Page 1

13-32G

Wheel Horse Rear Engine Rider

Model No. 70125—Serial No. 230000001 and Up

Form No. 3329-200

Operator ’s Manual

Original Instructions (GB)

Page 2

Important The engine in this product is not equipped

with a spark arrester muffler. In some areas it is a violation

of the law to use or operate this engine on any

forest-covered, brush-covered, or grass-covered land.

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operation Practices for Ride-on (Riding)

Rotary Lawn Mowers 3. . . . . . . . . . . . . . . . . . . .

Toro Riding Mower Safety 5. . . . . . . . . . . . . . . . . .

Sound Pressure Level 5. . . . . . . . . . . . . . . . . . . . . .

Sound Power Level 5. . . . . . . . . . . . . . . . . . . . . . .

Vibration Level 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Slope Chart 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 9. . . . . . . . . . . . . . . .

Gasoline and Oil 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Gasoline 11. . . . . . . . . . . . . . . . . . . .

Using Stabilizer/Conditioner 11. . . . . . . . . . . . . . . .

Filling the Fuel Tank 11. . . . . . . . . . . . . . . . . . . . . .

Checking the Engine Oil Level 11. . . . . . . . . . . . . .

Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Parking Brake 12. . . . . . . . . . . . . . . . . . . .

Positioning the Seat 12. . . . . . . . . . . . . . . . . . . . . . .

Using the Blade Control (PTO) 12. . . . . . . . . . . . . .

Setting the Height of Cut 13. . . . . . . . . . . . . . . . . . .

Starting the Engine 13. . . . . . . . . . . . . . . . . . . . . . . .

Stopping the Engine 14. . . . . . . . . . . . . . . . . . . . . . .

Driving the Machine Forward or Backward 14. . . . .

Selecting Ground Speeds 14. . . . . . . . . . . . . . . . . . .

Stopping the Machine 14. . . . . . . . . . . . . . . . . . . . . .

Pushing the Machine Manually 15. . . . . . . . . . . . . .

Using the Safety Interlock System 15. . . . . . . . . . . .

Testing the Safety Interlock System 16. . . . . . . . . . .

Emptying the Grass Collector 17. . . . . . . . . . . . . . .

Installing the Recycler) Cover 17. . . . . . . . . . . . . . .

Installing the Discharge Chute 19. . . . . . . . . . . . . . .

Operating Tips 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 20. . . . . . . . .

Servicing the Engine Oil 21. . . . . . . . . . . . . . . . . . .

Servicing the Battery 22. . . . . . . . . . . . . . . . . . . . . .

Servicing the Air Cleaner 24. . . . . . . . . . . . . . . . . . .

Servicing the Spark Plug 25. . . . . . . . . . . . . . . . . . .

Checking the Tire Pressure 26. . . . . . . . . . . . . . . . . .

Greasing and Lubricating the Machine 26. . . . . . . .

Page

Checking the Parking Brake 26. . . . . . . . . . . . . . . . .

Draining the Fuel Tank 27. . . . . . . . . . . . . . . . . . . . .

Replacing the Fuel Filter 27. . . . . . . . . . . . . . . . . . .

Servicing the Fuses 27. . . . . . . . . . . . . . . . . . . . . . . .

Servicing the Blade 28. . . . . . . . . . . . . . . . . . . . . . .

Leveling the Mower 29. . . . . . . . . . . . . . . . . . . . . . .

Washing under the Mower 29. . . . . . . . . . . . . . . . . .

Washing the Machine 30. . . . . . . . . . . . . . . . . . . . . .

Cleaning and Storage 30. . . . . . . . . . . . . . . . . . . . . .

Wiring Diagram 32. . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

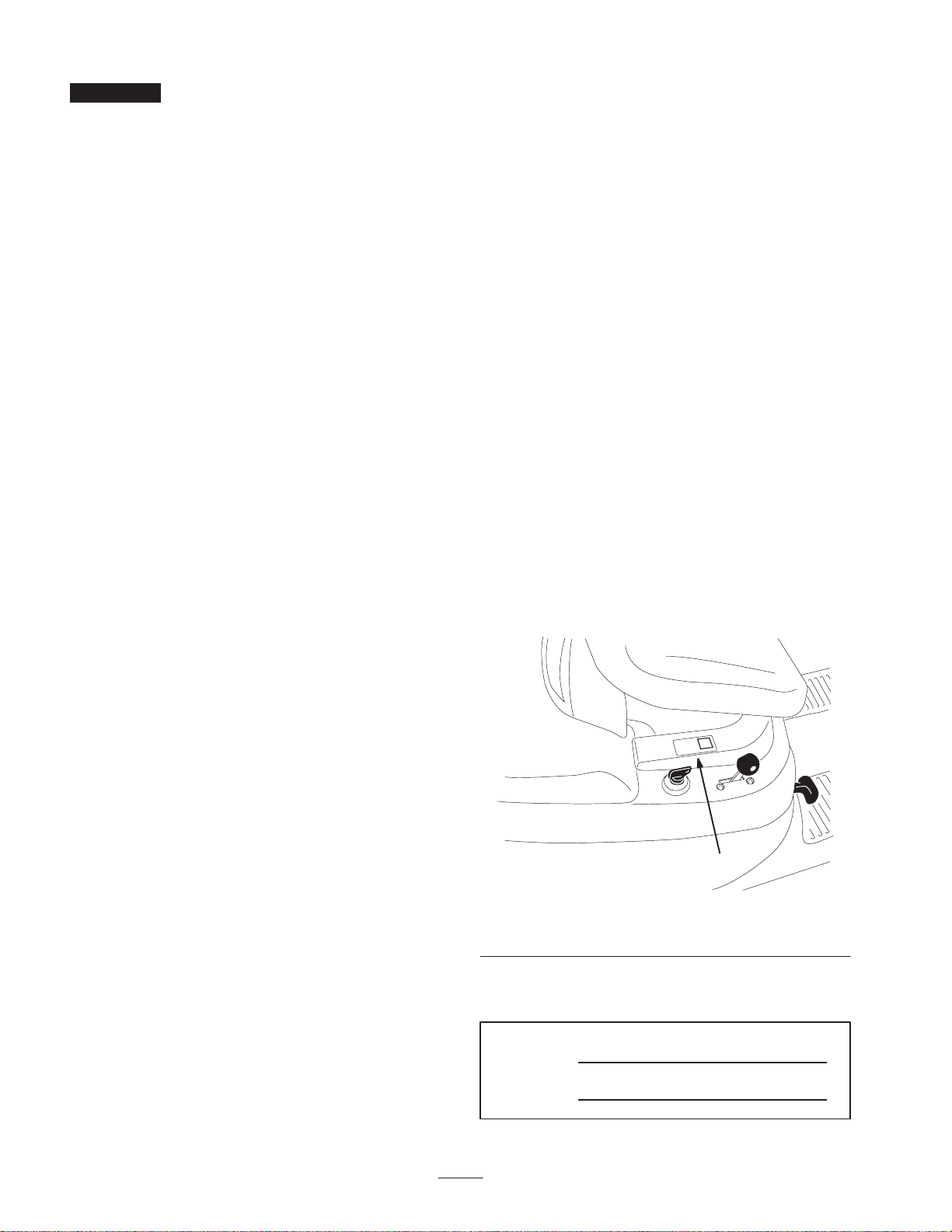

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

m-5975

Figure 1

1. Location of the model and serial numbers

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in Italy

2

Page 3

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses 2 other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

• All drivers should seek and obtain professional and

practical instruction. Such instruction should

emphasize:

– the need for care and concentration when working

with ride-on machines;

– control of a ride-on machine sliding on a slope will

not be regained by the application of the brake. The

main reasons for loss of control are:

• insufficient wheel grip;

• being driven too fast;

• inadequate braking;

• the type of machine is unsuitable for its task;

• lack of awareness of the effect of ground

conditions, especially slopes;

• incorrect hitching and load distribution.

Safety

Safe Operation Practices for

Ride-on (Riding) Rotary Lawn

Mowers

Read and understand the contents of this manual before

operating the machine.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

The following instructions are from the CEN standard EN

836:1997.

This product is capable of amputating hands and feet and of

throwing objects. Always follow all safety instructions to

avoid serious injury or death.

Training

• Read the instructions carefully. Be familiar with the

controls and the proper use of the equipment.

• Never allow children or people unfamiliar with these

instructions to use the lawnmower. Local regulations

can restrict the age of the operator.

• Never mow while people, especially children, or pets

are nearby.

Preparation

• While mowing, always wear substantial footwear and

long trousers. Do not operate the equipment when

barefoot or wearing open sandals.

• Thoroughly inspect the area where the equipment is to

be used and remove all objects which may be thrown by

the machine.

• Warning—Fuel is highly flammable.

– Store fuel in containers specifically designed for this

purpose.

– Refuel outdoors only and do not smoke while

refuelling.

– Add fuel before starting the engine. Never remove

the cap of the fuel tank or add fuel while the engine

is running or when the engine is hot.

– If fuel is spilled, do not attempt to start the engine

but move the machine away from the area of

spillage and avoid creating any source of ignition

until fuel vapors have dissipated.

– Replace all fuel tanks and container caps securely.

• Replace faulty silencers.

• Before using, always visually inspect to see that the

blade, blade bolt and cutter assembly are not worn or

damaged.

• Keep in mind that the operator or user is responsible for

accidents or hazards occurring to other people or their

property.

• Do not carry passengers.

Operation

• Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

• Mow only in daylight or in good artificial light.

3

Page 4

• Before attempting to start the engine, disengage all

blade attachment clutches and shift into neutral.

• Do not use on slopes of more than

–5 when mowing on side hills;

–10 when mowing uphill;

–15 when mowing downhill.

• Remember there is no such thing as a safe slope. Travel

on grass slopes requires particular care. To guard

against overturning:

– do not stop or start suddenly when going up or

downhill;

– engage clutch slowly, always keep machine in gear,

especially when travelling downhill;

– machine speeds should be kept low on slopes and

during tight turns;

– after striking a foreign object. Inspect the

lawnmower for damage and make repairs before

restarting and operating the equipment;

– if the machine starts to vibrate abnormally (check

immediately).

• Disengage drive to attachments when transporting or

not in use.

• Stop the engine and disengage drive to attachment

– before refuelling;

– before removing the grass catcher;

– before making height adjustment unless adjustment

can be made from the operator’s position.

• Reduce the throttle setting during engine run-out and, if

the engine is provided with a shut-off valve, turn the

fuel off at the conclusion of mowing.

– stay alert for humps and hollows and other hidden

hazards;

• Use care when pulling loads or using heavy equipment.

– Use only approved drawbar hitch points.

– Limit loads to those you can safely control.

– Do not turn sharply. Use care when reversing.

• Watch out for traffic when crossing or near roadways.

• Stop the blades from rotating before crossing surfaces

other than grass.

• When using any attachments, never direct discharge of

material toward bystanders nor allow anyone near the

machine while in operation.

• Never operate the machine with damaged guards or

without safety protective devices in place.

• Do not change the engine governor settings or

overspeed the engine. Operating the engine at excessive

speed can increase the hazard of personal injury.

• Before leaving the operator’s position:

– disengage the power take-off and lower the

attachments;

Maintenance and Storage

• Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

• Never store the equipment with fuel in the tank inside a

building where fumes can reach an open flame or spark.

• Allow the engine to cool before storing in any

enclosure.

• To reduce the fire hazard, keep the engine, silencer,

battery compartment and fuel storage area free of grass,

leaves, or excessive grease.

• Check the grass catcher frequently for wear or

deterioration.

• Replace worn or damaged parts for safety.

• If the fuel tank has to be drained, this should be done

outdoors.

• When machine is to be parked, stored or left

unattended, lower the cutting means unless a positive

mechanical lock is used.

– change into neutral and set the parking brake;

– stop the engine and remove the key.

• Disengage drive to attachments, stop the engine, and

disconnect the spark plug wire or remove the ignition

key

– before clearing blockages or unclogging chute;

– before checking, cleaning or working on the

lawnmower;

4

Page 5

Toro Riding Mower Safety

The following paragraph contains safety information

specific to Toro products or other safety information that

you must know that is not included in the CEN standard.

Use only Toro-approved attachments. Warranty may be

voided if used with unapproved attachments.

Sound Pressure Level

This unit has a maximum sound pressure level at the

operator’s ear of 87 dBA, based on measurements of

identical machines per Directive 98/37/EC.

Sound Power Level

This unit has a guaranteed sound power level of 100 dBA,

based on measurements of identical machines per Directive

2000/14/EC.

Vibration Level

This unit does not exceed a whole body vibration level of

2

0.5 m/s

Directive 98/37/EC.

based on measurements of identical machines per

5

Page 6

6

Page 7

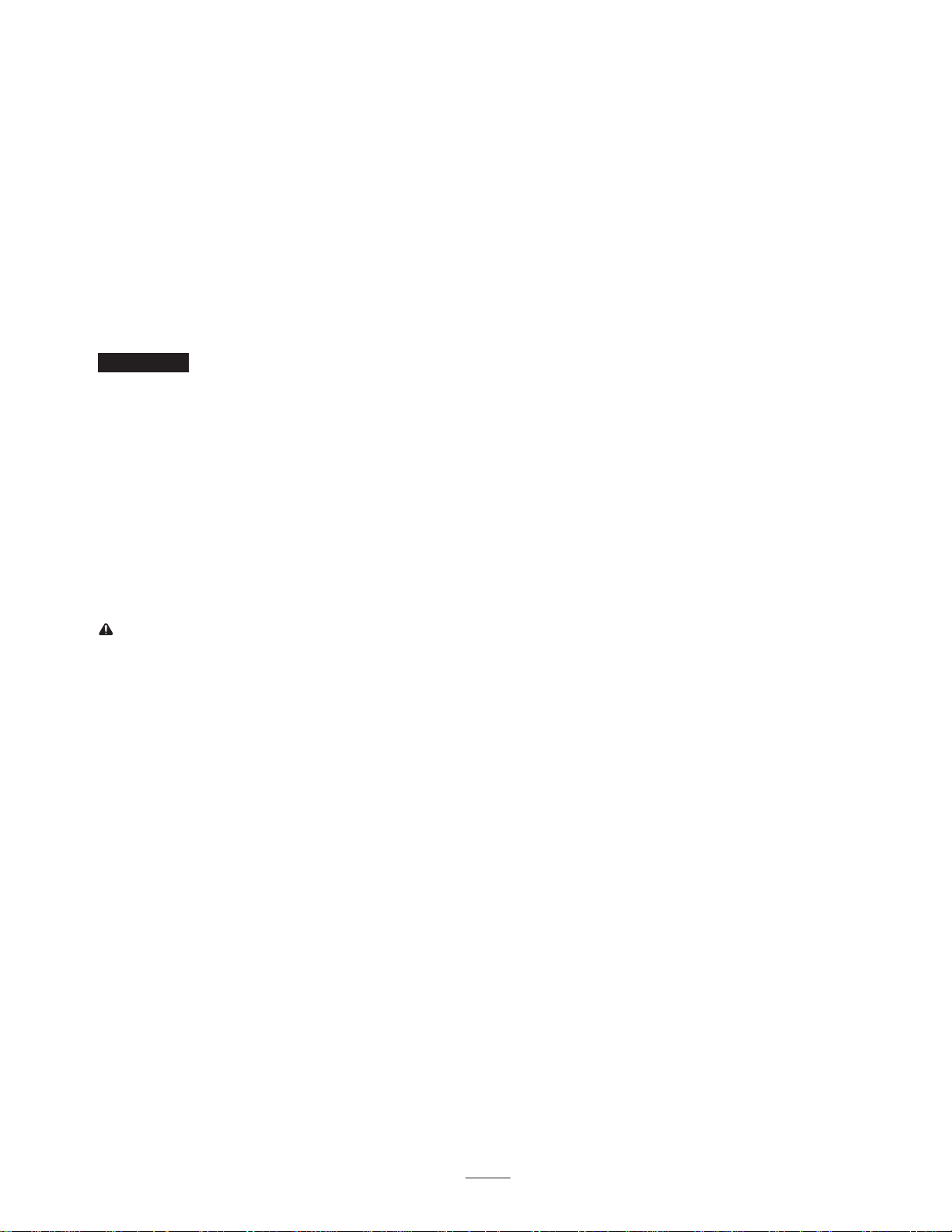

Slope Chart

7

Page 8

8

Page 9

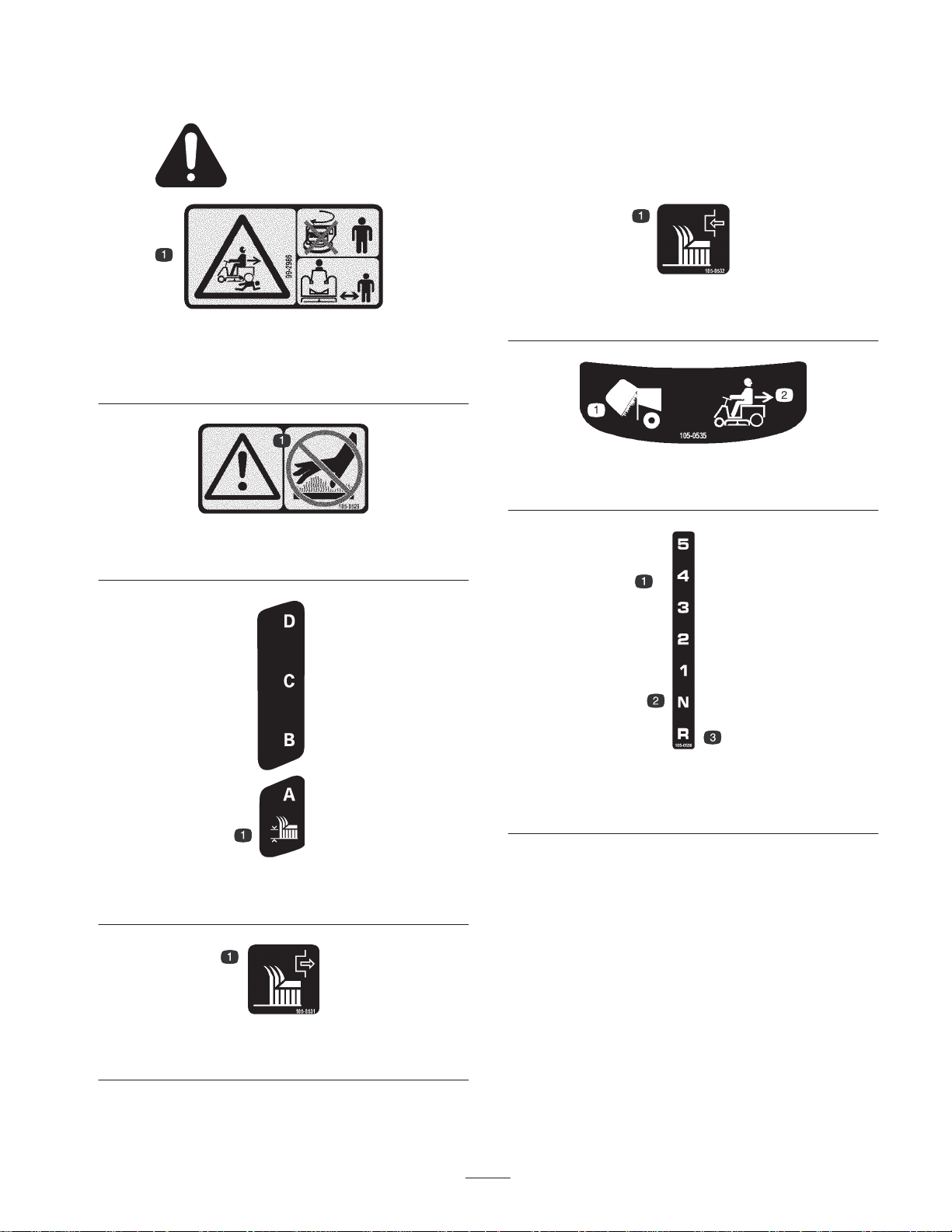

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

99-2986

1. Crushing/dismemberment hazard of bystanders—do not turn

the key while children are present; keep children a safe

distance from the machine.

105-0529

1. Warning—do not touch the hot surface.

105-0532

1. Engage the cutting blade.

105-0535

1. Grass collector full 2. Operating in reverse

105-0530

1. Height of cut

105-0531

1. Disengage the cutting blade.

1. Transmission speeds

2. Neutral

9

105-0538

3. Reverse

Page 10

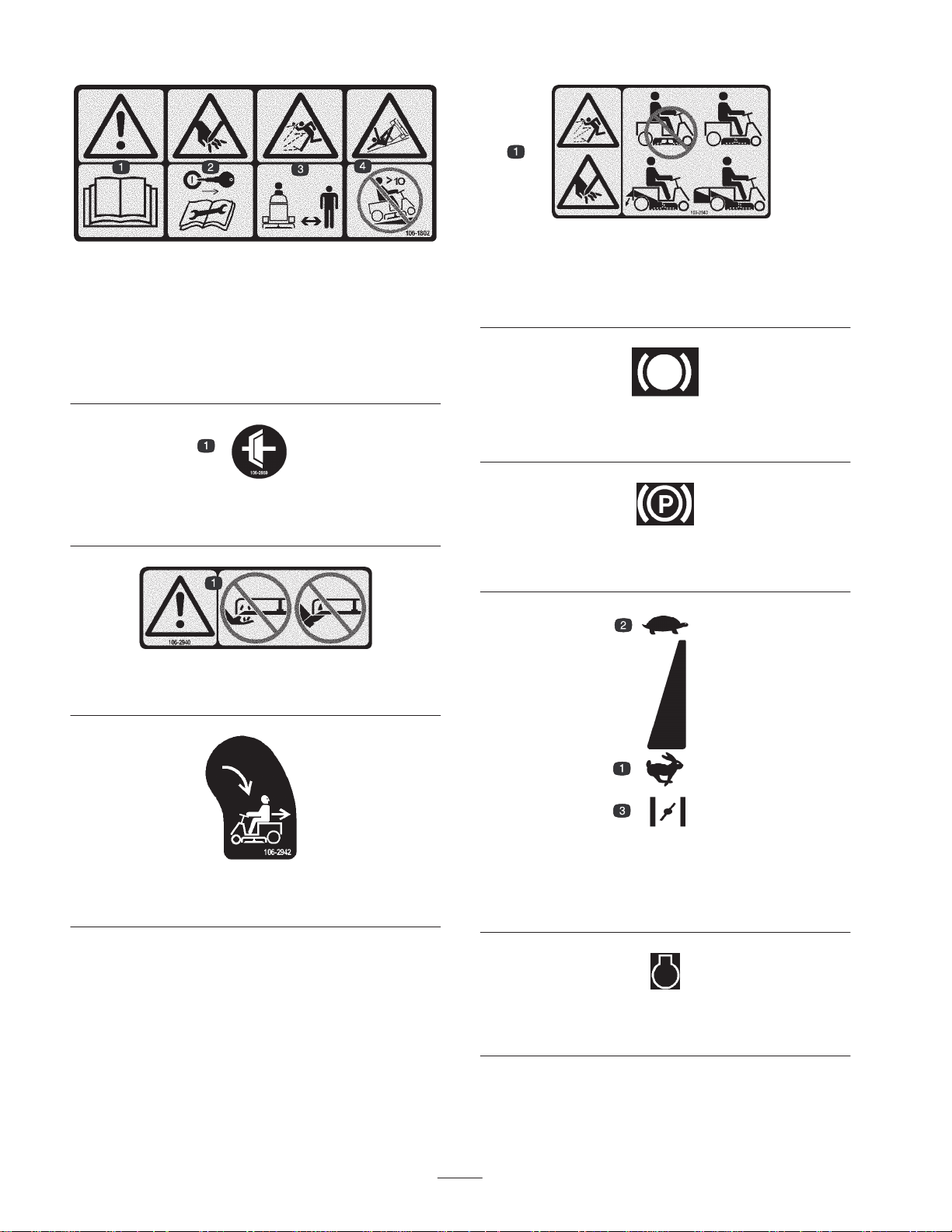

106-1802

1. Warning—read the

2. Cutting hazard of hand—remove the ignition key and read the

instructions before servicing or performing maintenance.

3. Thrown object hazard—keep bystanders a safe distance from

the machine.

4. Tipping hazard—do not drive up a slope greater than 10

degrees.

Operator’s Manual.

106-2859

1. Clutch

106-2940

1. Warning—do not place you hands or feet under the mower.

106-2943

1. Thrown object and cutting hazards—do not operate the

machine with the discharge opening uncovered; always

operate the machine with the recycling cover, rear discharge

deflector, or grass collector installed.

Molded into the floor near the brake pedal

1. Brake

Molded into the floor near the parking brake lever

1. Parking brake

106-2942

1. Turn the key to mow in reverse.

Molded into the body near the throttle control

lever

1. Fast

2. Slow

3. Choke

Molded into the body near the ignition switch

1. Engine

10

Page 11

Gasoline and Oil

Recommended Gasoline

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the machine to provide

the following benefits:

Use unleaded regular gasoline suitable for automotive use

(85 pump octane minimum). You may use leaded regular

gasoline if unleaded regular is not available.

Important Never use methanol, gasoline containing

methanol, or gasohol containing more than 10% ethanol

because the fuel system could be damaged. Do not mix oil

with gasoline.

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Fill the fuel tank outdoors in an open area when

the engine is cold. Wipe up any gasoline that

spills.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 6 to

13 mm below the bottom of the filler neck. This

empty space in the tank allows the gasoline to

expand.

• Never smoke when handling gasoline, and stay

away from an open flame or where a spark may

ignite the gasoline fumes.

• Store gasoline in an approved container and

keep it out of the reach of children.

• Never buy more than a 30-day supply of

gasoline.

• Always place gasoline containers on the ground

away from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle or

on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

• When practical, remove gas-powered equipment

from the truck or trailer and refuel the

equipment with its wheels on the ground.

• If this is not possible, refuel such equipment on

a truck or trailer from a portable container, not

from a gasoline dispenser nozzle.

• If you must use a gasoline dispenser, keep the

nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is

complete.

• It keeps gasoline fresh during storage for up to 90 days.

For longer storage, drain the fuel tank.

• It cleans the engine while it runs.

• It eliminates gum-like varnish buildup in the fuel

system, which causes hard starting.

Important Do not use fuel additives containing

methanol or ethanol.

Add the correct amount of fuel stabilizer/conditioner to the

gasoline.

Note: A fuel stabilizer/conditioner is most effective when it

is mixed with fresh gasoline. To minimize the chance of

varnish deposits in the fuel system, use a fuel

stabilizer/conditioner at all times.

Filling the Fuel Tank

1. Stop the engine and wait for all moving parts to stop.

2. Set the parking brake.

3. Clean around the fuel tank cap and remove the cap.

4. Add unleaded regular gasoline to the fuel tank until the

level is 6 to 13 mm below the bottom of the filler neck.

Do not fill the fuel tank completely full.

Note: This space in the tank allows gasoline to expand.

5. Install the fuel tank cap securely.

6. Wipe up any gasoline that spills.

Checking the Engine Oil Level

Before you start the engine and use the machine, check the

oil level in the engine crankcase; refer to Checking the Oil

Level on page 21.

11

Page 12

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Controls

Become familiar with the controls before you start the

engine and operate the machine.

Positioning the Seat

The seat can move forward and backward. Position the seat

where you have the best control of the machine and are

most comfortable.

1. Raise the seat and loosen the 4 bolts (Fig. 3).

Using the Parking Brake

Always set the parking brake whenever you stop the

machine or leave it unattended.

Setting the Parking Brake

1. Push the brake pedal (Fig. 2) down and hold it.

2

1

Figure 2

1. Brake pedal 2. Parking brake lever

2. Lift the parking brake lever (Fig. 2) up and gradually

take your foot off of the brake pedal.

1

m-5951

Figure 3

1. Bolt (4)

2. Move the seat to the desired position and tighten the

bolts.

Using the Blade Control (PTO)

The blade control (PTO) lever engages and disengages

power to the blade.

Engaging the Blade

1. Depress the brake pedal to stop the machine.

2. Slowly shift the blade control (PTO) to Engage (Fig. 4).

Note: The brake pedal should stay in the depressed

(locked) position.

Releasing the Parking Brake

1. Push down on the brake pedal (Fig. 2) and hold it.

2. Push the parking brake lever (Fig. 2) down and

gradually release the brake pedal.

1. Disengage

2. Engage

12

2

3

1

Figure 4

3. Blade control (PTO)

Page 13

Disengaging the Blade

3. Shift the ground speed lever into Neutral (N) (Fig. 6).

1. Depress the brake pedal to stop the machine.

2. Shift the blade control (PTO) to Disengage (Fig. 4).

Setting the Height of Cut

Use the height-of-cut lever to raise and lower the mower to

the desired cutting height. You can set the cutting height to

1 of 4 positions from approximately 3.8 to 9 cm.

1. Disengage the blade control (PTO).

2. Pull on the height-of-cut lever, move it to the desired

position, and release it slowly into the notch (Fig. 5).

9 cm

1

7.5 cm

5.5 cm

3.8 cm

m-5952

1

m-5972

Figure 6

1. Ground speed lever

4. Shift the blade control (PTO) lever to Disengage

(Fig. 7).

2

Figure 5

1. Height-of-cut lever

Starting the Engine

1. Sit down on the seat.

2. Set the parking brake; refer to Setting the Parking Brake

on page 12.

Note: The engine will not start unless you engage the

parking brake.

1. Disengage

2. Engage

3

1

Figure 7

3. Blade control (PTO)

13

Page 14

5. Shift the throttle lever to Choke (Fig. 8).

Stopping the Engine

1. Shift the throttle lever to Slow (Fig. 8).

2. Turn the ignition key to Stop (Fig. 9).

3. Remove the ignition key.

Driving the Machine Forward

or Backward

1

2

Figure 8

1. Choke

2. Fast

Note: An engine that has been running and is warm may

not require step 5.

6. Turn the ignition key clockwise and hold it in the Start

position (Fig. 9). When the engine starts, release the

key.

1

3

3. Slow

3

The throttle control regulates the engine speed as measured

in RPM (revolutions per minute).

1. Release the parking brake; refer to Releasing the

Parking Brake on page 12.

2. Depress the brake pedal.

3. Shift the ground speed lever to the desired forward

speed or to Reverse.

Note: As you slowly release the pedal, the machine will

begin to move. Steer the machine with the steering wheel.

Caution

Suddenly releasing the clutch pedal could cause

you to lose control and suddenly put the machine

in motion.

Always release the clutch pedal slowly when

starting the machine in motion.

Selecting Ground Speeds

2

Figure 9

1. Start

2. Run

Important If the engine does not start after 30 seconds

of continuous cranking, turn the ignition key to Stop and let

the starter motor cool; refer to Troubleshooting on page 33.

7. After the engine starts, slowly shift the throttle lever to

Fast (Fig. 8). If the engine stalls or hesitates, shift the

throttle lever back to Choke for a few seconds and then

shift the throttle lever to Fast. Repeat this step as

required.

3. Stop

Important To avoid transmission damage, always

depress the brake pedal before shifting into or out of

Reverse.

Always start the machine in motion by depressing the brake

pedal and shifting into the desired speed. Once the machine

is in motion, you can shift into any forward speed without

depressing the brake pedal. In most conditions, the machine

is powerful enough to move out in any speed. If it will not

move out in a selected speed due to a heavy load, shift to a

lower speed.

Important Do not shift on slopes. Choose a slow speed

so that you will not have to stop or shift while on the slope.

Stopping the Machine

1. Depress the brake pedal.

2. Shift the ground speed lever into Neutral.

3. Disengage the blade control (PTO).

4. Turn the ignition key to Off to stop the engine.

14

Page 15

5. Wait for all moving parts to stop.

6. Set the parking brake if you leave the machine

unattended; refer to Setting the Parking Brake on

page 12.

7. Remove the ignition key from the switch.

Understanding the Safety Interlock

System

The safety interlock system is designed to prevent the

engine from starting unless:

• You are sitting on the seat.

Caution

Children or bystanders may be injured if they

move or attempt to operate the machine while it is

unattended.

Always remove the ignition key and set the

parking brake when leaving the machine

unattended, even if just for a few minutes.

Important To prevent excessive wear, do not “ride the

brakes.” Shift the ground speed lever to a lower speed so

that you will not have to stop or shift while on the slope.

Pushing the Machine Manually

Important Always push the machine manually. Never

tow the machine because transaxle damage may occur.

1. Shift the ground speed lever to Neutral.

2. Disengage the blade (PTO).

3. Stop the engine and wait for all moving parts to stop.

4. Remove the ignition key.

5. Disengage the parking brake.

• The brake pedal is depressed.

• The blade control (PTO) lever is in the Disengage

position.

The safety interlock system is designed to stop the engine if

you do the following:

• You rise from the seat when the clutch/brake pedal is

released.

• You rise from the seat when the blade control (PTO)

lever is in the Engage position.

• You shift into reverse while the blade control (PTO)

lever is in the Engage position and the

operating-in-reverse interlock is not deactivated.

Setting the KeyChoice Switch to

Operate in Reverse

An interlock feature on the machine prevents the power

take-off (PTO) from operating when you back up the

machine. If you shift the ground speed lever into Reverse

with the PTO engaged (i.e., with mower blades or other

attachment running), the engine will stop. Do not mow in

reverse unless it is absolutely necessary.

If you need to use the blade control (PTO) while backing

up, turn off the interlock feature using the KeyChoice

switch located near the seat bracket (Fig. 10).

Using the Safety Interlock

System

Caution

If the safety interlock switches are disconnected or

damaged, the machine could operate unexpectedly,

causing personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

15

Page 16

Danger

You could back over a child or bystander while the

mower blade or other attachment is engaged and

cause serious injury or death.

• Do not mow in reverse unless absolutely

necessary.

• Do not insert the KeyChoice key unless it is

absolutely necessary.

• Always look backward and down before

backing up.

• Use the KeyChoice switch only if you are certain

no children or other bystanders will enter the

mowing area.

• Be very observant after deactivating the

interlock because the sound of the engine may

prevent you from noticing that a child or

bystander has entered the work area.

• Always remove both the ignition and KeyChoice

keys and put them in a safe place out of the

reach of children or unauthorized users when

leaving the unit unattended.

1. Engage the blade (PTO).

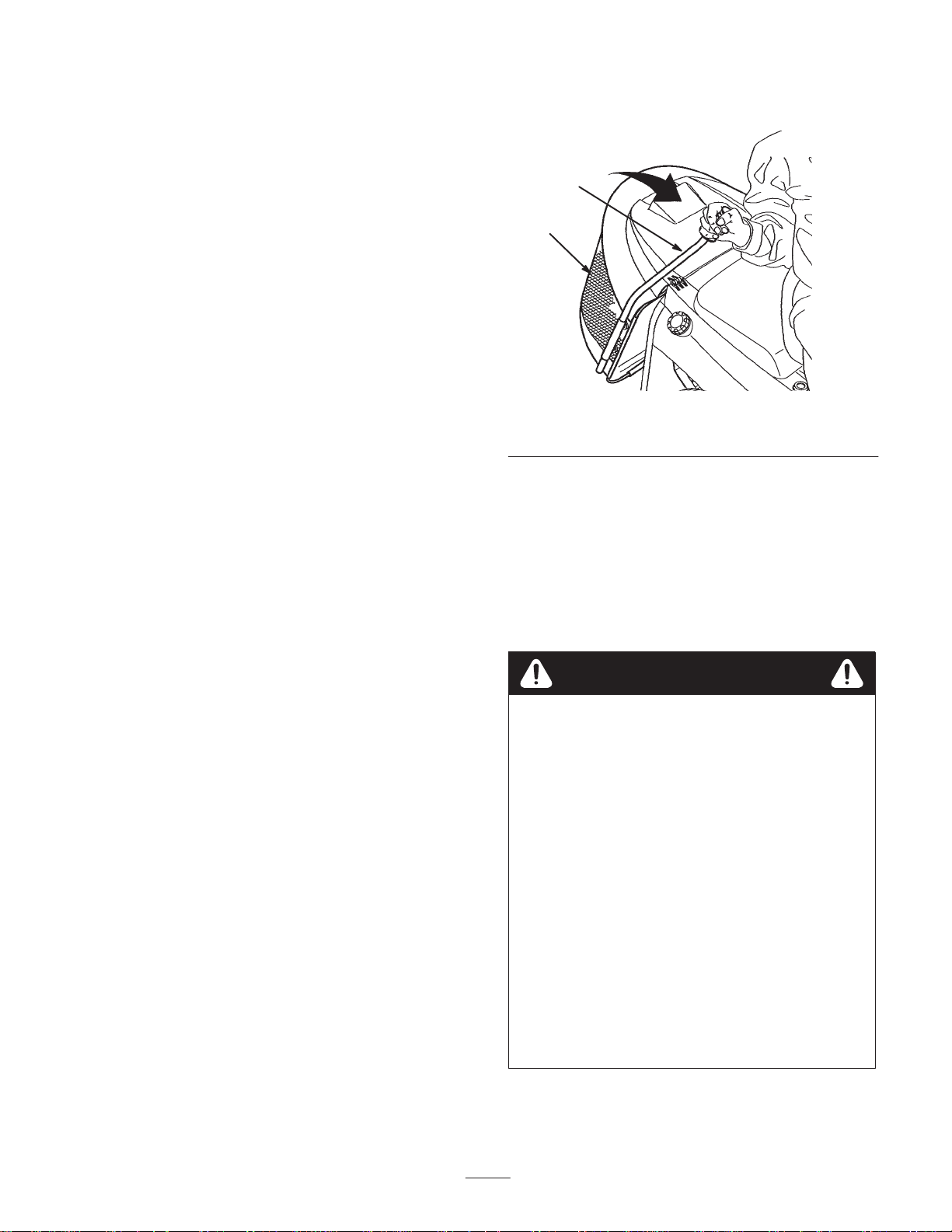

2. Insert the KeyChoice key into the switch (Fig. 10).

A red light on the front console (Fig. 11) turns on,

indicating that the interlock is disabled.

1

m-5974

Figure 11

1. Operating-in-reverse light

4. Shift the ground speed lever into Reverse and complete

your task.

5. Disengage the blade (PTO) to activate the interlock.

6. Remove the KeyChoice key and put it in a safe place

out of the reach of children.

1

Figure 10

1. KeyChoice switch

3. Turn the KeyChoice key.

m-5972

Testing the Safety Interlock

System

Caution

If safety interlock switches are disconnected or

damaged, the machine could operate unexpectedly,

causing personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

Test the safety interlock system before you use the machine

each time. If the safety interlock system does not operate as

described below, have an Authorized Service Dealer repair

it immediately.

1. Shift the ground speed lever into Neutral.

2. Shift the blade control (PTO) lever to Engage, sit on the

seat, and rotate the ignition key to Start: The engine

should not crank. If it does crank, the safety interlock

system is malfunctioning and must be repaired by an

Authorized Service Dealer. If the engine does not crank,

go to step 3.

16

Page 17

3. Shift the blade control (PTO) lever to Disengage, sit on

the seat, depress the brake and clutch pedals, engage the

parking brake, shift the ground speed lever into gear,

and rotate the ignition key to Start: The engine should

not crank. If it does crank, the safety interlock system is

malfunctioning and must be repaired by an Authorized

Service Dealer. If the engine does not crank, go to

step 4.

4. Sit on the seat, shift the ground speed lever into Neutral,

and shift the blade control (PTO) lever to Disengage.

Ensure that the parking brake is engaged and rotate the

ignition key to Start: The engine should start and

continue to run. Then engage the blade control (PTO)

lever and carefully rise from the seat: The engine

should stop. If the engine does not stop running, stop

the engine, wait for all moving parts to stop, and have

the safety interlock system repaired by an Authorized

Service Dealer. If the engine stops when you rise from

the seat, the safety interlock system is functioning

properly.

5. Shift the blade control (PTO) lever to Disengage, shift

the ground speed lever into Neutral, and start the

engine. While the engine is running, shift the blade

control (PTO) lever to Engage, push in the clutch, and

shift the ground speed lever to Reverse: The engine

should stop.

2. Pull the collector rod forward to tilt the collection bin

(Fig. 12).

1

2

Figure 12

1. Collector rod 2. Collection bin

3. Shake the collection bin until it is completely empty.

4. Slowly return the collection rod to the operating

position.

6. Shift the blade control (PTO) lever to Disengage, shift

the ground speed lever to Neutral, and start the engine.

Then shift the blade control (PTO) lever to Engage and

turn the KeyChoice key and release it: The KeyChoice

warning light should illuminate. Shift the blade control

(PTO) lever to Disengage: The KeyChoice warning

light should turn off.

Emptying the Grass Collector

When the collector warning light on the front console

comes on, the grass collector is full and must be emptied.

1. Disengage the blade control (PTO).

Installing the Recycler Cover

A Recycler cover is included with the machine. You can

use it when you do not want to bag the grass clippings.

Danger

Without the grass deflector, discharge cover, or

complete grass catcher assembly mounted in place,

you and others are exposed to blade contact and

thrown debris. Contact with the rotating mower

blade and thrown debris will cause injury or

death.

• Never remove the grass deflector from the

mower because the grass deflector routes

material down toward the turf. If the grass

deflector is ever damaged, replace it

immediately.

• Never put your hands or feet under the mower.

• Never try to clear the discharge area or mower

blades unless you disengage the power take-off

(PTO) and turn the ignition key to Off. Also

remove the key and disconnect the wire from the

spark plug.

1. Park the machine on a level surface.

2. Disengage the blade (PTO).

17

Page 18

3. Shift the ground speed lever into Neutral.

4. Set the parking brake.

5. Stop the engine and wait for all moving parts to stop.

6. Remove the ignition key.

7. Raise the grass collector and remove the hairpin,

2 washers, and clevis pin that secure the discharge tube

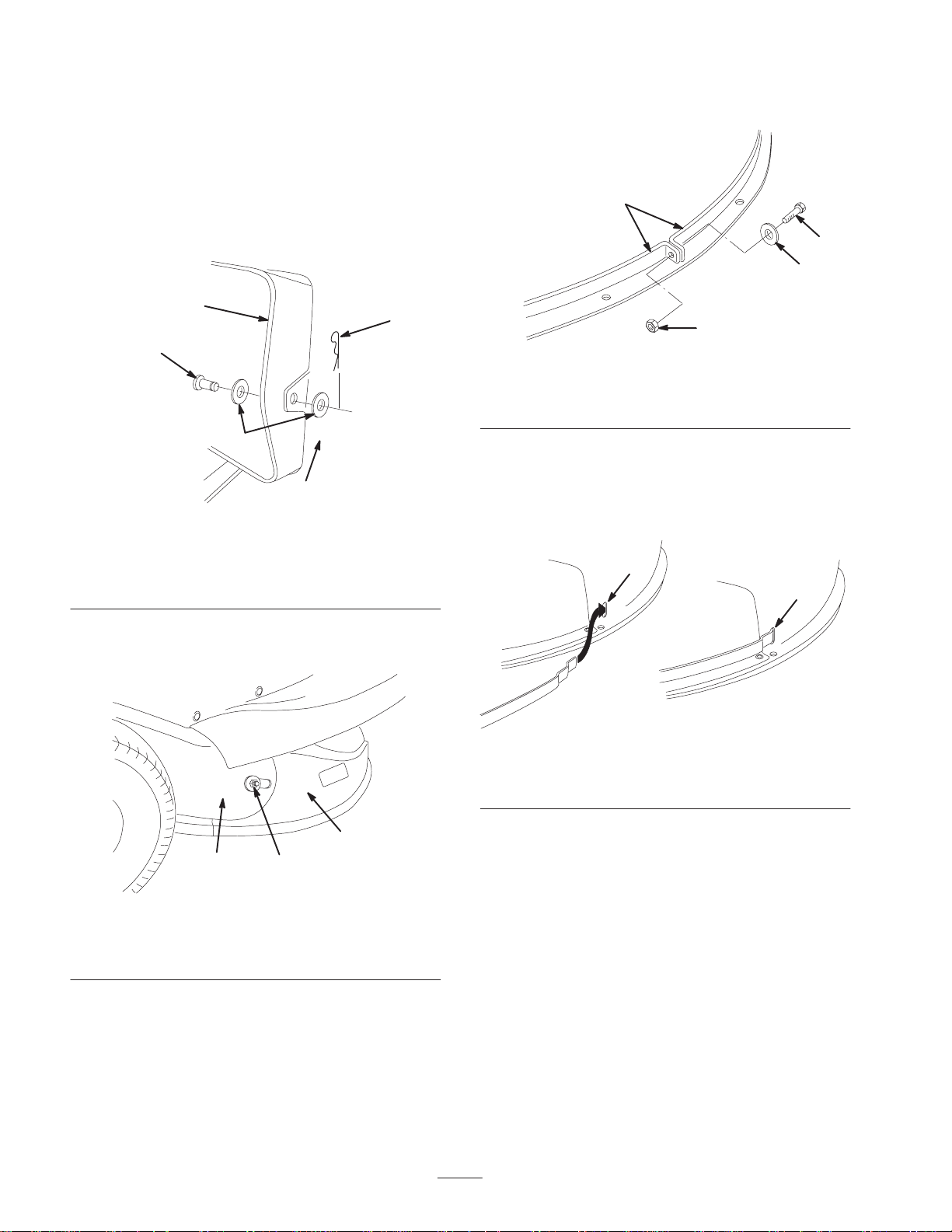

to the rear plate (Fig 13).

10.Remove the bolt, washer, and nut that secure the 2 strap

ends together (Fig. 15).

1

4

3

2

3

5

1

Figure 13

1. Rear plate

2. Discharge tube

3. Clevis pin

4. Hair pin

5. Washers

8. Remove the nut and outer washer that secure the

discharge chute to the discharge tube (Fig. 14).

4

m-6339

2

m-6338a

Figure 15

1. Straps

2. Nut

3. Washer

4. Bolt

11. Move the straps away from the the discharge chute.

Note: Do not remove the straps from the mower

housing. If a strap comes off the housing, insert it as

shown in Figure 16.

1

2

m-6362/m-6363

Figure 16

1. Inserting the strap into the

slot

2. The strap is inserted into

the slot

3

1

2

m-6340a

Figure 14

1. Discharge tube

2. Nut and outer washer

3. Discharge chute

9. Move the height-of-cut lever to the lowest position.

12.Remove the discharge chute from the mower housing.

Note: Attach the nut and outer washer that you

removed to the discharge chute to prevent losing them.

13.Install the Recycler cover onto the mower.

14.Join the 2 strap ends around the Recycler cover as

shown (Fig. 15).

15.Align the holes in the strap ends and fasten them

together snugly with the bolt, washer, and nut you

previously removed.

16.Raise the grass collector and install the clevis pin,

2 washers, and hairpin to secure the discharge tube to

the rear plate (Fig 13).

18

Page 19

Installing the Discharge Chute

Danger

16.Align the holes in the strap ends and fasten them

together snugly with the bolt, washer, and nut you

previously removed (Fig. 15).

Without the grass deflector, discharge cover, or

complete grass catcher assembly mounted in place,

you and others are exposed to blade contact and

thrown debris. Contact with the rotating mower

blade and thrown debris will cause injury or

death.

• Never remove the grass deflector from the

mower because the grass deflector routes

material down toward the turf. If the grass

deflector is ever damaged, replace it

immediately.

• Never put your hands or feet under the mower.

• Never try to clear the discharge area or mower

blades unless you disengage the power take-off

(PTO) and turn the ignition key to Off. Also

remove the key and disconnect the wire from the

spark plug.

1. Park the machine on a level surface.

2. Disengage the blade (PTO).

3. Shift the ground speed lever into Neutral.

Operating Tips

• For the best performance, operate the engine at the

maximum speed. The mower requires air to thoroughly

cut grass clippings, so do not set the height-of-cut too

low or completely surround the mower in uncut grass.

Always leave one side of the mower free from uncut

grass to allow the air to be drawn into the mower.

• Cut the grass slightly longer than normal to ensure that

the cutting height of the mower does not scalp any

uneven ground. When cutting grass longer than 15 cm

tall, cut the lawn twice to ensure an acceptable

appearance.

• It is best to cut only about 1/3 of the grass blade. Do not

cut more than that unless the grass is sparse or it is late

fall when grass grows more slowly.

• Alternate the mowing direction to keep the grass

standing straight. This also helps disperse clippings and

enhances decomposition and fertilization.

• Grass grows at different rates at different times of the

season. To maintain the same cutting height, which is a

good practice, mow more often in early spring. As the

grass growth rate slows in mid summer, mow less

frequently.

4. Set the parking brake.

5. Stop the engine and wait for all moving parts to stop.

6. Remove the ignition key.

7. Raise the grass collector and remove the hairpin and

clevis pin that secure the discharge tube to the rear plate

(Fig 13).

8. Move the height of cut lever to the lowest position.

9. Remove the bolt, washer, and nut that secure the 2 strap

ends together (Fig. 15).

10.Move the straps away from the the discharge chute.

Note: Do not remove the straps from the mower

housing.

11. Remove the Recycler cover from the mower housing.

12.Install the discharge chute onto the mower.

13.Raise the grass collector and install the clevis pin and

hairpin to secure the discharge tube to the rear plate

(Fig 13).

14.Install the nut and outer washer that secure the

discharge chute to the discharge tube (Fig. 14).

• If the grass is longer than normal, or if it contains a high

degree of moisture, raise the cutting height higher than

usual, cut the grass at that setting, and then cut the grass

again at the lower, normal setting.

• If you must stop the machine while mowing, you may

leave a clump of grass clippings on your lawn. To avoid

this, do the following:

– Engage the blade and move to a previously cut area.

– Disperse the clippings evenly by raising the mower

1 or 2 height-of-cut settings while driving forward

with the blade engaged.

• Use the washout port to clean clippings and dirt from

the underside of the mower after each use. If grass and

dirt build up inside the mower, the cutting quality will

eventually become unsatisfactory.

• Maintain a sharp blade throughout the season. A sharp

blade cuts grass cleanly without tearing or shredding the

grass blades. Tearing and shredding the grass turns it

brown at the edges, which slows its growth and

increases the chance of disease. Every 30 days, check

the blade for sharpness and file down any nicks.

15.Join the 2 strap ends around the discharge chute as

shown (Fig. 15).

19

Page 20

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule

Maintenance Service

Interval

Each use

Every 5 hours • Check the blade.

Every 25 hours

Every 50 hours

Every 100 hours

Before storage

Maintenance Procedure

• Check the tire pressure.

• Check the engine oil level.

• Check the safety system.

• Clean the mower housing.

• Check the parking brake.

• Check for loose parts.

• Grease the front wheels.

• Service the air cleaner paper element.

• Check the spark plug.

• Change the engine oil.

• Check the battery electrolyte.

• Replace the spark plug.

• Replace the fuel filter.

• Clean the cooling system.

• Perform all of the maintenance procedures listed above.

• Drain the fuel tank.

• Paint chipped surfaces.

• Charge the battery and disconnect the cables.

1

1

2

1

• Check the safety system.

After storage

1

Perform this procedure more often in dusty, dirty conditions.

2

Change the engine oil after the first 5 operating hours; change it more often than recommended when operating the engine under a heavy

load or in high temperatures.

Important Refer to your engine operator’s manual for additional maintenance procedures.

• Check the spark plug.

• Check the battery electrolyte.

• Check the tire pressure.

Caution

If you leave the key in the ignition switch, someone could accidently start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition and disconnect the wire from the spark plug before you do any

maintenance. Set the wire aside so that it does not accidentally contact the spark plug.

20

Page 21

Servicing the Engine Oil

Check the oil level daily or after every 8 hours.

Change the oil after the first 5 operating hours and every 50

operating hours thereafter.

Note: Change the oil more frequently when operating

conditions are extremely dusty or sandy.

Oil Type: Detergent oil (API service SF, SG, SH, SJ, or

higher)

Crankcase Capacity: 1400 cc/1.4 l

Viscosity: See the table below.

USE THESE SAE VISCOSITY OILS

8. Clean around the oil dipstick (Fig. 17) so that dirt

cannot fall into the filler hole and damage the engine.

1

3

Figure 17

1. Oil dipstick

2. Metal end

9. Unscrew the oil dipstick and wipe the metal end clean

(Fig. 17).

2

m-1868

3. Filler tube

–200 20406080100

°

F

–30°–20 –10 0 10 20 30 40

C

Checking the Oil Level

1. Park the machine on a level surface.

2. Disengage the blade (PTO).

3. Shift the ground speed lever to Neutral.

4. Set the parking brake.

5. Stop the engine and wait for all moving parts to stop.

6. Remove the ignition key.

7. Raise the seat.

10.Screw the oil dipstick fully onto the filler tube (Fig. 17).

Unscrew the dipstick again and look at the metal end. If

the oil level is low, slowly pour only enough oil into the

filler tube to raise the level to the Full mark on the

dipstick.

Important Do not overfill the crankcase with oil and

run the engine; engine damage may result.

Changing the Oil

1. Start the engine and let it run for 5 minutes.

Note: This warms the oil so that it drains better.

2. Park the machine so that the right front side is slightly

lower than the left side to ensure that the oil drains

completely.

3. Disengage the blade (PTO).

4. Shift the ground speed lever into Neutral.

5. Set the parking brake.

6. Stop the engine and wait for all moving parts to stop.

7. Remove the ignition key.

8. Raise the seat.

21

Page 22

9. Slide the draining funnel underneath the oil dipstick/fill

tube (Fig. 18).

Removing the Battery

Warning

2

1

3

m-5977

Figure 18

1. Oil drain plug

2. Oil dipstick/fill tube

10.Place a pan below the draining funnel.

11. Remove the drain plug (Fig. 18).

12.When the oil has drained completely, remove the

draining funnel and install the drain plug.

Note: Dispose of the used oil at a certified recycling center.

13.Slowly pour approximately 80% of the specified

amount of oil into the filler tube (Fig. 17). Check the oil

level; refer to steps 4 and 5 of Checking the Oil Level

on page 21.

3. Draining funnel

Servicing the Battery

Always keep the battery clean and fully charged. Use a

paper towel to clean the battery and battery box. If the

battery terminals are corroded, clean them with a solution

of 4 parts water and 1 part baking soda. Apply a light

coating of grease to the battery terminals to prevent

corrosion.

Battery terminals or metal tools could short

against metal machine components, causing

sparks. Sparks can cause the battery gasses to

explode, resulting in personal injury.

• When removing or installing the battery, do not

allow the battery terminals to touch any metal

parts of the machine.

• Do not allow metal tools to short between the

battery terminals and metal parts of the

machine.

1. Disengage the blade (PTO).

2. Shift the ground speed lever into Neutral.

3. Set the parking brake.

4. Stop the engine and wait for all moving parts to stop.

5. Remove the ignition key.

6. Remove the engine cover.

7. Disconnect the negative (black) ground cable from the

battery post.

Warning

Incorrect battery cable routing could damage the

machine and cables, causing sparks. Sparks can

cause the battery gasses to explode, resulting in

personal injury.

• Always disconnect the negative (black) battery

cable before disconnecting the positive (red)

cable.

• Always connect the positive (red) battery cable

before connecting the negative (black) cable.

Battery voltage and amperage: 12 volts, 155 cold-cranking

amps

8. Slide the rubber cover up the positive (red) cable.

9. Disconnect the positive (red) cable from the battery

post.

10.Remove the battery from the battery box.

22

Page 23

Installing the Battery

Adding Water to the Battery

1. Put the battery into the battery box in the chassis.

2. Using the bolt, washers, and nut, connect the positive

(red) cable to the positive (+) battery post.

3. Slide the rubber cover over the battery post.

4. Using the bolt, washers, and nut, connect the negative

(black) cable to the negative (–) battery post.

5. Install the engine cover.

Checking the Electrolyte Level

1. Remove the engine cover.

2. Look at the side of the battery. The electrolyte must be

up to the Upper line (Fig. 19).

1

2

3

m5004

Figure 19

1. Vent caps

2. Upper line

3. Lower line

The best time to add distilled water to the battery is just

before you operate the machine. This lets the water mix

thoroughly with the electrolyte solution.

1. Remove the battery from the machine; refer to

Removing the Battery on page 22.

2. Clean the top of the battery with a paper towel.

Important Never fill the battery with distilled water

while the battery is installed in the machine. Electrolyte

could be spilled on other parts and cause corrosion.

3. Remove the vent caps from the battery (Fig. 19).

4. Slowly pour distilled water into each battery cell until

the electrolyte level is up to the Upper line (Fig. 19) on

the battery case.

Important Do not overfill the battery because

electrolyte (sulfuric acid) can cause severe corrosion and

damage to the chassis.

5. Wait 5 to 10 minutes after filling the battery cells. Add

distilled water, if necessary, until the electrolyte level is

up to the Upper line (Fig. 19) on the battery case.

6. Install the battery vent caps.

Charging the Battery

Warning

Note: Do not allow the electrolyte to fall below the

Lower line (Fig. 19).

3. If the electrolyte is low, add the required amount of

distilled water; refer to Adding Water to the Battery on

page 23.

Danger

Battery electrolyte contains sulfuric acid, a deadly

poison that can severely burn you and others.

• Do not drink electrolyte and avoid contact with

skin, eyes or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

Charging the battery produces gasses that can

explode.

Never smoke near the battery and keep sparks and

flames away from battery.

Important Always keep the battery fully charged

(1.260 specific gravity). This is especially important to

prevent battery damage when the temperature is below

32°F (0°C).

1. Remove the battery from the chassis; refer to Removing

the Battery on page 22.

2. Check the electrolyte level; refer to Checking the

Electrolyte Level on page 23.

3. Ensure that the vent caps are installed in the battery.

Charge the battery for 1 hour at 25 to 30 amps or 6

hours at 4 to 6 amps. Do not overcharge the battery.

23

Page 24

4. When the battery is fully charged, unplug the charger

from the electrical outlet.

5. Disconnect the charger leads from the battery posts

(Fig. 20).

4

2

3

1

m-4970

Figure 20

1. Positive battery post

2. Negative battery post

3. Red (+) charger lead

4. Black (–) charger lead

8. Unscrew the knob and remove the air cleaner cover

(Fig. 21).

1

2

m–4815

Figure 21

1. Knob 2. Air cleaner cover

9. Unscrew the rubber nut and remove the paper element

(Fig. 22).

6. Install the battery in the machine and connect the

battery cables; refer to Installing the Battery on page 23.

Note: Do not run the machine with the battery

disconnected; electrical damage may occur.

Servicing the Air Cleaner

Service the paper element after every 25 operating hours or

yearly, whichever occurs first.

Note: Service the air cleaner more frequently if the

operating conditions are extremely dusty or sandy.

Removing the Paper Element

1. Disengage the blade (PTO).

2. Shift the ground speed lever into Neutral.

3. Set the parking brake.

4. Stop the engine and wait for all moving parts to stop.

5. Remove the ignition key.

6. Remove the engine cover.

1

2

m-1865

Figure 22

1. Rubber nut 2. Paper element

7. Clean around the air cleaner to prevent dirt from getting

into the engine and causing damage.

24

Page 25

Cleaning the Paper Element

1. Lightly tap the paper element on a flat surface to

remove dust and dirt (Fig. 23).

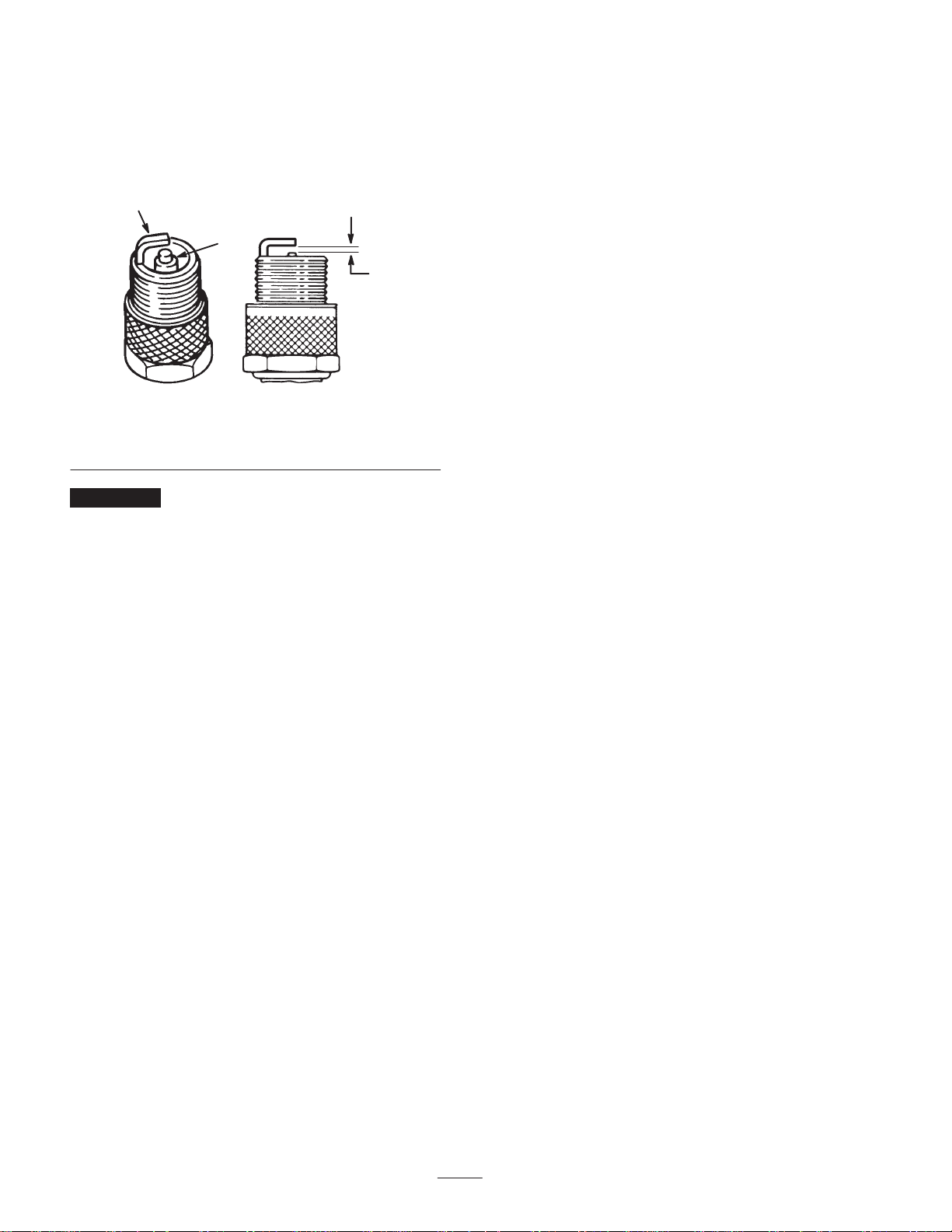

Servicing the Spark Plug

Check the spark plug after every 25 operating hours. Install

a new Champion RJ-19LM or equivalent spark plug after

every 100 operating hours. Ensure that the air gap between

the center and side electrodes is 0.76 mm before installing

the spark plug. Use a spark plug wrench for removing and

installing the spark plug and a gapping tool or feeler gauge

to check and adjust the air gap.

1

2

m-1867

Figure 23

1. Paper element 2. Rubber seal

2. Inspect the element for tears, an oily film, or damage to

the rubber seal.

Important Never clean the paper element with

pressurized air or liquids such as solvent, gasoline, or

kerosene. Replace the paper element if it is damaged or

cannot be cleaned thoroughly.

Installing the Paper Element

Important To prevent engine damage, always operate

the engine with the paper air element installed.

1. Slide the air cleaner assembly onto the long rod.

2. Screw the rubber nut finger-tight against the air cleaner

(Fig. 22).

Removing the Spark Plug

1. Disengage the blade (PTO).

2. Shift the ground speed into Neutral.

3. Set the parking brake.

4. Stop the engine and wait for all moving parts to stop.

5. Remove the ignition key.

6. Reach under the body of the machine above the left rear

wheel and disconnect the wire from the spark plug

(Fig. 24).

1

Note: Ensure that the rubber seal is flat against the air

cleaner base.

3. Install the air cleaner cover and knob (Fig. 21) and

tighten the knob snugly.

4. Install the engine cover.

2

Figure 24

1. Spark plug wire 2. Spark plug

7. Clean around the spark plug to prevent dirt from falling

into the engine and potentially causing damage.

8. Remove the spark plug and metal washer.

25

m-1884

Page 26

Checking the Spark Plug

1. Look at the center of the spark plug (Fig. 25). If you see

light brown or gray on the insulator, the engine is

operating properly. A black coating on the insulator

usually means that the air cleaner is dirty.

2

3

Greasing and Lubricating the

Machine

Grease the machine with a general-purpose grease after

every 25 operating hours or once a year, whichever occurs

first. Grease it more frequently when operating conditions

are extremely dusty or sandy.

1

0.76 mm

m-1870

Figure 25

1. Center electrode insulator

2. Side electrode

Important Do not clean the spark plug. Always

replace the spark plug when it has a black coating, worn

electrodes, an oily film, or cracks.

2. Check the gap between the center and side electrodes

(Fig. 25) and bend the side electrode if the gap is not

correct.

3. Air gap (not to scale)

Installing the Spark Plug

1. Install the spark plug and metal washer.

Note: Ensure that the air gap is set correctly.

2. Tighten the spark plug to 20 N⋅m.

3. Connect the wire to the spark plug (Fig. 24).

1. Disengage the blade (PTO).

2. Shift the ground speed lever into Neutral.

3. Set the parking brake.

4. Stop the engine and wait for all moving parts to stop.

5. Remove the ignition key.

6. Lubricate the front wheels.

7. Wipe up any excess grease.

Checking the Parking Brake

Always set the parking brake when you stop the machine or

leave it unattended. Check the parking brake daily to ensure

that it holds securely.

1. Park the machine on a level surface.

2. Disengage the blade (PTO).

3. Set the parking brake.

4. Stop the engine and wait for all moving parts to stop.

5. Remove the ignition key.

6. If the rear wheels lock and skid when you try to push

the machine forward, you do not need to adjust the

parking brake. But if the rear wheels turn and do not

lock, you need to have an Authorized Service Dealer

adjust the parking brake.

Checking the Tire Pressure

Maintain the air pressure in the tires at 80 kPa. Check the

tire pressure after each use. Check the tires when they are

cold to get the most accurate pressure reading.

26

Page 27

Draining the Fuel Tank

11. Slide the hose clamp close to the filter to secure the fuel

line and filter.

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Drain gasoline from the fuel tank when the

engine is cold. Do this outdoors in an open area.

Wipe up any gasoline that spills.

• Never smoke when draining gasoline, and stay

away from an open flame or where a spark may

ignite the gasoline fumes.

1. Park the machine so that the left front side is slightly

lower than the right side to ensure that the fuel tank

drains completely.

2. Disengage the blade (PTO).

3. Shift the ground speed lever into Neutral.

4. Set the parking brake.

5. Stop the engine.

6. Remove the ignition key.

7. Remove the engine cover.

12.Install the engine cover.

Replacing the Fuel Filter

Replace the fuel filter after every 100 operating hours or

yearly, whichever occurs first. The best time to replace the

fuel filter (Fig. 26) is when the fuel tank is empty. Never

install a dirty filter if it is removed from the fuel line.

1. Disengage the blade (PTO).

2. Shift the ground speed lever into Neutral.

3. Set the parking brake.

4. Stop the engine.

5. Remove the ignition key.

6. Remove the engine cover.

7. Squeeze the ends of the hose clamps together and slide

them away from the filter (Fig. 26).

8. Remove the filter from the fuel lines.

9. Install a new filter and move the hose clamps close to

the filter.

10.Install the engine cover.

8. Squeeze the ends of the hose clamp together and slide it

up the fuel line toward the fuel tank (Fig. 26).

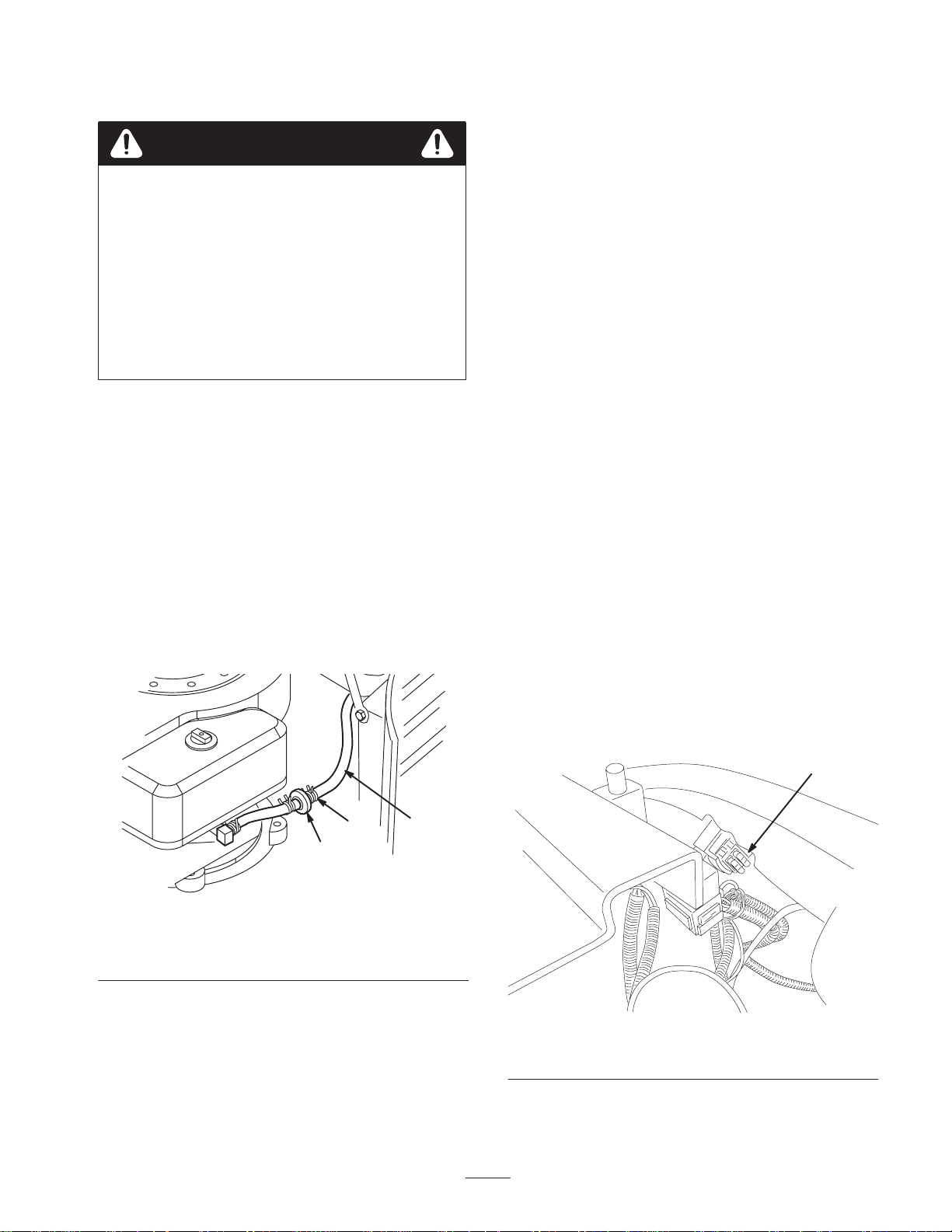

1

3

Figure 26

1. Hose clamp

2. Fuel line

9. Pull the fuel line off of the filter (Fig. 26) and allow the

gasoline to drain into a gas can or drain pan.

Note: Now is the best time to install a new fuel filter

because the fuel tank is empty.

3. Filter

2

m–1873

Servicing the Fuses

The electrical system is protected by 7.5 amp, blade-type

fuses. No maintenance is required, however, if a fuse

blows, check the circuit wiring for a short.

1. Pull out the fuse (Fig. 27) to remove it from the socket.

1

m-5970

Figure 27

1. Fuses (under the seat)

10.Install the fuel line onto the filter.

2. Push down on the fuse to insert it.

27

Page 28

Servicing the Blade

To ensure a superior quality of cut, keep the blade sharp.

For convenient sharpening and replacement, you may want

to have an extra blade.

Removing the Blade

1. Stop the engine and wait for all moving parts to stop.

2. Remove the ignition key.

3. Disconnect the wire from the spark plug.

Danger

A worn or damaged blade can break, and a piece

of the blade could be thrown into the operator’s or

bystander’s area, resulting in serious personal

injury or death.

• Inspect the blade periodically for wear or

damage.

• Replace a worn or damaged blade.

Inspecting the Blade

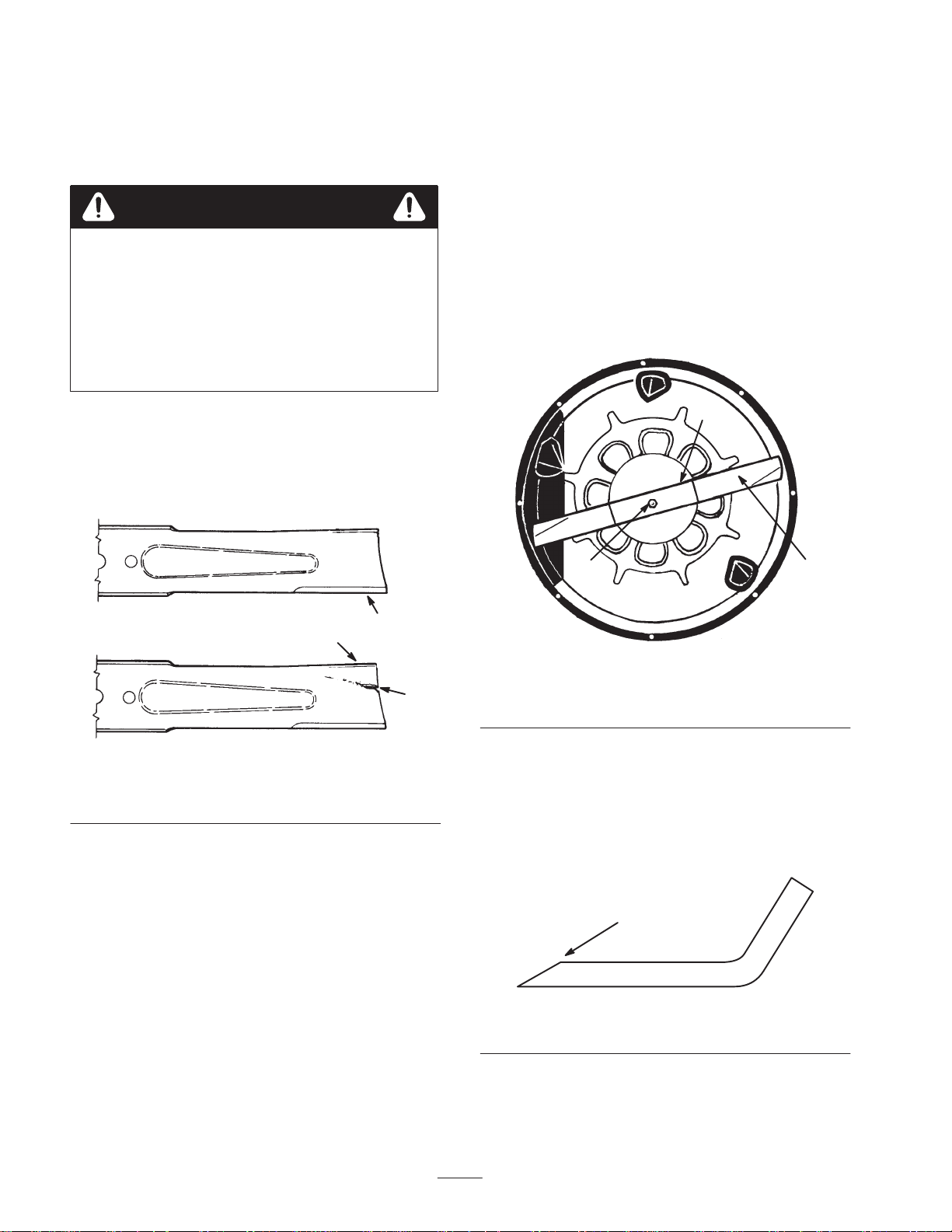

1. Inspect the cutting edges (Fig. 28). If the edges are not

sharp or have nicks, remove the blade and sharpen

them; refer to Sharpening the Blade on page 28.

2

1

4. Shift the transaxle into first gear.

5. Set the parking brake.

6. Grasp the end of the blade using a rag or thickly padded

glove. Then remove the blade bolt, curved washer,

blade stiffener, and blade (Fig. 29). A block of wood

may be wedged between the blade and the mower to

lock the blade when you are removing the bolt.

2

3

1

3

m-151

Figure 28

1. Cutting edge

2. Curved area

3. Wear/slot forming

2. Inspect the blade, especially the curved area (Fig. 28). If

you notice any damage, wear, or a slot forming in this

area (Fig. 28), immediately install a new blade.

Figure 29

1. Blade

2. Blade stiffener

3. Blade bolt and curved

washer

Sharpening the Blade

1. Use a file to sharpen the cutting edge at both ends of the

blade (Fig. 30). Maintain the original angle. The blade

retains its balance if the same amount of material is

removed from both cutting edges.

1

m-1854

Figure 30

1. Sharpen at original angle

28

Page 29

2. Check the balance of the blade by putting it on a blade

balancer (Fig. 31). If the blade stays in a horizontal

position, the blade is balanced and can be used. If the

blade is not balanced, file some metal off of the back

side of the blade. Repeat this step until the blade is

balanced.

2

1

Figure 31

1. Blade 2. Balancer

Installing the Blade

1. Install the blade, blade stiffener, curved washer, and

blade bolt (Fig. 29).

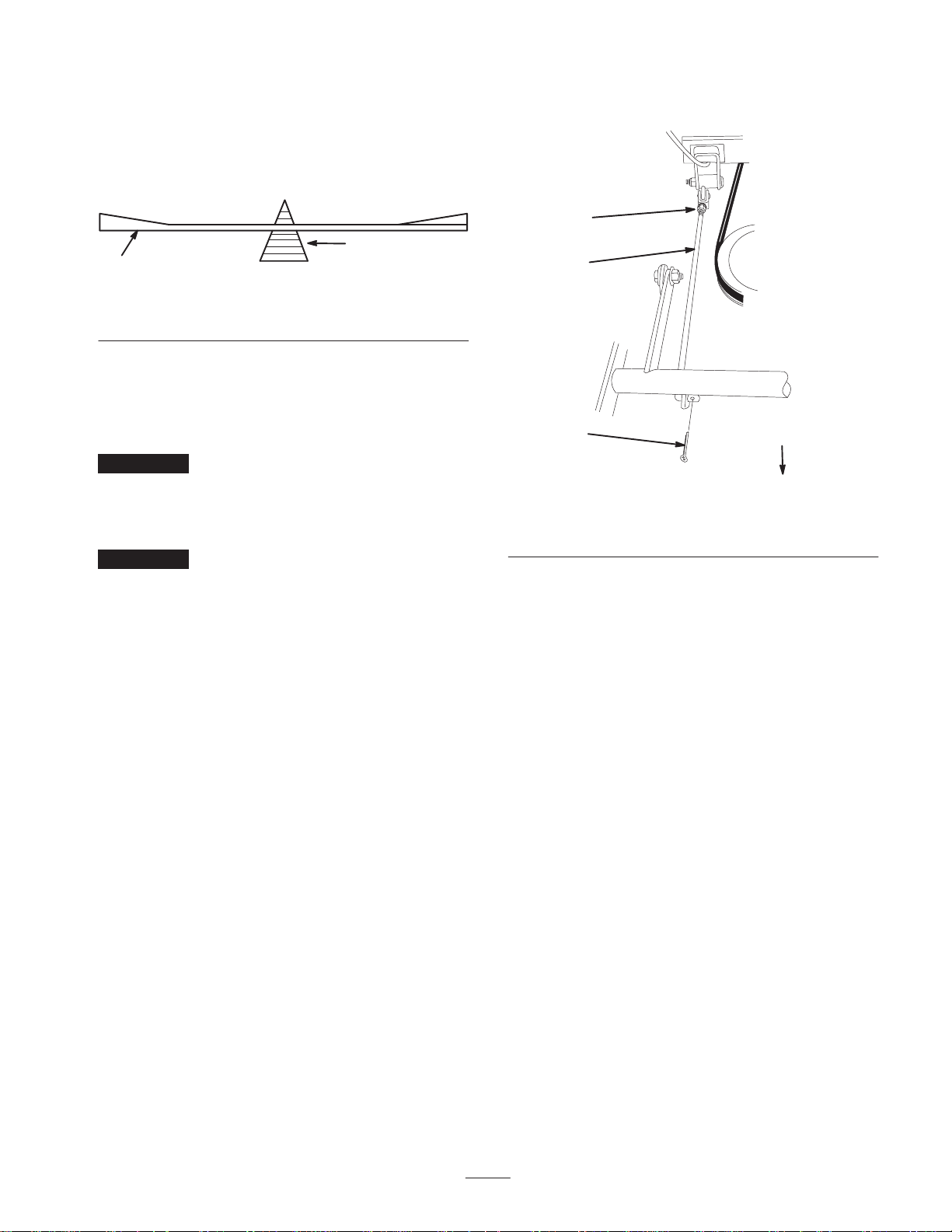

7. Remove the cotter pin at the front of the adjusting rod

(Fig. 32).

3

1

2

front of mower

Important The curved part of the blade must be

pointing toward the inside of the mower to ensure proper

cutting.

2. Tighten the blade bolt to 61 to 82 N⋅m.

Important Ensure that the cutting edge of the blade is

away from the mower housing.

Leveling the Mower

If the mower cuts unevenly and the cutting blade is not

bent, you must level the mower.

1. Move the machine to a level surface.

2. Set the parking brake.

3. Stop the engine and wait for all moving parts to stop.

4. Remove the ignition key.

5. Disconnect the wire from the spark plug.

6. Set the air pressure in the tires to the recommended

level; refer to Checking the Tire Pressure on page 26.

m-5976

Figure 32

1. Adjusting rod

2. Cotter pin

8. Loosen the nut at the rear of the adjusting rod (Fig. 32).

9. Turn the adjusting rod to the desired level.

10.Tighten the nut.

11. Install the cotter pin.

3. Nut

Washing under the Mower

After each use, wash under the mower to prevent grass

buildup for improved mulch action and clipping dispersal.

1. Park the machine on a hard level surface.

2. Disengage the blade (PTO).

3. Stop the engine and wait for all moving parts to stop.

4. Remove the ignition key.

29

Page 30

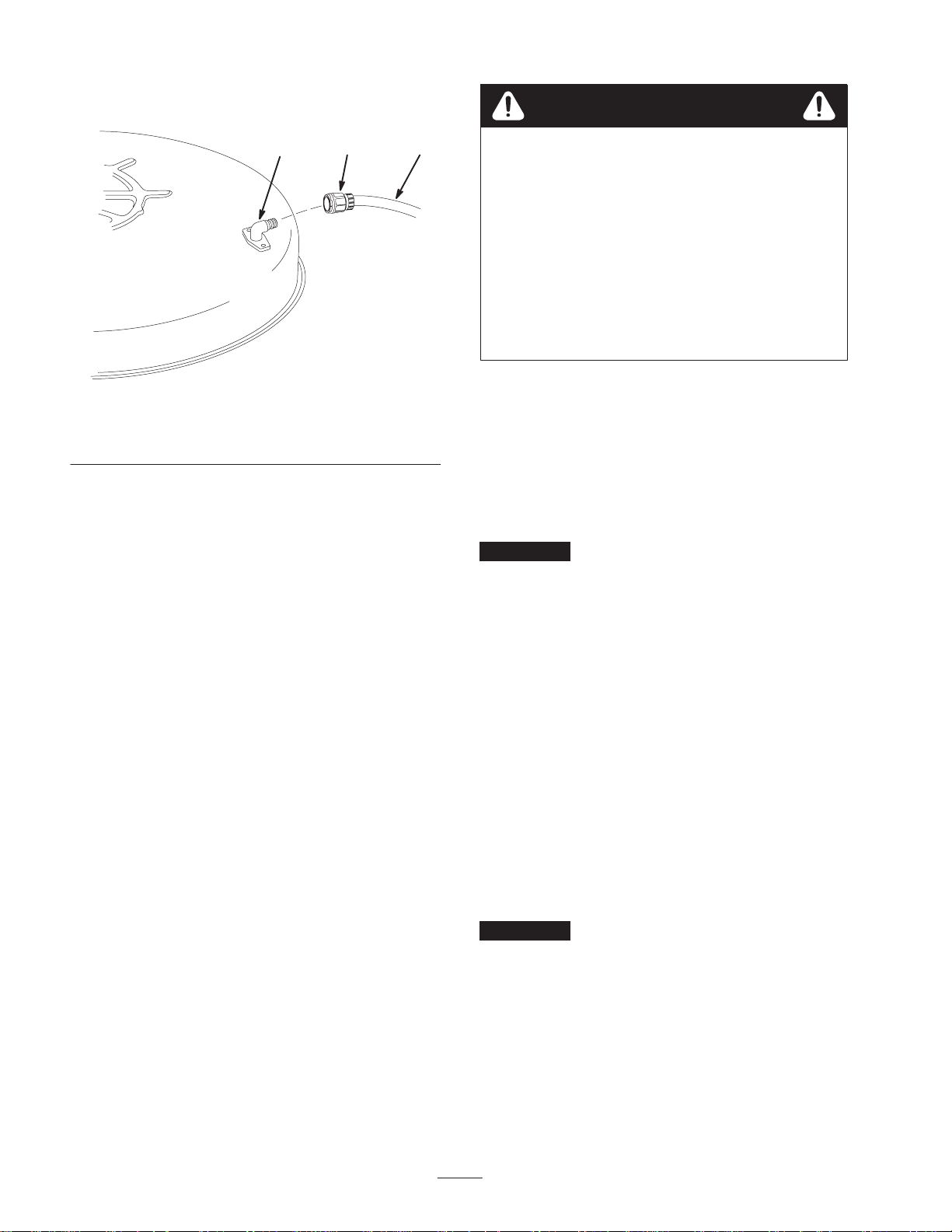

5. Attach the hose coupling to the end of the mower

washout fitting and turn the water on high (Fig. 33).

Warning

1

Figure 33

1. Washout port

2. Coupling

Note: Spread petroleum jelly on the washout fitting o-ring

to make the coupling slide on easier and to protect the

o-ring.

6. Set the mower to the second height-of-cut (B) level.

7. Sit on the seat and start the engine.

8. Engage the blade (PTO) and let the mower run for 1 to

3 minutes.

9. Disengage the blade (PTO).

3. Hose

2

3

m-3118

A broken or missing washout fitting could expose

you and others to thrown objects or blade contact.

Contact with the blade or thrown debris contact

may cause injury or death.

• Replace broken or missing washout fitting

immediately, before using mower again.

• Plug any holes in mower with bolts and

locknuts.

• Never put your hands or feet under the mower

or through openings in the mower.

Washing the Machine

1. Stop the engine and wait for all moving parts to stop.

2. Remove the ignition key.

3. Wait 10 to 15 minutes for the engine to cool down.

4. Wash the machine with mild detergent and water.

Important Do not use a pressure washer to wash the

machine. Pressure washing may damage the electrical

system or wash away necessary grease at friction points.

Avoid excessive use of water, especially near the control

panel, lights, engine, and battery.

5. Start the engine to dry it off.

10.Stop the engine and wait for all moving parts to stop.

11. Remove the ignition key.

12.Turn off the water off and remove the coupling from the

washout fitting.

Note: If the mower is not clean after one washing, soak it

and let it stand for 30 minutes. Then repeat the process.

13.Run the mower again for 1 to 3 minutes to remove the

excess water.

Cleaning and Storage

1. Disengage the blade (PTO).

2. Set the parking brake.

3. Stop the engine and wait for all moving parts to stop.

4. Remove the ignition key.

5. Remove grass clippings, dirt, and grime from the

external parts of the entire machine, especially the

engine. Clean the dirt and chaff from the outside of the

engine cylinder head fins and blower housing.

Important You can wash the machine with mild

detergent and water. Do not use a pressure washer to

wash the machine. Pressure washing may damage the

electrical system or wash away necessary grease at friction

points. Avoid excessive use of water, especially near the

control panel, lights, engine, and battery.

6. Check the parking brake; refer to Checking the Parking

Brake on page 26.

7. Service the air cleaner; refer to Servicing the Air

Cleaner on page 24.

30

Page 31

8. Change the engine oil; refer to Servicing the Engine Oil

on page 21.

9. Check the tire pressure; refer to Checking the Tire

Pressure on page 26.

10.When storing the machine for over 30 days, prepare it

as follows:

A. Add a petroleum based stabilizer/conditioner to the

fuel in the tank according to the instructions from

the stabilizer manufacturer. Do not use an alcohol

based stabilizer (ethanol or methanol).

Note: A fuel stabilizer/conditioner is most effective

when mixed with fresh gasoline and used at all times.

B. Run the engine for 5 minutes to distribute

conditioned fuel through the fuel system.

C. Stop the engine, allow it to cool, and drain the fuel

tank; refer to Draining the Fuel Tank on page 27.

D. Start the engine and run it until it stops.

E. Choke or prime the engine.

F. Start and run the engine until it will not start again.

G. Recycle the old fuel according to local codes.

Important Do not store stabilizer/conditioned gasoline

over 90 days.

11. Remove and inspect the spark plug; refer to Servicing

the Spark Plug on page 25. With the spark plug

removed from the engine, pour 2 tablespoons of engine

oil into the spark plug hole. Use the electric starter to

crank the engine and distribute the oil inside the

cylinder. Install the spark plug, but do not connect the

wire to the spark plug.

12.Disconnect the negative battery cable. Clean the battery

and battery terminals. Check the electrolyte level and

charge it fully; refer to Servicing the Battery on

page 22. Leave the negative battery cable disconnected

from the battery during storage.

Important The battery must be fully charged to prevent

it from freezing and being damaged at temperatures below

32°F (0°C). You can store a fully charged battery during the

winter without recharging.

13.Check and tighten all bolts, nuts, and screws. Repair or

replace any part that is worn or damaged.

14.Paint all scratched or bare metal surfaces. Paint is

available from an Authorized Service Dealer.

15.Store the machine in a clean, dry garage or storage area.

Remove the ignition and KeyChoice keys from the

mower and keep them in a memorable place. Cover the

machine to protect it and keep it clean.

31

Page 32

Wiring Diagram

GND

28

MAGNET

BLACK

29

S2

(PTO)

SHOWN WITH

TURQ./BLACK

TURQUOISE

11

16

17

TURQUOISE

15

TURQ./BLACK

12

10

14

ORANGE

BROWN

BLACK

28

13

1

2

K1

5

4

3

(KILL RELAY)

14

30

GREY

29

PTO DISENGAGED

TURQ./BLACK

17

S6

IN NEUTRAL

(REVERSE)

SHOWN

S5

(BRAKE)

SHOWN WITH

BRAKE DISENGAGED

S4

(SEAT)

SHOWN WHEN

OPERATOR IS NOT

5

32

RED/BLACK

18

S3

TURQ./BLACK

(OVER RIDE)

26

MOMENTARY

KEY SWITCH

10

BROWN

7

TURQUOISE

ON THE SEAT

TURQ./BLACK

15

16

20

RED

19

RED

18

TURQUOISE

TURQUOISE

11

BROWN

11 12

26

13

TAN

ORANGE

51462

BLACK

31

3

RED/BLACK

31

NMIR MODULE

6

GND

RED/BLACK

S7

(BAG FULL)

BAG IS FULL

WHEN GRASS

RED

ORANGE

SWITCH CLOSES

STARTER

ALTERNATOR

GNDSM

AM

GND

4

RED

RED

SOLENOID

WHITE/BLACK

30

9

3

2

2

7.5A F1

RED LAMP

(OVER RIDE)

(BAG FULL)

ORANGE LAMP

RED

ORANGE

RED

32

WHITE

WHITE

WHITE

3

25

22

1

BLACK

23+24

GND

19

20

12V DC

BATTERY

BLACK

RED

GND

BLACK

27

21

8

7.5A F2

S1

KEY SWITCH

(IGNITION)

ON B I A AND X Y

OFF NO CONNECTION

START B I S

ORANGE

TURQUOISE

RED/WHITE

7

9

8

SAB

I

S

X

Y

RED/BLACK

RED/BLACK

5

6

I

AB

Page 33

Troubleshooting

g

Problem Possible Causes Corrective Action

The starter does not crank.

The engine will not start, starts

hard, or fails to keep running.

1. The blade control (PTO) is

engaged.

2. The parking brake is not on. 2. Set the parking brake.

3. The battery is dead. 3. Charge the battery.

4. The electrical connections are

corroded or loose.

5. A fuse is blown. 5. Replace the fuse.

6. A relay or switch is damaged. 6. Contact an Authorized Service

1. The operator is not seated. 1. Sit on the seat.

2. The fuel tank is empty. 2. Fill the fuel tank with gasoline.

3. The air cleaner is dirty. 3. Clean or replace the air cleaner

4. The spark plug wire is loose or

disconnected.

5. The spark plug is pitted, fouled,

or the gap is incorrect.

6. The choke is not closing. 6. Adjust the throttle cable.

7. There is dirt in the fuel filter. 7. Replace the fuel filter.

1. Disengage the blade (PTO).

4. Check the electrical

connections for good contact.

Dealer.

element.

4. Connect the wire to the spark

plug.

5. Install a new, correctly-gapped

spark plug.

The engine loses power.

8. The idle speed is too low or the

mixture is incorrect.

9. Dirt, water, or stale fuel is in the

fuel system.

10.The engine is flooded. 10.Remove the spark plug and dry

11.The battery is dead. 11.Charge the battery.

1. The engine load is excessive. 1. Shift into a lower gear to

2. The air cleaner element is dirty. 2. Clean the air cleaner element.

3. The oil level in the crankcase is

low.

4. The cooling fins and air

passages under the engine

blower housing are plugged.

5. The spark plug is pitted, fouled,

or the gap is incorrect.

6. There is dirt in the fuel filter. 6. Replace the fuel filter.

7. Dirt, water, or stale fuel is in the

fuel system.

8. Adjust the carburetor idle

speed and idle mixture.

9. Contact an Authorized Service

Dealer.

it out.

reduce the ground speed.

3. Add oil to the crankcase.

4. Remove the obstruction from

the cooling fins and air

passages.

5. Install a new, correctly-gapped

spark plug.

7. Contact an Authorized Service

Dealer.

33

Page 34

Problem Corrective ActionPossible Causes

gg

g

The engine overheats.

There is an abnormal vibration.

The blade does not rotate.

1. The engine load is excessive. 1. Shift into a lower gear to

reduce the ground speed.

2. The oil level in the crankcase is

low.

3. The cooling fins and air

passages under the engine

blower housing are plugged.

1. The blade is bent or

unbalanced.

2. The blade mounting bolt is

loose.

3. The engine mounting bolts are

loose.

4. There is a loose engine pulley,

idler pulley, or blade pulley .

5. The engine pulley is damaged. 5. Contact an Authorized Service

1. The blade drive belt is worn,

loose, or broken.

2. The blade drive belt is off of the

pulley.

2. Add oil to the crankcase.

3. Remove the obstruction from

the cooling fins and air

passages.

1. Install a new blade.

2. Tighten the blade mounting

bolt.

3. Tighten the engine mounting

bolts.

4. Tighten the appropriate pulley.

Dealer.

1. Contact an Authorized Service

Dealer.

2. Contact an Authorized Service

Dealer.

The machine does not drive.

The cutting height is uneven.

The cutting quality is poor.

The grass collector fails to fill.

1. The traction belt is worn, loose,

or broken.

2. The traction belt is off the

pulley.

3. The transmission does not

shift.

1. The tire pressure is incorrect. 1. Set the tire pressure.

2. The mower is not level. 2. Level the mower.

3. The underside of the mower is

dirty.

1. The cutting blade is worn. 1. Sharpen or replace the cutting

2. The cutting height is incorrect. 2. Adjust the cutting height.

1. The cutting height is too low. 1. Raise the cutting height.

2. The grass is too heavy or

damp.

3. The cutting blade is worn. 3. Sharpen or replace the blade.

4. The grass is too high. 4. Raise the cutting height.

5. The discharge area is blocked. 5. Remove the obstruction from

1. Contact an Authorized Service

Dealer.

2. Contact an Authorized Service

Dealer.

3. Contact an Authorized Service

Dealer.

3. Clean under the mower.

blade.

2. Wait until the grass has dried.

the discharge area.

34

Page 35

35

Page 36

Loading...

Loading...