Page 1

FormNo.3421-181RevA

VR-2650RammerCompactor

ModelNo.68034—SerialNo.402000000andUp

ModelNo.68035—SerialNo.402000000andUp

ModelNo.68036—SerialNo.402000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-181*A

Page 2

WARNING

Introduction

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Becauseinsomeareastherearelocal,state,or

federalregulationsrequiringthatasparkarresterbe

usedontheengineofthismachine,asparkarresteris

availableasanoption.Ifyourequireasparkarrester,

contactyourAuthorizedServiceDealer.GenuineToro

sparkarrestersareapprovedbytheUSDAForestry

Service.

ItisaviolationofCaliforniaPublicResourceCode

Section4442touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,

andmaintainedforthepreventionofre.Otherstates

orfederalareasmayhavesimilarlaws.

Thismachineisdesignedtocompactawidearrayof

soilsubstances,includingclay,silt,gravel,sand,and

loam.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

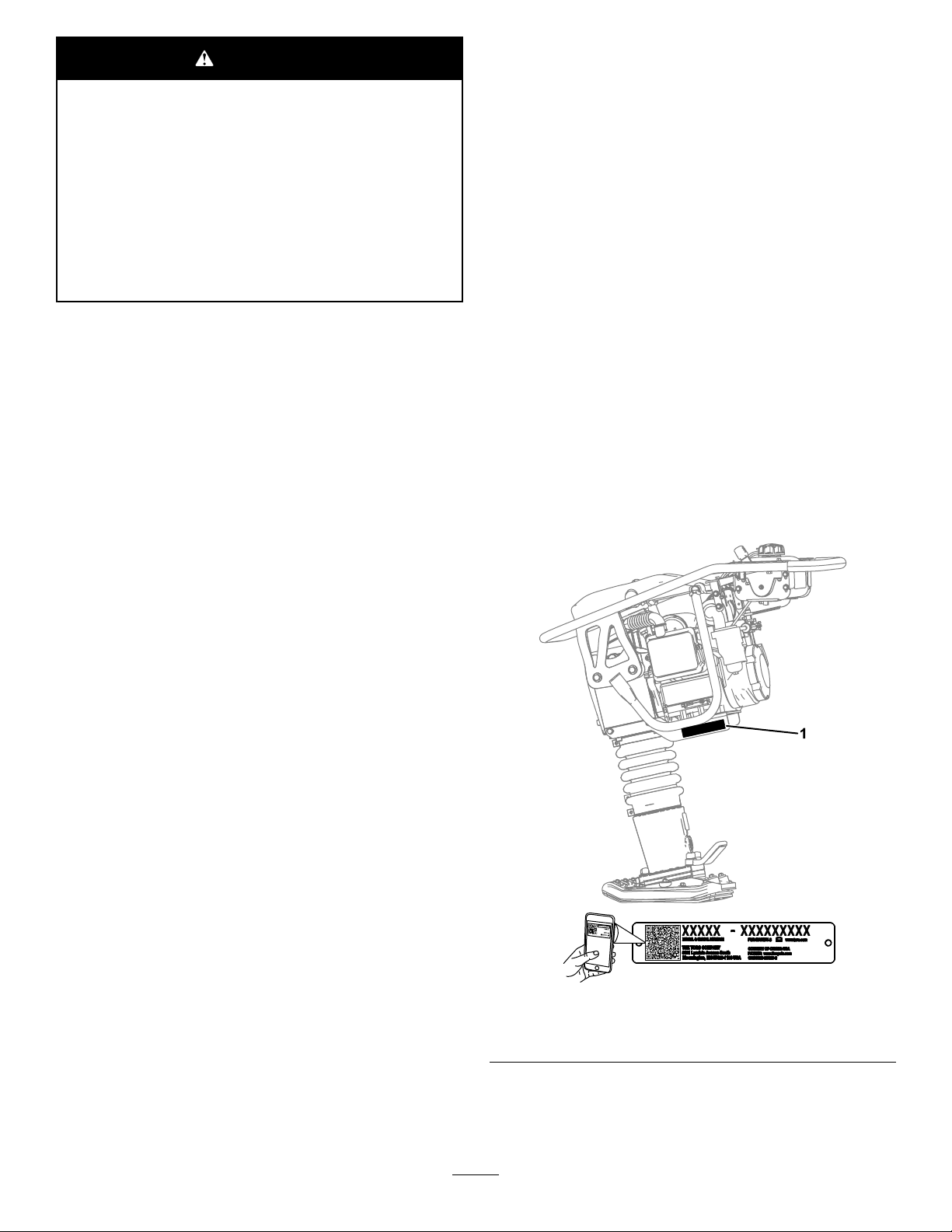

andserialnumbersofyourproductready.Figure

1illustratesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

g240400

Figure1

1.Modelandserialnumberplate

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................5

ProductOverview.....................................................7

Controls.............................................................7

Specications....................................................9

Operation..................................................................9

PreparingtoUsetheMachine.............................9

AddingFuel........................................................9

CheckingtheMachine-FluidLevels..................12

StartingtheEngine...........................................12

g000502

ShuttingOfftheEngine.....................................12

TransportingtheMachine.................................12

OperatingTips.................................................13

Maintenance...........................................................14

RecommendedMaintenanceSchedule(s)...........14

Pre-MaintenanceProcedures..............................14

DisconnectingtheSpark-PlugWire..................15

EngineMaintenance...........................................15

ServicingtheAirCleaner..................................15

ServicingtheEngineOil....................................17

ServicingtheSpring-HousingOil......................18

ServicingtheSparkPlug...................................20

CompactorShoeMaintenance.............................21

CheckingtheCompactorShoe.........................21

Cleaning..............................................................21

RemovingDebrisfromtheMachine..................21

Storage...................................................................22

.........................................................................22

RemovingtheMachinefromStorage................22

Troubleshooting......................................................23

3

Page 4

Safety

–Extinguishallcigarettes,cigars,pipes,and

othersourcesofignition.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans:

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofcausingseriousinjury .

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,

anodorless,deadlypoisonwhichislethalif

inhaled.

Donotruntheengineindoorsorinan

enclosedarea.

–Useonlyanapprovedcontainer

–Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

–Donotaddordrainfuelinanenclosedspace.

–Donotstorethemachineorfuelcontainer

wherethereisanopename,spark,orpilot

light,suchasonawaterheaterorother

appliance.

–Ifyouspillfuel,donotattempttostartthe

engine;avoidcreatinganysourceofignition

untilthefuelvaporshavedissipated.

•Checkthattheshieldsareattachedand

functioningproperly.Donotoperateunlessthey

arefunctioningproperly.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readorunderstandtheinformation,itisthe

owner'sresponsibilitytoexplainthismaterialto

them.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringpeopleordamage

toproperty.

Preparation

•Wearappropriateclothingincludinghardhat,eye

protection,longpants,substantial,slip-resistant

footwear,andhearingprotection.Tiebacklong

hair,securelooseclothing,anddonotwearloose

jewelry.

•Inspecttheareawheretheequipmentistobe

usedandensurethatallobjectsareremovedfrom

theareabeforeuse.

•Useextracarewhenhandlingfuel.Theyare

ammableandvaporsareexplosive.

•Neverrunanengineinanenclosedorpoorly

ventilatedarea.

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Stoponlevelground,setthethrottletoslow,and

shutofftheenginebeforeleavingtheoperator's

positionforanyreason.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Shutoffthemachineif

anyoneentersthearea.

•Keepbystandersoutoftheoperatingarea.Stop

themachineifanyoneentersthearea.

•Keepyourfeetclearoftheplatecompactor.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservice.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

4

Page 5

MaintenanceandStorage

•Lettheenginecoolbeforestoringanddonotstore

themachinenearanopename.

•Positionthemachineonalevelsurface,setthe

throttletoslow,andshutofftheengine.Waitfor

allmovementtostopbeforeadjusting,cleaning,

orrepairing.

•Cleandebrisfromdrives,mufers,andtheengine

tohelppreventres.Cleanupoilorfuelspills.

•Donotstorefuelnearamesordrainindoors.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Disconnectthesparkplugbeforemakingany

repairs.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Keepnutsandboltstight.Keepequipmentin

goodcondition.

•Stopandinspecttheequipmentifyoustrike

anobject.Makeanynecessaryrepairsbefore

restarting.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

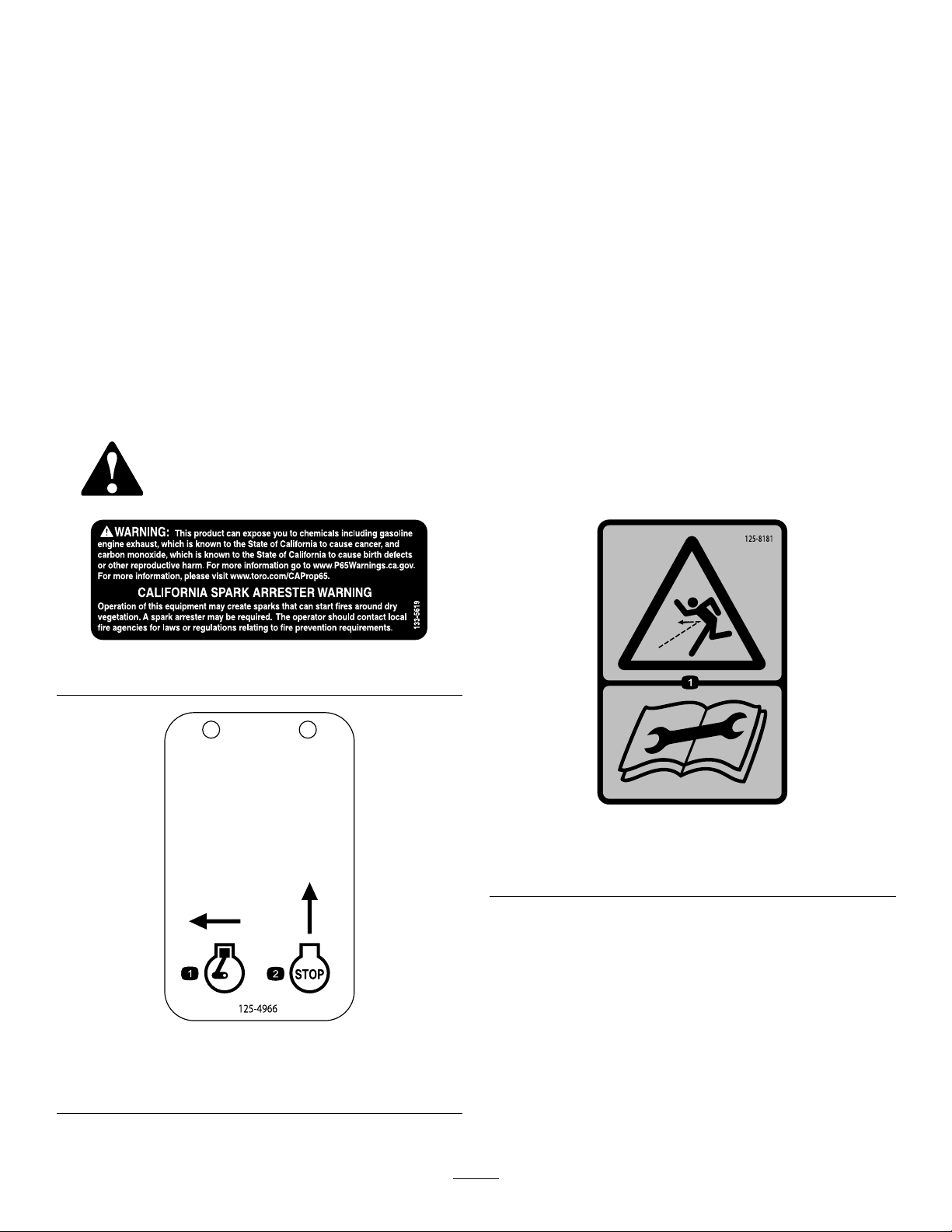

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

133-5619

•UseonlygenuineT ororeplacementpartsto

ensurethatoriginalstandardsaremaintained.

decal133-5619

1.Movelefttostartthe

engine.

decal125-8181

125-8181

1.Kickbackhazard—readtheOperator’sManualbefore

performingmaintenance.

decal125-4966

125-4966

2.Moveuptoshutoffthe

engine.

5

Page 6

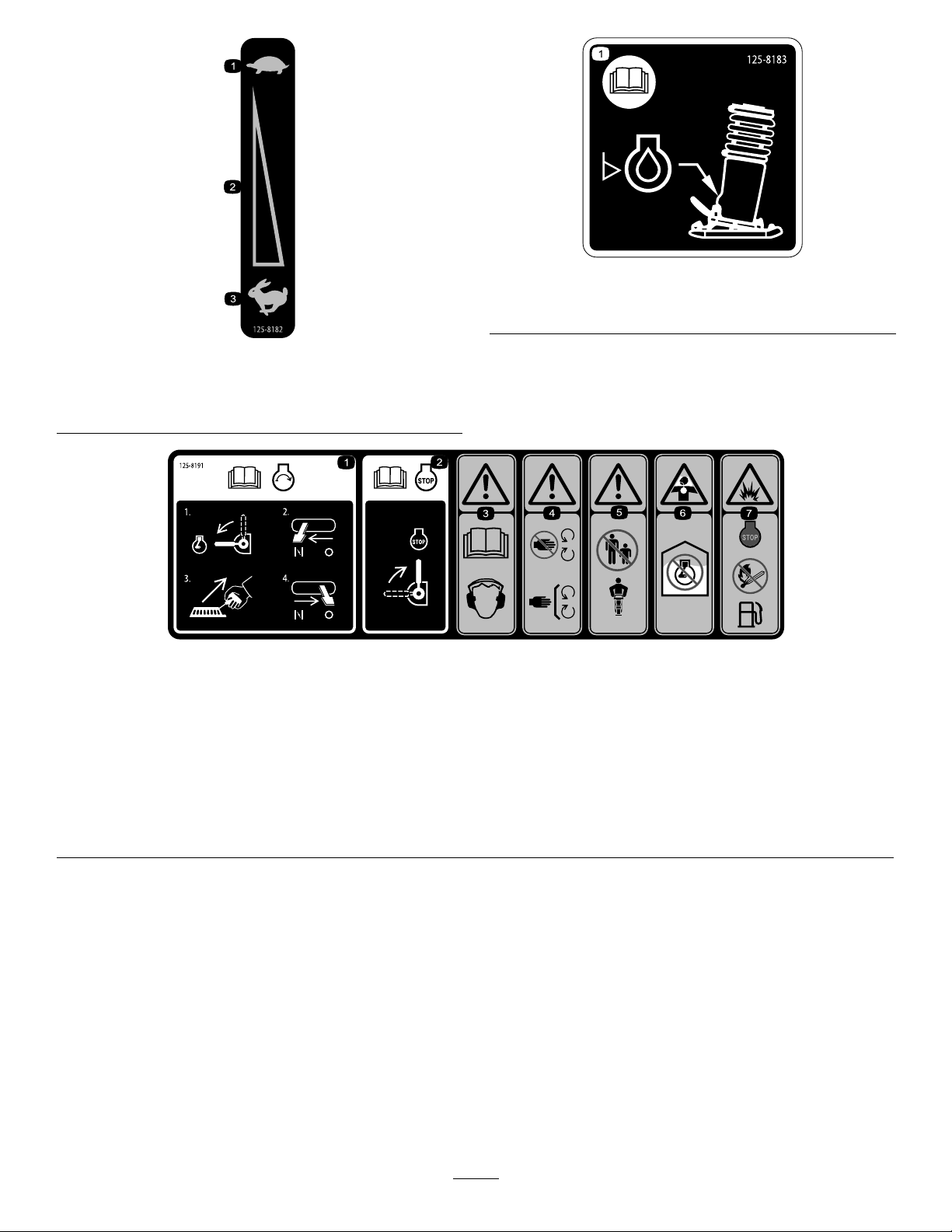

decal125-8183

125-8183

1.ReadtheOperator’sManual—checktheoillevel.

decal125-8182

125-8182

1.Slow

3.Fast

2.Variablespeedcontrol

1.ReadtheOperator’sManualforinformationonstartingthe

engine—1)Turnlevertotheenginestartposition;2)Closethe

choke;3)Pulltherecoilstarter;4)Openthechoke.

2.ReadtheOperator’sManualforinformationonshuttingoffthe

engine—turnlevertoenginestopposition.

3.Warning—readtheOperator’sManual;wearhearing

protection.

4.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

decal125-8191

125-8191

5.Warning—keepbystandersawaywhenoperatingthe

machine.

6.Chokinghazard—donotruntheengineinanenclosed

location.

7.Explosionhazard—shutofftheengineandextinguishall

amesbeforerefuelingthemachine.

6

Page 7

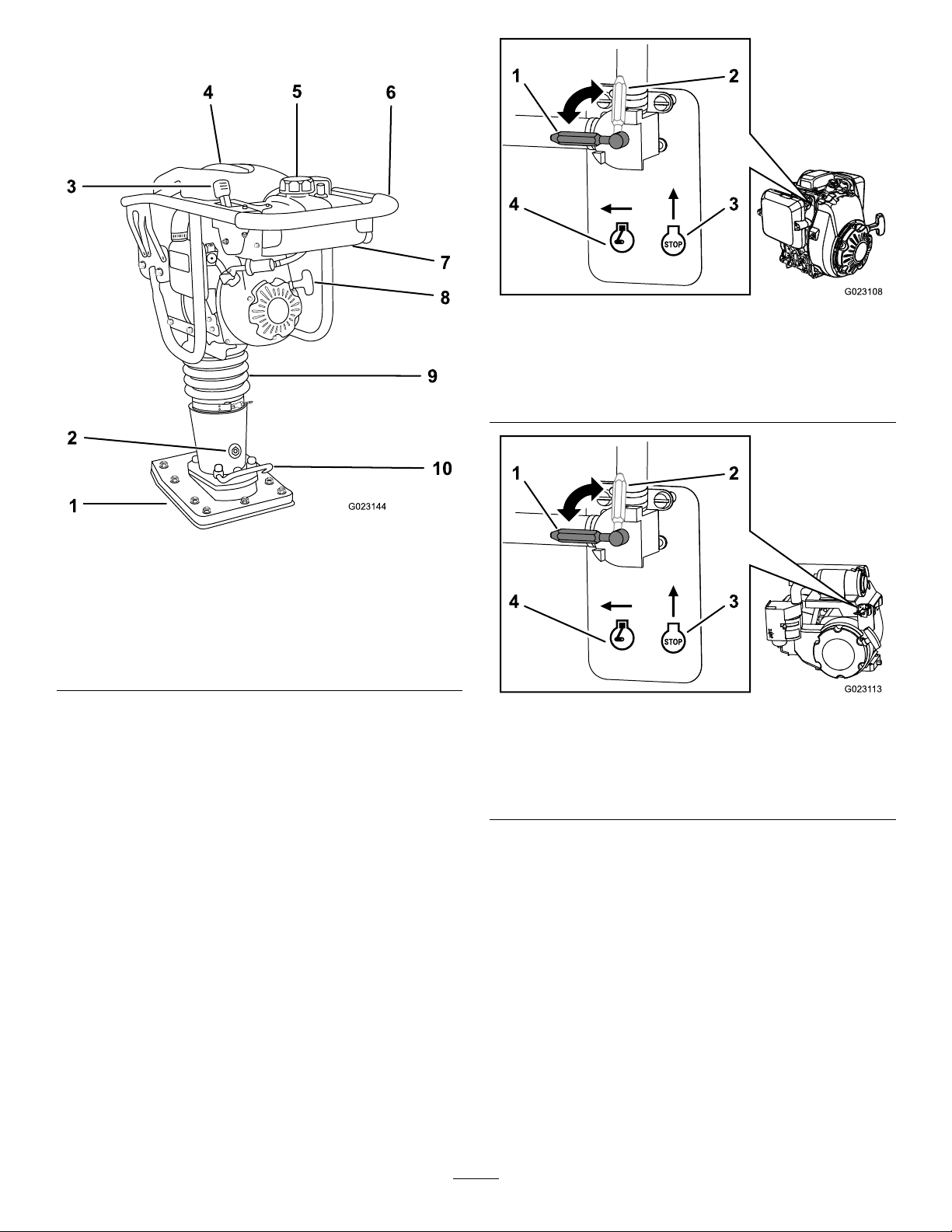

ProductOverview

g023108

Figure4

Models68034and68035

1.Switch—RUNposition3.Stop

2.Switch—STOPposition

4.Run

Figure3

1.Compactorshoe

2.Oilllplugandsightgauge

3.Throttlelever8.Recoil-starterhandle

4.Lifteye9.Springhousing

5.Fuel-tankcap

6.Handle

7.Fueltank

10.Lifthandle

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

EngineOn/OffSwitch

Theengineon/offswitchallowstheenginetorun

whenitisintheRUNposition.IntheSTOPposition,it

stopsthefuelfromowingtotheengineandprevents

theenginefromrunning(Figure4orFigure5).

g023144

g023113

Figure5

Model68036

1.Switch—RUNposition3.Stop

2.Switch—STOPposition

4.Run

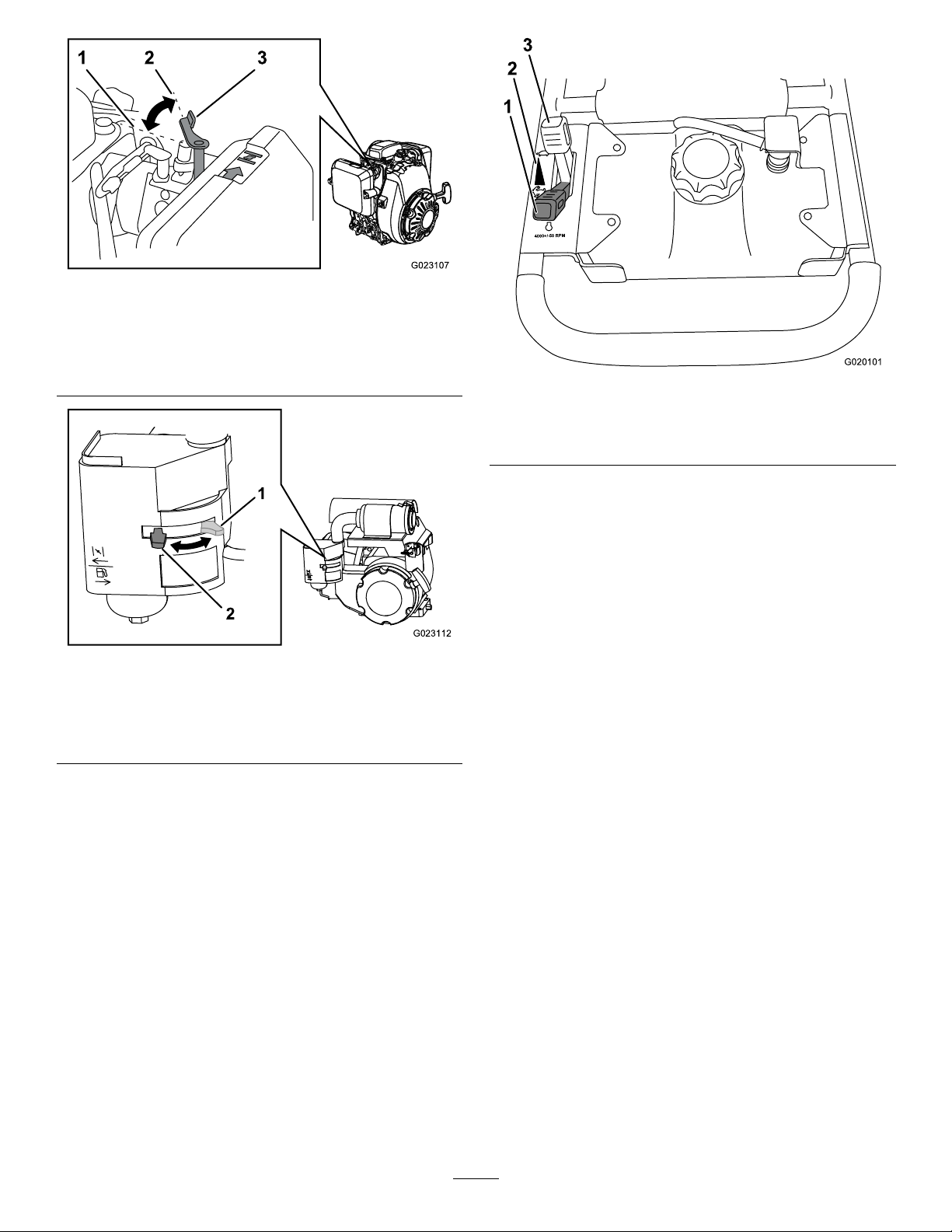

ChokeLever

Usethechokelever(Figure6orFigure7)tostarta

coldengine.Beforepullingtherecoil-starterhandle,

movethechokelevertotheclosedposition.Oncethe

engineisrunning,movethechokelevertotheopen

position.Donotusethechokeiftheengineisalready

warmeduporiftheairtemperatureishigh.

7

Page 8

Figure6

Models68034and68035

1.OPENposition3.Chokelever

2.CLOSEDposition

g023107

g020101

Figure8

Figure7

Model68036

1.ChokeleverintheOPEN

position

2.ChokeleverintheCLOSED

position

ThrottleLever

Thethrottlelevercontrolstheenginespeed.Whenthe

leverisintheSLOWposition,theenginerunsatidle

speed.Thisisalsothestartingposition.Whenyou

movethelevertotheFASTposition,thecentrifugal

clutchengages,andtheshoeofthemachinevibrates

andcompacts.

1.FASTposition

2.Variablecontrolspeed

g023112

3.SLOWposition

8

Page 9

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Model680346803568036

Weight

Length

Width

Height

Engine

ImpactForce1205kg

Maximum

Blows/Minute

60kg(132lb)65kg(144lb)70kg(154lb)

77cm(30.6

inches)

34cm(13.5

inches)

106cm(42

inches)

Honda®

GX100

(2,650lb)

727690655

75cm(29.7

inches)

37cm(14.9

inches)

106cm(42

inches)

Honda®

GX100

1409kg

(3,100lb)

85cm(33.8

inches)

41cm(16.4

inches)

11 1cm(44

inches)

Honda®

GX120

1591kg

(3,500lb)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Beforeoperating,checkthefueland

oillevelsandremovedebrisfromthemachine.

Also,ensurethattheareaisclearofpeopleand

debris.Youshouldalsoknowandhavemarked

thelocationsofallutilitylines.

PreparingtoUsethe Machine

•Checkthatthegroundisfreeofforeignobjects,

suchaselectricalcables,barbedwire,etc.

•Reviewallthesafetydecalsonthemachine.

•Usesteel-toeshoes,ahard-hat,hearing

protection,andeyeprotection.Ameshvisor

alonedoesnotprovidesufcienteyeprotection;

supplementwithprotectiveglasses.

•Ensurethatyouarefamiliarwithsafetyregulations

andshutdownproceduresdescribedinthe

Operator’sManual.

•Ensurethatallguardsareinplaceandingood

condition.

•Ensurethatthecompactorshoeisinplaceand

ingoodcondition.

•Ensurethateveryone,includingchildrenand

animals,maintainadistanceofatleast15m(50

ft)fromthemachine.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

9

Page 10

DANGER

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Donot

usefuelthathasbeenstoredformorethan

30days.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfromafuel

dispensernozzle.

•Ifafueldispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromnozzleandfuel

tankorconditionerbottleopening.

•Avoidcontactwithskin;washoffspills

withsoapandwater.

10

Page 11

UsingStabilizer/Conditioner

FillingtheFuelTank

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefuel

tankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

1.Parkthemachineonalevelsurfaceandstop

theengine.

2.Allowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit

(Figure9).

Figure9

1.Fillwithfuelhere

2.Fuelcap

4.Addfueltothefueltank,untilthelevelis6to

13mm(1/4to1/2inch)belowthebottomofthe

llerneck.

3.Fuelcontainer

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

5.Installthefueltankcapsecurely.

6.Wipeupanyspilledfuel.

11

g020337

Page 12

CheckingtheMachine-Fluid Levels

•Checktheengine-oillevel;refertoCheckingthe

Engine-OilLevel(page17).

•Checkthespring-housing-oillevel;referto

CheckingtheSpring-HousingOil(page18).

TransportingtheMachine

CAUTION

Ifyoutipthemachinewhentheengineon/off

switchisintheRUNposition,fuelcanleakout

ofthefueltank.Afuelleakcouldleadtoare

andcauseseriouspersonalinjury.

StartingtheEngine

1.Movetheengineon/offswitchtotheRUN

position(counterclockwise);refertoEngine

On/OffSwitch(page7).

2.MovethechokelevertotheCLOSEDpositionif

youarestartingacoldengine;refertoChoke

Lever(page7).

Note:Awarmorhotenginemaynotrequire

choking.

3.MovethethrottlelevertotheSLOWposition;

refertoThrottleLever(page8).

4.Pulltherecoil-starterhandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly.Gently

returnthehandletotheoriginalposition.

5.Aftertheenginestarts,graduallymovethe

chokeleverbacktotheOPENposition.Ifthe

enginestallsorhesitates,movethechokelever

backtotheCLOSEDpositionagainuntilthe

enginewarmsup.ThenmoveittotheOPEN

position.

ShuttingOfftheEngine

1.MovethethrottlelevertotheSLOWposition.If

theenginehasbeenworkinghardorishot,letit

runforaminute.Thishelpstocooltheengine

beforestopping.

Important:Toshutofftheengine

immediately,youcanmovetheengineon/off

switchtotheSTOPpositionbeforemoving

thethrottlelevertotheSLOWposition.

2.Movetheengineon/offswitchtotheSTOP

position(clockwise).

Drainthefueltankorensurethattheengine

on/offswitchisintheSTOPpositionbefore

tippingthemachine.

Important:Beforetransportingthemachine,

secureitwithstrapsorchainstopreventitfrom

fallingortippingover.

Ensurethattheliftingdeviceandstrapsorchains

areproperlyrated;refertoSpecications(page9).

Ifpossible,keepthemachinestandinguprightwhen

transportingit.Secureitwithstrapsorchains;donot

letitfallover.

Ifyoumusttransportthemachinehorizontally,doso

asfollows:

1.Shutofftheengineandallowittocoolfor15

minutes.Ensurethattheengineon/offswitch

isintheSTOPposition.

Theengineon/offswitchisalsoafuelvalve.

EnsuringthatitisintheSTOPpositionprevents

fuelfromleakingoutofthefueltank.

2.Usealiftingdevicewithadequateliftingcapacity

(atleast75kg,or165.3lb)toliftthemachine

intothetransportvehicle.

Important:Attachchainsorother

lifting-devicecomponentstoonlythelifteye

ofthemachine;refertoFigure3.

3.Carefullypositionthemachineasshownin

Figure10,andsecureitwithstrapsorchainsto

preventitfrommovingortipping.

Important:Donotlaythemachineontothe

rightorleftside;theengineoilcanleakinto

theairintakeortheexhaustsystem.Laythe

machinetippedforwardonly,sothatitrests

onthefrontbar.

12

Page 13

Figure10

4.Aftertransportingthemachine,standthe

machineinanuprightpositiontoallowtheoil

todrainthroughtheengineandsettlebackinto

thecrankcase.

Important:Allowtheoiltosettleforatleast

2minutesafterstandingthemachineupright

beforeyoustarttheengine.

OperatingTips

•Keepthemachineuprightsothatitcontactsthe

groundwiththeentireshoe,ratherthanwithjust

thefrontorbackedgeoftheshoe.

•Allowthemachinetodothework;pushing

downwardonthehandlelimitstheeffectivenessof

themachine.

•Onlevelsurfaces,themachinemovesforwardin

rapidjumps.Onunevensurfaces,tiltthemachine

asnecessarytoassisttheforwardmovement.

g023106

•Thejumpheightofthemachineincreasesasthe

groundbecomesmorecompacted.

13

Page 14

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Youmaytipthemachineforward,ifyoudrainthefueltankormovetheengineon/offswitch

totheSTOPposition,tomakecleaningorservicingthemachineeasier.Ifyoulaythemachineontothe

side,oilcandrainoutofthecrankcaseintotheaircleanerorthemufer.

Allowtheoiltosettleforatleast2minutesafterstandingthemachineuprightbeforeyoustartthe

engine.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Yearlyorbeforestorage

MaintenanceProcedure

•Changetheengineoil.

•Changethespring-housingoil.

•Checktheairlter.

•Checkthespring-housingoil.

•Checkthecompactorshoe.

•Removedebrisfromthemachine.

•Cleantheair-lterelements(morefrequentlyifconditionsaredustyorsandy).

•Cleantheprelter(Models68034and68035).

•Changetheengineoil(morefrequentlyiftheoperatingconditionsareextremely

dustyorsandy).

•Changethespring-housingoil.

•Checkthesparkplug.

•Replacethepaperair-lterelement(morefrequentlyifconditionsaredustyor

sandy).

•Changetheengineoil.

•Changethespring-housingoil.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

Pre-Maintenance

Procedures

Beforeperformingmaintenanceonthemachine,do

thefollowing:

1.Ensurethattheengineandmuferarecool.

2.Disabletheenginebydisconnectingthe

spark-plugwire;refertoDisconnectingthe

Spark-PlugWire(page15).

14

Page 15

Disconnectingthe Spark-PlugWire

Pullthespark-plugwireofftheterminalofthespark

plug(Figure11orFigure12).

Figure11

Models68034and68035

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Check

theairlter.

Every50hours—Cleantheair-lterelements

(morefrequentlyifconditionsaredustyor

sandy).

Every200hours—Replacethepaperair-lter

element(morefrequentlyifconditionsaredusty

orsandy).

Important:Donotoperatetheenginewithout

theair-lterassembly;extremeenginedamage

canoccur.

Note:Iftheengineislowonpower,producesblack

g023119

smoke,orrunsunevenly,theairltermaybeclogged.

CleaningthePrelter

1.Spark-plugwire

1.Spark-plugwire

Figure12

Model68036

Models68034and68035

ServiceInterval:Every50hours

1.Openthecoverofthemachine(Figure13).

g020404

Figure13

g023120

2.Removethescrewsthatsecurethecoverto

theprelterhousing(Figure14),andremove

thecover.

1.Prelterhousing2.Prelter

3.Removetheprelter.

4.Cleantheprelterasfollows:

15

g023121

Figure14

Page 16

A.Washtheprelterusingamilddetergent

andwater.

B.Squeezeitdrywithacleancloth.

C.Soakitwithnewengineoil.

D.Gentlywindtheprelterinanabsorbent

cloth,andsqueezeouttheexcessoil.

5.Installtheprelterasfollows:

A.Aligntheprelterinsideofthecover.

B.Alignthepreltercovertothehousing.

C.Securethecovertothehousingwiththe

screws.

ServicingtheAirFilter

Models68034and68035

1.Removethescrewsthatsecurethecovertothe

air-lterhousing(Figure15)

ServicingtheAirFilter

Model68036

1.Openthelatchoftheair-ltercover(Figure16).

Figure15

1.Air-lterhousing2.Airlter

2.Removetheairlterfromthehousingasshown

inFigure15.

3.Inspecttheairlterandreplaceitifitis

damaged,excessivelydirty,orsaturatedwith

oilorfuel.

4.Aligntheairlterinsideofthecover.

5.Aligntheairltercovertothehousing.

6.Securethecoverhousingwiththescrews.

g023124

Figure16

1.Latch3.Paperelement

2.Cover

g023122

2.Removetheairlterfromthehousingasshown

inFigure16.

4.Foamelement

3.Removethefoamelementfromthepaper

element.

4.Inspecttheelementsandreplacethemifthey

aredamagedorexcessivelydirty.

Note:Ifthepaperelementissaturatedwithoil

orfuel,replaceit.

5.Tapthepaperelementseveraltimesonahard

surfacetoremovethedirt.

6.Cleanthefoamelementinwarm,soapywater

orinanonammablesolvent.

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

7.Rinseanddrythefoamelementthoroughly .

8.Dipthefoamelementincleanengineoil,then

squeezeouttheexcessoil.

Note:Excessoilinthefoamelementrestricts

theairowthroughtheelementandmayreach

thepaperlterandclogit.

9.Wipedirtfromthehousingandthecoverwitha

moistrag.

16

Page 17

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

10.Installtheair-cleanerelementsandensurethat

theyareproperlypositioned(Figure17).

Important:Ensurethattheopenendof

theair-cleanerelementsarefacinginward

towardthemachine,asthemachinewill

notruniftheelementsarenotplacedinthe

properairorientationduetoairrestriction

(Figure17).

6.Pullthedipstickoutandlookattheend.

Theoilshouldbelevelwiththeupper-limitmark

(Figure18).

g019686

Figure18

Figure17

1.Openendofthepaper

element

2.Openendofthefoam

element

11.Securethecovertothehousingwiththelatch.

ServicingtheEngineOil

OilType:4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategorySJ,SL,

SM,orhigher.

CrankcaseCapacity:

•0.28L(9.47oz)formodels68034and68035

•0.40L(13.53oz)formodel68036

Viscosity:SAE10W-30isrecommendedforgeneral

use.

CheckingtheEngine-OilLevel

1.Shutofftheengineandallowittocool.

2.Tiltthemachinesothattheengineislevel.

Important:Propthemachineinthisposition

toensurethatitdoesnotfallover.

3.Cleanaroundtheoildipstick.

4.Removethedipstickandwipetheendclean.

5.Slidethedipstickfullyintothedipsticktube

withoutthreadingitintothellerneck.

g024809

1.Fillertube4.Lowerlimit

2.Dipstick

3.Upperlimit

5.Oil-drainbolt

Important:Runningtheenginewithalow

oillevelcancauseenginedamage.Thistype

ofdamageisnotcoveredbywarranty.

7.Iftheoillevelislow,slowlypouronlyenough

oilintothecrankcasetoraisetheleveltothe

upperlimit.

Important:Donotoverllthecrankcase

withoilbecausetheenginemaybedamaged.

8.Installandsecurethedipstick.

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

Yearlyorbeforestorage

ToroPremiumEngineOilisavailablefromyour

authorizedT orodistributor.

1.Starttheengineandletitrunfor5minutes;refer

toStartingtheEngine(page12).

2.Shutofftheengine;refertoShuttingOffthe

Engine(page12).

3.Tiltthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensurethatthe

oildrainscompletely.

17

Page 18

4.Placeadrainpanundertheoil-drainhole.

5.Removethedrainpluganddraintheoilfromthe

engine(Figure19).

Figure19

Servicingthe Spring-HousingOil

OilType:4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategorySJ,SL,

SM,orhigher.

Capacity:0.47L(15.89oz)

Viscosity:SAE10W-30isrecommendedforgeneral

use.

CheckingtheSpring-HousingOil

ServiceInterval:Beforeeachuseordaily

Checkthespring-housingoilasfollows:

1.Carefullytipthemachineslightlybackwardso

thatthemachinestandscompletelyuprightand

vertical.

Important:Propthemachineinthisposition

toensurethatitdoesnotfallover.

2.Checktheoilsightplug(Figure20),andensure

thattheoillevelishalfwaybetweenthetopand

g020104

bottomoftheoilsightplug.

1.Oilpan3.Oil-llhole

2.Oil-drainhole

6.Whentheoilhasdrainedcompletely,installthe

plugandwipeupanyspilledoil.

Note:Disposeoftheusedoilatacertied

recyclingcenter.

7.Removethedipstickandslowlypour

approximately80percentofthespecied

amountofoilintotheengine(Figure19).

8.Slowlyaddadditionaloiltobringtheoillevel

totheupper-limitmarkonthedipstick;referto

CheckingtheEngine-OilLevel(page17).

9.Installandsecurethedipstick.

g023141

Figure20

1.Oilsightplug

3.Iftheoillevelislow,addoil;refertoAddingOil

totheSpringHousing(page19).

ChangingtheSpring-HousingOil

ServiceInterval:Aftertherst25hours

18

Page 19

Every100hours

Yearlyorbeforestorage

1.Starttheengineandletitrunfor5minutes;refer

toStartingtheEngine(page12).

2.Shutofftheengine;refertoShuttingOffthe

Engine(page12).

3.Ensurethattheengineon/offswitchisinthe

STOPpositionsothatthefueldoesnotleakout

ofthefueltank.

4.Tiltthemachinesothattheoilsightplug

facesdownwardtoensurethattheoildrains

completely(Figure21).

AddingOiltotheSpringHousing

1.Tiltthemachinesothattheoilsightplugis

facingupward(Figure22).

g023143

Figure22

Figure21

1.Oilsightplug

2.Drainpan

5.Placeadrainpanundertheoilsightplug(Figure

21).

6.Removetheoilsightplug(Figure21).

7.Draintheoiloutoftheholeinthehousing

(Figure21).

8.Cleanthethreadsontheoilsightplugandapply

3layersofPTFEthread-sealingtape.

1.Openingfortheoil

2.Removetheoilsightplug.

3.Cleanthethreadsontheoilsightplugandapply

3layersofPTFEthread-sealingtape.

4.Addtheoiltothespringhousinginincrements

toensurethatyoudonotoverllthemachine;

refertoCheckingtheSpring-HousingOil(page

g023142

18)toensurethattheoilisatthecorrectlevel.

Note:Theoilcapacityofthespringhousingis

0.47L(0.5USqt);addthefullamountonlyifthe

springhousingisempty.

5.Installandtorquetheoilsightplugto54N∙m

(39.8ft-lb).

Important:Allowtheoiltosettleforatleast2

minutesafterstandingthemachineuprightbefore

startingtheengine.

9.Addoiltothespringhousing;refertoAddingOil

totheSpringHousing(page19).

10.Installandtorquetheoilsightplugto54N∙m

(39.8ft-lb).

Important:Allowtheoiltosettleforatleast2

minutesafterstandingthemachineuprightbefore

startingtheengine.

19

Page 20

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthespark

plug.

Ensurethattheairgapbetweenthecenterelectrode

andthesideelectrodeiscorrectbeforeinstallingthe

sparkplug.Useaspark-plugwrenchforremoving

andinstallingthesparkplugandagappingtool/feeler

gaugetocheckandadjusttheairgap.Installanew

sparkplugifnecessary.

Models68034and68035:UseaDENSO

U16FSR-UBoranNGKCR5HSBsparkplug.

Model68036:UseaDENSOW14EPR-UoranNGK

BP4ESsparkplug.

RemovingtheSparkPlug

1.Shutoffthemachineandletitcool.

2.Disconnectthewirefromthesparkplug(Figure

23).

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure24).

Ifyouseelightbrownorgrayontheinsulator,

theengineisoperatingproperly.Ablackcoating

ontheinsulatorusuallymeansthattheair

cleanerisdirty.

Important:Donotcleanthesparkplug.

Alwaysreplacethesparkplugwhenithasa

blackcoating,wornelectrodes,anoilylm,

orcracks.

g023105

Figure24

Figure23

1.Sparkplug

2.Wire

3.Cleanaroundthesparkplug.

4.Useaspark-plugwrenchtoremovethespark

plugandthemetalwasher.

1.Sideelectrode4.0.60to0.70mm(0.024to

2.Centerelectrode5.0.70to0.80mm(0.028

3.Insulator

0.028inch)gap(Models

68034and68035)

to0.031inch)gap(Model

68036)

2.Checkthegapbetweenthecenterandside

electrodes(Figure24).

g014506

3.Ifthegapisnotwithinthespeciedrange,do

thefollowing:

A.Ifthegapistoosmall,carefullybend

thesideelectrodeawayfromthecenter

electrodeuntilthegapbetweenthe

electrodesiscorrect.

B.Ifthegapistoolarge,carefullybendthe

sideelectrodetowardthecenterelectrode

untilthegapbetweentheelectrodesis

correct.

InstallingtheSparkPlug

1.Threadthesparkplugintothespark-plughole.

2.Tightenthesparkplugto27N∙m(20ft-lb).

Important:Ensurethatthesparkplugis

tightenedtothespeciedtorquevalue.A

loosesparkplugmaycausedamagetothe

cylinder,whileanovertightenedsparkplug

maycausedamagetothecylinder-head

threads.

3.Connectthewiretothesparkplug.

20

Page 21

CompactorShoe Maintenance

Cleaning

RemovingDebrisfromthe

CheckingtheCompactor Shoe

ServiceInterval:Beforeeachuseordaily

Amongthemostcriticalelementsofthemachineis

thecompactorshoe.Itisalsothemostsubjectto

damageandwear.Inthecourseofcompactingawide

arrayofgranularobjects,themachineencounters

numerousabrasivesandobjects,suchasdirt,stones,

andoccasionallyalargerockorburiedscrap.

Thewearofthecompactorshoecansignicantly

impairtheefciencyandperformanceofthemachine.

Therefore,itisimportanttomakefrequentchecksof

theconditionofthecompactorshoeforleaksand

cracks.(Figure25).

Machine

Regularcleaningandwashingwillincreasethelife

spanofthemachine.Cleanthemachineimmediately

afteruse,beforethedirthardens.

Checkbeforecleaningthatthefueltankcapis

properlyinplacetoavoidgettingwaterinthetank.

Usecarewhenusingahigh-pressuresprayer

becauseitcandamagewarningdecals,instruction

signs,andtheengine.

1.Compactorshoe

g020338

Figure25

21

Page 22

Storage

Forstorageover30days,preparethemachineas

follows:

1.Removedirtandgrimefromtheexternalparts

oftheentiremachine,especiallytheengine.

Cleanallgranularobjectsfromtheoutsideof

theenginecylinder-headnsandtheblower

housing.

Important:Storethemachineintheupright

position.Donottipthemachineonitsside,

orleavethemachinetippedforwardwiththe

frontbardownforalongperiodoftime.

17.Coverthemachinetoprotectitandkeepitclean.

RemovingtheMachine fromStorage

Important:Youcanwashthemachinewith

milddetergentandwater.

2.Addapetroleum-basedstabilizer/conditioner

tothefuelinthetank.Followthemixing

instructionsfromthestabilizermanufacturer.Do

notuseanalcohol-basedstabilizer(ethanolor

methanol).

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuelandused

atalltimes.

Important:Donotstore

stabilizer/conditionedfuelover90days.

3.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

4.Shutofftheengine,allowittocool,anddrainthe

fueltankusingapump-typesiphon.Disposeof

fuelproperly;recycleitaccordingtolocalcodes.

5.Starttheengineandrunituntilitstops.

6.Choketheengine.

7.Startandruntheengineuntilitwillnotstart

again.

1.Checkandtightenallfasteners.

2.Inspectthesparkplugandreplaceitifitisdirty,

worn,orcracked;refertotheengineOperator’s

Manual.

3.Installthesparkpluguntilitishand-tight,then

anadditional1/2turnifitisnew,otherwise,

tightenitanadditional1/8to1/4turn.

4.Performanyneededmaintenanceprocedures.

5.Checktheengine-oillevel;refertoCheckingthe

Engine-OilLevel(page17).

Important:Storethemachineintheupright

position.Donottipthemachineonitsside,

orleavethemachinetippedforwardwiththe

frontbardownforalongperiodoftime.

6.Checkthespring-housingoillevel;referto

CheckingtheSpring-HousingOil(page18).

7.Fillthefueltankwithfreshfuel;refertoFilling

theFuelT ank(page1 1).

8.Connectthewiretothesparkplug.

8.Servicetheaircleaner;refertoFigure13.

9.Changetheenginecrankcaseoil;refertoFigure

19.

10.Removethesparkplugandcheckthecondition;

refertoFigure23andFigure24.

11.Withthesparkplugremovedfromtheengine,

pour30ml(2tablespoons)ofengineoilintothe

spark-plughole.

12.Pulltherecoil-starterhandleslowlytocrankthe

engineanddistributetheoilinsidethecylinder.

13.Installthesparkplug,butdonotinstallthewire

onthesparkplug.

14.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamaged.

15.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

16.Storethemachineinaclean,drygarageor

storagearea.

22

Page 23

Troubleshooting

Theenginedoesnotstart.

Theenginerunsrough.

Problem

1.TheairlterforModel68036isplaced

backwardsintheair-ltercover.

2.Theengineon/offswitchisinthestop

position.

3.Thechokeisopen.

4.Thefueltankisempty.4.Fillthetankwithfreshfuel.

5.Thespark-plugwireislooseor

disconnected.

6.Thesparkplugisfouledorimproperly

gapped.

1.Thechokeisclosed.

2.Theairlterisclogged.2.Cleanorreplacetheairlter.

3.Thereiswaterorcontaminantsinthe

fuel.

4.Thesparkplugiswornorhasbuildup

ontheelectrodes.

PossibleCauseCorrectiveAction

1.Switchtheorientationoftheairlterin

theair-ltercover.

2.Movetheswitchtotherunposition.

3.Closethechokewhenstartingacold

engine.

5.Connectthespark-plugwire.

6.Correcttheelectrodegaporreplace

thesparkplug.

1.Openthechoke.

3.Drainandllthetankwithfreshfuel.

4.Correcttheelectrodegaporreplace

thesparkplug.

23

Page 24

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly .ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproductsAdditionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerwithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover ,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...