Page 1

FormNo.3421-314RevA

CM-1258Y-SDConcreteMixer

ModelNo.68011—SerialNo.402000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-314*A

Page 2

WARNING

accessoryinformation,helpndingadealer,orto

registeryourproduct.

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

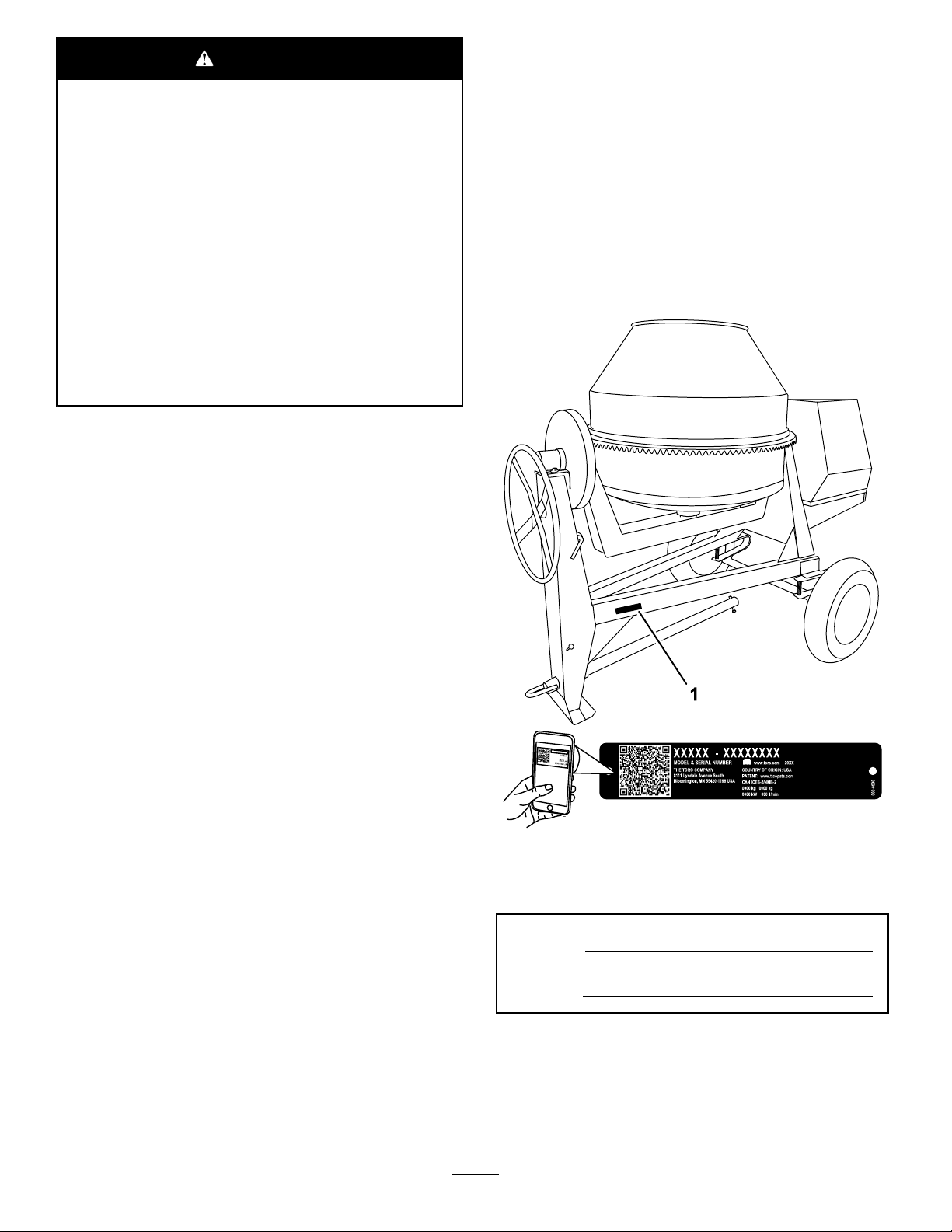

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

TireInformation—TheDOTtireinformationislocated

onthesideofeachtire.Thisinformationgivesload

andspeedratings.Replacementtiresshouldhavethe

sameorbetterratings;refertoSpecications(page

14)toensurethatthetiresonyourmachinemeetor

exceedtheweightrequirementsofyourmachine.

Introduction

Thismachineisdesignedtomixconcrete,plaster,

reproongmaterial,grout,andothersmall-grained

concreteproducts.Youcantowthemachinebehinda

vehicleequippedwithahitchappropriateforthetype

oftowpoleyourmachinehas(ball,pintle,orpinhitch).

g242288

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

g000502

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................7

Setup........................................................................9

1InstallingtheT owPole.....................................9

2InstallingtheSafetyChain..............................10

ProductOverview....................................................11

Controls............................................................11

Specications..................................................14

Operation................................................................14

PreparingtoT owtheMachine...........................14

TowingtheMachine..........................................18

PreparingtoUsetheMachine...........................19

OpeningandClosingtheCowl..........................19

AddingFuel......................................................20

CheckingtheEngine-OilLevel..........................22

StartingtheEngine...........................................23

ShuttingOfftheEngine.....................................24

UsingtheMachine............................................24

MixingtheMaterial...........................................25

UsingtheDrum.................................................25

Maintenance...........................................................27

RecommendedMaintenanceSchedule(s)...........27

Pre-MaintenanceProcedures..............................27

PreparingtheMachineforMaintenance............27

RemovingandInstallingtheDivider

Plate..............................................................27

Lubrication..........................................................28

LubricatingtheMachine....................................28

LubricatingtheDriveChain...............................29

EngineMaintenance...........................................29

ServicingtheAirCleaner..................................29

ChangingtheEngineOil...................................30

ServicingtheEngine-OilFilter...........................31

RemovingandInstallingtheEngine..................32

FuelSystemMaintenance...................................32

ServicingtheFuelSystem................................32

DriveSystemMaintenance..................................34

ServicingtheReductionCase...........................34

ServicingtheDriveChain.................................34

Cleaning..............................................................35

CleaningtheMachine.......................................35

Storage...................................................................36

StoringtheMachine..........................................36

Troubleshooting......................................................37

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury ,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alertsymbol

(Figure2),whichmeans:Caution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Always

followallsafetyinstructionstoavoidseriousinjuryor

death.

WARNING

Machiningorhandlingstone,masonry,

concrete,metal,andothermaterialscan

generatedust,mists,andfumescontaining

chemicals,suchassilica,knowntocause

seriousorfatalinjuryorillness,suchas

respiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthe

sourcewherepossible.Usewaterfordust

suppressionwhenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupational

andtradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenyoucannoteliminatethehazards

frominhalation,youandanybystanders

shouldweararespiratorapprovedby

OSHAforthematerialbeinghandled.

WARNING

Engineexhaustcontainscarbonmonoxide,

anodorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinan

enclosedarea.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readorunderstandtheinformation,itisthe

owner'sresponsibilitytoexplainthismaterialto

them.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriestopeopleordamageto

property.

Towing

Checkwithyourlocalcountyorstatetowingsafety

regulationsbeforetowingthemachine.

•Toreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,ensure

thatthetowingvehicleismechanicallysoundand

ingoodoperatingcondition.

•Shutofftheenginebeforetransportingthe

machine.

•Whentowingwithaballhitch,ensurethattheball

hitchyouareusingisthepropersizeforthehitch

coupleronthemachine.

•Whentowingwithapintlehitch,ensurethatthe

eyeofthetowpoleisthecorrectdimensionfor

thepintlehook.

•Donottowwithoutthesafetypininsertedintothe

topofthereceiver.

•Inspectthehitchandcouplingforwear.Nevertow

themachinewithdamagedordefectivehitches,

couplings,chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicle

andthemachine.

•Checkthetiretreadandsidewallfordamageand

wear.

•Properlyattachthesafetychainstothetowing

vehicle.

•Ensurethatthedirectionalandbrakelightsare

workingproperly(ifthemachineisequippedwith

thelightkit).

•Ensurethatthedirectional,backup,andbrake

lightsofthetowvehicleareworkingproperly(if

equipped).

•Beforetowing,ensurethatyourmachineis

correctlyandsecurelyattachedtothetowing

vehicle.

•Ensurethatthesafetychainsareproperlysecured

tothevehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhen

towing.

•Avoidsuddenstopsandstarts.Thiscancause

skidding,orjackkning.Smooth,gradualstarts

andstopswillimprovetowing.

•Avoidsharpturnstopreventrolling.T owonlywith

avehiclethathasahitchdesignedfortowing.Do

4

Page 5

notattachtowedequipmentexceptatthehitch

point.

•Donottowthemachinefasterthan88km/h(55

mph).

•Usecautionwhenbackingup;useaspotter

outsidethevehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehicle

beforeusingit.

•Securethemachinefrommovementbeforeyou

towit.

•Placechockblocksunderneaththetirestoprevent

themfromrollingwhilethemachineisparked.

Preparation

Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearpersonalprotectiveequipment(PPE)and

appropriateclothing,includingthefollowing:

–Hardhat

–Respiratorordustmask

–Faceshield

–Safetyglasses

–Hearingprotection

–Substantial,slip-resistantfootwear

–Longpants

–Shirtwithlongsleevesthataretightatthe

wrists

–Tight-ttinggloveswithoutdrawstringsorloose

cuffs

•Securelooseclothing,tiebacklonghair,anddo

notwearloosejewelry.

•Useextracarewhenhandlingfuels.Theyare

ammableandthevaporsareexplosive.Usethe

followingpracticeswhenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththe

enginerunning.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

–Installthefuelcapandtightenitsecurely.

–Keepthecontainernozzleincontactwiththe

tankduringlling.

–Neverllacontainerwhileitisinsideavehicle,

trunk,pickupbed,oranysurfaceotherthan

theground.

–Neverstorethemachineorfuelcontainer

insidewherethereisanopename,suchas

nearawaterheaterorfurnace.

–Ifyouspillfuel,wipeitofftheengineand

equipment.

•Ensurethatthemachineisonalevelsurface

beforeoperatingthemachine.

•Chockthetiresofthemachinetoprevent

unintendedmovement.

•Beforeeveryuse,dothefollowing:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly

(ifequipped).

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthewheellugnutsaretightand

torquedproperly.

–Ensurethatthemachineisproperlysecured.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverruntheengineinanenclosedorpoorly

ventilatedarea.

•Operatethemachineonlyingoodlighting

conditions.

•Beforestartingthemachine,ensurethatthere

arenopersonsorobstaclesnearorunderthe

machine.

•Shutofftheenginebeforeleavingthemachinefor

anyreason.

Neverleavearunningmachineunattended.

Alwaysshutofftheengineandverifythatall

movingpartshavestopped.

•Chockthetiresofthemachineorkeepitattached

tothetowingvehiclewhenitisnotinuse,to

preventitfromrolling.

•Avoidprolongedbreathingofexhaustfumes.

Engineexhaustfumescancausesicknessor

death.

•Keepyourhandsawayfromanymovingparts.

Keepyourfeetawayfromthetiresandthefront

post.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Keepbystanders,especiallysmallchildren,outof

theoperatingarea.Stopthemachineifanyone

entersthearea.

•Neverplaceyourhandsoranysolidobjectintothe

drumwhenthemachineisinoperation.

5

Page 6

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservicethemachine.

•Nevermovethemachinewhiletheengineis

running.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurely

inplacebeforeoperatingthemachine.

•Ifthemixingpaddlesstrikeaforeignobjectorifthe

machineshouldstartmakinganunusualnoiseor

vibration,shutofftheengineandemptythedrum.

Waitforallmovingpartstocometoacomplete

stopandcool.Vibrationisgenerallyawarningof

trouble.Inspectforcloggingordamage.Clean

andrepairand/orreplacedamagedparts.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Lightningcancausesevereinjuryordeath.Ifyou

seelightningorhearthunderinthearea,donot

operatethemachine;seekshelter.

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonalevelsurface.

–Shutofftheengine.Waitforallmovementto

stopandremovethesparkplugwirebefore

adjusting,cleaning,orrepairing.

–Allowtheenginetocoolbeforeperforming

maintenanceorstoring.

–Disengageallpowerandoperationcontrols

beforemakinganyrepairs.

•Neverlubricate,service,repair,oradjustthe

machinewhileitisrunning.

•Keepequipmentmaterialsclearfromthemufer

andenginetohelppreventres.Wipeupany

spilledoilorfuel.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Keepyourhands,feet,andclothingawayfrom

movingparts.Ifpossible,donotmakeadjustments

withtheenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Removeanybuildupofgrease,oil,ordebrisfrom

themachine.

•Stopthemachine,shutofftheengine,andinspect

themachineifaforeignobjectentersthedrumor

causesanotherobstruction.Makeanynecessary

repairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Securethemachinefrommovementandchock

thetireswhenstoringthemachine.

•Keepallnuts,bolts,screws,andhoseclamps

securelytightened.Keepthemachineingood

condition.

•UseonlygenuineT ororeplacementpartsto

ensurethattheoriginalstandardsaremaintained.

6

Page 7

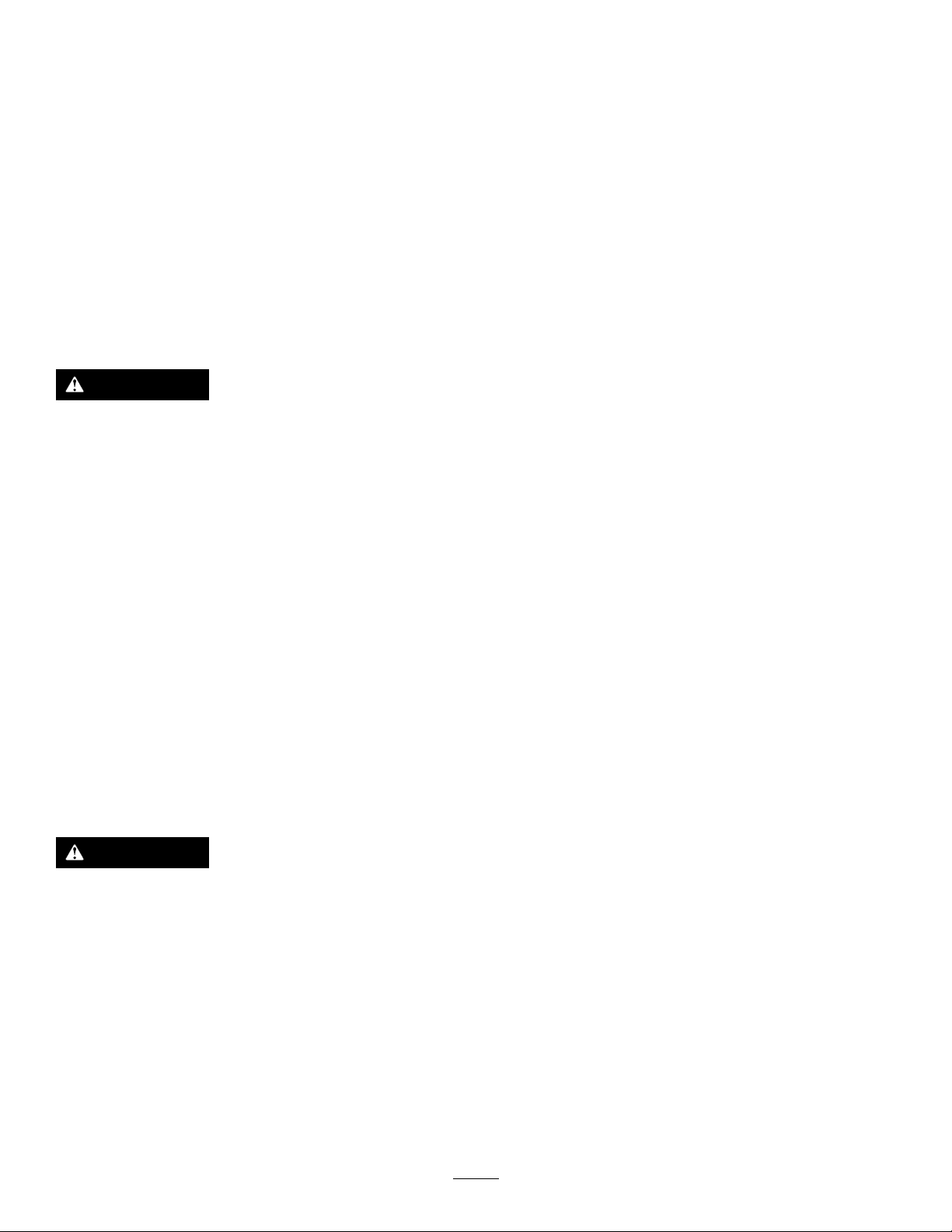

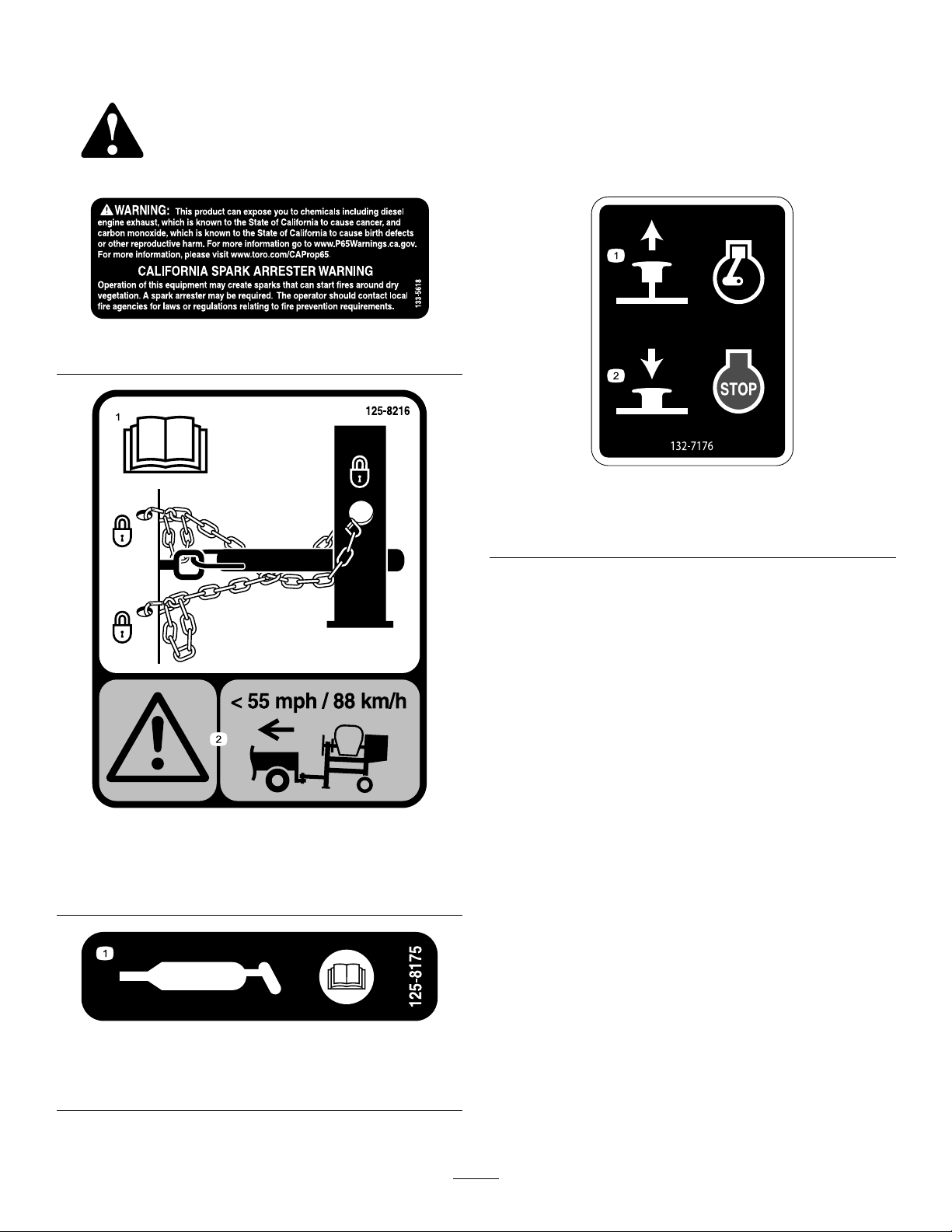

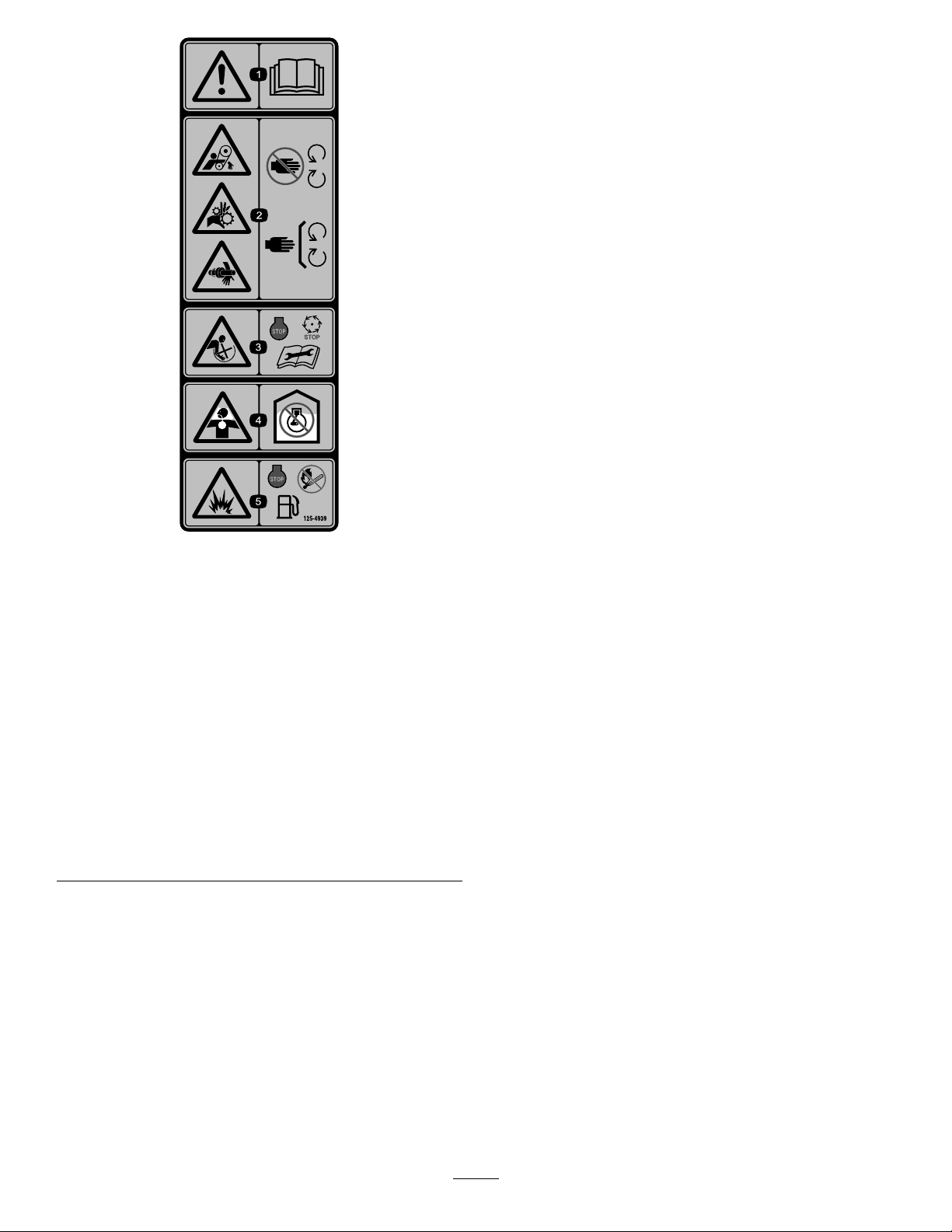

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

133-5618

decal133-5618

decal132-7176

132–7176

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

125–8216

2.Warning—limittowing

speedtolessthan88km/h

(55mph)

1.Pulluptostarttheengine.

decal125-8216

2.Pushdowntoshutoffthe

engine.

125–8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

decal125-8175

7

Page 8

decal125-4939

125–4939

1.Warning—readthe

Operator’sManual.

2.Handandarm

entanglementatthechain

drive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keephandsaway

frommovingparts;keep

allguardsandshieldsin

place.

3.Entanglementhazardat

paddles—stoptheengine

andwaitforallmoving

partstostopbefore

performingmaintenance.

4.Toxicgasinhalation

hazard—Donotrunthe

engineinanenclosed

space.

5.Explosionhazard—stop

theengineandkeep

awayfromameswhen

refueling.

8

Page 9

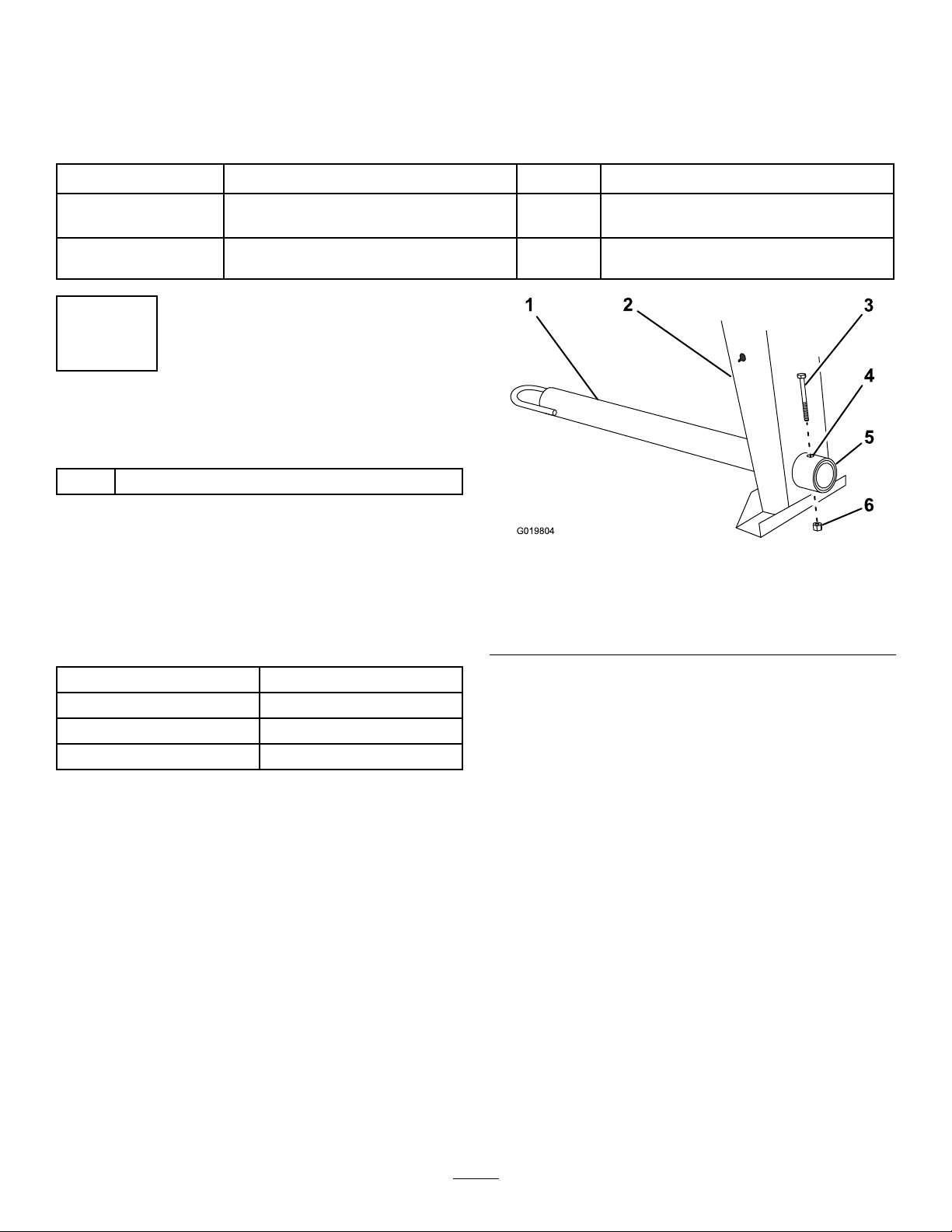

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

Towpolekit(soldseparately)

Safetychain

Connectinglink

1

InstallingtheTowPole

Partsneededforthisprocedure:

1

Towpolekit(soldseparately)

InstallingtheTowPoletothe

Machine

Note:Thetowpoleispurchasedseparatelyand

includesthenutandboltneededforinstallation.

Themachinehasthefollowingtowpoleoptions:

Qty.

1Installthetowpole.

1

2

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

Installthesafetychain.

Figure3

5.Frametting

Use

g019804

HitchTypeLength

50mm(2inch)ball—stamped127cm(50inches)

50mm(2inch)ball—forged127cm(50inches)

Pintle

1.Removetheboltandnutfromthetowpole

(Figure3).

127cm(50inches)

2.Slidethetowpoleforwardandaligntheholein

thepolewiththeholeintheframetting(Figure

3).

3.Inserttheboltthroughtheholesinthettingand

thepole(Figure3).

4.Threadthenutontotheboltandtightenthem

untiltheyaretightagainsttheframetting

(Figure3).

Note:Iftheself-lockingnyloninsertinthe

locknutwearswithuse,replacethenutwitha

newGrade5orGrade8locknut.

9

Page 10

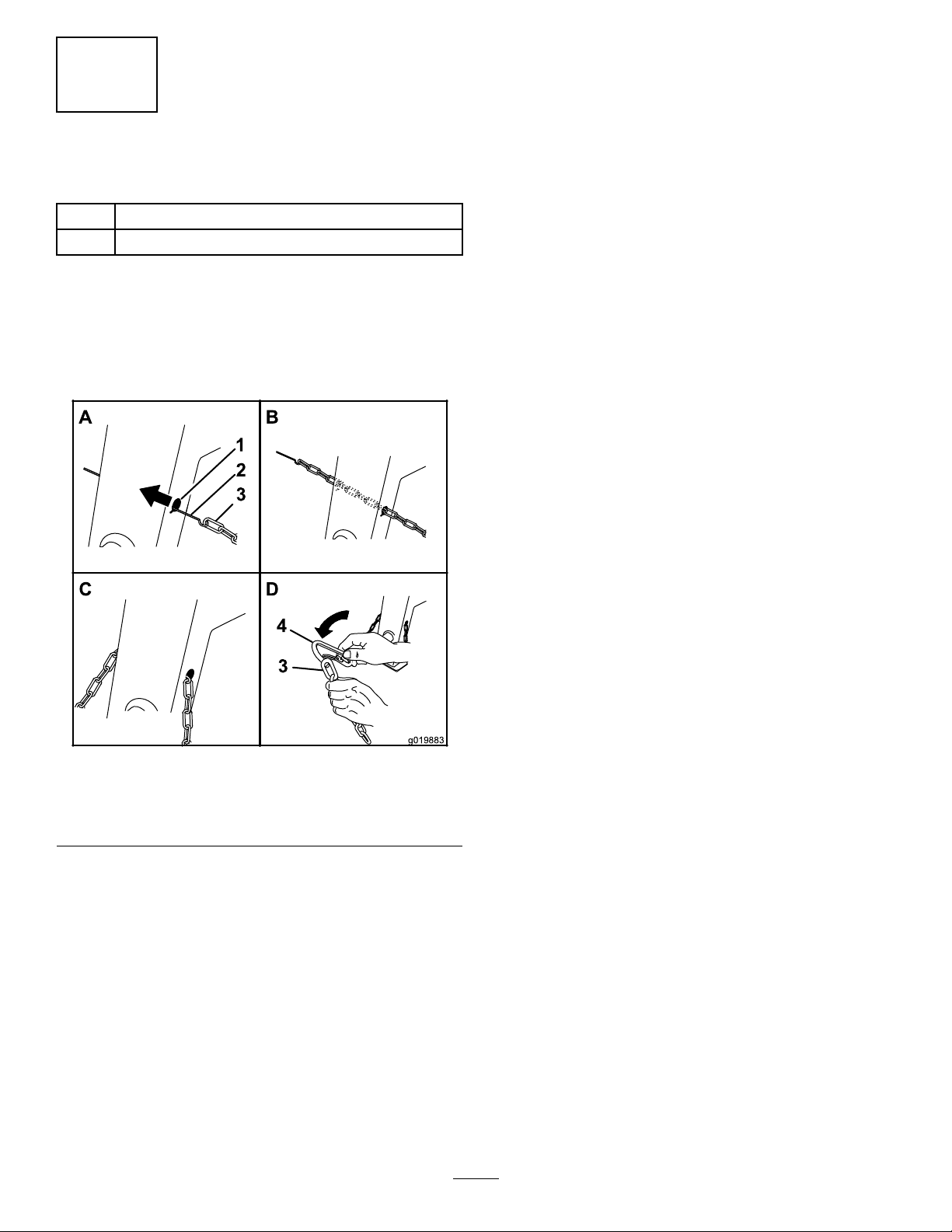

2

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain

2

Connectinglink

InstallingtheSafetyChain

1.Formahookontheendofabendablepiece

ofrodorstiffwire(notincluded),andinsertit

throughbothkeyholesinthefrontpostofthe

machine(Figure4A).

3.Repeatsteps1and2toinstalltheother

connectinglinkintheotherendofthesafety

chain.

Figure4

1.Keyhole

2.Rodorwire(notincluded)4.Connectinglink

2.Attachthesafetychaintothelengthofrodor

wire(Figure4A).

3.Pulltherod,orwire,andthesafetychain

throughbothkeyholes(Figure4B).

Note:Ensurethatapproximatelyequallengths

ofsafetychainextendfromeithersideofthe

frontpost.

3.Safetychain

InstallingtheConnectingLinks

1.Aligntheconnectinglinktothelastlinkinone

endofthesafetychain(Figure4D).

2.Inserttheconnectinglinkthroughthechainlink

untiltheconnectinglinksnapsclosed.

g019883

10

Page 11

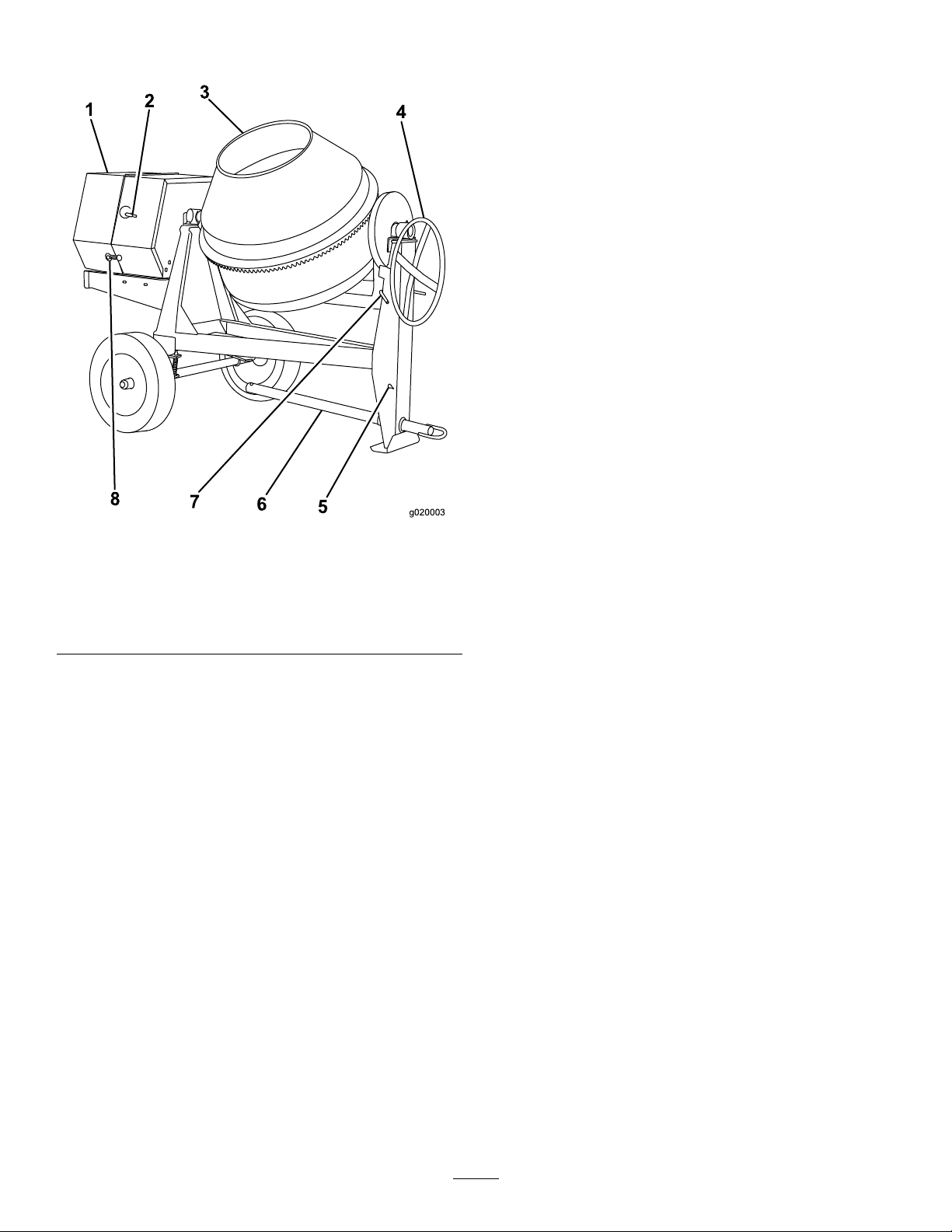

ProductOverview

Figure5

1.Enginecowl5.Towpole

2.Drum6.Drum-tiltbrake

3.Handwheel7.Rubberlatch

4.Safety-chainkeyholes

Controls

Becomefamiliarwithallofthecontrolsbeforeyou

starttheengineandoperatethemachine.

Handwheel

Thehandwheelcontrolsthetiltofthedrum.

Drum-TiltBrake

Thedrum-tiltbrakelocksthedrumintoposition.

g020003

11

Page 12

EngineControls

EngineSpeedControlHandle

Theengine-speed-controlhandle(Figure7)allows

theoperatortostartandshutofftheengine.Itis

locatedontheenginecowl,andisconnectedtothe

engine-speed-controlknob,whichislocatedonthe

engine(Figure8).T ocontroltheengine-speed-control

handle:

1.Rotatetheengine-speed-controlhandle

counterclockwisetounlockit.

2.Pullitallthewayoutandlockitbyrotatingit

clockwise.

3.Rotateitcounterclockwiseandpushitintostop

theengine.

Note:Thespeed-controlknobontheenginemustbe

loose(rotatedcounterclockwise)forthecowl-mounted

speed-controlhandletowork.

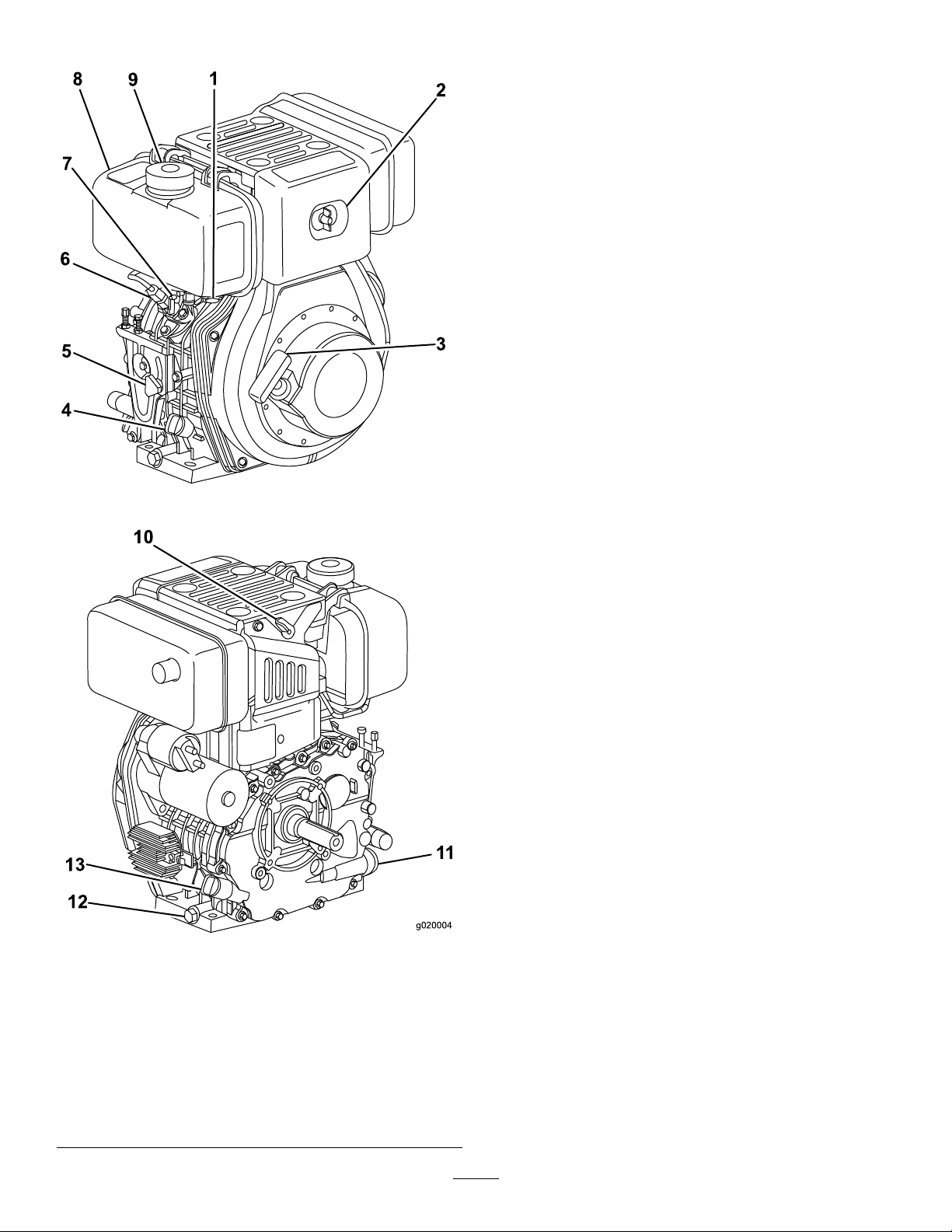

Figure6

1.Fueldrainplug8.Fueltank

2.Aircleaner9.Fuelcap

3.Recoil-starthandle10.Decompressionlever

4.Oilcap/dipstick11.Oillter

5.Engine-speed-control

knob

6.Fuel-injectionpump

7.Fuel-shutofflever

12.Oil-drainplug

13.Oilcap/dipstick

g020004

12

Page 13

Figure7

Fuel-ShutoffLever

Thefuel-shutoffleverislocatedunderneaththefuel

tank.Movethefuel-shutofflevertotheONposition

beforeattemptingtostarttheengine.Onceyouhave

nishedusingthemachineandyouhaveshutoffthe

engine,movethefuel-shutofflevertotheOFFposition.

g020357

1.Engine-speed-controlhandle

g020002

Figure9

1.Fuel-shutoffleverinOnposition

Recoil-StartHandle

Tostarttheengine,pulltherecoil-starthandle(Figure

6)quicklytoturntheengineover.Theenginecontrols

describedabovemustallbesetcorrectlyforthe

enginetostart.

1.Engine-speed-controlknob

g020001

Figure8

13

Page 14

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

3

BatchCapacity

TotalVolume0.56m

Length241cm

Width142cm

Height178cm

Weight407kg

0.34m

(12ft3)

3

(19.8ft3)

(95inches)

(56inches)

(70inches)

(897lb)

Operation

Important:Beforeoperatingthemachine,check

thefuelandoillevelsandremovedebrisfromthe

machine.Ensurethattheareaisclearofpeople.

PreparingtoTowthe Machine

Important:Ensurethatyourtowvehiclehas

towingcapacityfortheweightofthemachine.

Important:UseaClass2orlargerreceiver.

Note:Ensurethatyourtowvehiclehasthe

appropriatehitchtotowthemachine;optionsinclude

a50mm(2inch)ballhitchorapintlehitch.

Note:Ifthemachineisequippedwithatrailer-light

kit,ensurethattheelectricalconnectorofthetow

vehicleiscompatiblewiththeelectricalconnectorof

themachine.Ifyourtowvehiclehasadifferenttype

ofplug,obtainanadapterfromanautomotiveparts

store.

1.Ensurethattheengineisstopped,the

fuel-shutoffleverisoff,andthedrumisempty.

2.Usingthehandwheel,positionthedrumsothatit

ispointingdowntowardtheground(Figure10).

Figure10

1.Drumpointingdown3.Towpoleboltedinplace

2.Drum-tiltbrakeengaged

3.Lockthedrumintopositionbypushingdownon

thedrum-tiltbrakehandle(Figure1 1).

14

g019995

Page 15

Figure11

Drum-TiltBrake

1.Unlockedposition2.Lockedposition

Note:RefertoSpecications(page14)andensure

thatallreplacementtiresmeetorexceedtheratings

forthismachine.

1.Visuallyinspectthetiresfordamageandwear

(Figure12andFigure13).

g020836

Figure12

1.Exampleoftirewearcausedbyunderination

g019733

4.Ensurethattheenginecowlisclosedand

latched;refertoClosingtheCowl(page19).

5.Inspectthetiresandwheels;refertoChecking

theTiresandWheels(page15).

CheckingtheTiresandWheels

ServiceInterval:Beforeeachuseordaily—Inspect

thetiresandwheels.

Aftereachuse—T orquethelugnutsto108to

122N-m(80to90ft-lb)aftertowing.

WARNING

Failuretomaintaincorrecttirepressure

mayresultintirefailureandlossofcontrol,

resultinginpropertydamageandserious

injuryordeath.

•Checkthetirepressurefrequentlyto

ensureproperination.Ifthetiresarenot

inatedtothecorrectpressure,theywill

wearprematurely .

g010293

Figure13

1.Exampleoftirewearcausedbyoverination

2.Ensurethatthetiresareinatedtothecorrect

air-pressure.Thefollowingratingindicatesthe

appropriateairpressureforthetiresasinstalled

atthefactory.

Important:Alwayschecktheinformationon

theactualtiresforthecorrectairpressure

requirement.

Important:Themostcommoncauseoftire

troubleisunderination.Maintainfullair

pressure.

AirPressure:Max241kPa(35psi)

3.Ensurethatthewheellugnutsaretorquedto

108to122N-m(80to90ft-lb).

•Inspectthetireconditionbeforetowing

andafteranyoperatingaccident.

TheDOTtireinformationislocatedonthesideof

eachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note:Checkthetorqueofthewheellugnuts

initiallyandaftertowing.

Note:T orquethelugnutsinthesequence

showninFigure14.

15

Page 16

Figure14

HitchingaMachinewithaStamped BallCoupler

1.Applychassisgreasetothesocketofthecoupler

andtheareaoftheclampthatcontactstheball.

2.Oilthepivotpointsandslidingsurfacesofthe

couplerwithSAE30motoroil.

3.Openthecouplerlatch(Figure15).

g021107

g020359

Figure15

1.Bail

2.Safetypin

4.Positionthecouplerontopofthehitchball

(Figure15A).

5.Closethecouplerlatch(Figure15B).

6.Openthebailonthesafetypinandinsertthepin

throughtheholeinthelatch(Figure15B).

7.Rotatethefreeendofthebailovertheendof

thesafetypinthatisprotrudingthroughthelatch

(Figure15C).

8.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothe

wireplugofthemachine.

16

Page 17

HitchingaMachinewithaForged

HitchingaMachinewithaPintle

BallCoupler

1.Applyremovablethread-lockingcompoundto

thethreadsofthecouplerbolttopreventthe

couplerhandlefromcomingloose(Figure16).

Important:Applythread-lockingcompound

asneededinthefuture.

HitchTowPole

1.Removethepinfromthepintlehitchandopen

it(Figure17).

Figure16

1.Couplerhandle

2.Coupler

3.Clamp

4.Bolt

5.Hitchball

2.Applychassisgreasetothesocketofthecoupler

andtheareaoftheclampthatcontactstheball.

3.Pushthecouplerboltupthroughthecoupler

clampandthecouplertop,andconnectthe

couplerhandletothebolt(Figure16A).

4.Positionthecouplersothatthesocketisontop

ofthehitchballandtheclampisundertheball

(Figure16C).

5.Turnthecouplerhandleclockwisetothreadit

ontotheboltuntilitissecure(Figure16D).

Note:Useawrenchtokeeptheboltfrom

spinning.

6.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothe

wireplugofthemachine.

g019807

g019809

Figure17

2.Positiontheringonthetowpoleontothehook

ofthepintlehitch(Figure17).

3.Closethetopofthepintlehitchandsecureit

withthepin(Figure17).

4.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothe

wireplugofthemachine.

17

Page 18

ConnectingtheSafetyChainsto theTowVehicle

Connectthesafetychaintothemachineandthetow

vehicleasfollows:

1.Pullthesafetychainthroughtheslotsinthe

keyholeslocatedinthefrontpostofthemachine,

sothatthereisjustenoughslackoneachside

forturningaroundcornerswhentowingthe

machineFigure18).

Note:Stowtheexcesschaininsidethebottom

ofthefrontpostbypushingitintothekeyholes

andlatchingtheappropriatelinksintothe

keyholeslots.

2.Crossbothlengthsofchainunderthetowpole.

Note:Crossingthechainsdecreasesthe

chancesofthefrontofthemachinedropping

tothegroundifthehitchdoesnotholdthe

connection.

g021178

Figure19

1.Connectinglink3.Chainlink

2.Safetychainmounting

pointontowvehicle

TowingtheMachine

Figure18

1.Connectinglinks3.Chaincrossedundertow

pole

2.Keyholesinfrontpost

3.Connecteachlengthofchaintothesafety

chainmountingpointonthetowvehiclewiththe

connectinglinks(Figure19).

WARNING

Towingthemachineathighspeedincreases

theriskofahitchmalfunctionandtirefailure.

Higherspeedsalsoincreasethemomentum

ofthemachineandbrakingdistance.Ifthe

machinebecomesdetachedfromthetow

vehicleathighspeed,itcouldcausedamage

toproperty,orinjuryordeathtobystanders.

Donotexceed88km/h(55mph)whentowing

themachine.Forpoorroadconditionsor

g021177

inclementweather,reducespeedaccordingly.

WARNING

Towingthemachinewithmaterialinthedrum

increasestheriskofahitchmalfunctionand

tirefailure.Inaddition,materialcouldbounce

outofthedrumandhitothervehiclesand/or

people.Materialinthedrumincreasesthe

weight,whichaffectsmomentumandbraking

distance.

Donottowthemachinewithmaterialinthe

drum.

•ReviewandunderstandSafeOperatingPractices

(page4).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthe

machine.

18

Page 19

PreparingtoUsethe Machine

•Reviewallofthesafetydecalsonthemachine.

•Useahard-hat,hearingprotection,ashirtwith

longsleevesthataretightatthewrists,tight-tting

gloveswithoutdrawstringsorloosecuffs,eye

protection,andadustmaskorrespirator.A

meshvisoralonedoesnotprovidesufcienteye

protection;supplementwithprotectiveglasses.

•Ensurethatyouarefamiliarwiththesafety

regulationsandshutdownproceduresdescribed

intheOperator’sManualandEngineOwner’s

Manual.

•Ensurethatallguardsareinplaceandingood

condition.

•Ensurethatthepaddlesareinplaceandingood

condition.

•Checkthefuelandoillevelsoftheengine.

•Whenpreparingtomixmaterial:

1.Movethemachinetoaleveljob-sitesurface.

2.Removethemachinefromthetowvehicle.

3.Chockthefrontandbackofthetiresto

preventthemachinefrommoving.

4.Ensurethatthedrumisinthemixposition

(upright).

5.Ensurethatthedrum-tiltbrakeisengaged

andthatthedrumdoesnotrotatetowardthe

dumpposition.

Figure20

Openingandclosingthecowl

1.Latch3.Receiver

2.Latchanchor

2.Repeat1ontheoppositesideofthemachine.

3.Atthebackofthemachinewheretherearcowl

meetstheframeofthemachine,graspthering

ofthelatchandpullitofffromthelatchanchor

onthecowl(Figure20).

4.V-tting

g021318

OpeningandClosingthe

Cowl

OpeningtheCowl

1.Atthesideofthemachinewherethefrontcowl

andrearcowlmeet,grasptheringofthelatch

andpullitofffromthelatchanchorontherear

cowl(Figure20).

4.Rotatetherearcowlupandforwarduntilitis

fullypositionedontopofthefrontcowl(Figure

20).

ClosingtheCowl

1.Rotatetherearcowlrearwardanddownuntil

thereceiveratthebottomcenterofthecowlis

alignedwiththeV-ttingandushontheframe

ofthemachine(Figure20).

2.Atthebackofthemachine,grasptheringofthe

latchandpullitontothelatchanchoronthe

rearcowl.

3.Atthesideofthemachine,grasptheringofthe

latchandpullitontothelatchanchorontherear

cowl.

4.Repeatstep3ontheoppositesideofthe

machine(Figure20).

19

Page 20

AddingFuel

DANGER

•Useonlyultra-lowsulfur(<15ppm)dieselfuel.

•Purchasefuelinquantitiesthatcanbeusedwithin

30daystoensurefuelfreshness.

•Usesummer-gradedieselfuel(Number2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

dieselfuel(Number1-DorNumber1-D/2-Dblend)

below-7°C(20°F).

•Nevermixkerosene,usedengineoil,orresidual

fuelswiththedieselfuel.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinter.

•Fueladditivesarenotrecommended.Somefuel

additivesmaycausepoorengineperformance.

DANGER

Incertainconditions,dieselfuelisextremely

ammableandhighlyexplosive.Areor

explosionfromdieselcanburnyouand

othersandcandamageproperty.

Useonlydieselfuel.Fillingthefueltankwith

gasolinemayresultinare.

•Fillthefueltankandstorefuelina

well-ventilatedarea.

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailerand

fueltheequipmentwiththewheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

•Ifyoumustuseafueldispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

•Donotrefuelthefueltankwhiletheengine

isrunning.

•Donotllthefueltankcompletelyfull.Add

fueluntilitisatthesamelevelasthered

ring.Thisemptyspaceinthetankallows

fueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

maybeignitedbyaspark.

•Storedieselinanapprovedcontainerand

keepitoutofthereachofchildren.Donot

buymorethana30-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworking

condition.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

thefueltankorconditioneropening.

•Keepfuelawayfromyoureyesandskin.

DieselFuelSpecications

Important:Donotmixoilwithdiesel.

Dieselfuelshouldcomplywiththefollowing

specication.Thetablelists7worldwide

specicationsfordieselfuels.

DieselFuelSpecications

Number2-D,Number

1-D,ASTMD975-94

Ultra-lowSulfur(<15ppm)

EN590:96EuropeanUnion

ISO8217DMX

BS2869-A1orA2

JISK2204GradeNumber2

Location

USA

International

UnitedKingdom

Japan

20

Page 21

DieselFuelSpecications

KSM-2610

GB252China

Location

Korea

UsingFuelStabilizer/Conditioner

Useadieselfuelstabilizer/conditionerinthemachine

tokeepthefuelfreshduringstorageof90daysor

less.Ifyouarestoringthemachineforlonger,drain

thefueltank;refertoDrainingtheFuelT ankand

ReplacingtheOutletFuelFilter(page33).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionerto

thefuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuel.

FillingtheFuelTank

Capacity:4.7L(1.25USgallons)

1.Parkthemachineonalevelsurface,stopthe

engine,andallowtheenginetocool.

2.Cleanaroundthefuelcapandremoveit(Figure

21).

g019997

Figure21

1.Fuelcap3.Redring

2.Inlet-fuelscreen

Important:Keeptheinlet-fuelscreenand

theredringinthefueltankwhilepouringthe

fuel.

3.Addfueltothefueltankuntilthelevelisupto

theredring(Figure22).

Important:Thisspaceinthetankallows

thefueltoexpand.Donotllthefueltank

completelyfull.

21

Page 22

Figure22

4.Securelyinstallthefuelcap(Figure21).

5.Wipeupanyfuelthatmayhavespilled.

CheckingtheEngine-Oil Level

ServiceInterval:Beforeeachuseordaily—Check

theengine-oillevel.

ToroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

g020376

Figure23

Important:Ensurethattheengineoil,engine

oilstoragecontainers,andengineoillling

equipmentarefreeofsedimentsandwater.

g020005

1.Placethemachineonaat,levelsurface,and

stoptheengine.

2.Allowtheenginetocool.

3.Cleanaroundthedipstick.

4.Removethedipstickandwipetheendclean

(Figure24).

Important:Use4-cycleengineoilthatmeets

orexceedsthefollowingguidelinesand

classications:

•APIServiceCategoriesCH-4,CI-4,CJ-4orhigher

•ACEAServiceCategoriesE-3,E-4,andE-5

•JASOServiceCategoryDH-1

Crankcasecapacity:1.6L(1.7USqt)

Important:Iftheoillevelinthecrankcaseistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.Thistypeofdamageisnot

coveredbythewarranty.

Viscosity:RefertoFigure23.

g019993

Figure24

1.Dipstickupperlimit3.Fillport

2.Dipsticklowerlimit

22

Page 23

5.Slidethedipstickfullyintothellportwithout

threadingitintotheport(Figure24).

6.Removethedipstickandlookattheend.Ifthe

engineoillevelisbelowthehalfwaypointonthe

hatchmarks,slowlypouronlyenoughoilintothe

llporttoraisetheleveltothehalfwaypointon

thedipstick.

7.Installandsecurethedipstick(Figure24).

StartingtheEngine

1.ReadSafeOperatingPractices(page4)and

understandtheControls(page11)before

attemptingtostartthemachine.

2.Makesurethatthefuel-shutoffleverisinthe

ONposition.

g020001

Figure26

1.Engine-speed-controlknob

Figure25

1.Fuel-shutoffleverintheOnposition

3.Ensurethattheengine-speed-control

knobontheengineisloosebyrotatingit

counterclockwise(Figure26).

4.Rotatetheengine-speed-controlhandle

counterclockwisetounlockit,pullitalltheway

out,andlockitbyrotatingitclockwise(Figure

27).

g020002

1.Engine-speed-controlhandle

23

g020357

Figure27

Page 24

5.Pushthedecompressionlevertotheleft(Figure

6).

UsingtheMachine

Note:Thedecompressionleverstayscockedto

theleftandautomaticallyreturnstotheoriginal

positionwhentheyoupulltherecoil-starter

handleagain.

6.Grasptherecoil-starthandle,pullitoutslowly

untilyoufeelresistance,thenpullitalltheway

outwithastrongandevenmotion(Figure28).

Note:Use2handsifnecessary.

DANGER

Thismachineiscapableofamputatinghands.

•Stayintheoperator’spositionwhilethe

machineisrunning.

•Keepallbystandersasafedistancefrom

themachine.

•Stopthemachineimmediatelyifany

peopleoranimalsentertheworkarea.

•Neverplaceanypartofyourbodyintoa

positionthatcausesanunsafeoperating

condition.

1.Ensurethatthemachineisonlevelgroundand

thatthesurroundingareaisclearofobstacles.

Note:Disconnectthemachinefromthetow

vehicleandchockthefrontandbackofboth

tirestopreventanymovement.

2.Makesurethatyoureadalltherecommendations

fromtheSafetysection;refertoSafeOperating

Practices(page4)beforeusingthemachine.

Figure28

7.Slowlyreturntherecoil-starthandletotheinitial

position.

8.Iftheenginedoesnotstart,repeatsteps2

through7.

ShuttingOfftheEngine

1.Unlocktheengine-speed-controlhandleby

rotatingitcounterclockwise,andpushitin

slightly,totheidlesetting.

2.Runtheengineatlowidlespeedandwithout

aloadforatleast5minutestoallowengine

componentsthatoperateatahightemperature

tocooldown.

3.Pushtheengine-speed-controlhandletherest

ofthewayintoshutofftheengine.

3.Starttheengineandclosetheenginecowl.

g020367

Allowtheenginetowarmupatidlefor2minutes;

refertoStartingtheEngine(page23).

4.Usethehandwheeltomovethedrumintoan

upright,slightlytiltedpositiontoallowaccessfor

pouringmaterialsintothedrum.

Note:Thispositionalsoallowsthemixing

paddlestomixthematerialsmoreeffectively.

5.Pushthedrum-tiltbrakedowntolockthedrum

intopositionandavoidaccidentallydumpingthe

material.

Important:Ifyouneedtostopthemachine,use

theengine-speed-controlhandlelocatedonthe

cowl;refertoEngineSpeedControlHandle(page

12).

4.Movethefuel-shutofflevertotheCLOSED

positionaftertheenginestops.

Note:Iftheenginedoesnotstopafteryoupush

theengine-speed-controlhandleallthewayin,

stoptheenginebymovingthefuel-shutofflever

totheCLOSEDposition.

24

Page 25

MixingtheMaterial

1.Ensurethatthetiltbrakeisfullyengagedand

thatthedrumisoperatingatfullspeed.

DANGER

Eyeandskincontactwithconcretematerials

andbreathingthedustinvolvedishazardous

toyourhealth.

•Ensurethatthereisadequateair

ventilation.

•Wearadustmasktopreventinhalationof

dustwhileusingthemachine;refertoSafe

OperatingPractices(page4).

•Avoiddirectcontactofcementand

concretematerialswithskinandeyes.

Important:Donotaddmorematerialthan

thebatchcapacityofthemachine;referto

Specications(page14).

Note:Followthemanufacturer’sinstructionsthatare

printedonthepackagingoftheproduct.

Concretehasthefollowing4basicingredients:

•Sand

•Gravel

•Portlandcement

•Water

Dependingontheapplication,youcanusedifferent

ratiosofthese4ingredients.

Therearemanyvariationsofconcretemixrecipes,

dependingontheapplication.Itisimportanttouse

theappropriatequantityofwater.Usingtoolittlewater

resultsindryareasinthemix,butusingtoomuch

waterwillresultinweakerconcrete.Theamount

ofwaterneededvariesdependingonthemoisture

contentofthesandandgravel.Themixshouldhave

athicknesssimilarthatofpeanutbutter.

Keepthepouredconcretedampforseveraldaysto

obtainpropercuring.Evaporationresultsinweaker

concrete.Concretecuresthroughhydration,a

reactionbetweenwaterandcement.

2.Pourwaterintothedrum.

3.Addtherequiredamountofgravel.

4.AddtherequiredamountofPortlandcement.

5.Addtherequiredamountofsand.

6.Allowthedrumtoturnwhilethemixreachesthe

appropriateconsistency.

Note:Addingwaterandgravelbeforecementand

sandallowsthemixleftinthedrumfromtheprevious

batchtobetumbledoffthedrumandpaddlesandinto

thenextbatch.

UsingtheDrum

DANGER

Contactwiththemixingpaddlescouldcause

damageorinjury.

Neverputyourhandsinsidethedrumatany

time.

DumpingtheDrum

Note:Whendumpingabatchofmaterial,leavethe

enginerunningsothattherotatingdrumhelpsdump

thematerial.

1.Alignawheelbarroworsimilarcontainerof

adequatecapacityinthepathofthedrum

opening.

2.Whilethedrumisturning,rmlygraspthe

handwheelwithonehand.

3.Usingyourotherhand,pulluponthedrum-tilt

brakehandletoreleasethebrake.

4.Usingbothhands,slowlyturnthehandwheel,

allowingthedrumtotiltinthedesireddirection

anddumpthedesiredamountofmaterial.

MixingPre-MixConcrete

1.Ensurethatthetiltbrakeisfullyengagedand

thatthedrumisoperatingatfullspeed.

2.Pourwaterintothedrum.

3.Addtherequiredamountofdrypre-mix.

4.Allowthedrumtoturnwhilethemixreachesthe

appropriateconsistency.

MixingSand,Gravel,andCement

Thetypicalratioformixingconcreteis1partPortland

cement,2partssand,and3partsgravel.

5.Turnthehandwheelintheoppositedirectionto

returnthedrumintoanuprightposition.

6.Pushdownonthedrum-tiltbraketolock

thedrumintoposition,avoidingaccidental

dischargingofconcretemix.

7.Afterdumpingabatchofmaterial,cleanthe

drum;refertoCleaningtheDrum(page26).

Note:Thisstepwillcleanthepaddlesanddrum

betweenbatchesandpreventdriedmaterial

fromformingandcontaminatingthenextbatch

ofmaterial.

25

Page 26

CleaningtheDrum

ServiceInterval:Aftereachuse

Important:Donotstrikethedrumwitha

shovel,hammer,oranyotherdevicetoloosen

accumulationofdriedmaterials.

1.Whilethemachineisrunning,usethehandwheel

totiltthedrumslightly .

2.Engagethedrum-tiltbraketopreventthedrum

fromtiltingfurtheranddischargingthewater.

3.Asthedrumisrotating,sprayitthoroughlywith

waterbeforethematerialdries.

4.Allowthedrumtorotateandtumbletheloose

materialandwater,furtherlooseningtherestof

thematerial.

5.Continuetospraythedrumwithwatertoremove

allofthematerialfromthedrumandmixing

paddles.

6.Whenallthematerialhasbeenremovedfrom

thesurfacesofthedrumandmixingpaddles,

disengagethedrum-tiltbrakeandusethe

handwheeltotiltthedrumanddumpthewater

fromthedrum.

7.Ifsomematerialstillremainsinthedrum,spray

thedrumwithwaterwhileitistilteddownward,

allowingthewaterandmaterialtorunout.

26

Page 27

Maintenance

Important:Beforeperforminganymaintenanceprocedures,stoptheengineandwait5minutesto

allowallmovingpartstocometoacompletestopandcool.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every20hours

Every40hours

Every50hours

Every100hours

Every200hours

Every400hours

Every1,000hours

MaintenanceProcedure

•Changetheengineoil.

•Cleantheengine-oillter.Replaceitifitisdamaged.

•Inspectthetiresandwheels.

•Checktheengine-oillevel.

•Inspecttheaircleanerelements.

•Torquethelugnutsto108to122N-m(80to90ft-lb)aftertowing.

•Cleanthedrum.

•Inspectthedrivechainforrustanddebris.

•Inspectthedrivechaintensionandadjustitasnecessary .

•Lubricatethedrivechainwithanon-stickychainlubricant.

•Cleantheinlet-fuelscreen.

•Changetheengineoil.

•Cleantheaircleanerelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Replacetheoutlet-fuellter.

•Cleantheengineoil-lter.Replaceitifitisdamaged.

•Changethereductioncaseoil.

Monthly

•Greasethetrunnionsandthedrumspindle.

Pre-Maintenance

Procedures

PreparingtheMachinefor Maintenance

1.Parkthemachineonalevelsurface.

2.Removethemachinefromthetowvehicle.

3.Chockthetires.

4.Opentherearcowl;refertoOpeningtheCowl

(page19).

5.Ensurethattheengineandmuferarecool.

RemovingandInstalling theDividerPlate

Youneedtoremovethedividerplatetoprovideaccess

beforeperformingsomemaintenanceprocedures.

RemovingtheDividerPlate

1.Unlatchandopenthecowl;refertoOpeningthe

Cowl(page19).

2.Useawrenchtoremovethe4boltsthatsecure

thedividerplatetothefrontcowl.

Note:Keeptheboltsforinstallingthedivider

plate.

27

Page 28

Lubrication

LubricatingtheMachine

ServiceInterval:Monthly—Greasethetrunnionsand

thedrumspindle.

1.Cleanaroundeachgreasettingwitharagand

lifttheplasticcapoffthegreasetting(Figure

31).

Figure29

3.Toremovethedividerplate,liftitupwardand

rotateitcounterclockwisesothatitclears

variousenginecomponents.

InstallingtheDividerPlate

1.Guidethedividerplateintopositionagainstthe

frontcowl.

Note:Startwiththedividerplaterotatedslightly

counterclockwise,andthenrotateitclockwise

whileloweringitintoposition.

Ensurethatthedividerplateisnotbackward.

g020752

2.Useagreaseguntolubricatethegreasettings

ofbothtrunnionsandthedrumspindlewith

general-purposelithiumgrease(Figure31).

3.Wipeupanyexcessgrease.

Figure30

2.Aligntheboltholesinthedividerplateandthe

frontcowl.

3.Installeachofthe4bolts,andhand-tighten

themtopreventcross-threading.

4.Tightentheboltswithawrenchuntiltheyare

secure.

g020000

Figure31

g020753

Important:Donotlubricatethepiniongearand

ringgear.Lubricationwillcausethemtocollect

abrasivematerialsandacceleratewear.

28

Page 29

LubricatingtheDriveChain

ServiceInterval:Every40hours—Lubricatethe

drivechainwithanon-stickychain

lubricant.

Applyachainlubricantthatisnon-stickytohelp

preventdirtandabrasiveparticlesfromstickingtothe

chain(Figure32).

Figure32

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspect

theaircleanerelements.

Every200hours/Y early(whichevercomes

rst)—Cleantheaircleanerelements.Clean

themmorefrequentlyindustyoperating

conditions.

Important:Donotoperatetheenginewithout

theairlterassembly;extremeenginedamage

willoccur.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Turnthefuel-shutofflevertotheOFFposition.

3.Removethewingnutthatsecurestheair-cleaner

cover(Figure33).

g021306

1.Drivechain3.Enginesprocket

2.Reductioncase

g019996

Figure33

1.Wingnut3.Paperelement

2.Air-cleanercover4.Foamelement

4.Removetheair-cleanercover.

5.Removetheinternalwingnut.

6.Removethefoamandpaperelementsfromthe

base(Figure33).

7.Removethefoamelementfromthepaper

element(Figure33).

8.Inspectthefoamandpaperelements,and

replacethemiftheyaredamagedorexcessively

dirty.

Note:Nevertrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

9.Wipedirtfromthebaseandthecoverwitha

moistrag.

Note:Becarefultopreventdirtanddebris

fromenteringtheairductinsidetheair-cleaner

housing.

29

Page 30

10.Slidetheouterfoamelementoverthepaper

element.

DrainingtheEngineOil

11.Installtheaircleanerelementsandensurethat

theyareproperlypositioned.

12.Installtheinternalwingnut

13.Securelyinstallthecoverwiththeotherwingnut.

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours—Change

theengineoil.

Every100hours—Changetheengineoil.

ToroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

Important:Use4-cycleengineoilthatmeets

orexceedsthefollowingguidelinesand

classications:

•APIServiceCategoriesCH-4,CI-4,CJ-4orhigher

•ACEAServiceCategoriesE-3,E-4,andE-5

•JASOServiceCategoryDH-1

Crankcasecapacity:1.6L(1.7USqt)

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury .

Avoidcontactingthehotengineoilwhenyou

drainit.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Placeaoil-drainpanundertheoil-drainholeof

theengine(Figure35).

Important:Iftheoillevelinthecrankcaseistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.Thistypeofdamageisnot

coveredbythewarranty.

Viscosity:RefertoFigure34.

Figure34

g020382

Figure35

1.Oil-drainplug3.Oil-drainpan

g020376

2.Oil-drainhole

3.Removethedrainplugandcatchtheoilinthe

oil-drainpan(Figure35).

4.Whentheoilhasdrainedcompletely,installthe

drainplugwithanewwasher(Figure35).

Note:Disposeoftheusedoilatacertied

recyclingcenter.

30

Page 31

FillingtheEngineCrankcasewith Oil

1.Removethedipstick(Figure36)andslowlypour

oilintothellholeuntiltheoilisbetweenthe

upperandlowerlimitonthedipstick.

ServicingtheEngine-Oil Filter

ServiceInterval:Aftertherst50hours—Cleanthe

engine-oillter.Replaceitifitis

damaged.

Every400hours—Cleantheengineoil-lter.

Replaceitifitisdamaged.

InspectingandCleaningthe Engine-OilFilter

1.Removetheoil-lterretainingbolt.

2.Pulltheoil-ltercapoutandremovetheoillter.

1.Dipstickupperlimit

2.Dipsticklowerlimit

2.Installandsecurethedipstick.

3.Wipeupanyspilledoil.

Figure36

3.Oil-llerport

g020389

Figure37

g019993

1.Oillter3.Oil-lterretainingbolt

2.Oil-ltercap

3.Cleantheoillterorreplaceitifitisdamaged.

4.Installtheoillter.

5.Makesurethattheoil-ltercapisfullyseated.

6.Installandtightentheoil-lter-retainingbolt.

7.Addnewengineoil;refertoFillingtheEngine

CrankcasewithOil(page31).

8.Warmuptheenginebyrunningitfor5minutes,

andcheckforanyengineoilleaks.

9.Aftertheengineiswarm,turnitoffandletitsit

for10minutes.

10.Checktheengineoillevelbyfullyinserting,but

notscrewingin,thedipstick.

11.Addengineoilasneeded;refertoCheckingthe

Engine-OilLevel(page22)

31

Page 32

RemovingandInstalling

FuelSystem

theEngine

RemovingtheEngine

1.Opentherearcowl;refertoOpeningtheCowl

(page19).

2.Removethe4nutsandboltsthatsecurethe

enginetotheengine-mountingplate(Figure38).

Maintenance

ServicingtheFuelSystem

CleaningtheInlet-FuelScreen

ServiceInterval:Every50hours—Cleantheinlet-fuel

screen.

1.Cleantheareaaroundthefuelcap.

2.Removethefuelcap.

3.Lifttheinlet-fuelscreenoutofthefueltank.

Figure38

1.Nutsandbolts

3.Slidetheenginetotheright,andmovethedrive

chainawayfromtheenginesprocket.

4.Carefullylifttheengineupandoffthe

engine-mountingplate.

InstallingtheEngine

1.Settheengineontheengine-mountingplate,

andaligntheboltholes(Figure38).

2.Installthe4boltsandsecurethemwiththenuts

torquedto24N-m(18ft-lb).

3.Checkthedrivechaintension,andadjustitif

necessary;refertoCheckingtheDriveChain

Tension(page34)andAdjustingtheDriveChain

Tension(page34).

4.Closetherearcowl;refertoClosingtheCowl

(page19).

g020391

g021309

Figure39

1.Fuelcap3.Fueltank

2.Inlet-fuelscreen

4.Cleantheinlet-fuelscreenorreplaceitifitis

damaged.

5.Installtheinlet-fuelscreen.

6.Installthefuelcapandhandtightenit.

Note:Overtighteningthefuelcapwilldamage

it.

32

Page 33

DrainingtheFuelTankand ReplacingtheOutletFuelFilter

ServiceInterval:Every200hours—Replacethe

outlet-fuellter.

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Placeanapprovedcontainerunderthefueltank

tocollectthefuel.

3.Removethefuelcap(Figure40).

g021307

Figure41

1.Outlet-fuellter4.O-ring

2.Gasket5.Fuel-shutofflever

3.Fillerport6.Nut

6.RemoveanddiscardtheO-ring(Figure41).

Figure40

1.Fuelcap3.Drainplug

2.Gasket

4.Removethedrainplugandgaskettodrainthe

fuel(Figure40).

5.Loosenthenutsunderthefuel-shutofflever

(Figure41).

g021311

7.Pulltheoutlet-fuellterandgasketoutofthe

llerport(Figure41).

8.Installanewoutlet-fuellterandgasketthrough

thellerport,andseattheminthefueltank

(Figure41).

9.InstallanewO-ringonthefuel-shutofflever,and

installtheassemblytothefueltankusingthe

nutsunderthefuel-shutofflever(Figure41).

10.Installthedrainplugwithanewgasket(Figure

40).

11.Installthefuelcapandhandtightenit.

Note:Overtighteningthefuelcapwilldamage

it.

33

Page 34

DriveSystem

ServicingtheDriveChain

Maintenance

ServicingtheReduction Case

ChangingtheReductionCaseOil

ServiceInterval:Every1,000hours

Oiltype:non-detergentmotoroilwithaviscosityof

SAE50orless

Capacity:0.24L(8.0oz)

1.Removetheengine;refertoRemovingthe

Engine(page32).

2.Removethedrainplugandthevented-llerbolt

onthereductioncase.

ServiceInterval:Every20hours—Inspectthedrive

chainforrustanddebris.

Every20hours—Inspectthedrivechaintension

andadjustitasnecessary.

CheckingtheDriveChain

1.Stoptheengineandlockthe

engine-speed-controlhandletotheStop

position;refertoShuttingOfftheEngine(page

24),andmovethefuel-shutofflevertotheOFF

position.

2.Usingaashlight,carefullyinspectthechain.If

rustanddebrisarepresent,removethemwith

abrush.

CheckingtheDriveChainTension

1.Layastraightedgealongthedrivechainfrom

onesprockettotheother.

2.Pushonthechainwith6.8kg(15lb)ofpressure,

midwaybetweenthesprockets.

Figure42

1.Reductioncase4.Drainplug

2.Fillhole5.Drainhole

3.Vented-llerbolt

3.Tiptheenginesothattheoildrainscompletely,

toavoidmixingdifferenttypesofoil.

Important:Toavoiddamagingpartsofthe

engineorthereductioncase,becareful

whentippingtheengine.

4.Installthedrainplugintothedrainhole.

5.Ensurethattheengineislevel,andpour0.24L

(8.0oz)ofoilintothellhole.

6.Installthevented-llerboltintothellhole.

7.Installtheengine;refertoInstallingtheEngine

(page32).

3.Measurethedistancefromthechainto

thestraightedge.Thedistanceshouldbe

approximately2.5cm(1inch).

4.Ifthechaintensionneedsadjustment,referto

AdjustingtheDriveChainTension(page34).

AdjustingtheDriveChainTension

1.Stoptheengineandwaitforallmovingpartsto

stop.

2.Loosenthe4nutsandboltsthatsecurethe

g021305

enginetotheengine-mountingplate(Figure43).

34

Page 35

Figure43

1.Engine-mountingnutsandbolts(4each)

3.Slidetheenginelefttoincreasetensiononthe

drivechainorrighttodecreasetension.

Cleaning

CleaningtheMachine

Regularcleaningandwashingwithmilddetergentand

waterwillincreasethelifespanofthemachine.Clean

themachineaftereachusebeforethedirthardens.

Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleandirtand

concretematerialsfromtheoutsideoftheengine.

Ensurethatthefuelcapandoil-llcap/dipstickare

securetoavoidgettingwaterintheengine.

Usecarewhenusingahigh-pressuresprayer,

becauseitcandamagesafetydecals,instruction

g020391

signs,andtheengine.

4.Whenthechainhastheappropriateamount

oftension;refertoCheckingtheDriveChain

Tension(page34),torquethe4nutsandbolts

to24N•m(18ft-lb)each.

35

Page 36

Storage

StoringtheMachine

Wheneveryoustorethemachineover30days,

prepareitasfollows:

1.Cleanthemachine;refertoCleaningthe

Machine(page35).

2.Starttheengine.Allowtheenginetoidlefor3

minutesandthenstoptheengine.

3.Draintheengineoilwhiletheengineisstill

warm,andlltheenginewithnewoil;referto

ChangingtheEngineOil(page30).

4.Pushthedecompressionleverdownandholdit

whileslowlypullingtherecoilstarter2or3times.

Note:Donotstarttheengine.

5.Drainthefueltankbyunscrewingfueldrainplug

andcollectingfuelinafuelcontainer.

Note:Disposeofthefuelproperly;recycleit

accordingtolocalcodes.

6.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamaged.

7.Paintallscratchedorbaremetalsurfaceswith

paintavailablefromyourAuthorizedService

Dealer.

8.Storethemachineinaclean,drygarageor

storagearea.

9.Coverthemachinetoprotectitandkeepitclean.

36

Page 37

Troubleshooting

Problem

Theenginedoesnotstart.

Theenginerunsrough.

Thereiswhiteorblackexhaustsmoke.

PossibleCauseCorrectiveAction

1.Ontheenginecowl,the

engine-speed-controlhandleis

notallthewayintotheSTARTposition.

2.Thefuel-shutoffleverisintheOFF

position.

3.Thefueltankisempty.3.Fillthetankwithfreshfuel.

4.Thefuelisbad;theenginewasstored

withouttreatingordrainingthefuel,or

itwaslledwithbaddiesel.

5.Thefuellterisclogged.5.Replacethefuellter.

1.Theair-lterisclogged.1.Cleanorreplacetheairlter.

2.Thereiswaterorcontaminantsinthe

fuel.

3.Thereistoomuchoilintheengine.3.Draintheoiltotheproperlevel.

1.Theengineisoverloaded.1.Reducetheload.

2.Theair-cleanerelementisclogged.

3.Improperdieselfuelhasbeenputin

thefueltank.

4.Thefuel-injectionsystemhasan

incorrectspraypattern.

5.Thereisexcessiveintakeorexhaust

valveclearance.

6.Theengineisburningoil.

1.Pulltheengine-speed-controlhandle

totheSTARTpositionandlockit.

2.Movethefuel-shutofflevertotheON

position.

4.Drainthefueltankandllitwithfresh

diesel.

2.Drainandllthetankwithfreshfuel.

2.Cleantheelementorreplaceit.

3.Fillthetankwiththerecommended

dieselfuel.

4.ContactyourAuthorizedService

Dealer.

5.ContactyourAuthorizedService

Dealer.

6.ContactyourAuthorizedService

Dealer.

Thedrumdoesnotturn.1.Thechainislooseordamaged.

Thedrumdoesnottilt.1.Thedrum-tiltbrakeisengaged.1.Disengagethedrum-tiltbrake.

Thedrumchattersorturnserratically .

1.T eetharemissingfromthegears.

2.Thegearsaremisaligned.

1.Thereisdebrisinthedrum.1.Removethedebris. Themachinevibratesexcessively .

2.Themixingpaddlesaredamaged.

1.ContactyourAuthorizedService

Dealer.

1.ContactyourAuthorizedService

Dealer.

2.ContactyourAuthorizedService

Dealer.

2.ContactyourAuthorizedService

Dealer.

37

Page 38

Notes:

Page 39

Notes:

Page 40

Loading...

Loading...