Toro 68013, 68014, 68017, 68020, 68021 Operator's Manual

FormNo.3405-112RevB

MM-SeriesMortarMixer

ModelNo.68013—SerialNo.314000001andUp

ModelNo.68014—SerialNo.314000001andUp

ModelNo.68016—SerialNo.314000001andUp

ModelNo.68017—SerialNo.314000001andUp

ModelNo.68020—SerialNo.314000001andUp

ModelNo.68021—SerialNo.314000001andUp

ModelNo.68024—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3405-112*B

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

TireInformation—TheDOTtireinformationislocated

onthesideofeachtire.Thisinformationgivesload

andspeedratings.Replacementtiresshouldhavethe

sameorbetterratings;refertoSpecications(page

16)toensurethatthetiresonyourmachinemeetor

exceedtheweightrequirementsofyourmachine.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Introduction

Thismachineisdesignedtomixmortar,plaster,

reproongmaterial,grout,andothersmall-grained

Portlandcementproducts.Avehicleequippedwith

anappropriatepintlehitchorballhitchcantowthe

machine.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

2

g249232

Figure1

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................7

Setup......................................................................10

1InstallingtheDumpHandle............................10

2InstallingtheT owPole....................................11

3InstallingtheSafetyChain..............................12

ProductOverview...................................................13

Controls...........................................................14

EngineControls............................................15

Specications..................................................16

Operation................................................................17

ThinkSafetyFirst..............................................17

TowingtheMachine..........................................17

AdjustingtheAxleWidth...................................20

PreparingtoUsetheMachine...........................21

OpeningtheCowl.............................................21

ClosingtheCowl...............................................22

AddingFuel......................................................22

PerformingDailyMaintenance..........................24

StartingtheEngine...........................................24

ShuttingOfftheEngine.....................................24

MixingtheMaterial...........................................25

DumpingtheMaterial........................................26

CleaningtheDrum............................................26

Maintenance...........................................................27

RecommendedMaintenanceSchedule(s)...........27

Pre-MaintenanceProcedures..............................28

PreparingtheMachineforMaintenance............28

DisconnectingtheSpark-PlugWire..................28

RemovingtheDividerPlate..............................28

InstallingtheDividerPlate................................28

Lubrication..........................................................29

LubricatingtheBearingsandSeals...................29

EngineMaintenance...........................................30

ServicingtheAirCleaner..................................30

ServicingtheEngineOil....................................31

ServicingtheSparkPlug...................................33

CleaningtheSparkArrester..............................34

RemovingandInstallingtheEngine..................35

FuelSystemMaintenance...................................36

CleaningtheFuel-SedimentCup......................36

DrainingtheFuelT ank......................................37

DriveSystemMaintenance..................................37

g000502

TireAirPressure...............................................37

InspectingtheTires..........................................37

TorquingtheWheelLugNuts............................38

ServicingtheReductionCase...........................38

ServicingtheGearbox......................................40

BeltMaintenance................................................42

InspectingtheBelts..........................................42

AdjustingtheBeltT ension.................................42

ReplacingtheBelts...........................................43

AligningthePulleys..........................................45

PaddleMaintenance............................................46

AdjustingthePaddleBlades.............................46

Cleaning..............................................................47

CleaningtheMachine.......................................47

Storage...................................................................48

Troubleshooting......................................................49

3

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury ,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alertsymbol

(Figure2),whichmeans:Caution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Always

followallsafetyinstructionstoavoidseriousinjuryor

death.

WARNING

Machiningorhandlingstone,masonry,

concrete,metal,andothermaterialscan

generatedust,mists,andfumescontaining

chemicals,suchassilica,knowntocause

seriousorfatalinjuryorillness,suchas

respiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthe

sourcewherepossible.Usewaterfordust

suppressionwheneverpossible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupational

andtradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenyoucannoteliminatethehazards

frominhalation,youandallbystanders

shouldweararespiratorapprovedby

OSHAforthematerialthatyouare

handling.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichislethalifinhaled.

Donotruntheengineindoorsorinan

enclosedarea.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingthem.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriestopeopleordamageto

property.

Towing

•Checkwithyourlocalcountyorstatetowingsafety

regulationsbeforetowingthemachine.

•Toreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,ensure

thatthetowingvehicleismechanicallysoundand

ingoodoperatingcondition.

•Shutofftheenginebeforetransportingthe

machine.

•Whentowingwithaballhitch,ensurethatitisthe

propersizeforthehitchcoupleronthemachine.

•Whentowingwithapintlehitch,ensurethatthe

eyeofthetowpoleisthecorrectdimensionfor

thepintlehook.

•Inspectthehitchandcouplingforwear.Donot

towthemachinewithdamagedorwornhitches,

couplings,chains,orothercomponents.

•Checktheairpressureofthetiresonthetowing

vehicleandadjustthepressureasneeded.

•Checkthetiretreadandsidewallfordamageand

wearandreplacethetireifnecessary.

•Properlyattachthesafetychainstothetowing

vehiclebycrossingthechainsandremovingany

extraslack.

•Ensurethatthedirectionalandbrakelightsare

workingproperly(ifequipped).

•Ensurethatthedirectional,backup,andbrake

lightsofthetowvehicleareworkingproperly(if

equipped).

Training

•Parkthemachineonalevelsurface,shutoffthe

engine,waitforallmovingpartstostop,andallow

themachinetocoolbeforeadjusting,cleaning,

storing,orrepairingthemachine.

•Beforetowing,ensurethatyourmachineis

correctlyandsecurelyattachedtothetowing

vehicle.

•Ensurethatthesafetychainsareproperlysecured

tothevehicle,andleaveenoughslackforturning.

4

•Donotcarryanymaterialinthemachinewhen

towing.

•Avoidsuddenstopsandstarts.Thiscancause

skiddingorjackkning.Smooth,gradualstartsand

stopsimprovestowing.

•Avoidsharpturnstopreventrolling.T owonlywith

avehiclethathasahitchdesignedfortowing.Do

notattachtowedequipmentexceptatthehitch

point.

•Donottowthemachinefasterthan88km/h(55

mph).

•Usecautionwhenbackingup;useaspotter

outsidethevehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehicle

beforeusingit.

•Placechocksunderneaththetirestopreventthem

fromrollingwhilethemachineisparked.

Preparation

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearpersonalprotectiveequipmentand

appropriateclothingincluding:

–Hardhat

–Respiratorordustmask

–Faceshield

–Safetyglasses

–Hearingprotection

–Safetyshoes

–Longpants

–Shirtwithlongsleevesthataretightatthe

wrists

–Tight-ttinggloveswithoutdrawstringsorloose

cuffs

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry .

•Ensurethatthemachineisonalevelsurface

beforeoperatingit.

•Chockthetiresofthemachinetoprevent

unintendedmovement.

•Beforeeveryuse,dothefollowing:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly

(ifequipped).

–Ensurethatthetiresareproperlyinated.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotrunanengineinanenclosedorpoorly

ventilatedarea.

•Operatethemachineonlyingoodlighting

conditions.

•Beforestartingthemachine,ensurethatthereare

nopeopleorobstaclesnearorunderthemachine.

•Shutofftheenginebeforeleavingthemachinefor

anyreason.

Neverleavearunningmachineunattended.

Alwaysshutofftheengineandverifythatall

movingpartshavestopped.

•Chockthetiresofthemachineorkeepitattached

tothetowingvehiclewhenitisnotinuse.

•Keepyourhandsawayfromanymovingparts.

Keepyourfeetawayfromthetiresandthefront

post.

•Donotoperatethemachineundertheinuence

ofalcoholordrugs.

•Donotplaceyourhandsoranysolidobjectinto

thedrumwhenthemachineisinoperation.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Nevermovethemachinewhiletheengineis

running.

•Keepthecowlclosedandlatchedduringoperation.

5

•Ensurethatalltheguardsandshieldsaresecurely

inplacebeforeoperatingthemachine.

•Ifthemixingpaddlesstrikeanobjectorifthe

machinestartsmakinganunusualnoiseor

vibration,shutofftheengine,waitforallmoving

partstostop,andemptythedrum.Inspectfor

cloggingordamage.Clean,repair,and/orreplace

anydamagedparts.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Donotoperatethemachinewhenthereistherisk

oflightning.

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonalevelsurface.

–Shutofftheengineandwaitforallmovement

tostopbeforeadjusting,cleaning,orrepairing

themachine.

–Lettheenginecoolbeforeperforming

maintenanceorstoringthemachine.

–Disengageallpowerandoperationcontrols.

•Neverlubricate,service,repair,oradjustthe

machinewiththeenginerunning.

•Keepequipmentmaterialsclearfromthemufer

andenginetopreventres.Cleanupoilorfuel

spills.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Keepyourhands,feet,andclothingawayfrom

movingparts.Ifpossible,donotmakeadjustments

withtheenginerunning.

•Keepallpartsingoodworkingconditionandall

fastenerstightened.Replaceallwornordamaged

decals.

•Removeanybuildupofgrease,oil,ordebrisfrom

themachine.

•Stopandinspectthemachineifanobjectenters

thedrumorcausesanotherobstruction.Makeall

necessaryrepairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Chockthetireswhenstoringthemachine.

•Keepallfastenersandhoseclampssecurely

tightenedandallequipmentingoodcondition.

•UseonlygenuineTororeplacementparts.

6

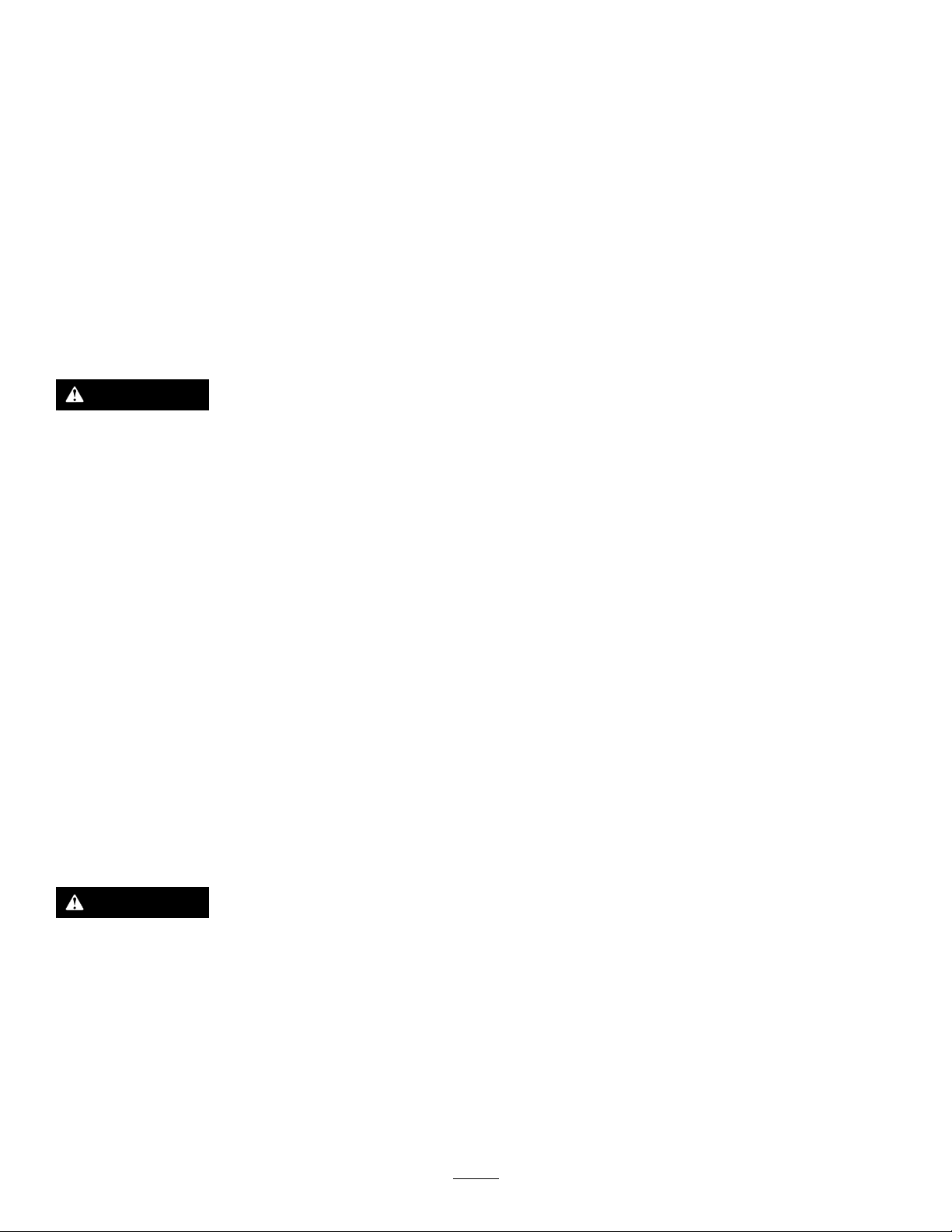

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

decal125-8175

125-8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

1.Warning—readthe

Operator’sManual.

2.Handandarm

entanglementatthe

beltdrive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keepyourhands

awayfrommovingparts;

keepallguardsand

shieldsinplace.

3.Entanglementhazard

atpaddles—shutoff

theengineandwait

forallmovingpartsto

stopbeforeperforming

maintenance.

decal125-4939

125-4939

4.Toxicgasinhalation

hazard—Donotrunthe

engineinanenclosed

space.

5.Explosionhazard—shut

offtheengineandkeep

awayfromameswhen

refueling.

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

125-8216

2.Warning—limittowing

speedtolessthan88km/h

(55mph).

decal125-8216

7

decal133-5619

decal130-8322

133-5619

130-8322

1.Usefuelwithanalcohol

contentbyvolumeunder

10%only.

2.ReadtheOperator's

Manualformore

informationonfuel.

3.Donotusefuelwithan

alcoholcontentgreater

than10%byvolume.

1.ReadtheOperator'sManualformoreinformationonservicingthemachine.

decal132-3997

132-3997

8

1.ReadtheOperator'sManualformoreinformationonservicingthemachine.

decal132-4043

132-4043

9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Dumphandle1

1

2

3

Bolt2

Nut2

Towpolekit(soldseparately)

Safetychain(includedwiththetowpole

kit)

Connectinglink(includedwiththetow

polekit)

1

InstallingtheDumpHandle

Partsneededforthisprocedure:

1Dumphandle

2Bolt

2Nut

Qty.

Use

Installthedumphandle.

1

1

2

Installthetowpole(side-dumpmodels

only).

Installthesafetychain.

Procedure

1.Cutthecabletiestoremovethedumphandle

fromtheundersideofthegrate.

2.Installthedumphandletothesideofthedrum

using2boltsandnutsasshowninFigure3,

Figure4,orFigure5,asappropriateforyour

model.

g022169

Figure3

Models68013,68016,68020

g022150

Figure4

Models68014,68017,68021

10

Figure5

Model68024

g022149

g019804

Figure6

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

5.Frametting

2

InstallingtheTowPole

Partsneededforthisprocedure:

1

Towpolekit(soldseparately)

TowPoleSpecications

Purchasethetowpolekit(includingfasteners)that

meetsyourneedsfromyourAuthorizedService

Dealer.Themachinehasthefollowingtowpole

options:

HitchTypeLength

50mm(2inch)ball—stamped78.7cm(31inches)or127cm

50mm(2inch)ball—forged78.7cm(31inches)or127cm

Pintle

(50inches)

(50inches)

78.7cm(31inches)or127cm

(50inches)

2.Slidethetowpoleforwardandaligntheholein

thepolewiththeholeintheframetting(Figure

6).

3.Inserttheboltthroughtheholesinthettingand

thepole(Figure6).

4.Threadthenutontotheboltandtightenthem

untiltheyaretightagainsttheframetting

(Figure6).

Note:Iftheself-lockingnyloninsertinthe

locknutwearswithuse,replacethenutwitha

newGrade5orGrade8locknut.

InstallingtheTowPole

1.Removetheboltandnutfromthetowpole

(Figure6).

11

3

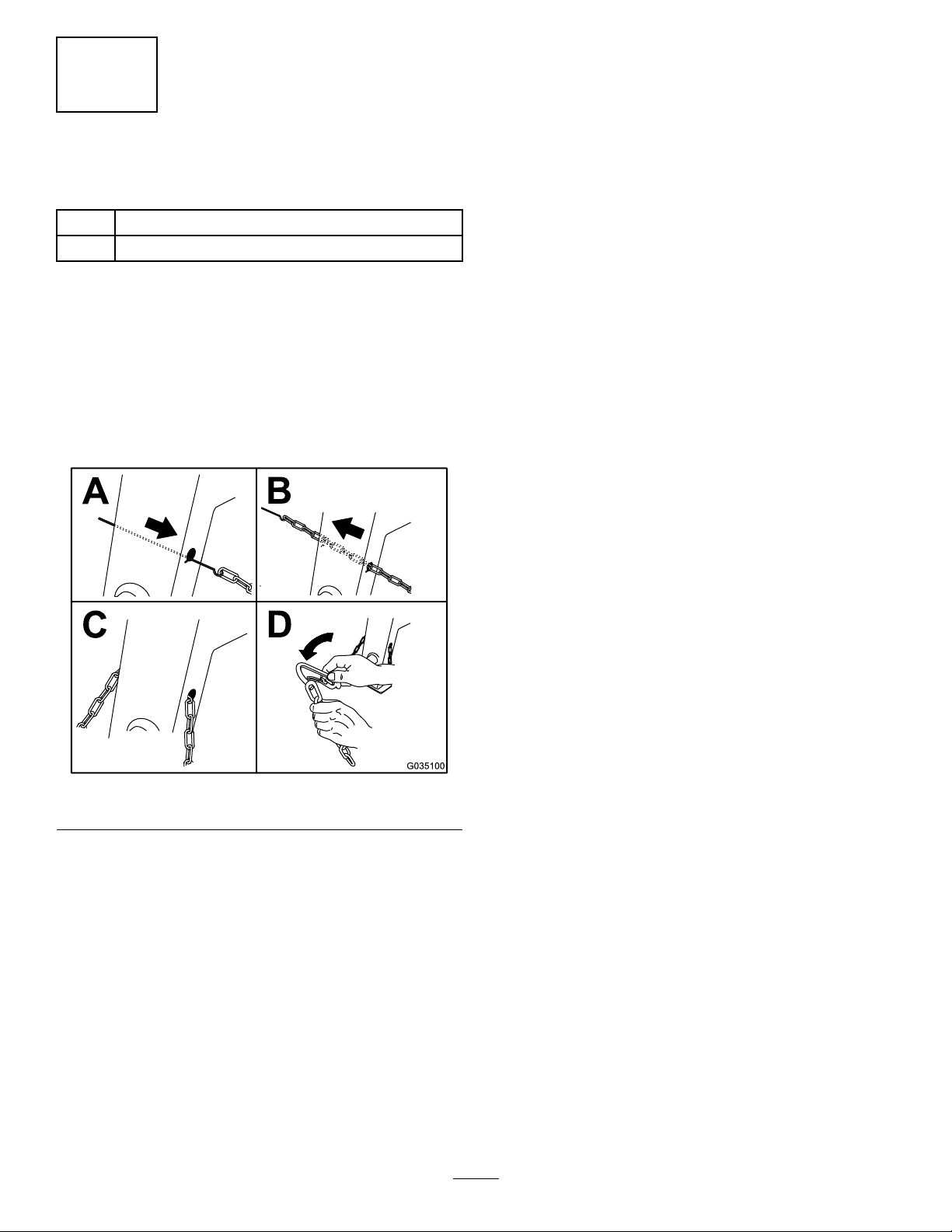

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain(includedwiththetowpolekit)

2

Connectinglink(includedwiththetowpolekit)

Procedure

Safetychainandconnectinglinkareincludedinthe

towpolekit(soldseparately);referto2Installingthe

TowPole(page1 1).

Formahookontheendofabendablepieceofrodor

stiffwire(notincluded)andinstallthesafetychainand

connectinglinksasshowninFigure7.

Figure7

Note:Ensurethatapproximatelyequallengthsof

safetychainextendfromeithersideofthefrontpost.

g035100

12

ProductOverview

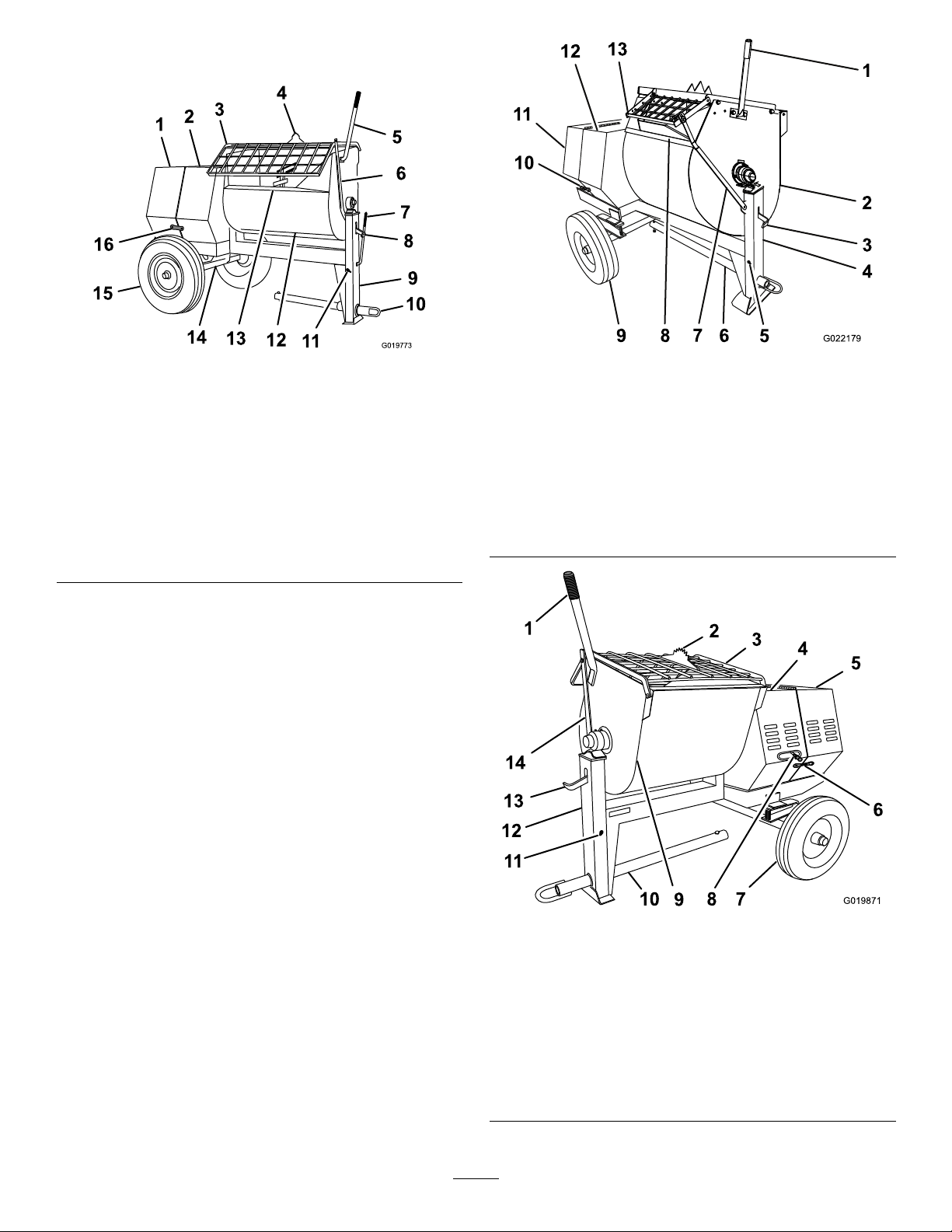

Figure8

RightSide(Belt-DriveModels)

1.Rearcowl

2.Frontcowl8.Drumlatch14.Axle

3.Grate

4.Bagsplitter10.Towpole

5.Dumphandle

6.Grateliftarm

7.Clutchlever13.Chute

9.Frontpost15.Wheel

11.Safety-chain

keyhole

12.Drum

16.Cowllatch

g019773

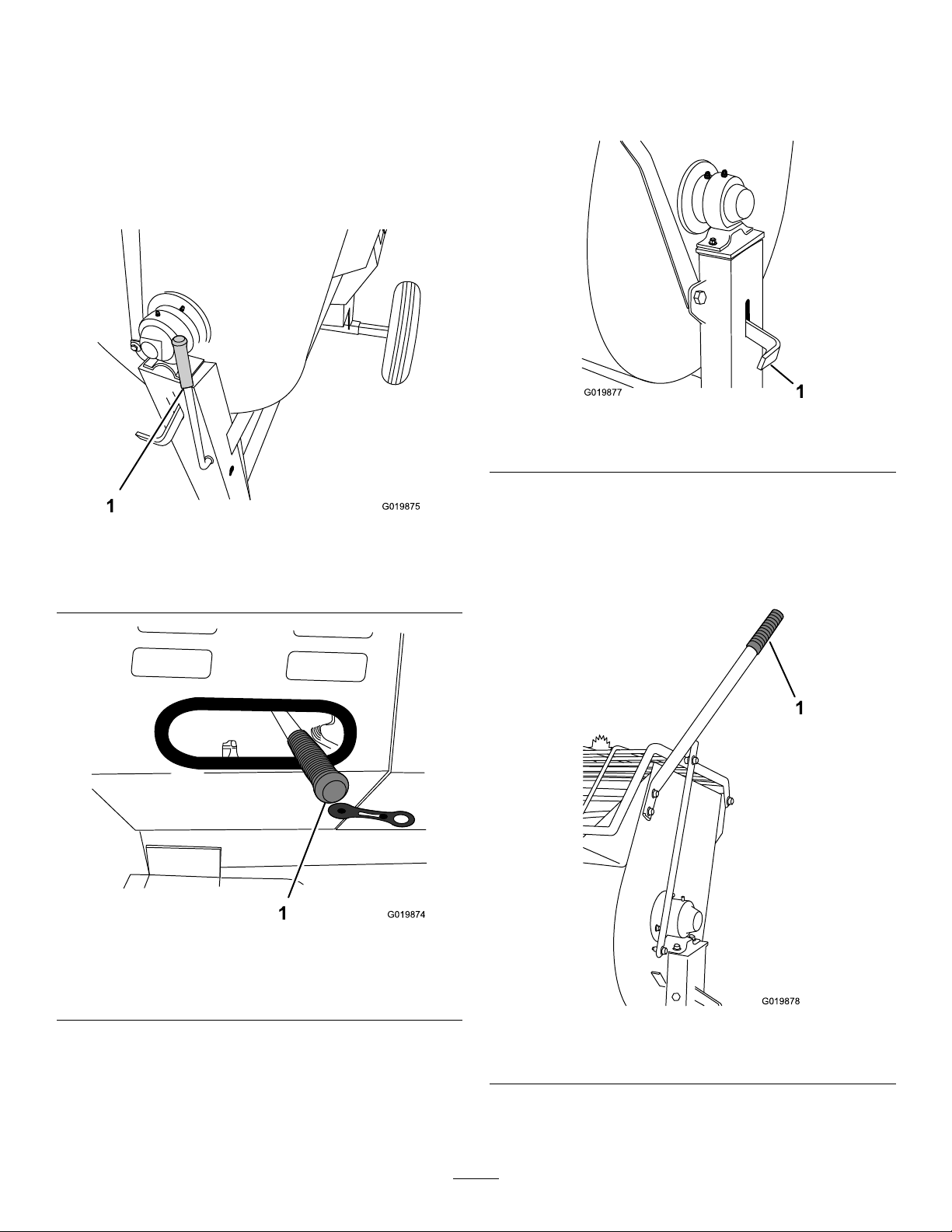

Figure9

g022179

RightSide(GearboxModel)

1.Dumphandle6.Towpole11.Rearcowl

2.Drum

3.Drumlatch

assembly

4.Frontpost9.Wheel

5.Safety-chain

keyhole

7.Grateliftarm

8.Chute13.Grate

assembly

10.Cowllatch

12.Frontcowl

1.Dumphandle

2.Bagsplitter7.Wheel

3.Grate8.Clutchlever

4.Frontcowl9.Drum

5.Rearcowl10.T owpole

13

g019871

Figure10

LeftSide(GearboxModel)

6.Cowllatch11.Safety-chain

keyhole

12.Frontpost

assembly

13.Drumlatch

14.Grateliftarm

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

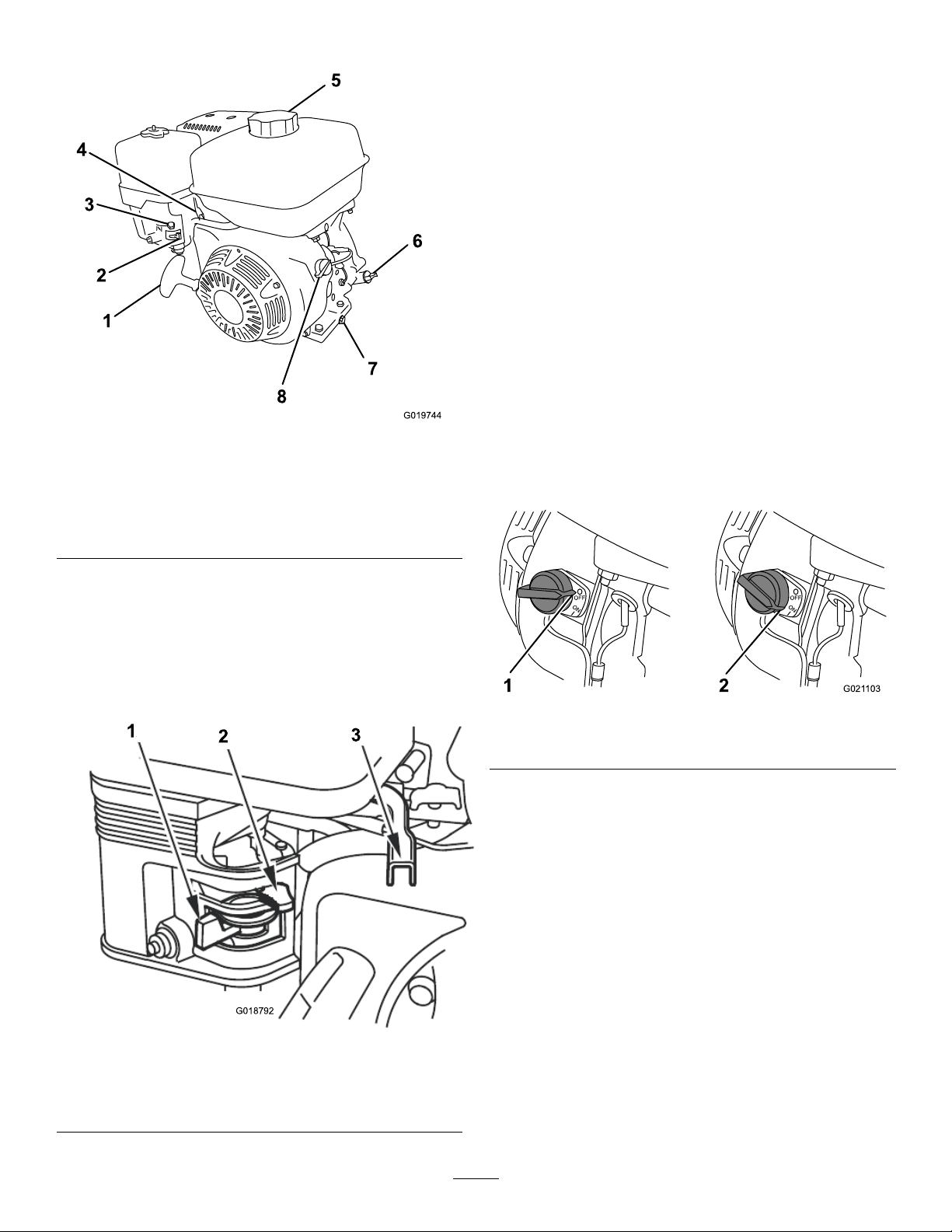

ClutchLever

Usetheclutchlevertoengageanddisengagethe

paddles.

DrumLatch

Usethedrumlatchtosecurethedrumtothemix

position(upright)formixingoperationsandwhen

transportingthemachine.

g019877

Figure13

1.Drumlatch

1.Clutchlever

Belt-DriveModels

GearboxModel

Figure11

Figure12

g019875

DumpHandle

Usethedumphandletorotatethedrumtothedump

positionandtorotatethedrumtothemixposition

(upright).

g019874

1.Clutchlever

g019878

Figure14

1.Dumphandle

14

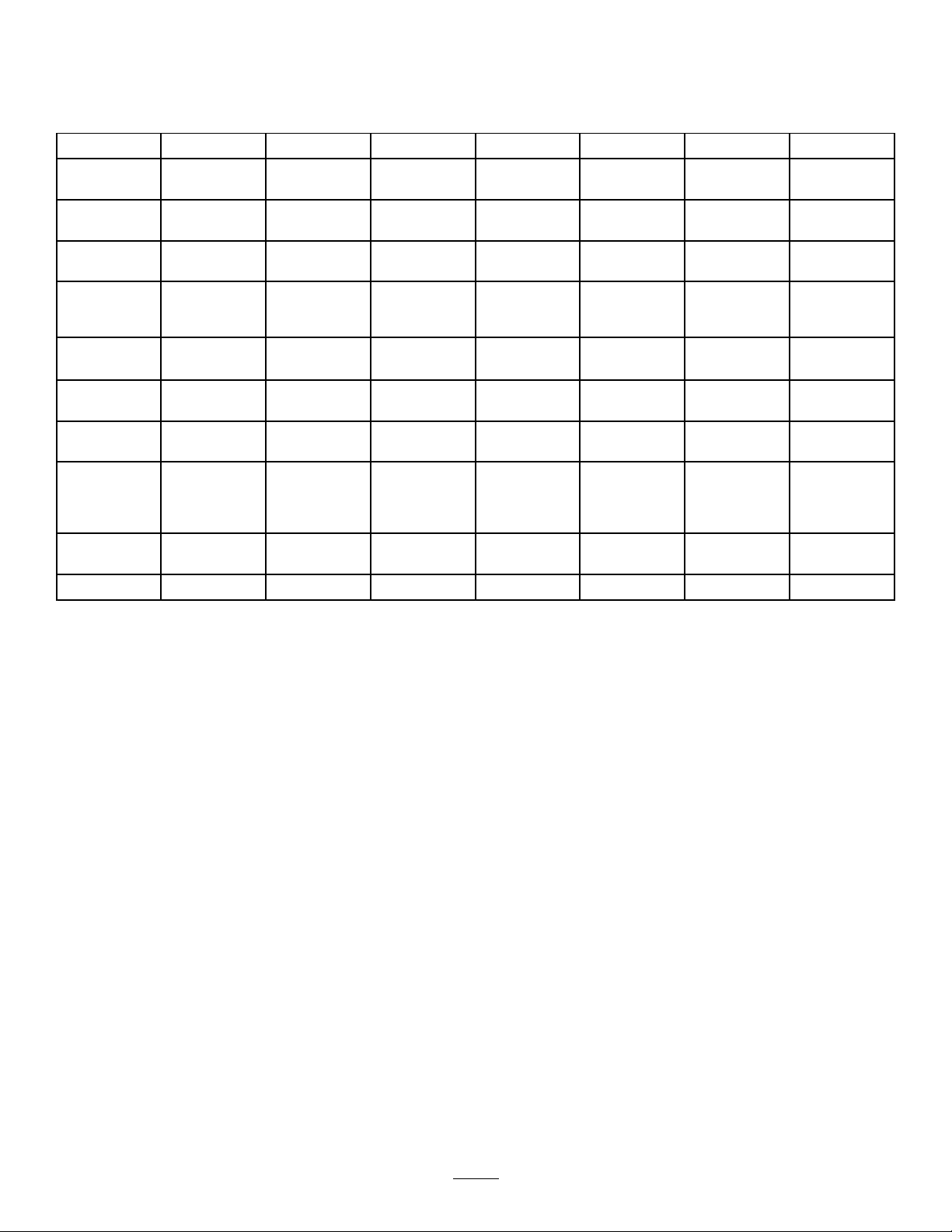

EngineControls

ChokeLever

Usethechokelever(Figure16)tostartacoldengine.

Beforepullingtherecoil-starthandle,movethechoke

levertotheCLOSEDposition.Oncetheengineis

running,movethechokelevertotheOPENposition.

Donotusethechokeiftheengineisalreadywarmed

uporiftheairtemperatureishigh.

ThrottleLever

Thethrottlelever(Figure16)controlsthespeed(rpm)

oftheengine.Itislocatednexttothechokelever.It

setstheenginespeedandthereforecanincreaseand

decreasetherotationspeedofthemixingpaddles.

Forbestperformance,setthiscontroltotheFAST

positionwhenmixingmaterial.

EngineOn/OffSwitch

Figure15

1.Recoil-starthandle5.Fuelcap

2.Fuelvalve

3.Chokelever

4.Throttlelever

FuelValve

6.Oildipstick

7.Oil-drainplug

8.On/Offswitch

Thefuelvalve(Figure16)islocatedunderneaththe

chokelever.Movetheleverforthefuelvalvetothe

ONpositionbeforeattemptingtostarttheengine.

Whenyouhavenishedmixing,shutofftheengine

andmovethefuel-valvelevertotheOFFposition.

g019744

TheOn/Offswitchislocatedonthefrontoftheengine.

•RotateittotheONpositiontostartandrunthe

engine.

•RotateittotheOFFpositiontoshutofftheengine.

g021103

Figure17

1.OFFposition2.ONposition

Recoil-StartHandle

Tostarttheengine,pulltherecoil-starthandle(Figure

15)quicklytoturntheengineover.Theengine

controlsdescribedabovemustallbesetcorrectlyfor

theenginetostart.

Figure16

1.Fuelvalve3.Throttlelever

2.Chokelever

Oil-LevelSwitch

Theoil-levelswitchislocatedinsidetheengine,andit

doesnotallowtheenginetorunintheeventtheoil

levelisbelowthesafeoperatinglimit.

g018792

15

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

MachineSpecications

Model68013680146801668017680206802168024

Batch

Capacity

TotalV olume

Drum

Material

Length

(withouttow

pole)

Width86cm

0.17m

(6.0ft3)

0.20m

ft3)

Steel

163cm

(64inches)

(34inches)

3

3

(6.9

0.17m

(6.0ft3)

0.20m

ft3)

Polyethylene

163cm

(64inches)

86cm

(34inches)

3

3

(6.9

0.17m

(6.0ft3)

0.20m

ft3)

Steel

163cm

(64inches)

86cm

(34inches)

3

3

(6.9

0.17m

(6.0ft3)

0.20m

ft3)

Polyethylene

163cm

(64inches)

86cm

(34inches)

3

3

(6.9

0.23m

(8.0ft3)

0.25m

ft3)

Steel

193cm

(86inches)

86cm

(34inches)

3

0.23m

(8.0ft3)

3

(9.0

0.25m

ft3)

Polyethylene

193cm

(86inches)

86cm

(34inches)

3

0.34m

3

(12.0ft3)

3

(9.0

0.42m

3

(14.8

ft3)

Steel

205.7cm

(81inches)

142.2cm

(50inches)

Height137cm

(54inches)

Weight250kg

(550lb)

Axle86to1 17

cm(34to

46inches)

extendable

EngineHonda

GX160

®

137cm

(54inches)

241kg

(530lb)

86to1 17

cm(34to

46inches)

extendable

Honda

GX160

137cm

(54inches)

250kg

(550lb)

86to1 17

cm(34to

46inches)

extendable

®

®

Honda

GX240

137cm

(54inches)

241kg

(530lb)

86to1 17

cm(34to

46inches)

extendable

Honda

GX240

137cm

(54inches)

275kg

(605lb)

86to1 17

cm(34to

46inches)

extendable

®

®

Honda

GX240

DriveBeltBeltBeltBeltBeltBelt

137cm

0(54inches)

266kg

(585lb)

86to1 17

cm(34to

46inches)

extendable

Honda

GX240

150cm

(59inches)

508kg

(1120lb)

142cm

(56inches)

xed

®

®

Honda

GX340

Gearbox

16

Loading...

Loading...