Page 1

Installation Procedure

To assure maximum performance from your 640 Series

Rotary Sprinklers, read these instructions completely prior to

installing or servicing the sprinkler.

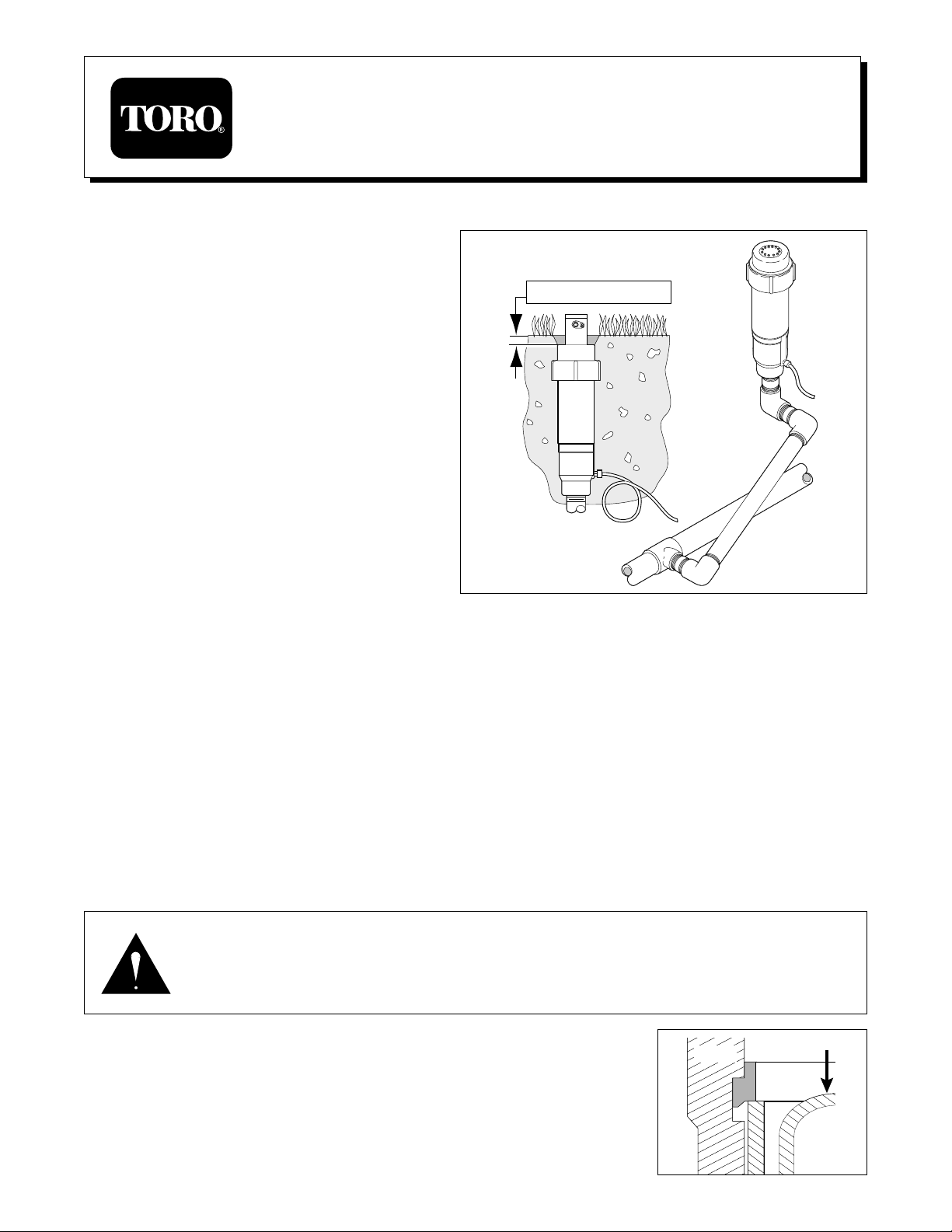

Construct Swing Joints

1. Construct triple swing joints for each sprinkler as shown

in Figure 1. Use PVC or ABS pipe nipple for sprinkler

connection.

Note: On sites where the possibility of heavy equipment

rolling over a sprinkler exists, the swing joint will flex

preventing damage to the lateral or main lines. On a new

installation in raw ground where the sprinklers are to be

initially installed above the finished grade and lowered

when new turf is established, the swing joint allows

sprinkler repositioning without changing risers. This is a

common and practical procedure which eliminates the

problem of dirt being accidentally introduced into the

lateral lines when a riser is changed.

2. Flush lines thoroughly prior to installing sprinkler.

3. Apply Teflon

™

tape on riser threads. Install sprinkler to

riser and tighten.

CAUTION

Use only Teflon tape on riser threads. Use of pipe dope or other types of sealing compounds can

cause deterioration of plastic threads and components.

4. Install sprinkler on riser. Align part-circle heads by rotating sprinkler body on riser until radius adjustment slot on top of the nozzle

rubber cover is positioned to the left side of the intended coverage area.

5. Valve-In-head models only: Remove tube retainer and cap from sprinkler fitting. Provide a service loop in control tube at

sprinkler to prevent binding. Slide tube retainer over end of control tube. Push control tube onto sprinkler fitting and secure with

tube retainer.

6. Install sprinklers flush with grade to 1/2 in. (0–13mm) below grade.

7. Backfill and compact soil around sprinkler avoiding contact with nozzle assembly.

Servicing the Sprinkler

Valve Replacement

WARNING

POSITIVELY SHUT OFF WATER SUPPLY AT SOURCE PRIOR TO DISASSEMBLING SPRINKLER.

BLEED ALL PRESSURE FROM SPRINKLER SYSTEM INCLUDING CONTROL TUBES. FAILURE TO

DEPRESSURIZE SYSTEM PRIOR TO VALVE SNAP RING REMOVALMAY CAUSE VALVE MECHANISM

TO FORCIBLY EJECT FROM SPRINKLER BODY RESULTING IN POSSIBLE SERIOUS INJURY.

1. Remove cap set screw with 1/8 in. hex wrench and unscrew cap.

2. Remove nozzle container seal, nozzle retainer and nozzle/drive assembly from body.

3. Depress valve mechanism using a long screwdriver or similar tool (see CAUTION below).

CAUTION

Do not continue valve removal procedure if the valve cannot be pressed

down with minimum force. Confirm that water pressure is off and the

control tube is bled before continuing.

1

Installation and Service Instructions

640 Series Rotary Sprinkler

0 in.–1/2 in. (0–13mm)

FIGURE 1

Body

Snap

Ring

Valve

Page 2

4. With the valve depressed, grasp snap ring "ears" with TORO snap ring pliers

(Model No. 995-07), release snap ring from groove and remove from body.

5. Remove valve mechanism with TORO Valve Removal Tool (Model No. 995-08) or

carefully grasp one valve rib with snap ring pliers, pulling valve up and out of body.

6. Reassemble valve mechanism in reverse order.

Note: Due to limited work space in 640 sprinklers, use of Toro Valve Insertion Tool

(Model No. 995-35) is recommended to simplify valve and snap ring installation.

7. See Reinstalling Nozzle/Drive Assembly.

Changing Nozzle and Stator

Note: Nozzle changes may be accomplished by

changing the entire nozzle assembly or by removing

the nozzle container end changing only the upper

nozzle. In either case, the appropriate matching

stator must be installed (i.e., No. 42 Nozzle and No.

42 Stator, etc.) to ensure proper sprinkler operation.

Changing Complete Nozzle Assembly

1. Remove cap set screw with 1/3 in. hex wrench and

unscrew cap.

2. Remove nozzle container seal, nozzle retainer and

nozzle/drive assembly from body.

3. Remove 1/16 in. allen set screw in side of nozzle

canister.

4. Unscrew nozzle assembly from drive assembly.

5. Assure nozzle seal is located at bottom of nozzle

base threads.

6. Install new nozzle assembly — HAND-TIGHTEN

ONLY, DO NOT OVER-TORQUE.

7. Turn set screw clockwise until contact with riser

threads is made (see CAUTION below).

CAUTION

Do not over-torque set screw. Over-tightening

will cause thread damage and possible water

leak between lower nozzle base and drive

assembly.

8. Remove boss on nozzle rubber cover to identify drive

assembly arc.

2

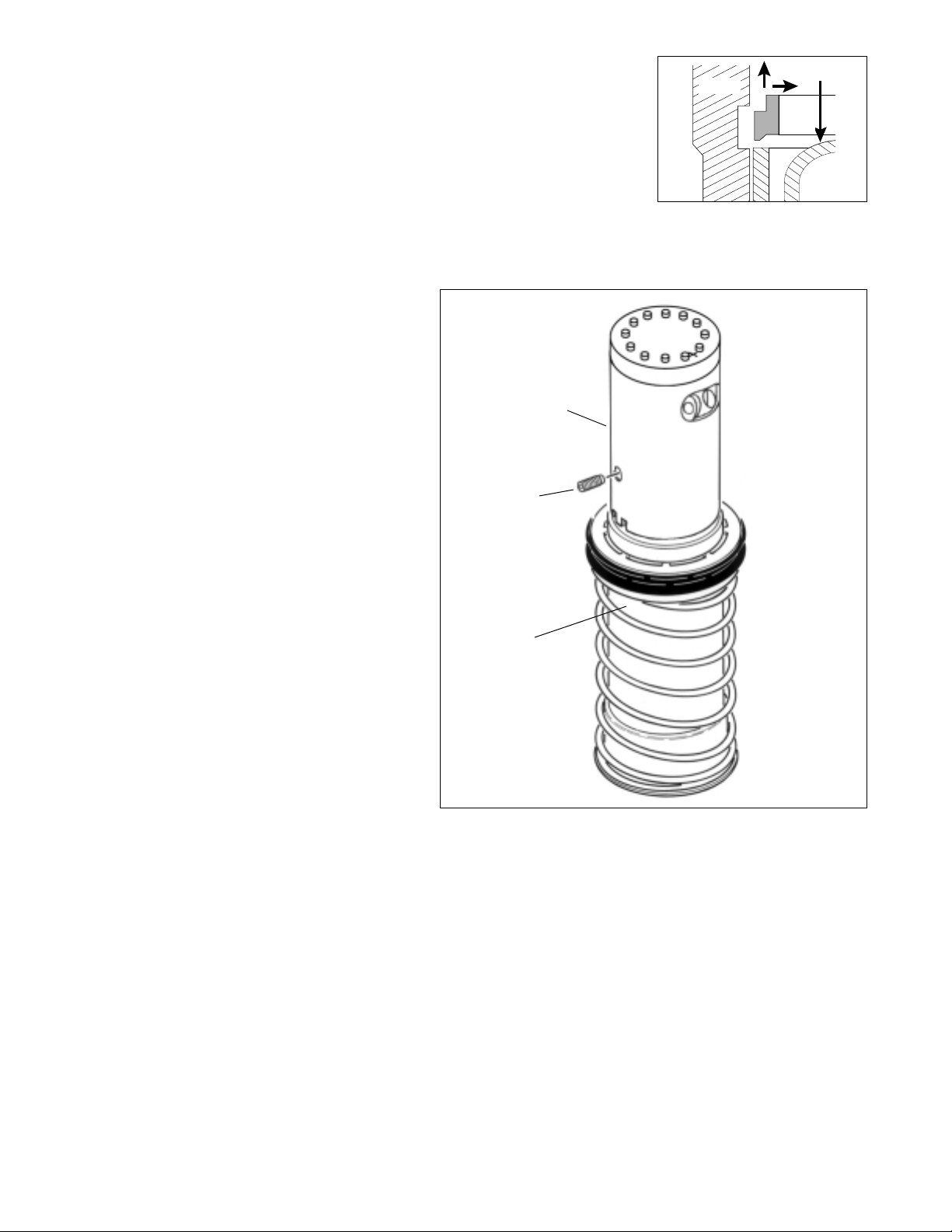

FIGURE 2

Body

Valve

Set Screw

Drive

Assembly

Nozzle

Assembly

Snap

Ring

Page 3

Changing Upper Nozzle

Note: Some of the nozzle assembly components

shown in the following procedure are no longer

available from Toro as service parts. This procedure

should only be used if the upper nozzle assembly is

already on hand.

1. Remove cap set screw with 1/8 in. hex wrench and

unscrew cap.

2. Remove nozzle container seal, nozzle retainer and

nozzle/drive assembly from body.

3. Straighten locking tabs on nozzle container with

nozzle container removal tool, Model No. 995-42 or

other appropriate tool (see Figure 3).

4. Remove nozzle container, nozzle screws and upper

nozzle assembly (see Figure 4).

5. Position new upper nozzle assembly and secure with

nozzle screws. DO NOT OVER-TIGHTEN

SCREWS. (See Figure 4 and Note below.)

Note: Over-tightening nozzle screws will expand

plastic nozzle base causing difficult nozzle container

replacement.

6. Align nozzle opening in container with nozzle orifices and press container downward until fully seated on nozzle assembly.

7. Bend locking tabs into notches approximately 90° to secure nozzle container.

Changing Stator

1. Place nozzle/drive assembly on a flat

work surface, nozzle down, and

compress return spring to expose

stator assembly (see Figure 5).

2. Separate stator from drive assembly

(held together by press fit) and

CAREFULLY relieve return spring

tension.

3. Press in new stator assembly to fully

seated position.

3

FIGURE 3

FIGURE 4 FIGURE 5

Container

Removal Tool

995-42

Upper

Nozzle

Assembly

Lower

Nozzle

Assembly

Stator

Assembly

Page 4

Reinstalling Nozzle/Drive Assembly

1. Part Circle Only: Holding drive assembly stationary, slowly rotate nozzle assembly counterclockwise to left side of arc pattern

(see Figure 6).

2. Check drive assembly key tab for approximately 30° upward bend, adjust if necessary (see Figure 7).

3. Insert nozzle/drive assembly into body until seal is approximately one (1) inch below top of body.

Part Circle Only: Align main nozzle orifice with left edge of watering arc before inserting (see Figure 8).

4. Place nozzle retainer over nozzle assembly aligning keyway and drive assembly key (see Figure 9).

5. Rotate nozzle retainer, interlocked

with nozzle/drive assembly, to align

the nearest of six (6) alignment slots

with tabs on body (see Figure 10).

6. Press retainer into body to interlock

alignment slot and body tab.

7. Install riser seal over nozzle

assembly placing peg into retainer

keyway (see Figure 11).

8. Install cap and secure with set

screw.

9. Check watering arc. If minor

adjustments are required (1/6 of a

turn or less); rotate sprinkler body

on riser. Do not make adjustments

by turning nozzle assembly (see

CAUTION below).

CAUTION

Rotating nozzle assembly to

make watering arc adjustments

may cause severe internal

damage to drive assembly.

Note: Refer to Illustrated Parts

Breakout Book Form No. 368-0044

for current parts listing.

4

© 1998 THE TORO COMPANY

Irrigation Division • An ISO 9001-Certified Facility

PRINTING DATE P.O. Box 489 • Riverside, CA 92502 PART NO.

FEBRUARY 1998 REV. E Printed in U.S.A. 362-0052

FIGURE 6 FIGURE 7

FIGURE 9

FIGURE 10 FIGURE 11

FIGURE 8

Rotate

Counterclockwise

Drive

Assembly Key

Nozzle Retainer

Keyway

(Shaded Area)

Nozzle Retainer

Keyway

Body

Tab

Alignment Slots

Riser

Seal Peg

Nozzle

Retainer

Keyway

Drive

Assembly

Key

1"

Loading...

Loading...