Page 1

FormNo.3421-193RevB

PT-36PowerTrowel

ModelNo.68048—SerialNo.402000000andUp

ModelNo.68049—SerialNo.402000000andUp

ModelNo.68050—SerialNo.402000000andUp

ModelNo.68051—SerialNo.402000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-193*B

Page 2

WARNING

Introduction

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,

andmaintainedforthepreventionofre.Otherstates

orfederalareasmayhavesimilarlaws.GenuineT oro

sparkarrestersareapprovedbytheUSDAForestry

Service.

Thismachineisusedtocreateasmoothnishto

concreteslabs.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

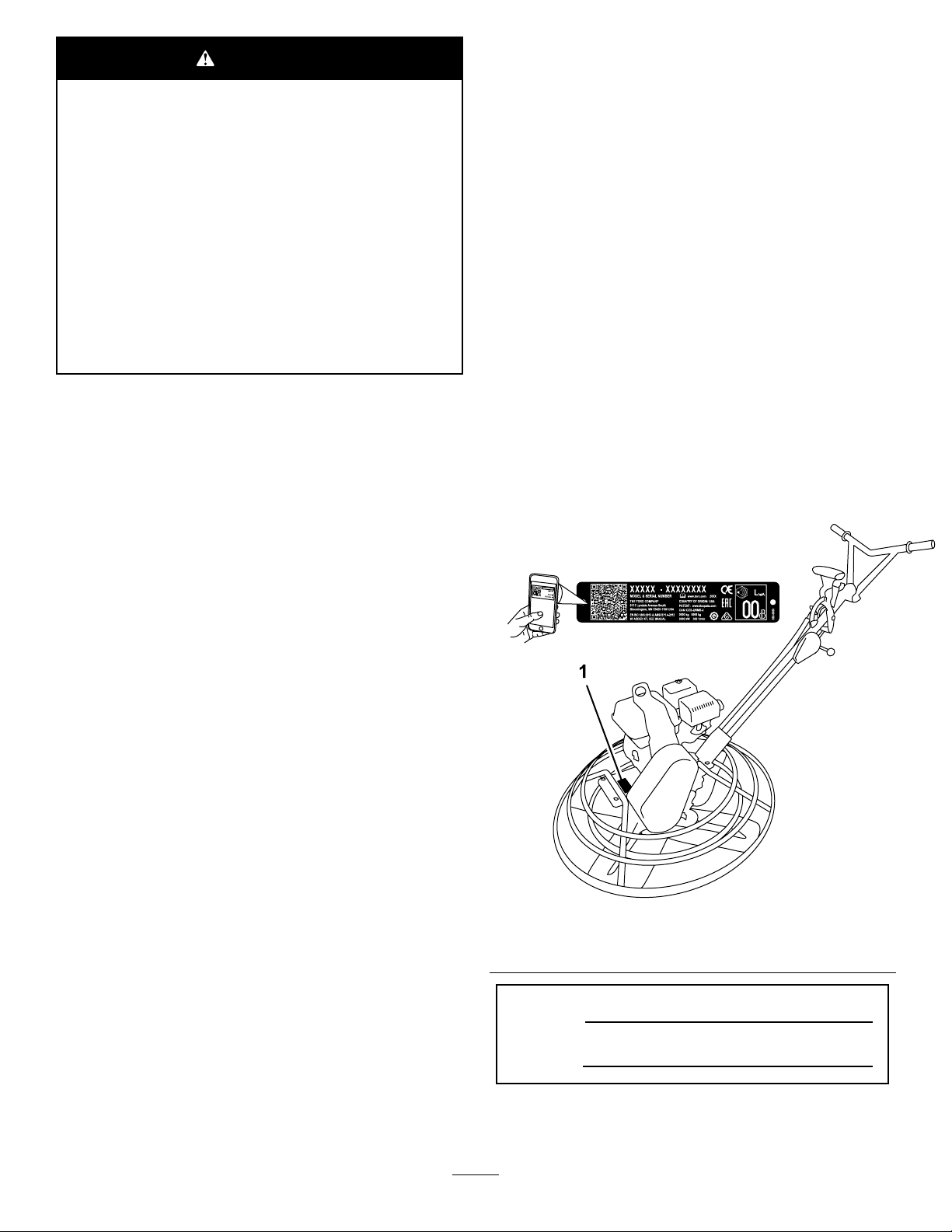

andserialnumbersofyourproductready.Figure

1illustratesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Becauseinsomeareastherearelocal,state,or

federalregulationsrequiringthatasparkarresterbe

usedontheengineofthismachine,asparkarresteris

availableasanoption.Ifyourequireasparkarrester,

contactyourAuthorizedServiceDealer.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

g239848

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

SerialNo.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................6

ProductOverview.....................................................7

Controls.............................................................7

g000502

Specications....................................................9

Attachments/Accessories...................................9

Operation..................................................................9

CheckingtheEngine-OilLevel............................9

CheckingtheGearcaseOilLevel......................10

CleaningDebrisfromtheMachine....................10

FoldingandUnfoldingtheHandle.....................10

AddingFuel.......................................................11

StartingtheEngine...........................................13

ShuttingOfftheEngine.....................................13

OperatingtheMachine.....................................13

Maintenance...........................................................14

RecommendedMaintenanceSchedule(s)...........14

Pre-MaintenanceProcedures..............................14

DisconnectingtheSpark-PlugWire..................14

Lubrication..........................................................15

LubricatingtheBladeArms...............................15

EngineMaintenance...........................................15

ServicingtheAirCleaner..................................15

ServicingtheEngineOil....................................16

ServicingtheGearcaseOil...............................17

ServicingtheSparkPlug...................................18

BeltMaintenance................................................19

CheckingtheBelt,PulleyAlignment,Belt

Tension,andBelt-GuideGap........................19

RemovingtheBeltGuard..................................19

InstallingtheBeltGuard....................................19

RemovingtheBelt............................................20

InstallingtheBelt..............................................20

AligningthePulleys..........................................20

AdjustingtheDyna-Clutch................................20

AdjustingtheBeltGuide...................................21

ControlsSystemMaintenance.............................22

AdjustingtheTiltKnob......................................22

AdjustingtheProPitchLinkageRod..................22

TestingtheDyna-ClutchLever..........................23

AdjustingtheBlades.........................................23

AdjustingtheBladeArms..................................25

Storage...................................................................25

Troubleshooting......................................................26

3

Page 4

Safety

–Extinguishallcigarettes,cigars,pipes,and

othersourcesofignition.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofcausingseriousinjury .

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,

anodorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinan

enclosedarea.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readorunderstandtheinformation,itisthe

owner'sresponsibilitytoexplainthismaterialto

them.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringpeopleordamage

toproperty.

–Useonlyanapprovedcontainer

–Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

–Donotaddordrainfuelinanenclosedspace.

–Donotstorethemachineorfuelcontainer

wherethereisanopename,spark,orpilot

light,suchasonawaterheaterorother

appliance.

–Ifyouspillfuel,donotattempttostartthe

engine;avoidcreatinganysourceofignition

untilthefuelvaporshavedissipated.

•Checkthattheshieldsareattachedand

functioningproperly.Donotoperateunlessthey

arefunctioningproperly.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverrunanengineinanenclosedorpoorly

ventilatedarea.

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Stoponlevelground,setthethrottletoslow,and

shutofftheenginebeforeleavingtheoperator's

positionforanyreason.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Shutoffthemachineif

anyoneentersthearea.

•Keepbystandersoutoftheoperatingarea.Stop

themachineifanyoneentersthearea.

•Keepyourfeetclearoftheplatecompactor.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

Preparation

•Wearappropriateclothingincludinghardhat,eye

protection,longpants,substantial,slip-resistant

footwear,andhearingprotection.Tiebacklong

hair,securelooseclothing,anddonotwearloose

jewelry.

•Inspecttheareawheretheequipmentistobe

usedandensurethatallobjectsareremovedfrom

theareabeforeuse.

•Useextracarewhenhandlingfuel.Theyare

ammableandvaporsareexplosive.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservice.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

4

Page 5

MaintenanceandStorage

•Lettheenginecoolbeforestoringanddonotstore

themachinenearanopename.

•Positionthemachineonalevelsurface,setthe

throttletoslow,andshutofftheengine.Waitfor

allmovementtostopbeforeadjusting,cleaning,

orrepairing.

•Cleandebrisfromdrives,mufers,andtheengine

tohelppreventres.Cleanupoilorfuelspills.

•Donotstorefuelnearamesordrainindoors.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthesparkplugbeforemakingany

repairs.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Keepnutsandboltstight.Keepequipmentin

goodcondition.

•Stopandinspecttheequipmentifyoustrike

anobject.Makeanynecessaryrepairsbefore

restarting.

•UseonlygenuineT ororeplacementpartsto

ensurethatoriginalstandardsaremaintained.

5

Page 6

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

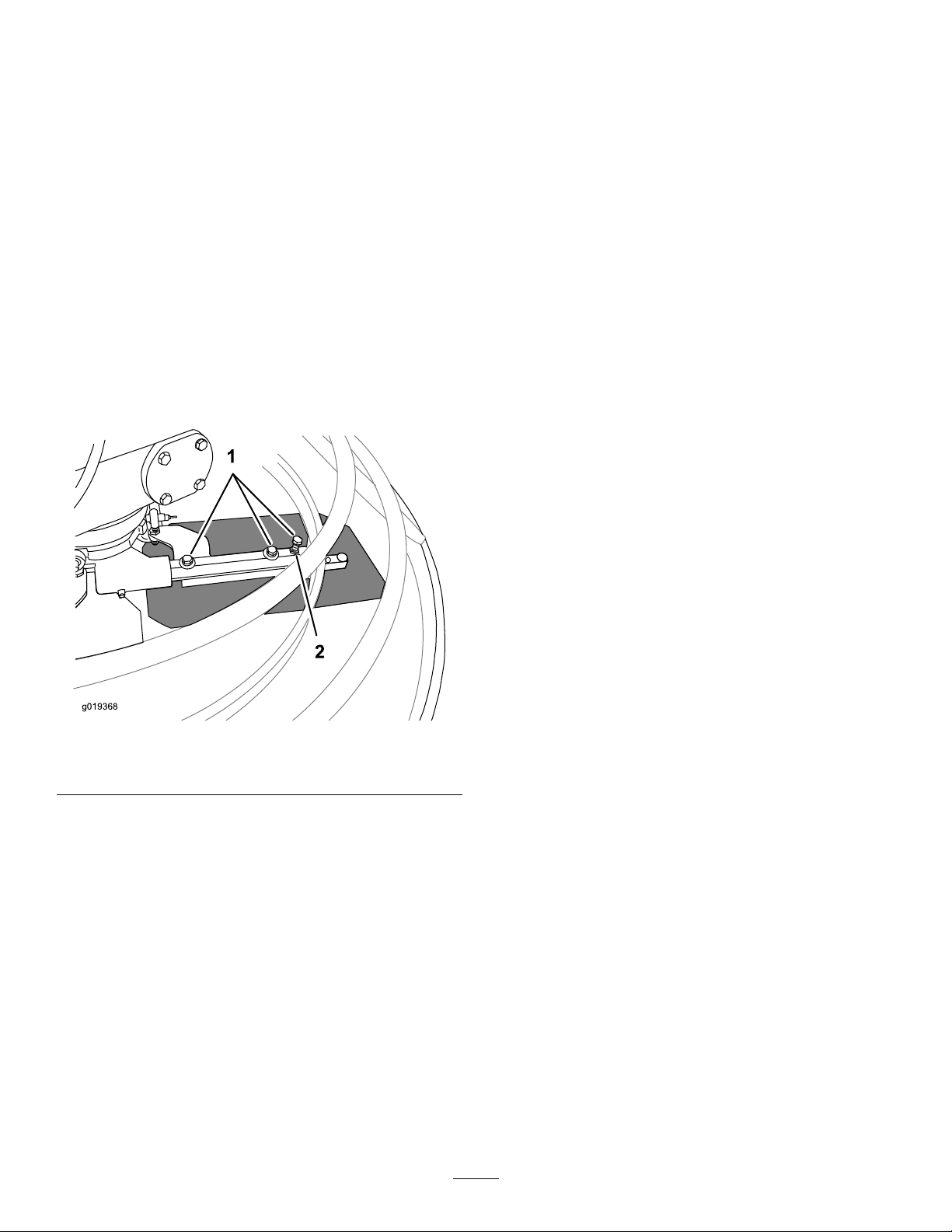

93-9084

decal93-9084

1.Liftpoint

2.Tie-downpoint

117–4979

1.Entanglementhazard,belt—keepawayfrommovingparts;

keepallguardsandshieldsinplace

125–4933

1.Warning—readthe

Operator’sManual.

2.Warning—wearhearing

protection.

3.Warning—keep

bystandersawayfrom

themachine.

4.Chokinghazard—donot

runtheengineinan

unventilatedarea.

5.Explosionhazard—shut

offtheengineand

extinguishallames

beforerefueling.

decal125-4934

125–4934

1.ReadtheOperator’s

Manual.

2.Disengageclutch

decal117-4979

3.Engageclutch

decal125-4935

125–4935

Models68049and68051only

decal125-4933

1.Lowertheblades2.Raisetheblades

decal133-5619

133-5619

6

Page 7

ProductOverview

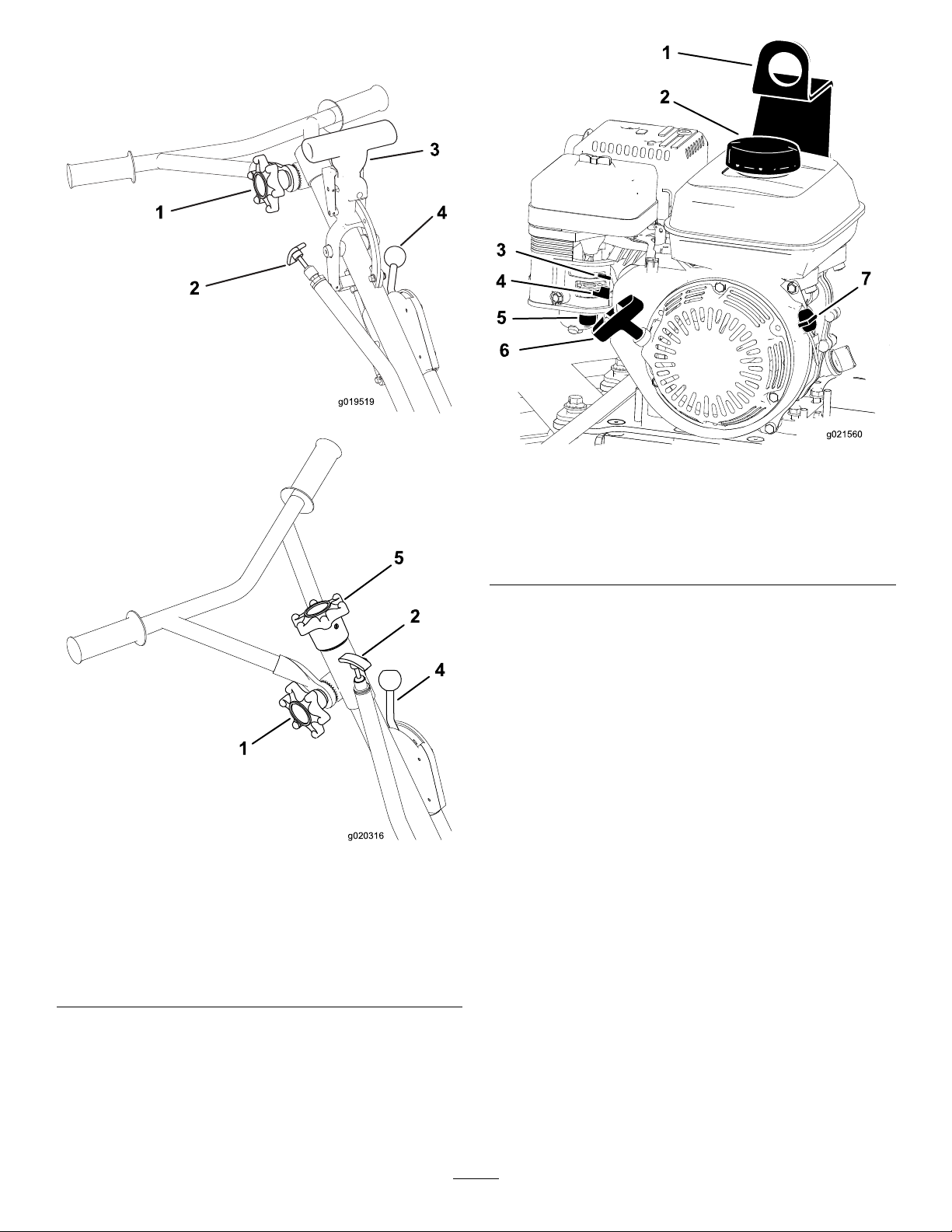

g019519

g021560

Figure4

1.Liftingpoint5.Sedimentcup

2.Fuel-tankcap6.Recoil-starterhandle

3.Chokelever7.EngineOn/Offswitch

4.Fuelvalve

Figure3

1.Handle-adjustmentknob

2.Throttlehandle5.Tilt-adjustmentknob

3.ProPitchhandle(Models

68049and68051only)

4.Dyna-Clutchlever

(Models68048and68050

only)

Controls

Recoil-StarterHandle

Pulltherecoil-starterhandletostarttheengine

(Figure4).

FuelValve

Closethefuelvalvewhentransportingorstoringthe

g020316

machine(Figure4).

ChokeLever

Usethechokelever(Figure4)tostartacoldengine.

Beforepullingtherecoil-starterhandle,movethe

chokelevertotheclosedposition.Oncetheengineis

running,movethechokelevertotheopenposition.

Note:Awarmenginerequireslittleornochoking.

EngineOn/OffSwitch

TheOn/Offswitch(Figure4)allowstheoperatorof

themachinetostartandshutofftheengine.This

switchislocatedonthefrontoftheengine.Rotatethe

On/OffswitchtotheOnpositiontostartandrunthe

7

Page 8

engine.RotatetheOn/OffswitchtotheOffpositionto

shutofftheengine.

ThrottleHandle

Pullthethrottlehandle(Figure3)toincreasethe

enginespeed,andpushthehandletodecreasethe

enginespeed.Turnthehandleclockwisetolock

thethrottleataspecicspeed.Turnthehandle

counterclockwisetounlockthethrottle.

Handle-AdjustmentKnob

Turntheknobcounterclockwisetoloosenandmove

thehandletothedesiredposition.Turntheknob

clockwisetotightenandlockthehandleinplace

(Figure3).

Dyna-ClutchLever

MovetheDyna-Clutchlever(Figure5)totheOn

position(up)toallowthebladestorotate.Movethe

levertotheOffposition(down)tostoptheblades.In

theeventthatyoureleasethehandlewhiletheblades

areturning,thecentrifugalforcefromtheswingofthe

handlewillthrowtheclutchlevertotheStopposition.

g019367

Figure6

1.Tripbutton2.Handle

Tilt-AdjustmentKnob

Models68048and68050Only

Turntheknobclockwisetoincreasetheangleofthe

blades(Figure6).Turntheknobcounterclockwiseto

attenordecreasetheangleoftheblades.

Figure5

1.Dyna-Clutchlever

ProPitch

Models68049and68051Only

Pullthehandletoincreasetheangleoftheblades

totheconcrete.Pressthetripbuttontoreleasethe

lock,andpushthehandletodecreasetheangleof

theblades.

TM

Handle

g019978

Figure7

1.Tilt-adjustmentknob

8

g021559

Page 9

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Models68048and6804968050and68051

Width

Length(operating)177cm(70inches)190.5cm(75

Height(operating)99cm(39inches)99cm(39inches)

Weight

Attachments/Accessories

Aselectionofapprovedattachmentsandaccessories

areavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorized

ServiceDealerorDistributororgotowww.T oro.com

foralistofallapprovedattachmentsandaccessories.

92cm(36.5inches)117cm(46inches)

102kg(225lb)112kg(245lb)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CheckingtheEngine-Oil

inches)

Level

ServiceInterval:Beforeeachuseordaily

Themachinecomesfromthefactorywithoilinthe

enginecrankcase.However,itmaybenecessaryto

addoil.Addonlyenoughoiltoraisetheleveltothe

Fullmarkonthedipstick;refertoServicingtheEngine

Oil(page16).

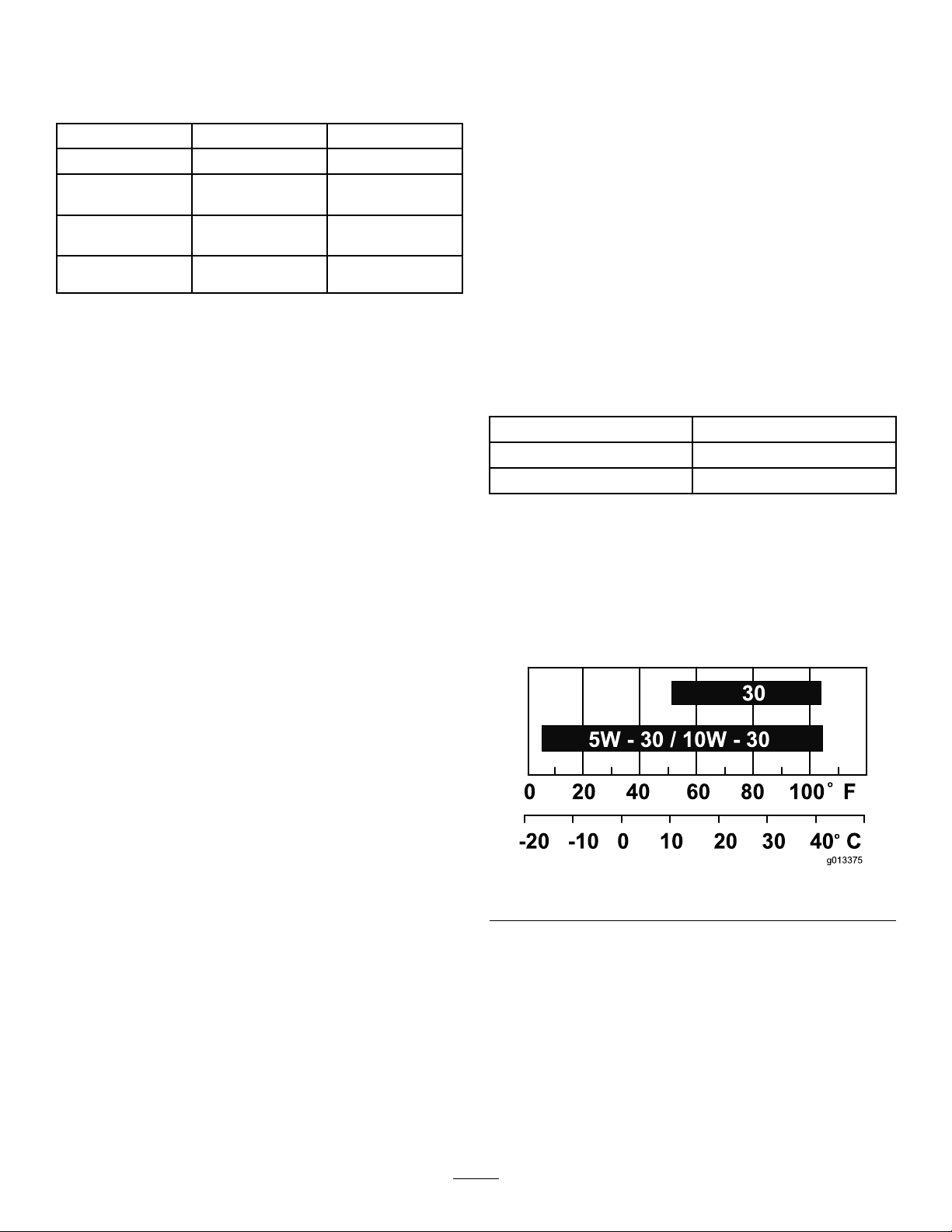

OilType:4-cycleengineoilthatmeetsorexceedsthe

requirementsforAPIservicecategorySJorhigher

Models

68048and68049

68050and68051

CrankcaseCapacity

0.58L(0.61USqt)

1.1L(1.2USqt)

Important:Ifyouruntheenginewhiletheoil

levelinthecrankcaseistoolowortoohigh,you

maydamagetheengine.

Note:UseSAE10W-30forgeneraluse.Youcan

usetheotherviscositiesshowninthechartwhen

theaveragetemperatureinyourareaiswithinthe

indicatedrange(Figure8).

Figure8

1.Positionthemachineonalevelsurface.

g013375

2.SettheDyna-ClutchlevertotheStopposition,

shutofftheengine,waitforallmovingpartsto

stop,andturnofftheengineswitch.

3.Cleanaroundthedipstick(Figure9)sothat

dirtcannotfallintothellportanddamagethe

engine.

9

Page 10

Figure9

g019746

Figure10

g021590

1.Fillport

2.Dipstick

4.Unscrewthedipstickandwipetheendclean

(Figure9).

5.Slidethedipstickfullyintothellport(Figure9)

withoutthreadingitintotheport.

6.Removethedipstickandlookattheend.Ifthe

engineoillevelislow,slowlypouronlyenough

oilintothellporttoraisetheleveltotheFull

markonthedipstick(Figure9).

7.Installandsecurethedipstick.

3.Oil-levelupperlimit

4.Oil-levellowerlimit

CheckingtheGearcaseOil Level

ServiceInterval:Beforeeachuseordaily

1.Positionthemachineonalevelsurface.

2.SettheDyna-ClutchlevertotheSTOPposition,

shutofftheengine,andwaitforallmovingparts

tostop.

3.Lookatthesightglassinthegearcaseplug

(Figure10).Theoillevelshouldbe3/4full.

Iftheoillevelisnotcorrect,refertoServicingthe

GearcaseOil(page17).

CleaningDebrisfromthe Machine

ServiceInterval:Beforeeachuseordaily

1.SettheDyna-ClutchlevertotheSTOPposition,

shutofftheengine,waitforallmovingpartsto

stop,andshutofftheengine.

2.Brushdirtanddebrisawayfromtheaircleaner

andengineopenings.

FoldingandUnfoldingthe Handle

1.Turnthehandle-adjustmentknob

counterclockwisetoloosenthehandle.

2.Placethehandletothedesiredpositionandturn

thehandle-adjustmentknobclockwisetotighten

thehandle(Figure11).

10

Page 11

Figure11

1.Handlefullyextended3.Handlefolded

2.Handle-adjustmentknob

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

g019366

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan10%

ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty..

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Donot

usefuelthathasbeenstoredformorethan

30days.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

11

Page 12

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfromafuel

dispensernozzle.

•Ifafuel-dispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

UsingFuelStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

keepthefuelfreshduringstorageof90daysorless.

Ifyouarestoringthemachineforlonger,drainthefuel

tank;refertoStorage(page25).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionerto

thefuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuel.Tominimizethechanceof

varnishdepositsinthefuelsystem,usefuelstabilizer

atalltimes.

12

Page 13

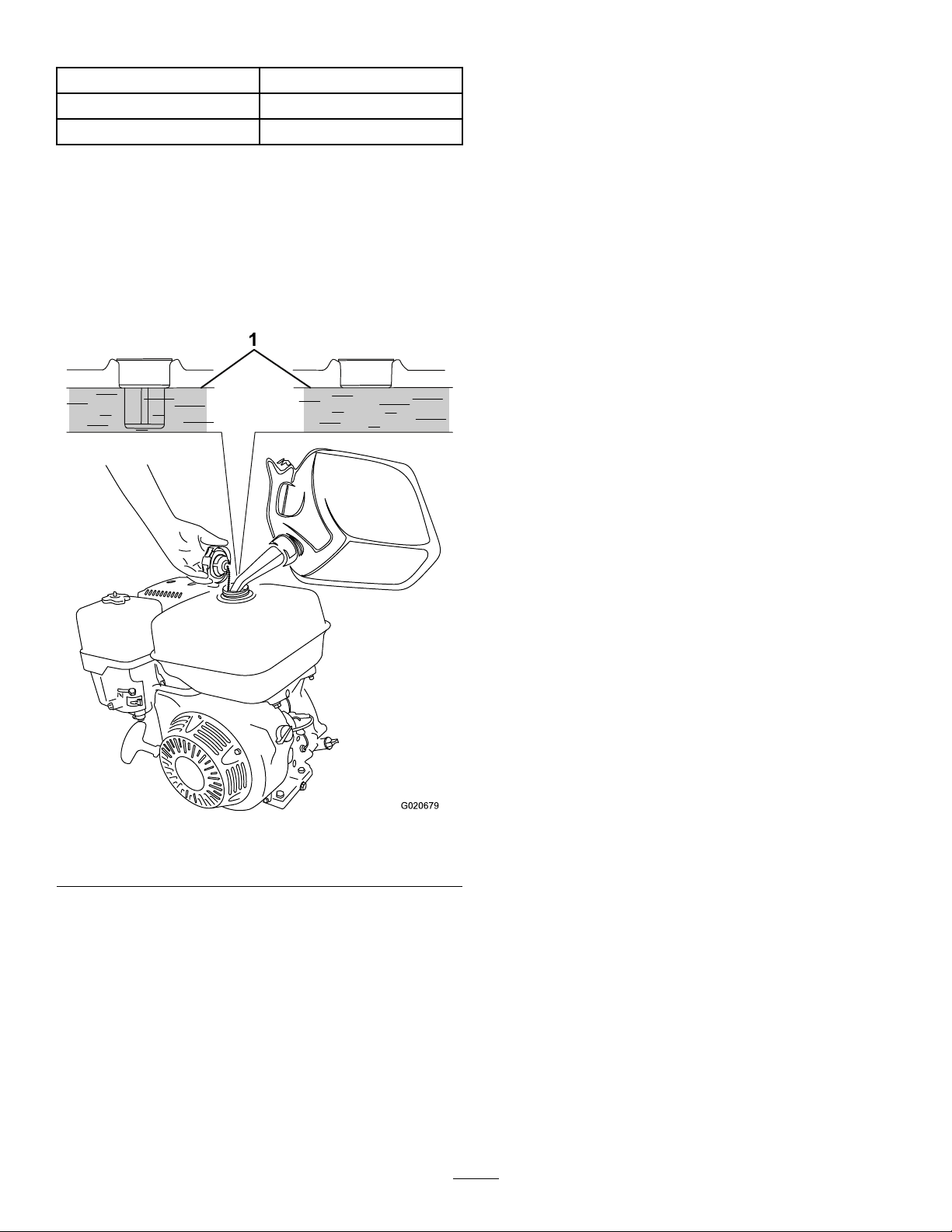

FillingtheFuelTank

Models

68048and68049

68050and68051

1.SettheDyna-ClutchlevertotheSTOPposition,

shutofftheengine,waitforallmovingpartsto

stop,andturnofftheengineswitch.

2.Allowtheenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit

(Figure12).

Note:Thecapistetheredtothefueltank.

FuelTankCapacity

3.1L(0.82USgallons)

5.3L(1.40USgallons)

StartingtheEngine

1.Setthethrottletofullspeedandsetthe

Dyna-ClutchlevertotheSTOPposition.

2.MovetheengineswitchtotheONpositionand

turnonthefuelvalve.

3.Movethechokelevertotheleftifyouare

startingacoldengine.

Note:Awarmorhotenginemaynotrequire

choking.

4.Pulltherecoil-starthandleslowlyuntilyoufeel

someresistance,thenpulltheitsharplytostart

theengine.

5.Aftertheenginestarts,graduallymovethe

choketotheright.Iftheenginestallsor

hesitates,movethechokeleftagainuntilthe

enginewarmsup.

6.Movethethrottlelevertodesiredsetting.

ShuttingOfftheEngine

1.Reducetheenginespeedtoidle.

2.Turntheengineswitchandfuelvalveoff.

3.Waitforallmovingpartstostopbefore

proceeding.

Figure12

1.Maximumfuellevel

4.Addunleadedfueltothefueltankuntilthe

levelisatthebottomofthemaximumfuellevel

(Figure12).

Important:Theextraspaceinthetank

allowsthefueltoexpand.Donotllthefuel

tankcompletelyfull.

5.Installthefuel-tankcapsecurely.

6.Wipeupanyspilledfuel.

OperatingtheMachine

Important:Usethemachineonconcretethathas

notsetcompletely,butensurethattheconcrete

hassetenoughtosupporttheweightofthe

machine.

1.Starttheengine.

2.Aftertheenginehaswarmedup,adjustthe

throttletoapproximatelyhalfspeed.

3.Adjustthebladestothedesiredposition.

g020679

•Foroating,setthebladesat,butwith

sometensiononthecable.

•Fornishing,setthepitchofthebladesto

approximately6to9mm(1/4to3/8inches),

orapproximately5to10°.

4.Holdthehandlermlywith1hand,andmove

theDyna-ClutchlevertotheOnpositiontostart

themovementoftheblades.

5.Guidethetrowelovertheconcreteinacircular

back-and-forthmotion.

Note:Ifthebladesstarttodigintotheconcrete

decreasetheamountofthepitch.

6.SettheDyna-ClutchlevertotheOffposition,

waitforanymovingpartstostopmoving,and

shutofftheengine;refertoShuttingOffthe

Engine(page13).

13

Page 14

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Every40hours

Every50hours

Every100hours

Every150hours

Every200hours

Every300hours

Yearlyorbeforestorage

MaintenanceProcedure

•Changetheengineoil.

•Checktheengine-oillevel.

•Checkthegearcaseoillevel.

•Cleandebrisfromtheaircleanerandengine.

•Lubricatethebladearms.

•Inspecttheaircleanerelements.

•Checkforloosefasteners.

•Checkthebelt,pulleyalignment,belttension,andbelt-guidegap.

•Cleantheairlterelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil.

•Inspectandadjustthesparkplug;replaceitifnecessary .

•Changethegearcaseoil.

•Replacethesparkplug.

•Replacethepaperaircleanerelement.Replaceitmorefrequentlyindustyoperating

conditions.

•Touchupchippedpaint

Pre-Maintenance

Procedures

Disconnectingthe Spark-PlugWire

Beforeperforminganymaintenanceontheengine,

belts,orblades,disconnectthespark-plugwirefrom

thesparkplug(Figure13).

g019430

Figure13

1.Spark-plugwire

14

Page 15

Lubrication

EngineMaintenance

LubricatingtheBladeArms

ServiceInterval:Beforeeachuseordaily

GreaseType:General-purposegrease.

1.Cleanaroundeachgreasettingwitharagand

lifttheplasticcapoffeachgreasetting.

2.Pumpseveralshotsofgreaseintoeachtting

untilitstartstooozeoutofthebearing(Figure

14andFigure15).

Important:Pumpgreaseinslowlyand

carefullytopreventdamagetothebearing

seals.

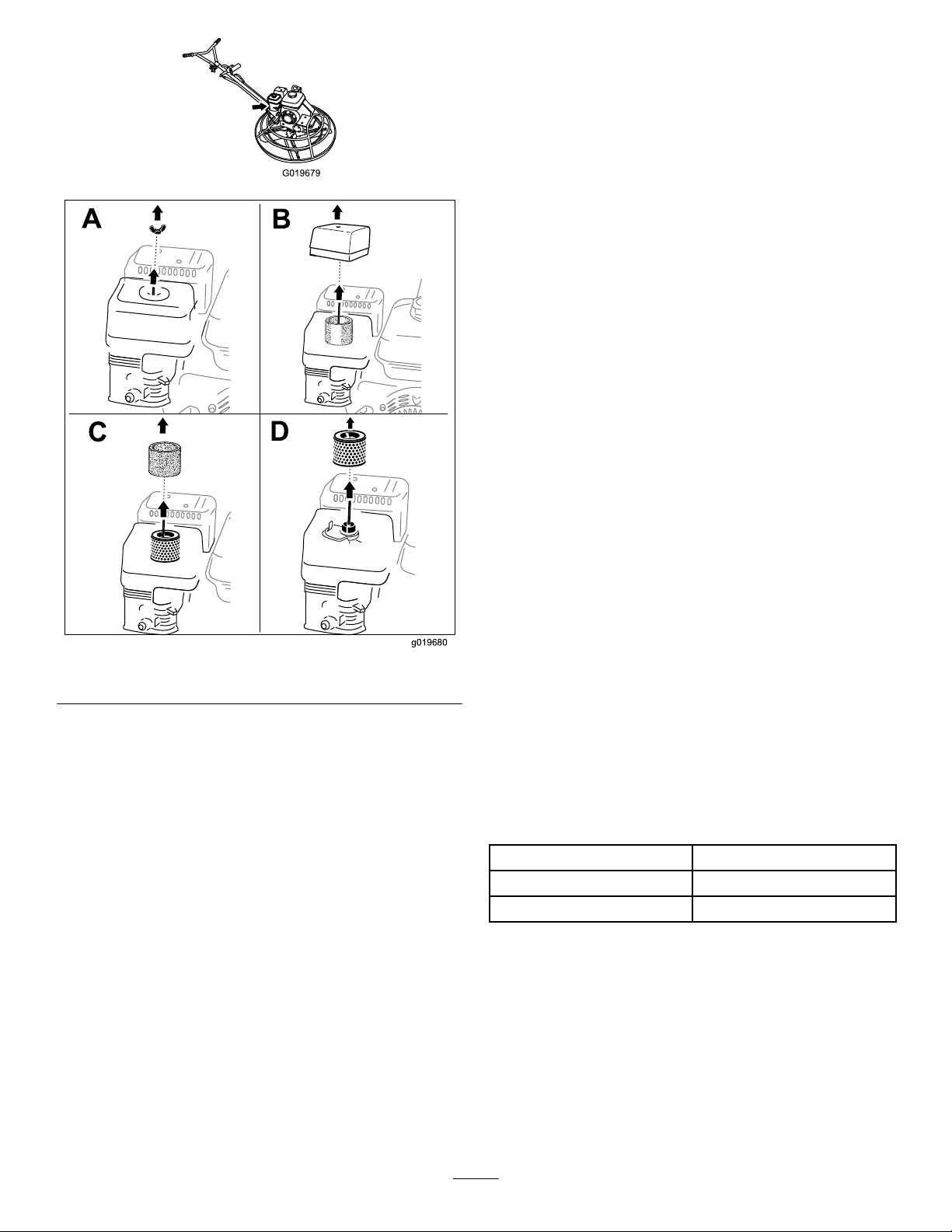

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspect

theaircleanerelements.

Every50hours—Cleantheairlterelements.

Cleanthemmorefrequentlyindustyoperating

conditions.

Every300hours/Y early(whichevercomes

rst)—Replacethepaperaircleanerelement.

Replaceitmorefrequentlyindustyoperating

conditions.

Important:Donotoperatetheenginewithout

theair-cleanerassembly;extremeenginedamage

willoccur.

1.SettheDyna-ClutchlevertotheSTOPposition,

shutofftheengine,andwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Removethenutthatsecurestheair-cleaner

cover(Figure16BoxA).

3.Wipeupanyexcessgrease.

g019383

Figure14

g019396

Figure15

15

Page 16

4.Removethecover(Figure16BoxB).

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamandpaperelementsfromthe

base(Figure16BoxC).

g019679

6.Removethefoamelementfromthepaper

element(Figure16BoxD).

7.Inspectthefoamandpaperelements,and

replacethemiftheyaredamagedorexcessively

dirty.

Note:Nevertrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

8.Cleanthefoamelementinwarm,soapywater

orinanonammablesolvent.

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

9.Rinseanddrythefoamelementthoroughly .

10.Dipthefoamelementincleanengineoil,then

squeezeouttheexcessoil.

Note:Excessoilinthefoamelementrestricts

theairowthroughtheelementandmayreach

thepaperlterandclogit.

11.Wipedirtfromthebaseandthecoverwitha

moistrag.

Figure16

Note:Becarefultopreventdirtanddebrisfrom

g019680

enteringtheairductleadingtothecarburetor.

12.Installtheaircleanerelementsandensurethat

theyareproperlypositioned.

13.Securelyinstallthecoverwiththenut.

ServicingtheEngineOil

OilType:4-cycleengineoilthatmeetsorexceedsthe

requirementsforAPIservicecategorySJorhigher

Models

68048and68049

68050and68051

Important:Iftheoillevelinthecrankcaseistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.

Viscosity:UseSAE10W-30forgeneraluse.You

canusetheotherviscositiesshowninthechartwhen

theaveragetemperatureinyourareaiswithinthe

indicatedrange(Figure8).

CrankcaseCapacity

0.58L(0.61USqt)

1.1L(1.2USqt)

16

Page 17

7.Removethedipstick(Figure9)andslowlypour

oilintothellholeuntiltheoilisbetweenthe

upperandlowerllmarksonthedipstick.

8.Installandsecurethedipstick.

9.Wipeupanyspilledoil.

ServicingtheGearcaseOil

Figure17

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury .

Avoidcontactingthehotengineoilwhenyou

drainit.

1.Positionthemachineonalevelsurface.

2.SettheDyna-ClutchlevertotheSTOPposition,

shutofftheengine,andwaitforallmovingparts

tostop.

3.Disconnectthewirefromthesparkplug.

4.Placeapanunderthedrainplugtocatchtheoil.

5.Removethedrainplug(Figure18).

g013375

ServiceInterval:Every150hours

OilType:80W-90gearoilthatmeetsorexceeds

APIservicecategoryGL-5.

Capacity:1.18L(1.25USqt)

1.SettheDyna-ClutchlevertotheSTOPposition,

shutofftheengine,andwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Placeapanunderthedrainplugtocatchtheoil.

4.Removethegearcaseplug(Figure18).

g021574

Figure19

Figure18

1.Drainplug

6.Replacetheplugwhentheoilhasdrained

completely.

Note:Disposeoftheusedoilatacertied

recyclingcenter.

1.Gearcaseplug

5.Tipthemachineanddraintheoilcompletelyout

ofthegearcase.

Note:Disposeoftheusedoilatacertied

recyclingcenter.

6.Returnthemachinetoanupright,levelposition.

g019417

7.Placea3.8cm(1-1/2inch)blockunder

thestationarybladeguard(outerring)so

thatthesideofthegearboxwiththeplugis

approximately6mm(1/4inch)higherthanthe

othersideofthegearbox.

8.Slowlypouroilintotheplugholeuntiltheoil

reachesthethreadsofthehole.

Note:Ifnecessary,useaexiblefunnel.

17

Page 18

9.Applythread-sealingcompoundtothethreads

oftheplug.

10.Installandtightenthepluguntilitissecure,and

returnthemachinetoanupright,levelposition.

Note:Theoillevelinthesightglassoftheplug

shouldbe3/4full(Figure20).

ServicingtheSparkPlug

ServiceInterval:Every100hours—Inspectand

adjustthesparkplug;replaceitif

necessary.

Every200hours—Replacethesparkplug.

UseanNGKBPR6ESsparkplugorequivalent.

1.SettheDyna-ClutchlevertotheSTOPposition,

shutofftheengine,andwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes,

becausegritenteringthecylindercan

damagetheengine.

5.Setthegapontheplugto0.76mm(0.030inch);

refertoFigure21.

Figure20

g021590

g019300

Figure21

1.Sideelectrode

2.Centerelectrode4.0.76mm(0.030inch)gap

3.Insulator

6.Carefullyinstallthesparkplugbyhand(toavoid

crossthreading)untilitishandtight.

7.Tightenthesparkpluganadditional1/2turnif

itisnew;otherwise,tightenitanadditional1/8

to1/4turn.

Important:Aloosesparkplugcanbecome

veryhotandcandamagetheengine;

overtighteningasparkplugmaydamagethe

threadsinthecylinderhead.

8.Connectthewiretothesparkplug.

18

Page 19

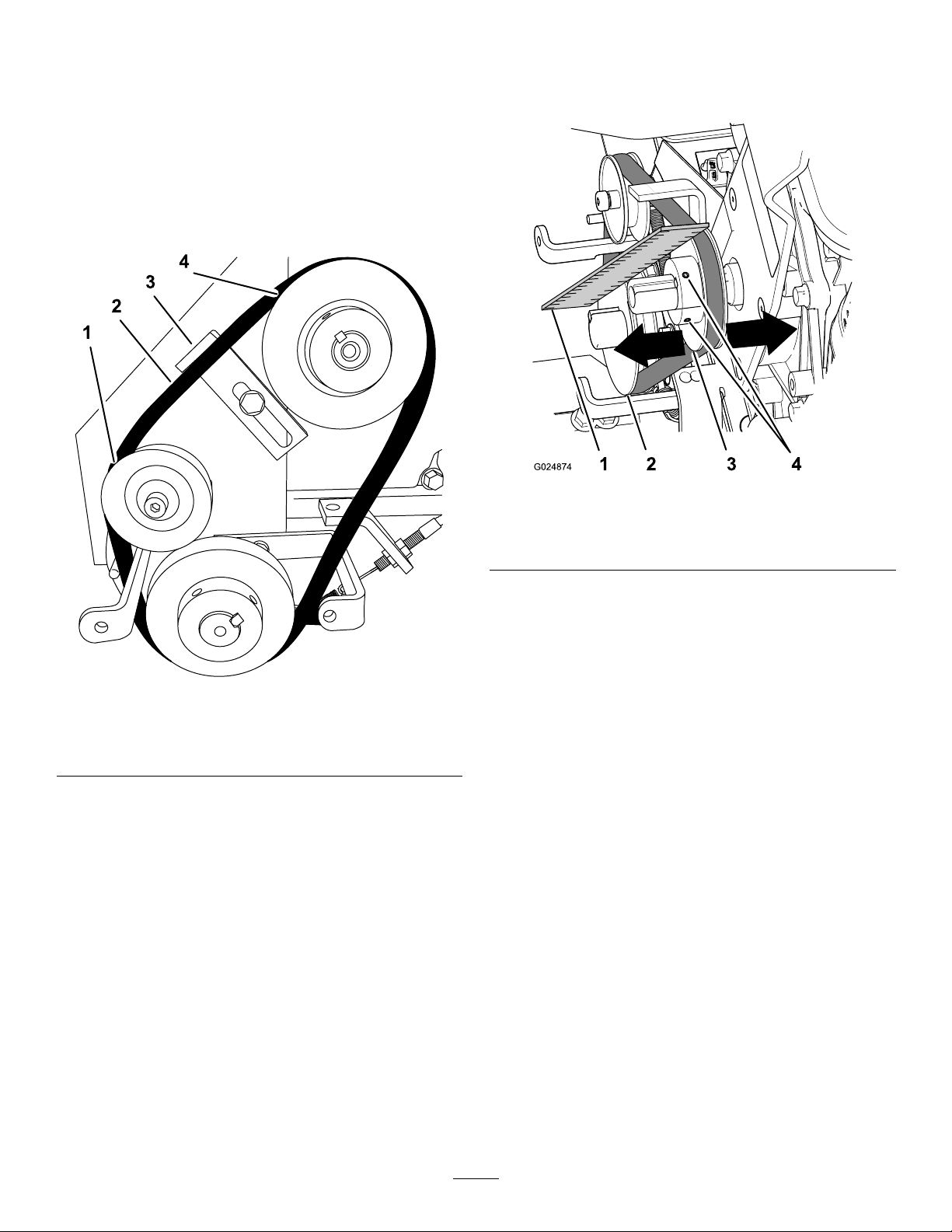

BeltMaintenance

CheckingtheBelt,Pulley Alignment,BeltTension, andBelt-GuideGap

ServiceInterval:Every40hours

1.Removethebeltguard;refertoRemovingthe

BeltGuard(page19).

2.MovetheDyna-ClutchlevertotheSTOPposition.

3.Checktheconditionofthebeltforwearor

damage.

Note:Ifthebeltiswornordamaged,replace

thebelt;refertoRemovingtheBelt(page20)

andInstallingtheBelt(page20).

RemovingtheBeltGuard

1.Removethe2hex-washerheadbolts(5/16x1

inch)thatsecurethebeltguardtothebelt-guard

bracket(Figure22).

g024872

Figure22

4.MovetheDyna-ClutchlevertotheRUNposition.

5.Checkthatthebeltisalignedstraightbetween

pulleys.

Note:Ifthebeltdoesnotrunstraightbetween

pulleys,alignthepulleys;refertoAligningthe

Pulleys(page20).

6.Checkthatthebelthasenoughtensiontoatten

itbetweentheenginepulleyandthebelttension

pulley.

Note:Ifbelttensionistoolow,adjustthe

tensionofthebelt-tensionpulley;referto

AdjustingtheDyna-Clutch(page20).

7.Measurethegapbetweenthebeltandthebelt

guide.Theairgapshouldbeapproximately6

mm(1/4inch).

Note:Iftheairgapislargerorsmallerthan6

mm(1/4inch),adjustthebeltguide(Figure26);

refertoAdjustingtheBeltGuide(page21).

8.Installthebeltguard;refertoInstallingtheBelt

Guard(page19).

1.Hex-washerheadbolt3.Belt-coverbracket

2.Beltcover

2.Pullthebeltguardawayfromtheengineand

thenup(Figure22).

InstallingtheBeltGuard

1.Aligntheholesinthebeltguardwiththeholesin

thebelt-coverbracket(Figure22).

2.Securethebeltguardtothebracketwiththe2

hex-washerheadbolts(5/16x1inch).

19

Page 20

RemovingtheBelt

AligningthePulleys

1.Positionthemachineonalevelsurface,place

theDyna-ClutchleverintheSTOPposition,shut

offtheengine,anddisconnectthespark-plug

wire.

2.Removethebeltguard;refertoRemovingthe

BeltGuard(page19).

3.Slipthebeltoffthebelt-tensionpulley(Figure

23).

1.Placeastraight-edgeruleracrosstheengine

pulleyandthegearboxpulley(Figure24).

Figure24

1.Straightedge

2.Gearboxpulley4.Setscrew

3.Enginepulley

g024874

Figure23

1.Belt-tensionpulley

2.Belt4.Enginepulley

4.Slipthebeltoffthegearboxpulley(Figure23).

5.Slipthebeltofftheenginepulleyandremove

thebelt(Figure23).

3.Gearboxpulley

InstallingtheBelt

1.EnsuretheDyna-ClutchleverintheSTOP

position.

2.Alignthebeltovertheenginepulley(Figure23).

3.Alignthebeltoverthegearboxpulley(Figure

23).

4.Slipthebeltoverthebelt-tensionpulley(Figure

23).

5.Installthebeltguard;refertoInstallingtheBelt

Guard(page19).

2.Ifthepulleysareoutofalignment,performthe

followingsteps:

A.Loosenthe2setscrewsthatsecurethe

enginepulleytotheengineshaft(Figure

g241621

24).

B.Gentlytaptheenginepulleytowardor

awayfromtheengineuntilthegearboxand

enginepulleysaligntothestraight-edge

ruler(Figure24).

C.Tightenthe2setscrewsthatsecurethe

enginepulleytotheengineshaft(Figure

24).

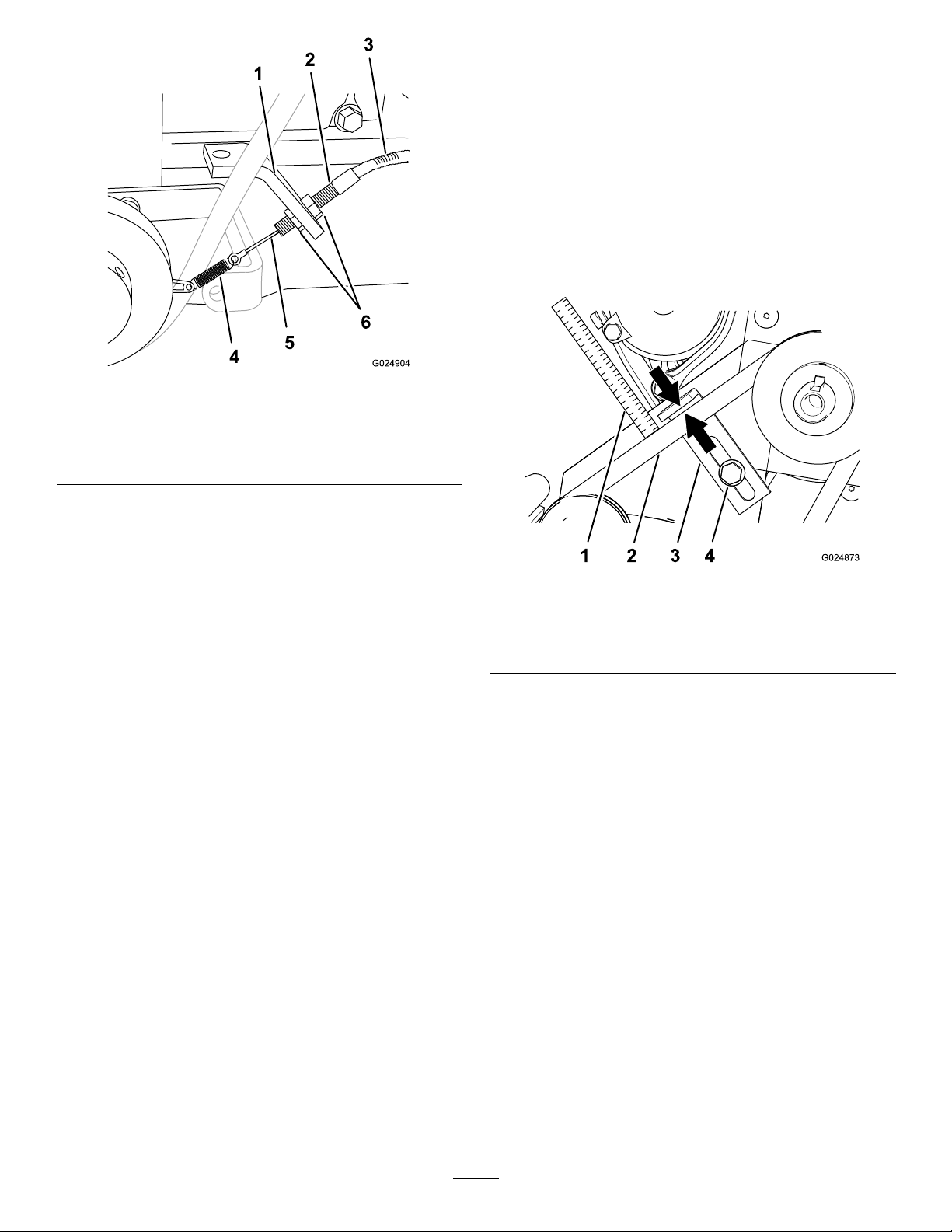

AdjustingtheDyna-Clutch

Important:Thisadjustmentprocedureaffectsthe

operationoftheDyna-Clutchandiscriticaltothe

safeoperationofthemachine.

Adjustthetension-pulleyspringasneededtotighten

thebelt.

1.MovetheDyna-ClutchlevertotheSTOPposition;

refertoDyna-ClutchLever(page8).

2.Loosenthe2jamnutsthatsecurethebarrelof

theclutchcabletotheclutchbracket,androtate

thenutstoeitherendofthreadsonthebarrel

(Figure25).

20

Page 21

Figure25

1.Clutchbracket4.Spring

2.Barrel

3.Cablehousing

Note:Ifthebladescontinuetorotatewhenthe

Dyna-ClutchisintheSTOPposition,thereistoo

muchtensionontheclutchcable.Shutoffthe

engineandrepeatstep7untilthebladesdo

notrotatewhentheengineisrunningandthe

Dyna-ClutchisintheSTOPposition.

AdjustingtheBeltGuide

1.PlacetheDyna-ClutchleverintheRUNposition.

2.Measuretheairgapbetweenthebeltandthe

beltguide(Figure26).

g024904

5.Cable

6.Locknuts

3.Graspthebarrelwith1handandliftthecable

housinglightly(Figure25).

Note:Liftingthecablehousingatthebarrel

shouldremovetheslackfromthecablebut

applynotensiontothespring.

4.Whileholdingtensiononthecable,useyour

otherhand,rotatethejamnutsuntilthenutsare

ushtotheclutchbracket(Figure25).

5.Tightenthejamnutstosecurethebarreltothe

bracket(Figure25).

6.Checkthetensionofthecontrolcable.Repeat

steps2through4untilthereistensiononthe

Dyna-Clutchcablebutnotensiononthespring.

Note:Ifthereistoomuchtensiononthecable

andspring,theDyna-Clutchwillnotrelease

completely.Ifthereisnotenoughtensiononthe

cable,thecablemaydisconnectfromthepulley

bracket.

7.Ifyouneedtomakeanercableadjustment,

performthefollowing:

A.Loosenthe2jamnutsslightly(Figure25).

Figure26

1.6mm(1/4inch)

measures-airgap

2.Belt4.Hex-headbolt

3.Beltguide

Theairgapshouldbeapproximately6mm(1/4

inch).Ifanadjustmentneedstobedone,performthe

following:

1.Loosenthehex-angeheadboltthatsecures

thebeltguidetotheengineplate(Figure26).

2.Whilekeepingthetopofthebeltguideparallel

tothebelt,movethebeltguidetowardoraway

fromthebeltuntiltheairgapiscorrect(Figure

26).

3.Tightenthehex-angeheadboltthatsecures

thebeltguidetotheengineplate(Figure26).

g024873

B.Rotatethejamnutstoclockwisetoincrease

cabletensionorcounterclockwiseto

decreasetension(Figure25).

C.Tightenthejamnutstosecurethebarrelto

theclutchbracket(Figure25).

8.StartthemachineandsetDyna-Clutchtothe

RUNpositionforafewmoments,thenmovethe

Dyna-ClutchtotheSTOPposition.

21

Page 22

ControlsSystem

AdjustingtheProPitch

Maintenance

AdjustingtheTiltKnob

1.SettheDyna-ClutchlevertotheStopposition,

shutofftheengine,andwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Attachanoverheadlifttotheliftingpointonthe

machineandliftitoffoftheground.

4.Turnthetiltknobuntilthereisenoughcable

slacktoaccessthetiltlocknut(Figure27).

LinkageRod

1.SettheDyna-ClutchlevertotheStopposition,

shutofftheengine,andwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Attachanoverheadlifttotheliftingpointonthe

machineandliftifoffoftheground.

4.Loosenthenutontheupperendofthelinkage

rodtoallowslackintheliftcable(Figure28).

Figure27

1.Tiltknob6.Nut

2.Bearing7.Tiltblock

3.Tiltrod8.Tiltcable

4.Tiltlocknut

5.Washer

5.Tightenthelocknutagainstthebearingthen

loosenitslightly .Setitwiththesetscrew(Figure

27).

6.Adjustthenutsinsidethetiltblocktotakeup

anycableslack.

9.Setscrew

g019445

Figure28

1.Nut4.Linkagerod

2.Swivel

3.Nut6.Yokeend

5.PositiontheProPitchhandleinthefulltilt

position.

g019446

6.Adjustthenutonthebacksideoftheswivel

attheupperendofthelinkageroduntilyou

achievethepropergapofapproximately0.4

mm(1/64inch)betweenthetiltleverandthe

gearcase.

7.Tightenthenutontheoutsideoftheswivelto

lockthelinkagerodintoposition.

5.Nut

Note:Replacethecablesiffulltiltisnolonger

obtainable.

22

Page 23

TestingtheDyna-Clutch Lever

TestingtheDyna-ClutchOperation

Ensurethattheareaisclearofanydebrisor

bystandersbeforebeginningthetestingprocedures.

1.Startthetrowel,engagetheDyna-Clutchlever,

andrunthemachineforafewmoments.

2.MovetheDyna-ClutchlevertotheStopposition.

3.Watchthebladesforanysignofcontinued

rotation.

Ifthebladesdonotstop,thereistoomuch

tensiononthecableandspring.Shutoffthe

engineanddecreasetheamountoftension

toallowtheDyna-Clutchlevertodisengage

completely.

Ensurethatthereisstillenoughtensiononthecable

andspringtopreventpartsfromcomingunhooked

duringoperation.Ifthetendencyforthebladesto

rotatewhentheDyna-Clutchleverisdisengaged

cannotbeadjustedoutofthesystemwithouttakingall

tensionoffofthecableandspring,carefullyinspect

thedrivebeltandDyna-Clutchleversystemforwear

ordamage.Ensurethatallpartsareoperatingfreely .

IftheDyna-Clutchleverdoesnotstoptheblades,see

anAuthorizedServiceDealer.

TestingtheDyna-ClutchLever Adjustment

Important:Ensurethatthetestingofthe

Dyna-Clutchleverisdoneisaclearandopenarea.

Important:Clearthetestareaofbystanders.

1.MovetheDyna-ClutchlevertotheSTOPposition;

refertoDyna-ClutchLever(page8).

2.Startthetrowel.

3.MovethefuelvalvetotheOFFposition(Figure

29).

Figure29

1.Fuelvalve

4.Holdontothehandleandengagethe

Dyna-Clutchlever;refertoDyna-ClutchLever

(page8).

5.Letgoofthehandle.

TheDyna-Clutchlevershouldswitchtothe

STOPpositionwithin1rotation.Ifitdoesnot,

keepclearoftheareaandwaitforthemachine

torunoutoffuel.

2.Offposition

Note:IftheDyna-Clutchdoesnotstopthe

machinewithin1rotation,adjusttheDyna-Clutch

orbringthemachinetoanauthorizedservice

location;refertoAdjustingtheDyna-Clutch

(page20).

6.MovetheDyna-ClutchlevertotheSTOPposition.

AdjustingtheBlades

Adjustthebladestoremoveexcessiveshakingofthe

machine.

1.Disconnectthesparkplugwireandmovethe

Dyna-ClutchlevertotheSTOPposition.

2.Place3or4blocksofequalheightunderthe

stationarybladeguard(outerring)toraisethe

bladesoffoftheoor.

g025040

Important:Youmustmovethefuelvalve

totheOFFpositionbeforecontinuingthis

procedure.

Note:Ensurethattheblocksareclearofthe

bladessothatthebladescanberotatedwithout

touchingtheblocks.

23

Page 24

Figure32

g019517

Figure30

1.Stationarybladeguard

2.Block

3.Measurefromtheoortotheleadingedgeof

theblade.Notethemeasurement.

4.Placeamarkonthebladeandonthespoton

theoorfromwherethemeasurementwas

taken(Figure31).

1.Ruler

2.Spotonoorfromrst

measurement

3.Secondblade

7.Comparethe2measurements.

Iftheheightofthesecondbladeisnotwithin0.8

mm(1/32inch)oftheheightoftherstblade,

adjustthesecondblade.

8.Loosenthelocknutsontheblade(Figure33).

g019516

Figure31

1.Spotontheoorwherethe

measurementwastaken

2.Ruler

3.Blade

5.Rotatethebladesuntilthenextbladeisin

thesamepositionasthepreviouslymeasured

blade.

6.Measurethesecondbladefromthespot

previouslymarkedontheoortothesecond

bladesleadingedge(Figure32).

g019518

Figure33

1.Rodendbearing4.Bladearmlever

g019517

2.Thrustplate5.Bladearm

3.Locknuts

9.Adjustthebladearmleverupordownas

necessarytomakethesecondbladeheight

thesameheightoftherstbladethatwas

measured.

10.Tightenthelocknuts.

11.Repeatasnecessaryfortheremainingblades.

24

Page 25

AdjustingtheBladeArms

Adjustthebladearmsifthemachinestillshakes

excessivelyafterthebladeshavebeenadjusted.

1.Placethemachineonaatsurface.

2.Disconnectthesparkplug.

3.Turnthetiltadjustmentknobcounterclockwise

untilallofthetensionisoffofthetiltadjustment

cableandthebladesareatagainsttheoor.

Bladearmsshouldbeunbentandattothe

oor.Ifabladeisbent,continuethisprocedure

toadjustthebladearm.Ifbladesareunbent

andattotheoor,examinethemachinefor

otherwornparts.

Note:Donotscrewtheknobcompletelyout

ofthehandle.

4.Loosenthebolts3to4turns(Figure34).

Storage

1.SettheDyna-ClutchlevertotheStopposition,

shutofftheengine,anddisconnectthe

spark-plugwire.

2.Removedirtandgrimefromtheentiremachine.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressure

washthemachine.Avoidexcessiveuseof

water,especiallyneartheengine.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page15).

Changetheengineoil;refertoChangingthe

EngineOil(page17).

4.Forstorageover30days,preparethemachine

asfollows:

A.Addapetroleumbased

stabilizer/conditionertofuelinthe

tank.Followthemixinginstructionsfrom

stabilizermanufacturer.Donotusean

alcohol-basedstabilizer(ethanolor

methanol).

Figure34

1.Bolts2.Locknut

5.Loosenthelocknutandtightentheoutermost

boltuntilthebladelaysatagainsttheoor.

6.Tightenthelocknutandbolts.

7.Repeatforotherbladesasnecessary.

Ifthebladearmcannotbeadjustedtolayat,replace

thebladearm.

Ifthemachinecontinuesshakingexcessivelyafter

thebladearmshavebeenadjusted,examinethe

remainderofthemachineforanyotherwornparts.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfueland

usedatalltimes.

B.Runtheengineuntilitstopsfromrunning

outoffuel.

C.Choketheengine.

D.Startandruntheengineuntilitwillnotstart

again.

g019368

E.Disposeoffuelproperly.Recycleasper

localcodes.

Important:Donotstore

stabilizer/conditionedfuelover90days.

5.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamaged.

6.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

7.Storethemachineinaclean,drygarageor

storagearea.

8.Coverthemachinetoprotectitandkeepitclean.

25

Page 26

Troubleshooting

Problem

Thetrowelbladeturnswhentherecoilis

pulled.

Thetrowelbladesarewearingunevenly.

Thetrowelbounces,rocks,ordigsintothe

concrete.

Thetiltknobisdifculttoturn.

PossibleCauseCorrectiveAction

1.Theclutchisengaged.

2.Theclutchisnotproperlyadjusted.

3.Thebeltguidebracketisbent.

1.Thebladearmisbent.

2.Thebladearmneedtobeadjusted.

3.Thetiltmechanismneedstobe

adjusted.

4.Therodendbearingsarewornor

needstobeadjusted.

1.Thebladearmisbent.

2.Thebladearmneedstobeadjusted.

3.Thearmbearingsareworn.

4.Theoutputshaftisbent.4.SeeanAuthorizedServiceDealer.

1.Thetiltrodandnutareseized.1.Lubricatethetiltrodthreads.

2.Thetiltpivotisnotseatedproperly.

3.Thetiltlocknutneedstobeadjusted.

4.Thethrustplateiswornorhasseized.

5.Thetiltleveriswornorbent.

6.TheProPitchcamisbentorworn.

1.DisengagetheClutch.

2.SeeAdjustingtheDyna-ClutchLever.

3.SeeanAuthorizedServiceDealer.

1.SeeAdjustingtheBladeArms.

2.SeeAdjustingtheBladeArms.

3.SeeAdjustingtheBladeArms.

4.SeeAdjustingtheBladeArms.

1.SeeAdjustingtheBladeArms.

2.SeeAdjustingtheBladeArms.

3.SeeanAuthorizedServiceDealer.

2.SeeAdjustingtheTiltKnob.

3.SeeAdjustingtheTiltKnob.

4.Lubricatethethrustplate.Seean

AuthorizedServiceDealer .

5.SeeanAuthorizedServiceDealer.

6.SeeAdjustingthePro-PitchLinkage

Rod.SeeanAuthorizedService

Dealer.

TheDyna-Clutchleverisdifcultto

engage.

Thebeltslips.

Thegearcaseisemittingagrindingnoise.1.Thebearingsareworn.

Theenginedoesnotstart.

Theenginerunsrough.

1.Thetensionneedstobeadjusted.

2.TheDyna-Clutchleverisworn.2.SeeanAuthorizedServiceDealer.

3.Thecablehasseized.

1.Thetensionontheclutchspringneeds

tobeadjusted.

2.Thebeltisworn.

1.Thechokeisopen.

2.Thefueltankisempty.2.Fillthetankwithfreshfuel.

3.Thesparkplugwireislooseor

disconnected.

1.Thechokeislefton.1.Openthechoke.

2.Theairlterisclogged.

3.

Thefuellineisclogged.

4.Thereiswaterorcontaminantsinthe

fuel.

5.Thesparkplugsarewornorhave

buildupontheelectrodes.

1.SeeAdjustingtheDyna-ClutchLever.

3.SeeanAuthorizedServiceDealer.

1.SeeAdjustingtheDyna-ClutchLever.

2.SeeAdjustingtheTransmissionDrive

BeltTension.

1.SeeanAuthorizedServiceDealer.

1.Closethechokewhenstartingacold

engine.

3.Checktheelectrodegapandcleanor

replacethesparkplug.

2.Cleanorreplacetheairlter.See

ServicingtheAirCleaner.

3.

Cleanthesedimentcup.

4.Drainandllthetankwithfreshfuel.

5.Checktheelectrodegapandcleanor

replacethesparkplug.

26

Page 27

Notes:

Page 28

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproductsAdditionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerwithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalprovideexposurelimitrequirements.WhiletheexposurefromToroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...