Page 1

FormNo.3382-989RevA

G020728

VS-400andVS-800Screed

ModelNo.68052—SerialNo.314000001andUp

ModelNo.68053—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3382-989*A

Page 2

WARNING

G020789

1

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

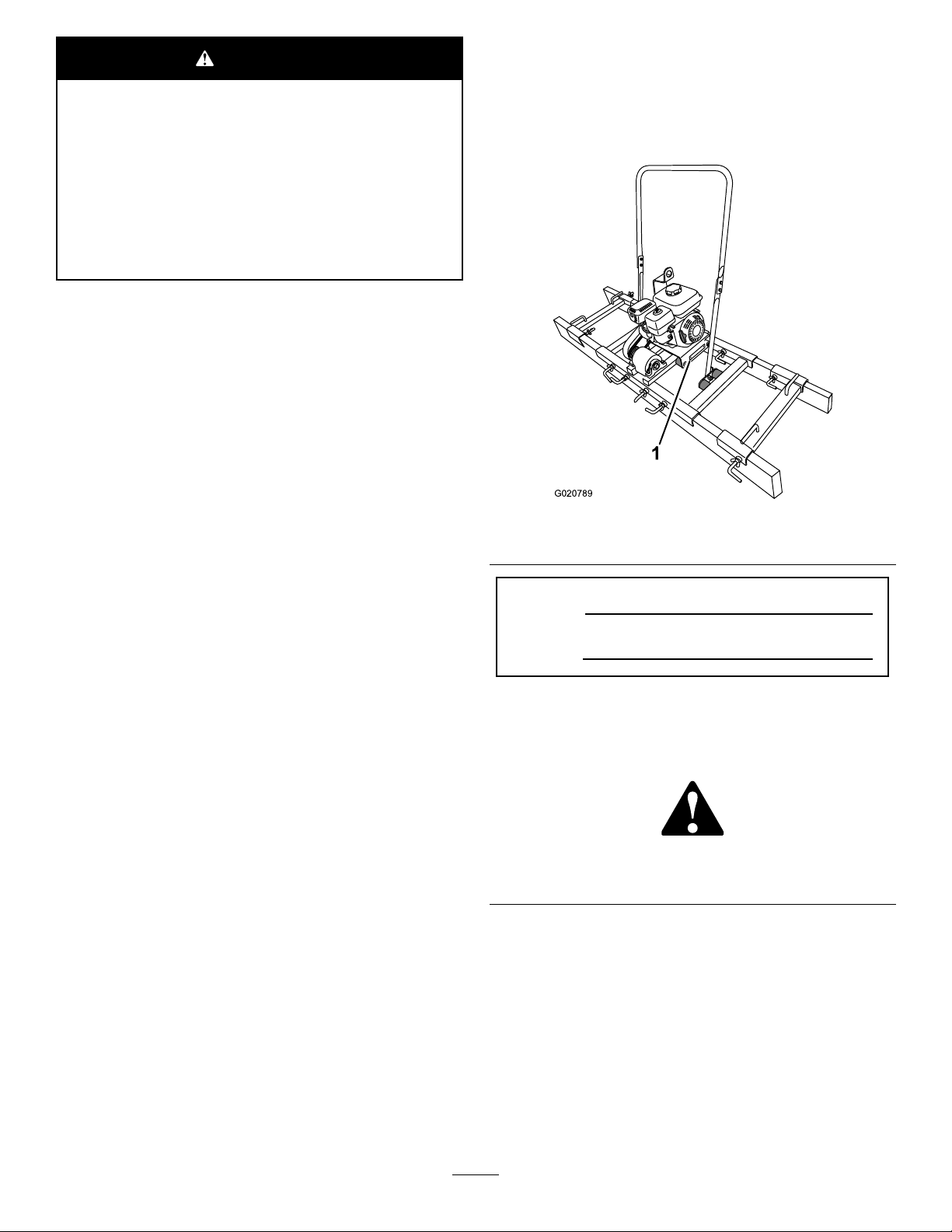

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisavibratingconcretescreedintendedforuse

invariousconcrete-formingwork.Themachineisdesigned

tooperatewithavarietyofoperator-providedboardwidths

includingcontouredscreedboards.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

machineproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................5

Setup............................................................................6

1InstallingtheHandlebar.........................................6

2InstallingtheTowRope.........................................6

3InstallingtheL-bolts.............................................6

4CheckingtheOilLevel...........................................7

ProductOverview..........................................................8

Controls................................................................8

Specications.........................................................9

Operation....................................................................10

PreparingtoUsetheMachine...................................10

OperatorPosition...................................................10

AddingFuel...........................................................10

CheckingtheEngineOilLevel.................................12

StartingandStoppingtheEngine..............................13

InstallingandRemovingtheScreedBoards................14

ScreedingaConcreteSurface...................................15

LiftingtheMachine................................................16

Maintenance.................................................................17

RecommendedMaintenanceSchedule(s)......................17

PremaintenanceProcedures........................................18

PreparingtheMachineforMaintenance.....................18

DisconnectingtheSpark-plugWire...........................18

Lubrication...............................................................18

GreasingtheMachine.............................................18

EngineMaintenance..................................................19

ServicingtheAirCleaner.........................................19

ChangingtheEngineOil.........................................20

ServicingtheSparkPlug..........................................21

FuelSystemMaintenance...........................................22

ServicingtheFuelSystem........................................22

DriveSystemMaintenance.........................................23

LubricatingtheClutch.............................................23

BeltMaintenance......................................................24

RemovingandInstallingtheBeltGuard.....................24

ServicingtheBelt...................................................25

ReplacingtheBelt...................................................25

Cleaning...................................................................27

CleaningtheMachine..............................................27

Storage........................................................................27

Troubleshooting...........................................................29

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

,which

—personalsafety

SafeOperatingPractices

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthemachine,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

themachine.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Wearappropriateclothingincludinghardhat,safety

glasses,longpants,safetyshoes,andhearingprotection.

Longhair,looseclothingorjewelrymaygettangledin

movingparts.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapproved-fuelcontainer.

–Neverremovethefuel-tankcaporaddfuelwiththe

enginerunning.

–Allowtheenginetocoolbeforefueling.

–Donotsmokewhilefueling.

–Neverrefuelordrainthemachineindoors.

•Checkthattheswitches,enginecontrols,andshieldsare

attachedandfunctioningproperly.Donotoperateunless

theyarefunctioningproperly.

3

Page 4

Operation

MaintenanceandStorage

•Neverrunanengineinanenclosedarea.

•Onlyoperatethemachineingoodlight.

•Onlystarttheenginefromtheoperator'sposition.

•Neveroperatewiththeguardsnotsecurelyinplace.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelgroundandshutofftheenginebefore

leavingtheoperator'spositionforanyreason.

•Keeppetsandbystandersawaywhileoperatingthe

machine.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Movetheenginecontrolsinasmooth,steadymotion.

•Watchfortrafcwhenoperatingonornearroadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Ensurethatyouoperatethemachineinareaswherethere

arenoobstaclesincloseproximitytotheoperator.Only

operatetheunitinareaswherethereissufcientclearance

fortheoperatortosafelymaneuvertheproduct.

•Donotplaceyourfeetunderthemachineorscreed

boards.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Stoptheengineandwaitforallmovementtostopbefore

adjusting,cleaning,orrepairingthemachine.

•Cleandebrisfromthemuferandenginetohelpprevent

res.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringthemachine,anddo

notstoreitnearanopename.

•Donotstorefuelnearamesordrainfuelfromthe

machineindoors.

•Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportmachinewhenrequired.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingcondition.Replaceall

wornordamageddecals.

•Keepallhardwareofthemachinetight.Keepthe

machineingoodcondition.

•Nevertamperwithsafetydevices.

•Whenpresent,cleanupoilorfuelspillage.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Storefuelinanapprovedcontainer.

–Donotremovethegascaporaddfuelwhilethe

engineisrunning.

–Allowtheenginetocoolbeforefuelingthemachine.

–Donotsmokewhilefuelingthemachine.

–Donotfuelthemachineindoors.

–Donotstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Donotllacontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Makeanynecessaryrepairstothemachinebeforestarting.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

4

Page 5

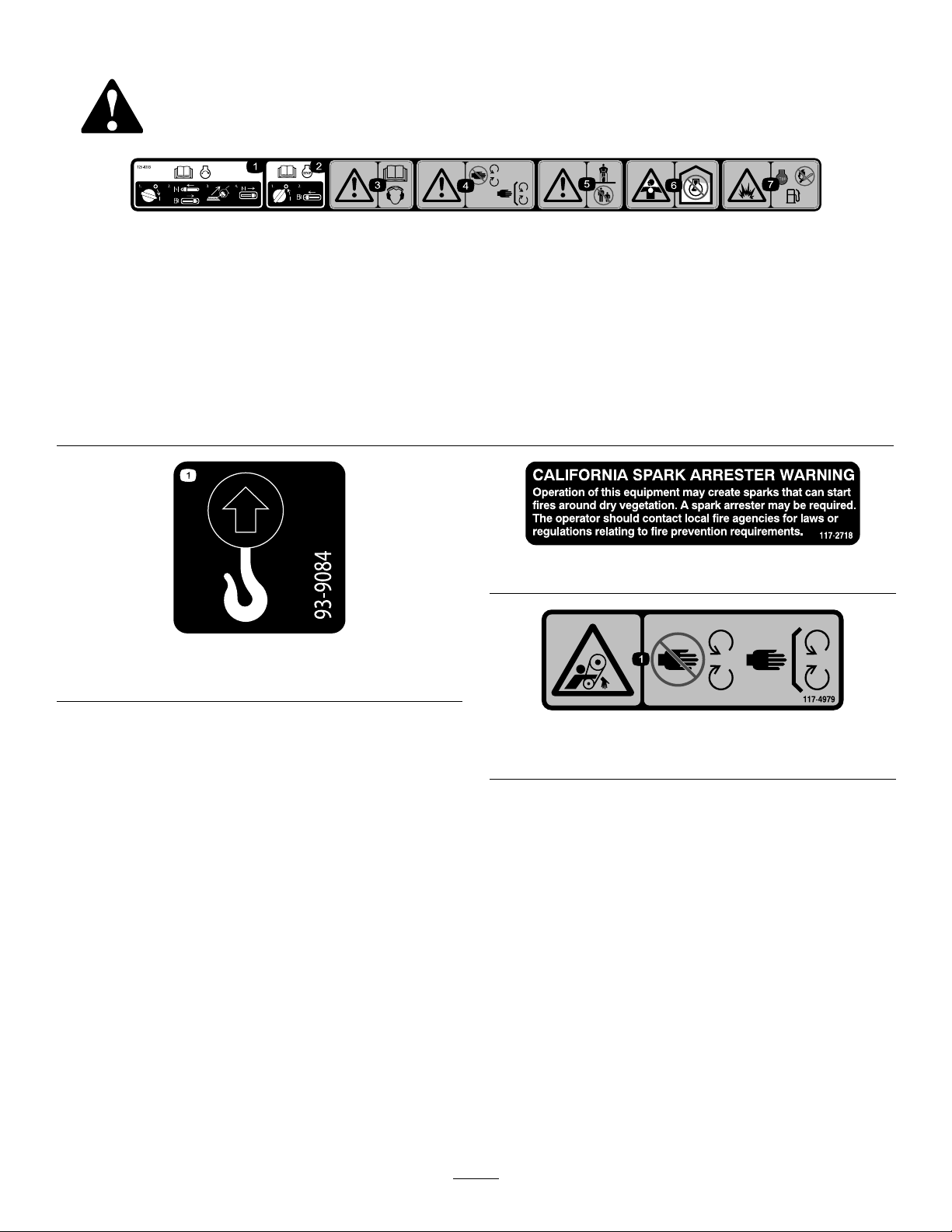

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125–8203

1.ReadtheOperator’sManualforinformationonstartingthe

engine—1)Turnontheengineswitch;2)Closethechoke

andturnonthefuelswitch;3)Pulltherecoilstarter;4)Open

thechoke.

2.ReadtheOperator’sManualforinformationonstoppingthe

engine—1)Turnofftheengineswitch;2)Turnoffthefuel

switch.

3.Warning—readtheOperator’sManual;wearhearing

protection.

4.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

93-9084

1.Liftpoint

5.Warning—keepbystandersaway.

6.Chokinghazard—donotruntheengineinanunventilated

area.

7.Explosionhazard—stoptheengineandextinguishallames

beforerefueling.

117–2718

117–4979

1.Rotatingbelt—Keepguardinplace

5

Page 6

Setup

G020818

1

2

3

4

G020823

1

2

3

4

1

2

1

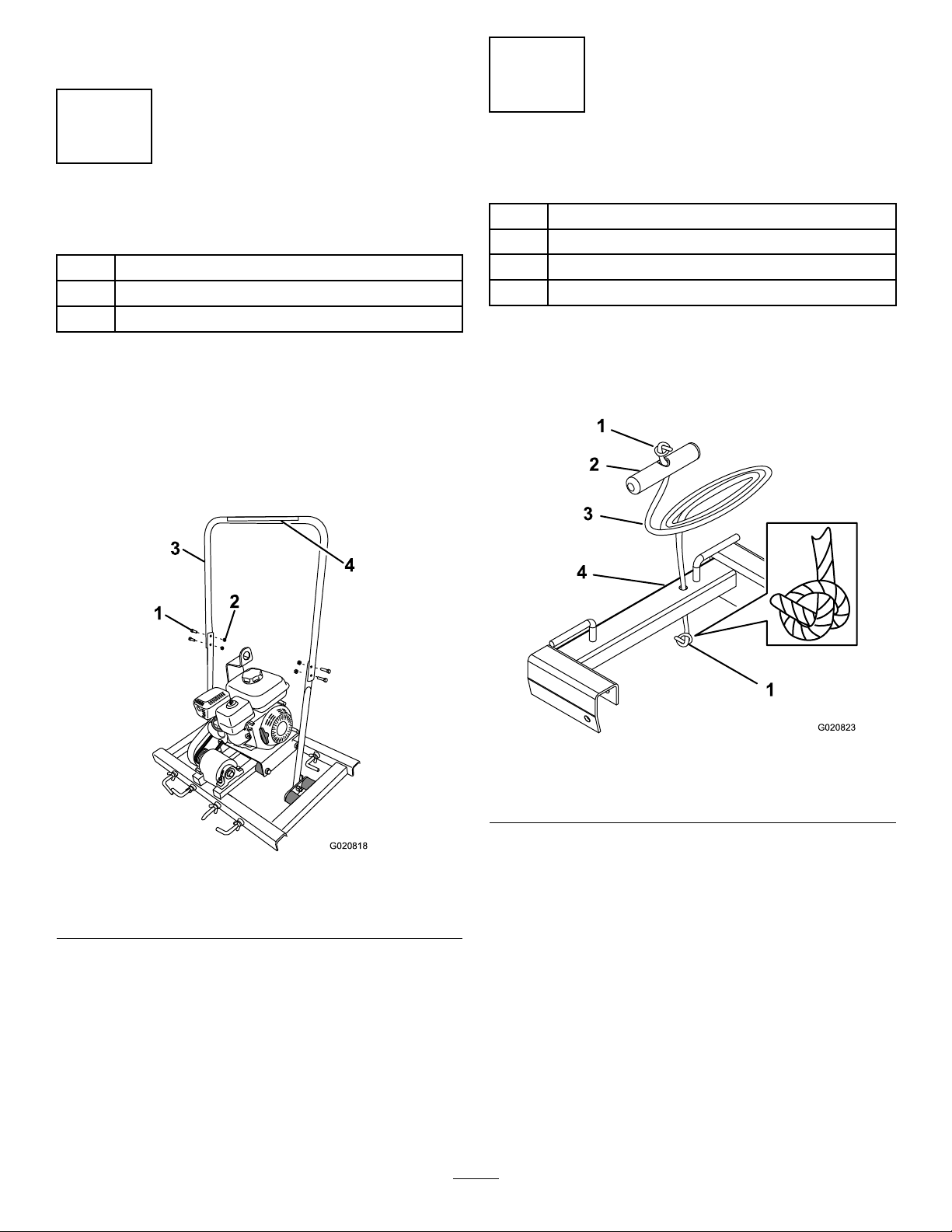

InstallingtheHandlebar

Partsneededforthisprocedure:

1Upperhandlebar

4

Bolt(5/16x1inch)

4

Nut(5/16inch)

Procedure

Placetheupperhandlebarsothatitcanbeinstalledusing

thenutsandbolts.(Figure3).

Note:Ensurethatthedecalisinthecorrectpositionsoit

canbereadbytheoperatorwhileintheoperatorsposition;

refertoFigure11.

InstallingtheTowRope

Partsneededforthisprocedure:

1

Leftspreader

1Rightspreader

2Pullgrip

2Rope

Procedure

1.Threadtheendoftheropethroughapullgrip(Figure

4).

Figure4

1.Pullgrip3.Rope

2.Overhandknot4.Spreader(right)

2.Tieanoverhandknotinthefreeendoftherope

Figure3

1.Bolt3.Upperhandlebar

2.Nut4.Decal

6

(Figure4).

3.Threadthefreeendoftheropethroughtheholeinthe

rightspreader(Figure4).

4.Tieanoverhandknotintheshortendoftherope.

5.Repeatsteps1and2withtheothersegmentofrope

andpullgrip.

6.Threadthelongendoftheropethroughtheholein

theleftspreader.

7.Tieanoverhandknotinthefreeendoftherope.

Page 7

3

G020862

1

2

3

4

5

6

1

4

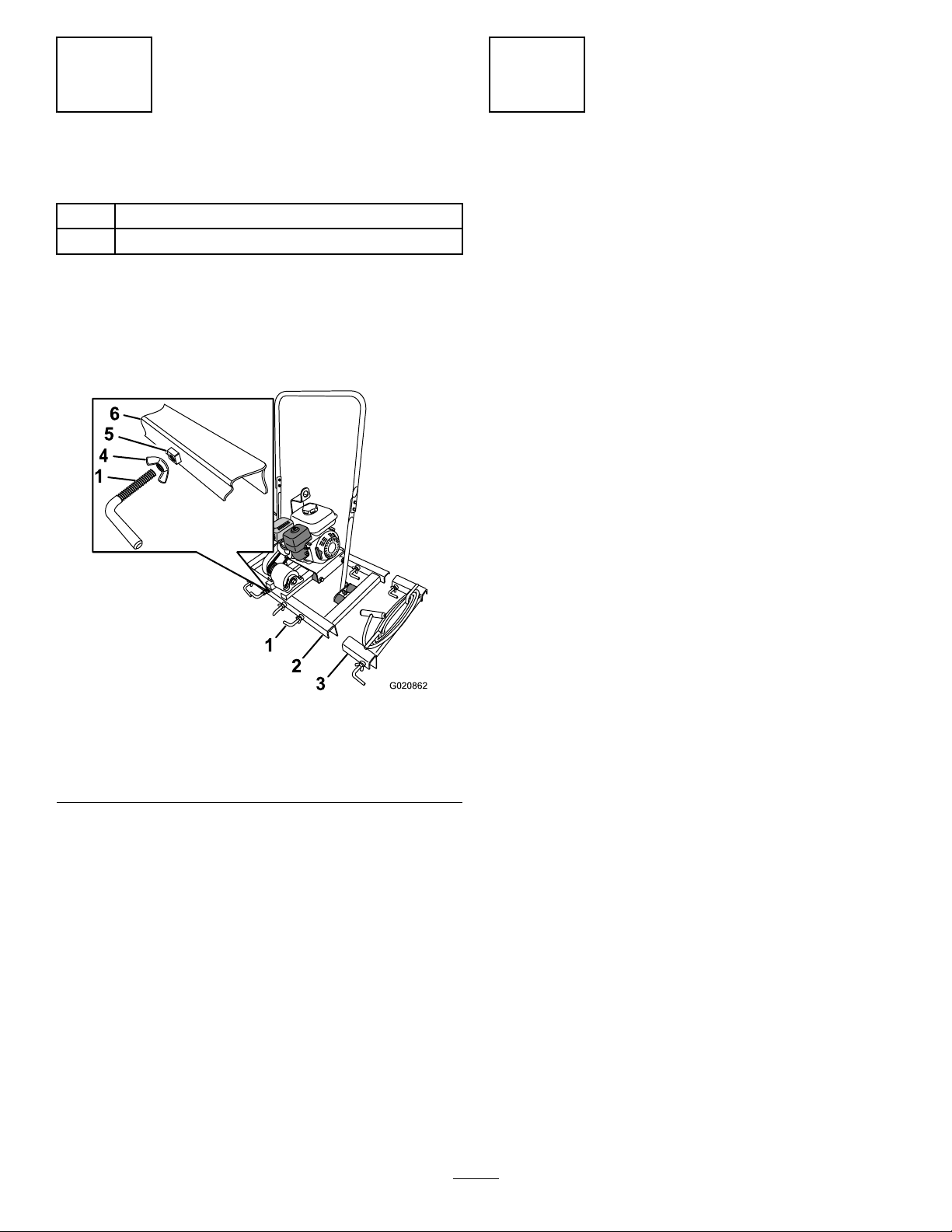

InstallingtheL-bolts

Partsneededforthisprocedure:

10L-bolt

10Wingnut

AssemblingtheL-boltstotheMachine

andSpreaders

1.Ifnotinstalled,threadthewingnutsontotheL-bolt

(Figure5).

CheckingtheOilLevel

NoPartsRequired

Procedure

Beforestartingtheengineforthersttime,checktheengine

oillevel;refertoCheckingtheEngineOilLevel(page12).

Figure5

1.L-bolt4.Wingnut

2.Channel(frame)

3.Channel(spreader)6.Channel

2.ThreadtheL-bolts2or3rotationsintotheweldnutsin

theU-channelsoftheframeandthespreaders(Figure

5).

5.Weldnut

7

Page 8

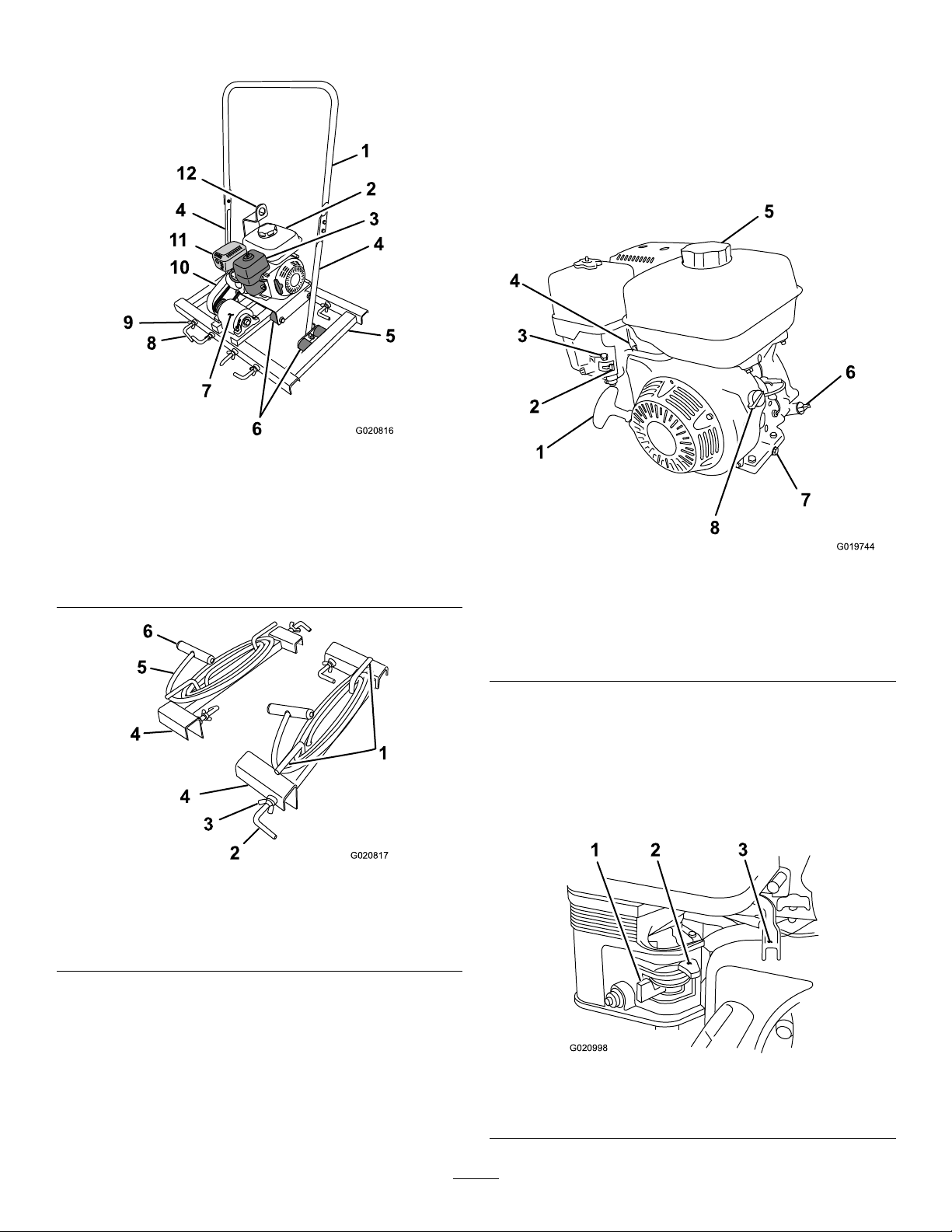

ProductOverview

1

2

4

4

5

6

7

8

9

10

11

12

3

G020816

6

5

4

4

3

2

1

G020817

1

2

3

4

5

6

7

8

G019744

G020998

1 2

3

Figure6

1.Upperhandlebar7.Eccentricguard

2.Fueltank8.L-bolt

3.Air-lterhousing

4.Lowerhandlebar10.Beltguard

5.Frame

6.Isolator

9.Wingnut

11.Mufer

12.Liftingbracket

Controls

Becomefamiliarwithalltheenginecontrolsbeforeyoustart

andoperatethemachine.

EngineControls

Figure8

1.Recoil-starthandle5.Fuelcap

2.Fuelvalve

3.Chokelever7.Oil-drainplug

4.Throttlelever

6.Oilcap/dipstick

8.On/Offswitch

Figure7

1.Cleat4.Channel(spreader)

2.L-bolt5.Rope

3.Wingnut6.Pullgrip

FuelValve

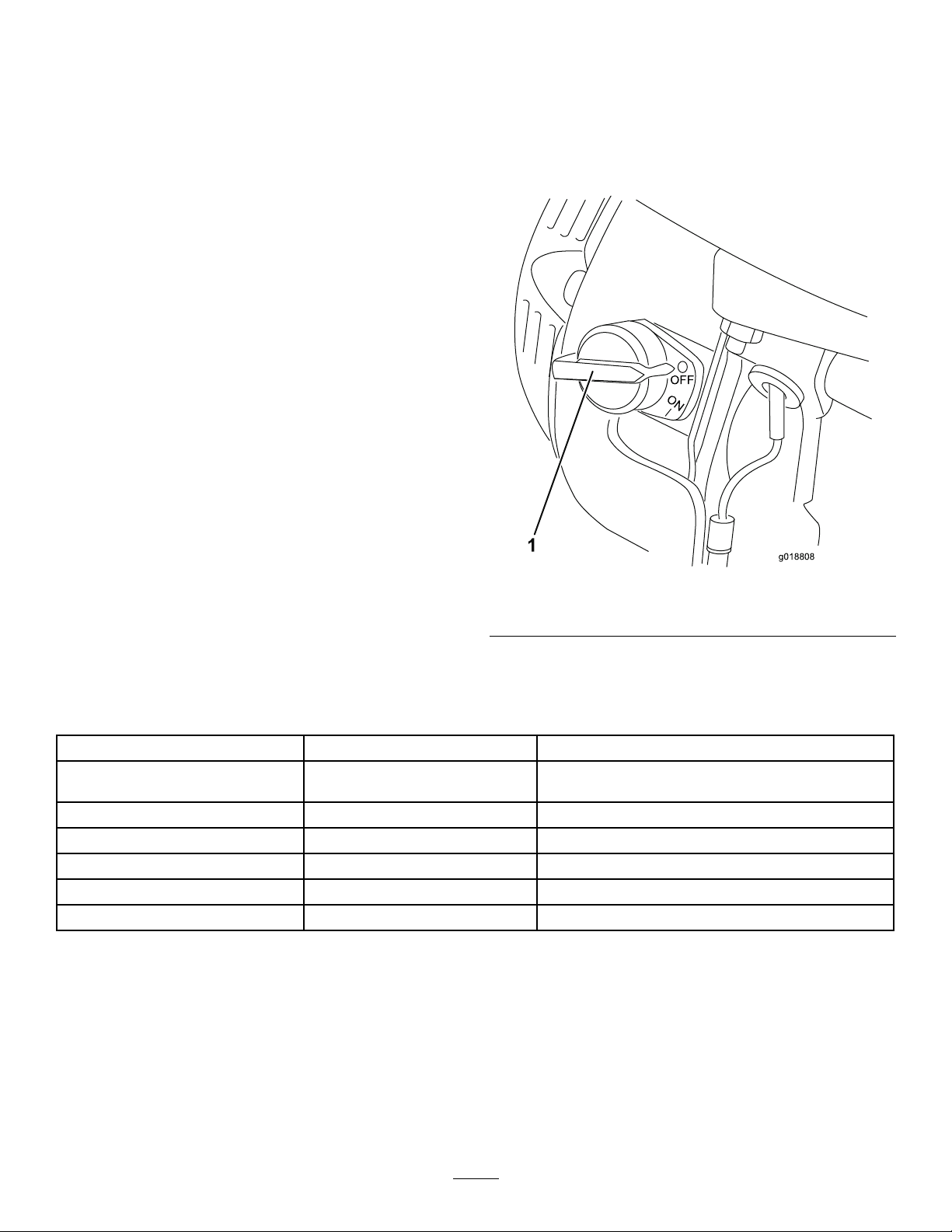

Thefuelvalve(Figure9)islocatedunderneaththechoke

lever.MovetheleverforthefuelvalvetotheOnposition

beforeattemptingtostarttheengine.Whenyouhavenished

screeding,stoptheengineandmovethefuelvalveleverto

theOffposition.

Figure9

1.Fuelvalve3.Throttlelever

2.Chokelever

8

Page 9

ChokeLever

OFF

ON

g018808

1

EngineOn/OffSwitch

Thechokelever(Figure9)isrequiredwhenstartingacold

engine.Beforepullingontherecoil-starthandle,move

thechokelevertotheclosedposition.Oncetheengineis

running,movethechokelevertotheopenposition.Do

notusethechokeiftheengineisalreadywarmeduporthe

airtemperatureishigh.

ThrottleLever

Thethrottlelever(Figure9)controlsthespeed(rpm)ofthe

engine.Itislocatednexttothechokelever.

Recoil-startHandle

Tostarttheengine,pulltherecoil-starthandle(Figure8)

quicklytoturntheengineover.Theenginecontrolsdescribed

abovemustallbesetcorrectlyfortheenginetostart.

Oil-levelSwitch

Theoil-levelswitchislocatedinsidetheengine,anditwill

notallowtheenginetorunwhenoillevelisbelowthesafe

operatinglimit.

TheOn/Offswitch(Figure10)allowstheoperatorofthe

machinetostartandstoptheengine.Thisswitchislocated

onthefrontoftheengine.Itismarkedl(On)andO(Off).

RotatetheOn/OffswitchtotheOnpositiontostartandrun

theengine.RotatetheOn/OffswitchtotheOffpositionto

stoptheengine.

Figure10

1.EngineOn/Offswitch

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Model68052Model68053

Width(withoutspreadersandscreed

board)

Length

Height(withoutscreedboard)122cm(48inch)122cm(48inch)

Weight(withoutscreedboard)53kg(116lb)61kg(134lb)

Screedboardthicknessandheight5cmx15–20cm(2inchx6–8inch)5cmx15–20cm(2inchx6–8inch)

Maximumscreedboardwidth

89cm(35inch)89cm(35inch)

56cm(22inch)56cm(22inch)

457cm(15ft)914cm(30ft)

9

Page 10

Operation

G023140

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperatingthemachine,checkthe

fuelandoillevels,andremovedebrisfromthemachine.

PreparingtoUsetheMachine

•Reviewallofthesafetydecalsonthemachine.

•Useahardhat,hearingprotection,tight-ttinggloves

withoutdrawstringsorloosecuffs,andeyeprotection.

Ameshvisoralonedoesnotprovidesufcienteye

protection;supplementwithprotectiveglasses.

•Ensurethatyouarefamiliarwithsafetyregulationsand

theshutdownproceduresdescribedintheOperator’s

ManualandtheEngineManual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Ensurethatthescreedboardsareingoodcondition,

alignedcorrectlyandsecuretothemachineandspreaders.

•Checkthefuelandoillevelsoftheengine.

OperatorPosition

Youmustbefamiliarwiththeoperatingpositionwhenusing

themachine(Figure11).

and/orenginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelisno

higherthanthescreenonthelterinthefuel

tank.Thisemptyspaceinthetankallows

gasolinetoexpand.

Figure11

AddingFuel

ETHANOL:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolumeis

acceptable.EthanolandMTBEarenotthesame.Gasoline

with15%ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan10%ethanolby

volume,suchasE15(contains15%ethanol),E20(contains

20%ethanol),orE85(containsupto85%ethanol).Using

unapprovedgasolinemaycauseperformanceproblems

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatethemachinewithoutentire

exhaustsysteminplaceandinproperworking

condition.

10

Page 11

DANGER

1

G019799

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacethegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefuelthemachine

ontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturerofthe

stabilizer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

FillingtheFuelTank

Fueltankcapacity:3.1L(0.82USgallon)

Important:Theunusedspaceinthetankallowsthe

gasolinetoexpandwithchangesintemperature.Donot

llthefueltankcompletelyfull.

1.Parkthemachineonalevelsurface,stoptheengine,

andallowtheenginetocool.

2.Cleanaroundthefuelcapandremoveit(Figure12).

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

fuel-containeropening.

•Keepgasawayfromeyesandskin.

Important:Donotmixoilwiththefuel.

RecommendedFuel

UnleadedGasoline

U.S.

Except

U.S.

Pumpoctanerating87orhigher

Researchoctanerating92orhigher

Pumpoctanerating87orhigher

Figure12

1.Fuelcap

3.Addunleadedgasolinetothefueltank,untilthelevel

isatthebottomofthemaximumfuellevelasshown

inFigure13.

UsingFuelStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeepthe

fuelfreshduringstorage.

Important:Donotusefueladditivescontaining

methanolorethanol.

11

Page 12

G020679

1

Figure13

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

1

2

3

4

G019746

1.Maximumfuellevel

4.Installthefuelcapsecurely(Figure12).

5.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

Figure14

Note:T oroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

1.Placethemachineonaat,levelsurface,andstopthe

engine.

2.Allowtheenginetocool.

3.Cleanaroundtheoildipstick.

4.Removetheoilcap/dipstickandwipetheendclean

(Figure15).

ServiceInterval:Beforeeachuseordaily

Important:Use4-cyclemotoroilthatmeetsorexceeds

therequirementsforAPIservicecategory

equivalent).AlwayschecktheAPIservicelabelonthe

oilcontainertobesureitincludestheSJorlater(or

equivalent)rating.

Donotoverllthecrankcasewithoilbecausetheengine

maybedamaged.

Runningtheenginewithalowoillevelcancauseengine

damage.Thistypeofdamageisnotcoveredbythe

warranty.

Note:SAE10W -30isrecommendedforgeneraluse.The

otheroilviscositiesshowninthechartmaybeusedwhenthe

averagetemperatureinyourareaiswithintheindicatedrange.

SJ or later

(or

Figure15

1.Fillport

2.Oilcap/dipstick4.Oillevel(lowerlimit)

3.Oillevel(upperlimit)

5.Slidethedipstickfullyintothellportwithout

threadingitintotheport(Figure15).

6.Removethedipstickandlookattheend.Iftheengine

oillevelislow ,slowlypouronlyenoughoilintothell

porttoraisetheleveltotheFullmarkonthedipstick

(Figure15).

7.Replaceandsecurethedipstick(Figure15).

12

Page 13

StartingandStoppingthe

G019815

1

2

3

G019747

Engine

StartingtheEngine

1.Ontheengine,movethethrottleleverawayfromthe

Minposition,1/3ofthewaytowardtheMaxposition

(Figure16);refertoThrottleLever(page9).

Figure17

Note:IfthechokeleverissettotheClosedpositiontostart

theengine,graduallymovethechokeleverbacktowardthe

Openpositionastheenginewarmsup.Iftheenginestalls

orhesitates,movethechokeleverbacktowardtheClosed

positionuntiltheenginerunssmooth.Allowtheengineto

warmup,thenmovethechokelevertotheOpenposition;

refertoChokeLever(page9).

Figure16

1.Chokelever

2.Fuelvalve

2.MovetheleverofthefuelvalvetotheOnposition—all

thewaytotheright(Figure16);refertoFuelValve

(page8).

3.Positionthechokeleverasfollows:

3.Throttlelever

•Tostartacoldengine,movethechokelevertothe

Closedposition—allthewaytotheleft(Figure16);

refertoChokeLever(page9).

•Tostartawarmengine,movethechokeleverin

theOpenposition—allthewaytotheright.

4.RotatetheengineswitchtotheOnposition(Figure

16);refertoEngineOn/OffSwitch(page9).

StoppingtheEngine

WARNING

Inanemergencysituation,stoptheengine

immediately.

Important:Duringnormaloperation,iftheengine

hasbeenworkinghardorishot,letitidleforaminute

beforestoppingtheengine.Thishelpstocoolthe

enginebeforestopping .

1.EnsurethatthechokeleverisintheOffposition

(Figure16);refertoChokeLever(page9).

2.MovethethrottlelevertotheMinposition(Figure16);

refertoThrottleLever(page9).

3.RotatetheengineswitchtotheOffposition;referto

EngineOn/OffSwitch(page9).

5.Pulltherecoil-starthandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly(Figure17).

Note:Returntherecoil-starthandlegently.

13

Page 14

InstallingandRemovingthe

G020865

5

8

9

5

3

4

7

2

6

ScreedBoards

5.Raisetherearofthemachine10to12inches,and

aligntherearscreedboardtotherearU-channelof

theframe(Figure18).

Note:Usestraight5cmx15to20cm(2inchx6to8inch)

boardsor2-inchthickcontouredmaterial.

Maximumscreedboardwidths:

•Model68052—457cm(15ft)

•Model68053—914cm(30ft)

InstallingtheScreedBoardstothe

Machine

1.Placethemachineonalevel,atsurface.

2.Raisethefrontofthemachine10to12inches,

andaligntheforwardscreedboardtotheforward

U-channeloftheframe(Figure18).

Note:ThefrontU-channelislocatedadjacenttothe

eccentriccover.

6.AlignthescreedboardtotheU-channel,andcenter

theboardtothemachine(Figure18).

7.Securethescreedboardtothemachinebytightening

alltheL-boltsandwingnuts(Figure18).

InstallingtheSpreaders

SpreaderPositionTable

Screed

board

length

Spreader

position

(fromthe

endofthe

screed

board)

457cm

(15ft)

61cm

(2ft)

1.UsingtheSpreaderPositionTable,locateandmarkthe

positionsofthespreadersonbothendsofthescreed

board.

2.Alignchannelsofthespreadertothescreedboards

andseatthespreaderontotheboards(Figure18).

3.Slidethespreaderalongtheboardsuntiltheoutside

edgeofthespreaderisalignedwiththemarkonthe

boardcreatedinstep1.

610cm

(20ft)

91cm

(3ft)

762cm

(25ft)

122cm

(4ft)

914cm

(30ft)

152cm

(5ft)

Figure18

1.U-channel(rightspreader)

2.Eccentricguard7.U-channel

3.U-channel(frame)

4.U-channel(leftspreader)

5.Forwardscreedboard

6.Rearscreedboard

8.Wingnut

9.L-bolt

3.AlignthescreedboardtotheU-channelandcenterthe

boardthemachine(Figure18).

4.LightlytightentheL-boltsintheforwardU-channel

(Figure18).

4.Securethespreadertothescreedboardswiththe

L-boltsandwingnuts(Figure18).

5.Attachthespreadertotheotherendofthescreed

boardbyrepeatingsteps2,3,and4.

RemovingtheSpreadersandScreed

Boards

1.Placethemachineonalevel,atsurface.

2.LoosenthewingnutsandL-boltsthatsecurethe

spreaderstothescreedboards,andremovethe

spreaders(Figure18).

3.Raisetherearofthemachine10to12inches,and

removetherearscreedboardfromtherearU-channel

oftheframe(Figure18).

4.LoosenthewingnutsandL-boltsthatsecuretherear

screedboardtotherearU-channeloftheframe,and

removethescreedboard(Figure18).

5.Raisethefrontofthemachine10to12inches,and

removetheforwardscreedboardfromtheforward

U-channeloftheframe(Figure18).

6.LoosenthewingnutsandL-boltsthatsecurethe

forwardscreedboardtotheforwardU-channelofthe

frame,andremovethescreedboard(Figure18).

7.Carefullylowerthemachine.

14

Page 15

ScreedingaConcreteSurface

G020895

1

2

3

4

5

G020886

LevelingtheConcreteSurface

Thisprocedurelevelsafreshlypouredconcreteprojectto

theformheight.

Note:Theforwardscreedboardislocatedadjacenttothe

eccentricguard.

1.Liftandalignthescreedontotheendoftheconcrete

formswiththeforwardscreedboardatthefrontof

thescreedpass.

2.Starttheengine;refertoStartingtheEngine(page13).

3.MovethethrottlelevertotheFastposition;referto

ThrottleLever(page9).

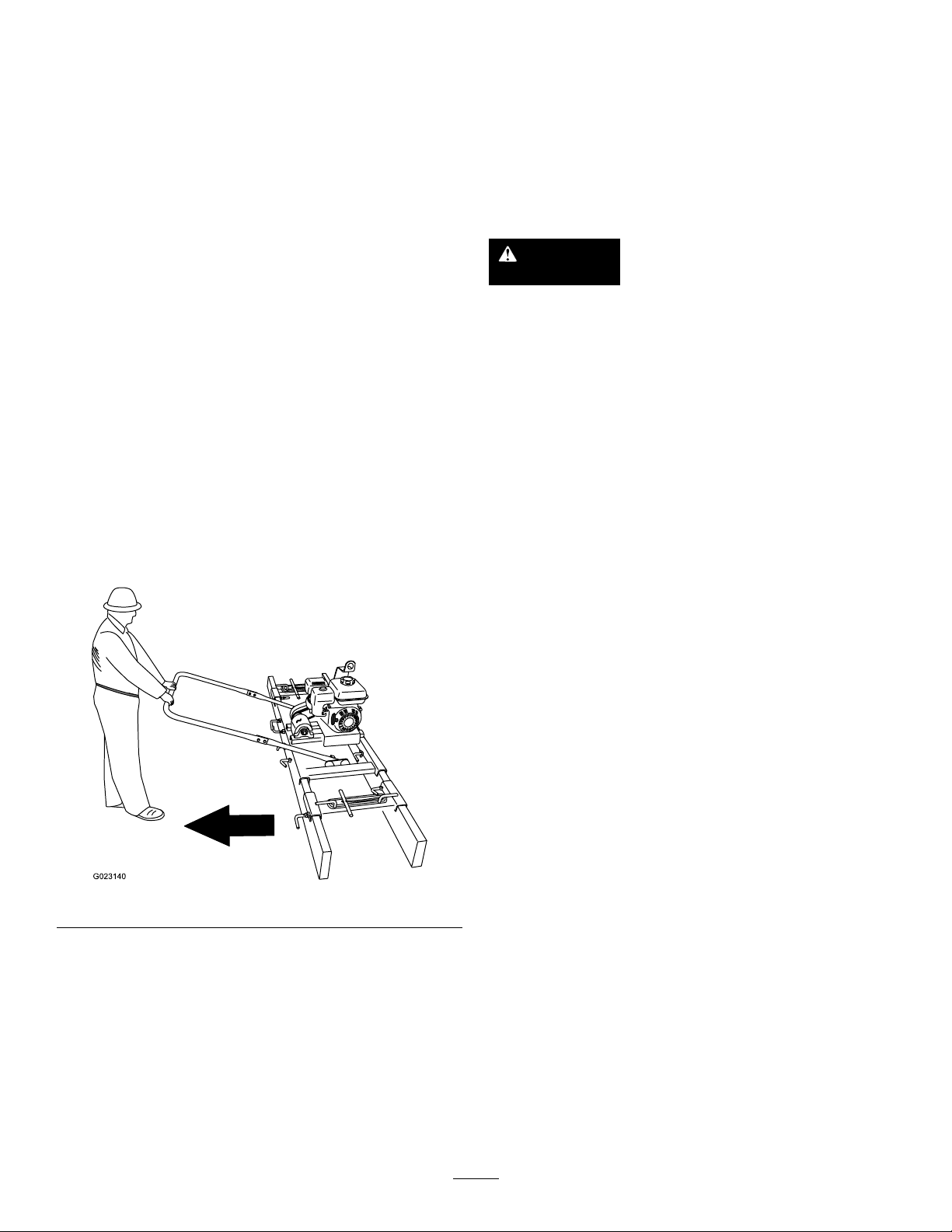

4.Pullthescreedinslow,steadymotionalongthe

concreteforms(Figure20).

Note:Ensurethatanadequateamountofconcreteis

loadedaheadoftheforwardscreedboardfortheentire

screedingpass.

Figure20

Figure19

1.Forwardscreedboard

2.Handlebar5.Rearscreedboard

3.Eccentricguard

4.Liftbracket

Note:Useadditionalpeopletomovethescreedby

havingthempullthescreedwiththetowgripsand

ropesthatareattachedtothespreaders(Figure20).

5.Attheendofthescreedpass,movetheenginethrottle

totheidlepositionandallowtheenginetoidlefor1

minute.

6.Stoptheengineandmovethescreedofftheforms;

refertoStoppingtheEngine(page13).

7.Cleanthescreedofcement,sand,andaggregateafter

eachpasswithwaterandasoft-bristlebrush.

15

Page 16

LiftingtheMachine

G020991

1

2

MovingtheMachinewiththeLifting

Plate

Important:Useliftingequipmentwitha61kg(134lb)

orgreaterliftcapacity.

1.Removethespreadersandscreedboardsfromthe

machine;refertoRemovingtheSpreadersandScreed

Boards(page14).

2.MovetheleverforthefuelvalvetotheOffposition,

refertoFuelValve(page8).

3.Alignthehook,strap,orcableoftheliftingequipment

totheholeintheliftingbracket(Figure21).

Figure21

1.Liftingequipment2.Liftbracket

4.Raisethemachineandmoveittothedesiredlocation.

5.Carefullylowerthemachine.

6.Removetheliftingequipment(Figure21).

16

Page 17

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every300hours

Monthly

MaintenanceProcedure

•Inspectandadjustthebelt.

•Changetheoil.

•Checktheengineoillevel.

•Greasethemachine.

•Inspecttheaircleanerelements.

•Checkforloosefasteners.

•Cleanthemachine.

•Changetheoilwhenoperatedunderheavyloadsorinhightemperatures.

•Cleantheairlterelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheoil.

•Checkthesparkplug.

•Cleanthesedimentcup.

•Replacethepaperaircleanerelement.Replaceitmorefrequentlyindustyoperating

conditions.

•Replacethesparkplug.

•Lubricatetheclutch.

•Inspectandadjustthebelt.

Yearlyorbeforestorage

Important:Refertoyour

•Changetheoil.

•Cleanthefuelsedimentcup.

•T ouchupchippedpaint

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

17

Page 18

CAUTION

G019281

1

G020901

4

5

2

2

3

Disconnectthewiresfromthesparkplugsbeforeyoudoanymaintenance.Setthewiresasidesothat

theydonotaccidentallycontactthesparkplugs.

Premaintenance

Procedures

PreparingtheMachinefor Maintenance

1.Movethemachinetoalevelsurface.

2.Ensurethattheengineandmuferarecool.

3.Removethesparkplugwire,refertoDisconnectingthe

Spark-plugWire(page18).

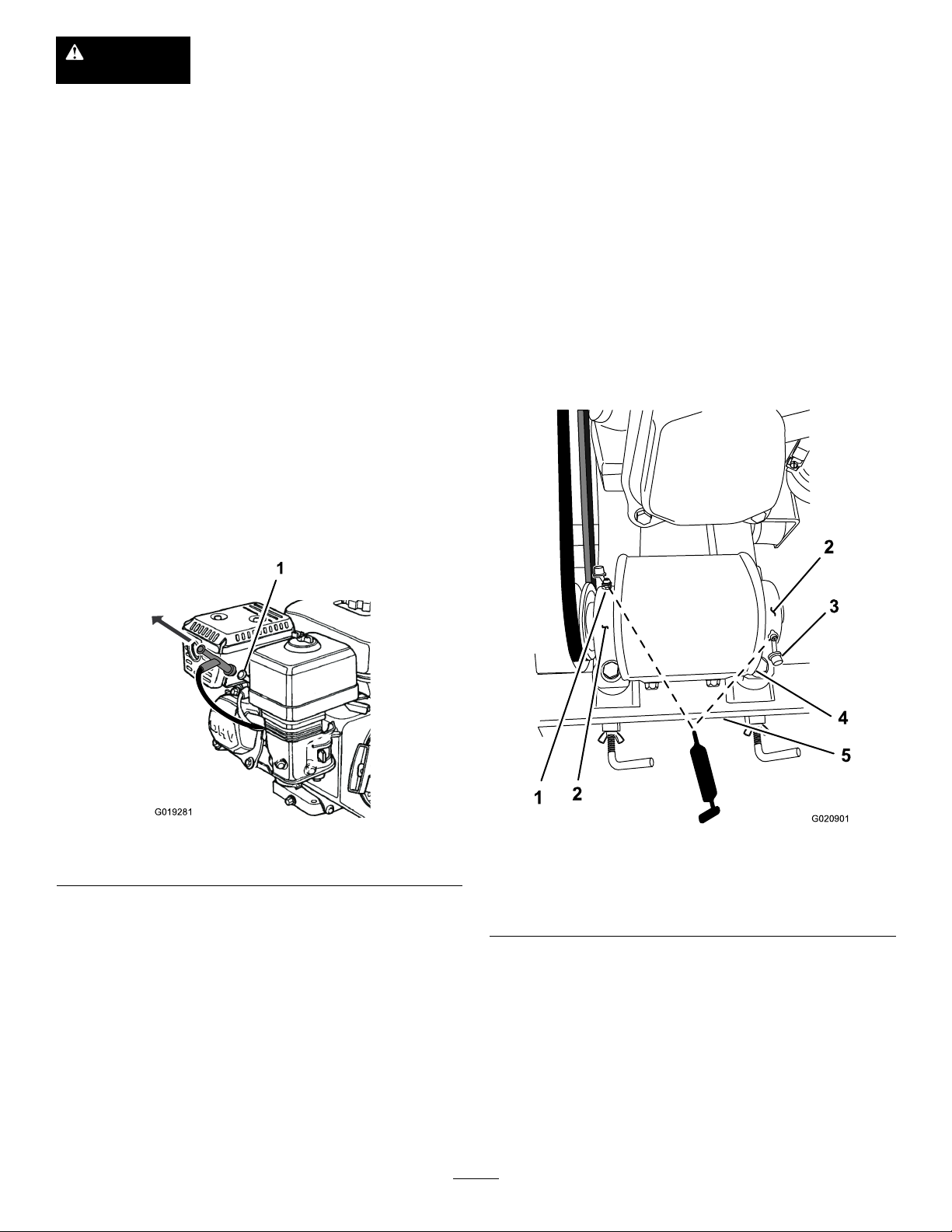

DisconnectingtheSpark-plug Wire

Pullthespark-plugwireofftheterminalofthesparkplug

(Figure22).

Lubrication

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily

Greaseeccentricbearingsevery8operatinghoursand

immediatelyaftereverywashing.

GreaseType:Lithium-basedgrease.

1.Locatethesupportbearingsattheleftandrightsides

oftheeccentricguard(Figure23).

Figure22

1.Sparkplug

1.Greasetting

2.Supportbearing5.Channel(frame)

3.Dustcap

2.Openthedustcapsthatcoverthegreasettingsthat

inthesupportbearings(Figure23).

3.Cleanthegreasettingswitharag.

4.Connectagreaseguntoeachtting(Figure23).

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately1or2pumps).

6.Wipeupanyexcessgreasewithacleanrag.

7.Closethedustcaps(Figure23).

18

Figure23

4.Eccentricguard

Page 19

EngineMaintenance

1

2

3

4

5

6

G019728

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspecttheair

cleanerelements.

Every50hours—Cleantheairlterelements.Clean

themmorefrequentlyindustyoperatingconditions.

Every300hours/Yearly(whichevercomes

rst)—Replacethepaperaircleanerelement.Replace

itmorefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagewilloccur.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug;referto.

3.Removethenutthatsecuresthecover(Figure24).

5.Removethefoamandpaperelementsfromthebase

(Figure24).

6.Removethefoamelementfromthepaperelement

(Figure24).

7.Inspectthefoamandpaperelements,andreplacethem

iftheyaredamagedorexcessivelydirty.

8.Ifthepaperelementisexcessivelydirty,replaceit.

Note:Nevertrytobrushdirtoffthepaperelement;

brushingforcesthedirtintothebers.

9.Cleanthefoamelementinwarm,soapywaterorin

anonammablesolvent.

Note:Donotusegasolinetocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

10.Rinseanddrythefoamelementthoroughly.

11.Dipthefoamelementincleanengineoil,thensqueeze

outtheexcessoil.

Note:Excessoilinthefoamelementrestrictstheair

owthroughtheelementandmayreachthepaper

lterandclogit.

12.Wipedirtfromthebaseandthecoverwithamoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

13.Installtheaircleanerelementsandensurethattheyare

properlypositioned.

14.Securelyinstallthecoverwiththenut.

Figure24

1.Covernut

2.Cover

4.Removethecover.

3.Wingnut5.Paperelement

4.Foamelement6.Base

19

Page 20

ChangingtheEngineOil

G019297

1

2

3

4

5

0 20 40 60

80

10 0°F

-20 -10 0 10 20 30 40 °C

5W–30 · 10 W– 30

30

1

G019298

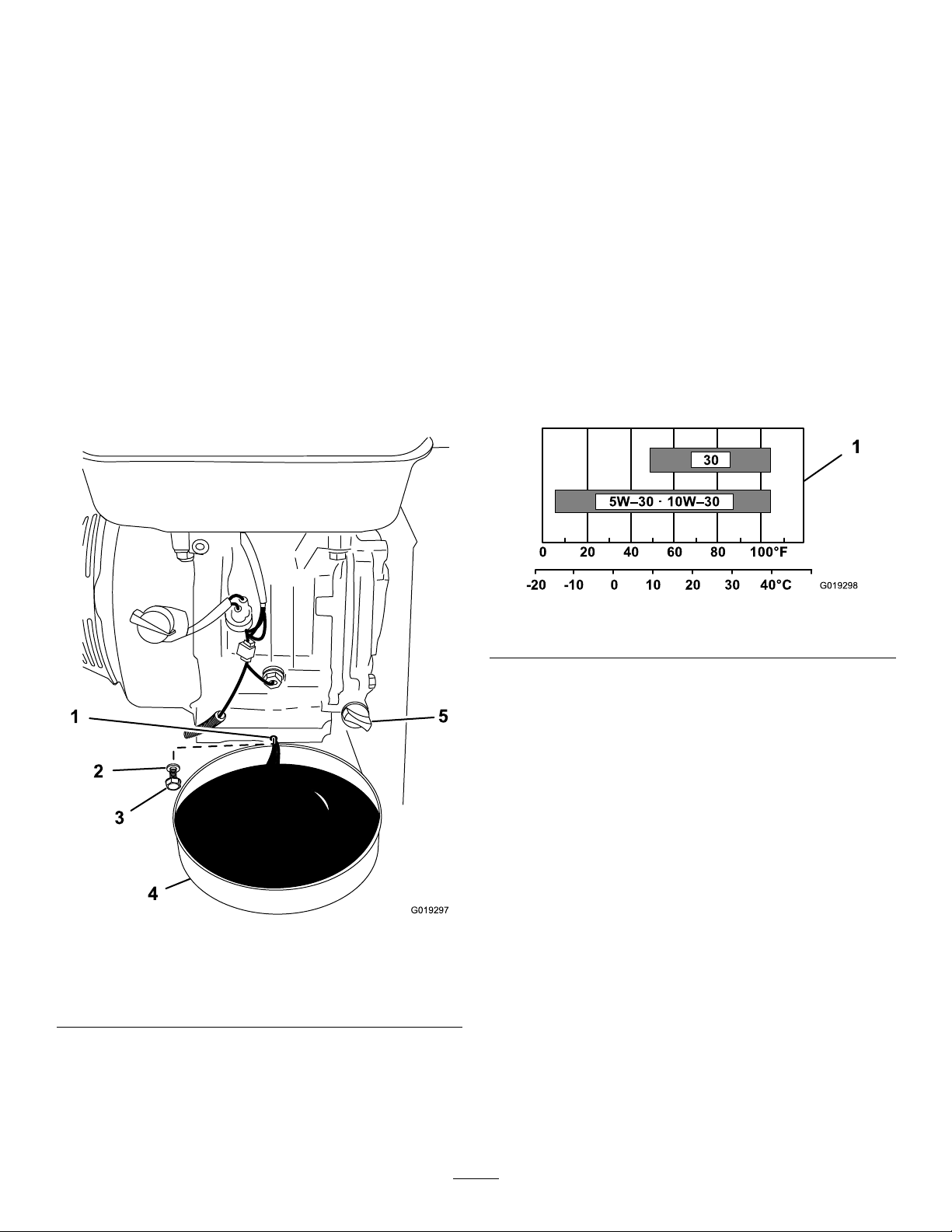

ServiceInterval:Aftertherst50hours/Monthly

(whichevercomesrst)—Changetheoil.

Every100hours/Every6months(whichevercomes

rst)—Changetheoil.

Every25hours—Changetheoilwhenoperatedunder

heavyloadsorinhightemperatures.

Yearlyorbeforestorage—Changetheoil.

DrainingtheEngineOil

1.Starttheengineandletitrunveminutes;referto

StartingtheEngine(page13).

Note:Thiswarmstheoilsoitdrainsbetter.

2.Placeadrainpan,witha1.9L(2USqt)capacityor

greater,undertheoil-drainportoftheengine(Figure

25).

Note:Disposeoftheusedoilatacertiedrecycling

center.

FillingtheEngineCrankcasewithOil

Important:Use4-strokemotoroilthatmeetsorexceeds

therequirementsforAPIservicecategory

equivalent).AlwayschecktheAPIservicelabelonthe

oilcontainertobesureitincludestheSJorlater(or

equivalent).

Runningtheenginewithalowoillevelcancauseengine

damage.Thistypeofdamageisnotcoveredbywarranty.

Donotoverllthecrankcasewithoilbecausetheengine

maybedamaged.

Note:SAE10W-30isrecommendedforgeneraluse.

Otherviscositiesshowninthechartmaybeusedwhenthe

averagetemperatureinyourareaiswithintheindicatedrange.

Crankcaseoilcapacity:0.85L(0.61USqt)

SJ or later

(or

Figure26

1.Oilviscosityrangeforambientoperatingtemperatures

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDealer.

1.Removetheoilcap/dipstick(Figure27).

Figure25

1.Drainport4.Drainpan

2.Washer

3.Drainplug

5.Oilcap/dipstick

3.Removethedrainplugandwasher,anddraintheoil

(Figure25).

4.Whentheoilhasdrainedcompletely,installthedrain

plugwithanewwasher,andwipeupanyspilledoil

(Figure25).

20

Page 21

1

2

3

4

G019746

Figure28

G019749

Figure27

1.Fillport

2.Oilcap/dipstick4.Oillevel(lowerlimit)

3.Oillevel(upperlimit)

2.Slowlypourapproximately80%ofthespecied

amountofoilintothellport(Figure27).

3.Addadditionaloiltobringtheoilleveltotheupper

limitmarkonthedipstick;refertoCheckingthe

EngineOilLevel(page12).

4.Installtheoilcap/dipstick(Figure27).

ServicingtheSparkPlug

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Checkthe

sparkplug.

Every300hours/Yearly(whichevercomes

rst)—Replacethesparkplug.

Note:Usea20mm(13/16inch)sparkplugwrenchfor

removingandinstallingthesparkplug.

RemovingtheSparkPlug

1.Parkthemachineonalevelsurfaceandturnoffthe

engine;refertoStoppingtheEngine(page13).

2.Ensurethatthemachinesurfacesarecool.

3.Pullthespark-plugwireofftheterminalofthespark

plug(Figure28).

1.Sparkplug

2.Wire

4.Cleanaroundthesparkplug.

5.Rotatethesparkplugcounterclockwiseusinga20mm

(13/16inch)spark-plugwrenchtoremovetheplug

andsealingwasher(Figure29).

Figure29

CheckingtheSparkPlug

Note:Useagappingtool/feelergaugetocheckandadjust

theairgap.Installanewsparkplugifnecessary.

AirGap:0.7to0.8mm(0.028to0.031inch)

Sparkplugtype:BPR6ES(NKG)orequivalent

1.Lookatthecenterofthesparkplug(Figure30).Ifyou

seelightbrownorgrayontheinsulator,theengineis

operatingproperly.

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

21

Page 22

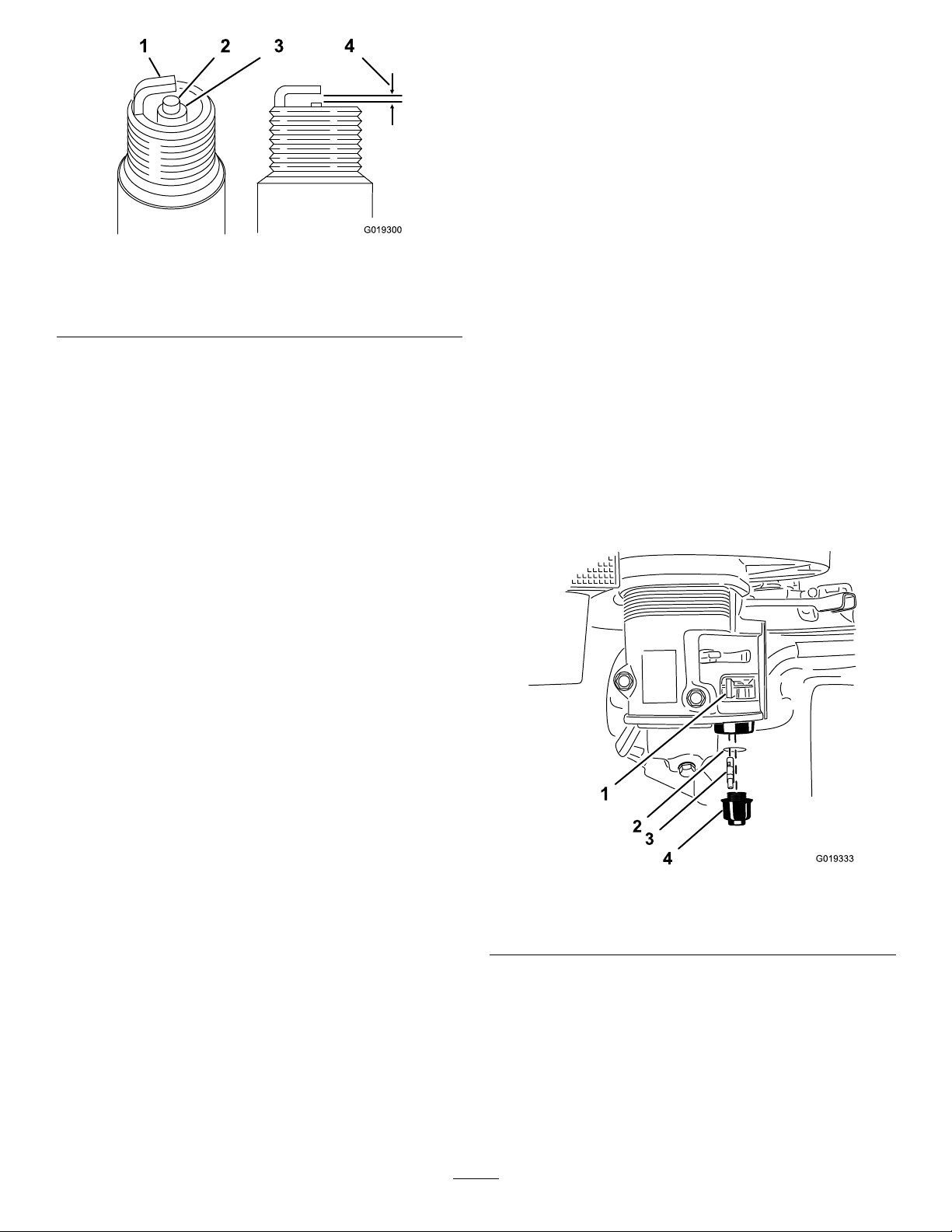

G019300

1 2

4

3

Figure30

2

3

4

1

G019333

1.Sideelectrode

2.Centerelectrode4.0.7to0.8mm(0.028to

2.Useagappingtoolforsparkplugsorafeelergaugeto

measurethegapbetweenthesideelectrodeandcenter

electrode(Figure30).

3.Ifthemeasuredgapisnotwithinthespeciedrange,

dothefollowing:

A.Ifthegapistoosmall,carefullybendtheside

electrodeawayfromthecenterelectrodeuntilthe

gapbetweentheelectrodesiswithinthemeasured

airgaprange.

B.Ifthegapistoolarge,carefullybendtheside

electrodetowardfromthecenterelectrodeuntil

thegapbetweentheelectrodesiswithinthe

measuredairgaprange.

3.Insulator

0.031inch)gap

FuelSystem

Maintenance

ServicingtheFuelSystem

CleaningtheSedimentCup

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Cleanthe

sedimentcup.

Yearlyorbeforestorage—Cleanthefuelsedimentcup.

Underneaththefuelvalveisasedimentcuptocatchdirtin

thefuel.

1.Parkthemachineonalevelsurfaceandstoptheengine;

refertoStoppingtheEngine(page13).

2.Ensurethattheengineandtheexhaustsystemsurfaces

arecool.

3.MovetheleverofthefuelvalvetotheOffposition,all

thewaytotheleft(Figure31).

4.Unscrewthesedimentcup.

5.RemovethefuellterandO-ring(Figure31).

Note:MakesurenottomisplacetheO-ring

InstallingtheSparkPlug

Important:Ensurethatthegapbetweenthesideand

centerelectrodesiscorrectbeforeinstallingthespark

plug.

1.Threadthesparkplugclockwiseintothespark-plug

holebyhand.

Note:Avoidcrossthreadingthesparkplugwiththe

threadsofthespark-plughole.

2.Rotatesparkplugclockwiseusinga20mm(13/16

inch)spark-plugwrenchuntiltheplugandsealing

washerareseated(Figure29).

3.Tightentheplugasfollows:

•Wheninstallinganin-servicesparkplug,tighten

thepluganadditional1/8to1/4turn.

•Wheninstallinganewsparkplug,tightentheplug

anadditional1/2turn.

4.Installthespark-plugwirepushingthewireontothe

terminaloftheplug(Figure28).

Figure31

1.Fuelvalve(Off)3.Fuellter

2.O-ring4.Sedimentcup

Note:DonotcleantheO-ringinsolvent.

6.Cleanthefuellterandsedimentcupusinga

nonammablesolventanddrycarefully.

7.WipetheO-ringwithaclean,drycloth.

8.Installthefuellterinthebottomofthecarburetor

(Figure31).

9.AligntheO-ringintothegrooveinthesedimentcup

andinstallthesedimentcuptofuelvalvehousing.

22

Page 23

10.MovetheleverofthefuelvalvetotheOnposition(all

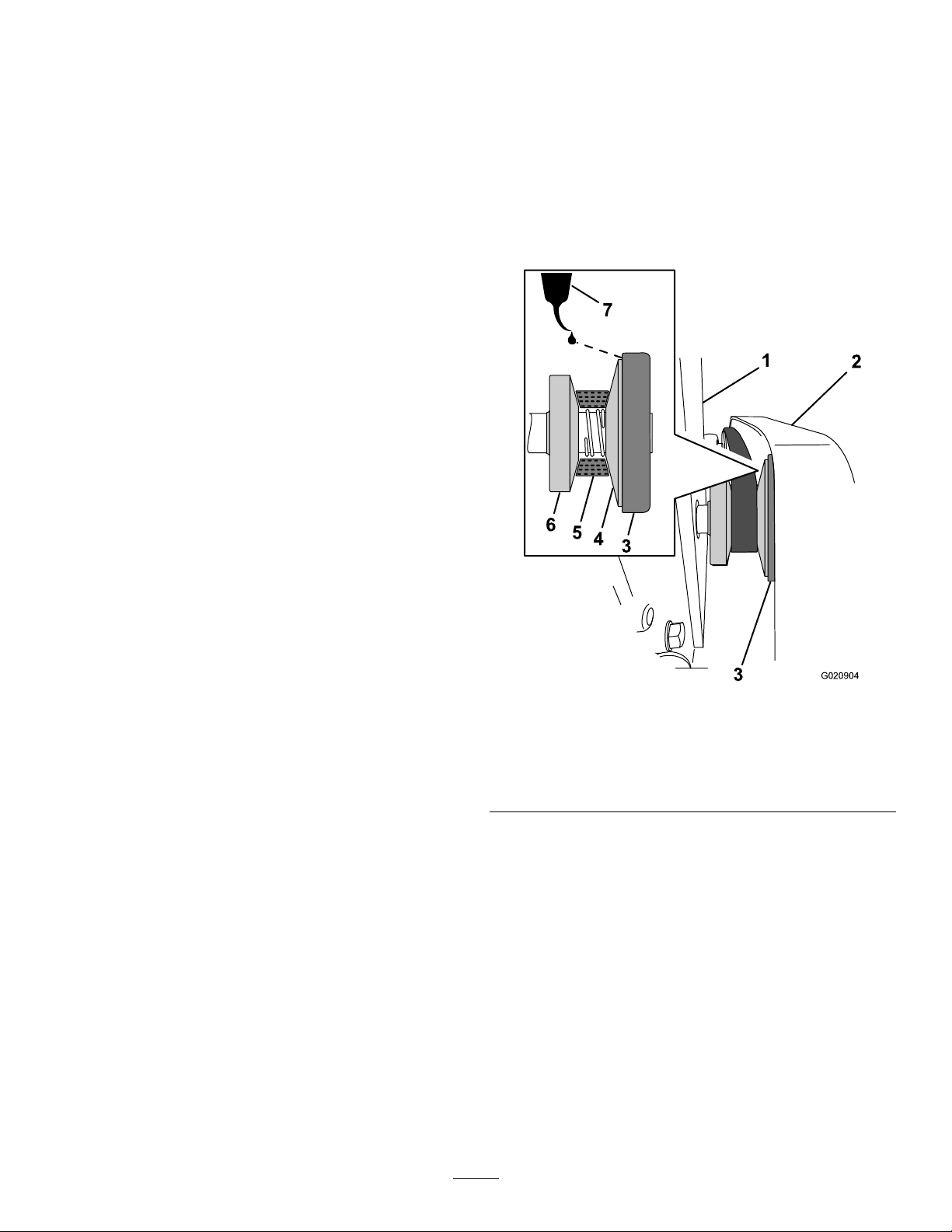

G020904

1

2

3

7

3

4

5

6

thewaytotheright)andcheckforleaks.Ifitleaks,

replacetheO-ring.

DriveSystem

Maintenance

LubricatingtheClutch

ServiceInterval:Monthly

1.Fromthebackofthemachine,locatetheclutchcover

thatisbetweentheliftingbracketandthebelt(Figure

32).

Figure32

1.Liftingbracket

2.Beltguard6.Fixedcone

3.Clutchcover7.SAE5W-30oil

4.Slidingcone

2.Apply2or3dropsofSAE5W-30oilbetweenthe

clutchcoverandtheslidingcone(Figure32).

5.Belt

23

Page 24

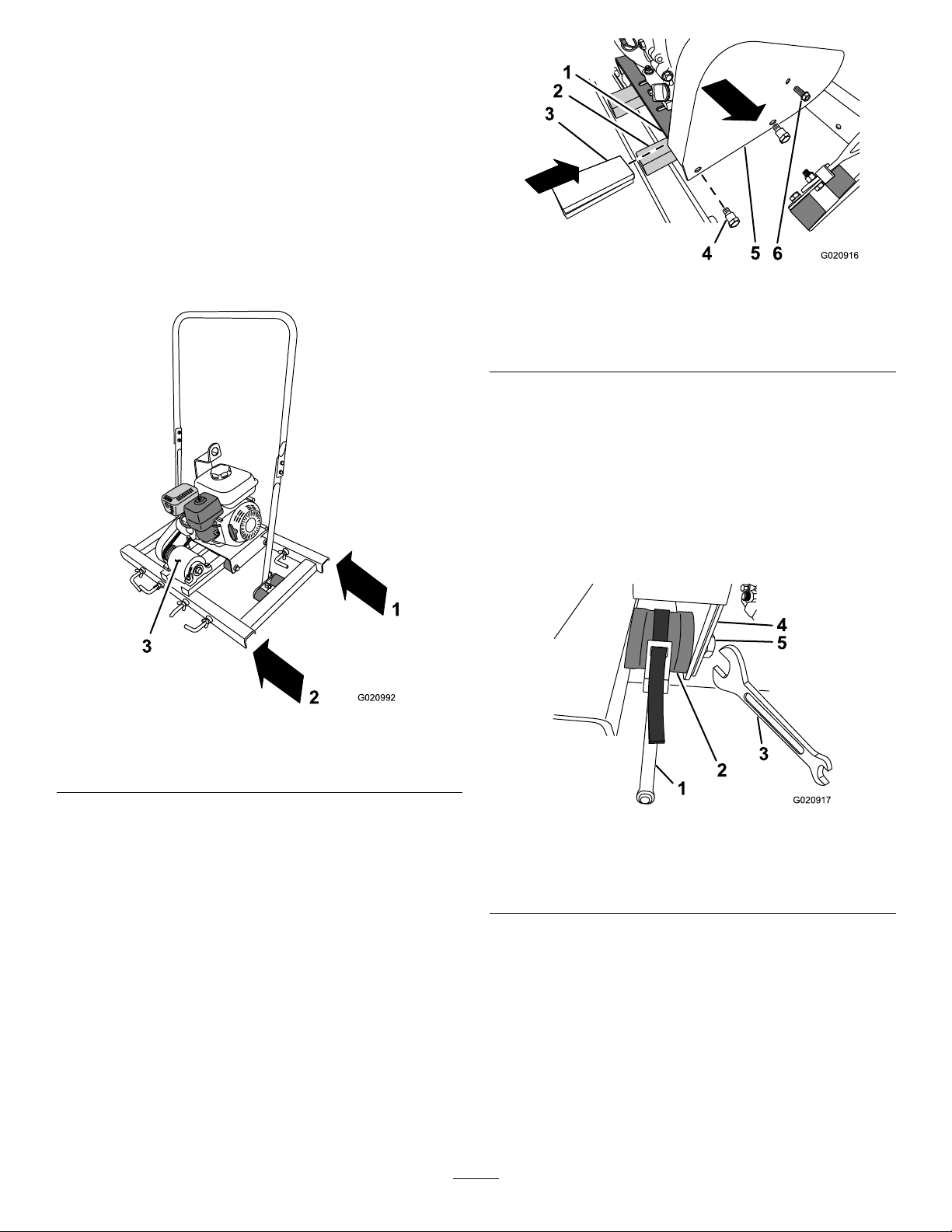

BeltMaintenance

1

2

3

G020992

G020916

1

2

3

6

4

5

G020917

4

5

3

2

1

RemovingandInstallingthe BeltGuard

RemovingtheBeltGuard

1.Atthebackofthemachine,locatetheright-cross

channeloftheframe(Figure33andFigure34).

Note:Thebackofthemachineisonthesideopposite

fromtheeccentricguard.

Figure33

Figure34

1.Enginedeck

2.Right-crosschannel5.Beltguard

3.Spacer6.Bolt(1/4inch)

4.Shoulderbolt(3/8inch)

Note:Thespacerwillsupporttheenginewhenthe2

bolts(3/8inch)areremoved.

3.Removethebolt(1/4inch)fromthebeltguard(Figure

34).

4.Removethe2shoulderbolts(3/8inch)fromthebelt

guard,andremovethebeltguard(Figure34).

Note:Useastrapwrenchtokeeptheisolatorfrom

rotatingwhenremovingthe3/8inchbolt(Figure35).

1.Backofthemachine

2.Frontofthemachine

2.Inserta32to38mm(1-1/4to1-1/2inch)spacer

betweentheright-crosschannelandtheengineplate

(Figure34).

3.Eccentricguard

Figure35

1.Strapwrench

2.Isolator

3.Wrench

4.Beltguard

5.Bolt(3/8inch)

24

Page 25

InstallingtheBeltGuard

G020922

1

2

3

1

2

G020942

1.Alignthebeltguardoverthepulleys.

2.Applymediumstrength(serviceremovablethread

lockingcompoundtothethreadsofthebolt(1/4inch

and2shoulderbolts(3/8inch).

3.Alignthe(1/4inch)holeinthebeltguardwiththehole

inthebeltguardbracket(Figure34andFigure36).

4.Threadthebolt(1/4inch)throughthebeltguardand

intothebelt-guardbracket(Figure34andFigure36).

Note:Donottightenthe1/4inchbolt.

5.Aligntheholes(3/8inch)inthebeltguardwiththe

threadsintheisolators(Figure34andFigure35).

6.Securebeltguardtotheisolatorswiththe2shoulder

bolts(3/8inch)(Figure34).

Note:Useastrapwrenchkeeptheisolatorfrom

rotatingwhentighteningthe3/8inchbolt(Figure35).

7.Tightenthe1/4inchbolt.

8.Removethespacersthatarebetweentheright-cross

channelandtheengineplate(Figure34).

Figure36

ServicingtheBelt

ServiceInterval:Aftertherst25hours—Inspectand

adjustthebelt.

Monthly—Inspectandadjustthebelt.

InspectingtheBelt

1.Removethebeltguard;refertoRemovingtheBelt

Guard(page24).

2.Examinethebeltforwearordamage.Ifthebeltsare

wornordamaged,replacethebelts;refertoInspecting

theBelt(page25).

3.Examinethepulleysforwear,damageand

misalignment.

4.Lubricatetheclutch;refertoLubricatingtheClutch

(page23).

5.Installthebeltguard;refertoInstallingtheBeltGuard

(page25).

ReplacingtheBelt

RemovingtheBelt

1.Eccentricpulley3.Belt-guardbracket

2.Belt

3.Slipthebeltofftheclutchandremovefromthe

machine(Figure37).

Figure37

1.Belt

2.Clutch

1.Removethebeltguard;refertoRemovingtheBelt

Guard(page24).

2.Liftthebeltupandovertheshoulderoftheeccentric

pulley(Figure36).

Note:Rotatetheeccentricpulleybyhandtohelp

removethebelt.

25

Page 26

InstallingtheBelt

G020967

1

2

3

4

213 1

1 2 13

G020966

4

1.Alignthebeltovertheclutch(Figure37).

2.Pullthebelttowardtheeccentricpulley(Figure36).

3.Slipthebeltovertheshoulderoftheeccentricpulley

(Figure36).

Note:Rotatetheeccentricpulleybyhandtohelp

installthebelt.

AdjustingtheBelt

1.Attheclutch,alignthebeltagainstthexedcone.

Note:Useaatbladedscrewdrivertopositionthe

beltagainstthexedcone.

Figure39

1.Bolt3.Enginedeck

2.Nut4.Eccentricpulley

4.Adjustthegapbetweenthebeltandtheclutchas

follows:

•Movetheengineawayfromtheeccentricpulleyto

reducethegapbetweenthebeltandthesliding

cone(Figure39).

•Movetheenginetowardfromtheeccentricpulley

toincreasethegapbetweenthebeltandthe

slidingcone(Figure39).

5.Whenthegapmeasurementiswithinthe0.76to1.27

mm(0.03to0.05inch)range(Figure38),tightenthe

boltsandnutsthatsecuretheenginetotheenginedeck

to18N-m(13lb-ft).

6.Installthebeltguard;refertoInstallingtheBeltGuard

(page25).

Figure38

1.Fixedcone

2.Belt

2.Measurethegapbetweenthebeltandtheslidingcone

3.0.76to1.27mm(0.03to

0.05inch)gap

4.Slidingcone

(Figure38).Ifthegapis0.76to1.27mm(0.03to0.05

inch),skiptostep6.

3.Loosentheboltsandnutsthatsecuretheenginetothe

enginedeck(Figure39).

26

Page 27

Cleaning

CleaningtheMachine

Regularcleaningandwashingwillincreasethelifespanof

themachine.Cleanthemachineaftereachuse,beforethe

cementdries.

Ensurethatthefueltankcapandoilcap/dipstickaresecure

toavoidgettingwaterinthetank.

Usecarewhenusingahigh-pressuresprayer,becauseitcan

damagewarningdecals,instructionsigns,andtheengine.

Important:Lubricatetheeccentricbearingsafter

cleaning;refertoLubrication(page18).

Storage

Important:Youcanwashthemachinewithmild

detergentandwater.Donotpressurewashtheengine

oreccentricbearings.

1.Removeconcrete,sand,andaggregatefromthe

externalpartsofthemachine,especiallytheengine.

Cleandirtfromtheoutsideoftheengine'scylinder

headnsandhousing.

2.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page19).

3.Greasethemachine;refertoGreasingtheMachine

(page18).

4.Lubricatetheclutch;refertoLubricatingtheClutch

(page23).

5.Changetheengineoil;refertoChangingtheEngine

Oil(page20).

6.Removethesparkplugandchecktheconditionof

each;refertoServicingtheSparkPlug(page21).

7.Forstorageover30days,conditionthefuelsystemas

follows:

Important:Donotuseanalcohol-basedstabilizer

(ethanolormethanol).

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuelandusedatalltimes.

Donotstorestabilizerconditionedfuelforover90

days.

A.Addapetroleumbasedstabilizer/conditionerto

fuelinthetank.Followmixinginstructionsfrom

stabilizermanufacturer.

B.Starttheengineandrunituntilitstops.

C.Choketheengine.

D.Startandruntheengineuntilitwillnotstartagain.

E.Disposeoffuelproperly .Recycleasperlocal

codes.

8.Forstorageover90days,conditiontheengineas

follows:

A.Removethespark-plugwirefromthesparkplug

B.Removethesparkplugfromtheengineandpour

twotablespoonsofengineoilintothesparkplug

hole.

C.Placeragsoverthesparkplugholetocatchany

oilsprayandthenpulltherecoil-starthandleto

distributetheoilinsidethecylinder.

D.Installthesparkplug,butdonotinstallthe

spark-plugwire.

9.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamagedordefective.

10.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

27

Page 28

11.Storethemachineunitinaclean,drygarageorstorage

area.

12.Coverthemachinetoprotectitandkeepitclean.

28

Page 29

Troubleshooting

Problem

Theenginewillnotstart.

Theenginelackspowerorrunsrough.

PossibleCauseCorrectiveAction

1.Thefuel-valveleverisintheOff

position.

2.Thechokeisclosed.

3.Thechokeisopen.

4.TheengineOn/OffswitchisintheOff

position.

5.Theengineoillevelislow(engines

withtheoil-levelswitch).

6.Thefueltankisempty.6.Fillthefueltankwithfreshfuel.

7.Theenginecontainsbad/oldfuel.7.Drainthefueltankandcarburetor.

8.Thesparkplugisfouledorimproperly

gapped.

9.Thesparkplugiswetwithfuel(ooded

engine).

10.Thespark-plugwireislooseor

disconnected.

1.Theairlterisrestricted.1.Cleanorreplacetheairlter

2.Theenginecontainsbad/oldfuel.2.Drainthefueltankandcarburetor.

3.Thereiswaterorcontaminationinthe

fuel.

4.Thefuellineisrestricted.4.Cleanthefuellterandsedimentcup.

5.Thechokeisclosed

6.Thesparkplugiswornorhasbuildup

ontheelectrodes.

7.Thereistoomuchoilintheengine

crankcase.

1.Movethefuel-valvelevertotheOn

position.

2.Openthechokewhenstartingahot

engine.

3.Closethechokewhenstartingacold

engine.

4.RotatetheswitchtotheOnposition.

5.Filltheengine,withtherecommended

oil,totheproperlevel.

Fuelthemachinewithfreshgasoline.

8.Gaporreplacethesparkplug.

9.Removethesparkplug,dryit,and

installtheplug.Starttheenginewith

thethrottleintheMaxposition.

10.Removethespark-plugwire,cleanthe

spark-plugterminalandtheterminal

socketinthebootofthespark-plug

wire,andreinstallthespark-plugwire.

element(s).

Refuelwithfreshgasoline.

3.Drainthefueltankandcarburetor.

Fuelthemachinewithfreshgasoline.

5.Openthechoke.

6.Checktheelectrodegapandadjustor

replacethesparkplug.

7.Draintheoiltotheproperlevel.

Thebeltslipsorcomesoffthepulleys.

Theeccentricrotateswhenthethrottleof

theengineisintheidleposition.

throttleoftheengineisintherunposition.

throttleoftheengineisintherunposition.

1.Thebelttensionisinsufcient.

2.Thebeltisworn.2.Replacethebelt.

3.Theeccentricpulleyorclutchisworn.

4.Theeccentricpulleyismisalignedto

theclutch.

1.Thebelttensionisnotadjusted

correctly.

1.Thebelttensionisnotadjusted

correctly.

2.Theclutchisstuck.

1.Thebeltisworn.1.Replacethebelt. Theeccentricrotateslowlywhenthe

2.Thebelttensionisnotadjusted

correctly.

1.Adjustthebelttension.

3.ContactyourAuthorizedService

Dealer.

4.Alignthepulleytotheclutch.

1.Adjustthebelttension.

1.Adjustthebelttension. Theeccentricdonotrotatewhenthe

2.ContactyourAuthorizedService

Dealer.

2.Adjustthebelttension.

29

Page 30

Notes:

30

Page 31

Notes:

31

Page 32

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

Concrete,

Masonry,and

Compaction

Equipment

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourT oroConcrete,Masonry ,

andCompactionEquipmentProductslistedbelowtobefreefromdefectsin

materialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ConcreteMixers

•SpindleBearingsLifetime*(originalowneronly)

MortarMixers1year

•DrumBearingsandSealsLifetime*(originalowneronly)

ForwardPlateCompactors

ReversiblePlates1year

RammerCompactors

MudBuggy1year

VibratingTrenchRoller2years

ConcreteSaws

MasonrySaws

PowerTrowels1year

Screeds

ConcreteVibrators

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

LifetimeWarranty-Ifthebearing(s)orseal(s)onyourmixerfail,itwillbereplacedunderwarranty ,

atnocostforpartsorlabor.

1year

2years

2years

1year

1year

1year

1year

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow .

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’sanalysis

orwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:800-888-9926

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromT oroandhave

signedtheT oroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

productoperationinclude,butarenotlimitedto,belts,wipers,spark

plugs,tires,lters,gaskets,wearplates,seals,O-rings,drivechains,

clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0288RevC

Loading...

Loading...