Page 1

Form No. 3352-284 Rev B

206cc OHV Vacuum Blower

Model No. 62925 —Serial No. 250000001 and Up

Register your product at www.Toro.com Original Instructions (EN)

Page 2

T his spark ignition system complies with Canadian

ICES-002

T he enclosed Engine Owner’ s Man ual is

supplied f or inf or mation r egarding the US

En vir onmental Pr otection Agency (EP A) and

the Calif or nia Emission Contr ol R egulation of

emission systems, maintenance, and w ar ranty .

R eplacements may be order ed thr ough the

engine man uf actur er .

Introduction

R ead this infor mation carefully to lear n ho w to

operate and maintain y our product properly and

to a v oid injur y and product damag e . Y ou are

responsible for operating the product properly

and safely .

Y ou ma y contact T oro directly at www .T oro .com

for product and accessor y infor mation, help

finding a dealer , or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts ,

or additional infor mation, contact an A uthorized

Ser vice Dealer or T oro Customer Ser vice and ha v e

the model and serial n umbers of y our product

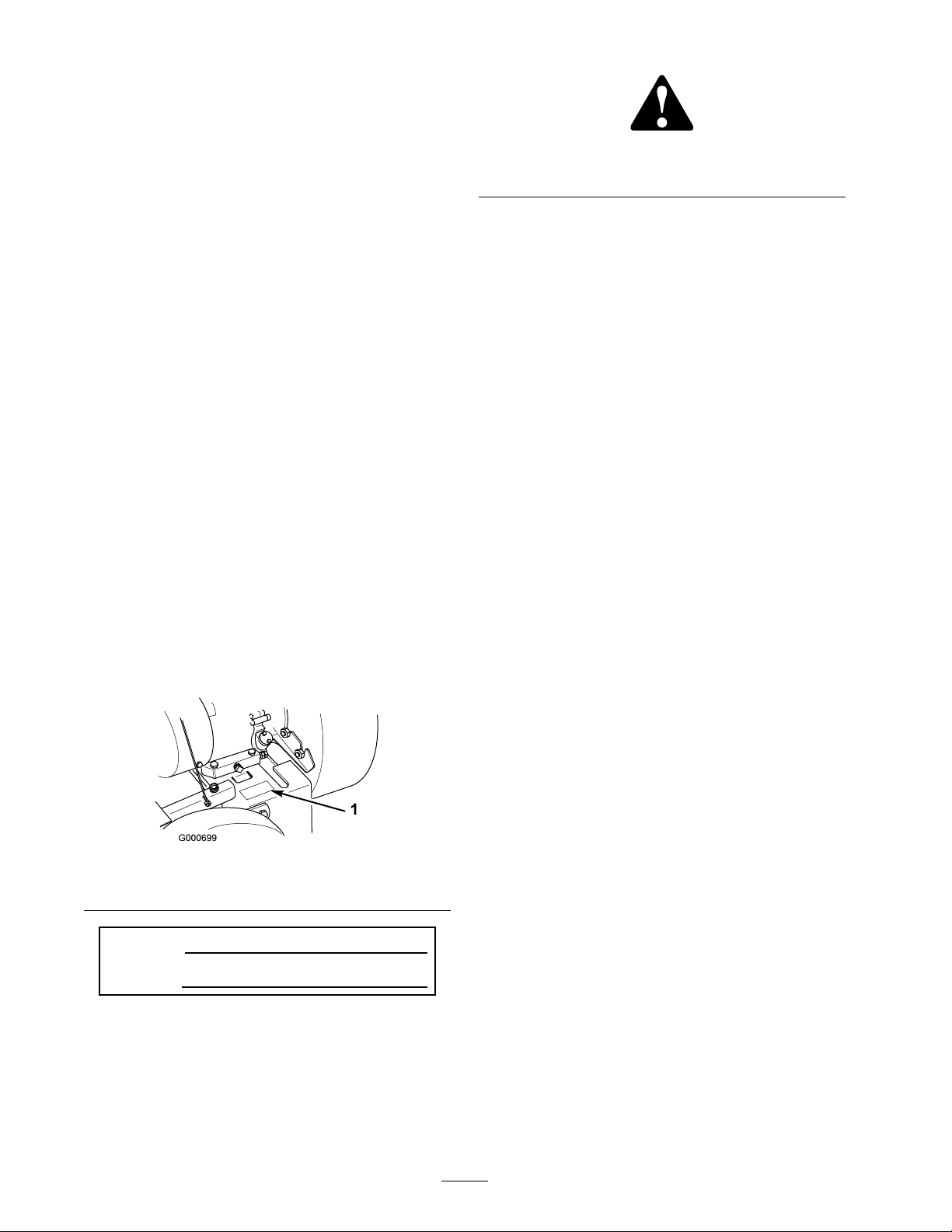

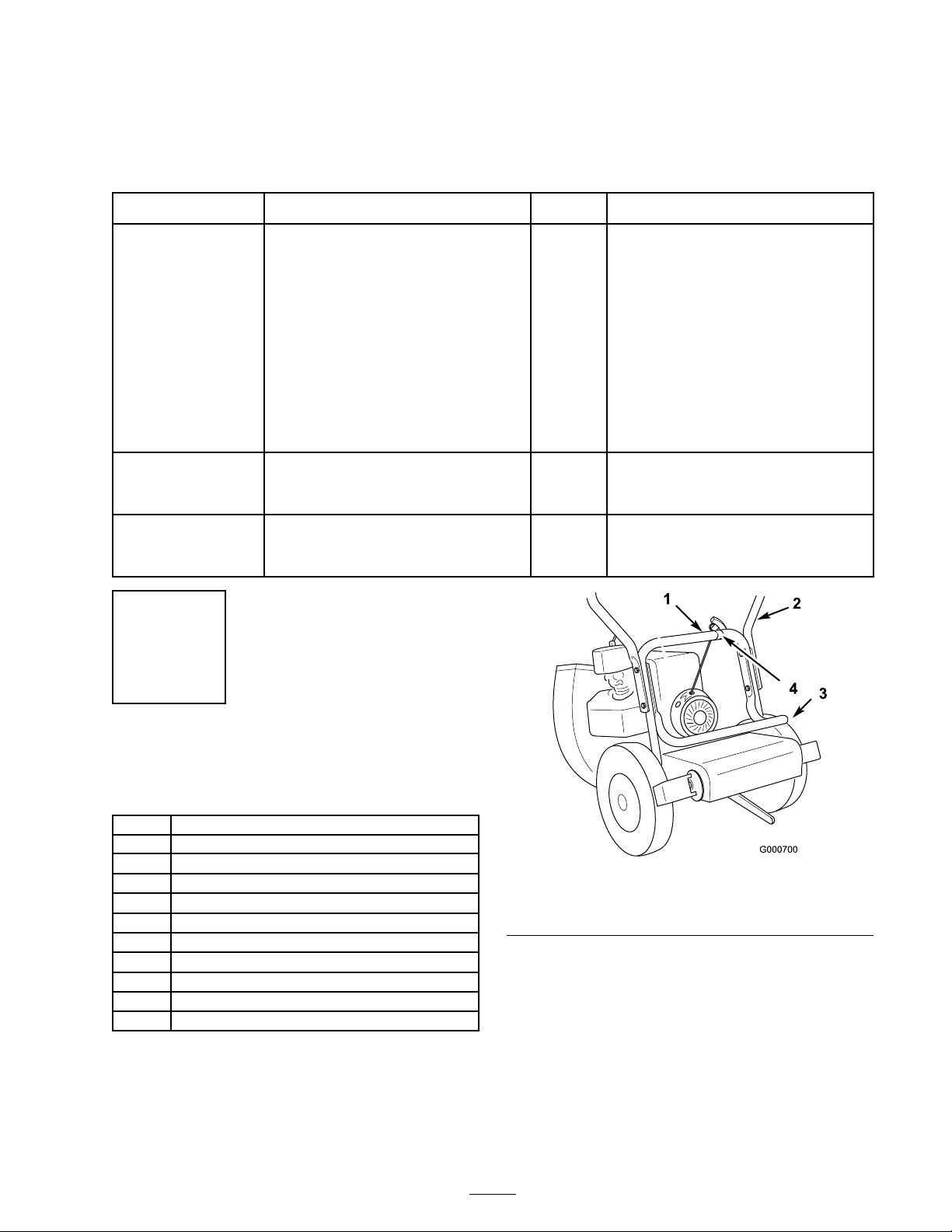

ready . Figure 1 identifies the location of the model

and serial n umbers on the product. W rite the

n umbers in the space pro vided.

Figure 1

1. Location of the model and serial numbers

Model No.

Serial No.

T his man ual identifies potential hazards and has

safety messag es identified b y the safety aler t

symbol ( Figure 2 ), whic h signals a hazard that ma y

cause serious injur y or death if y ou do not follo w

the recommended precautions .

Figure 2

1. Safety alert symbol.

T his man ual uses tw o other w ords to highlight

infor mation. Impor tant calls attention to special

mec hanical infor mation and Note emphasizes

g eneral infor mation w or th y of special attention.

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety and Instr uctional Decals . . . . . . . . . . . . 6

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1 Installing the Upper Handle and

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Installing the Disc harg e Chute

and Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Installing the Snout . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Ov er view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Adding Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chec king the Oil Lev el . . . . . . . . . . . . . . . . . . . . . . . 13

Star ting and Stopping the

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting the Intak e Housing

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dri ving the Mac hine F orw ard . . . . . . . . . . . . 15

Using the Debris Bag . . . . . . . . . . . . . . . . . . . . . . . . . 15

Con v er ting from V acuum to

Blo w er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

R ecommended Maintenance

Sc hedule(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Premaintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . 18

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Oiling the Caster W heels and Pi v ot

P oints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Greasing the R ear Idler

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Changing the Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ser vicing the Air Cleaner . . . . . . . . . . . . . . . . . . . 19

Ser vicing the Spark Plug . . . . . . . . . . . . . . . . . . . . 20

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 21

© 2006—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Contact us at www.Toro.com.

2

Printed in the USA.

All Rights Reserved

Page 3

Emptying the Fuel T ank . . . . . . . . . . . . . . . . . . . . . 21

Dri v e System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 21

Adjusting the T raction Dri v e . . . . . . . . . . . . . . 21

Belt Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Adjusting the Dri v e Belt . . . . . . . . . . . . . . . . . . . . . 22

R e placing the Dri v e Belt . . . . . . . . . . . . . . . . . . . . 22

Storag e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

R emo ving the Mac hine from

Storag e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3

Page 4

Safety

T o ensure maxim um safety and best perfor mance ,

and to g ain kno wledg e of the product, it is essential

that y ou and any other operator of the mac hine

read and understand the contents of this man ual

before the engine is ev er star ted.

T his is the safety aler t symbol. It is used to aler t

y ou to potential personal injur y hazards . Obey all

safety messag es that follo w this symbol to a v oid

possible injur y or death.

Improperly using or maintaining this mac hine

could result in injur y or death. T o reduce this

potential, comply with the follo wing safety

instr uctions .

Engine exhaust contains carbon mono xide,

an odor less, deadl y poison that can kill y ou.

Do not r un the engine indoor s or in an

enclosed ar ea.

General Safety

Training

• R ead this operator’ s man ual carefully . Be

thoroughly familiar with the controls and the

proper use of the mac hine before star ting it.

• Nev er allo w c hildren to operate the mac hine .

Local regulations ma y restrict the ag e of the

operator .

• Nev er allo w adults unfamiliar with these

instr uctions to operate the mac hine .

• Nev er use the mac hine while people (especially

c hildren) or pets are nearb y . Stop the mac hine

if any one enters the area.

• T ragic accidents can occur if the operator is

not aler t to the presence of c hildren. Children

are often attracted to the mac hine . Nev er

assume that c hildren will remain where y ou

last sa w them.

• K ee p c hildren out of the w ork area and under

the w atc hful care of a responsible adult.

• Be aler t and tur n the mac hine off if c hildren

enter the area.

• Use extra care when approac hing blind cor ners ,

shr ubs , trees , or other objects that ma y obscure

vision.

• K ee p in mind that the operator or user is

responsible for accidents or hazards occur ring

to other people or their proper ty .

• See the man ufacturer’ s instr uctions for proper

operation and installation of accessories . Use

only the accessories that are appro v ed b y the

man ufacturer .

Preparation

• W hile operating, alw a ys w ear substantial

footw ear and long trousers .

• Do not operate the mac hine when barefoot or

w earing open sandals .

• Alw a ys w ear safety g og gles or safety glasses

with side shields when operating the mac hine .

• W ar ning: Gasoline is highly flammable . T ak e

the follo wing precautions:

– Store fuel in containers specifically designed

for this pur pose .

– R efuel outdoors only and do not smok e

while refuelling .

– Add fuel before star ting the engine . Nev er

remo v e the cap of the fuel tank or add

g asoline while the engine is r unning or

when the engine is hot.

– If g asoline is spilled, do not attempt to star t

the engine . Mo v e the mac hine a w a y from

the area of spillag e to a v oid creating any

source of ignition until the g asoline v apors

ha v e dissipated.

– R e place all fuel tank and container caps

securely .

– If y ou m ust drain the fuel from the fuel

tank, do it outdoors .

• R e place faulty m ufflers .

• Before using, alw a ys visually inspect the

mac hine for w ear or damag e . R e place w or n

or damag ed par ts .

Operation

• Do not operate the engine in a confined space

where dang erous carbon mono xide fumes can

collect.

• Operate only in da ylight or in g ood ar tificial

light.

4

Page 5

• Alw a ys be sure of y our footing on slopes .

• W alk; nev er r un.

• K ee p a fir m hold on the handle .

• Ex ercise caution when c hanging the direction

on slopes .

• Do not operate on stee p slopes .

• Nev er operate the mac hine with damag ed or

missing guards or shields , or without safety

devices (suc h as blo w er tube or debris bag) in

place .

• Diseng ag e the traction dri v e lev er before

star ting the engine .

• Do not put y our hands or feet near or under

the snout. K ee p clear of the the snout and

blo w er tube (when installed) at all times .

• Stop the engine and disconnect the spark-plug

wire:

– before clearing bloc kag es

– before c hec king, cleaning, or w orking on

the mac hine

– before c hanging from v acuum to blo w er

or blo w er to v acuum

• Stop the engine:

– whenev er y ou lea v e the mac hine

– before refuelling

• Shut the engine off and w ait until the impeller

comes to a complete stop before remo ving the

debris bag .

• Do not operate the mac hine while under the

influence of alcohol or dr ugs .

• If the mac hine should star t to vibrate

abnor mally , stop the engine and c hec k

immediately for the cause . Vibration is

g enerally a w ar ning of trouble .

• Do not operate near drop-offs , ditc hes , or

embankments . Y ou could lose y our footing or

balance .

• Do not operate on w et g rass . R educed footing

could cause slipping .

Maintenance and Storage

• K ee p all n uts , bolts , and screws tight to ensure

that the mac hine is in safe w orking condition.

• Nev er store the mac hine with g asoline in the

tank inside a building where fumes ma y reac h

an open flame or spark.

• Allo w the engine to cool before storing the

mac hine in any enclosure .

• T o reduce the fire hazard, k ee p the engine ,

m uffler , and g asoline storag e area free of g rass ,

lea v es , or ex cessi v e g rease .

• Chec k the debris bag frequently for w ear or

deterioration.

• R e place w or n or damag ed par ts .

• Use extra care when handling g asoline; g asoline

v apors are explosi v e .

• K ee p the mac hine free of g rass , lea v es , or

other debris buildup . Clean up any oil or fuel

that spills .

• Stop and inspect the mac hine if y ou strik e an

object. R e pair the mac hine , if necessar y , before

star ting the engine .

• Debris bag components are subject to w ear ,

damag e , and deterioration, whic h could expose

mo ving par ts or allo w objects to be thro wn.

F requently c hec k the components and re place

them with the man ufacturer’ s recommended

par ts when necessar y .

• Do not c hang e the speed settings on the

engine .

• If y ou m ust drain the fuel from the fuel tank,

do it outdoors .

• T o ensure the best perfor mance and safety ,

purc hase only g en uine T oro re placement par ts

and accessories .

• Maintain or re place safety and instr uction

decals when necessar y .

Sound Pressure Level

T his unit has an equi v alent contin uous A-w eighted

sound pressure at the operator ear of 97 dB(A),

based on measurements of identical mac hines per

procedures described in EN 11201.

Sound Power Level

T his unit has a sound po w er lev el of 107 dB(A),

based on measurements of identical mac hines per

procedures described in EN 11094.

Vibration Level

T his unit has a maxim um hand-ar m vibration lev el

of 6.4 m/s2, based on measurements of identical

mac hines per procedures described in EN 1033.

5

Page 6

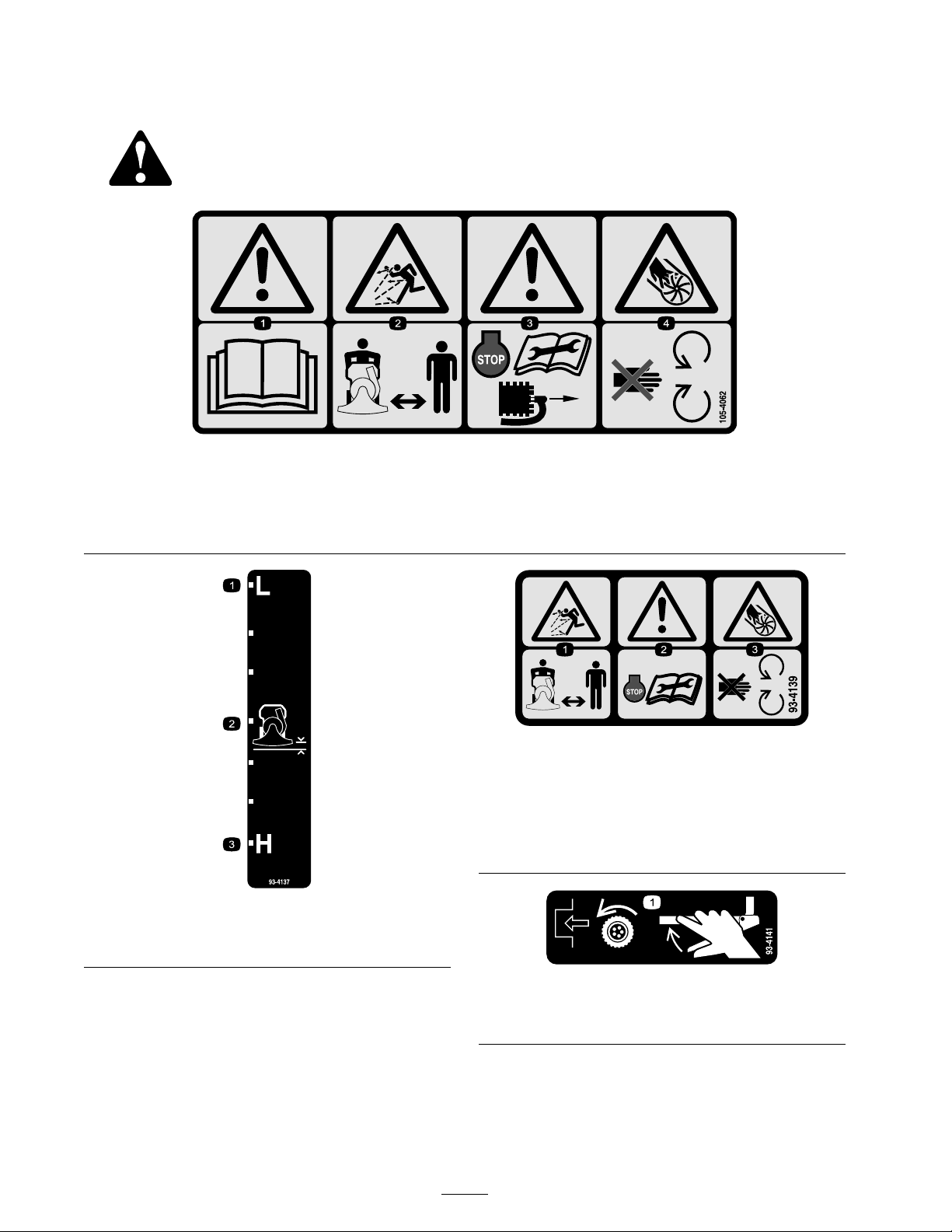

Safety and Instructional Decals

Safety decals and instr uctions are easily visible to the operator and are located near any

area of potential dang er . R e place any decal that is damag ed or lost.

105-4062

1. Warning—read the Operator’s Manual .

2. Thrown object hazard—stay a safe distance from the machine. 4. Cutting/dismemberment hazard, impeller—stay away from

3. Warning—stop the engine, remove the wire from the spark

plug, and read the instructions before servicing or performing

maintenance.

moving parts.

1. Low.

2. Height of vacuum snout

93-4139

1. Thrown object

hazard—stay a safe distance

from the machine.

2. Warning—stop the engine

and read the instructions

before servicing or

performing maintenance.

3. Cutting/dismemberment

hazard, impeller—stay

away from moving parts.

93-4137

3. High

93-4141

1. To engage the traction drive, move the traction drive lever

to the handle.

6

Page 7

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

Upper handle assembly

Bag support 1

Bolt (5/16 x 1-1/2 inches)

Locknut (5/16 inch)

Bolt (10-32)

1

2

3

Locknut (10-32)

Rope guide

Bolt (1/4 x 3/4 inch)

Locknut (1/4 inch)

Height control rod

Hair pin cotter

Bolt (1/4 x 1/2 inch)

Lock washer (1/4 inch)

Debris bag

Blower tube

Blower intake screen

Locknut

Description

Qty.

1

4

4

1

1

1

1

1

1

2

1

1

1

1

1

3

Install the upper handle and

controls.

Install the discharge chute.

Install the snout.

Use

Step

1

Installing the Upper Handle

and Controls

Parts needed for this step:

1

Upper handle assembly

1 Bag support

4

Bolt (5/16 x 1-1/2 inches)

4

Locknut (5/16 inch)

1

Bolt (10-32)

1

Locknut (10-32)

1

Rope guide

1

Bolt (1/4 x 3/4 inch)

1

Locknut (1/4 inch)

1

Height control rod

2

Hair pin cotter

Procedure

1. Attac h the upper handle to the lo w er handle

with 4 bolts (5/16 x 1-1/2 inc hes) and loc kn uts

(5/16 inc h) ( Figure 3 ).

Figure 3

1. Lower handle

2. Upper handle 4. Rope guide

3. Bag support

2. Secure the bag suppor t to the inside of the

lo w er handle while mounting the handle

( Figure 3 ).

3. Secure star ter rope guide to the lo w er handle

with a bolt (1/4 x 1-3/4 inc hes) and loc kn ut

(1/4 inc h) ( Figure 4 ).

7

Page 8

1. Bolt (1/4 x 1-3/4 inches)

2. Locknut (1/4 inch)

Figure 4

3. Pull rope through rope

Figure 6

1. Height control rod

guide

2. Front wheel support

bracket

3. Hairpin cotter

4. Pull the star ter rope through the guide

( Figure 4 ).

5. Hook the lo w er end (ball end) of the traction

control wire in the k eyhole slot in the ar m on

the traction dri v e guard ( Figure 5 ).

Figure 5

1. Traction control wire

2. Traction drive guard

3. Bolt and nut (10–32)

8. Secure the upper end of the height control rod

to the height adjustment handle with a hair pin

cotter ( Figure 7 ).

Figure 7

1. Height control rod

2. Height adjustment handle

3. Hairpin cotter

Step

2

Installing the Discharge

Chute and Bag

6. Secure the ball in the k eyhole slot with a bolt

(10-32) and n ut (10-32) ( Figure 5 ).

Note: Mak e sure ball end of cable is not

betw een screw head and dri v e guard.

7. Secure the lo w er end of the height control rod

to the brac k et on the front wheel suppor t with

a hair pin cotter ( Figure 6 ).

Parts needed for this step:

1

Bolt (1/4 x 1/2 inch)

1

Lock washer (1/4 inch)

1

Debris bag

Procedure

1. Install the disc harg e c hute and secure it with

a bolt (1/4 x 1/2 inc h) and loc k w asher (1/4

inc h) ( Figure 8 ).

8

Page 9

Figure 8

1. Chute

2. Bolt (1/4 inch) and lock

washer

2. P osition the bag onto the handle , hooking the

g rommets o v er the pins and the bag strap o v er

the handle ( Figure 9 ).

Step

3

Installing the Snout

Parts needed for this step:

1

Blower tube

1

Blower intake screen

3

Locknut

Procedure

1. Mount the lo w er edg e of the snout flang e into

the mounting brac k et ( Figure 10 ).

Figure 9

1. Grommets

2. Elasticized neck

3. Slip the elasticized nec k of the bag o v er the

flang es on the c hute ( Figure 9 ).

Figure 10

1. Vacuum snout

2. Lower edge of ange 4. Locknut

3. Retainer ange

2. P osition the retainer flang e o v er the 3 bolt ends

protr uding through the snout ( Figure 10 ).

3. Secure the snout and flang e to the blo w er with

3 w ashers and loc kn uts ( Figure 10 ).

9

Page 10

Product Overview

Figure 12

1. Height adjustment control

Traction Control Lever

Hold the traction control lev er ( Figure 13 ) ag ainst

the handle to mo v e forw ard. R elease the traction

control lev er to stop forw ard motion.

Figure 11

1. Engine

2. Vacuum snout

3. Height adjustment control 6. Debris bag

4. Handle

5. Traction control lever

Controls

Height Adjustment Control

Y ou can adjust the clearance betw een the air

intak e housing and the g round b y mo ving height

adjustment control ( Figure 12 ) to desired position.

Set the height to lo w (L) for v acuuming hard

surfaces suc h as sidew alks or dri v ew a ys and to

high (H) for thic k lush turf with a hea vy co v ering

of lea v es or clippings . T he v acuum will w ork best

when y ou k ee p the intak e as close to the g round as

is practical for the task y ou are perfor ming .

Figure 13

1. Traction control lever (disengaged)

Choke and Throttle Levers

R efer to Star ting and Stopping the Engine in

Operation , pag e 12 for detailed instr uctions on

using these controls .

10

Page 11

Figure 14

1. Choke lever 4. Choke position

2. Throttle lever 5. Slow position

3. Run position 6. Fast position

11

Page 12

Operation

Before operating, c hec k the fuel and oil lev el, and

remo v e debris from the mac hine . Also , ensure that

the area is clear of people and debris .

Adding Fuel

In cer tain conditions, gasoline is extr emel y

flamma ble and highl y explosi v e. A fir e or

explosion fr om gasoline can bur n y ou and

other s and can dama ge pr oper ty .

• Fill the fuel tank outdoor s, in an open

ar ea, when the engine is cold. W ipe up

an y gasoline that spills.

• Do not fill the fuel tank completel y full.

Add gasoline to the fuel tank until the

lev el is 1/4 to 1/2 inch (6 to 13 mm)

belo w the bottom of the filler neck. T his

empty space in the tank allo ws gasoline

to expand.

• Nev er smok e when handling gasoline,

and stay a w ay fr om an open flame or

wher e gasoline fumes may be ignited by

a spar k.

• Stor e gasoline in an appr o v ed container

and k eep it out of the r each of childr en.

Nev er buy mor e than a 30-day suppl y of

gasoline.

• Al w ays place gasoline container s on the

g r ound a w ay fr om y our v ehicle bef or e

filling .

• Do not fill gasoline container s inside

a v ehicle or on a tr uck or trailer bed

because interior car pets or plastic tr uck

bed liner s may insulate the container and

slo w the loss of an y static charge.

• W hen practical, r emo v e gas-po w er ed

equipment fr om the tr uck or trailer and

r efuel the equipment with its wheels on

the g r ound.

• If this is not possible, then r efuel such

equipment on a tr uck or trailer fr om a

por ta ble container , rather than fr om a

gasoline dispenser nozzle.

• If a gasoline dispenser nozzle must be

used, k eep the nozzle in contact with the

rim of the fuel tank or container opening

at all times until fueling is complete.

12

Page 13

Use unleaded g asoline (87 pump octane minim um).

Leaded, regular g asoline ma y be used if unleaded

is not a v ailable .

Important: Do not use methanol, gasoline

containing methanol, or gasohol containing

mor e than 10% ethanol because the fuel

system could be dama ged. Do not mix oil

with gasoline.

Checking the Oil Level

Important: T he machine is shipped

without oil in the crankcase. Y ou must fill

the crankcase with 20 oz. (0.6 l) of SAE 30 or

10W -30, high quality detergent oil with an API

classification of SF , SG , or SH. Sev er e engine

dama ge will r esult if y ou attempt to r un it

without oil.

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the traction

unit to pro vide the follo wing benefits:

• K ee ps g asoline fresh during storag e of 90 da ys

or less . F or long er storag e it is recommended

that the fuel tank be drained.

• Cleans the engine while it r uns

• Eliminates gum-lik e v ar nish buildup in the fuel

system, whic h causes hard star ting

Important: Do not use fuel additi v es

containing methanol or ethanol.

Add the cor rect amount of g as

stabilizer/conditioner to the g as .

Note: A fuel stabilizer/conditioner is most

effecti v e when mix ed with fresh g asoline . T o

minimize the c hance of v ar nish de posits in the

fuel system, use fuel stabilizer at all times .

1. P ark the mac hine on a lev el surface and stop

the engine .

2. Allo w the engine to cool.

3. Clean around the oil dipstic k ( Figure 15 ).

Figure 15

1. Oil dipstick 2. Metal end

4. Pull out the dipstic k and wipe the metal end

clean ( Figure 15 ).

5. Slide the dipstic k fully into the dipstic k tube

and tighten it ( Figure 15 ).

Filling the Fuel Tank

1. P ark the mac hine on a lev el surface and stop

the engine .

2. Allo w the engine to cool.

3. Clean around the fuel tank cap and remo v e it.

4. Add unleaded g asoline to the fuel tank, until

the lev el is 1 inc h (26 mm) belo w the bottom

of the filler nec k.

Important: T his space in the tank allo ws

gasoline to expand. Do not fill the fuel

tank completel y full.

5. Install the fuel tank cap securely .

6. Wipe up any g asoline that ma y ha v e spilled.

6. R emo v e the dipstic k and look at the metal end.

7. If the oil lev el is lo w , slo wly pour only enough

oil into the dipstic k tube to raise the lev el to

the F (full) mark.

Important: Do not o v erfill the crankcase

with oil because the engine may be

dama ged.

8. R e place and tighten the dipstic k.

An unco v er ed discharge opening will

allo w objects to be thr o wn in operator’ s

or bystander’ s dir ection which may cause

serious injur y .

Nev er operate the v acuum unless the ba g

is installed.

13

Page 14

T he traction belt dri v e pulley is r otating

whenev er the engine is r unning , ev en

when the traction dri v e is disenga ged.

Contact with the pulley could cause

sev er e injur y .

Stay a w ay fr om mo ving pulleys and other

par ts.

Starting and Stopping the

Engine

Important: Do not pull the r ecoil r ope

to its limit or let go of the star ter handle

when the r ope is pulled out because the

r ope may br eak or the r ecoil assembl y may

be dama ged.

4. As the engine w ar ms up , slo wly mo v e the

c hok e lev er to the Off position ( Figure 16 ).

Stopping the Engine

Mo v e the throttle lev er all the w a y to the left in the

Slo w position ( Figure 16 ).

Starting the Engine

1. Mo v e the c hok e lev er (located on the left

side of the engine) to the Chok e position

( Figure 16 ).

Figure 16

1. Choke lever 4. Choke position

2. Throttle lever 5. Slow position

3. Run position 6. Fast position

2. Mo v e the throttle lev er (located on the right

side of the engine) to the F ast position

( Figure 16 ).

T he impeller contin ues to r otate f or a few

seconds after the engine is stopped, and can

cause serious per sonal injur y .

Do not place an y par t of y our body into the

impeller ar ea until y ou a cer tain that it has

stopped.

Adjusting the Intake

Housing Height

Y ou can adjust the clearance betw een the air

intak e housing and the g round b y mo ving height

adjustment control to desired position. Set the

height to lo w (L) for v acuuming hard surfaces

suc h as sidew alks or dri v ew a ys and to high (H)

for thic k lush turf with a hea vy co v ering of lea v es

or clippings . T he v acuum will w ork best when

y ou k ee p the intak e as close to the g round as is

practical for the task y ou are perfor ming .

1. Stop the engine .

2. Tip the mac hine slightly to the rear to tak e the

w eight off the castor wheels while adjusting .

3. Mo v e the height adjustment control forw ard to

lo w er the intak e housing; mo v e it to the rear to

raise the housing ( Figure 17 ).

3. Pull the recoil star ter handle out until positi v e

eng ag ement results , then pull it vig orously

to star t the engine . Allo w the recoil rope to

retract slo wly .

14

Page 15

Figure 17

1. Height adjustment control

4. R etur n the castor wheels to the g round

Driving the Machine

Forward

Hold the traction control lev er ( Figure 18 ) ag ainst

the handle to mo v e forw ard. R elease the traction

control lev er to stop forw ard motion.

Figure 18

1. Traction control lever (disengaged)

Figure 19

1. Zipper for emptying

2. Bag vent

4. Close the zipper before star ting the engine .

A w or n de bris ba g could allo w small

stones and other similar de bris to be

thr o wn in the operator’ s or bystander’ s

dir ection and r esult in serious per sonal

injur y or death to the operator or

bystander s.

Check the de bris ba g fr equentl y . If it is

dama ged, install a new T or o r eplacement

ba g .

Using the Bag Vent

Using the Debris Bag

Emptying the Debris Bag

W hen the debris bag is full, empty it as follo ws:

Note: Y ou do not need to remo v e the bag to

empty it.

1. Dri v e to the location where y ou w ant to dump

the debris .

2. Stop the engine .

3. Unzip the side of the bag and dump the

contents ( Figure 19 ).

T he bag has a zippered v ent ( Figure 19 ). W hen

v acuuming an area whic h is basically free of dust,

open the side v ent should be open to allo w free

mo v ement of air . W hen v acuuming a dusty area,

close the v ent.

Important: K eep the inside of the ba g clean

to allo w the air to circulate pr oper l y .

Converting from Vacuum to

Blower

1. Stop the engine .

2. R emo v e the loc kn uts , w ashers , and retainer

flang e securing the snout and remo v e the snout

( Figure 20 ).

15

Page 16

Figure 20

1. Vacuum snout

2. Lower edge of ange 4. Locknut

3. Retainer ange

3. R emo v e the bag nec k from blo w er disc harg e

c hute ( Figure 21 ). (Y ou ma y remo v e the entire

bag if desired.)

Figure 22

Housing in Vacuum Position

1. Bolt 4. Locknuts and housing

2. Housing

3. Engine bracket 6. Stabilizer bracket

mounting studs

5. Locknuts

7. R emo v e the 2 loc kn uts securing housing

to engine brac k et and remo v e the brac k et

( Figure 22 ).

Figure 21

1. Bag neck 3. Blower tube

2. Blower discharge chute 4. Blower intake screen

4. R emo v e the retaining bolt and loc k w asher

securing the blo w er disc harg e c hute and

remo v e the c hute ( Figure 21 ).

5. Install the blo w er tube , securing it with the

fasteners remo v ed in ste p 4 ( Figure 21 ).

6. R emo v e bolt securing blo w er housing to

engine brac k et ( Figure 22 ).

8. Install the 2 loc kn uts on the housing mounting

studs for safe k ee ping .

9. R emo v e the 2 loc kn uts securing housing to

stabilizer brac k et ( Figure 22 ).

10. Lift blo w er housing slightly and rotate it 120°

cloc kwise (as y ou face the blo w er) ( Figure 21 ).

11. R eseat the housing, nesting the lo w er blo w er

housing mounting brac k et onto the front edg e

of the engine base ( Figure 23 ).

12. Install engine brac k et on the housing mounting

studs with 2 loc kn uts ( Figure 23 ).

16

Page 17

Figure 23

Housing in Blower Position

1. Lower blower housing

mounting bracket

2. Front edge of engine base 5. Locknuts and housing

3. Bolt

4. Engine bracket

mounting studs

13. Secure the brac k et to the engine brac k et with

the bolt remo v ed previously ( Figure 23 ).

14. Install the blo w er intak e screen, securing it

with 1 of the w ashers and loc kn uts remo v ed

in ste p 2 ( Figure 21 ).

Note: Do not use the retainer flang e with the

blo w er intak e screen.

T he air str eam comes out of the blo w er

in ex cess of 100 mph (160 km/h)and can

cause bodil y injur y or pr oper ty dama ge.

Ensur e that the air str eam is not aimed

dir ectl y at an ybody or an ything .

17

Page 18

Maintenance

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

After the rst 8 operating

Before each use or daily

Every 25 hours

Every 50 hours

Every 100 hours

Before storage

Yearly or before storage

Premaintenance

Procedures

Maintenance Procedure

hours

• Change the oil.

• Check the oil level.

• Check the foam air cleaner element.

• Grease the rear idler assembly (more often in dusty or dirty conditions).

• Clean the foam and paper air cleaner elements (more often in dusty or

dirty conditions).

• Change the oil (more often in dusty or dirty conditions).

• Check the spark plug.

• Clean the foam and paper air cleaner elements.

• Change the oil.

• Grease the rear idler assembly.

• Check the spark plug.

• Oil the caster wheels and pivot points.

If y ou lea v e the wir e on the spar k plug ,

someone could star t the engine and seriousl y

injur e y ou or other bystander s.

Disconnect the wir e fr om the spar k plug

( Figur e 24 ) bef or e y ou do an y maintenance.

Set the wir e aside so that it does not

accidentall y contact the spar k plug .

Figure 24

1. Spark plug wire

Lubrication

Oiling the Caster Wheels

and Pivot Points

Lubricate the caster wheels and pi v ot points yearly .

1. Stop the engine and pull the wire off of the

spark plug .

2. Place a few drops of engine oil in the follo wing

locations:

18

Page 19

• Eac h of the caster wheel bushings

• W here the front wheel suppor t pi v ots in

the engine base ( Figure 25 )

• W here the rear traction shafts pi v ot in the

engine base ( Figure 25 )

Figure 25

1. Rear idler assembly

2. Oil point 4. Traction shafts

3. Grease point

3. Clean around the oil dipstic k and remo v e it

( Figure 26 ).

Figure 26

1. Oil dipstick 2. Metal end

4. Clean the area around the drain plug

( Figure 27 ).

Greasing the Rear Idler

Assembly

Lubricate the rear idler assembly with No . 2

g eneral pur pose g rease after ev er y 25 hours of

operation or more frequently when conditions are

dusty or sandy ( Figure 25 ). Pump g rease into the

fitting until it oozes out of the bearings .

Engine Maintenance

Changing the Oil

Chang e oil after the first 5 operating hours and

then ev er y 50 operating hours thereafter or yearly

whic hev er comes first.

Note: Chang e oil more frequently when

operating conditions are extremely dusty or sandy .

Oil T ype: SAE 30 or 10W -30 deterg ent oil (API

ser vice SG , SH, SJ , or higher)

Crankcase Capacity: 20 oz. (0.6 l)

1. Star t the engine and let it r un for fiv e min utes .

T his w ar ms the oil so it drains better .

2. P ark the mac hine on a lev el surface , stop the

engine and pull the wire off of the spark plug .

Figure 27

1. Drain plug

5. Place a drain pan under the drain plug to catc h

the oil.

6. R emo v e the oil drain plug and allo w oil to flo w

into the drain pan.

7. W hen finished, install the drain plug and wipe

up any oil that spilled.

8. Slo wly pour only enough oil (about 20 oz. (0.6

l)) into the dipstic k tube to raise the lev el to

the F (full) mark.

Important: Do not o v erfill the crankcase

with oil because the engine may be

dama ged.

9. R e place and tighten the dipstic k.

Servicing the Air Cleaner

Chec k foam element before eac h use . Clean the

foam and paper elements ev er y 25 operating hours .

19

Page 20

Clean them more often if y ou operate in dusty or

dir ty conditions . R e place both elements if they are

ex cessi v ely dir ty of damag ed.

T o clean the elements , complete the follo wing:

Important: Do not star t the engine

without the air cleaner elements installed

otherwise extr eme engine w ear and

dama ge will r esult.

1. Stop the engine and pull the wire off of the

spark plug .

2. Unscrew the knob and remo v e the air cleaner

co v er ( Figure 28 ).

Figure 28

1. Knob 3. Paper element

2. Cover

4. Foam element

3. Slide the foam element off of the paper

car tridg e and clean it as follo ws:

Servicing the Spark Plug

Chec k the spark plug after ev er y 100 operating

hours or yearly whic hev er comes first. Ensure that

the air g ap betw een the center and side electrodes

is cor rect before installing the spark plug . Use a

spark plug wrenc h for remo ving and installing

the spark plug and a g apping tool/feeler g aug e to

c hec k and adjust the air g ap . Install a new spark

plug if necessar y .

T ype: Champion R CJ-8 or equi v alent.

Air Gap: 0.030 inc h (0.76 mm)

Removing the Spark Plug

1. Stop the engine .

2. Pull the wire off of the spark plug ( Figure 29 ).

A. W ash the foam element in a solution of

liquid soap and w ar m w ater , squeezing it

to remo v e dir t, but do not twist because

it ma y tear .

B . Rinse the element thoroughly in clear w ater .

C . Dr y the element b y wrapping it in a clean

rag, squeezing the rag and element.

Important: Do not oil either element.

4. Clean the paper element b y tapping it on a

hard surface to knoc k the dir t out of it.

Important: Do not w ash the paper

element, or clean it with solv ent such as

k er osene. Do not use pr essuriz ed air to

clean it. Cleaning it with an y of these

methods could dama ge the element.

5. Install the foam element o v er the paper

element.

6. Install the elements into the air cleaner .

7. Install the air cleaner co v er , securing it with

the knob .

Figure 29

1. Spark plug wire

3. Clean the area around the spark plug .

4. R emo v e the plug from the cylinder head.

Checking the Spark Plug

1. Look at the center of the spark plug ( Figure 30 ).

If y ou see light bro wn or g ra y on the insulator ,

the engine is operating properly . A blac k

coating on the insulator usually means the air

cleaner is dir ty .

Important: Nev er clean the spar k plug .

Al w ays r eplace the spar k plug when it has

a black coating , w or n electr odes, an oil y

film, or cracks.

20

Page 21

2. Chec k the g ap betw een the center and side

electrodes ( Figure 30 ).

3. Bend the side electrode ( Figure 30 ) if the g ap

is not cor rect.

Figure 30

1. Center electrode insulator

2. Side electrode

Installing the Spark Plug

1. T hread the spark plug into the spark plug hole .

2. Tighten the spark plug to 15 ft.-lb . (20 N·m).

3. Air gap (not to scale)

Drive System

Maintenance

Adjusting the Traction Drive

As the friction wheels and tires experience nor mal

w ear , it will be necessar y to adjust the traction

dri v e linkag e occasionally .

1. Stop the engine .

2. Loosen the lo w er n ut on the bottom side of

the brac k et ( Figure 31 ).

3. Push the wire onto the spark plug ( Figure 29 ).

Fuel System

Maintenance

Emptying the Fuel Tank

1. Stop the engine and w ait for it to cool.

Important: Drain gasoline fr om a cold

engine onl y .

2. Disconnect the wire from the spark plug .

3. R emo v e the cap from the fuel tank.

4. Use a pump-type syphon to drain the g asoline

into a clean appro v ed g asoline container .

5. Connect the wire onto the spark plug .

6. R un the engine until it stops .

7. Star t the engine ag ain to mak e sure that all the

g asoline is out of the carburetor .

Figure 31

1. Lower nut

2. Upper nut

3. Tighten the upper n ut to mo v e the cable

housing upw ard ( Figure 31 ), whic h in tur n

mo v es the friction wheel closer to the tire . (In

effect, this shor tens the cable to compensate

for the w ear .)

Note: If y ou cannot adjust the cable any

fur ther , mo v e the brac k et to the upper hole in

the handle and star t the adjustment procedure

o v er ag ain ( Figure 31 ).

4. W hen the proper adjustment is attained,

tighten the lo w er n ut ag ainst the brac k et to

secure the adjustment ( Figure 31 ).

3. Bracket

4. Upper hole

If y ou adjusted the traction dri v e but the

wheels do not tur n when the lev er is operated,

adjust the dri v e belt.

21

Page 22

Belt Maintenance

Adjusting the Drive Belt

Adjust the dri v e belt if loss of traction occurs or if

the belt slips . Adjust the traction dri v e first.

1. Stop the engine and pull the wire off of the

spark plug .

2. Loosen the n ut and slide the pulley until belt is

at the proper tension ( Figure 32 ).

Figure 33

1. Vacuum snout

2. Lower edge of ange 4. Locknut

3. Retainer ange

7. Slip the bag off of the c hute and remo v e the

c hute ( Figure 33 ).

8. Loosen the tw o loc kn uts securing the blo w er

housing to the stabilizer brac k et ( Figure 34 ).

Figure 32

1. Nut

2. Pulleys

3. Tighten the n ut just enough so the belt does

not slip; do not o v er -tighten it.

Note: W hen y ou can no long er adjust a pulley ,

use the other pulley . W hen the adjustment is

used up on both pulleys , re place the belt.

Replacing the Drive Belt

1. Stop the engine and pull the wire off of the

spark plug .

2. Drain the g asoline from fuel tank;

refer to Emptying the Fuel T ank in

Fuel System Maintenance , pag e 21 .

3. Drain the oil from crankcase; refer to Changing

Engine Oil in Engine Maintenance , pag e 19 .

4. Cut the old belt and remo v e it ( Figure 32 ).

5. Loosen the adjustment n uts on the belt

tightener pulleys ( Figure 32 ).

6. R emo v e the front snout ( Figure 33 ).

Figure 34

1. Locknuts 3. Bolt

2. Stabilizer bracket

22

Page 23

9. R emo v e the bolt securing the blo w er housing

and lift the housing as m uc h as the impeller

allo ws ( Figure 34 ).

10. R oute the new belt around the blo w er housing

( Figure 35 ).

Figure 35

1. Belt around housing

11. Inser t the belt o v er the pulley and do wn

through the opening ( Figure 36 ).

Figure 37

1. Cotter pin

2. Set screws

3. Shaft

4. Belt

5. Sprockets

15. Install the belt around the dri v e shaft pulley

( Figure 37 ).

Important: T he belt must be installed

as sho wn in Figur e 37 or the traction dri v e

will r un backw ard.

Figure 36

1. Housing

2. Feed belt down through

opening

12. Install and secure the blo w er housing with the

bolt remo v ed previously and tighten the tw o

n uts y ou loosened.

13. Tip the unit bac k onto the handles .

14. R emo v e the cotter pin from the end of the

traction dri v e shaft, loosen the set screw in

eac h of the collars , and tap the shaft to the left

far enough so the new belt can be installed

( Figure 37 ).

16. R etur n the shaft to its original position, secure

the collars with the set screws , and the shaft

with the cotter pin ( Figure 37 ).

17. Ensure that the sproc k ets are aligned properly

( Figure 37 ).

18. Adjust the belt; refer to Adjusting the Dri v e

Belt.

23

Page 24

Storage

1. Stop the engine and remo v e the wire from the

spark plug .

2. R emo v e dir t and g rime from the exter nal par ts

of the entire mac hine , especially the engine .

Clean dir t and c haff from the outside of the

engine cooling system.

Important: Do not pr essur e w ash the

engine.

3. Ser vice the air cleaner; refer to Ser vicing the

Air Cleaner in Engine Maintenance , pag e 19 .

4. Lubricate the mac hine; refer to Lubrication ,

pag e 18 .

5. Chang e the oil; refer to Changing Engine Oil

in Engine Maintenance , pag e 19 .

6. R emo v e and c hec k the spark plug;

refer to Ser vicing the Spark Plug in

Engine Maintenance , pag e 19 .

7. With the spark plug remo v ed from the engine ,

pour 2 tablespoons (10 ml) of engine oil into

the spark plug hole .

8. Place rags o v er the spark plug hole to catc h any

oil spra y , then use the star ter rope to crank the

engine and distribute the oil inside the cylinder .

9. Install the spark plug, but do not install the

wire on it.

E. Chok e the engine .

F . Star t and r un the engine until it will not

star t ag ain.

G . Dispose of fuel properly . R ecycle as per

local codes .

Important: Do not stor e

sta biliz er/conditioned gasoline

o v er 90 days.

11. Chec k and tighten all bolts , n uts , and screws .

R e pair or re place any par t that is damag ed or

defecti v e .

12. P aint all scratc hed or bare metal surfaces . P aint

is a v ailable from y our A uthorized Ser vice

Dealer .

13. Store the mac hine in a clean, dr y g arag e or

storag e area. R emo v e the k ey from the ignition

switc h and k ee p it in a memorable place .

14. Co v er the mac hine to protect it and k ee p it

clean.

Removing the Machine from

Storage

1. Chec k and tighten all fasteners .

2. R emo v e the spark plug and spin engine rapidly

using star ter to blo w ex cess oil from the

cylinder .

10. F or storag e o v er 30 da ys , pre pare the traction

unit as follo ws .

A. Add a petroleum based

stabilizer/conditioner to fuel in the

tank. F ollo w mixing instr uctions from

stabilizer man ufacturer . (1 oz. per g allon).

Do not use an alcohol based stabilizer

(ethanol or methanol).

Note: A fuel stabilizer/conditioner is

most effecti v e when mix ed with fresh

g asoline and used at all times .

B . R un the engine to distribute conditioned

fuel through the fuel system (5 min utes).

C . Stop the engine , allo w it to cool and

drain the fuel tank using a pump type

syphon; refer to Emptying the Fuel T ank

Fuel System Maintenance , pag e 21 .

D . R estar t the engine and r un it until it stops .

3. Install the spark plug and tor que it to 15 ft.-lbs .

(20 N·m).

4. Fill fuel tank with fresh, clean g asoline .

5. Chec k engine oil lev el.

6. Connect spark plug wire .

24

Loading...

Loading...