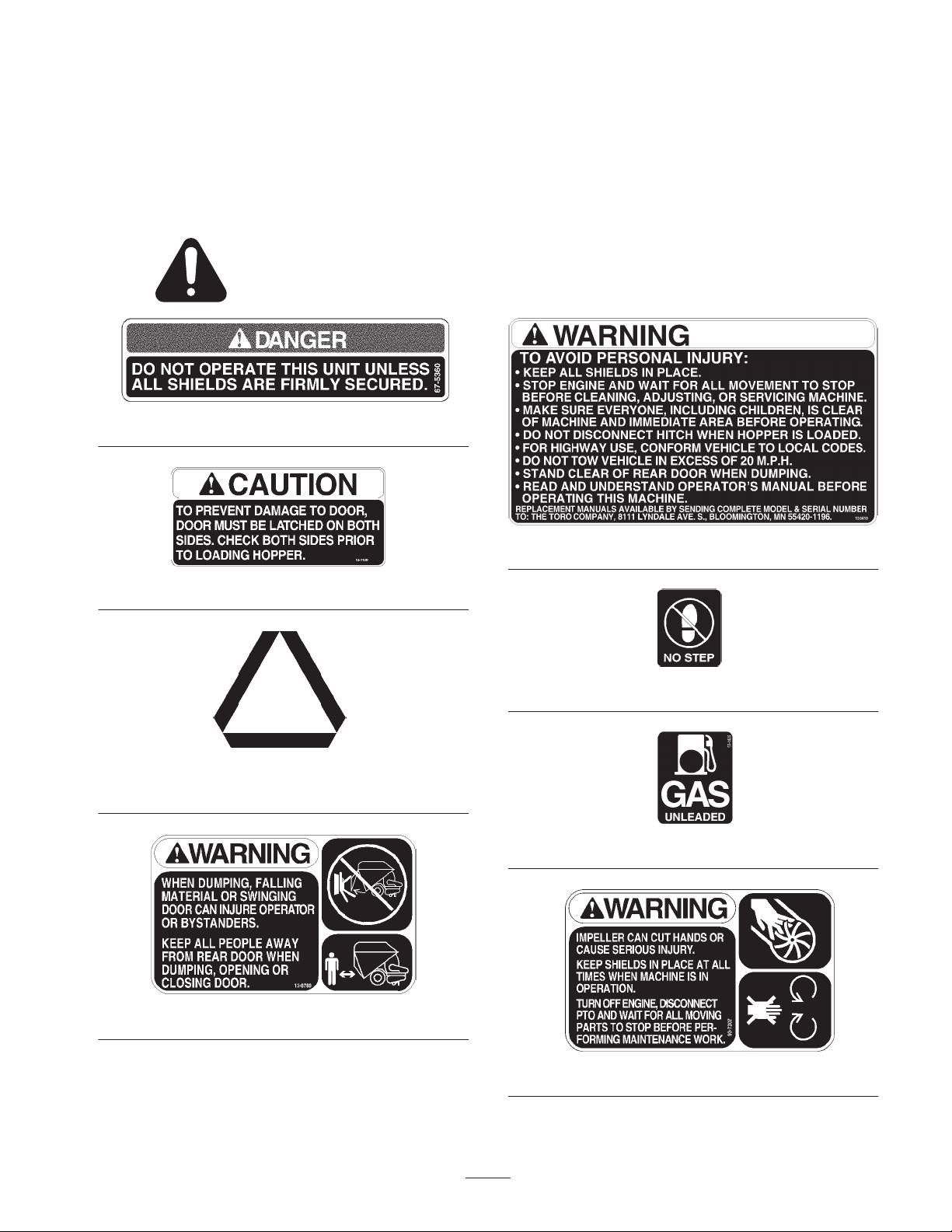

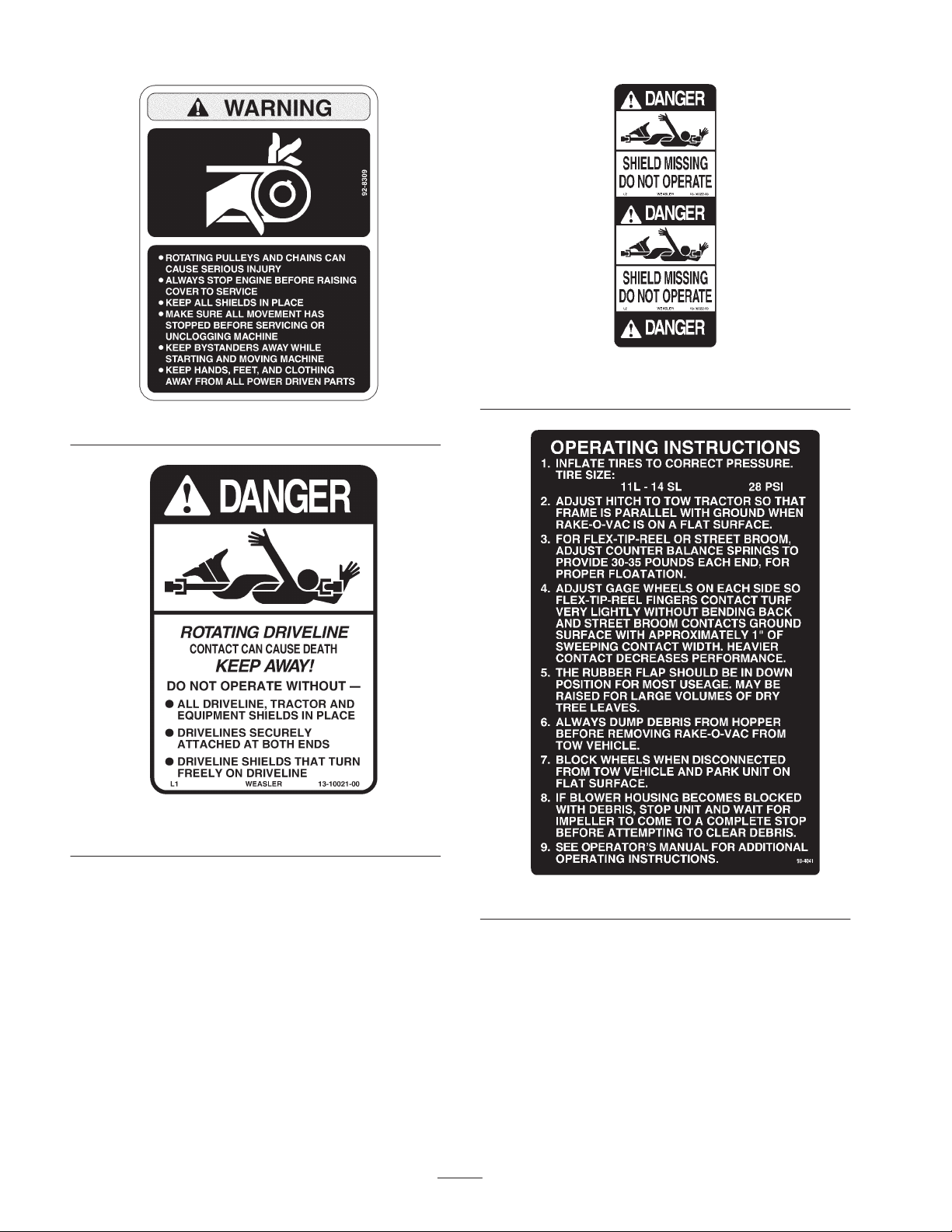

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

67-5360

• To be sure of optimum performance and safety, always

purchase genuine TORO replacement parts and

accessories. Replacement parts and accessories made by

other manufacturers could be dangerous. Such use

could void the product warranty of The Toro Company.

1. Slow moving vehicle

13-6410

13-7430

61-5950

13-2930

53-4420

13-6760

93-7307

5

92-8309

92-1581

(Model 07052)

92-1582

(Model 07052)

93-4041

6

Specifications

Note: Specifications and design are subject to change without notice.

(Model 07050): Kohler, 4 cycle air cooled 22 H.P. engine @ 3600 rpm, 41.1 cu. in.

Machine Drive

Frame All welded structural rectangular 11 ga. tubing.

Hitch (Model 07050) Pin–type, 3/4” dia. vertically adjustable in 1” increments.

(674 cc) displacement. Oil capacity is 4 pints w/filter. Mechanical fuel pump. Gas

tank capacity is 4 gallons.

(Model 07052): Powered by Power Take Off drive from prime mover–540 RPM.

Hitch (Model 07052)

Fan

Fan Drive (Model 07050)

Fan Drive (Model 07052)

Hopper

Flex Tip Reel

Flex Tip Reel Drive

(Model 07050)

Pin–type, 3/4” dia. three vertical positions for tractor hitches ranging from 7–1/4” to

17–1/4” in height.

Centrifugal type–double inlet; 4 blade, 16” wide, 23–14” diameter, 3/16” thick, high

tensile steel. Shaft mounted in self–aligning, sealed ball bearings. Blower inlet area

is 286 sq. in., blower discharge area is 255 sq. in. Twin fan hood construction for

uniform air distribution: 4–1/2” deep x 63” wide (inlet area–283 sq. in.); variable

position from weighted rubber flap.

Banded double drive belt direct from drive shaft to fan impeller drive shaft with

driver pulley, fan with driven pulley. Fan impeller runs at 1580 R.P.M. (tip speed

9100 ft./min.) at 3250 engine R.P.M.

Banded double drive belt direct from drive shaft to fan impeller drive shaft with

driver pulley, fan with driven pulley. Fan impeller runs at 1490 R.P.M. (tip speed

9100 ft./min.) with 540 PTO R.P.M.

5–3/4 cu. yd. volume; 18 gauge top section with 16 gauge bottom section–rib

reinforced; full width self cleaning semi–automatic dumping.

Forward spinning with 6 rows of teeth. All steel construction with replaceable nylon

teeth; each row containing 11 individually spring–loaded flexible sets, 552 teeth

total; shaft set in self–aligning sealed bearings. Reel supported by adjustable

counter balance springs and adjustable gauge wheels. Gauge wheels are steel

construction with non–scuffing rubber tires and sealed ball bearings; infinitely

adjustable vertically.

Banded double drive belt from engine pulley to jackshaft pulley; belt from jack shaft

(driver) pulley to flex tip reel (driven) pulley. Flex tip runs at 275 R.P.M. (tip speed

1355 ft./min.) at 3250 engine R.P.M.

Flex Tip Reel Drive

(Model 07052)

#60 roller chain from 40 tooth side shaft sprocket to 29 tooth jackshaft sprocket.

Belt jack shaft (driver) pulley flex tip reel (driven) pulley. Flex tip runs at 260 R.P.M.

(tip speed 1,230 ft./min.) with 540 R.P.M.

Dimensions and Weights

(approx.)

Width 85–1/2”

Height 79–1/2”

Length 13’ 3” (Model 07050)

14’ (Model 07052)

Empty Weight 2160 lb. (Model 07050)

1980 lb. (Model 07052)

Optional Equipment

Hard Surface Brush Kit Model No. 07162

Thatching Reel Kit Model No. 07178

Flex Tip Reel Model No. 07164

Spark Arrester Muffler* Kohler No 1218902

* Contact Your Local Kohler Dealer

7

Setup

Note: Determine the left and right side of the machine from the normal operating position.

Description Qty. Use

Clutch Adjusting Plates

Bolt

Nut

Operator’s Manual

Engine Operator’s Manual

Parts Catalog 1

Registration Card 1 Fill out and return to Toro.

Remove, Activate And Charge

Battery

(Model 07050 only)

1. If Battery is not filled with electrolyte or activated, bulk

electrolyte with 1.260 specific gravity must be

purchased from a local battery supply outlet and added

to battery.

Danger

Battery electrolyte contains sulfuric acid which is a

deadly poison and causes severe burns.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

2

4

4

1

1

Use to torque clutch

Read before operating the machine.

2. When battery is charged, disconnect charger from

electrical outlet and battery posts. Allow battery to sit

for 5 to 10 minutes before proceeding to next step.

3. Unhook springs from battery cover, remove cover and

lift battery out of battery box.

4. Remove filler caps from battery and slowly fill each

cell until electrolyte is up to fill line.

5. Replace filler caps and connect a 3 to 4 amp battery

charger to the battery posts. Charge the battery at a rate

of 3 to 4 amperes for 4 to 8 hours.

Warning

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks and

flames away from battery.

6. Remove filler caps and slowly add electrolyte to each

cell until level is up fill line. Install filler caps.

Warning

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

Important Do not overfill battery. Electrolyte will

overflow onto other parts of the machine and severe

corrosion and deterioration will result.

Install Battery

(Model 07050 only)

1. Slide the battery into battery box with the terminals to

the inside.

8

Warning

5. Adjust sweeper hitch tongue to same level as hitch of

prime mover as follows:

Battery terminals or metal tools could short

against metal tractor components causing sparks.

Sparks can cause the battery gasses to explode,

resulting in personal injury.

• When removing or installing the battery, do not

allow the battery terminals to touch any metal

parts of the tractor.

• Do not allow metal tools to short between the

battery terminals and metal parts of the tractor.

2. Attach the negative cable (wire from engine block) to

the negative (–) terminal of the battery.

Warning

Incorrect battery cable routing could damage the

tractor and cables causing sparks. Sparks can

cause the battery gasses to explode, resulting in

personal injury.

• Always disconnect the negative (black) battery

cable before disconnecting the positive (red)

cable.

• Always connect the positive (red) battery cable

before connecting the negative (black) cable.

Model 07050

• Remove capscrews and locknuts securing hitch tongue

to frame (Fig. 2).

• Raise or lower hitch tongue to position approximately

level with prime move hitch and secure with (2)

capscrews and locknuts.

1

3

23–1/2”

3. Attach the positive cable (wire from ignition switch) to

the positive (+) terminal.

4. Coat the terminals and mounting fasteners with

petroleum jelly to prevent corrosion.

5. Install battery cover and secure with springs.

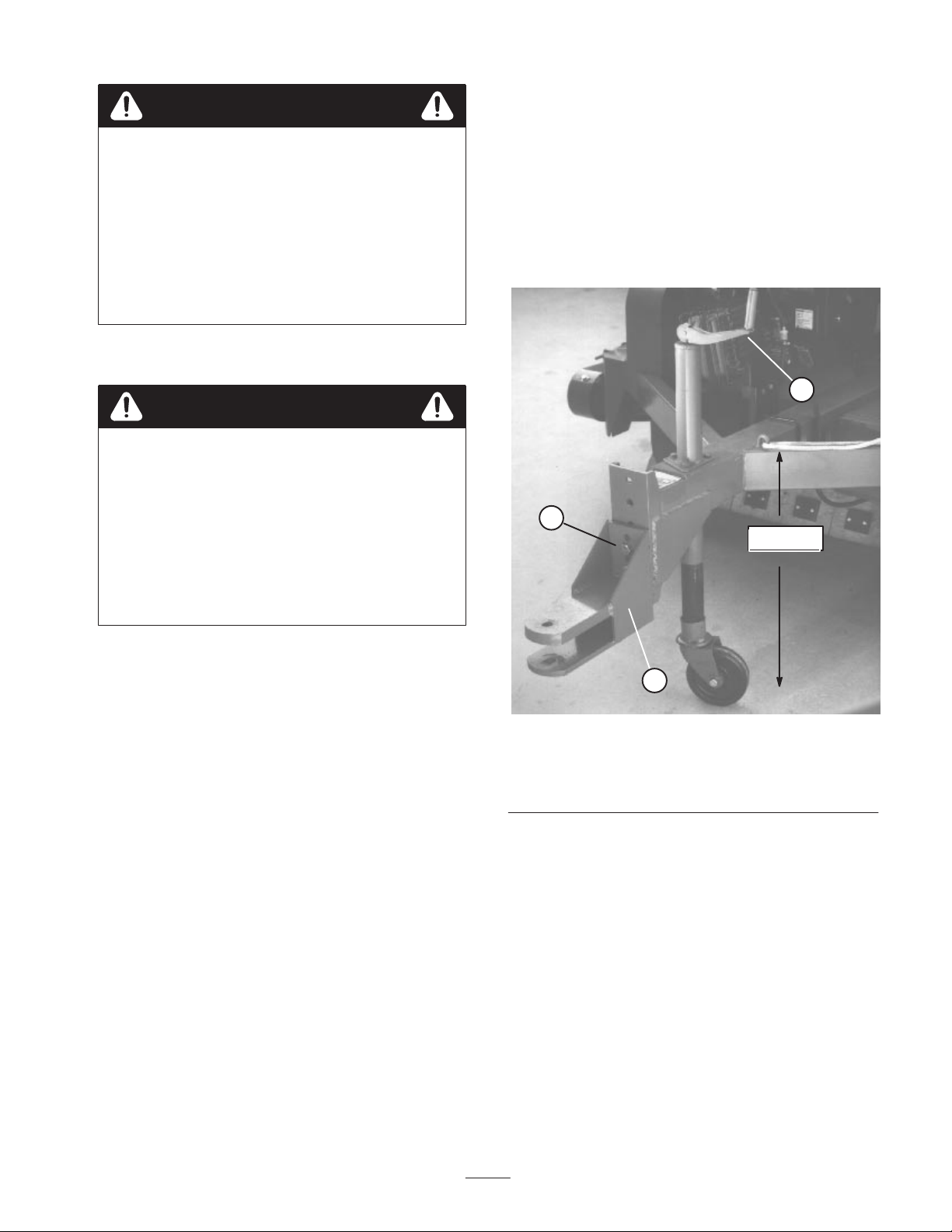

Mount Sweeper To Prime

Mover

To assure proper debris pickup, make sure sweeper frame is

parallel with the ground.

1. Position sweeper on a flat, level surface.

2. Insert sweeper jack caster wheel onto sweeper end of

jack tube.

3. Adjust sweeper jack so distance from top of frame to

ground is approximately 23–1/2” (Fig. 2).

4. Back prime mover up to sweeper.

2

Figure 2

1. Sweeper jack

2. Hitch tongue

(Model 07050)

3. Adjusting screws

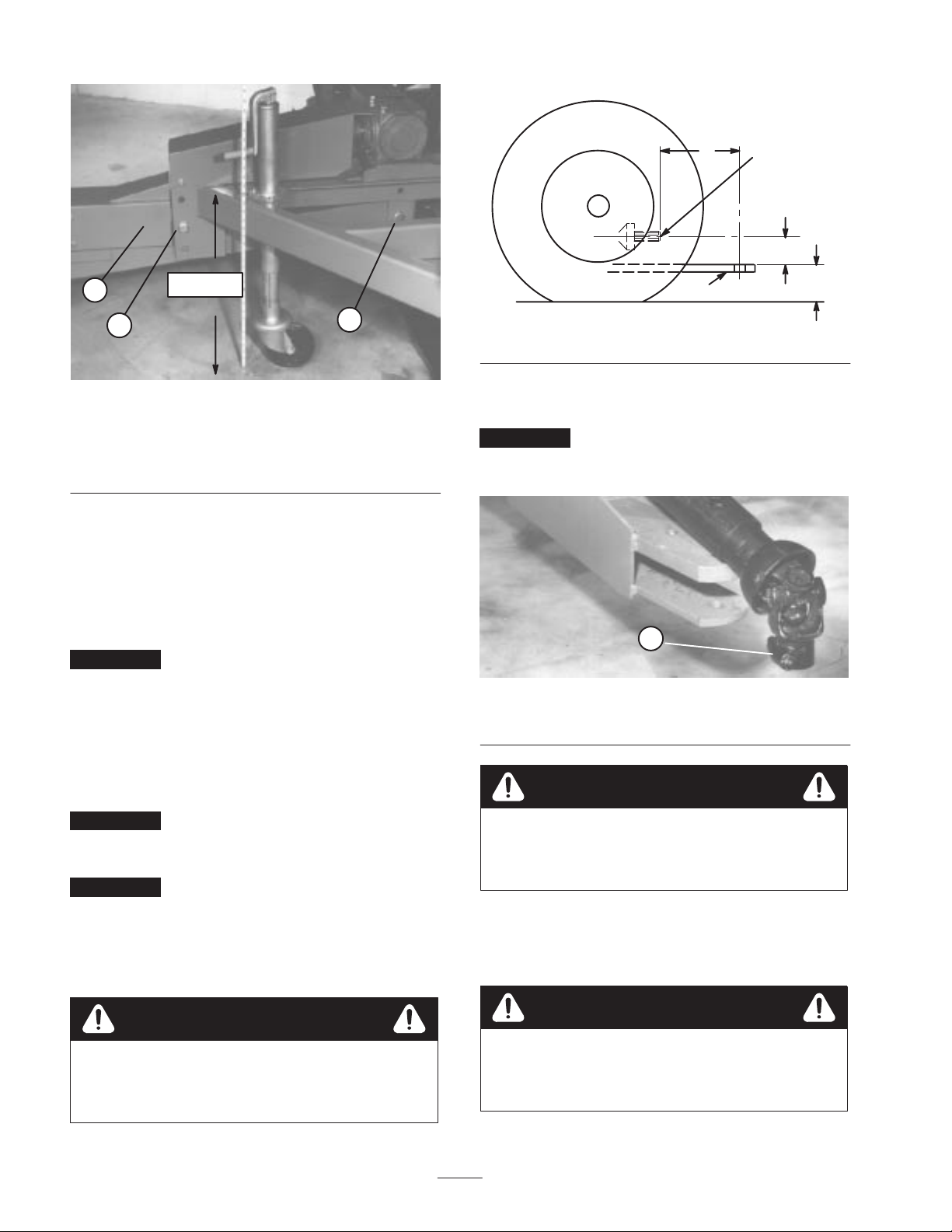

Model 07052

• Remove front and rear capscrews and locknuts securing

hitch tongue to frame (Fig. 3).

• Raise or lower hitch tongue to position it approximately

level with prime move hitch and secure with (2)

capscrews and locknuts. The main frame should be

parallel with the ground surface about 23–1/2” when

attached to tractor.

9

A = 13–1/2” TO 14–l/2”

B = 2–3/4” TO 11–1/2’’

C = 7–1/4” TO 17–1/4”

A

P.T.O. SHAFT

(540 RPM)

B

1

2

1. Hitch tongue

(Model 07052)

2. Front adjustment

capscrew

6. Secure sweeper hitch tongue to prime mover hitch with

hitch pin and hair pin cotter.

7. Raise sweeper jack caster wheel tube up to frame and

fold handle down.

8. Store caster wheel in compartment on left side of

machine in front of hopper.

Important After first ten hours of operation, re–tighten

capscrews and locknuts securing hitch tongue to sweeper.

23–1/2”

3

Figure 3

3. Rear adjustment

capscrew

Connecting Drive Shaft to

DRAW BAR

Figure 4

1. Attach drive shaft quick disconnect to P.T.O. shaft of

prime mover.

Important A shield should be provided on tractor to

cover drive shaft universal joint. Do not operate drive shaft

without this shield in place.

1

Figure 5

1. Drive shaft quick coupler

C

Prime Mover PTO Shaft

(Model 07052 only)

Important Mating tractor must have the dimensions

shown in figure 4. Do not operate sweeper with tractor of

different dimensions.

Important The distance (“A” Figure 4) between the

hole in the tractor hitch and the point where the drive shaft

coupler attaches to the prime mover, P.T.O. shaft must be

14’’ plus or minus 1/2”. If 14” is not attained, an

adjustment to the tractor hitch must be made before

operating sweeper.

Warning

If ”B” dimension (Fig. 4) is less than 3”, extreme

caution must be used when tractor and sweeper

unit crests tops of steep hills.

Warning

This sweeper is designed for a 540 RPM P.T.O.

shaft only. Do not operate with a 1000 RPM P.T.O.

tractor.

Removing Sweeper From

Prime Mover

Warning

Always empty sweeper hopper before

disconnecting hopper from prime mover or

sweeper may tip backwards and cause injury.

1. Park sweeper on a level surface and block wheels.

10

Loading...

Loading...