Page 1

FormNo.3421-187RevA

FP-2200ForwardPlate

Compactor

ModelNo.68025—SerialNo.402300000andUp

ModelNo.68026—SerialNo.402300000andUp

ModelNo.68027—SerialNo.402300000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-187*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Thisengineisnotequippedwithasparkarrester

mufer.ItisaviolationofCaliforniaPublicResource

CodeSection4442touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilar

laws.

Introduction

Thismachineisdesignedtocompactawidearrayof

soilsubstances,includingclay,silt,gravel,sand,and

loam.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

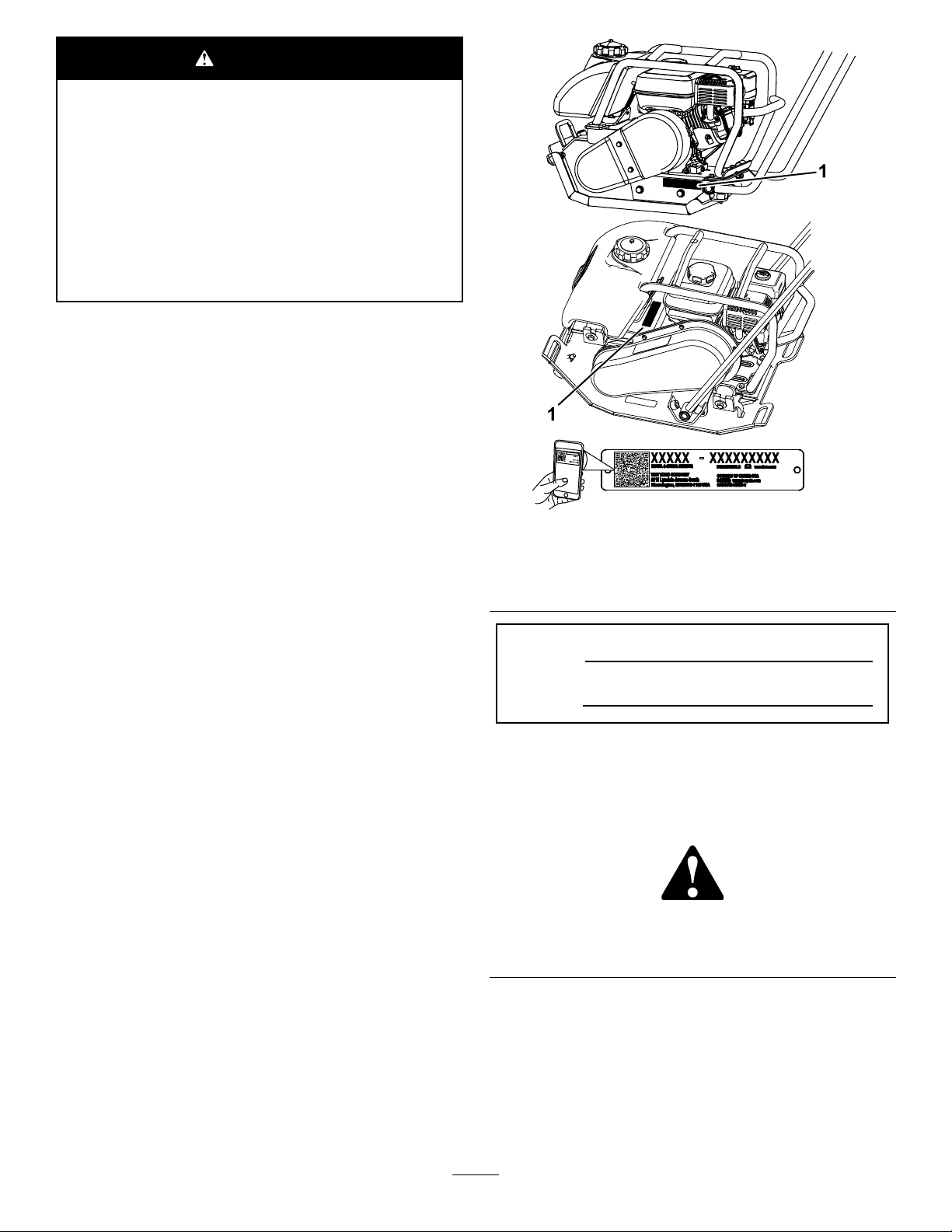

andserialnumbersofyourproductready.Figure

1illustratesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g239795

Figure1

2200—Top;3000/4000—Bottom

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety.......................................................................3

SafeOperatingPractices....................................3

SafetyandInstructionalDecals..........................5

Setup........................................................................6

InstallingtheHandle...........................................6

CheckingtheEngine-OilLevel............................6

CheckingtheEccentric-OilLevel........................6

ProductOverview.....................................................7

Operation..................................................................7

CheckingtheEngine-OilLevel............................7

CleaningDebrisfromtheMachine......................8

AddingFuel........................................................8

CompactingAsphalt.........................................10

StartingtheEngine............................................11

ShuttingOfftheEngine.....................................12

OperatingtheCompactor.................................12

TransportingtheMachine.................................12

Maintenance...........................................................13

RecommendedMaintenanceSchedule(s)...........13

DisconnectingtheSpark-PlugWire..................13

EngineMaintenance.........................................13

BeltMaintenance..............................................18

Storage...................................................................20

Troubleshooting......................................................21

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofcausingseriousinjury .

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,

anodorless,deadlypoisonwhichislethalif

inhaled.

Donotruntheengineindoorsorinan

enclosedarea.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readorunderstandtheinformation,itisthe

owner'sresponsibilitytoexplainthismaterialto

them.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringpeopleordamage

toproperty.

Preparation

•Wearappropriateclothingincludinghardhat,eye

protection,longpants,substantial,slip-resistant

footwear,andhearingprotection.Tiebacklong

hair,securelooseclothing,anddonotwearloose

jewelry.

•Inspecttheareawheretheequipmentistobe

usedandensurethatallobjectsareremovedfrom

theareabeforeuse.

•Useextracarewhenhandlingfuel.Theyare

ammableandvaporsareexplosive.

–Extinguishallcigarettes,cigars,pipes,and

othersourcesofignition.

3

Page 4

–Useonlyanapprovedcontainer

–Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

–Donotaddordrainfuelinanenclosedspace.

–Donotstorethemachineorfuelcontainer

wherethereisanopename,spark,orpilot

light,suchasonawaterheaterorother

appliance.

–Ifyouspillfuel,donotattempttostartthe

engine;avoidcreatinganysourceofignition

untilthefuelvaporshavedissipated.

•Checkthattheshieldsareattachedand

functioningproperly.Donotoperateunlessthey

arefunctioningproperly.

MaintenanceandStorage

•Lettheenginecoolbeforestoringanddonotstore

themachinenearanopename.

•Positionthemachineonalevelsurface,setthe

throttletoslow,andshutofftheengine.Waitfor

allmovementtostopbeforeadjusting,cleaning,

orrepairing.

•Cleandebrisfromdrives,mufers,andtheengine

tohelppreventres.Cleanupoilorfuelspills.

•Donotstorefuelnearamesordrainindoors.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverrunanengineinanenclosedorpoorly

ventilatedarea.

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Stoponlevelground,setthethrottletoslow,and

shutofftheenginebeforeleavingtheoperator's

positionforanyreason.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Shutoffthemachineif

anyoneentersthearea.

•Keepbystandersoutoftheoperatingarea.Stop

themachineifanyoneentersthearea.

•Keepyourfeetclearoftheplatecompactor.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Disconnectthesparkplugbeforemakingany

repairs.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Keepnutsandboltstight.Keepequipmentin

goodcondition.

•Stopandinspecttheequipmentifyoustrike

anobject.Makeanynecessaryrepairsbefore

restarting.

•UseonlygenuineT ororeplacementpartsto

ensurethatoriginalstandardsaremaintained.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservice.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

4

Page 5

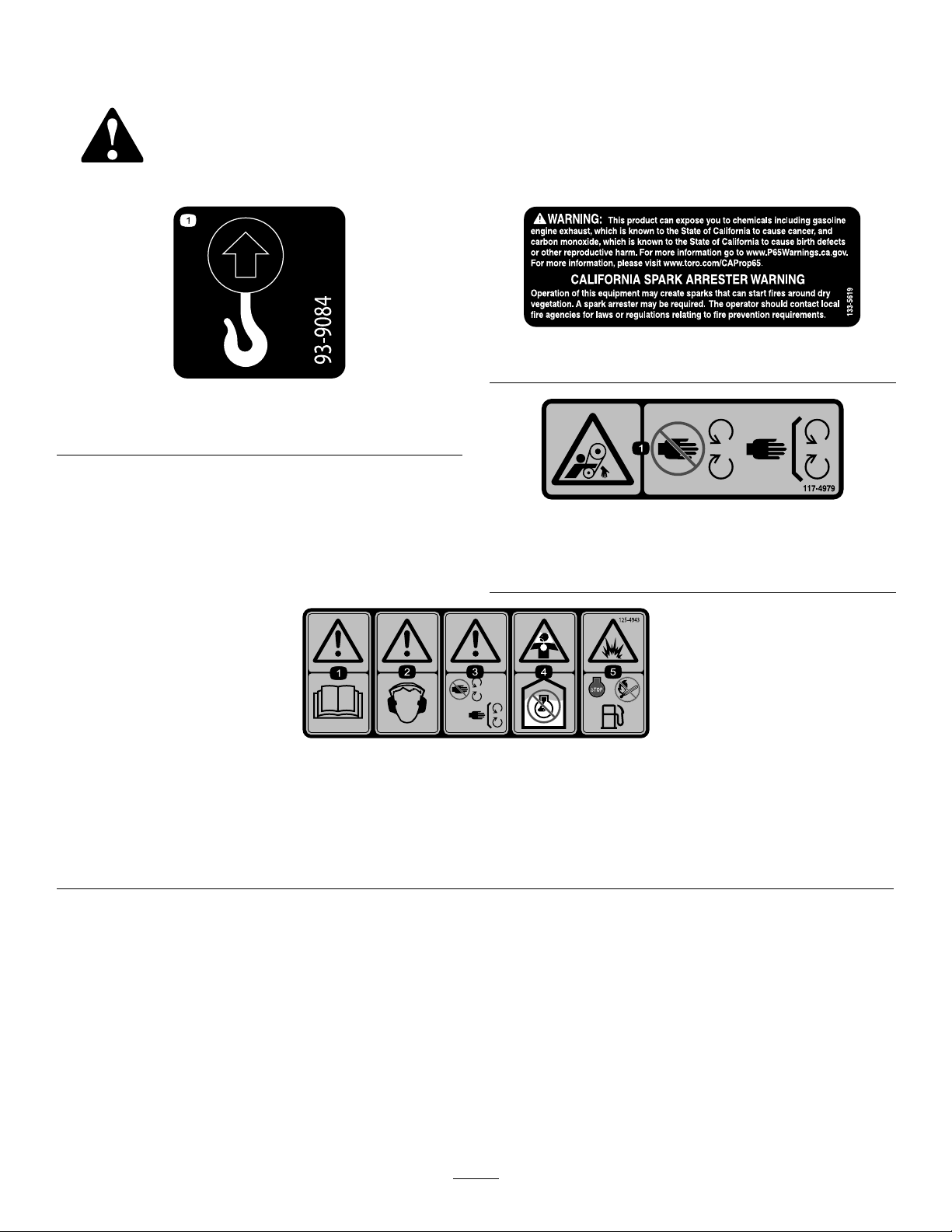

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93-9084

1.Liftpoint

decal133-5619

133-5619

decal93-9084

decal117-4979

117-4979

1.Entanglementhazard,belt—keepawayfrommovingparts;

keepallguardsandshieldsinplace

125-4943

1.Warning—readtheOperator’sManual.4.Chokinghazard—donotoperatethemachineindoors.

2.Warning—wearhearingprotection.

3.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

5.Explosionhazard—shutofftheengineandextinguishall

amesbeforerefuelingthemachine.

decal125-4943

5

Page 6

Setup

InstallingtheHandle

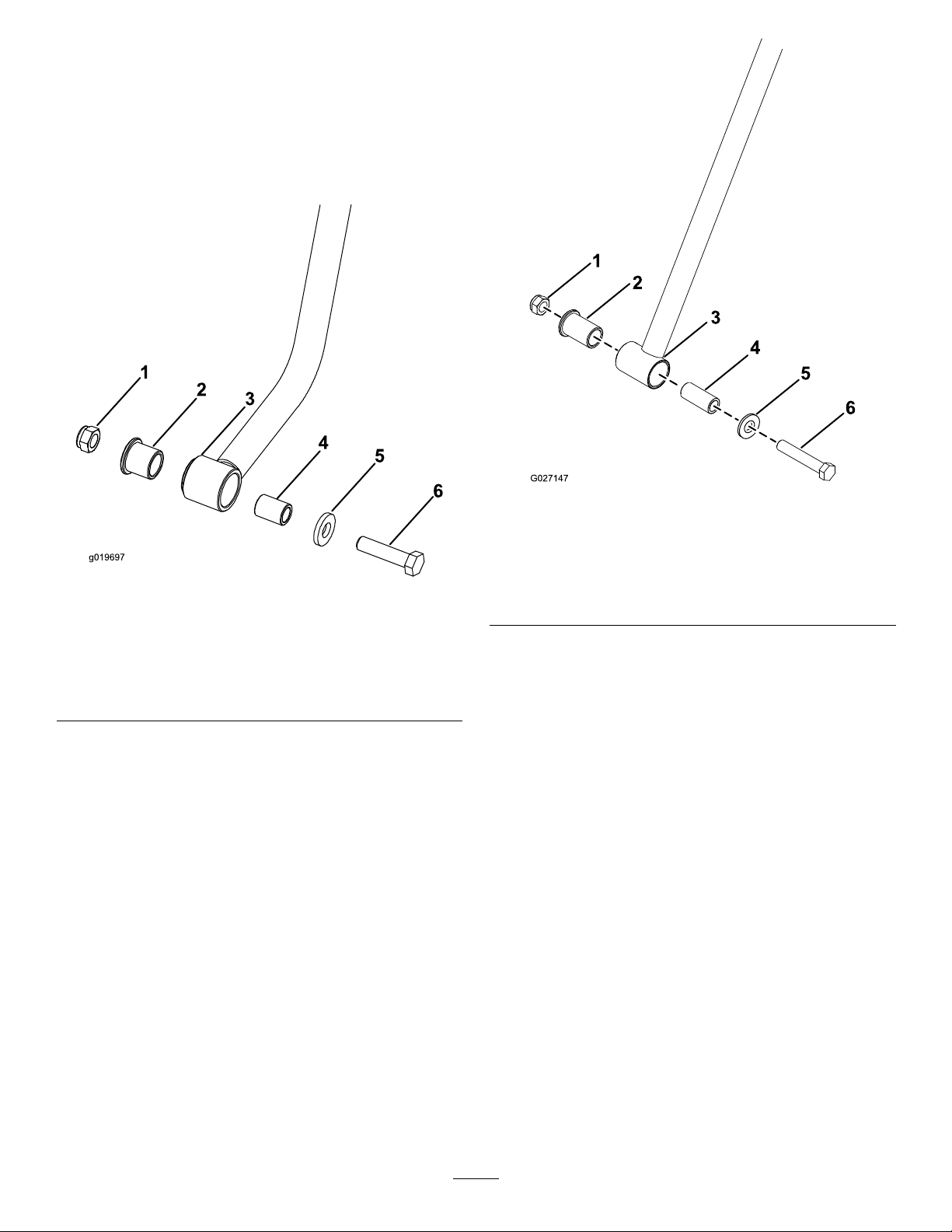

Secureeachsideofthehandletotheplatecompactor

frameusingabolt,atwasher,spacer,bearing,and

locknut(Figure3orFigure4).

g027147

Figure4

Model3000/4000

Figure3

Model2200

1.Locknut

2.Bearing5.Flatwasher

3.Handle6.Bolt

1.Locknut

g019697

4.Spacer

2.Bearing5.Flatwasher

3.Handle6.Bolt

4.Spacer

CheckingtheEngine-Oil

Level

Themachinecomesfromthefactorywithoilinthe

enginecrankcase;however,itmaybenecessaryto

addoil;refertoCheckingtheEngine-OilLevel(page

7).AddonlyenoughoiltoraisetheleveltotheFull

markonthedipstick.

CheckingtheEccentric-Oil

Level

Themachinecomesfromthefactorywitheccentricoil

intheeccentrichousing;however,itmaybenecessary

toaddoil;refertoServicingtheEccentricOil(page

17).Addonlyenoughoilsothattheoillevelisush

withtheoilplugonthesideoftheeccentrichousing.

6

Page 7

ProductOverview

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CheckingtheEngine-Oil Level

ServiceInterval:Beforeeachuseordaily

Oilcrankcasecapacity:

•0.56L(0.59USqt)forModel68025

•0.58L(0.61USqt)forModels68026and68027

1.Positionthemachineonalevelsurface.

2.Setthethrottletoslow,shutofftheengine,and

waitforallmovingpartstostop.

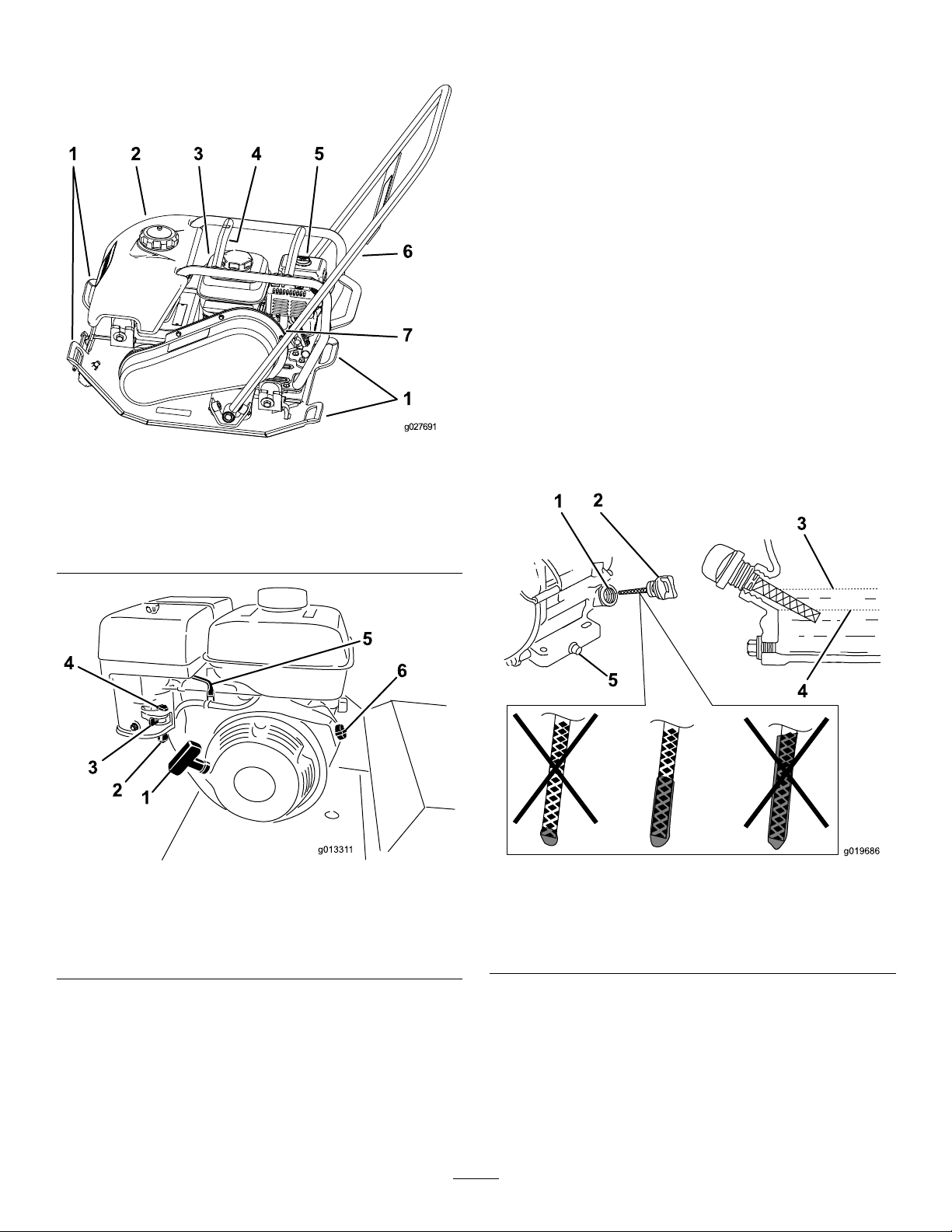

Figure5

1.Lifthandles5.Airlter

2.Watertank6.Handle

3.Engine7.Beltcover

4.Rollcagelifteye

Figure6

1.Recoilstarter

2.Sedimentcup

3.Fuel-shutoffvalve6.EngineOn/Offswitch

4.Chokelever

5.Throttlelever

g027691

g013311

3.Cleanaroundthedipsticksothatdirtcannot

fallintothellerholeanddamagetheengine

(Figure7).

Figure7

1.Fillertube4.Lowerlimit

2.Dipstick

3.Upperlimit

5.Oil-drainbolt

g019686

4.Removethedipstickandwipetheendclean.

5.Slidethedipstickfullyintothedipsticktube

withoutthreadingitintothellerneck.

6.Pullthedipstickoutandinspecttheend.

Note:Theoilshouldbelevelwiththeupper-limit

mark(Figure7).

7

Page 8

Important:Runningtheenginewithalow

oillevelcancauseenginedamage.Thistype

ofdamageisnotcoveredbywarranty.

Theengineisequippedwithanoilalert

systemthatwillautomaticallyshutoffthe

enginebeforetheoillevelfallsbelowthe

safelimit.

7.Iftheoillevelislow,slowlypouronlyenough

oilintothecrankcasetoraisetheleveltothe

upperlimit.

Important:Donotoverllthecrankcase

withoil,becausetheenginemaybe

damaged.

8.Installandsecurethedipstick.

CleaningDebrisfromthe Machine

ServiceInterval:Beforeeachuseordaily

1.Setthethrottletoslow,shutofftheengine,and

waitforallmovingpartstostop.

WARNING

Contactwithhotpartsonthemachine

cancausesevereburns.

Waitforallpartstocoolbeforetouching

themachine.

2.Brushdirtanddebrisawayfromtheaircleaner

andengineopenings.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

3.Checkthesprinklermanifold(Figure10)and

removeanydirtordebris.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

8

Page 9

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfromafuel

dispensernozzle.

•Ifyoumustuseafueldispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

WARNING

FillingtheFuelTank

1.Setthethrottletoslow,shutofftheengine,and

waitforallmovingpartstostop.

2.Allowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit

(Figure8).

Note:Thecapistetheredtothefueltank.

g013315

Figure8

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastank

orconditionerbottleopening.

•Avoidcontactwithskin;washoffspills

withsoapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefuel

tankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

4.Addunleadedfueltothefueltankuntilthelevel

isjustinsidethemeshlterbasket.

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

5.Installthefueltankcapsecurely.

6.Wipeupanyspilledfuel.

9

Page 10

CompactingAsphalt

Whenusingthemachineonasphalt,thewatersystem

isusedtowetthesurfaceofthecompactortoprevent

theasphaltfromstickingtothecompactor.

AddingWaterwiththeTank Installed

1.Removethecapfromthewatertank(Figure9).

AddingWaterwiththeTank Removed

1.Detachthevalvecoupler(Figure10).

Figure9

1.Water-tankcap3.Watertank

2.Water

2.Fillthetankwithwater(Figure9).

3.Installthecapontothewatertank(Figure9).

g024875

g024848

1.Shutoffvalve

2.Femalecoupler

Figure10

3.Malecoupler

4.Sprinklermanifold

2.Removethewatertankfromtheframebypulling

upontheelastictanklatch(Figure11).

g019702

Figure11

1.Elastictanklatch

3.Fillthetankwithwater,assembleittotheframe,

andattachthecoupler.

10

Page 11

StartingtheEngine

1.MovetheengineswitchtotheONposition

(Figure12).

g019774

Figure14

1.Choke

Figure12

1.Engineswitch

2.MovethefuelvalvetotheONposition(Figure

13).

g019703

4.Movethethrottlelevermidwaybetweenthe

SLOW(turtle)andFAST(rabbit)positions(Figure

15).

Note:Awarmorhotenginemaynotrequire

choking.

Figure13

1.Fuelvalve

3.Movethechokelevertotheleftifyouare

startingacoldengine(Figure14).

g019704

1.Throttle

Figure15

g019775

5.Pulltherecoilhandlesharplytostarttheengine.

6.Aftertheenginestarts,graduallymovethe

choketotheright.

11

Page 12

Important:Iftheenginestallsorhesitates,

movethechokeleftagainuntiltheengine

warmsup.

7.Movethethrottlelevertomaximumthrottle.

ShuttingOfftheEngine

1.MovethethrottlelevertotheSLOW(turtle)

position.

2.Turntheengineswitchandfuelvalveoff.

OperatingtheCompactor

Withtheengineatfullthrottle,thecompactormoves

forwardwhilevibrating.

Graspthehandlelightlywithbothhandsandallowthe

compactortomoveforwardonitsown.Usethehandle

toguidethedirectionoftraveltoavoidobstructions.

TransportingtheMachine

Model68025weighs64kg(140lb)

Model68026weighs93kg(205lb)

Model68027weighs98kg(215lb)

Youcanusetherollcagelifteyetoliftandtransportthe

machinewithstrapsoracrane(Figure16).

Alternatively,2peoplecantransportthemachine

byliftingthecompactorusingthefrontandrearlift

handles(Figure16).

Figure16

1.Rollcagelifteye2.Lifthandles

g027692

12

Page 13

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every300hours

Monthly

Disconnectingthe

MaintenanceProcedure

•Changetheengineoil.

•Checktheengine-oillevel.

•Cleandebrisfromtheaircleaner.

•Inspecttheair-cleanerelements.

•Cleantheair-lterelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Inspect,clean,andadjustthesparkplug;replaceitifnecessary.

•Cleanthesedimentcup.

•Changetheengineoil.

•Checkthebelttension.Adjustthebelttensionifnecessary.

•Replacethesparkplug.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindusty

operatingconditions.

•Changetheeccentricoil.

•Checktheeccentric-oillevel.

EngineMaintenance

Spark-PlugWire

Beforeperforminganymaintenanceontheengine,

disconnectthespark-plugwirefromthesparkplug

(Figure17).

Figure17

ServicingtheSparkPlug

ServiceInterval:Every100hours—Inspect,clean,

andadjustthesparkplug;replaceit

ifnecessary.

Every200hours—Replacethesparkplug.

UseanNGKBPR6ESsparkplugorequivalent.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercan

damagetheengine.

5.Setthegapontheplugto0.76mm(0.03inch)

g019690

asshowninFigure18.

1.Spark-plugwire

13

Page 14

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

r:\g000533

Figure18

6.Carefullyinstallthesparkplugbyhand(toavoid

crossthreading)untilitishandtight.

7.Tightenthesparkpluganadditional1/2turnif

itisnew;otherwise,tightenitanadditional1/8

to1/4turn.

Important:Aloosesparkplugcanbecome

veryhotandcandamagetheengine;

overtighteningasparkplugmaydamagethe

threadsinthecylinderhead.

8.Connectthewiretothesparkplug.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspect

theair-cleanerelements.

Every50hours—Cleantheair-lterelements.

Cleanthemmorefrequentlyindustyoperating

conditions.

Every300hours/Y early(whichevercomes

rst)—Replacethepaperair-cleanerelement.

Replaceitmorefrequentlyindustyoperating

conditions.

RemovingtheAirFilter

Important:Donotoperatetheenginewithout

theairlterassembly;extremeenginedamage

willoccur.

1.Setthethrottletoslow,shutofftheengine,and

waitforallmovingpartstostop.

g027313

Figure19

1.Wingnut(cover)5.Foamlterelement

2.Air-ltercover6.Seal(rubber)

3.Wingnut(lter)7.Carburetorbase

4.Paperlterelement

4.Removethewingnutthatsecurestheair-lter

covertothecarburetorandremovethecover

(Figure19).

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamlterelementfromthepaper

lterelement(Figure19).

6.Inspectthefoamelementfordamage.

Note:Ifthefoamlterelementisdamaged,

replaceit.Ifthefoamelementisdirty,cleanit;

refertoCleaningtheFoamFilter(page14).

7.Removethewingnutthatsecuresthepaper

lterelementtothecarburetor(Figure19).

8.Removethepaperelementandinspectthe

paperlterelementfordamageandexcessive

amountsofdirtintheelement.

Note:Replacethepaperlterelementifitis

damagedorexcessivelydirty.

Note:Nevertrytocleanthepaperelement;

onlyreplaceit.

2.Disconnectthespark-plugwirefromthespark

plug.

3.Wipetheairltercover(Figure19)sothatitis

clean.

CleaningtheFoamFilter

1.Cleanthefoamlterelementinwarmsoapy

waterandrinsetheelementincleanwater,or

cleanthefoamlterelementinanonammable

solvent.

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

14

Page 15

2.Allowthefoamlterelementtocompletelydry.

3.Dipthefoamelementincleanengineoil,then

squeezeouttheexcessoil.

Note:Iftoomuchoilisleftinthefoamelement

whentheengineisstarted,theenginewill

smoke.Excessoilinthefoamelementmayalso

restricttheairowthroughtheelementandmay

reachthepaperlterandclogit.

4.Assemblethefoamelementontothepaperlter

element(Figure19).

InstallingtheAirFilter

1.Wipecleanthedirtfromthecarburetorbaseand

theinsideofthecoverwithamoistrag(Figure

19).

Note:Donotallowdirtanddebristoenterthe

airductleadingintothecarburetor.

2.Ensurethattherubbergasketisalignedand

seatedontothemountingbaseofthecarburetor

(Figure19).

Note:Therubbergasketmightsticktothe

bottomoftheoldpaperlterelement.Remove

itfromtheoldpaperelementandinstallitonto

thecarburetor.

3.Alignthepaperlterelementwiththecarburetor

andensurethatthehold-downrodofthe

carburetorpassesthroughthetopplateofthe

lter(Figure19).

4.Securetheltertothecarburetorwiththelter

wingnutandtightenitngertight(Figure19).

5.Aligntheair-ltercoverovertheairlter

elementswiththehold-downrodofthe

carburetorpassingthroughthetopcover(Figure

19).

6.Securethecovertotheenginewiththecover

wingnutandtightenitngertight(Figure19).

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Movethefuel-shutoffvalvetotheOFFposition.

4.RemovethesedimentcupandO-ring(Figure6).

Figure20

1.Fuel-shutoffvalve(OFF

positionshown)

2.O-ring

5.Washthesedimentcupinanonammable

solventanddryitthoroughly.

6.PlacetheO-ringinthefuelvalveandinstallthe

sedimentcup,tighteningitsecurely.

7.Movethefuel-shutofflevertotheOnposition.

3.Sedimentcup

Note:Ifanyfuelleaks,repeatthisprocedure

andreplacetheO-ring.

g025917

CleaningtheSedimentCup

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Setthethrottletoslow,shutofftheengine

andkeepheat,sparks,andameaway .

•Handlefuelonlyoutdoors.

•Wipeupspillsimmediately.

•Donotsmokewhilehandlingfuel.

15

Page 16

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorhigher)

Oilcrankcasecapacity:

•0.56L(0.59USqt)forModel68025

•0.58L(0.61USqt)forModels68026and68027

Viscosity:Seetablebelow

Figure21

ChangingtheEngineOil

g019692

Figure22

1.Drainplug

Note:Y oumayhavetotipthecompactor

g013375

backwardstodraintheoil.

4.Whentheoilhasdrainedcompletely ,replace

theplug.

Note:Disposeoftheusedoilatacertied

recyclingcenter.

ServiceInterval:Aftertherst25hours

Every100hours

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury .

Avoidcontactingthehotengineoilwhenyou

drainit.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug.

3.Removethedrainplug(Figure22).

5.Removethedipstick(Figure7)andslowlypour

oilintothellerholeuntiltheoilpoursoutofthe

llerhole.

6.Replaceandsecurethedipstick.

7.Wipeupanyspilledoil.

16

Page 17

ServicingtheEccentricOil

ChangingtheEccentricOil

Oiltype:10W30(APIserviceSJorhigher)

Oilcapacity:

•1.3L(1.4USqt)forModel68025

•3.3L(3.5USqt)forModel68026

•3.5L(3.7USqt)forModel68027

CheckingtheEccentric-OilLevel

ServiceInterval:Monthly

1.Setthethrottletoslow,shutofftheengine,and

waitforallmovingpartstostop.

2.Placeadrainpanundertheoilplugandremove

theoil-plugscrewonthesideoftheeccentric

housing(Figure23).

ServiceInterval:Every300hours

1.Setthethrottletoslow,shutofftheengine,and

waitforallmovingpartstostop.

2.Placeanoildrainpanundertheoilplugand

removethellplugandtheoilplugscrew

(Figure23).

3.Tiptheplatecompactorforwardslightlyanduse

asuctionguntoremovetheoilthroughtheller

hole(Figure23).

4.Slowlypouroilintothellerholeuntiltheoil

comesouttheoilplug(Figure23).

5.Wipeupanyspilledoil.

6.Replacethellplugandtheoilplugscrew.

Figure23

1.Oilplug2.Eccentric-oil-llerhole

3.Verifythattheeccentricoilislevelwiththebolt

hole.

4.Wipeupanyspilledoil.

5.Replacetheoil-plugscrew.

g020132

17

Page 18

BeltMaintenance

RemovingtheBeltCover

1.Removetheanged-headboltsthatsecurethe

beltcovertotheengine(Figure24orFigure25).

Figure24

Model2200

1.Boltlocations2.Flanged-headbolt

CheckingtheBeltTension

ServiceInterval:Every100hours

Important:Thebestbelttensionforthemachine

isthelowesttensionatwhichthebeltsdonotslip

underfullpower.

1.Layastraightedgeonthebeltandacrossthe

pulleys(Figure26).

g027329

g024879

Figure26

Figure25

Model3000/4000

1.Boltlocations2.Flanged-headbolt

2.Removethebeltcover.

1.Straightedge2.Beltdeected7.6mm(0.3

inch)at1.4to2.3kg(3to

5lb)offorce

2.Withaforcegauge,pushdownonthebelt,

midwaybetweenthepulleys(Figure26).

Note:Thebeltshoulddeect7.6mm(0.3inch)

fromthestraightedgewhenpushingdownon

thebeltwith1.4to2.3kg(3to5lb)offorce

(Figure26).

Note:Ifthebelttensionistoolowortoohigh,

adjustthebelttension;refertoAdjustingtheBelt

g027330

Tension(page19).

18

Page 19

AdjustingtheBeltTension

1.Removethewatertank;refertoAddingWater

withtheT ankRemoved(page10).

2.Loosenthe2hex-socketbolts(5/16-24x1.75

inches)thatsecurethefrontoftheengine

(Figure27).

Figure27

1.Hex-socketbolts(5/16-24x1.75inches)

8.Tightenthe2angenuts(8mm)thatsecurethe

backoftheengineto23to29N∙m(17to21

ft-lb)asshowninFigure28.

9.Applymedium-gradethread-lockingcompound

tothethreadsoftheanged-headboltsthatyou

removedinstep1ofRemovingtheBeltCover

(page18).

10.Alignthebeltcovertothemachineandsecure

thecoverwiththeanged-headboltsthatyou

removedinstep1ofRemovingtheBeltCover

(page18).

11.Torquetheboltsto972to1198N∙cm(86to106

in-lb).

g024877

3.Loosenthe2angenuts(8mm)thatsecurethe

backoftheengine(Figure28).

Figure28

1.Flangenuts(8mm)

2.Belt-tensioningbolt

4.Loosenthejamnut,androtatethe

belt-tensioningboltclockwisetotension

thebelt,orrotatethebelt-tensioningbolt

counterclockwisetoloosenthetensiononthe

belt(Figure28).

g024878

5.Checkthebelttension;refertoCheckingthe

BeltT ension(page18).

6.Whenthecorrecttensionisreached,tightenthe

jamnutonthebelt-tensioningbolt.

7.Tightenthe2hex-socketbolts(5/16-24x1-3/4

inches)thatsecurethefrontoftheengineto

12.5to16.4N∙m(9.2to12.1ft-lb)asshownin

Figure27.

19

Page 20

Storage

1.Shutofftheengineanddisconnectthe

spark-plugwirefromthesparkplug.

2.Removedirtandgrimefromtheentiremachine.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressure

washthemachine.Avoidexcessiveuseof

water,especiallyneartheengine.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page14).

4.Changetheengineoil;refertoChangingthe

EngineOil(page16).

5.Forstorageover30days,preparetheunitas

follows:

A.Addapetroleum-basedfuel

stabilizer/conditionertofuelinthe

tank.Followmixinginstructionsfrom

stabilizermanufacturer(1ozpergallon).

Donotuseanalcohol-basedstabilizer

(ethanolormethanol).

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfueland

usedatalltimes.

B.Runtheengineuntilitstopsfromrunning

outoffuel.

C.Choketheengine.

D.Startandruntheengineuntilitdoesnot

startagain.

E.Disposeoffuelproperly.Recycleasper

localcodes.

Important:Donotstore

stabilizer/conditionedfuelover90days.

6.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamaged.

7.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

8.Storethemachineinaclean,drygarageor

storagearea.

9.Coverthemachinetoprotectitandkeepitclean.

20

Page 21

Troubleshooting

Problem

Theenginedoesnotstart,startshard,or

failstokeeprunning.

Theplatedoesnotvibrateatfullspeed.

Theclutchisextremelyhot.

Theplatedoesnotvibratewhenthe

engineisrunning.

Thereisinsufcientwaterow.

PossibleCauseCorrectiveAction

1.Thefueltankisempty.1.Fillthefueltankwithfuel.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

3.Theaircleanerisdirty.

1.Theoillevelintheeccentrichousing

istoohigh.

2.Thebeltisloose.2.Adustthebelttension.

1.Aforeignobjectislodgedagainstthe

eccentricsheave.

2.Theoillevelintheeccentrichousing

istoohigh.

3.Theclutchhasslipped.3.Adjustthecarburetor.

4.Engineisnotreachingfullspeed.

1.Thebeltisbroken.1.Replacethebelt.

2.Theclutchisbrokenorwornout.2.Replacetheclutch.

3.Theeccentrichasseized.

1.Thewatertankisempty.1.Fillthewatertank.

2.Thesprinklerisclosed.

3.Thesprinklermanifoldisclogged.3.Removeandcleanthemanifold.

2.Installanew,correctlygappedspark

plug.

3.Cleanorreplacetheaircleaner

elements.

1.Checktheoillevelanddrainas

necessary.

1.Removetheobstruction.

2.Checktheoillevelanddrainas

necessary.

4.Adjustthethrottlesotheengineruns

at3,400rpm.

3.Ensuretheeccentricisfreeturning.

2.Openthesprinklervalve.

21

Page 22

Notes:

Page 23

Notes:

Page 24

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproductsAdditionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerwithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover ,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...