Page 1

FormNo.3379-369RevA

G018845

TR-34DTrenchRoller

ModelNo.68039—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3379-369*A

Page 2

WARNING

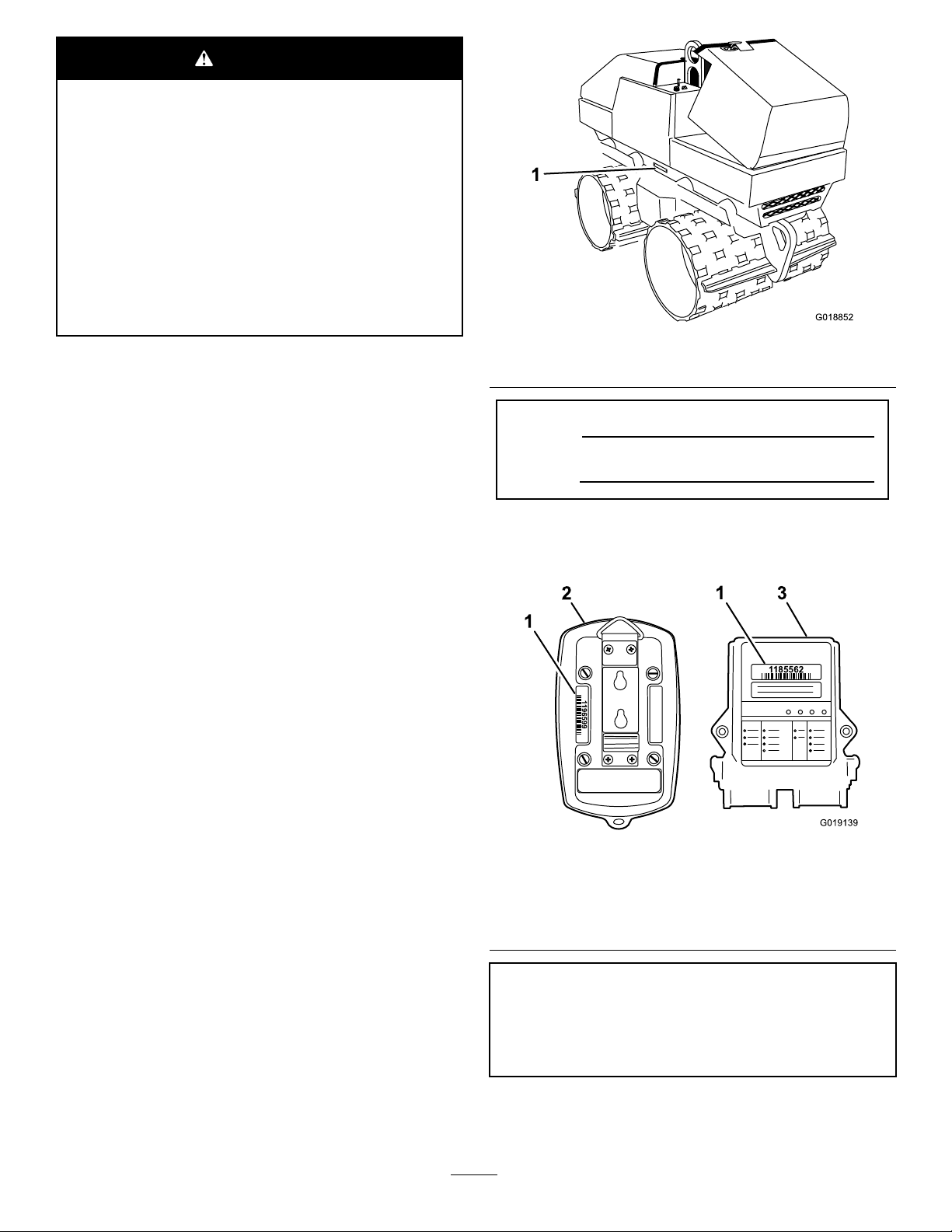

G018852

1

1185562

1196599

G019139

1

2

1

3

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Figure1

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachineisintendedforuseinvarioussoilfor

landscapingandconstructionwork.Itisdesignedtoperform

aspecializedfunction.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperly,andtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1identiesthelocationofthe

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Figure2showsthelocationoftheidenticationnumberson

radio-controltransmitterandradio-controlreceiver.Writethe

numbersinthespaceprovided.

Figure2

1.Transmitterserialnumber

tag

2.Radio-controltransmitter4.Receiverserialnumber

3.Radio-controlreceiver

tag

TransmitterSerialNo._____________________________

ReceiverSerialNo._______________________________

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure3),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure3

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

3

Page 4

Contents

Introduction..................................................................2

Safety...........................................................................5

SafeOperatingPractices...........................................5

StabilityData..........................................................7

SlopeChart............................................................8

TiltChart...............................................................9

SafetyandInstructionalDecals................................10

ProductOverview.........................................................13

Controls...............................................................14

Specications........................................................21

Operation....................................................................21

Pre-startChecklist..................................................22

Fuel......................................................................22

AccessingtheMachine............................................24

EngineOilandHydraulicFluid................................25

StartingandStoppingtheEngine..............................27

StoppingtheMachine.............................................28

UsingtheParkingBrake..........................................28

MovingaNon-functioningMachine.........................30

LiftingtheMachine................................................30

PreparingtheMachineforTransport.........................31

MovingandVibratingOperation..............................32

RecoveringtheMachineAfteraTip-over

Event................................................................35

Maintenance.................................................................39

RecommendedMaintenanceSchedule(s)......................39

PremaintenanceProcedures........................................40

Lubrication...............................................................40

GreasingtheMachine.............................................40

EngineMaintenance..................................................41

ChangingtheEngineOilandFilter...........................41

ServicingtheAirFilter............................................44

EngineHardware...................................................45

FuelSystemMaintenance...........................................46

ReplacingtheFuelFilter/WaterSeparator

Canister.............................................................46

DrainingtheFuelTank...........................................47

FuelLinesandFuelInjectors...................................48

ElectricalSystemMaintenance....................................49

ServicingtheBattery...............................................49

ElectricalandElectronic..........................................51

CoolingSystemMaintenance......................................53

ServicingtheCoolingSystem...................................53

HydraulicSystemMaintenance....................................54

ReplacingtheHydraulicFilter..................................54

ChangingtheHydraulicFluid...................................55

CheckingtheHydraulicLines...................................56

HydraulicandFuelTankAccess...................................57

RemovingtheRight-sidePanel.................................57

InstallingtheRight-sidePanel..................................57

EccentricMaintenance...............................................58

ChangingtheEccentricLubricant.............................58

Cleaning...................................................................59

RemovingDebrisfromtheMachine..........................59

CleaningtheChassis...............................................59

Storage........................................................................60

RemovingtheMachinefromStorage.........................60

Troubleshooting...........................................................61

4

Page 5

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Caution

,

W ar ning

,or

Danger

—personalsafety

–Neveraddfueltothemachineordrainfuelfromthe

machineindoors.

–Allowtheenginetocoolbeforefuelingthemachine.

–Donotsmokewhilefuelingthemachine.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

•Beforecompactingsoil,havetheareamarkedfor

undergroundutilities.

Thisproductiscapableofcrushingoramputatinghandsand

feet.Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminetheproperandsafe

actionstoperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,longpants,safetyshoes,andhearingprotection.

Longhair,looseclothingorjewelrymaygettangledin

movingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchastools,buildingmaterials,and

personalitemswhichcanbedamagedbythemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainerforstoringand

transportingfuel.

–Neverremovethefuelcaporaddfueltothemachine

withtheenginerunning.

Operation

•Neverrunanengineinanenclosedarea.

•Nevercarrypeople,animals,orequipmentontopofthe

machine.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealltractioncontrolsareinneutralandparking

brakeisengagedbeforestartingtheengine.

•Slowdownanduseextracareonhillsides.Soilconditions

affectthemachine'sstability.

•Neverparkonahill.

•Neveroperatethemachinewiththevibrationfunction

On,andmovingacrossthesideofahill.

•Donotoperateinstandingwater.

•Donotparkthemachineforanextendedperiodina

trench,ditch,orlow-lyingareathatmightllwithwater.

Liftormovethemachinetoalevel,welldrainedsurface.

•Donotoperateattheedgeofembankmentsorroads

becausethemachinemaytipover.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Stoponlevelground,engageparkingbrake,shutoffthe

enginebeforeleavingtheoperator'spositionforany

reason.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Keepfeetclearofdrums.

•Hearingprotectionisrequiredwhenoperatingthis

equipment.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Locatethepinchpointareasmarkedonthemachineand

keephandsandfeetawayfromtheseareas.

5

Page 6

•Forfootprotection,wearsteeltoeshoesortoepads.

•Neveroperatewiththeguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,and

functioningproperty.

•Donotexceedtheratedoperatingcapacityofthe

machine,asthemachinemaybecomeunstablewhichmay

resultinlossofcontrol.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Neverleavethemachinerunningunattended.Always

stoptheengine,settheparkingbrake,andremovethe

keybeforeleaving.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Checkforoverheadclearances(i.e.branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthemachine

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Donotparkthemachineonahillsideorslope.

•Ifpossible,avoiddrivingthemachineacrossaslope.

Whencrossingaslopeisnecessary,drivethemachine

straightuptheslope,acrossthetop,andthenstraight

downtheslope.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotoperatethemachineonhillsidesorslopes

exceedingtheanglesrecommendedinStabilityData

(page7).SeealsotheSlopeChart(page8)andTiltChart

(page9).

•Neveroperatethemachinewiththevibrationfunction

On,andmovingupordownagradethatisgreaterthan

45percent(24°).

•Neveroperatethemachinewiththevibrationfunction

Off,andmovingupordownagradethatisgreaterthan

55percent(29°).

•Neveroperatethemachinewiththevibrationfunction

Off,andmovingacrossthesideofahillwithagradethat

isgreaterthan18percent(10°).

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

terraincouldoverturnthemachine.Tallgrasscanhide

obstacles.

•UseonlyToro-approvedattachments.Attachmentscan

changethestabilityandtheoperatingcharacteristics

ofthemachine.Warrantymaybevoidedifusedwith

unapprovedattachments.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthemachine

losestraction,ensurethatthevibrationfunctionisturned

totheOffpositionandproceedslowly ,straightdown

theslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly .

•Donotoperateneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifadrumgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

MaintenanceandStorage

•Parkthemachineonalevelsurface,settheparking

brake,stoptheengine,andremovethekey .W aitforall

movementtostopbeforeadjusting,cleaning,orrepairing.

•Cleandebrisfromthedrives,mufer,andengineto

helppreventres.Cleanupfuel,oil,andhydraulicuid

spillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentsofthemachine

whenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Reconnectpositiverstandnegativelast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

6

Page 7

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthemachinefreefromthebuildupofmud,rocks,

orotherdebris.Cleanupoilorfuelspillage.Allowthe

machinetocoolbeforestoring.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

–Neverremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllafuelcontainerwhileitisinsideavehicle,

trunk,cargoboxofatruck,oranysurfaceotherthan

theground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

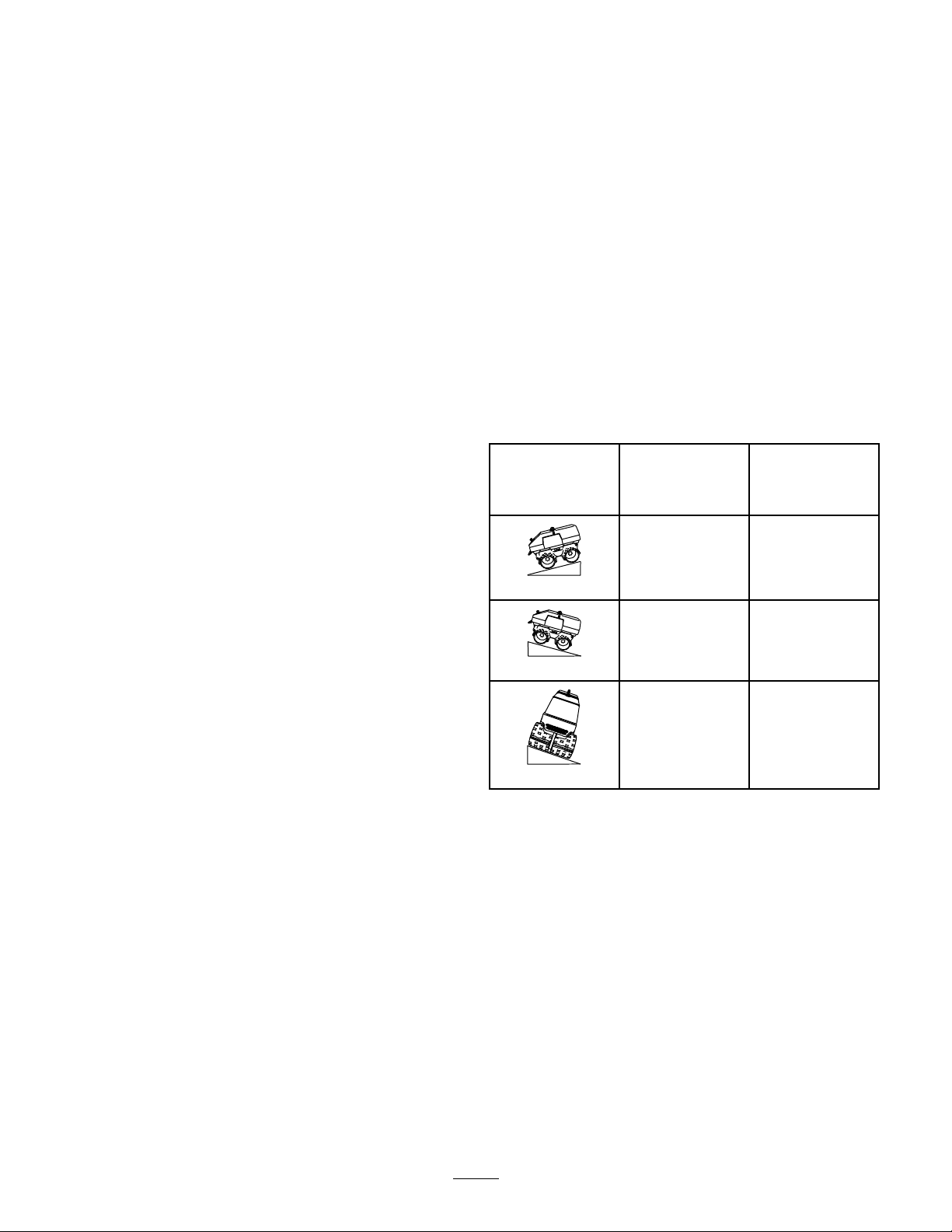

StabilityData

Thefollowingtableslistthemaximumsloperecommended

forthemachineinthepositionslistedinthetables.Slopes

overthelisteddegreeinthestabilitydatatablemaycausethe

machinetobecomeunstable.

StabilityDataTable

SlopeOperation

Type:

Uphill

Downhill

Operational

Limit:

VibrationOff

Grade(Degrees)

55%(29°)45%(24°)

55%(29°)45%(24°)

18%(10°)0%(0°)

Operational

Limit:

VibrationOn

Grade(Degrees)

7

Acrossthehill

Page 8

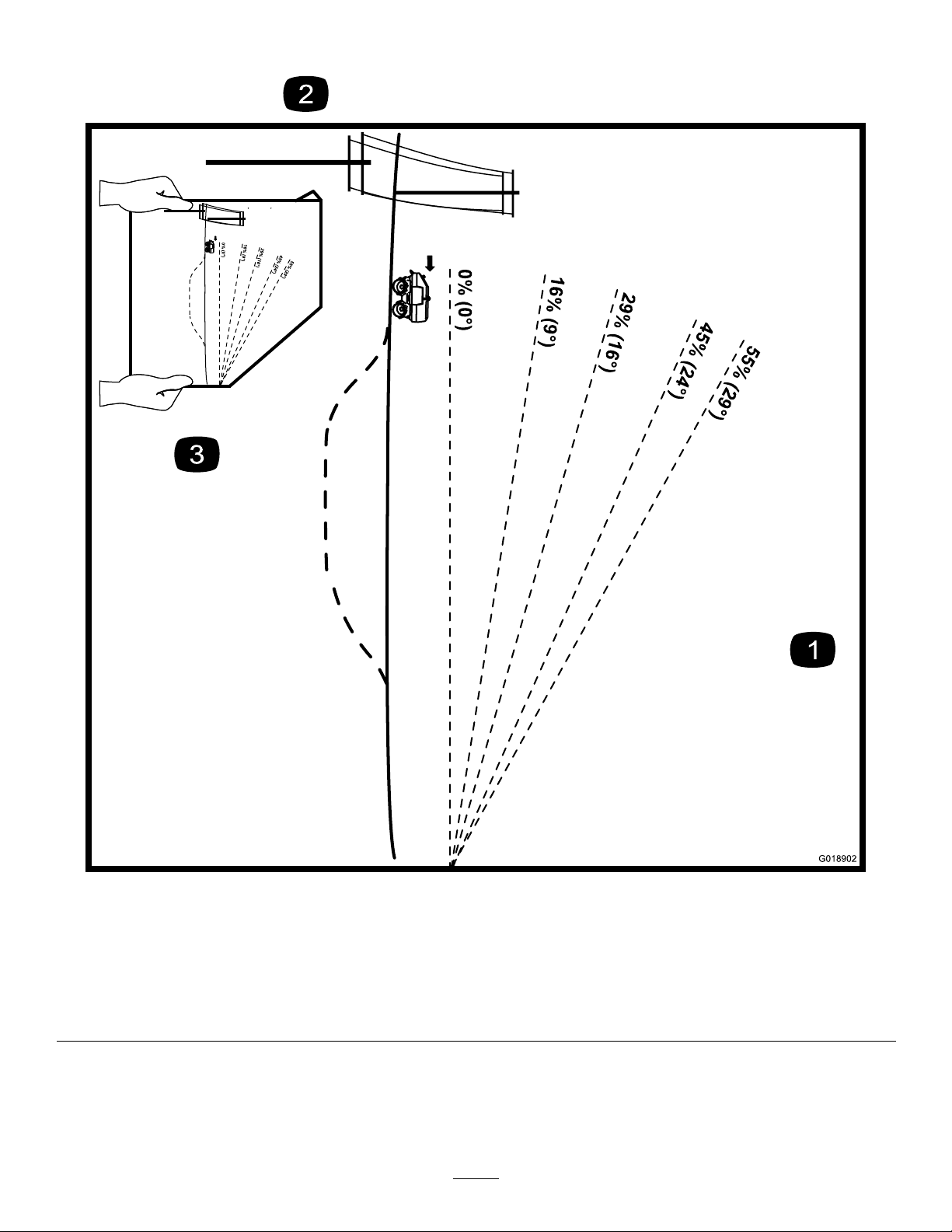

SlopeChart

0% (0°)

0% (0°)

G018902

Figure4

Thispagemaybecopiedforpersonaluse.

1.Todeterminethemaximumslopeyoucansafelyoperatethemachine,refertotheStabilityDatasection.Usethegradeindicator

todeterminethegradeofinclinebeforeoperating.Donotoperatethismachineonagradegreaterthanthatspeciedinthe

StabilityDatasection.Foldalongtheappropriatelinetomatchtheobservedgrade.

2.Alignthisedgewithaverticalsurfacesuchasautilitypole,tree,building,etc.

3.Exampleofhowtocomparegradewithfoldededge.

Note:Fortiltlimits,refertoFigure5.

8

Page 9

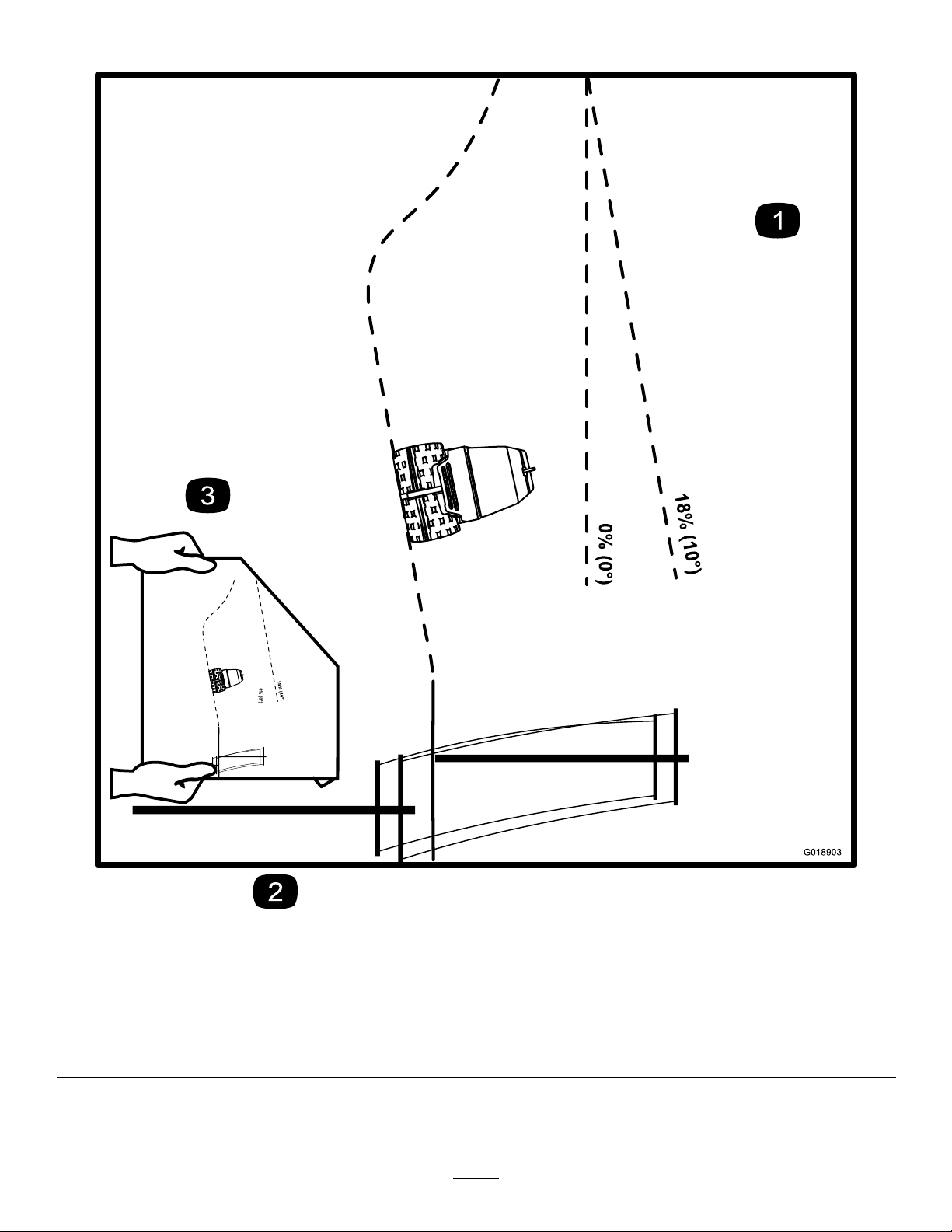

TiltChart

0% (0°)

G018903

0% (0°)

18% (10°)

Figure5

Thispagemaybecopiedforpersonaluse.

1.Todeterminethemaximumtiltyoucansafelyoperatethemachine,refertotheStabilityDatasection.Usethetiltindicatorto

determinethedegreeofslopebeforeoperating.Donotoperatethismachineonaslopegreaterthanthatspeciedinthe

StabilityDatasection.Foldalongtheappropriatelinetomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurfacesuchasautilitypole,tree,building,etc.

3.Exampleofhowtocompareslopewithfoldededge.

Note:Forslopelimits,refertoFigure4.

9

Page 10

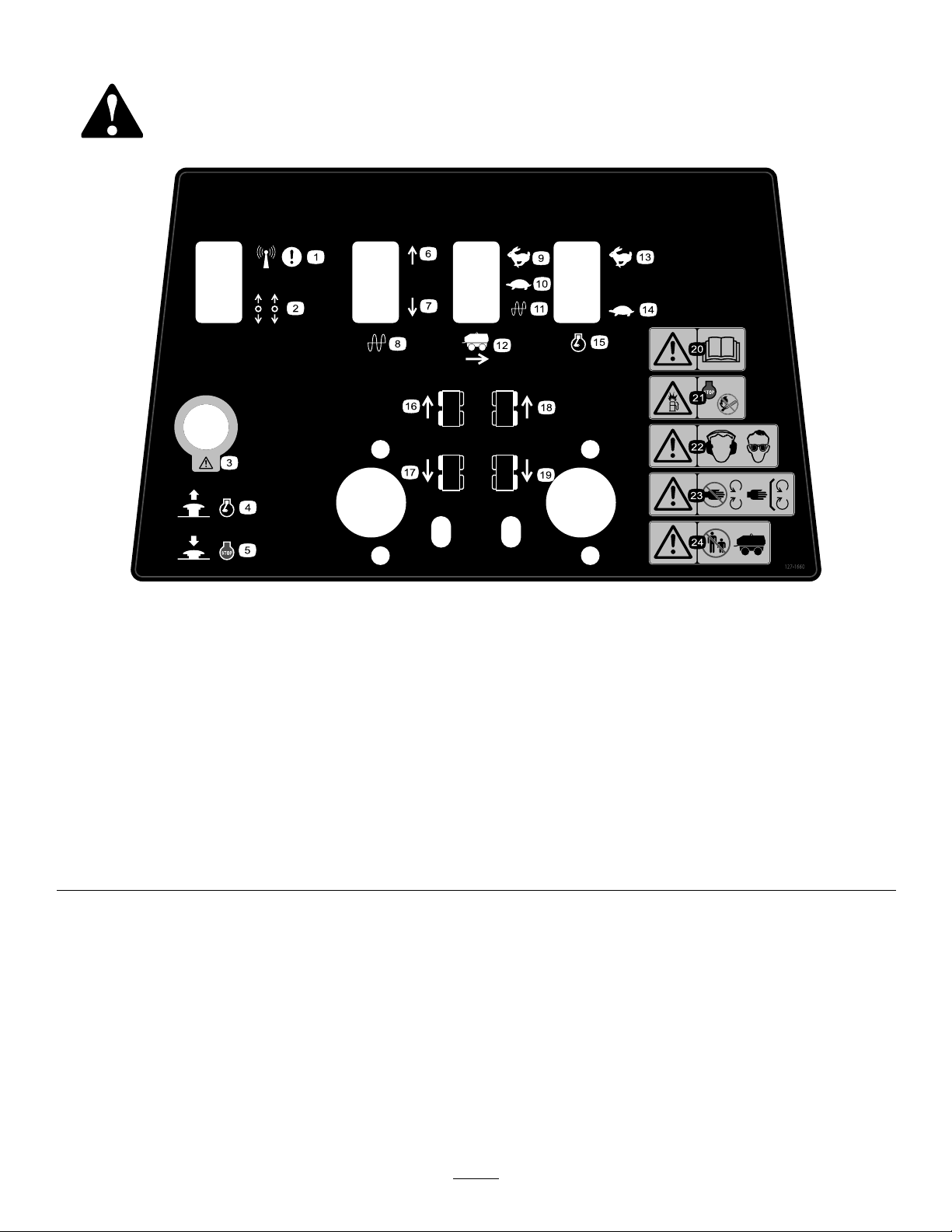

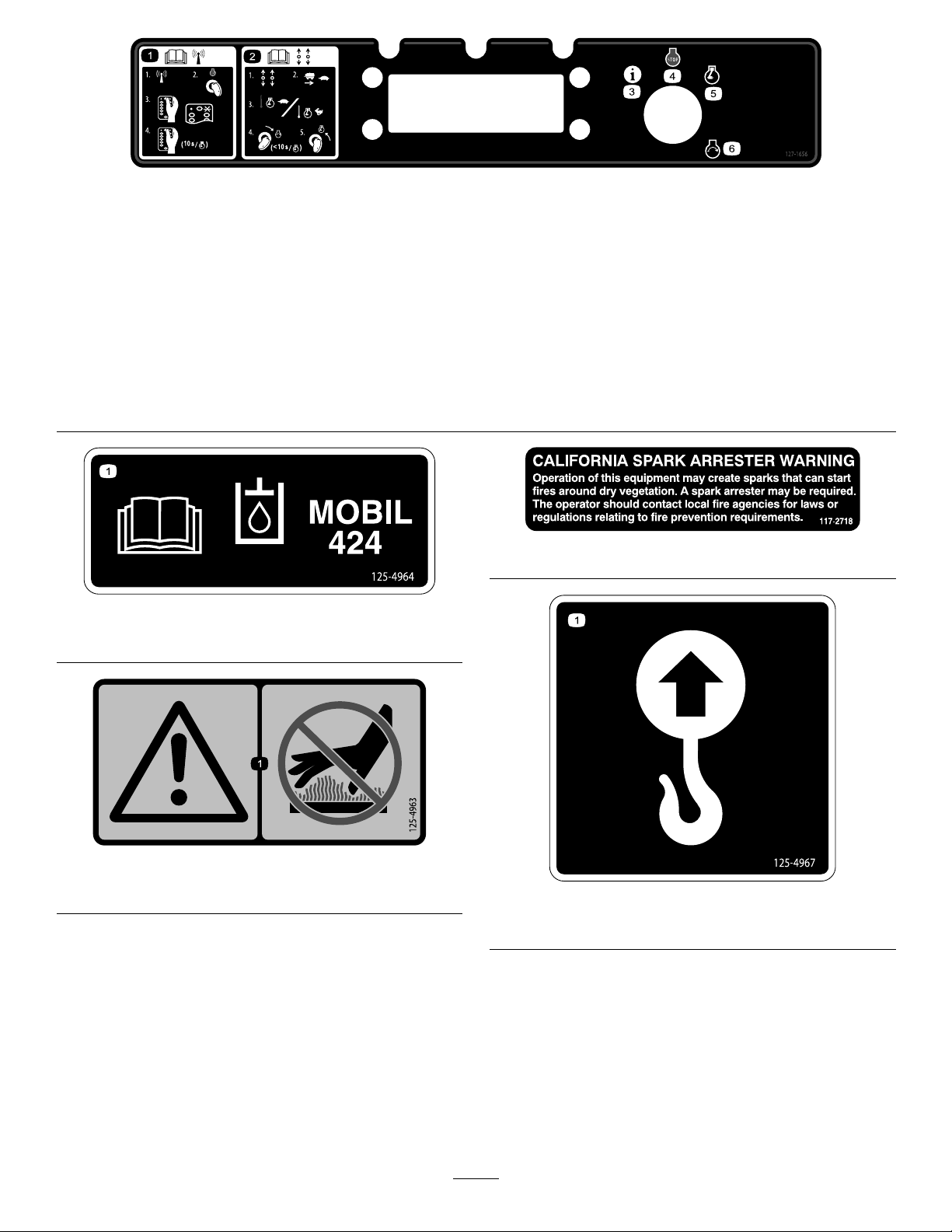

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1.Remote-controlmode9.Fast—travelspeed

2.Manualmode

3.Warning—emergencystop

4.Pulluptoruntheengine

5.Pressdowntostoptheengine13.Fast—enginespeed

6.Forwardvibration

7.Reversevibration15.Enginespeedcontrol

8.Vibrationdirectiontoggle

10.Slow—travelspeed18.Right-forwardtraction

11.VibrationOn

12.Travel-speed/vibration20.Warning—readtheOperator’sManual.

14.Slow—enginespeed

16.Left-forwardtraction

127–1660

17.Left-reversetraction

19.Right-reversetraction

21.Explosionhazard,fuel—stopthe

engineandextinguishallamesbefore

refueling.

22.Warning—wearhearingprotection;

weareyeprotection.

23.Warning—keepawayfrommoving

parts;keepguardsandshieldsin

place.

24.Warning—keepbystandersawaywhen

operatingthemachine.

10

Page 11

127–1656

1.ReadtheOperator’sManualforinformationonthe

radio-controlmode—1)Positiontheswitchtotheradio-control

mode;2)Rotatethekeytotheengine-stopposition;3)Press

thelink/startbuttononce—waitfortheactive-linklightto

illuminate;4)Pressthelink/startbuttontostarttheengine.

2.ReadtheOperator’sManualforinformationonthemanual

mode—1)Positiontheswitchtothemanualmode;2)Position

thetractionswitchtoslow;3)Iftheengineiswarm,position

theengine-speedswitchtoslow;iftheengineiscold,

positiontheengine-speedswitchtofast;4)Turnthekeyto

theengine-startpositionfor10secondsorlesstostartthe

engine,thenreleasethekeytotheengine-runposition.

3.LEDdisplay6.Engine—start

125–4964

1.ReadtheOperator’sManualforoilinformation.

4.Engine—stop

5.Engine—run

117–2718

125–4963

1.Warning—keephandsawayfromhotsurfaces

125–4967

1.Liftpoint

11

Page 12

1.Dieselfuel

125–8478

1.Tiedownlocation

125–6694

125–8187

1.Warning—disconnectthebatterandconsulttheOperator’s

Manualbeforeperformingserviceormaintenanceonthe

machine.

125–8189

1.ReadtheOperator’s

Manualforinformation

onoperatingtheparking

brake.

2.Toreleasetheparking

brake,pulltheknob

upfully ,rotateit90°

clockwise,andthengently

releasetheknob.

3.Tosettheparkingbrake,

pulltheknobupslightly ,

rotateit90°clockwise,

andthengentlyrelease

theknob.

125–8188

1.Warning—readtheOperator’sManualforinformationon

fuses.

12

Page 13

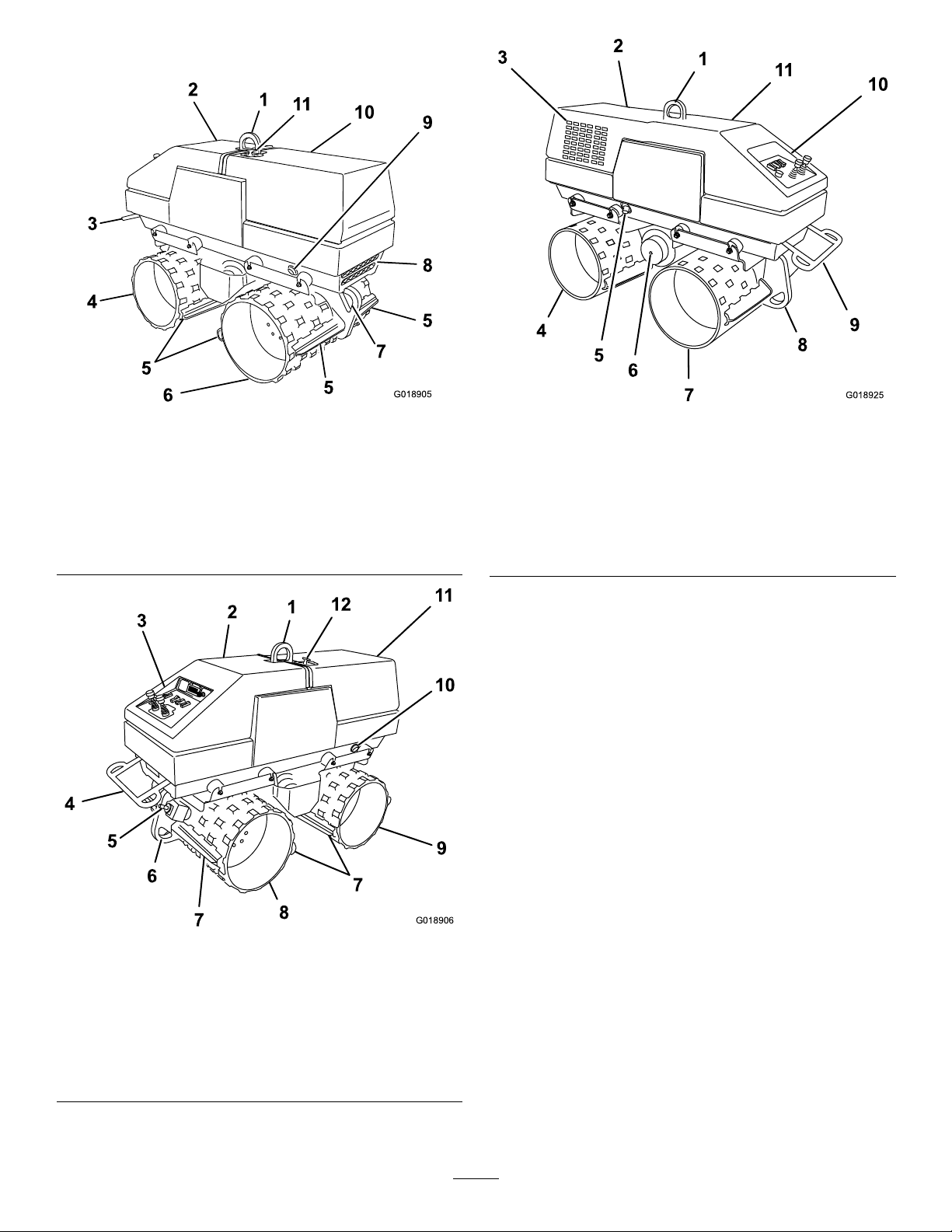

ProductOverview

G018905

1

2

3

4

5

6

5

7

5

8

9

10

11

G018906

1

2

3

4

5

6

7

9

10

8

11

7

12

4

7

G018925

1

2

3

5

6

8

9

10

11

Figure6

1.Liftingring

2.Rearhood8.Airinlet

3.Safetybar9.Oil-coolerduct

4.Right-reardrum10.Fronthood

5.Scraperbar

6.Right-frontdrum

7.Forward,tie-downring

11.Hood-latchhandle

Figure8

1.Liftingring7.Left-reardrum

2.Fronthood8.Rear,tie-downring

3.Enginegrill

4.Left-frontdrum10.Controlpanel

5.Engine-exhaustpipe11.Rearhood

6.Eccentricoilplug

9.Safetybar

1.Liftingring

2.Rearhood8.Right-reardrum

3.Controlpanel9.Right-frontdrum

4.Safetybar10.Oil-coolerduct

5.Parkingbrake11.Fronthood

6.Rear,tie-downring12.Hood-latchhandle

Figure7

7.Drumscraper

13

Page 14

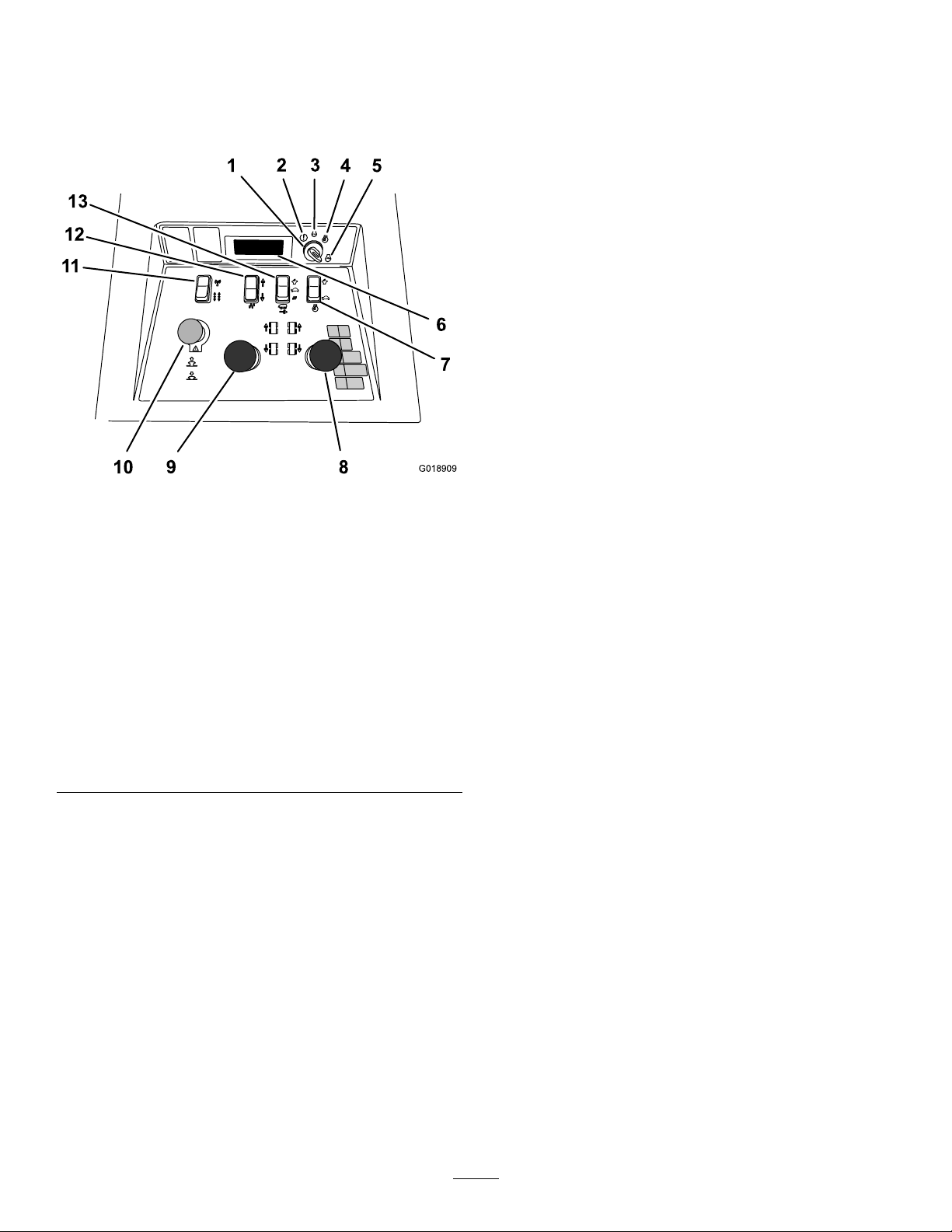

Controls

STOP

!

!

G018909

7

13

12

11

10

9

8

5

4

32

6

1

Becomefamiliarwithallthecontrols(Figure9andFigure17)

beforeyoustarttheengineandoperatethemachine.

ControlPanel

Displaywhenthekeyswitchisintheinformation

position—hourmeter—faults/warnings—software

version:Toviewoperationinformationforthemachine,

rotatethekeyswitchtotheinformationposition

(counterclockwisefromtheOffposition).

•Hourmeter

•Faultmessages

•Faulthistory

•Warnings

•Softwareversion

Note:Operationinformationisstoredinnonvolatile

memory.Intheeventthatbatterypowerislost,this

informationremainsintact.Uponrestoringbatterypower,

thestoredoperationinformationisavailablefordisplay.

HourMeter

Thehourmeterdisplayindicatesthetotalnumberofhours

themachinehasrun.

Figure9

1.Keyandkeyswitch8.Right,traction-control

2.Information9.Left,traction-control

3.Engine—stop10.Emergency-stopbutton

4.Engine—run11.Modeswitch

5.Engine—start12.Vibration-directionswitch

6.LEDdisplay

7.Engine-speedswitch(fast

|slow)

LEDDisplay

(forward/reverse)

(forward/reverse)

(remote-controlmode|

manualmode)

(forward|reverse)

13.Travel-speed/vibration

switch(fast|slow|

vibrationOn)

Locationandoperation:TheLEDdisplayislocated

onthecontrolpanel.Thedisplayisembeddedintothe

electronicignitioncontrolblock,andiscontrolledthrough

themicroprocessor.Thedisplayprovidestheoperatoror

mechanicoperatinginformationaboutthesystemsonthe

machine.Thefollowingsectiondescribestheinformation

showninthedisplay .

Displaywhilestarting-up—voltage:Duringengine

start-up,thedisplayshowsthebatteryvoltagelevel.Rotatethe

keyswitchtotheStartpositiontodisplaythebatteryvoltage.

Displaywhilerunningthemachine—rpm:Whenthe

engineisrunning,thedisplayshowstheenginerpm.After

startingthemachine,thekeyswitchwillrotatebackto

engine-runpositionandtheenginerpmisindicatedinthe

display.

RotatethekeyswitchtotheAccessorypositiontodisplay

thehourmeterinformation.

FaultMessages

Thefaultmessagesdenethesituationsthatcausetheengine

ofthemachinetoshutdownornotstart.Thesesafeguards

includeengineprotectcircuitsorothermachineprotection

devices.Faultmessageswillbeshownonthedisplayandwill

indicatewhateventhasshutdowntheengine.

Rotatethekeyswitchtotheinformationpositiontoviewthe

faultmessagesshouldtheyoccur.

•LOWOIL—thismessagedisplayswhentheproperoil

pressureisnotachievedormaintained(monitoredbythe

oilpressureswitch).

•CYLHEADTEMP—thismessagedisplayswhen

thetemperatureofthecylinderheadexceedsthesafe

operatingtemperature(monitoredbythetemperature

switchinthecylinderhead).

•TILT—thismessagedisplayswhenthemachinetipangle

isexceeded(monitoredbythetipswitch).

•ESTOP—thismessagedisplayswhentheemergency

stopbuttononthecontrolpanelisdepressed,andhas

notbeenreset(monitoredbytheemergencystopbutton

position).

Note:TheLEDdisplayalwaysindicatesthelastfault

messagethatoccurred.Thenonvolatilememoryinthe

microprocessoralwaysrequiresaninput,thereforethelast

messagewillbedisplayedevenafterthefaulthasbeen

corrected.

14

Page 15

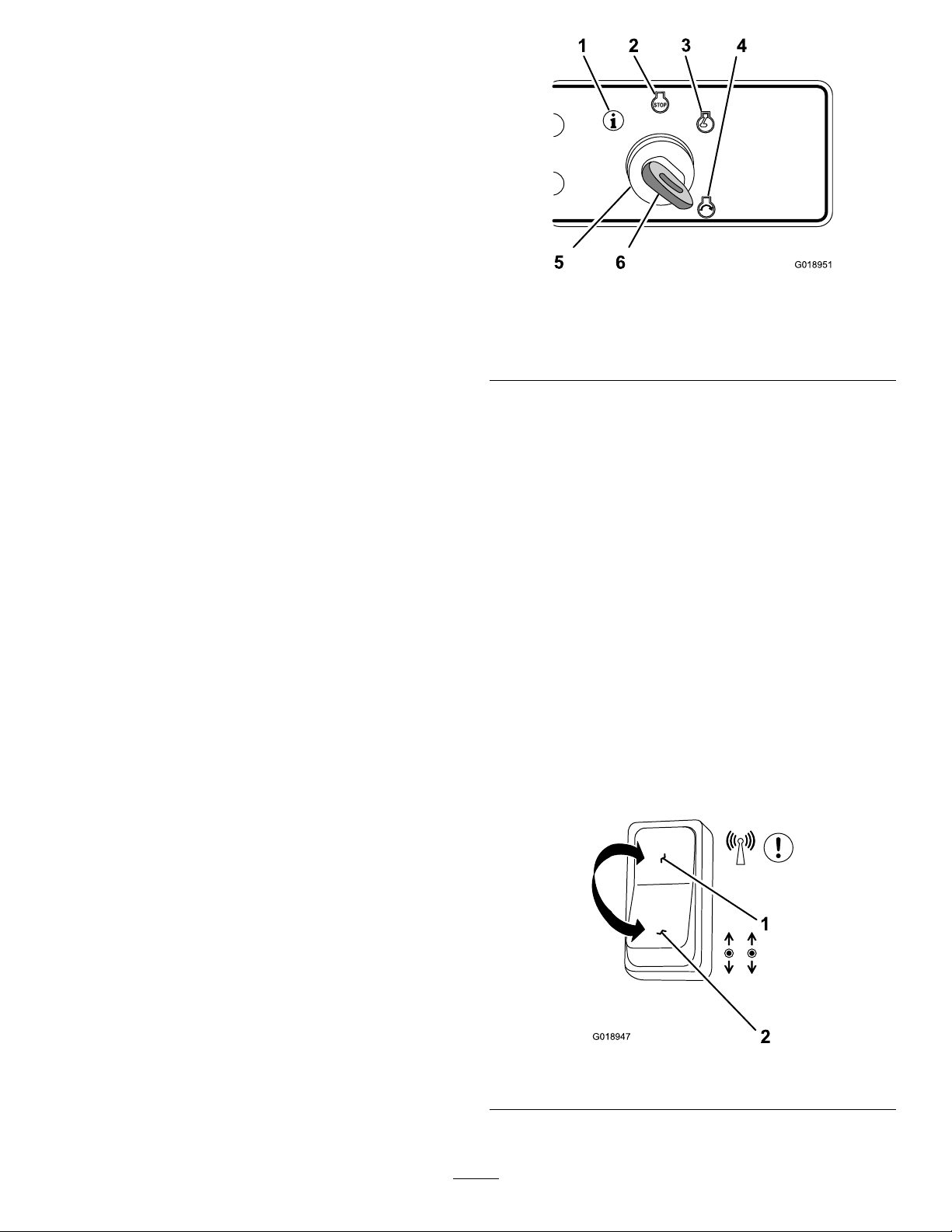

FaultHistory

G018951

1 2

3

4

5

6

G018947

2

1

Themicroprocessorrecordsthelast20faultmessagestothe

nonvolatilememory;accessthefaulthistoryasfollows:

1.RotatethekeyswitchtotheInformationpositionto

displaythehourmeter,lastfault,andsoftwareversion

level.

2.Duringthedisplayofthelastfault,quicklyrotatethe

keyswitchtotheOffposition,andthenrotatethekey

switchtotheInformationposition.

Note:Thedisplaywillshowthelast20faults,beginningwith

themostrecent.Toturnoffthedisplayatanytime,turnthe

keyswitchtotheOffposition.

Warnings

Warningmessagesaredenedasmessagesthatindicatethe

electricalsystemisnotoperatingcorrectly.Warningmessages

willashinthedisplaywhenthemachineisrunninginthe

manualoperatormode.The3warningmessagesareas

follows:

Note:IftheVRegLortheBatLowmessageisindicatedin

thedisplay ,stoptheengine.IfaVRegLwarningmessageis

indicated,refertoyourEngineOperator'sManual.IfaBatLow

warningmessageisindicated,checkthealternatoroutput

voltageandchargeorreplacethebattery.

•VREG—thevoltageregulatorlowmessageindicatesthat

theelectricalsystemisnotchargingcorrectly.

•BATLOW—thebatterylowmessageindicatesthe

voltagelevelofthebatteryislow .Thismessagewill

displaywhenthebatteryoutputis10voltsorless.

•RPMLOW—therevolutionsperminutelowmessage

indicatestheenginespeedisbelowtheminimumspeed

(monitoredbyalternatoroutput).

SoftwareVersion

Thesoftwareversiondisplayindicatesrevisionlevelofthe

softwareforthemicroprocessor.

Figure10

1.Information

2.Engine—Off

3.Engine—run6.Key

4.Engine—start

5.Keyswitch

•Stoptheenginebyrotatingthekeyswitchtothe

engine-Offposition(Figure10).

•Displaythehourmeter,thelastfaultmessage,and

thesoftwareversionbyrotatingthekeyswitchtothe

Informationposition(Figure10).

ModeSwitch

Usethemodeswitchtocontrolthereceptionofcommands

fromtheremote-controltransmitter.Selectingtheswitchto

theradio-controlmodeormanual-modepositionchanges

intendedmachineformofoperation(Figure11).

Important:Prolongthebatterylifeofthemachineby

selectingthemodeswitchtothe

whenthemachineisnotinuse.

Note:Selectthemodeswitchtotheradio-controlmode

positiontooperatethemachinewiththeremote-control

transmitter.

Selectthemodeswitchtothemanual-modepositionto

operatethemachinewiththecontrolpanel.

man ual mode

position

Todisplaythesoftwareversioninformation,rotatethekey

switchtotheInformationposition.

KeySwitch

Usethekeyswitchtostartandruntheengine,stopthe

engine,andpowertheaccessorydisplay.Thekeyswitchhas4

positions:Information,Off,Run,andStart.

•Starttheenginebyrotatingthekeyswitchtothe

engine-startposition,andthenreleasingthekeywhen

enginestarts;thekeyitwillmoveautomaticallytothe

engine-runposition(

Figure10).

Figure11

1.Radio-controlmode2.Manualmode

15

Page 16

VibrationDirectionSwitch

2

1

G018948

3

1

2

G018949

2

1

G018950

G021430

G018946

1

2

Usethevibrationdirectionswitchtoselectthedirection

eccentricrotationwhenthevibrationfunctionactive(Figure

12).

Figure12

1.Vibrateforward

2.Vibratereverse

Important:Performmachineoperationssuchas

movingthemachineandvibrationfunctionswiththe

engine-speedswitchinthefast,engine-speedposition.

Figure14

1.Fast,engine-speed

2.Slow,engine-speed

•Vibrationmovementinaforwarddirection.

•Vibrationmovementinthereversedirection.

Travel-speed/VibrationSwitch

Important:Selecttheslow,travel-speedsettingwhen

movingthemachineinandoutofthetrench,when

loadingthemachineontoatransportvehicle,andwhen

unloadingthemachinefromatransportvehicle.

Usethetravel-speedswitchtocontroltravelspeedofthe

machine(vibrationOff)oractivatethemachine-vibration

function(Figure13).

Note:Thevibrationfunctionisinoperativewhenmoving

themachineinthefast-travelspeedortheslow-travelspeed

settings.

EmergencyStopButton

Usetheemergencystopinanysituationwhentheimmediate

stopofthemachineisrequired.Pressingtheemergencystop

buttonwillshutthemachineoffimmediately.

Theemergencystopbuttonislocatedonthecontrolpanel

andislabeled

belowthered-coloredbutton.

Performthefollowingstepstostopthemachineinan

emergencysituation,andresetthemachinewhenthe

emergency-stopconditioniscorrected:

1.Presstheemergencystopbuttondowntoimmediately

shutoffthemachine(Figure15).

Figure13

1.Fast-travel(vibration-off)3.VibrationOn(slowtravel)

2.Slow-travel(vibration-off)

Engine-speedSwitch

Usetheengine-speedswitchtochangetheengineRPM

betweentheslowandfast,engine-speedsettings(

Figure14).

Figure15

1.Emergencystopposition

2.Resetfornormaloperation

2.Pulltheemergencystopbuttonuptoresumenormal

machineoperation(

16

Figure15).

Page 17

TractionControls

G019077

1 2

ENG INE S PEE D

TRAVE L SPEE D

R

L

VIBE ON

REV

FWD

TRAVE L

G018910

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Remote-controlTransmitter

Movetheleftandright,traction-controlleverstomanually

movethemachineintheforwardorreversedirection

Important:Keeptheremote-controltransmitterdry.

Donotpressurewashtheremote-controltransmitter.

(straight,leftorright)(Figure16).

Figure16

RadioSet

Aradiosetisamatchedaddresscodeandradiofrequency

foraradio-controltransmitterandtheradio-controlreceiver.

Theaddresscodesandradiofrequencyfortheradiosetare

unique,andmustmatchforthemachinetofunctionproperly.

Thisrelationshipassuresthatthetransmittercancontrolonly

onereceiver/machine,andthatmultiplecompactorscanbe

usedonthejobsitewithoutinterference.Refertothe7digit

serialnumbersthatyourecordedonpagetitledIntroduction

(Figure2).

1.Link/startbutton(green)8.Emergency-stop/power-Off

2.Lowbatterylight

(remote-control

transmitter)

3.Left,forward-traction

button(uparrow)

4.Left,reverse-traction

button(downarrow)

5.Slow,travel-speedbutton

(vibrationOff)

6.Reversevibrationbutton

(vibrationOn)

7.Slow,engine-speedbutton

(notfunctional)

Figure17

button

9.Fast,engine-speedbutton

(notfunctional)

10.Forwardvibrationbutton

(vibrationOn)

11.Fast,travel-speedbutton

(vibrationOff)

12.Right,reverse-traction

button(downarrow)

13.Right,forward-traction

button(uparrow)

14.Activelinklight(ashes)

Link/StartButton

Pressthelink/startbutton(greenbutton)toestablisharadio

linkbetweentheremote-controltransmitterandtheradio

receiverinthemachineandtostarttheengineinthemachine

(

Figure17).

Note:Thelink/startbuttonisthetopbutton(centeredleft

andright)ontheremote-controltransmitter.

Functions:

1.Establishalinktotheradioreceiverofthemachine.

2.Starttheengineofthemachine.

17

Page 18

Traction-controlButtons

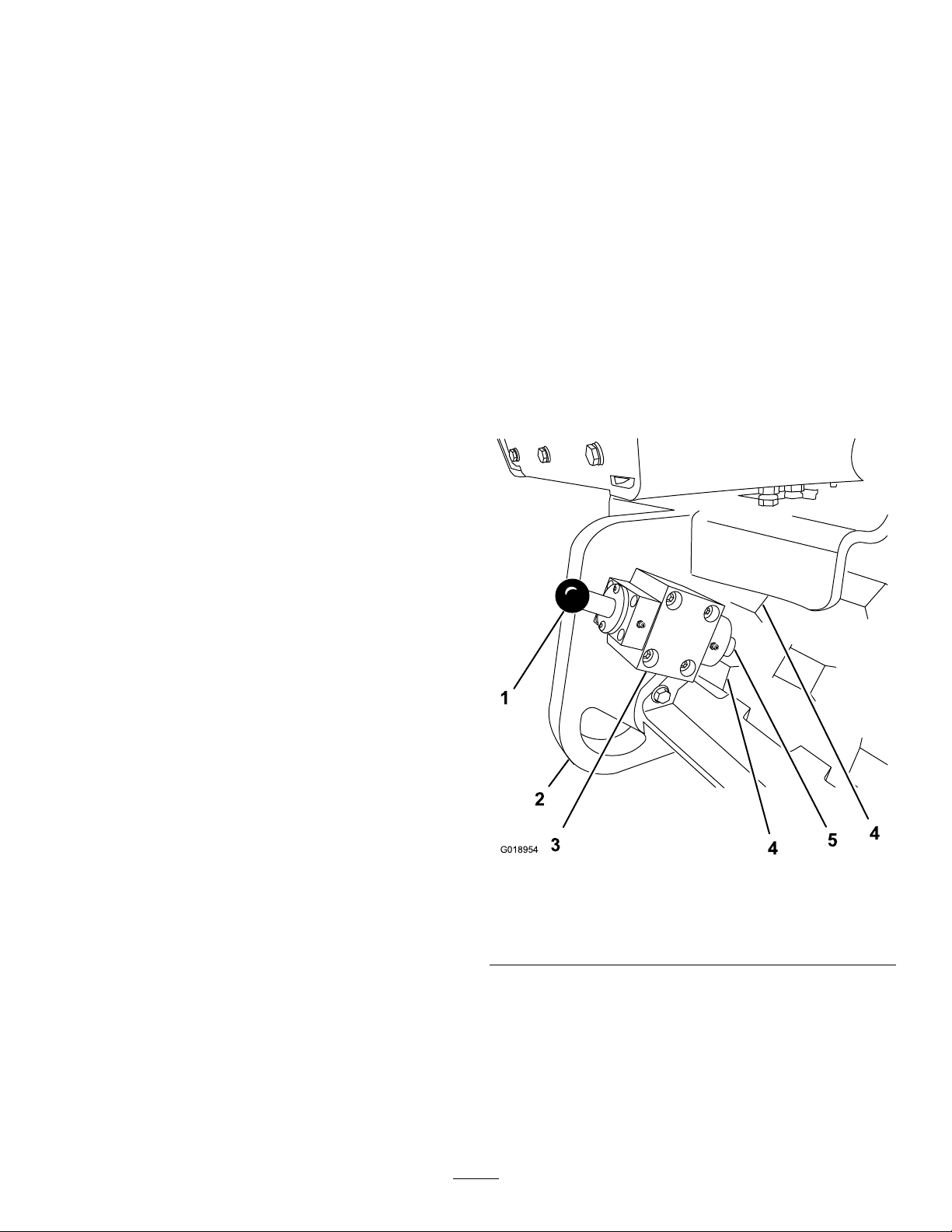

G018954

1

2

4

5

4

3

Emergency-stop/Power-OffButton

Pressandholdthetraction-controlbuttonstomovethe

machineintheforwardorreversedirection(straight,leftor

right)(Figure17).

Important:T ostopthemovementofthemachine,

releasethetraction-controlbuttons.

•Movethemachineforward.

•Movethemachinebackward.

•Turnthemachineleft.

•Turnthemachineright.

TravelSpeedButtons

Important:Usetheslow-travelspeedsettingwhen

movingthemachineinandoutoftrenches,when

loadingthemachineontoatrailer,andwhenunloading

themachinefromatrailer.

Usethetravelspeedbuttonsontheremote-control

transmittertocontrolthetravelspeedofthemachine

(vibrationOff)oractivatethevibrationfunctionofthe

machine(Figure17).

Note:Thevibrationfunctionisinoperativewhenmovingthe

machineinthefasttravel-speedsettingorslowtravel-speed

setting.

Presstheemergency-stop/power-Offbutton(redbutton)

turnoffthemachineinanemergencysituationorduring

normaloperation(Figure17).

Note:Theemergancy-stop/power-Offbuttonisthebottom

button(centeredleftandright)ontheremote-control

transmitter.

•Turnoffthemachineoffimmediatelyinanemergency

situation.

•Turnoffthemachineduringnormaloperation.

ParkingBrake

Theparkingbrakemechanismisaspringloadedplunger

thatrestsagainstthesurfaceofthedrumwhenthebrakeis

engaged.Usethebrakeknobtoengageanddisengagethe

parkingbrakeofthemachine;refertoUsingtheParking

Brake(page28).

•Movethemachineatminimum-travelspeed.

•Movethemachineatmaximum-travelspeed.

•Stopthevibrationfunction(pressandreleaseeitherthe

sloworfast,travel-speedbutton).

VibrationOnButtons

UsethevibeOnbuttonstoselectthedirectioneccentric

rotationwhenthevibrationfunctionactive(Figure17).

Note:Tostopthevibrationfunctionwiththeremote-control

transmitter,presstheslow,travel-speedbutton;refertoTravel

SpeedButtons(page18).

•Vibrateinaforwarddirection.

•Vibrateinareversedirection.

EngineSpeedButtons

Theengine-speedbuttonsontheremote-controltransmitter

donotfunction.Theenginespeedisautomaticallycontrolled

bythemicroprocessorinthemachinewhenoperatinginthe

remote-controlmode.

Figure18

1.Brakeknob4.Drumpad

2.Rear,tie-downring5.Plunger

3.Parkingbrake

Whenthemachineisstartedwiththeremote-control

transmitter,theenginewillstartattheslow-enginespeed,

after1secondtheenginewillautomaticallyacceleratetothe

fast-enginespeedandsustainthatspeed.

18

Page 19

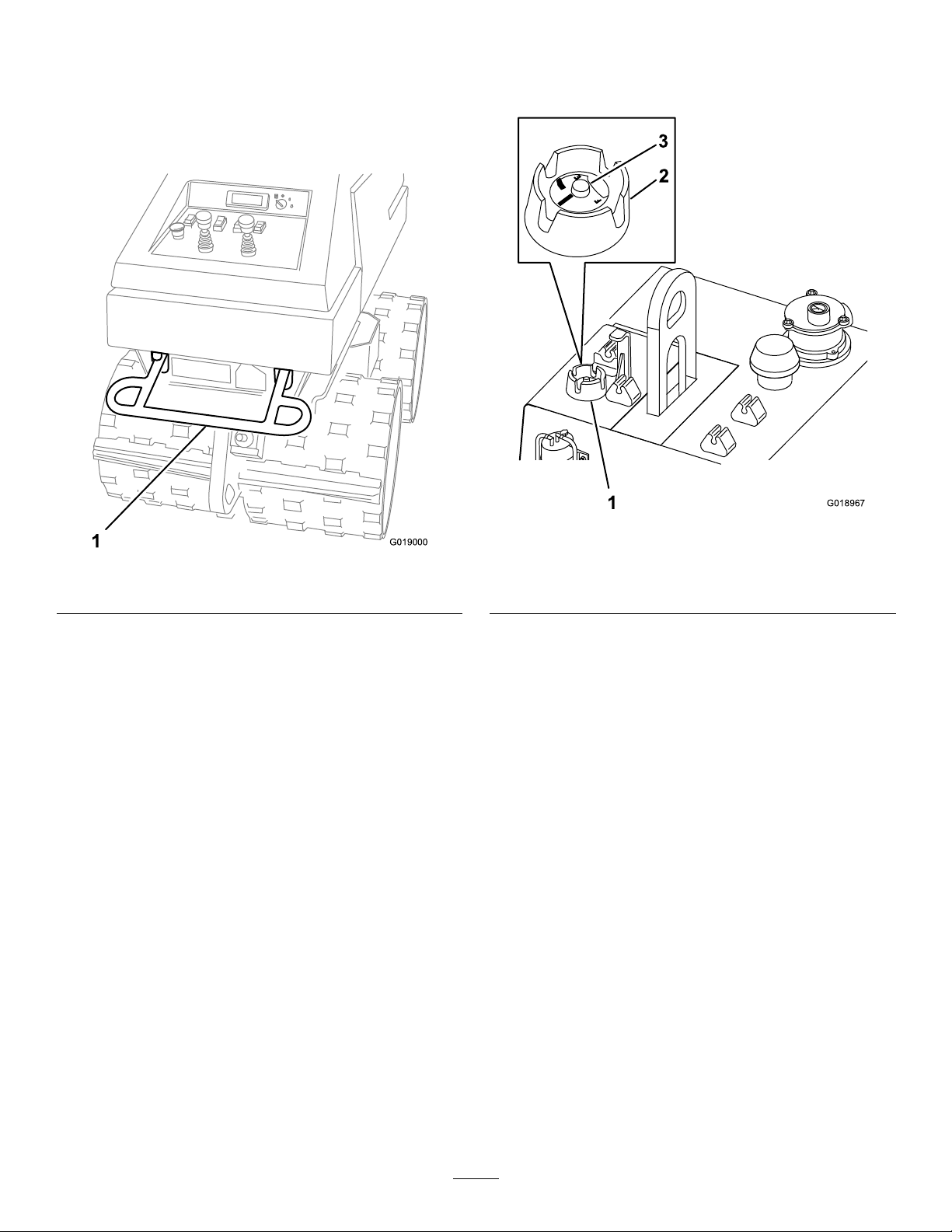

Anti-crushBar

G019000

1

G018967

2

1

3

FuelGauge

Theanti-crushbarisasafetydevicethatislocatedattherear

ofthemachine,andbelowthecontrolpanel.Whentriggered,

theanti-crushbarpreventsthemachinefromreversetravel

intheeventthattheoperatorbecomesentrappedbehindthe

machine.

Thefuelgaugeispartofthefuel-tankcap,andindicatesthe

leveloffuelinthefueltank.

Figure20

1.Anti-crushbar

Figure19

1.Fuel-tankcapandfuel

gauge

2.Fuel-tankcap

3.Fuelgauge

19

Page 20

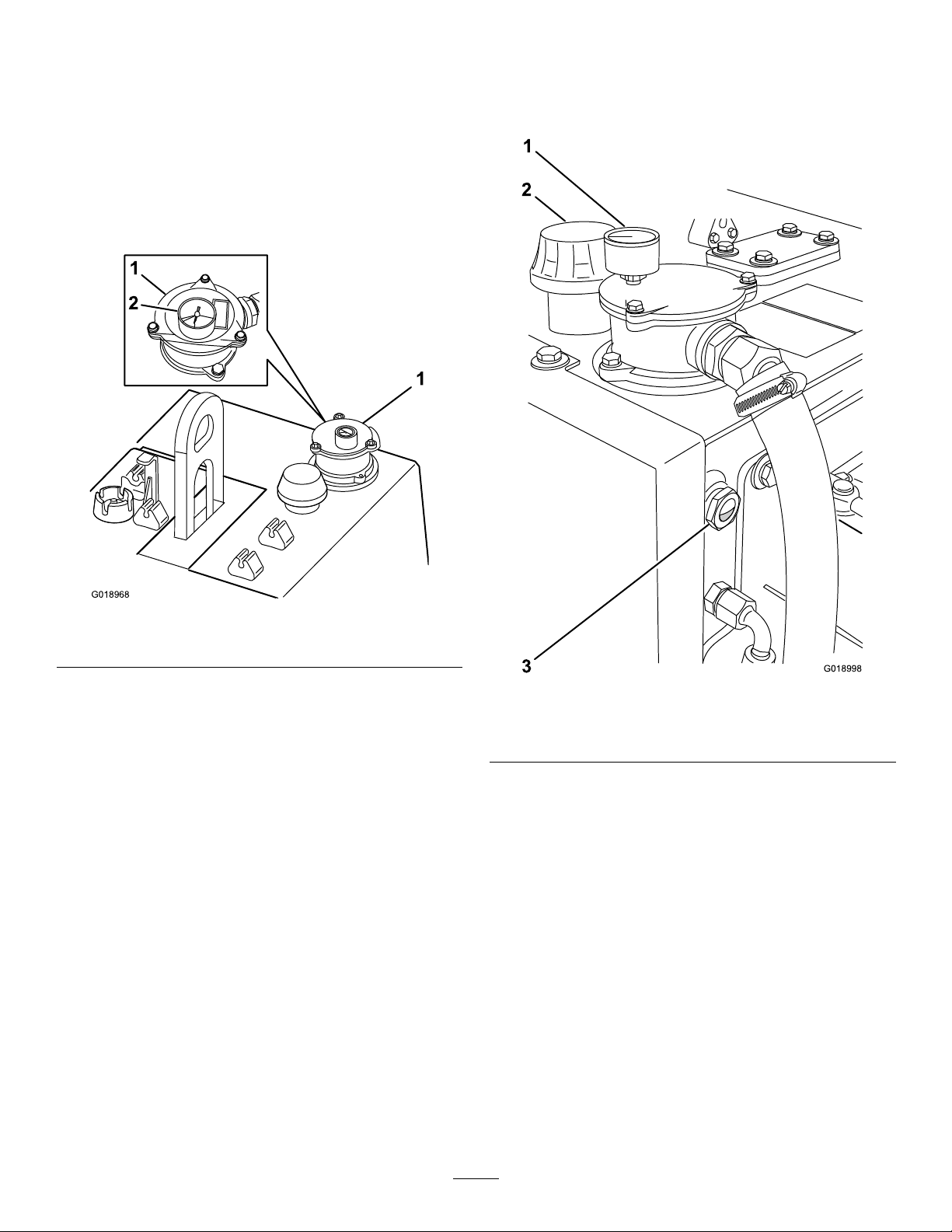

Hydraulic-lterGauge

G018968

1

1

2

G018998

1

2

3

Hydraulic-tankGauge

Thehydraulic-ltergaugeindicatesthepressureofhydraulic

uidowingthroughthehydrauliclter.

Thepressurerangesforthehydraulic-ltergaugeareas

follows:

•Normal(green):0to137kPa(0to20PSI)

•Caution(yellow):137to172kPa(20to25PSI)

•Servicethelter(red):172to689kPa(25to100PSI)

Usethehydraulic-tankgaugetoobservethelevelofhydraulic

uidinthetank.Thetankgaugeislocatedontheleft-rear

sideofthehydraulictank.

Figure21

1.Hydraulic-lterhousing2.Hydraulic-ltergauge

Figure22

1.Hydraulic-ltergauge

2.Cap/breather

3.Hydraulic-tankgauge

20

Page 21

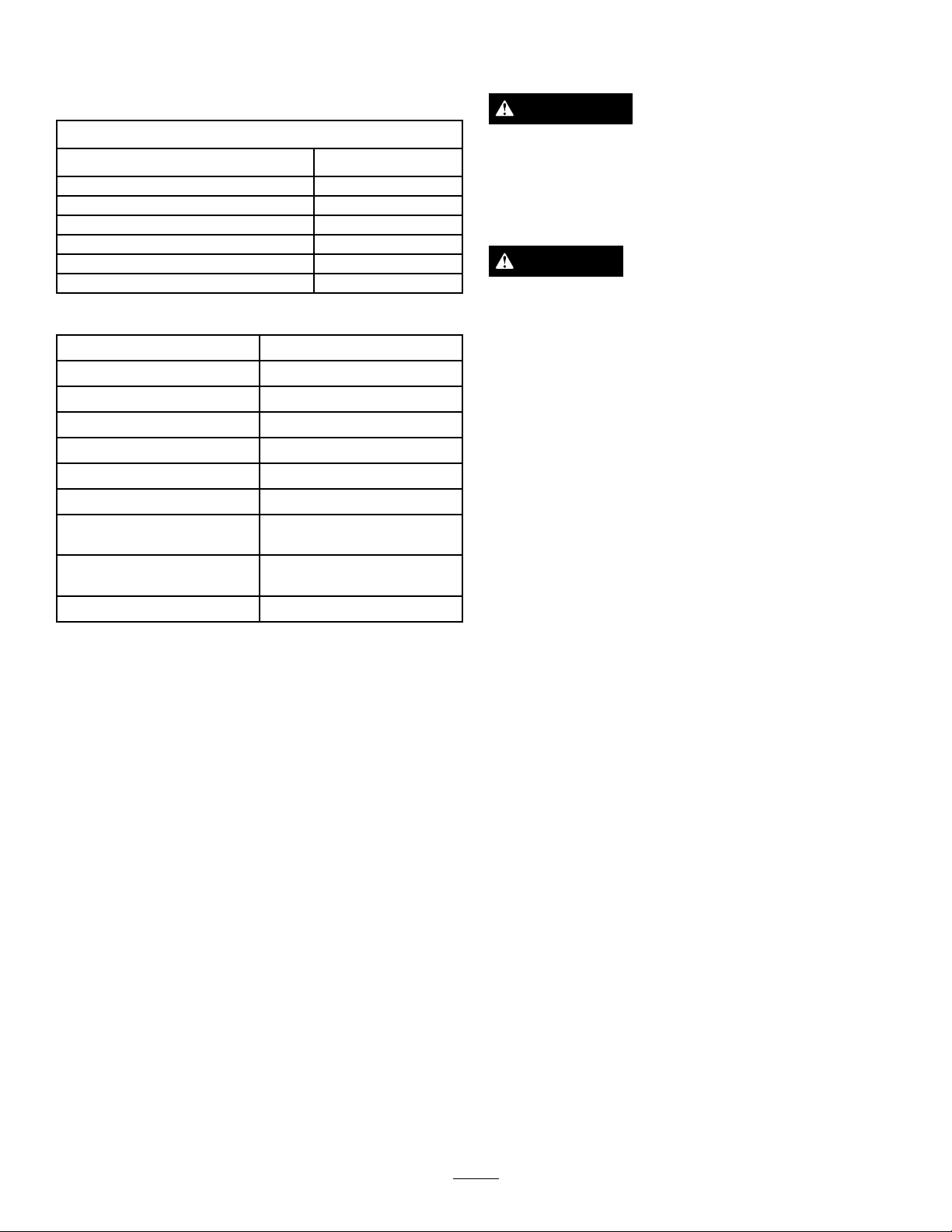

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Model68039

Width

Length

Height

Weight

Engineoilcapacity

Fuelcapacity

Hydraulictankcapacity

VibrationSpecications

DescriptionValue

VibrationFrequency

CentrifugalForce69.87kN(15709lb)

TotalAppliedForce

StaticLinearPressure85N/cm(48psi)

DynamicLinearPressure

TotalAppliedLinearPressure

StaticAppliedPadfoot

Pressure

DynamicAppliedPadfoot

Pressure

TotalAppliedPadfootPressure647.5N/cm(443.3psi)

33.3Hz(2000vpm)

82.7kN(18609lb)

432N/cm(247psi)

516N/cm(295psi)

516N/cm(73.06psi)

127N/cm(370psi)

86cm(34inch)

167.7cm(66inch)

119cm(46.4inch)

1406Kg(3100lb)

0.95L(2qt)

11.3L(3USgallon)

49L(13USgallon)

Operation

WARNING

•Nevermovethemachineacrossaslopegreater

than18%grade(10°).

•Neverparkthemachineonahill.

CAUTION

•Beforestartingthemachine,makesurethat

therearenopersonsnearthemachineor

obstaclesunderthemachine.

•Exposuretoloudnoisecancausehearing

impairmentorloss.Wearearprotectionwhen

operatingthemachine.

•Themachinecaninjureyourfeet.Keepfeet

clearofdrumsandwearfootprotection,steeltoe

shoes,ortoepadswhenoperatingthemachine.

Important:Usersmustbetrainedtooperatethe

machine.Readthe

Owner’ s Man ual.

Important:Beforeoperatingthemachine,checkthe

fuelandoillevel,andremovedebrisfromthemachine.

Ensurethattheareaisclearofpeopleanddebris.Y ou

shouldalsoknowandhavemarkedthelocationsofall

utilitylines.

Operator’ s Man ual

and

Engine

Learntooperatethemachinesafely.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

21

Page 22

Pre-startChecklist

FillingtheFuelTank

1.Checktheengineoillevel.

2.Checktheengineairlterelement.

3.Checktheenginefuellevel.

Note:Alwaysuseclean,freshfueltopreventdamage

tothefuelinjectioncomponents.

4.Checkthehydraulicuidlevel.

5.Checkthehardwareforlooseness.

6.Checkthehosesforloosettingsandsignsofaleak.

7.CheckthattheEmergencyStopbuttonisnotdamaged,

andthatthebottommovesupanddown.

8.CheckthattheAnti-crushbar,switch,andactuation

componentsarenotdamaged,andthatallpartsmove

andworkproperly .

Fuel

Useonlyclean,freshdieselfuelwithanultralow(<15ppm)

sulfurcontent.Theminimumcetaneratingforthedieselfuel

shouldbe40.Purchasefuelinquantitiesthatcanbeused

within30daystoensurefuelfreshness.

Fueltankcapacity:11.5L(3USgallon)

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

•Outsideairtemperaturesabove20°F(-7°C),use

summergradedieselfuel(No.2-D)

Note:Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

power.

•Outsideairtemperaturesbelow20°F(-7°C),usewinter

grade(No.1-DorNo.1-D/2-Dblend)

Note:Useofwintergradefuelatlowertemperatures

provideseasierstartingandreducefuellterplugging.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromnozzleandfueltank

orfuelcontaineropening .

•Keepfuelawayfromyoureyesandskin.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to1/2

in.(6to13mm)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenfuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafueldispensernozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

Important:Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

1.Removethecapforthefueltankbyturningthecap

counterclockwiseandtheliftingthecapupuntilthe

quantitysensorisclearofthellerneckofthefuel

tank.(

Figure23).

22

Page 23

Note:Donotallowthedirtanddebristoenterthe

G019002

1 2

3

4

G019027

2

1

3

5

4

fueltankortoaccumulateonthequantitysensor.

Figure23

2.Opentheforwardhood;referto

OpeningtheHood

(page24).

3.Ensurethatthefuellevelinthetankisgreaterthat

one-thirdfull.

4.Removethefuelcapandsensorassembly(Figure24).

Note:Donotallowthedirtanddebristoenterthe

fueltankoraccumulateonthequantitysensor.

1.Fuelcap

2.Quantitysensor

3.Fillerneck(fueltank)

4.Hoodclip

2.Fillthetankwithfueluntilthelevelis6to13mm(1/4

to1/2inch)belowthebottomofthellerneck.

3.Installthefueltankcapbyinsertingthequantitysensor

ofthefuelcapthroughthellerneck.

4.Tightenthefuelcapclockwisehandtight(Figure23).

PrimingtheFuelSystem

Bleedthefuelsystembeforestartingtheengineifanyofthe

followingconditionsoccur:

•Initialstartupofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuelsystem

components(e.g.,lterreplaced).

Note:Whenperformed,theengineshouldstartafter

primingthefuelsystem.However,ifenginedoesnotstart,

airmaybetrappedbetweeninjectionpumpandinjectors;

contactyourAuthorizedServiceDealer.

1.Removethekey,andallowtheenginetocool.

Figure24

1.Fuelreturnline4.Hoodclip

2.Fuel-shutoffvalve5.Fuelcap/sensor

3.Fuel/waterseparator

5.Atthefuelpump,operatetheprimingleveruntilfuel

isheardowingbackintothefueltankthroughthe

fuelreturnline.(

Figure25).

23

Page 24

2

3

4

1

G019026

Figure25

G019041

1

4

5

7

2

3

6

1.Fuelline3.Fuelpump

2.Fuelpriminglever

4.Oillter

AccessingtheMachine

OpeningtheHood

Opentheforwardhoodasfollows:

1.Attheforwardhood,pivotthelatchhandleforthe

hoodtotheverticalposition(Figure26).

6.Installthefuelcapandsensorassembly(Figure24).

7.Closetheforwardhood;refertoClosingtheHood

(page25).

Figure26

1.Forwardhood5.Rearhood

2.Latchhandle(stowed)

3.Latchhandle(vertical)

4.Forwardhoodopening

2.Rotatethelatchhandleclockwise(Figure26).

3.Graspthelatchhandletightly,andpulluprmlyto

unseatthehoodfromthehoodclips(Figure26).

6.Hoodclip

7.Rearhoodopening

4.Rotatethehoodup(Figure26).

Opentherearhoodasfollows:

Note:Ensurethattheforwardhoodisopenbeforeopening

therearhood.

1.Grasptheforwardedgeoftherearhood.

2.Pulluprmlyonthehoodtounseatitfromthehood

clips(

Figure26).

3.Rotatethehoodup(Figure26).

24

Page 25

ClosingtheHood

1

2

3

4

5

6

G019012

Note:Iftherearhoodandtheforwardhoodareopen,the

rearhoodmustbeclosedbeforeclosingtheforwardhood.

Closetherearhoodasfollows:

1.Grasptheforwardedgeoftherearhood.

3.Opentheforwardhood;referto

OpeningtheHood

(page24).

4.Cleanaroundtheoildipstickanddipsticktting

(Figure28).

2.Rotatethehooddown(

Figure26).

3.Pushdownrmlyonthehoodtoseatitintothehood

clips.

Closetheforwardhoodasfollows:

Note:Ensurethattherearhoodisclosedbeforeclosing

theforwardhood.

1.Graspthelatchhandle,androtatethehooddown

(Figure26).

2.Pushdownrmlyonthehoodtoseatitintothehood

clips.

3.Rotatethelatchhandlecounterclockwise(

4.Pivotthehandledowntothestowedposition(Figure

26).

EngineOilandHydraulicFluid

CheckingtheLeveloftheEngineOil

ServiceInterval:Beforeeachuseordaily

OilType:Detergentdieselengineoil(alltrademarkoils

whichfullatleastoneofthefollowingspecications:

ACEA-B2/E2orhigher,orAPIserviceCH-4orhigher)

CrankcaseCapacity:1.9L(2qt)

Figure26).

Figure28

1.Oil-llercap

2.Oil-llerneck

3.Dipsticktting

4.Dipstick

5.Minoil-level

6.Maxoil-level

5.Pulloutthedipstickandwipethemetalendclean.

6.Slidethedipstickintothedipsticktting.

7.Pullthedipstickoutandlookatthemetalend.

8.IftheoillevelisbelowtheMin-levelmarkonthe

dipstick(

Figure28),performthefollowingsteps:

Viscosity:RefertoFigure27.

Figure27

1.Parkthemachineonalevelsurface.

2.Stoptheengine,removethekey,andallowtheengine

tocool.

A.Cleanaroundtheoil-llercap,andremovethe

cap(Figure28).

B.Slowlypourenoughoilintotheoil-lltubeto

raisethelevelonthedipsticktobetweentheMinandMax-oillevel(Figure28).

C.Installtheoil-llercap(Figure28).

9.

Important:Donotoverllthecrankcasewithoil

becausetheenginemaybedamaged.

10.Insertthedipstickintothedipsticktting,andseatthe

dipstickrmly.

11.Closethehood;referto

ClosingtheHood(page25).

25

Page 26

CheckingtheHydraulicFluidLevel

G019024

1

2

3

ServiceInterval:Beforeeachuseordaily

HydraulicTankCapacity:49L(13USgallons)

•ToroPremiumTransmission/HydraulicTractor

Fluid(refertoyourAuthorizedToroDealerformore

information)

•ToroPremiumAllSeasonHydraulicFluid(referto

yourAuthorizedToroDealerformoreinformation)

•IfeitheroftheaboveTorouidsarenotavailable,you

mayuseMobiluid424multipurposetractorlubricant.

Important:Alwaysusethecorrecthydraulicuid.

Unspecieduidswilldamagethehydraulicsystem.

Note:Thehydraulicuidspecicationsmustfallwithin

thelistedrangeforallofthefollowingmaterialproperties

andtheuidshouldmeetthelistedindustrystandards.

Torowillnotassumeresponsibilityfordamagecaused

byimpropersubstitutions,souseonlyproductsfrom

reputablemanufacturerswhowillstandbehindtheir

recommendations.

HydraulicFluidTable—

MaterialProperties

Viscosityindex,ASTMD2270

cStat40°C(104°F):55to62 Viscosity,ASTMD445

cStat110°C(230°F):9.1to

9.8

140to152

1.Breather/cap3.Sightgauge

2.Hydraulictankllerneck

Figure29

5.Checkthattheuidleveldisplayedinthesightgauge

PourPoint,ASTMD97-37to-43°C(-35to-46°F)

IndustryStandards

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT,JohnDeereJ20C,Vickers

35VQ25andVolvoWB-101/BM.

Note:Manyhydraulicuidsarealmostcolorless,making

itdifculttospotleaks.Areddyeadditiveforthe

hydraulicsystemoilisavailablein2/3oz.(20ml)bottles.

Onebottleissufcientfor4-6gal(15-22l)ofhydraulic

oil.Orderpartno.44-2500fromyourAuthorizedT oro

Dealer.

1.Parkthemachineonalevelsurface.

2.Stoptheengine,removethekey,andallowtheengine

tocool.

3.Opentherearhood;refertoOpeningtheHood(page

24).

4.Cleantheareaaroundthecap/breatherandllerneck

ofthehydraulictank.Cleanthehydraulictanksight

gauge(Figure29).

indicatesa6.35to12.5mm(0.25to0.50inch)air

bubbleseenatthetopofthegauge(Figure29).

6.Ifthehydraulicuidlevelislow,performthefollowing

steps:

DANGER

Thebreather/capisdesignedtopressurize

thehydraulictankto34.5kPa(5PSI).Loosen

thecapslowlytoavoidinjurywheneveradding

uidormaintainingthehydraulicsystem.

A.Placearagoverthehydraulictankbreather/cap,

andslowlyturnthecapcounterclockwiseto

removethebreather/cap.

B.Addfreshhydraulicuidtothetankthroughthe

hydraulictankllerneck.

Note:Addhydraulicuiduntiltheuidlevel

indicatesa6.35to12.5mm(0.25to0.50inch)air

bubbleseenatthetopofthesightgauge.

C.Installthebreather/caponthehydraulictank

llerneck.

7.Closetherearhood;referto

25).

26

ClosingtheHood(page

Page 27

StartingandStoppingthe

StoppingtheEngine—ManualMode

Engine

Startandstopthemachineineitherthemanualmode(at

thecontrolpanel)orintheremote-controlmode(withthe

remote-controltransmitter).

StartingtheEngine—ManualMode

Important:Iftheengineisrunathighspeedswhen

thehydraulicsystemiscold(i.e.,whentheambient

airtemperatureisnearfreezingorlower),hydraulic

systemdamagecouldoccur.Whenstartingtheengine

incoldconditions,allowthehydraulicsystemtowarm

byoperatingtheengineatslow-enginespeedfor2to5

minutesbeforeswitchingtothefast-enginespeed.

1.Ensurethatthehandleofthefuel-shutoffvalvetothe

Onposition.(Figure24).

2.Atthecontrolpanel,pressthemodeswitchtothe

manual-modeposition;referto

3.Presstheengine-speedswitchtotheslow,engine-speed

position;refertoEngine-speedSwitch(page16)

4.Insertthekeyintothekeyswitch,androtatethekey

clockwisetotheStartposition.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa30-secondcooldownperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

5.Releasethekeywhenenginestarts.

ModeSwitch(page15).

Theseinstructionsdescribehowtostoptheengineatthe

controlpanelundernormaloperatingcircumstances.

1.Ensurethatthemodeswitchisselectedtothe

manual-controlposition;refertoModeSwitch(page

15)

2.Pressthetravel-speed/vibrationswitchtothe

slow,travel-speedposition(vibrationOff);referto

Travel-speed/VibrationSwitch(page16).

3.Presstheengine-speedswitchtotheslowposition;

refertoEngine-speedSwitch(page16).

Note:Iftheenginehasbeenworkinghardorishot,

allowthemachinetorunattheslow-enginespeed

settingfora1or2minutesbeforeturningtheignition

keyoff.Thishelpscooltheenginebeforeitisstopped.

Inanemergency,stoptheengineimmediately.

4.RotatethekeyswitchcounterclockwisetotheOff

position;refertoKeySwitch(page15).

StoppingtheEngine—Remote-control

Mode

Theseinstructionsdescribehowtostoptheenginewith

theradio-controltransmitterundernormaloperating

circumstances.

1.Ontheradio-controltransmitter,presstheslow,

travel-speedbutton(vibrationOff);refertoTravel

SpeedButtons(page18).

Note:Thekeyitwillmoveautomaticallytothe

engine-runposition.

StartingtheEngine—Remote-control

Mode

Important:Whentheambientairtemperatureis

nearfreezingorlower,starttheengineinthemanual

modeandallowthehydraulicsystemtowarmbefore

operatingthemachineintheremote-controlmode;refer

toStartingtheEngine—ManualMode(page27).

1.Atthecontrolpanel,pressthemodeswitchtothe

remote-controlmodeposition;refertoModeSwitch

(page15).

2.EnsurethatthekeyswitchisrotatedtotheOff

position;refertoKeySwitch(page15).

3.Attheradio-controltransmitter,presstheOnbutton

oncetoestablisharadiolinkwiththemachine.

4.PressandholdtheOnbuttonagaintostarttheengine.

Note:Theenginespeedisautomaticallycontrolled

bythemicroprocessoronthemachine.Theengine

willstartandoperateattheslow-enginespeedforone

second,andthenautomaticallyacceleratetheengine

tothefast-enginespeed.

Note:Iftheenginehasbeenworkinghardorishot,

allowthemachinetorunfora1or2minutesbefore

turningtheignitionkeyoff.Thishelpscooltheengine

beforeitisstopped.Inanemergency,stoptheengine

immediately.

2.Ontheradio-controltransmitter,pressthe

emergency-stop/power-offbutton(theredbutton);

refertoEmergency-stop/Power-OffButton(page18).

Note:Storetheradio-controltransmitterinasafe,dryplace

(thetransmitterstoragecompartmentundertherearhood).

EmergencyStop—ManualMode

Important:Theemergencystopbuttononthecontrol

panelwillstoptheengineinboththemanualmodeand

theremote-controlmode.

Thisinstructiondescribehowtostoptheengineatthe

controlpanelinanemergencycircumstance.

Atthecontrolpanel,presstheEmergencyStopbutton

down;refertoEmergencyStopButton(page16).

Note:Pulltheemergencystopbuttonuptoresumenormal

machineoperation.

27

Page 28

EmergencyStop—Remote-control

Mode

Important:Theemergencystopbuttononthecontrol

panelwillstoptheengineinboththemanualmodeand

theremote-controlmode.

Thisinstructiondescribehowtostoptheenginewiththe

radio-controltransmitterinanemergencycircumstance.

Attheradio-controltransmitter,presstheEmergency

Stop/Poweroffbutton(theredbutton);referto

Emergency-stop/Power-OffButton(page18).

StoppingtheMachine

WARNING

Neverparkthemachineonahill.

3.Selectthemodeswitchonthecontrolpaneltothe

manualmodeposition;refertoModeSwitch(page15).

4.Settheparkingbrake;refertoUsingtheParkingBrake

(page28).

5.Removethekeyfromthekeyswitch;refertoKey

Switch(page15).

UsingtheParkingBrake

WARNING

Failuretosettheparkingbrakewhenthemachine

isleftunattendedcouldcausedamagetothe

machineorinjury.Alwayssettheparkingbrake

beforeleavingthemachine.

CAUTION

CAUTION

Achildoruntrainedbystandercouldattemptto

operatethemachineandbeinjured.

Removethekeyfromtheswitchwhenleavingthe

machine,evenifjustforafewseconds.

Important:Donotparkthemachineforanextended

periodinatrench,ditch,orlow-lyingareathatmight

llwithwater.Liftormovethemachinetoalevel,well

drainedsurface.

StoppingtheMachine—ManualMode

1.ReleasebothofthetractioncontrolsrefertoTraction

Controls(page17).

2.Stoptheengine;refertoStoppingtheEngine—Manual

Mode(page27).

3.Settheparkingbrake;refertoUsingtheParkingBrake

(page28).

4.Removethekeyfromthekeyswitch;refertoKey

Switch(page15).

Failuretodisengagetheparkingbrakebefore

movingthemachinemaycausedamagetothe

parkingbrakeorthemachineorboth.Releasethe

parkingbrakebeforemovingthemachine.

SettingtheParkingBrake

Important:Wheneverpossible,parkthemachineon

arm,levelsurface.

Important:Theplungerfortheparkingbrakemustbe

ontheagainstthesideofthedrumpadandthesurface

ofthedrum.

1.Setthemachinetomanualmode;refertoMovingthe

Machine—ManualMode(page32).

2.Settheengine-speedswitchtotheslow ,engine-speed

position,refertoEngine-speedSwitch(page16).

3.Setthetravelspeedtotheslow-travel/vibration-off

position;referto

16)

.

4.Usingthetractioncontrols,centertheparkingbrake

between2drumpads;referto

17)

.

Travel-speed/VibrationSwitch(page

TractionControls(page

StoppingtheMachine—Remote-control

Mode

Important:Toavoiddepletingthebatteryofthe

machine,selectthemodeswitchtothemanual-mode

positionwhenstoppingthemachine.

1.Releaseallthetraction-controlbuttons;referto

Traction-controlButtons(page18).

2.Stoptheengine;refertoStoppingthe

Engine—Remote-controlMode(page27).

5.Pullthebrakeknoboftheparkingbrakeoutslightly

androtatetheknobapproximately90°clockwiseor

unittheplungerisreleased(Figure30).

28

Page 29

G023082

1

2

G021 104

1

2

2

4

5

3

3

Figure31

G021 106

2

3

4

Figure30

1.Knob2.Parkingbrake

6.Gentlyreleasethebrakeknoboftheparkingbrake,

allowingittoretractintotheparkingbrakehousing,

untiltheplungerisrestingagainstthesideofthedrum

padandthesurfaceofthedrum(Figure32,Figure31,

Figure34,andFigure33).

7.Alignthepadofthedrumandtheplungerofthe

parkingbrakebymovingthemachineforwardor

backwardasfollows:

•Foramachinethatisparkeddownhill—alignthe

sideofthedrumpadthatisrotatingupward

againstthesideoftheplungeroftheparkingbrake

(Figure32andFigure31).

1.Parked

machine—downhill

2.Brakeknob

3.Parkingbrake

1.Parkingbrake3.Drumpadrotatingupward

2.Plunger

4.Plunger

5.Drumpad(downhill

position)

Figure32

(parkingthemachine

downhill)

4.Drumsurface

•Foramachinethatisparkeduphill—alignthe

sideofthedrumpadthatisrotatingdownward

againstthesideoftheplungeroftheparkingbrake

(Figure34andFigure33).

29

Page 30

2

2

3

4

3

3

1

G021 105

G021 109

1

2

4

3

MovingaNon-functioning

G019040

1

3

1

2

Machine

Important:Donottoworpullanon-functioning

machine.Retrieveandtransportthemachineusing

liftingequipment,refertoLiftingtheMachine(page30)

andPreparingtheMachineforTransport(page31).

Important:Donotallowanon-functioningmachineto

remainlocatedinatrench,ditch,orlow-lyingareathat

mightllwithwater.Liftthenon-functioningmachine

andlocateitonalevel,welldrainedsurface.

LiftingtheMachine

Important:Ensuretheliftingequipmenthasa2110Kg

(4650lb)verticalliftcapacity.

Figure33

1.Parkedmachine—uphill4.Plunger

2.Brakeknob

3.Parkingbrake

1.Parkingbrake3.Drumpadrotating

2.Plunger

5.Drumpad(uphillposition)

Figure34

downward(parkingthe

machineuphill)

4.Drumsurface

8.Stoptheengineandremovethekey;refertoStopping

theEngine—ManualMode(page27).

Important:Neverliftamachinewiththeengine

running.

Liftthemachineusingtheliftring(Figure35)asfollows:

1.Stoptheengine;refertoStoppingthe

Engine—ManualMode(page27)andStoppingthe

Engine—Remote-controlMode(page27).

2.Ensurethattheforwardhoodandrearhoodareclosed

andlatched.

3.Connecttheliftriggingtotheliftringonthemachine

(Figure35),andliftthemachine.

ReleasingtheParkingBrake

Note:Whentheparkingbrakeisreleased,theplungeris

intheup-lockposition,approximately12.7mm(1/2inch)

abovethedrumpads.

1.Pulltheparkingbrakehandleoutfullyandrotatethe

handleapproximately90°clockwiseoruntilitsnaps

intotheup-lockposition(

2.Gentlyreleasetheparkingbrakehandle,allowingitto

retractuntiltheparkingbrakeisrestingintheretract

detent(

Figure30).

Figure31andFigure33).

1.LiftRing

2.Forward,tie-downring

30

Figure35

3.Rear,tie-downring

Page 31

PreparingtheMachinefor

G021 114

1

1

2

2

3

4

5

Transport

Important:Ensurethatthetransportvehicleisratedfor

a1406Kg(3100lb)loadandhastie-downpoints.

•Liftthemachineontoatransportvehicle;referto

LiftingtheMachine(page30).

•Drivethemachineonatransportvehicle.

DANGER

5.Securethemachinetothetransportvehicleusing

blockingandloadbindersbetweentheanchorrings

onthetransportvehicleandthetie-downringsonthe

machine(

Figure36).

Youcanloseofcontrolofthemachinewhen

drivingitonrampsontooroffofthetransport

vehiclewhenleft-handandright-handdrums

haveunequaltraction.

Ensurethattherampsanddrumsprovideequal

tractiontotheleft-handandright-handsidesof

themachine.

Important:Userampsthathavea2110Kg(4650lb)

capacityandasolid,continuous-tractionsurface.

Important:Therampusedtosupportthemachine

whileloadingitontothetransportvehiclecannot

exceed55%(29°)anglelimitofthemachine;referto

TiltChart(page9).

Note:Donotoperateordrivethemachineonthe

roadway.

1.Setthemachinetotheslow-travelspeed(vibration

Off);refertoTravel-speed/VibrationSwitch(page16)

andTravelSpeedButtons(page18).

2.Settheenginespeedtothefast,engine-speedposition;

refertoEngine-speedSwitch(page16).

Figure36

1.Anchorring4.Blocking

2.Loadbinder5.Rear,tie-downring

3.Forward,tie-downring

6.Ensurethattherampsaresecurebeforetransporting

themachine.

3.Drivethemachineontothetransportvehicle.

4.Stoptheengine;referto

Engine—ManualMode(page27)andStoppingthe

Engine—Remote-controlMode(page27).

Stoppingthe

31

Page 32

MovingandVibrating

1

2

4

G021 141

G020673

G018936

Operation

MovingtheMachine—ManualMode

Usethetractioncontrolstomovethemachineforwardor

backward,andturnthemachineleftorright.

CAUTION

Trencheswithoutwallsupportcancollapseandtrap

equipmentandpersonnel.Intrencheswithoutwall

supports,operatethemachineintheremote-control

mode.

Important:Usetheslow,travel-speedsettingforthe

followingoperations:

•Whenmovingthemachineup,down,oracross

slopes.

•Whenmovingthemachineinandoutoftrenches.

•Whenmovingthemachinearoundcorners.

•Whenloadingthemachineontothetransport

vehicle.

•Whenunloadingthemachinefromthetransport

vehicle.

MovingtheMachineAcrossaSlope

CAUTION

Ifthemachinetipsover,engineoilcanoodthe

cylinders;startingthemachineafteratip-over

eventwillcausedamagetotheengine.Follow

theinstructionsforrecoveringthemachineafter

atip-overevent;referto

AfteraTip-overEvent(page35).

RecoveringtheMachine

CAUTION

Donotoperatethemachinewiththeparkingbrake

engaged.Failuretodisengagetheparkingbrake

maycausedamagetotheparkingbrakeorthe

machineorboth.

Important:Whenmovingandsteeringthemachine,

keepbothhandsonthetraction-controllevers.

1.Starttheengineusingthemanualmode;referto

StartingtheEngine—ManualMode(page27).

2.Selecttheengine-speedswitchtothefast,engine-speed

position;referto

3.Selectatravel-speed/vibrationswitchpositionforthe

followingoperations:

RefertoTravel-speed/VibrationSwitch(page16)

•Movethemachineforward:slow-travelspeedor

fast-travelspeed.

•Movethemachinebackward:slow-travelspeed.

•Turnthemachine:slow-travelspeed.

4.Disengagetheparkingbrake;referto

ParkingBrake(page30).

5.Moveandsteerthemachinebydoingthefollowing:

•Tostopthemovementorturningofthemachine,

returntheleverstotheneutral(default)position

Figure38).

(

Engine-speedSwitch(page16).

Releasingthe

Figure38

•Tomovethemachineforward,grasptheboth

traction-controlleverswithyourhandsandpush

bothleversforward(

Figure37

1.Donotmovethemachine

acrossaninclinewhere

themachineispartiallyon

theplane.

2.Movethemachineacross

whenfullyontheplane.

3.Donotmovethemachine

acrossaninclinewhere

themachineispartiallyon

theslope

4.Whennecessary,move

themachineacrossan

inclinewherethemachine

isfullyonaslopeof18%

(10°)orless.

32

Figure39).

Figure39

Page 33

•Tomovethemachinebackward,graspthe

G018937

G018938

G018939

L

R

TRAVEL

G019078

5

3

4

2

1

traction-controlleverswithyourhandsandpull

backonbothlevers.Tostopthemachine,return

theleverstotheneutralposition(Figure40).

MovingtheMachine—Remote-control

Mode

Thetraction-controlbuttonsformovingthemachinein

theforwardorbackwarddirection(straight,leftorright)

arelocatedontheremote-controltransmitter.Usethe

remote-controltransmittertomoveandsteerthemachine

asfollows:

Important:T ostopthemovementofthemachine,

releasethetraction-controlbutton.

1.Starttheengineusingtheremote-controlmode;refer

toStartingtheEngine—Remote-controlMode(page

27)

Figure40

•Toturnthemachineleft,grasptheboth

traction-controlleverswithyourhandsandpullthe

left,traction-controlleverbackward,andpushthe

right,traction-controlleverforward(Figure41).

Figure41

•Toturnthemachineright,grasptheboth

traction-controlleverswithyourhandsandpush

theleft,traction-controlleverforward,andpullthe

right,traction-controlleverbackward(Figure42).

Note:Theenginespeedisautomaticallycontrolled

bythemicroprocessoronthemachine.Theengine

willcrankoverandoperateattheslow-enginespeed

foronesecond,andthenautomaticallyacceleratethe

enginetothefast-enginespeed.

2.Selectthetravel-speed/vibrationbuttonsforthe

followingoperations:

RefertoTravel-speed/VibrationSwitch(page16)

•Movethemachineforward:sloworfast,

travel-speedbutton.

•Movethemachinebackward:slow ,travel-speed

button.

•Turnthemachine:slow,travel-speedbutton.

3.Performthefollowingstepstomoveandcontrolthe

machinedirectionoftravel:

Note:Thebuttonsmustbepushedandhelddownto

movethemachine.

•Tostopthemovementorturningofthemachine,

releasethetractionbutton(s).

•Tomovethemachineforward,pressandhold

theleft,forward-tractionbuttonandtheright,

forward-tractionbutton(

Figure43).

Figure43

1.Remote-control

Figure42

33

transmitter

2.Left,forward-traction

button

3.Right,forward-traction

button

4.Left,reverse-traction

button

5.Right,reverse-traction

button

Page 34

•Tomovethemachinebackward,pressandhold

4

32

1

6 5

G019084

ENGINE S PE ED

TRAVEL SP EED

VIBE O N

REV

FWD

G019085

1

3

5

2

4

theleft,reverse-tractionbuttonandtheright,

reverse-tractionbutton(Figure43).

•Toturnthemachineleft,pressandholdthe

left,reverse-tractionbuttonandtheright,

forward-tractionbutton(Figure43).

•Toturnthemachineright,pressandhold

theleft,forward-tractionbuttonandtheright,

reverse-tractionbutton(Figure43).

VibratingOperation

Moveandsteerthemachinetoalignittothesitelocation;

refertoMovingtheMachine—ManualMode(page32)or

MovingtheMachine—Remote-controlMode(page33).

•WhenoperatingintheManualmode(controlpanel)

startthevibrationfunctionbyperformthefollowing:

1.Selecttheengine-speedswitchtothefast,

engine-speedposition(

Figure44).

3.Selectthetravel-speed/vibrationswitchtothe

vibrationOnposition(fullybackward).

4.Steerthemachineusingthetractioncontrols;refer

toMovingtheMachine—ManualMode(page32).

5.Stopthevibrationfunctionbyselecting

travel-speed/vibrationswitchtotheslow-travel

speed(fullyforward)position,ortothemiddle

position(fast-travelspeed).

•WhenoperatingintheRemote-controlmode

(remote-controltransmitter)startthevibrationfunction

byperformthefollowing:

1.Selectavibrationdirectionasfollows:

–Startthevibrationfunctionintheforward

directionbypressingandreleasingthe

forward-vibrationbutton(

–Startthevibrationfunctioninthereverse

directionbypressingandreleasingthe

reverse-vibrationbutton(Figure45)

Figure45).

Figure44

1.Vibration-direction

switch—forward

2.Vibration-direction

switch—reverse

3.Travel-speed/vibration

switch—vibrationOn

2.Selectavibrationdirectionasfollows:

–Startthevibrationfunctionintheforward

directionbypressingthevibrationdirection

switchforward(Figure44).

–Startthevibrationfunctioninthereverse

directionbypressingthevibrationdirection

4.Engine-speed

switch—fast

5.Travel-speed/vibration

switch—slow

6.Travel-speed/vibration

switch—fast

1.Slow,travel-speedbutton

2.Fast,travel-speedbutton5.Remote-control

3.Forward-vibrationbutton

2.Steerthemachineusingthetraction

controlbuttons;refertoMovingthe

Machine—Remote-controlMode(page

33).

3.Stopthevibrationfunctionbyselecteither

selectingtheslow,travel-speedbuttonorthefast,

travel-speedbutton.

Figure45

4.Reverse-vibrationbutton

transmitter

switchbackward(Figure44)

34

Page 35

RecoveringtheMachineAfter

G021 164

1

G021 165

aTip-overEvent

RetrievingtheMachine

1.Connecttheliftingequipmenttotheoneofthe

followingliftingpointsforthefollowingrolloverevent.

•Themachineisonitsside:

A.Securetheliftingequipmenttotheliftingring

ofthemachine(Figure46);refertoLifting

theMachine(page30).

Figure46

B.Slowlyraisetheliftingequipmenttorotate

themachinesothetopofthemachineisup

(Figure46).

Note:Whenliftingthemachine,ensurethat

itdoesnotswingexcessively.

•Themachineisupsidedown:

Note:Recoveringamachinethatisupsidedown

requires2unitsofliftingequipment.

A.Attachtherstunitofliftingequipmentto

theforwardorreartie-downring(Figure47).

2.Movethemachinetoalevelsurface.

3.Lowerthemachineanddisconnectthelifting

4.Cleananydebrisfromtheexhaustduct,oil-coolerduct,

5.Inspectthemachinefordamage.

B.Slowlyraisetheliftingequipmenttorotatethe

machinevertical(Figure47).

C.Attachthesecondunitofliftingequipment

totheliftingring(Figure47);refertoLifting

theMachine(page30).

D.Transfertheweightofthemachinefromthe

rstunitofliftingequipmenttothesecond

liftingunit(

Note:Themachineshouldbealignedwith

thetopup.

equipment(

controlpanel,andtheforwardandsidegrills;referto

ProductOverview(page13).

Figure47

Figure47).

Figure47).

Important:Repairdamagetothemachinebefore

operatingit.

Note:Closelyinspecttheanti-crushbar,control

panel,parkingbrake,andthehydrauliclinesforthe

motorontheeccentric.

35

Page 36

6.Checktheengine,air-lterelementbylookingatthe

G021 182

1 2

3

4

5

G021 174

2

3

4

5

6

4

1

6

3

5

7

8

9

G021 183

8

7

6

5

4

3

2

1

pleatsoftheelementwhileshiningabrightlighton

theinsideofthelter.

Note:Replacetheair-lterelementifitiscovered

withoil,dirt,ordust;refertoServicingtheAirFilter

(page44).

RemovingtheFuelInjectors

1.Opentheforwardhood;refertoOpeningtheHood

(page24).

2.Closethefuel-shutoffvalve(Figure24).

3.Cleananydirtanddebrisfromtheengine.

Note:Ensurethatnodirtisonthecylinderheadarea

nearthefuelinjectors.

4.Removethebolt,washer,andclampthatsecures

thefuelhosetothetop-forwardsideofthe

forward-cylinderhead.

Figure49

1.Bolt6.Retainernut

2.Forward-fueltube7.Rearfueltube

3.Retainer

4.Rubberhose

5.Tubenut

8.Clamp

9.Nut(6mm)

6.Loosenthetubenutsforbothofthefuelinjectors

(Figure49andFigure50).

7.Pullthefueltubesawayfromthefuelinjectors.

8.Removetheretainernuts,washers,lockwashers,and

retainersthatsecurethefuelinjectorstothecylinder

Figure50).

head(

1.Fuelhose

2.Bolt5.Forward-cylinderhead

3.Washer

5.Removetheboltandnutthatsecurethefuel-tube

clamptothesupportbracket,andremovetheclamp.

Figure48

4.Clamp

Figure50

1.Retainernut

2.Washer6.Tubenut

3.Lockwasher7.Fuelhose

4.Retainer8.Injector

5.Stud

36

Page 37

Note:Donotremovetherubberhosesfromthe

G021 188

1

2

2

3

G021 189

2

1

G021 190

2

3

1

injectors.

9.Usingatwistingandpullingmotion,removethe

rear-fuelinjectorfromthecylinderhead(Figure51).

Note:Ifnecessary,removethecabletiesthatsecure

thefuelhose.

Note:Securethefuel-injectorgasketsforinstallation

instep

1-AofInstallingtheFuelInjectors(page37).

InstallingtheFuelInjectors

1.Installthefuelinjectorsasfollows:

A.Installthegasketsaroundthebottomtipsofthe

fuelinjectors.

Figure52

1.Rear-fuelinjector

1.Fuelinjector

Figure51

B.Installtheforward-fuelinjectorintothecylinder

2.Gasket

head.

10.Usingatwistingandpullingmotion,removethe

forward-fuelinjectorfromthecylinderhead(Figure

51).

PurgingtheCylindersofOil

1.Wraptheendofthefueltubesandthefuelinjectors

withacleanrag.

Note:Theseragswillprotectthetubesandinjectors

fromcontamination.

2.Looselypackragsintothecylinder-headareaofthe

fuelinjectorholes.

Note:Theseragswillabsorbtheoilthatisejected

1.Forward-fuelinjector3.Gasket

2.Rear-fuelinjector

fromthecylinder.

Important:Standawayfromtheengine.

3.Selecttheengine-speedswitchtotheslow ,engine-speed

position.

4.Usethekeyswitchtocranktheenginefor3seconds.

5.Replaceanyoil-soakedragsattheareaofthefuel

injectorholes.

6.Repeatsteps4and5untiloilstopsejectingfromthe

fuelinjectorholes.

7.Removetheragsfromthefuel-injectorholesandthe

fuelinjectors.

C.Installtherear-fuelinjectorintothecylinderhead.

Important:Ensurethatthefuelinjectorsare

fullyseatedintothecylinderhead.

D.Installtheretainers,washers,lockwashers,and

nutsthatwereremovedinstep8ofRemovingthe

FuelInjectors(page36)

E.Torquetheretainernutsto23N-m(17lbft).

F.Alignthefueltubesoverthefuelinjectors.

G.Threadthefuel-tubenutsontothefuelinjectors.

Figure53

.

37

Page 38

H.Securethefueltubestothesupportbracketwith

theclamp,bolt,andnutthatwereremovedinstep

5ofRemovingtheFuelInjectors(page36).

I.Tightenthefuel-tubenutsto25N-m(19ft-lb).

J.Securethefuelhosetothetop-forwardsideof

theforward-cylinderheadwiththebolt,washer,

andclampremovedinstep4ofRemovingthe

FuelInjectors(page36).

2.Checktheleveloftheengineoil;refertoCheckingthe

LeveloftheEngineOil(page25).

3.Checkthehydraulicuidlevel;refertoCheckingthe

HydraulicFluidLevel(page26).

4.Openthefuel-shutoffvalve(Figure24).

5.Primethefuelsystem;refertoPrimingtheFuelSystem

(page23).

6.Selecttheengine-speedswitchtotheslow ,engine-speed

position.

7.Starttheengine,refertoStartingtheEngine—Manual

Mode(page27).

Note:Theenginemayinitiallyproduceblue-white

smokewhileitruns.

8.Runtheengineinthefollowingorder:

A.slow-engine-speedfor2minutes

B.fast-engine-speedfor5minutes

C.slow-engine-speedfor1minute

D.stoptheengine.

Note:Referto

Engine-speedSwitch(page16)and

StoppingtheEngine—ManualMode(page27).

38

Page 39

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours