Page 1

FormNo.3382-965RevA

G021 119

MMX-1158H-SMortarMixer

ModelNo.68023C—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3382-965*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

1-800-424-9153);gotohttp://www.safercar.gov;orwrite

to:Administrator,NHTSA,1200NewJerseyAvenue,

SEWestBuilding,Washington,DC20590.Youcanalso

obtainotherinformationaboutmotorvehiclesafetyfrom

http://www.safercar.gov.

•TocontactTransportCanada,youmaycall

1-800-333-0510or(819)994-3328;goto

http://www.tc.gc.ca/roadsafety/;writeto:Road

SafetyandMotorVehicleRegulationDirectorate,

TransportCanada,TowerC,PlacedeVille,330

SparksStreet,Ottawa,Ontario,K1A0N5;oremail

RoadSafety@tc.gc.ca.

Introduction

Thismachineisdesignedtomixmortar,plaster,reproong

material,grout,andothersmall-grainedcementproducts.A

vehicleequippedwithanappropriatepintlehitchorballhitch

cantowthemachine..

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Ifyoubelievethatyourmachinehasadefectwhichcould

causeacrashorcouldcauseinjuryordeath,youshould

immediatelyinformtheNationalHighwayTrafcSafety

Administration(NHTSA)ifyouliveintheUnitedStates,

orTransportCanadaifyouliveinCanada,inadditionto

notifyingTheToroCompany.

IfNHTSAorTransportCanadareceivessimilarcomplaints,

itmayopenaninvestigation,andifitndsthatasafetydefect

existsinagroupofmachines,itmayorderarecallandremedy

campaign.However,NHTSAorTransportCanadacannot

becomeinvolvedinindividualproblemsbetweenyou,your

dealer,orTheToroCompany.

Engine Owner's Man ual

issuppliedfor

•TocontactNHTSA,youmaycalltheV ehicle

SafetyHotlinetoll-freeat1-888-327-4236(TTY:

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

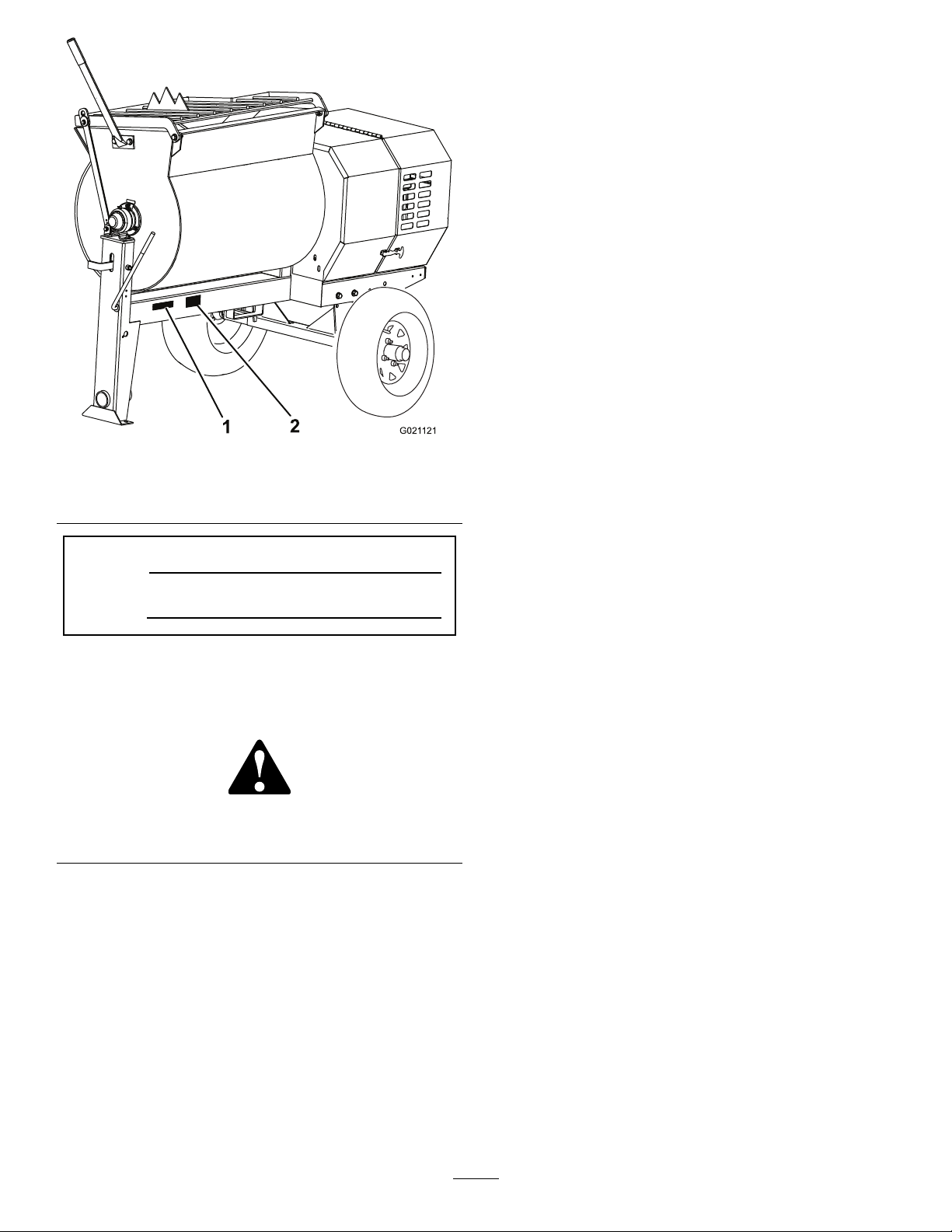

2

1

G021 121

Figure1

1.Modelandserialnumber

location

ModelNo.

SerialNo.

2.Vehicleidentication

number(VIN)location

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

TheDOTtireinformationislocatedonthesideofeachtire.

Thisinformationgivesloadandspeedratings.Replacement

tiresshouldhavethesameorbetterratings.

Note:Referto

Specications(page12)andensurethatall

replacementtiresmeetorexceedtheratingsforthismachine.

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

SafetyandInstructionalDecals.................................7

Setup............................................................................8

1InstallingtheDumpHandle...................................8

2InstallingtheTowPole..........................................8

3InstallingtheSafetyChain......................................9

ProductOverview.........................................................10

Controls...............................................................10

Specications........................................................12

Operation....................................................................12

PreparingtoT owtheMachine..................................12

ExtendingtheAxle.................................................16

TowingtheMachine...............................................17

PreparingtoUsetheMachine...................................17

OpeningandClosingtheCowl.................................17

AddingFuel...........................................................18

CheckingtheEngineOilLevel.................................19

StartingandStoppingtheEngine..............................20

ControllingthePaddles...........................................21

MixingtheMaterial.................................................21

UsingtheDrum.....................................................22

AdjustingthePaddleBlades.....................................23

Maintenance.................................................................24

RecommendedMaintenanceSchedule(s)......................24

PremaintenanceProcedures........................................25

PreparingtheMachineforMaintenance.....................25

DisconnectingtheSpark-plugWire...........................25

RemovingandInstallingtheDividerPlate..................25

Lubrication...............................................................26

LubricatingtheBearingsandSeals............................26

EngineMaintenance..................................................27

ServicingtheAirCleaner.........................................27

ChangingtheEngineOil.........................................28

ServicingtheSparkPlug..........................................29

ServicingtheSparkArrester.....................................30

RemovingandInstallingtheEngine..........................31

FuelSystemMaintenance...........................................32

ServicingtheFuelSystem........................................32

BeltMaintenance......................................................33

ServicingtheBelts..................................................33

ReplacingtheBelts.................................................34

AligningthePulleys................................................36

ReplacingtheLightBulbs............................................37

ReplacingtheRear-facingBulbs................................37

ReplacingtheSide-facingBulbs................................37

ReplacingtheSide-markerLightBulb........................37

Cleaning...................................................................38

CleaningtheMachine..............................................38

Storage........................................................................38

StoringtheMachine................................................38

Troubleshooting...........................................................40

3

Page 4

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans:

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

SafeOperatingPractices

Thismachineiscapableofamputatinghands.Alwaysfollow

allsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Machiningorhandlingstone,masonry,concrete,

metal,andothermaterialscangeneratedust,mists,

andfumescontainingchemicals,suchassilica,

knowntocauseseriousorfatalinjuryorillness,

suchasrespiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Usewaterfordustsuppression,

whenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufacturer

orsupplier,CCOHS,OSHA,andother

occupationalandtradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyCCOHSor

OSHAforthematerialbeinghandled.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

Caution

,

W ar ning

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

,

property.

Towing

Checkwithyourlocalcountyorstatetowingsafety

regulations,inadditiontomeetingTransportCanada(or

DepartmentofTransportationifintheU.S.)towingsafety

regulations,beforetowingthemachine.

•Inordertoreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,makesurethat

thetowingvehicleismechanicallysoundandingood

operatingcondition.

•Shutdowntheenginebeforetransportingthemachine.

•Whentowingwithaballhitch,ensurethattheballhitch

youareusingisthepropersizeforthehitchcoupleron

themachine.

•Whentowingwithapintlehitch,ensurethattheeyeof

thetowpoleisthecorrectdimensionforthepintlehook.

•Inspectthehitchandcouplingforwear.Nevertowthe

machinewithdamagedordefectivehitches,couplings,

chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicleandthe

machine.

•Checkthetiretreadandsidewallfordamageandwear.

•Properlyattachthesafetychainstothetowingvehicle.

•Ensurethatthedirectionalandbrakelightsareworking

properly.

•Ensurethatthedirectional,backup,andbrakelightsof

thetowvehicleareworkingproperly.

•Beforetowingchecktomakecertainthatyourmachineis

correctlyandsecurelyattachedtothetowingvehicle.

•Ensurethatthesafetychainsareproperlysecuredtothe

vehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhentowing.

•Avoidsuddenstopsandstarts.Thiscancauseskidding,

orjackkning.Smooth,gradualstartsandstopswill

improvetowing.

•Avoidsharpturnstopreventrolling.Towonlywitha

vehiclethathasahitchdesignedfortowing.Donot

attachtowedequipmentexceptatthehitchpoint.

•Donottowthemachinefasterthan88km/h(55mph).

•Usecautionwhenbackingup;useaspotteroutsidethe

vehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehiclebefore

usingit.

•Placechockblocksunderneaththetirestopreventthem

fromrollingwhilethemachineisparked.

4

Page 5

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Wearpersonalprotectiveequipmentandappropriate

clothingincluding:

–Hardhat

–Respiratorordustmask

–Faceshield

–Safetyglasses

–Hearingprotection

–Safetyshoes

–Longpants

–Shirtwithlongsleevesbuttonedatthewrists

–Tight-ttinggloveswithoutdrawstringsorloosecuffs

•Securelonghair,looseclothing,orjewelrythatmayget

tangledinmovingparts.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andthevaporsareexplosive.Usethefollowingpractices

whenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

–Replacethefuelcapandtightenitsecurely .

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Iffuelisspilled,wipeitofftheengineandequipment.

•Ensurethatthemachineisonalevelsurfacebefore

operatingthemachine.

•Chockthetiresofthemachinetopreventunintended

movement.

•Beforeeveryuse:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly(if

equippedwithalightkit).

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

Operation

•Neverrunanengineinanenclosedorpoorlyventilated

area.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Shutofftheenginebeforeleavingthemachineforany

reason.

Neverleavearunningmachineunattended.Alwaysstop

theengineandverifythatallmovingpartshavestopped.

•Chockthetiresofthemachineorkeepitattachedtothe

towingvehiclewhenitisnotinuse,topreventitfrom

rolling.

•Avoidprolongedbreathingofexhaustfumes.Engine

exhaustfumescancausesicknessordeath.

•Keephandsawayfromanymovingparts.Keepfeetaway

fromthetiresandthefrontpost.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Ensurethattheareaisclearofotherpeopleorpetsbefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverplaceyourhandsoranysolidobjectintothedrum

whenthemachineisinoperation.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Nevermovethemachinewhiletheengineisrunning.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•Disconnectthespark-plugwireandkeepitawayfromthe

sparkplugtopreventaccidentalstartingwhileadjusting

themachine.

•Ifthemixingpaddlesstrikeaforeignobjectorifthe

machineshouldstartmakinganunusualnoiseor

vibration,stoptheengineandemptythedrum.Waitfor

allmovingpartstocometoacompletestopandcool.

Vibrationisgenerallyawarningoftrouble.Disconnect

thespark-plugwireandinspectforcloggingordamage.

Cleanandrepairand/orreplacedamagedparts.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

5

Page 6

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonlevelground.

–Stoptheengine.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

–Lettheenginecoolbeforeperformingmaintenance

orstoring.

–Removethespark-plugwirebeforemakingany

repairs.

–Disengageallpowerandoperationcontrols.

•Neverlubricate,service,repair,oradjustthemachine

whileitisrunning.

•Keepequipmentmaterialsclearfromthemuferand

enginetohelppreventres.Cleanupanyoilorfuel

spillage.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Stopandinspectthemachineifaforeignobjectentersthe

drumorcausesanotherobstruction.Makeanynecessary

repairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Chockthetireswhenstoringthemachine.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•UseonlygenuineTororeplacementpartstoensurethat

theoriginalstandardsaremaintained.

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117–2718

125–8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

125–8216

2.Warning—limittowing

speedtolessthan55mph

/88km/h.

1.Warning—readthe

Operator’sManual.

2.Handandarm

entanglementatthe

beltdrive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keephandsaway

frommovingparts;keep

allguardsandshieldsin

place.

3.Entanglementhazardat

paddles—stoptheengine

andwaitforallmoving

partstostopbefore

performingmaintenance.

125–4939

4.Toxicgasinhalation

hazard—Don’trunthe

engineinanenclosed

space.

5.Explosionhazard—stop

theengineandkeep

awayfromameswhen

refueling.

7

Page 8

Setup

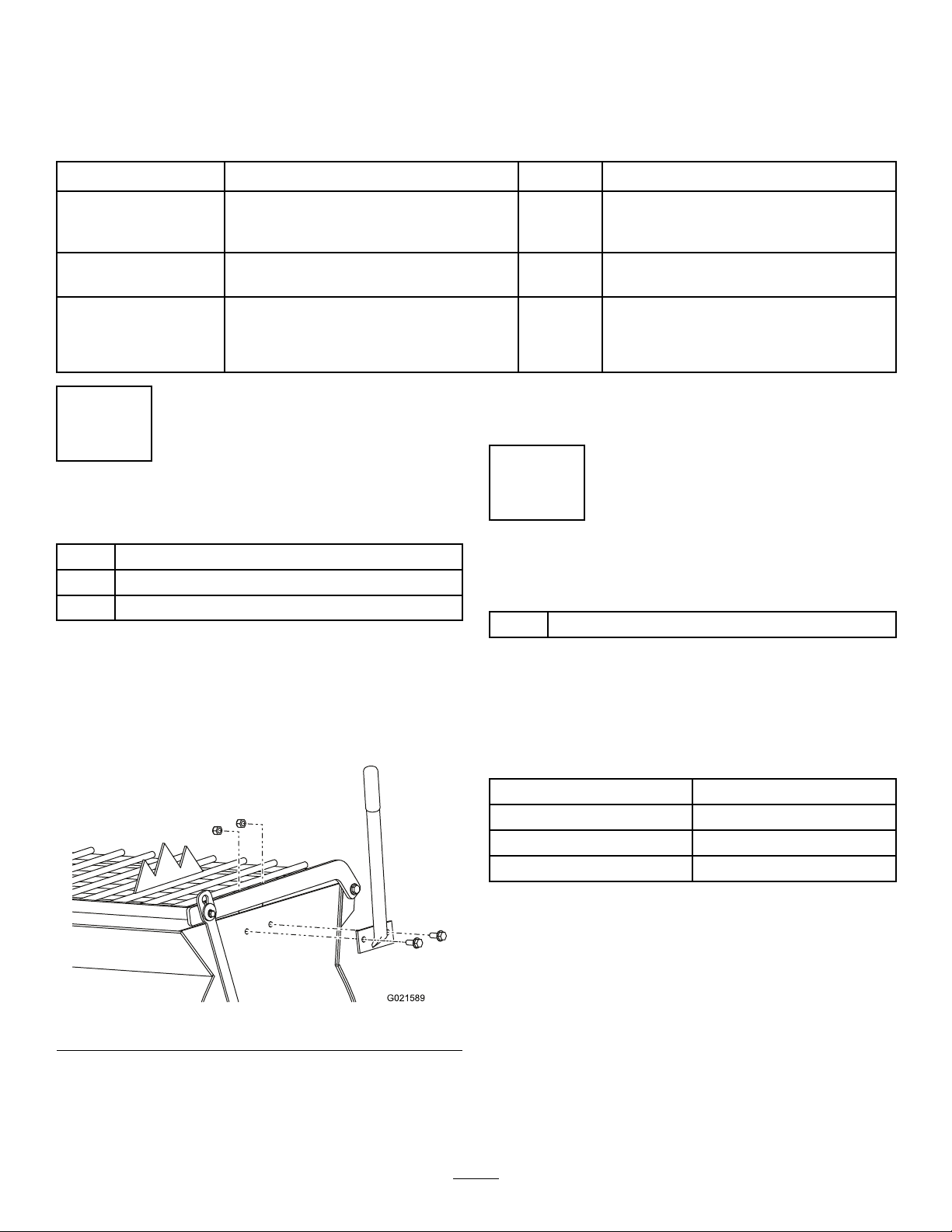

G021589

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

1

InstallingtheDumpHandle

Partsneededforthisprocedure:

1Dumphandle

2Bolt

2Nut

Dumphandle1

Bolt2

Nut2

Towpolekit(soldseparately)

Safetychain(includedwiththetowpole

kit)

Connectinglink(includedwiththetow

polekit)

5.Tightenthenutswithawrenchwhileusinganother

wrenchtokeeptheboltsfromspinning.

2

InstallingtheTowPole

Partsneededforthisprocedure:

1

Qty.

Installthedumphandle.

1Installthetowpole.

1

Installthesafetychain.

2

Towpolekit(soldseparately)

Use

InstallingtheDumpHandletotheDrum

1.Cutthecabletiestoremovethedumphandlefrom

theundersideofthegrate.

2.Positionthedumphandlesothattheboltholesalign

withtheboltholesinthedrum(

Figure3

3.Insertthe2boltsthroughtheboltholesinthedump

handleandthedrum(Figure3).

4.Installanutontoeachbolt,andtightenthembyhand

topreventcross-threading.

Figure3).

InstallingtheTowPoletotheMachine

Note:Thetowpoleispurchasedseparatelyandincludesthe

nutandboltneededforinstallation.

Themachinehasthefollowingtowpoleoptions:

HitchTypeLength

50mm(2inch)ball—stamped127cm(50inches)

50mm(2inch)ball—forged127cm(50inches)

Pintle

1.Removetheboltandnutfromthetowpole(Figure4).

127cm(50inches)

8

Page 9

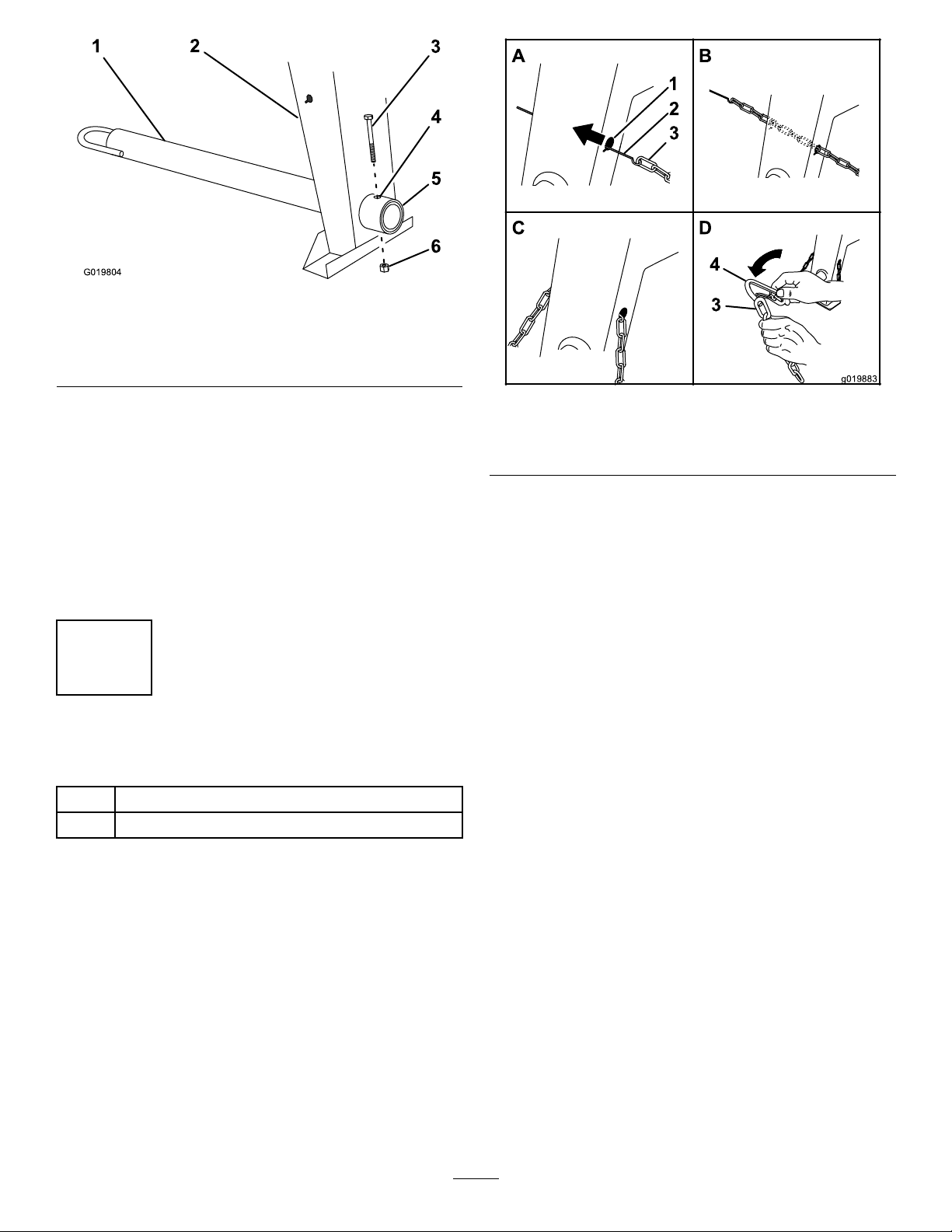

5

1

2

4

6

3

G019804

Figure4

A

B

D

g019883

2

3

4

3

1

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

5.Frametting

2.Slidethetowpoleforwardandaligntheholeinthe

polewiththeholeintheframetting(Figure4).

3.Inserttheboltthroughtheholesinthettingandthe

pole(Figure4).

4.Threadthenutontotheboltandtightenthemuntil

theyaretightagainsttheframetting(Figure4).

Note:Iftheself-lockingnyloninsertinthelocknut

wearswithuse,replacethenutwithanewGrade5or

Grade8locknut.

3

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain(includedwiththetowpolekit)

2

Connectinglink(includedwiththetowpolekit)

Figure5

1.Keyhole

2.Rodorwire(notincluded)4.Connectinglink

2.Attachthesafetychaintothelengthofrodorwire

(Figure5).

3.Pulltherod,orwire,andthesafetychainthroughboth

keyholes(Figure5).

Note:Ensurethatapproximatelyequallengthsof

safetychainextendfromeithersideofthefrontpost.

3.Safetychain

InstallingtheConnectingLinks

1.Aligntheconnectinglinktothelastlinkinoneendof

thesafetychain(Figure5).

2.Inserttheconnectinglinkthroughthechainlinkuntil

theconnectinglinksnapsclosed(Figure5).

3.Repeatsteps1and2toinstalltheotherconnectinglink

intheotherendofthesafetychain.

InstallingtheSafetyChaintothe

Machine

1.Formahookontheendofabendablepieceofrod

orstiffwire(notincluded),andinsertitthroughboth

keyholesinthefrontpostofthemachine(Figure5).

9

Page 10

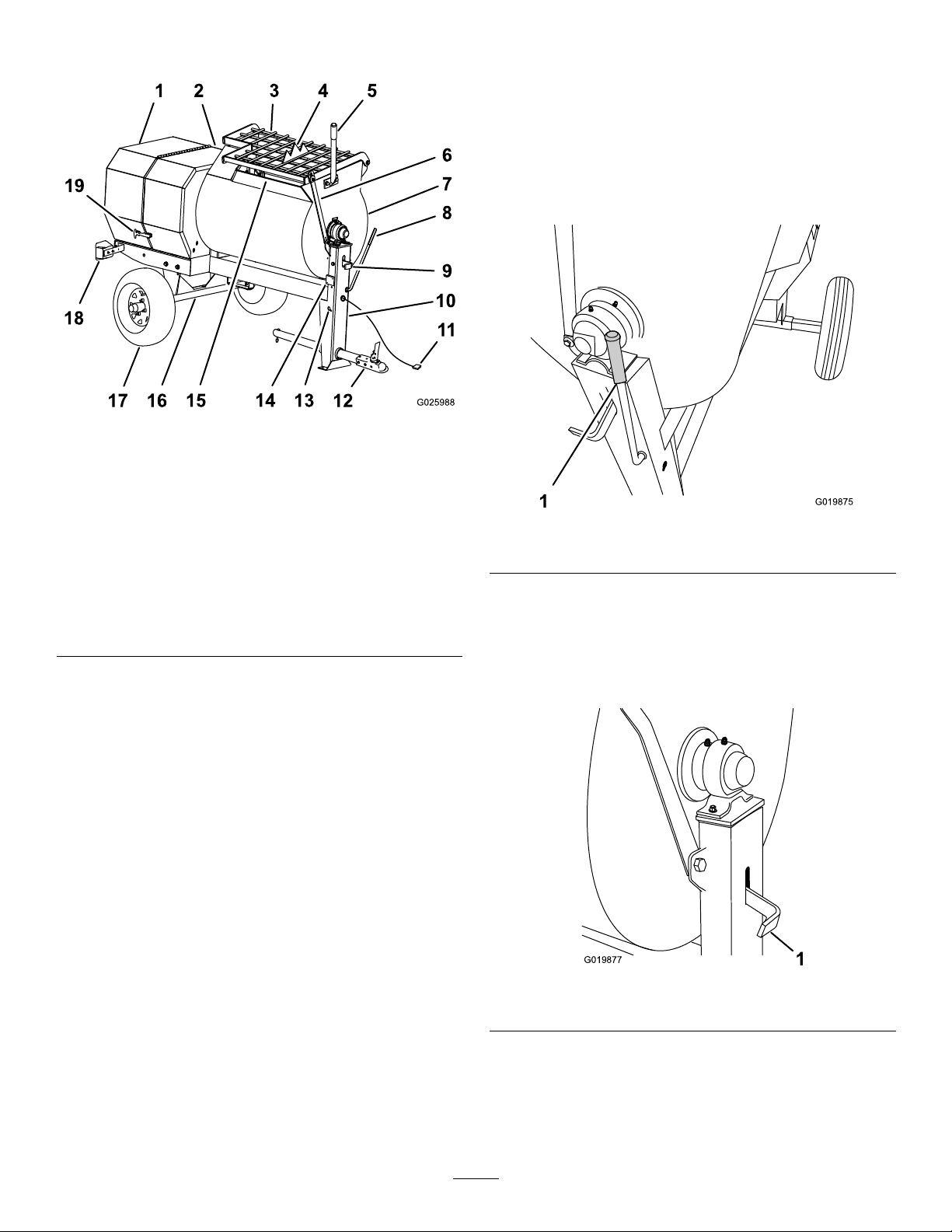

ProductOverview

G019875

1

1

G019877

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

ClutchLever

Theclutchlever(Figure7)engagesanddisengagesengine

powertothepaddles.

Figure6

1.Rearcowl

2.Frontcowl9.Drumlatch16.Axle

3.Grate

4.Bagsplitter11.Lighting-wiring

5.Dumphandle12.Towpole

6.Gratelifterarm13.Safety-chain

7.Drum

8.Clutchlever15.Chute

10.Frontpost17.Wheel

harness

keyhole

14.Side-marker

light(2)

assembly

18.Trailerlight(2)

19.Cowllatch

Figure7

1.Clutchlever

DrumLatch

Thedrumlatch(Figure8)securesthedrumtothe

mixposition(upright)formixingoperationsandwhen

transportingthemachine.

Figure8

1.Drumlatch

10

Page 11

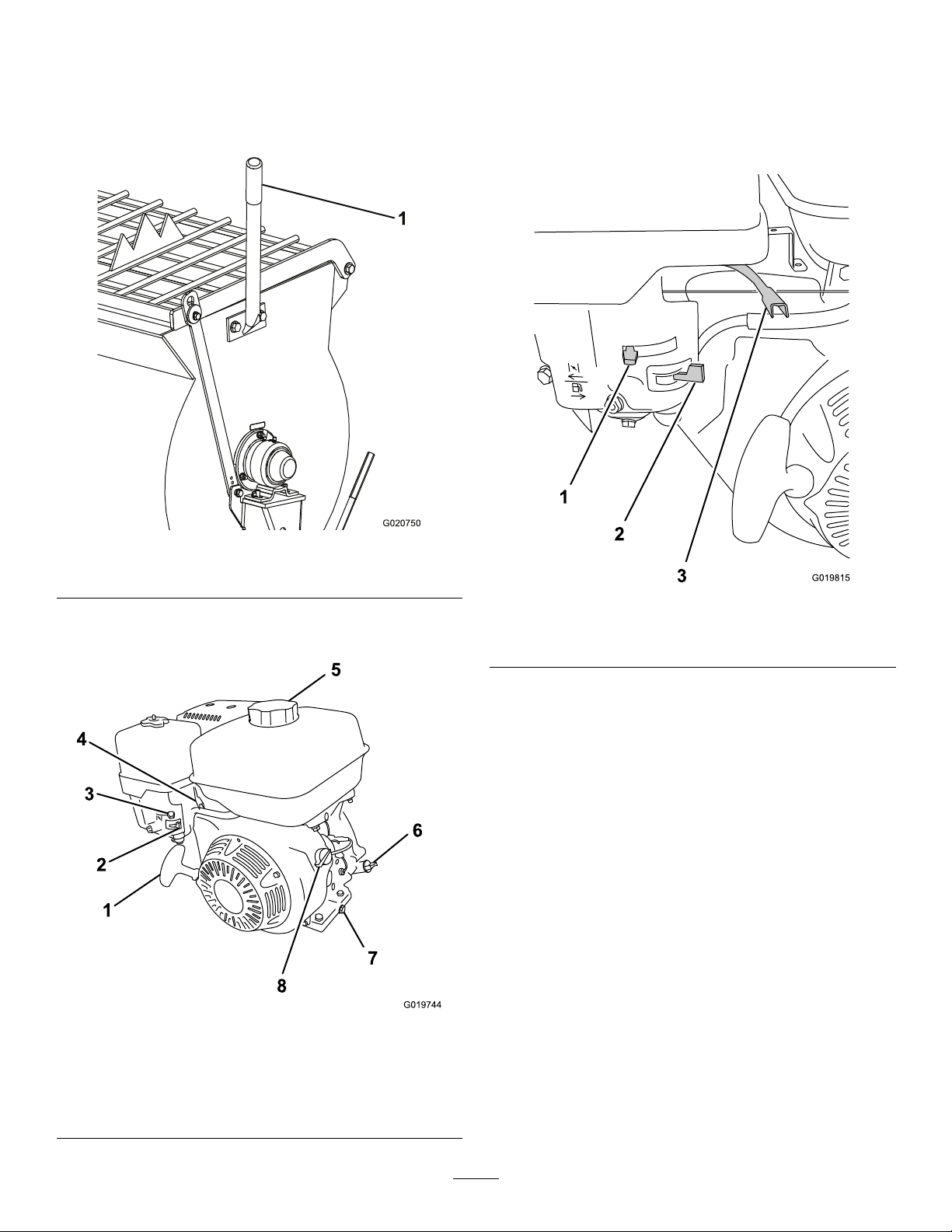

DumpHandle

G020750

1

1

2

3

4

5

6

7

8

G019744

G019815

1

2

3

FuelValve

Thedumphandle(Figure9)allowstheoperatortorotate

thedrumbetweenthedumppositionandthemix(upright)

position.

Thefuelvalve(Figure11)islocatedunderneaththechoke

lever.MovetheleverforthefuelvalvetotheOnposition

beforeattemptingtostarttheengine.Whenyouhavenished

mixing,stoptheengineandmovethefuelvalvelevertothe

Offposition.

Figure9

1.Dumphandle

Figure11

1.Chokelever

EngineControls

2.Fuelvalve

3.Throttlelever

ChokeLever

Thechokelever(Figure11)isrequiredwhenstartinga

coldengine.Beforepullingontherecoil-starthandle,move

thechokelevertotheclosedposition.Oncetheengineis

running,movethechokelevertotheopenposition.Do

notusethechokeiftheengineisalreadywarmeduporthe

airtemperatureishigh.

ThrottleLever

Thethrottlelever(Figure11)controlsthespeed(rpm)ofthe

engine.Itislocatednexttothechokelever.Itsetstheengine

speedandthereforecanincreaseanddecreasetherotation

speedofthemixingpaddles.Forbestperformance,setthis

controltothefastpositionwhenmixingmaterial.

1.Recoil-starthandle5.Fuelcap

2.Fuelvalve

3.Chokelever7.Oil-drainplug

4.Throttlelever

Figure10

6.Oilcap/dipstick

8.On/Offswitch

EngineOn/OffSwitch

TheOn/Offswitch(Figure12)allowstheoperatorofthe

machinetostartandstoptheengine.Thisswitchislocated

onthefrontoftheengine.RotatetheOn/Offswitchtothe

Onpositiontostartandruntheengine.RotatetheOn/Off

switchtotheOffpositiontostoptheengine.

11

Page 12

OFF

ON

1

OFF

ON

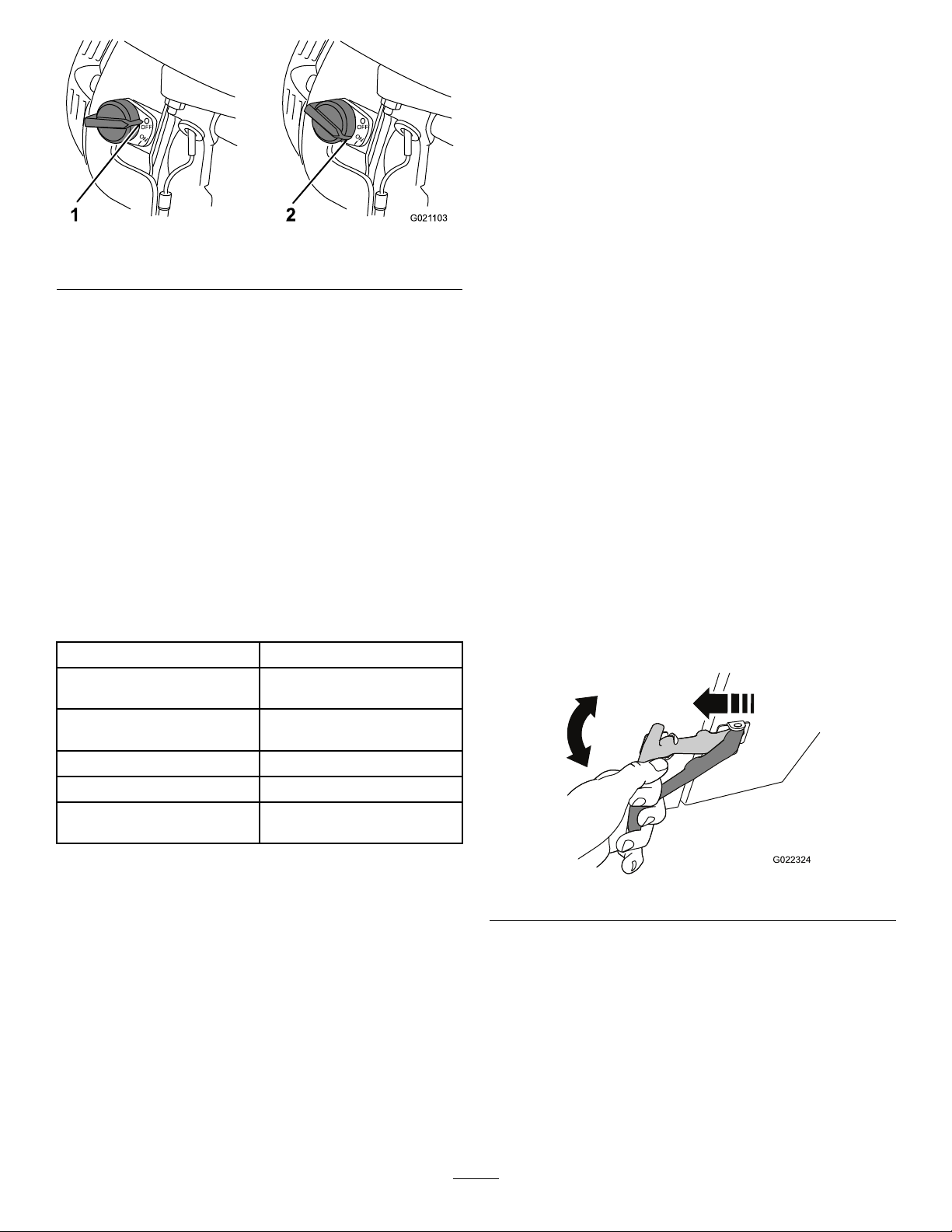

G021 103

2

Operation

G022324

Important:Beforeoperating,checkthefuelandoil

levels,andremovedebrisfromthemachine.Ensurethat

theareaisclearofpeople.

PreparingtoTowtheMachine

Figure12

1.Offposition2.Onposition

Recoil-startHandle

Tostarttheengine,pulltherecoil-starthandle(Figure10)

quickly.Ensurethattheenginecontrolsdescribedaboveare

allsetcorrectlyfortheenginetostart.

Oil-levelSwitch

Theoil-levelswitchislocatedinsidetheengine,andit

preventstheenginefromrunningiftheoillevelisbelowthe

safeoperatinglimit.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

BatchCapacity0.31cubicm(11.1cuft)

Length

(withtowpole)

Width

255cm(101inches)

122cm(48inches)

Important:Ensurethatyourtowvehiclehastowing

capacityfortheweightofthemachine.

Important:UseaClass2orlargerreceiver.

Note:Ensurethatyourtowvehiclehastheappropriatehitch

totowthemachine;optionsincludea50mm(2inch)ball

hitchorapintlehitch.

Note:Ensurethattheelectricalconnectorofthetowvehicle

iscompatiblewiththeelectricalconnectorofthemachine.

Themachineusesastandard4-atplug.Ifyourtowvehicle

hasadifferenttypeofplug,obtainanadapterfroman

automotivepartsstore.

1.Ensurethattheengineisstopped,thefuelvalveisoff,

andthedrumisempty.

2.Ifthedrumhasaccumulatedanywater,dumpthe

drum;refertoDumpingtheDrum(page22),steps1,

3,4,and5.

3.Usingthedumplever,positionthedrumsothatitisin

themixposition(upright)andlocked.

4.Closetheenginecowlandsecurethecowllatches

(Figure13).

Height

Weight

Axle

(extendable)

173cm(68inches)

389kg(860lb)

91to119cm(36to47inches)

Figure13

5.Extendtheaxle;refertoExtendingtheAxle(page16).

12

Page 13

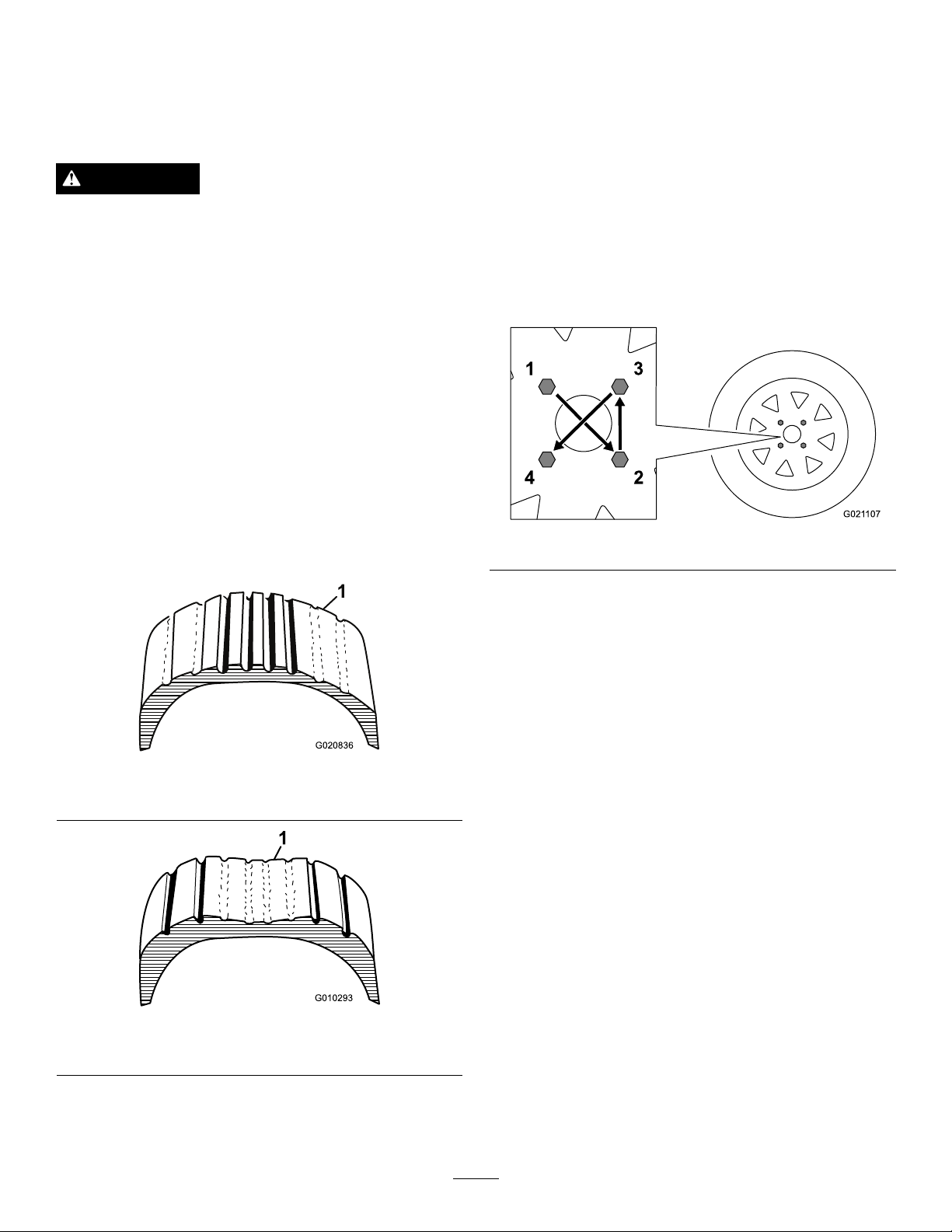

CheckingtheTiresandWheels

G020836

1

2

3

4

G021 107

AirPressure:Max241kPa(35psi)

ServiceInterval:Beforeeachuseordaily—Inspectthetires

andwheels.

Aftereachuse—Torquethelugnutsto108to122

N-m(80to90ft-lb)aftertowing.

WARNING

Failuretomaintaincorrecttirepressuremayresult

intirefailureandlossofcontrol,resultingin

propertydamageandseriousinjuryordeath.

•Checkthetirepressurefrequentlytoensure

properination.Ifthetiresarenotinatedto

thecorrectpressure,theywillwearprematurely.

•Inspectthetireconditionbeforetowingand

afteranyoperatingaccident.

TheDOTtireinformationislocatedontheside

ofeachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note:Referto

replacementtiresmeetorexceedtheratingsforthismachine.

1.Visuallyinspectthetiresfordamageandwear(

14andFigure15)

Specications(page12)andensurethatall

Figure

Important:Alwayschecktheinformation

ontheactualtiresforthecorrectairpressure

requirement.

Important:Themostcommoncauseoftire

troubleisunderination.Maintainfullair

pressure.

3.Ensurethatthewheellugnutsaretorquedto108to

122N-m(80to90ft-lb).Checkthetorqueofthe

wheellugnutsinitiallyandaftertowing.

Note:Torquethelugnutsinthesequenceshownin

Figure16.

Figure16

1.Exampleoftirewearcausedbyunderination

1.Exampleoftirewearcausedbyoverination

2.Ensurethatthetiresareinatedtothecorrectair

pressure.Thefollowingratingindicatestheappropriate

airpressureforthetiresasinstalledatthefactory.

Figure14

Figure15

13

Page 14

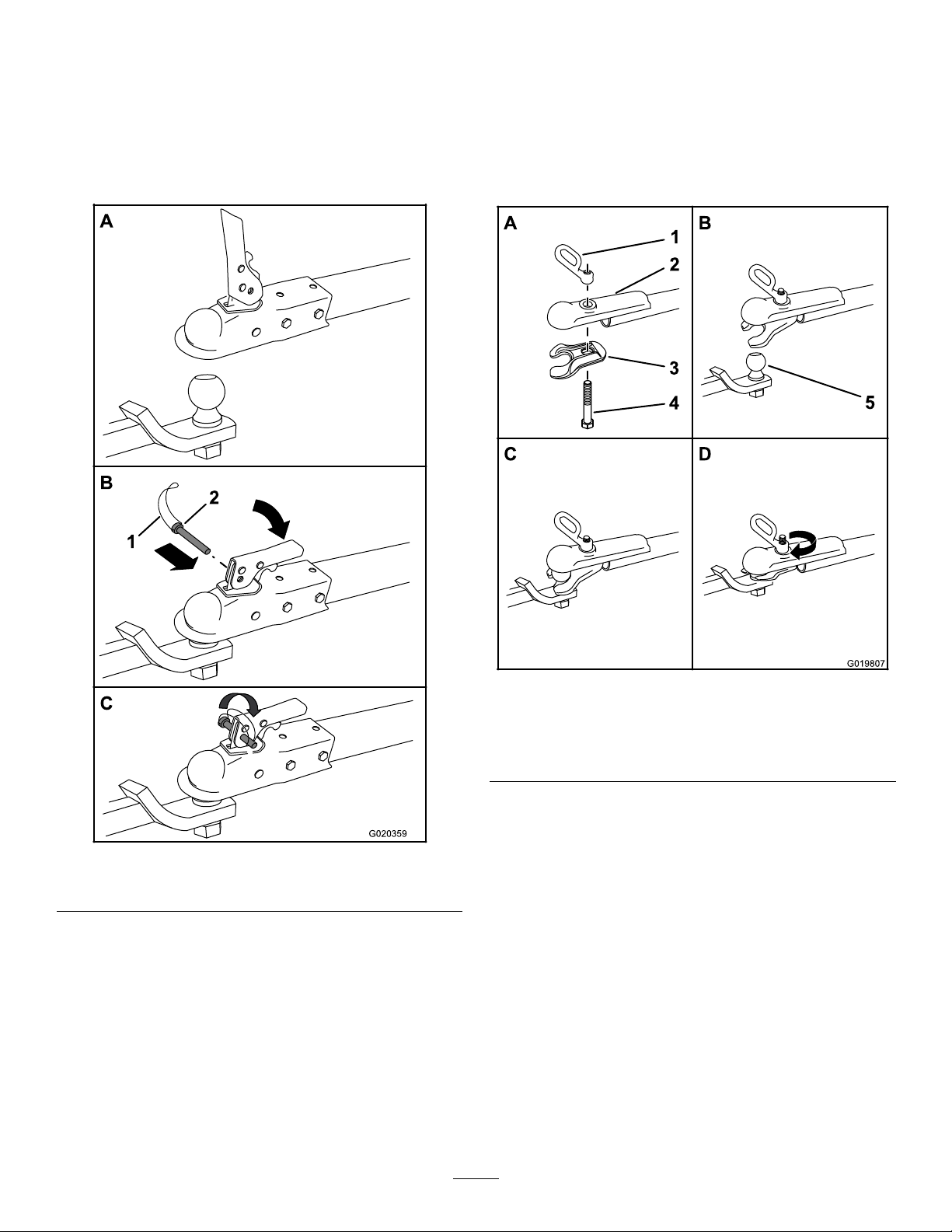

HitchingaMachinewithaStampedBall

A

B

C

G020359

2

1

A

B

D

G019807

5

1

2

3

4

Coupler

HitchingaMachinewithaForgedBall

Coupler

1.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.Oilthe

pivotpointsandslidingsurfacesofthecouplerwith

SAE30motoroil.

2.Openthecouplerlatch(

Figure17).

1.Applyremovablethread-lockingcompoundtothe

threadsofthecouplerbolttopreventthecoupler

handlefromcomingloose(Figure18).

Important:Applythread-lockingcompoundas

neededinthefuture.

Figure17

1.Bail

3.Positionthecouplerontopofthehitchball(Figure17).

4.Closethecouplerlatch(Figure17).

5.Openthebailonthesafetypinandinsertthepin

throughtheholeinthelatch(Figure17).

6.Rotatethefreeendofthebailovertheendofthesafety

pinthatisprotrudingthroughthelatch(Figure17).

7.Connecttheplugofwiringharnessforthetowvehicle

intotheplugofthewiringharnessforthemachine;

referto

16)

ConnectingtheLighting-wiringHarness(page

.

2.Safetypin

Figure18

1.Couplerhandle

2.Coupler

3.Clamp

4.Bolt

5.Hitchball

2.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.

3.Pushthecouplerboltupthroughthecouplerclamp

andthecouplertop,andconnectthecouplerhandleto

thebolt(

Figure18).

4.Positionthecouplersothesocketisontopofthehitch

ballandtheclampisundertheball.

5.Turnthecouplerhandleclockwisetothreaditontothe

boltuntilitissecure(Figure18).

Note:Useawrenchtokeeptheboltfromspinning.

6.Connecttheplugofwiringharnessforthetowvehicle

intotheplugofthewiringharnessforthemachine;

referto

ConnectingtheLighting-wiringHarness(page

16).

14

Page 15

HitchingaMachinewithaPintleHitch

G019809

1

2

3

G021 177

G021 178

1

2

3

TowPole

1.Removethepinfromthepintlehitchandopenit

(Figure19).

isjustenoughslackoneachsideforturningaround

cornerswhentowingthemachine

Figure20).

Note:Stowtheexcesschaininsidethebottomofthe

frontpostbypushingitintothekeyholes.

2.Crossbothlengthsofchainunderthetowpole.

Note:Crossingthechainsdecreasesthechancesof

thefrontofthemachinedroppingtothegroundifthe

hitchmalfunctions.

Figure20

1.Connectinglinks3.Chaincrossedundertow

2.Keyholesinfrontpost

pole

3.Connecteachlengthofchaintothesafetychain

mountingpointonthetowvehiclewiththeconnecting

links(Figure21).

Figure19

2.Positiontheringonthetowpoleontothehookofthe

pintlehitch(Figure19).

3.Closethetopofthepintlehitchandsecureitwiththe

pin(Figure19).

4.Connecttheplugofwiringharnessforthetowvehicle

intotheplugofthewiringharnessforthemachine;

refertoConnectingtheLighting-wiringHarness(page

16).

ConnectingtheSafetyChainstothe

TowVehicle

Connectthesafetychaintothemachineandthetowvehicle

1.Connectinglink3.Chainlink

2.Safetychainmounting

pointontowvehicle

asfollows:

Figure21

1.Pullthesafetychainthroughtheslotsinthekeyholes

locatedinthefrontpostofthemachine,sothatthere

15

Page 16

ConnectingtheLighting-wiring

G020828

G0 2047 6

1

1 2

3

4

3

5

6

5

G020020

Harness

Connecttheelectricalplugofthemachinewiththeelectrical

plugofthetowvehicle,asshowninFigure22.

Figure22

AdjustingtheAxleWidth

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

themachineandcauseseriousinjury.

Usejackstandswhensupportingthemachine.

1.Alignajackwithanadequateliftheightandweight

capacityundertheaxle;refertoSpecications(page

12).

2.Liftthemachineuntilthetiresareofftheground.

Note:Themachineusesastandard4-atplug.Ifyourtow

vehiclehasadifferenttypeofplug,obtainanadapterfroman

automotivepartsstore.

Important:Routinelycheckthelightstoensurethat

theyareworkingproperly,includingthetaillights,brake

lights,andeachappropriateturnsignal.

CheckingtheLights

•Ensurethatthetaillightsandmarkerlightsofthemachine

illuminatewhenyouturnontheheadlightsoftowvehicle.

•Ensurethatthebrakelightsofthemachineilluminate

whenyoupressthebrakepedalofthetowvehicle.

•Ensurethattheappropriateturnsignalasheswhenyou

operatethecorrespondingturnsignalofthetowvehicle.

ExtendingtheAxle

WARNING

Themachineisnotstablewhentowingitwiththe

axleinthenarrowposition.

3.Useajackstandateachsupportpointontherear

frameextension(

1.Supportpoint(2)

4.Removetheboltsandnutsthatsecuretheinneraxleto

theouteraxle(Figure24).

Figure23).

Figure23

Towthemachinewiththeaxleinthewideposition.

Important:Adjusttheaxletothenarrowpositiononly

tomovethemachinethroughanarrowaccesspoint,

suchasthegateofafenceorthedoorwayofabuilding.

PreparingtoChangetheAxleWidth

1.Movethemachinetoaleveljob-sitesurface.

2.Disconnectthemachinefromthetowvehicle.

3.Chockthetires.

4.Ensurethatthedrumisemptyandinthemixposition

(upright).

5.Ensurethatthedrumlatchisengagedandthatthe

drumdoesnotrotatetowardthedumpposition.

Figure24

1.Wideposition(towing)4.Nut(narrowposition)

2.Narrowposition

3.Nut(wideposition)6.Bolt(narrowposition)

5.Aligntheinneraxletothedesiredpositionasfollows:

16

5.Bolt(wideposition)

Page 17

•Slideeachsideoftheaxleinwardtothenarrow

A B

C D

1

G022323

1 2

position(Figure24).

•Slideeachsideoftheaxleoutwardtothewide

(tow)position(

6.Aligntheholesoftheinneraxlewiththeholesofthe

outeraxle.

7.Inserttheboltsthroughtheaxleholes(

8.Threadthenutsontothebolts,andtorquethenuts

to87N-m(64ft-lb).

Figure24).

Figure24).

TowingtheMachine

WARNING

Towingthemachineathighspeedincreasesthe

riskofahitchmalfunctionandtirefailure.Higher

speedsalsoincreasethemomentumofthemachine

andbrakingdistance.Ifthemachinebecomes

detachedfromthetowvehicleathighspeed,it

couldcausedamagetoproperty,orinjuryordeath

tobystanders.

•Ensurethatthepaddlesareinplaceandingood

condition.

•Checkthefuelandoillevelsoftheengine.

•Whenpreparingtomixmaterial,dothefollowing:

1.Movethemachinetoaleveljob-sitesurface.

2.Removethemachinefromthetowvehicle.

3.Chockthefrontandbackofthetirestoprevent

themachinefrommoving.

4.Ensurethatthedrumisinthemixposition

(upright).

5.Ensurethatthedrumlatchisengagedandthatthe

drumdoesnotrotatetowardthedumpposition.

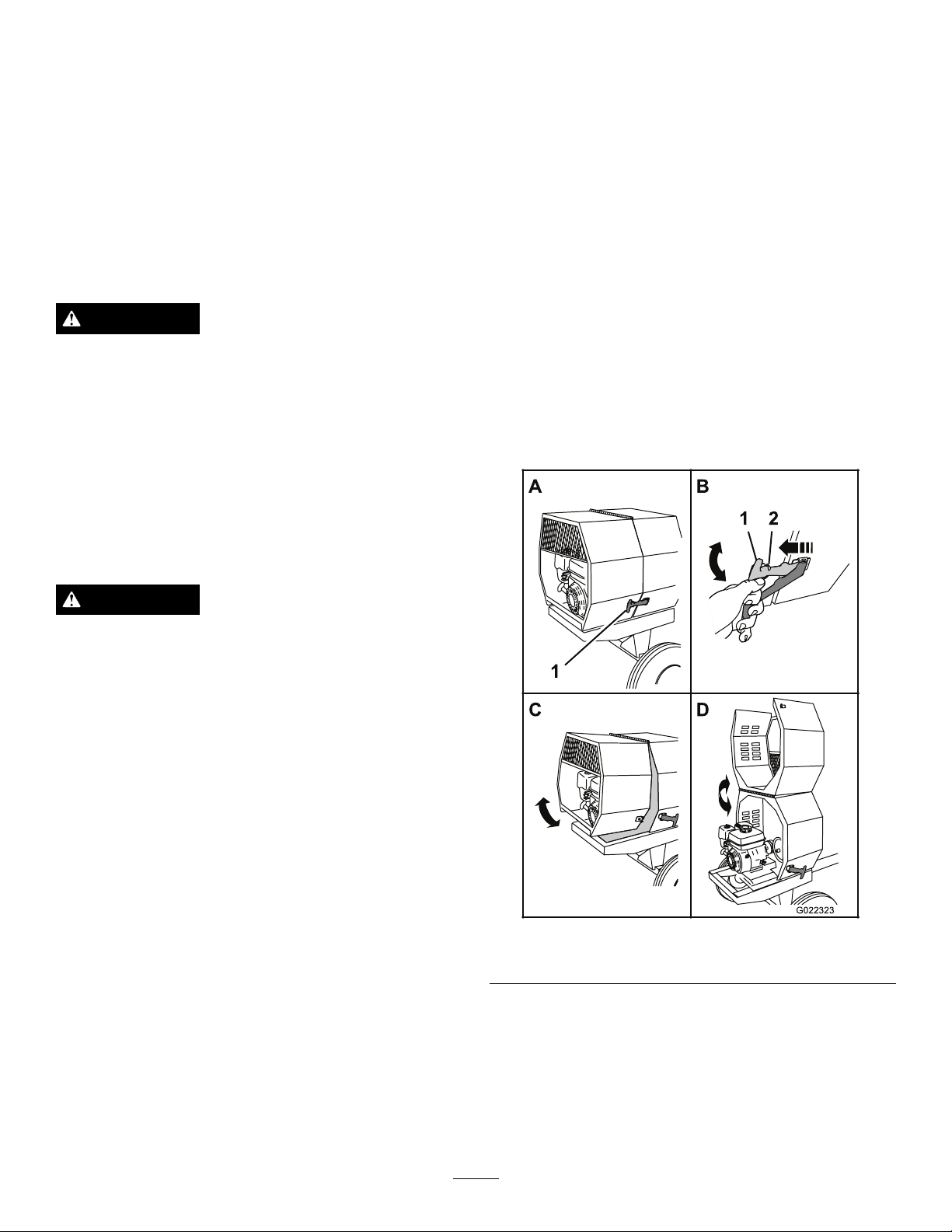

OpeningandClosingtheCowl

OpeningtheCowl

1.Atthesideofthemachinewherethefrontcowland

rearcowlmeet,graspthelatchandpullitofffromthe

latchanchorontherearcowl(Figure25).

Donotexceed88km/h(55mph)whentowingthe

machine.Forpoorroadconditionsorinclement

weather,reducespeedaccordingly.

WARNING

Towingthemachinewithmaterialinthedrum

increasestheriskofahitchmalfunctionandtire

failure.Inaddition,materialcouldbounceoutof

thedrumandhitothervehiclesand/orpeople.

Materialinthedrumincreasestheweight,which

affectsmomentumandbrakingdistance.

Donottowthemachinewithmaterialinthedrum.

•ReviewandunderstandSafeOperatingPractices(page4).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthemachine.

PreparingtoUsetheMachine

•Reviewallofthesafetydecalsonthemachine.

•Useahard-hat,hearingprotection,ashirtwithlong

sleevesbuttonedatthewrists,tight-ttinggloveswithout

drawstringsorloosecuffs,eyeprotection,andadust

maskorrespirator.Ameshvisoralonedoesnotprovide

sufcienteyeprotection;supplementwithprotective

glasses.

•Ensurethatyouarefamiliarwiththesafetyregulations

andshutdownproceduresdescribedintheOperator’s

ManualandtheEngineOwner’sManual.

•Ensurethatallguardsareinplaceandingoodcondition.

Figure25

1.Latch2.Latchanchor

2.Repeatstep1ontheoppositesideofthemachine.

3.Rotatetherearcowlupandforwarduntilitisfully

positionedontopofthefrontcowl(Figure25).

ClosingtheCowl

1.Rotatetherearcowlrearwardanddownuntilitisush

ontheframeofthemachine(Figure25).

17

Page 18

2.Atthesideofthemachine,graspthelatchandpullit

ontothelatchanchorontherearcowl.

3.Repeatstep2ontheoppositesideofthemachine

(Figure25).

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•ETHANOL:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

upto85%ethanol).Usingunapprovedgasolinemay

causeperformanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removefuel-poweredequipment

fromthetruckortrailerandfueltheequipment

withthewheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltothegasoline.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelisnohigher

thanthescreenonthelterinthefueltank.

Thisemptyspaceinthetankallowsthefuelto

expand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleandthe

fueltankorconditioneropening.

•Keepfuelawayfromyoureyesandskin.

Important:Donotmixoilwithgasoline.

RecommendedFuel

UnleadedGasoline

U.S.

Except

U.S.

Pumpoctanerating87orhigher

Researchoctanerating92orhigher

Pumpoctanerating87orhigher

UsingFuelStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeepthe

fuelfreshduringstorageof90daysorless.Ifyouarestoring

themachineforlonger,drainthefueltank;refertoStoring

theMachine(page38).

Important:Donotusefueladditivescontaining

methanolorethanol.

18

Page 19

Addthecorrectamountoffuelstabilizer/conditionertothe

1

G019799

G020679

1

fuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshfuel.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

FillingtheFuelTank

Thefueltankcapacityis5.3L(1.4USgallons).

1.Parkthemachineonalevelsurface,stoptheengine,

andallowtheenginetocool.

2.Cleanaroundthefuelcapandremoveit(Figure26).

Figure26

1.Fuelcap

3.Addunleadedgasolinetothefueltank,untilthelevel

isatthebottomofthemaximumfuellevel,asshown

inFigure27.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

Figure27

1.Maximumfuellevel

4.Installthefuelcapsecurely(Figure26).

5.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategory

or higher

.

CrankcaseCapacity:1.1L(1.2USqt)

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

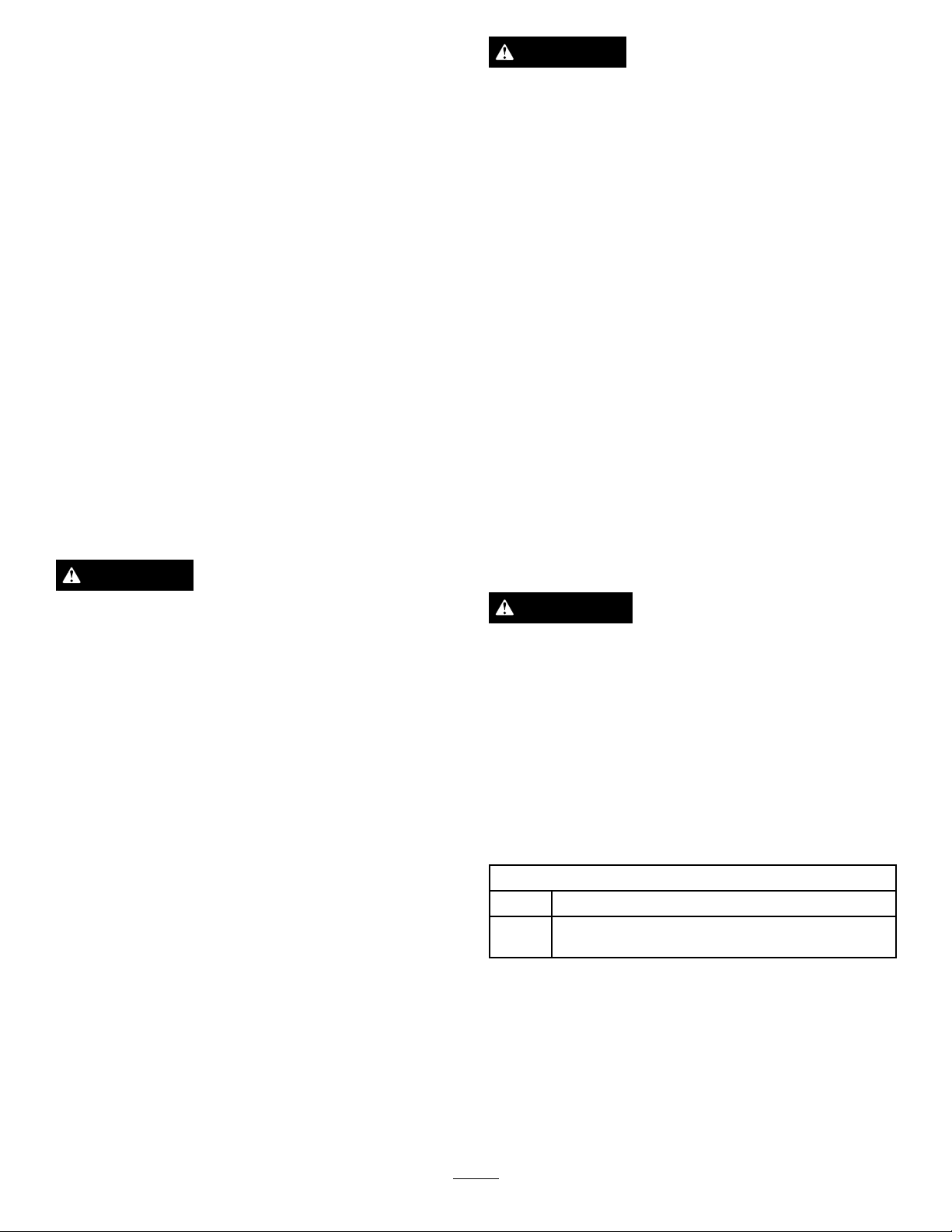

Note:UseSAE10W-30forgeneraluse.Youcanuse

theotherviscositiesshowninthechartwhentheaverage

temperatureinyourareaiswithintheindicatedrange(

28).

SJ , SL, SM,

Figure

19

Page 20

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

Figure28

1

2

3

4

G019746

G019815

1

2

3

1.Placethemachineonaat,levelsurface,andstopthe

engine.

2.Allowtheenginetocool.

3.Cleanaroundthedipstick.

4.Removethedipstickandwipetheendclean(Figure29).

StartingandStoppingthe Engine

StartingtheEngine

1.EnsurethattheclutchleverisintheOffposition;refer

toControllingthePaddles(page21).

2.Ontheengine,movethethrottleleverawayfromthe

Minposition,1/3ofthewaytowardtheMaxposition

(Figure30);refertoThrottleLever(page11).

Figure29

1.Fillport

2.Dipstick

3.Oil-levelupperlimit

4.Oil-levellowerlimit

5.Slidethedipstickfullyintothellportwithout

threadingitintotheport(Figure29).

6.Removethedipstickandlookattheend.Iftheengine

oillevelislow ,slowlypouronlyenoughoilintothell

porttoraisetheleveltotheFullmarkonthedipstick

(

Figure29).

Note:ToroPremiumEngineOilisavailablefrom

yourAuthorizedToroDealer.

7.Replaceandsecurethedipstick(Figure29).

Figure30

1.Chokelever

2.Fuelvalve

3.Throttlelever

3.MovetheleverofthefuelvalvetotheOnposition—all

thewaytotheright(Figure30);refertoFuelValve

(page11).

4.Positionthechokeleverasfollows:

•Tostartacoldengine,movethechokelevertothe

Closedposition—allthewaytotheleft(

refertoChokeLever(page11).

•Tostartawarmengine,movethechokeleverin

theOpenposition—allthewaytotheright.

5.RotatetheengineswitchtotheOnposition(

30);refertoEngineOn/OffSwitch(page11).

6.Pulltherecoil-starthandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly.Returnthe

recoil-starthandlegently(

Figure31).

Figure30);

Figure

20

Page 21

G019747

Figure31

G019873

1

2

Note:IfthechokeleverissettotheClosedpositiontostart

theengine,graduallymovethechokeleverbacktowardthe

Openpositionastheenginewarmsup.Iftheenginestalls

orhesitates,movethechokeleverbacktowardtheClosed

positionuntiltheenginerunssmooth.Allowtheengineto

warmup,thenmovethechokelevertotheOpenposition;

referto

ChokeLever(page11).

Usetheclutchlevertocontrolthepowertransmissiontothe

paddlesofthemachine.

UsingtheClutchLever

Movetheclutchleverclockwisetoengagetheclutch,and

counterclockwisetodisengagetheclutch(Figure32).

StoppingtheEngine

WARNING

Inanemergencysituation,stoptheengine

immediately.

Important:Duringnormaloperation,iftheengine

hasbeenworkinghardorishot,letitidleforaminute

beforestoppingtheengine.Thishelpstocoolthe

enginebeforestopping .

1.EnsurethatthechokeleverisintheOffposition

(Figure30);refertoChokeLever(page11).

2.MovethethrottlelevertotheMinposition(

refertoThrottleLever(page11).

3.RotatetheengineswitchtotheOffposition;referto

EngineOn/OffSwitch(page11).

Figure30);

ControllingthePaddles

DANGER

Thismachineiscapableofamputatinghands.

•Stayintheoperator’spositionwhilethemachine

isrunning.

•Keepallbystandersasafedistancefromthe

machine.

•Stopthemachineimmediatelyifanypeopleor

animalsentertheworkarea.

•Neverplaceanypartofyourbodyintoaposition

thatcausesanunsafeoperatingcondition.

Figure32

1.Offposition2.Onposition

MixingtheMaterial

DANGER

Eyeandskincontactwithconcretematerialsand

breathingthedustinvolvedishazardoustoyour

health.

•Ensurethatthereisadequateairventilation.

•Wearadustmasktopreventinhalationofdust

whileusingthemachine;referto

Practices(page4).

•Avoiddirectcontactofcementandconcrete

materialswithskinandeyes.

DANGER

Contactwiththemixingpaddlescouldcause

damageorinjury.

Neverputyourhandsinsidethedrumatanytime.

Important:Donotaddmorematerialthanthebatch

capacityofthemachine;refertoSpecications(page12).

Note:Followthemanufacturer’sinstructionsthatareprinted

onthepackagingoftheproductthatyouareusing.

SafeOperating

21

Page 22

MixingaBatchofMaterialinthe

A

B

D

G021 179

G020478

1

2

3

4

Machine

1.Ensurethatthereisnoold,loosematerialinthedrum

thatcancontaminatethebatchofmaterial;referto

CleaningtheDrum(page23)andDumpingtheDrum

(page22),thenreturnthedrumtotheuprightposition.

Note:Ensurethatthedrumisinthemixposition

(upright)andthedrumlatchisengaged.

2.MovetheclutchlevertotheOffposition;referto

UsingtheClutchLever(page21).

3.Starttheengine;referto

Note:Allowtheenginetowarm-upat2/3throttle

for1to2minutes.

4.SetthethrottleleverontheenginetotheMaxposition;

referto

5.MovetheclutchlevertotheOnposition;referto

UsingtheClutchLever(page21).

6.Addtheingredientsforthebatchasfollows:

A.Pourwaterintothedrumthroughthegratingof

B.Addtheplaster,cement,orotherbindingmaterial.

ThrottleLever(page11).

thedrumguard.

StartingtheEngine(page20).

8.Releasethedrumlatchanddumpthedrum;referto

DumpingtheDrum(page22).

UsingtheDrum

DANGER

Contactwiththemixingpaddlescouldcause

damageorinjury.

Neverputyourhandsinsidethedrumatanytime.

DumpingtheDrum

Note:Whendumpingabatchofmaterial,leavetheengine

runningandtheclutchintheOnpositionsotherotating

paddleshelpdischargethematerial.

1.Alignawheelbarroworsimilarcontainerofadequate

capacityinthepathofthedrumopening.

2.Graspthedumphandlewithyourlefthand(Figure34).

Note:Youcanopenbagsofcement,plaster,and

bindingmaterialsbyloweringthebagontothe

bagsplitter(

Figure33).

Figure33

Figure34

1.Dumphandle(mix

position)

2.Drumlatch(release

position)

Note:Whendumpingabatchofmaterial,aligna

wheelbarroworasimilarcontainerofadequatecapacity

beneaththechute.

3.Liftthehandleofthedrumlatch(Figure34).

3.Drumlatch(locked

position)

4.Dumphandle(dump

position)

C.Ifyouareusingsandand/orotherreinforcing

materials,addthemintothedrum.

7.Allowthepaddlestomixthematerialuntilthe

ingredientshaveauniformappearance.

Note:Ifneeded,addwaterorplaster,cement,or

otherbindingmaterialuntiltheconsistencyofthe

batchiscorrect.

4.Withbothhandsonthedumphandle,rotateit

counterclockwisetodischargethecontentsofthe

drum(

Figure34).

22

Note:Allowthemachinetocompletelydischargethe

contentsofthedrum.

5.Rotatethedumphandleclockwiseuntilthedrum

latchlocksthedrumintheuprightposition(Figure34).

Page 23

6.Afterdischargingabatchofmaterial,cleanthedrum;

G022321

1

2

G022322

refertoCleaningtheDrum(page23).

Note:Thisstepwillcleanthepaddlesanddrum

betweenbatchesandpreventdriedmaterialfrom

forming,andcontaminatingthenextbatchofmaterial.

CleaningtheDrum

Important:Donotstrikeonthedrumwithashovel,

hammer,oranyotherdevicetoloosenanyaccumulated

driedmaterials.

1.Stoptherotationofthepaddlesbymovingtheclutch

levertotheOffposition;refertoUsingtheClutch

Lever(page21).

2.RotatetheengineOn/OffswitchtotheOffposition;

refertoStoppingtheEngine(page21).

3.Ensurethatthedrumisinthemixposition(upright);

refertoDumpingtheDrum(page22),step5.

4.Spraythemachinewithwatertoremoveany

accumulatedmaterial.

5.Starttheengine;referto

6.Starttherotationofthepaddlesbymovingtheclutch

levertotheOnposition;refertoUsingtheClutch

Lever(page21).

7.Dumpthedrum;refertoDumpingtheDrum(page

22).

StartingtheEngine(page20).

AdjustingthePaddleBlades

Note:Adjustingthepaddlebladesisoptional.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-plugWire(page25).

3.Removethenutsandboltsthatsecurethegratetothe

drum,andremovethegrate(Figure35).

Figure35

4.Loosenthenutsandboltsthatsecurethepaddleblades

tothepaddles(Figure36).

Note:Ifnecessary,tipthedrumtothedumpposition

toaccessthepaddles.

Figure36

1.Paddleblade2.Nutandbolt

5.Movethepaddlebladestothepreferredposition,and

tightenthenutsandboltstosecurethebladestothe

paddles.

Note:EnsurethattheclutchleverisintheOff

position,androtatethepaddlesasneeded.

6.Installthegratewiththenutsandboltsthatyou

removedinstep

theyaresecure.

23

3,andtightenthenutsandboltsuntil

Page 24

Maintenance

Important:Beforeperforminganymaintenanceprocedures,rststoptheengine,wait5minutestoallowallmoving

partstocometoacompletestopandcool,anddisconnectthespark-plugwire.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Aftereachuse

Every40hours

Every50hours

Every100hours

Every300hours

MaintenanceProcedure

•Changetheengineoil.

•Inspectthebeltsandadjustasnecessary.

•Inspectthetiresandwheels.

•Checktheengineoillevel.

•Inspecttheair-cleanerelements.

•T orquethelugnutsto108to122N-m(80to90ft-lb)aftertowing.

•Cleanthedrumbetweenmixingbatchesofmaterial.

•Lubricatethetrunnions.

•Cleanthemachine.

•Inspectthebeltsandadjustasnecessary.

•Checktheclutchoperation.

•Cleantheair-cleanerelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil.

•Checkthesparkplug.

•Cleanthesparkarrester.

•Cleanthesedimentcup.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindustyoperating

conditions.

•Replacethesparkplug.

Monthly

Yearlyorbeforestorage

Every2years

Important:Refertoyour

•Lubricatethepillow-blockbearings.

•Cleanthefuelsedimentcup.

•Replacethebelts.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

24

Page 25

Premaintenance

G019281

1

G020752

G020753

Procedures

PreparingtheMachinefor Maintenance

1.Parkthemachineonalevelsurface.

2.Removethemachinefromthetowvehicle.

3.Chockthetires.

4.Opentherearcowl;refertoOpeningtheCowl(page

17).

5.Ensurethattheengineandmuferarecool.

6.Disabletheengine;refertoFigure37.

DisconnectingtheSpark-plug Wire

Pullthespark-plugwireofftheterminalofthesparkplug

(Figure37).

Figure38

3.Toremovethedividerplate,liftitupwardandrotate

itcounterclockwisesothatitclearsvariousengine

components.

InstallingtheDividerPlate

1.Guidethedividerplateintopositionagainstthefront

cowl.

Note:Startwiththedividerplaterotatedslightly

counterclockwise,andthenrotateitclockwisewhile

loweringitintoposition.

Ensurethatthedividerplateisnotbackward.

Figure37

1.Sparkplug

RemovingandInstallingthe DividerPlate

Youneedtoremovethedividerplatetoprovideaccessbefore

performingsomemaintenanceprocedures.

RemovingtheDividerPlate

1.Unlatchandopenthecowl;refertoOpeningtheCowl

(page17).

2.Useawrenchtoremovethe4boltsthatsecurethe

dividerplatetothefrontcowl.

Note:Keeptheboltsforinstallingthedividerplate.

Figure39

2.Aligntheboltholesinthedividerplateandthefront

cowl.

3.Installeachofthe4bolts,andhand-tightenthemto

preventcross-threading.

4.Tightentheboltswithawrenchuntiltheyaresecure.

25

Page 26

Lubrication

2

3

G020684

1

3

G020685

LubricatingtheBearingsand Seals

ServiceInterval:Aftereachuse—Lubricatethetrunnions.

Monthly—Lubricatethepillow-blockbearings.

Note:Thepillow-blockbearingsareinsidethe

cowl—removethedividerplatetoaccessthem;referto

RemovingtheDividerPlate(page25).

GreaseType:#2general-purposelithium-basedgrease.

1.Cleanaroundeachgreasettingwitharagandliftthe

plasticcapoffthegreasetting(

Figure40).

2.Pumpgreaseintoeachttingasfollows:

•Forthepillow-blockbearings,pump1shotof

greaseintoeachtting(Figure40).

•Forthetrunnions,pumpseveralshotsofgrease

intoeachttinguntilitstartstooozeoutofthe

bearinghousing(Figure40).

Important:Pumpgreaseinslowlyandcarefully

topreventdamagetothebearingseals.

3.Wipeupanyexcessgrease.

Figure40

1.Pillow-blockbearings3.Fronttrunnion

2.Reartrunnion

26

Page 27

EngineMaintenance

1

2

3

4

5

6

G019728

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspectthe

air-cleanerelements.

Every50hours—Cleantheair-cleanerelements.Clean

themmorefrequentlyindustyoperatingconditions.

Every300hours/Yearly(whichevercomes

rst)—Replacethepaperair-cleanerelement.Replace

itmorefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithoutthe

air-lterassembly;extremeenginedamagewilloccur.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-plugWire(page25).

3.Removethenutthatsecuresthecover(Figure41).

Figure41

1.Covernut

2.Cover

3.Wingnut6.Base

4.Removethecover.

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

4.Foamelement

5.Paperelement

5.Removethefoamandpaperelementsfromthebase

(Figure41).

6.Removethefoamelementfromthepaperelement

(Figure41).

7.Inspectthefoamandpaperelements,andreplacethem

iftheyaredamagedorexcessivelydirty.

8.Ifthepaperelementisexcessivelydirty,replaceit.

Note:Nevertrytobrushdirtoffthepaperelement;

brushingforcesthedirtintothebers.

9.Cleanthefoamelementinwarm,soapywaterorina

nonammablesolvent.

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

27

Page 28

10.Rinseanddrythefoamelementthoroughly.

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

1

2

3

G0 2048 1

11.Dipthefoamelementincleanengineoil,thensqueeze

outtheexcessoil.

Note:Excessoilinthefoamelementrestrictstheair

owthroughtheelementandmayreachthepaper

lterandclogit.

12.Wipedirtfromthebaseandthecoverwithamoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

13.Installtheair-cleanerelementsandensurethattheyare

properlypositioned.

14.Securelyinstallthecoverwiththenut.

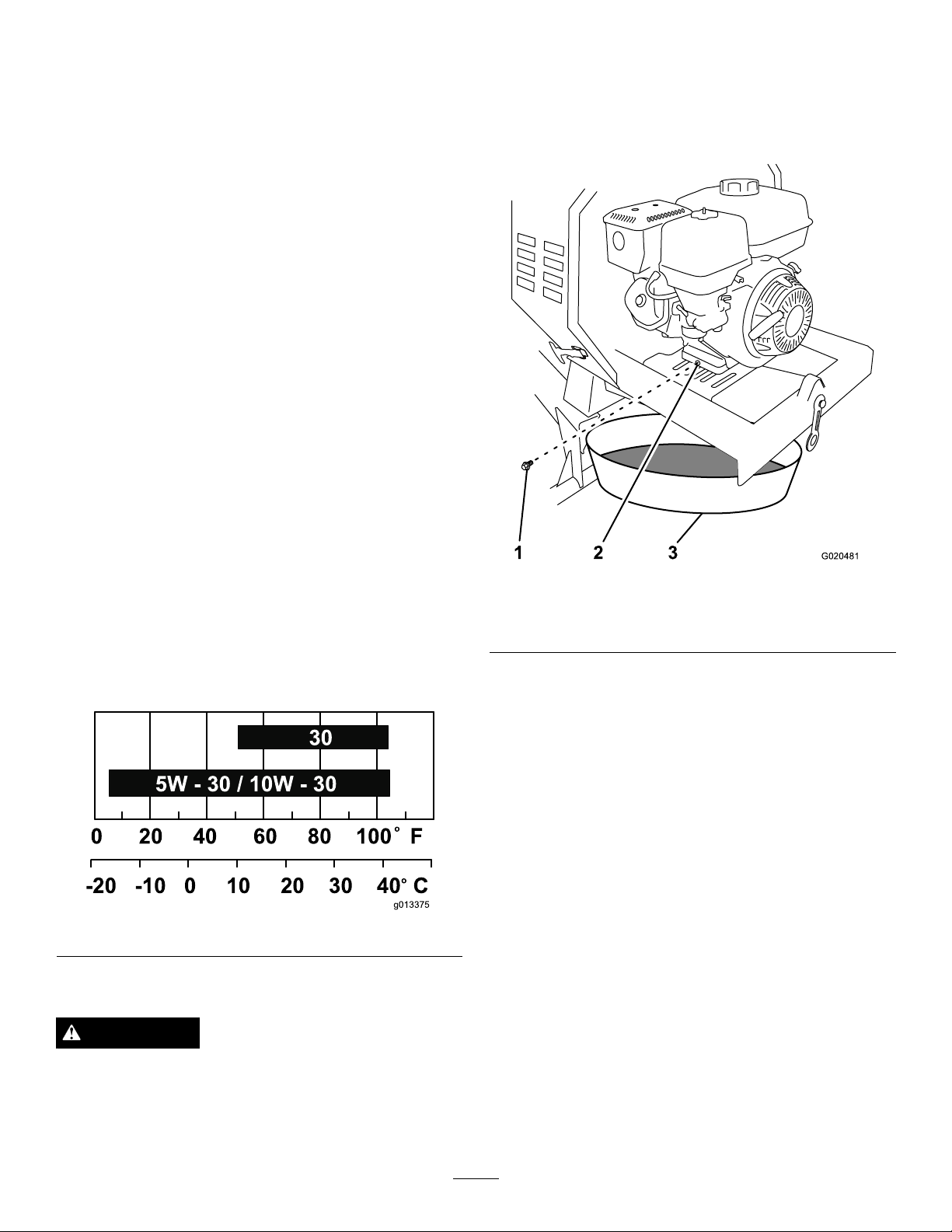

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDealer.

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategory

SJ or higher

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-plugWire(page25).

3.Placeadrainpanundertheoildrainholeoftheengine

(Figure43).

.

CrankcaseCapacity:1.1L(1.2USqt)

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

Note:UseSAE10W-30forgeneraluse.Youcanuse

theotherviscositiesshowninthechartwhentheaverage

temperatureinyourareaiswithintheindicatedrange(

42).

Figure42

Figure43

1.Oildrainplug3.Oildrainpan

2.Oildrainhole

Figure

4.Removethedrainplugandcatchtheoilintheoildrain

pan(Figure43).

5.Whentheoilhasdrainedcompletely,installthedrain

plugwithanewwasher(Figure43).

Note:Disposeoftheusedoilatacertiedrecycling

center.

DrainingtheEngineOil

WARNING

Oilmaybehotaftertheenginehasbeenrun,and

contactwithhotoilcancauseseverepersonalinjury.

Avoidcontactingthehotengineoilwhenyoudrain

it.

28

Page 29

FillingtheEngineCrankcasewithOil

1

2

3

4

G019746

G019749

RemovingtheSparkPlug

1.Removethedipstick(Figure44)andslowlypouroil

intothellholeuntiltheoilreachestheupper-limit

mark(bottomedgeoftheoil-llhole)onthedipstick.

Figure44

1.Oilllhole3.Oil-levelupperlimit

2.Dipstick

4.Oil-levellowerlimit

1.Parkthemachineonalevelsurfaceandturnoffthe

engine;refertoStoppingtheEngine(page21).

2.Ensurethatthemachinesurfacesarecool.

3.Pullthespark-plugwireofftheterminalofthespark

plug(Figure45).

Figure45

1.Sparkplug2.Spark-plugwire

4.Cleanaroundthesparkplug.

5.Rotatethesparkplugcounterclockwiseusinga13/16

inch(21mm)spark-plugwrenchtoremovetheplug

andthesealingwasher(Figure46).

2.Replaceandsecurethedipstick.

3.Wipeupanyspilledoil.

ServicingtheSparkPlug

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Checkthe

sparkplug.

Every300hours/Yearly(whichevercomes

rst)—Replacethesparkplug.

Type:NGKBPR6ESorequivalent

Gap:0.7to0.8mm(0.028to0.031inch)

Note:Usea13/16inch(21mm)spark-plugwrenchfor

removingandinstallingthesparkplug.

Figure46

29

Page 30

CheckingtheSparkPlug

G019300

1 2

4

3

G019331

10

10

1

2

3

4

5

6

7

8

9

11

12

Note:Useagappingtool/feelergaugetocheckandadjust

thegap.Installanewsparkplugifnecessary.

1.Lookatthecenterofthesparkplug(Figure47).Ifyou

seelightbrownorgrayontheinsulator,theengineis

operatingproperly.

•Wheninstallinganin-servicesparkplug,tighten

thepluganadditional1/8to1/4turn.

•Wheninstallinganewsparkplug,tightentheplug

anadditional1/2turn.

4.Pushthespark-plugwireontotheterminalofthespark

plug(Figure45).

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Figure47

1.Sideelectrode

2.Centerelectrode4.0.7to0.8mm(0.028to

2.Useagappingtoolforsparkplugsorafeelergaugeto

measurethegapbetweenthesideelectrodeandcenter

electrode(Figure47).

3.Ifthegapisnotwithinthespeciedrange,dothe

following:

3.Insulator

0.031inch)gap

ServicingtheSparkArrester

CleaningtheSparkArrester

ServiceInterval:Every100hours

Note:Asparkarresterisavailableasanoption.Ifyou

requireasparkarrester,contactyourAuthorizedToroService

Dealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

WARNING

Iftheenginehasbeenrunning,themuferwillbe

hotandcanburnyou.

Donottouchthemuferaftertheenginehasbeen

running.

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page25).

2.Removethe2nuts(8mm)andremovethemufer

fromthecylinder(Figure48).

InstallingtheSparkPlug

Important:Ensurethatthegapbetweenthesideand

centerelectrodesiscorrectbeforeinstallingthespark

plug.

A.Ifthegapistoosmall,carefullybendtheside

electrodeawayfromthecenterelectrodeuntil

thegapbetweentheelectrodesis0.7to0.8mm

(0.028to0.031inch).

B.Ifthegapistoolarge,carefullybendtheside

electrodetowardthecenterelectrodeuntilthe

gapbetweentheelectrodesis0.7to0.8mm(0.028

to0.031inch).

1.Threadthesparkplugclockwiseintothespark-plug

holebyhand.

Note:Avoidcross-threadingthesparkplugwiththe

threadsofthespark-plughole.

2.Rotatethesparkplugclockwiseusinga13/16inch

(21mm)spark-plugwrenchuntiltheplugandsealing

washerareseated(

3.Tightenthesparkplugasfollows:

Figure46).

Figure48

1.Deector(if

applicable)

2.Protector

3.Screw(6mm)7.Gasket

4.Mufer8.Bolt(8mm)12.Screw(4mm)

5.Exhaustpipe

6.Nut,8mm(2)10.Screws(5mm)

9.Sparkarrester

11.Exhaustport

30

Page 31

3.Removethe3screws(4mm)fromtheexhaust

1

2

G019332

3

2

4

1

5

G0201 19

G020120

1

2

3

5

6

4

deectorandremovethedeector(Figure48).

4.Removethescrews(5mmand6mm)fromthemufer

protector,andremovethemuferprotector(Figure

48).

5.Removethescrew(4mm)fromthesparkarresterand

removethesparkarresterfromthemufer(Figure48).

6.Useabrushtocarefullyremovecarbondepositsfrom

thespark-arresterscreen(

Figure49).

Note:Replacethesparkarresterifithasbreaksor

holes.

Note:Leavetheotherendofthespringattachedto

theframeofthemachine.

Figure50

Figure49

1.Screen

2.Brush

7.Installthesparkarrester,muferprotector,exhaust

deector,andmuferinthereverseorderof

disassembly.

8.Installthedividerplate;refertoInstallingtheDivider

Plate(page25).

RemovingandInstallingthe Engine

RemovingtheEngine

1.Anchorbracket

2.Enginedeck

3.Spring-removaltool(T oro

part92-5771)

4.Spring-removaltool

(springremoved)

5.Spring(springremoved)

6.Removetheboltandnutthatsecurestherearbracket

fortheenginedeckhingetotheframeofthemachine

(Figure51).

WARNING

Thespringisundertensionwheninstalledandcan

thereforecausepersonalinjury.

Becarefulwhenremovingthespring .

1.Parkthemachineonalevelsurfaceandstoptheengine;

refertoStoppingtheEngine(page21).

2.Ensurethattheengineandtheexhaustsystemsurfaces

arecool.

3.Removethebeltguide;refertoRemovingtheBelts

(page34).

4.Removethebelts;refertoRemovingtheBelts(page

34)

.

5.Usingaspring-removaltool,(T oropart92-5771),

removethespringfromtheanchorbracketonthe

enginedeck(Figure50).

Figure51

1.Enginedeck4.Frame

2.Pivot5.Nut

3.Rearhingebracket6.Bolt

7.Liftupontherearedgeoftheenginedeckandremove

thehingebracket(

Figure51).

8.Slidetheenginedeckrearwardandoutfromthe

forwardhingebracket(Figure52).

Note:Donotremovetheforwardhingebracket.

31

Page 32

G020121

Figure52

2

3

4

1

G019333

9.Removetheengineandenginedeckfromthemachine

Figure52).

(

InstallingtheEngine

1.Aligntheengineandenginedecktotherearframeof

themachine.

FuelSystem

Maintenance

ServicingtheFuelSystem

CleaningtheSedimentCup

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Cleanthe

sedimentcup.

Yearlyorbeforestorage—Cleanthefuelsedimentcup.

Underneaththefuelvalveisasedimentcuptocatchdirtin

thefuel.

1.Parkthemachineonalevelsurfaceandstoptheengine;

refertoStoppingtheEngine(page21).

2.Ensurethattheengineandtheexhaustsystemsurfaces

arecool.

3.MovetheleverofthefuelvalvetotheOffposition,all

thewaytotheleft(Figure53).

4.Unscrewthesedimentcup(Figure53).

5.RemovethefuellterandO-ring(Figure53).

Note:DonotmisplacetheO-ring.

Note:Thedrivepulleyontheenginemustalign

forward.

2.Alignthepivotontheenginedeckwiththeforward

hingebracket(Figure52).

3.Slidetheenginedeckforwardandthepivotintothe

forwardhingebracket(Figure52).

4.Aligntherearhingebracketwiththepivotonthe

engine-deckhinge(Figure52).

5.Liftupontherearedgeoftheenginedeckandslipthe

hingebracketontothepivot.

6.Securetherearbrackettotheframeofthemachine

usingtheboltandnut(Figure51)removedinstep6of

RemovingtheEngine(page31).

7.Usingaspring-removaltool,(T oropart92-5771),

installthetensionspringtotheanchorbracketonthe

enginedeck(

8.Installthebeltsandbeltguide;refertoInstallingthe

Belts(page35).

9.Adjustthebeltguide;refertoAdjustingtheBeltGuide

(page35).

Figure50).

Figure53

1.Fuelvalve(Off)3.Fuellter

2.O-ring4.Sedimentcup

Note:DonotcleantheO-ringinsolvent.

6.Cleanthefuellterandsedimentcupusinga

nonammablesolvent,anddryitcarefully.

7.WipetheO-ringwithaclean,drycloth.

8.Installthefuellterinthebottomofthecarburetor

Figure53).

(

9.AligntheO-ringintothegrooveinthesedimentcup

andinstallthesedimentcuptofuelvalvehousing.

32

Page 33

10.MovetheleverofthefuelvalvetotheOnposition(all

1

2

G020122

G019976

1

2

3

thewaytotheright)andcheckforleaks.Ifitleaks,

replacetheO-ring.

DrainingtheFuelTank

1.Removetheengine;refertoRemovingtheEngine

(page31).

2.Removethefuelcapbyrotatingitcounterclockwise.

Figure54

3.Alignadrainpantothehingeoftheenginedeck.

BeltMaintenance

ServicingtheBelts

InspectingtheBelts

ServiceInterval:Aftertherst25hours—Inspectthebelts

andadjustasnecessary.

Every40hours—Inspectthebeltsandadjustas

necessary.

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page25).

2.MovetheclutchlevertotheOffposition;referto

ControllingthePaddles(page21).

3.Examinethebeltsforwearordamage.Ifthebeltsare

wornordamaged,replacethem;refertoInspecting

theBelts(page33).

4.Examinethepulleysforwear,damage,and

misalignment;refertoAligningthePulleys(page36).

5.Installthedividerplate;referto

Plate(page25).

InstallingtheDivider

4.Rotatetheengineonthehingesideoftheenginedeck

anddrainthefuelfromthetank.

5.Carefullylowertheengineandenginedeck.

6.Installthefuelcap.

7.Installtheengine;refertoInstallingtheEngine(page

32).

AdjustingtheBeltT ension

Clutchairgap:6.35to9.52mm(1/4to3/8inch)

1.MovetheclutchlevertotheOnposition;referto

UsingtheClutchLever(page21).

2.Measuretheairgapbetweentheenginedeckandthe

rollerontheclutch(

Figure55).

Figure55

1.Enginedeck

2.Clutchroller

3.Ifthemeasuredairgapisnotwithinthespecied

range,adjustthegapasfollows:

33

3.Clutchairgap:6.35to

9.52mm(1/4to3/8inch)

Page 34

A.MovetheclutchlevertotheOffposition;referto

1

2

3

3 4

4 3

G020480

G020009

1 2

3

4

5

6 7 8

2

G020010

UsingtheClutchLever(page21).

B.Loosenthenutsandboltsthatsecuretheengine

totheenginedeck(

Figure56).

E.Ifneeded,pivottheengineontheenginedeck

untiltheenginepulleyandtheidlerpulleyare

alignedtothestraightedge(Figure57).

F.Tightenthenutsandboltsthatsecuretheengine

totheenginedecktoatorqueof18N-m(13

ft-lb).

G.Checktheairgapbetweentheenginedeckand

therollerontheclutch.Iftheairgapisnotwithin

thespeciedrange,repeatstep3untiltheairgap

measurementiswithinthespeciedrange.

Figure56

1.Idlerpulley3.Nutandbolt

2.Setscrew

4.Enginedeck

C.Movetheenginepositionasfollows:

•Increasetheairgap—movetheengine

awayfromtheidlerpulley(Figure56).

•Decreasetheairgap—movetheengine

towardtheidlerpulley(Figure56).

D.Alignastraightedgeacrosstheenginepulleyand

theidlerpulley(

Figure57).

H.Installthedividerplate;referto

Installingthe

DividerPlate(page25).

ReplacingtheBelts

ServiceInterval:Every2years—Replacethebelts.

RemovingtheBelts

1.MovetheclutchlevertotheOffposition;referto

UsingtheClutchLever(page21).

2.Removethedividerplate;refertoRemovingthe

DividerPlate(page25).

3.Removetheboltthatsecuresthebeltguidetothe

engine,andremovethebeltguide(

Figure58).

1.Enginepulley

2.Idlerpulley6.Jamnut

3.Reductioncase(engine)7.Setscrew

4.Beltguide

Figure57

5.Idlershaft

8.Straightedge

Figure58

1.Bolt2.Beltguide

4.Sliptheforwardbeltforwardandofftheidlerpulley

(Figure59).

34

Page 35

2

3

4

1

G020012

Figure59

G02001 1

3 4

5

1

2

1.Enginepulley3.Idlerpulley

2.Forwardbelt4.Rearbelt

5.Sliptherearbeltrearwardandofftheidlerpulley

(Figure59).

6.Slipthebeltsofftheenginepulley.

AdjustingtheBeltGuide

Note:Toaccessthebeltguide,removethedividerplate;

refertoRemovingtheDividerPlate(page25).

Guideairgap:2.5to4.0mm(3/32to5/32inch)

1.EnsurethattheclutchleverisintheOnposition;refer

toUsingtheClutchLever(page21).

2.Ensurethatthebelttensioniscorrect;referto

AdjustingtheBeltTension(page33).

3.Checkthattheairgapbetweenthebeltguideandthe

beltsis2.5to4.0mm(3/32to5/32inch);referto

Figure60.

7.Removethebeltsfromthemachine.

InstallingtheBelts

1.EnsurethattheclutchleverisintheOffposition;refer

toUsingtheClutchLever(page21).

2.Aligntherearbelttothereargrooveintheengine

pulley.

Note:Donotaligntherearbelttotheidlerpulley .

3.Aligntheforwardbelttotheforwardgrooveofthe

idlerpulley.

4.Sliptherearbeltovertheidlerpulleyandalignthebelt

totherearpulleygroove.

5.Sliptheforwardbeltovertheenginepulleyandalign

thebelttotheforwardpulleygroove.

6.Checkthebelttension;refertostep1,step2,andstep

3inAdjustingtheBeltTension(page33).

7.Looselysecurethebeltguidetotheengine(Figure58)

withtheboltthatwasremovedinstep3ofRemoving

theBelts(page34).

8.Adjustthebeltguide;refertoAdjustingtheBeltGuide

9.Installthedividerplate;refertoInstallingtheDivider

(page35)

Plate(page25).

Figure60

1.Enginepulleys4.Beltguide

2.Belts5.Bolt

3.Guideairgap:2.5to4.0

mm(3/32to5/32inch)

4.Iftheairgapisnotwithinthespeciedrange,dothe

following:

A.Loosentheboltthatsecuresthebeltguidetothe

engine(Figure60).

Important:Ensurethatthebeltguideis

towardtheenginepulley.

B.Rotatethebeltguideupordownuntilthereis

anairgapof2.5to4.0mm(3/32to5/32inch)

betweentheguideandeachbelt(Figure60).

Important:Thebeltguideshouldnot

contactthebeltswiththeclutchleverinthe

Onposition.

Note:Iftheairgapbetweenthebeltguideand

.

bothbeltscannotbeattained,thenoneofthe

beltsistoolong.

C.Tightentheboltthatsecuresthebeltguidetothe

engine(

Figure60).

D.Checktheclutchoperation;refertoCheckingthe

ClutchOperation(page36).

5.Installthedividerplate;referto

InstallingtheDivider

Plate(page25).

35

Page 36

CheckingtheClutchOperation

G020015

53 6

1 2

4

ServiceInterval:Every40hours—Checktheclutch

operation.

Important:Thepaddlesmustnotrotateinanempty

drumwhentheclutchleverisintheOffposition.

1.MovetheclutchlevertotheOffposition;referto

UsingtheClutchLever(page21).

2.Starttheengine;refertoStartingtheEngine(page20).

3.IfthepaddlesrotatewiththeclutchlevertotheOff

positiondothefollowing:

A.Stoptheengine;refertoStoppingtheEngine

(page21).

B.Checktheairgapbetweenthebeltguideandthe

belts.

Note:Iftheairgapislargerthan4.0mm(5/32

inch),decreasethegapbetweenthebeltguide

andthebelts;refertoAdjustingtheBeltGuide

(page35).

4.Repeatsteps1,2,and3untilallthefollowing

conditionsaremet:

•Theengineisrunat2/3throttle.

•TheclutchleverisintheOffposition.

•Thepaddlesdonotrotateinanemptydrum.

Note:Bothpulleysmustbealignedushwiththe

straightedge.

3.Ifthepulleysarenotaligneddothefollowing:

A.MovetheclutchlevertotheOffposition.

B.Loosenthelocknutsandsetscrewsthatsecurethe

idlerpulleytotheidlershaft(

C.Usingasoft-facemallet,taptheidlerpulley

forwardorbackwardalongtheidlershaftuntil

theenginepulleyandtheidlerpulleyarealigned

tothestraightedge(Figure61).

D.Tightenthesetscrewsandlocknutsthatsecurethe

idlerpulleytotheidlershaft(Figure61).

4.Installthedividerplate;refertoInstallingtheDivider

Plate(page25).

Figure61).

AligningthePulleys

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page25).

2.Placeastraightedgeacrossthefaceoftheenginepulley

andtheidlerpulley(Figure61).

Figure61

1.Enginepulley

2.Idlerpulley5.Locknut

3.Straightedge6.Setscrew

4.Idlershaft

36

Page 37

ReplacingtheLight

A

B

C

E

F

G020829

A

B

C

E

F

G020830

Bulbs

ReplacingtheRear-facing Bulbs

Bulbtype:#1157(Bay15Dbase,12.8–14volt,26.88–8.26

watt)

Note:Theleftrear-facingbulbalsoilluminateslicenseplate.

1.Useascrewdrivertoremovethe4screwsfromthe

largesquarelensonthelight(Figure62).

Figure62

2.Removethelens(Figure62).

3.Pushandrotatethebulbcounterclockwisetoremoveit

fromthesocket(Figure62).

4.Insertanewbulbofthespeciedtypeintothesocket

andthenrotateitclockwise(

Figure62).

Figure63

2.Removethelens(Figure63).

3.Pullthebulboutofthesocket(Figure63).

4.Insertanewbulbofthespeciedtypeintothesocket

(Figure63).

5.Installthelensandthe2screws(Figure63).

ReplacingtheSide-marker LightBulb

Bulbtype:#193(Miniaturewedgebase,14volt,and4.62

watt)

1.Usingascrewdriver,removethe2screwsfromthe

smallrectangular,amberlensontheside-markerlight

(Figure64).

5.Installthelensandthe4screws(Figure62).

ReplacingtheSide-facing Bulbs

Bulbtype:#168(Miniaturewedgebase,14volt,and4.9

watt)

1.Useascrewdrivertoremovethe2screwsfromthe

smallrectangularlensonthesideofthelight(Figure

63

).

Figure64

2.Removetheamberlens(Figure64).

3.Pullthebulboutofthesocket(Figure64).

4.Insertanewbulbofthespeciedtypeintothesocket

(

Figure64).

5.Installtheamberlensandthe2screws(Figure64).

37

Page 38

Cleaning

Storage

CleaningtheMachine

Regularcleaningandwashingwillincreasethelifespanof

themachine.Cleanthemachineaftereachuse,beforethe

dirthardens.

Ensurethatthefueltankcapandoilcap/dipstickaresecure

toavoidgettingwaterinthetank.

Usecarewhenusingahigh-pressuresprayerbecauseitcan

damagewarningdecals,instructionsigns,andtheengine.

Important:Lubricatethetrunnionsaftercleaning;refer

toLubricatingtheBearingsandSeals(page26).

StoringtheMachine

Forstorageover30days,preparethemachineasfollows:

1.Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleandirtand

debrisfromtheoutsideoftheenginecylinder-head

nsandblowerhousing.

Important:Youcanwashthemachinewithmild

detergentandwater.