Page 1

FORM NO. 3321–891

Wheel Horse

12–32

RecyclerRider

Model No. 70171 – 9900001 & Up

Operator’s Manual

IMPORTANT: Read this manual carefully. It contains information about your

safety and the safety of others. Also become familiar with the controls and

their proper use before you operate the product.

International English (GB)

Page 2

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied

with your new product, so feel free to contact your

local Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

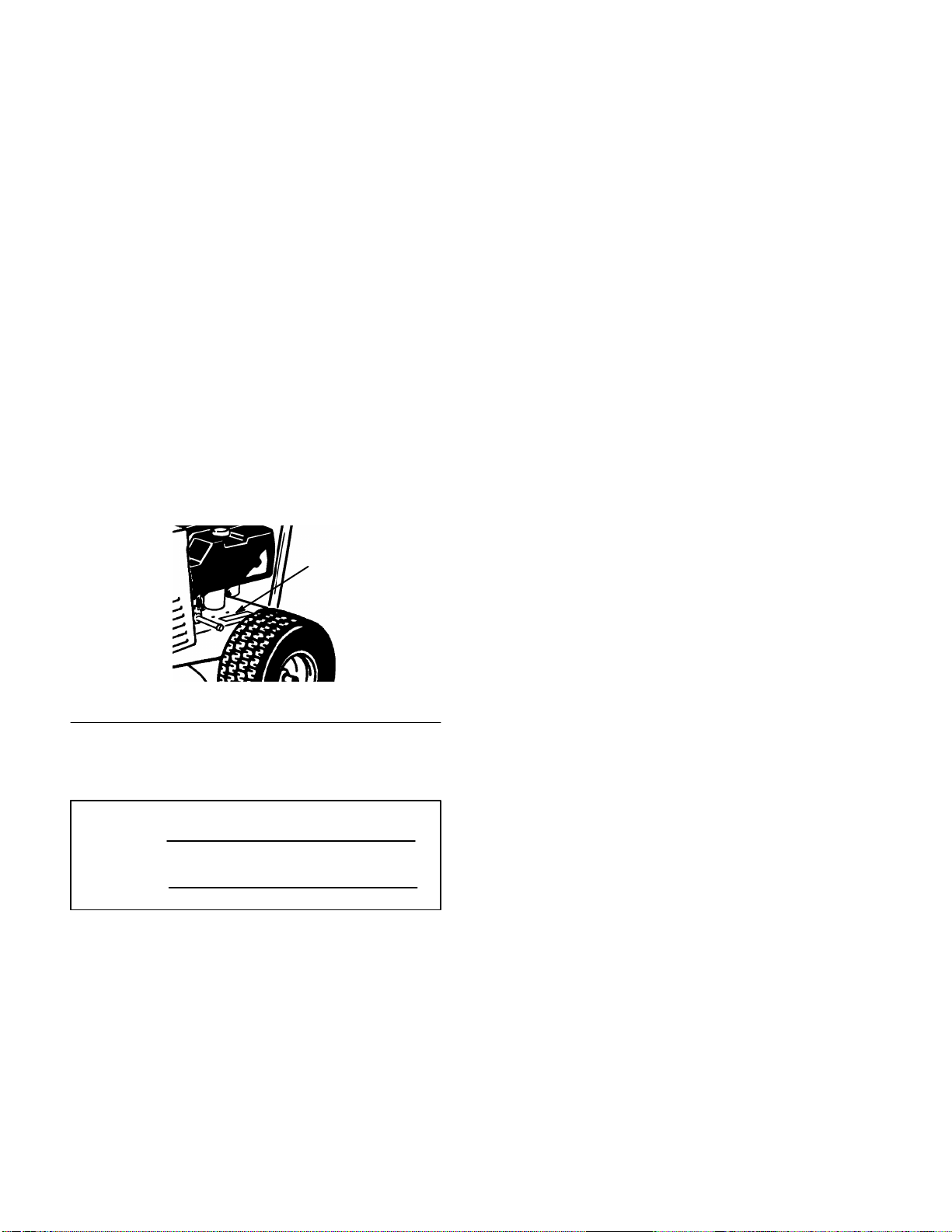

product. You will find the model and serial number

plate located in a unique place on the product as

shown below.

1

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

1. Model and Serial Number Plate (on left frame)

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

Read this manual carefully to learn how to operate

and maintain your product correctly. Reading this

manual will help you and others avoid personal injury

and damage to the product. Although we design,

produce and market safe, state-of-the-art products,

you are responsible for using the product properly

and safely. You are also responsible for training

persons, who you allow to use the product, about safe

operation.

The left and right side of the machine is determined

by sitting on the seat in the normal operator’s

position.

The Toro Comany – 1998

All Rights Reserved

Page 3

Contents

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 2. . . . . . . . . . . . . .

Sound Pressure Level 4. . . . . . . . . . . . . . . . .

Sound Power Level 4. . . . . . . . . . . . . . . . . .

Vibration Level 4. . . . . . . . . . . . . . . . . . . . .

Slope Chart 5. . . . . . . . . . . . . . . . . . . . . . . . .

Symbols Glossary 7. . . . . . . . . . . . . . . . . . .

Symbols Glossary 8. . . . . . . . . . . . . . . . . . .

Symbols Glossary 9. . . . . . . . . . . . . . . . . . .

Gasoline and Oil 10. . . . . . . . . . . . . . . . . . . . . . . .

Recommended Gasoline 10. . . . . . . . . . . . . .

Stabilizer/Conditioner 11. . . . . . . . . . . . . . . .

Filling the Fuel Tank 11. . . . . . . . . . . . . . . . .

Check Engine Oil Level 11. . . . . . . . . . . . . . .

Assembly 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 12. . . . . . . . . . . . . . . . . . . . . . . . .

Install Front Wheels 13. . . . . . . . . . . . . . . . . .

Install Steering Wheel 13. . . . . . . . . . . . . . . .

Install Seat 13. . . . . . . . . . . . . . . . . . . . . . . . .

Activate the Battery 14. . . . . . . . . . . . . . . . . .

Fill Crankcase With Oil 16. . . . . . . . . . . . . . .

Operation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First 17. . . . . . . . . . . . . . . . . . .

Controls 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Shift 17. . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Pedal 17. . . . . . . . . . . . . . . . . . . . . . . .

Brake Pedal 17. . . . . . . . . . . . . . . . . . . . . . . .

Parking Brake 17. . . . . . . . . . . . . . . . . . . . . . .

Ignition Switch 18. . . . . . . . . . . . . . . . . . . . . .

Deck Engagement Lever 18. . . . . . . . . . . . . .

Height–of–Cut Control 18. . . . . . . . . . . . . . .

Key Choice 18. . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Control 18. . . . . . . . . . . . . . . . . . . . .

Starting and Stopping the Engine 18. . . . . . .

Page

Page

Break–In 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Height–of–Cut 19. . . . . . . . . . . . . .

Operating Procedure 19. . . . . . . . . . . . . . . . .

The Safety Interlock System 20. . . . . . . . . . .

Operating–in–Reverse 20. . . . . . . . . . . . . . . .

Side Discharging or Bagging 22. . . . . . . . . . .

Driving Forward or Backward 23. . . . . . . . . .

Stopping the Machine 23. . . . . . . . . . . . . . . .

Positioning the Seat 24. . . . . . . . . . . . . . . . . .

RecyclerrMowing Tips 24. . . . . . . . . . . . . . . .

Tips for Cutting Grass 25. . . . . . . . . . . . . . . .

Maintenance 28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 28. . . . . . . . . . . . . . . .

Air Cleaner 29. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil 30. . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug 31. . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication 32. . . . . . . . . . . . . .

Tire Pressure 33. . . . . . . . . . . . . . . . . . . . . . . .

Brake 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank 35. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Wheel Toe-In 35. . . . . . . . . . . . . . . . . .

Battery 36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing Cutter Blade 38. . . . . . . . . . . . . . . .

Removing/Installing Cutting Unit 39. . . . . . .

Replacing Blade Drive Belt 40. . . . . . . . . . . .

Adjusting Blade Drive Belt 40. . . . . . . . . . . .

Replacing Traction Drive Belt 40. . . . . . . . . .

Leveling Cutting Unit 41. . . . . . . . . . . . . . . .

Adjusting Gear Shift Neutral Position 42. . . .

Wiring Diagram 43. . . . . . . . . . . . . . . . . . . . .

Cleaning and Storage 44. . . . . . . . . . . . . . . . .

Washing Underside of Mower 45. . . . . . . . . .

Troubleshooting 46. . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 4

Safety

This machine meets or exceeds European

Standards in effect at the time of production.

However, improper use or maintenance by the

operator or owner can result in injury. To reduce

the potential for injury, comply with these safety

instructions and always pay attention to the safety

alert

WARNING, or DANGER—“personal safety

instruction.” Failure to comply with the

instruction may result in personal injury or death.

symbol, which means CAUTION,

Safe Operating Practices

This product is capable of amputating hands and feet

and throwing objects. Always follow all safety

instructions to avoid serious injury or death.

POTENTIAL HAZARD

• Engine exhaust contains carbon monoxide,

which is an odorless, deadly poison.

WHAT CAN HAPPEN

• Carbon monoxide can kill you and is also

known to the State of California to cause

birth defects.

General Operation

1. Read, understand, and follow all instructions in

the operator’s manual and on the machine before

starting.

2. Allow only responsible adults who are familiar

with the instructions to operate the machine.

3. Clear the area of objects such as rocks, toys,

wire, etc., which could be picked up and thrown

by the blade.

4. Be sure the area is clear of other people before

mowing. Stop the machine if anyone enters the

area.

5. Never carry passengers.

6. Do not mow in reverse unless absolutely

necessary. Always look down and behind before

and while backing.

7. Be aware of the mower discharge direction and

do not point it at anyone. Do not operate the

mower without either the entire grass catcher or

the guard in place.

8. Slow down before turning. Sharp turns on any

terrain may cause loss of control.

HOW TO AVOID THE HAZARD

• Do not run engine indoors or in an enclosed

area.

2

9. Never leave a running machine unattended.

Always turn off blades, set parking brake, stop

engine, and remove key before dismounting.

10. Turn off blades when not mowing.

11. Keep hands, feet, hair and loose clothing away

from attachment discharge area, underside of

mower and any moving parts while engine is

running.

12. Stop the engine before removing the grass

catcher or unclogging the chute.

13. Mow only in daylight or good artificial light.

Page 5

Safety

14. Do not operate the machine while under the

influence of alcohol or drugs.

15. Watch for traffic when operating near or crossing

roadways.

16. Use extra care when loading or unloading the

machine onto a trailer or truck.

17. Do not touch equipment or attachment parts

which may be hot from operation. Allow to cool

before attempting to maintain, adjust or service.

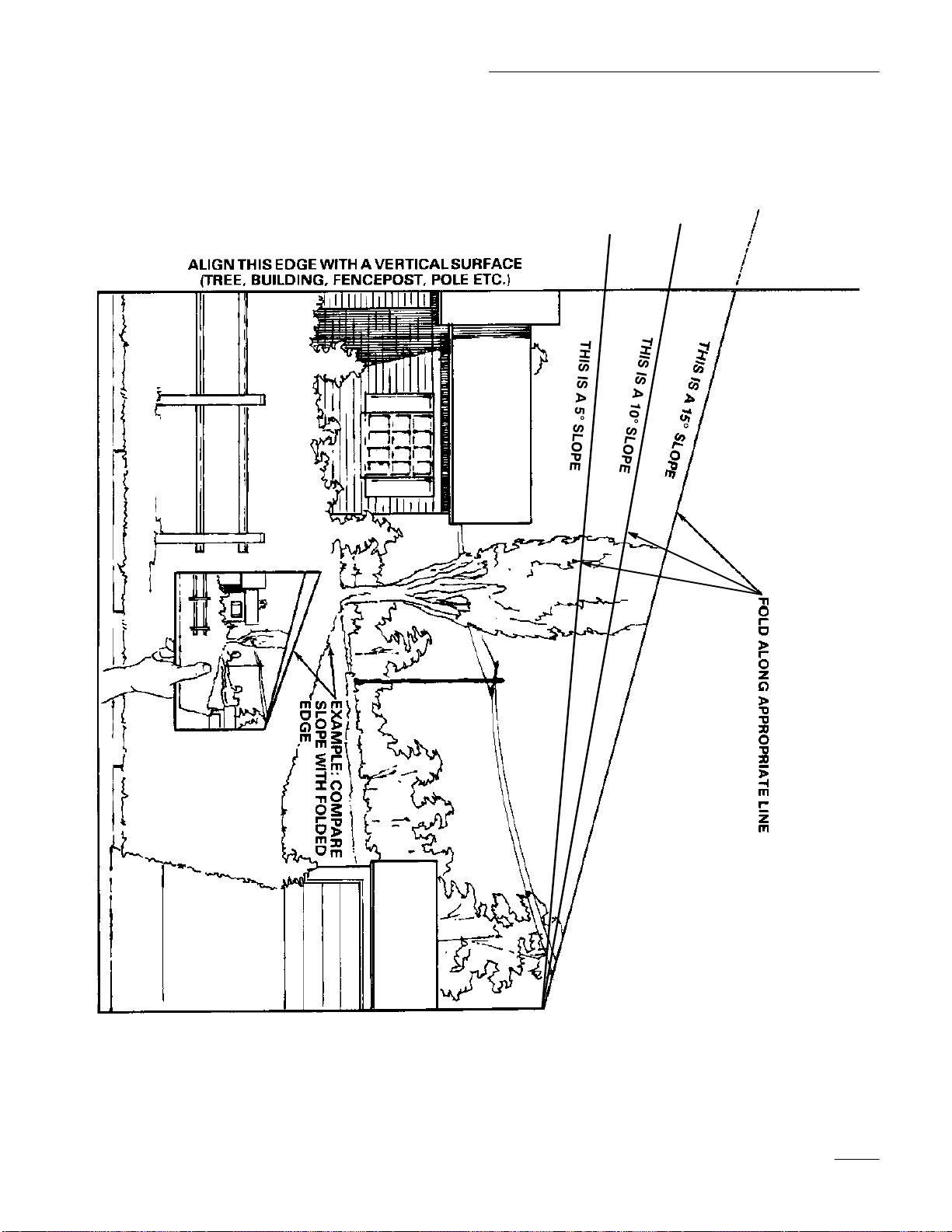

Slope Operation

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra caution. If

you cannot back up the slope or if you feel uneasy on

it, do not mow it.

DO

• Keep all movement on slopes slow and gradual.

Do not make sudden changes in speed or

direction.

• Avoid starting or stopping on a slope. If tires

lose traction, disengage the blades and proceed

slowly straight down the slope.

DO NOT

• Do not operate machine on hillsides or slopes

exceeding 15°.

• Avoid turning on slopes. If you must turn, turn

slowly and gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or

embankments. The machine could suddenly turn

over if a wheel goes over the edge of a cliff or

ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction

could cause sliding.

• Mow up and down slopes greater than 5°, not

across.

• Mow downhill only on slopes above 10°, never

mow uphill. If a steep slope must be ascended,

back up the hill, and drive forward down the hill,

keeping the machine in gear.

• Remove obstacles such as rocks, tree limbs, etc.

from the mowing area. Watch for holes, ruts or

bumps, as uneven terrain could overturn the

machine. Tall grass can hide obstacles.

• Use slow speed. Choose a low gear so that you

will not have to stop or shift while on the slope.

• Follow the manufacturer’s recommendations for

wheel weight or counterweights to improve

stability.

• Use extra care with grass catchers or other

attachments. These can change the stability of

the machine.

• Do not try to stabilize the machine by putting

your foot on the ground.

• Do not use a grass catcher on steep slopes.

Heavy grass bags could cause loss of control or

overturn the machine.

Children

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them. The following requirements must be

followed to prevent injury to children.

1. Keep children out of the mowing area and under

the watchful care of another responsible adult.

2. Be alert and turn the machine off if children

enter the area.

3. Before and while backing, look behind and down

for small children.

3

Page 6

Safety

4. Never carry children. They may fall off and be

seriously injured or interfere with safe machine

operation.

5. Never allow children to operate the machine.

6. Use extra care when approaching blind corners,

shrubs, trees, the end of a fence or other objects

that may obscure vision.

Service

1. Stop the engine and disconnect spark plug

wire(s) before performing any service, repairs,

maintenance or adjustments.

2. Use extra care when handling gasoline and other

fuels. They are flammable and vapors are

explosive.

A. Use only an approved container.

B. Never remove the gas cap or add fuel when

the engine is running. Allow the engine to

cool before refueling. Do not smoke.

C. Never refuel the machine indoors.

D. Never store the machine or fuel container

inside where there is an open flame, such as

near a water heater or furnace.

Frequently check components and replace with

manufacturer’s recommended parts, when

necessary.

9. Mower blades are sharp and can cut. Wrap the

blade(s) or wear gloves, and use extra caution

when servicing them.

10. Use only genuine replacement parts to ensure

that original standards are maintained.

11. Check brake operation frequently. Adjust and

service as required.

12. Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing.

Protect your face, eyes and clothing when

working with a battery.

13. Battery gases can explode. Keep cigarettes,

sparks and flames away from battery.

Sound Pressure Level

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 87 dB(A), based

on measurements of identical machines per

procedures outlined in Directive 84/538/EEC and

amendments.

3. Never run a machine inside a closed area.

4. Keep nuts and bolts tight, especially the blade

attachment bolts. Keep equipment in good

condition.

5. Never tamper with safety devices. Check safety

systems for proper operation before each use.

6. Keep the machine free of grass, leaves, or other

debris build-up. Clean up oil or fuel spillage.

Allow the machine to cool before storing.

7. Stop and inspect the equipment if you strike an

object. Repair, if necessary, before restarting.

8. Grass catcher components are subject to wear,

damage and deterioration, which could expose

moving parts or allow objects to be thrown.

4

Sound Power Level

This unit has a sound power level of: 100 Lwa based

on measurements of identical machines per

procedures outlined in Directive 84/538/EEC and

amendments.

Vibration Level

This unit has a maximum hand-arm vibration level of

4.5 m/s

based on measurements of identical machines per EN

1033 and EN 1032..

2

and whole body vibration level of 0.25 m/s2,

Page 7

Slope Chart

Read all safety instructions on pages 2–4.

Safety

5

Page 8

6

Page 9

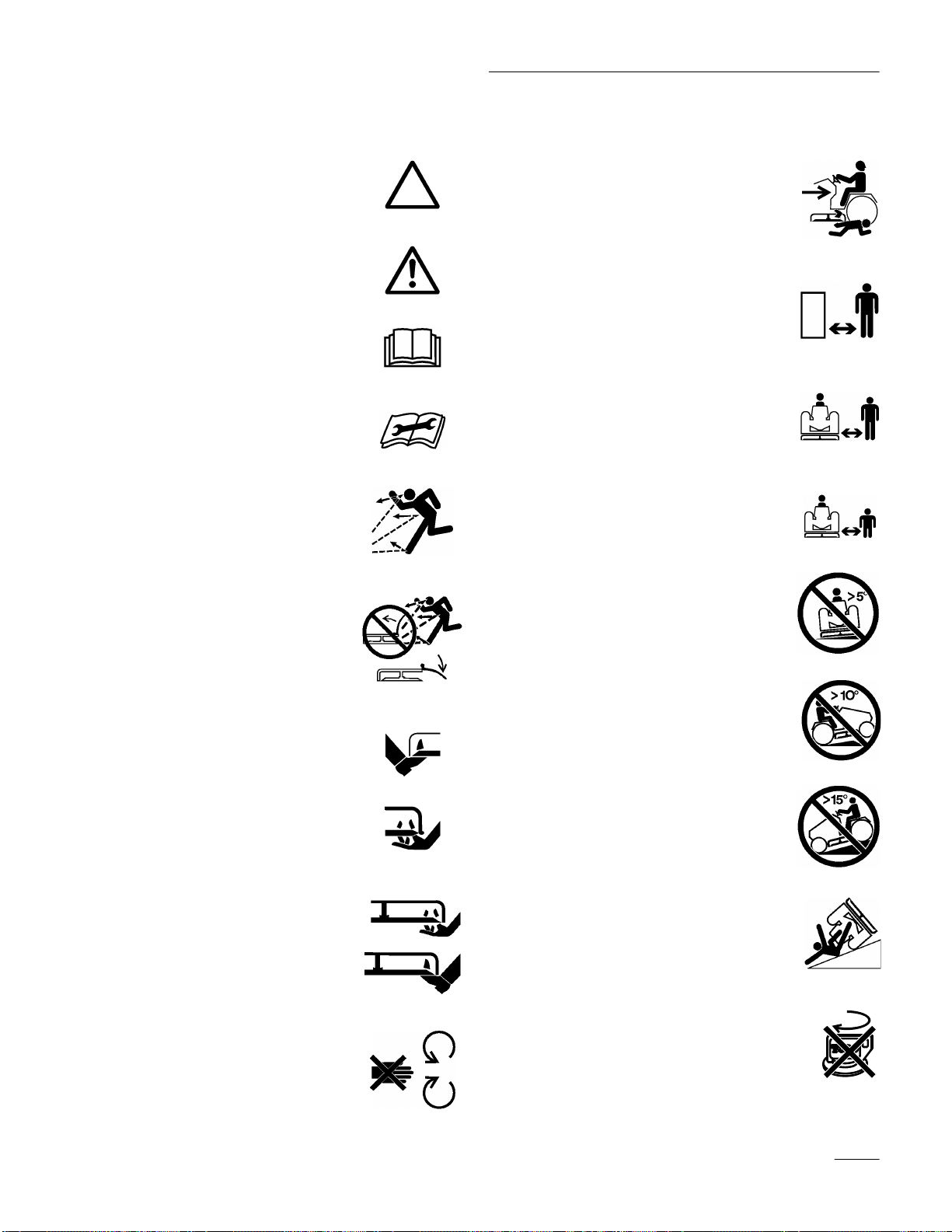

Symbols Glossary

Safety

Safety alert symbol

Safety alert symbol

Read operator’s manual

Consult Technical Manual for

proper service procedures

Thrown or flying objects–

Whole body exposure

Thrown or flying objects–

Rotary side-mounted mower.

Keep deflector shield in place

Dismemberment–Mower

in rearward motion

Stay a safe distance

from the machine

Stay a safe distance

from the mower

Keep children a safe distance

from machine

Machine rollover

side hill

Severing toes or foot–

mower blade

Severing fingers or hand–

mower blade

Rotating blade can cut off

toes or fingers. Stay clear

of blade as long as engine

is running

Do not open or

remove safety shields

while engine is running

Machine rollover

up hill

Machine rollover

down hill

Machine rollover

ROPS

Operating in reverse not

allowed unless deactivated

by Key Choice switch

7

Page 10

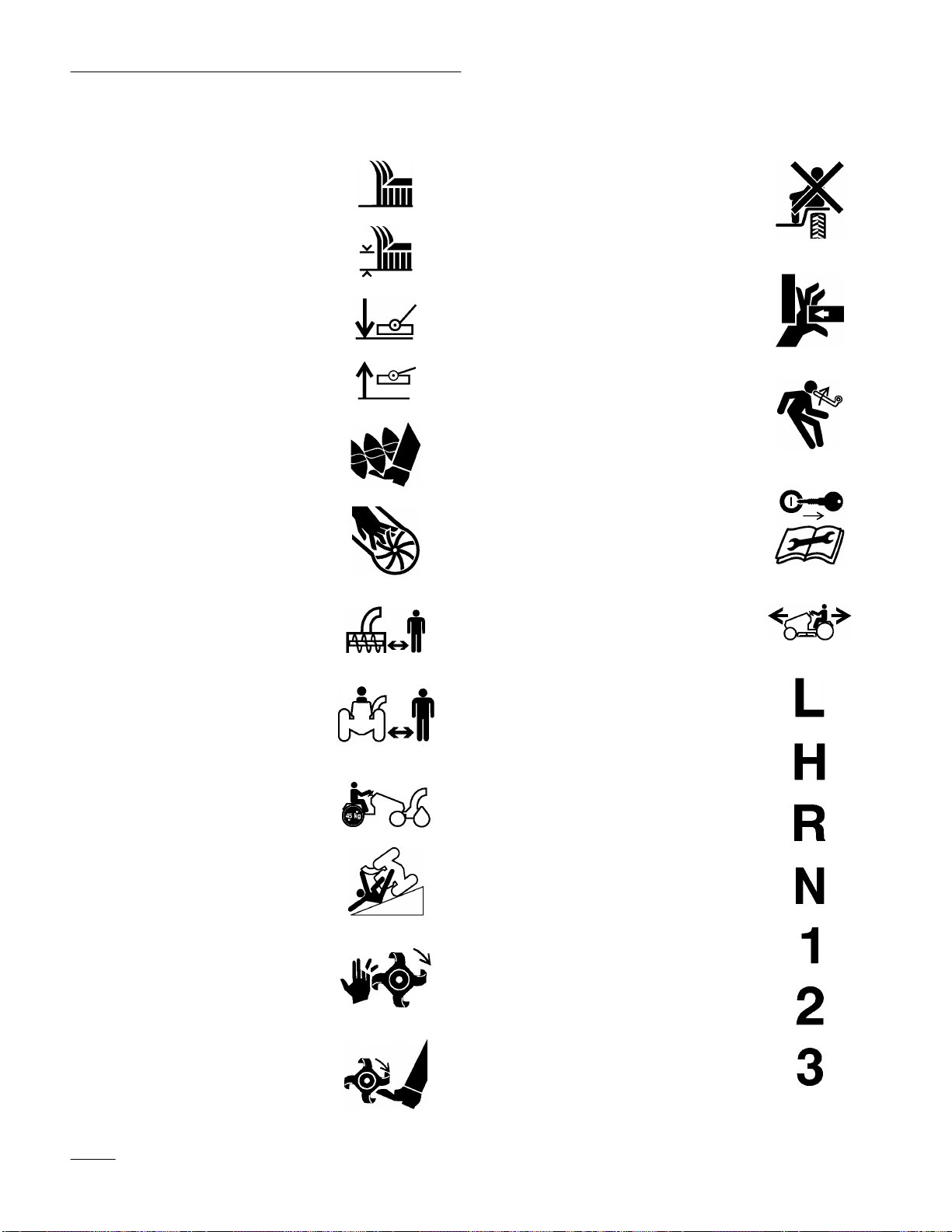

Safety

Symbols Glossary

Cutting element–

basic symbol

Cutting element–

height adjustment

Cutting unit–lower

Cutting unit-raised

Cutting or entanglement

of foot–Rotating auger

Severing of fingers or hand–

impeller blade

Keep a safe distance from

snowthrower

Riding on this machine is allowed

only on a passenger seat & only

if the driver’s view is not hindered

Crushing of fingers

or hands–Force applied

from side

Kickback or upward

motion–Stored energy

Shut off engine & remove key

before performing maintenance

or repair work

Machine travel direction–

combined

Stay a safe distance

from the snowthrower

Tractors must be equipped

with 45kg rear wheel weight

with this attachment installed

Machine rollover

ROPS snowthrower

Severing of hand–

Rotating knives

Severing of foot–

Rotating knives

Low

High

Reverse

Neutral

First gear

Second gear

Third gear up to

maximum # of

forward gears

8

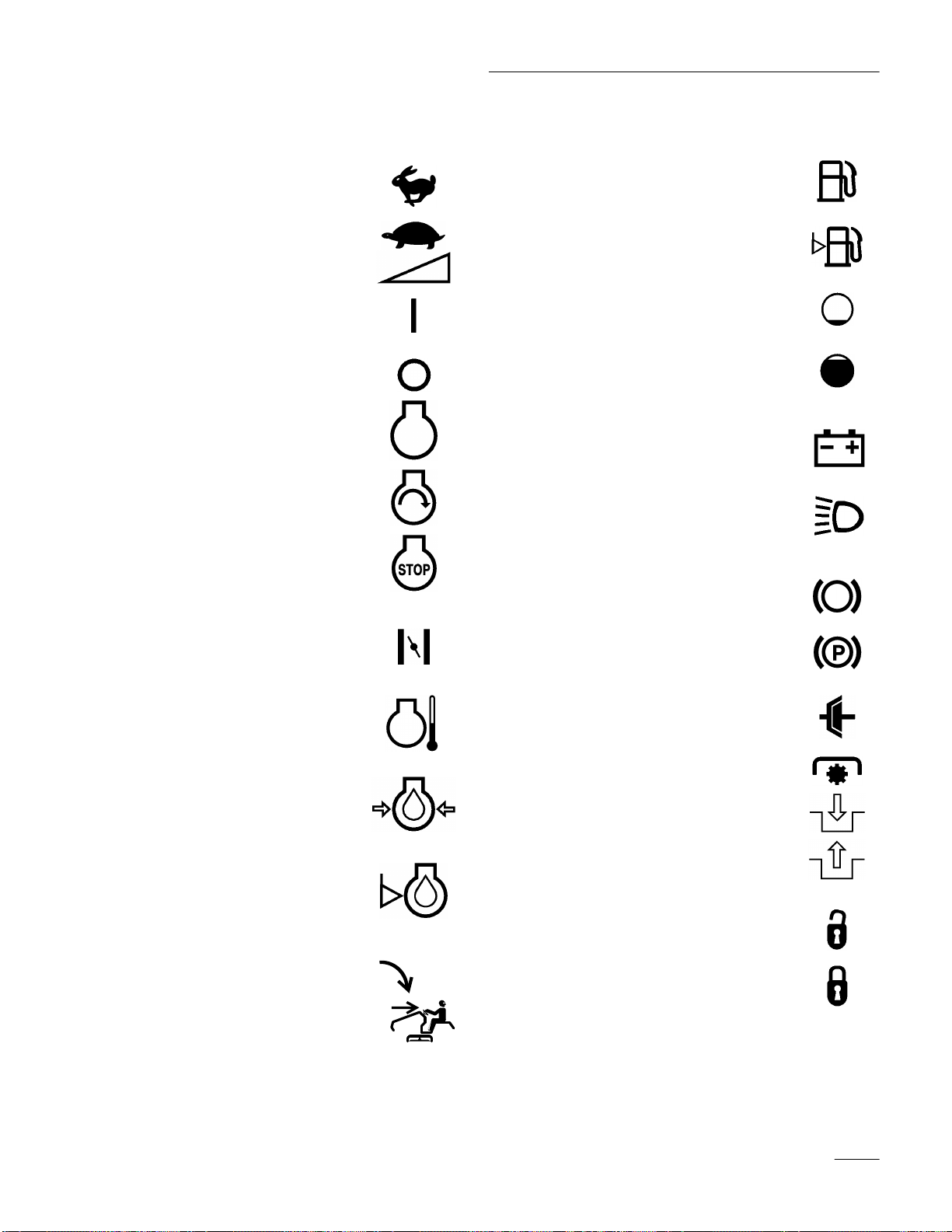

Page 11

Symbols Glossary

Safety

Fast

Slow

Decreasing/Increasing

On/Run

Off/Stop

Engine

Engine start

Engine stop

Fuel

Fuel level

Volume empty

Volume full

Battery charging conditin

Head lights–

Main/high beam

Brake system

Choke

Engine temperature

Engine lubricating

oil pressure

Engine lubricating oil level

Key Choice Switch

Parking brake

Clutch

PTO (Power Take Off)

Engage

Disengage

Unlock

Lock

9

Page 12

Gasoline and Oil

Recommended Gasoline

Use UNLEADED Regular Gasoline suitable for

automotive use (85 pump octane minimum). Leaded

regular gasoline may be used if unleaded regular is

not available.

IMPORTANT: Never use methanol, gasoline

containing methanol, or gasohol containing

more than 10% ethanol because the fuel

system could be damaged. Do not mix oil with

gasoline.

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AVOID THE HAZARD

• Use a funnel and fill the fuel tank outdoors,

in an open area, when the engine is cold.

Wipe up any gasoline that spills.

• Do not fill the fuel tank completely full.

Add gasoline to the fuel tank until the level

is 1/4” to 1/2” (6 mm to 13 mm) below the

bottom of the filler neck. This empty space

in the tank allows gasoline to expand.

• Never smoke when handling gasoline, and

stay away from an open flame or where

gasoline fumes may be ignited by a spark.

• Store gasoline in an approved container

and keep it out of the reach of children.

Never buy more than a 30-day supply of

gasoline.

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AVOID THE HAZARD

• Always place gasoline containers on the

ground away from your vehicle before

filling.

• Do not fill gasoline containers inside a

vehicle or on a truck or trailer bed because

interior carpets or plastic truck bed liners

may insulate the container and slow the

loss of any static charge.

• When practical, remove gas–powered

equipment from the truck or trailer and

refuel the equipment with its wheels on the

round.

• If this is not possible, then refuel such

equipment on a truck or trailer from a

portable container, rather than from a

gasoline dispenser nozzle.

• If a gasoline dispenser nozzle must be used,

keep the nozzle in contact with the rim of

the fuel tank or container opening at all

times until fueling is complete.

10

Page 13

Gasoline and Oil

Stabilizer/Conditioner

Add the correct amount of gas stabilizer/conditioner

to the gas. Using a stabilizer/conditioner in the

machine:

• Keeps gasoline fresh during storage of 90 days

or less. For longer storage it is recommended

that the fuel tank be drained.

• Cleans the engine while it runs

• Eliminates gum-like buildup in the fuel system,

which causes hard starting

IMPORTANT: Never use fuel additives

containing methanol or ethanol.

Filling the Fuel Tank

1. Shut the engine off and set the parking brake.

2. Clean around each fuel tank cap and remove the

cap. Add unleaded regular gasoline to both fuel

tanks, until the level is 1/4 to 1/2 inch (6 mm to

13 mm) below the bottom of the filler neck. This

space in the tank allows gasoline to expand. Do

not fill the fuel tanks completely full.

3. Install fuel tank caps securely. Wipe up any

gasoline that may have spilled.

4. Fuel gauge is located in right side tank.

Check Engine Oil Level

Before you start the engine and use the machine,

check the oil level in the engine crankcase; refer to

Checking Oil Level, page 30.

11

Page 14

Assembly

Loose Parts

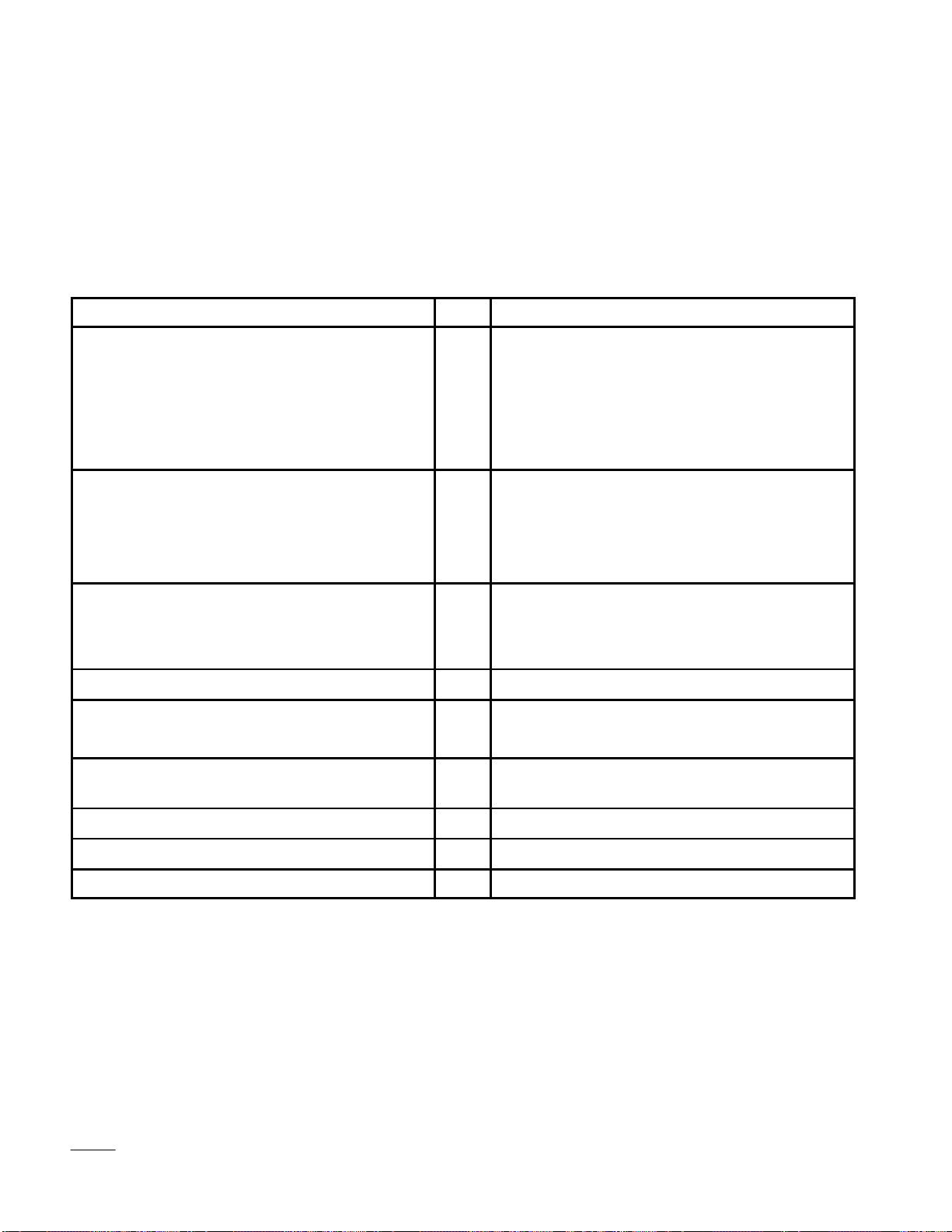

Note: Use the chart below to verify all parts have been shipped.

DESCRIPTION QTY. USE

Seat

Wire Tie

Clamp

Seat Spacer

Locknut

Front Wheel Assembly

Flat Washer

Hub Cap

Cotter Pin

Steering Wheel

Roll Pin

Steering Shaft Cover

Key

Capscrew

Wing Nut

Hose coupling

1

1

1

4

4

2

2

2

2

1

1

1

2

2

2

1

Install Seat, page 10.

Install Front Wheels, page 10.

Install Steering Wheel Assembly, page 10.

Use in ignition and Key Choice Switches

Secure battery cables to battery, page 11.

Connect garden hose to washout port during

maintenance

Operator‘s Manual

Registration Card

Hang Tag

12

1

1

1

Read manual before operating rider.

Fill out and mail to Toro.

Read for Warranty information.

Page 15

Assembly

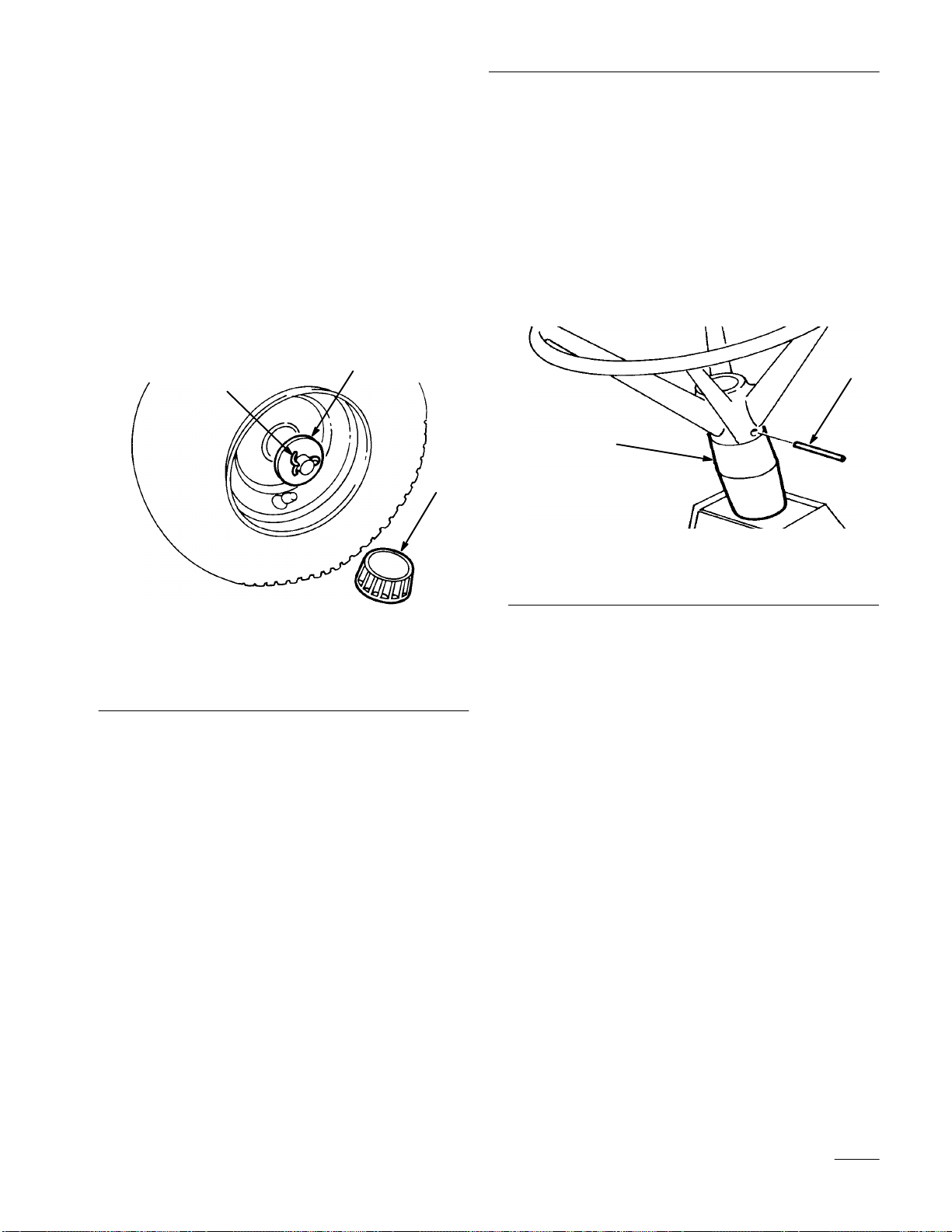

Install Front Wheels

Note: Grease axle shafts before installing

wheels

1. Install wheel onto axle.

2. Mount flat washer onto axle, insert cotter pin

and open pin ends with pliers (Fig. 1).

3. Install hub caps.

1

2

Install Steering Wheel

1. Position wheels in straight ahead direction and

slide steering shaft cover over steering shaft.

2. Slip steering wheel over shaft and line the

steering wheel mount hole with the shaft

mounting hole (Fig. 2). Toro logo should be

readable from operator’s position.

2

1

3

Figue 2

1. Steering shaft cover 2. Roll pin

Figure 1

1. Flat washer

2. Cotter pin

3. Hub cap

4. Repeat steps 1-3 on opposite side.

5. Check front and rear tires for proper inflation.

Refer to Maintenance section under Tire

Pressure, page 33 for proper inflation pressure.

6. Lubricate both front wheels with No. 2 general

purpose grease. Pump grease gun until grease

comes through bearings. Wipe up any excess

grease.

3. Insert a drift punch partially through the holes to

maintain alignment and insert the roll pin in

from the opposite side.

4. Drive the roll pin in until it is flush with the

outside of the wheel (Fig. 2).

Install Seat

1. Thread (4) seat spacers into bottom of seat

(Fig. 3).

2. Position seat onto seat base, inserting seat switch

cable thru slot and spacer studs through

mounting holes (Fig. 3).

3. Slide wire clamp over seat switch wire (Fig. 3).

13

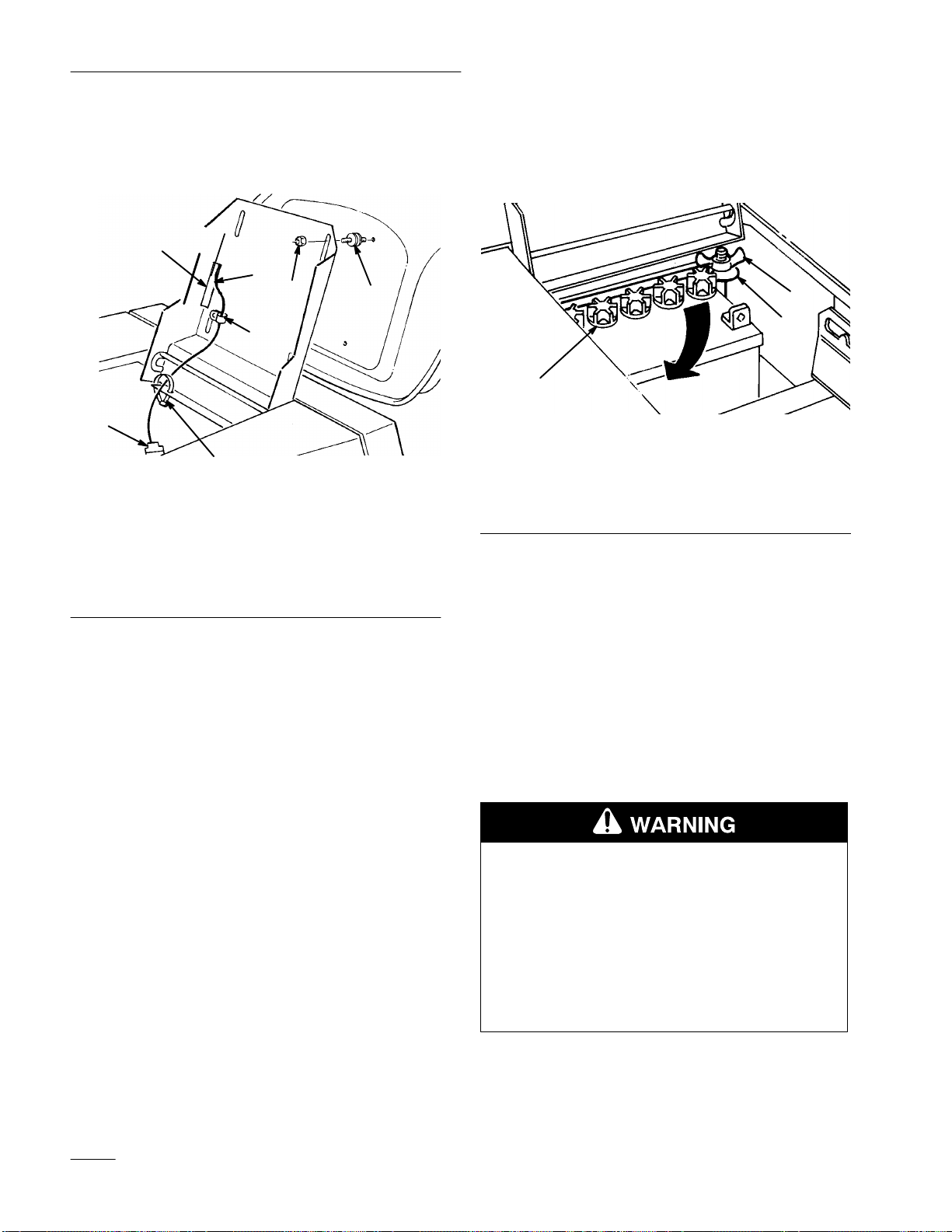

Page 16

Assembly

4. Using left front spacer stud, loosely secure wire

clamp and seat to seat base with a locknut

(Fig. 3).

5

3

1

6

1. Seat spacers

2. Wire clamp

3. Seat switch wire

4. Locknut

4

2

7

Figure 3

5. Seat switch slot

6. Seat switch connector

7. Wire tie

2. Remove wing nut securing battery hold downs to

rider chassis (Fig.4).

1

2

3

Figure 4

1. Wing nut

2. Battery hold–down

3. Filler cap

3. Lift up on top battery hold down and pivot

rearward

4. Remove battery from chassis and set it aside.

5. Mount seat to seat base with (3) remaining

locknuts.

Note: Seat may be adjusted for operator

comfort by positioning seat as desired

in seat base slots.

6. Tighten all locknuts.

7. Insert seat switch connector into wire harness

connector.

8. Secure wire harness to front of seat base with

wire tie.

Activate the Battery

The battery must be removed from the machine so it

can be filled with electrolyte and charged. Remove

the battery and activate it as follows:

1. Tip seat forward exposing battery.

5. Remove filler caps from battery and slowly fill

each cell until electrolyte is just above the

“LOWER” fill line.

6. Leave filler caps off and connect a 3-4 amp

battery charger to battery posts. Charge battery at

a rate of 4 amperes or less for 4 hours (12 volt).

POTENTIAL HAZARD

• Charging battery produces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AVOID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

7. When battery is charged, disconnect charger

from electrical outlet and battery posts.

14

Page 17

Assembly

8. Slowly add electrolyte or distilled water to each

cell until level is just below the “UPPER” fill

line. Reinstall filler caps. Once battery is in

service, distilled water only should be added;

never add more electrolyte.

IMPORTANT:

Do not overfill battery.

Electrolyte will overflow onto other parts and

severe corrosion and deterioration will result.

9. Install the battery with the terminal posts toward

the rear of the machine and vent tube on left

side

of battery, thru hole in frame (Fig. 5).

1

11. Install the red positive cable (rubber boot over

end) to the positive (+) terminal and the negative

cable (black) to the negative (–) terminal of the

battery and secure with capscrews and wing

nuts. Slide the rubber boot over the positive

terminal to prevent a possible short-out from

occurring (Fig. 5).

2

Figure 5

1. Vent tube 2. Throttle cable

10. Reinstall battery hold downs.

POTENTIAL HAZARD

• The battery terminals could short against

the battery hold–down or metal tractor

components.

WHAT CAN HAPPEN

• Sparks can cause the battery gasses to

explode.

HOW TO AVOID THE HAZARD

• When removing or installing the battery, do

not allow the battery terminals to touch any

metal parts of the tractor.

• Always keep the battery hold–down rods

in place to protect and secure the battery.

15

Page 18

Assembly

Fill Crankcase With Oil

The rider is shipped from the factory without oil in

the crankcase.

1. Place rider on a level surface.

2. Unscrew and remove the dipstick from the oil

fill tube (Fig. 6).

3. Insert a funnel into the tube and slowly add

engine oil into the crankcase, using oil fill chart

below. Use a high quality detergent oil classified

“For Service SF, SG, SH”. Oil viscosity (weight)

must be selected according to anticipated

ambient temperature. See table below.

4.

Oil Fill Chart

1232 Rear Engine Rider 48 ounces of oil

5. Ensure the oil level is to the full mark on the

dipstick when it is fully installed. Do not overfill

or engine damage may result.

6. Insert the dipstick and turn it clockwise to secure

it in the fill tube.

Note: Check the oil level every 5 operating

hours or each time rider is used.

Initially, drain the oil and replace it

after the first 5 hours of operation to

remove the contaminants produced by

normal engine break-in; thereafter,

under normal conditions, change oil

after every 25 hours of operation.

Change the oil more frequently when

the engine is operated in dusty or dirty

conditions.

2

1

Figure 6

1. Dipstick 2. Fuel tank cap

USE THESE SAE VISCOSITY OILS

–20 0 20 40 60 80 100

°

F

–30°–20 –10 0 10 20 30 40

C

16

Page 19

Operation

Think Safety First

Please carefully read all the safety instructions on

pages 2–7. Knowing this information could help you,

your family, pets or bystanders avoid injury.

Controls

Become familiar with all the controls (Fig. 7) before

you start the engine and operate the machine.

Gear Shift

(Fig. 7)—Transaxle has five forward speeds, neutral

and reverse. The gear shift lever is located at right

side of operator. An interlock switch prevents engine

from being started when transaxle is in any gear

except neutral.

Clutch Pedal

(Fig. 8)—Used in conjunction with gear shift.

Depress clutch pedal fully when shifting gears and

whenever brake is used.

Brake Pedal

(Fig. 8)—Must be depressed to slow down or stop the

rider. When pedal is depressed, a caliper engages the

brake disc at side of transaxle. Remember to depress

clutch pedal when using brake.

Note: Avoid depressing brake pedal while

clutch is engaged otherwise premature

brake wear will occur. Do not rest foot

on pedal while mowing.

Parking Brake

1

1. Gear shift

Always set the parking brake when you stop the

machine or leave it unattended.

(Fig. 8)—Parking brake must be used in conjunction

with brake pedal. When pedal is depressed, end of

parking brake lever holds brake pedal in depressed

position and a caliper engages the brake disc at side

of transaxle.

Setting the Parking Brake

1. Depress brake pedal fully and shift transaxle to

neutral.

Figure 7

2. Move parking brake control upward and release

brake pedal.

17

Page 20

Operation

Releasing the Parking Brake

1. To release the parking brake, depress brake

pedal, and parking brake lever will return it to its

disengaged position. Release brake pedal slowly.

Ignition Switch

(Fig. 8)—Switch is part of engine ignition system,

and it has three positions: OFF, RUN and START.

Key automatically returns to RUN position from

START position when released after engine starts.

4

1

3

2

Key Choice

(Fig. 9)—A hold and release switch used for

deactivating the “Operating–In–Reverse” interlock

feature. Located on panel in front of and below the

seat.

Throttle Control

(Fig. 9)—Connects to and operates carburetor

mounted throttle and choke. Control has four

positions: IDLE, HOT RESTART, OPERATE and

CHOKE. Push control slightly to the left and upward

to obtain CHOKE position.

1

Figure 8

1. Clutch pedal

2. Brake pedal

3. Parking brake lock

4. Ignition switch

Deck Engagement Lever

(Fig. 9)—Engages and disengages the cutter blade.

An interlock switch prevents engine from starting

when control is in the ENGAGE position. Engine

will start when control is in DISENGAGE position

only.

Height–of–Cut Control

(Fig. 9)—Control varies the cutting height from

approx. 1 to 3 1/2 inches (25 to 89 mm) in six

increments.

4

2

3

Figure 9

1. Deck engagement lever

2. “Key choice” switch

3. Height–of–cut control

4. Throttle control

Starting and Stopping

the Engine

Starting

1. Shift into neutral (N), move deck engagement

lever to DISENGAGE. Lock the parking brake.

18

Page 21

Operation

2. Move throttle control to CHOKE position, and

rotate ignition key to START. When the engine

starts, release the key and immediately move

throttle control between OPERATE and IDLE

positions if choke was used for starting.

3. Select desired height-of-cut and move deck

engagement lever to ENGAGE. Release parking

brake (if necessary), depress clutch pedal and

shift into gear.

4. Release clutch pedal slowly and smoothly.

Stopping

1. Depress clutch and brake pedals, move throttle

control lever to SLOW position, move deck

engagement lever to DISENGAGE, and rotate

ignition key to OFF.

2. Shift transaxle to neutral and engage parking

brake.

3. Remove key from ignition switch. Wait for all

moving parts to stop before getting off seat.

Break–In

The engine requires no special break-in other than

changing oil after the first five hours of operation.

Operate the transaxle in all gears to ensure that drive

system is functioning correctly. After the first five

hours of operation, check the condition of the belts.

3. To engage blade for cutting, move deck

engagement lever to ENGAGE.

Operating Procedure

1. Move deck engagement lever to DISENGAGE

2. Start the engine: refer to Starting/Stopping

Instructions, page 18.

IMPORTANT: When rider is used for the

first time, operate the transaxle in all gears to

ensure that drive system is functioning

correctly, and become familiar with the

controls and operating characteristics. Never

shift while the machine is moving or without

first depressing the clutch pedal; transaxle

damage could result.

3. Depress clutch pedal and shift transaxle into

selected gear. Then release pedal slowly until

traction drive engages.

IMPORTANT: To avoid a jerky start and

putting a heavy load on the transaxle, release

clutch pedal slowly. If shifting into reverse

gear is difficult, jog clutch pedal in and out to

get gears to mesh. Do not force the gear shift

because damage may result. Should you

encounter a jerking or grabbing condition

during operation, contact your local

Authorized TORO Service Dealer for

assistance.

Adjusting Height–of–Cut

The height-of-cut may be set in one of six positions

from approximately 1 to 3 1/2 inches (25 to 89 mm).

1. Ensure the deck engagement lever is in

DISENGAGE position.

2. Move height-of-cut control into desired setting.

4. To engage blade for cutting, move height-of-cut

control to the desired setting. Place throttle in

OPERATE position. Then move deck

engagement lever to ENGAGE position.

5. To stop engine, in sequence, depress clutch and

brake pedals, move throttle control to IDLE,

deck engagement lever into DISENGAGE, gear

shift into neutral, engage parking brake, and

rotate key to OFF position after allowing the

engine to idle a short period.

19

Page 22

Operation

The Safety Interlock System

Understanding the Safety Interlock

System

The safety interlock system is designed to prevent the

engine from starting unless:

• The power take off (PTO) is “OFF”

• The gear shift lever is in “N” neutral.

The safety system is designed to stop the engine if:

• You rise from the seat when the clutch/brake

pedal is released.

• You rise from the seat when the blade (PTO) is

“ENGAGED.”

• You shift into reverse with the power take off

(PTO) engaged and the operating–in–reverse

interlock not deactivated.

Before deactivating this feature, be sure there are no

children present on or near the property where you are

using the tractor, and that none are likely to appear

while you are mowing or operating an attachment.

Be extra observant after you have chosen to

deactivate the interlock feature because the sound of

the tractor’s engine might prevent you from being

aware that a child or a bystander has entered the area

where you are operating the tractor.

If you are certain that you can safely mow in reverse

or operate an attachment, deactivate the

operating–in–reverse interlock feature by turning the

“Key Choice” switch (Fig. 10), located in front of and

below the seat, after engaging the blade (PTO). A red

light on the front console (Fig. 11) will turn on as a

reminder that the operating–in–reverse interlock has

been deactivated. Once the interlock is deactivated it

stays in this mode––with your mower blade or

PTO–driven attachment operating whenever you back

up–– and the console light stays on until either the

blade (PTO) is disengaged, or the engine is turned

off.

Operating–in–Reverse

An interlock feature is provided that prevents the

Power Take Off (PTO) from operating while the

tractor is traveling in reverse. If the unit is shifted

into reverse while the mower blade or other PTO

driven attachment is engaged, the engine will stop.

Do not mow while backing up unless it is

absolutely necessary. If you need to mow while in

reverse gear or use other PTO driven attachments

(such as a snowthrower or tiller), this

operating–in–reverse interlock feature may be

temporarily deactivated.

Note: Do not insert the “Key Choice” key

unless it is absolutely necessary to

mow in reverse or operate an

attachment. The “Key Choice” key

should also be removed from the unit

if it will be operated by someone other

than a responsible, experienced

operator. This will prevent the unit

from operating in reverse with the

mower blade or other PTO attachment

engaged. Always remove both the

ignition and the “Key Choice” keys

and put them in a safe place out of the

reach of children when leaving the unit

unattended.

20

Page 23

POTENTIAL HAZARD

• A child or bystander could be backed over

by a riding mower with its blade(s)

engaged.

WHAT CAN HAPPEN

• Blade contact will cause serious personal

injury or death.

HOW TO AVOID THE HAZARD

• Do not mow in reverse unless absolutely

necessary.

• Always look backward and down before

backing up.

• Use “Key Choice” switch only if you are

certain no children or other bystanders will

appear in the mowing area.

• Always remove both the ignition and Key

Choice keys and put them in a safe place

out of the reach of children or unauthorized

users when leaving the unit unattended.

Operation

1

Figure 11

1. Operating–in–reverse light

Testing the Safety Interlock System

Test the safety interlock system before you use the

machine each time. If the safety system does not

operate as described below, have an Authorized

Service Dealer repair the safety system immediately.

1. Move gear shift into neutral

2. Move deck engagement lever into ENGAGE. Sit

on the seat and rotate ignition key to START.

Engine should not crank; but if it does, the

interlock system is malfunctioning and it must

be repaired by an Authorized TORO Service

Dealer. If engine does not crank, proceed to step

3.

1. “Key choice” switch

1

Figure 10

3. Move deck engagement lever into

DISENGAGE. Sit on the seat, depress the brake

and clutch pedals, engage the parking brake and

shift into gear. Rotate ignition key to START.

Engine should not crank; but if it does, the

interlock system is malfunctioning and must be

repaired by an Authorized TORO Service Dealer.

If engine does not crank, proceed to step 4.

21

Page 24

Operation

4. Sit on the seat, move gear shift into neutral, deck

engagement lever into DISENGAGE and ensure

parking brake is engaged. Rotate ignition key to

START. Engine should start and continue to run.

Then engage deck engagement lever and

carefully raise off the seat: the engine should

stop. If the engine does not stop running, shut

the engine off and have interlock system repaired

by an Authorized TORO Service Dealer. If the

engine shuts off when you raise off the seat, the

interlock system is functioning correctly and the

rider can be operated safely.

5. Put the PTO lever in the “disengage” position

and the gear shifter in neutral. Now start the

engine. While the engine is running, move the

PTO lever to the “engage” position, push in the

clutch and put the gear shifter in reverse. The

engine should stop.

6. Put the PTO lever in the “disengage” position

and the gear shifter in neutral. Now start the

engine. Move the PTO lever to the “engage”

position and turn the “Key Choice” key and

release. The Key Choice warning light should

illuminate. Move the PTO lever to the

“disengage” position and the Key Choice

warning light should turn off.

Side Discharging or Bagging

To side discharge or use bagging attachment, stop the

engine and wait for all moving parts to stop.

1. Shut the engine off and remove the ignition key.

2. Remove the wing nut securing the discharge

cover (Fig. 12) to the mower housing. NEVER

REMOVE THE GRASS DEFLECTOR

FROM THE MOWER HOUSING (Fig. 12).

3. Lift the grass deflector and metal tab together to

enable the removal of the metal tab. Continue to

lift the grass deflector enough to remove the

plastic discharge cover off the long bolt. Save

the discharge cover and metal tab for possible

future reinstallation.

4. Reinstall the wing nut and tighten. Lower the

grass deflector fully down. Unit is ready for side

discharge or bagging.

3

1

22

2

1. Wing nut

2. Long bolt

3. Plastic discharge cover

4

Figure 12

4. Metal tab

5. Grass deflector

5

For improved bagger performance change to high sail

blade and remove Recycler kickers. If you no

longer wish to side discharge or bag clippings, the

discharge cover can be reinstalled by securing it the

mower housing with the wing nut.

Page 25

Operation

IMPORTANT: When the discharge cover is in

place, it must be secured to the grass deflector

with the metal tab and wingnut.

POTENTIAL HAZARD

• Without the grass deflector, discharge

cover, or complete grass catcher assembly

mounted in place, you and others are

exposed to blade contact and thrown

debris.

WHAT CAN HAPPEN

• Contact with rotating mower blades(s) and

thrown debris will cause injury or death.

HOW TO AVOID THE HAZARD

• NEVER remove the grass deflector from

the mower because the grass deflector

routes material down toward the turf. If

the grass deflector is ever damaged, replace

it immediately.

• Never put your hands or feet under the

mower.

• Never try to clear discharge area or mower

blades unless you move the power take off

(PTO) to “OFF” and rotate the ignition key

to “OFF”. Also remove the key and pull

the wire off the spark plug(s).

Note: For reverse motion, with the PTO

engaged, the operating–in–reverse

interlock must be deactivated by the

key choice switch located in front of

and below the seat.

Stopping the Machine

To stop the machine, push the clutch in and shift to

neutral (”N”). Disengage the power take off (PTO),

and turn the ignition key to “OFF” to stop the engine.

Also set the parking brake if you leave the machine

unattended; refer to Setting the Parking Brake,

page 17. Remember to remove the keys from the

ignition and “Key Choice” switches.

POTENTIAL HAZARD

• Someone could move or attempt to operate

the tractor while it is unattended.

WHAT CAN HAPPEN

• Children or bystanders may be injured if

they use the tractor.

HOW TO AVOID THE HAZARD

• Always remove the ignition and “Key

Choice” keys and set the parking brake

when leaving the machine unattended, even

if just for a few minutes.

Driving Forward or Backward

The throttle control regulates the engine speed as

measured in rpm (revolutions per minute). Place the

throttle control in the “FAST” position for best

performance while mowing.

To go forward push the clutch in and place the gear

shifter in a forward gear, release the parking brake:

refer to Releasing the Parking Brake, page 18 and

slowly release the clutch. To go in reverse push the

clutch in to stop and after stopping completely, place

the gear shifter in reverse. Slowly release the clutch.

IMPORTANT: Do not “Ride the Brakes”.

Shift to a lower speed for slower ground

speed. Choose a slow speed so that you will

not have to stop or shift while on the slope.

23

Page 26

Operation

Positioning the Seat

The seat can move forward and backward. Position

the seat where you have the best control of the

machine and are most comfortable.

1. Raise the seat and loosen the lock nuts (Fig. 13).

2. Slide the seat to the desired position and tighten

the lock nuts.

1

RecyclerMowing Tips

Recycler Rider Features

Your Toro Recycler rider has a new and completely

different cutting concept. It leaves your lawn with a

bagged look without bagging clippings.The rider is

equipped with special parts (Fig. 14) which increase

your rider’s ability to cut and recut grass clippings,

leaves, and other yard debris into tiny particles which

are injected down into the grass. These parts are:

• Deck ring

• Special blade and blade stiffener

• Discharge cover

• Four special “kickers” strategically positioned on

the underside of the mower deck. A fifth kicker

is molded into the discharge cover.

3

Figure 13

1. Lock nuts

3

2

6

3

1. Deck ring

2. Discharge cover

3. Kickers

5

4

1

394

Figure 14

4. Blade

5. Blade stiffener

6. Grass deflector

24

Page 27

Tips for Cutting Grass

Operation

Even with the Recycler rider, you may encounter

conditions where it is not possible to incorporate all

of the grass clippings or leaves all of the time into the

grass. Follow these instructions for the best cutting

results and lawn appearance:

• Always use FAST (full) throttle when mowing.

• Maintain a sharp blade

season. A sharp blade cuts cleanly and without

tearing or shredding the grass blades like a dull

blade. Tearing and shredding causes the grass to

turn brown at the edges which impairs growth

and increases susceptibility to diseases. About

every 30 days, remove the wire from the spark

plug and check the cutter blade for sharpness.

File down any nicks on blade to restore its sharp

edge.

• Clean any residue from the underside of the rider

housing and kickers after each use. If residue is

allowed to build up in rider housing and on

kickers, cutting performance may be

unsatisfactory.

• Very long or extremely wet grass can be cut, but

specific operating techniques must be used. Start

by setting height-of-cut in the highest position.

Using 1st gear and maximum throttle speed,

move into the grass and cut a swath that is only

half as wide as the mower housing. If side

discharging, direct grass clippings toward area

that was cut previously. Stop forward movement

occasionally to allow discharge area to clear

itself. Cutting too much grass may clog the

mower housing and discharge area. If mower

housing does clog, shut engine off, disengage

blade and remove the obstruction with a stick.

throughout the cutting

POTENTIAL HAZARD

• Unexpected blade contact can occur

WHAT CAN HAPPEN

• Personal injury can occur from contact

with blade

HOW TO AVOID THE HAZARD

• Depress clutch and brake pedals, shift into

neutral and turn ignition key to “OFF”

position. Remove wire from spark plug to

prevent someone from accidentally starting

the machine.

• When the rider is used to cut a lawn for the first

time, cut grass slightly longer than normal to

ensure that cutting height of mower housing will

not cause scalping, which could result from

severe undulations of the ground. In general,

however, the cutting height used in the past is

probably the best one to use. When cutting grass

over six inches tall, you may want to cut the

lawn twice to hide clippings down in the grass.

• If the grass is ever allowed to grow slightly

longer than normal, or if it contains a high

degree of moisture, raise cutting height higher

than usual and cut the grass at this setting. Next,

cut the grass again using the lower, normal

setting. This method of cutting long grass results

in an even distribution of clippings and an

acceptable quality-of-cut.

• In the heat of the summer, it is best to cut only

about 1/3 of the grass blade. Cutting below the

3rd setting is not recommended unless grass is

sparse or it is late fall when grass growth begins

to slow down.

• If the cutting width of the rider is wider than the

mower previously used, raise height-of-cut

setting one notch to ensure undulations in turf

are not cut too short.

25

Page 28

Operation

• MOWING IN EXTREME CONDITIONS—Air

is required to cut and recut grass clippings in

rider housing, so do not set height-of-cut too low

or totally surround housing by uncut grass.

Always try to have one side of the rider housing

free from uncut grass, allowing air to be drawn

into housing. When making an initial cut thru

center of uncut area, operate rider at a slower

ground speed and back up if rider starts to clog.

• STOPPING RIDER—If forward motion of rider

has to be stopped while cutting, a clump of grass

clippings may be deposited on lawn. Follow this

procedure for stopping while cutting:

A. With blade engaged, move onto a

previously cut area.

B. Raise deck one or two height-of-cut settings

while driving rider forward and deck is in

operation.

C. Depress clutch and brake pedals, move

throttle control lever to IDLE position,

disengage mower and rotate ignition key to

OFF.

• MOW AT PROPER INTERVALS—Under most

normal conditions you’ll need to mow

approximately every 4–5 days. But remember,

grass grows at different rates at different times.

This means that in order to maintain the same

height-of-cut, which is a good practice, you’ll

need to cut more frequently in early spring; as

the grass growth rate slows in mid summer, cut

only every 8–10 days. If you are unable to mow

for an extended period due to weather conditions

or other reasons, mow first with the height-of-cut

at a high level; then mow again 2–3 days later

with a lower height setting.

cover to the mower housing. NEVER

REMOVE THE GRASS DEFLECTOR

FROM THE MOWER HOUSING.

POTENTIAL HAZARD

• Without the grass deflector, discharge

cover, or complete grass catcher assembly

mounted in place, you and others are

exposed to blade contact and thrown

debris.

WHAT CAN HAPPEN

• Contact with rotating mower blades(s) and

thrown debris will cause injury or death.

HOW TO AVOID THE HAZARD

• NEVER remove the grass deflector from

the mower because the grass deflector

routes material down toward the turf. If

the grass deflector is ever damaged, replace

it immediately.

• Never put your hands or feet under the

mower.

• Never try to clear discharge area or mower

blades unless you move the power take off

(PTO) to “OFF” and rotate the ignition key

to “OFF”. Also remove the key and pull

the wire off the spark plug(s).

The Recycler rider’s special features reduce clipping

size, thus decreasing amount of grass to be disposed

of and number of times bagger will have to be

emptied.

Note: When bagger is full, mower will begin

to inject clippings down into the grass.

• Alternate mowing direction. This helps disperse

clippings over lawn for even fertilization.

• SIDE DISCHARGING OR BAGGING—To

side discharge or use bagging attachment, stop

the engine and wait for all moving parts to stop.

Then remove the wing nut securing the discharge

26

Page 29

If the lawn appearance is not satisfactory after

mowing, try one of the following:

• Sharpen the blade.

• Raise the height-of-cut setting on your mower.

• Cut your grass more frequently.

• Reduce ground speed.

• Overlap cutting swaths instead of cutting a full

swath with each pass.

• Mow across the marginal areas a second time.

Tips For Cutting Leaves

In the fall, you can cut your leaves up into finely cut

particles and inject the particles down into the grass.

When spring arrives, the leaf particles will have

decomposed and restored valuable nutrients to the

soil.

Operation

• When cutting is complete, always be sure that

50% of the lawn shows through the finely cut

leaf cover. This may require one or more passes

over the leaves.

• If there are more than five inches of leaves on

lawn, raise the deck one or two notches higher.

This makes it easier to feed leaves under mower

deck.

• If leaves are not cut up finely enough to be

hidden down in the grass, make a second pass 90

degrees to the first pass.

• If you cut up a lot of oak leaves, you might want

to add lime to your grass in the spring. Lime

reduces the acidity of oak leaves.

27

Page 30

Maintenance

M

dusty, dirty,

dust

conditions.

Service Interval Chart

5

Service Operation

Change Oil (Initial) X

Change Oil (Periodic) X X

Check System Interlock X X X X

Check Cutter Blade X X X

Check Brake X X X X

Grease Front Axle Spindles (2) & Wheel

Bearings (2) and Rear Axle (2)

Lubricate Pivot Points X X

Service Air Cleaner X X

Check Spark Plug X X X

Check Blade Drive Belt X

Check Traction Drive Belt X

Drain Gasoline X

Clean Outside of Engine X X

Wash Underside of Mower X X

Hours25Hours

Storage

Service

X X

Spring

Service2Years

Notes

Before each

use

ore often in

dusty, dirty,

conditions.

More often in

y, dirty,

conditions.

28

Paint Chipped Surfaces X

Remove Rear Wheels and Grease

Axles

Remove Rear Wheels and Grease Axle

Zerks

X

X

Page 31

POTENTIAL HAZARD

• If you leave the key in the ignition switch, someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of the engine could seriously injure you or other bystanders.

HOW TO AVOID THE HAZARD

• Remove the key from the ignition switch and pull the wire(s) off the spark plug(s)

before you do any maintenance. Also push the wire(s) aside so it does not

accidentally contact the spark plug(s).

Air Cleaner

Service Interval/Specification

Foam Element: Clean and re-oil after every 25

operating hours, or yearly, whichever occurs

first.Paper Element: Replace after every 100

operating hours or yearly, whichever occurs first.

Service the air cleaner more frequently (every few

hours) if operating conditions are extremely dusty or

sandy.

Maintenance

1. Remove the wire from the spark plug (Fig. 18).

2. Remove the knob and air cleaner cover (Fig. 15).

3. Every 25 hours the foam pre–cleaner should be

cleaned (Fig. 15). Remove foam pre–cleaner by

sliding it off the paper cartridge (Fig. 15).

A. Wash the foam pre–cleaner in liquid soap

and warm water. Rinse thoroughly in clear

water.

B. Wrap the foam pre–cleaner in cloth and

squeeze it dry

C. .Saturate the foam in engine oil. Squeeze it

to remove excess oil.

4. The paper air cleaner cartridge should be

replaced every 100 hours. Remove one nut from

the top of the paper cartridge (Fig. 15).

Figure 15

1. Knob

2. Air cleaner cover

3. Foam pre–cleaner

4. Paper cartridge

5. Nut

5. Clean the air cleaner body carefully to prevent

dirt from entering carburetor. Remove and

discard the paper cartridge.

29

Page 32

Maintenance

6. Insert a new paper cartridge into the air cleaner

body. Reassemble the air cleaner.

IMPORTANT: Petroleum solvents, such as

kerosene, are not to be used to clean the paper

cartridge. They may cause deterioration of

the cartridge. DO NOT OIL THE

CARTRIDGE. DO NOT USE

PRESSURIZED AIR TO CLEAN THE

CARTRIDGE.

IMPORTANT: Always operate the engine

with the air cleaner element in place or engine

damage will result.

Engine Oil

Service Interval/Specification

Change oil:

Checking Oil Level

1. Park the machine on a level surface, disengage

the power take off (PTO), set the parking brake,

and turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Clean around the oil dipstick (Fig. 16) so dirt

cannot fall into the filler hole and damage the

engine.

3. Unscrew the oil dipstick and wipe the metal end

clean (Fig. 16).

4. Screw dipstick fully into filler neck; then remove

it and check oil level on dipstick. If level is low,

add only enough oil to raise level to FULL mark.

Do not overfill or engine damage may result.

IMPORTANT: Do not overfill the crankcase

with oil because the engine may be damaged.

2

• After the first 5 operating hours.

• After every 25 operating hours.

Note: Change oil more frequently when

operating conditions are extremely

dusty or sandy.

Oil Type: Detergent oil (API service SF, SG, SH)

Crankcase Capacity: 48 oz. (1.4 l)

Viscosity: See table below

USE THESE SAE VISCOSITY OILS

–20 0 20 40 60 80 100

°

F

1

Figure 16

1. Oil dipstick 2. Fuel tank cap

Changing/Draining Oil

1. Start the engine and let it run five minutes. This

warms the oil so it drains better.

–30°–20 –10 0 10 20 30 40

C

30

Page 33

Maintenance

2. Park the machine so that the drain side is slightly

lower than the opposite side to assure the oil

drains completely. Then disengage the power

take off (PTO), set the parking brake, and turn

the ignition key to “OFF” to stop the engine.

Remove the key.

3. Place drain pan below drain plug (Fig. 17).

Remove drain cap. Allow all oil to flow into

drain pan. Reinstall drain cap after oil stops

flowing.

Note: Dispose of the used oil at a certified

recycling center.

1

after every 25 operating hours. Recommended air gap

is 0.030 of an inch (0.762 mm). Correct spark plug to

use is: Champion RJ -19LM.

Note: The spark plug usually lasts a long time;

however, the plug should be removed and checked

whenever the engine malfunctions.

Removing the Spark Plug

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

2. Pull the wire off the spark plug (Fig. 18).

3. Clean area around spark plug so foreign matter

cannot fall into cylinder when spark plug is

removed.

4. Remove the spark plug(s).

Figure 17

1. Drain cap

4. Unscrew dipstick and add oil to crankcase. Refer

to Fill Crankcase With Oil, page 16. Crankcase

capacity is 48 oz. DO NOT OVERFILL or

engine damage may result.

Spark Plug

Service Interval/Specification

Since air gap between center and side electrodes of

the spark plug increases gradually during normal

operation of the engine, check condition of electrodes

1

2

Figure 18

1. Spark plug wire 2. Spark plug

31

Page 34

Maintenance

Checking the Spark Plug

1. Look at the center of the spark plug(s) (Fig. 19).

If you see light brown or gray on the insulator,

the engine is operating properly. A black coating

on the insulator usually means the air cleaner is

dirty.

IMPORTANT: Never clean the spark plug(s).

Always replace the spark plug(s) when it has:

a black coating, worn electrodes, an oily film,

or cracks.

2. Check the gap between the center and side

electrodes (Fig. 19). Bend the side electrode

(Fig. 19) if the gap is not correct.

2

1

3

0.030”

(.762 mm)

Greasing and Lubrication

Service Interval/Specification

Grease the machine after every 50 operating hours or

yearly, whichever occurs first. Grease more frequently

when operating conditions are extremely dusty or

sandy.

Grease Type: General-purpose grease.

How to Grease

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

2. Clean the grease fittings with a rag. Make sure to

scrape any paint off the front of the fitting(s).

3. Connect a grease gun to the fitting. Pump grease

into the fittings until grease begins to ooze out of

the bearings.

Figure 19

1. Center electrode insulator

2. Side electrode

3. Air gap (not to scale)

Installing the Spark Plug(s)

1. Install the spark plug. Make sure the air gap is

set correctly.

2. Tighten the spark plug(s) to 15 ft–lb (20.4 Nm).

3. Push the wire(s) onto the spark plug (Fig. 18).

4. Wipe up any excess grease.

Where to Add Grease

1. Lubricate the front wheels and spindles until

grease begins to ooze out of the bearings

(Fig. 20).

Figure 20

32

Page 35

2. Grease rear axles with one to two pumps of No.

2 general purpose grease. The zerks are located

just inside of the rear tires on the bottom of the

transaxle (Fig. 21).

Lubricate Pivot Points

The mechanical pivot points on the rider must be

oiled after every 25 hours of operation; lubricate more

frequently when conditions are dusty or sandy.

3. Oil pivot points of steering, drive, brake, clutch,

and deck engagement linkage with light oil (Fig.

21). Wipe up any excess oil.

Maintenance

Figure 22

6. Install mower: refer to Removing / lnstalling

Cutting Unit, page 34.

Figure 21

4. Remove mower: refer to Removing / lnstalling

Cutting Unit, page 34.

Tire Pressure

Service Interval/Specification

Maintain the air pressure in the front and rear tires as

specified. Check the pressure at the valve stem after

every 25 operating hours or monthly, whichever

occurs first (Fig. 23). Check the tires when they are

cold to get the most accurate pressure reading.

• Set pressure to 12 psi (83 kPa) front and

rear for tractors with serial numbers

9902000 and prior.

• Set pressure to 20 psi (138 kPa) (tires with

markings of “Kenda”, “Super Turf”) for

tractors with serial numbers 9902001 and

up.

5. Lubricate mower mounts (Fig. 22). Wipe up any

excess oil.

33

Page 36

Maintenance

1

Figure 23

1. Valve stem

Brake

Always set the parking brake when you stop the

machine or leave it unattended. If the parking brake

does not hold securely, an adjustment is required.

2323

2. Tighten locknut approximately 1/4 turn

clockwise (Fig. 24).

3. Check operation of the brake by pushing rider:

no brake drag should be evident. If drag is

evident, rotate locknut an additional 1/8 turn

counter-clockwise or until there is no drag.

IMPORTANT: With the parking brake

released, the rear wheels must rotate freely

when you push the mower. If brake action

and free wheel rotation cannot be achieved

contact your service dealer immediately.

Checking the Brake

1. Park the machine on a level surface, disengage

the power take off (PTO), set the parking brake,

and turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Rear wheels must lock and skid when you try to

push the tractor forward. Adjustment is required

if the wheels turn and do not lock; refer to

Adjusting the Brake, page 34.

3. Release the brake and push the tractor forward.

The wheels should rotate freely.

4. If both conditions are met no adjustment is

required.

Adjusting the Brake

Adjust brake pucks if the parking brake does not hold

or braking power is not sufficient when brake pedal is

depressed. The brake is located on the left side of the

transaxle (Fig. 24).

1

Figure 24

1. Locknut

1. Shut engine off and remove wire from spark

plug.

34

Page 37

Maintenance

Fuel Tank

Draining The Fuel Tank

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AVOID THE HAZARD

• Drain gasoline from the fuel tank when the

engine is cold. Do this outdoors in an open

area. Wipe up any gasoline that spills.

• Never drain gasoline near an open flame or

where gasoline fumes may be ignited by a

spark.

• Never smoke a cigarette, cigar or pipe.

1. Clean area around fuel tank cap so foreign matter

cannot enter filler hole when cap is removed.

Next, remove cap from fuel tank.

Front Wheel Toe-In

Service Interval/Specification

Maintain toe-in of the front wheels as specified. If

uneven tire wear, lawn scuffing or hard steering

develop adjustment may be required. Check the toe-in

after every 100 operating hours or yearly, whichever

occurs first (Fig. 25).

Specification: .06” (1.5 mm) – .25” (6.3 mm) toe-in

on front wheels.

Measuring Toe-in

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

2. Push front tires out, at front, to remove normal

looseness in the linkage.

3. Measure, between the wheels, at spindle level, in

the front and rear of the wheels (Fig. 25).

4. The front measurement should be less than the

rear, as specified under Adjusting Toe–in.

2. Using a pump-type syphon, drain gasoline into a

clean gas can.

Note: There is no other recommended way to

drain gasoline from the fuel tank, other

than by using a pump-type syphon. An

inexpensive syphon can be purchased

at a hardware store.

Adjusting Toe-In

1. To align front wheels, loosen jam nut and turn

tie rod end (there is only one adjustable tie rod)

until center line distance across front of wheels

(d’) is .06 inch (1.5 mm) to .25 inch (6.3 mm)

less than center line distance across rear of front

wheels (d”) (Fig. 25 & 26).

35

Page 38

Maintenance

Removing the Battery

1. Disengage the power take off (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine. Remove the key.

2. Tip seat forward exposing battery.

2

1

1. Tie rod (only one rod is

adjustable)

Figure 25

2. Jam nut

Figure 26

2

3. Disconnect the negative (black) ground cable

from the battery post (Fig. 27).

1

4. Lift the rubber cover up on the positive (red)

cable. Disconnect the positive (red) cable from

the battery post (Fig. 27).

5. Remove wing nut securing battery hold downs to

rider chassis (Fig.27).

6. Lift up on top battery hold down and pivot

rearward

7. Remove battery from chassis.

1

2

3

Battery

Service Interval/Specification

Check the electrolyte level in the battery every 5

hours. Always keep the battery clean and fully

charged. Use a paper towel to clean the battery case.

If the battery terminals are corroded, clean them with

a solution of four parts water and one part baking

soda. Apply a light coating of grease to the battery

terminals to prevent corrosion.

Voltage: 12 v, 160 Cold Cranking Amps

36

1. Wing nut

2. Battery hold down

Figure 27

3. Filler cap

Page 39

Maintenance

Installing the Battery

8. Install the battery into the chassis (Fig. 28).

9. Secure battery in chassis with hold down rods.

10. Using the bolt and wing nut, connect the positive

(red) cable to the positive (+) battery post

(Fig. 28). Slide the rubber cover over the battery

post.

11. Using the bolt and wing nut, connect the

negative (black) cable to the negative (–) battery

post (Fig. 28).

4

3

1

2

1

2

1. Filler caps

2. Lower part of tube

Figure 29

3. Plates

3

1262

Adding Water to the Battery

The best time to add distilled water to the battery is

just before you operate the machine. This lets the

water mix thoroughly with the electrolyte solution.

1. Clean the top of the battery with a paper towel.

2. Lift off the filler caps (Fig. 29).

3. Slowly pour distilled water into each battery cell

until the level is up to the lower part of the tube

(Fig. 29).

Figure 28

1. Positive (red) battery

cable

2. Rubber boot

3. Wing nut and bolt

4. Negative (black) battery

cable

Checking Electrolyte Level

1. With the engine off, lift the seat to see the

battery.

2. Open covers to see into the cells. The electrolyte

must be up to the lower part of the tube

(Fig. 29). Do not allow the electrolyte to get

below the plates. (Fig. 29).

3. If the electrolyte is low, add the required amount

of distilled water; refer to Adding Water to the

Battery, page 37.

IMPORTANT: Do not overfill the battery

because electrolyte (sulfuric acid) can cause

severe corrosion and damage to the chassis.

4. Press the filler caps onto the battery.

Charging the Battery

IMPORTANT: Always keep the battery fully

charged (1.260 specific gravity). This is

especially important to prevent battery

damage when the temperature is below 32°F

(0°C).

1. Remove the battery from the chassis; refer to

Removing the Battery, page 36.

2. Check the electrolyte level; refer to Checking

Electrolyte Level, page 37, steps 2–3.

3. Remove the filler caps from the battery and

connect a 3 to 4 amp battery charger to the

battery posts. Charge the battery at a rate of 4

37

Page 40

Maintenance

amperes or less for 4 hours (12 volts). Do not

overcharge the battery. Install the filler caps after

the battery is fully charged.

POTENTIAL HAZARD

• Charging the battery produces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AVOID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

2

3

1

4. Install the battery in the chassis; refer to

Installing the Battery, page 37.

Servicing Cutter Blade

1. Shut off engine and remove wire from spark

plug. Remove ignition key.

2. Shift transaxle into 1st gear and engage parking

brake.

3. Remove cutting unit: refer to

Removing/Installing Cutting Unit, page 39.

4. Grasp end of blade using a rag or thickly padded

glove; then remove blade bolt, curved washer,

blade stiffener and blade (Fig. 30).

Note: Since blade bolt is tightened to 45-60

ft-lb (61-81 Nm) at the factory, it may

be difficult to remove. If the bolt

cannot be removed, contact an

Authorized TORO Service Dealer or a

“service station” for assistance.

394

Figure 30

1. Blade

2. Blade stiffener

3. Blade bolt and curved

washer

5. Using a file, sharpen cutting edge at both ends of

the blade (Fig. 31).

Figure 31

38

Page 41

POTENTIAL HAZARD

• Worn, eroded or cracked blade can be

dangerous.

WHAT CAN HAPPEN

• Blade can fail and cause personal injury to

bystanders.

HOW TO AVOID THE HAZARD

• Check blade often

• Replace if bent or out of balance

• Use genuine Toro replacement blade to

ensure safety and best performance.

NEVER USE A WILL–FIT

REPLACEMENT BLADE.

IMPORTANT: Sharpen top side of the blade

and maintain original cutting angle to ensure

a sharp cutting edge. The blade will remain

balanced if same amount of material is

removed from both cutting edges.

6. Check balance of blade by putting it on a blade

balancer. (An inexpensive balancer can be

purchased at a hardware store.) A balanced blade

will stay in a horizontal position on the balancer.

By contrast, a blade that is not balanced will

settle to the heavy side. If blade is not balanced,

file more material off cutting edge of the blade.

Continue to file and check the blade until it is

balanced.

Maintenance

8. Reinstall cutting unit: refer to

Removing/Installing Cutting Unit, page 34.

Removing/Installing Cutting

Unit

1. Shut off engine and pull wire off spark

plug. Remove ignition key

2. Lock parking brake and turn front wheels to a

full turn position to allow more clearance for

cutting unit.

3. Set height-of-cut control to lowest setting.

4. Loosen belt guides near engine pulley and rotate

them out of the way. Remove deck belt from

engine pulley (Fig. 32).

3

1

1

2

7. In sequence, install blade, blade stiffener, curved

washer and blade bolt (Fig. 30). The concave

side of the curved washer must point toward the

blade. Tighten blade bolt to 45-60 ft-lb (61-81

Nm)

IMPORTANT: Make sure cutting edge of

blade is away from mower housing.

Figure 32

1. Belt guides

2. Engine pulley

3. Deck belt

5. Remove cotter pin from adjustment rod and pull

from pivot tube arm (Fig. 33).

39

Page 42

Maintenance

2

3

4

Figure 33