Page 1

TrailerLightKit

Side-DumpMixers

ModelNo.68062

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Installation

FormNo.3377-600RevB

InstallationInstructions

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Bracket2

1

2

3

4

Bolt4

Nut4

Wireharness1

Cableclamp

Edgeclip—parallel4

Edgeclip—perpendicular1

Fir-treemount2

Bolt

Nut

Cabletie

Grommet

Light2

License-plateholder1

Nut4

Reector

Bolt2

Nut2

Qty.

Use

Installthebrackets.

7

Installthewires.

5

5

5

2

Installthelights.

2

Installthereectors.

5

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Registeratwww.T oro.com.

–

Replacethelightbulbs.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3377-600*B

Page 2

1

1

G020909

G021014

G020910

1

2

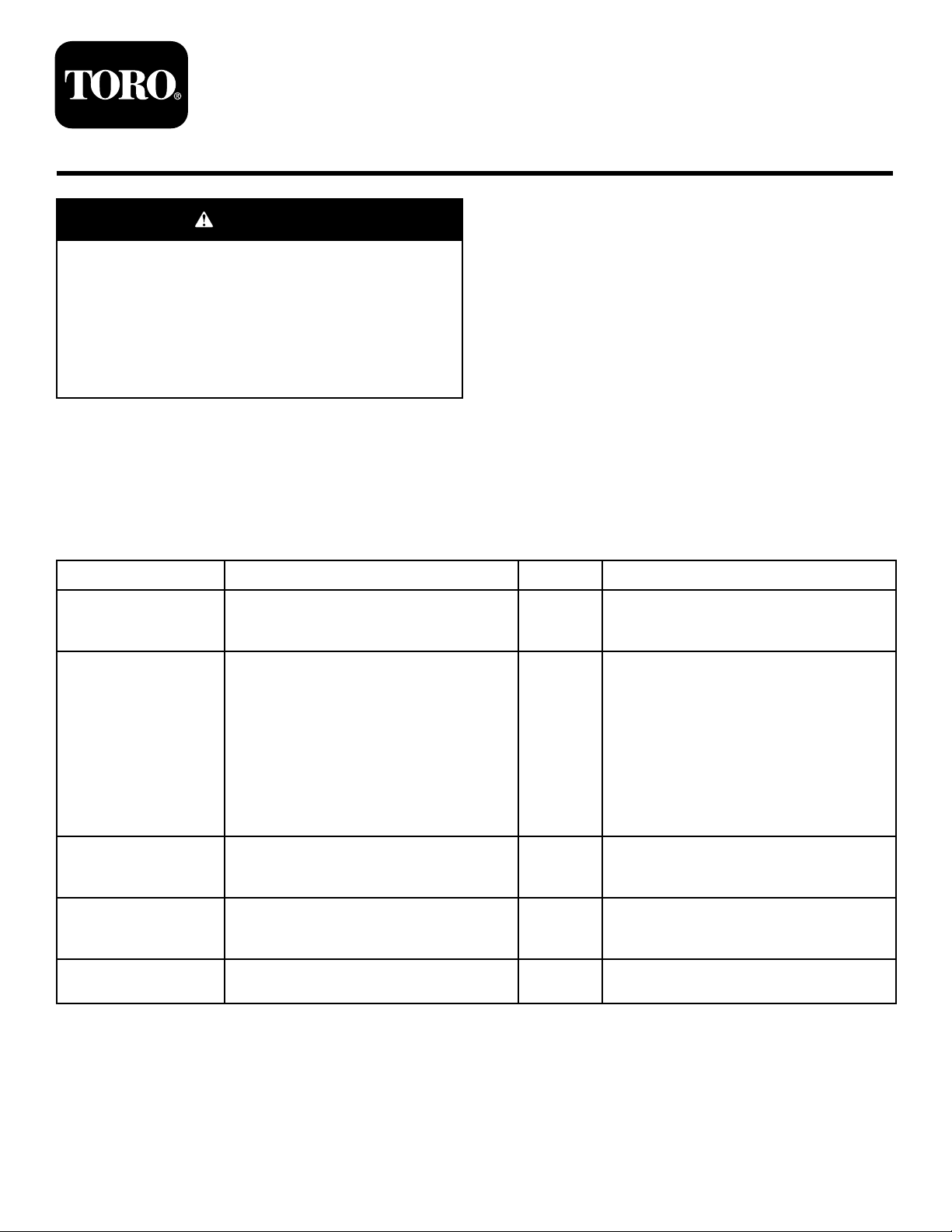

InstallingtheBrackets

Partsneededforthisprocedure:

2Bracket

4Bolt

4Nut

Procedure

1.Aligntheboltholesofabracketwiththeboltholesin

thesideframerailunderthecowl(Figure1).

Note:Foroldermodels,drill(2)7.5mm(9/32inch)

holesoneachsideoftheframe,spaced5.1cm(2

inches)apart,toaccommodatethe2mountingbolts

foreachbracket.

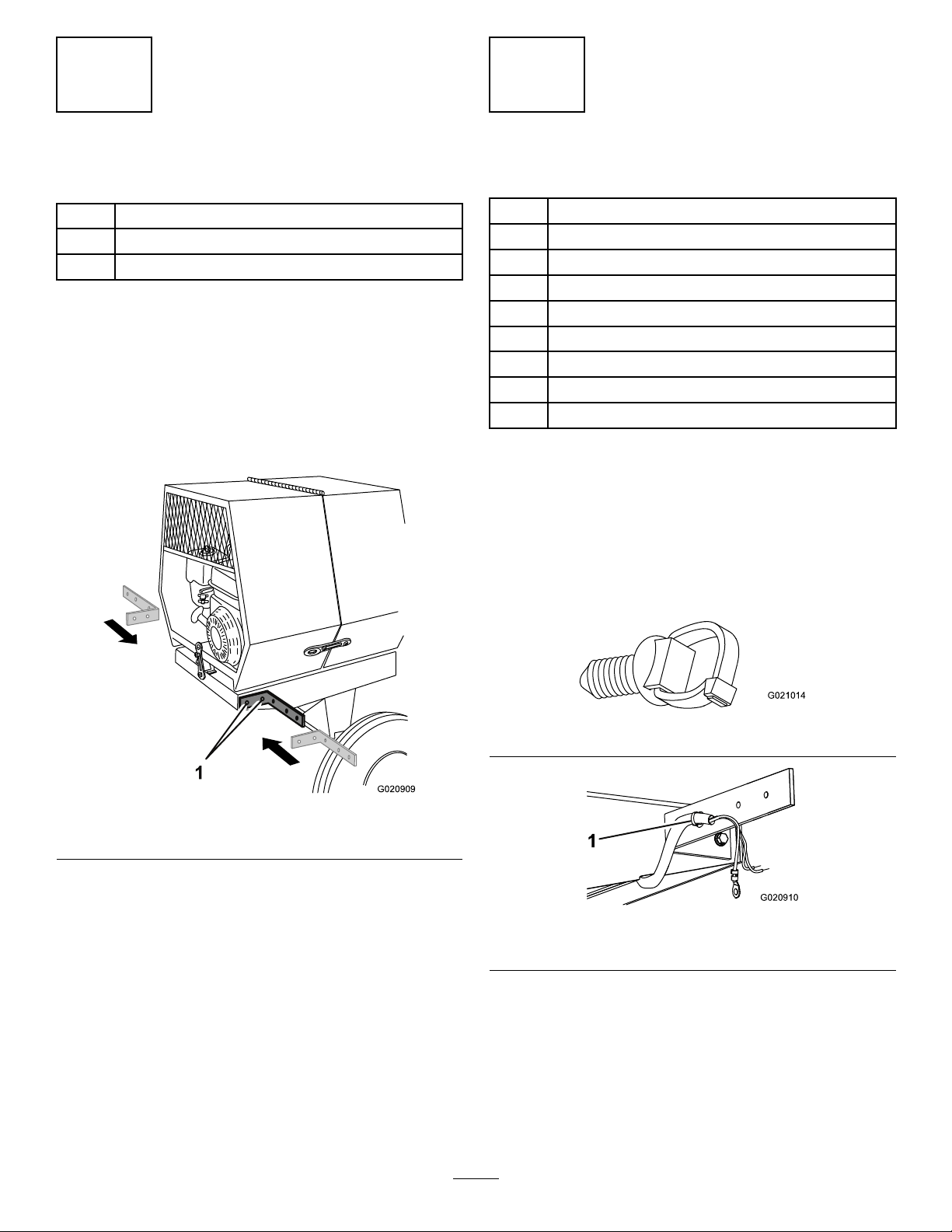

InstallingtheWires

Partsneededforthisprocedure:

1Wireharness

7

Cableclamp

4Edgeclip—parallel

1Edgeclip—perpendicular

2Fir-treemount

5

Bolt

5

Nut

5

Cabletie

2

Grommet

Procedure

Differentmodelsuseadifferentnumberoffasteners.Usethe

appropriatenumberoffastenersforyourmachine.

1.Pushthepre-installedr-treemount(

shortbranch(withtheyellowwire)ofthewireharness

intotheholeclosesttothemachine,intheleftlight

bracket(Figure3).

Figure2)onthe

Figure2

Figure1

1.Boltholes

2.Insertaboltthrougheachofthe2holesinthebracket

andtheframe.

3.Installanutoneachbolt.

Note:Tightenthesenutsandboltslater,when

youmountthecableclamps;refertostep4in

2InstallingtheWires(page2).

4.Repeatsteps1through3ontheothersideofthe

machine.

1.Fir-treemount

Note:Ensurethateachsideofthewireharnessgoes

tothecorrectsideofthemachine.Ifyouswitchthe

wiringofthelights,eachturnsignalwillashonthe

wrongside.

2.Pushthepre-installedr-treemountonthelong

branch(withthegreenwire)ofthewireharnessinto

theholeclosesttothemachine,intherightlight

bracket(

Figure3).

Figure3

2

Page 3

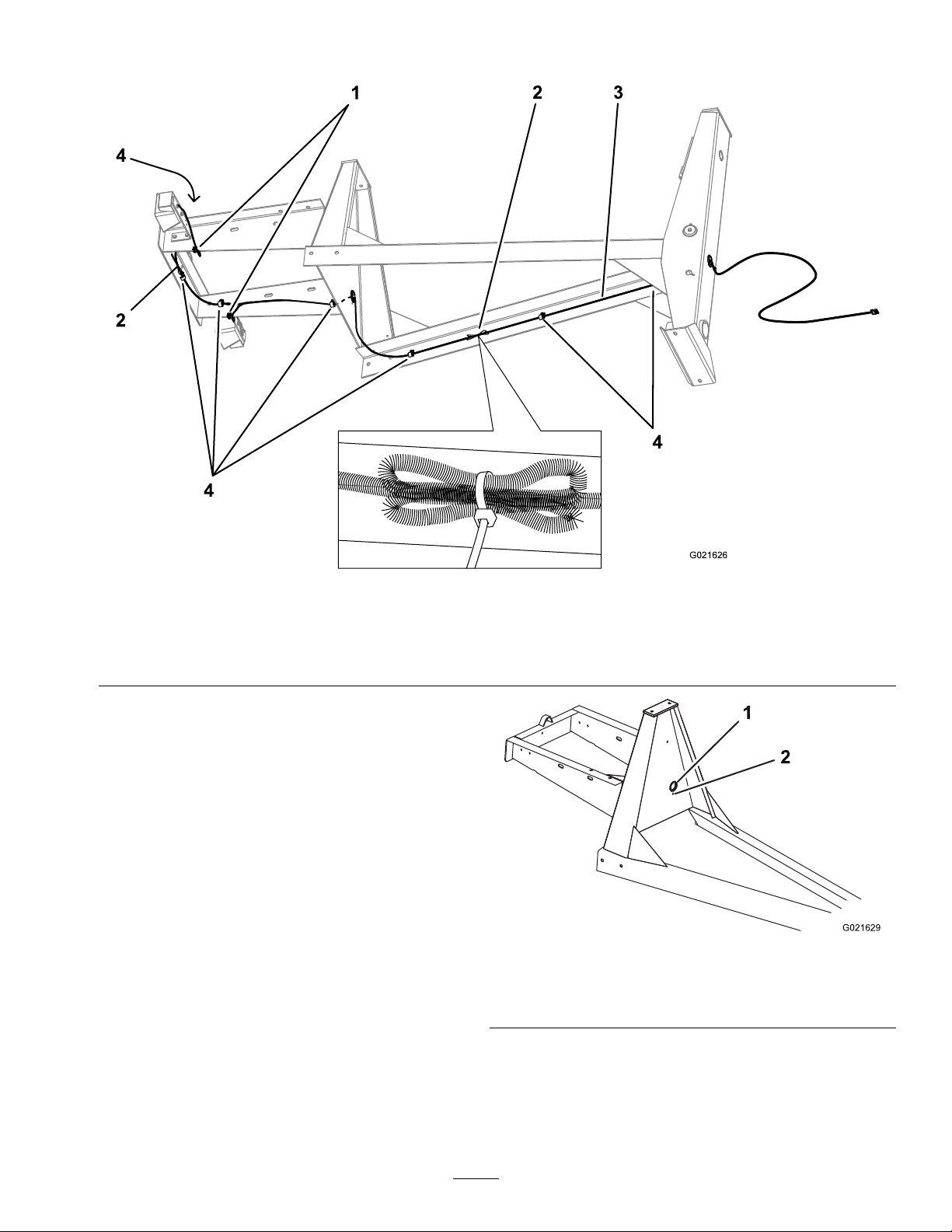

3.RoutethewireharnessasshowninFigure4,Figure7,

1

2

4

4

3

4

G021626

2

1

2

G021629

orFigure8,dependingonthemodel.

Figure4

Concretemixers(frameundersideshownforclarity)

1.Edgeclip3.Wireharness

2.Excesswire

4.Cableclamp

Note:Someconcretemixers(Figure4)haveaholein

therearverticalpartoftheframe;installagrommetin

thehole,routethewireharnessthroughthegrommet,

andsecurethewireharnessbypushingar-treemount

intothesmallholeunderthegrommet(Figure5).If

yourmachinedoesnothaveahole,routethewire

harnessundertheframe,andsecureitwithanedge

clip(Figure6).

Figure5

Framewithhole

1.Holeandgrommet

2.Holeforr-treemount

3

Page 4

1

G021630

1.Edgecliplocation

1

4

2

4

3

G021627

2

Figure6

Framewithouthole

Figure7

Belt-drivemortarmixers(frameundersideshownforclarity)

1.Edgeclip3.Wireharness

2.Excesswire

4.Cableclamp

4

Page 5

1

2

3

4

4

G021628

Figure8

G020912

21

G020980

1

Gear-boxmortarmixer(frameundersideshownforclarity)

1.Edgeclip3.Wireharness

2.Excesswire

4.Usecableclampsandedgeclipstosecurethewire

harnessalongtheinsideoftheframe(Figure9).

4.Cableclamp

Figure9

1.Cableclamp

2.Edgeclip

Note:Touseacableclamp,spreaditapartandt

thewireharnessintoit.Thensqueezetheclampback

together.Fastentheclamptotheframeofthemachine

withanutandabolt,usingthepre-drilledholesalong

theframe.Tightenthenutsandboltsuntiltheyare

secure.

Foroldermodels,drilla7.5mm(9/32inch)holefor

eachbolt.

Ineachofthe2rearcornersoftheframe,useanut

andboltthatsecurethelightbrackettoalsosecurea

cableclamp(Figure10).

Note:Ensurethatyoutightenthe2nutsandbolts

1.Nutandbolt

Note:Touseanedgeclip,pushitintopositionalong

theedgeoftheframeandinsertacabletiethroughthe

slot.Usethecabletietosecurethewireharness.

5.Pullthefrontendofthewireharnessoutthroughthe

holeinthefrontpostofthemachinesothatthereis

about61cm(24inches)ofslackbeyondthefrontof

theinstalledtowpole(Figure11).

Note:Foroldermodels,useaholesawtodrilla4.2

cm(1-5/8inch)holeinthefrontpostofthemachine,

sothatthewireharnessexitstheframeinlinewith

thehorizontalframerails.

Figure10

foreachbracket.

5

Page 6

1

2

3

G02091 1

Figure11

G020981

G020913

1

2

3

4

5

3

InstallingtheLights

Partsneededforthisprocedure:

2Light

1License-plateholder

4Nut

1.Grommet3.Cabletie

2.Fir-treemount

6.Slidethegrommetoverthe4-pinconnector(Figure12)

onthefrontofthewireharness,andinstallitinthe

holeinthefrontpost(Figure11).

Figure12

7.Pushther-treemountintothesmallholenextto

wherethewireentersthefrontpost,andinsertacable

tiethroughtheslot.

Note:Usethecabletietosecurethewireharness.

Foroldermodels,drilla7mm(17/64inch)holefor

ther-treemount.

8.Stowtheexcesswireasfollows:

•Forconcretemixers,stowtheexcesswireonthe

undersideoftheleftframerail.Usecabletiesto

securetheexcesswiretothepreviouslyinstalled

sectionofwire.

•Formortarmixers,coiltheexcesswireandbundle

itwithacabletie.Stowthebundledexcesswire

insidethecenterframerail,andsecurethebundle

withanothercabletieasnearaspossibletothe

edgeclip.

•Ifthereisexcesswirebetweentheleftlightand

therightlight,bundleitwithacabletie,andsecure

ittoapreviouslyinstalledsectionofwirewith

anothercabletie.

Important:Ensurethatanyexcesslengthinthe

wireharnessissecurewithcabletiesandwillnot

comeloose.

Procedure

1.Positionthelicense-plateholderontothepostsofthe

lightwiththeclearbottomlens,sothattheclearlensis

facingthelicense-plateholder(Figure13).

Figure13

Leftlight

1.Yellowwire—stopandturn4.License-plateholder

2.Brownwire—taillight

3.Whitewire—ground

Note:Thisistheleftlight,whichilluminatesthe

licenseplatethroughtheclearlens.

2.Installthelightsothatthepostsgointotheholesin

thebracketontheleftsideofthemachine(Figure13).

3.Installtheroundterminalofthegroundwire(white)

ontotheoutsidethreadedpost(Figure13).

4.Installthenutsontothethreadedposts;tightenthem

byhandtopreventcross-threading,thenuseawrench

tosecurethemuntiltheyaresnug.

Important:Donotovertightenthenuts,orthe

plastichousingwillbreak.

5.Pushthewiresintotheappropriateholesinthelight

Figure13).

(

Note:Ifyouneedtoremoveawirefromthelight,

inserttheendofapaperclipintothesmallholeunder

thewire,thenpullthewireout.

5.Clearlens

6.Repeatsteps2through5forthelightontheright-hand

sideofthemachine(

Figure14).

6

Page 7

G020914

1

2

3

Figure14

1

G020915

1

G020921

Rightlight

1.Greenwire—stopandturn

2.Brownwire—taillight

3.Whitewire—ground

4

InstallingtheReectors

Partsneededforthisprocedure:

2

Reector

2Bolt

2Nut

Procedure

1.Aligntheholeinareectortotheholein1sideofthe

frontpostonthemachine(Figure15).

Note:Foroldermodels,drilla7.5mm(9/32inch)

holeforeachbolt.

Figure16

Model68024

1.Reector

2.Insertaboltthroughthereectorandtheframe,and

installanutontheotherside.

3.Useawrenchontheboltandanotherwrenchonthe

nuttotightenthemuntiltheyaresnug.

Important:Donotovertightenthenutsandbolts,

ortheplasticreectorswillbreak.

4.Repeatsteps1through3fortheotherside.

Figure15

1.Reector

Note:Formodel68024,mountthereectorsonthe

triangularsupports(Figure16).

7

Page 8

5

A

B

C

E

F

G020829

A

B

C

E

F

G020830

ReplacingtheLightBulbs

NoPartsRequired

ReplacingtheRear-facingBulbs

Note:Theleftrear-facingbulbalsoilluminateslicenseplate.

1.Useascrewdrivertoremovethe4screwsfromthe

largesquarelensonthelight(Figure17).

Figure17

2.Removethelens(Figure17).

3.Pushandtwistthebulbcounterclockwisetoremoveit

fromthesocket(Figure17).

4.Pushanew1157bulbintothesocketandthentwistit

clockwise(Figure17).

Figure18

2.Removethelens(Figure18).

3.Pullthebulboutofthesocket(Figure18).

4.Pushanew168bulbintothesocket(Figure18).

5.Installthelensandthe2screws(Figure18).

5.Installthelensandthe4screws(

ReplacingtheSide-facingBulbs

1.Useascrewdrivertoremovethe2screwsfrom

thesmallrectangularlensonthesideofthelight

(Figure18).

Figure17).

8

Loading...

Loading...