Page 1

FormNo.3421-309RevA

CM-658H-SConcreteMixer

ModelNo.68004—SerialNo.402000000andUp

ModelNo.68006—SerialNo.402000000andUp

ModelNo.68007—SerialNo.402000000andUp

ModelNo.68008—SerialNo.402000000andUp

ModelNo.68009—SerialNo.402000000andUp

ModelNo.68009HD—SerialNo.402000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-309*A

Page 2

WARNING

Introduction

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Becauseinsomeareastherearelocal,state,or

federalregulationsrequiringthatasparkarresterbe

usedontheengineofthismachine,asparkarrester

isavailableasanoption.Ifyourequireaspark

arrester,contactyourAuthorizedT oroServiceDealer.

GenuineT orosparkarrestersareapprovedbythe

USDAForestryService.

Thismachineisdesignedtomixconcrete,plaster,

reproongmaterial,grout,andothersmall-grained

concreteproducts.Youcantowthemachinebehinda

vehicleequippedwithahitchappropriateforthetype

oftowpoleyourmachinehas(ball,pintle,orpinhitch).

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

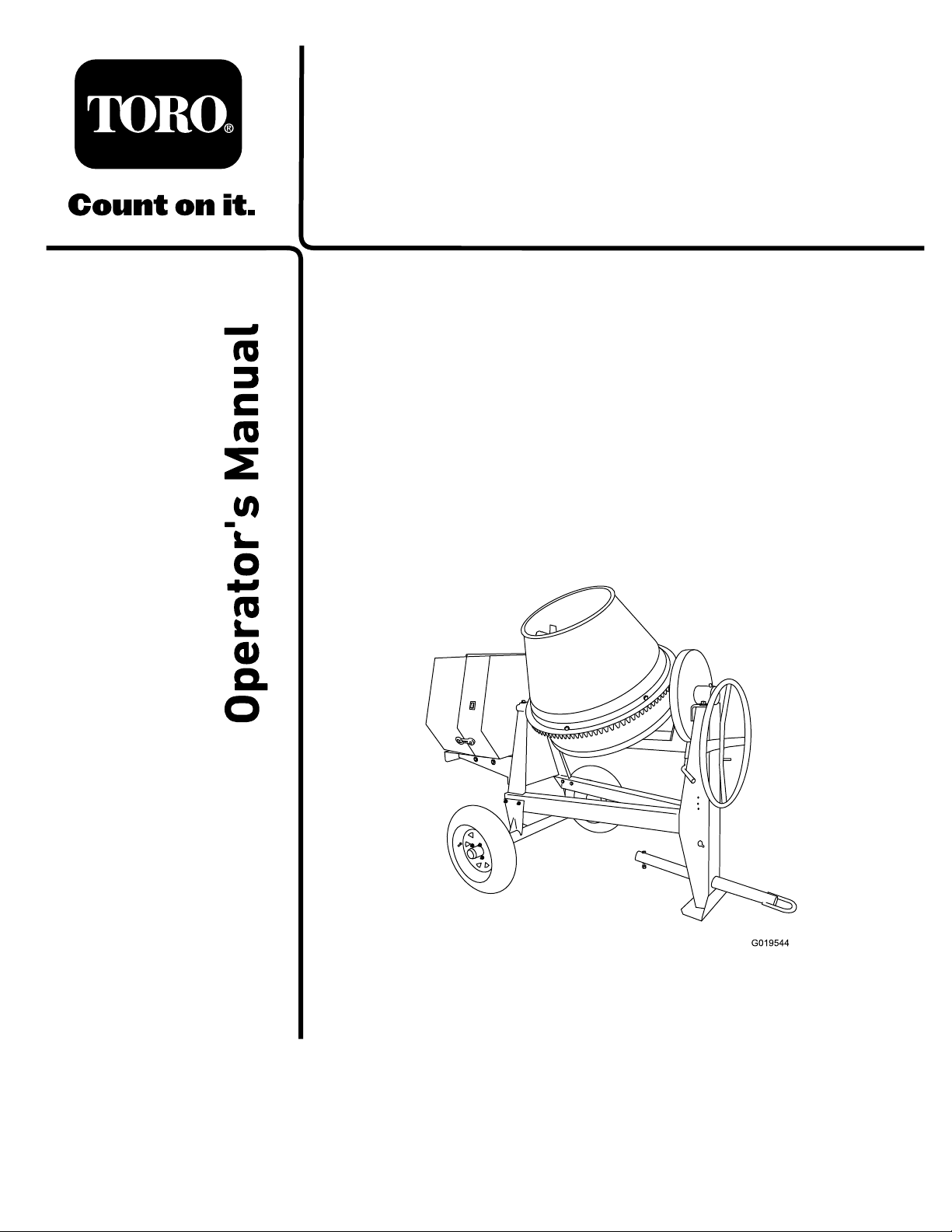

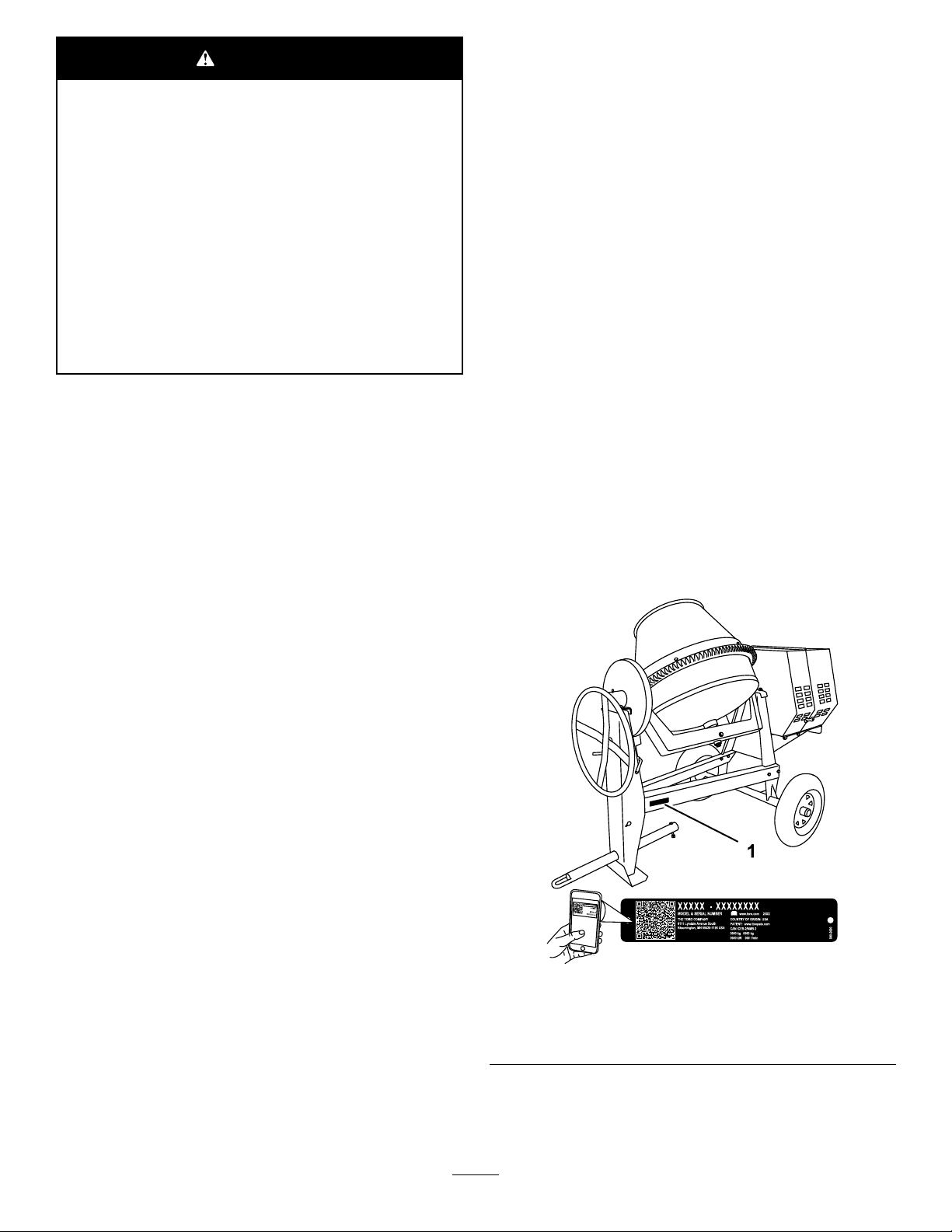

andserialnumbersofyourproductready .Figure1

andFigure2identifythelocationofthemodeland

serialnumbersontheproduct.Writethenumbersin

thespaceprovided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

TheDOTtireinformationislocatedonthesideof

eachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesameor

betterratings;refertoSpecications(page15)to

ensurethatthetiresonyourmachinemeetorexceed

theweightrequirementsofyourmachine.

g241810

Figure1

Side-DumpModels

1.Modelandserialnumberlocation

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Figure2

End-DumpModels

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure3),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure3

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................7

Setup......................................................................10

1InstallingtheT owPole...................................10

2InstallingtheT ongue......................................10

3InstallingtheSafetyChain...............................11

ProductOverview...................................................13

Controls...........................................................14

EngineControls............................................14

Specications..................................................15

Operation................................................................16

ThinkSafetyFirst..............................................16

TowingtheMachine..........................................16

g241813

g000502

PreparingtoUsetheMachine...........................22

LoweringtheStabilizerLegs.............................22

OpeningtheCowl.............................................23

ClosingtheCowl...............................................23

AddingFuel......................................................23

PerformingDailyMaintenance..........................25

StartingtheEngine...........................................25

ShuttingOfftheEngine.....................................26

MixingtheMaterial...........................................26

DumpingtheMaterial........................................27

CleaningtheDrum............................................28

Maintenance...........................................................29

RecommendedMaintenanceSchedule(s)...........29

Pre-MaintenanceProcedures..............................29

PreparingtheMachineforMaintenance............29

DisconnectingtheSpark-PlugWire..................30

RemovingtheDividerPlate..............................30

InstallingtheDividerPlate................................30

Lubrication..........................................................31

LubricatingtheMachine....................................31

EngineMaintenance...........................................31

ServicingtheAirCleaner..................................31

ServicingtheEngineOil....................................32

ServicingtheSparkPlug...................................34

CleaningtheSparkArrester..............................35

FuelSystemMaintenance...................................36

CleaningtheFuel-SedimentCup......................36

DriveSystemMaintenance..................................37

TireAirPressure...............................................37

InspectingtheTires..........................................37

TorquingtheWheelLugNuts............................38

BeltMaintenance................................................38

CheckingtheDrive-BeltTension.......................38

AdjustingtheDrive-beltTension........................39

ReplacingtheDriveBelts..................................39

Cleaning..............................................................40

CleaningtheMachine.......................................40

Storage...................................................................41

Troubleshooting......................................................42

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury ,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alertsymbol

(Figure3),whichmeans:Caution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Always

followallsafetyinstructionstoavoidseriousinjuryor

death.

WARNING

Machiningorhandlingstone,masonry,

concrete,metal,andothermaterialscan

generatedust,mists,andfumescontaining

chemicals,suchassilica,knowntocause

seriousorfatalinjuryorillness,suchas

respiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthe

sourcewherepossible.Usewaterfordust

suppressionwhenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupational

andtradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenyoucannoteliminatethehazards

frominhalation,youandanybystanders

shouldweararespiratorapprovedby

OSHAforthematerialbeinghandled.

WARNING

Engineexhaustcontainscarbonmonoxide,

anodorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinan

enclosedarea.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readorunderstandtheinformation,itisthe

owner'sresponsibilitytoexplainthismaterialto

them.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriestopeopleordamageto

property.

Towing

Checkwithyourlocalcountyorstatetowingsafety

regulationsbeforetowingthemachine.

•Toreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,ensure

thatthetowingvehicleismechanicallysoundand

ingoodoperatingcondition.

•Shutofftheenginebeforetransportingthe

machine.

•Whentowingwithaballhitch,ensurethattheball

hitchyouareusingisthepropersizeforthehitch

coupleronthemachine.

•Whentowingwithapintlehitch,ensurethatthe

eyeofthetowpoleisthecorrectdimensionfor

thepintlehook.

•Donottowwithoutthesafetypininsertedintothe

topofthereceiver.

•Inspectthehitchandcouplingforwear.Nevertow

themachinewithdamagedordefectivehitches,

couplings,chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicle

andthemachine.

•Checkthetiretreadandsidewallfordamageand

wear.

•Properlyattachthesafetychainstothetowing

vehicle.

•Ensurethatthedirectionalandbrakelightsare

workingproperly(ifthemachineisequippedwith

thelightkit).

•Ensurethatthedirectional,backup,andbrake

lightsofthetowvehicleareworkingproperly(if

equipped).

•Beforetowing,ensurethatyourmachineis

correctlyandsecurelyattachedtothetowing

vehicle.

•Ensurethatthesafetychainsareproperlysecured

tothevehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhen

towing.

•Avoidsuddenstopsandstarts.Thiscancause

skidding,orjackkning.Smooth,gradualstarts

andstopswillimprovetowing.

•Avoidsharpturnstopreventrolling.T owonlywith

avehiclethathasahitchdesignedfortowing.Do

4

Page 5

notattachtowedequipmentexceptatthehitch

point.

•Donottowthemachinefasterthan88km/h(55

mph).

•Usecautionwhenbackingup;useaspotter

outsidethevehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehicle

beforeusingit.

•Securethemachinefrommovementbeforeyou

towit.

•Placechockblocksunderneaththetirestoprevent

themfromrollingwhilethemachineisparked.

Preparation

Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearpersonalprotectiveequipment(PPE)and

appropriateclothing,includingthefollowing:

–Hardhat

–Respiratorordustmask

–Faceshield

–Safetyglasses

–Hearingprotection

–Substantial,slip-resistantfootwear

–Longpants

–Shirtwithlongsleevesthataretightatthe

wrists

–Tight-ttinggloveswithoutdrawstringsorloose

cuffs

•Securelooseclothing,tiebacklonghair,anddo

notwearloosejewelry.

•Operatingtheequipmentsafelyrequiresthefull

attentionoftheoperator.Donotwearradioor

musicheadphoneswhileoperatingthemachine.

•Useextracarewhenhandlingfuels.Theyare

ammableandthevaporsareexplosive.Usethe

followingpracticeswhenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththe

enginerunning.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

–Installthefuelcapandtightenitsecurely.

–Keepthecontainernozzleincontactwiththe

tankduringlling.

–Neverllacontainerwhileitisinsideavehicle,

trunk,pickupbed,oranysurfaceotherthan

theground.

–Neverstorethemachineorfuelcontainer

insidewherethereisanopename,suchas

nearawaterheaterorfurnace.

–Ifyouspillfuel,wipeitofftheengineand

equipment.

•Ensurethatthemachineisonalevelsurface

beforeoperatingthemachine.

•Chockthetiresofthemachinetoprevent

unintendedmovement.

•Beforeeveryuse,dothefollowing:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly

(ifequipped).

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthewheellugnutsaretightand

torquedproperly.

–Ensurethatthemachineisproperlysecured.

Operation

•Neverruntheengineinanenclosedorpoorly

ventilatedarea.

•Operatethemachineonlyingoodlighting

conditions.

•Beforestartingthemachine,ensurethatthere

arenopersonsorobstaclesnearorunderthe

machine.

•Shutofftheenginebeforeleavingthemachinefor

anyreason.

Neverleavearunningmachineunattended.

Alwaysshutofftheengineandverifythatall

movingpartshavestopped.

•Chockthetiresofthemachineorkeepitattached

tothetowingvehiclewhenitisnotinuse,to

preventitfromrolling.

•Avoidprolongedbreathingofexhaustfumes.

Engineexhaustfumescancausesicknessor

death.

•Keepyourhandsawayfromanymovingparts.

Keepyourfeetawayfromthetiresandthefront

post.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Ensurethattheareaisclearofotherpeopleor

petsbeforeoperatingthemachine.Stopthe

machineifanyoneentersthearea.

•Neverplaceyourhandsoranysolidobjectintothe

drumwhenthemachineisinoperation.

5

Page 6

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservicethemachine.

•Nevermovethemachinewhiletheengineis

running.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurely

inplacebeforeoperatingthemachine.

•Ifthemixingpaddlesstrikeaforeignobjectorifthe

machineshouldstartmakinganunusualnoiseor

vibration,shutofftheengineandemptythedrum.

Waitforallmovingpartstocometoacomplete

stopandcool.Vibrationisgenerallyawarningof

trouble.Inspectforcloggingordamage.Clean

andrepairand/orreplacedamagedparts.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Lightningcancausesevereinjuryordeath.Ifyou

seelightningorhearthunderinthearea,donot

operatethemachine;seekshelter.

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonalevelsurface.

–Shutofftheengine.Waitforallmovementto

stopandremovethesparkplugwirebefore

adjusting,cleaning,orrepairing.

–Allowtheenginetocoolbeforeperforming

maintenanceorstoring.

–Disengageallpowerandoperationcontrols

beforemakinganyrepairs.

•Neverlubricate,service,repair,oradjustthe

machinewhileitisrunning.

•Keepequipmentmaterialsclearfromthemufer

andenginetohelppreventres.Wipeupany

spilledoilorfuel.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Keepyourhands,feet,andclothingawayfrom

movingparts.Ifpossible,donotmakeadjustments

withtheenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Removeanybuildupofgrease,oil,ordebrisfrom

themachine.

•Stopthemachine,shutofftheengine,andinspect

themachineifaforeignobjectentersthedrumor

causesanotherobstruction.Makeanynecessary

repairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Securethemachinefrommovementandchock

thetireswhenstoringthemachine.

•Keepallnuts,bolts,screws,andhoseclamps

securelytightened.Keepthemachineingood

condition.

•UseonlygenuineT ororeplacementpartsto

ensurethattheoriginalstandardsaremaintained.

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

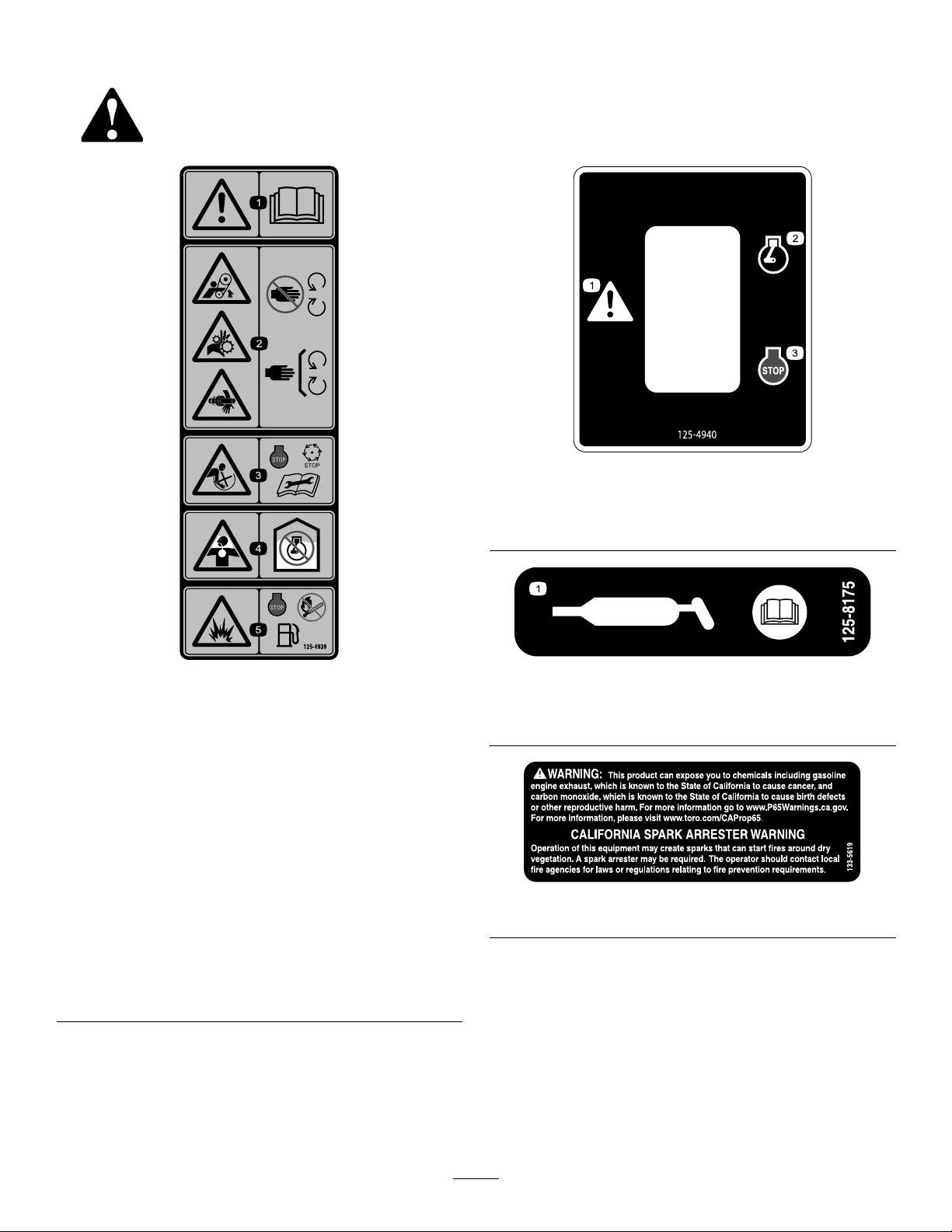

decal125-4940

125-4940

1.Warning—readthe

Operator’sManual.

2.Handandarm

entanglementatthe

beltdrive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keepyourhands

awayfrommovingparts;

keepallguardsand

shieldsinplace.

3.Entanglementhazard

atpaddles—shutoff

theengineandwait

forallmovingpartsto

stopbeforeperforming

maintenance.

1.Warning

2.Engine—run

decal125-4939

125-4939

4.Toxicgasinhalation

hazard—Donotrunthe

engineinanenclosed

space.

5.Explosionhazard—shut

offtheengineandkeep

awayfromameswhen

refueling.

1.ReadtheOperator’sManualforinformationongreasing

themachine.

3.Engine—shutoff

decal125-8175

125-8175

decal133-5619

133-5619

7

Page 8

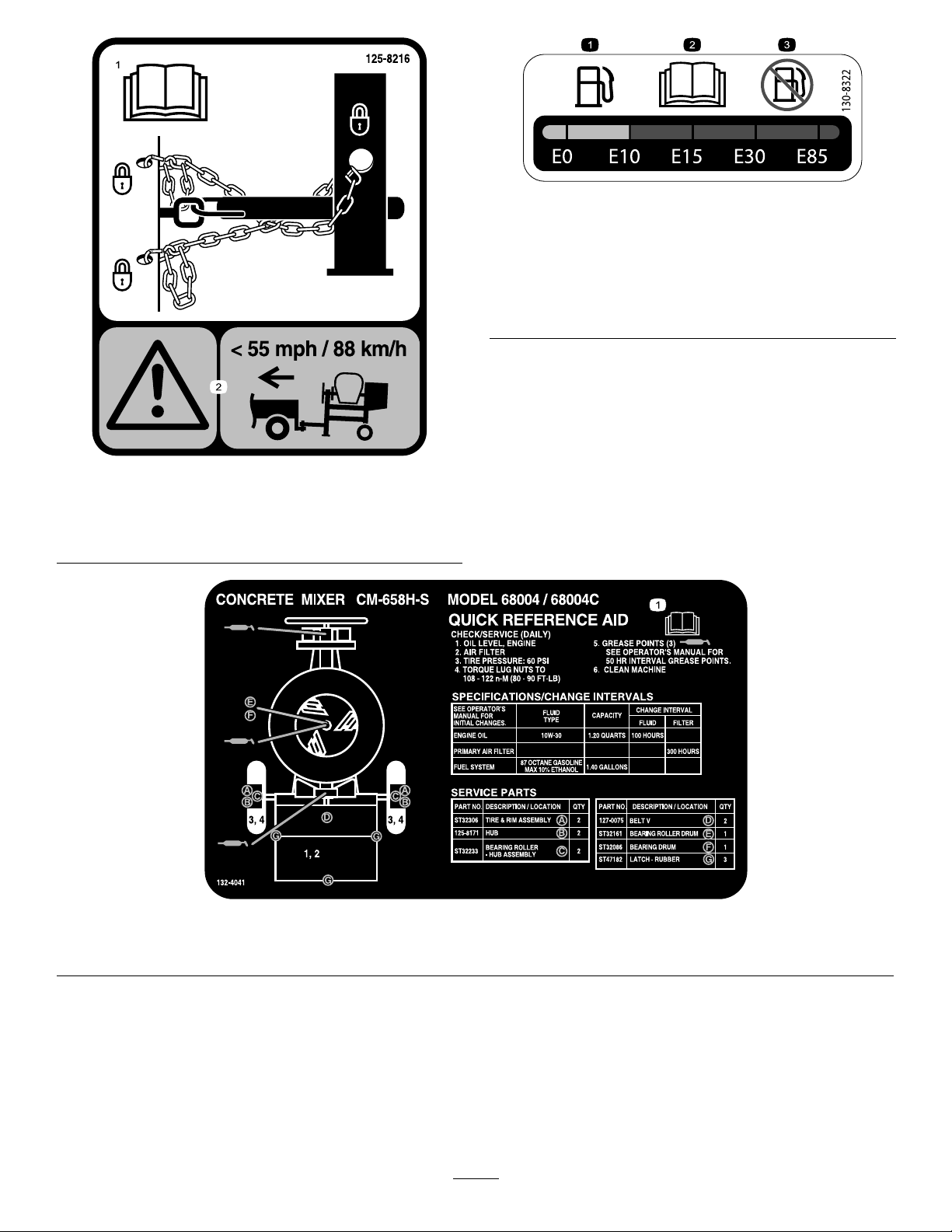

decal130-8322

130-8322

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

125-8216

2.Warning—limittowing

speedtolessthan88km/h

(55mph).

1.Onlyusefuelwithan

alcoholcontentbyvolume

under10%.

3.Donotusefuelwithan

alcoholcontentbyvolume

greaterthan10%.

2.ReadtheOperator's

Manualformore

informationonfuel.

decal125-8216

1.ReadtheOperator'sManualformoreinformationonservicingthemachine.

decal132-4041

132-4041

8

Page 9

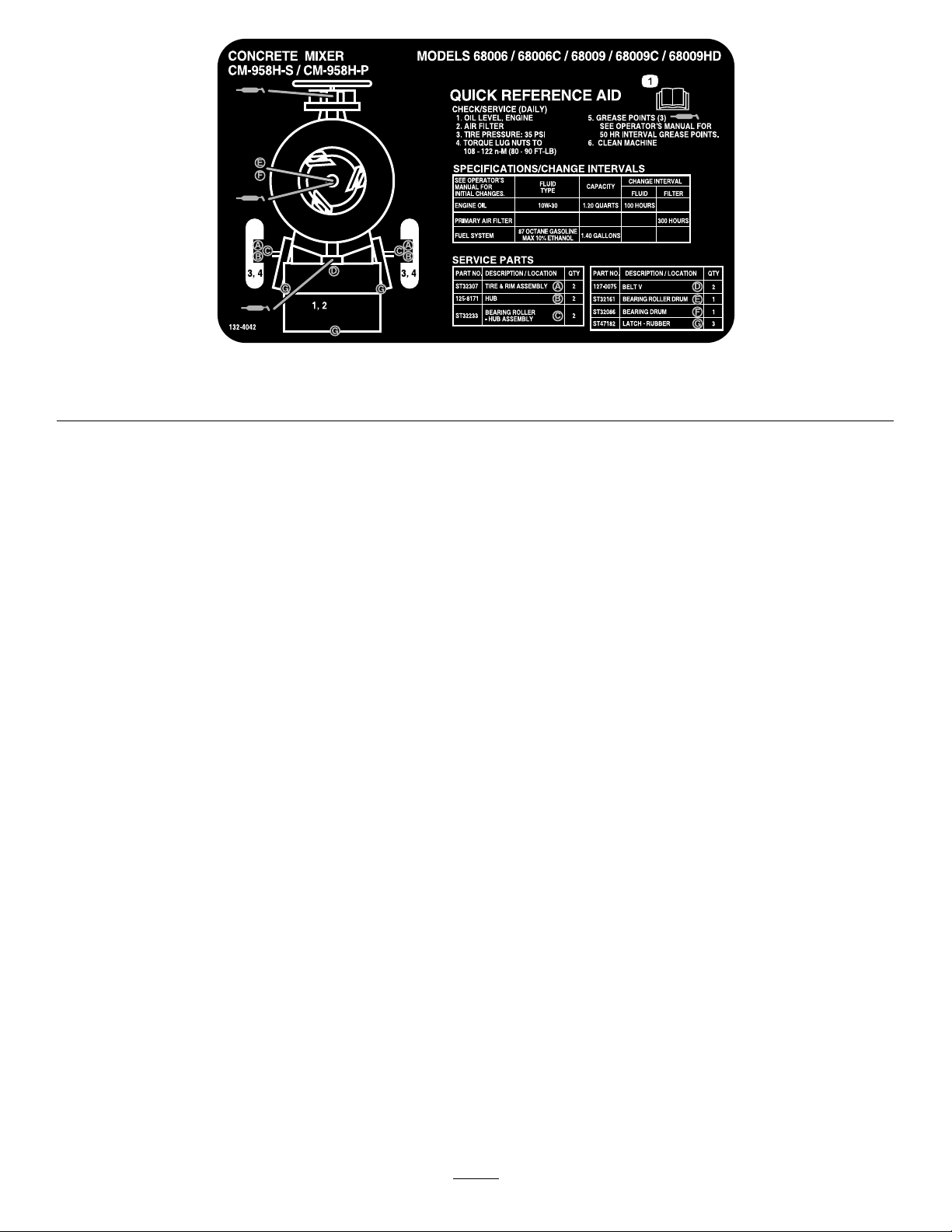

1.ReadtheOperator'sManualformoreinformationonservicingthemachine.

decal132-4042

132-4042

9

Page 10

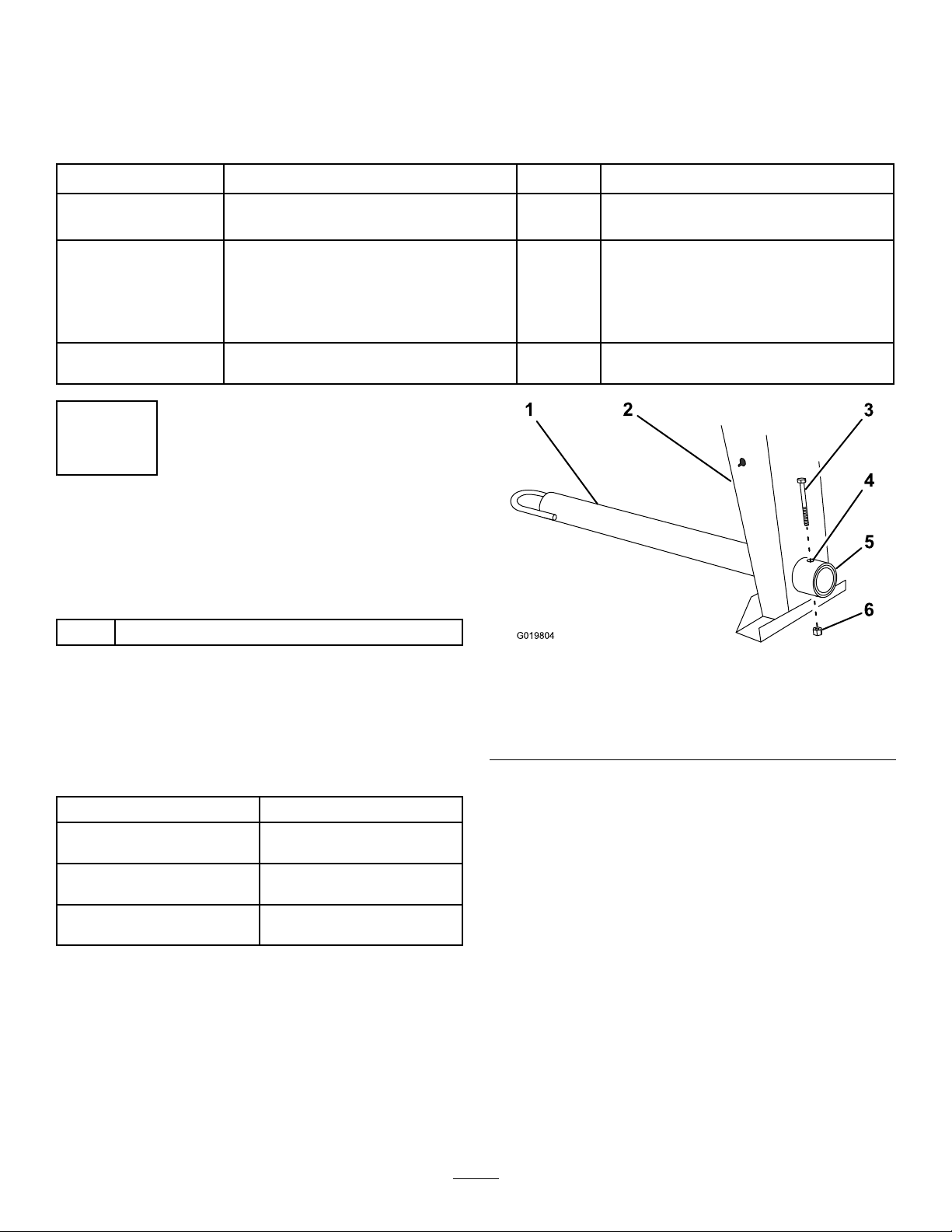

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Towpolekit(soldseparately)

Tongue1

Frontstabilizerleg1

Shortbolt

Longbolt1

Nut

Safetychain

Connectinglink

1

InstallingtheTowPole

Side-DumpModelsOnly

Partsneededforthisprocedure:

Qty.

Use

1

6

7

1

2

Installthetowpole(side-dumpmodels

only).

Installthetongue(end-dumpmodels

only).

Installthesafetychain.

1

Towpolekit(soldseparately)

TowPoleSpecications

Purchasethetowpolekit(includingfasteners)that

meetsyourneedsfromyourAuthorizedService

Dealer.Themachinehasthefollowingtowpole

options:

HitchTypeLength

50mm(2inch)ball—stamped78.7cm(31inches)or127cm

50mm(2inch)ball—forged78.7cm(31inches)or127cm

Pintle

(50inches)

(50inches)

78.7cm(31inches)or127cm

(50inches)

InstallingtheTowPole

1.Removetheboltandnutfromthetowpole

(Figure4).

Figure4

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

2.Slidethetowpoleforwardandaligntheholein

thepolewiththeholeintheframetting(Figure

4).

3.Inserttheboltthroughtheholesinthettingand

thepole(Figure4).

4.Threadthenutontotheboltandtightenthem

untiltheyaretightagainsttheframetting

(Figure4).

5.Frametting

Note:Iftheself-lockingnyloninsertinthe

locknutwearswithuse,replacethenutwitha

newGrade5orGrade8locknut.

g019804

10

Page 11

2

InstallingtheTongue

End-DumpModelsOnly

Partsneededforthisprocedure:

1Tongue

1Frontstabilizerleg

6

Shortbolt

1Longbolt

7

Nut

Procedure

1.Lowertherearstabilizerlegs;refertoLowering

theStabilizerLegs(page22).

2.Placejackstandsunderthefrontframerail

topreventthemachinefromtippingforward

(Figure5).

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseserious

injury.

Usejackstandswhensupportingthe

machine.

Figure6

1.Frontstabilizerleg

4.Installthetongueintotheopeningatthefront

ofthemachineandsecureitwith6nutsand

shortboltstorquedto102N∙m(75ft-lb);refer

toFigure7.

Figure7

1.Clevispin

2.Longbolt5.Tongue

3.Shortbolt

4.Nut

6.Frontstabilizerleg

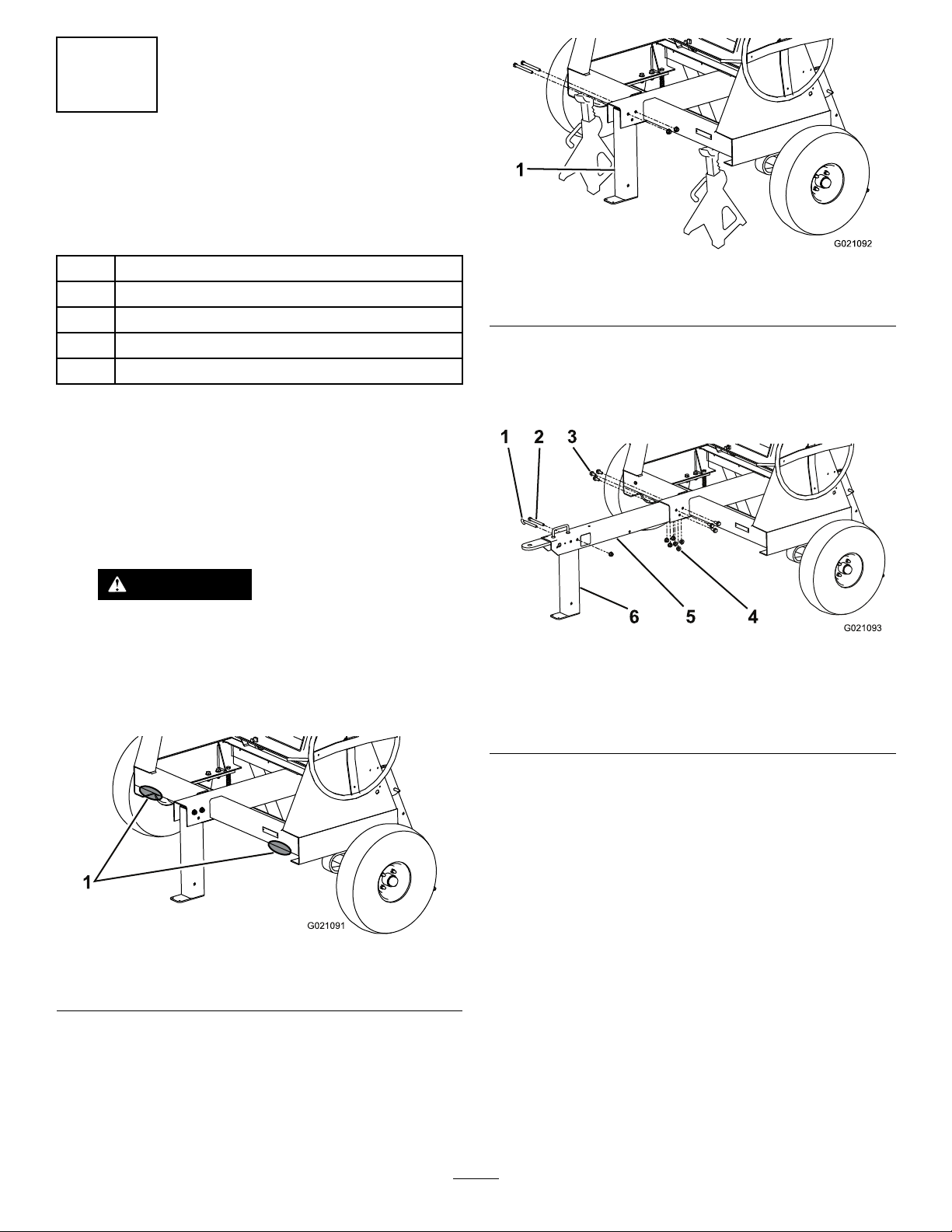

g021092

g021093

Figure5

1.Supportpoints

3.Removethe2nutsandboltsthatsecurethe

frontstabilizerlegtotheframe(Figure6)and

removethefrontstabilizerleg.

5.Alignthetoprearholeinthefrontstabilizerleg

totheholepastthehandleinthefrontofthe

tongue(Figure7).

6.Installthelongboltthroughtheholesandsecure

itwithanuttorquedto102N∙m(75ft-lb);refer

toFigure7.

Note:Thestabilizerlegpivotsrearwardonthe

g021091

11

bolt.Ifyouinstalltheboltintothewronghole,

thestabilizerlegwillnotworkproperly.

7.Inserttheclevispintolockthefrontstabilizerleg

inposition(Figure7).

Page 12

3

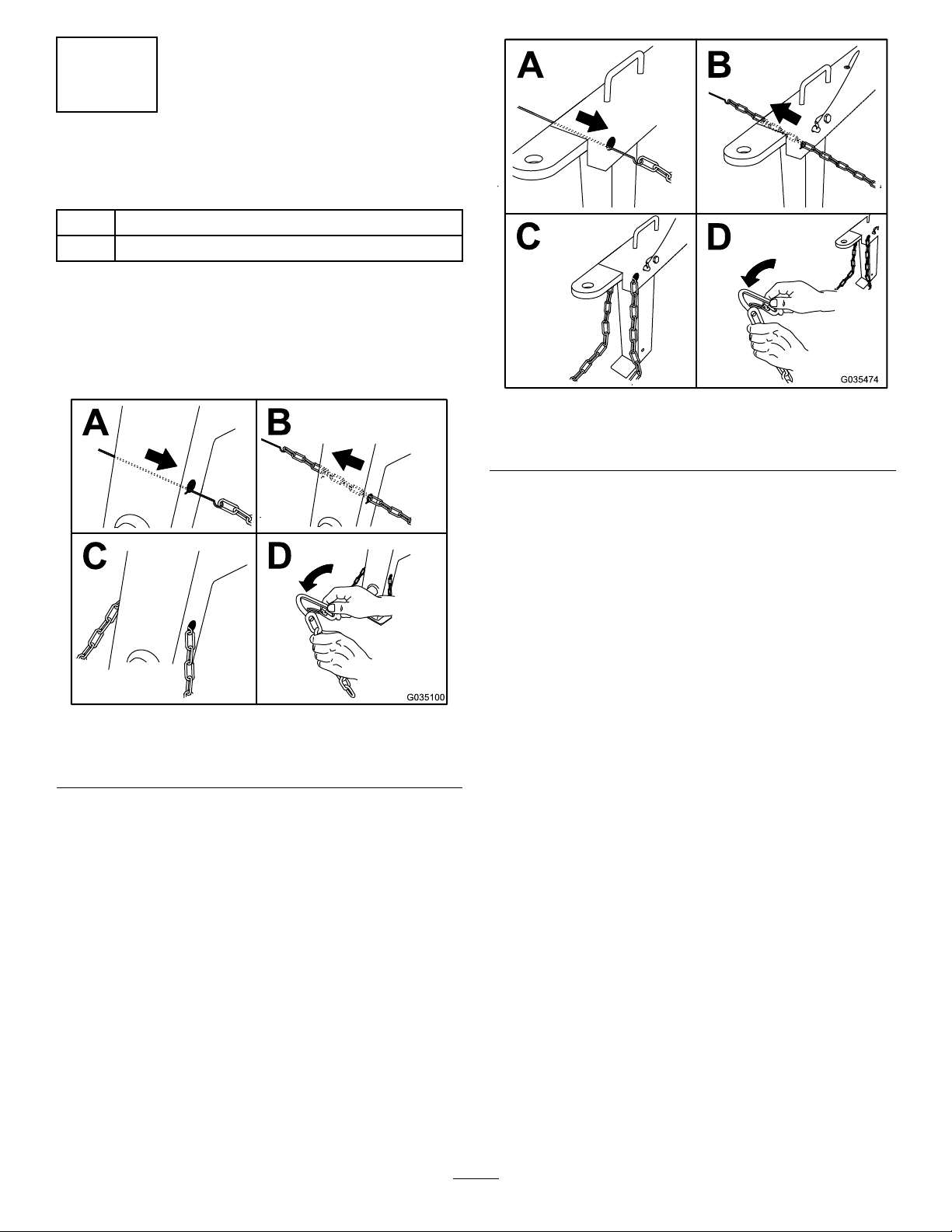

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain

2

Connectinglink

Procedure

Formahookontheendofabendablepieceofrodor

stiffwire(notincluded)andinstallthesafetychainand

connectinglinksasshowninFigure8or.Figure9

g035474

Figure9

End-DumpModels

Note:Ensurethatapproximatelyequallengthsof

safetychainextendfromeithersideofthefrontpost.

Side-DumpModels

g035100

Figure8

12

Page 13

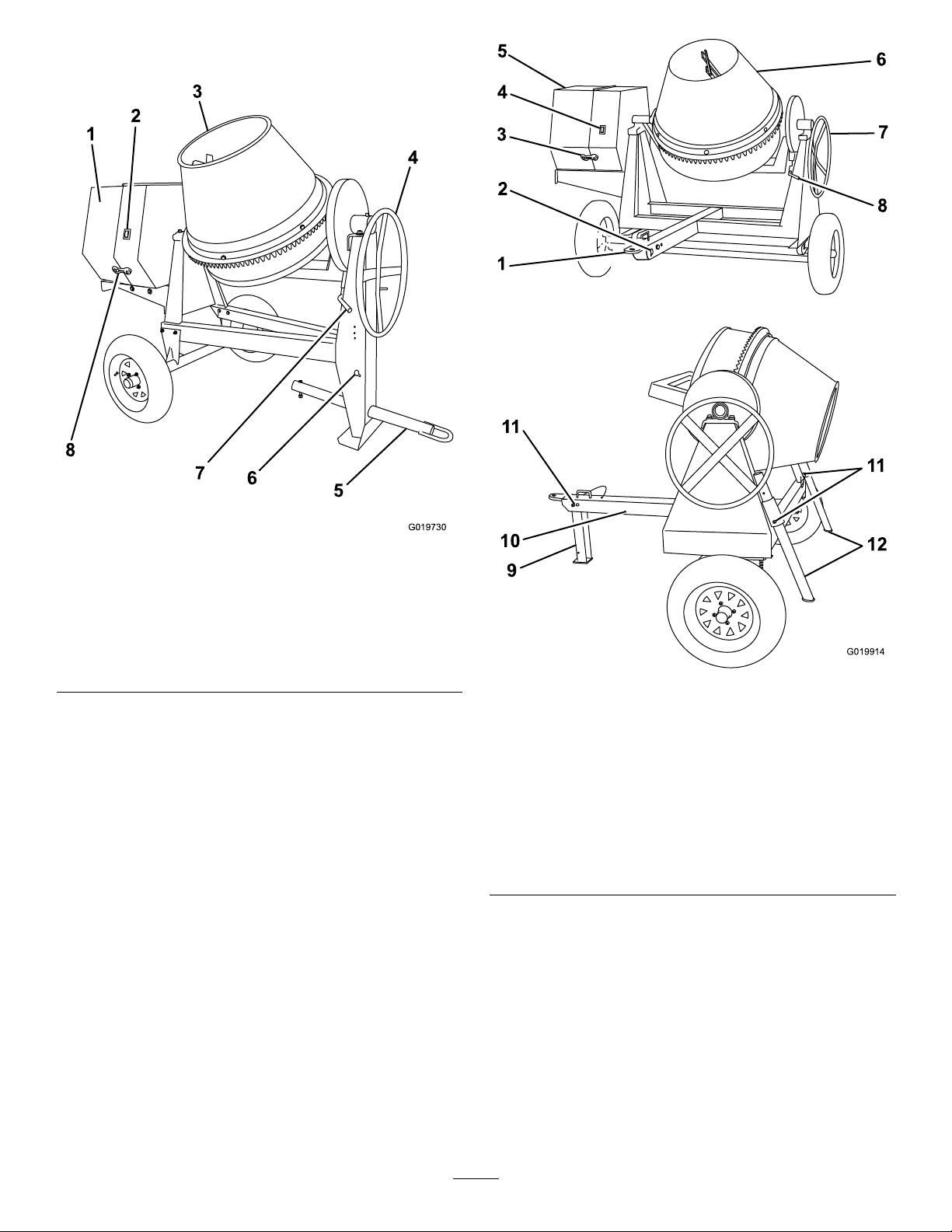

ProductOverview

Figure10

Side-DumpModels

1.Enginecowl5.Towpole

2.Engineswitch

3.Drum7.Drum-tiltbrake

4.Handwheel8.Rubberlatch

6.Safety-chainkeyholes

g019730

g019914

Figure11

End-DumpModels

1.Tongue-mountedtow

coupler

2.Safety-chainkeyholes

3.Rubberlatch9.Frontstabilizerleg

4.Engineswitch10.Rearwardpinhole

5.Enginecowl

6.Drum12.Rearstabilizerlegs

7.Handwheel

8.Drum-tiltbrake

11.Clevispin

13

Page 14

Controls

Becomefamiliarwithallofthecontrolsbeforeyou

starttheengineandoperatethemachine.

EngineSwitch

WhentheengineswitchonthecowlisintheRUN

position,itallowstheenginetorun.Movingtheengine

switchtotheSTOPpositionshutsofftheengine.

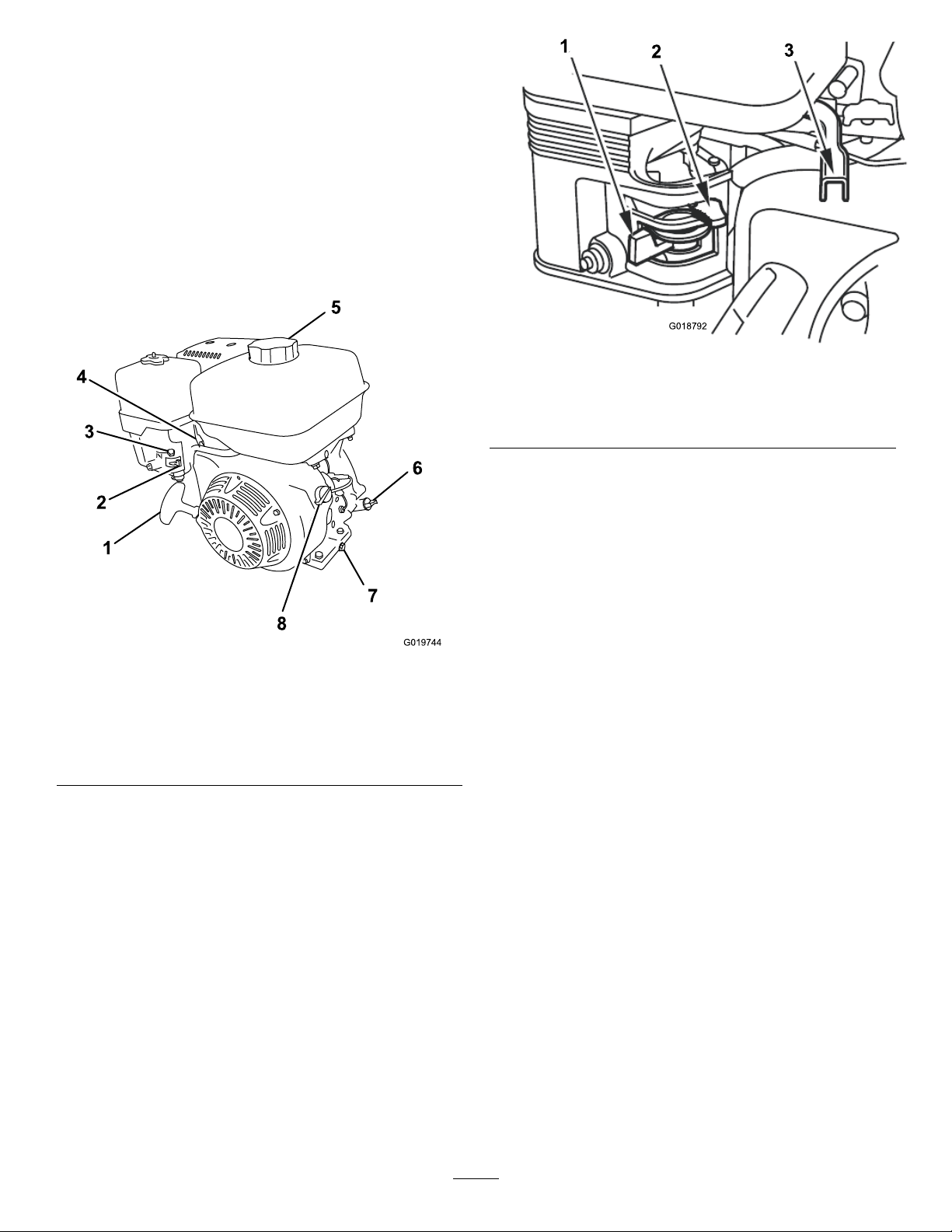

EngineControls

g018792

Figure13

1.Fuelvalve3.Throttlelever

2.Chokelever

ChokeLever

Figure12

1.Recoil-starthandle5.Fuelcap

2.Fuelvalve

3.Chokelever7.Oil-drainplug

4.Throttlelever

FuelValve

6.Oildipstick

8.On/Offswitch

Thefuelvalve(Figure13)islocatedunderneaththe

chokelever.Movetheleverforthefuelvalvetothe

ONpositionbeforeattemptingtostarttheengine.

Whenyouhavenishedmixing,shutofftheengine

andmovethefuel-valvelevertotheOFFposition.

Usethechokelever(Figure13)tostartacoldengine.

Beforepullingtherecoil-starthandle,movethechoke

levertotheCLOSEDposition.Oncetheengineis

running,movethechokelevertotheOPENposition.

Donotusethechokeiftheengineisalreadywarmed

uporiftheairtemperatureishigh.

g019744

ThrottleLever

Thethrottlelever(Figure13)controlsthespeed(rpm)

oftheengine.Itislocatednexttothechokelever.It

setstheenginespeedandthereforecanincreaseand

decreasetherotationspeedofthemixingpaddles.

Forbestperformance,setthiscontroltotheFAST

positionwhenmixingmaterial.

EngineOn/OffSwitch

TheOn/Offswitchislocatedonthefrontoftheengine.

•RotateittotheONpositiontostartandrunthe

engine.

•RotateittotheOFFpositiontoshutofftheengine.

14

Page 15

Handwheel

Thehandwheelcontrolsthetiltofthedrum.

Drum-tiltBrake

Thedrum-tiltbrakelocksthedrumintoanupright

positionoradischargingposition.

g021103

Figure14

1.OFFposition2.ONposition

Recoil-StartHandle

Tostarttheengine,pulltherecoil-starthandle(Figure

12)quicklytoturntheengineover.Theengine

controlsdescribedabovemustallbesetcorrectlyfor

theenginetostart.

Recoil-StartHandle

Tostarttheengine,pulltherecoil-starthandle(Figure

12)quicklytoturntheengineover.Theengine

controlsdescribedabovemustallbesetcorrectlyfor

theenginetostart.

Oil-LevelSwitch

Theoil-levelswitchislocatedinsidetheengine,andit

doesnotallowtheenginetorunintheeventtheoil

levelisbelowthesafeoperatinglimit.

Oil-LevelSwitch

Theoil-levelswitchislocatedinsidetheengine,andit

doesnotallowtheenginetorunintheeventtheoil

levelisbelowthesafeoperatinglimit.

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Model6800468006680076800868009

BatchCapacity

TotalV olume0.255m

DrumMaterial

Length198cm

Width1 17cm

Height147cm

Weight313kg

0.17m

(6.0ft3)

(9.0ft3)

SteelSteelSteel

(78inches)

(46inches)

(58inches)

(690lb)

3

3

0.255m

(9.0ft3)

0.43m

(15.1ft3)

213cm

(84inches)

142cm

(56inches)

165cm

(65inches)

363kg

(800lb)

3

3

0.255m

(9.0ft3)

0.43m

(15.1ft3)

216cm

(85inches)

216cm

(85inches)

180cm

(71inches)

397kg

(875lb)

3

3

0.255m

(9.0ft3)

0.43m

(15.1ft3)

PolyethylenePolyethylene

216cm

(85inches)

216cm

(85inches)

180cm

(71inches)

397kg

(875lb)

3

3

0.255m

(9.0ft3)

0.43m

(15.1ft3)

213cm

(84inches)

142cm

(56inches)

165cm

(65inches)

381kg

(837lb)

3

3

15

Page 16

Operation

Important:Beforeoperating,checkthefueland

oillevels,andremovedebrisfromthemachine.

Ensurethattheareaisclearofpeople.

TowingtheMachine

Beforetowingthemachine,readalltheinformation

andperformalltheapplicableprocedurestointhis

sectiontoensuresafeandpropertowing.

WARNING

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsin

thismanual,ontheproductdecals,andothermedia

suppliedwiththeproduct.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

Knowhowtoquicklyshutdownthemachineinan

emergency.

Useahard-hat,hearingprotection,ashirtwithlong

sleevesthataretightatthewrists,tight-ttinggloves

withoutdrawstringsorloosecuffs,eyeprotection,and

adustmaskorrespirator.Ameshvisoralonedoes

notprovidesufcienteyeprotection;supplementwith

protectiveglasses.

CAUTION

Thismachineproducessoundlevelsthatcan

causehearinglossthroughextendedperiods

ofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Towingthemachineathighspeedincreases

theriskofahitchmalfunctionandtirefailure.

Higherspeedsalsoincreasethemomentum

ofthemachineandbrakingdistance.Ifthe

machinedetachesfromthetowvehicleathigh

speed,itcouldcausedamagetoproperty,or

injuryordeathtobystanders.

Donotexceed88km/h(55mph)whentowing

themachine.Forpoorroadconditionsor

inclementweather,reducespeedaccordingly.

WARNING

Towingthemachinewithmaterialinthedrum

increasestheriskofahitchmalfunctionand

tirefailure.Inaddition,materialcouldbounce

outofthedrumandhitothervehiclesand/or

people.Materialinthedrumincreasesthe

weight,whichaffectsmomentumandbraking

distance.

Donottowthemachinewithmaterialinthe

drum.

1.Wearhearingprotection.

Figure15

•ReviewandunderstandtheSafeOperating

Practices(page4).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthe

g242004

machine.

TowVehicleRequirements

Beforeconnectingthemachinetoyourtowvehicle,

ensurethatyourvehicleispreparedasfollows:

•Ensurethatyourtowvehiclehastowing

capacityfortheweightofthemachine;referto

Specications(page15).

•UseaClass2orlargerreceiver.

•Ensurethatyourtowvehiclehastheappropriate

hitchtotowthemachine;optionsincludea50mm

(2inch)ballhitchorapintlehitch.

•Ifthemachineisequippedwithatrailer-lightkit,

ensurethattheelectricalconnectorofthetow

vehicleiscompatiblewiththeelectricalconnector

ofthemachine.Themachineusesastandard

4-pin,atplug.Ifyourtowvehiclehasadifferent

typeofplug,obtainanadapterfromanautomotive

partsstore.

16

Page 17

PreparingtheMachineforTowing

1.Shut-offtheengineandfuelvalve.

2.Emptythedrum.

3.Usingthehandwheel,positionthedrumsothatit

ispointingdowntowardtheground(Figure16).

g019741

Figure18

Figure16

1.Drumpointingdown3.Towpoleboltedinplace

2.Drum-tiltbrakeengaged

4.Lockthedrumintopositionbypushingdownthe

drum-tilt-brakehandle(Figure17).

g019806

6.Inspectthetires;refertoInspectingtheTires

(page37).

RaisingtheStabilizerLegs

End-DumpModelsOnly

End-dumpmodelshaveafrontstabilizerlegand2

rearstabilizerlegs.

Raisethestabilizerlegsbeforetowingthemachine.

1.Adjustthemachinesothatthereisnoweight

restingontherearstabilizerlegs.

2.Pulltheclevispinoutfrom1oftherearstabilizer

legsandthebracket(Figure19).

Figure17

Drum-TiltBrake

1.Unlockedposition2.Lockedposition

5.Closetheenginecowlandsecurethecowl

latches(Figure18).

g019733

g019917

Figure19

17

Page 18

3.Slidethestabilizerlegupinthebracketand

alignthepinholeofthebracketwiththelower

holeinthestabilizerleg(Figure19).

4.Pushtheclevispinthroughtheholeinthe

bracketandthestabilizerleg(Figure19).

5.Repeatsteps1through4fortheotherrear

stabilizerleg.

6.Liftupwardonthetonguesothatthereisno

weightrestingonthefrontstabilizerleg.

7.Pulltheclevispinoutfromthefrontstabilizerleg

andthetongue(Figure20).

HitchingtheMachinetoaTow Vehicle

Yourmachineisequippedwith1ofthefollowing

hitchtypes;hitchitasdescribedintheappropriate

procedure:

•Stamped-ballcoupler—HitchingaStamped-Ball

Coupler(page18)

•Forged-ballcoupler—HitchingaForged-Ball

Coupler(page19)

•Pintle-hitchcoupler—HitchingaPintle-Hitch

Coupler(page19)

•Pin-hitchcoupler—HitchingaPin-HitchCoupler

(page20)

HitchingaStamped-BallCoupler

1.Applychassisgreasetothesocketofthecoupler

andtheareaoftheclampthatcontactstheball.

2.Oilthepivotpointsandslidingsurfacesofthe

couplerwithSAE30motoroil.

Figure20

1.Removetheclevispin.3.Installtheclevispin.

2.Rotatethestabilizerleg

up.

8.Rotatethefrontstabilizerlegupintothetongue

(Figure20).

9.Pushtheclevispinthroughtherearwardholein

thetongueandthefrontstabilizerleg(Figure

20).

3.HitchthemachineasshowninFigure21.

g019915

18

Page 19

Figure21

HitchingaForged-BallCoupler

1.Applyremovablethread-lockingcompoundto

thethreadsofthecouplerbolttopreventthe

couplerhandlefromcomingloose.

g035115

Figure22

Note:Useawrenchtokeeptheboltfrom

spinning.

HitchingaPintle-HitchCoupler

g035113

Important:Applythread-lockingcompound

asneededinthefuture.

2.Applychassisgreasetothesocketofthecoupler

andtheareaoftheclampthatcontactstheball.

3.HitchthemachineasshowninFigure22.

g035164

Figure23

19

Page 20

HitchingaPin-HitchCoupler

Figure24

Note:Usea19mm(3/4inch)or22mm(7/8inch)

hitchpin.

g021177

Figure25

g035116

1.Connectinglinks3.Chaincrossedundertow

2.Keyholesinfrontpost

Side-DumpModels

pole

ConnectingtheSafetyChainsto theTowVehicle

1.Pullthesafetychainthroughtheslotsinthe

keyholes,sothatthelengthsoneachsideare

equal.

2.Crossbothlengthsofchainunderthetow

pole(underthetongueforend-dumpmodels).

Forside-dumpmodels,refertoFigure25.For

end-dumpmodels,refertoFigure26.

Note:Crossingthechainsdecreasesthe

chancesofthefrontofthemachinedropping

tothegroundifthehitchdoesnotholdthe

connection.

Figure26

End-DumpModels

1.Connectinglinks3.Chaincrossedunder

2.Keyholes

tongue

4.Chain

3.Connecteachlengthofchaintothesafety

chainmountingpointonthetowvehiclewiththe

connectinglinks(Figure27).

Important:Ensurethatthechainhas

enoughslackforturningaroundcorners

whentowingthemachine.

Note:Forside-dumpmodels,stowtheexcess

chaininsidethebottomofthefrontpostby

pushingitintothekeyholesandlatchingthe

appropriatelinksintothekeyholeslots.

g019928

Note:Forend-dumpmodels,connectthe

connectinglinkstotheappropriatelinksinthe

safetychain(Figure27).Iftheexcesschain

hangstoolowandtouchestheground,connect

20

Page 21

itagaintotheconnectinglinktoraiseitaway

fromtheground.

Figure27

1.Connectinglink3.Chainlink

2.Safetychainmounting

pointontowvehicle

4.Chain

C.Operateeachturnsignalofthetowvehicle

inturn.

Thecorrespondingturn-signallightsofthe

machineshouldilluminate.

g020365

ConnectingandCheckingthe Lights

MachinesEquippedwithaLightKitOnly

1.Connecttheelectricalplugofthemachinewith

theelectricalplugofthetowvehicle(Figure28).

Figure28

Note:Themachineusesastandard4-pin,at

plug.Ifyourtowvehiclehasadifferenttype

ofplug,obtainanadapterfromanautomotive

partsstore.

2.EnsurethatthetowvehicleisintheNEUTRAL

position,engagetheparkingbrake,andstart

theengine.

g020828

3.Testthelightsasfollows:

A.Turnontheheadlightsofthetowvehicle.

Thetaillightsofthemachineshould

illuminate.

B.Pressthebrakepedalofthetowvehicle.

Thebrakelightsofthemachineshould

illuminate.

21

Page 22

PreparingtoUsethe Machine

1.Parkthemachineonalevelsurfaceand

disconnectthemachinefromthetowvehicle.

2.Ensurethatallguardsandpaddlesareinplace

andingoodcondition.

3.Performalldailymaintenanceprocedures

prescribedinMaintenance(page29).

4.Chockthefrontandbackofthetirestoprevent

themachinefrommoving.

5.Forend-dumpmodels,lowerthefrontandrear

stabilizerlegs;refertoLoweringtheStabilizer

Legs(page22).

6.Movethedrumtotheuprightpositionandlockit.

LoweringtheStabilizer Legs

4.Repeatsteps1through3fortheotherrear

stabilizerleg.

5.Liftupwardonthetonguetoprovideclearance

forthefrontstabilizerleg.

6.Pulltheclevispinoutfromthefrontstabilizerleg

andthetongue(Figure30).

End-DumpModelsOnly

End-dumpmodelshaveafrontstabilizerlegand

2rearstabilizerlegstokeepthemachinefrom

tippingforwardorbackwardduringoperation.Move

thestabilizerlegsintotheloweredpositionbefore

operatingthemachine.

1.Pulltheclevispinoutfrom1stabilizerlegand

thebracket(Figure29).

g019916

Figure30

1.Removetheclevispin.3.Installtheclevispin.

2.Rotatethestabilizerleg

down.

7.Rotatethefrontstabilizerlegdowntowardthe

ground(Figure30).

8.Pushtheclevispinthroughthefrontholeinthe

tongueandthefrontstabilizerleg(Figure30)

andcarefullylowerthemachinetotheground.

Figure29

2.Slidethestabilizerlegdowninthebracketand

alignthepinholeofthebracketwiththeupper

holeinthestabilizerleg(Figure29).

3.Pushtheclevispinthroughtheholeinthe

bracketandthestabilizerleg(Figure29).

g019918

22

Page 23

OpeningtheCowl

AddingFuel

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltanksoutdoors,inanopen

area,whentheengineiscold.Wipeupany

fuelthatspills.

•Neverllthefueltanksinsideanenclosed

trailer.

•Neversmokewhenhandlingfuelandstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

ClosingtheCowl

Figure31

g035134

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark

thatcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbed,becauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfrom

thetruckortrailerandrefueltheequipment

withitswheelsontheground.

Figure32

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainerratherthanfroma

fuel-dispensernozzle.

g035135

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

23

Page 24

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankopening.

•Keepfuelawayfromyoureyesandskin.

FuelRecommendations

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

FillingtheFuelTank

1.Parkthemachineonalevelsurface,shutoffthe

engine,andallowtheenginetocool.

2.Cleanaroundthefuelcapandremoveit(Figure

33).

g019799

Figure33

1.Fuelcap

•Donotstorefueleitherinthefueltankorinfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Important:T oreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithfuel

lessthan30daysold;runthemachinedrybefore

storingitformorethan30days.

Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizers

withanalcoholbasesuchasethanol,methanol,

orisopropanol.

FuelTankCapacity

5.3L(1.4USgallons)

3.Addfueltothefueltankuntilthelevelisatthe

maximumfuellevel(Figure34).

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

24

Page 25

StartingtheEngine

1.EnsurethattheclutchleverisintheOFF

position.

2.MovethefuelvalvetotheOPENposition,allthe

waytotheright(Figure35).

Figure34

1.Maximumfuellevel

4.Installthefuelcapsecurely(Figure33).

5.Wipeupanyspilledfuel.

PerformingDaily Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page29).

g020679

g019815

Figure35

1.Chokelever

2.Fuelvalve

3.Throttlelever

3.MovethechokelevertotheONposition(Figure

35).

Note:Awarmorhotenginemaynotrequire

choking.

4.Movethethrottlelever1/3ofthewaytowardthe

MAXposition.

5.MovetheengineswitchtotheONposition

(Figure36).

1.Engineswitch—OFF

position

25

g021103

Figure36

2.Engineswitch—ON

position

Page 26

6.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly(Figure

37).Returnthestarterhandlegently.

MixingtheMaterial

ConcreteBasics

DANGER

Eyeandskincontactwithconcretematerials

andbreathingthedustinvolvedishazardous

toyourhealth.

•Ensurethatthereisadequateair

ventilation.

•Wearadustmasktopreventinhalationof

dustwhileusingthemachine;refertoSafe

OperatingPractices(page4).

Figure37

7.Aftertheenginestarts,graduallymovethe

chokeleverbacktotheOFFposition.Ifthe

enginestallsorhesitates,movethechokeback

totheONpositionagainuntiltheenginewarms

up.ThenmoveittotheOFFposition.

ShuttingOfftheEngine

Inanemergency,shutofftheenginequicklyby

pressingtheEmergencyShutoffswitchlocatedon

thecowl,holdingituntiltheengineandmovingparts

havestopped.

1.MovethethrottlelevertotheMINposition

(Figure35).

Note:Iftheenginehasbeenworkinghardor

ishot,letitidleforaminutebeforeshuttingoff

theengine.Thishelpstocooltheenginebefore

shuttingitoff.Inanemergency ,shutoffthe

engineimmediately.

2.MovetheengineswitchtotheOFFposition.

3.MovethefuelvalvetotheCLOSEDposition,all

thewaytotheleft.

g019747

•Avoiddirectcontactofcementand

concretematerialswithskinandeyes.

Note:Followthemanufacturer’sinstructionsthatare

printedonthepackagingoftheproductthatyouare

using.

Concretehasthefollowing4basicingredients:

•Sand

•Gravel

•Portlandcement

•Water

Dependingontheapplication,youcanusedifferent

ratiosofthese4ingredients.Thetypicalratiofor

mixingconcreteis1partPortlandcement,2parts

sand,and3partsgravel.

Therearemanyvariationsofconcretemixrecipes,

dependingontheapplication.Itisimportanttouse

theappropriatequantityofwater.Usingtoolittlewater

resultsindryareasinthemix,butusingtoomuch

waterresultsinweakerconcrete.Theamountofwater

neededvariesdependingonmoisturecontentofthe

sandandgravel.Themixshouldhaveathickness

similartopeanutbutter.

Keepthepouredconcretedampforseveraldaysto

obtainpropercuring.Evaporationresultsinweaker

concrete.Concretecuresthroughhydration,a

reactionbetweenwaterandcement.

26

Page 27

PreparingtoMix

MixingConcrete

DANGER

Thismachineiscapableofamputatinghands.

•Keepallbystandersasafedistanceaway

fromthemachine.

•Stopthemachineimmediatelyifany

peopleoranimalsentertheworkarea.

•Neverplaceanypartofyourbodyintoa

positionthatcausesanunsafeoperating

condition.

1.ReadalltherecommendationsfromSafe

OperatingPractices(page4)beforeusingthe

machine.

2.Ensurethatthemachineisonlevelgroundand

thesurroundingareaisclearofobstacles.

3.Removethemachinefromthetowvehicle.

4.Securethemachinefrommovement.

5.Usethehandwheeltomovethedrumintoan

upright,slightlytiltedpositiontoallowaccessfor

pouringmaterialsintothedrum.

Note:Thispositionalsoallowsthemixing

paddlestomixthematerialsmoreeffectively.

Important:Donotaddmorematerialthanthe

batchcapacityforyourspecicmachinemodel;

refertoSpecications(page15).

1.Ensurethatthetiltbrakeisfullyengagedand

thatthedrumisoperatingatfullspeed.

2.Pourwaterintothedrum.

3.Addtheconcreteingredientsasfollows:

•Ifyouareusingpre-mixedconcrete,addthe

requiredamountofdrypre-mix.

•Ifyouaremixingsand,gravel,andcement,

addthemasfollows:

A.Addtherequiredamountofgravel.

Note:Addingwaterandgravelbefore

cementandsandallowsthemixleftin

thedrumfromthepreviousbatchtobe

tumbledoffthedrumandpaddlesand

intothenextbatch.

B.AddtherequiredamountofPortland

cement.

C.Addtherequiredamountofsand.

4.Allowthedrumtoturnwhilethemixreachesthe

appropriateconsistency.

6.Pushthedrum-tiltbrakedowntolockthedrum

intopositionandavoidaccidentallydumpingthe

material.

7.Starttheengine.Allowtheenginetowarmup

atidlefor2minutes;refertoStartingtheEngine

(page25).

Important:Ifyouneedtoshutoff

themachinequickly,usetheengine

switch/speed-controlhandle(asequipped)

locatedonthecowl;refertoEngineSwitch

(page14).

8.Usetheenginethrottlelever/speed-control

handle(asequipped),tocontrolthespeedof

theengineanddrum.

9.Closetheenginecowl.

DumpingtheMaterial

Note:Whendumpingabatchofmaterial,leavethe

enginerunningsothattherotatingdrumhelpsdump

thematerial.

1.Alignawheelbarroworsimilarcontainerof

adequatecapacityinthepathofthedrum

opening.

2.Whilethedrumisturning,rmlygraspthe

handwheelwith1hand.

3.Usingyourotherhand,pullupwardonthe

drum-tilt-brakehandletoreleasethebrake.

4.Usebothhandstoslowlyturnthehandwheel,

allowingthedrumtotiltinthedesireddirection

anddumpthedesiredamountofmaterial.

5.Turnthehandwheelintheoppositedirectionto

returnthedrumintoanuprightposition.

6.Pushdownonthedrum-tiltbraketolock

thedrumintoposition,avoidingaccidental

dischargingofconcretemix.

7.Afterdumpingabatchofmaterial,clean

thedrumtopreventdriedmaterialfrom

contaminatingthenextbatchofmaterial;referto

CleaningtheDrum(page28).

27

Page 28

CleaningtheDrum

Important:Donotstrikeonthedrumwitha

shovel,hammer,oranyotherdevicetoloosenany

accumulateddriedmaterials.

1.Whilethemachineisrunning,usethehandwheel

totiltthedrumslightly .

2.Engagethedrum-tiltbraketopreventthedrum

fromtiltingfurtheranddischargingthewater.

3.Asthedrumisrotating,sprayitthoroughlywith

waterbeforethematerialdries.

4.Allowthedrumtorotateandtumbletheloose

materialandwater,furtherlooseningtherestof

thematerial.

5.Continuetospraythedrumwithwatertoremove

allmaterialfromthedrumandmixingpaddles.

6.Whenyouhaveremovedallmaterialfrom

thesurfacesofthedrumandmixingpaddles,

disengagethedrum-tiltbrakeandusethe

handwheeltotiltthedrumanddumpthewater

fromit.

7.Ifsomematerialstillremainsinthedrum,spray

thedrumwithwaterwhileitistilteddownward,

allowingthewaterandmaterialtorunout.

28

Page 29

Maintenance

WARNING

Failuretoproperlymaintainthemachinecouldresultinprematurefailureofmachinesystems

causingpossibleharmtoyouorbystanders.

Keepthemachinewellmaintainedandingoodworkingorderasindicatedintheseinstructions.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst25hours

Beforeeachuseordaily

Aftereachuse

Every20hours

Every50hours

Every100hours

Every300hours

Monthly

MaintenanceProcedure

•Changetheengineoil.

•Inspecttheair-cleanerelements.

•Checktheengine-oillevel.

•Inspectthetires.

•Cleanthedrum.

•T orquethewheellugnutsto108to122N∙m(80to90ft-lb)aftertowing.

•Checkthedrive-belttensionandadjustitasnecessary.Replacethedrivebeltsif

theyshowanysignsofwear,cracks,glazing,ordamage.

•Cleantheair-cleanerelements.Cleanthemmorefrequentlyindustyoperating

conditions.

•Changetheengineoil.

•Checkthesparkplug.

•Cleanthesparkarrester(ifequipped).

•Cleanthefuel-sedimentcup.

•Replacethedrivebelts.

•Replacethepaperair-cleanerelement.Replaceitmorefrequentlyindusty

operatingconditions.

•Replacethesparkplug.

•Greasethetrunnionsandthedrumspindle.

Yearlyorbeforestorage

•Cleanthefuel-sedimentcup.

Pre-Maintenance

Procedures

PreparingtheMachinefor Maintenance

1.Shutofftheengineandallowittocool

completely.

2.Parkthemachineonalevelsurface.

3.Removethemachinefromthetowvehicle.

4.Securethemachinefrommovement.

5.Disconnectthespark-plugwire.

29

Page 30

Disconnectingthe

InstallingtheDividerPlate

Spark-PlugWire

Pullthespark-plugwireofftheterminalofthespark

plug(Figure38).

Figure38

1.Sparkplug

Whennishedperformingmaintenance,installthe

dividerplateasfollows:

1.Guidethedividerplateintopositionagainstthe

frontcowl.

Note:Startwiththedividerplatetiltedslightly

back,thentiltitforwardwhileloweringitinto

position.

g019281

g021102

Figure40

RemovingtheDividerPlate

Ifyourmodelhasadividerplate,youmayneed

toremoveitbeforeperformingsomemaintenance

procedures:

1.Openthecowl.

2.Useawrenchtoremovethe4boltsthatsecure

thedividerplatetothefrontcowl.

Note:Retainthefastenersforinstallingthe

dividerplate.

Figure39

2.Aligntheboltholesinthedividerplateandthe

frontcowl.

3.Installeachofthe4boltsandhand-tightenthem

topreventcross-threading.

4.Tightentheboltswithawrenchuntiltheyare

secure.

g021094

3.Toremovethedividerplate,liftitupwardandtilt

itbacksothatitclearsvariouscomponents.

30

Page 31

Lubrication

EngineMaintenance

LubricatingtheMachine

ServiceInterval:Monthly—Greasethetrunnionsand

thedrumspindle.

GreaseType:No.2lithiumgrease.

1.CompletetheprocedureslistedinPreparingthe

MachineforMaintenance(page29).

2.Cleanaroundeachgreasettingwitharagand

lifttheplasticcapoffthegreasetting(Figure

41).

3.Useagreaseguntolubricatethegreasettings

ofbothtrunnionsandthedrumspindlewithNo.

2lithiumgrease(Figure41).

4.Wipeupanyexcessgrease.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Inspect

theair-cleanerelements.

Every50hours—Cleantheair-cleaner

elements.Cleanthemmorefrequentlyindusty

operatingconditions.

Every300hours/Y early(whichevercomes

rst)—Replacethepaperair-cleanerelement.

Replaceitmorefrequentlyindustyoperating

conditions.

Important:Donotoperatetheenginewithout

theair-lterassembly;extremeenginedamage

willoccur.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page30).

3.Removethenutthatsecuresthecover(Figure

42).

Figure41

Important:Donotlubricatethepiniongearand

ringgear.Lubricationcausesthemtocollect

abrasivematerialsandacceleratewear.

g019678

31

Page 32

9.Rinseanddrythefoamelementthoroughly .

10.Dipthefoamelementincleanengineoil,then

squeezeouttheexcessoil.

Note:Excessoilinthefoamelementrestricts

theairowthroughtheelementandmayreach

thepaperlterandclogit.

11.Wipedirtfromthebaseandthecoverwitha

moistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

12.Installtheair-cleanerelementsandensurethat

theyareproperlypositioned.

13.Securelyinstallthecoverwiththenut.

ServicingtheEngineOil

Engine-OilSpecications

ToroPremiumEngineOilisavailablefromyour

AuthorizedT oroDealer.

Figure42

1.Covernut

2.Cover

3.Wingnut6.Base

4.Foamelement

5.Paperelement

4.Removethecover.

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

5.Removethefoamandpaperelementsfromthe

base(Figure42).

6.Removethefoamelementfromthepaper

element(Figure42).

7.Inspectthefoamandpaperelementsand

replacethemiftheyaredamagedorexcessively

dirty.

Note:Nevertrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

8.Cleanthefoamelementinwarm,soapywater

orinanonammablesolvent.

Important:Use4-cycleengineoilthatmeetsor

exceedstherequirementsforAPIservicecategory

SJ,SL,SM,orhigher.

CrankcaseCapacity:1.1L(1.2USqt)

Important:Iftheoillevelinthecrankcaseistoo

g019728

lowortoohighandyouruntheengine,youmay

damagetheengine.Thistypeofdamageisnot

coveredbythewarranty.

Note:UseSAE10W-30forgeneraluse.Youcan

usetheotherviscositiesshowninthechartwhen

theaveragetemperatureinyourareaiswithinthe

indicatedrange(Figure43).

g013375

Figure43

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

32

Page 33

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury .

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page30).

4.Cleanaroundthedipstick.

5.ChecktheoillevelasshowninFigure44.

Avoidcontactingthehotengineoilwhenyou

drainit.

1.Shutofftheengineandwaitforallmovingparts

tostop.

2.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page30).

3.Placeadrainpanundertheoil-drainholeofthe

engine(Figure45).

Figure44

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

g019750

Figure45

1.Oil-drainplug3.Oil-drainpan

2.Oil-drainhole

4.Removethedrainplugandcatchtheoilinthe

oil-drainpan(Figure45).

5.Whentheoilhasdrainedcompletely,installthe

g035136

drainplugwithanewwasher(Figure45).

Note:Disposeoftheusedoilatacertied

recyclingcenter.

6.Removethedipstick(Figure44)andslowly

pouroilintothellholeuntiltheoilreachesthe

upper-limitmark(bottomedgeoftheoil-llhole)

onthedipstick.

7.Replaceandsecurethedipstick.

8.Wipeupanyspilledoil.

33

Page 34

ServicingtheSparkPlug

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Checkthe

sparkplug.

Every300hours/Y early(whichevercomes

rst)—Replacethesparkplug.

SparkPlugSpecications

Type:NGKBPR6ESorequivalent

Gap:0.7to0.8mm(0.028to0.031inch)

Note:Usea21mm(13/16inch)spark-plugwrench

forremovingandinstallingthesparkplug.

RemovingtheSparkPlug

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Ensurethatthemachinesurfacesarecool.

3.Pullthespark-plugwireofftheterminalofthe

sparkplug(Figure46).

g019749

Figure47

CheckingtheSparkPlug

Important:Donotcleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,

theengineisoperatingproperly.Ablackcoatingon

theinsulatorusuallymeansthattheaircleanerisdirty.

Figure46

1.Sparkplug

4.Cleanaroundthesparkplug.

5.Rotatethesparkplugcounterclockwiseusing

a21mm(13/16inch)spark-plugwrenchto

removetheplugandthesealingwasher(Figure

47).

2.Wire

Setthegapto0.7to0.8mm(0.028to0.031inch).

g014506

Figure48

g206628

34

Page 35

InstallingtheSparkPlug

CleaningtheSparkArrester

Important:Ensurethatthegapbetweentheside

andcenterelectrodesiscorrectbeforeinstalling

thesparkplug.

1.Threadthesparkplugclockwiseintothe

spark-plugholebyhand.

Note:Avoidcross-threadingthesparkplugwith

thethreadsofthespark-plughole.

2.Rotatethesparkplugclockwiseusinga21mm

(13/16inch)spark-plugwrenchuntiltheplug

andsealingwasherareseated(Figure47).

3.Tightenthesparkplugasfollows:

•Wheninstallinganin-servicesparkplug,

tightenthepluganadditional1/8to1/4turn.

•Wheninstallinganewsparkplug,tightenthe

pluganadditional1/2turn.

Important:Aloosesparkplugmaycause

thecylindertooverheat.Anover-tightspark

plugmaydamagethethreadsinthecylinder

head.

4.Pushthespark-plugwireontotheterminalofthe

sparkplug(Figure46).

ServiceInterval:Every100hours

Note:Asparkarresterisavailableasanoption.If

yourequireasparkarrester,contactyourAuthorized

ServiceDealer.GenuineT orosparkarrestersare

approvedbytheUSDAForestryService.

WARNING

Iftheenginehasbeenrunning,themufer

willbehot.Contactwithhotsurfacesmay

causepersonalinjury.

Keepyourhands,feet,face,clothingand

otherbodypartsawayfromthemuferand

otherhotsurfacesuntiltheyhavecooled.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page30).

4.Removethedividerplate(ifequipped);referto

RemovingtheDividerPlate(page30).

5.Removethe2nuts(8mm)andremovethe

muferfromthecylinder(Figure49).

Figure49

1.Deector(if

applicable)

2.Protector

3.Screw(6mm)7.Gasket

4.Mufer8.Bolt(8mm)12.Screw(4mm)

6.Removethe3screws(4mm)fromtheexhaust

deector,andremovethedeector(Figure49).

35

5.Exhaustpipe

6.Nut(8mm)10.Screws(5mm)

g019331

9.Sparkarrester

11.Exhaustport

Page 36

7.Removethescrews(5mmand6mm)from

themuferprotector,andremovethemufer

protector(Figure49).

8.Removethescrews(4mm)fromthespark

arrester,andremovethesparkarresterfromthe

mufer(Figure49).

FuelSystem

Maintenance

CleaningtheFuel-Sediment

9.Useabrushtocarefullyremovecarbondeposits

fromthespark-arresterscreen(Figure50).

Note:Replacethesparkarresterifithas

breaksorholes.

Figure50

1.Screen

10.Installthesparkarrester,muferprotector,

exhaustdeector,andmuferinthereverse

orderofdisassembly.

11.Installthedividerplate(ifequipped);referto

InstallingtheDividerPlate(page30).

2.Brush

Cup

ServiceInterval:Every100hours/Every6months

(whichevercomesrst)—Cleanthe

fuel-sedimentcup.

Yearlyorbeforestorage—Cleanthe

fuel-sedimentcup.

Underneaththefuelvalveisasedimentcuptocatch

dirtinthefuel.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

g208746

2.Ensurethattheengineandtheexhaustsystem

surfacesarecool.

3.MovetheleverofthefuelvalvetotheOFF

position,allthewaytotheleft(Figure51).

4.Unscrewthesedimentcup(Figure51).

5.RemoveandretainthefuellterandO-ring

(Figure51).

Note:DonotcleantheO-ringinsolvent.

Figure51

1.Fuelvalve—Offposition3.Fuellter

2.O-ring4.Sedimentcup

6.Cleanthefuellterandsedimentcupusinga

nonammablesolvent,anddryitcarefully.

7.WipetheO-ringwithaclean,drycloth.

8.Installthefuellterinthebottomofthe

carburetor(Figure51).

36

g019333

Page 37

9.AligntheO-ringintothegrooveinthesediment

cupandinstallthesedimentcuptothefuel-valve

housing.

10.MovetheleverofthefuelvalvetotheON

position(allthewaytotheright)andcheckfor

leaks.Ifitleaks,replacetheO-ring.

DriveSystem

Maintenance

TireAirPressure

Thefollowingtableshowstheappropriateairpressure

forthetiresasinstalledatthefactory.

Important:Alwayschecktheinformationon

theactualtiresforthecorrectairpressure

requirement.

ModelMaximumAirPressure

68004

68006,68007,68008,68009,

and68011

InspectingtheTires

ServiceInterval:Beforeeachuseordaily

414kPa(60psi)

241kPa(35psi)

WARNING

Failuretomaintaincorrecttirepressure

mayresultintirefailureandlossofcontrol,

resultinginpropertydamageandserious

injuryordeath.

•Checkthetirepressurefrequentlyto

ensureproperination.Ifthetiresarenot

inatedtothecorrectpressure,theywill

wearprematurely .

•Inspectthetireconditionbeforetowing

andafteranyoperatingaccident.

TheDOTtireinformationislocatedonthesideof

eachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesameor

betterratings

Note:Ensurethatanytiresinstalledonyourmachine

meetorexceedtheweightrequirementsofyour

machineaslistedinSpecications(page15).

1.Visuallyinspectthetiresfordamageandwear

(Figure52andFigure53).

37

Page 38

1.Exampleoftirewearcausedbyunderination

Figure52

Figure53

BeltMaintenance

CheckingtheDrive-Belt Tension

ServiceInterval:Every20hours—Checkthe

g020836

Thedrivebeltsshouldeachhave1cm(13/32inch)

ofexwhenapplying6.8kg(15lb)ofpressure,at

mid-span(Figure55).

g010293

drive-belttensionandadjustitas

necessary.Replacethedrivebelts

iftheyshowanysignsofwear,

cracks,glazing,ordamage.

1.Exampleoftirewearcausedbyoverination

2.Ensurethatthetiresareinatedtothecorrect

airpressure;refertoTireAirPressure(page37).

Important:Themostcommoncauseoftire

troubleisunder-ination.Maintainfullair

pressure.

TorquingtheWheelLug Nuts

ServiceInterval:Aftereachuse

Torquethewheellugnutsinitiallyandaftertowing.

Torquethewheellugnuts108to122N∙m(80to90

ft-lb),inthesequenceshowninFigure54.

g019731

Figure55

DriveBelts

Figure54

1.Flexof1cm(13/32inch)2.Straightedge

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

g021107

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page30).

38

Page 39

4.Removethedividerplate;refertoRemovingthe

DividerPlate(page30).

7.Checkthedrive-belttension;refertoChecking

theDrive-BeltT ension(page38).

5.Layastraightedgealong1drivebelt,from1

pulleytotheother(Figure55).

6.Withyournger,pushonthebeltwith6.8kg

(15lb)ofpressure,midwaybetweenthepulleys

(Figure55).

7.Measurethedistancefromthebelttothe

straightedge.Thedistanceshouldbe

approximately1cm(13/32inch)asshownin

Figure55.

Note:Ifthebelttensionneedsadjustment,refer

toAdjustingtheDrive-beltTension(page39).

8.Installthedividerplate;refertoInstallingthe

DividerPlate(page30).

AdjustingtheDrive-belt Tension

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Disconnectthewirefromthesparkplug;referto

DisconnectingtheSpark-PlugWire(page30).

4.Removethedividerplate;refertoRemovingthe

DividerPlate(page30).

5.Loosenthe4nutsandboltsthatsecurethe

enginetotheenginemountingplate(Figure56).

Note:Whenthebeltshavetheappropriate

amountoftension,torquethe4nutsandboltsto

24N∙m(18ft-lb)each.

8.Installthedividerplate;refertoInstallingthe

DividerPlate(page30).

ReplacingtheDriveBelts

ServiceInterval:Every100hours

Note:Themachinehas2drivebelts.Rememberto

buy2beltsforreplacement.

1.Completesteps1through5inAdjustingthe

Drive-beltT ension(page39).

2.Slidetheenginetotherighttodecreasethebelt

tension.

3.Removethedrivebeltsfromthepulleys.

4.Installthenewdrivebeltsonthepulleys.

5.Slidetheenginetotheleftuntilthebeltshave

thecorrecttension;refertoAdjustingthe

Drive-beltT ension(page39).

6.T orquethe4mountingnutsandboltsto24N∙m

(18ft-lb)each(Figure56).

7.Installthedividerplate;refertoInstallingthe

DividerPlate(page30).

Figure56

1.Engine-mountingnutsandbolts(4each)

6.Slidetheenginelefttoincreasetensiononthe

drivebeltorrighttodecreasetension.

g020391

39

Page 40

Cleaning

CleaningtheMachine

Regularcleaningandwashingwithmilddetergentand

waterincreasesthelifespanofthemachine.Clean

themachineaftereachusebeforethedirthardens.

Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleandirtand

concretematerialsfromtheoutsideoftheengine.

Ensurethatthefuelcapandtheoil-llcap/dipstickare

securetoavoidgettingwaterintheengine.

Usecarewhenusingahigh-pressuresprayer

becauseitcandamagethesafetydecals,instruction

signs,andtheengine.

Important:Lubricatethebearingsandsealsafter

cleaning;refertoLubricatingtheMachine(page

31).

40

Page 41

Storage

plug.

Note:Donotinstallthewireonthespark

Forstorageover30days,preparethemachineas

follows:

1.Removedirtandgrimefromtheexternalpartsof

theentiremachine,especiallytheengine.Clean

dirtanddebrisfromtheoutsideoftheengine

cylinder-headnsandblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.

2.Conditionthefuelsystemasfollows:

A.Addapetroleum-based

stabilizer/conditionertofuelinthe

tank.Followthemixinginstructionsfrom

thestabilizermanufacturer.Donotuse

analcohol-basedstabilizer(ethanolor

methanol).

Important:Donotstore

stabilizer/conditionedfuelover90

days.

Note:Fuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfueland

usedatalltimes.

B.Runtheenginefor5minutestodistribute

theconditionedfuelthroughthefuelsystem.

C.Shutofftheengine,allowittocool,and

drainthefueltankusingapump-type

siphon.Disposeoffuelproperly;recycleit

accordingtolocalcodes.

D.Starttheengineandrunituntilitstops.

E.Choketheengine.

F.Startandruntheengineuntilitdoesnot

startagain.

3.Cleanthesedimentcup;refertoCleaningthe

Fuel-SedimentCup(page36).

4.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page31).

5.Changetheengineoil;refertoChangingthe

EngineOil(page33).

6.Removethesparkplugandcheckthecondition;

refertoServicingtheSparkPlug(page34).

7.Conditiontheengineasfollows:

A.Pour2tablespoonsofengineoilintothe

spark-plughole;refertoRemovingthe

SparkPlug(page34).

B.Pulltherecoil-starthandleslowlytocrank

theengineanddistributetheoilinsidethe

cylinder.

C.Installthesparkplug;refertoServicingthe

SparkPlug(page34).

8.Greasethemachine;refertoLubricatingthe

Machine(page31).

9.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamaged.

10.Paintallscratchedorbaremetalsurfaceswith

paintavailablefromyourAuthorizedService

Dealer.

11.Storethemachineinaclean,drygarageor

storagearea.

12.Coverthemachinetoprotectitandkeepitclean.

41

Page 42

Troubleshooting

Problem

Theenginedoesnotstart.

Theenginelackspowerorrunsrough.

PossibleCauseCorrectiveAction

1.Theengineswitchonthecowlisinthe

STOPposition.

2.ThefuelvalveisintheOFFposition.2.Movethefuel-valvelevertotheON

3.Thechokeisopen.

4.Thechokeisclosed.

5.TheengineOn/OffswitchisintheOFF

position.

6.Theengine-oillevelislow.6.Filltheenginetotheproperlevelwith

7.Thefueltankisempty.7.Fillthefuelstankwithfreshfuel.

8.Thespark-plugwireislooseor

disconnected.

9.Thesparkplugisfouledorimproperly

gapped.

10.Thesparkplugiswetwithfuel(ooded

engine).

11.Thefuelisoldorbad.11.Drainthefueltankandcarburetor.Fill

1.Theairlterisrestricted.

2.Theenginecontainsbadoroldfuel.

3.Thereiswaterorcontaminationinthe

fuel.

4.Thefuellineisrestricted.4.Cleanthefuellterandsedimentcup.

5.Thechokeisclosed

6.Thesparkplugiswornorhasbuildup

ontheelectrodes.

7.Thereistoomuchoilintheengine

crankcase.

1.PresstheengineswitchtotheRUN

position.

position.

3.Closethechokewhenstartingacold

engine.

4.Openthechokewhenstartingahot

engine.

5.TurntheswitchtotheONposition.

therecommendedoil.

8.Connectthespark-plugwire.

9.Gaporreplacethesparkplug.

10.Removethesparkplug,dryit,and

installtheplug.Starttheenginewith

thethrottleintheMAXposition.

thefueltankwithfreshfuel.

1.Cleanorreplacetheair-lter

element(s).

2.Drainthefueltankandcarburetor.

Refuelwithfreshfuel.

3.Drainthefueltankandcarburetor.

Refuelwithfreshfuel.

5.Openthechoke.

6.Checktheelectrodegapandadjustor

replacethesparkplug.

7.Draintheoiltotheproperlevel.

Thedrivebeltsarewornorburned,orthey

jumpoffthepulley.

Thedrumdoesnotturn.1.Thebeltsarelooseordamaged.

Thedrumdoesnottilt.1.Thedrum-tiltbrakeisengaged.1.Disengagethedrum-tiltbrake.

Thedrumchattersorturnserratically .

1.Thedrive-belttensionneeds

adjustment.

2.Thedrivebeltsmaybestretched.2.Replacethedrivebelts.

3.Thepulleysareoutofalignment.

1.T eetharemissingfromthegears.

2.Thegearsaremisaligned.

1.Thereisdebrisinthedrum.1.Removethedebris. Themachinevibratesexcessively .

2.Themixingpaddlesaredamaged.

1.Adjustthedrive-belttension.

3.ContactyourAuthorizedService

Dealer.

1.Checkthedrivebelts.

1.ContactyourAuthorizedService

Dealer.

2.ContactyourAuthorizedService

Dealer.

2.ContactyourAuthorizedService

Dealer.

42

Page 43

Notes:

Page 44

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproductsAdditionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerwithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalprovideexposurelimitrequirements.WhiletheexposurefromToroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...