Page 1

FormNo.3404-694RevA

G019544

CM-958H-PConcreteMixer

ModelNo.68009HD—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3404-694*A

Page 2

WARNING

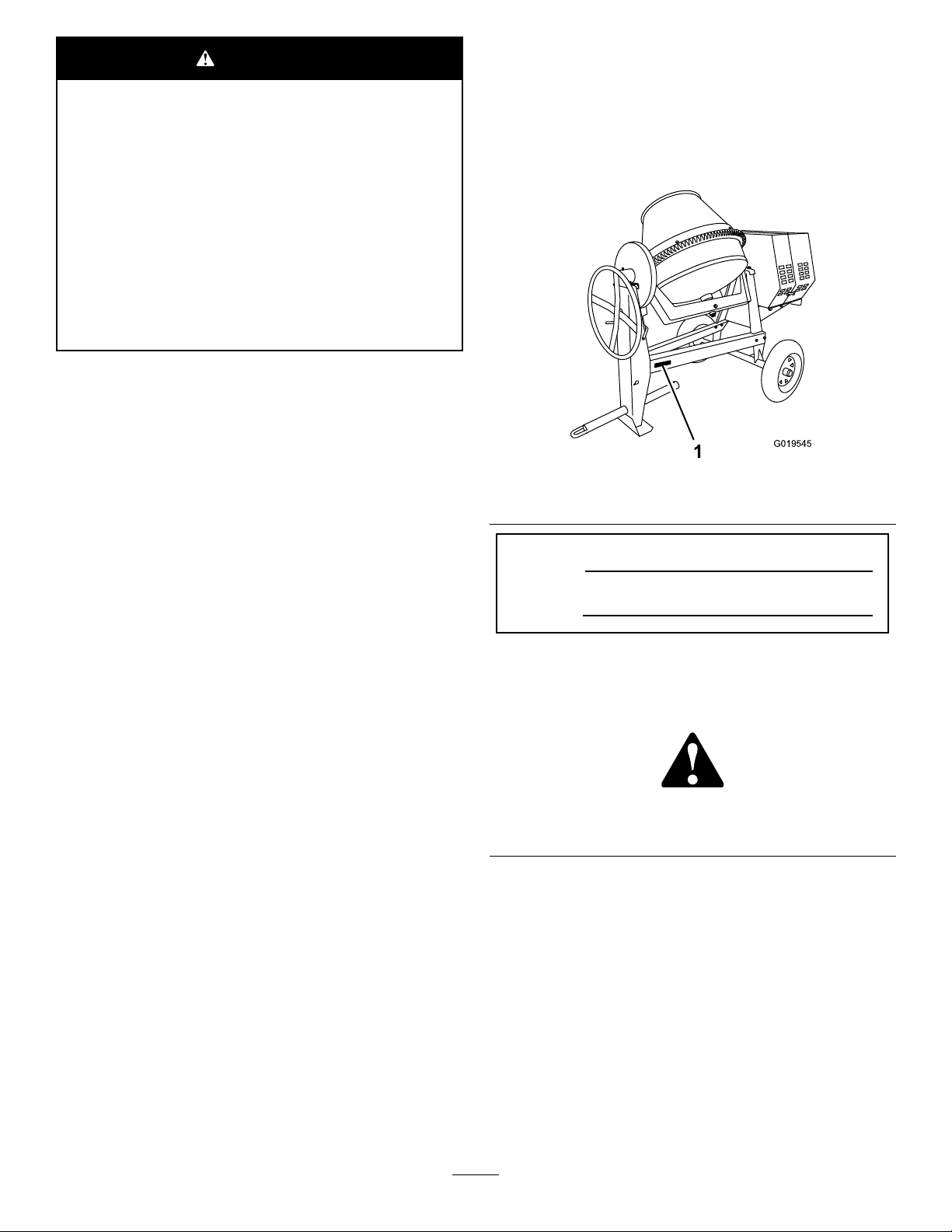

1

G019545

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

Figure1

1.Modelandserialnumberlocation

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisdesignedtomixconcrete,plaster,reproong

material,grout,andothersmall-grainedconcreteproducts.

Themachinecanbetowedbehindavehicleequippedwith

ahitchappropriateforthetypeoftowpoleyourmachine

has(ball,pintle,orpinhitch).

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

TireInformation

TheDOTtireinformationislocatedontheside

ofeachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note:RefertoSpecications(page11)toensurethatthe

tiresonyourmachinemeetorexceedtheweightrequirements

ofyourmachine.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................6

Setup............................................................................8

1InstallingtheTowPole..........................................8

2InstallingtheSafetyChain......................................9

ProductOverview..........................................................9

Controls................................................................9

Specications........................................................11

Operation....................................................................11

PreparingtoT owtheMachine..................................11

TowingtheMachine...............................................15

PreparingtoUsetheMachine...................................15

OpeningandClosingtheCowl.................................15

AddingFuel...........................................................16

CheckingtheEngine-OilLevel.................................18

StartingandShuttingOfftheEngine.........................18

UsingtheMachine..................................................19

MixingtheMaterial.................................................19

UsingtheDrum.....................................................20

Maintenance.................................................................21

RecommendedMaintenanceSchedule(s)......................21

PremaintenanceProcedures........................................21

PreparingtheMachineforMaintenance.....................21

DisconnectingtheSpark-plugWire...........................21

RemovingandInstallingtheDividerPlate..................22

Lubrication...............................................................23

LubricatingtheMachine..........................................23

EngineMaintenance..................................................23

ServicingtheAirCleaner.........................................23

ServicingtheEngineOil..........................................24

ServicingtheSparkPlug..........................................26

ServicingtheSparkArrester.....................................27

FuelSystemMaintenance...........................................28

CleaningtheFuel-SedimentCup...............................28

BeltMaintenance......................................................29

CheckingtheDrive-BeltTension..............................29

AdjustingtheDrive-beltTension..............................30

ReplacingtheDriveBelts.........................................30

Cleaning...................................................................31

CleaningtheMachine..............................................31

Storage........................................................................31

StoringtheMachine................................................31

Troubleshooting...........................................................33

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

,whichmeans:

Caution

,

W ar ning

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Alwaysfollow

allsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Machiningorhandlingstone,masonry,concrete,

metal,andothermaterialscangeneratedust,mists,

andfumescontainingchemicals,suchassilica,

knowntocauseseriousorfatalinjuryorillness,

suchasrespiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Watershouldbeusedfordust

suppressionwhenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupationaland

tradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyOSHAfor

thematerialbeinghandled.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

,

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

3

Page 4

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriestopeopleordamagetoproperty.

Towing

Checkwithyourlocalcountyorstatetowingsafetyregulations

beforetowingthemachine.

•Inordertoreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,makesurethat

thetowingvehicleismechanicallysoundandingood

operatingcondition.

•Shutdowntheenginebeforetransportingthemachine.

•Whentowingwithaballhitch,ensurethattheballhitch

youareusingisthepropersizeforthehitchcoupleron

themachine.

•Whentowingwithapintlehitch,ensurethattheeyeof

thetowpoleisthecorrectdimensionforthepintlehook.

•Inspectthehitchandcouplingforwear.Nevertowthe

machinewithdamagedordefectivehitches,couplings,

chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicleandthe

machine.

•Checkthetiretreadandsidewallfordamageandwear.

•Properlyattachthesafetychainstothetowingvehicle.

•Ensurethatthedirectionalandbrakelightsareworking

properly(ifthemachineisequippedwiththelightkit).

•Ensurethatthedirectional,backup,andbrakelightsof

thetowvehicleareworkingproperly(ifthemachineis

equippedwiththelightkit).

•Beforetowing,checktomakecertainyourmachineis

correctlyandsecurelyattachedtothetowingvehicle.

•Ensurethatthesafetychainsareproperlysecuredtothe

vehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhentowing.

•Avoidsuddenstopsandstarts.Thiscancauseskidding,

orjackkning.Smooth,gradualstartsandstopswill

improvetowing.

•Avoidsharpturnstopreventrolling.T owonlywitha

vehiclethathasahitchdesignedfortowing.Donot

attachtowedequipmentexceptatthehitchpoint.

•Donottowthemachinefasterthan88km/h(55mph).

•Usecautionwhenbackingup;useaspotteroutsidethe

vehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehiclebefore

usingit.

•Securethemachinefrommovementbeforeyoutowit.

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Wearpersonalprotectiveequipmentandappropriate

clothing,includingthefollowing:

–Hardhat

–Respiratorordustmask

–Faceshield

–Hearingprotection

–Substantial,slip-resistantfootwear

–Longpants

–Shirtwithlongsleevesthataretightatthewrists

–Tight-ttinggloveswithoutdrawstringsorloosecuffs

•SSecurelooseclothing,tiebacklonghairanddonotwear

jewelry.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andthevaporsareexplosive.Usethefollowingpractices

whenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

–Replacethefuelcapandtightenitsecurely .

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Iffuelisspilled,wipeitofftheengineandequipment.

•Ensurethatthemachineisonalevelsurfacebefore

operatingthemachine.

•Securethemachinefrommovementbeforeyoubegin

toworkonit

•Beforeeveryuse,dothefollowing:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly(ifthe

machineisequippedwithalightkit).

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthelugnutsaretightandtorqued

properly.

4

Page 5

–Ensurethatthemachineisproperlysecured.

Operation

•Neverrunanengineinanenclosedorpoorlyventilated

area.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Shutofftheenginebeforeleavingthemachineforany

reason.

Neverleavearunningmachineunattended.Always

shutofftheengineandverifythatallmovingpartshave

stopped.

•Avoidprolongedbreathingofexhaustfumes.Engine

exhaustfumescancausesicknessordeath.

•Keephandsawayfromanymovingparts.Keepfeetaway

fromthetiresandthefrontpost.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Ensurethattheareaisclearofotherpeopleorpetsbefore

operatingthemachine.Shutoffthemachineifanyone

entersthearea.

•Neverplaceyourhandsoranysolidobjectintothedrum

whenthemachineisinoperation.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Nevermovethemachinewhiletheengineisrunning.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•Ifthemixingpaddlesstrikeaforeignobjectorifthe

machineshouldstartmakinganunusualnoiseor

vibration,shutofftheengineandemptythedrum.W ait

forallmovingpartstocometoacompletestopandcool.

Vibrationisgenerallyawarningoftrouble.Inspectfor

cloggingordamage.Cleanandrepairand/orreplace

damagedparts.

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonlevelground.

–Shutofftheengine.W aitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

–Lettheenginecoolbeforeperformingmaintenance

orstoring.

–Disengageallpowerandoperationcontrols.

•Neverlubricate,service,repair,oradjustthemachine

whileitisrunning.

•Keepequipmentmaterialsclearfromthemuferand

enginetohelppreventres.Cleanupanyoilorfuel

spillage.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Stopandinspectthemachineifaforeignobjectentersthe

drumorcausesanotherobstruction.Makeanynecessary

repairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Securethemachinefrommovementwhenstoringthe

machine.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•UseonlygenuineTororeplacementpartstoensurethat

theoriginalstandardsaremaintained.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

5

Page 6

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117-2718

125-4940

1.Warning

2.Engine—run

3.Engine—shutoff

125-8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

1.Onlyusefuelwithan

alcoholcontentbyvolume

under10%.

2.ReadtheOperator's

Manualformore

informationonfuel.

125-8216

2.Warning—limittowing

speedtolessthan55mph

/88km/h.

130-8322

3.Donotusefuelwithan

alcoholcontentbyvolume

greaterthan10%.

6

Page 7

125-4939

1.Warning—readthe

Operator’sManual.

2.Handandarm

entanglementatthe

beltdrive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keephandsaway

frommovingparts;keep

allguardsandshieldsin

place.

3.Entanglementhazard

atpaddles—shutoff

theengineandwait

forallmovingpartsto

stopbeforeperforming

maintenance.

4.Toxicgasinhalation

hazard—Don’trunthe

engineinanenclosed

space.

5.Explosionhazard—shut

offtheengineandkeep

awayfromameswhen

refueling.

7

Page 8

Setup

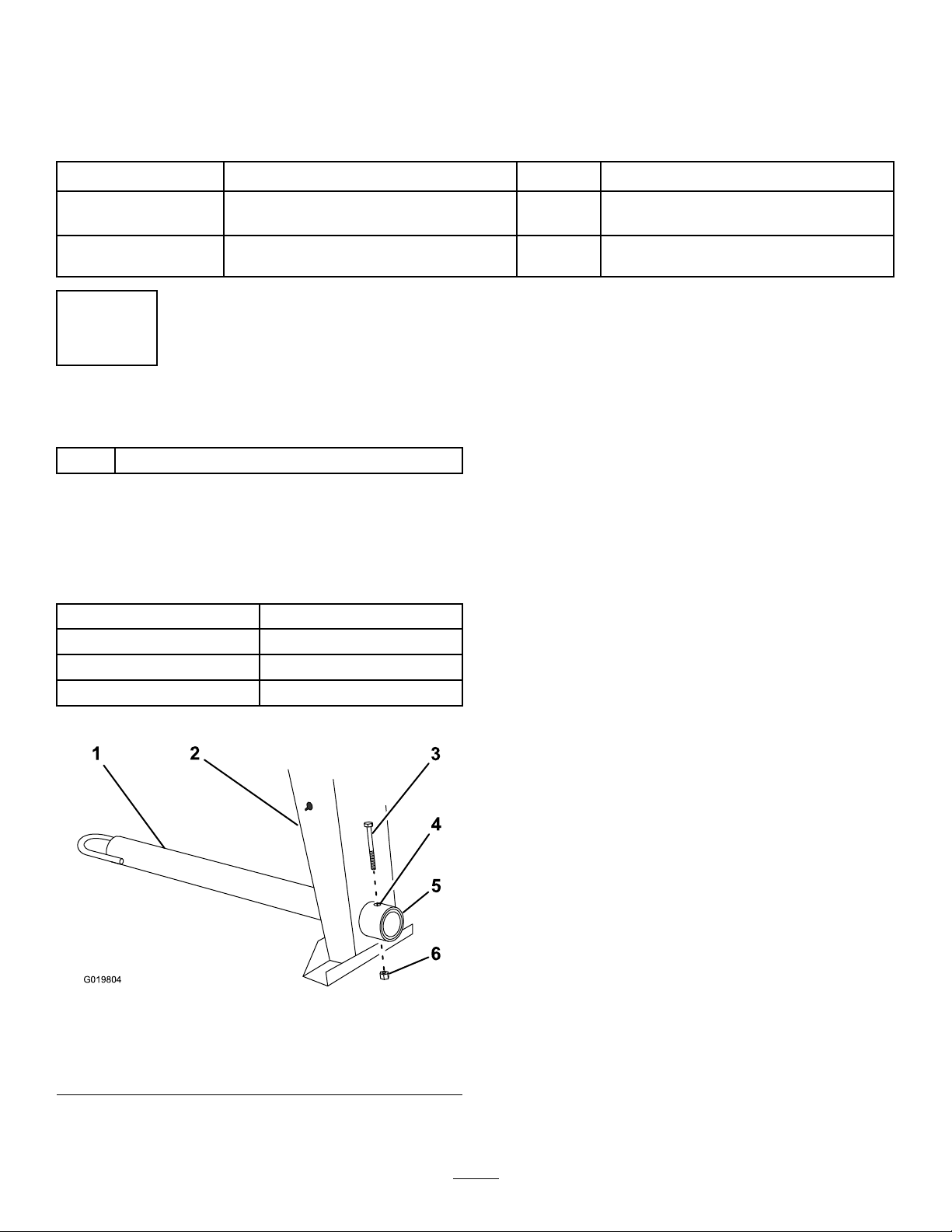

5

1

2

4

6

3

G019804

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

Towpolekit(soldseparately)

Safetychain

Connectinglink

1

InstallingtheTowPole

Partsneededforthisprocedure:

1

Towpolekit(soldseparately)

Procedure

Note:Thetowpoleispurchasedseparatelyandincludesthe

nutandboltneededforinstallation.

Themachinehasthefollowingtowpoleoptions:

HitchT ypeLength

50mm(2inch)ball—stamped78.7cm(31inches)

50mm(2inch)ball—forged78.7cm(31inches)

Pintle

78.7cm(31inches)

Qty.

1Installthetowpole.

1

2

3.Inserttheboltthroughtheholesinthettingandthe

pole(Figure3).

4.Threadthenutontotheboltandtightenthemuntil

theyaretightagainsttheframetting(Figure3).

Note:Iftheself-lockingnyloninsertinthelocknut

wearswithuse,replacethenutwithanewGrade5or

Grade8locknut.

Installthesafetychain.

Use

1.Removetheboltandnutfromthetowpole(Figure3).

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

2.Slidethetowpoleforwardandaligntheholeinthe

polewiththeholeintheframetting(Figure3).

Figure3

5.Frametting

8

Page 9

2

G019730

1

2

3

4

5

6

7

8

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain

2

Connectinglink

Procedure

Formahookontheendofabendablepieceofrodorstiff

wire,(notincluded),andinstallthesafetychainasshownin

Figure4.

ProductOverview

Figure4

Note:Ensurethatapproximatelyequallengthsofsafety

chainextendfromeithersideofthefrontpost.

Figure5

1.Enginecowl5.Towpole

2.Engineswitch

3.Drum7.Drum-tiltbrake

4.Handwheel8.Rubberlatch

6.Safety-chainkeyholes

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

EngineSwitch

WhentheengineswitchonthecowlisintheRUNposition,

itallowstheenginetorun.Movingtheengineswitchtothe

STOPpositionshutsofftheengine.

Handwheel

Thehandwheelcontrolsthedischargingactionofthedrum.

Drum-tiltBrake

Thedrum-tiltbrakelocksthedrumintoanuprightposition

oradischargingposition.

9

Page 10

EngineControls

1

2

3

4

5

6

7

8

G019744

1

2

3

G018792

OFF

ON

1

OFF

ON

G021 103

2

Figure6

1.Recoil-starthandle5.Fuelcap

2.Fuelvalve6.Dipstick

3.Chokelever7.Oil-drainplug

4.Throttlelever

8.On/Offswitch

ChokeLever

Usethechokelever(Figure7)tostartacoldengine.Before

pullingtherecoil-starthandle,movethechokelevertothe

CLOSEDposition.Oncetheengineisrunning,movethe

chokelevertotheOPENposition.Donotusethechokeifthe

engineisalreadywarmeduporiftheairtemperatureishigh.

ThrottleLever

Thethrottlelever(Figure7)controlsthespeed(rpm)ofthe

engine.Itislocatednexttothechokelever.Itsetstheengine

speedandthereforecanincreaseanddecreasetherotation

speedofthemixingpaddles.Forbestperformance,setthis

controltotheFASTpositionwhenmixingmaterial.

EngineOn/OffSwitch

UsetheOn/Offswitch(Figure8)tostartandshutoffthe

engine.Thisswitchislocatedonthefrontoftheengine.

RotatetheOn/OffswitchtotheONpositiontostartandrun

theengine.RotatetheOn/OffswitchtotheOFFposition

toshutofftheengine.

FuelValve

Thefuelvalve(Figure7)islocatedunderneaththechoke

lever.MovetheleverforthefuelvalvetotheONposition

beforeattemptingtostarttheengine.Whenyouhavenished

mixing,shutofftheengineandmovethefuelvalveleverto

Figure8

theOFFposition.

1.Offposition2.Onposition

Recoil-startHandle

Tostarttheengine,pulltherecoil-starthandle(Figure6)

quicklytoturntheengineover.Theenginecontrolsdescribed

abovemustallbesetcorrectlyfortheenginetostart.

Oil-levelSwitch

Theoil-levelswitchislocatedinsidetheengine,anditdoes

notallowtheenginetorunintheeventtheoillevelisbelow

thesafeoperatinglimit.

Figure7

1.Fuelvalve3.Throttlelever

2.Chokelever

10

Page 11

Specications

G019806

1

2

3

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

BatchCapacity

TotalVolume0.43m

DrumMaterialPolyethylene

Length213.4cm

Width142.2cm

Height165.1cm

Weight380.9kg

Operation

Important:Beforeoperatingthemachine,checkthe

fuelandoillevels,andremovedebrisfromthemachine.

Ensurethattheareaisclearofpeople.

0.255m

(9.0ft3)

(15.1ft3)

(84inches)

(56inches)

(65inches)

(837lb)

3

3

PreparingtoTowtheMachine

Important:Ensurethatyourtowvehiclehastowing

capacityfortheweightofthemachine.

Important:UseaClass2orlargerreceiver.

Note:Ensurethatyourtowvehiclehastheappropriatehitch

totowthemachine;optionsincludea50mm(2inch)ball

hitchorapintlehitch.

Note:Ifthemachineisequippedwithatrailer-lightkit,

ensurethattheelectricalconnectorofthetowvehicleis

compatiblewiththeelectricalconnectorofthemachine.

Ifyourtowvehiclehasadifferenttypeofplug,obtainan

adapterfromanautomotivepartsstore.

1.Ensurethattheengineisshutoff,thefuelvalveisin

theOFFposition,andthedrumisempty.

2.Usingthehandwheel,positionthedrumsothatitis

pointingdowntowardtheground(Figure9).

Figure9

1.Drumpointingdown3.Towpoleboltedinplace

2.Drum-tiltbrakeengaged

3.Lockthedrumintopositionbypushingdownthe

drum-tilt-brakehandle(Figure10).

11

Page 12

1

2

G019733

Figure10

G020836

1

2

3

4

G021 107

Drum-TiltBrake

1.Unlockedposition2.Lockedposition

4.Ensurethattheenginecowlisclosedandlatched;refer

toClosingtheCowl(page16).

5.Inspectthetiresandwheels;refertoCheckingthe

TiresandWheels(page12).

CheckingtheTiresandWheels

ServiceInterval:Beforeeachuseordaily—Inspectthetires

andwheels.

Figure12

1.Exampleoftirewearcausedbyoverination

2.Ensurethatthetiresareinatedtoamaximumof241

kPa(35psi).

Important:Alwayschecktheinformation

ontheactualtiresforthecorrectairpressure

requirement.

Important:Themostcommoncauseoftire

troubleisunderination.Maintainfullair

pressure.

3.Ensurethatthewheellugnutsaretorquedto108to

122N∙m(80to90ft-lb).

Note:Checkthetorqueofthewheellugnutsinitially

andaftertowing.

Note:Torquethelugnutsinthesequenceshownin

Figure13.

TheDOTtireinformationislocatedontheside

ofeachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note:RefertoSpecications(page11)toensurethatthe

tiresonyourmachinemeetorexceedtheweightrequirements

ofyourmachine.

1.Visuallyinspectthetiresfordamageandwear(Figure

11andFigure12).

1.Exampleoftirewearcausedbyunderination

Figure11

Figure13

12

Page 13

HitchingaMachinewithaStampedBall

Coupler

1.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.

2.Oilthepivotpointsandslidingsurfacesofthecoupler

withSAE30motoroil.

3.HitchthemachineasshowninFigure14.

2.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.

3.InstallhitchthemachineasshowninFigure15.

Figure15

Note:Useawrenchtokeeptheboltfromspinning.

4.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

Figure14

4.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

HitchingaMachinewithaForgedBall

Coupler

1.Applyremovablethread-lockingcompoundtothe

threadsofthecouplerbolttopreventthecoupler

handlefromcomingloose.

Important:Applythread-lockingcompoundas

neededinthefuture.

HitchingaMachinewithaPintleHitch

Coupler

1.HitchthemachineasshowninFigure16.

Figure16

2.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

13

Page 14

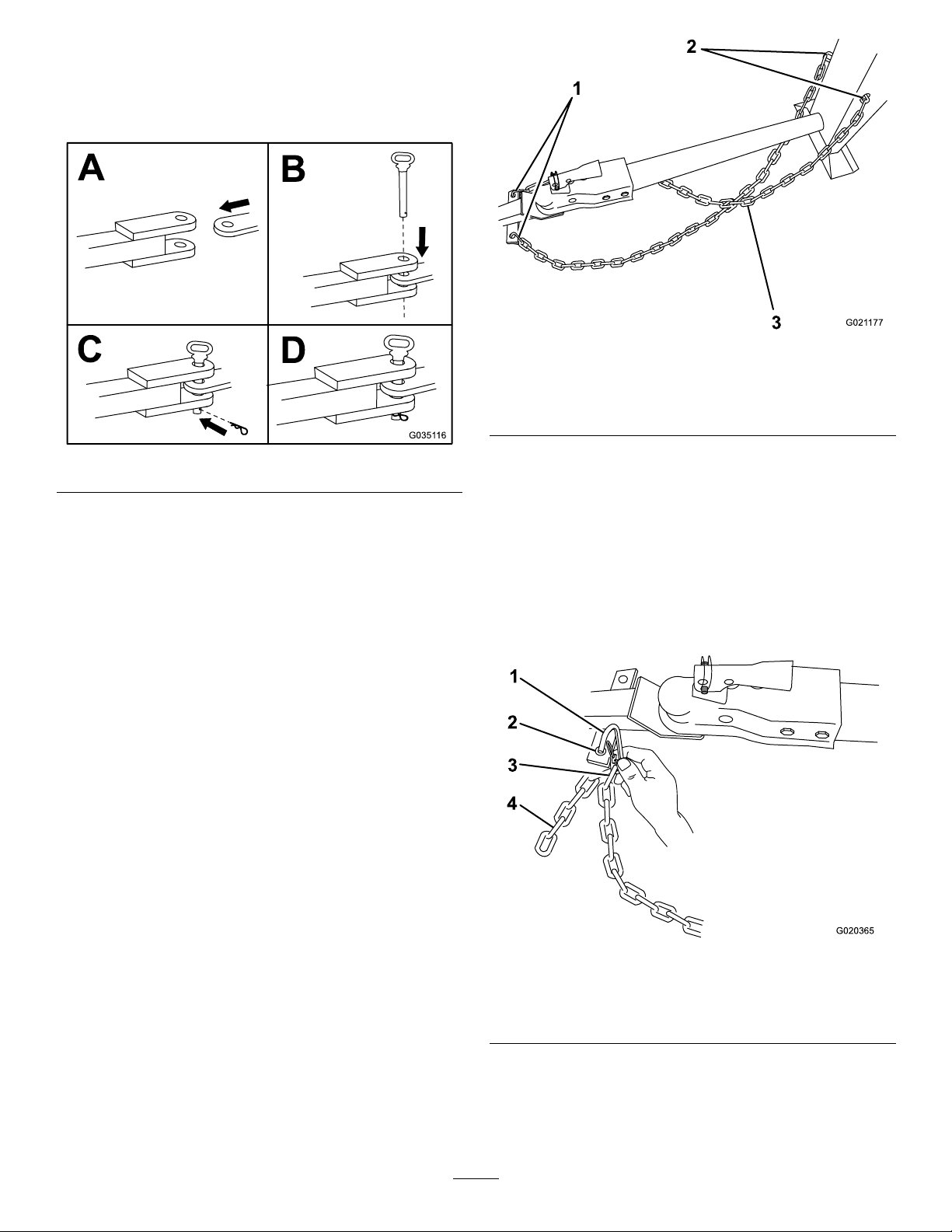

HitchingaMachinewithaPinHitch

1

2

3

G021 177

G020365

1

2

3

4

Coupler

1.Usinga19mm(3/4inch)or22mm(7/8inch)hitch

pin,hitchthemachineasshowninFigure17.

Figure18

Figure17

2.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

ConnectingtheSafetyChainstothe

TowVehicle

1.Pullthesafetychainthroughtheslotsinthekeyholes,

sothatthelengthsoneachsideareequal.

2.Crossbothlengthsofchainunderthetowpole.

Note:Crossingthechainsdecreasesthechancesof

thefrontofthemachinedroppingtothegroundifthe

hitchdoesnotholdtheconnection.

1.Connectinglinks3.Chaincrossedundertow

pole

2.Keyholesinfrontpost

3.Connecteachlengthofchaintothesafetychain

mountingpointonthetowvehiclewiththeconnecting

links(Figure19).

Important:Ensurethatthechainhasenough

slackforturningaroundcornerswhentowingthe

machine.

Note:Stowtheexcesschaininsidethebottomofthe

frontpostbypushingitintothekeyholesandlatching

theappropriatelinksintothekeyholeslots.

1.Connectinglink3.Chainlink

2.Safetychainmounting

pointontowvehicle

Figure19

4.Chain

14

Page 15

TowingtheMachine

4.Ensurethatthedrumisinthemixposition

(upright).

WARNING

Towingthemachineathighspeedincreasesthe

riskofahitchmalfunctionandtirefailure.Higher

speedsalsoincreasethemomentumofthemachine

andbrakingdistance.Ifthemachinebecomes

detachedfromthetowvehicleathighspeed,it

couldcausedamagetoproperty,orinjuryordeath

tobystanders.

Donotexceed88km/h(55mph)whentowingthe

machine.Forpoorroadconditionsorinclement

weather,reducespeedaccordingly.

WARNING

Towingthemachinewithmaterialinthedrum

increasestheriskofahitchmalfunctionandtire

failure.Inaddition,materialcouldbounceoutof

thedrumandhitothervehiclesand/orpeople.

Materialinthedrumincreasestheweight,which

affectsmomentumandbrakingdistance.

Donottowthemachinewithmaterialinthedrum.

5.Ensurethatthedrumlatchisengagedandthatthe

drumdoesnotrotatetowardthedumpposition.

OpeningandClosingtheCowl

OpeningtheCowl

•ReviewandunderstandSafeOperatingPractices(page3).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthemachine.

PreparingtoUsetheMachine

•Reviewallofthesafetydecalsonthemachine.

•Useahard-hat,hearingprotection,ashirtwithlong

sleevesthataretightatthewrists,tight-ttinggloves

withoutdrawstringsorloosecuffs,eyeprotection,and

adustmaskorrespirator.Ameshvisoralonedoes

notprovidesufcienteyeprotection;supplementwith

protectiveglasses.

•Ensurethatyouarefamiliarwithsafetyregulationsand

shutdownproceduresdescribedinthisOperator’sManual

andtheEngineOwner’ sManual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Ensurethatthepaddlesareinplaceandingood

condition.

•Checkthefuelandoillevelsoftheengine.

•Whenpreparingtomixmaterial:

Figure20

1.Movethemachinetoaleveljob-sitesurface.

2.Removethemachinefromthetowvehicle.

3.Securethemachinefrommovementbeforeyou

useit.

15

Page 16

ClosingtheCowl

Figure21

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsfuel

toexpand.

•Neversmokewhenhandlingfuelandstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkthat

canignitethegasolinevapors.Areorexplosion

fromfuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbed,becauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

16

Page 17

WARNING

1

G019799

G020679

1

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillswith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless.For

longerstorageitisrecommendedthatthefueltankbe

drained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Figure22

1.Fuelcap

3.Addfueltothefueltank,untilthelevelisatthebottom

ofthemaximumfuellevel,asshowninFigure23.

Important:Thisspaceinthetankallowsthefuel

toexpand.Donotllthefueltankcompletelyfull.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshfuel.Tominimizethechanceof

varnishdepositsinthefuelsystem,usefuelstabilizerat

alltimes.

FillingtheFuelT ank

Capacity:5.3L(1.4USgallons)

1.Parkthemachineonalevelsurface,shutofftheengine,

andallowtheenginetocool.

2.Cleanaroundthefuelcapandremoveit(Figure22).

Figure23

1.Maximumfuellevel

17

Page 18

4.Installthefuelcapsecurely(Figure22).

G019821

1

G019815

1

2

3

G019747

5.Wipeupanyfuelthatmayhavespilled.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page25).

StartingandShuttingOffthe Engine

StartingtheEngine

1.Ontheenginecowl,movetheengineswitchtotheON

position(Figure24).

Figure25

Figure24

1.Engineswitch

2.Ontheengine,movethethrottleleverawayfromthe

MINposition,1/3ofthewaytowardtheMAXposition

(Figure25).

1.Chokelever

2.Fuelvalve

3.MovetheleverofthefuelvalvetotheONposition,all

thewaytotheright(Figure25).

4.Positionthechokeleverasfollows:

3.Throttlelever

•Tostartacoldengine,movethechokelevertothe

CLOSEDposition,allthewaytotheleft(Figure25).

•Tostartawarmengine,movethechokeleverin

theOPENposition,allthewaytotheright.

5.RotatetheengineOn/OffswitchtotheONposition.

6.Pulltherecoil-starthandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly .Returnthe

starterhandlegently(Figure26).

Figure26

Note:IfthechokeleverissettotheCLOSEDpositionto

starttheengine,graduallymoveittowardtheOPENposition

18

Page 19

astheenginewarmsup.Iftheenginestallsorhesitates,move

thechokelevertowardtheCLOSEDpositionuntiltheengine

runssmooth.Allowtheenginetowarmup,thenmovethe

chokelevertotheOPENposition.

ShuttingOfftheEngine

1.MovethethrottlelevertotheSLOW(turtle)position

(Figure25).

2.Turnthecowl-mountedengineswitchtotheOFF

position(Figure24).

3.MovethefuelvalvetotheOFFposition(Figure25)and

rotatetheengineOn/OffswitchtotheOFFposition.

Important:Ifyouneedtoshutofftheengine

immediately,usetheengineswitchlocatedonthe

outsideoftheenginecowl(Figure24).

UsingtheMachine

DANGER

Thismachineiscapableofamputatinghands.

•Stayintheoperator’spositionwhilethemachine

isrunning.

•Keepallbystandersasafedistancefromthe

machine.

MixingtheMaterial

DANGER

Eyeandskincontactwithconcretematerialsand

breathingthedustinvolvedishazardoustoyour

health.

•Ensurethatthereisadequateairventilation.

•Wearadustmasktopreventinhalationofdust

whileusingthemachine;refertoSafeOperating

Practices(page3).

•Avoiddirectcontactofcementandconcrete

materialswithskinandeyes.

Important:Donotaddmorematerialthanthebatch

capacityforyourspecicmachinemodel;referto

Specications(page11).

Note:Followthemanufacturer’sinstructionsthatareprinted

onthepackagingoftheproductthatyouareusing.

Concretehasthefollowing4basicingredients:

•Sand

•Gravel

•Portlandcement

•Water

•Shutoffthemachineimmediatelyifanypeople

oranimalsentertheworkarea.

•Neverplaceanypartofyourbodyintoaposition

thatcausesanunsafeoperatingcondition.

1.Ensurethatthemachineisonlevelgroundandthe

surroundingareaisclearofobstacles.Disconnectthe

machinefromthetowvehicleandsecurethemachine

frommovement.

2.ReadalltherecommendationsfromSafeOperating

Practices(page3)beforeusingthemachine.

3.Starttheengineandclosetheenginecowl.Allow

theenginetowarmupatidlefor2minutes;referto

StartingtheEngine(page18).

4.Usethehandwheeltomovethedrumintoanupright,

slightlytiltedpositiontoallowaccessforpouring

materialsintothedrum.

Note:Thispositionalsoallowsthemixingpaddlesto

mixthematerialsmoreeffectively.

5.Pushthedrum-tiltbrakedowntolockthedruminto

positionandavoidaccidentallydumpingthematerial.

Dependingontheapplication,youcanusedifferentratios

ofthese4ingredients.

Therearemanyvariationsofconcretemixrecipes,depending

ontheapplication.Itisimportanttousetheappropriate

quantityofwater.Usingtoolittlewaterresultsindryareasin

themix,butusingtoomuchwaterresultsinweakerconcrete.

Theamountofwaterneededvariesdependingonmoisture

contentofthesandandgravel.Themixshouldhavea

thicknesssimilartopeanutbutter.

Keepthepouredconcretedampforseveraldaystoobtain

propercuring.Evaporationresultsinweakerconcrete.

Concretecuresthroughhydration,areactionbetweenwater

andcement.

Beforeyoumixmaterial,completethefollowing:

1.Movethemachinetoaleveljob-sitelocation.

2.Removethemachinefromthetowvehicle.

3.Securethemachinefrommovement.

4.Ensurethatthedrumisinthemixposition(upright).

5.Engagethedrumlatchandensurethatitdoesnot

rotatetowardthedumpposition.

Important:Ifyouneedtoshutoffthemachine,use

theengineswitchlocatedonthecowl;refertoShutting

OfftheEngine(page19).

19

Page 20

MixingPre-MixConcrete

1.Ensurethatthetiltbrakeisfullyengagedandthatthe

drumisoperatingatfullspeed.

2.Pourwaterintothedrum.

3.Addtherequiredamountofdrypre-mix.

7.Afterdumpingabatchofmaterial,cleanthedrum;

refertoCleaningtheDrum(page20).

Note:Cleaningthepaddlesanddrumbetweenbatches

preventsmaterialfromdryingandcontaminatingthe

nextbatchofmaterial.

4.Allowthedrumtoturnwhilethemixreachesthe

appropriateconsistency.

MixingSand,Gravel,andCement

Thetypicalratioformixingconcreteis1partPortland

cement,2partssand,and3partsgravel.

1.Ensurethatthetiltbrakeisfullyengagedandthatthe

drumisoperatingatfullspeed.

2.Pourwaterintothedrum.

3.Addtherequiredamountofgravel.

4.AddtherequiredamountofPortlandcement.

5.Addtherequiredamountofsand.

6.Allowthedrumtoturnwhilethemixreachesthe

appropriateconsistency.

Note:Addingwaterandgravelbeforecementandsand

allowsthemixleftinthedrumfromthepreviousbatchtobe

tumbledoffthedrumandpaddlesandintothenextbatch.

UsingtheDrum

DANGER

Contactwiththemixingpaddlescouldcause

damageorinjury.

CleaningtheDrum

ServiceInterval:Aftereachuse

Important:Donotstrikeonthedrumwithashovel,

hammer,oranyotherdevicetoloosenanyaccumulated

driedmaterials.

1.Whilethemachineisrunning,usethehandwheelto

tiltthedrumslightly .

2.Engagethedrum-tiltbraketopreventthedrumfrom

tiltingfurtheranddischargingthewater.

3.Asthedrumisrotating,sprayitthoroughlywithwater

beforethematerialdries.

4.Allowthedrumtorotateandtumbletheloosematerial

andwater,furtherlooseningtherestofthematerial.

5.Continuetospraythedrumwithwatertoremoveall

materialfromthedrumandmixingpaddles.

6.Whenyouhaveremovedallmaterialfromthesurfaces

ofthedrumandmixingpaddles,disengagethe

drum-tiltbrakeandusethehandwheeltotiltthedrum

anddumpthewaterfromthedrum.

7.Ifsomematerialstillremainsinthedrum,spraythe

drumwithwaterwhileitistilteddownward,allowing

thewaterandmaterialtorunout.

Neverputyourhandsinsidethedrumatanytime.

DumpingtheDrum

Note:Whendumpingabatchofmaterial,leavetheengine

runningsothattherotatingdrumhelpsdumpthematerial.

1.Alignawheelbarroworsimilarcontainerofadequate

capacityinthepathofthedrumopening.

2.Whilethedrumisturning,rmlygraspthehandwheel

with1hand.

3.Usingyourotherhand,pullupwardonthe

drum-tilt-brakehandletoreleasethebrake.

4.Use2handstoslowlyturnthehandwheel,allowing

thedrumtotiltinthedesireddirectionanddumpthe

desiredamountofmaterial.

5.Turnthehandwheelintheoppositedirectiontoreturn

thedrumintoanuprightposition.

6.Pushdownonthedrum-tiltbraketolockthedrum

intoposition,avoidingaccidentaldischargingof

concretemix.

20

Page 21

Maintenance

G019281

1

Important:Beforeperforminganymaintenanceprocedures,rstshutofftheengine,wait5minutestoallowall

movingpartstocometoacompletestopandcool,anddisconnectthespark-plugwire.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Aftereachuse

Every20hours

Every50hours

Every100hours

Every300hours

Monthly

MaintenanceProcedure

•Changetheengineoil.

•Inspectthetiresandwheels.

•Inspecttheair-cleanerelements.

•Checktheengine-oillevel.

•T orquethelugnutsto108to122N∙m(80to90ft-lb)aftertowing.

•Cleanthedrum.

•Checkthedrive-belttensionandadjustitasnecessary.Replacethedrivebeltsif

theyshowanysignsofwear,cracks,glazing,ordamage.

•Cleantheair-cleanerelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil.

•Checkthesparkplug.

•Cleanthesparkarrester.

•Cleanthefuel-sedimentcup.

•Replacethedrivebelts.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindusty

operatingconditions.

•Replacethesparkplug.

•Greasethetrunnionsandthedrumspindle.

Yearlyorbeforestorage

•Cleanthefuel-sedimentcup.

Premaintenance

Procedures

PreparingtheMachinefor Maintenance

1.Parkthemachineonalevelsurface.

2.Removethemachinefromthetowvehicle.

3.Securethemachinefrommovement.

4.Opentherearcowl;refertoOpeningtheCowl(page

15).

5.Ensurethattheengineandmuferarecool.

6.Disconnectthespark-plugwire;refertoFigure27.

DisconnectingtheSpark-plug Wire

Pullthespark-plugwireofftheterminalofthesparkplug

(Figure27).

Figure27

1.Sparkplug

21

Page 22

RemovingandInstallingthe

G021094

G021 102

DividerPlate

Youneedtoremovethedividerplatetoprovideaccessbefore

performingsomemaintenanceprocedures.

RemovingtheDividerPlate

1.Unlatchandopenthecowl;refertoOpeningtheCowl

(page15).

2.Useawrenchtoremovethe4boltsthatsecurethe

dividerplatetothefrontcowl.

Note:Retaintheboltsandwashersforinstallingthe

dividerplate.

InstallingtheDividerPlate

1.Guidethedividerplateintopositionagainstthefront

cowl.

Note:Startwiththedividerplatetiltedslightlyback,

thentiltitforwardwhileloweringitintoposition.

Figure29

2.Aligntheboltholesinthedividerplateandthefront

cowl.

Figure28

3.Toremovethedividerplate,liftitupwardandtiltit

backsothatitclearsvariousenginecomponents.

3.Installeachofthe4boltsandhand-tightenthemto

preventcross-threading.

4.Tightentheboltswithawrenchuntiltheyaresecure.

22

Page 23

Lubrication

G019678

EngineMaintenance

LubricatingtheMachine

ServiceInterval:Monthly—Greasethetrunnionsandthe

drumspindle.

1.Cleanaroundeachgreasettingwitharagandliftthe

plasticcapoffthegreasetting(Figure30).

2.Useagreaseguntolubricatethegreasettingsofboth

trunnionsandthedrumspindlewithgeneral-purpose,

lithiumgrease(Figure30).

3.Wipeupanyexcessgrease.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspectthe

air-cleanerelements.

Every50hours—Cleantheair-cleanerelements.Clean

themmorefrequentlyindustyoperatingconditions.

Every300hours/Yearly(whichevercomes

rst)—Replacethepaperair-cleanerelement.Replace

itmorefrequentlyindustyoperatingconditions.

Important:Donotoperatetheenginewithoutthe

air-lterassembly;extremeenginedamagewilloccur.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-plugWire(page21).

3.Removethenutthatsecuresthecover(Figure31).

Figure30

Important:Donotlubricatethepiniongearand

ringgear.Lubricationcausesthemtocollectabrasive

materialsandacceleratewear.

23

Page 24

1

2

3

4

5

6

G019728

10.Dipthefoamelementincleanengineoil,thensqueeze

g013375

0 20 40 60 80 100 F

-20 -10 0 10 20 30 40 C

o

o

30

5W - 30 / 10W - 30

outtheexcessoil.

Note:Excessoilinthefoamelementrestrictstheair

owthroughtheelementandmayreachthepaper

lterandclogit.

11.Wipedirtfromthebaseandthecoverwithamoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

12.Installtheair-cleanerelementsandensurethattheyare

properlypositioned.

13.Securelyinstallthecoverwiththenut.

ServicingtheEngineOil

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDealer.

Important:Use4-cycleengineoilthatmeetsorexceeds

therequirementsforAPIservicecategory

or higher

.

CrankcaseCapacity:1.1L(1.2USqt)

SJ , SL, SM,

Figure31

1.Covernut

2.Cover

3.Wingnut6.Base

4.Foamelement

5.Paperelement

4.Removethecover.

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamandpaperelementsfromthebase

(Figure31).

6.Removethefoamelementfromthepaperelement

(Figure31).

7.Inspectthefoamandpaperelementsandreplacethem

iftheyaredamagedorexcessivelydirty.

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

Note:UseSAE10W-30forgeneraluse.Youcanuse

theotherviscositiesshowninthechartwhentheaverage

temperatureinyourareaiswithintheindicatedrange(Figure

32).

Figure32

Note:Nevertrytobrushdirtoffthepaperelement;

brushingforcesthedirtintothebers.

8.Cleanthefoamelementinwarm,soapywaterorin

anonammablesolvent.

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

9.Rinseanddrythefoamelementthoroughly.

24

Page 25

CheckingtheEngine-OilLevel

1

2

3

G019750

ChangingtheEngineOil

ServiceInterval:Beforeeachuseordaily

1.Placethemachineonaat,levelsurface,andshutoff

theengine.

2.Allowtheenginetocool.

3.Cleanaroundthedipstick.

4.ChecktheoillevelasshowninFigure33.

ServiceInterval:Aftertherst25hours

Every100hours

WARNING

Oilmaybehotaftertheenginehasbeenrun,and

contactwithhotoilcancauseseverepersonalinjury.

Avoidcontactingthehotengineoilwhenyoudrain

it.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-plugWire(page21).

3.Placeadrainpanundertheoil-drainholeoftheengine

(Figure34).

Figure34

1.Oil-drainplug3.Oil-drainpan

Figure33

2.Oil-drainhole

4.Removethedrainplugandcatchtheoilintheoil-drain

pan(Figure34).

5.Whentheoilhasdrainedcompletely,installthedrain

plugwithanewwasher(Figure34).

Note:Disposeoftheusedoilatacertiedrecycling

center.

6.Removethedipstick(Figure35)andslowlypouroil

intothellholeuntiltheoilreachestheupper-limit

mark(bottomedgeoftheoil-llhole)onthedipstick.

25

Page 26

1

2

3

4

G019746

Figure35

G019749

1.Oil-llhole3.Oil-levelupperlimit

2.Dipstick

4.Oil-levellowerlimit

ServicingtheSparkPlug

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Checkthe

sparkplug.

Every300hours/Yearly(whichevercomes

rst)—Replacethesparkplug.

Type:NGKBPR6ESorequivalent

Gap:0.7to0.8mm(0.028to0.031inch)

Note:Usea21mm(13/16inch)spark-plugwrenchfor

removingandinstallingthesparkplug.

RemovingtheSparkPlug

1.Parkthemachineonalevelsurfaceandshutoffthe

engine.

2.Ensurethatthemachinesurfacesarecool.

3.Pullthespark-plugwireofftheterminalofthespark

plug(Figure36).

7.Replaceandsecurethedipstick.

8.Wipeupanyspilledoil.

Figure36

1.Sparkplug

2.Wire

4.Cleanaroundthesparkplug.

5.Rotatethesparkplugcounterclockwiseusinga21mm

(13/16inch)spark-plugwrenchtoremovetheplug

andthesealingwasher(Figure37).

Figure37

26

Page 27

CheckingtheSparkPlug

B

A

g027479

G019331

10

10

1

2

3

4

5

6

7

8

9

11

12

Important:Donotcleanthesparkplug.Alwaysreplace

thesparkplugwhenithas:ablackcoating,worn

electrodes,andoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

Setthegapto0.7to0.8mm(0.028to0.031inch).

ServicingtheSparkArrester

CleaningtheSparkArrester

ServiceInterval:Every100hours

Note:Asparkarresterisavailableasanoption.Ifyou

requireasparkarrester,contactyourAuthorizedToroService

Dealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Figure38

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page22).

2.Removethe2nuts(8mm)andremovethemufer

fromthecylinder(Figure39).

InstallingtheSparkPlug

Important:Ensurethatthegapbetweenthesideand

centerelectrodesiscorrectbeforeinstallingthespark

plug.

1.Threadthesparkplugclockwiseintothespark-plug

holebyhand.

Note:Avoidcross-threadingthesparkplugwiththe

threadsofthespark-plughole.

2.Rotatethesparkplugclockwiseusinga21mm(13/16

inch)spark-plugwrenchuntiltheplugandsealing

washerareseated(Figure37).

3.Tightenthesparkplugasfollows:

•Wheninstallinganin-servicesparkplug,tighten

thepluganadditional1/8to1/4turn.

•Wheninstallinganewsparkplug,tightentheplug

anadditional1/2turn.

4.Pushthespark-plugwireontotheterminalofthespark

plug(Figure36).

1.Deector(if

applicable)

2.Protector

3.Screw(6mm)7.Gasket

4.Mufer8.Bolt(8mm)12.Screw(4mm)

Figure39

5.Exhaustpipe

6.Nut(8mm)10.Screws(5mm)

9.Sparkarrester

11.Exhaustport

3.Removethe3screws(4mm)fromtheexhaust

deectorandremovethedeector(Figure39).

4.Removethescrews(5mmand6mm)fromthemufer

protector,andremovethemuferprotector(Figure

39).

5.Removethescrew(4mm)fromthesparkarresterand

removethesparkarresterfromthemufer(Figure39).

27

Page 28

6.Useabrushtocarefullyremovecarbondepositsfrom

1

2

G019332

2

3

4

1

G019333

thespark-arresterscreen(Figure40).

FuelSystem

Note:Replacethesparkarresterifithasbreaksor

holes.

Figure40

1.Screen

7.Installthesparkarrester,muferprotector,exhaust

deector,andmuferinthereverseorderof

disassembly.

8.Installthedividerplate;refertoInstallingtheDivider

Plate(page22).

2.Brush

Maintenance

CleaningtheFuel-Sediment Cup

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Cleanthe

fuel-sedimentcup.

Yearlyorbeforestorage—Cleanthefuel-sedimentcup.

Underneaththefuelvalveisasedimentcuptocatchdirtin

thefuel.

1.Parkthemachineonalevelsurfaceandshutoffthe

engine.

2.Ensurethattheengineandtheexhaustsystemsurfaces

arecool.

3.MovetheleverofthefuelvalvetotheOFFposition,all

thewaytotheleft(Figure41).

4.Unscrewthesedimentcup(Figure41).

5.RemoveandretainthefuellterandO-ring(Figure

41).

Note:DonotcleantheO-ringinsolvent.

Figure41

1.Fuelvalve—Offposition3.Fuellter

2.O-ring4.Sedimentcup

6.Cleanthefuellterandsedimentcupusinga

nonammablesolvent,anddryitcarefully .

7.WipetheO-ringwithaclean,drycloth.

8.Installthefuellterinthebottomofthecarburetor

(Figure41).

9.AligntheO-ringintothegrooveinthesedimentcup

andinstallthesedimentcuptothefuel-valvehousing.

28

Page 29

10.MovetheleverofthefuelvalvetotheONposition(all

1

2

G019731

thewaytotheright)andcheckforleaks.Ifitleaks,

replacetheO-ring.

BeltMaintenance

CheckingtheDrive-Belt Tension

ServiceInterval:Every20hours—Checkthedrive-belt

tensionandadjustitasnecessary.Replace

thedrivebeltsiftheyshowanysignsof

wear,cracks,glazing,ordamage.

Thedrivebeltsshouldeachhave1cm(13/32inch)ofex

whenapplying6.8kg(15lb)ofpressure,atmid-span(Figure

42).

Figure42

DriveBelts

1.Flexof1cm(13/32inch)2.Straightedge

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page22).

2.Layastraightedgealong1drivebelt,from1pulleyto

theother(Figure42).

3.Withyournger,pushonthebeltwith6.8kg(15lb)

ofpressure,midwaybetweenthepulleys(Figure42).

29

Page 30

4.Measurethedistancefromthebelttothestraightedge.

1

G019732

Thedistanceshouldbeapproximately1cm(13/32

inch)asshowninFigure42.

ReplacingtheDriveBelts

ServiceInterval:Every100hours

Note:Ifthebelttensionneedsadjustment,referto

AdjustingtheDrive-beltTension(page30).

5.Installthedividerplate;refertoInstallingtheDivider

Plate(page22).

AdjustingtheDrive-belt Tension

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Removethedividerplate;refertoRemovingthe

DividerPlate(page22).

3.Loosenthe4nutsandboltsthatsecuretheengineto

theenginemountingplate(Figure43).

Note:Themachinehas2drivebelts.Remembertobuy2

beltsforreplacement.

1.Completesteps1through3inAdjustingtheDrive-belt

Tension(page30).

2.Slidetheenginetotherighttodecreasethebelttension.

3.Removethedrivebeltsfromthepulleys.

4.Installthenewdrivebeltsonthepulleys.

5.Slidetheenginetotheleftuntilthebeltshavethe

correcttension;refertoCheckingtheDrive-Belt

Tension(page29).

6.Torquethe4mountingnutsandboltsto24N∙m(18

ft-lb)each(Figure43).

7.Installthedividerplate;refertoInstallingtheDivider

Plate(page22).

Figure43

1.Enginemountingnutsandbolts(4each)

4.Slidetheenginelefttoincreasetensiononthedrive

beltorrighttodecreasetension.

5.Checkthedrive-belttension;refertoCheckingthe

Drive-BeltTension(page29).

Note:Whenthebeltshavetheappropriateamount

oftension,torquethe4nutsandboltsto24N∙m(18

ft-lb)each.

6.Installthedividerplate;refertoInstallingtheDivider

Plate(page22).

30

Page 31

Cleaning

Storage

CleaningtheMachine

Regularcleaningandwashingwithmilddetergentandwater

increasesthelifespanofthemachine.Cleanthemachine

aftereachusebeforethedirthardens.

Removedirtandgrimefromtheexternalpartsoftheentire

machine,especiallytheengine.Cleandirtandconcrete

materialsfromtheoutsideoftheengine.

Ensurethatthefuelcapandtheoil-llcap/dipstickare

securetoavoidgettingwaterintheengine.

Usecarewhenusingahigh-pressuresprayerbecauseitcan

damagesafetydecals,instructionsigns,andtheengine.

StoringtheMachine

Forstorageover30days,preparethemachineasfollows:

1.Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleandirtand

debrisfromtheoutsideoftheenginecylinder-head

nsandblowerhousing.

Important:Y oucanwashthemachinewithmild

detergentandwater.

2.Conditionthefuelsystemasfollows:

A.Addapetroleum-basedstabilizer/conditionerto

fuelinthetank.Followthemixinginstructions

fromthestabilizermanufacturer.Donotusean

alcohol-basedstabilizer(ethanolormethanol).

Important:Donotstore

stabilizer/conditionedfuelover90days.

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuelandusedat

alltimes.

B.Runtheenginefor5minutestodistributethe

conditionedfuelthroughthefuelsystem.

C.Shutofftheengine,allowittocool,anddrainthe

fueltankusingapump-typesiphon.Disposeof

fuelproperly;recycleitaccordingtolocalcodes.

D.Starttheengineandrunituntilitstops.

E.Choketheengine.

F.Startandruntheengineuntilitdoesnotstart

again.

3.Cleanthesedimentcup;refertoCleaningthe

Fuel-SedimentCup(page28).

4.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page23).

5.Changetheenginecrankcaseoil;refertoChangingthe

EngineOil(page25).

6.Removethesparkplugandcheckthecondition;refer

toRemovingtheSparkPlug(page26).

7.Conditiontheengineasfollows:

A.Removethesparkplugandpour2tablespoons

ofengineoilintothespark-plughole;referto

RemovingtheSparkPlug(page26).

B.Pulltherecoil-starthandleslowlytocrankthe

engineanddistributetheoilinsidethecylinder.

C.Installthesparkplug;refertoInstallingtheSpark

Plug(page27).

Note:Donotinstallthewireonthesparkplug.

8.Greasethemachine;refertoLubricatingtheMachine

(page23).

31

Page 32

9.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

10.Paintallscratchedorbaremetalsurfaceswithpaint

availablefromyourAuthorizedToroDealer.

11.Storethemachineinaclean,drygarageorstoragearea.

12.Coverthemachinetoprotectitandkeepitclean.

32

Page 33

Troubleshooting

Theenginedoesnotstart.

Theenginerunsrough.

Problem

1.Theengineswitchonthecowlisinthe

STOPposition.

2.ThefuelvalveisintheOFFposition.2.Movethefuel-valvelevertotheON

3.Thechokeisopen.

4.Thechokeisclosed.

5.TheOn/Offswitchontheengineisin

theOFFposition.

6.Theengineoillevelislow.6.Filltheenginetotheproperlevelwith

7.Thefueltankisempty.7.Fillthetankwithfreshfuel.

8.Thespark-plugwireislooseor

disconnected.

9.Thesparkplugisfouledorimproperly

gapped.

10.Thesparkplugiswetwithfuel(ooded

engine).

11.Thefuelisoldorbad.11.Drainthefueltankandcarburetor.Fill

1.Thechokeislefton.1.Openthechoke.

2.Theairlterisclogged.2.Cleanorreplacetheairlter.

3.Thefuellineisclogged.3.Cleanthesedimentcup.

4.Thereiswaterorcontaminantsinthe

fuel.

5.Thesparkplugiswornorhasbuildup

ontheelectrodes.

6.Thereistoomuchoilintheengine

crankcase.

PossibleCauseCorrectiveAction

1.PresstheengineswitchtotheRUN

position.

position.

3.Closethechokewhenstartingacold

engine.

4.Openthechokewhenstartingahot

engine.

5.RotatetheswitchtotheONposition.

therecommendedoil.

8.Connectthespark-plugwire.

9.Gaporreplacethesparkplug.

10.Removethesparkplug,dryit,and

installtheplug.Starttheenginewith

thethrottleintheMAXposition.

thefueltankwithfreshfuel.

4.Drainandllthetankwithfreshfuel.

5.Checktheelectrodegaporreplacethe

sparkplug.

6.Draintheoiltotheproperlevel.

Thedrivebeltsarewornorburned,orthey

jumpoffofthepulley.

Thedrumdoesnotturn.1.Thebeltsarelooseordamaged.

Thedrumdoesnottilt.1.Thedrum-tiltbrakeisengaged.1.Disengagethedrum-tiltbrake.

Thedrumchattersorturnserratically .

1.Thedrive-belttensionneeds

adjustment.

2.Thedrivebeltsmaybestretched.2.Replacethedrivebelts.

3.Thepulleysareoutofalignment.3.ContactyourAuthorizedService

1.Teetharemissingfromthegears.1.ContactyourAuthorizedService

2.Thegearsaremisaligned.

1.Thereisdebrisinthedrum.1.Removethedebris. Themachinevibratesexcessively .

2.Themixingpaddlesaredamaged.

1.Adjustthedrive-belttension.

Dealer.

1.Checkthedrivebelts.

Dealer.

2.ContactyourAuthorizedService

Dealer.

2.ContactyourAuthorizedService

Dealer.

33

Page 34

Notes:

34

Page 35

Notes:

35

Page 36

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

Concrete,

Masonry,and

Compaction

Equipment

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourT oroConcrete,Masonry ,

andCompactionEquipmentProductslistedbelowtobefreefromdefectsin

materialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ConcreteMixers

•SpindleBearingsLifetime*(originalowneronly)

MortarMixers1year

•DrumBearingsandSealsLifetime*(originalowneronly)

ForwardPlateCompactors

ReversiblePlates1year

RammerCompactors

MudBuggy1year

VibratingTrenchRoller2years

ConcreteSaws

MasonrySaws

PowerTrowels1year

Screeds

ConcreteVibrators

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

LifetimeWarranty-Ifthebearing(s)orseal(s)onyourmixerfail,itwillbereplacedunderwarranty,

atnocostforpartsorlabor.

1year

2years

2years

1year

1year

1year

1year

InstructionsforObtainingWarrantyService

IfyouthinkthatyourToroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’sanalysis

orwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:800-888-9926

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromT oroandhave

signedtheT oroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

productoperationinclude,butarenotlimitedto,belts,wipers,spark

plugs,tires,lters,gaskets,wearplates,seals,O-rings,drivechains,

clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0288RevC

Loading...

Loading...