Page 1

FormNo.3374-363RevA

G019180

CS-1andCS-2ConcreteSaw

ModelNo.68045—SerialNo.313000001andUp

ModelNo.68046—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3374-363*A

Page 2

WARNING

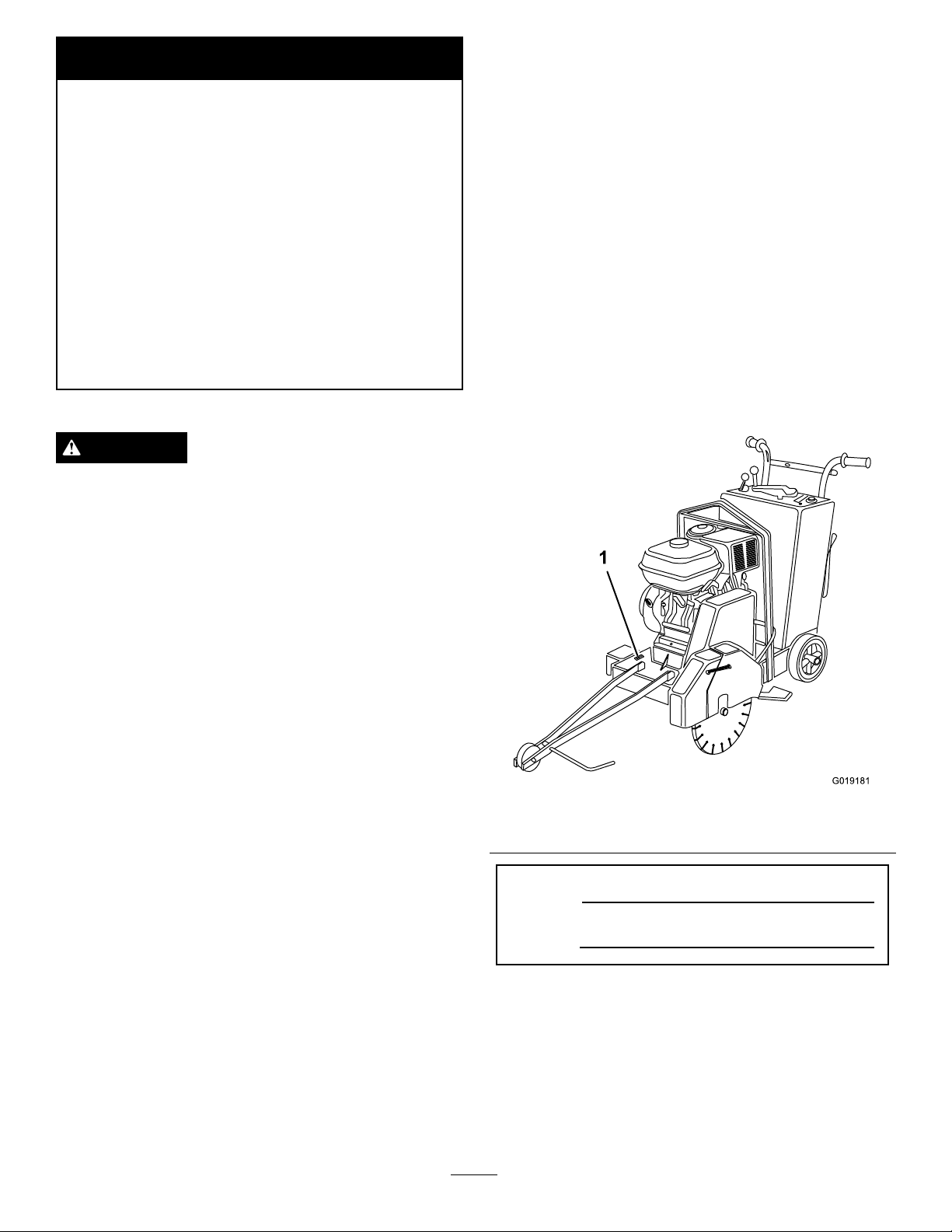

1

G019181

Introduction

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoucutintothem.

Thismachineisdesignedtoatsawasphaltandconcrete.It

isnotintendedtocutwoodanyothermaterialotherthan

asphaltandconcrete.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready.Figure1showsthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporatedwith

themuferassembly.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................5

ProductOverview..........................................................7

Controls................................................................8

Specications........................................................10

Attachments/Accessories........................................10

Operation....................................................................11

BeforeyouStart.....................................................11

AdjustingtheHandleBar(Model68046)....................11

RemovingandInstallingtheSawBlade......................11

AdjustingtheCuttingDepth....................................14

AligningthePointer................................................15

AddingFuel...........................................................16

ServicingtheEngineOil..........................................18

StartingandStoppingtheEngine..............................19

CuttingtheJob-SiteSurface.....................................20

ChangingtheCuttingPosition..................................22

TransportingtheMachine........................................25

Maintenance.................................................................26

RecommendedMaintenanceSchedule(s)......................26

Lubrication...............................................................27

GreasingtheMachine.............................................27

LubricatetheElevationScrew..................................27

EngineMaintenance..................................................28

ServicingtheAirFilter............................................28

ChangingtheEngineOil.........................................29

ServicingtheFuelSystem........................................30

ServicingtheSparkPlug..........................................31

ServicingtheSparkArrester.....................................32

BeltMaintenance......................................................33

ServicingtheDriveBelts.........................................33

SawBladeMaintenance...............................................38

CheckingtheConditionandFunction.......................38

Cleaning...................................................................40

CleaningtheMachine..............................................40

Storage........................................................................40

StoringtheMachine................................................40

Troubleshooting...........................................................42

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

—personalsafety

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

WARNING

Machiningorhandlingstone,masonry,concrete,

metal,andothermaterialscangeneratedust,mists,

andfumescontainingchemicals,suchassilica,

knowntocauseseriousorfatalinjuryorillness,

suchasrespiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Watershouldbeusedfordust

suppressionwhenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupationaland

tradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyOSHAfor

thematerialbeinghandled.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

3

Page 4

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Decidewhetherwetcuttingordrycuttingisperformed

andevaluatethejobsitematerial(s)todeterminewhat

bladeapplicationisneededtoproperlyandsafelyperform

thejob.Onlyusebladesapprovedforthecutting

operationbythemanufacturerofthesawblade.

•Wearappropriateclothingincludinghardhat,faceshield,

safetyglasses,longpants,safetyshoes,respiratorordust

mask,andhearingprotection.Longhair,looseclothing,

orjewelrymaygettangledinmovingparts.

•Inspectthejobsitewheretheequipmentistobeused

andremoveallobjectssuchasloosesitematerials,rocks,

woodproducts,toolsandhardwarewhichcanbethrown

bythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainertostoreandtransport

fuel.

–Neverremovethegascaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmokewhilefuelingthemachine.

–Neverrefuelordrainthemachineindoors.

•Checkthattheguardsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Ensurethatthebladeiselevatedabovethejob-site

surfacebeforestartingtheengine.Onlystarttheengine

fromtheoperator’sposition.

•Elevatethebladeabovethejob-sitesurfaceaftereach

cuttingpass.

•Ensurethatthebladeiselevatedwhenmovingthe

machinetothejobsite,fromthejobsite,andtoanew

cuttingpath.

•Neveroperatewiththeguardsnotsecurelyinplace.

•Donotchangetheenginegovernorsettingorover-speed

theengine.

•Beforeleavingtheoperatorpositionforanyreason,

elevatethebladeabovethesitesurface,reducethethrottle

toidle,andpressthestopswitch.

•Keephandsandfeetawayfromtheblade.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Keeppetsandbystandersaway.

•Usecaremovingthemachinebetweenjobsites.Slow

downwhenandusecautionwhenmakingturnsand

whencrossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverleavearunningmachineunattended.Always

elevatetheblade,stoptheengineandverifytheblade

hasstoppedrotating.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthemachine

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Locatethepinchpointareasmarkedonthemachineand

keephandsandfeetawayfromtheseareas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

MaintenanceandStorage

•Elevatethebladeabovethejob-sitesurfaceandstop

theengine.Waitforthebladetostopbeforeadjusting,

cleaning,orrepairing.

•Cleandebrisfromtheblade,bladeguard,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Removethesparkplugwirebeforemakinganyrepairs.

4

Page 5

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

buildup.Cleanupoilorfuelspillage.Allowthemachine

tocoolbeforestoring.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainertostorefuel.

–Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

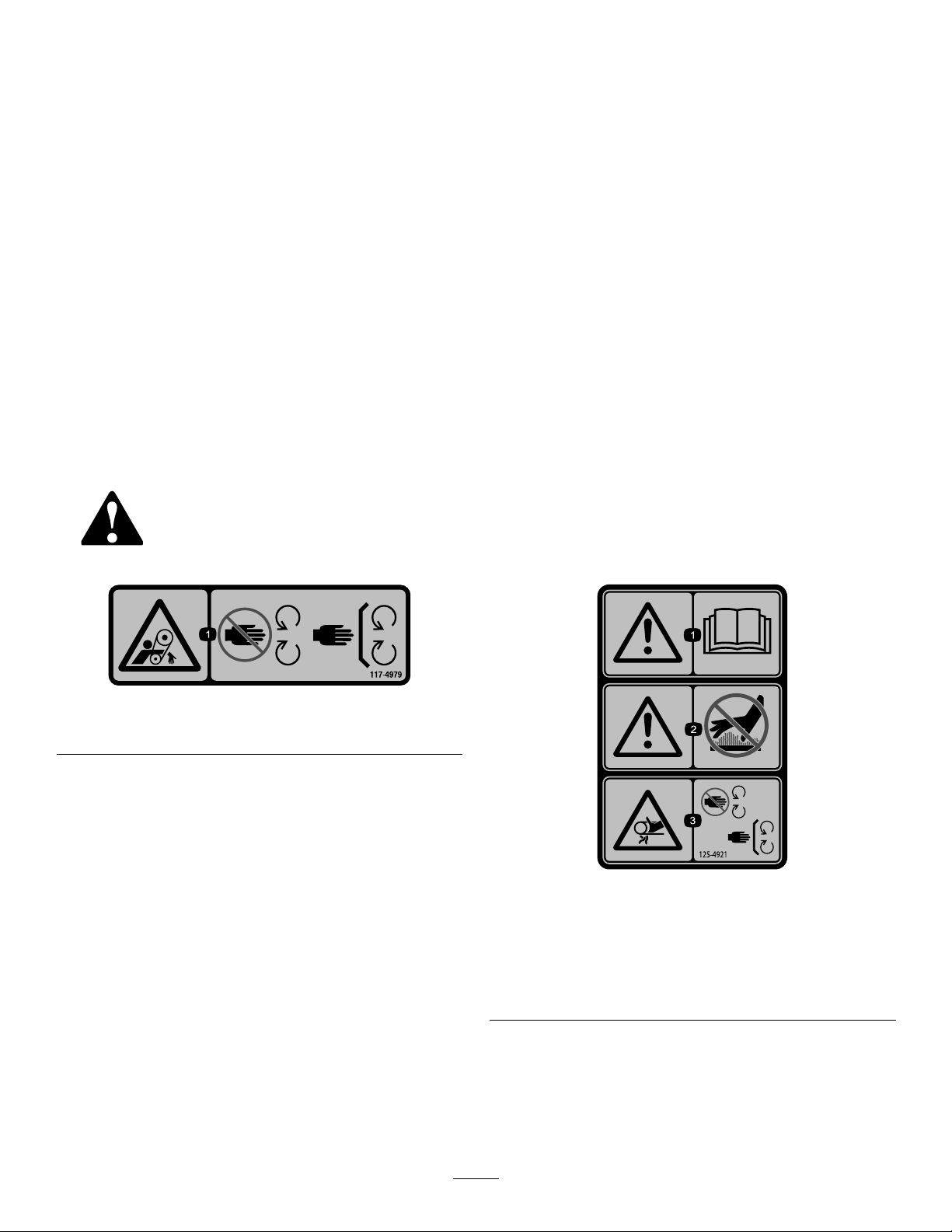

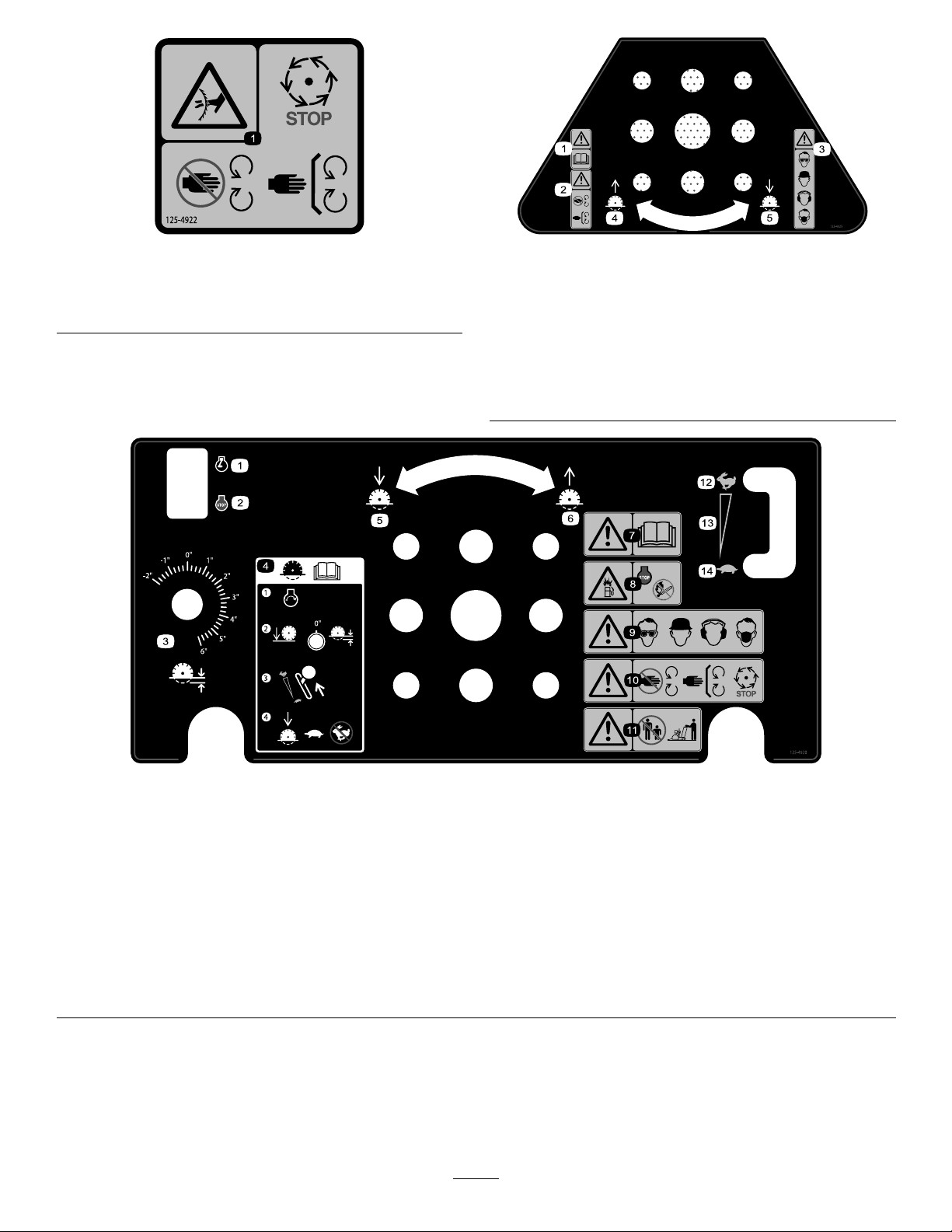

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

–Neverllacontainerwhileitisinsideavehicle,the

cargoboxofatruck,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

117–4979

1.Rotatingbelt—Keepguardinplace

1.Warning—readthe

Operator’sManual.

2.Warning—keephands

awayfromhotsurfaces.

125–4921

3.Entanglementhazard,

belt—keephandsaway

frommovingparts;keep

allguardsinplace.

5

Page 6

125–4922

00

00

125–4925

1.Cutting/dismembermenthazardofhand,circular

blade—stoptheblade;keephandsawayfrommoving

parts;keepallguardsinplace.

1.Warning—readthe

Operator’sManual.

2.Warning—keephands

awayfrommovingparts;

keepallguardsinplace.

3.Warning—weareye,head,

hearing,andrespiratory

protection.

4.Raiseblade

5.Lowerblade

125–4920

1.Engine—run

2.Engine—stop9.Warning—weareye,head,hearing,andrespiratoryprotection.

3.Adjustcuttingheight

4.ReadtheOperator’sManual—1)Starttheengine;2)Setthe

bladeheightto0inches;3)Setthebladespeedtofast;

4)Whenloweringthebladeforcutting,setthespeedtoslow.

5.Lowertheblade12.Fast

6.Raisetheblade13.Variablespeed

7.Warning—readtheOperator’sManual.14.Slow

8.Explosionhazard,fueling—stoptheengineandkeepames

awaywhenfueling.

10.Warning—keepawayfrommovingparts;keepallguardsin

place;waitformovingpartstostop.

11.Warning—keepbystandersawayfromthemachine.

6

Page 7

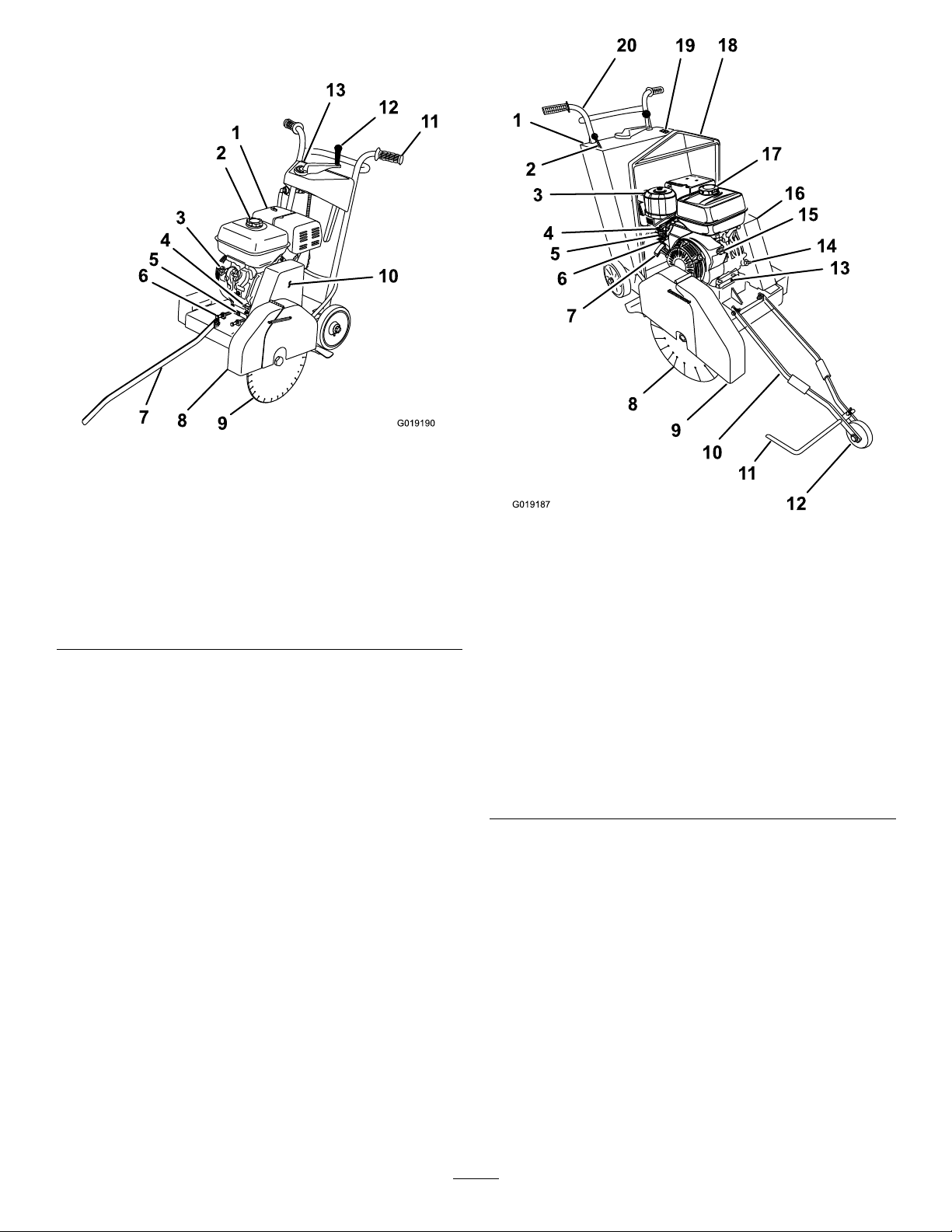

ProductOverview

G019190

2

3

4

5

6

7

8

9

10

11

12

13

1

G019187

1

2

3

4

5

6

8

9

11

12

13

14

15

16

17

18

19

20

10

7

Figure3

Overview(Model68045)

1.Airltercover

2.Fueltankcap

3.Engineswitch10.Beltguard

4.Oilllercap/dipstick

5.Oildrainbolt

6.Belttensionbolt

7.Forwardpointer

8.Bladeguard

9.Sawblade

11.Handlebar

12.Elevationcrank

13.Operatorpanel

Figure4

Overview(Model68046)

1.Operatorpanel

2.Throttlelever12.Pointerwheel

3.Airltercover13.Oildrainbolt

4.Chokelever14.Oilllercap/dipstick

5.Fuelvalvelever

6.Sedimentcup

7.Recoilstarthandle17.Fueltankcap

8.Sawblade18.Liftingbale

9.Bladeguard

10.Pointerfork

11.Forwardpointer

15.Engineswitch(engine

location)

16.Beltguard

19.Engineswitch(operator

panellocation)

20.Handlebar

7

Page 8

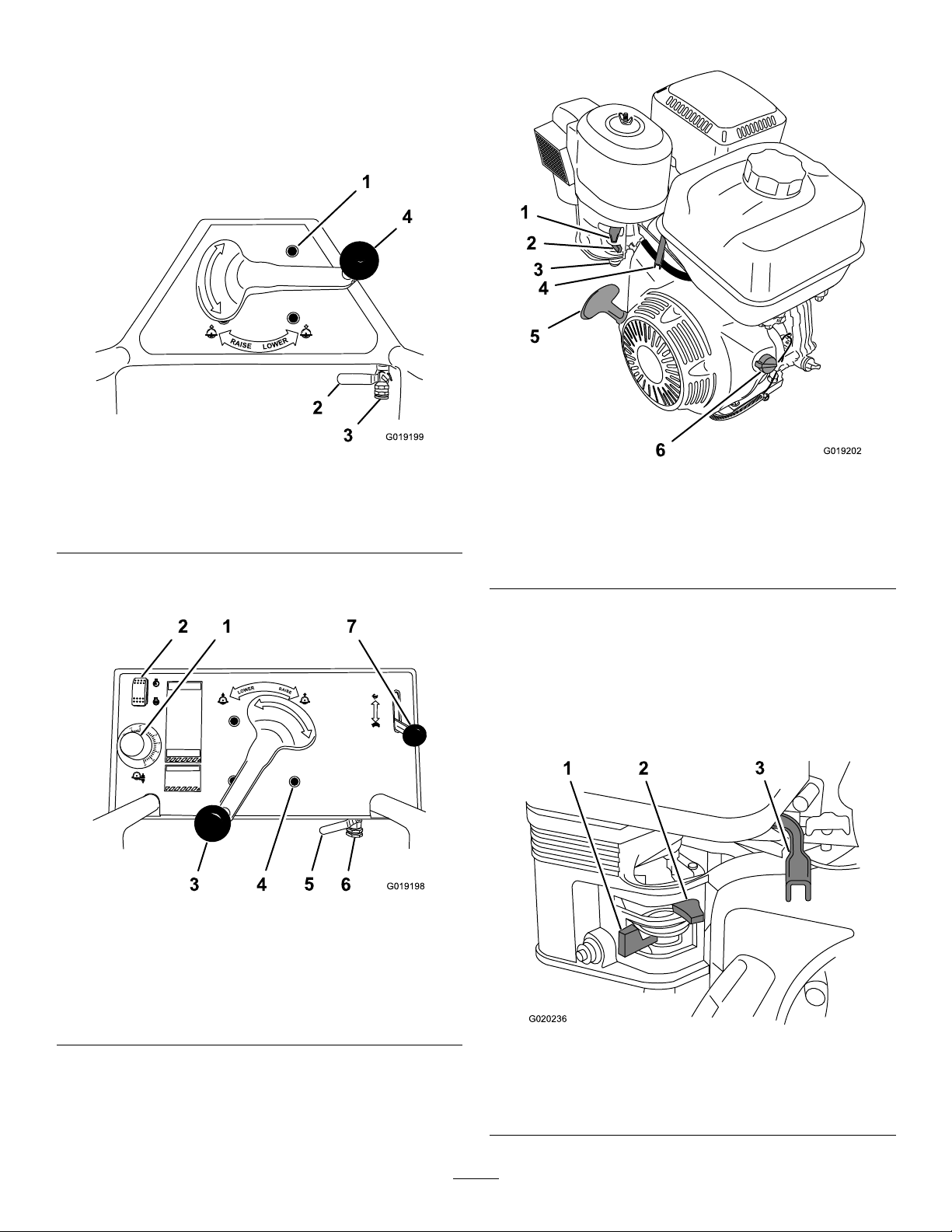

Controls

1

2

3

4

G019199

STOP

G019198

12

3 4

5

6

7

G019202

1

2

3

4

5

6

G020236

1 2

3

Becomefamiliarwithallthecontrols(Figure5,Figure6,and

Figure7)beforeyoustarttheengineandoperatethemachine.

OperatorPanel(Model68045)

EngineControls

Figure5

OperatorPanel(Model68045)

1.Indexhole3.Waterconnector

2.Watervalvehandle4.Elevationcrank

OperatorPanel(Model68046)

Figure6

OperatorPanel(Model68046)

Figure7

EngineControls(Models68045and68046)

1.Chokelever

2.Fuelvalvelever5.Recoilstarthandle

3.Sedimentcup

4.Throttlelever

6.Engineswitch

FuelValve

Thefuelvalve(Figure8)islocatedunderneaththechoke

lever.TheleverforthefuelvalvemustbemovedtotheOn

positionbeforeattemptingtostarttheengine.Onceyouhave

nishedusingthemachineandyouhaveturnedtheengine

off,movetheleverforthefuelvalvetotheOffposition.

1.Bladedepthgauge5.Watervalvehandle

2.Engineswitch6.Waterconnector

3.Bladeelevationcrank7.Throttle

4.Indexhole

Figure8

EngineControls

1.Fuelvalve3.Throttlelever

2.Chokelever

8

Page 9

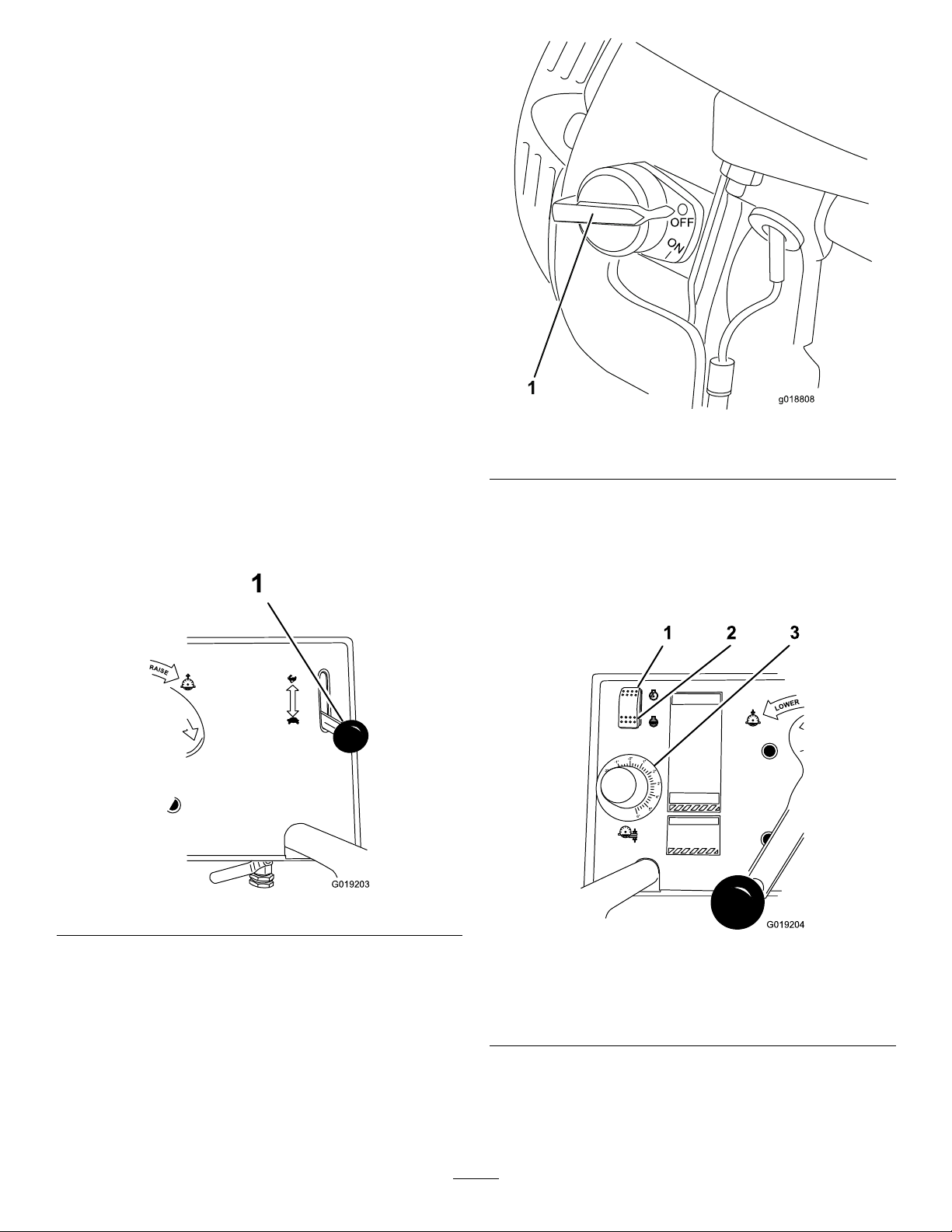

ChokeLever

G019203

1

OFF

ON

g018808

1

STOP

G019204

1 2

3

Thechokelever(Figure8)isrequiredwhenstartingacold

engine.Beforepullingontherecoilstarterhandle,move

thechokelevertotheclosedposition.Oncetheengineis

running,movethechokelevertotheopenposition.Do

notusethechokeiftheengineisalreadywarmeduporthe

airtemperatureishigh.

ThrottleLever(Model68045)

Thethrottlelever(Figure8)controlsthespeed(RPM)of

theengine.Itislocatednexttothechokelever.Itsetsthe

engineRPMandthereforecanincreaseanddecreasethe

rotationspeedofthesawblade.Forbestperformanceitis

recommendedyousetthiscontroltothefastposition.

ThrottleControl(Model68046)

Important:Model68046only—donotusethethrottle

leverontheengine.Damagetothethrottlelinkagemay

occurtotheoperatorpanelthrottlecontrol.

Thethrottlecontrolislocatedontheoperatorpanel

(Figure9),andcontrolsthespeed(RPM)oftheengine.It

setstheengineRPMandthereforecanincreaseanddecrease

therotationspeedofthesawblade.Forbestperformanceit

isrecommendedyousetthiscontroltothefastposition.

Figure10

1.EngineOn/Offswitch

EngineSwitch(Model68046)

Theengineswitchislocatedontheoperatorpanel(Figure11).

Usetheengineswitchtostoptheengineduringroutine

machineoperationandwhenshuttingthemachineOffin

anemergencysituation.

Figure9

EngineOn/OffSwitch

TheOn/Offswitch(Figure10)allowstheoperatorofthe

machinetostartandstoptheengine.Thisswitchislocated

onthefrontoftheengine.Itismarkedl(ON)andO(OFF).

Tostartthemachine,youmustrstmovethiscontroltothe

Onposition.Whenyouwanttostoptheengine,movethis

switchtotheOffposition.

Figure11

EngineSwitchandBladeDepthGauge(Model68046)

1.Runengine3.Bladedepthgauge

2.Stopengine

RecoilStarter

Tostarttheengine,pullontherecoilstarthandle(Figure7)

quicklytoturntheengineover.Thecontrolsontheengine

9

Page 10

describedabovemustallbesetcorrectlyfortheengineto

start.

OilAlertSystem

TheOilAlertsystemisdesignedtopreventenginedamage

causedbyaninsufcientamountofoilinthecrankcase.

Beforetheoillevelinthecrankcasecanfallbelowasafelimit,

theOilAlertsystemwillautomaticallystoptheengine(the

engineswitchwillremainintheONposition).Iftheengine

stopsandwillnotrestart,checktheengineoillevelbefore

troubleshootinginotherareas.

BladeDepthGauge(Model68046)

Thebladedepthgauge(Figure11)isusedtoindicatethesaw

bladeelevationabovethejobsitesurfaceandblade-cutdepth

intothejob-sitesurface.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Model68045Model68046

Length

Width

Height

Weight

ArborSpeed

(Max.)

ArborDiameter

BladeDiameter

/CuttingDepth

(Max)

92.7cm(36.5inch)†120.1cm(47.3inch)

67.5cm(26.6inch)67.6cm(26.6inch)

87.4cm(34.4inch)93.3cm(36.75inch)

80Kg(175lb)141Kg(310lb)

55.3Hz(3200RPM)55.3Hz(3200RPM)

25.4mm(1inch)25.4mm(1inch)

356mm(14inch)

blade/1 17mm(4.63

inch)depth

†

‡

356mm(14inch)

blade/117mm

(4.63inch)depth

406mm(16inch)

blade/143mm

(5.63inch)depth

457mm(18inch)

blade/168mm

(6.63inch)depth

†Pointerintheupposition.

‡Handlesinthemidposition.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesare

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

10

Page 11

Operation

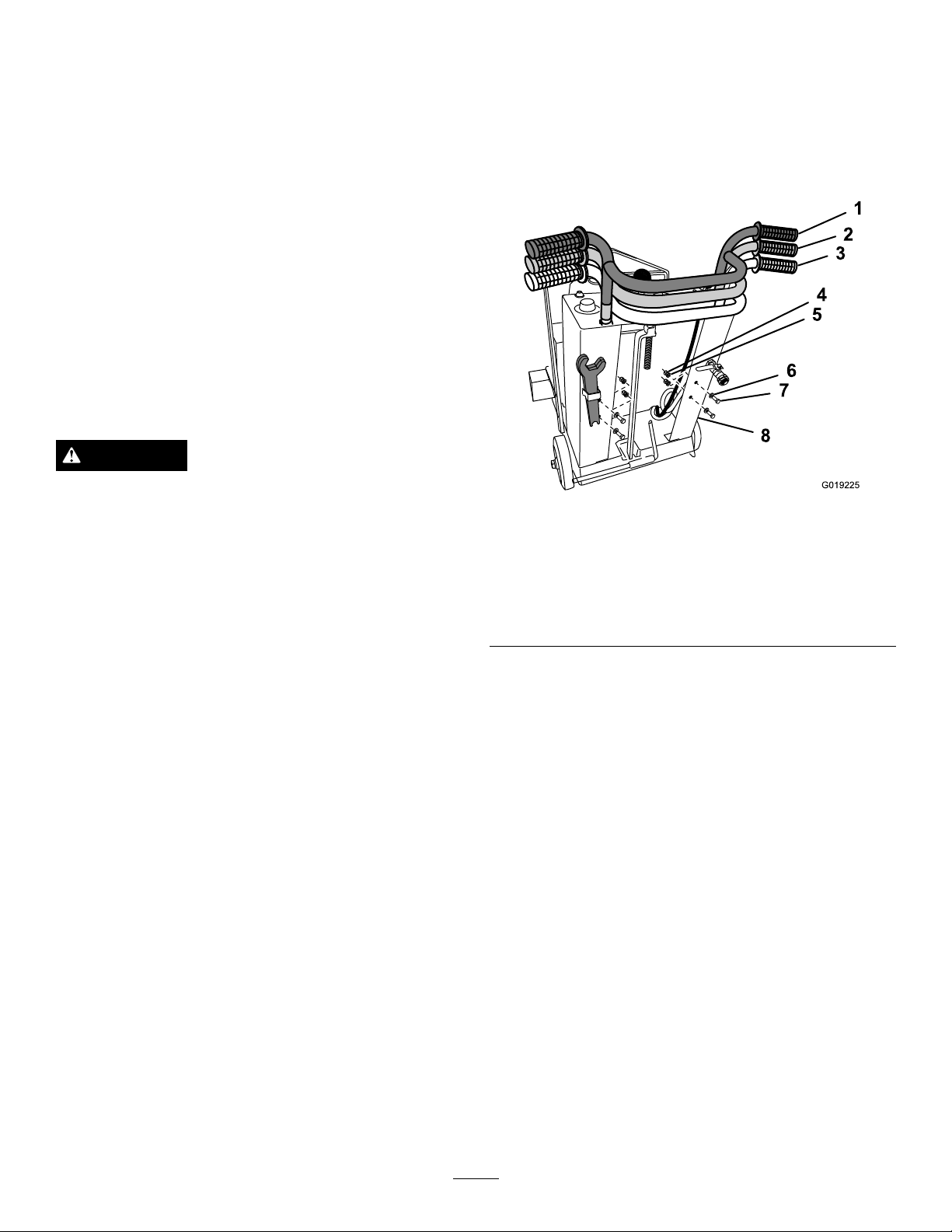

G019225

1

2

3

4

5

6

7

8

Important:Beforeoperating,checkthefuelandoil

level,andremovedebrisfromthemachine.Also,ensure

thattheareaisclearofpeopleanddebris.Y oushould

alsoknowandhavemarkedthelocationsofallutility

lines.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Model68045:Useforsurfacesawingasphaltandconcrete

ofsmallerjobssuchasoorandpavementrepair,expansion

jointcutting,conduitchannelcutting,andotheratwork.

Model68046:Useforsurfacesawingasphaltandconcreteof

jobsthatrequireprecisioncuttingincludingoors,walkways,

ramps,andotheratsurfaces.

BeforeyouStart

DANGER

Identifyandmarkthelocationandrouteofwater,

gas,andelectricallines.Lossoflifeordamageto

propertymayoccuriftheseutilitiesarecut.

AdjustingtheHandleBar (Model68046)

RaisingandLoweringtheHandleBar

1.Locatetheboltsthatsecurethehandlebarstotheback

oftheconsole(Figure12).

Figure12

HandleBarAdjustment(Model68046)

•Usethecorrectbladeforthematerialbeingcut.

•Ensurethatthearbor,collars,andarbornutare

undamaged.

•Installthebladewithbotharborwrenches.

•Whenwetcutting,ensurethatthewaterjetsproduce

adequatewaterow .

•Alignthepointer(s)withthesawblade.

•Removeallequipmentandloosedebrisfromthejobsite

cuttingpath.Removelooseconcrete,asphalt,orboth

fromthecuttingpath.

•Reviewallthemachine’ ssafetydecals.

•Wearahard-hat,respiratorordustmask,hearing

protection,andeyeprotectionwhenoperatingthe

machine.

•Ensurethatyouarefamiliarwithsafetyregulationsand

shutdownproceduresdescribedintheOperator’sManual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Ensurethatthebladeishasnodamageorunusualwear,

andissecuretothearbor.

•Ensurethateveryone,includingchildrenandanimals,

maintainadistanceofatleast50feet(15m)fromthe

machine.Debriscanbethrownoutandinjurepeople

andanimals.

1.Highposition5.Lockwasher

2.Middleposition6.Flatwasher

3.Lowposition7.Bolt

4.Nut

2.Removethebolts,nuts,andwashersthatsecurethe

handlebartotheconsole(Figure12).

3.Raiseorlowerthehandlebar(Figure12).

4.Aligntheholesinthehandlebarwiththemounting

holesintheconsole.

5.Securethehandlebartotheconsolewiththebolts,

nuts,andwashersremovedinstep2(Figure12).

8.Console

RemovingandInstallingthe SawBlade

Important:Beforeremovingorinstallingthesawblade,

removethesparkplugwirefromthesparkplug.

Note:Ensurethatthefollowingconditionsaremetwhen

installingthesawblade:

•Ensurethatthebladeisratedfor3200RPMorgreater

beforeinstallingitonthemachine.

•Checkthecoolingrequirementsforthebladeandcutting

operation.

Alwaysusewaterwithawet-cuttingdiamondblade.A

dry-cuttingbladecanbeusedwithorwithoutwater.

11

Page 12

•Ensurethatthebladespecicationandsizematchesthe

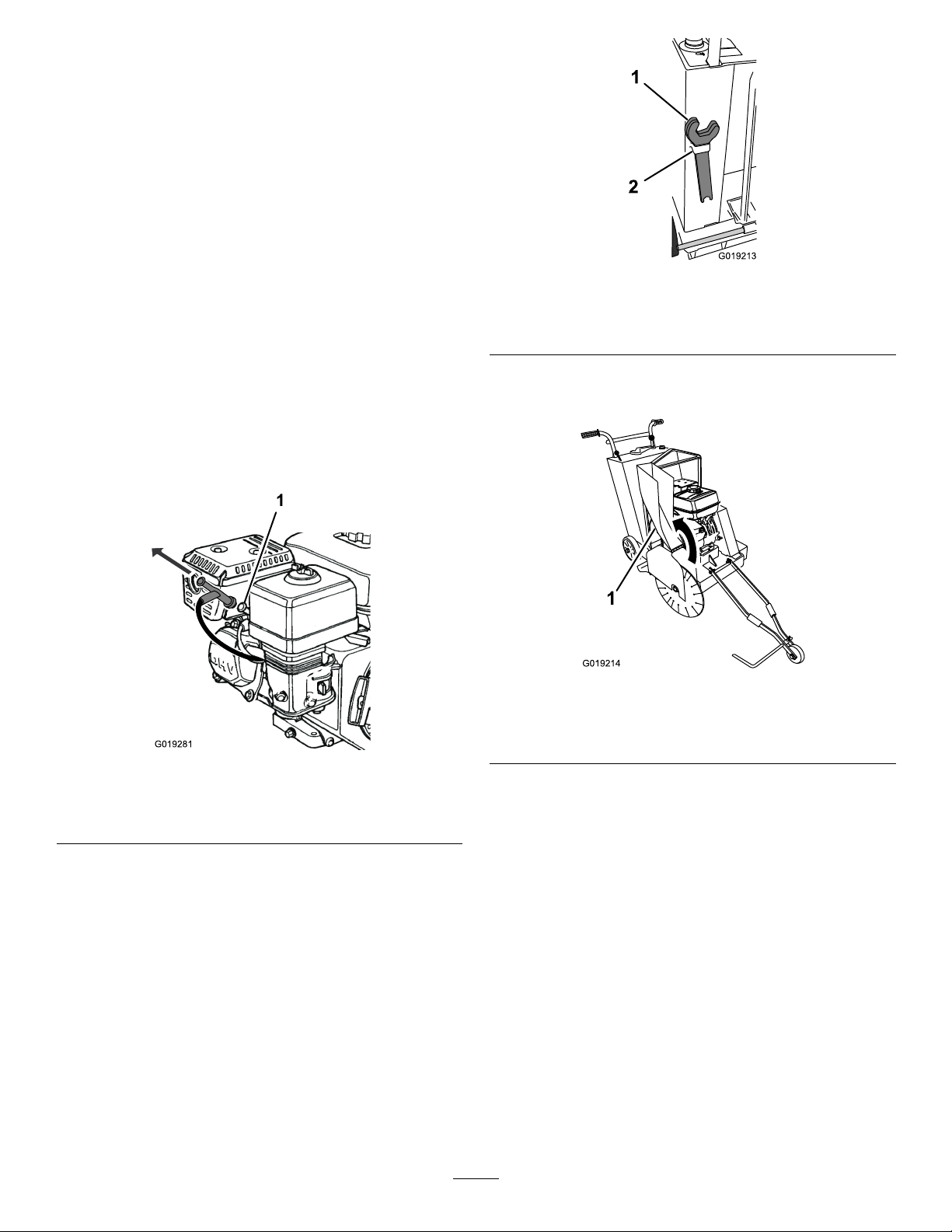

G019281

1

G019213

1

2

1

G019214

cuttingapplication.Checkwiththeblademanufacturer

fortheproperapplication.

•Ensurethatthebladeisnotdamagedwithanyofthe

followingconditions:

–Worncore

–Crackedcore

–Missingsegments

–Wornarborhole

–Worndrive-pinhole

RemovingtheBlade

1.RaisethesawbladetotheStartElevation;referto

stepCinChangingCutDepth(page14).

2.Parkthemachineonalevelsurfaceandturnoffthe

engine;refertoStoppingtheEngine(page19).

3.Ensurethatthemachinesurfacesarecool.

4.Disconnectthesparkplug(

Figure13).

Figure14

ArborWrenchStorage

1.Wrenches

2.Storagebracket

6.Rotatetheforwardsectionofthebladeguardopen

(Figure15).

Figure15

BladeGuard

1.Forwardbladeguardsection

Figure13

DisablingtheEngine

1.Sparkplugwire

7.Placeonewrenchontheatsoftheinnercollarand

placetheotherwrenchonthearbornut.Removethe

arbornutbyrotatingitcounterclockwise(Figure16).

5.Removethe2wrenchesfromthestoragebracketatthe

back-leftsideoftheoperatorpanel(Figure14).

12

Page 13

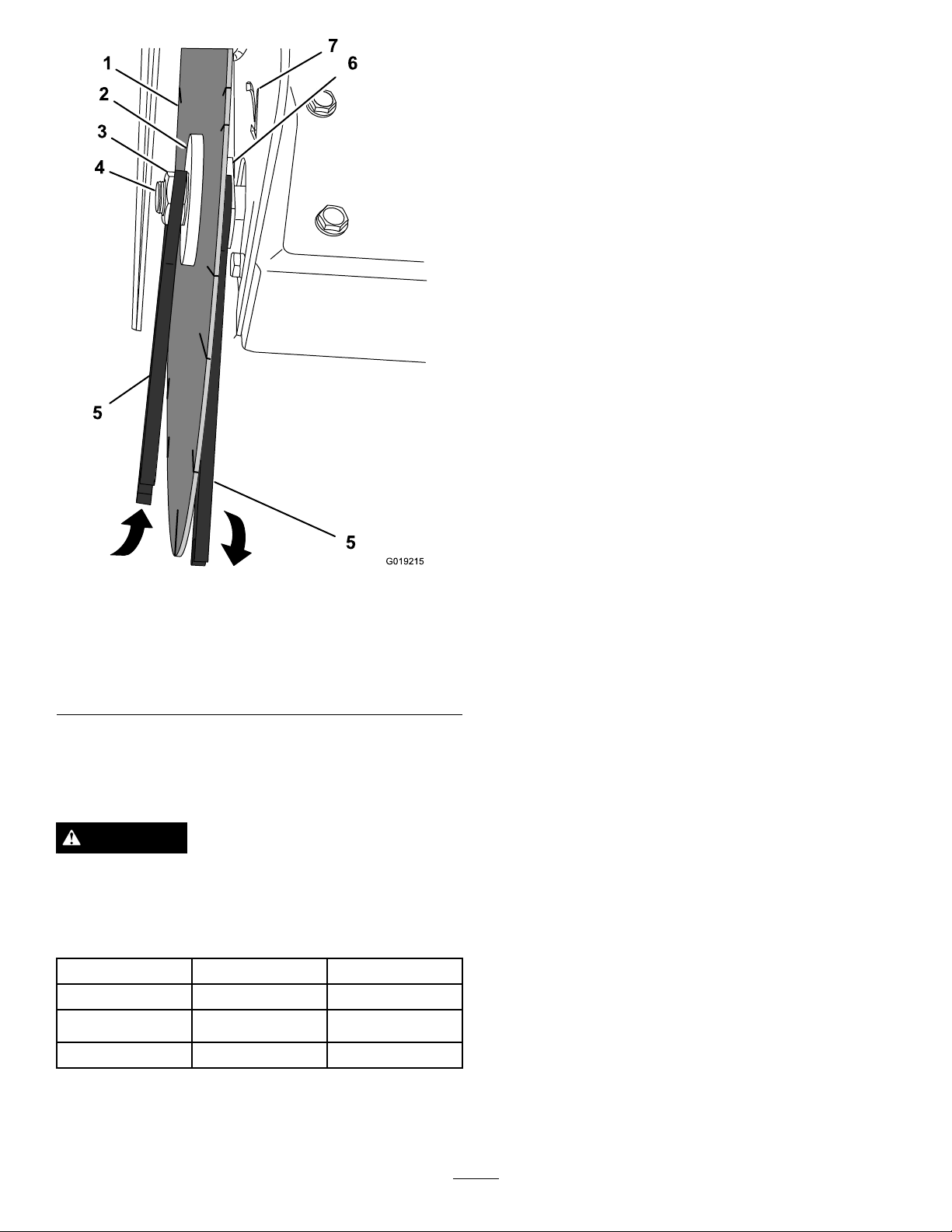

G019215

1

2

3

4

5

5

6

7

B.Ensurethatthemachinesurfacesarecool.

C.Disconnectthesparkplug(

Figure13).

D.Removethe2arborwrenchesfromthestorage

bracketattheback-leftsideoftheoperatorpanel;

refertoRemovingtheBlade(page12).

E.Opentheforwardsectionofthebladeguard;

referto

RemovingtheBlade(page12).

F.Inspecttheoutercollar,innercollar,drivepin,

andarborfordamage.Cleanthecollarclamping

surfaces,drivepin,andarborwithacleanrag.

G.Inspecttheinnercollarandensurethatitis

mountedtightonthearbor.

H.Removeanyburrsonthearbor,collarclamping

surfacesandsawbladeclampingsurfaces.

I.Inspectthebladeguardandthewatertubesinside

thebladeguardfordamage.

2.Installthebladeasfollows:

A.Ensurethattherotationarrowonthesawblade

pointsinthesamedirectionastherotationarrow

ontheouterbladeguardside.

Note:Ensurethatthebladeelevationisraised

adequatelytoinstalltheblade.

Figure16

BladeandArbor

1.Sawblade

2.Outercollar

3.Arbornut7.Arborrotationarrow

4.Arbor

5.Wrench

6.Innercollar

arborandmovethebladetowardtheinnercollar

Figure17).

(

B.Alignthearborholeinthesawbladetothe

8.Removethelockwasher,outercollar,andsawblade.

RefertoInstallingtheBlade(page13)

InstallingtheBlade

DANGER

Donotrunthemachinewithlooseormissingarbor

parts.

Important:Alwaysusethepropersizebladeguardand

splashguard.

BladeGuardSize

35.56cm(14in)StandardOptional

40.64cm(16in)Optional

Model68045Model68046

45.72cm(18in)Standard

1.Dothefollowingbeforeinstallingthesawblade:

A.Parkthemachineonalevelsurfaceandturnoff

theengine;refertoStoppingtheEngine(page19).

13

Page 14

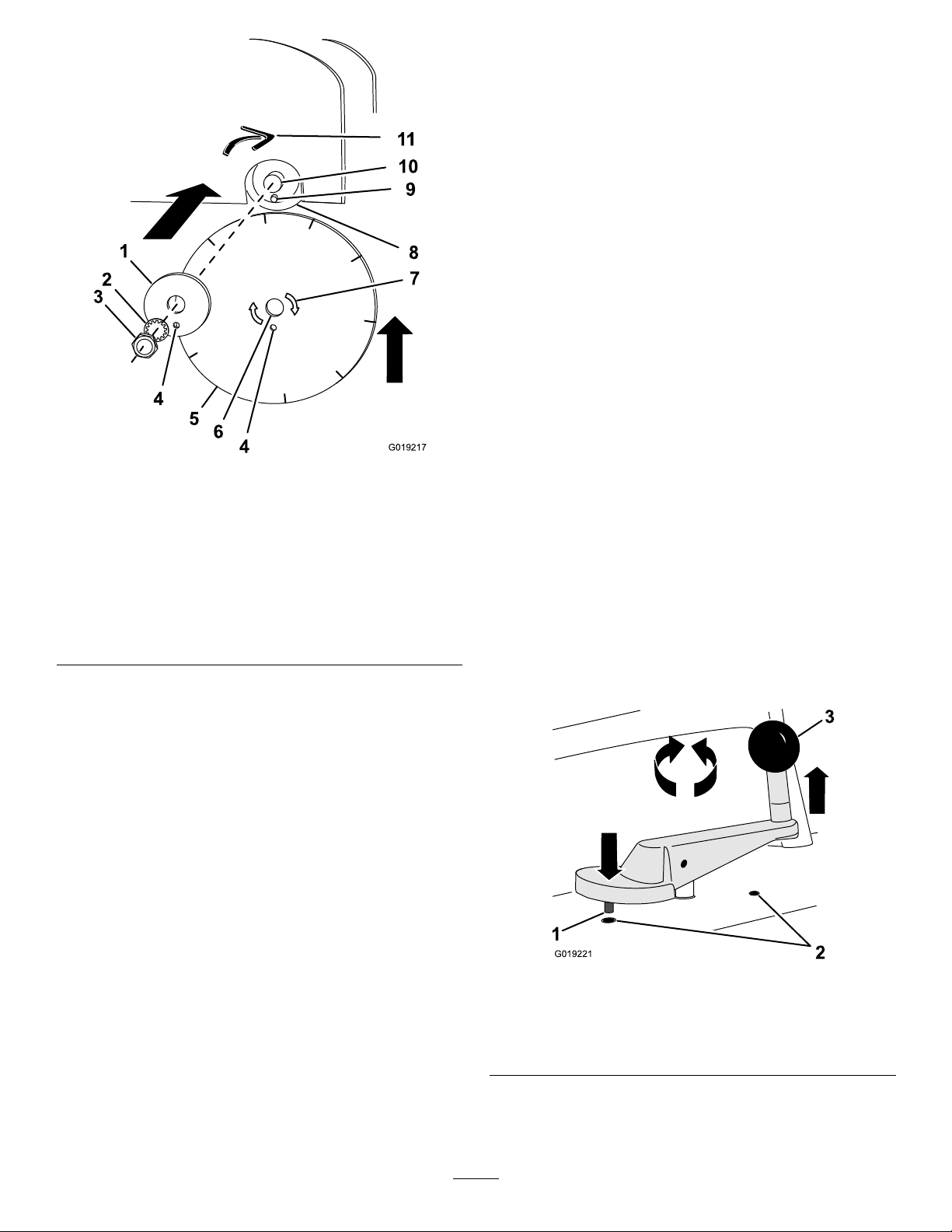

G019217

1

2

3

4

5

6

4

8

9

10

11

7

H.Placeonearborwrenchontheatsoftheinner

G019221

1

2

3

collarandplacetheotherwrenchonthearbor

nut.Tightenthearbornutbyrotatingitclockwise.

3.Lowerthefrontbladeguardsection,stowthearbor

wrenchedinstoragebracket,andconnectthespark

plug.

4.Starttheengineandallowthemachineto

runatfullthrottlefor30seconds;referto

StartingtheEngine(page19).

5.Stoptheengine.

AdjustingtheCuttingDepth

Important:Forcutdepthlimits,refertothemachine

Specications(page10).

Note:Rotatetheelevationcrankclockwisetoraisetheblade;

rotatetheelevationcrankcounterclockwisetolowertheblade.

ChangingCutDepth

Figure17

BladeInstallation

1.Outercollar7.Rotationarrow(sawblade)

2.Lockwasher8.Innercollar

3.Arbornut9.Drivepin

4.Drive-pinhole10.Arbor

5.Sawblade11.Rotationarrow(blade

guard)

6.Arborhole

C.Alignthedrive-pinholeinthebladetothedrive

pinthatisprotrudingfromtheinnercollar.Seat

thebladeagainsttheinnercollar(Figure17).

Important:Ensurethatthesawbladehasa

sliptwiththearboranddrivepin.Ifthere

isexcessivemovementbetweentheblade

andthearborandpin,replacethewornparts

beforeoperatingthemachine.

Note:Checkthatthewatertubesinsidetheblade

guardareclearoftheblade.

Important:Eachrevolutionofthebladeelevationcrank

raisesorlowersthebladeapproximately11mm(7/16

inch).

1.AdjustthesawbladetotheStartElevationbydoing

thefollowing:

A.Alignthemachinetothecuttingpathofthe

job-sitesurface.

B.Usingthebladeelevationcrank(Figure18),rotate

thecrankcounterclockwisetolowertheblade

untiltheittouchesthejob-sitesurface.

Note:Thebladeisatthe+0mm(+0inch)

elevation.

D.Aligntheoutercollartothearborandmoveit

towardtheblade(

Figure17).

E.Alignthedrive-pinholeintheoutercollarwiththe

drivepinprotrudingthroughthesawblade,and

thenseatthecollaragainsttheblade(Figure17).

F.Rotatetheoutercollarandsawbladeinthe

oppositedirectionoftherotationarrowonthe

bladeguardtoremoveanyresidualdrivepin

1.Indexpin3.Elevationcrank

2.Index-pinhole

Figure18

Elevationcrank

backlash

G.Installthelockwasherandarbornut(

Figure17).

C.Rotatetheelevationcrank1revolutionclockwise

toraisethebladeelevation(Figure18).The

machineisattheStartElevation.

14

Page 15

Note:TheStartElevationiswhenthesaw

STOP

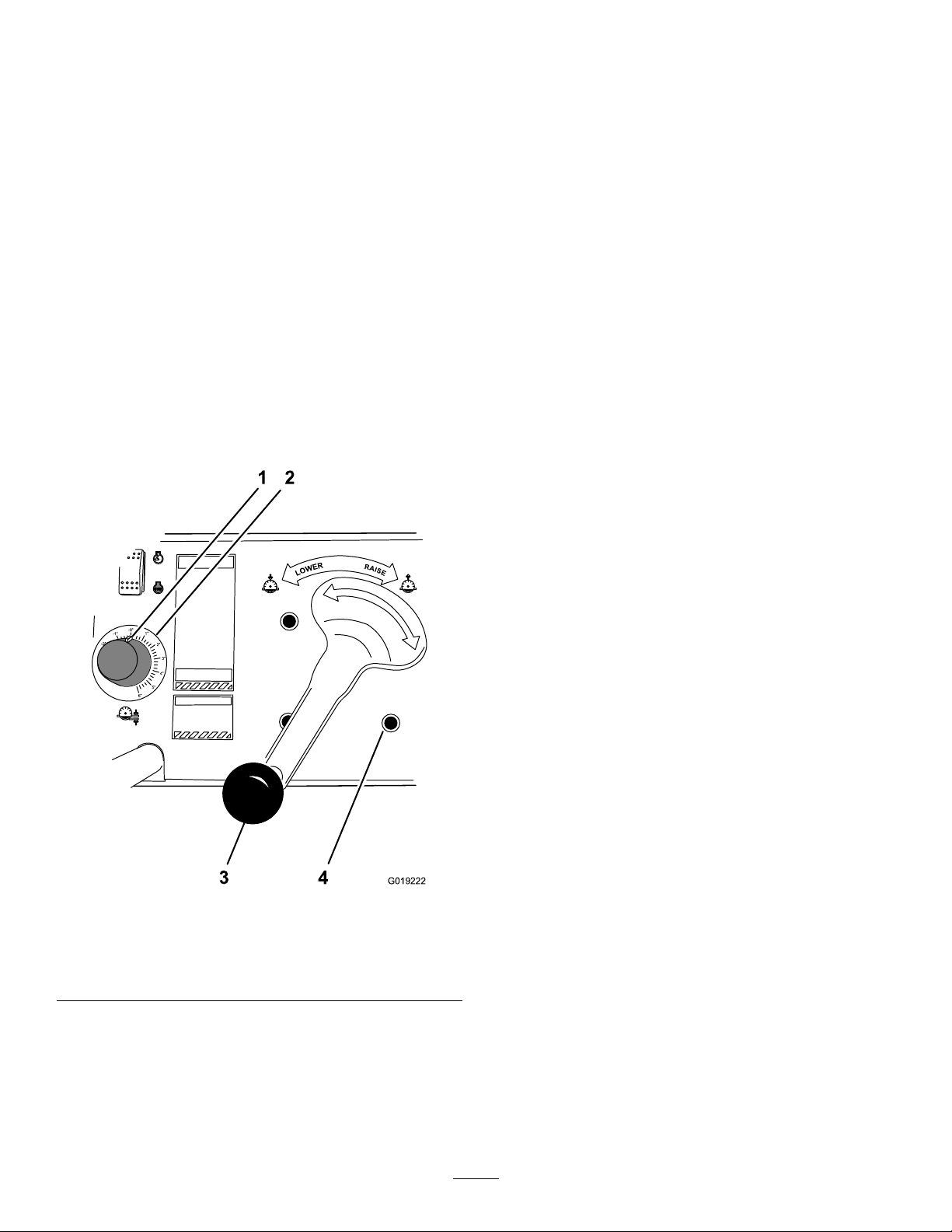

G019222

21

3

4

bladeisat+11mm(+7/16inch)abovethe

job-sitesurface.Raisethesawbladetothestart

elevationwhenmovingthemachine,maintaining

themachine,andstartingandstoppingtheengine

2.Adjustthecutdepthofthesawbladeasfollows:

•Rotatetheelevationcrankclockwisetoraisethe

bladeelevation.

•Rotatetheelevationcrankcounterclockwiseto

lowerthebladeelevation.

AdjustingtheBlade-DepthGauge

(Model68046)

1.Adjustthebladeelevationtothe+0mm(+0

inch)elevation;refertostepsAandBin

ChangingCutDepth(page14).

2.Rotatethedialoftheblade-depthgaugeuntilthe

pointer(white)isalignedwiththe“-0”markonthe

gauge(Figure18).

LockingtheBladeElevation

Thebladeelevationcanbelockedwhenmaintainingtheblade

elevationisdesirable.Lockthebladeelevationasfollows:

1.Raiseorlowerthesawbladebyrotatingtheelevation

crankuntilthedesiresbladeelevationisachieved

(Figure18).

2.Ifnecessary,rotatetheelevationcranktoalignthe

indexpininthebottomofthecrankhandlewitha

index-pinholeintheoperatorpanel(Figure18).

3.Pulltheelevationcrankuptoengagetheindexpinin

thehole(Figure18).

Note:Tounlockthebladeelevation,pushdownthe

elevationcranktodisengagetheindexpinfromthe

indexhole.

AligningthePointer

Note:Model68045hasafrontpointer.Model68046hasa

frontandbackpointer.

1.EnsurethatthesawbladeisattheStartElevation;

refertostepCinChangingCutDepth(page14).

Figure19

BladeDepthGauge

1.Dialandpointer3.Elevationcrank

2.Blade-depthgauge4.Index-pinhole

2.Parkthemachineonalevelsurfaceandturnoffthe

engine;refertoStoppingtheEngine(page19).

3.Ensurethatthemachinesurfacesarecool.

Note:Ensurethatthebladeisinstalled;referto

InstallingtheBlade(page13).

AligningtheFrontPointer

Note:Thefrontpointeralignmentprocedurerequiresa1.2

m(4ft)minimumlengthofmasonline.

1.Lowertheforwardpointer.

2.Pullalengthofmasonlineacrossthesurfaceofthe

saw-bladecoreandextendittotheendofthepointer

(onestraightline)asshowningureFigure20.

3.Adjustthepointerpositionasfollows:

•Model68045—Alignthefrontpointerbycarefully

bendingthebarofthepointeruntilitisaligned

withthemasonline(Figure20).

3.RaisethesawbladetotheStartElevation;referstep

CinChangingCutDepth(page14).

Note:Refertothebladedepthgaugewhenraising

andloweringthesawblade(Figure19).

15

Page 16

G019226

1

2

3

Figure20

G019228

1

2

3

4

5

6

G019231

1

2

3

4

6

7

5

PointerAlignment(Model68045)

1.Pointer

2.Mason’sline

3.Saw-bladecore

•Model68046—Alignthefrontpointerbydoing

thefollowing:

A.Loosenthumbscrewthatsecurestheforward

pointertothepointerfork(

Figure21

ForwardPointerAlignment(Model68046)

1.Pointerfork4.3–6mm(1/8–1/4inch)

2.Thumbscrew5.Masonline

3.Forwardpointer

6.Saw-bladecore

Figure21).

Figure22

RearPointerAlignment(Model68046)

1.Forwardpointer

2.Sawblade

3.Rearpointer

4.Chalkline

5.3–6mm(1/8–1/4inch)

6.Thumbscrew

7.Console

2.Alignthesawbladeandtheforwardpointertotheline

markingthejobsitesurface(

Figure22).

3.Atthebackoftheconsole,loosenthumbscrewthat

securesthepointertothebackofthebaseandrotate

thepointerdown(Figure22).

4.Slidethepointerleftorrighttoalignittotheline

markingthejobsitesurface,andelevatethepointer3–6

mm(1/8–1/4inch)abovethesitesurface(Figure22).

5.Tightenthethumbscrewthatsecuresthepointerto

baseofthemachine(Figure22).

B.Slidethepointerleftorrighttoalignit

withthemasonline,andelevated3–6mm

(1/8–1/4inch)abovethejobsitesurface

(Figure21).

C.Tightenthethumbscrewthatsecures

theforwardpointertothepointerfork

(Figure21).

AddingFuel

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•DoNotuseethanolblendsofgasoline(suchasE15

AligningtheRearPointer(Model68046)

Note:Therearpointeralignmentprocedurerequiresa3m

(10ft)minimumlengthofchalkline.

Note:Alignthefrontpointerbeforealigningtherear

pointer;refertoAligningtheFrontPointer(page15).

1.Marka3m(10ft)orlongerlineonthejobsitesurface

bysnappingachalklineonthesurface(

Figure22).

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•DoNotaddoiltogasoline.

16

Page 17

DANGER

WARNING

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

Important:Donotmixoilwithgasoline.

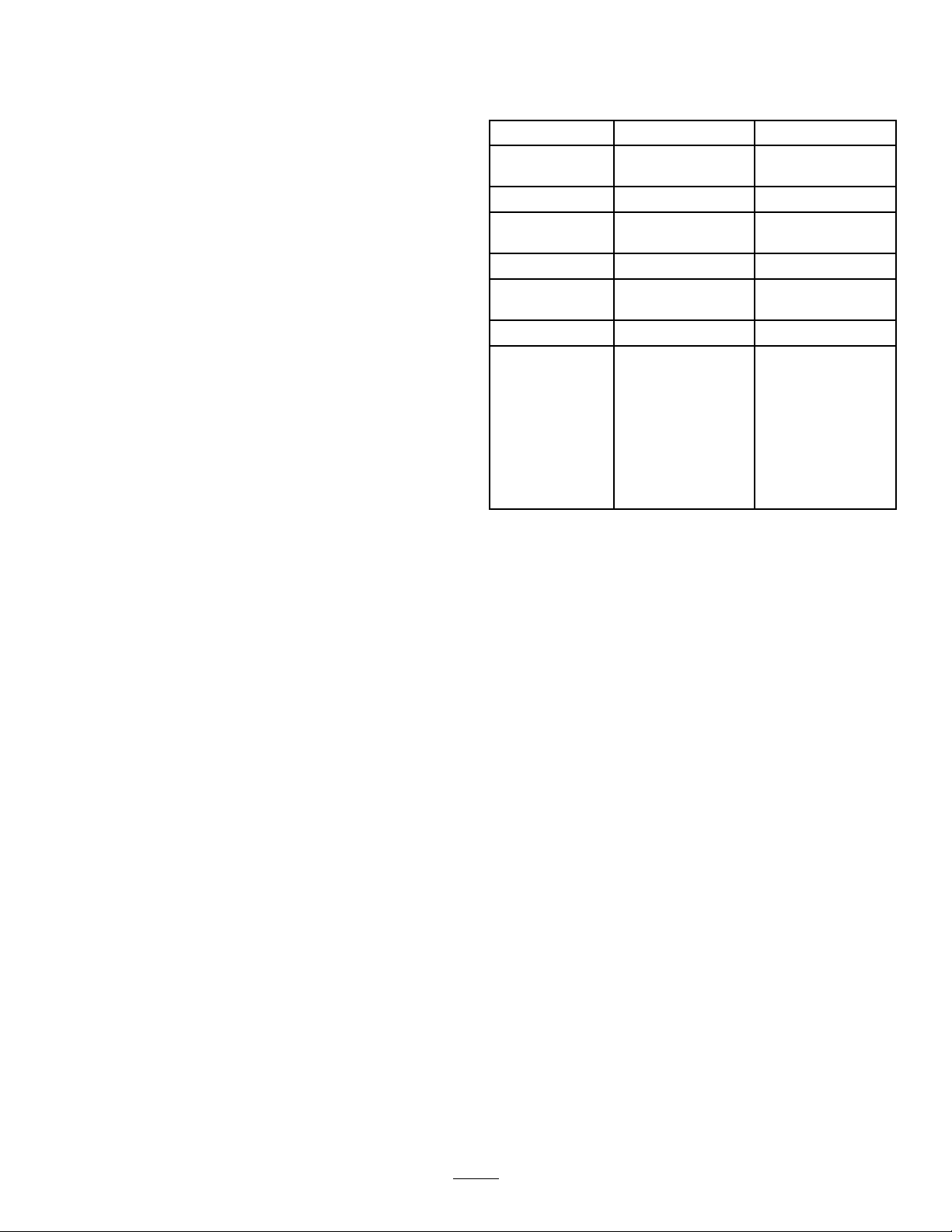

RecommendedFuel

UnleadedGasoline

U.S.

Except

U.S.

Pumpoctanerating87orhigher

Researchoctanerating92orhigher

Pumpoctanerating87orhigher

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Cleanstheenginewhileitruns.

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

FillingtheFuelTank

Note:Thefueltankcapacityis6.1liter(1.61USGallon).

1.Parkthemachineonalevelsurface,stoptheengine,

andallowtheenginetocool.

2.Cleanaroundthefueltankcapandremoveit

(

Figure23).

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

17

Page 18

G019224

Figure23

0 20 40 60

80

10 0°F

-20 -10 0 10 20 30 40 °C

5W–30 · 10 W– 30

30

1

G019298

1

2

G018670

3

1.Fueltankcap

3.Addunleadedgasolinetothefueltank,untilthelevelis

1/4to1/2inchbelowthebottomofthellerneck.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

Note:SAE10W-30isrecommendedforgeneraluse.Other

viscositiesshowninthechartmaybeusedwhentheaverage

temperatureinyourareaiswithintheindicatedrange.

CheckingtheEngineOilLevel

Important:Runningtheenginewithlowoillevelcan

causeenginedamage.Thistypeofdamageisnot

coveredbywarranty.

Theengineisequippedwithanoilalertsystemthatwill

automaticallystoptheenginebeforetheoillevelfalls

belowthesafelimit.

1.Ifthesawbladeisinstalled,dothefollowing:

A.Ensurethatthesawbladeisatthe

StartElevation;refertostep

AdjustingtheCuttingDepth(page14).

B.Removethesawblade;referto

RemovingtheBlade(page12).

2.Leveltheenginebyraisingorlowering

itwiththeelevationcrank;referto

AdjustingtheCuttingDepth(page14).

3.Cleanaroundtheoildipstick.

4.Removetheoilller/dipstickandwipeitclean

(Figure25).

Cin

4.Installthefueltankcapsecurely.

5.Wipeupanygasolinethatmayhavespilled.

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checktheengine

oillevel.

Important:Use4-strokemotoroilthatmeetsofexceeds

therequirementsforAPIservicecategory

equivalent).AlwayschecktheAPIservicelabelonthe

oilcontainertobesureitincludestheSJorlater(or

equivalent).

Figure24

RecommendedOilViscosity

SJ or later

(or

Figure25

OilFiller/DipStick

1.Oilllercap/dipstick

2.Fillerport

3.DrainPlug

5.Inserttheoilller/dipstickintothellerneckas

showningureFigure26,butdonotthreaditinto

thellerneck.

1.Oilviscosityrangeforambientoperatingtemperatures

18

Page 19

1

2

G018669

Figure26

G019270

MaximumandMinimumOilLevels

1.Upperoillimit2.Loweroillimit

Note:Onmodel68046machines,donotusethe

throttlecontrolleverontheengine.

4.Ontheengine,movetheleverofthefuelvalveto

theOnposition—allthewaytotheright;referto

FuelValve(page8).

5.Tostartacoldengine,movethechokelevertothe

Closedposition—allthewaytotheleft;referto

ChokeLever(page9).

Note:T orestartawarmengine,leavethechokelever

intheOpenposition(allthewaytotheright).

6.Ontheengine,rotatetheengineswitchtotheOn

position;refertoEngineOn/OffSwitch(page9).

7.Pulltherecoilstarthandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly .Returnthe

starterhandlegently(Figure27).

6.Removetheoilller/dipstickfromthellerportand

lookattheendofthedipstick.Theoillevelshouldbe

tothetopoftheupperlimitrange(Figure26).

Important:Donotoverllthecrankcasewithoil

becausetheenginemaybedamaged.

7.Iftheoillevelislow ,slowlypouronlyenoughoilinto

theenginecrankcasetoraisetheleveltotheupperlimit.

8.Threadthedipstickintothellerporthandtight.

9.Ifthemachineisbeingoperated,installthesawblade;

reference

InstallingtheBlade(page13).

StartingandStoppingthe Engine

StartingtheEngine

1.RaisethesawbladetotheStartElevation;referto

stepCinAdjustingtheCuttingDepth(page14).

2.Model68046—Ontheoperatorpanel,press

theengineswitchtotheRunposition;referto

EngineSwitch(Model68046)(page9).

3.Positionthethrottleasfollows:

•Model68045—Ontheengine,movethethrottle

leverawayfromtheMIN.position,1/3of

thewaytowardtheMAXposition;referto

ThrottleLever(Model68045)(page9).

•Model68046—Ontheoperatorpanel,move

thethrottlecontrolawayfromtheSlowposition,

1/3ofthewaytowardtheFastposition;referto

ThrottleControl(Model68046)(page9).

Figure27

StartingtheEngine

8.IfthechokeleverissettotheClosedpositionto

starttheengine,graduallymovethechokeleverback

towardtheOpenpositionastheenginewarmsup.

Iftheenginestallsorhesitates,movethechokelever

backtowardstheClosedpositionuntiltheengineruns

smooth.Allowtheenginetowarmup,thenmovethe

chokelevertotheOpenposition.

StoppingtheEngine

WARNING

Inanemergencysituation,stoptheengine

immediately.

Important:Duringnormaloperation,iftheenginehas

beenworkinghardorishot,letitrunforaminutebefore

stoppingtheengine.Thishelpstocooltheengine

beforestopping .

Duringnormaloperatingconditions,shutdowntheengine

asfollows:

19

Page 20

1.RaisethesawbladetotheStartElevation;referto

AdjustingtheCuttingDepth(page14)

CuttingtheJob-SiteSurface

2.EnsurethatthechokeleverisintheOffposition;refer

toChokeLever(page9).

3.Dothefollowingtostoptheengine:

•Model68045

A.Ontheengine,movethethrottle

levertotheMIN.position;referto

ThrottleLever(Model68045)(page9).

B.RotatetheengineswitchtotheOffposition;

refertoEngineOn/OffSwitch(page9).

•Model68046

A.Ontheoperatorpanel,movethethrottle

controltotheSlowposition;referto

ThrottleControl(Model68046)(page9).

B.Ontheoperatorpanel,presstheengine

switchtotheStopposition;referto

EngineSwitch(Model68046)(page9).

C.Ontheengine,rotatetheengine

switchtotheOffposition;referto

EngineOn/OffSwitch(page9).

4.MovetheleveronthefuelvalvetotheOffposition;

refertoFuelValve(page8).

EmergencyStop

Inanemergencysituation,shutdownthemachineasfollows:

•Model68045—Ontheengine,rotatetheengineswitchto

theOffposition;refertoEngineOn/OffSwitch(page9).

•Model68046—Ontheoperatorpanel,Press

theengineswitchtotheStopposition;referto

EngineSwitch(Model68046)(page9).

CAUTION

•Operatethemachinewiththesafetyguardsin

placeandingoodcondition.

•Donotoperatethemachinewithablade

diameterlargerthanthespeciedcapacity;refer

Specications(page10).

to

•DonotexceedthemaximumRPMofthe

blade;refertothemaximumarborspeedin

Specications(page10).

•Checkthebladecoolingrequirements.

Wet-cuttingdiamondbladesmustbeusedwith

coolant.Drycuttingbladescanbeusedwith

orwithoutcoolant.

•Donotmakelongcontinuouscutswhendry

cutting.Neverdrycutformorethan30seconds

atatime.Allowthebladetocoolbetweeneach

pass.

•Donotdrycutwithabladerecommendedfor

wetcutting .

•Donotforcethebladeintothematerial;allow

thebladetocutatitsownrate.

•Donotcutorgrindwiththesideofblade.Do

notcutacurveofradius.

•Inspecttheconditionofthesawbladedailyfor

excessivecorewear,cracks,missingsegments,

arborholewear,anddriveholewear.Replace

wornordamagedblades.

•Usecarewhenloweringathebladeintoan

existingcut.Ensurethatthebladeisaligned

withthecut.

ConnectingtheWaterSupply

1.Ensurethatthewatersupplytothehoseisturnedoff.

2.Atthebackofthemachineandbelowtheoperator’s

console,locatethewatershutoffvalveandcoupling

(Figure28).

20

Page 21

G019273

1

2

3

4

Figure28

G019280

1

4

2

3

2

3

WaterShutoffV alveandConnector

1.Offposition3.Shutoffvalveandcoupling

2.Onposition

4.Watersupplyhose

3.Ensurethatthehandlefortheshutoffvalveisinthe

Offposition(

Figure28).

4.Alignthehosewiththecouplingandthreadthe

couplingandhosetogether(

5.Tightenthecoupling.

CuttingOperation

Prepareforthecuttingoperationbydoingthefollowing:

1.RaisethesawbladetotheStartElevationandlock

thebladeelevationbyengagingtheindexpinofthe

crankhandlewithanindexholeintheoperatorpanel;

refertoAdjustingtheCuttingDepth(page14)and

LockingtheBladeElevation(page15).

2.Iftheforwardpointerisstowedintheupposition,

rotatetheextendedposition(Figure29).

Figure28).

Figure29

ForwardPointer(Models68045and68046)

1.Model680453.Extendedposition

2.Stowedposition

4.Model68046

3.Movethemachinetoalignthepointer(s)andsawblade

tothecuttingpathofthejob-sitesurface.

4.Ifwetsawing,dothefollowing:

A.Connectthewaterline;referto

ConnectingtheWaterSupply(page20).

B.Ensurethatthehandleofthewatershutoffvalve

isintheOffpositionandwatersupplytothe

hoseisturnedon.

5.Starttheengine;referto

StartingtheEngine(page19).

Note:Allowtheenginetowarmupuntilitruns

smoothlywiththechokeleverintheOpenposition.

6.Adjusttheenginespeedasfollows:

Note:Allsawingisdoneatfullenginespeed.

•Model68045—Movethethrottlelevertothe

MAXposition.

•Model68046—Movethethrottlecontroltothe

Fastposition.

7.Ifwetsawing,rotatethehandleofthewatershutoff

valvetotheOnposition(

Figure28).

Important:Ensurethatwaterisowingtothe

sawblade.

Beginthecuttingpassbydoingthefollowing:

21

Page 22

Important:Forcutsdeeperthan102mm(4inch),

G019282

1 2

3

4

severalcuttingpassesshouldbemadein38mm(1–1/2

inch)to51mm(2inch)stepsuntilthedesiredcutdepth

isreached.

1.Unlockthebladeelevationbypushingtheelevation

crankdowntodisengagetheindexpin.Rotatethe

elevationcrankcounterclockwisetolowerthesaw

bladetotouchthejob-sitesurface.

Note:Thebladeisat+0mm(+0inch)elevation.

Note:Formodel68046machines,rotate

thedialofthebladedepthgaugetoalign

themarkwithzero;refertostep2

inAdjustingtheBlade-DepthGauge(Model68046)(page15).

2.Slowlyrotatetheelevationcrankcounterclockwiseto

lowerthesawbladeintothecuttingpathofthejob-site

surface.

3.Whenthesawbladeisatthedesiredcuttingdepth,

aligntheindexpinintheelevationcrankwithanindex

holeintheoperatorpanelandlockthebladeelevation;

refertoLockingtheBladeElevation(page15).

Important:Avoidexcessivesidepressureor

twistingofthebladewhileitisinthecut.Use

onlyenoughsidepressureonthehandlebarofthe

machinetoaligntheittothecuttingpath.

4.Pushthemachinesteadilyforward.Feedthemachine

intothecutasfastasthesawbladewillallow .Ifthe

bladeclimbsoutofthecut,reducetheforward-feed

forceorreducethedepthofthecut.

ChangingtheCuttingPosition

Usethisproceduretocongureamachinewiththebladeon

therightsidetoamachinewiththebladeontheleftside,or

changethesawbladepositionfromtheleftsidetotheright.

Note:Theillustrationsbelowshowchangingtheblade

positionfromaleft-handinstallationtoaright-hand

installation.

PreparingtheMachineforthePosition

Change

1.Preparethemachineforthepositionchangebydoing

thefollowing:

A.RaisethesawbladetotheStartElevation;refer

tostepCinChangingCutDepth(page14).

B.Parkthemachineonalevelsurfaceandturnoff

theengine;refertoStoppingtheEngine(page19).

C.Ensurethatthemachinesurfacesarecool.

D.Disconnectthesparkplug(

2.Removethebladeasfollows:

A.Removethe2wrenchesfromthestorage

bracketattheback-leftsideoftheoperator

panelandremovethesawblade;referto

RemovingtheBlade(page12).

B.Assembletheoutercollar,lockwasher,andarbor

nuttothearbor.Tightenthenut.

Figure13).

Note:Exertenoughfeedforceonthemachinesothat

theenginebeginstolabor,butthebladeRPMdoesnot

slow .Iftheenginebeginstostall,reducethefeedforce

tothemachineuntilthefullbladeRPMisrestored.

Finishthecuttingpassbydoingthefollowing:

1.Attheendofthecuttingpass,unlocktheblade

elevationandraisethesawbladetotheStartElevation;

refertoAdjustingtheCuttingDepth(page14).

2.Lockthebladeelevation;referto

LockingtheBladeElevation(page15).

3.Ifwetsawing,rotatethehandleofthewatershutoff

valvetotheOffposition(Figure28).

4.Adjusttheenginespeedandallowittoidleatminimum

enginespeedfor5minutesasfollows:

•Model68045—MovethethrottlelevertotheMIN

position.

•Model68046—Movethethrottlecontroltothe

Slowposition.

Note:Idlingtheenginebeforeshuttingtheitoff

improvestheengineservicelife.

5.Shutofftheengine;referto

StoppingtheEngine(page19).

ChangingtheWaterHosePosition

Repositionthewaterhoseasfollows:

1.Releasetheinnerandouterserratedsegmentsfromthe

hoseclampthatsecuresthewaterhosetothebarbed

ttinginthebladeguard(Figure30).

Figure30

WaterHoseandFitting

1.Sawbladeguard

2.Barbedtting

3.Hoseclamp

4.Waterhose

22

Page 23

2.Removethewaterlinefromthebarbedtting.

G019283

1 2

G019285

1

3

4

2

1

2

G019286

Note:Removethehoseclampfromthewaterline

andretainit.

3.Routethewaterlineasfollows:

•Model68045—Routethewaterhosetothe

oppositesideofthemachine.

•Model68046

A.Pushthewaterhoseinthroughtheopening

atthebottom-forwardcorneroftheconsole

Figure31).

(

Figure31

ReroutingtheWaterHose

1.Leftposition

2.Rightposition

Figure32

BladeGuardRemoval

1.Forwardboltandwashers3.Rotationarrow

2.Bladeguard4.Rearboltandwashers

B.Supportthebeltguardandremovetherearbolt

andwashersthatsecurestheguardtothebase.

Removetheguard(Figure32).

C.Removetheboltsandwashersthatsecurethe

shaftguardtothebaseofthemachine,and

removetheguard(Figure33).

B.Frominsidetheconsole,pushthewater

hoseoutthroughtheopeningatthe

bottom-forwardcorneroftheconsoleonthe

oppositeside(Figure31).

ChangingtheGuardPosition

1.Removethebladeguardandshaftguardasfollows:

A.Usingawrenchfromthemachine,removethe

forwardboltandwashers,locatedinsidethebelt

guard,thatsecuretheguardtothebaseofthe

machine(Figure32).

ShaftGuardRemoval

1.Shaftguard

2.Installthebladeguardasfollows:

Important:

Left-hand

thatthearrowonoutsideofthebladeguard

indicates

23

counterclockwise

Figure33

2.Boltandwashers

bladeinstallation—ensure

rotation.

Page 24

Important:

G019287

1 2

3

4

1

2

3

4

5

6

G019288

Right-hand

bladeinstallation—ensure

thatthearrowonoutsideofthebladeguard

indicates

clockwise

rotation.

A.Positionthebladeguardattheoppositesideof

themachine.

B.Alignthecutoutinthebladeguardwiththearbor.

C.Alignthemountingholesofthebladeguardwith

theholesinthebaseofthemachine.

D.Looselyassembletherearboltandwashers,

removedinstep1–A,tothebladeguardandinto

thebaseofthemachine.

E.Securetheguardandtothebasewiththeforward

boltandwashersthatwereremovedinstep1–B.

F.Tightentherearbolt.

A.Removethebolt,washers,andnutthatsecure

thepointertothemountingtabonbaseofthe

machine(Figure35).

Figure35

PointerPositionChange(Model68045)

3.Installthewaterlineasfollows:

A.Sliptheclamp,removedinstep

ofChangingtheWaterHosePosition(page22),

overthefreeendofthewaterhose(Figure34).

Figure34

WaterHoseAssembly

1.Hoseclamp

2.Waterhose4.Bladeguard

3.Barbedtting

B.Aligntheendofthewaterhosetothebarbed

ttinginthebladeguard(Figure34).

1.Nut

2

2.Washer5.Washer

3.Right-handposition6.Bolt

4.Left-handposition

B.Alignthepointertotheothersideofthemachine

(

Figure35).

C.Aligntheholeinthepointerwiththemounting

tabonthebase.

D.Securethepointertothebasewiththebolt,

washersandnutremovedinstep

A(Figure35).

2.Installthesawblade;referto

InstallingtheBlade(page13).

3.Alignthepointer(s);referto

AligningtheFrontPointer(page15).

ChangingtheForwardandRearPointer

Position(Model68046)

1.Changethepositionoftheforwardpointerasfollows:

A.Attheforwardpointer,loosenthethumbscrew

thatsecuresthepointertothepointerfork

(Figure36).

C.Centertheclampoverthettingandsqueezethe

clamptight.

4.Installtheshaftguardasfollows:

A.Alignthemountingholesintheshaftguardwith

theholesinthebase.

B.Securetheshaftguardtothebaseofthemachine

withtheboltsremovedinstep1–C.

ChangingtheForwardPointerPosition

(Model68045)

1.Changethepositionoftheforwardpointerasfollows:

24

Page 25

1

2

3

4

2

5

G019289

TransportingtheMachine

PreparetheMachineforTransport

1.Removethesawblade.

2.Rotatetheelevationcrankcounterclockwisetolower

themachinetothelowestelevationheight.

3.MovetheleveronthefuelvalvetotheOffposition—all

thewaytotheleft;refertoFuelValve(page8).

4.Raiseandsecuretheforwardpointertothestowed

position(

5.Model68046—stowtherearpointer(Figure22).

LiftingtheMachine

Movethemachineontothetransportvehicleasfollows:

•Usingarampthatisratedfortheweightofthemachine,

pushtheituptherampandontothevehicle.

•Liftthemachineontothetransportvehicle.

Note:Model68046—Ifaliftingequipmentofadequate

capacityisavailable,securethecable,chain,orstrapto

theliftingbaleandliftthemachine.

Figure29).

Figure36

PointerPositionChange(Model68046)

SecuringtheMachineforTransport

Dothefollowingtopreventmovementofthemachineon

1.Forwardpointer ,left-hand

position

2.Thumbscrewandcross

tube

3.Forwardpointer,

right-handposition

4.Rearpointer,right-hand

position

5.Rearpointer,right-hand

position

thetransportvehicle:

•Securethemachinewithcabling,straps,orchainstothe

transportvehicle.

•Protectthemachinebypaddingthecabling,straps,and

chainswherecontactwiththesurfacesofthemachine

occurs.

B.Removethepointerfromthecrosstubeinthe

pointerforkandinsertitintothecrosstubeatthe

•Secureblockingtothebedofthetransportvehicle,and

aroundthebaseofthemachine.

oppositesideofthefork(Figure36).

C.Tightenthethumbscrew .

2.Changethepositionoftheforwardpointerasfollows:

A.Attherearpointer,loosenthethumbscrewthat

securesthepointertothecrosstubeonthebase

ofthemachine(

Figure36).

B.Removethepointerfromthecrosstubeand

insertitintotheoppositeendofthecrosstube

(Figure36).

C.Tightenthethumbscrew .

3.Installthesawblade;referto

InstallingtheBlade(page13).

4.Aligntheforwardandrearpointersasdescribedin

AligningthePointer(page15).

25

Page 26

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Themachinemaybetippedbackwardoronitssidetofacilitateaccessforcleaningorservice,butno

longerthan2minutes.Ifthemachineisheldinthispositionfortoolong,theenginecanbedamagedbygasoline

drainingintothecrankcase.Shouldthishappen,performanextraoilchangeontheengine.Thenturntheengine

overafewrevolutionswiththerecoilstarthandlebeforestartingtheengineagain.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every40hours

Every50hours

Every100hours

Every300hours

MaintenanceProcedure

•Changetheoil.

•Checktheengineoillevel.

•Greasethemachine.

•Lubricatetheelevationscrew .

•Checktheairltercondition.Checkmorefrequentlyifoperatingconditionsaredusty.

•Checktheconditionofthesawbladeconditionforwearanddamage.

•Cleanthemachine.

•Changetheoilwhenoperatedunderheavyloadsorinhightemperatures.

•Checkthepulleysecurityandalignment,andthedrivebelttension.Replacethe

damagedbeltsasneeded.

•Servicethecyclonehousing/lter.Cleanthehousing/ltermorefrequentlywhen

operatingthemachineindustyconditions.

•Cleantheairlter.Cleanmorefrequentlyifoperatingconditionsaredusty.

•Changetheoil.

•Cleanthesedimentcup.

•Checkthesparkplug.

•Cleanthesparkarrester.

•Replacetheairlter.Changetheairltermorefrequentlyifoperatingconditions

aredusty.

•Replacethesparkplug.

Yearlyorbeforestorage

Every2years

Important:Refertoyour

•Changetheoil.

•Cleanthefuelsedimentcup.

•Replacealldrivebelts.Replacethebeltsifanyshowsanysignsofwear,cracks,

glazing,ordamage.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

26

Page 27

Lubrication

G019290

G019303

3

2

1

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily

GreaseType:General-purposegrease.

1.Greasethetiltbearingandarborbearingblocksby

doingthefollowing:

A.Elevatethebladetoitshighestposition.

B.Atthefrontofthemachine,ndthegrease

ttingsforthetiltbearingandarborbearing

blocksthatarelocatedbeneaththebaseofthe

machine(Figure37).

LubricatetheElevationScrew

ServiceInterval:Beforeeachuseordaily

1.Usingarag,wipetheelevationscrewandtiltarmclean

ofexcesslubricant,dirt,anddust.

Figure38

LubricatingtheBladeElevationScrew

Figure37

C.Cleanthegreasettingswitharag.

D.Connectagreaseguntoeachtting.

E.Pumpgreaseintothettingsuntileithergrease

beginstooozeoutofthebearingsor3pumps.

F.Wipeupanyexcessgrease.

Important:Pumpgreaseinslowlyand

carefullytopreventdamagetothebearing

seals.

G.LowerthesawbladeelevationtotheStart

Elevation.

1.Tiltarm3.Dry-graphitelubricant

(120-4817)

2.Elevationscrew

2.Slowlyrotatetheelevationcrankwhileapplyingacoat

ofdry-graphitelubricant(Toropartnumber120-4817)

orequivalentonthethreadsoftheelevationscrew .

2.Greasethewheelbearingsasfollows:

A.Locatethegreasettingsattherearwheels

(

Figure37).

B.Cleanthegreasettingswitharag.

C.Connectagreaseguntoeachtting.

D.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

E.Wipeupanyexcessgrease.

Important:Pumpgreaseinslowlyand

carefullytopreventdamagetothebearing

seals.

27

Page 28

EngineMaintenance

5.Aligntheairintakescreenofthecyclonehousingwith

theopeningintheairltercover.Carefullyassemble

thecyclonehousingthelterhousing(

Figure39).

ServicingtheAirFilter

ServiceInterval:Beforeeachuseordaily—Checktheair

ltercondition.Checkmorefrequently

ifoperatingconditionsaredusty.

Every50hours—Servicethecyclonehousing/lter.

Cleanthehousing/ltermorefrequentlywhen

operatingthemachineindustyconditions.

Every50hours—Cleantheairlter.Cleanmore

frequentlyifoperatingconditionsaredusty.

Every300hours/Yearly(whichevercomes

rst)—Replacetheairlter.Changetheairltermore

frequentlyifoperatingconditionsaredusty.

Thecycloneairltercollectsthelargestcontaminantparticles,

whichcollectinthecontainer.Whenyoucanseealayerof

dirtatthebottomofthecontainer,cleanthecyclonehousing,

airchannels,andairintakescreen.

ServicingtheCycloneAirFilter

1.Removethe3screwsthatsecurethecyclonehousing

totheairlterhousing.

Note:Ensurethattheslotinthecyclonecoverthat

isadjacenttheairintakescreenisalignedwiththetab

inthebottomoftheairltercover;Donotuseforce;

alignitinplace.

6.Securethecyclonehousingtotheairltercoverwith

thescrewsremovedinstep1(Figure39).

CleaningtheAirFilter

Important:Iftheengineislowonpower,produces

blacksmokeorrunsunevenly,theairltermaybe

restricted.

1.Removethewingnutandliftofftheairltercoverand

cyclonehousing(

Figure40).

2.Removethecyclonehousingwiththeairintakescreen,

andremovetheairguide(Figure39).

Figure39

1.Airltercover

2.Screw4.Cyclonehousingwithair

Note:Theairguidemayremainintheairltercover

whenthecyclonehousingisremoved.Grasptheair

guideandcarefullypulldowntoremoveit.

3.Cleanthecomponentsusingwaterandabrush.Dry

carefully.

4.Seattheairguideintothecyclonehousing.

3.Airguide

intakescreen

Figure40

1.Wingnut

2.Airltercoverandcyclone

housing

3.Foampre-lter

Important:Replacethefoampre-lterorthe

air-lterelementorbothifdamaged.

2.Removethefoampre-lter.Cleanitasfollows:

A.Cleanthepre-lterusingwarmsoapywater.

B.Rinsethepre-lterincleanwater,squeezethe

waterout,andallowtheltertodry.

C.Soakitwithnewengineoil.

4.Air–lterelement

5.Stud

28

Page 29

D.Gentlywindthelterinanabsorbentclothand

squeezeoutexcessoil.

3.Removethewingnutontopoftheairlterand

removethepaperlter(Figure40).

4.Taptheair-lterelementagainstaxedsurfaceseveral

timestoremovedirt.Ifthepaperlterisstilldirtyor

damaged,replacethelterelement.

Important:Donotusecompressedairtoblow

outthepaperelement,thiscandamageit.

ChangingtheEngineOil

ServiceInterval:Aftertherst50hours/Monthly

(whichevercomesrst)—Changetheoil.

Every100hours/Every6months(whichevercomes

rst)—Changetheoil.

Every25hours—Changetheoilwhenoperatedunder

heavyloadsorinhightemperatures.

Yearlyorbeforestorage—Changetheoil.

Note:Replacetheair-lterelementevery300hours.

5.Aligntheair-lterelementonthelowerair-lter

housingandsecureitwiththewingnutremovedin

step3(Figure40).

6.Positionthefoampre-lterovertheair-lterelement

(Figure40).

7.Aligntheair-ltercoverandcyclonehousingwiththe

studandlowerair-lterhousing,andsecurethecover

withthewingnutremovedinstep

1(Figure40).

ReplacingtheAirFilter

1.Removethewingnutandliftofftheairltercoverand

cyclonehousing(Figure40).

2.Removethewingnutontopoftheairlterandremove

thepre-lterandair-lterelement(Figure40).

3.Alignthenewpre-lterandair-lterelementwiththe

lowerair-lterhousingandsecureitwiththewingnut

removedinstep2(Figure40).

4.Aligntheair-ltercoverandcyclonehousingwiththe

studandlowerair-lterhousing,andsecurethecover

withthewingnutremovedinstep1(Figure40).

DrainingtheEngineOil

Draintheengineoilasfollows:

1.EnsurethatthesawbladeisattheStartElevation;

refertostepCinAdjustingtheCuttingDepth(page14).

2.Starttheengineandletitrunveminutes;referto

StartingtheEngine(page19).

Note:Thiswarmstheoilsoitdrainsbetter.

3.Removethesawblade;referto

RemovingtheBlade(page12)

4.Lowerthefrontoftheenginebyrotating

theelevationcrankcounterclockwise;referto

AdjustingtheCuttingDepth(page14).

5.Placeadrainpanwitha1.9liter(2USquart)capacity

undertheoil-drainportoftheengine(

Figure41).

29

Page 30

G019297

1

2

3

4

5

Figure41

0 20 40 60

80

10 0°F

-20 -10 0 10 20 30 40 °C

5W–30 · 10 W– 30

30

1

G019298

DrainingtheEngineOil

1.Oil-drainport4.Drainpan,1.9liter(2US

2.Washer

3.Drainplug

quart)

5.Oilllcap/dipstick

Figure42

RecommendedOilViscosity

1.Oilviscosityrangeforambientoperatingtemperatures

Note:SAE10W-30isrecommendedforgeneraluse.Other

viscositiesshowninthechartmaybeusedwhentheaverage

temperatureinyourareaiswithintheindicatedrange.

1.Leveltheenginebyraisingitwiththeelevationcrank;

refertoAdjustingtheCuttingDepth(page14).

2.Removetheoilllcap/dipstickandslowlypour

approximately80percentofthespeciedamountof

oilintotheengine(Figure41).

3.Slowlyaddadditionaloiltobringtheoillevel

totheupperlimitmarkonthedipstick.Refer

toCheckingtheEngineOilLevel(page18).

4.Installtheoilllcap/dipstick.

5.Installthesawblade;referto

InstallingtheBlade(page13).

ServicingtheFuelSystem

6.Removethedrainplugandwasher,anddraintheoil

(Figure41).

7.Whentheoilhasdrainedcompletely,installthedrain

plugwithanewwasher,andwipeupanyspilledoil

(Figure41).

Note:Disposeoftheusedoilatacertiedrecycling

CleaningtheSedimentCup

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Cleanthe

sedimentcup.

Yearlyorbeforestorage—Cleanthefuelsedimentcup.

center.

Underneaththefuelvalveisasedimentcuptocatchdirtin

thefuel.

FillingtheEngineCrankcasewithOil

1.RaisethesawbladetotheStartElevation;referto

Fillthecrankcasewithoilasfollows:

Important:Use4-strokemotoroilthatmeetsofexceeds

therequirementsforAPIservicecategory

SJ or later

(or

equivalent).AlwayschecktheAPIservicelabelonthe

oilcontainertobesureitincludestheSJorlater(or

equivalent).

stepCinChangingCutDepth(page14).

2.Parkthemachineonalevelsurfaceandturnoffthe

engine;referto

StoppingtheEngine(page19).

3.Ensurethatthemachinesurfacesarecool.

4.MovetheleverofthefuelvalvetotheOffposition,all

thewaytotheleft(Figure43).

5.Unscrewthesedimentcup.Removethefuellterand

O-ring(

Figure43).

Note:MakesurenottomisplacetheO-ring

30

Page 31

2

3

4

1

G019333

3.Pullthesparkplugwireofftheterminalofthespark

G019300

1 2

4

3

plug(Figure44).

Figure44

Figure43

SedimentCupandFuelFilter

1.Fuelvalve(Off)3.Fuellter

2.O-Ring4.Sedimentcup

Note:DonotcleantheO-ringinsolvent.

6.Cleanthefuellterandsedimentcupusinga

nonammablesolventanddrycarefully .

7.WipetheO-ringwithaclean,drycloth.

8.Installthefuellterinthebottomofthecarburetor

Figure43).

(

9.AligntheO-ringintothegrooveinthesedimentcup

andinstallthesedimentcuptofuelvalvehousing.

10.MovetheleverofthefuelvalvetotheOnposition(all

thewaytotheright)andcheckforleaks.Ifitleaks,

replacetheO-ring.

ServicingtheSparkPlug

1.Sparkplug

2.Wire

4.Cleanaroundthesparkplug.

5.Rotatethesparkplugcounterclockwiseusinga20mm

(13/16inch)sparkplugwrenchtoremovetheplug

andsealingwasher.

CheckingtheSparkPlug

Note:Useagappingtool/feelergaugetocheckandadjust

theairgap.Installanewsparkplugifnecessary.

1.Lookatthecenterofthesparkplug(Figure45).Ifyou

seelightbrownorgrayontheinsulator,theengineis

operatingproperly.

Important:NeverCleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Checkthe

sparkplug.

Every300hours/Yearly(whichevercomes

rst)—Replacethesparkplug.

Type:BPR6ES(NKG)orW20EPR-U(DENSO),or

equivalent

AirGap:0.7–0.8mm(0.28–0.031inch)

Note:Usea20mm(13/16inch)sparkplugwrenchfor

removingandinstallingthesparkplug.

RemovingtheSparkPlug

1.Parkthemachineonalevelsurfaceandturnoffthe

engine;refertoStoppingtheEngine(page19).

2.Ensurethatthemachinesurfacesarecool.

Figure45

SparkPlugAirGap

1.Sideelectrode

2.Centerelectrode4.0.7–0.8mm(028–.031

3.Insulator

inch)measuredairgap

range

2.Withagappingtoolforsparkplugsorfeelergauge,

measurethegapbetweenthesideelectrodeandcenter

electrode.

1.Checkthegapbetweenthecenterandsideelectrodes

(Figure45)ifthegapisnotcorrect.

31

Page 32

2.Ifthemeasuredairgapisnotwithinthespeciedair

G019331

10

10

1

2

3

4

5

6

7

8

9

11

12

gaprange,dothefollowing:

A.Ifthegapistoosmall,carefullybendtheside

electrodeawayfromthecenterelectrodeuntilthe

gapbetweentheelectrodesiswithinthemeasured

airgaprange.

B.Ifthegapistoolarge,carefullybendtheside

electrodetowardfromthecenterelectrodeuntil

thegapbetweentheelectrodesiswithinthe

measuredairgaprange.

InstallingtheSparkPlug

Important:Ensurethattheairgapbetweentheside

andcenterelectrodesarecorrectbeforeinstallingthe

sparkplug.

1.Threadthesparkplugclockwiseintothesparkplug

holebyhand.

Note:Avoidcrossthreadingthesparkplugwiththe

threadsofthesparkplughole

2.Rotatesparkplugclockwiseusinga20mm(13/16

inch)sparkplugwrenchuntiltheplugandsealing

washerareseated.

ServicingtheSparkArrester

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Cleanthespark

arrester.

CleaningtheSparkArrester

1.Removethesparkarrestorasfollows:

A.Removethetwo8mmnutsandremovethe

muferfromtheengineexhaustport(Figure46).

3.Tightentheplugasfollows:

•Wheninstallinganin-servicesparkplug,tighten

thepluganadditional1/8–1/4turn.

•Wheninstallinganewsparkplug,tightentheplug

anadditional1/2turn.

4.Installthesparkplugwirepushingthewireontothe

terminaloftheplug.

MuferandSparkArrester

1.Exhaustdeector

2.Muferprotector8.Stud

3.6mmscrew

4.Mufer

5.Exhaustpipe11.Exhaustport

6.Nut12.4mmscrew

Note:Retaintheexhaust-pipegasketforthe

sparkarresterinstallation.

Figure46

7.Exhaust-pipegasket

9.Sparkarrester

10.5mmscrew

B.Removethethree4mmscrewsfromtheexhaust

deector,andremovethedeectorfromthe

muferprotector(Figure46).

C.Removethe6mmscrewandfour5mmscrews

fromthemuferprotectorandremovethe

muferprotectorfromthemufer(Figure46).

D.Removethe5mmscrewsfromthesparkarrester,

2.Useabrushtoremovecarbondepositsfromthespark

andremovethesparkarresterfromthemufer

(

Figure46).

arresterscreen.Replacethesparkarresterifithas

breaksorholes(Figure47).

32

Page 33

1

2

G019332

BeltMaintenance

4

3

2

1

5

2

1

G019304

ServicingtheDriveBelts

ServiceInterval:Every40hours—Checkthepulleysecurity

andalignment,andthedrivebelttension.

Replacethedamagedbeltsasneeded.

Figure47

CleaningtheSparkArrester

1.Sparkarresterscreen

Note:Becarefulnottodamagethescreen.

3.Installthesparkarresterasfollows:

A.Aligntheholesofthesparkarrestertothespark

arrestermountingpointsinthemufer.

B.Securethesparkarrestertothemuferwiththe5

mmscrewsremovedinstep

(Figure46).

C.Alignthemuferprotectortothemuferand

secureitwiththe6mmscrewand5mmscrews

removedinstep1-C(Figure46).

D.Aligntheexhaustdeectorwiththemufer

protectorandsecureitwiththe4mmscrews

removedinstep1-B(Figure46).

E.Aligntheexhaustpipegaskettothestudsofthe

exhaustportandushwiththeport.

2.Brush

1-D.

Every2years—Replacealldrivebelts.Replacethe

beltsifanyshowsanysignsofwear,cracks,glazing,

ordamage.

RemovingtheBeltGuard

1.Parkthemachineonalevelsurfaceandturnoffthe

engine;refertoStoppingtheEngine(page19).

2.Ensurethatthemachinesurfacesarecool.

3.Pullthesparkplugwireofftheterminalofthespark

plug(Figure44).

4.Loosentheboltsthatsecuretherearmountingpointof

thebeltguardtothebaseofthemachine(

Figure48).

F.Alignmountingpointsoftheexhaustpipewith

thestudsoftheexhaustportandsecureitwith

thenutsremovedinstep

1-A(Figure46).

Figure48

BeltGuardRemoval

1.Bolt4.Beltguard

2.Washer5.Rearmountingpoint

3.Forwardmountingpoint

5.Removetheforwardboltsthatsecuretheforward

mountingpointofthebeltguardtobase(Figure48).

6.Slidethebeltguardforwardandlifttheguardto

removeit(Figure48).

33

Page 34

CheckingthePulleysandDriveBelts

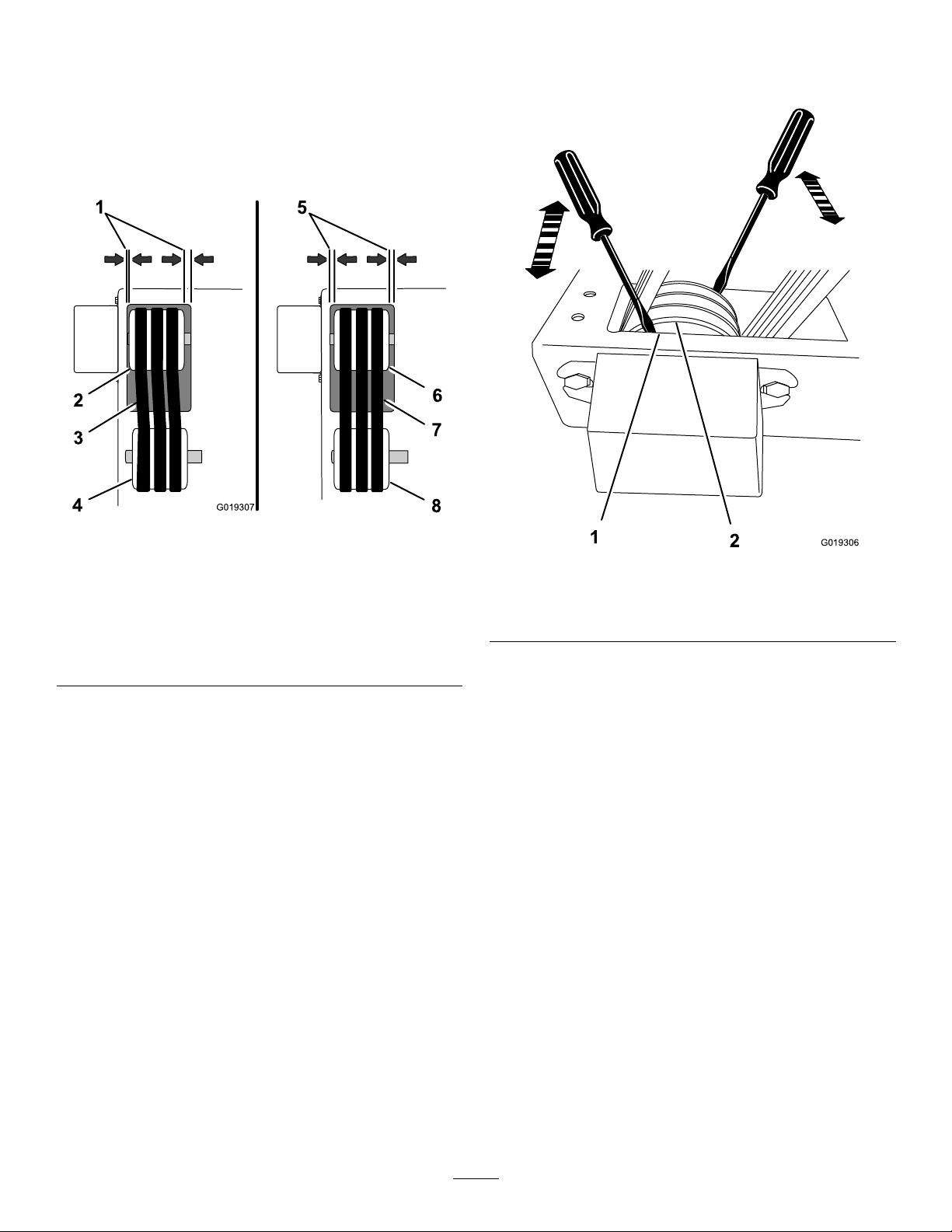

G019307

4

7

1

2

3

5

6

8

G019306

1

2

1.Removethebeltguard;referto

RemovingtheBeltGuard(page33).

2.Checkthatthearborpulleyiscenteredinthe

openinginthebaseofthemachine.Ifthe

arborpulleyismisaligned,refertostep3in

AligningthePulleys(page36)(Figure49).

(Figure50).Ifthepulleyislooseonthearbor,

alignandsecurethepulley;refertostep3in

AligningthePulleys(page36).

Figure49

PulleyAlignment

1.Unequalspacingdistance5.Equalspacingdistance

2.Misalignedarborpulley6.Alignedarborpulley

3.Misaligneddrivebelts7.Aligneddrivebelts

4.Misaligneddrive-shaft

pulley

3.Checkpulleyalignmentbylookingatthesidesof

thebelts,eachshouldruninastraightlineoverand

betweeneachpulley(Figure49).Ifthebeltsand

pulleysaremisaligned,alignthepulleys;referto

AligningthePulleys(page36).

Note:Drivebeltmisalignmentisanindicationofa

pulley(s)thatarenotsecuretothearbororthedrive

shaftoftheengineorboth.

4.Checkthatthepulleysaresecureasfollows:

Note:Usemoderateforcewhencheckingthesecurity

ofthepulleys.Belttensionmayneedtobereduced

tocheckforaloosepulley .

A.Checkthatthedrive-shaftpulleyissecuretothe

engineshaftbygraspingthepulleyandpushit

towardtheengineandawayfromtheengine.If

thepulleyislooseonthedriveshaftoftheengine,

alignandsecurethepulley;refertostep5in

AligningthePulleys(page36).

8.Aligneddrive-shaftpulley

Figure50

LowerPulleyCheck

1.Lowerpulley

2.Openinginthebase

5.Checkthetensionofthedrivebeltsbydoingthe

following:

Note:Thebestdrivebelttensionforthemachineis

thelowesttensionatwhichthebeltswillnotslipunder

fullload.

A.Layastraightedgeoneachbeltandacrossthe

driveshaftandarborpulleys(Figure51).

B.Checkthatthearborpulleyissecuretothe

arborbypryingbetweentheopeninginthe

baseandendsofpulleywithascrewdriver

34

Page 35

G019310

1

2

Figure51

G01931 1

1

2

3

MeasuringBeltT ension

AdjustingtheDriveBeltTension

1.Removethebeltguard;referto

RemovingtheBeltGuard(page33).

2.Loosentheenginemountinghardwareasfollows:

•Model68045

A.Elevatethebladetoitshighestposition.

B.Loosenthebolts,washers,andnutsthat

securetheenginetothebaseofthemachine

Figure52).

(

1.Straightedge2.Deect5mmat2kg(.19

inchat4.2lb)

B.Withyournger,pushdownonthedrivebelt,

midwaybetweenthepulleys(Figure51).

Note:Checkthetensionofall3drivebelts.

C.Eachbeltshoulddeectapproximately5mm

at2kg(0.19inchat4.2lb)fromthestraight

edge(Figure51).Ifthebelttensionistoolow

ortoohigh,adjustthebelttension;referto

AdjustingtheDriveBeltTension(page35).

6.Installthebeltguard;referto

InstallingtheBeltGuard(page35).

7.Installthesparkplugwirepushingthewireontothe

terminaloftheplug.

InstallingtheBeltGuard

1.Alignthebeltguardoverthedrivebeltsandpulleys

andlowerittothebaseofthemachine.

2.Slidetheguardbacksothattherearangeoftheguard

isunderneaththeboltheadsattherearmounting

pointsoftheguard.

Figure52