Page 1

TowPoleHitch

forEnd-DumpConcreteMixers

ModelNo.68130

ModelNo.68131

ModelNo.68132

FormNo.3379-218RevA

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Safety

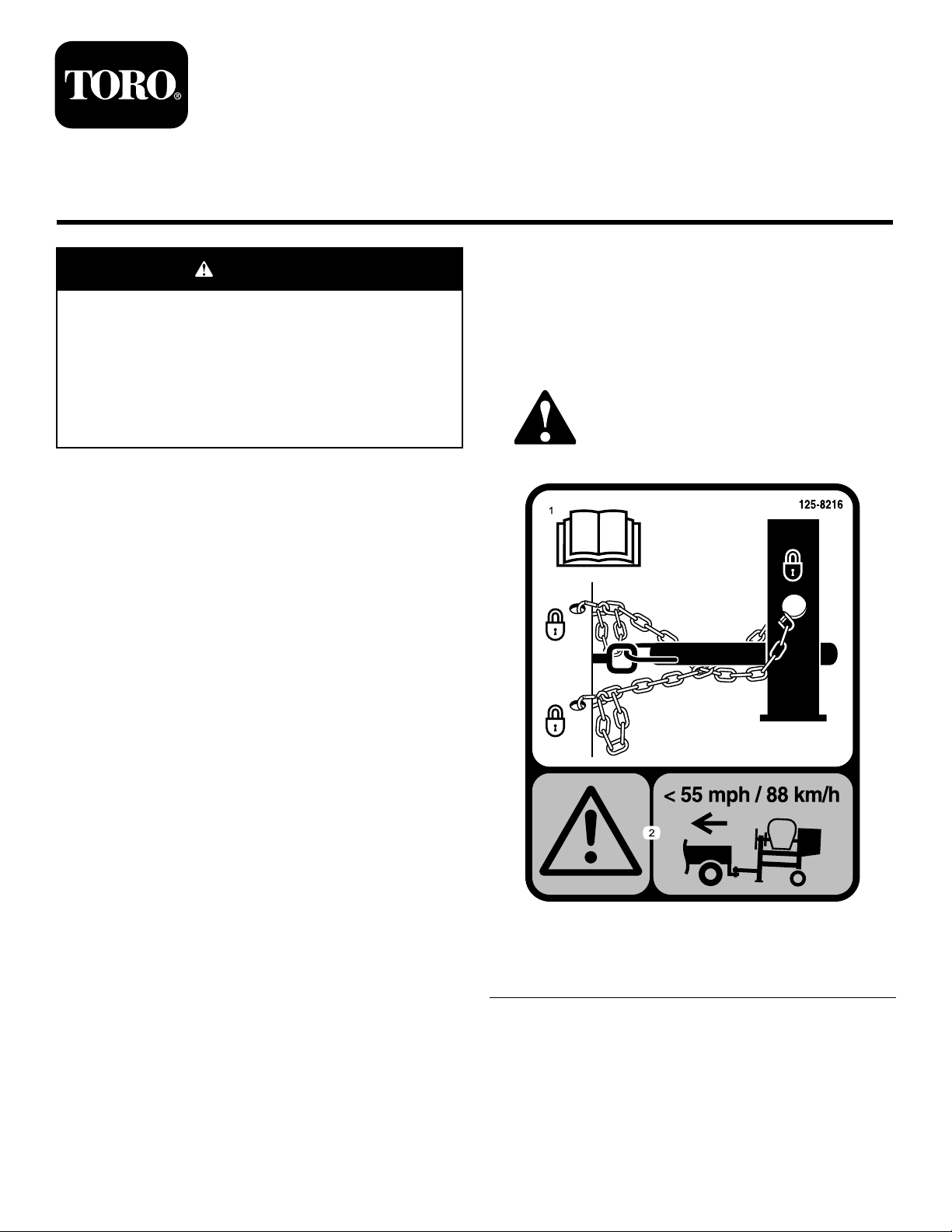

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasily

visibletotheoperatorandarelocatednear

anyareaofpotentialdanger.Replaceany

decalthatisdamagedorlost.

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

OriginalInstructions(EN)

AllRightsReserved

125–8216

2.Warning—limittowing

speedtolessthan55mph

/88km/h.

PrintedintheUSA

*3379-218*A

Page 2

Installation

G021091

1

G021092

1

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

1

Partsneededforthisprocedure:

1Towpole

1

Frontstabilizerleg(shippedwiththemachine)

6

Shortbolt

1Longbolt

7

Locknut

Towpole1

Frontstabilizerleg(shippedwiththe

machine)

Shortbolt

Longbolt1

Locknut

Hitchassembly1

Flange-headbolt2

Locknut2

Safetychain

Connectinglink

1.Supportpoints

Qty.

Use

1

6

7

1

2

Installthetowpole.

Installthehitchassembly.

Installthesafetychainandconnecting

links.

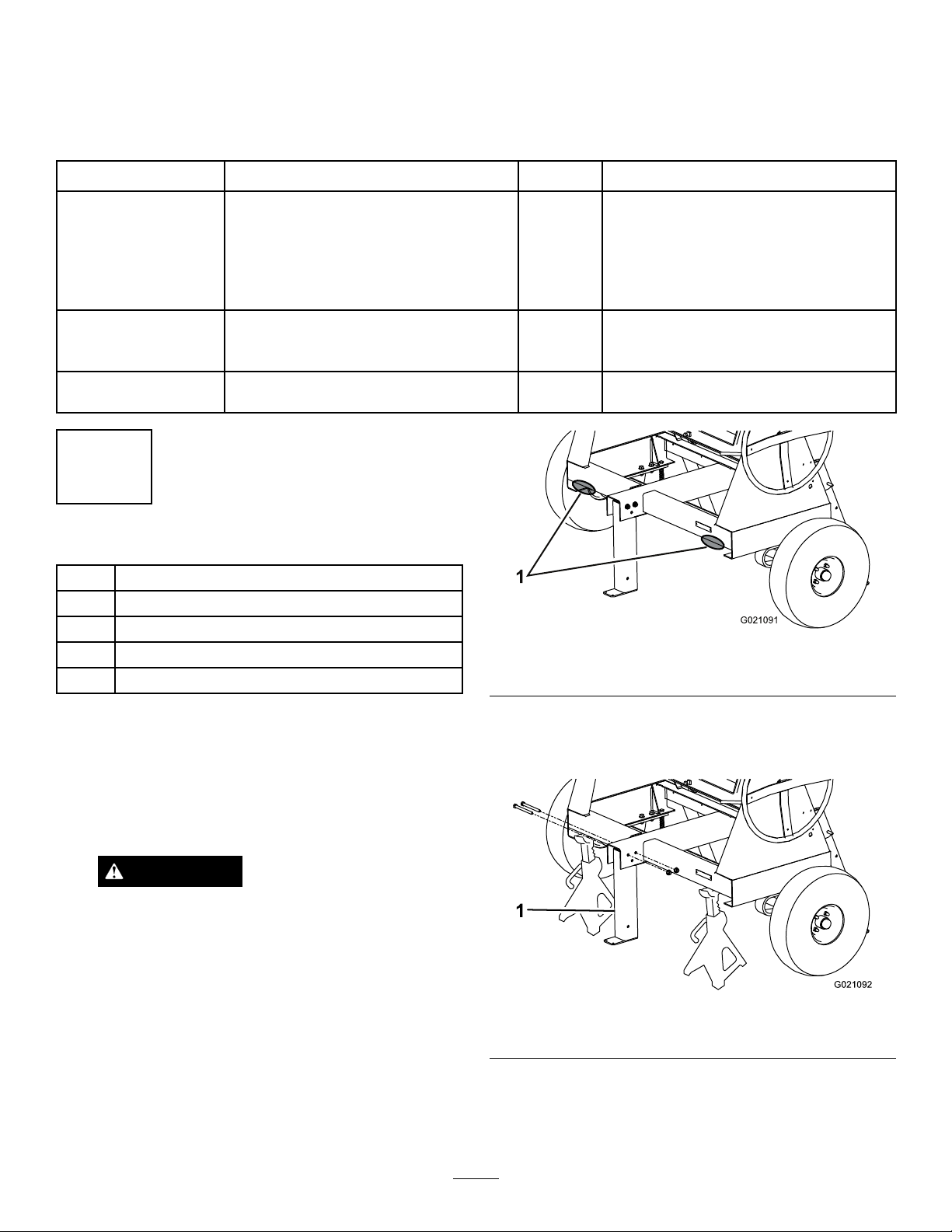

Figure1

3.Removethe2nutsandboltsthatsecurethefront

Procedure

1.Lowertherearstabilizerlegs;refertothemachine

Operator’sManual.

2.Placejackstandsunderthefrontframerailtoprevent

themachinefromtippingforward(

Figure1).

stabilizerlegtotheframe(

frontstabilizerleg.

Figure2),andremovethe

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseseriousinjury.

Usejackstandswhensupportingthemachine.

Figure2

1.Frontstabilizerleg

4.Installthetowpoleintotheopeningatthefrontofthe

machine,andsecureitwith6shortboltsand6locknuts

torquedto102N-m(75ft-lb);referto

Figure3.

2

Page 3

G023350

2

3

1

4

G023351

2

2

4

3

1

G023352

InstallingtheHitchAssembly

Partsneededforthisprocedure:

1Hitchassembly

2Flange-headbolt

2Locknut

Figure3

5.Alignthetoprearholeinthefrontstabilizerleg(Figure

4)totherearmostholenearthehandleatthefront

ofthetowpole.

Procedure

1.Using2ange-headboltsand2locknuts,loosely

installthehitchassemblyinthemiddlepositionofthe

mountingplate.

Figure5

Ballhitchshown

1.Locknut(2)3.Flange-headbolt(2)

2.Mountingplate4.Hitchassembly

2.Positionthemachinesothatthetowpoleislevel.

Figure4

1.Locknut

2.Longbolt4.Frontstabilizerleg

6.Installthelongboltthroughtheholes,andsecureit

withalocknuttorquedto102N-m(75ft-lb);referto

Figure4.

Note:Thestabilizerlegpivotsrearwardonthebolt.

Ifyouinstalltheboltintothewronghole,thestabilizer

legwillnotworkproperly.

3.Clevispin

3.Checktherelationshipbetweenthehitchofthe

machineandthehitchofthetowvehicle,andmount

thehitchassemblyin1ofthefollowingpositions:

•Ifthehitchesareapproximatelythesameheight,

keepthehitchassemblyinthemiddlepositionof

themountingplate;refertoFigure6.

•Ifthehitchofthetowvehicleishigh,mountthe

hitchassemblyinthetopposition.

•Ifthehitchofthetowvehicleislow ,mountthe

hitchassemblyinthebottomposition.

7.Inserttheclevispin(Figure4)tolockthefront

Note:Rotatethestabilizerlegupfortowingthemachine,

anddownwhenthemachineisstationary.Alwaysinsertthe

clevispinthroughtheappropriateholestoensurethatthe

stabilizerlegdoesnotmoveunexpectedly.

stabilizerleginposition.

3

Page 4

1

2

3

G023353

Figure6

A B

C D

G023355

2

3

4

3

1

Ballhitchshown

1.Topposition3.Bottomposition

2.Middleposition

Figure7

1.Keyhole

2.Rodorwire(notincluded)4.Connectinglink

3.Safetychain

4.Torquethe2nutsand2boltsto102N-m(75ft-lb).

Important:Refertothemachine

informationabouthitchingandtowingthemachine.

3

InstallingtheSafetyChainand ConnectingLinks

Partsneededforthisprocedure:

1

Safetychain

2

Connectinglink

InstallingtheSafetyChain

1.Formahookontheendofabendablepieceofrod

orstiffwire(notincluded),andinsertitthroughboth

keyholesinthetowpoleofthemachine(Figure7).

Operator’ s Man ual

2.Attachthesafetychaintothelengthofrodorwire

(Figure7).

for

3.Pulltherod,orwire,andthesafetychainthroughboth

keyholes(Figure7).

Note:Ensurethatapproximatelyequallengthsof

safetychainextendfromeithersideofthetowpole.

4

Loading...

Loading...