Page 1

FormNo.3377-557RevB

1

G021551

VIB-2.5BPConcreteVibrator

ModelNo.68043—SerialNo.313000001andUp

Operator'sManual

Introduction

Thisconcretevibratorisdesignedforvibratingand

consolidatingconcreteproductsbyremovingairpocketsand

voids.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

Figure1

1.Modelandserialnumberlocation

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ModelNo.

ForestryService.

Important:ItisaviolationofCaliforniaPublic

SerialNo.

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3377-557*B

Page 2

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

SafeOperatingPractices

Alwaysfollowallsafetyinstructionstoavoidseriousinjury

ordeath.

Contents

Introduction..................................................................1

SafeOperatingPractices...........................................2

SafetyandInstructionalDecals.................................4

Setup............................................................................5

1FillingtheEnginewithOil......................................5

2InstallingtheThrottleArm.....................................6

ProductOverview..........................................................7

Controls................................................................8

Specications.........................................................9

Operation.....................................................................9

ReadtheInstructionManual.....................................9

Attachments/Accessories.........................................9

AddingFuel............................................................9

CheckingtheEngineOilLevel.................................11

InstallingtheHeadontotheShaft.............................11

RemovingtheHeadfromtheShaft...........................13

ConnectingtheShafttotheMachine.........................14

StartingandStoppingtheEngine..............................14

UsingtheMachine..................................................14

OperatingTips......................................................15

Maintenance.................................................................16

RecommendedMaintenanceSchedule(s)......................16

PreparingtheMachineforMaintenance.....................16

LubricatingtheShaft...............................................16

ServicingtheAirCleaner.........................................17

ChangingtheEngineOil.........................................17

ServicingtheSparkPlug..........................................18

ServicingtheSparkArrester.....................................20

ServicingtheFuelSystem........................................20

ServicingtheBelt...................................................21

Storage........................................................................22

PreparingtheMachineforStorage............................22

Troubleshooting...........................................................23

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol(Figure2)whichmeansCaution,

Warning,orDanger—personalsafetyinstruction.

Failuretocomplywiththeinstructionmayresultin

personalinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriestopeopleordamagetoproperty.

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Wearpersonalprotectiveequipmentandappropriate

clothingincluding:

–safetyglasses

–hearingprotection

–safetyshoes

–longpants

–shirtwithlongsleevesthataretightatthewrists

–tight-ttinggloveswithoutdrawstringsorloosecuffs

•Securelonghair,looseclothing,orjewelrythatmayget

tangledinmovingparts.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andthevaporsareexplosive.Usethefollowingpractices

whenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

2

Page 3

–Neverrefuelordrainthemachineindoors.

MaintenanceandStorage

–Replacethefuelcapandtightenitsecurely.

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Iffuelisspilled,wipeitofftheengineandequipment.

Operation

•Neverrunanengineinanenclosedorpoorlyventilated

area.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Shutofftheenginebeforeleavingthemachineforany

reason.Neverleavearunningmachineunattended.

Alwaysstoptheengineandverifythatallmovingparts

havestopped.

•Avoidprolongedbreathingofexhaustfumes.Engine

exhaustfumescancausesicknessordeath.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•Beforeperformingmaintenance,dothefollowing:

–Placethemachineonlevelground.

–Stoptheengine.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairingthemachine.

–Lettheenginecoolbeforeperformingmaintenance

orstoringthemachine.

–Disengageallpowerandoperationcontrols.

•Donotlubricate,service,orrepairthemachinewhileitis

running.

•Keepequipmentmaterialsclearfromthemuferand

enginetohelppreventres.Cleanupanyoilorfuel

spillage.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Stopandinspectthemachineifaforeignobjectcausesan

obstruction.Makeanynecessaryrepairsbeforestarting

themachine.

•Donottamperwithsafetydevices.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•UseonlygenuineTororeplacementpartstoensurethat

theoriginalstandardsaremaintained.

•Ifthemachinestrikesaforeignobjectorifthemachine

startsmakinganunusualnoiseorvibration,stopthe

engine.Waitforallmovingpartstocometoacomplete

stopandcool.Vibrationisgenerallyawarningoftrouble.

Inspectforcloggingordamage.Cleanandrepairand/or

replacedamagedparts.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

3

Page 4

SafetyandInstructional

Decals

Important:Safetyandinstructiondecalsarelocated

nearareasofpotentialdanger.Replacedamageddecals.

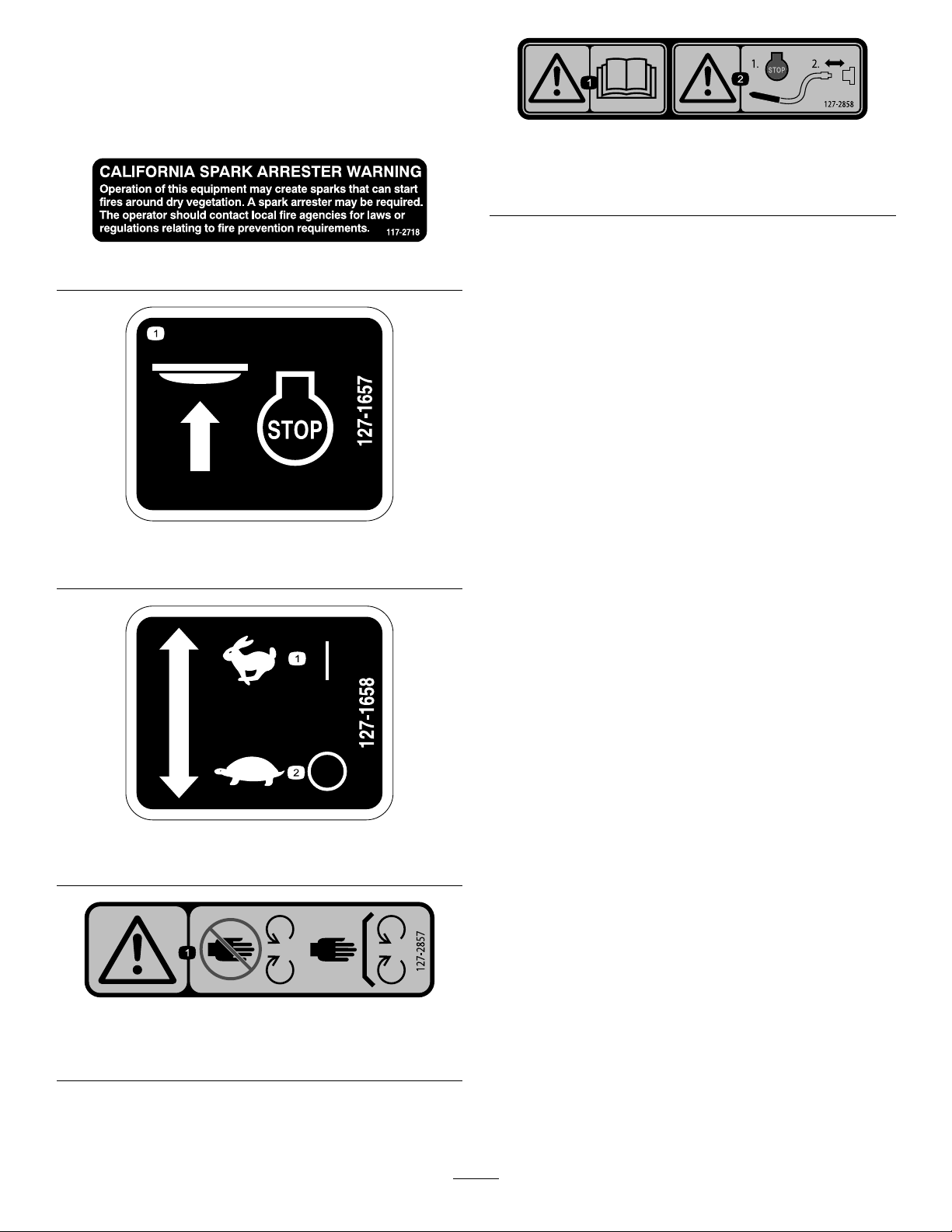

127–2858

1.Pushtostoptheengine.

1.Warning—readthe

Operator’sManual.

117–2718

127–1657

2.Warning—1)Stopthe

engine;2)Disconnectthe

shaft.

127–1658

1.Fast—on

1.Warning—keepawayfrommovingparts;keepallguards

andsafetiesinplace.

2.Slow—off

127–2857

4

Page 5

Setup

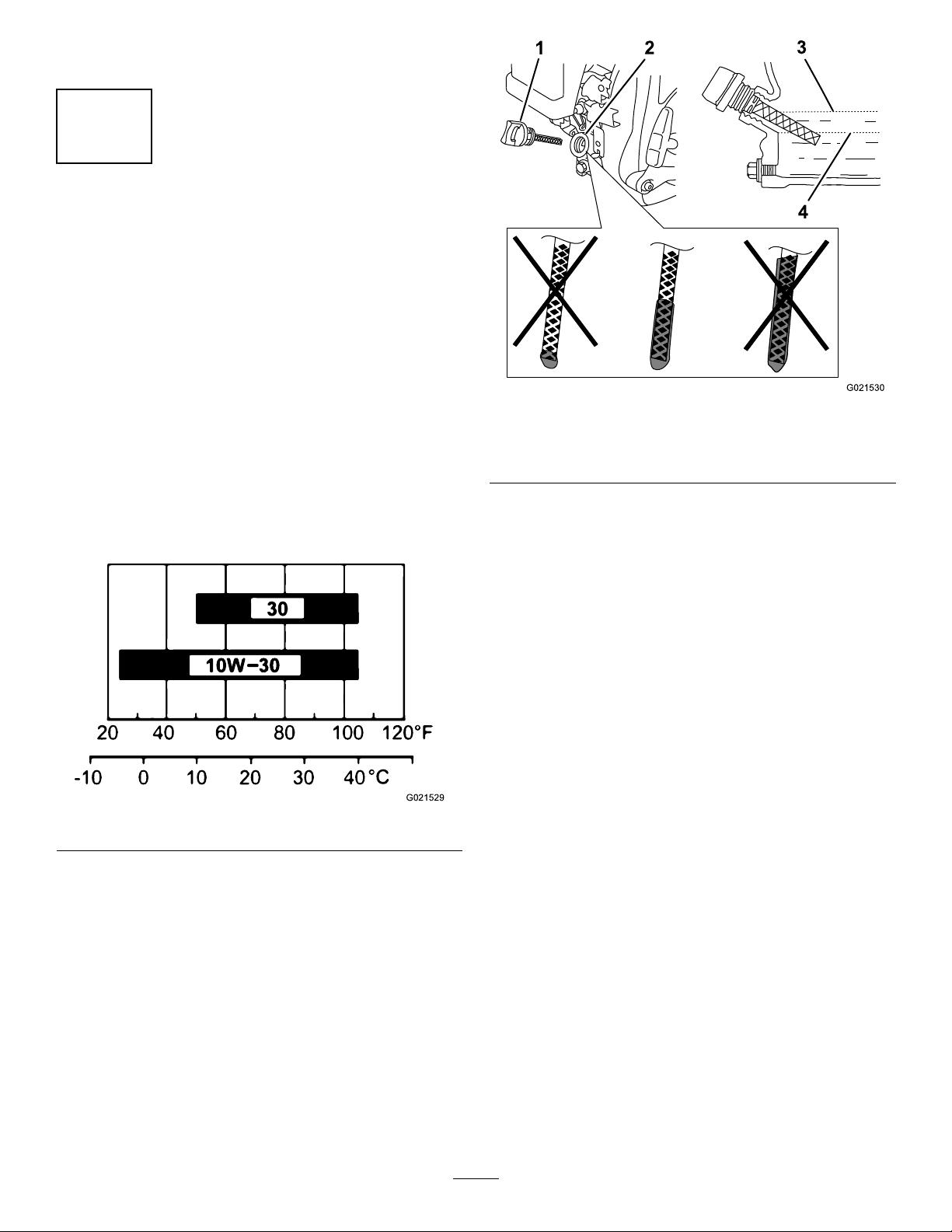

G021529

3

4

G0 215 30

1

2

1

FillingtheEnginewithOil

NoPartsRequired

Procedure

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategory

or higher

Crankcasecapacity:0.25L(0.26USqt)

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

.

SJ , SL, SM,

Figure4

1.Oilllhole3.Oil-levelupperlimit

2.Dipstick

4.Oil-levellowerlimit

Note:UseSAE10W-30forgeneraluse.YoucanuseSAE

30whentheaveragetemperatureinyourareaiswithinthe

indicatedrange(Figure3).

Figure3

1.Removethedipstick(Figure4)andslowlypouroilinto

thellholeuntiltheoilreachestheupper-limitmark

(bottomedgeoftheoil-llhole)onthedipstick.

2.Replaceandsecurethedipstick.

3.Wipeupanyspilledoil.

5

Page 6

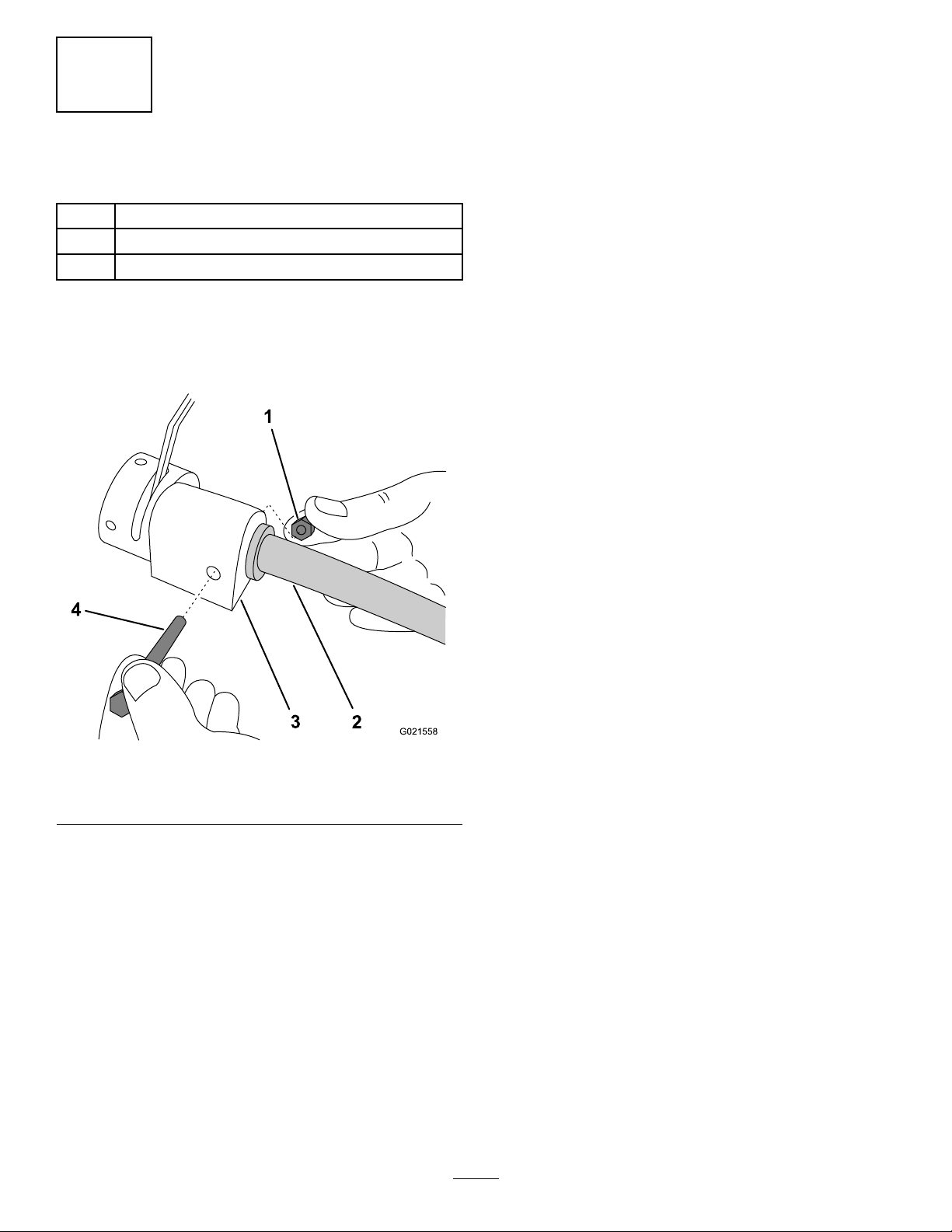

2

G021558

1

2

4

3

InstallingtheThrottleArm

Partsneededforthisprocedure:

1Throttlearm

1Bolt

1Locknut

Procedure

1.Aligntheinnercoreofthehandlewiththecoreadapter

onthethrottlecontrolbox(Figure5),andinsertitfully.

Figure5

1.Locknut3.Throttlecontrolbox

2.Throttlearm4.Bolt

Note:Ensurethattheatareaonthetubeisonthe

bottom.

2.Inserttheboltthroughthethrottlecontrolbox,and

secureitwiththelocknut(

3.Connectthemaleelectricalconnectorfromtheengine

switchonthethrottlearmtothefemaleconnectoron

theengine.

Note:Ensurethattheconnectorsareconnected

securely.

Figure5).

6

Page 7

ProductOverview

G021553

1

2

3

4

7

8

6

5

1

2

4

6

7

8

10

5

9

3

G021524

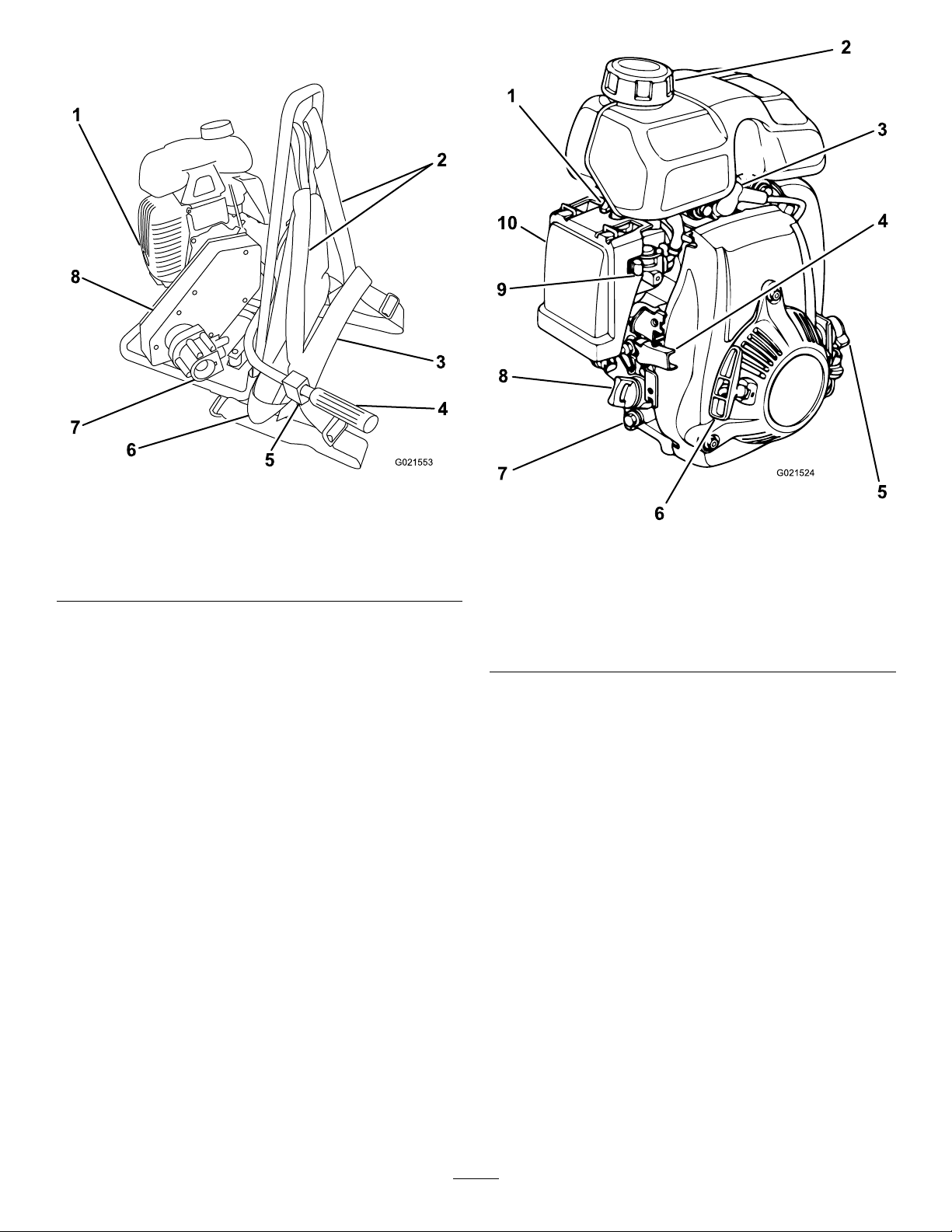

Figure6

1.Mufer

2.Shoulderstraps

3.Cheststrap7.Shaftcoupling

4.Throttlegrip8.Beltguard

5.Enginestopbutton

6.Waiststrap

Figure7

1.Chokelever

2.Fuelcap

3.Spark-plugwire

4.Throttle9.Fuelvalve

5.On/Offswitch

6.Recoil-starthandle

7.Oildrainplug

8.Dipstick

10.Aircleaner

7

Page 8

Controls

G021527

1

1

G021525

G021552

2

1

G021526

1

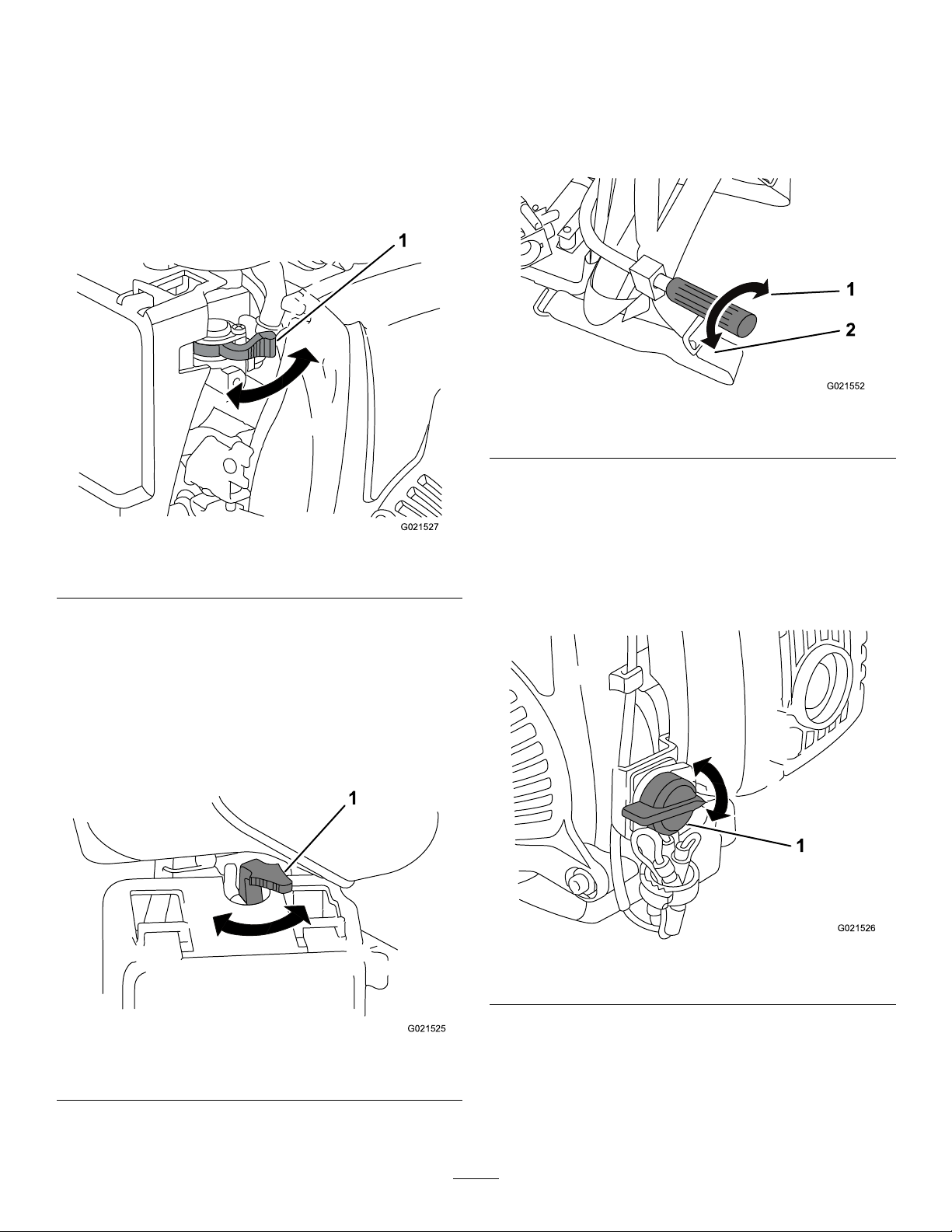

FuelValve

Thefuelvalve(Figure8)islocatedtotherightofandbelow

thechokelever.MovetheleverforthefuelvalvetotheOn

positionbeforeattemptingtostarttheengine.Whenyou

havenishedusingthemachine,stoptheengineandmove

thefuelvalvelevertotheOffposition.

ThrottleGrip

Thethrottlelever(Figure10)controlsthespeed(rpm)ofthe

engine.Itislocatedattheendofthethrottlearm.Itsets

theenginespeedandthereforecanincreaseanddecreasethe

vibrationspeedofthehead.Forbestperformance,setthis

controltothefastpositionwhenusingthemachine.

Figure10

Figure8

1.Fuelvalve

ChokeLever

Usethechokelever(Figure9)tostartacoldengine.Before

pullingtherecoil-starthandle,movethechokelevertothe

closedposition(right).Oncetheengineisrunning,movethe

chokelevertotheopenposition(left).Donotusethechoke

iftheengineisalreadywarmeduportheairtemperatureis

high.

1.Slow(idle)

2.Fast

EngineOn/OffSwitch

TheOn/Offswitch(Figure11)allowstheoperatorofthe

machinetostartandstoptheengine.RotatetheOn/Off

switchtotheOnposition(clockwise)tostartandrunthe

engine.RotatetheOn/OffswitchtotheOffposition

(counterclockwise)tostoptheengine.

1.Chokelever

Figure9

1.On/Offswitch

Figure11

Recoil-startHandle

Tostarttheengine,pulltherecoil-starthandle(Figure7)

quickly.Ensurethattheenginecontrolsdescribedaboveare

allsetcorrectly.

8

Page 9

EngineStopButton

G021593

1

G0 231 52

Theenginestopbutton(Figure12)islocatedunderthe

throttlearmandnearthethrottlegrip.Pressitifyouneedto

stoptheenginequickly.

Operation

ReadtheInstructionManual

Figure13

Symbollocatedonthenon-serviceableserial-numberplate

Figure12

1.Enginestopbutton

Oil-levelSwitch

Theoil-levelswitchislocatedinsidetheengine,anditwillnot

allowtheenginetorunwhentheoillevelisbelowthesafe

operatinglimit.

Specications

WeightLengthWidthHeight

5.5kg

(12.1lb)

33cm

(13inches)

34.9cm

(14inches)

58.4cm

(23inches)

1.Warning–T oreducetheriskofinjury ,usermustreadand

understandtheinstructionmanual.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

AddingFuel

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•Donotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessitcontainsafuelstabilizer.

•Donotaddoiltogasoline.

9

Page 10

DANGER

1

2

G021528

WARNING

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelisnohigher

thanthescreenonthelterinthefueltank.

Thisemptyspaceinthetankallowsthefuelto

expand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleandthe

fueltankorconditioneropening .

•Keepfuelawayfromyoureyesandskin.

Important:Donotmixoilwithfuel.

RecommendedFuel

UnleadedGasoline

U.S.

Except

U.S.

Pumpoctanerating87orhigher

Researchoctanerating92orhigher

Pumpoctanerating87orhigher

UsingFuelStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeepthe

fuelfreshduringstorageof90daysorless.Ifyouarestoring

themachineforlonger,drainthefueltank;refertoDraining

theFuelTankandCarburetor(page20).

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling .

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removefuel-poweredequipment

fromthetruckortrailerandfueltheequipment

ontheground.Ifthisisnotpossible,then

fuelsuchequipmentonatruckortrailerfrom

aportablecontainerratherthanfromafuel

dispensernozzle.

•Ifyoumustuseafueldispensernozzle,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshfuel.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

FillingtheFuelTank

Capacity:0.77L(0.20USgallon)

1.Placethemachineonalevelsurface,stoptheengine,

andallowtheenginetocool;refertoStoppingthe

Engine(page14).

2.Cleanaroundthefuelcap,andremoveit.

1.Fuel-levelmark

Figure14

2.Maximumfuellevel

10

Page 11

3.Addunleadedgasolinetothefueltank,untilthelevelis

G021529

3

4

G0 215 30

1

2

atthefuel-levelmark,asshowninFigure14.

Important:Thisspaceinthetankallowsthefuel

toexpand.Donotllthefueltankcompletelyfull.

4.Installthefuelcapsecurely(Figure14).

5.Wipeupanyfuelthatmayhavespilled.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategory

or higher

Crankcasecapacity:0.25L(0.26USqt)

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

Note:UseSAE10W-30forgeneraluse.YoucanuseSAE

30whentheaveragetemperatureinyourareaiswithinthe

indicatedrange(

.

Figure15).

SJ , SL, SM,

Figure16

1.Fillport

2.Dipstick

5.Slidethedipstickfullyintothellportwithout

threadingitintotheport(Figure16).

3.Oil-levelupperlimit

4.Oil-levellowerlimit

Figure15

1.Placethemachineonaat,levelsurface,andstopthe

engine;refertoStoppingtheEngine(page14).

2.Allowtheenginetocool.

3.Cleanaroundthedipstick.

4.Removethedipstickandwipetheendclean(Figure16).

6.Removethedipstickandlookattheend.Iftheengine

oillevelislow ,slowlypouronlyenoughoilintothell

porttoraisetheleveltotheFullmarkonthedipstick

(Figure16).

Note:T oroPremiumEngineOilisavailablefrom

yourAuthorizedToroDealer.

7.Replaceandsecurethedipstick(Figure16).

InstallingtheHeadontothe Shaft

Note:Theheadandshaftaresoldseparately.Thereisa

varietyofsizesavailablefromyourAuthorizedT oroDealer.

1.Holdthethreadedendoftheshaftinapipevise,and

coatthethreadsoftheshaftwithathreadsealantto

preventwaterfromenteringthehead(Figure17).

11

Page 12

A

B

G021363

Figure17

2.Bringthethreadedendoftheheadtogetherwiththe

shaft,andthreadthemtogetherbyhand.

Note:Theheadandshafthavereverse,orleft-hand

threads.

3.Placeapipewrenchascloseaspossibletotheendof

thehead,asshowninFigure17B,toavoidloosening

anypartsofthehead.

Important:Ifanypartsoftheheadareloose,they

couldcomeoffandgetlostintheconcrete.

4.Usethepipewrenchtoturntheheadcounterclockwise

totightenitontotheshaftuntilitistight.

12

Page 13

AvailableShafts

ShaftModel

68117

68118

68119

68120

68121

68122

68123

68124

68125

68126

AvailableHeads

HeadModelDiameterLength

68110

(requiresa

narrowshaft)

6811 12.5cm

681123.2cm

681133.8cm

681144.4cm

681155.1cm

681166.4cm

1.9cm

(3/4inch)

(1inch)

(1-1/4inch)

(1-1/2inch)

(1-3/4inch)

(2inch)

(2-1/2inch)

30.5cm

(12inches)

33.0cm

(13inches)

33.0cm

(13inches)

35.6cm

(14inches)

35.6cm

(14inches)

35.6cm

(14inches)

33.0cm

(13inches)

Centrifugal

Force(at10,600

rpm)

0.50kN

(112lbf)

0.81kN

(183lbf)

1.91kN

(430lbf)

3.38kN

(760lbf)

4.89kN

(1100lbf)

6.45kN

(1450lbf)

10.36kN

(2330lbf)

Length

0.91m(3ft)—narrow,forusewithnarrowheadmodel68110

2.13m(7ft)—narrow,forusewithnarrowheadmodel68110

3.05m(10ft)—narrow,forusewithnarrowheadmodel68110

4.27m(14ft)—narrow,forusewithnarrowheadmodel68110

0.91m(3ft)

1.53m(5ft)

2.13m(7ft)

3.05m(10ft)

4.27m(14ft)

6.40m(21ft)

Radiusof

Inuence

10.2cm

(4inches)

12.7cm

(5inches)

17.8cm

(7inches)

35.6cm

(14inches)

45.7cm

(18inches)

55.9cm

(22inches)

63.5cm

(25inches)

CapacityOperating

3.06cubic

m/hour(4cubic

yards/hour)

4.59cubic

m/hour(6cubic

yards/hour)

6.12cubic

m/hour(8cubic

yards/hour)

9.18cubic

m/hour(12cubic

yards/hour)

18.35cubic

m/hour(24cubic

yards/hour)

26.76cubic

m/hour(35cubic

yards/hour)

29.05cubic

m/hour(38cubic

yards/hour)

Weight

1.36kg

(3lb)

1.36kg

(3lb)

1.81kg

(4lb)

2.72kg

(6lb)

3.63kg

(8lb)

4.08kg

(9lb)

4.99kg

(11lb)

RemovingtheHeadfromthe Shaft

Removetheheadfromtheshaftintheoppositeorderof

installingit;refertoInstallingtheHeadontotheShaft(page

11).

13

Page 14

ConnectingtheShafttothe

G021364

A

B

Machine

Note:Theheadandshaftaresoldseparatelyfromthe

machine.Thereisavarietyofsizesavailablefromyour

AuthorizedToroDealer.

1.EnsurethattheOn/OffswitchisintheOffposition.

2.Rotatethecouplinglevercounterclockwise,andinsert

theshaftintothecoupling(

Figure18A).

Note:IfthechokeleverissettotheClosedposition

tostarttheengine,graduallymoveitbacktowardthe

Openpositionastheenginewarmsup.Iftheengine

stallsorhesitates,movethechokeleverbacktowardthe

Closedpositionuntiltheenginerunssmooth.Allow

theenginetowarmup,thenmovethechokeleverto

theOpenposition;referto

ChokeLever(page8).

StoppingtheEngine

1.MovethethrottlegriptotheIdleposition;referto

ThrottleGrip(page8).

2.Removethemachinefromyourback,andplaceiton

aat,levelsurface.

Figure18

3.Whentheshaftisfullyinserted,rotatethecoupling

leverclockwise,backtotheoriginalposition(Figure

18B).

Important:Ensurethatthecouplingleverlocks

theshaftinplacesothattheshaftdoesnotbecome

detachedduringoperation.

StartingandStoppingthe Engine

StartingtheEngine

1.Placethemachineonanelevated,at,levelsurface.

Note:Thiswillmakeiteasiertogetthemachineonto

yourbackafterstartingit.

2.Ensurethatthemachine,shaft,andheadaresecurely

attached.

3.EnsurethatthethrottlegripisintheSlow(idle)

positionandthattheheadisinapositionwhereitwill

notinjureanyoneorcausedamagetoproperty.

4.MovethefuelvalvelevertotheOnposition;referto

FuelValve(page8).

5.Positionthechokeleverasfollows:

•Tostartacoldengine,movethechokelevertothe

Closedposition—allthewaytotheright(open);

refertoChokeLever(page8).

•Tostartawarmengine,movethechokeleverto

theOpenposition—allthewaytotheleft(closed).

6.RotatetheengineOn/OffswitchtotheOnposition;

refertoEngineOn/OffSwitch(page8).

7.Pulltherecoil-starthandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly.Returnthe

starterhandlegently.

3.MovethefuelvalvetotheOffposition;referto

Valve(page8),androtatetheengineOn/Offswitch

totheOffposition;refertoEngineOn/OffSwitch

(page8).

Note:Ifyouneedtostoptheengineimmediately ,use

theenginestopbuttonlocatedunderthethrottlearm;

referto

EngineStopButton(page9).

UsingtheMachine

Important:Donotoperatethevibratorheadoutof

theconcretemixformorethanafewminutes.The

wetconcretekeepstheheadattheproperoperating

temperature.

1.Starttheengine;referto

2.Usingtheshoulder,chestandwaiststraps,strapthe

machinetoyourback.

Note:Adjustthestrapssothatyouarecomfortable

andthemachineissecure.

3.Whileholdingtheexibleshaftinyourlefthand,use

yourrighthandtocontrolthethrottlegrip.

Note:Thethrottlegriphas2positions:Slow(idle)

andFast.

4.Insertthevibratorheadverticallyintotheconcrete,and

allowtheweightofittosinkittothedesireddepth.

Note:Forcingthevibratorheadmaycauseitto

becomestuckbetweenpiecesofrebar.

5.Keepthevibratorheadinplacefor5to15seconds,

andthenslowlyliftitup.

Note:Allowabout15secondsformovingthevibrator

a61cm(2foot)distanceupandoutoftheconcrete.

Usingaslightupanddownmovementwillclosethe

holeformedbythevibratorhead.

6.Removethevibratorquicklywhenitisnearthetop

oftheconcrete.

7.Insertthevibratoratadistance1.5timestheradiusof

inuenceawayfromthelastinsertionpoint,andrepeat

theprocedure(

Figure19).

StartingtheEngine(page14).

Fuel

14

Page 15

5

4

1

2

3

G021592

Figure19

1.Insertionpoints4.Distancebetween

2.Concrete5.Radiusofinuence

3.Forms

8.Whenyouarenishedusingthemachine,stopthe

engine,andwipethemachineclean.

Note:Youcanspraywaterontheheadandshaft,but

becarefulnottodamagetheengine.

insertionpoints

OperatingTips

•Matchthevibratorpowerunit,shaft,andheadtothejob.

Selectthelargestvibratorsuitableforthejob.Selectthe

shortestshaftpossibletodothejobtoassuremaximum

powertothevibratorhead.

•Forthehighestefciency,avoidmakingsharpbendsin

theexibleshaft.

•Donotusethevibratortomovetheconcretelaterally.

Doingsowillcausesegregation.Useashovelinstead.

•Limitpoursto2feethigh;thiswillresultinlessresistance

forairtoescape.

•Allowthevibratortopenetrate3to6inchesintothe

precedinglayertoknitthe2layerstogether,preventing

liftlines.

•Fliptheshaftaround(sothatthecouplerendisatthe

head,andviceversa)periodicallytoextendtheservicelife.

Note:Thenarrowshaftsarenotreversible;referto

AvailableShafts(page13).

15

Page 16

Maintenance

1

G021549

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every40hours

Every100hours

Every300hours

Beforestorage

Yearly

Yearlyorbeforestorage

Important:Refertoyour

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Checktheaircleanerfordirty,loose,ordamagedparts,andcleanorreplacethem

ifnecessary.

•Lubricatetheshaftwithlithium-basedgrease.

•Replacetheair-cleanerelement(morefrequentlywhenoperatingthemachinein

dustyordirtyoperatingconditions).

•Changetheengineoil.

•Checkthesparkplug.

•Cleanthesparkarrester.

•Inspectthebeltandbelttension,andadjustorreplacethebeltasneeded.

•Replacethesparkplug.

•Emptythefueltankbeforerepairsasdirectedandbeforeannualstorage.

•RefertoyourEngineOperator'sManualforanyadditionalyearlymaintenance

procedures.

•Drainthefueltankandcarburetor.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

PreparingtheMachinefor Maintenance

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthespark-plugwirefromthesparkplug

(Figure20)beforeperforminganymaintenance

procedure.

Figure20

1.Spark-plugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthespark-plugwiretothesparkplug.

WARNING

Tippingthemachinemaycausethefuelto

leak.Gasolineisammableandexplosiveand

cancausepersonalinjury.

Runtheenginedryorremovethegasoline

withahandpump;neversiphon.

LubricatingtheShaft

ServiceInterval:Every40hours—Lubricatetheshaftwith

lithium-basedgrease.

Lubricatetheexibleshafttopreventdryspotsthatcause

overheating.

1.Disconnecttheexibleshaftfromthevibratorhead

andthepowerunit.

2.Removetheinnercoreandwipeitclean(Figure21A).

16

Page 17

A

G021331

1 2

3

G021535

Figure22

1.Air-cleanercover3.Air-cleanerhousing

2.Air-cleanerelement

3.Coatthecorewith1.5mm(1/16inch)oflithium-based

4.Installthecoreintotheshaftcasing(Figure21C).

5.Installtheshaftontothepowerunit.

6.Installtheheadontotheshaft.

ServicingtheAirCleaner

ServiceInterval:Every25hours/Y early(whichevercomes

1.Performthepre-maintenanceprocedures;referto

Figure21

grease(Figure21B).

Note:Over-lubricatingthecorewillshortenthelife

oftheshaft.

rst)—Checktheaircleanerfordirty,

loose,ordamagedparts,andcleanor

replacethemifnecessary.

Every100hours/Y early(whichevercomes

rst)—Replacetheair-cleanerelement(more

frequentlywhenoperatingthemachineindustyor

dirtyoperatingconditions).

PreparingtheMachineforMaintenance(page16).

3.Replacetheair-cleanerelement.

4.Installtheair-cleanercover.

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDealer.

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategory

or higher

Crankcasecapacity:0.25L(0.26USqt)

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

Note:UseSAE10W-30forgeneraluse.YoucanuseSAE

30whentheaveragetemperatureinyourareaiswithinthe

indicatedrange(Figure23).

.

SJ , SL, SM,

2.Pressthebuttonontheair-cleanercover(Figure22)

andopenthecover.

17

Page 18

G021529

Figure23

1

G021550

2

3

4

G0 215 30

1

2

DrainingtheEngineOil

WARNING

Oilmaybehotaftertheenginehasbeenrun,and

contactwithhotoilcancauseseverepersonalinjury.

FillingtheEngineCrankcasewithOil

1.Removethedipstick(Figure25)andslowlypouroil

intothellholeuntiltheoilreachestheupper-limit

mark(bottomedgeoftheoil-llhole)onthedipstick.

Avoidcontactingthehotengineoilwhenyoudrain

it.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug;referto

PreparingtheMachineforMaintenance(page16).

3.Placeadrainpanundertheoil-drainholeoftheengine

(Figure24).

Figure24

1.Oil-drainplug2.Oil-drainhole

4.Removethedrainplugandcatchtheoilintheoil-drain

pan(Figure24).

Figure25

1.Oil-llhole3.Oil-levelupperlimit

2.Dipstick

4.Oil-levellowerlimit

2.Replaceandsecurethedipstick.

3.Wipeupanyspilledoil.

ServicingtheSparkPlug

ServiceInterval:Every100hours/Y early(whichevercomes

rst)—Checkthesparkplug.

Every300hours/Every2years(whichevercomes

rst)—Replacethesparkplug.

Type:NGKCR5HSBorequivalent

Gap:0.6to0.7mm(0.024to0.028inch)

Note:Usea5/8inch(16mm)spark-plugwrenchfor

removingandinstallingthesparkplug.

5.Whentheoilhasdrainedcompletely,installthedrain

plugwithanewwasher(

Figure24).

Note:Disposeoftheusedoilatacertiedrecycling

center.

18

Page 19

RemovingtheSparkPlug

1

2

G021531

G019300

1 2

4

3

CheckingtheSparkPlug

1.Placethemachineonalevelsurfaceandturnoffthe

engine;refertoStoppingtheEngine(page14).

2.Ensurethatthemachinesurfacesarecool.

3.Pullthespark-plugwireofftheterminalofthespark

plug.

4.Cleanaroundthesparkplug.

5.Rotatethesparkplugcounterclockwiseusinga5/8

inch(16mm)spark-plugwrenchtoremovetheplug

andthesealingwasher(Figure26).

Note:Useagappingtool/feelergaugetocheckandadjust

thegap.Installanewsparkplugifnecessary.

1.Lookatthecenterofthesparkplug(

Figure27).Ifyou

seelightbrownorgrayontheinsulator,theengineis

operatingproperly.

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Figure27

1.Sideelectrode

2.Centerelectrode4.0.6to0.7mm(0.024to

3.Insulator

0.028inch)

1.Spark-plugwrench

2.Useagappingtoolforsparkplugsorafeelergaugeto

measurethegapbetweenthesideelectrodeandcenter

electrode(Figure27).

3.Ifthegapisnotwithinthespeciedrange,dothe

following:

A.Ifthegapistoosmall,carefullybendtheside

Figure26

2.Wire

electrodeawayfromthecenterelectrodeuntil

thegapbetweentheelectrodesis0.6to0.7mm

(0.024to0.028inch).

B.Ifthegapistoolarge,carefullybendtheside

electrodetowardthecenterelectrodeuntilthe

gapbetweentheelectrodesis0.6to0.7mm(0.024

to0.028inch).

InstallingtheSparkPlug

Important:Ensurethatthegapbetweenthesideand

centerelectrodesiscorrectbeforeinstallingthespark

plug.

1.Threadthesparkplugclockwiseintothespark-plug

holebyhand.

Note:Avoidcross-threadingthesparkplugwiththe

threadsofthespark-plughole.

2.Rotatethesparkplugclockwiseusinga5/8inch(16

mm)spark-plugwrenchuntiltheplugandsealing

washerareseated(

Figure26).

3.Tightenthesparkplugasfollows:

19

Page 20

•Wheninstallinganin-servicesparkplug,tighten

1

2

3

4

5

G021533

1

2

G019332

G021532

1

2

thepluganadditional1/8to1/4turn.

•Wheninstallinganewsparkplug,tightentheplug

anadditional1/2turn.

4.Pushthespark-plugwireontotheterminalofthespark

plug(Figure26).

ServicingtheSparkArrester

CleaningtheSparkArrester

ServiceInterval:Every100hours

Note:Asparkarresterisavailableasanoption.Ifyou

requireasparkarrester,contactyourAuthorizedToroService

Dealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

WARNING

Iftheenginehasbeenrunning,themuferwillbe

hot.

Avoidcontactingthemufer.

1.Removethe3bolts(5mm),andremovethemufer

protector(Figure28).

Figure29

1.Screen

4.Installthesparkarresterandmuferprotectorinthe

reverseorderofdisassembly.

2.Brush

ServicingtheFuelSystem

DrainingtheFuelTankandCarburetor

ServiceInterval:Yearlyorbeforestorage—Drainthefuel

tankandcarburetor.

1.Placethemachineonalevelsurfaceandstopthe

engine;referto

2.Ensurethattheengineandtheexhaustsystemsurfaces

arecool.

3.Placeanapprovedgasolinecontainerbelowthe

carburetor(Figure30).

Note:Useafunneltoavoidspillingfuel.

StoppingtheEngine(page14).

Figure28

1.Mufer3.Bolts(5mm)5.Sparkarrester

2.Specialscrew4.Mufer

2.Removespecialscrewfromthesparkarrester,and

removethesparkarresterfromthemufer(Figure28).

3.Useabrushtocarefullyremovecarbondepositsfrom

thespark-arresterscreen(Figure29).

Note:Replacethesparkarresterifithasbreaksor

holes.

protector

Figure30

1.Carburetor

20

2.Drainbolt

Page 21

4.Removethecarburetordrainbolt(Figure30).

G021554

1

2

2

G021555

1

5.MovethefuelvalvelevertotheOnposition.

6.Afterallthefuelhasdrainedintothecontainer,install

thedrainboltandtightenitsecurely.

ServicingtheBelt

CheckingandAdjustingtheBelt

Tension

ServiceInterval:Every100hours—Inspectthebeltandbelt

tension,andadjustorreplacethebeltas

needed.

1.Placethemachineonalevelsurfaceandstopthe

engine;refertoStoppingtheEngine(page14).

2.Removethe5screwsthatsecurethebeltguardtothe

beltmountingplate(

1.Plasticwasher(5)2.Screw(5)

3.Removethebeltguard.

4.Layastraightedgealongthedrivebelt,fromonepulley

totheother.

5.Withyournger,pushonthebeltwith6.8kg(15lb)

ofpressure,midwaybetweenthepulleys(Figure32).

Figure31).

Figure31

Figure32

1.Flexof1cm(13/32inch)

6.Measurethedistancefromthebelttothestraightedge.

Thedistanceshouldbeapproximately1cm(13/32

inch).

7.Ifthebelttensionisnotcorrect,adjustitasfollows:

A.Loosenthe3boltsthatsecurethelowerpulleyto

thebeltmountingplate.

B.Pivotthelowerpulleycounterclockwisetotighten

thebelt,orclockwisetoloosenthebelt.

C.Whenthebelttensioniscorrect,tightenthebolts.

8.Installthebeltguardwiththe5screwsandplastic

washers(

Figure31).

2.Bolts

ReplacingtheBelt

1.Placethemachineonalevelsurfaceandstopthe

engine;refertoStoppingtheEngine(page14).

2.Removethe5screwsthatsecurethebeltguardtothe

beltmountingplate,andremovethebeltguard.

3.Removethe3boltsthatsecurethelowerpulleytothe

beltmountingplate.

4.Installanewbeltontheupperpulley .

5.Alignthebeltoverthelowerpulley,andinstallthe

21

lowerpulleywiththe3bolts.

6.Adjustthebelttension;refertoCheckingandAdjusting

theBeltTension(page21).

7.Installthebeltguardwiththe5screwsandplastic

washers

Figure31.

Page 22

Storage

Storethemachineinacool,clean,dryplace.

PreparingtheMachinefor Storage

WARNING

Gasolinevaporscanexplode.

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosurenear

anopename.

•Allowtheenginetocoolbeforestoringit.

1.Onthelastrefuelingoftheyear,addfuelstabilizerto

thefuelasdirectedbytheenginemanufacturer.

2.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

3.Primetheengineandstartitagain.

4.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

5.Disconnectthewirefromthesparkplug.

6.Removethesparkplug,add30ml(1oz.)ofoilthrough

thesparkplughole,andpullthestarterropeslowly

severaltimestodistributeoilthroughoutthecylinder

topreventcylindercorrosionduringtheoff-season.

7.Installthesparkplugandtightenitwithatorque

wrenchto20N-m(15ft-lb).

8.Tightenallnuts,bolts,andscrews.

22

Page 23

Troubleshooting

Problem

Theenginedoesnotstart.

Theenginestartshardorlosespower.

PossibleCauseCorrectiveAction

1.ThefuelvalveisintheOffposition.1.Movethefuel-valvelevertotheOn

2.Thechokeisopen.

3.Thechokeisclosed.

4.TheOn/Offswitchontheengineisin

theOffposition.

5.Theengineoillevelislow .5.Filltheenginetotheproperlevelwith

6.Thewireisnotconnectedtothespark

plug.

7.Thefuelcapventholeisplugged.7.Cleanthefuelcapventholeorreplace

8.Thesparkplugispitted,fouled,or

incorrectlygapped.

9.Thesparkplugiswetwithfuel(ooded

engine).

10.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

1.Thefuelcapventholeisplugged.1.Cleanthefuelcapventholeorreplace

2.Theairlterelementisdirtyandis

restrictingtheairow.

3.Thesparkplugispitted,fouled,or

incorrectlygapped.

4.Theengineoillevelistoolow,toohigh,

orexcessivelydirty .

5.Thefueltankcontainsstalefuel.5.Drainandllthefueltankwithfresh

position.

2.Closethechokewhenstartingacold

engine.

3.Openthechokewhenstartingahot

engine.

4.RotatetheswitchtotheOnposition.

therecommendedoil.

6.Connectthewiretothesparkplug.

thefuelcap.

8.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

9.Removethesparkplug,dryit,and

installtheplug.Starttheenginewith

thethrottleintheMaxposition.

10.Drainand/orllthefueltankwith

freshgasoline.Iftheproblempersists,

contactanAuthorizedServiceDealer .

thefuelcap.

2.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

3.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

4.Checktheengineoil.Changetheoilif

itisdirty;addordraintheoiltoadjust

theoilleveltotheFullmarkonthe

dipstick.

gasoline.

Theenginerunsrough.

Thedrivebeltiswornorburned,orit

jumpsoffofthepulley .

Themachineorenginevibrates

excessively.

1.Thechokeislefton.1.Openthechoke.

2.Thewireisnotconnectedtothespark

plug.

3.Theairlterelementisdirtyandis

restrictingtheairow.

4.Thesparkplugispitted,fouled,or

incorrectlygapped.

5.Thereistoomuchoilintheengine

crankcase.

1.Thedrive-belttensionneeds

adjustment.

2.Thedrivebeltmaybestretched.2.Replacethedrivebelt.

3.Thepulleysareoutofalignment.3.ContactyourAuthorizedService

1.Theenginemountingboltsareloose.1.Tightentheenginemountingbolts.

2.Connectthewiretothesparkplug.

3.Cleanorreplacetheairlterelement.

4.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

5.Draintheoiltotheproperlevel.

1.Adjustthedrive-belttension.

Dealer.

23

Page 24

Alimitedwarranty(seewarrantyperiodsbelow)

TheT oroWarranty

Concrete,Masonry,

andCompaction

Equipment

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourT oroConcrete,Masonry,

andCompactionEquipmentProductslistedbelowtobefreefromdefects

inmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ConcreteMixers

•SpindleBearingsLifetime*(originalowneronly)

MortarMixers1year

•DrumBearingsandSealsLifetime*(originalowneronly)

ForwardPlateCompactors

ReversiblePlates1year

RammerCompactors

MudBuggy1year

VibratingTrenchRoller2years

ConcreteSaws

MasonrySaws

PowerTrowels1year

Screeds

ConcreteVibrators

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

LifetimeW arranty-Ifthebearing(s)orseal(s)onyourmixerfail,itwillbereplacedunderwarranty ,

atnocostforpartsorlabor.

1year

2years

2years

1year

1year

1year

1year

InstructionsforObtainingWarrantyService

IfyouthinkthatyourToroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.Tolocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Youmayalsocallourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’s

analysisorwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:800-888-9926

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromT oroandhave

signedtheT oroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalproductoperationinclude,butarenotlimitedto,belts,wipers,

sparkplugs,tires,lters,gaskets,wearplates,seals,O-rings,drive

chains,clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorT oroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty .Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty.Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EP A)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter .Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0288RevB

Loading...

Loading...