Page 1

FormNo.3377-532RevB

GrateKit

6cu.ft.and8cu.ft.MortarMixers

ModelNo.68080C—SerialNo.313000001andUp

ModelNo.68081C—SerialNo.313000001andUp

InstallationInstructions

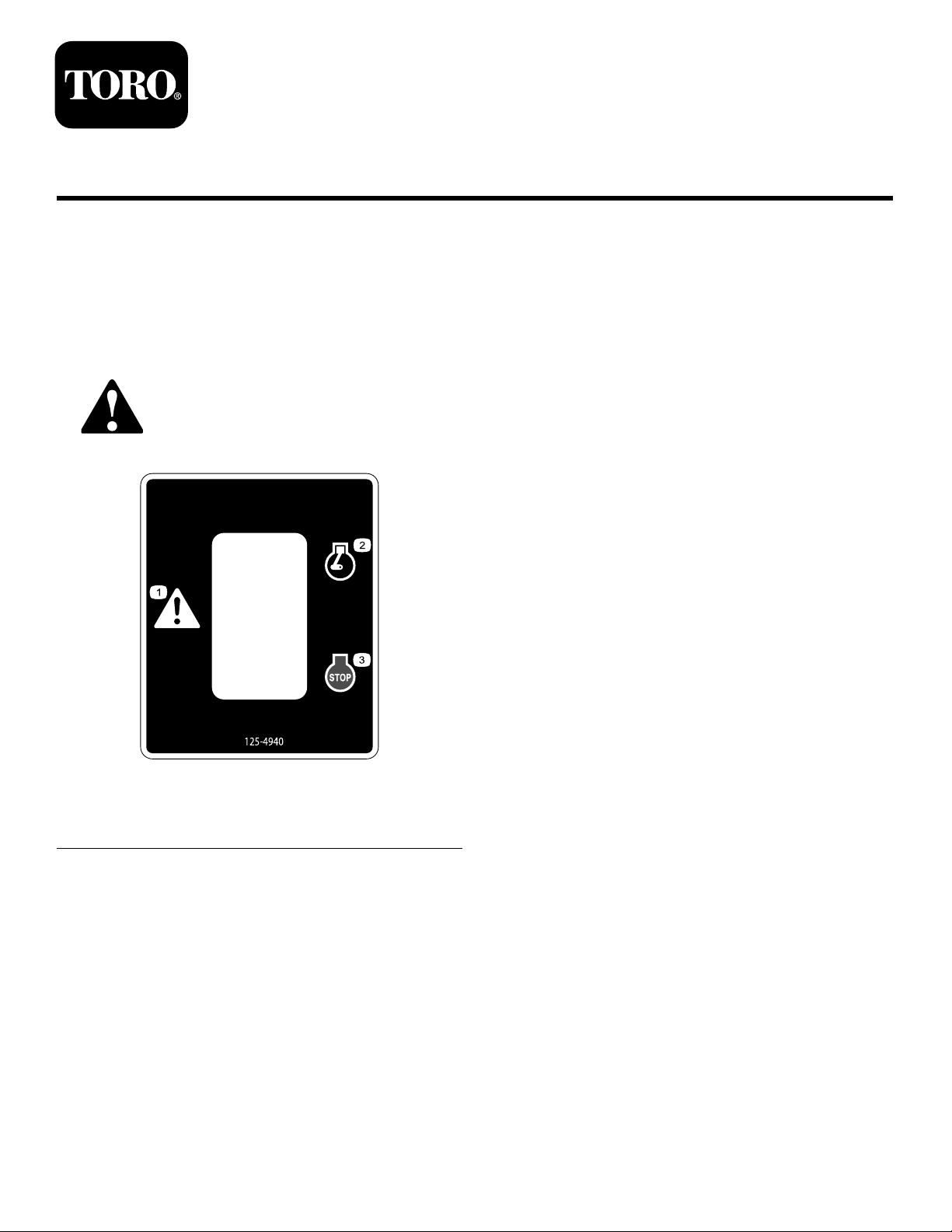

Safety

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1.Warning3.Engine—stop

2.Engine—run

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

125–4940

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3377-532*B

Page 2

Installation

1

2

3

G021 168

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Nopartsrequired

Stationaryguard

Movableguard1

Liftarm

Dumphandle1

Longbolt4

Shoulderbolt

Nut6

Switch

Switchhousing

Wireharness1

Shortbolt

Nut2

Decal1

1

RemovingtheLiftArm,Grate,

Qty.

Use

–

1

1

2

1

1

2

Removethegrateanddumphandle.

Installthegrateanddumphandle.

Installtheswitch.

andDumpHandle

NoPartsRequired

Procedure

1.Removethe2shoulderbolts,2nuts,andfenderwasher

thatsecuretheliftarmtothefrontpostandthegrate

(Figure1).Discardtheliftarm.

Note:Savethehardwareforinstallingthenewliftarm.

Figure1

1.Dumphandle

2.Frontpost

2.Removethe2shoulderboltsandnutsthatsecurethe

gratetothepivotholesontheleftsideofthedrum

(Figure1).

3.Carefullyliftthegrateoffthemachine,anddiscardit.

4.Removethe2nutsandboltsthatsecurethedump

handletothedrum,andremovethedumphandlefrom

themachine(Figure1).

3.Liftarm

2

Page 3

2

G0 2118 6

1

2

1

2

3

4

5

6

7

9

4

10

5

4

G021 169

8

InstallingtheLiftArm,Grate,

andDumpHandle

Partsneededforthisprocedure:

1

Stationaryguard

1Movableguard

1

Liftarm

1Dumphandle

4Longbolt

2

Shoulderbolt

6Nut

Procedure

1.Placethestationaryguardontopofthedrum,sothat

thepivotholesareontherightside,nearthechute

(Figure2).

Figure2

1.Pivotholes

2.Chute

1.Longbolt

2.Stationaryguard7.Shoulderbolts(existing)

3.Dumphandle

4.Nut

5.Shoulderbolt

3.Installthedumphandleontothe2frontbolts,and

securetheguardandthehandlewithnutstorquedto

41N-m(30ft-lb);referto

Note:Ensurethatthestationaryguardislevelwith

theedgesofthedrum.

4.Securethe2boltsattherearoftheguardwithnuts

torquedto41N-m(30ft-lb);refertoFigure3.

5.Aligntheboltholesinthestationaryguardandthe

movableguard,andsecurethemwiththe2shoulder

boltsandnutstorquedto22N-m(16ft-lb);referto

Figure3.

2.Insertthe4longboltsthroughthemountingholesin

thedrumandthestationaryguard,fromtheinsideof

thedrum(Figure3).

6.Aligntheslotintheliftarmwiththeboltholeinthe

frontcornerofthemovableguard,andsecureitwitha

shoulderbolt,fenderwasher,andnut(fromtheoriginal

liftarm)torquedto22N-m(16ft-lb);refertoFigure3.

Figure3

6.Liftarm

8.Fenderwasher(existing)

9.Nuts(existing)

10.Movableguard

Figure3.

7.Alignthebottomholeintheliftarmwiththehole

inthetabonthefrontpost,andsecureitwiththe

othershoulderboltandnut(fromtheoriginalliftarm)

torquedto22N-m(16ft-lb);referto

Figure3.

3

Page 4

3

1

G021 170

2

3

4

5

6

7

2

4

5

6

7

G021 173

3

8

1

InstallingtheEngineSwitch

7.Center-punchthemark,anddrilla10mm(3/8inch)

holethere(Figure4).

InstallingtheSwitch

1.Opentherearcowl.

Partsneededforthisprocedure:

1

Switch

1

Switchhousing

1Wireharness

2

Shortbolt

2Nut

1Decal

DrillingtheHolesintheCowl

1.Ontherightsideoftheforwardcowl,makeamark

15.2cm(6inches)upfromthesidebend,and16.5cm

(6-1/2inches)backfromthefrontedge(Figure4).

2.Removethedividerplate;refertothemachineOperator’ s

Manual.

3.Cliptheswitchintotheswitchhousing(

Ensurethattheroundedendoftheswitchistoward

thestoppositionontheswitchhousing.

Figure5).

Figure5

1.Nuts

Figure4

1.15.2cm(6inches)5.Holeforther-treemount

2.16.5cm(6-1/2inches)6.8.9cm(3-1/2inches)

3.6.4cm(2-1/2inches)7.7.0cm(2-3/4inches)

4.Holesfortheswitch

2.Makeamark6.4cm(2-1/2inches)abovetherst

markandanothermark6.4cm(2-1/2inches)below

therstmark(Figure4).

3.Center-puncheachmarktoensurethatthedrillbit

doesnottraveloffofeachmark.

4.Drilla51mm(2inch)holeonthecentermark(

4).

5.Drilla10mm(3/8inch)holeonthetopmark,and

another10mm(3/8inch)holeonthebottommark

(

Figure4).

6.Ontherightsideoftheforwardcowl,makeamark8.9

cm(3-1/2inches)belowthebendand7.0cm(2-3/4

inches)infrontofthebackedge(Figure4).

Figure

2.Grommet6.Switchhousing

3.Decal7.Wireharness

4.Switch

4.Installthegrommetintothecenterhole(Figure5).

5.Routethewireharnessthroughthecenterholewith

thegrommet,andplugitintotheswitch(Figure5).

6.Installtheswitchhousingontotheforwardcowlwith

the2shortboltsandnutstorquedto22N-m(16ft-lb);

refertoFigure5.

Note:Positiontheswitchandhousingsothatthe

stopposition(andtheroundedendoftheswitch)is

atthebottom.

5.Shortbolt(2)

8.Fir-treemount

4

Page 5

ConnectingtheWires

G021 171

2

3

4

1

1

2

G021 167

3

4

G021 172

2

345

1

1.Opentheengine-mountedcliptoaccessthewires

(Figure6).

Note:Youmayneedtouseascrewdriveroranother

tooltoprytheclipopen.

Figure8

Figure6

1.Engine-mountedclip3.Blackwire

2.Yellowwire4.Redwire

2.Disconnecttheblackwireontheengine-mounted

switchfromtheblackwireontheengine(Figure6).

3.Connectthegraywireonthecowl-mountedswitch

totheblackwireontheengine-mountedswitch

(Figure7andFigure8).

1.Engine-mountedclip

2.Blackwire(engine)

3.Blackwire(cowl-mounted

switch)

4.Graywire(cowl-mounted

switch)

5.Blackwire

(engine-mountedswitch)

4.Connecttheblackwireonthecowl-mountedswitchto

theblackwireontheengine(Figure7andFigure8).

Note:Donotdisconnecttheredwireortheyellow

wire.

5.Bundleandsecurethewireswiththeengine-mounted

clip.

6.Installther-treeclipintothe10mm(3/8inch)hole

thatyoudrilledintheforwardcowlinstep

6ofDrilling

theHolesintheCowl(page4).

7.Installthedividerplate;refertothemachineOperator’ s

Manual.

Note:Ensurethatthedividerplatedoesnotstretch

orpinchthewireharness.

TestingtheSwitches

Fortheenginetostartandrun,theengine-mountedswitch

mustbeintheOnposition,andthecowl-mountedswitch

mustbeintheRunposition.

1.Blackwire

(engine-mountedswitch)

2.Graywire(cowl-mounted

switch)

Figure7

3.Blackwire(cowl-mounted

switch)

4.Blackwire(engine)

1.Switchtheengine-mountedswitchtotheOnposition

andthecowl-mountedswitchtotheRunposition.

2.Starttheengine;refertothemachineOperator’sManual.

3.Whiletheengineisrunning,movethecowl-mounted

switchtotheStopposition.Theengineshouldstop.

4.Repeatsteps1and2,andmovetheengine-mounted

switchtotheOffposition.Theengineshouldstop.

Note:Ifthereisanyproblemwiththeenginestartingor

stopping,ensurethatthewiresareconnectedasdescribedin

ConnectingtheWires(page5).

5

Page 6

Notes:

6

Page 7

Notes:

7

Page 8

Loading...

Loading...