Page 1

FormNo.3378-862RevA

g021660

CM-250E-PCandCM-250E-PWB

ConcreteMixer

ModelNo.68001—SerialNo.313000001andUp

ModelNo.68003—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3378-862*A

Page 2

WARNING

g021796

1

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

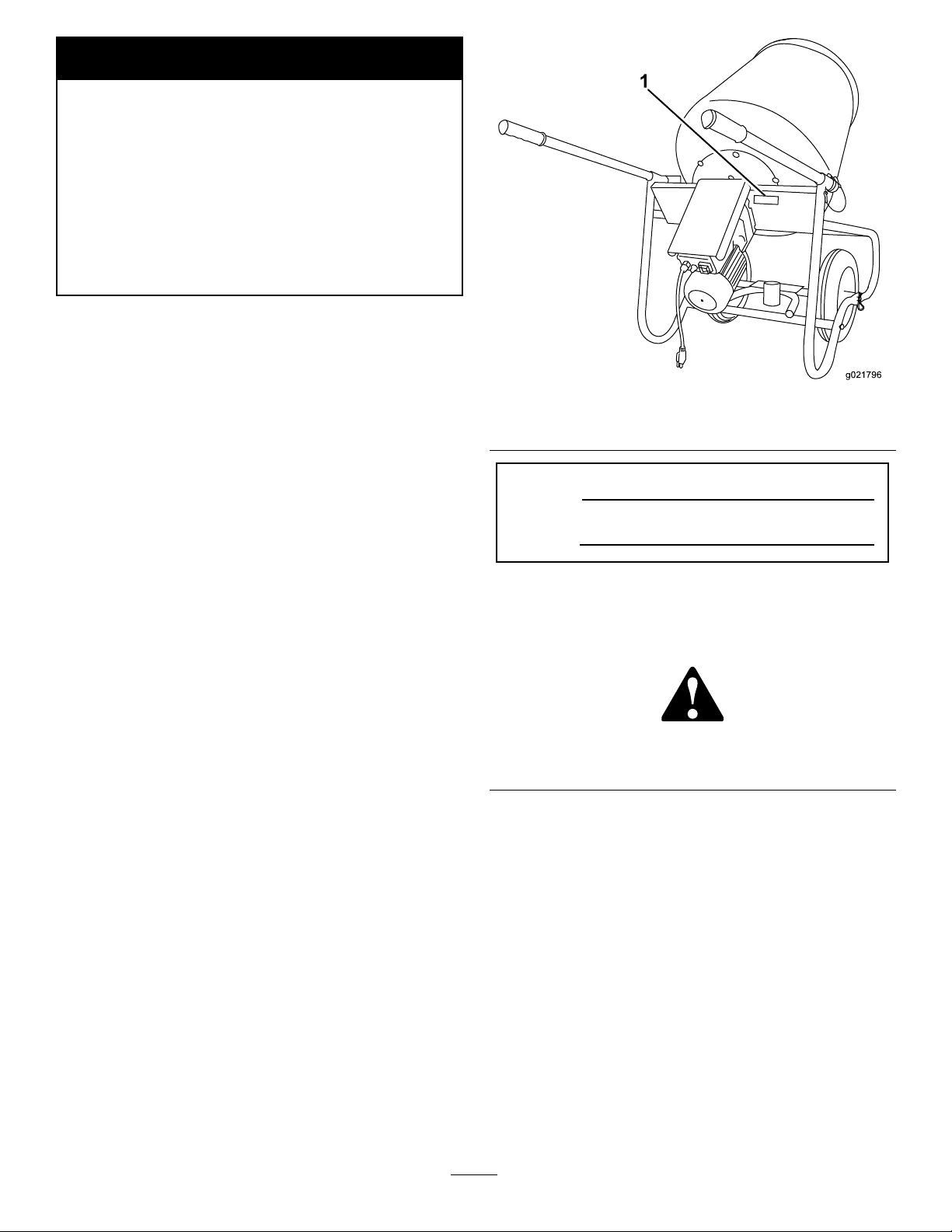

Introduction

Thismachineisdesignedtomixconcreteproducts.

Figure1

1.Modelandserialnumberplate

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .

Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2)

Whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................5

Setup............................................................................6

1InstallingtheWheelsandAxle................................6

2InstallingtheFrameStop.......................................6

3InstallingtheMotor...............................................6

4InstallingtheDrum...............................................7

5InstallingtheMotorCover.....................................8

6InstallingtheHandlebars.......................................8

ProductOverview..........................................................9

Controls................................................................9

Specications.........................................................9

Operation....................................................................10

OperatingtheMachine............................................10

ElectricalPower.....................................................10

StartingandStoppingtheMotor...............................11

UsingthePedestal..................................................11

MixingtheMaterial.................................................13

Maintenance.................................................................14

RecommendedMaintenanceSchedule(s)......................14

Lubrication...............................................................14

OiltheGearbox.....................................................14

Cleaning...................................................................14

............................................................................14

Storage........................................................................15

............................................................................15

Troubleshooting...........................................................16

Improperuseormaintenanceofthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans:

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

Caution

,

W ar ning

WARNING

Machiningorhandlingstone,masonry,concrete,

metal,andothermaterialscangeneratedust,mists,

andfumescontainingchemicals,suchassilica,

knowntocauseseriousorfatalinjuryorillness,

suchasrespiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Usewaterfordustsuppression

whenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupationaland

tradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyOSHAfor

thematerialbeinghandled.

,

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriestopeople,ordamagetoproperty.

Preparation

•W earappropriateclothingincludinghardhat,faceshield,

safetyglasses,longpants,safetyshoes,andhearing

3

Page 4

protection.Longhair,looseclothing,orjewelrymayget

tangledinmovingparts.

•Connectthemachineonlytoa3-polereceptaclewithlive,

neutral,andgroundcircuits.

•Wheneverpossible,usecircuitsorreceptaclesprotected

withaGroundFaultCircuitInterrupter(GFCI)device.

•Inspecttheelectricalcordsfordamage.Replacethe

damagedcordbeforeoperatingthemachine.

•Inspecttheelectricalplugandsocketsfordamage.

Replacethedamagedelectricalconnector(s)before

operatingthemachine.

•Keepelectricalconnectorsoffthegroundanddry.

Operation

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryduringoperationif

theoperatorisnotattentivetothesurroundings.Operate

themachineinareaswherethereissufcientclearance

fortheoperatortosafelymaneuverthemachine.

•Keephandsandfeetawayfromthemovingparts.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Neverleavearunningmachineunattended.

•Beforeworkingonthemixer,stopthemotorandunplug

themachine.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Locatethepinchpointareasonthemachineandkeep

handsandfeetawayfromtheseareas.

•Donotoperatethemachineatavoltageotherthanthe

voltagespeciedonthedataplateofthemotor.

•Donotoperatethemachineinstandingwater.

•Donotoperatethemachineintherain.

•Donotusewithdamagedcordorplug.Ifmachineisnot

workingasitshould,hasbeendropped,damaged,left

outdoors,ordroppedintowater,returnittoaservice

dealer.

•Donotpullorcarrybycord,usecordashandle,closea

dooroncord,orpullcordaroundsharpedgeorcorners.

Keepcordawayfromheatedsurfaces.

•Donotunplugbypullingoncord.T ounplug,graspthe

plug,notthecord.

•Whenusinganextensioncordandanin-lineGround

FaultCircuitInterrupter(GFCI)device,installtheGFCI

deviceasclosetotheelectricalsourceaspossible.

•EnsurethattheOn/OffswitchisrotatedtotheOff

positionbeforeconnectingthemachinetotheelectrical

source.

•Themotorandmotorshroudmaybehot.Allowtocool

beforepreforminganyservicework.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

MaintenanceandStorage

•Stopthemotor.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

•Unplugthemachinebeforemakinganyrepairs.

•Cleandebrisfromthegears,drives,drum,andmotor.

•Letthemotorcoolbeforestoring.

•Neverserviceoradjustmachinewhileitismoving.

•Alwayssetthemachineonlevelground.

•Neverallowuntrainedpersonneltoservicethemachine.

•Donotmodifytheelectricalconnectorsorwiring.

•Donotconnectthegroundcircuitofthemachinetothe

energizedcircuitoftheelectricalsource.

•Keephandsandfeetawayfrommovingparts.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Securelysupportanymachineelementsthatmustbe

raisedforservicework.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Stopandinspecttheequipmentifthemachine

unexpectedlystops.Makenecessaryrepairsbefore

restarting.

•Disposeofwasteproperly .Improperlydisposedwaste

canthreatentheenvironment.

•Storethemachineindoors.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Donothandleplugorappliancewithwethands.

•Turnoffallcontrolsbeforeunplugging.

•Useonlya3-wireextensioncordswithterminalsand

socketsforthelive,neutral,andgroundcircuits.

4

Page 5

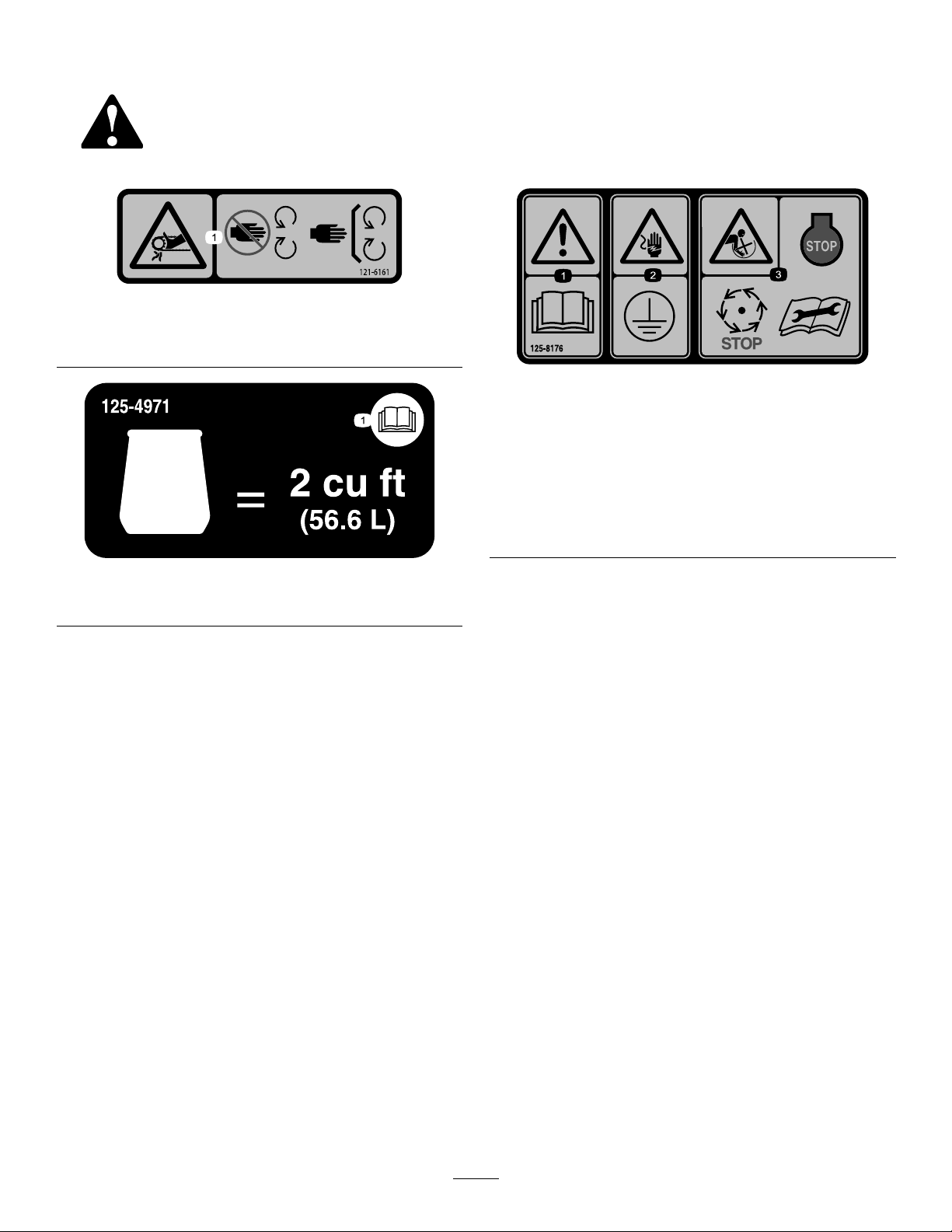

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

121–6161

1.Entanglementhazard,belt—keephandsawayfrommoving

parts;keepallguardsandsafetiesinplace.

125–8176

125–4971

1.ReadtheOperator’sManual.

1.Warning—readthe

Operator’sManual.

2.Electricshock

hazard—properlyground

equipmentbeforeuse.

3.Entanglement,severing

hazard—stoptheengine

andwaitforallmoving

partstostopbefore

performingmaintenance

onthemachine.

5

Page 6

Setup

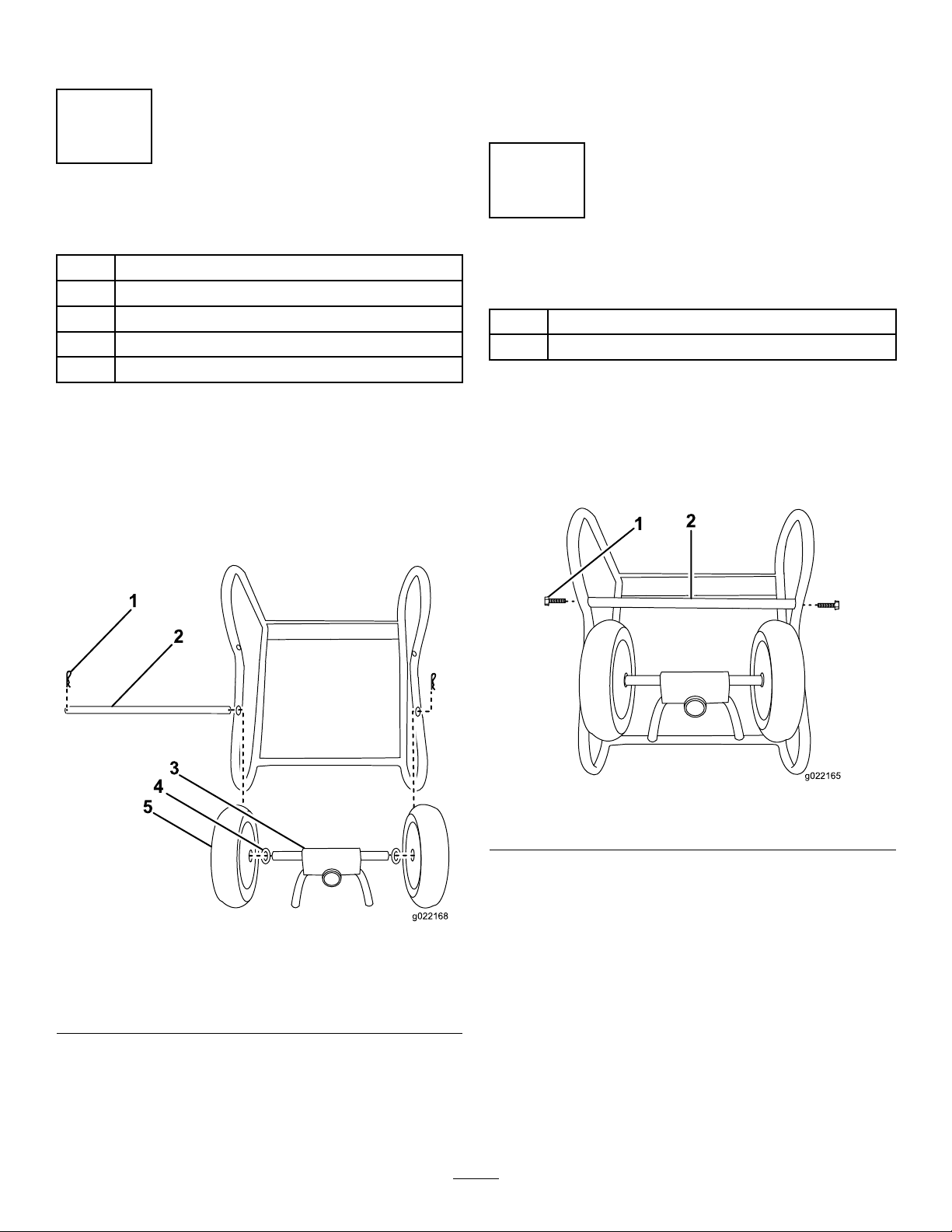

g022168

1

2

3

4

5

g022165

1

2

1

InstallingtheWheelsandAxle

Note:Ifyouarenotusingthepedestal,youmayusea

spaceraxlepieceinsteadofthepivotmountplate.

3.Securethewheelsandaxlerodinplacewithcotter

pins;refertoFigure3.

2

Partsneededforthisprocedure:

2

Cotterpin

1Axlerod

1Pivotmountplate

2Washer

2Wheel

Procedure

Note:Thepivotmountplateisincludedwithpedestal

model(68001).Aspaceraxleisusedonthewheelbarrow

onlymodel(68003).

1.Slidetheaxlerodintotheframeofthemachine;refer

toFigure3.

InstallingtheFrameStop

Partsneededforthisprocedure:

2Bolts

1Framestop

Procedure

Note:Theframestopisincludedonlywiththepedestal

(model68001).

Installtheframestop;refertoFigure4.

1.Cotterpin

2.Axlerod5.Wheel

3.Pivotmountplate

2.Slidetheaxlerod,wheels,washers,andpivotmount

plateintoplace;referto

Note:Thewheelsshouldhavethesidewiththegrease

ttingsfacingoutward.

Figure3

4.Washer

Figure3.

Figure4

1.Bolt2.Framestop

6

Page 7

3

1

2

3

4

g022156

1

2

g022157

4

InstallingtheMotor

Partsneededforthisprocedure:

1ElectricMotor

4Nut

4Washer

4LockWasher

Procedure

1.Movethemotorintopositionontheframeofthe

machine;refertoFigure5.

InstallingtheDrum

Partsneededforthisprocedure:

1Drum

1Bolt

1Nut

Procedure

1.Movethedrumintoplace;refertoFigure6.

Figure5

1.Nut3.Washer

2.Lockwasher4.Motor

2.Securethemotorontothemachinewithnuts,washers,

andlockwashers;refertoFigure5.

Figure6

1.Drum2.Motor

2.Connectthedrumtothemotorwiththeboltandnut.

RefertoFigure7.

7

Page 8

1

2

3

4

g022158

Figure7

g022175

1

2

3

g021661

1

2

1.Bolt3.Drum

2.Nut4.Motor

Figure8

1.Motorcover3.Nuts

2.Bolts

5

InstallingtheMotorCover

Partsneededforthisprocedure:

1Motorcover

2Bolt

2Nut

Procedure

Fastenmotorcovertotheframeofthemachine;referto

Figure8.

6

InstallingtheHandlebars

Partsneededforthisprocedure:

2Handlebar

2

HandlebarGrips

Procedure

1.Slidehandlebarsintoplace,andsecurethemusingthe

lockingpin(Figure9).

Figure9

1.Lockingpin2.Handlebar

2.Slidetherubberhandgripsintoplace.

8

Page 9

ProductOverview

g021662

1

2

3

4

2

3

1

g021663

Figure10

1.Dumphandles3.Drum

2.Powercord4.Electricmotor

Figure11

Controls

MotorControls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

motorandoperatethemachine.

1.Powercord

2.Resetbutton

3.On/Offswitch

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Capacity:ConcreteVolume

Total(wet)

Length

Width

Height

Weight

Motor0.5HP;110–120volt;5.3

61.6cm(24.25inches)

56.6L(2cuft)

127cm(50inches)

101.6cm(40inches)

55.79Kg(123lbs)

amperes;60Hz

9

Page 10

Operation

g021664

damagedcord.Donotrunthecordthroughstanding

waterorwetgrass.

Important:Beforeoperating,removedebrisfromthe

machine.Also,ensurethattheareaisclearofpeople

anddebris.

OperatingtheMachine

•Reviewallofthesafetydecals.

•Useahard-hat,andeyeprotection.Ameshvisoralone

doesnotprovidesufcienteyeprotection;supplementit

withprotectiveglasses.

•Ensurethatyouarefamiliarwiththesafetyregulations

andshutdownproceduresdescribedinthismanual.

•Ensurethateveryone,includingchildrenandanimals,

maintainadistanceofatleast15m(50feet)fromthe

machine.

ElectricalPower

ConnectingtoaPowerSource

DANGER

Contactwithwaterwhileoperatingtheproduct

couldcauseelectricshock,causinginjuryordeath.

•Don'thandletheplugorthemachinewithwet

handsorwhilestandinginwater.

•Useonlyanextensioncordrecommendedfor

outdooruse.

Important:Useonly3-wireextensioncordswith

terminalsandsocketsforthelive,neutral,andground

circuits.

Important:Onlyconnectthemachinetoa3-pole

receptaclewithlive,neutral,andgroundcircuits.

Important:Theconnectingwiresorextensioncord

shouldbeasshortaspossibleandinonepiece.

Important:Onlyplugthemachineinto115single

phase,60–cycle,fusedoutlets.

Important:Donotuseanextensioncordover30.4m

(100ft)long.

Important:Onlyusepowercordsthatareratedfor

outdooruse.

Important:Onlyusepowercordsthatareratedforthe

motorloadofthemachine.

Toreducetheriskofelectricshock,thismachinehas

polarizedplugs(i.e.,uniquebladeshapesandwidths).Use

onlyapolarizedplugandsocketthatiscompliantwith

NEMAspecicationsandextensioncordsthatareUL-listed

(CSAcertiedinCanada)andrecommendedforoutdooruse.

Apolarizedplugwilltinapolarizedcordonlyoneway.If

theplugdoesnottfullyinthecord,reversethecord.Ifit

stilldoesnott,purchaseapolarizedextensioncord.Ifyou

haveapolarizedextensioncordandtheextensioncordplug

doesnottfullyintothewallreceptacle,reversetheplug.

Ifitstilldoesnott,contactaqualiedelectriciantoinstall

theproperoutlet.Donotchangethemachineorextension

cordpluginanyway.

Note:Connectthepowercordtotheextensioncordas

showninFigure12.

Figure12

Important:Checktheextensioncordfrequentlyduring

useforholesorcracksintheinsulation.Donotusea

10

Page 11

StartingandStoppingthe

UsingthePedestal

Motor

StartingtheElectricMotor

Important:Checkanyextensioncordcarefullyfor

brokenconnectors,barewires,ordamagedinsulation.

Donotuseanycordfoundtobeinpoorcondition.

Makesurethattheextensioncordisnotroutedthrough

standingwaterandthatallconnectionsaretight.Use

theshortestextensioncordpossible.

1.Plugthepowercordintoany115singlephase,60-cycle,

fusedoutlet.

2.TurnthemotoronbyippingtheOn/Offswitchto

theOnposition;referto

Note:Theswitchismarkedl(On)andO(Off).

StoppingtheElectricMotor

1.TurnthemotoroffbyippingtheOn/Offswitchto

theOffposition;refertoFigure11.

2.Disconnectthepowercord.

Figure11.

Note:ForModel68001only

AssemblingthePedestal

1.Place2halvesofthesupportlegstogether,andinsert

pivottubethroughthecenterofthelegs(Figure13).

2.Insertthelockingpinthroughthebottomofthepivot

tube(Figure13).

ResettingtheElectricMotor

Ifthemotordrawstoomuchcurrent,itwillautomatically

shutoff.Inthatevent,followthesesteps:

1.MovetheOn/OffswitchtotheOffposition;referto

Figure11.

2.Unplugthemachinefromthepowersource.

3.Allowtheelectricmotortocoolfor3to5minutes.

4.Intheeventofamotorshutoff:

•Checktomakesurethemotorfancoverisnot

blocked.

•Checktoseeifthedrumisoverlledorobstructed.

Important:Whenremovinganythingfrom

thedrumbyhand,alwaysmakesurethatthe

machineisunplugged.

•Checktomakesurethatthemachineisplugged

intoacorrectoutlet;refertoConnectingtoa

PowerSource(page10).

5.Presstheresetbutton;refertoFigure11.

6.Plugthemachineintothepowersource.

Figure13

7.MovetheOn/OffswitchtotheOnposition;referto

Figure11.

Note:Ifthemotorcontinuestooverheatafterthese

measureshavebeentaken,takethemachinetoanAuthorized

ServiceDealer.

11

Page 12

AttachingPedestalStandtothe

g019656

1

2

Machine

1.Tipthemixer,asifdumpingcontents,andplaceit

squarelyonthedrumopening.

CAUTION

Thepivotmountwillrotatefreelyaboutthe

axlewhentippingthemixerontothedrum

opening.Therotatingpivotmountcancause

painandinjurytolegs.

Standclearofwheelaxle.

2.Rotatethepivotmountplateawayfromthedrumand

ontothefrontstop(Figure14).

Figure14

1.Pivotmount2.Framestop

3.Insertthepedestalstandassemblythroughthepivot

mount(Figure15).

CAUTION

Use2peopletotiltthemixeruprightontothe

stand.

Figure15

4.Movetothefrontofthemachineandbegintiltingit

uprightontothestand(Figure15).

Note:Alwaysbendyourkneesandusecorrectposture

forlifting.

12

Page 13

WARNING

Donottiltmixeruprightontostandonawet,

uneven,orslipperysurface.Failuretofollow

thisinstructioncouldresultinpersonalinjury

anddamagetotheequipment.

Setupthepedestalonatgroundwith

plentyoftractionbeforeattemptingtotiltthe

machineuprightontothestand.

5.Tiltthemachinetotheuprightmixingposition.

MixingPre-MixConcrete

1.Turnthemachineon.

2.Pourwaterintothedrum.

3.Addtherequiredamountofdrypre-mixconcrete.

4.Allowthedrumtoturnwhilethemixreachesthe

appropriateconsistency.

5.Pourtheproperlymixedconcretequickly .

6.Startnextbatchrightawayorcleanoutthedrum

immediately.

MixingtheMaterial

DANGER

Eyeandskincontactwithconcretematerialsand

breathingthedustinvolvedishazardoustoyour

health.

•Wearadustmasktopreventinhalationofdust

whileusingthemachine;referto

•Avoiddirectcontactofcementandconcrete

materialswithskinandeyes.

Important:Donotaddmorematerialthanthebatch

capacityforyourspecicmachinemodel;referto

Specications(page9).

Note:Followthemanufacturer’sinstructionsthatareprinted

onthepackagingoftheproduct.

Thereare4basicingredientsinconcrete:

•Sand

•Gravel

(page).

MixingSand,Gravel,andCement

Thetypicalratioformixingconcreteis1partPortland

cement,2partssand,and3partsgravel.

1.Turnthemachineon.

2.Pourwaterintothedrum.

3.Addtherequiredamountofgravel.

4.AddtherequiredamountofPortlandcement.

5.Addtherequiredamountofsand.

6.Allowthedrumtoturnwhilethemixreachesthe

appropriateconsistency.

7.Pourtheproperlymixedconcretequickly .

8.Addthewaterandgraveltothedrumtobeginnext

batchandloosenupmixleftbythepreviousbatch.

Note:Addingwaterandgravelbeforecementandsand

allowsthemixleftinthedrumfromthepreviousbatchto

tumbleoffthedrumandpaddlesandintothenextbatch.

•Portlandcement

•Water

Dependingontheapplicationyoucanusedifferentratios

ofthese4ingredients.

Therearemanyvariationsofconcretemixrecipes,depending

ontheapplication.Itisimportanttousetheappropriate

quantityofwater.Usingtoolittlewaterwillresultindryareas

inthemix,butusingtoomuchwaterwillresultinweaker

concrete.Theamountofwaterneededwillvarydepending

onmoisturecontentofthesandandgravel.Themixshould

haveathicknesssimilartopeanutbutter.

Keepthepouredconcretedampforseveraldaystoobtain

propercuring.Evaporationresultsinweakerconcrete.

Concretecuresthroughhydration,areactionbetweenwater

andcement.

13

Page 14

Maintenance

g021812

1

2

4

3

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftereachuse

Every200hours

Important:RefertoyourMotorOperator'sManualforadditionalmaintenanceprocedures.

Lubrication

OiltheGearbox

ServiceInterval:Every200hours

1.Removethemotorcover(Figure16).

MaintenanceProcedure

•Removedebrisfromthemachine.

•Cleanthemachine.

•Drainandreplacetheoilinthegearbox.

Cleaning

Coatthedrumandframewithaconcretepreventative.This

willmakecleaningthemachineeasier.

Regularcleaningandwashingwillincreasethelifespanof

themachine.Cleanthemachinedirectlyafteruse,beforethe

cementhardens.

Usecarewhenusingahigh-pressuresprayer,becauseitcan

damagewarningdecals,instructionsigns,andthemotor.

Washthemachinewithmilddetergentandwater.Donot

getthemotorwet.

Figure16

1.Motorcover3.Nuts

2.Bolts

2.Removetheoilplug(Figure16).

3.Draintheoil.

Note:Carefullyipthemachineupsidedowntoa

waitingoilpanfortheoiltodrain.Whennished,ip

themachineright-sideup.

4.Pour0.2L(8.0oz)ofoilintothegearbox.

Note:UseMobil1LS75W–90GearLubricantor

equivalent.

5.Installtheoilplugandmotorcover.

4.Oilplug

14

Page 15

Storage

Forstorageover30days,preparethemachineasfollows:

1.Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallythemotor.Cleandirtand

concretefromtheinsideandoutsideofthedrum;refer

toCleaning(page14).

2.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

3.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

4.Inspecttheelectricalcordandelectricalconnectorsfor

damage.

5.Storethemachineinaclean,drygarageorstoragearea.

6.Coverthemachinetoprotectitandkeepitclean.

15

Page 16

Troubleshooting

Problem

Theelectricmotorwillnotstart.

Themotorrunsbutthemixerrotationis

underpowered.

PossibleCauseCorrectiveAction

1.Theconnectorforthemachineisnot

pluggedintoapowersource.

2.Thecurrentprotectorfortheelectrical

sourceisopen.

1.Thedrumisoverlled.

2.Extensioncordistoolongortoohigh

ofagauge.

1.Plugtheconnectorintoasocketor

andextensioncordfromanelectrical

source.

2.Resetthecircuitprotector .

1.Dumpoutconcreteuntilthemotorruns

atfullpower.

2.Pluginmixerusingshorterextension

cordorcordofalowergauge.

16

Page 17

Notes:

17

Page 18

Notes:

18

Page 19

Notes:

19

Page 20

ToroCompactUtilityEquipmentWarranty

AOne-YearLimitedWarranty

CUEProducts

ConditionsandProductsCovered

TheT oro®Companyanditsafliate,T oroWarrantyCompany ,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCompactUtility

Equipment(“Product”)tobefreefromdefectsinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

Loaders,Trenchers,StumpGrinders,

Chippers,LogSplittersandAttachments

KohlerEngines3years

AllotherEngines2years

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1yearor1000operating

hours,whicheveroccursrst

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroCompactUtilityEquipment(CUE)

ServiceDealertoarrangeserviceattheirdealership.Tolocatea

dealerconvenienttoyou,accessourwebsiteatwww.Toro.com.

YoumayalsocallourToroCustomerCareDepartmenttollfree

at888-865-5676(U.S.customers)or888-865-5691(Canadian

customers).

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

LCBCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1 196

TollFree:888-865-5676(U.S.customers)

TollFree:888-865-5691(Canadacustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

Partsscheduledforreplacementasrequiredmaintenance(“Maintenance

Parts”),arewarrantedfortheperiodoftimeuptothescheduled

replacementtimeforthatpart.Failuretoperformrequiredmaintenance

andadjustmentscanbegroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thisexpresswarranty

doesnotcoverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,teeth,tines,

blades,sparkplugs,tires,tracks,lters,chains,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecalsorwindows,

etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedT oroCompactUtilityEquipment(CUE)Service

Dealerisyoursoleremedyunderthiswarranty .

NeitherTheToro®CompanynorToroWarrantyCompanyisliable

forindirect,incidentalorconsequentialdamagesinconnectionwith

theuseoftheToroProductscoveredbythiswarranty ,including

anycostorexpenseofprovidingsubstituteequipmentorservice

duringreasonableperiodsofmalfunctionornon-usepending

completionofrepairsunderthiswarranty.Allimpliedwarranties

ofmerchantabilityandtnessforusearelimitedtotheduration

ofthisexpresswarranty.Somestatesdonotallowexclusionsof

incidentalorconsequentialdamages,orlimitationsonhowlong

animpliedwarrantylasts,sotheaboveexclusionsandlimitations

maynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

ThehourlimitationssetforthabovedonotapplytotheEmissions

ControlSystemWarranty.RefertotheCaliforniaEmissionControl

WarrantyStatementsuppliedwithyourProductorcontainedintheengine

manufacturer’sdocumentationfordetails.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany .

374-0261RevB

Loading...

Loading...