Page 1

TowPoleHitchKit,Pintel,Stamped,1inPin

End-DumpConcreteMixer

ModelNo.68130

ModelNo.68131

ModelNo.68132

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3381-180RevA

Addendum

ProcedureDescription

TowPole1

Clevispinandcable

1

2

Note:Ifnecessary,attachtheclevispinandcabletothetow

pole,andasneeded,shimthehitchassemblybeforeinstalling

thetowpoleontothemachine.

Screw(10-24x5/8inch)

Locknut(10-24inch)

Hitchassembly1

Flanged-headbolt(1/2x4-1/2inch)

Washer(1/2inch)

Locknut(1/2inch)

1

AttachingtheClevisPinand CabletotheTowPole

Qty.

1

1

1

2

2

2

Note:Ensurethatthecablepointstowardthe

mountingbracketofthetowpoleandisangled45°to

thesideasshowninFigure1.

Attachtheclevispinandcabletothe

towpole.

Shimthehitchassembly.

Use

Partsneededforthisprocedure:

1TowPole

1

Clevispinandcable

1

Screw(10-24x5/8inch)

1

Locknut(10-24inch)

Procedure

Usethisprocedureiftheclevispinandlanyardisnotfactory

installedonthetowpole.

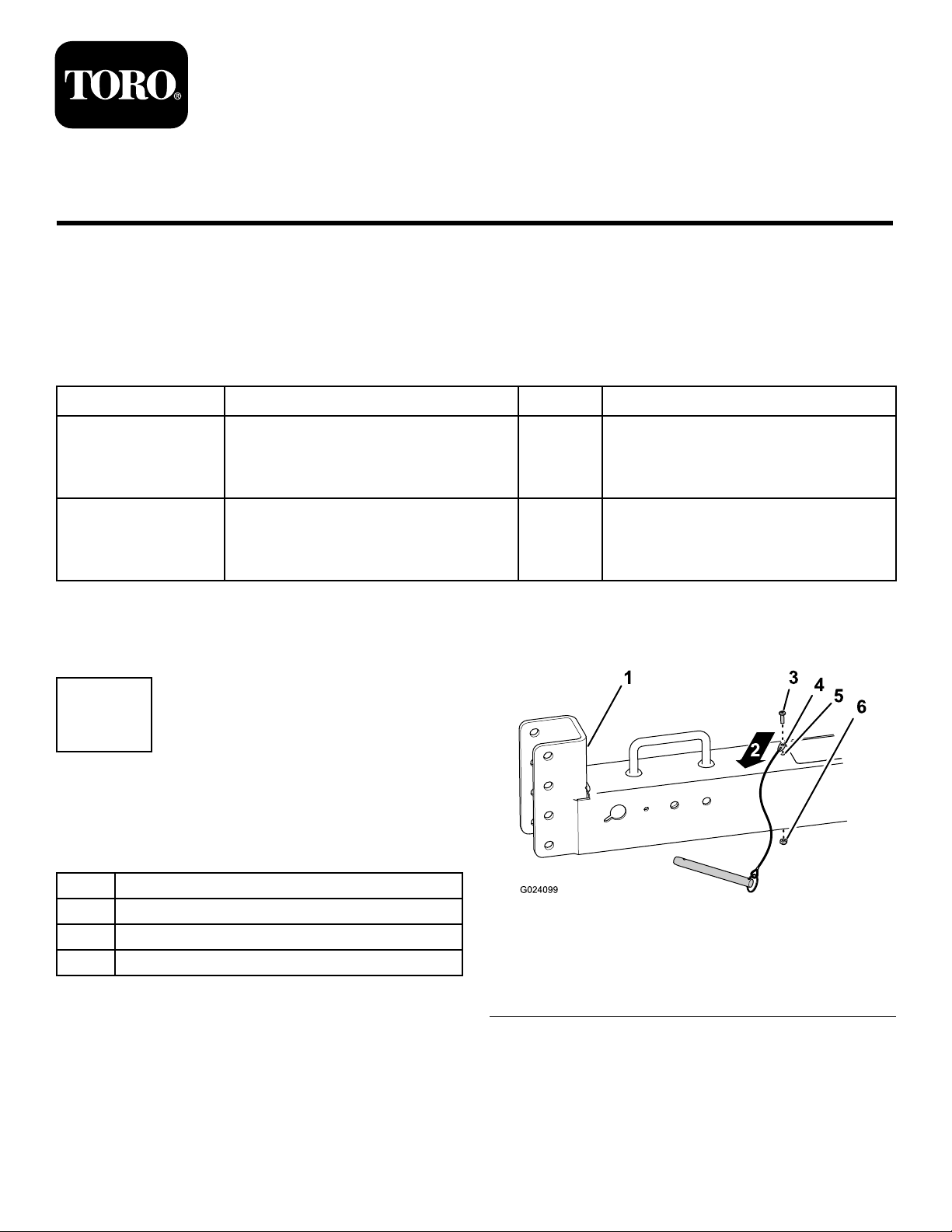

1.Aligntheholeinthemountingtabofthecabletothe

4.7mm(3/16inch)holeinthetopofthetowpole

(

Figure1).

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Figure1

1.Mountingbracket(tow

pole)

2.45°

3.Screw(10-24x5/8inch)6.Locknut(10-24)

2.Securethemountingtabofthecabletothetotowpole

withthescrew(10-24x5/8inch)andlocknut(Figure

1).

OriginalInstructions(EN)

PrintedintheUS

AllRightsReserved

4.Mountingtab(cable)

5.Hole

*3381-180*A

Page 2

2

ShimmingtheHitchAssembly

Partsneededforthisprocedure:

1Hitchassembly

2

Flanged-headbolt(1/2x4-1/2inch)

2

Washer(1/2inch)

2

Locknut(1/2inch)

Procedure

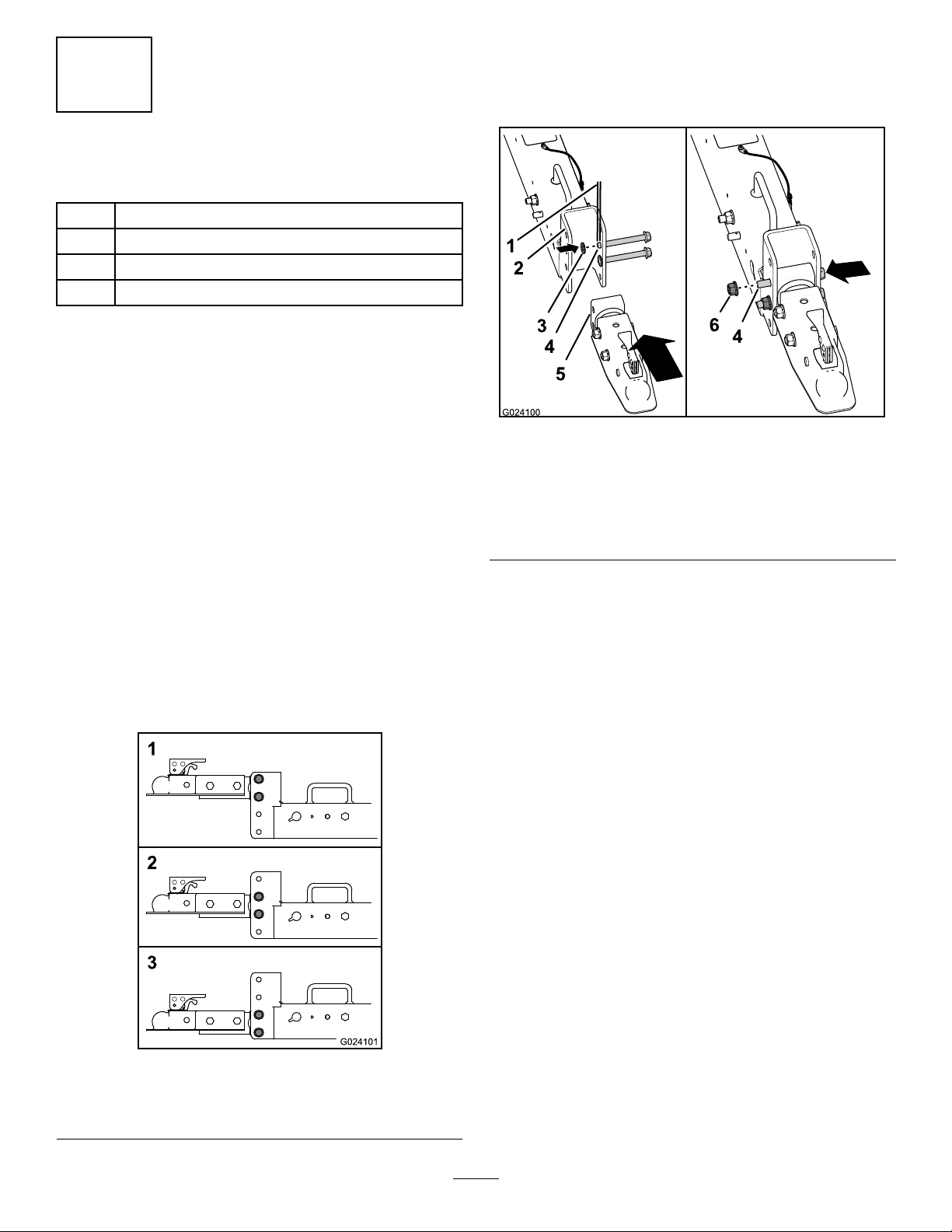

Usethisproceduretoreducethegapbetweenthemounting

plateofthetowpoleandthehitchassembly.

2.Partiallyinsertthe2anged-headbolt(1/2x4-1/2

inch)throughtheholesinthemountingplatewith3.1

mm(1/8inch)ofthethreadsprojectingtotheinside

ofthebracket(Figure3).

Note:Thestampedballhitchassemblyisshown,the

installationofthepinteland1inchpinhitchassembliesare

similar.

1.Checktherelationshipbetweenthehitchofthe

machineandthehitchofthetowvehicle(Figure2),

andmountthehitchassemblyin1ofthefollowing

positions:

•Ifthehitchesareapproximatelythesameheight,

keepthehitchassemblyinthemiddlepositionof

themountingplate.

•Ifthehitchofthetowvehicleishigh,mountthe

hitchassemblyinthetopposition.

•Ifthehitchofthetowvehicleislow,mountthe

hitchassemblyinthebottomposition.

Figure3

1.3.1mm(1/8inch)4.Flanged-headbolt(1/2x

2.Mountingbracket

3.Washer(1/2inch)6.Locknut(1/2inch)

3.Slipawasher(1/2inch)overthethreadedendofeach

ofthebolts(Figure3).

4.Aligntheholesinthehitchassemblywiththeholesin

themountingplate(Figure3).

5.Fullyinserttheboltsthroughthehitch,washers,and

plate(Figure3).

6.Threadthe2locknuts(1/2inch)intothebolts(

3

)andtorquethemto102N-m(75ft-lb).

4-1/2inch)

5.Hitchassembly(stamped

ballshown)

Figure

Figure2

1.Topposition3.Bottomposition

2.Middleposition

2

Loading...

Loading...