Page 1

FormNo.3377-563RevB

g021465

VS-70andVS-80Screed

ModelNo.68054—SerialNo.313000001andUp

ModelNo.68055—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3377-563*B

Page 2

WARNING

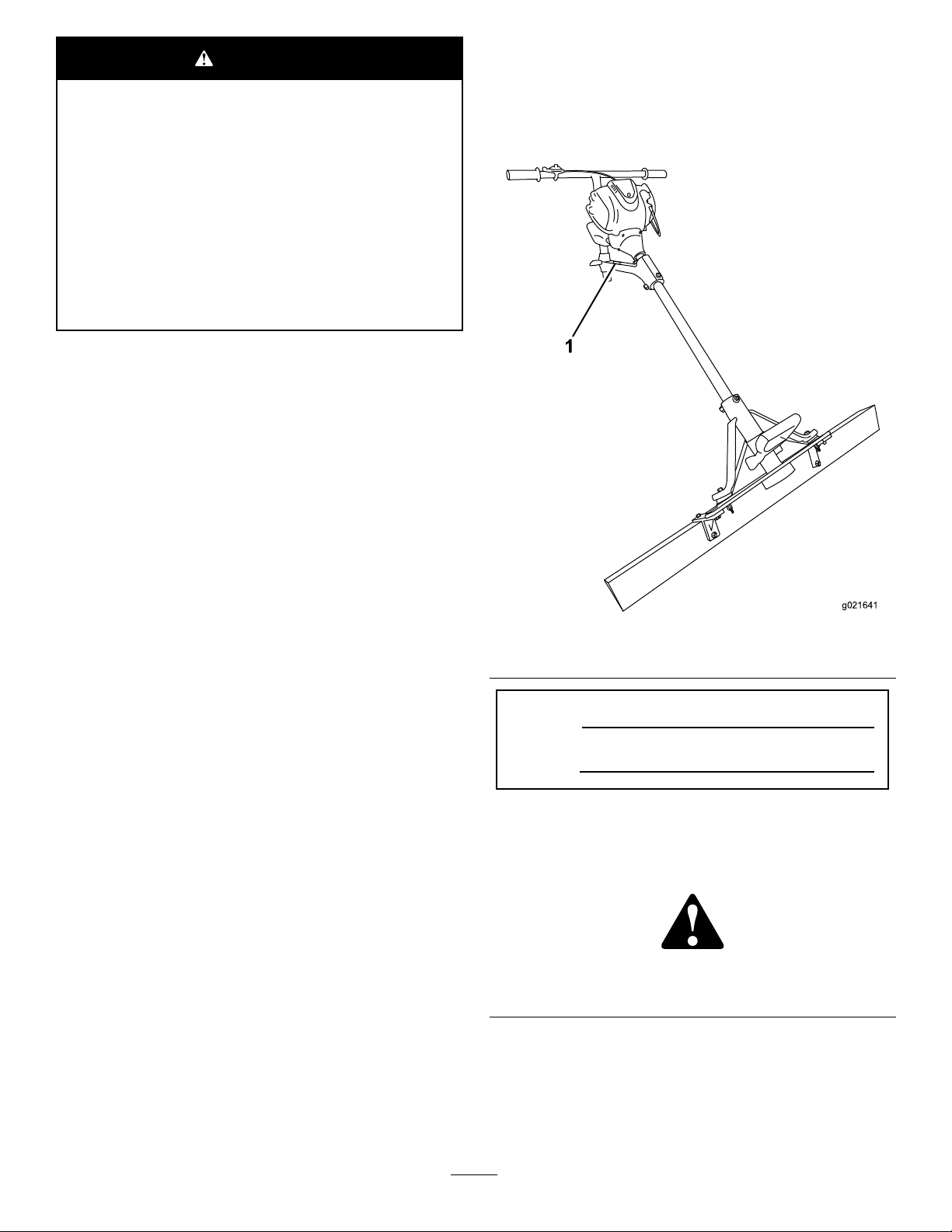

g021641

1

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporatedwith

themuferassembly.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .

Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisavibratingconcretescreedintendedforuse

invariousconcrete-formingwork.Themachineisdesigned

tooperatewithaluminumscreedboards.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

machineproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................5

Setup............................................................................6

1InstallingtheHandlebarandThrottle

Cable.................................................................6

2AddingOiltotheEngine.......................................6

ProductOverview..........................................................7

Controls................................................................7

Specications.........................................................9

Operation....................................................................10

PreparingtoUsetheMachine...................................10

OperatorPositions.................................................10

AddingFuel...........................................................11

CheckingtheEngineOilLevel.................................13

StartingandStoppingtheEngine..............................13

ScreedingaConcreteSurface...................................14

TransportingtheMachine........................................15

Maintenance.................................................................16

RecommendedMaintenanceSchedule(s)......................16

PremaintenanceProcedures........................................17

PreparingtheMachineforMaintenance.....................17

DisconnectingtheSpark-plugWire...........................17

EngineMaintenance..................................................18

ServicingtheAirCleaner.........................................18

ChangingtheEngineOil.........................................19

ServicingtheSparkPlug..........................................20

FuelSystemMaintenance...........................................22

ServicingtheFuelSystem........................................22

Cleaning...................................................................23

CleaningtheMachine..............................................23

Storage........................................................................23

Troubleshooting...........................................................24

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

—personalsafety

SafeOperatingPractices

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthemachine,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

themachine.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamageto

property.

Preparation

•Wearappropriateclothingincludinghardhat,safety

glasses,longpants,safetyshoes,andhearingprotection.

Longhair,looseclothingorjewelrymaygettangledin

movingparts.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapproved-fuelcontainer.

–Neverremovethefuel-tankcaporaddfuelwiththe

enginerunning.

–Allowtheenginetocoolbeforefueling.

–Donotsmokewhilefueling.

–Neverrefuelordrainthemachineindoors.

•Checkthattheswitches,enginecontrols,andcoversare

attachedandfunctioningproperly.Donotoperateunless

theyarefunctioningproperly.

3

Page 4

Operation

MaintenanceandStorage

•Neverrunanengineinanenclosedarea.

•Onlyoperatethemachineingoodlight.

•Onlystarttheenginefromtheoperator'sposition.

•Neveroperatewiththecoversnotsecurelyinplace.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelgroundandshutofftheenginebefore

leavingtheoperator'spositionforanyreason.

•Keeppetsandbystandersawaywhileoperatingthe

machine.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Movetheenginecontrolsinasmooth,steadymotion.

•Watchfortrafcwhenoperatingonornearroadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Stoptheengineandwaitforallmovementtostopbefore

adjusting,cleaning,orrepairingthemachine.

•Cleandebrisfromthemufer,sparkarrester,andengine

tohelppreventres.

•Lettheenginecoolbeforestoringthemachine,anddo

notstoreitnearanopename.

•Donotstorefuelnearamesordrainfuelfromthe

machineindoors.

•Neverallowuntrainedpersonneltoservicethemachine.

•Donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingcondition.Replaceall

wornordamageddecals.

•Keepallhardwareofthemachinetight.Keepthe

machineingoodcondition.

•Nevertamperwithsafetydevices.

•Whenpresent,cleanupoilorfuelspillage.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

•Storefuelinanapprovedcontainer.

•Ensurethatyouoperatethemachineinareaswherethere

arenoobstaclesincloseproximitytotheoperator.Only

operatetheunitinareaswherethereissufcientclearance

fortheoperatortosafelymaneuvertheproduct.

•Donotplaceyourfeetunderthescreedboards.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Makeanynecessaryrepairstothemachinebeforestarting.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

4

Page 5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117–2718

125–8192

1.ReadtheOperator’sManualfor

informationonstartingtheengine—1)

Turntheengineswitchon;2)Closethe

choke;3)Pulltherecoilstarthandle;

4)Openthechoke.

2.ReadtheOperator’sManual

forinformationonstoppingthe

engine—turntheengineswitchoff.

3.Warning—readtheOperator’sManual;

wearhearingprotection.

4.Warning—keepawayfrommoving

parts;keepallguardsandshieldsin

place.

5.Warning—keepbystandersawaywhen

operatingthemachine.

6.Chokinghazard—donotruntheengine

indoors.

7.Explosionhazard—stoptheengineand

extinguishallamesbeforerefueling.

5

Page 6

Setup

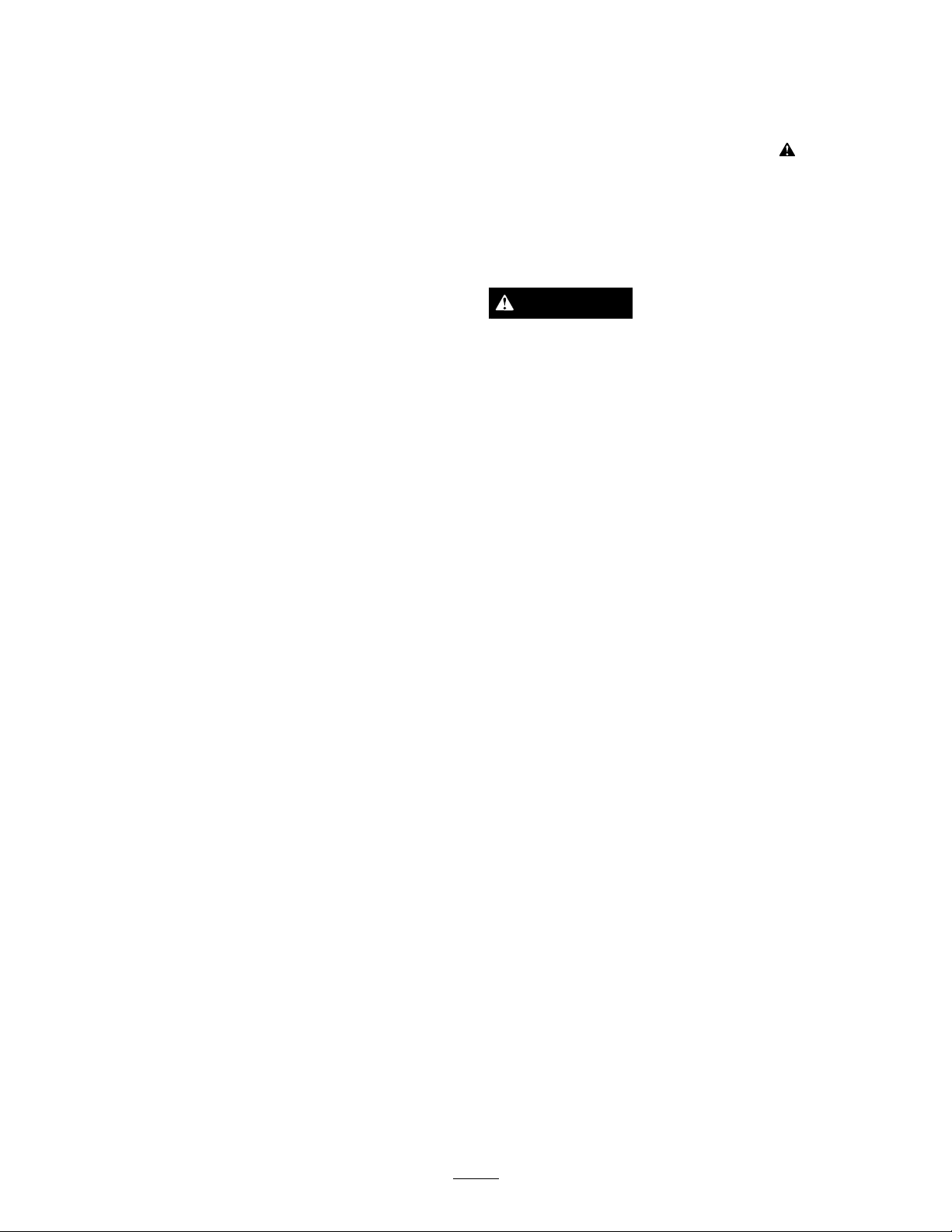

g021481

4

1

2

3

1

2

3

4

5

6

g022042

1 2

3

4

5

6

g022043

1

InstallingtheHandlebarand ThrottleCable

NoPartsRequired

Procedure

1.Slidethehandlebarintoposition(Figure3).

Figure4

1.Cabletting4.Cable

2.Washer

3.Nut

5.Movetheassemblyintoplace,letthecablestopslide

intoplace,andtightenthecablettingandnut;refer

toFigure5.

1.Cabletting4.Cable

2.Washer

3.Nut

5.Cableanchor

6.Cablestop

Figure5

5.Cableanchor

6.Cablestop

Figure3

1.Bolt3.Washer

2.Knob4.Handlebar

2.Installthebolt,washer,andknobtosecurethe

handlebartothemachine(Figure3).

3.Removetheaircleanercover;refertoFigure24.

4.Attachthethrottlecablebyplacingthecableintothe

cableanchor(

Figure4).

2

AddingOiltotheEngine

NoPartsRequired

Procedure

Thismachinedoesnotcomewithoil.Whenthemachineis

beingusedforthersttime,llwithoil.RefertoFillingthe

EngineCrankcasewithOil(page19).

6

Page 7

ProductOverview

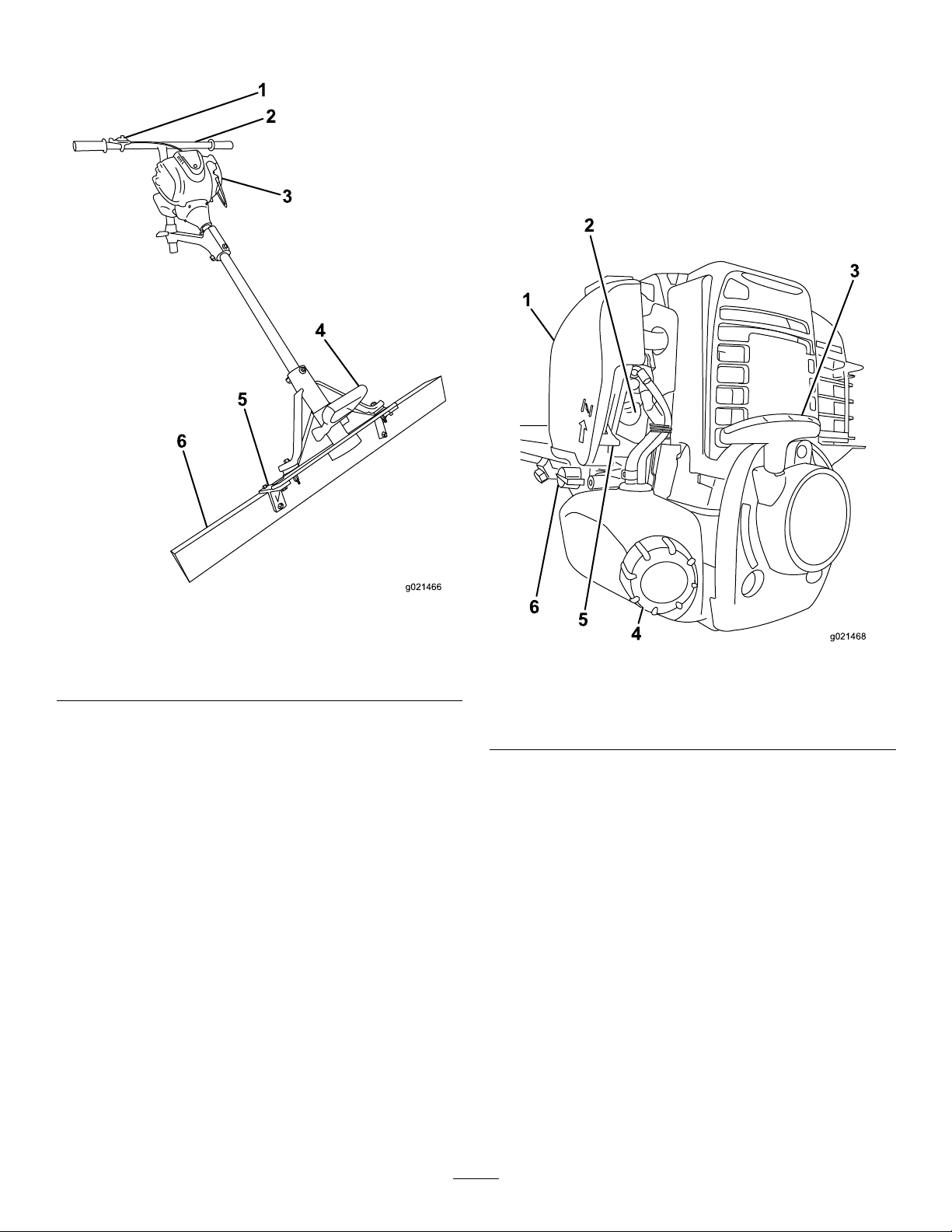

g021466

1

2

3

4

5

6

g021468

6

5

4

1

2

3

Controls

Becomefamiliarwithalltheenginecontrolsbeforeyoustart

andoperatethemachine.

EngineControls

Figure6

1.Throttlelever

2.handlebar5.Boardclamp

3.Engine6.Aluminumboard

4.Lifthandle

Figure7

1.Aircleanercover4.Fuelcap

2.Primingbulb

3.Recoilstarter

5.Chokelever

6.On/Offswitch

7

Page 8

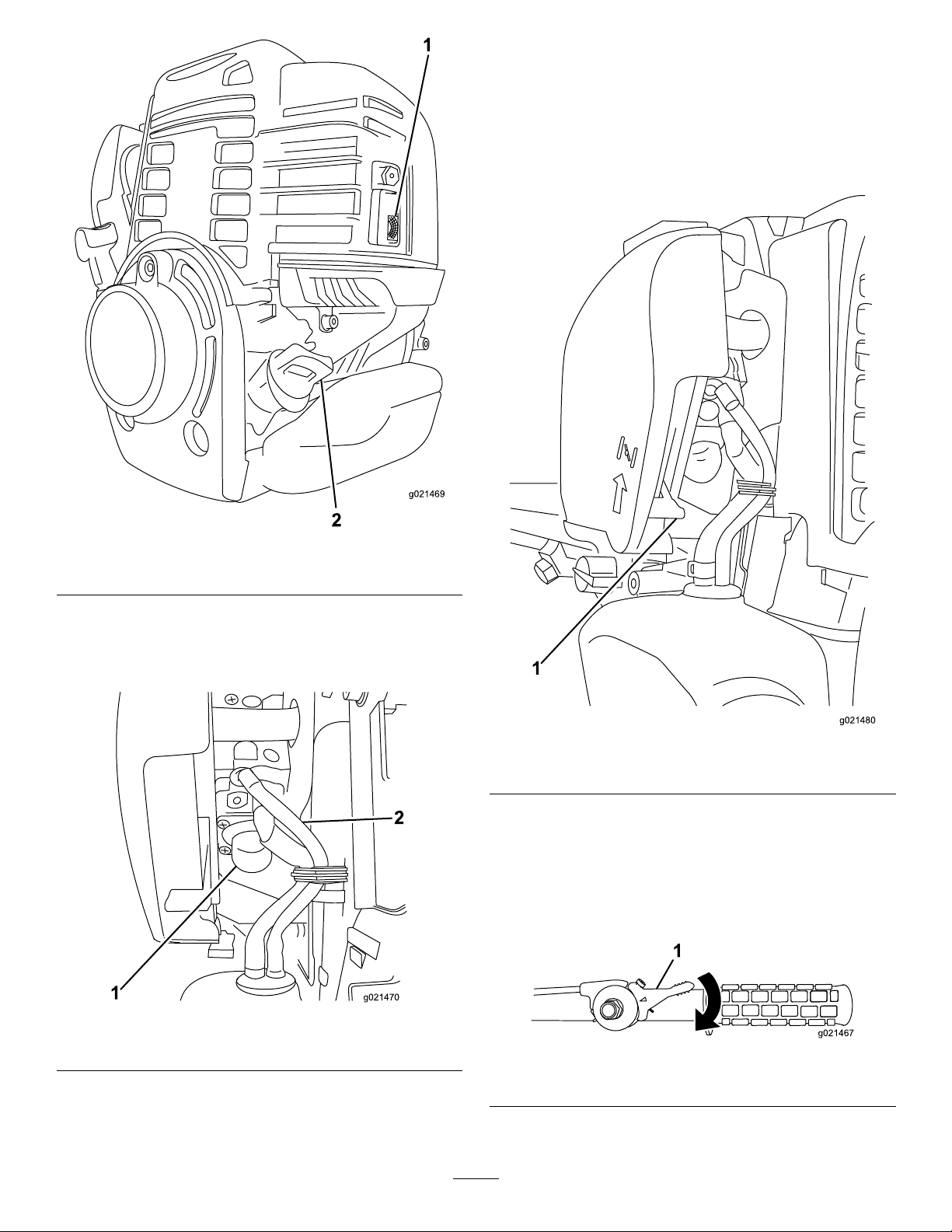

g021469

1

2

g021470

2

ChokeLever

g021480

1

g021467

1

Thechokelever(Figure10)isrequiredwhenstartinga

coldengine.Beforepullingontherecoil-starthandle,move

thechokelevertotheclosedposition.Oncetheengineis

running,movethechokelevertotheopenposition.Do

notusethechokeiftheengineisalreadywarmeduporthe

airtemperatureishigh.

Figure8

1.Sparkarrestor2.Oilcap

Primingbulb

Theprimingbulb(Figure9)islocatedabovethefuelcap.

Figure10

1.Chokeleverinopenposition

ThrottleLever

Thethrottlelever(Figure11)controlsthespeed(rpm)of

theengine.Itislocatedonthehandlebar.Moveittowards

themaximumpositionasshownin

throttle.

Figure11toincreasethe

Figure9

1.Primingbulb2.Fuelreturnpump

Figure11

1.Throttleleverinminimumposition

8

Page 9

Recoil-startHandle

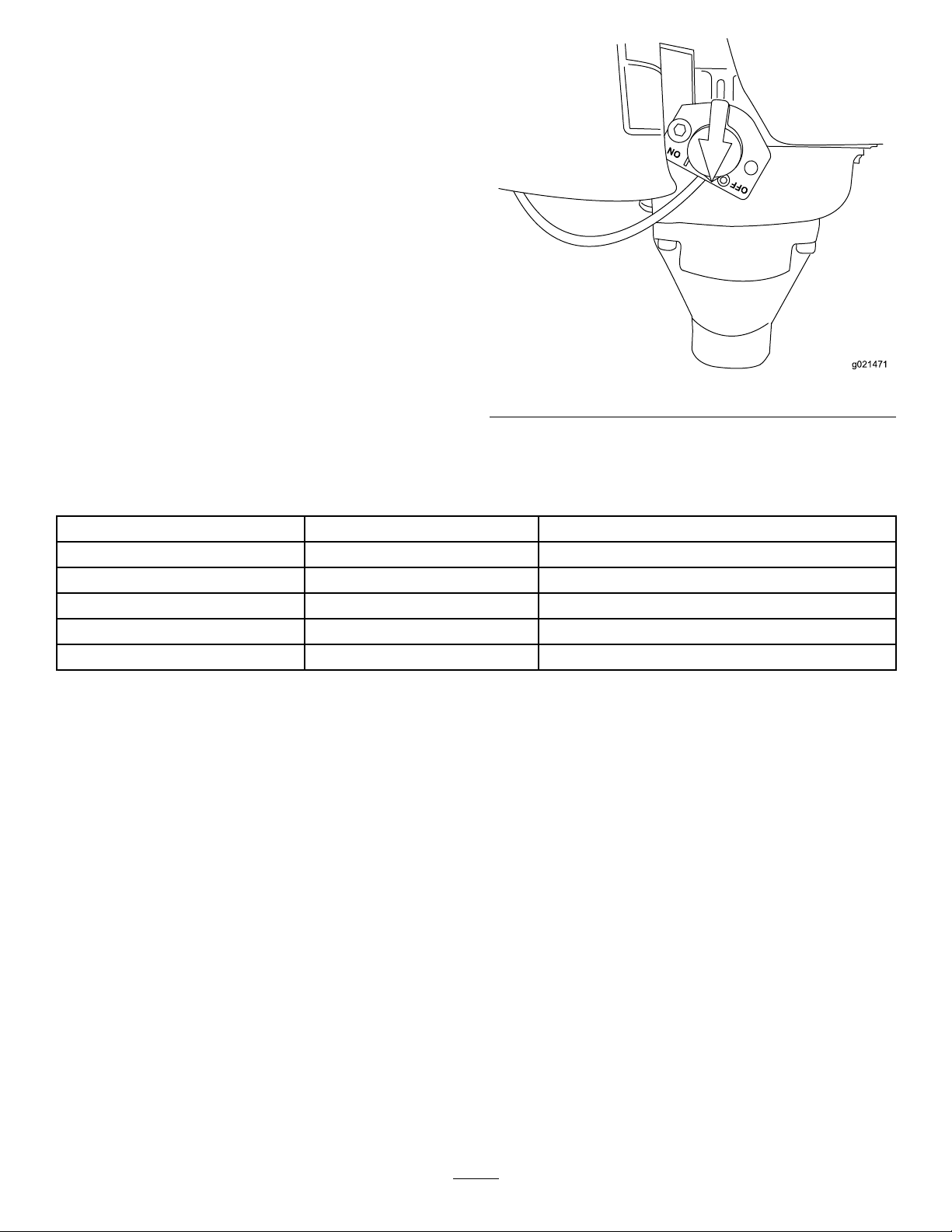

g021471

OFF

ON

Tostarttheengine,pulltherecoil-starthandle(Figure7).

EngineOn/OffSwitch

TheOn/Offswitch(Figure12)allowstheoperatorofthe

machinetostartandstoptheengine.Thisswitchislocated

onthefrontoftheengine.Itismarkedl(On)andO(Off).

RotatetheOn/OffswitchtotheOnpositiontostartandrun

theengine.RotatetheOn/OffswitchtotheOffpositionto

stoptheengine.

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Figure12

VS-70VS-80

Width(withoutscreedboard)70.0cm(27.5inch)89.0cm(35.0inch)

Length

Height(withoutscreedboard)73.7cm(29.0inch)122.0cm(48.0inch)

Weight(withoutscreedboard)11.3kg(25.0lb)14.5kg(32.0lb)

Maximumscreedboardwidth

119.4cm(47.0inch)56.0cm(22.0inch)

3.7m(12.0ft)4.9m(16.0ft)

9

Page 10

Operation

g021642

g021643

Important:Beforeoperatingthemachine,checkthe

fuelandoillevels,andremovedebrisfromthemachine.

PreparingtoUsetheMachine

•Reviewallofthesafetydecalsonthemachine.

•Useahardhat,hearingprotection,tight-ttinggloves

withoutdrawstringsorloosecuffs,andeyeprotection.

Ameshvisoralonedoesnotprovidesufcienteye

protection;supplementwithprotectiveglasses.

•Ensurethatyouarefamiliarwithsafetyregulationsand

theshutdownproceduresdescribedintheOperator’s

ManualandtheEngineManual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Ensurethatthescreedboardisingoodcondition,aligned

correctlyandsecuredtothemachine.

•Checkthefuelandoillevelsoftheengine.

OperatorPositions

Youmustbefamiliarwiththreepositionswhenusingthe

machine.

•Usetheoperatingposition(Figure13)whenrunningthe

machinetoscreedconcrete.

•Usetherestingpositionwhenleavingthemachine.

(Figure14).Neverleavetheenginerunningwhilethe

machineisintherestposition.Alwayssetthemachine

onaatsurface.

Figure13

Figure14

10

Page 11

•Usethegas-llingpositionwheneveryoullthegas

g021644

tank(Figure15).Witharmhandontheshaftofthe

machineandagascannexttotheoperator,unscrewthe

gascap,pickupthegascan,andllupthegastankon

themachine.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelisno

higherthanthescreenonthelterinthefuel

tank.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

Figure15

AddingFuel

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•Donotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessyouuseafuelstabilizer.

•Donotaddoiltothefuel.

•Donotoperatethemachinewithoutentire

exhaustsysteminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacethegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefuelthemachine

ontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

11

Page 12

WARNING

g021472

1

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

fuel-containeropening.

•Keepgasawayfromeyesandskin.

FillingtheFuelTank

Fueltankcapacity:0.65L(0.172USgallon)

Important:Theunusedspaceinthetankallowsthe

gasolinetoexpandwithchangesintemperature.Donot

llthefueltankcompletelyfull.

1.Stoptheengine;refertoStoppingtheEngine(page

14),movethemachinetoalevelsurface,andallowthe

enginetocool.

2.Placeacanofunleadedgasolinenexttoyourmachine.

Important:Donotmixoilwiththefuel.

RecommendedFuel

UnleadedGasoline

U.S.

Except

U.S.

Pumpoctanerating86orhigher

Researchoctanerating91orhigher

Pumpoctanerating86orhigher

UsingFuelStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeepthe

fuelfreshduringstorage.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturerofthe

stabilizer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

3.Movethemachinetothegas-llingposition(Figure

15).

4.Cleanaroundthefuelcapandremoveit(Figure16).

Figure16

1.Fuelcap

5.Pickupthecanandaddunleadedgasolinetothefuel

tankasshowninFigure17.

Note:W atchthetankasitllswithgasolineandstop

pouringbeforethetankisfull.Thiswillallowforthe

gastoexpandinthetank.

12

Page 13

g021474

Figure17

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

1

2

g021473

6.Installthefuelcapsecurely(Figure16).

7.Wipeupanyspilledgasoline.

CheckingtheEngineOilLevel

1.Movethemachineonaat,levelsurface,andstop

theengine.

2.Allowtheenginetocool.

3.Cleanaroundtheoildipstick.

4.Removetheoilcap/dipstickandwipetheendclean

Figure19).

(

ServiceInterval:Beforeeachuseordaily

Important:Use4-cyclemotoroilthatmeetsorexceeds

therequirementsforAPIservicecategory

equivalent).AlwayschecktheAPIservicelabelonthe

oilcontainertobesureitincludestheSJorlater(or

equivalent)rating .

Donotoverllthecrankcasewithoilbecausetheengine

maybedamaged.

Runningtheenginewithalowoillevelcancauseengine

damage.Thistypeofdamageisnotcoveredbythe

warranty.

Note:SAE10W -30isrecommendedforgeneraluse.The

otheroilviscositiesshowninthechartmaybeusedwhenthe

averagetemperatureinyourareaiswithintheindicatedrange.

Crankcasecapacity:0.10L(0.11USqt)

SJ or later

(or

Figure19

1.Fillport

5.Slidethedipstickfullyintothellportwithout

threadingitintotheport(Figure19).

6.Removethedipstickandlookattheend.Iftheengine

oillevelislow ,slowlypouronlyenoughoilintothell

porttoraisetheleveltotheFullmarkonthedipstick

(Figure19).

7.Replaceandsecurethedipstick(Figure19).

2.Oilcap/dipstick

StartingandStoppingthe Engine

StartingtheEngine

Figure18

Note:T oroPremiumEngineOilisavailablefromyour

AuthorizedToroDealer.

1.Ensurethethrottleisatitslowestsetting(Figure11).

2.Tostartacoldengine,movethechokelevertothe

closedposition.Torestartawarmengine,leavethe

chokeleverintheopenposition(

3.Presstheprimingbulbrepeatedlyuntilfuelcanbeseen

intheprimingbulb(Figure9).

4.TurntheengineswitchtotheOnposition.

13

Figure10).

Page 14

5.Pulltherecoil-starthandlelightlyuntilyoufeel

g021475

1

2

3

4

5

6

7

g021484

resistance,thenpullthehandlebriskly(Figure20).

ScreedingaConcreteSurface

Note:Returntherecoil-starthandlegently.

Figure20

6.IfthechokeleverissettotheClosedpositionto

starttheengine,graduallymovethechokeleverback

towardtheOpenpositionastheenginewarmsup.

Iftheenginestallsorhesitates,movethechokelever

backtowardtheClosedpositionuntiltheengineruns

smooth.Allowtheenginetowarmup,thenmovethe

chokelevertotheOpenposition;referto(Figure10).

InstallingtheAluminumScreedBoard

Note:Onlyuseequilateraltrianglealuminumscreedboards

designedforthismachine.

Screedboardwidths:

VS-70VS-80

1.2meters(4feet)

1.8meters(6feet)

2.4meters(8feet)

3.0meters(10feet)

3.7meters(12feet)

4.3meters(14feet)

4.9meters(16feet)

1.Installtheboardclamptotheframeofthemachine

usingsquareboltsandsplit-lockwashers(

xx

xx

xx

xx

x

x

x

Figure21).

7.Allowtheenginetowarmupfor2to5minutes.

StoppingtheEngine

WARNING

Inanemergencysituation,stoptheengine

immediately.

Important:Duringnormaloperation,iftheengine

hasbeenworkinghardorishot,letitidleforaminute

beforestoppingtheengine.Thishelpstocoolthe

enginebeforestopping.

1.Movethethrottlelevertotheminimumposition

(Figure11).

2.RotatetheengineswitchtotheOffposition(Figure

12).

1.Nut

2.Split-lockwasher

3.Squarebolt

4.Hexbolt

Figure21

5.Split-lockwasher

6.Aluminumboard

7.Boardclamp

2.Installthealuminumboardtotheboardclampusing

hexboltsandsplit-lockwashers(Figure21).

14

Page 15

Note:Toremovethescreedboard,reversethesteps

1

2

3

4

g021668

ofthisprocedure.

LevelingtheConcreteSurface

Thismachinecanoatoverwetconcretewithorwithout

theaidofforms.

1.Applyaconcretedeactivatortothesurfaceofthe

aluminumscreedboardandanyotherpartofthe

machinethatmaycomeincontactwithconcrete.

Note:Donotputconcretedeactivatorontheengine.

2.Liftthescreedontotheconcrete.

3.Starttheengine;referto

4.Movethethrottlelevertothemaximumposition;refer

toFigure11.

StartingtheEngine(page13).

7.Attheendofthescreedpass,movetheenginethrottle

totheidlepositionandallowtheenginetoidlefor1

minute.

8.Stoptheengineandmovethescreedoffthecement;

referto

9.Cleanthescreedofcement,sand,andaggregateafter

eachpasswithwaterandasoft-bristlebrush.

StoppingtheEngine(page14).

TransportingtheMachine

Whentransportingthemachine,makesureto;

1.Emptythegastank;refertoFigure33.

2.Removethesquareboltssecuringthemachinetothe

boardclamps(Figure21).

Note:Alwaysoperatetheengineatfullthrottlewhen

smoothingmaterial.

5.Pullthescreedinaslow ,steadymotionalongthe

concretewhilewalkingbackward.Raisetheleading

edgeofscreedboardtoallowforcompaction;refer

to

Figure22.

3.Removethehandlebar(Figure3)

4.Placethemachineandscreedboardsecurelyinyour

vehicle.

Figure22

1.Aluminumscreedboard3.Leadingedge

2.Trailingedgeatgrade

Note:Makesuretheareabehindtheoperatoris

clear.Havesomeoneguidetheoperatorastheymove

backwards.

Note:Ensurethatanadequateamountofconcreteis

loadedaheadoftheleadingedgeofthescreedboard

fortheentirescreedingpass.

6.Allowforabout2.5cm(1inch)ofconcretetobuildup

infrontofscreedboard;referto

importantasitkeepsthetrailingedgeongrade.

Note:Y ouwillhavetohaveatleastoneotherperson

toconstantlykeepconcretebuilduponthebar.

4.Concretebuildup

Figure22.Thisisvery

15

Page 16

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every300hours

Yearlyorbeforestorage

Important:Refertoyour

MaintenanceProcedure

•Changetheoil.

•Checktheengineoillevel.

•Inspecttheaircleanerelements.

•Checkforloosefasteners.

•Cleanthemachine.

•Changetheoilwhenoperatedunderheavyloadsorinhightemperatures.

•Cleantheairlterelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheoil.

•Checkthesparkplug.

•Cleanthefuellter .

•Replacethepaperaircleanerelement.Replaceitmorefrequentlyindustyoperating

conditions.

•Replacethesparkplug.

•Changetheoil.

•T ouchupchippedpaint.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

16

Page 17

CAUTION

g021476

1

2

1

2

g021477

Disconnectthewirefromthesparkplugbeforeyoudoanymaintenance.Setthewireasidesothatitdoes

notaccidentallycontactthesparkplug .

Premaintenance

Procedures

PreparingtheMachinefor Maintenance

1.Turnthemachineoff,moveittoalevelsurface,and

setitdownintherestposition.

2.Ensurethattheengineandmuferarecool.

3.Removethetopcoverandthespark-plugwire.

4.Removethescreedboardsfromthemachine.

DisconnectingtheSpark-plug Wire

1.Removethetopcover.

2.Pullthespark-plugwireofftheterminalofthespark

plug(Figure24).

Figure24

1.Sparkplug2.Spark-plugwire

Figure23

1.Topcover2.Hexbolt

17

Page 18

EngineMaintenance

g021486

1

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspecttheair

cleanerelements.

Every50hours—Cleantheairlterelements.Clean

themmorefrequentlyindustyoperatingconditions.

Every300hours/Yearly(whichevercomes

rst)—Replacethepaperaircleanerelement.Replace

itmorefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagewilloccur.

1.Stoptheengineandwaitfortheenginetocooldown.

2.Disconnectthewirefromthesparkplug;referto

RemovingtheSparkPlug(page20).

3.Unclipandremovetheaircleanercover(Figure25).

9.Wipedirtfromthebaseandthecoverwithamoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

10.Installthefoamelementsandensurethatitisproperly

positioned.

11.Securelyinstalltheaircleanercover.

12.Reconnectthespark-plugwire.

13.Installthetopcoverandsecurewithbolt.

Figure25

1.Aircleanercover

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

4.Removethefoamelementfromthebase.

5.Inspectthefoamelement,andreplaceitifdamaged

orexcessivelydirty.

6.Cleanthefoamelementinwarm,soapywaterorina

nonammablesolvent.

Note:Donotusegasolinetocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

7.Rinseanddrythefoamelementthoroughly.

8.Dipthefoamelementincleanengineoil,thensqueeze

outtheexcessoil.

Note:Excessoilinthefoamelementrestrictstheair

owthroughtheelementandmayreachthepaper

lterandclogit.

18

Page 19

ChangingtheEngineOil

g021483

0 20 40 60

80

10 0°F

-20 -10 0 10 20 30 40 °C

5W–30 · 10 W– 30

30

1

G019298

1

2

g021473

ServiceInterval:Aftertherst50hours/Monthly

(whichevercomesrst)—Changetheoil.

Every100hours/Every6months(whichevercomes

rst)—Changetheoil.

Every25hours—Changetheoilwhenoperatedunder

heavyloadsorinhightemperatures.

Yearlyorbeforestorage—Changetheoil.

FillingtheEngineCrankcasewithOil

Important:Use4-strokemotoroilthatmeetsorexceeds

therequirementsforAPIservicecategory

equivalent).AlwayschecktheAPIservicelabelonthe

oilcontainertobesureitincludestheSJorlater(or

equivalent).

Runningtheenginewithalowoillevelcancauseengine

damage.Thistypeofdamageisnotcoveredbywarranty.

Donotoverllthecrankcasewithoilbecausetheengine

maybedamaged.

SJ or later

(or

DrainingtheEngineOil

1.Starttheengineandletitrun5minutesStartingthe

Engine(page13)thenturnitoff.

Note:Thiswarmstheoilsoitdrainsbetter.

2.Removescreedboardsiftheyareattached.

3.Placeadrainpan,witha1.9L(2USqt)capacityor

greaterontheground

4.Removetheoilcap.

5.Witharmgriponthehandlebarsandtheshaftofthe

machine,pourtheoilintothepan(

Figure26).

Note:SAE10W-30isrecommendedforgeneraluse.

Otherviscositiesshowninthechartmaybeusedwhenthe

averagetemperatureinyourareaiswithintheindicatedrange.

Crankcaseoilcapacity:0.10L(0.11USqt)

Figure27

1.Oilviscosityrangeforambientoperatingtemperatures

Note:T oroPremiumEngineOilisavailablefromyour

AuthorizedToroDealer.

1.Removetheoilcap/dipstick(Figure28).

Figure26

6.Whentheoilhasdrainedcompletely,installtheoilcap,

andwipeupanyspilledoil(Figure26).

Note:Disposeoftheusedoilatacertiedrecycling

center.

Figure28

1.Fillport

19

2.Oilcap/dipstick

Page 20

2.Slowlypourapproximately80%ofthespecied

1

2

g021477

G019300

1 2

4

3

amountofoilintothellport(Figure28).

3.Addadditionaloiltobringtheoilleveltotheproper

llamount;referto(Figure28).

4.Installtheoilcap/dipstick(Figure28).

ServicingtheSparkPlug

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Checkthe

sparkplug.

Every300hours/Yearly(whichevercomes

rst)—Replacethesparkplug.

Note:Usea5/8inchsparkplugwrenchforremovingand

installingthesparkplug.

RemovingtheSparkPlug

1.TurnofftheengineStoppingtheEngine(page14)and

placethemachineintherestingposition(Figure14).

2.Ensurethatthemachinesurfacesarecool.

3.Removethetopcover.

4.Pullthespark-plugwireofftheterminalofthespark

plug(

Figure29).

CheckingtheSparkPlug

Note:Useagappingtool/feelergaugetocheckandadjust

theairgap.Installanewsparkplugifnecessary.

AirGap:0.6to0.7mm(0.024to0.028inch)

Sparkplugtype:CM5H(NKG),CMR5H(NGK),or

equivalent

1.Lookatthecenterofthesparkplug(

seelightbrownorgrayontheinsulator,theengineis

operatingproperly.

Important:Nevercleanthesparkplug .Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Figure30

1.Sideelectrode

2.Centerelectrode4.0.6to0.7mm(0.024to

3.Insulator

0.028inch)gap

Figure30).Ifyou

1.Sparkplug

5.Cleanaroundthesparkplug.

6.Rotatethesparkplugcounterclockwiseusinga5/8

inchspark-plugwrenchtoremovetheplugandsealing

washer.

2.Useagappingtoolforsparkplugsorafeelergaugeto

measurethegapbetweenthesideelectrodeandcenter

electrode(

Figure30).

3.Ifthemeasuredgapisnotwithinthespeciedrange,

dothefollowing:

A.Ifthegapistoosmall,carefullybendtheside

electrodeawayfromthecenterelectrodeuntilthe

gapbetweentheelectrodesiswithinthemeasured

airgaprange.

B.Ifthegapistoolarge,carefullybendtheside

electrodetowardfromthecenterelectrodeuntil

thegapbetweentheelectrodesiswithinthe

measuredairgaprange.

InstallingtheSparkPlug

Important:Ensurethatthegapbetweenthesideand

centerelectrodesiscorrectbeforeinstallingthespark

plug.

Figure29

2.Wire

1.Threadthesparkplugclockwiseintothespark-plug

holebyhand.

Note:Avoidcrossthreadingthesparkplugwiththe

threadsofthespark-plughole.

2.Rotatesparkplugclockwiseusinga5/8inchspark-plug

wrenchuntiltheplugandsealingwasherareseated.

3.Tightentheplugasfollows:

20

Page 21

•Wheninstallinganin-servicesparkplug,tighten

1

2

g021479

g021487

1

thepluganadditional1/8to1/4turn.

•Wheninstallinganewsparkplug,tightentheplug

anadditional1/2turn.

4.Installthespark-plugwirepushingthewireontothe

terminaloftheplug(Figure29).

CleaningtheSparkArrester

1.Removethetopcoverandsparkplugwire.

2.Removethesparkarrester(Figure31).

Figure32

1.Sparkarrestor

Figure31

1.Screw2.Sparkarrestor

3.Useabrushtoremovecarbondepositsfromthespark

arresterscreen(Figure32).

21

Page 22

FuelSystem

g021482

1

2

g021478

Maintenance

ServicingtheFuelSystem

Cleaningthefuellter

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)—Cleanthefuellter.

Insidethefueltankisafuelltertocatchdirtinthefuel.

1.Turnofftheengine;refertoStoppingtheEngine

(page14)andplacethemachineintherestingposition

(Figure14).

2.Ensurethattheengineandtheexhaustsystemsurfaces

arecool.

3.Disconnectthewirefromthesparkplug;referto

RemovingtheSparkPlug(page20).

4.Emptythefueltank(Figure33).

Figure33

5.Useabentpapercliptocarefullypullthefuellterout

ofthefueltank(Figure34).

Figure34

1.Paperclip

6.Cleanthefuellterbygentlywashingwitha

nonammablesolvent.

Note:Ifthefuellterisexcessivelydirty,replaceit.

7.Insertthefuellterintothefueltankandtightenthe

fuelcap.

2.Fuellter

22

Page 23

Cleaning

CleaningtheMachine

Storage

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashtheengine.

Regularcleaningandwashingwillincreasethelifespanof

themachine.Cleanthemachineaftereachuse,beforethe

cementdries.

Ensurethatthefueltankcapandoilcap/dipstickaresecure

toavoidgettingwaterinthetank.

Usecarewhenusingahigh-pressuresprayer,becauseitcan

damagewarningdecals,instructionsigns,andtheengine.

Cleanthescreedofcement,sand,andaggregateaftereach

usewithwaterandasoft-bristlebrush.

1.Removeconcrete,sand,andaggregatefromthe

externalpartsofthemachine,especiallytheengine.

Cleandirtfromtheoutsideoftheengine'scylinder

headnsandhousing.

2.Servicetheaircleaner;referto

Cleaner(page18).

3.Changetheengineoil;referto

Oil(page19).

4.Removethesparkplugandchecktheconditionof

each;referto

5.Forstorageover30days,conditionthefuelsystemas

follows:

Important:Donotuseanalcohol-basedstabilizer

(ethanolormethanol).

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuelandusedatalltimes.

Donotstorestabilizerconditionedfuelforover90

days.

A.Addapetroleumbasedstabilizer/conditionerto

fuelinthetank.Followmixinginstructionsfrom

stabilizermanufacturer.

ServicingtheSparkPlug(page20).

ServicingtheAir

ChangingtheEngine

B.Starttheengineandrunituntilitstops.

C.Choketheengine.

D.Startandruntheengineuntilitwillnotstartagain.

E.Disposeoffuelproperly .Recycleasperlocal

codes.

6.Forstorageover90days,conditiontheengineas

follows:

A.Removethespark-plugwirefromthesparkplug

B.Removethesparkplugfromtheengineandpour

twotablespoonsofengineoilintothesparkplug

hole.

C.Placeragsoverthesparkplugholetocatchany

oilsprayandthenpulltherecoil-starthandleto

distributetheoilinsidethecylinder.

D.Installthesparkplug,butdonotinstallthe

spark-plugwire.

7.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamagedordefective.

8.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

9.Storethemachineunitinaclean,drygarageorstorage

area.

10.Coverthemachinetoprotectitandkeepitclean.

23

Page 24

Troubleshooting

Problem

Theenginewillnotstart.

Theenginelackspowerorrunsrough.

PossibleCauseCorrectiveAction

1.Thefuel-valveleverisintheOff

position.

2.Thechokeisclosed.

3.Thechokeisopen.

4.TheengineOn/OffswitchisintheOff

position.

5.Thefueltankisempty.5.Fillthefueltankwithfreshfuel.

6.Theenginecontainsbad/oldfuel.6.Drainthefueltankandcarburetor.Fuel

7.Thesparkplugisfouledorimproperly

gapped.

8.Thesparkplugiswetwithfuel(ooded

engine).

9.Thespark-plugwireislooseor

disconnected.

1.Theairlterisrestricted.1.Cleanorreplacetheairlterelement(s).

2.Theenginecontainsbad/oldfuel.2.Drainthefueltankandcarburetor.

3.Thereiswaterorcontaminationinthe

fuel.

4.Thefuellineisrestricted.4.Cleanthefuellterandsedimentcup.

5.Thechokeisclosed

6.Thesparkplugiswornorhasbuildup

ontheelectrodes.

7.Thereistoomuchoilintheengine

crankcase.

1.Movethefuel-valvelevertotheOn

position.

2.Openthechokewhenstartingahot

engine.

3.Closethechokewhenstartingacold

engine.

4.RotatetheswitchtotheOnposition.

themachinewithfreshgasoline.

7.Gaporreplacethesparkplug.

8.Removethesparkplug,dryit,and

installtheplug.Starttheenginewith

thethrottleintheMaxposition.

9.Removethespark-plugwire,cleanthe

spark-plugterminalandtheterminal

socketinthebootofthespark-plug

wire,andreinstallthespark-plugwire.

Refuelwithfreshgasoline.

3.Drainthefueltankandcarburetor.Fuel

themachinewithfreshgasoline.

5.Openthechoke.

6.Checktheelectrodegapandadjustor

replacethesparkplug.

7.Draintheoiltotheproperlevel.

Themachineisnotsmoothingthe

concreteproperly .

1.Thereisanexcessiveamountof

concretebuildupalongtheedgesof

theboard.

2.Theoperatorismovingtooslowly.

3.Thereistoomuchvibrationforthetype

ofconcrete.

4.Theconcreteistoohighorlowonone

side.

5.Theboardisnotpositionedcorrectly.5.Repositiontheboard.

1.Removeexcessiveconcretefromthe

board.

2.Movethescreedatafasterpace.

3.Reduceenginespeedandmovethe

screedatafasterpace.

4.Haveworkersshapetheconcreteas

closeaspossibletograde.Maintain

about1inchofconcreteacrossthe

frontoftheboardatalltimes.

24

Page 25

Notes:

25

Page 26

Notes:

26

Page 27

Notes:

27

Page 28

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

Concrete,Masonry,

andCompaction

Equipment

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourT oroConcrete,Masonry ,

andCompactionEquipmentProductslistedbelowtobefreefromdefects

inmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ConcreteMixers

•SpindleBearingsLifetime*(originalowneronly)

MortarMixers1year

•DrumBearingsandSealsLifetime*(originalowneronly)

ForwardPlateCompactors

ReversiblePlates1year

RammerCompactors

MudBuggy1year

VibratingTrenchRoller2years

ConcreteSaws

MasonrySaws

PowerTrowels1year

Screeds

ConcreteVibrators

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

LifetimeWarranty-Ifthebearing(s)orseal(s)onyourmixerfail,itwillbereplacedunderwarranty,

atnocostforpartsorlabor.

1year

2years

2years

1year

1year

1year

1year

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.Tolocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1 196

TollFree:800-888-9926

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromToroandhave

signedtheToroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitToro’ sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalproductoperationinclude,butarenotlimitedto,belts,wipers,

sparkplugs,tires,lters,gaskets,wearplates,seals,O-rings,drive

chains,clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty ,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty.Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty.Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0288RevB

Loading...

Loading...