Page 1

FormNo.3383-608RevA

RP-1200DandRP-1400D

ReversiblePlateCompactor

ModelNo.68074—SerialNo.313000001andUp

ModelNo.68075—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3383-608*A

Page 2

Introduction

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

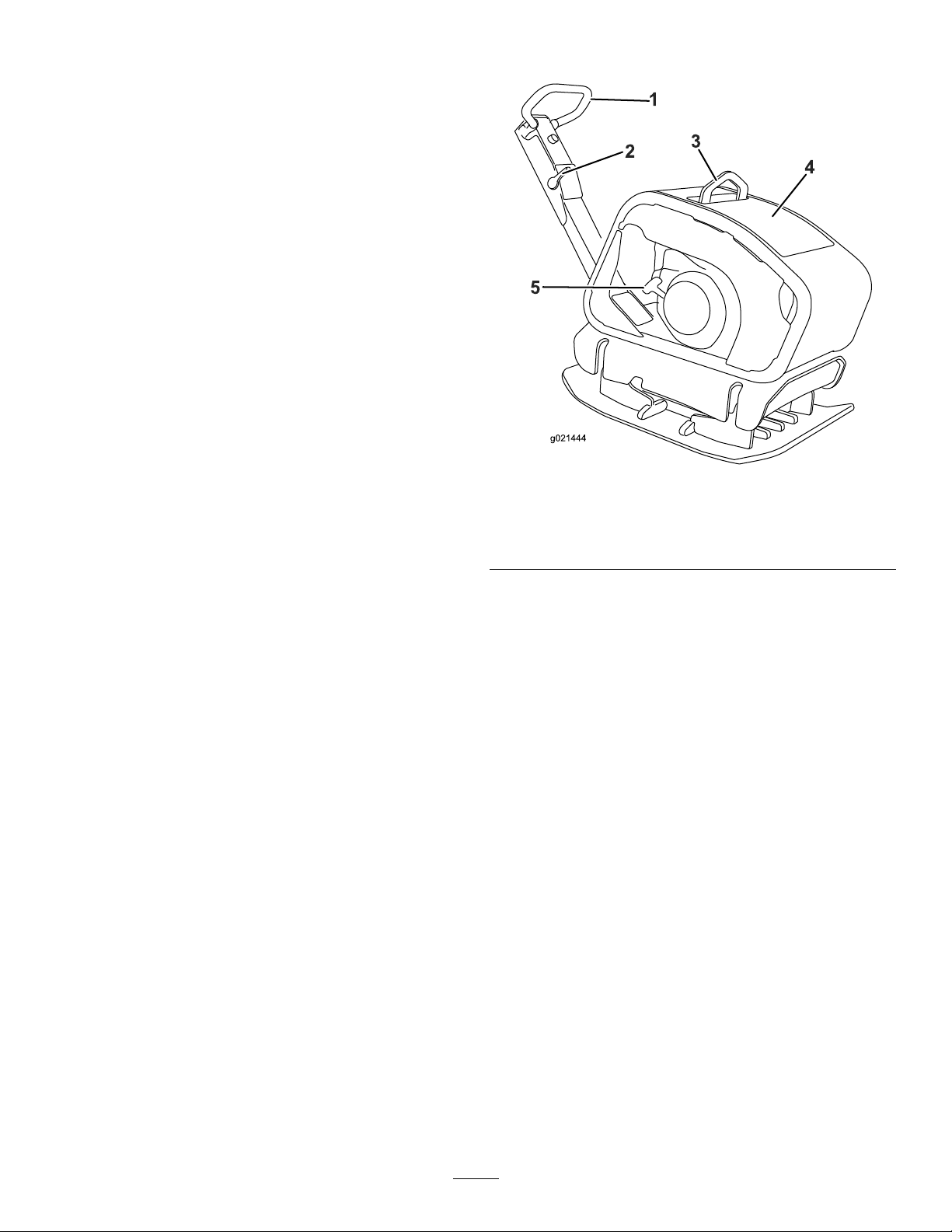

Figure1

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1illustratesthelocationofthe

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................5

Setup............................................................................7

CheckingtheEngine-OilLevel..................................7

CheckingtheEccentric-OilLevel..............................7

ProductOverview..........................................................7

Controls................................................................8

Specications.........................................................8

Operation.....................................................................8

CheckingtheEngine-OilLevel..................................8

CheckingtheW aterTrap..........................................9

CleaningDebrisfromtheMachine.............................9

AddingFuel...........................................................10

StartingandStoppingtheEngine..............................11

OperatingtheCompactor........................................12

TransportingtheMachine........................................12

Maintenance.................................................................13

RecommendedMaintenanceSchedule(s)......................13

ServicingtheAirCleaner.........................................13

ReplacingtheFuelFilter..........................................14

ServicingtheEngineOil..........................................15

ServicingtheEccentricOil......................................16

ServicingtheBattery(Model68075only)...................17

ServicingtheBelt...................................................18

Storage........................................................................19

Troubleshooting...........................................................20

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

means

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

—personalsafety

SafeOperatingPractices

Thisproductiscapableofcrushingoramputatinghandsand

feet.Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,and

odorless,deadlypoisonthatcankillyou

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminetheproperandsafe

actionstoperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,longpants,safetyshoes,andhearingprotection.

Longhair,looseclothingorjewelrymaygettangledin

movingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchastools,buildingmaterials,and

personalitemswhichcanbedamagedbythemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethefuelcaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

3

Page 4

–Neverrefuelordrainthemachineindoors.

MaintenanceandStorage

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Donotoperateinstandingwater.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Keeppetsandbystandersaway .

•Keepfeetclearoftheplatecompactor.

•Earprotectionisrequiredwhenoperatingthisequipment.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Forfootprotection,wearsteeltoeshoesortoepads.

•Neveroperatewiththeguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly ,and

functioningproperty.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Neverleavethemachinerunningunattended.Always

setthethrottletoslow ,stoptheengine,andwaitforall

movingpartstostopbeforeleaving.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Beforecompactingsoil,havetheareamarkedfor

undergroundutilities.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Parkthemachineonalevelsurface,setthethrottleto

slow,andstoptheengine.Waitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

•Cleandebrisfromthedrives,mufers,andenginetohelp

preventres.Cleanupfuelandoilspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Keepthemachinefreefromthebuild-upofmud,rocks,

orotherdebris.Cleanupoilorfuelspillage.Allowthe

machinetocoolbeforestoring.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllafuelcontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability ,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

4

Page 5

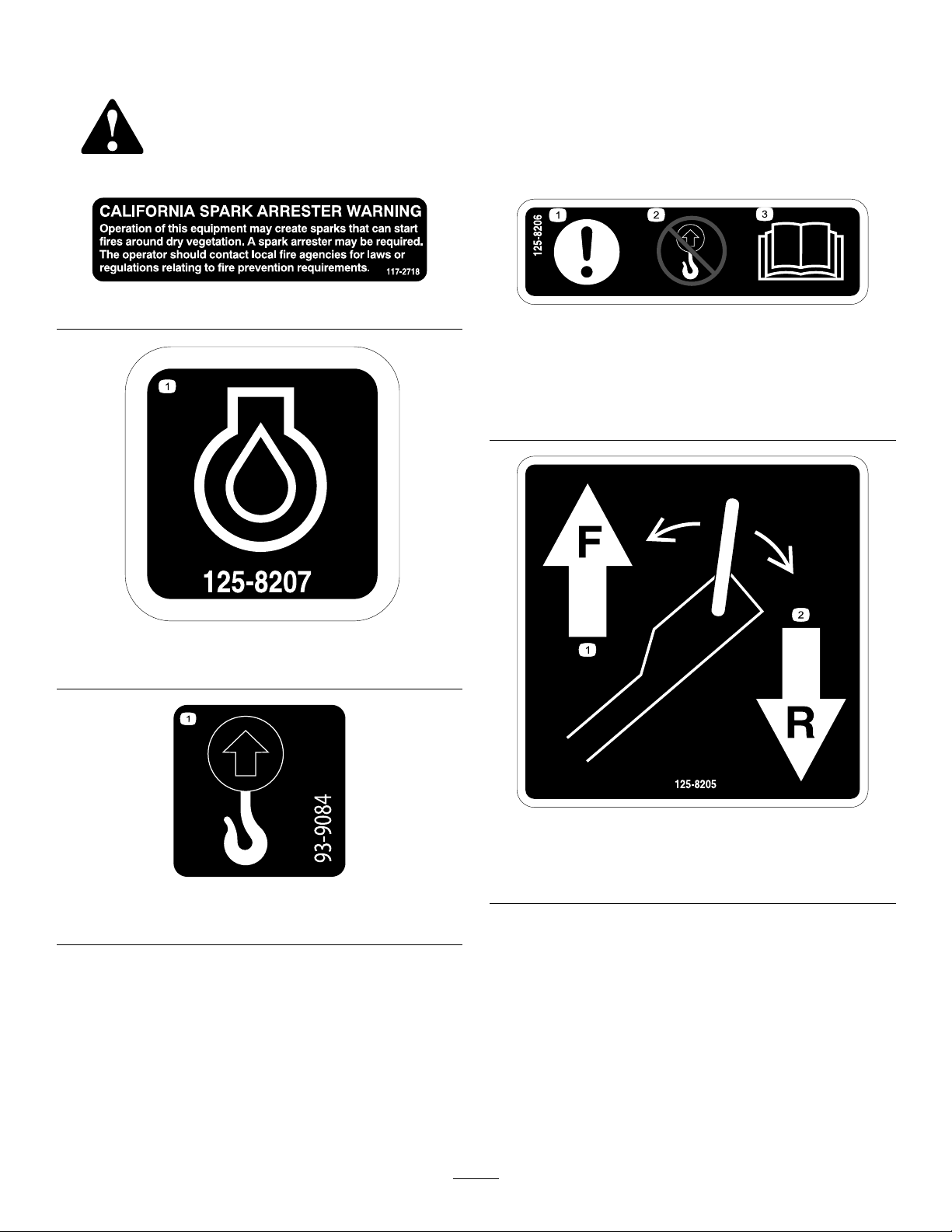

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117–2718

125–8206

1.Engineoil

1.Caution3.ReadtheOperator’s

Manualforinformationon

liftingthemachine.

2.Donotliftthecompactor

bythehandle.

125–8207

1.Liftpoint

125–8205

1.Pushthehandleforward

tomovethecompactor

93–9084

forward.

2.Pullthehandlebackward

tomovethecompactor

backward.

5

Page 6

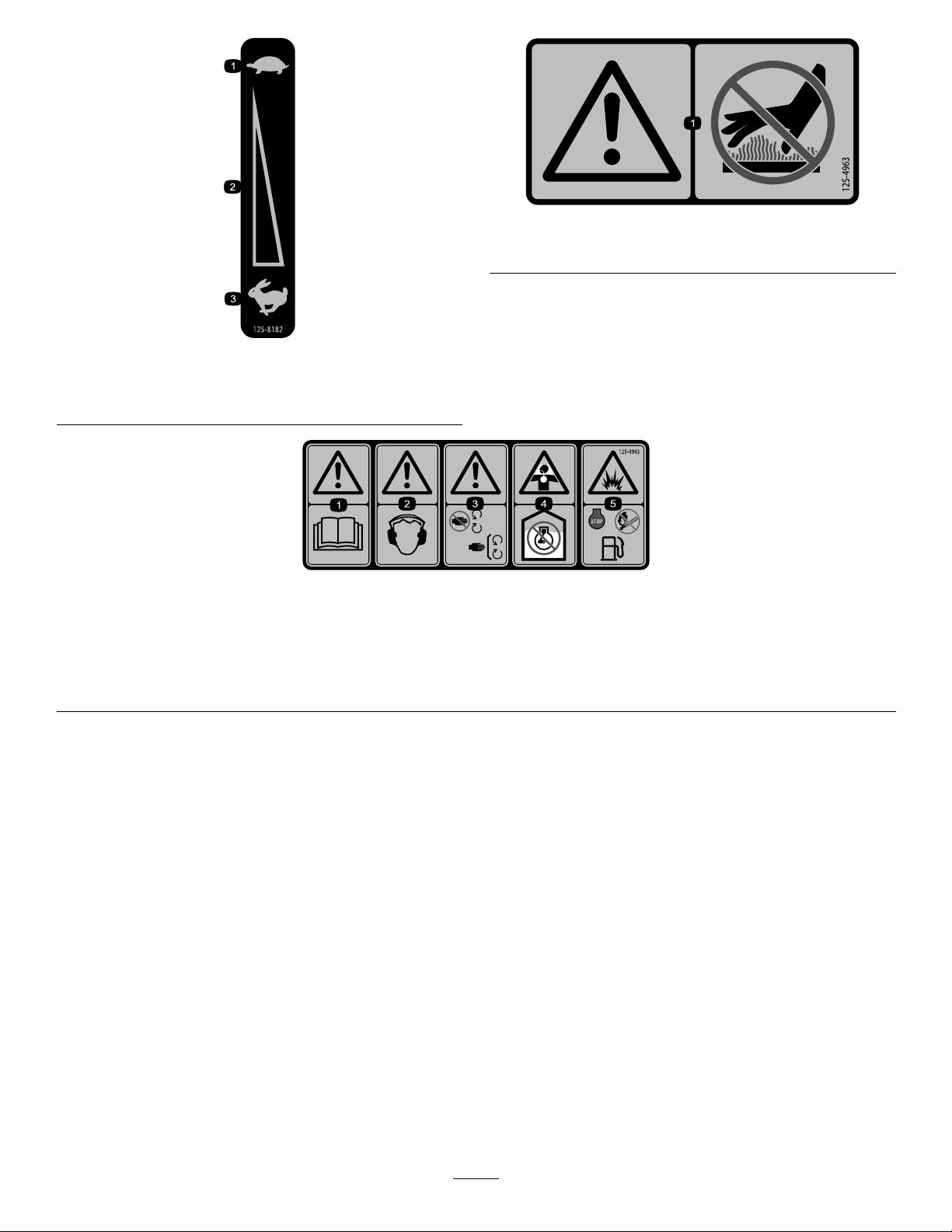

125–4963

1.Warning—keephandsawayfromhotsurfaces

125–8182

1.Slow

2.V ariablespeedcontrol

3.Fast

125–4943

1.Warning—readtheOperator’sManual.4.Chokinghazard—donotoperatethemachineindoors.

2.Warning—wearhearingprotection.

3.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

5.Explosionhazard—stoptheengineandextinguishallames

beforerefuelingthemachine.

6

Page 7

Setup

CheckingtheEngine-OilLevel

Themachinecomesfromthefactorywithoilintheengine

crankcase;however,itmaybenecessarytoaddoil.Referto

CheckingtheEngine-OilLevel(page8).Addonlyenoughoil

toraisetheleveltotheFullmarkonthedipstick.

CheckingtheEccentric-Oil

Level

Themachinecomesfromthefactorywitheccentricoilinthe

eccentrichousing;however,itmaybenecessarytoaddoil.

RefertoCheckingtheEccentric-OilLevel(page16).Add

onlyenoughoilsothattheoillevelisushwiththeoilplug

onthesideoftheeccentrichousing.

ProductOverview

Figure3

1.Travel-controllever

2.Throttlecontrol5.Recoil-starthandle

3.Liftpoint

4.Cover

7

Page 8

Controls

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

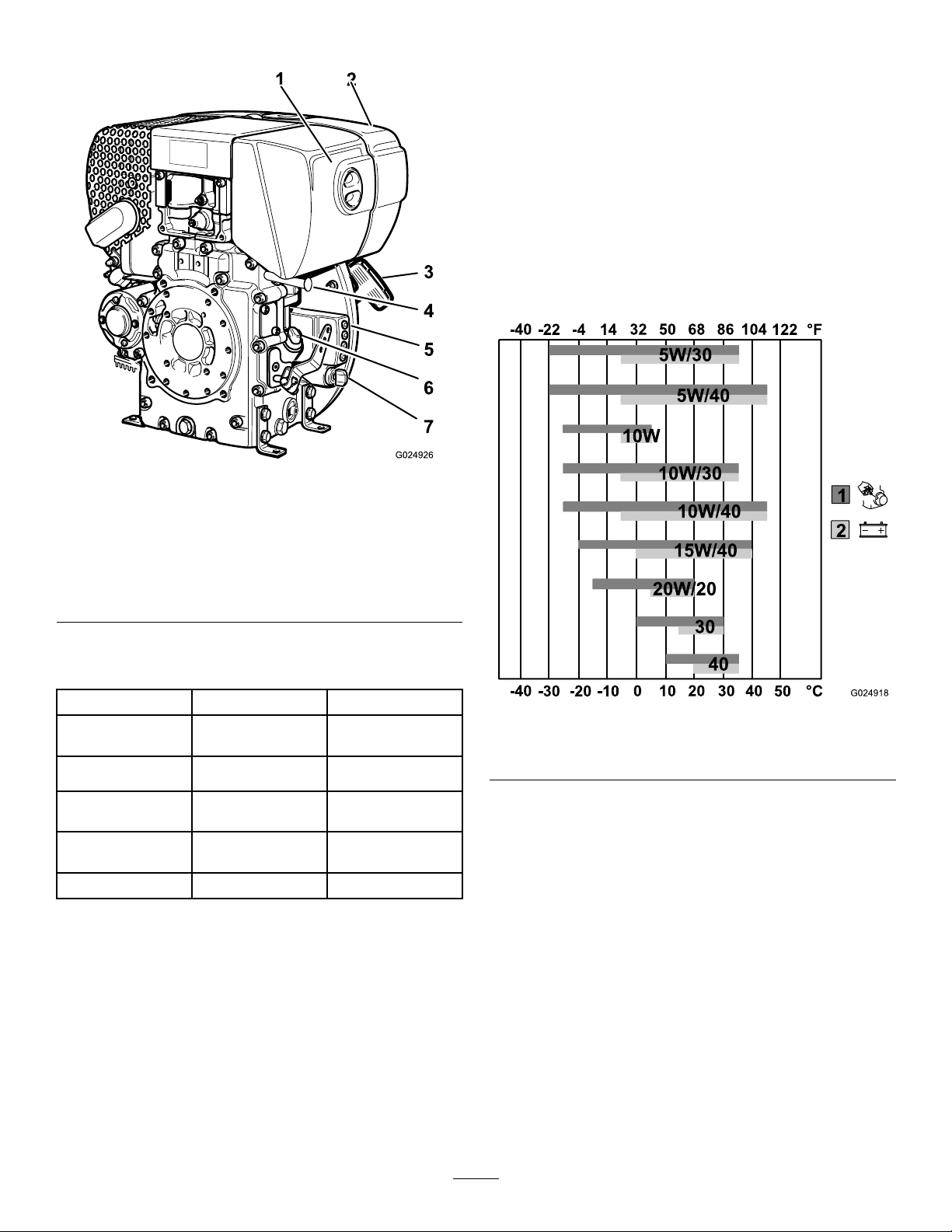

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Oiltype:APICD,CE,CF,CF-4,CG-4orhigher

Refertothetablebelowtodeterminethecorrectoilviscosity

fortheambientairtemperatureinwhichthemachineis

operated:

Figure4

1.Airlter

2.Fueltank6.Dipstick

3.Recoil-starthandle

4.Engine-shutoffswitch

Specications

ModelnumberRP-1200DRP-1400D

Length

Width

Height(handle

lowered)

Height(handle

raised)

Weight

142cm(55.9

inches)

60cm(23.6inches)75cm(29.5inches)

106cm(41.5

inches)

115cm(45.3

inches)

350kg(771.6lb)440kg(970lb)

5.Engineindicatorlights

(Model68075only)

7.Startswitch(Model68075

only)

150cm(59inches)

104cm(40.9

inches)

113cm(44.5

inches)

Figure5

1.Pull-starttemperature

range

2.Electric-starttemperature

range

1.Stopthemachineonalevelsurface.

2.Setthethrottletoslow ,presstheredbuttonforthe

engine-shutoffswitch,andwaitforallmovingparts

tostop.

3.Cleanaroundthedipstick(Figure6)sothatdirtcannot

fallintothellerholeanddamagetheengine.

8

Page 9

1

G024105

4.Assoonasdieselfuelemerges,tightenthewater-trap

bolt.

5.Disposeofthewaterandthefuelaccordingto

environmentalregulations.

CleaningDebrisfromthe Machine

ServiceInterval:Beforeeachuseordaily

1.Setthethrottletoslow,stoptheengine,andwaitfor

allmovingpartstostop.

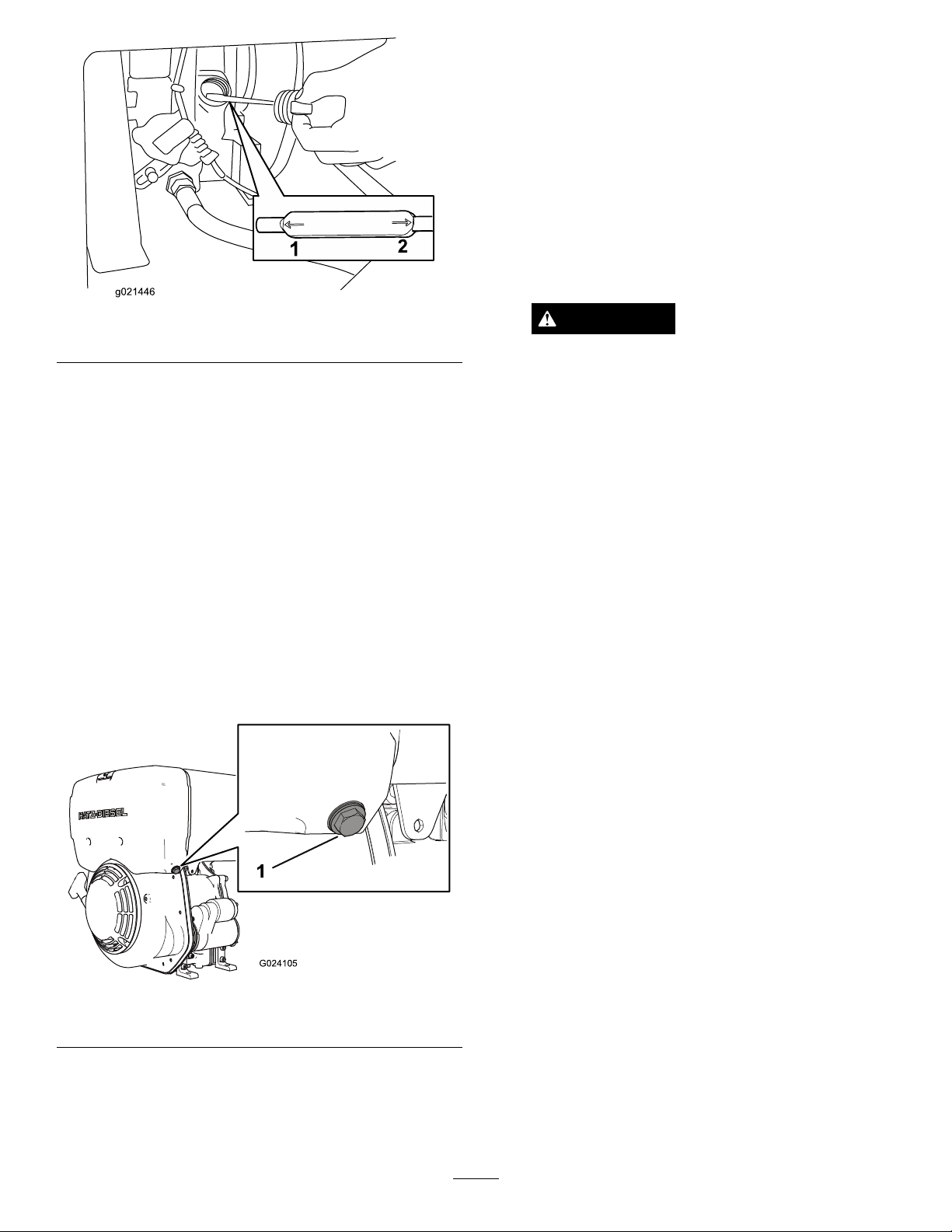

Figure6

1.Minimumoillevel2.Maximumoillevel

4.Unscrewthedipstickandwipetheendclean(Figure6).

5.Screwthedipstickfullyontothellertube(Figure6).

6.Unscrewthedipstickagainandlookattheend.Ifthe

engineoillevelislow,slowlypouronlyenoughofthe

speciedoilintothellertubetoraisetheleveltothe

Fullmarkonthedipstick.

Important:Donotoverllthecrankcasewith

engineoilandruntheengine;enginedamage

mayresult.

CheckingtheWaterTrap

ServiceInterval:Beforeeachuseordaily

1.Setthethrottletoslow,stoptheengine,andwaitfor

allmovingpartstostop.

2.Loosenthewater-trapbolt3to4rotations(Figure7).

WARNING

Contactwithhotpartsonthemachinecan

causesevereburns.

Waitforallpartstocoolbeforetouchingthe

machine.

2.Brushdirtanddebrisawayfromtheair-cleanerhousing

andengineopenings.

3.Checkthesprinklertubeandremoveanydirtordebris.

Figure7

1.Water-trapbolt

3.Useatransparentcontainertocatchthedripsfrom

thebolt.

Note:Becausewaterisdenserthandieselfuel,any

waterthatispresentwillemergerst.

9

Page 10

AddingFuel

DieselFuelSpecications

•Theenginerunsonclean,freshultra-lowsulfurdiesel

fuelwithaminimumcetaneratingof40.

•Purchasefuelinquantitiesthatcanbeusedwithin30days

toensurefuelfreshness.

•Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergradedieselfuel(No.

1-D)or(No.1-D/2-Dblend)below-7°C(20°F).

•Nevermixkerosene,usedengineoil,orresidualfuels

withthedieselfuel.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinter.

•Fueladditivesarenotrecommended.Somefueladditives

maycausepoorengineperformance.

DANGER

Incertainconditions,dieselfuelisextremely

ammableandhighlyexplosive.Areorexplosion

fromdieselcanburnyouandothersandcan

damageproperty.

•Onlyllthefueltankwithdieselfuel.Fillingthe

fueltankwithgasolinemayresultinare.

•Fillthefueltankandstorefuelina

well-ventilatedarea.

Important:Donotmixoilwithdiesel.

Useultra-lowsulfurdieselfuelthatcomplieswiththe

followingspecication.Thetablelists7worldwide

specicationsfordieselfuels.

DieselFuelSpecications

No.2–D,No.1–D,ASTM

D975–94

EN590:96EuropeanUnion

ISO8217DMX

BS2869–A1orA2

JISK2204GradeNo.2

KSM-2610

GB252China

Location

U.S.A.

International

UnitedKingdom

Japan

Korea

FillingtheFuelTank

Note:Beforestartingforthersttimeorifthefuelsystem

isempty ,llthefueltankfullywithdieselfuel.Thiscauses

thefuelsystemtobebledautomatically.

Automaticbleedingiscompletedafterawaitingperiodof1

to2minutes.Theengineisreadytostart.

1.Parkthemachineonalevelsurface,stoptheengine,

andallowtheenginetocool.

•Neverrefuelthefueltankwithenginerunning.

•Donotllthefueltankcompletelyfull.Addfuel

untilitisatthesamelevelastheredring.This

emptyspaceinthetankallowsfueltoexpand.

•Neversmokewhenhandlingdiesel,andstay

awayfromanopenameorwheredieselmay

beignitedbyaspark.

•Storedieselinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuymore

thana30-daysupplyofdiesel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

WARNING

Dieselisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

2.Liftthecover(Figure8).

Figure8

1.Coverhandle

3.Cleanaroundthefueltankcapandremoveit(Figure9).

•Keepfaceawayfromnozzleanddieseltankor

conditioneropening.

•Keepdieselawayfromeyesandskin.

10

Page 11

Figure9

1.Fuelcap3.Redring

2.Inletfuelscreen

4.Adddieseltothefueltank.(Figure10).

Important:Donotoverllthefueltank.

Figure10

Figure11

1.Throttlecontrol(slow

position)

2.Slowlypulltherecoil-starthandleuntilyouencountera

slightresistance(Figure12).

2.Throttlecontrol(fast

position)

5.Installthefuel-tankcapsecurely(Figure9).

6.Wipeupanydieselfuelthatmayhavespilled.

7.Lowerthecover.

StartingandStoppingthe Engine

StartingtheEngine

Model68074:

1.SetthethrottletotheSlowposition(Figure11).

Figure12

3.Lettheroperunbackinrecoilstarter.

4.Holdtherecoil-starthandlewithbothhands.

5.Pullthestartingropeevenlyandwithincreasingspeed

untiltheenginestarts.

Note:Donotsharplypulltherecoil-starthandle.

6.Movethethrottlelevertothefastposition(Figure11).

Note:Thecompactorwillbeginvibratingwhenthe

throttleissettofastthrottle.

Model68075:

1.Setthethrottletotheslowposition(

2.Insertthekeyintothestarterswitchandrotateit

clockwisetostarttheengine(

Note:Releasethekeyoncetheenginebeginstorun.

11

Figure11).

Figure13).

Page 12

Figure13

g021448

1

1.Engine-runlight4.Engine-temperaturelight

2.Battery-chargelight5.Engine-preheatlight

3.Oil-pressure-warninglight

6.Key

OperatingtheCompactor

ControllingtheDirectionofTravel

•Movethetravel-controlhandleforwardtodrivethe

machineforward(Figure15).

3.MovethethrottlelevertotheFastposition(Figure11).

Note:Thecompactorwillbeginvibratingwhenthe

throttleissettofastthrottle.

StoppingtheEngine

1.Movethethrottle-controllevertotheSlowposition

(Figure11).

2.Pushtheredbuttonoftheengine-shutoffswitchfor3

secondstostoptheengine(Figure14).

Figure15

1.Travel-controlhandle

(forwardtravelposition)

2.Travel-controlhandle

(backwardtravelposition)

•Pullthetraveltravel-controlhandlebackwardtodrivethe

machinebackward(Figure15).

TransportingtheMachine

Liftingequipmentcapacity:440kg(970lb)

Usetherollcageliftpointtoliftandtransportthemachine

withstrapsoracrane(

Figure16).

Figure14

1.Redbutton

3.Model68075only:Rotatethekeycounterclockwiseto

theOffposition(allindicatorlampswillturnoff)and

removekeyfromthestarterswitch(Figure13).

Note:Whenthemachineisnotrunning,turnthe

startingkeytoOffpositionorelsethebatterymay

becomefullydischarged.

Figure16

1.Rollcageliftpoint

12

Page 13

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Every50hours

Every100hours

Every300hours

Every500hours

Every1,000hours

Monthly

Yearly

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Checkthewatertrap.

•Cleandebrisfromtheair-cleanerhousing.

•Inspecttheaircleanerelement.

•Cleantheairlterelement.Cleanitmorefrequentlyindustyoperatingconditions.

•Changetheengineoil.

•Checkthebatterycableconnections.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindustyoperating

conditions.

•Changetheeccentricoil.

•Replacethefuellter.

•Adjustthebelt.

•Cleantheoillter.

•Checktheeccentric-oillevel.

•Changetheeccentricoil.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspecttheair

cleanerelement.

Every50hours—Cleantheairlterelement.Cleanit

morefrequentlyindustyoperatingconditions.

Every300hours/Yearly(whichevercomes

rst)—Replacethepaperair-cleanerelement.Replace

itmorefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagewilloccur.

1.Setthethrottletoslow,stoptheengine,andwaitfor

allmovingpartstostop.

2.Unscrewtheplasticwingnutandremovethecover

(Figure17).

Figure17

1.Wingnut

3.Unscrewthenutandremovethepaperelement(Figure

18).

13

Page 14

Figure18

1

G024104

2

1.Knurlednut

2.Air-ltercartridge

4.Inspectthepaperelement,andreplaceair-lter

cartridgeiftheelementisdamagedorexcessivelydirty.

Note:Nevertrytobrushdirtoffthepaperelement;

brushingforcesthedirtintothebers.

5.Wipedirtfromthebaseandthecoverwithamoistrag.

6.Installtheaircleanercartridge,ensurethatitisproperly

positioned,andsecureitwiththeknurlednut(Figure

).

18

7.Securelyinstallthecoverwiththewingnut(

Figure17).

ReplacingtheFuelFilter

ServiceInterval:Every500hours

Note:Theenginehasadual-ltersystem.Replaceonlythe

externallter.

1.Stoptheengine,removethekey,andwaitforthe

enginetocooldown.

Figure19

1.Fuel-tankcap

2.Fuellter

4.Pullthelteroffthefuelhose.

5.Installanewlterintothefuelhose.

6.Placethelterintothefueltank,andinstallthe

fuel-tankcap.

2.Removethefuel-tankcap.

3.Pullthefuellteroutofthefueltank(Figure19).

Note:Thelteristetheredtothefuel-tankcap.

14

Page 15

ServicingtheEngineOil

CrankcaseCapacity:RP-1200D–1.1liter(37oz)

CrankcaseCapacity:RP-1400D–1.5liter(50.7oz)

Oiltype:APICD,CE,CF,CF-4,CG-4orhigher

Refertothetablebelowtodeterminethecorrectoilviscosity

fortheambientairtemperatureinwhichthemachineis

operated:

Figure21

1.Drainplug

3.Removethedrainplug(Figure21).

Figure20

1.Pull-starttemperature

range

2.Electric-starttemperature

range

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

WARNING

Oilmaybehotaftertheenginehasbeenrun,and

contactwithhotoilcancauseseverepersonalinjury.

Avoidcontactingthehotengineoilwhenyoudrain

it.

Note:Youmayhavetotipthecompactorbackward

todraintheoil.

4.Whentheoilhasdrainedcompletely,replacetheplug.

Note:Disposeoftheusedoilatacertiedrecycling

center.

5.Removethedipstick(Figure6)andslowlypourthe

speciedquantityandtypeofoilintothellerhole.

6.Insertthedipstickandchecktheengineoillevel;refer

toCheckingtheEngine-OilLevel(page8).

7.Replaceandsecurethedipstick.

8.Wipeupanyspilledoil.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Placeadrainpanunderthedrainplug(

Figure21).

15

Page 16

CleaningtheOilFilter

ServicingtheEccentricOil

ServiceInterval:Every1,000hours

1.Draintheengineoil;referto

ChangingtheEngineOil

(page15).

2.Loosenthesocket-hexboltapproximately5turns

counterclockwise(Figure22).

Figure22

Oilcapacity:0.5liter(6.9oz)

OilType:Detergentoil(APIserviceSJorhigher)

Oilviscosity:15W -40

CheckingtheEccentric-OilLevel

ServiceInterval:Monthly

1.Movethemachinetoalevelsurface.

2.Setthethrottletoslow,stoptheengine,andwaitfor

allmovingpartstostop.

3.Placeragsbelowtheoilplugattherightsideofthe

eccentrichousing(

Figure23).

1.T ensionspring

2.Filterhousing

3.Socket-hexbolt

4.Oillter

5.Airgun(compressedair)

3.Pulltheoillteroutofthelterhousing(Figure22).

4.Blowouttheoillterwithcompressedairfromthe

insidetotheoutside(Figure22).

5.Checkthegasketontheoillterfordamage.

Note:Ifthegasketisdamaged,replaceitbefore

installingtheoillter.

6.Inserttheoillterintothelterhousing(Figure22).

Note:Ensurethatthelterisfullyseatedinthe

housing.

7.Beforetighteningthescrew,ensurethatthetension

springrestagainsttheoillteratbothends(

Figure22).

8.Tightenthesocket-hexbolt(Figure22).

9.Addoiltotheengine;referto

ChangingtheEngine

Oil(page15).

Figure23

1.Oilplug

4.Removetheoilplug(Figure23).

5.Verifythattheeccentricoilislevelwiththebolthole.

Note:Ifaddingoilisrequired,useafunnelwitha

hosetoaddthespeciedoilintotheeccentrichousing

untiltheoillevelislevelwiththeoilplughole.

6.Wipeupanyspilledoil.

7.Replacetheoilplug(Figure23).

16

Page 17

ChangingtheEccentricOil

ServicingtheBattery(Model

ServiceInterval:Yearly

Every300hours

1.Movethemachinetoalevelsurface.

2.Setthethrottletoslow,stoptheengine,andwaitfor

allmovingpartstostop.

3.Raisethemachinewithliftingequipmentwitha440kg

(970lb)liftcapacity.

4.Placeanoildrainpanundertheoilplugandremove

theplugfromtheeccentrichousing(

5.Tiptheplatecompactorslightlytotheright,anduse

asuctionguntoremovetheoilthroughtheoilplug

hole(Figure23).

6.Tiptheplatecompactorslightlytotheleft,andslowly

pour0.5liter(6.9oz)ofthespeciedoilintotheoil

plughole(Figure23).

Note:Useafunnelwithahosetopouroilintothe

oilplugholeifnecessary.

7.Lowerthemachineontothelevelsurface.

8.Verifythattheoilleveliscorrectwhenthereisaslight

owofoiloutoftheoilplugholewhenthecompactor

islevel.

Figure23).

68075only)

CheckingandCleaningtheBattery

ServiceInterval:Every100hours—Checkthebatterycable

connections.

Keepthetopofthebatteryclean.Ifthemachineisstoredin

alocationwheretemperaturesareextremelyhigh,thebattery

willdischargemorerapidlythanifthemachineisstoredin

acoolerlocation.

Keepthetopofthebatterycleanbywashingitwithabrush

dippedinammoniaorasolutionofsodiumbicarbonate.

Flushthetopsurfacewithwateraftercleaning.Donot

removethellcapwhilecleaningthebattery.

Thebatterycablesmustbetightontheterminalstoprovide

goodelectricalcontact.

Ifcorrosionoccursatthebatteryterminals,disconnectthe

cables,negative(-)cablerst,andscrapetheclampsand

terminalsseparately.Connectthecables,positive(+)cable

rst,andcoattheterminalswithpetroleumjelly.

ChargingtheBattery

Note:Ifadditionaloilisrequired,useafunnelwitha

hosetoaddthespeciedoilintotheeccentrichousing

untiltheoillevelislevelwiththeoilplughole.

9.Wipeupanyspilledoil.

10.Replacetheoilplugscrew .

WARNING

Chargingthebatteryproducesgasesthatcan

explode,seriouslyinjuringyouorbystanders.

Neversmokenearthebattery,andkeepsparksand

amesawayfromthebattery.

Important:Alwayskeepthebatteryfullycharged.This

isespeciallyimportanttopreventbatterydamagewhen

thetemperatureisbelow0°C(32°F).

1.Chargethebatteryfor10to15minutesat25to30

amps,or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,anddisconnectthecharger

leadsfromthebatteryposts(Figure24).

3.Installthebatteryinthemachineandconnectthe

batterycables;refertoReplacingtheBattery(page18).

Important:Donotrunthemachinewiththe

batterydisconnected;electricaldamagemay

occur.

17

Page 18

4.Removethebattery.

Note:Recycletheoldbatteryatanauthorizedfacility .

5.Placethenewbatteryinthetray .

6.Installthepositive(red)batterycabletothepositive

(+)batteryterminal,andtightenthenutontothebolt.

7.Installthenegative(black)groundcabletothenegative

(-)batteryterminal,andtightenthenutontothebolt.

8.Installthecoverofthebatterybox,andsecureitwith

thestrap.

Figure24

1.Positivebatterypost

2.Negativebatterypost

Ifthebatterynolongerholdsacharge,replaceit;referto

ReplacingtheBattery(page18).

3.Red(+)chargerlead

4.Black(-)chargerlead

ReplacingtheBattery

1.Removethecoverofthebatterybox.

2.Disconnectthenegative(black)groundcablefromthe

batterypost.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygasestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

ServicingtheBelt

CheckingtheBeltTension

1.Removetheboltsholdingthebeltcoverinplace

(Figure25).

Figure25

1.Bolts

2.Apply2kg(4.4lb)ofpressuretothemiddleofthebelt.

Note:Whenthebeltistensionedcorrectly,itshould

deectapproximately0.5cm(0.2inches).

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

themachine.

3.Removethepositive(red)batterycable.

3.Ifthebeltisnottensionedproperly ,refertoAdjusting

theBeltTension(page18).

AdjustingtheBeltTension

ServiceInterval:Every500hours

1.Removetheboltsholdingthebeltcoverinplace

(

Figure25).

2.Loosentheenginemountingbolts.

3.Adjustthepositionoftheengineuntilyouobtainthe

belttensionspeciedin2ofCheckingtheBeltTension

(page18).

4.Tightentheenginemountingboltsandreplacethebelt

cover.

18

Page 19

Storage

1.Stoptheengine.

2.Removedirtandgrimefromtheentiremachine.

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashthe

machine.Avoidexcessiveuseofwater,especially

neartheengine.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page13).

4.Changetheengineoil;refertoChangingtheEngine

Oil(page15).

5.Fillthefueltank;refertoFillingtheFuelTank(page

10).

6.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

7.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

8.Storethemachineinaclean,drygarageorstoragearea.

9.Coverthemachinetoprotectitandkeepitclean.

19

Page 20

Troubleshooting

Problem

Theenginewillnotstart,startshard,or

failstokeeprunning.

Theplatedoesnotvibrateatfullspeed.

Theclutchisextremelyhot.

Theplatedoesnotvibratewhenthe

engineisrunning.

PossibleCauseCorrectiveAction

1.Thefueltankisempty.1.Fillthefueltankwithfuel.

2.Theaircleanerisdirty.

1.Theoillevelintheeccentrichousing

istoohigh.

2.Thebeltisloose.2.Adustthebelttension.

1.Aforeignobjectislodgedagainstthe

eccentricsheave.

2.Theoillevelintheeccentrichousing

istoohigh.

3.Theclutchisslipping.

4.Theenginespeedisnotreachingfull

rpm.

1.Thebeltisbroken.1.Replacethebelt.

2.Theclutchisbrokenorwornout.2.Replacetheclutch.

3.Theeccentrichasseized.

2.Cleanorreplacetheaircleaner

element.

1.Checktheoillevelanddrainas

necessary.

1.Removetheobstruction.

2.Checktheoillevelanddrainas

necessary.

3.SeeyourauthroizedToroservice

dealer.

4.SeeyourauthroizedToroservice

dealer.

3.Ensuretheeccentricisfreeturning.

20

Page 21

Notes:

21

Page 22

Notes:

22

Page 23

Notes:

23

Page 24

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

Concrete,Masonry,

andCompaction

Equipment

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourT oroConcrete,Masonry ,

andCompactionEquipmentProductslistedbelowtobefreefromdefects

inmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ConcreteMixers

•SpindleBearingsLifetime*(originalowneronly)

MortarMixers1year

•DrumBearingsandSealsLifetime*(originalowneronly)

ForwardPlateCompactors

ReversiblePlates1year

RammerCompactors

MudBuggy1year

VibratingTrenchRoller2years

ConcreteSaws

MasonrySaws

PowerTrowels1year

Screeds

ConcreteVibrators

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

LifetimeWarranty-Ifthebearing(s)orseal(s)onyourmixerfail,itwillbereplacedunderwarranty ,

atnocostforpartsorlabor.

1year

2years

2years

1year

1year

1year

1year

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow .

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:800-888-9926

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromToroandhave

signedtheToroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitToro’ sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalproductoperationinclude,butarenotlimitedto,belts,wipers,

sparkplugs,tires,lters,gaskets,wearplates,seals,O-rings,drive

chains,clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty ,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty.Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty.Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0288RevB

Loading...

Loading...