Page 1

FormNo.3390-592RevA

G020896

MM-658H-P ,MM-858H-P ,and

MM-12511H-SMortarMixer

ModelNo.68017C—SerialNo.316000001andUp

ModelNo.68021C—SerialNo.316000001andUp

ModelNo.68024C—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3390-592*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

to:Administrator,NHTSA,1200NewJerseyAvenue,

SEWestBuilding,Washington,DC20590.Youcanalso

obtainotherinformationaboutmotorvehiclesafetyfrom

http://www.safercar.gov.

•TocontactTransportCanada,youmaycall

1-800-333-0510or(819)994-3328;goto

http://www.tc.gc.ca/roadsafety/;writeto:Road

SafetyandMotorVehicleRegulationDirectorate,

TransportCanada,TowerC,PlacedeVille,330

SparksStreet,Ottawa,Ontario,K1A0N5;oremail

RoadSafety@tc.gc.ca.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosedengineowner'smanualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughtheengine

manufacturer.

Ifyoubelievethatyourmachinehasadefectwhichcould

causeacrashorcouldcauseinjuryordeath,youshould

immediatelyinformtheNationalHighwayTrafcSafety

Administration(NHTSA)ifyouliveintheUnitedStates,

orTransportCanadaifyouliveinCanada,inadditionto

notifyingTheToroCompany.

IfNHTSAorTransportCanadareceivessimilarcomplaints,

itmayopenaninvestigation,andifitndsthatasafetydefect

existsinagroupofmachines,itmayorderarecallandremedy

campaign.However,NHTSAorTransportCanadacannot

becomeinvolvedinindividualproblemsbetweenyou,your

dealer,orTheToroCompany.

•TocontactNHTSA,youmaycalltheV ehicle

SafetyHotlinetoll-freeat1-888-327-4236(TTY:

1-800-424-9153);gotohttp://www.safercar.gov;orwrite

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

1

G020900

2

Thismachineisdesignedtomixmortar,plaster,reproong

material,grout,andothersmall-grainedPortlandcement

products.Avehicleequippedwithanappropriatepintlehitch

orballhitchcantowthemachine.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

TireInformation

TheDOTtireinformationislocatedonthesideofeachtire.

Thisinformationgivesloadandspeedratings.Replacement

tiresshouldhavethesameorbetterratings.

Note:Thevariousmachinesinthismanualhavedifferent

weights;refertoSpecications(page13)toensurethatthe

tiresonyourmachinemeetorexceedtheweightrequirements

ofyourmachine.

Figure1

1.Modelandserialnumber

location

ModelNo.

SerialNo.

2.Vehicleidentication

number(VIN)location

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

3

Page 4

Contents

Safety...........................................................................5

SafeOperatingPractices...........................................5

Setup............................................................................8

1InstallingtheDumpHandle...................................8

2InstallingtheTowPole..........................................8

3InstallingtheSafetyChain......................................8

4AdjustingtheMixingPaddles..................................9

ProductOverview.........................................................10

Controls...............................................................11

Specications........................................................13

Attachments/Accessories........................................13

Operation....................................................................14

ThinkSafetyFirst...................................................14

PreparingtoT owtheMachine..................................14

ExtendingtheAxle—Belt-DriveModels...................18

TowingtheMachine...............................................19

PreparingtoUsetheMachine...................................19

OpeningandClosingtheCowl.................................20

AddingFuel...........................................................20

CheckingtheEngine-OilLevel.................................22

StartingandShuttingOfftheEngine.........................23

ControllingthePaddles...........................................24

MixingtheMaterial.................................................25

UsingtheDrum.....................................................26

Maintenance.................................................................27

RecommendedMaintenanceSchedule(s)......................27

PremaintenanceProcedures........................................28

PreparingtheMachineforMaintenance.....................28

DisconnectingtheSpark-PlugWire...........................28

RemovingandInstallingtheDividerPlate..................28

Lubrication...............................................................29

LubricatingtheBearingsandSeals............................29

EngineMaintenance..................................................30

ServicingtheAirCleaner.........................................30

ChangingtheEngineOil.........................................31

ServicingtheSparkPlug..........................................32

ServicingtheSparkArrester.....................................33

RemovingandInstallingtheEngine..........................34

FuelSystemMaintenance...........................................35

ServicingtheFuelSystem........................................35

DriveSystemMaintenance.........................................36

ServicingtheGearCase—Gear-CaseModel...............36

BeltMaintenance......................................................38

ServicingtheBelts—Belt-DriveModels.....................38

ReplacingtheBelts—Belt-DriveModels....................39

AligningthePulleys—Belt-driveModels....................41

ReplacingtheLightBulbs............................................41

ReplacingtheRear-FacingTaillightBulbs...................41

ReplacingtheSide-FacingTaillightBulbs...................41

ReplacingtheFrontAmberBulbs.............................42

MaintainingtheMixingPaddles....................................42

AdjustingthePaddles..............................................42

Cleaning...................................................................44

CleaningtheMachine..............................................44

Storage........................................................................44

StoringtheMachine................................................44

Troubleshooting...........................................................46

4

Page 5

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeans:

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

SafeOperatingPractices

Thismachineiscapableofamputatinghands.Alwaysfollow

allsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Machiningorhandlingstone,masonry,concrete,

metal,andothermaterialscangeneratedust,mists,

andfumescontainingchemicals,suchassilica,

knowntocauseseriousorfatalinjuryorillness,

suchasrespiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Usewaterfordustsuppression,

whenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufacturer

orsupplier,CCOHS,OSHA,andother

occupationalandtradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyCCOHSor

OSHAforthematerialbeinghandled.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

Caution

,

W ar ning

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

,

property.

Towing

Checkwithyourlocalcountyorstatetowingsafety

regulations,inadditiontomeetingTransportCanada(or

DepartmentofTransportationifintheU.S.)towingsafety

regulations,beforetowingthemachine.

•Inordertoreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,makesure

thetowingvehicleismechanicallysoundandingood

operatingcondition.

•Shutofftheenginebeforetransportingthemachine.

•Whentowingwithaballhitch,ensurethattheballhitch

youareusingisthepropersizeforthehitchcoupleron

themachine.

•Whentowingwithapintlehitch,ensurethattheeyeof

thetowpoleisthecorrectdimensionforthepintlehook.

•Inspectthehitchandcouplingforwear.Nevertowthe

machinewithdamagedordefectivehitches,couplings,

chains,orothercomponents.

•Checkthetire-airpressureonthetowingvehicleandthe

machine.

•Checkthetiretreadandsidewallfordamageandwear.

•Properlyattachthesafetychainstothetowingvehicle.

•Ensurethatthedirectionalandbrakelightsareworking

properly.

•Ensurethatthedirectional,backup,andbrakelightsof

thetowvehicleareworkingproperly.

•Beforetowingchecktomakecertainyourmachineis

correctlyandsecurelyattachedtothetowingvehicle.

•Ensurethatthesafetychainsareproperlysecuredtothe

vehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhentowing.

•Avoidsuddenstartsandstops.Thiscancauseskidding,

orjackkning.Smooth,gradualstartsandstopswill

improvetowing.

•Avoidsharpturnstopreventrolling.Towonlywitha

vehiclethathasahitchdesignedfortowing.Donot

attachtowedequipmentexceptatthehitchpoint.

•Donottowthemachinefasterthan88km/h(55mph).

•Usecautionwhenbackingup;useaspotteroutsidethe

vehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehiclebefore

usingit.

•Ensurethattheyousecurethemachinefromrolling

whilethemachineisparked.

5

Page 6

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Wearpersonal-protectiveequipmentandappropriate

clothingincluding:

–Hardhat

–Respiratorordustmask

–Eyeprotection

–Hearingprotection

–Safetyshoes

–Longpants

–Shirtwithlongsleevesbuttonedatthewrists

–Tight-ttinggloveswithoutdrawstringsorloosecuffs

•Tiebacklonghairanddonotwearjewelry.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andthevaporsareexplosive.Usethefollowingpractices

whenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

–Replacethefuelcapandtightenitsecurely .

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Iffuelisspilled,wipeitofftheengineandequipment.

•Ensurethatthemachineisonalevelsurfacebefore

operatingthemachine.

•Ensurethatyousecurethemachinetopreventunintended

movement.

•Beforeeveryuse:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly(if

equippedwithalightkit).

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

Operation

•Neverrunanengineinanenclosedorpoorlyventilated

area.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Shutofftheenginebeforeleavingthemachineforany

reason.

Neverleavearunningmachineunattended.Always

shutofftheengineandverifythatallmovingpartshave

stopped.

•Ensurethatthemachineissecurefrommovementor

keepitattachedtothetowingvehiclewhenitisnotin

use,topreventitfromrolling.

•Avoidprolongedbreathingofexhaustfumes.

Engine-exhaustfumescancausesicknessordeath.

•Keephandsawayfromanymovingparts.Keepfeetaway

fromthetiresandthefrontpost.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Ensurethattheareaisclearofotherpeopleorpetsbefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverplaceyourhandsoranysolidobjectintothedrum

whenthemachineisinoperation.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Nevermovethemachinewhiletheengineisrunning.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•Disconnectthespark-plugwireandkeepitawayfromthe

sparkplugtopreventaccidentalstartingwhilemaintaining

themachine.

•Ifthemixingpaddlesstrikeaforeignobjectorifthe

machineshouldstartmakinganunusualnoiseor

vibration,shutofftheengineandemptythedrum.Wait

forallmovingpartstocometoacompletestopandcool.

Vibrationisgenerallyawarningoftrouble.Disconnect

thespark-plugwireandinspectforcloggingordamage.

Cleanandrepairand/orreplacedamagedparts.

•Donotchangetheengine-governorsettingoroverspeed

theengine.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonlevelground.

6

Page 7

–Shutofftheengine.Waitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

–Lettheenginecoolbeforeperformingmaintenance

orstoring.

–Removethespark-plugwirebeforemakingany

repairs.

–Disengageallpowerandoperationcontrols.

•Neverlubricate,service,repair,oradjustthemachine

whileitisrunning.

•Keepequipmentmaterialsclearfromthemuferand

enginetohelppreventres.Cleanupanyoilorfuel

spillage.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Shutofftheengineandinspectthemachineifaforeign

objectentersthedrumorcausesanotherobstruction.

Makeanynecessaryrepairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Ensurethatthemachineissecurefrommovementbefore

youuseit.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•UseonlygenuineTororeplacementpartstoensurethat

theoriginalstandardsaremaintained.

7

Page 8

Setup

5

1

2

4

6

3

G019804

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

1

InstallingtheDumpHandle

Partsneededforthisprocedure:

1Dumphandle

2Bolt

2Nut

Dumphandle1

Bolt2

Nut2

Towpolekit(soldseparately)

Safetychain

Connectinglink

Nopartsrequired

1.Removetheboltandnutfromthetowpole(Figure3).

Qty.

Installthedumphandle.

1Installthetowpole.

1

2

–

Installthesafetychain.

Adjustthemixingpaddles.

Use

2

InstallingtheTowPole

Partsneededforthisprocedure:

1

Towpolekit(soldseparately)

InstallingtheTowPoletotheMachine

Note:Thetowpoleispurchasedseparatelyandincludesthe

nutandboltneededforinstallation.

Themachinehasthefollowingtowpoleoptions:

HitchTypeLength

50mm(2inch)ball—stamped78.7cm(31inches)or127cm

50mm(2inch)ball—forged78.7cm(31inches)or127cm

Pintle

(50inches)

(50inches)

78.7cm(31inches)or127cm

(50inches)

Figure3

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

2.Slidethetowpoleforwardandaligntheholeinthe

polewiththeholeintheframetting(Figure3).

3.Inserttheboltthroughtheholesinthettingandthe

pole(Figure3).

4.Threadthenutontotheboltandtightenthemuntil

theyaretightagainsttheframetting(Figure3).

Note:Iftheself-lockingnyloninsertinthelocknut

wearswithuse,replacethenutwithanewGrade5or

Grade8locknut.

5.Frametting

8

Page 9

3

A

B

D

g019883

2

3

4

3

1

4

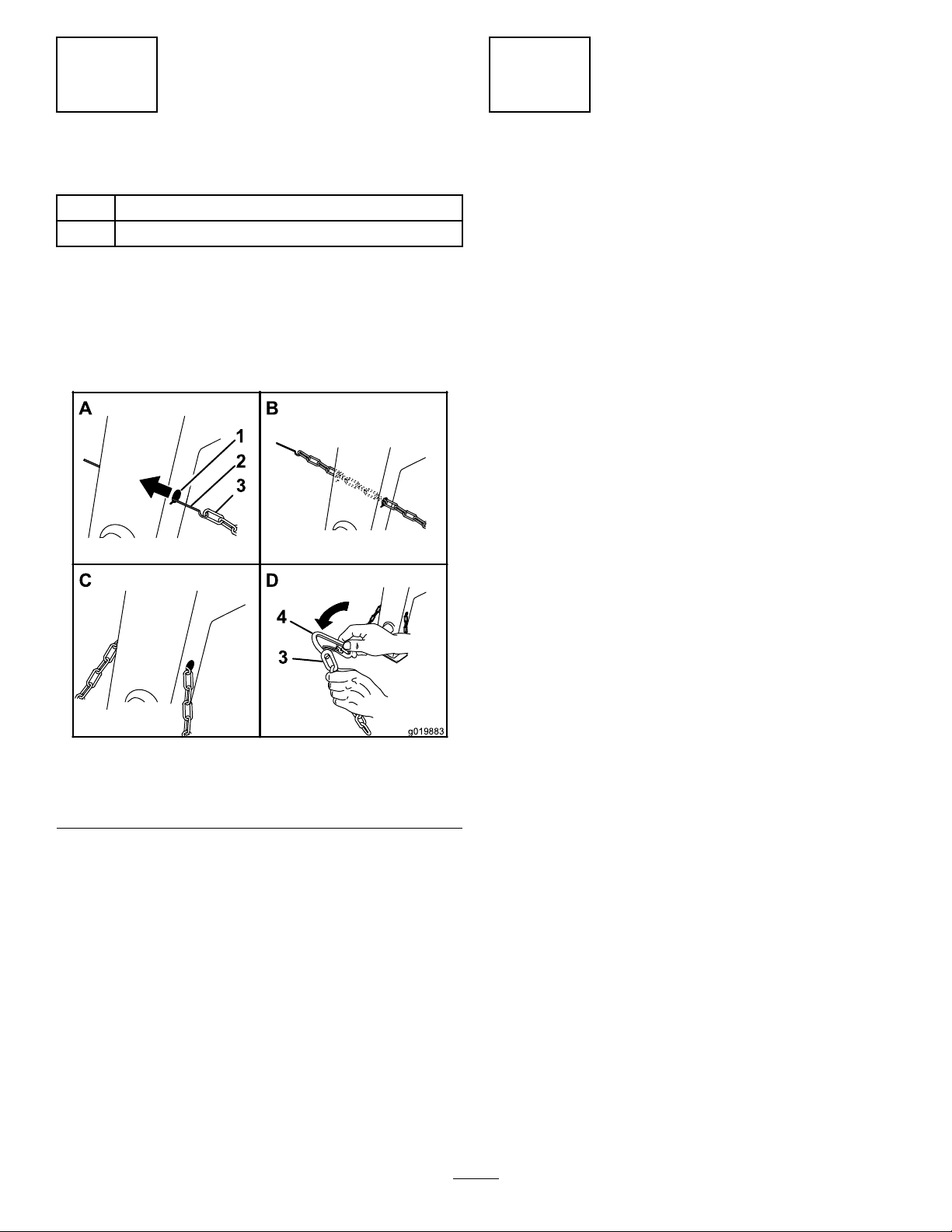

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain

2

Connectinglink

InstallingtheSafetyChaintothe

Machine

1.Formahookontheendofabendablepieceofrod

orstiffwire(notincluded),andinsertitthroughboth

keyholesinthefrontpostofthemachine(Figure4).

AdjustingtheMixingPaddles

NoPartsRequired

Procedure

Ifthemixingpaddlesandwipersneedadjustment,adjustthe

paddlesandwipers;refertoAdjustingthePaddles(page42)

Figure4

1.Keyhole

2.Rodorwire(notincluded)4.Connectinglink

2.Attachthesafetychaintothelengthofrodorwire

(Figure4).

3.Pulltherod,orwire,andthesafetychainthroughboth

keyholes(Figure4).

Note:Ensurethatapproximatelyequallengthsof

safetychainextendfromeithersideofthefrontpost.

3.Safetychain

InstallingtheConnectingLinks

1.Aligntheconnectinglinktothelastlinkinoneendof

thesafetychain(Figure4).

2.Inserttheconnectinglinkthroughthechainlinkuntil

theconnectinglinksnapsclosed(Figure4).

3.Repeatsteps1and2toinstalltheotherconnectinglink

intheotherendofthesafetychain.

9

Page 10

ProductOverview

G020897

1

2

3

4

5

6

8

9

10

12

13

14

15

16

7

11

17

18

G022173

1

2

3

4

67

8

9

10

11

12

13

5

14

15

15

16

G022174

13

1

2

3

4

5

6

7

8

9

10

11

12

14

Figure5

Rightside(Models68017Cand68021C)

1.Rearcowl

2.Frontcowl8.Drumlatch

3.Grate

4.Bagsplitter10.T owpole16.Wheel

5.Dumphandle11.Lightingwire

6.Grateliftarm12.Safety-chain

7.Clutchlever

9.Frontpost15.Axle

harness

keyhole

13.Drum

14.Chute

assembly

17.Light(2)

18.Cowllatch

Leftside(Model68024C)

1.Dumphandle

2.Bagsplitter8.Wheel

3.Grate9.Clutchlever

4.Frontcowl10.Drum

5.Rearcowl11.T owpole

6.Cowllatch

7.Light(2)13.Safety-chain

assembly

12.Lightingwire

harness

Figure7

keyhole

14.Frontpost

15.Drumlatch

16.Grateliftarm

1.Dumphandle

2.Drum7.Towpole

3.Drumlatch

4.Frontpost

5.Lightingwire

harness

Rightside(Model68024C)

6.Safety-chain

8.Grateliftarm

9.Chute

10.Wheel

Figure6

keyhole

assembly

11.Light(2)

12.Cowllatch

13.Rearcowl

14.Frontcowl

15.Grate

10

Page 11

Controls

G019875

1

1

G019874

1

G019877

G019878

1

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

ClutchLever

Theclutchleverengagesanddisengagesenginepowertothe

paddles.

•Belt-drivemodels(models68017Cand68021C)

DrumLatch

Thedrumlatchsecuresthedrumtothemixposition(upright)

formixingoperationsandwhentransportingthemachine.

Figure10

1.Drumlatch

DumpHandle

1.Clutchlever

•Gear-casemodel(model68024C)

Belt-drivemodels

Gear-casemodel

Figure8

Figure9

Usethedumphandletorotatethedrumtothedumpposition

andtorotatethedrumtothemixposition(upright).

Figure11

1.Dumphandle

1.Clutchlever

11

Page 12

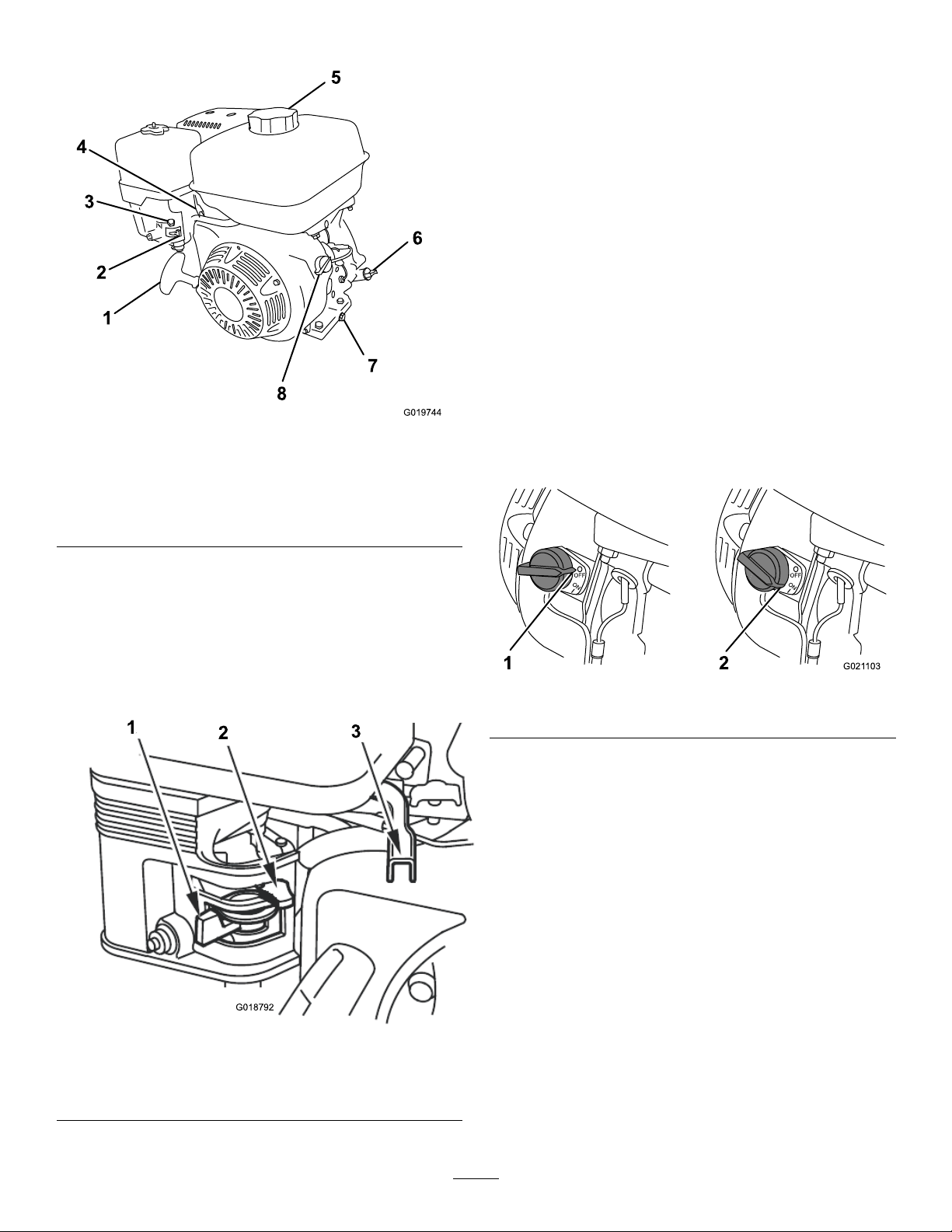

EngineControls

1

2

3

4

5

6

7

8

G019744

1

2

3

G018792

OFF

ON

1

OFF

ON

G021 103

2

Figure12

1.Recoil-starthandle5.Fuelcap

2.Fuelvalve

3.Chokelever7.Oil-drainplug

4.Throttlelever

6.Oilcap/dipstick

8.On/Offswitch

ChokeLever

Usethechokelever(Figure13)tostartacoldengine.Before

pullingtherecoil-starthandle,movethechokelevertothe

closedposition.Oncetheengineisrunning,movethechoke

levertotheopenposition.Donotusethechokeiftheengine

isalreadywarmeduportheairtemperatureishigh.

ThrottleLever

Thethrottlelever(Figure13)controlsthespeed(rpm)ofthe

engine.Itislocatednexttothechokelever.Itsetstheengine

speedandthereforecanincreaseanddecreasetherotation

speedofthemixingpaddles.Forbestperformance,setthis

controltothefastpositionwhenmixingmaterial.

EngineOn/OffSwitch

TheON/OFFswitch(Figure14)allowstheoperatorofthe

machinetostartandshutofftheengine.Thisswitchis

locatedonthefrontoftheengine.RotatetheON/OFFswitch

totheONpositiontostartandruntheengine.Rotatethe

ON/OFFswitchtotheOFFpositiontoshutofftheengine.

FuelValve

Thefuelvalve(Figure13)islocatedunderneaththechoke

lever.MovetheleverforthefuelvalvetotheONposition

beforeattemptingtostarttheengine.Whenyouhavenished

mixing,shutofftheengineandmovethefuel-valveleverto

Figure14

theOFFposition.

1.OFFposition2.ONposition

Recoil-StartHandle

Tostarttheengine,pulltherecoil-starthandle(Figure12)

quicklytoturntheengineover.Theenginecontrolsdescribed

abovemustallbesetcorrectlyfortheenginetostart.

Oil-LevelSwitch

Theoil-levelswitchislocatedinsidetheengine,anditdoes

notallowtheenginetorunintheeventtheoillevelisbelow

thesafeoperatinglimit.

Figure13

1.Fuelvalve3.Throttlelever

2.Chokelever

12

Page 13

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

MachineSpecications

Model

BatchCapacity0.17cubicm(6.0cubicft)0.23cubicm(8.0cubicft)0.34cubicm(12.0cubicft)

TotalVolume

DrumMaterialPolyethylenePolyethylene

Length

(withouttowpole)

Width86cm

Height137cm

Weight241kg

Axle

Engine

Drivebeltbeltgearbox

68017C68021C68024C

0.20cubicm(6.9cubicft)0.25cubicm(9.0cubicft)0.42cubicm(14.8cubicft)

Steel

163cm

(64inches)

(34inches)

(54inches)

(530lb)

86to117cm(34to46inches)

extendable

®

Honda

GX240Honda

193cm

(86inches)

86cm

(34inches)

137cm

0(54inches)

266kg

(585lb)

86to117cm(34to46inches)

extendable

®

GX240Honda

205.7cm

(81inches)

142.2cm

(50inches)

150cm

(59inches)

508kg

(1120lb)

142cm(56inches)

xed

®

GX340

Attachments/Accessories

AselectionofT oroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpandits

capabilities.ContactyourAuthorizedServiceDealerorDistributor.

TobestprotectyourinvestmentandmaintainoptimalperformanceofyourToroequipment,countonTorogenuineparts.

Whenitcomestoreliability,Torodeliversreplacementpartsdesignedtotheexactengineeringspecicationofourequipment.

Forpeaceofmind,insistonT orogenuineparts.

13

Page 14

Operation

G009027

1

2

G019741

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure15

1.Wearsafetyglasses.

2.Wearhearingprotection.

PreparingtoTowtheMachine

Important:Ensurethatyourtowvehiclehastowing

capacityfortheweightofthemachine.

Important:UseaClass2orlargerreceiver.

Note:Ensurethatyourtowvehiclehastheappropriatehitch

totowthemachine;optionsincludea50mm(2inch)ball

hitchorapintlehitch.

Figure16

5.Extendtheaxle(Modelsand68021C);referto

ExtendingtheAxle—Belt-DriveModels(page18).

Note:Ensurethattheelectricalconnectorofthetowvehicle

iscompatiblewiththeelectricalconnectorofthemachine.

Themachineusesastandard4-atplug.Ifyourtowvehicle

hasadifferenttypeofplug,obtainanadapterfroman

automotivepartsstore.

1.Ensuretheengineisshutoff,thefuelvalveisoff,and

thedrumisempty.

2.Ifthedrumhasaccumulatedanywater,dumpthe

drum;refertoDumpingtheDrum(page26),steps1,

3,4,and5.

3.Usingthedumplever,positionthedrumsothatitisin

themixposition(upright)andlocked.

4.Closetheenginecowlandsecurethecowllatches

(Figure16).

14

Page 15

CheckingtheTiresandWheels

G020836

1

2

3

4

G021 107

ServiceInterval:Beforeeachuseordaily—Inspectthetires

andwheels.

Aftereachuse—Torquethelugnutsto108to122

N∙m(80to90ft-lb)aftertowing.

WARNING

Failuretomaintaincorrecttirepressuremayresult

intirefailureandlossofcontrol,resultingin

propertydamageandseriousinjuryordeath.

•Checkthetirepressurefrequentlytoensure

properination.Ifthetiresarenotinatedto

thecorrectpressure,theywillwearprematurely.

•Inspectthetireconditionbeforetowingand

afteranyoperatingaccident.

TheDOTtireinformationislocatedontheside

ofeachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

2.Ensurethatthetiresareinatedtothecorrectair

pressure.ThefollowingTire-AirPressuretableshows

theappropriateairpressureforthetiresasinstalledat

thefactory.

Important:Alwayschecktheinformation

ontheactualtiresforthecorrectairpressure

requirement.

Important:Themostcommoncauseoftire

troubleisunderination.Maintainfullair

pressure.

TireAirPressure

ModelTirepressure

68017CMax414kPa(60psi)

68021Cand68024CMax241kPa(35psi)

3.Ensurethatthelugnutsaretorquedto108to122

N∙m(80to90ft-lb).Checkthetorqueofthelugnuts

initiallyandaftertowing.

Note:Torquethelugnutsinthesequenceshownin

Figure19.

Note:Thevariousmachinesinthismanualhavedifferent

weights;refertoSpecications(page13)toensurethatthe

tiresonyourmachinemeetorexceedtheweightrequirements

ofyourmachine.

1.Visuallyinspectthetiresfordamageandwear(Figure

17andFigure18)

Figure17

1.Exampleoftirewearcausedbyunderination

Figure19

1.Exampleoftirewearcausedbyoverination

Figure18

15

Page 16

HitchingaMachinewithaStampedBall

A

B

C

G020359

2

1

A

B

D

G019807

5

1

2

3

4

Coupler(optionalkit)

HitchingaMachinewithaForgedBall

Coupler(optionalkit)

1.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.

2.Oilthepivotpointsandslidingsurfacesofthecoupler

withSAE30motoroil.

3.Openthecouplerlatch(Figure20).

1.Applyremovablethread-lockingcompoundtothe

threadsofthecouplerbolttopreventthecoupler

handlefromcomingloose(Figure21).

Important:Applythread-lockingcompoundas

neededinthefuture.

Figure20

1.Bail

4.Positionthecouplerontopofthehitchball(Figure20).

5.Closethecouplerlatch(Figure20).

6.Openthebailonthesafetypin,andinsertthepin

7.Rotatethefreeendofthebailovertheendofthesafety

8.Connectthewireplugofthetowvehicletothewire

2.Safetypin

throughtheholeinthelatch(Figure20).

pinthatisprotrudingthroughthelatch(Figure20).

plugofthemachine.

Figure21

1.Couplerhandle

2.Coupler

3.Clamp

4.Bolt

5.Hitchball

2.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.

3.Pushthecouplerboltupthroughthecouplerclamp

andthecouplertop,andconnectthecouplerhandleto

thebolt(Figure21).

4.Positionthecouplersothatthesocketisontopofthe

hitchballandtheclampisundertheball.

5.Turnthecouplerhandleclockwisetothreaditontothe

boltuntilitissecure(Figure21).

Note:Useawrenchtokeeptheboltfromspinning.

6.Connectthewireplugofthetowvehicletothewire

plugofthemachine.

16

Page 17

HitchingaMachinewithaPintleHitch

G019809

A

B

D

G020084

1

2

3

4

Coupler(optionalkit)

1.Removethepinfromthepintlehitchandopenit

(Figure22).

Figure22

2.Positiontheringonthetowpoleontothehookofthe

pintlehitch(Figure22).

3.Closethetopofthepintlehitchandsecureitwiththe

pin(Figure22).

4.Connectthewireplugofthetowvehicletothewire

plugofthemachine.

HitchingaMachinewithaPinHitch

Coupler(optionalkit)

1.Positionthefrontofthepin-hitchcouplersothatit

islocatedbetweenthetopandbottomplatesofthe

pin/clevishitchofthetowvehicle,andensurethatthe

holesarealigned(Figure23).

Figure23

1.Hitchpin3.Pin-hitchcoupler

2.Hairpincotter

2.Inserta19mm(3/4inch)or22mm(7/8inch)hitch

pinthroughtheholesinthecouplerandthereceiver

hitch(Figure23).

3.Insertahairpincotterthroughtheholeinthebottom

ofthehitchpin(Figure23).

4.Connectthewireplugofthetowvehicletothewire

plugofthemachine.

4.Pin/clevis-hitchreceiver

ConnectingtheSafetyChainstothe

TowVehicle

Connectthesafetychaintothemachineandthetowvehicle

asfollows:

1.Pullthesafetychainthroughtheslotsinthekeyholes

locatedinthefrontpostofthemachine,sothatthe

lengthsoneachsideareequal(Figure24).

2.Crossbothlengthsofchainunderthetowpole.

Note:Crossingthechainsdecreasesthechancesof

thefrontofthemachinedroppingtothegroundifthe

hitchdoesnotholdtheconnection.

17

Page 18

1

2

3

G021 177

Figure24

G021 178

1

2

3

G020828

1.Connectinglinks3.Chaincrossedundertow

pole

2.Keyholesinfrontpost

3.Connecteachlengthofchaintothesafety

chain-mountingpointonthetowvehiclewiththe

connectinglinks(Figure25).

Important:Ensurethatthechainhasenough

slackforturningaroundcornerswhentowingthe

machine.

Figure26

Note:Themachineusesastandard4-atplug.Ifyourtow

vehiclehasadifferenttypeofplug,obtainanadapterfroman

automotive-partsstore.

Important:Routinelycheckthelightstoensurethat

theyareworkingproperly,includingthetaillights,brake

lights,andeachappropriateturnsignal.

CheckingtheLights

•Ensurethatthetaillightsofthemachineilluminatewhen

youturnontheheadlightsoftowvehicle.

•Ensurethatthebrakelightsofthemachineilluminate

whenyoupressthebrakepedalofthetowvehicle.

•Ensurethattheappropriateturnsignalasheswhenyou

operatethecorrespondingturnsignalofthetowvehicle.

ExtendingtheAxle—Belt-Drive

Note:Stowtheexcesschaininsidethebottomofthe

frontpostbypushingitintothekeyholesandlatching

theappropriatelinksintothekeyholeslots.

Models

Models68017Cand68021C

WARNING

Themachineisnotstablewhentowingitwiththe

axleinthenarrowposition.

Towthemachinewiththeaxleinthewideposition.

Important:Adjusttheaxletothenarrowpositiononly

tomovethemachinethroughanarrowaccesspoint,

suchasthegateofafenceorthedoorwayofabuilding.

PreparingtoChangetheAxleWidth

1.Movethemachinetoaleveljob-sitesurface.

2.Disconnectthemachinefromthetowvehicle.

Figure25

1.Connectinglink3.Chainlink

2.Safetychainmounting

pointontowvehicle

3.Ensurethatthemachineissecurefrommovement

beforeyouuseit.

4.Ensurethatthedrumisemptyandinthemixposition

(upright).

ConnectingtheLightingWireHarness

Connecttheelectricalplugofthemachinewiththeelectrical

plugofthetowvehicle,asshowninFigure26.

5.Ensurethatthedrumlatchisengagedandthatthe

drumdoesnotrotatetowardthedumpposition.

18

Page 19

AdjustingtheAxleWidth

G020019

1

1 2

3

4

3

5

6

5

G020020

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

themachineandcauseseriousinjury .

Usejackstandswhensupportingthemachine.

1.Alignajackwithanadequateliftheightandweight

capacityundertheaxle;refertoSpecications(page

13).

•Slideeachsideoftheaxleinwardtothenarrow

position(Figure28).

•Slideeachsideoftheaxleoutwardtothewide

(tow)position(Figure28).

6.Aligntheholesoftheinneraxlewiththeholesofthe

outeraxle.

7.Inserttheboltsthroughtheaxleholes(Figure28).

8.Threadthenutsontothebolts,andtorquethenuts

to87N∙m(64ft-lb).

2.Liftthemachineuntilthetiresareofftheground.

3.Useajackstandateachsupportpointontherear

frameextension(Figure27).

Figure27

1.Supportpoint(2)

4.Removetheboltsandnutsthatsecuretheinneraxleto

theouteraxle(Figure28).

TowingtheMachine

WARNING

Towingthemachineathighspeedincreasesthe

riskofahitchmalfunctionandtirefailure.Higher

speedsalsoincreasethemomentumofthemachine

andbrakingdistance.Ifthemachinebecomes

detachedfromthetowvehicleathighspeed,it

couldcausedamagetoproperty,orinjuryordeath

tobystanders.

Donotexceed88km/h(55mph)whentowingthe

machine.Forpoorroadconditionsorinclement

weather,reducespeedaccordingly.

WARNING

Towingthemachinewithmaterialinthedrum

increasestheriskofahitchmalfunctionandtire

failure.Inaddition,materialcouldbounceoutof

thedrumandhitothervehiclesand/orpeople.

Materialinthedrumincreasestheweight,which

affectsmomentumandbrakingdistance.

1.Wideposition(towing)4.Nut(narrowposition)

2.Narrowposition

3.Nut(wideposition)6.Bolt(narrowposition)

5.Aligntheinneraxletothedesiredpositionasfollows:

Figure28

5.Bolt(wideposition)

Donottowthemachinewithmaterialinthedrum.

•ReviewandunderstandSafeOperatingPractices(page5).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthemachine.

PreparingtoUsetheMachine

•Reviewallofthesafetydecalsonthemachine.

•Useahard-hat,hearingprotection,ashirtwithlong

sleevesbuttonedatthewrists,tight-ttinggloveswithout

drawstringsorloosecuffs,eyeprotection,andadust

maskorrespirator.Ameshvisoralonedoesnotprovide

sufcienteyeprotection;supplementwithprotective

glasses.

•Ensurethatyouarefamiliarwiththesafetyregulations

andshutdownproceduresdescribedintheOperator’s

ManualandtheEngineOwner’sManual.

•Ensurethatallguardsareinplaceandingoodcondition.

19

Page 20

•Ensurethatthepaddlesareinplaceandingood

A

B

D

1

G019879

2

3

4

1

condition.

•Checkthefuelandoillevelsoftheengine.

•Whenpreparingtomixmaterial:

1.Movethemachinetoaleveljob-sitesurface.

2.Removethemachinefromthetowvehicle.

3.Ensurethatthemachineissecurefrommovement

beforeyouuseit.

4.Ensurethatthedrumisinthemixposition

(upright).

5.Ensurethatthedrumlatchisengagedandthatthe

drumdoesnotrotatetowardthedumpposition.

OpeningandClosingtheCowl

4.Rotatetherearcowlupandforwarduntilitisfully

positionedontopofthefrontcowl(Figure29).

ClosingtheCowl

1.Rotatetherearcowlrearwardanddownuntilthe

receiveratthebottomcenterofthecowlisalignedwith

theV -ttingandushontheframeofthemachine

(Figure29).

2.Atthebackofthemachine,grasptheringofthelatch

andpullitontothelatchanchorontherearcowl.

3.Atthesideofthemachine,grasptheringofthelatch

andpullitontothelatchanchorontherearcowl.

4.Repeatstep3ontheoppositesideofthemachine

(Figure29).

OpeningtheCowl

1.Atthesideofthemachinewherethefrontcowland

rearcowlmeet,grasptheringofthelatchandpullit

offfromthelatchanchorontherearcowl(Figure29).

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

fuelmaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusefuelcontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltofuel.

Figure29

1.Latch3.Receiver

2.Latchanchor

2.Repeatstep1ontheoppositesideofthemachine.

3.Atthebackofthemachinewheretherearcowlmeets

theframeofthemachine,grasptheringofthelatch

andpullitofffromthelatchanchoronthecowl

(Figure29).

4.V-tting

20

Page 21

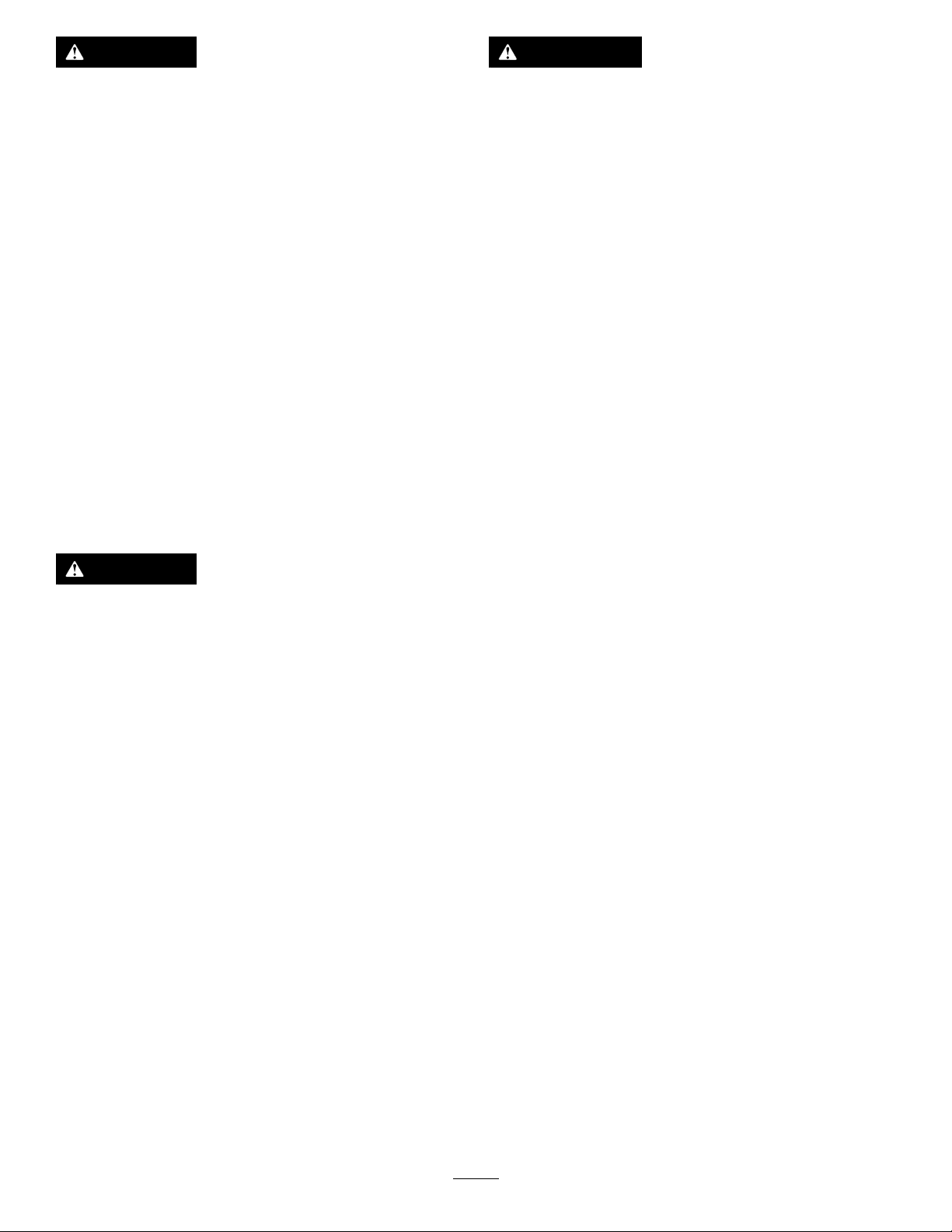

DANGER

WARNING

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storethefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless.For

longerstorageitisrecommendedthatthefueltankbe

drained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruck-bedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuel.T ominimizethechanceof

varnishdepositsinthefuelsystem,usefuelstabilizerat

alltimes.

21

Page 22

FillingtheFuelTank

1

G019799

G020679

1

Model(s)

68017Cand68021C5.3L(1.40USgallons)

68024C6.1L(1.61USgallons)

Fueltankcapacity

1.Parkthemachineonalevelsurface,shutofftheengine,

andallowtheenginetocool.

2.Cleanaroundthefuelcapandremoveit(Figure30).

Figure30

1.Fuelcap

3.Addunleadedgasolinetothefueltank,untilthelevel

isatthebottomofthemaximumfuellevel,asshown

inFigure31.

Important:Thisspaceinthetankallowsfuelto

expand.Donotllthefueltankcompletelyfull.

Figure31

1.Maximumfuellevel

4.Installthefuelcapsecurely(Figure30).

5.Wipeupanyfuelthatmayhavespilled.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategory

or higher

Model(s)Crankcasecapacity

68017C,68021C,and68024C1.1L(1.2USqt)

.

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

Note:UseSAE10W-30forgeneraluse.Youcanuse

theotherviscositiesshowninthechartwhentheaverage

temperatureinyourareaiswithintheindicatedrange(Figure

32).

SJ , SL, SM,

22

Page 23

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

Figure32

G019815

1

2

3

1.Placethemachineonaat,levelsurface,andshutoff

theengine.

2.Allowtheenginetocool.

3.Cleanaroundtheoildipstick.

4.Removetheoil-llcap/dipstickandwipetheendclean

(Figure33).

Figure34

Figure33

1.Fillport

2.Dipstick

3.Oil-levelupperlimit

4.Oil-levellowerlimit

5.Slidethedipstickfullyintothellportwithout

threadingitintotheport(Figure33).

6.Removethedipstickandlookattheend.Ifthe

engine-oillevelislow ,slowlypouronlyenoughoilinto

thellporttoraisetheleveltotheFullmarkonthe

dipstick(Figure33).

Note:ToroPremiumEngineOilisavailablefrom

yourAuthorizedToroDealer.

1.Chokelever

2.Fuelvalve

3.Throttlelever

2.MovetheleverofthefuelvalvetotheONposition—all

thewaytotheright(Figure34);refertoFuelValve

(page12).

3.Positionthechokeleverasfollows:

•Tostartacoldengine,movethechokelevertothe

CLOSEDposition—allthewaytotheleft(Figure

34);refertoChokeLever(page12).

•Tostartawarmengine,movethechokeleverin

theOPENposition—allthewaytotheright.

4.RotatetheengineswitchtotheONposition(Figure

34);refertoEngineOn/OffSwitch(page12).

5.Pulltherecoil-starthandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly.Returnthe

recoil-starthandlegently(Figure35).

7.Replaceandsecurethedipstick(Figure33).

StartingandShuttingOffthe Engine

StartingtheEngine

1.Ontheengine,movethethrottleleverawayfromthe

MINposition,1/3ofthewaytowardtheMAXposition

(Figure34);refertoThrottleLever(page12).

23

Page 24

G019747

Figure35

G019873

1

2

Note:IfthechokeleverissettotheCLOSEDpositionto

starttheengine,graduallymovethechokeleverbacktoward

theOPENpositionastheenginewarmsup.Iftheengine

stallsorhesitates,movethechokeleverbacktowardthe

CLOSEDpositionuntiltheenginerunssmooth.Allowthe

enginetowarmup,thenmovethechokelevertotheOPEN

position;refertoChokeLever(page12).

Usetheclutchlevertocontrolthepowertransmissiontothe

paddlesofthemachine.

ControllingthePaddles—Belt-drive

Models

Models68017Cand68021Conly

ShuttingOfftheEngine

WARNING

Inanemergencysituation,shutofftheengine

immediately.

Important:Duringnormaloperation,iftheengine

hasbeenworkinghardorishot,letitidleforaminute

beforeshuttingofftheengine.Thishelpstocoolthe

enginebeforeshuttingoff.

1.EnsurethatthechokeleverisintheOFFposition

(Figure34);refertoChokeLever(page12).

2.MovethethrottlelevertotheMINposition(Figure

34);refertoThrottleLever(page12).

3.RotatetheengineswitchtotheOFFposition;referto

EngineOn/OffSwitch(page12).

ControllingthePaddles

DANGER

Thismachineiscapableofamputatinghands.

•Stayintheoperator’spositionwhilethemachine

isrunning.

•Keepallbystandersasafedistancefromthe

machine.

•Stopthemachineimmediatelyifanypeopleor

animalsentertheworkarea.

•Neverplaceanypartofyourbodyintoaposition

thatcausesanunsafeoperatingcondition.

Figure36

1.Offposition2.Onposition

24

Page 25

ControllingthePaddles—Gear-case

1

2

G019872

A

B

D

G019973

Model

Model68024Conly

Figure37

1.Onposition2.Offposition

MixingtheMaterial

DANGER

Eyeandskincontactwithconcretematerialsand

breathingthedustinvolvedishazardoustoyour

health.

MixingaBatchofMaterialinthe

Machine

1.Ensurethatthereisnoold,loosematerialinthedrum

thatcancontaminatethebatchofmaterial;referto

CleaningtheDrum(page26)andDumpingtheDrum

(page26),thenreturnthedrumtotheuprightposition.

Note:Ensurethatthedrumisinthemixposition

(upright)andthedrumlatchisengaged.

2.MovetheclutchlevertotheOFFposition;referto

ControllingthePaddles(page24).

3.Starttheengine;refertoStartingtheEngine(page23).

Note:Allowtheenginetowarm-upat2/3throttle

for1to2minutes.

4.SetthethrottleleverontheenginetotheMAXposition;

refertoThrottleLever(page12).

5.MovetheclutchlevertotheONposition;referto

ControllingthePaddles(page24).

6.Addtheingredientsforthebatchasfollows:

A.Pourwaterintothedrumthroughthegratingof

thedrumguard.

B.Addtheplaster,cement,orotherbindingmaterial.

Note:Youcanopenbagsofcement,plaster,and

bindingmaterialsbyloweringthebagontothe

bagsplitter(Figure38).

•Ensurethatthereisadequateairventilation.

•Wearadustmasktopreventinhalationofdust

whileusingthemachine;refertoSafeOperating

Practices(page5).

•Avoiddirectcontactofcementandconcrete

materialswithskinandeyes.

DANGER

Contactwiththemixingpaddlescouldcause

damageorinjury.

Neverputyourhandsortoolsinsidethedrumwhile

theengineisrunning.

Important:Donotaddmorematerialthanthebatch

capacityofthemachine;refertoSpecications(page13).

Note:Followthemanufacturer’sinstructionsthatareprinted

onthepackagingoftheproductyouareusing.

Figure38

C.Ifyouareusingsandand/orotherreinforcing

materials,addthemintothedrum.

7.Allowthepaddlestomixthematerialuntilthe

ingredientshaveauniformappearance.

Note:Ifneeded,addwaterorplaster,cement,or

otherbindingmaterialuntiltheconsistencyofthe

batchiscorrect.

25

Page 26

8.Releasethedrumlatchanddumpthedrum;referto

1

2

3

4

G019972

DumpingtheDrum(page26).

UsingtheDrum

DANGER

Note:Allowthemachinetocompletelydischargethe

contentsofthedrum.

5.Rotatethedumphandleclockwiseuntilthedrum

latchlocksthedrumintheuprightposition(Figure39).

6.Afterdischargingabatchofmaterial,cleanthedrum;

refertoCleaningtheDrum(page26).

Contactwiththemixingpaddlescouldcause

damageorinjury.

Neverputyourhandsinsidethedrumwhilethe

engineisrunning.

DumpingtheDrum

Note:Whendumpingabatchofmaterial,leavetheengine

runningandtheclutchintheONpositionsothattherotating

paddleshelpdischargethematerial.

1.Alignawheelbarroworsimilarcontainerofadequate

capacityinthepathofthedrumopening.

2.Graspthedumphandlewithyourlefthand(Figure39).

Note:Thisstepcleansthepaddlesanddrumbetween

batchesandpreventdriedmaterialfromforming,and

contaminatingthenextbatchofmaterial.

CleaningtheDrum

Important:Donotstrikeonthedrumwithashovel,

hammer,oranyotherdevicetoloosenanyaccumulated

driedmaterials.

1.Stoptherotationofthepaddlesbymovingtheclutch

levertotheOFFposition;refertoControllingthe

Paddles(page24).

2.RotatetheengineON/OFFswitchtotheOFFposition;

refertoShuttingOfftheEngine(page24).

3.Ensurethatthedrumisinthemixposition(upright);

refertoDumpingtheDrum(page26),step5.

4.Spraythemachinewithwatertoremoveany

accumulatedmaterial.

5.Starttheengine;refertoStartingtheEngine(page23).

6.Starttherotationofthepaddlesbymovingtheclutch

levertotheOnposition;refertoControllingthe

Paddles(page24).

Figure39

1.Dumphandle(mix

position)

2.Drumlatch(release

position)

3.Drumlatch(locked

position)

4.Dumphandle(dump

position)

Note:Whendumpingabatchofmaterial,aligna

wheelbarroworasimilarcontainerofadequatecapacity

beneaththechute.

3.Liftthehandleofthedrumlatch(Figure39).

4.Withbothhandsonthedumphandle,rotateit

counterclockwisetodischargethecontentsofthe

drum(Figure39).

7.Dumpthedrum;refertoDumpingtheDrum(page

26).

26

Page 27

Maintenance

Important:Beforeperforminganymaintenanceprocedures,rstshutofftheengine,wait5minutestoallowall

movingpartstocometoacompletestopandcool,anddisconnectthespark-plugwire.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Aftereachuse

Every40hours

Every50hours

Every100hours

Every300hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthegear-caseclutch(Model68024Conly).

•Inspectthebeltsandadjustasnecessary.

•Inspectthetiresandwheels.

•Checktheengine-oillevel.

•Inspecttheair-cleanerelements.

•Checktheclutchoperation(Model68024Conly).

•T orquethelugnutsto108to122N∙m(80to90ft-lb)aftertowing.

•Cleanthedrumbetweenmixingbatchesofmaterial.

•Lubricatethetrunnions.

•Cleanthemachine.

•Checkthegear-caseoil(Model68024Conly).

•Inspectthebeltsandadjustasnecessary.

•Checktheclutchoperation(Models68014C,68017C,and68021Conly).

•Cleantheair-cleanerelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil.

•Checkthesparkplug.

•Cleanthesparkarrester.

•Cleanthesedimentcup.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindusty

operatingconditions.

•Replacethesparkplug.

Every800hours

Monthly

Yearlyorbeforestorage

Every2years

•Replacethegear-caseoil(Model68024Conly).

•Lubricatethepillow-blockbearings.

•Cleanthefuel-sedimentcup.

•Replacethebelts.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

27

Page 28

Premaintenance

G019281

1

G020752

G020753

Procedures

PreparingtheMachinefor Maintenance

1.Parkthemachineonalevelsurface.

2.Removethemachinefromthetowvehicle.

3.Ensurethatthemachineissecurefrommovement

beforeyouuseit.

4.Opentherearcowl;refertoOpeningtheCowl(page

20).

5.Ensurethattheengineandmuferarecool.

6.Disabletheengine;refertoDisconnectingthe

Spark-PlugWire(page28).

DisconnectingtheSpark-Plug Wire

Pullthespark-plugwireofftheterminalofthesparkplug

(Figure40).

RemovingtheDividerPlate

1.Unlatchandopenthecowl;refertoOpeningtheCowl

(page20).

2.Useawrenchtoremovethe4boltsthatsecurethe

dividerplatetothefrontcowl.

Note:Keeptheboltsforinstallingthedividerplate.

Figure41

3.Toremovethedividerplate,liftitupwardandrotate

itcounterclockwisesothatitclearsvariousengine

components.

Figure40

1.Sparkplug

RemovingandInstallingthe DividerPlate

Youneedtoremovethedividerplatetoprovideaccessbefore

performingsomemaintenanceprocedures.

Note:Model68024Cdoesnothaveadividerplate.

InstallingtheDividerPlate

1.Guidethedividerplateintopositionagainstthefront

cowl.

Note:Startwiththedividerplaterotatedslightly

counterclockwise,andthenrotateitclockwisewhile

loweringitintoposition.

Ensurethatthedividerplateisnotbackward.

Figure42

2.Aligntheboltholesinthedividerplateandthefront

cowl.

3.Installeachofthe4bolts,andhand-tightenthemto

preventcross-threading.

4.Tightentheboltswithawrenchuntiltheyaresecure.

28

Page 29

Lubrication

2

3

G020684

1

3

G020685

LubricatingtheBearingsand Seals

ServiceInterval:Aftereachuse—Lubricatethetrunnions.

Monthly—Lubricatethepillow-blockbearings.

Note:Thepillow-blockbearingsareinsidethe

cowl—removethedividerplatetoaccessthem;referto

RemovingtheDividerPlate(page28).

Model68024Cdoesnothaveadividerplate.

GreaseType:No.2lithiumgrease.

1.Cleanaroundeachgreasettingwitharagandliftthe

plasticcapoffthegreasetting(Figure43).

2.Pumpgreaseintoeachttingasfollows:

•Forthepillow-blockbearings,pump1shotof

greaseintoeachtting(Figure43).

•Forthetrunnions,pumpseveralshotsofgrease

intoeachttinguntilitstartstooozeoutofthe

bearinghousing(Figure43).

Important:Pumpgreaseinslowlyandcarefully

topreventdamagetothebearingseals.

3.Wipeupanyexcessgrease.

Figure43

1.Pillow-blockbearings3.Fronttrunnion

2.Reartrunnion

29

Page 30

EngineMaintenance

G020216

1

2

3

4

5

6

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspectthe

air-cleanerelements.

Every50hours—Cleantheair-cleanerelements.Clean

themmorefrequentlyindustyoperatingconditions.

Every300hours/Yearly(whichevercomes

rst)—Replacethepaperair-cleanerelement.Replace

itmorefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithoutthe

air-lterassembly;extremeenginedamagecanoccur.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

3.Removethenutthatsecuresthecover(Figure44).

Figure44

1.Covernut

2.Cover

3.Wingnut6.Base

4.Removethecover.

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamandpaperelementsfromthebase

(Figure44).

6.Removethefoamelementfromthepaperelement

(Figure44).

7.Inspectthefoamandpaperelements,andreplacethem

iftheyaredamagedorexcessivelydirty.

8.Ifthepaperelementisexcessivelydirty,replaceit.

Note:Nevertrytobrushdirtoffthepaperelement;

brushingforcesthedirtintothebers.

9.Cleanthefoamelementinwarm,soapywaterorin

anonammablesolvent.

4.Foamelement

5.Paperelement

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

30

Page 31

10.Rinseanddrythefoamelementthoroughly.

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

1

2

3

G019750

11.Dipthefoamelementincleanengineoil,thensqueeze

outtheexcessoil.

Note:Excessoilinthefoamelementrestrictstheair

owthroughtheelementandmayreachthepaper

lterandclogit.

12.Wipedirtfromthebaseandthecoverwithamoistrag.

DrainingtheEngineOil

WARNING

Oilmaybehotaftertheenginehasbeenrun,and

contactwithhotoilcancauseseverepersonalinjury.

Avoidcontactingthehotengineoilwhenyoudrain

it.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

13.Installtheair-cleanerelementsandensurethattheyare

properlypositioned.

14.Securelyinstallthecoverwiththenut.

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDealer.

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategory

or higher

68017C,68021C,and68024C1.1L(1.2USqt)

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

.

SJ , SL, SM,

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page28).

3.Placeadrainpanunderthedrainholeoftheengine

(Figure46).

Note:UseSAE10W-30forgeneraluse.Youcanuse

theotherviscositiesshowninthechartwhentheaverage

temperatureinyourareaiswithintheindicatedrange(Figure

45).

Figure45

Figure46

1.Drainplug3.Drainpan

2.Drainhole

4.Removethedrainplugandcatchtheoilinthedrain

pan(Figure46).

5.Whentheoilhasdrainedcompletely,installthedrain

plugwithanewwasher(Figure46).

Note:Disposeoftheusedoilatacertiedrecycling

center.

FillingtheEngineCrankcasewithOil

1.Removethedipstick(Figure47)andslowlypouroil

intothellholeuntiltheoilreachestheupper-limit

mark(bottomedgeoftheoil-llhole)onthedipstick.

31

Page 32

Figure47

G019749

G019300

1 2

4

3

1.Oil-llhole3.Oil-levelupperlimit

2.Dipstick

4.Oil-levellowerlimit

2.Replaceandsecurethedipstick.

3.Wipeupanyspilledoil.

ServicingtheSparkPlug

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Checkthe

sparkplug.

Every300hours/Yearly(whichevercomes

rst)—Replacethesparkplug.

Type:NGKBPR6ESorequivalent

Gap:0.7to0.8mm(0.028to0.031inch)

Note:Usea20mm(13/16inch)spark-plugwrenchfor

removingandinstallingthesparkplug.

5.Rotatethesparkplugcounterclockwiseusinga20mm

(13/16inch)spark-plugwrenchtoremovetheplug

andthesealingwasher(Figure49).

Figure49

CheckingtheSparkPlug

Note:Useagappingtool/feelergaugetocheckandadjust

thegap.Installanewsparkplugifnecessary.

1.Lookatthecenterofthesparkplug(Figure50).Ifyou

seelightbrownorgrayontheinsulator,theengineis

operatingproperly.

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

RemovingtheSparkPlug

1.Parkthemachineonalevelsurfaceandshutoffthe

engine;refertoShuttingOfftheEngine(page24).

2.Ensurethatthemachinesurfacesarecool.

3.Pullthespark-plugwireofftheterminalofthespark

plug(Figure48).

1.Sparkplug

4.Cleanaroundthesparkplug.

Figure50

1.Sideelectrode

2.Centerelectrode4.0.7to0.8mm(0.028to

3.Insulator

0.031inch)gap

2.Useagappingtoolforsparkplugsorafeelergaugeto

measurethegapbetweenthesideelectrodeandcenter

electrode(Figure50).

Figure48

2.Wire

3.Ifthegapisnotwithinthespeciedrange,dothe

following:

A.Ifthegapistoosmall,carefullybendtheside

electrodeawayfromthecenterelectrodeuntil

thegapbetweentheelectrodesis0.7to0.8mm

(0.028to0.031inch).

32

Page 33

B.Ifthegapistoolarge,carefullybendtheside

G019331

10

10

1

2

3

4

5

6

7

8

9

11

12

electrodetowardthecenterelectrodeuntilthe

gapbetweentheelectrodesis0.7to0.8mm(0.028

to0.031inch).

InstallingtheSparkPlug

Important:Ensurethatthegapbetweenthesideand

centerelectrodesiscorrectbeforeinstallingthespark

plug.

1.Threadthesparkplugclockwiseintothespark-plug

holebyhand.

Note:Avoidcross-threadingthesparkplugwiththe

threadsofthespark-plughole.

2.Rotatesparkplugclockwiseusinga20mm(13/16

inch)spark-plugwrenchuntiltheplugandsealing

washerareseated(Figure49).

ServicingtheSparkArrester

CleaningtheSparkArrester

ServiceInterval:Every100hours

Note:Asparkarresterisavailableasanoption.Ifyou

requireasparkarrester,contactyourAuthorizedToroService

Dealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

WARNING

Iftheenginehasbeenrunning,themuferwillbe

hot.

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page28).

3.Tightenthesparkplugasfollows:

•Wheninstallinganin-servicesparkplug,tighten

thepluganadditional1/8to1/4turn.

•Wheninstallinganewsparkplug,tightentheplug

anadditional1/2turn.

4.Pushthespark-plugwireontotheterminalofthespark

plug(Figure48).

Note:Model68024Cdoesnothaveadividerplate.

2.Removethe2nuts(8mm)andremovethemufer

fromthecylinder(Figure51).

Figure51

1.Deector(if

applicable)

2.Protector6.Nut,8mm

3.Screw(6mm)7.Gasket

4.Mufer8.Bolt(8mm)12.Screw(4mm)

3.Removethe3screws(4mm)fromtheexhaust

deectorandremovethedeector(Figure51).

4.Removethescrews(5mmand6mm)fromthemufer

protector,andremovethemuferprotector(Figure

51).

5.Removethescrew(4mm)fromthesparkarresterand

removethesparkarresterfromthemufer(Figure51).

5.Exhaustpipe

9.Sparkarrester

10.Screws(5mm)

11.Exhaustport

33

Page 34

6.Useabrushtocarefullyremovecarbondepositsfrom

1

2

G019332

3

2

4

1

5

G0201 19

G020120

1

2

3

5

6

4

thespark-arresterscreen(Figure52).

Note:Replacethesparkarresterifithasbreaksor

holes.

Figure53

Figure52

1.Screen

2.Brush

7.Installthesparkarrester,muferprotector,exhaust

deector,andmuferinthereverseorderof

disassembly.

8.Installthedividerplate;refertoInstallingtheDivider

Plate(page28).

RemovingandInstallingthe Engine

Models68017Cand68021Conly

RemovingtheEngine

WARNING

Thespringisundertensionwheninstalledandcan

causepersonalinjury.

1.Anchorbracket

2.Enginedeck

3.Spring-removaltool(Toro

part92-5771)

4.Spring-removaltool

(springremoved)

5.Spring(springremoved)

7.Removetheboltandnutthatsecuretherearbracket

fortheengine-deckhingetotheframeofthemachine

(Figure54).

Becarefulwhenremovingthespring .

1.Parkthemachineonalevelsurfaceandshutoffthe

engine;refertoDisconnectingtheSpark-PlugWire

(page28).

2.Ensurethattheengineandtheexhaust-systemsurfaces

arecool.

3.Removethedividerplate;refertoRemovingand

InstallingtheDividerPlate(page28).

4.Removethebeltguide;refertoRemovingtheBelts

(page39).

5.Removethebelts;refertoRemovingtheBelts(page

39).

6.Usingaspring-removaltool(T oropart92-5771),

removethespringfromtheanchorbracketonthe

enginedeck(Figure53).

Note:Leavetheotherendofthespringattachedto

theframeofthemachine.

Figure54

1.Enginedeck4.Frame

2.Pivot5.Nut

3.Rearhingebracket6.Bolt

8.Liftupontherearedgeoftheenginedeckandremove

thehingebracket(Figure54).

9.Slidetheenginedeckrearwardandoutfromthe

forwardhingebracket(Figure55).

Note:Donotremovetheforwardhingebracket.

34

Page 35

G020121

Figure55

2

3

4

1

G019333

10.Removetheengineandenginedeckfromthemachine

(Figure55).

InstallingtheEngine

1.Aligntheengineandenginedecktotherearframeof

themachine.

FuelSystem

Maintenance

ServicingtheFuelSystem

CleaningtheSedimentCup

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Cleanthe

sedimentcup.

Yearlyorbeforestorage—Cleanthefuel-sedimentcup.

Underneaththefuelvalveisasedimentcuptocatchdirtin

thefuel.

1.Parkthemachineonalevelsurfaceandshutoffthe

engine;refertoShuttingOfftheEngine(page24).

2.Ensurethattheengineandtheexhaust-systemsurfaces

arecool.

3.Movethefuel-valvelevertotheOFFposition,allthe

waytotheleft(Figure56).

4.Unscrewthesedimentcup(Figure56).

5.RemovethefuellterandO-ring(Figure56).

Note:DonotmisplacetheO-ring.

Note:Thedrivepulleyontheenginemustalign

forward.

2.Alignthepivotontheenginedeckwiththeforward

hingebracket(Figure55).

3.Slidetheenginedeckforwardandthepivotintothe

forwardhingebracket(Figure55).

4.Aligntherearhingebracketwiththepivotonthe

engine-deckhinge(Figure55).

5.Liftupontherearedgeoftheenginedeckandslipthe

hingebracketontothepivot.

6.Securetherearbrackettotheframeofthemachine

usingtheboltandnut(Figure54)removedinstep7of

RemovingtheEngine(page34).

7.Usingaspring-removaltool,(T oropart92-5771),

installthetensionspringtotheanchorbracketonthe

enginedeck(Figure53).

8.Installthebeltsandbeltguide;refertoReplacingthe

Belts—Belt-DriveModels(page39).

9.Adjustthebeltguide;refertoAdjustingtheBeltGuide

(page40).

10.Installthedividerplate;refertoRemovingand

InstallingtheDividerPlate(page28).

Figure56

1.Fuelvalve(Off)3.Fuellter

2.O-ring4.Sedimentcup

Note:DonotcleantheO-ringinsolvent.

6.Cleanthefuellterandsedimentcupusinga

nonammablesolvent,anddryitcarefully.

7.WipetheO-ringwithaclean,drycloth.

8.Installthefuellterinthebottomofthecarburetor

(Figure56).

9.AligntheO-ringintothegrooveinthesedimentcup

andinstallthesedimentcuptofuel-valvehousing.

35

Page 36

10.MovetheleverofthefuelvalvetotheONposition(all

1

2

G020122

thewaytotheright)andcheckforleaks.Ifitleaks,

replacetheO-ring.

DrainingtheFuelTank

1.Removetheengine;refertoRemovingtheEngine

(page34).

DriveSystem

Maintenance

ServicingtheGear Case—Gear-CaseModel

2.Removethefuelcapbyrotatingitcounterclockwise.

Figure57

3.Alignadrainpantothehingeoftheenginedeck.

4.Rotatetheengineonthehingesideoftheenginedeck

anddrainthefuelfromthetank.

5.Carefullylowertheengineandenginedeck.

6.Installthefuelcap.

7.Installtheengine;refertoInstallingtheEngine(page

35).

Model68024Conly

CheckingtheClutchOperation

ServiceInterval:Beforeeachuseordaily—Checktheclutch

operation(Model68024Conly).

1.MovetheclutchlevertotheOFFposition;referto

ControllingthePaddles(page24).

2.Starttheengine;refertoStartingtheEngine(page23).

3.Ensurethattheenginethrottleissettothe2/3

position.

4.IfthepaddlesrotatewiththeclutchlevertotheOFF

positiondothefollowing:

A.Shutofftheengine;refertoShuttingOffthe

Engine(page24).

B.Checktheclutch-leverforce;refertoChecking

theClutchLever(page36).

CheckingtheClutchLever

ServiceInterval:Aftertherst25hours—Checkthe

gear-caseclutch(Model68024Conly).

Important:Checkthegear-caseclutchifthepaddles

rotatewhentheclutchleverisintheOFFposition,ifthe

paddlesrotateslowly,oriftheclutchbeginstoslip.

1.EnsurethattheengineisOFF;refertoShuttingOff

theEngine(page24).

2.Locatetheclutchleveratthebackofthemachine;refer

toClutchLever(page11).

3.MovetheclutchlevertotheOFFposition;referto

ControllingthePaddles(page24).

4.Attachaspringscalewitharangeof15to30kg(35to

55lb)tothegripoftheclutchlever(Figure58).

36

Page 37

G022166

1

2

3

Figure58

G019900

1

2

3

1.Springscale3.Clutchlever

2.15to30kg(35to55lb)

5.Usingthespringscale,pulltheclutchhandletotheON

positionasshowninFigure58.

6.Observethespringscalewhilepullingtoseewhatthe

highestpressureiswhenmovingtheclutchhandle

fromtheOFFpositiontotheOnposition(Figure58).

Figure59

Note:Normalclutchpressureis15to30kg(35to

55lb).

7.Iftheclutchpressureisgreaterthanorlessthan

15to30kg(35to55lb),contactanAuthorizedT oro

ServiceDealer.

CheckingtheGear-CaseOil

ServiceInterval:Every40hours—Checkthegear-caseoil

(Model68024Conly).

Important:Iftheoillevelinthegearcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengineorthegearcase.Thistypeofdamageisnot

coveredbythewarranty .

OilType:SAE90gearoil

Gear-caseCapacity:2.13L(72oz)

1.Locatethegearcasebetweentheengineandthefront

cowl.

2.Attherightsideofthegearcase,examinetheoillevel

inthesightglass(Figure59).

1.Fillplug3.Drainplug

2.Sightglass

3.Iftheoillevelisbelowthebottom1/3ofthesight

glass,addoilasfollows:

A.Removethellplugfromthellportinthe

housingofthegearcase(Figure59).

B.Slowlyaddthespeciedoilintothellportuntil

theoillevelisbetween1/3and1/2ofthesight

glass(Figure59).

C.Cleanthellplug.

D.ApplyPTFEthread-sealingtapetothethreads

oftheplug.

E.Installtheplugintothellportinthehousing

(Figure59).

ReplacingtheGear-CaseOil

ServiceInterval:Every800hours—Replacethegear-case

oil(Model68024Conly).

1.Alignadrainpanwitha3-quartcapacityunderthe

drainplug(Figure59).

2.Removethedrainplugfromthedrainport,and

completelydrainthegear-caseoil(Figure59).

3.Removethellplug(Figure59).

4.Cleanthedrainandllplugs,andapplyPTFE

thread-sealingtapetotheplugthreads.

5.Installthedrainpluginthedrainport(Figure59).

6.Slowlyaddthespeciedoilintothellportuntilthe

oillevelisbetween1/3and1/2ofthesightglass

(Figure59).

7.Installthellpluginthellport(Figure59).

37

Page 38

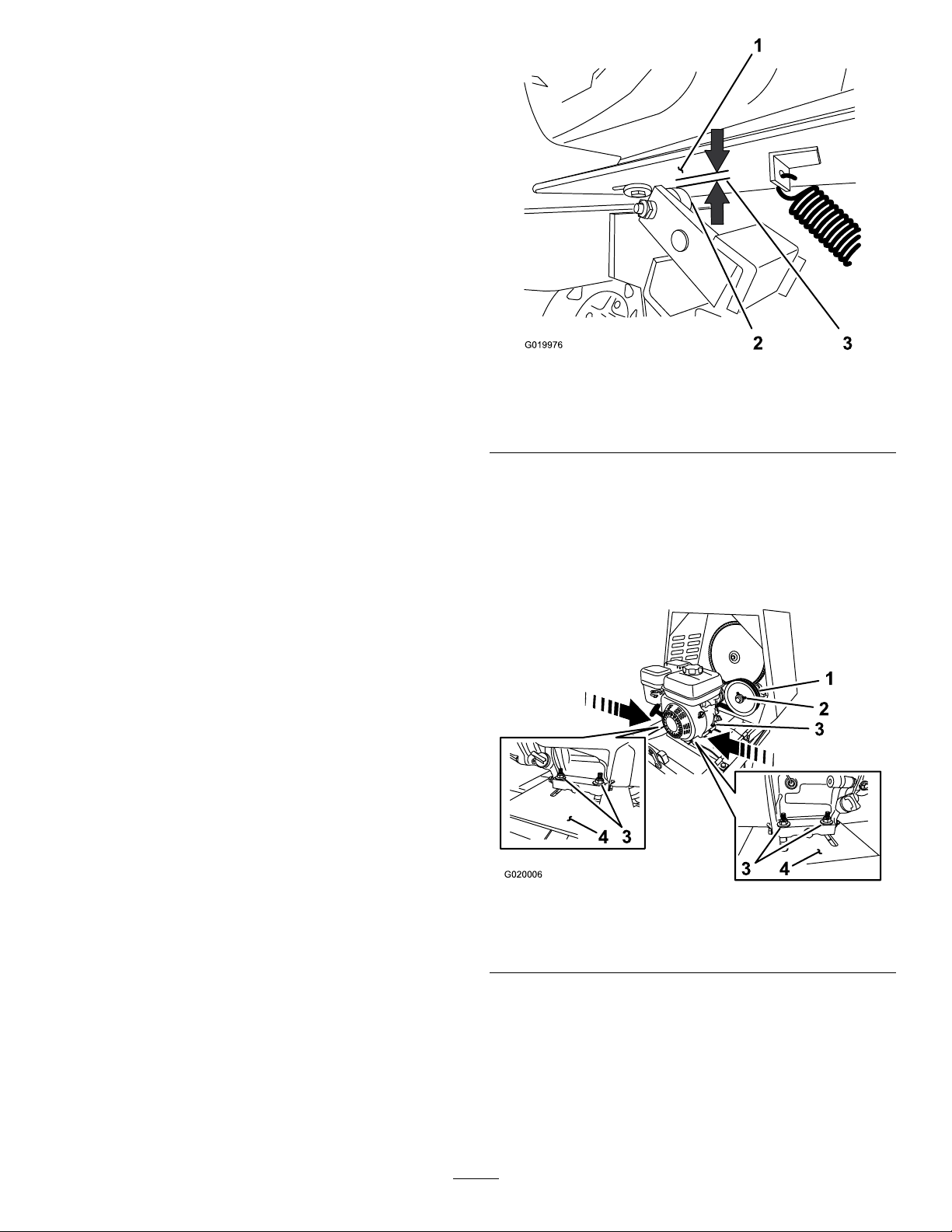

BeltMaintenance

G019976

1

2

3

4

3

4

3

1

2

3

G020006

ServicingtheBelts—Belt-Drive Models

Models68017Cand68021Conly

InspectingtheBelts

ServiceInterval:Aftertherst25hours—Inspectthebelts

andadjustasnecessary.

Every40hours—Inspectthebeltsandadjustas

necessary.

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page28).

2.MovetheclutchlevertotheOFFposition;referto

ControllingthePaddles—Belt-driveModels(page24).

3.Examinethebeltsforwearordamage.Ifthebeltsare

wornordamaged,replacethem;refertoServicingthe

Belts—Belt-DriveModels(page38).

4.Examinethepulleysforwear,damage,and

misalignment;refertoReplacingtheBelts—Belt-Drive

Models(page39).

5.Installthedividerplate;refertoInstallingtheDivider

Plate(page28).

AdjustingtheBeltT ension

Clutchairgap:6to10mm(1/4to3/8inch)

1.MovetheclutchlevertotheONposition;referto

ControllingthePaddles(page24).

2.Measuretheairgapbetweentheenginedeckandthe

rollerontheclutch(Figure60).

Figure60

1.Enginedeck

2.Clutchroller

3.Ifthemeasuredairgapisnotwithinthespecied

range,adjustthegapasfollows:

A.MovetheclutchlevertotheOFFposition;refer

toControllingthePaddles(page24).

B.Loosenthenutsandboltsthatsecuretheengine

totheenginedeck(Figure61).

3.Clutchairgap:6to10mm

(1/4to3/8inch)

Figure61

1.Idlerpulley3.Nutandbolt

2.Setscrew

C.Movetheenginepositionasfollows:

•Increasetheairgap—movetheengine

awayfromtheidlerpulley(Figure61).

•Decreasetheairgap—movetheengine

towardtheidlerpulley(Figure61).

D.Alignastraightedgeacrosstheenginepulleyand

theidlerpulley(Figure62).

38

4.Enginedeck

Page 39

G020009

1 2

3

4

5

6 7 8

Figure62

2

G020010

2

3

4

1

G020012

Figure63

1.Bolt2.Beltguide

4.Sliptheforwardbeltforwardandofftheidlerpulley

(Figure64).

1.Enginepulley

2.Idlerpulley6.Jamnut

3.Reductioncase(engine)7.Setscrew

4.Beltguide

5.Idlershaft

8.Straightedge

E.Ifneeded,pivottheengineontheenginedeck

untiltheenginepulleyandtheidlerpulleyare

alignedtothestraightedge(Figure62).

F.Tightenthenutsandboltsthatsecuretheengine

totheenginedecktoatorqueof18N∙m(13ft-lb).

G.Checktheairgapbetweentheenginedeckand

therollerontheclutch.Iftheairgapisnotwithin

thespeciedrange,repeatstep3untiltheairgap

measurementiswithinthespeciedrange.

H.Installthedividerplate;refertoInstallingthe

DividerPlate(page28).

Replacingthe Belts—Belt-DriveModels

ServiceInterval:Every2years—Replacethebelts.

Models68017Cand68021Conly

RemovingtheBelts

1.MovetheclutchlevertotheOFFposition;referto

2.Removethedividerplate;refertoRemovingthe

3.Removetheboltthatsecuresthebeltguidetothe

ControllingthePaddles—Belt-driveModels(page24).

DividerPlate(page28).

engine,andremovethebeltguide(Figure63).

Figure64

1.Enginepulley3.Idlerpulley

2.Forwardbelt4.Rearbelt

5.Sliptherearbeltrearwardandofftheidlerpulley

(Figure64).

6.Slipthebeltsofftheenginepulley.

7.Removethebeltsfromthemachine.

InstallingtheBelts

1.EnsurethattheclutchleverisintheOFFposition;

refertoControllingthePaddles—Belt-driveModels

(page24).

2.Aligntherearbelttothereargrooveintheengine

pulley.

Note:Donotaligntherearbelttotheidlerpulley .