Toro 38607, 622R Power Throw, 622E Power Throw Operator's Manual

622Rand622EPowerThrow

ModelNo.38606—SerialNo.270000001andUp

ModelNo.38607—SerialNo.270000001andUp

FormNo.3355-529RevG

®

Snowthrowers

Operator'sManual

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

injuryordeathifyoudonotfollowtherecommended

precautions.

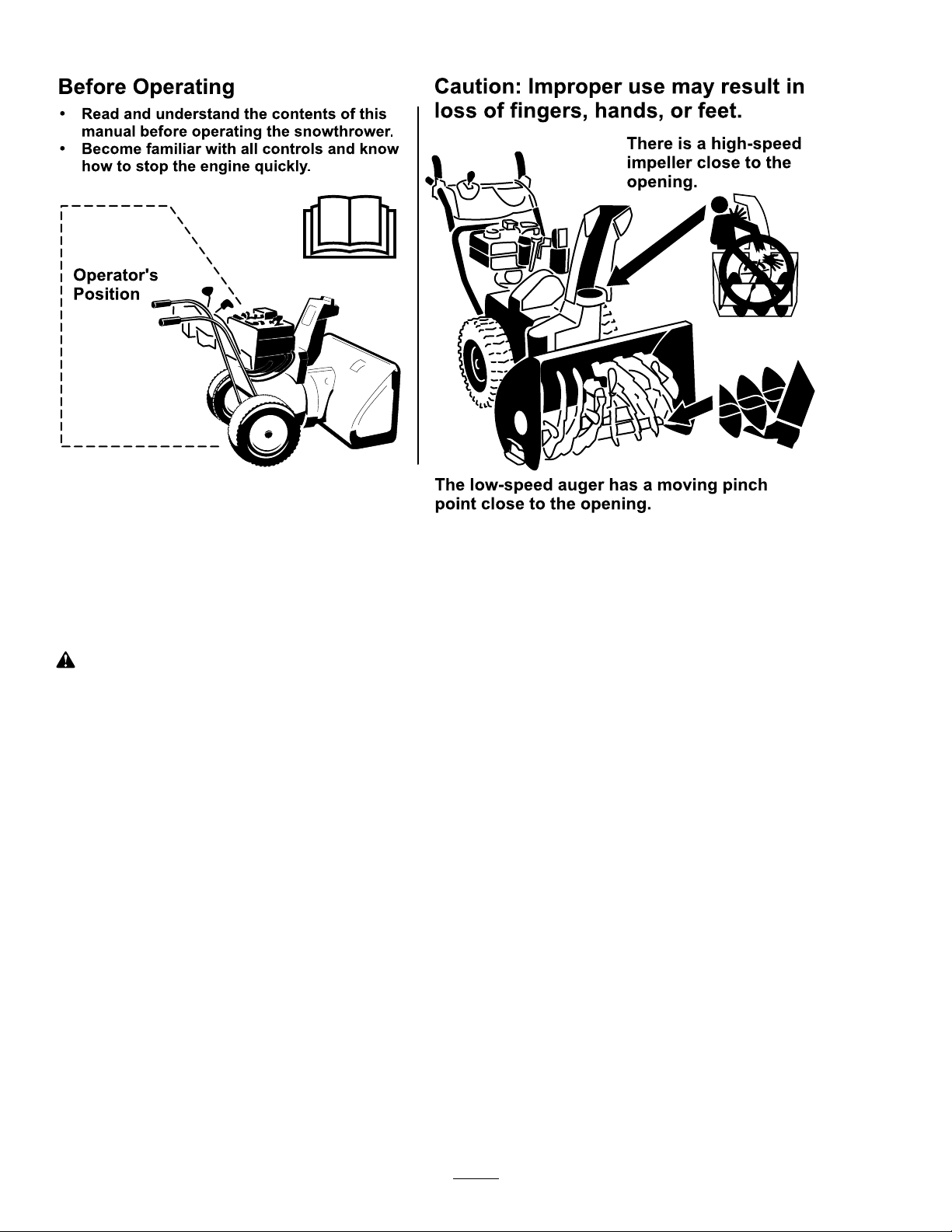

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

ReplacementEngineOwner’sManualsmaybe

orderedthroughtheenginemanufacturer.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

©2008—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

Safety

BeforeOperating

?

?

Readandunderstandthecontentsofthis

manualbeforeoperatingthesnowthrower .

Becomefamiliarwithallcontrolsandknow

howtostoptheenginequickly .

Operator 's

Position

Thelow-speedaugerhasamovingpinch

pointclosetotheopening.

Caution:Improperusemayresultin

lossoffingers,hands,orfeet.

Thereisahigh-speed

impellerclosetothe

opening.

ThissnowthrowermeetsorexceedstheISO

standard8437ineffectatthetimeofproduction.

Readandunderstandthecontentsofthismanual

beforetheengineiseverstarted.

Thisisthesafetyalertsymbol.Itisusedtoalert

youtopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoid

possibleinjuryordeath.

Improperlyusingormaintainingthissnowthrower

couldresultininjuryordeath.Toreducethis

potential,complywiththefollowingsafety

instructions.

Training

•Readtheoperatingandserviceinstructionmanual

carefully.Bethoroughlyfamiliarwiththecontrols

andtheproperuseoftheequipment.Knowhowto

stoptheunitanddisengagethecontrolsquickly.

•Neverallowchildrentooperatetheequipment.

Neverallowadultstooperatetheequipmentwithout

properinstruction.

•Keeptheareaofoperationclearofallpersons,

particularlysmallchildren,andpets.

Preparation

•Thoroughlyinspecttheareawheretheequipmentis

tobeusedandremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Disengageallclutchesandshiftintoneutralbefore

startingtheengine.

•Donotoperatetheequipmentwithoutwearing

adequatewintergarments.Wearfootwearwhichwill

improvefootingonslipperysurfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningorhotengine.

–Fillfueltankoutdoorswithextremecare.Never

–Replacegasolinecapssecurelyandwipeup

•Adjustthecollectorhousingheighttocleargravel

orcrushedrocksurface.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning(exceptwherespecically

recommendedbymanufacturer).

•Letengineandmachineadjusttooutdoor

temperaturesbeforestartingtoclearsnow.

llfueltankindoors.

spilledfuel.

•Exercisecautiontoavoidslippingorfalling,

especiallywhenoperatinginreverse.

•Theoperationofanypoweredmachinecanresultin

foreignobjectsbeingthrownintotheeyes.Always

2

wearsafetyglassesoreyeshieldsduringoperationor

whileperforminganadjustmentorrepair.

•Useonlyattachmentsandaccessoriesapprovedby

themanufacturerofsnowthrower(suchaswheel

weights,counterweights,cabs,etc.).

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalertfor

hiddenhazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,

removethewirefromthespark-plug,thoroughly

inspectthesnowthrowerforanydamage,andrepair

thedamagebeforerestartingandoperatingthesnow

thrower.

•Iftheunitshouldstarttovibrateabnormally,stop

theengineandcheckimmediatelyforthecause.

Vibrationisgenerallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingthecollector/impeller

housingordischargeguide,andwhenmakingany

repairs,adjustments,orinspections.

•Whencleaning,repairing,orinspecting,makecertain

thecollector/impellerandallmovingpartshave

stopped.Disconnectthespark-plugwire,andkeep

thewireawayfromtheplugtopreventaccidental

starting.

•Donotruntheengineindoors,exceptwhenstarting

itandformovingthesnowthrowerinoroutofthe

building.Opentheoutsidedoors;exhaustfumes

aredangerous.

•Donotclearsnowacrossthefaceofslopes.Exercise

extremecautionwhenchangingdirectiononslopes.

Donotattempttoclearsteepslopes.

•Neveroperatethesnowthrowerwithoutproper

guards,plates,orothersafetyprotectivedevicesin

place.

•Neveroperatethesnowthrowernearglass

enclosures,automobiles,windowwells,drop-offs,

etc.withoutproperadjustmentofthesnow

dischargeangle.Keepchildrenandpetsaway .

•Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofastarate.

•Neveroperatethemachineathightransportspeeds

onslipperysurfaces.Usecarewhenreversing.

•Neverdirectdischargeatbystandersorallowanyone

infrontoftheunit.

•Disengagepowertothecollector/impellerwhen

snowthroweristransportedornotinuse.

•Neveroperatethesnowthrowerwithoutgood

visibilityorlight.Alwaysbesureofyourfooting,and

keeparmholdonthehandles.Walk;neverrun.

•Neveroperatethesnowthrowerwithoutgood

visibilityorlight.

•Takeallpossibleprecautionswhenleavingthe

machineunattended.Shiftintoneutral,setthe

parkingbrake,stoptheengineandremovethekey.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesuretheequipmentisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltank

insideabuildingwhereignitionsourcesarepresent

suchashotwaterandspaceheaters,clothesdryers,

etc.Allowtheenginetocoolbeforestoringinany

enclosure.

•Alwaysrefertoowner’sguideinstructionsfor

importantdetailsifthesnowthroweristobestored

foranextendedperiod.

•Maintainorreplacesafetyandinstructionslabels,

asnecessary.

•Runthemachineafewminutesafterthrowingsnow

topreventfreeze-upofthecollector/impeller.

ToroSnowthrowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknow.

•Rotatingrotorbladescaninjurengersor

hands.Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthesnowthrower.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Beforeadjusting,cleaning,repairing,andinspecting

thesnowthrower,andbeforeuncloggingthe

dischargechute,stoptheengine,removethekey,

andwaitforallmovingpartstostop.

•Usethecleanouttool,notyourhands,toremove

obstructionsfromthedischargechute.

•Beforeleavingtheoperatingposition,stopthe

engine,removethekey,andwaitforallmovingparts

tostop.

3

•Donotwearloose-ttingclothingthatcouldget

caughtinmovingparts.

container.Removethekeyfromtheignitionswitch

beforestoringthesnowthrower.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,orlost,repairorreplaceitbeforebeginning

operation.Also,tightenanyloosefasteners.

•Donotsmokewhilehandlinggasoline.

•Donotusethesnowthroweronaroof.

•Donottouchtheenginewhileitisrunningorsoon

afterithasstoppedbecausetheenginemaybehot

enoughtocauseaburn.

•Performonlythosemaintenanceinstructions

describedinthismanual.Beforeperformingany

maintenance,service,oradjustment,stoptheengine,

removethekey,anddisconnectthewirefromthe

sparkplug.Ifmajorrepairsareeverneeded,contact

anAuthorizedServiceDealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthesnowthrowerformorethan30

days,drainthefuelfromthefueltanktoprevent

apotentialhazard.Storefuelinanapprovedfuel

•PurchaseonlygenuineTororeplacementpartsand

accessories.

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operator’searof95dBA,basedonmeasurementsof

identicalmachinesperEN11201.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof108

dBA,basedonmeasurementsofidenticalmachinesper

EN3744.

Vibration

Thisunitdoesnotexceedahand/armvibrationlevelof

3.1m/s

perEN1033.

2

,basedonmeasurementsofidenticalmachines

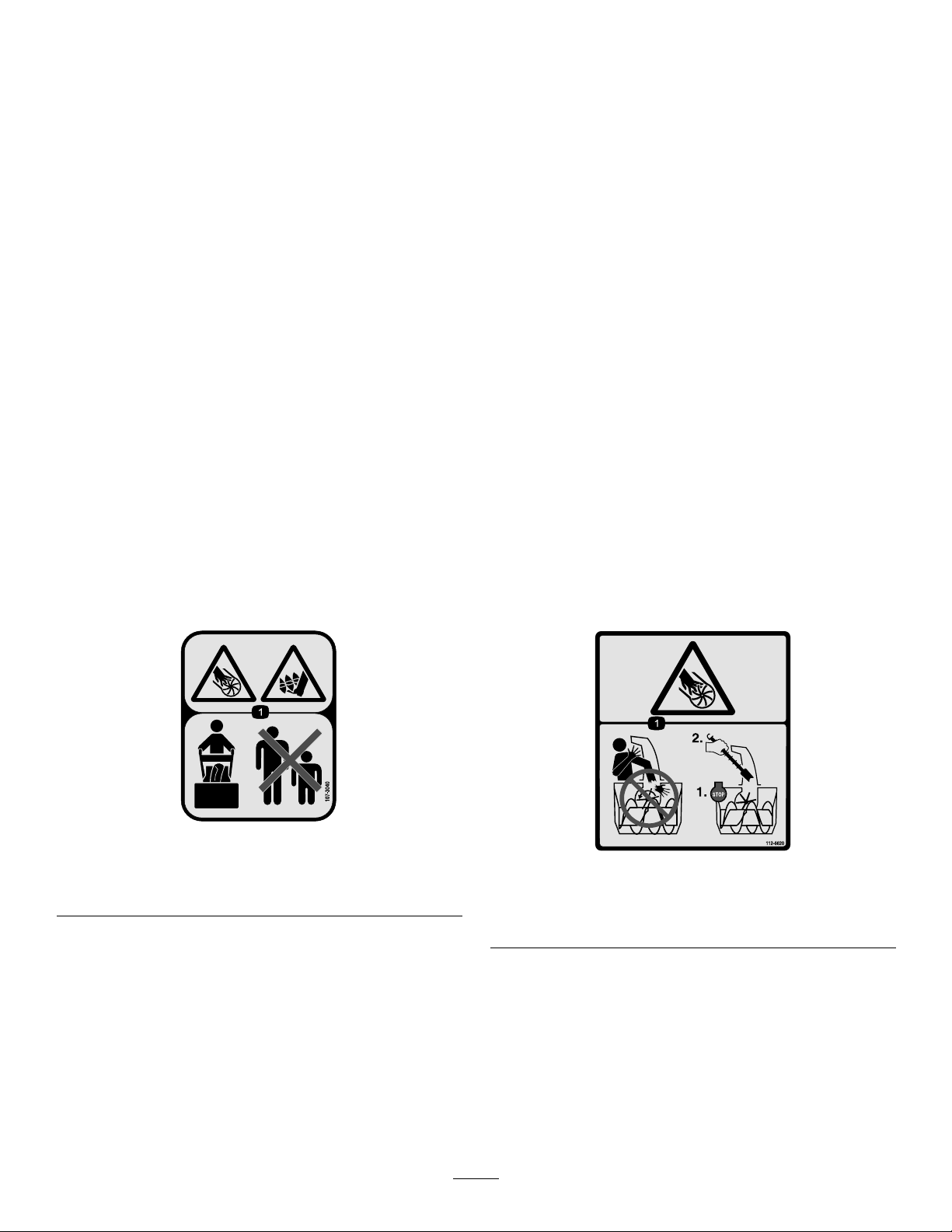

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamaged

decals.

107-3040

1.Cuttingdismemberment,impellerandcutting

dismemberment,augerhazards—keepbystandersasafe

distancefromthesnowthrower.

1.Cutting/dismembermenthazard,impeller—donotplace

yourhandinthechute;stoptheenginebeforeleavingthe

operator’sposition,usethetooltoclearthechute.

112-6620

4

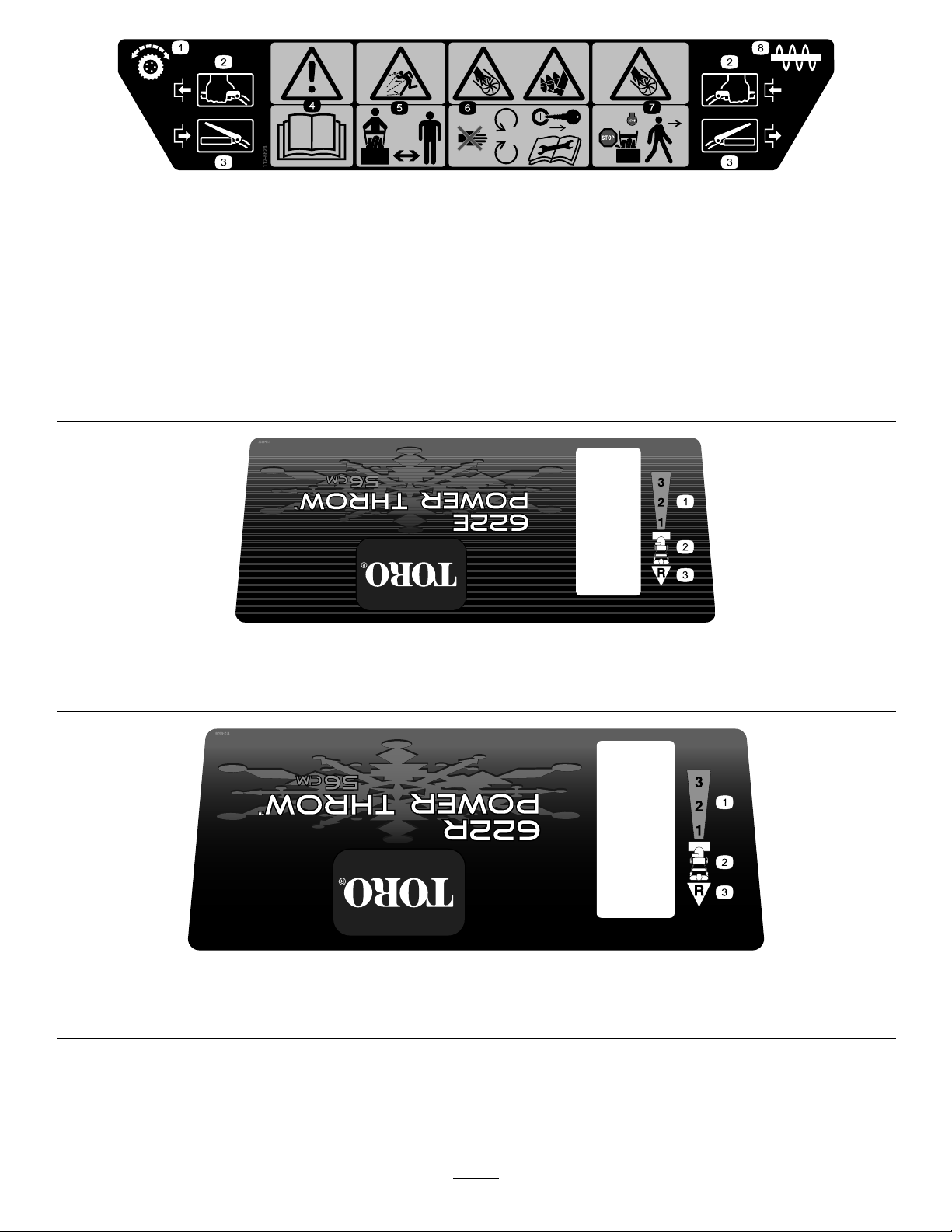

112-6624

1.Wheeldrive3.Disengage5.Thrownobject

2.Engage4.Warning—readthe

Operator’sManual.

hazard—keepbystanders

asafedistancefromthe

snowthrower.

6.Cutting/dismemberment

hazard,impeller—keep

awayfrommovingparts;

removetheignitionkeyand

readtheinstructionsbefore

servicingorperforming

maintenance.

7.Cutting/dismemberment

hazard,impeller—stop

theengineandwaitforall

movingpartstostopbefore

leavingtheoperator’s

position.

8.Auger

1.Forwarddrivespeedsettings

1.Forwarddrivespeedsettings

2.Speedselector

2.Speedselector

112-6637

Model38607only

3.Reversedrivespeedsetting

112-6638

Model38606only

3.Reversedrivespeedsetting

5

1.Warning—hotsurface,donottouch

1

2

3

4

5

6

5

7

TecumsehPartNo.36501

1.Primer

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

TecumsehPartNo.35077

1.Keyignition5.Increasingscale

2.Engagetostarttheengine

3.Disengagetostopthe

engine

4.Fast

6.Slow

7.Stoptheengine

ProcedureDescription

1.

2.

3.

4.

5.

6.

Qty.

Handle1

Bolts4

Bellevillewashers4

Flangenut1

Speedselectorrod

Cotterpin

Flatwasher1

Flangelocknut1Installthetractionrod.

Clevispin

Cotterpin

Chutecontrolrodassembly(rodand

bracket,wormgear,andbracket)

Bellevillewasher1

Bolt2

Carriagebolt

Locknut3

Curvedwasher

Flatwasher1

Nopartsrequired

1

1

1

1

1

1

1

–

Installthehandle.

Installthespeedselectorrod.

Installtheauger/impellerdrivecontrol

linkage.

Installthechutecontrolrod.

Filltheenginewithoil.

Use

7.

8.

Nopartsrequired

Nopartsrequired

6

–

–

Checkthetirepressure.

Checktheskidsandscraper.

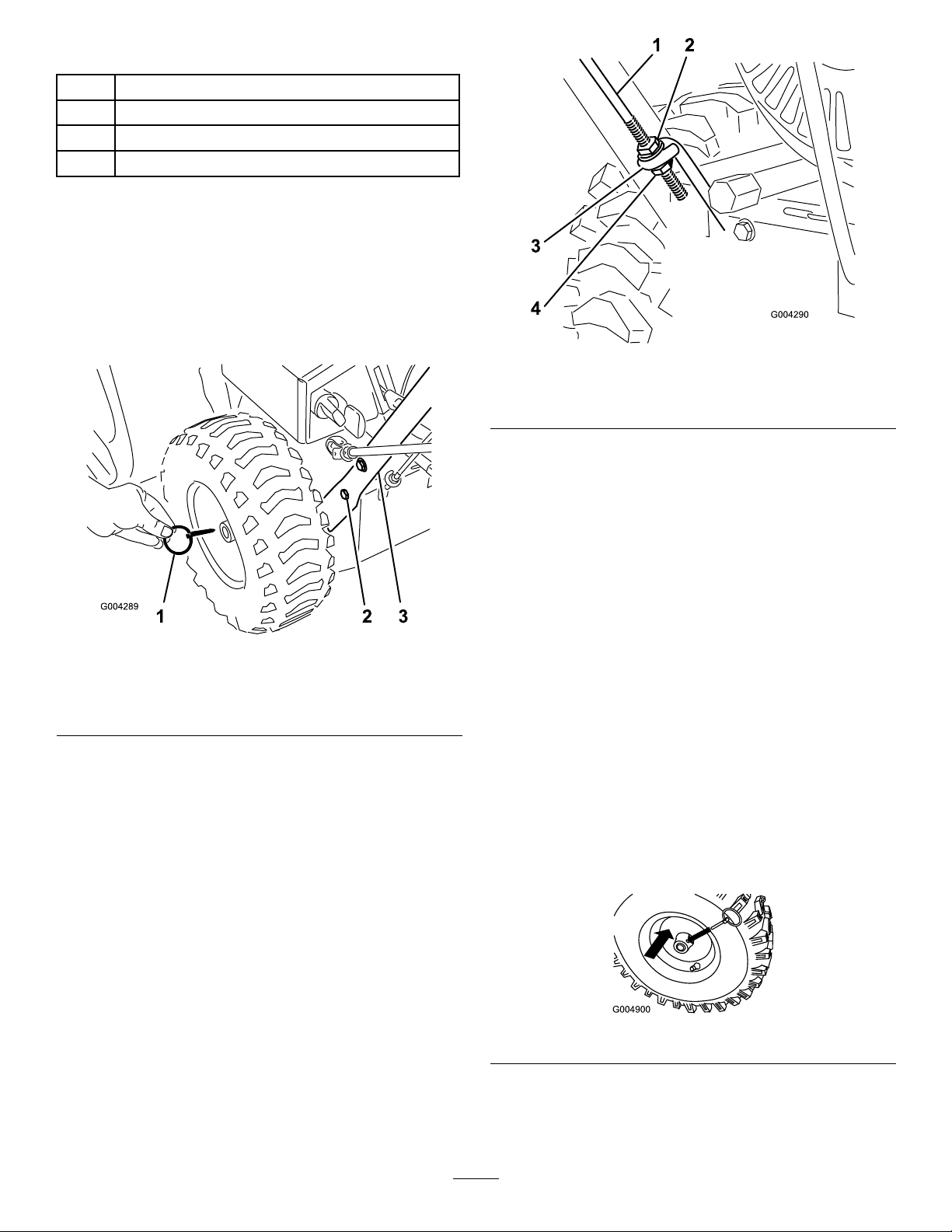

1.InstallingtheHandle

1Handle

4Bolts

4Bellevillewashers

1Flangenut

Procedure

1.Removethetiestrapsthatsecurethecontrolrods

tothehandle.

2.Removetheaxlepinsfrombothwheelsandslide

thewheelsoutwardontheaxleapproximately1inch

(2.5cm)(Figure3).

Figure4

1.Tractionrod3.Lowertractionrodloop

2.Flangenut4.Flangelocknut

4.Positiontheleftsideofthehandleassemblyagainst

thesideofthesnowthrowerandinserttheendof

thetractionrodthroughthelowertractionrodloop

(Figure4).

Figure3

1.Axlepin(2)

2.CapscrewandBelleville

washer(4)

3.Handle

3.Threadaangenut(nottheangelocknut)withthe

angedownontothetractionrodattachedtothe

leftsideofthehandle(Figure4).

5.Aligntheholesintheleftsideofthehandleassembly

withtheholesintheleftsideplate,andsecurethe

handlewith2capscrewsandBellevillewashersuntil

theyarengertight(Figure3).

Note:TheconcavesideoftheBellevillewasher

goesagainsttheoutsideofthehandle.

6.Aligntheholesintherightsideofthehandle

assemblywiththeholesintherightsideplate,and

securethehandlewith2capscrewsandBelleville

washersuntiltheyarengertight.

7.Ensurethatthehandlesareatthesameheight,then

tightenthehandlefastenerssecurely .

8.Slidethewheelsinwardandinserteachaxlepin

throughtheholeineachwheelhubandthroughthe

outerholeoftheaxle(Figure5).

Figure5

Note:Tousetirechains(optional),installtheaxle

pinsthroughtheouteraxleholes.

7

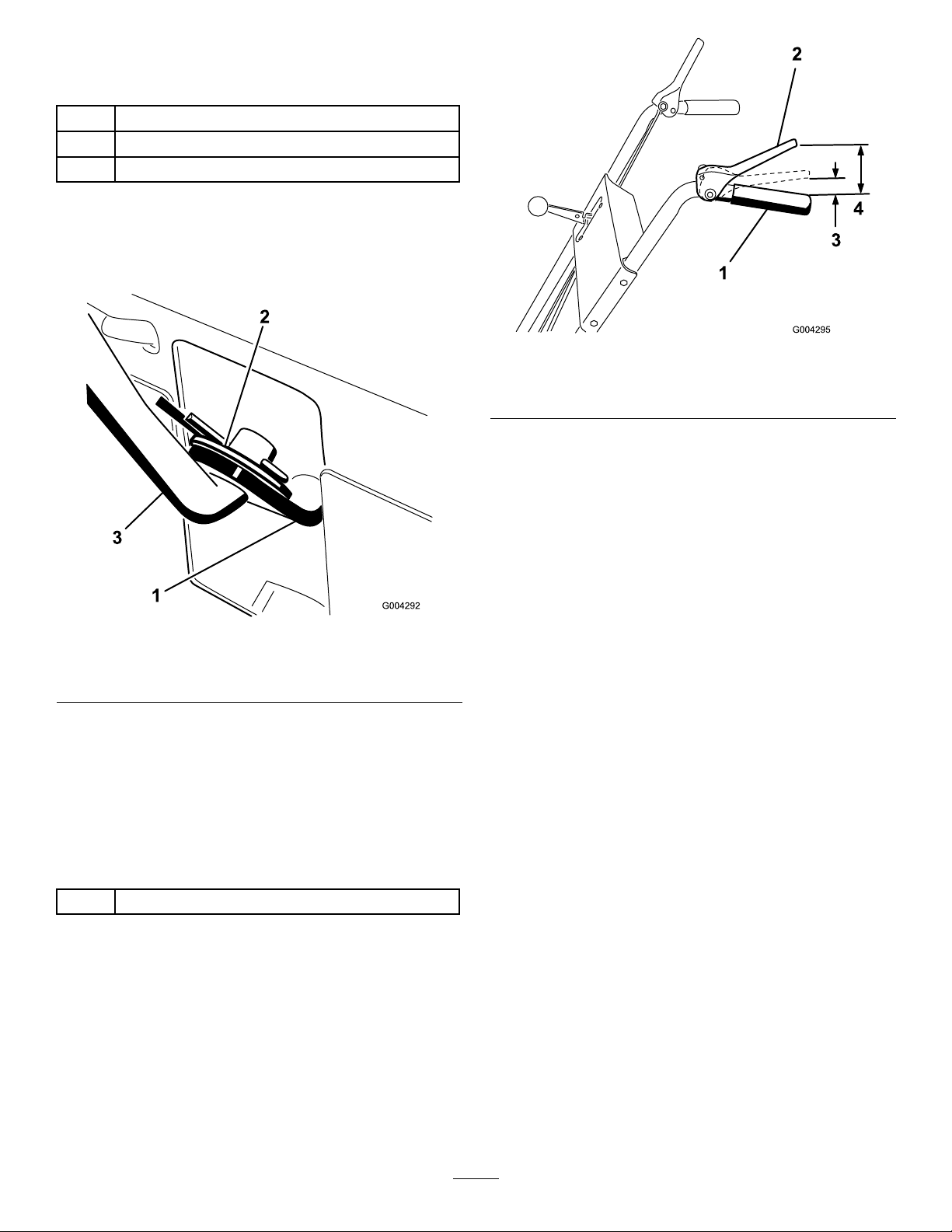

2.InstallingtheSpeedSelector

Rod

1

Speedselectorrod

1

Cotterpin

1Flatwasher

Procedure

1.Pullthespeedselectorarm(Figure6)tothemost

outwardposition.

Figure7

1.Handgrip

2.Tractioncontrollever

3.1to2inches(2.5to5cm)

4.4-1/2inches(11.4cm)

3.Tightenthe2angenutsuntiltheyarengertight.

4.Movethespeedselectorlever(Figure7)intothird

gear.

Figure6

1.Speedselectorarm3.Speedselectorrod

2.Flatwasherandcotterpin

2.Movethespeedselectorlever(Figure13)onthe

controlpaneltotheR(Reverse)position.

3.Installthespeedselectorrodintothespeedselector

arm,addaatwasherontheselectorrod,andsecure

itwithacotterpin(Figure6).

3.InstallingtheTractionRod

1Flangelocknut

Procedure

Note:Ifthespeedselectorleverdoesnotmove

intothirdgear,adjustthespeedselectorbefore

continuing.RefertoAdjustingtheSpeedSelector.

5.Slowlypullthesnowthrowerbackwardwhileslowly

pressingthetractioncontrollevertowardthe

handgrip.

Note:Theadjustmentiscorrectwhenthewheels

stoprollingbackwardandthedistancebetweenthe

topofthehandgripandthebottomofthetraction

controlleveris1to2inches(2.5to5cm)asshown

inFigure7.

6.Adjustthe2angenuts,ifnecessary,toobtainthe

properdistancebetweenthetopofthehandgripand

thebottomofthetractioncontrollever.

7.Tightentheangenutssecurely.

1.Threadtheangelocknut(angesideup)ontothe

bottomofthetractioncontrolrod,belowtheloop

inthelowertractionrod(Figure4).

2.Adjustthe2angenutsupordownonthetraction

roduntilthedistancebetweenthetopofthe

handgripandthebottomofthetractioncontrol

leverisapproximately4-1/2inches(11.4cm)as

showninFigure7.

8

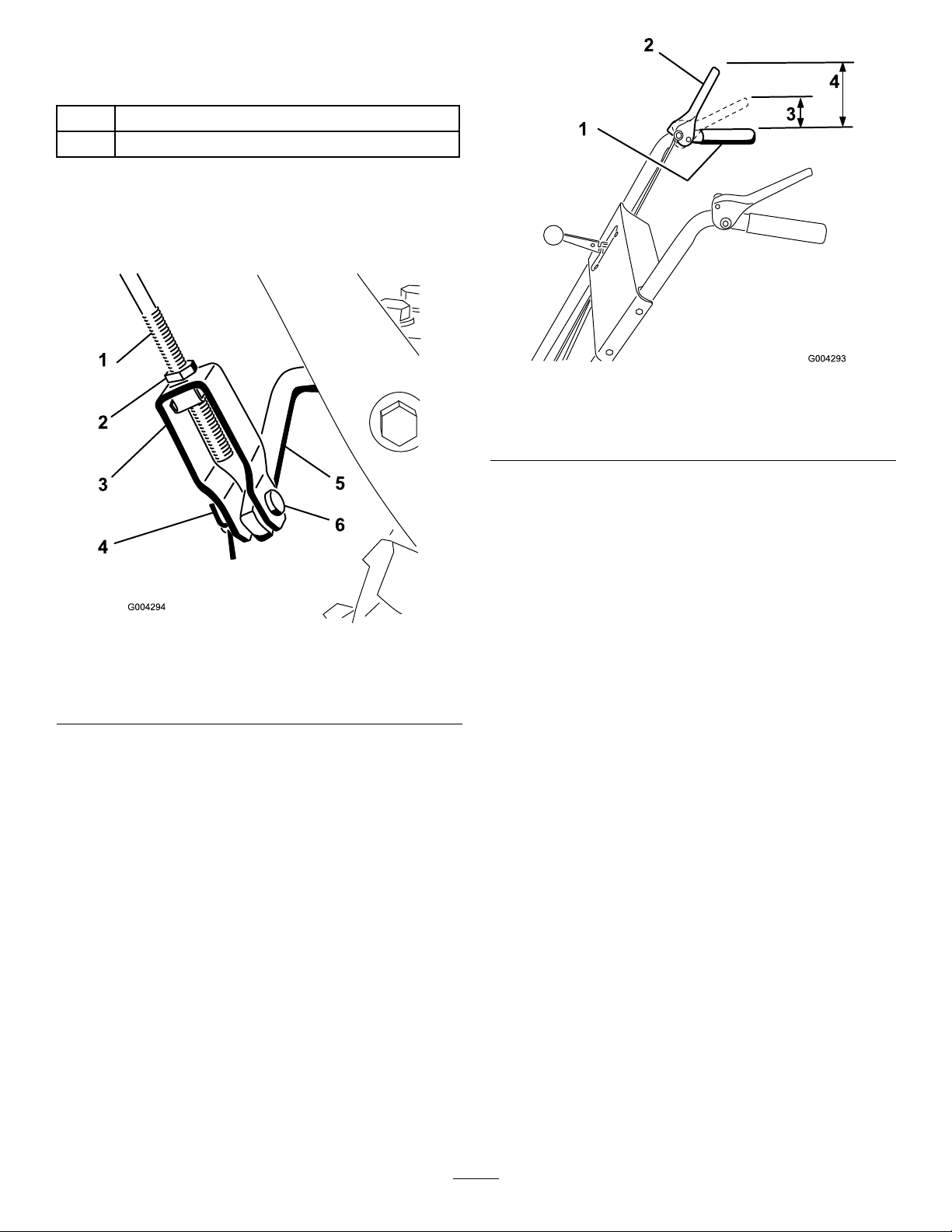

4.InstallingtheAuger/Impeller

DriveControlLinkage

1

Clevispin

1

Cotterpin

Procedure

1.Loosenthejamnutabovetheclevisontheupper

controlrod(Figure8).

Figure9

1.Handgrip

2.Auger/impellercontrol

lever

3.1to2inches(2.5to5cm)

4.5inches(12.7cm)

Note:Thedistanceshouldbeapproximately5

inches(12.7cm).

Figure8

1.Uppercontrolrod

2.Jamnut5.Lowercontrolrod

3.Clevis6.Clevispin

4.Cotterpin

2.Aligntheholesintheclevisandthelowercontrol

rodandinserttheclevispin(Figure8).

3.Checkthedistancebetweenthetopofthehandgrip

andthebottomoftheauger/impellerdrivecontrol

lever(Figure9).

4.Presstheauger/impellerdrivecontrolleverslowly

towardthehandgrip.

Note:Theamountofforceneededtocompressthe

leverincreasesnoticeablywhenyouremovetheslack

fromtheauger/impellerdrivebelt(approximately

1/2ofthelevermovement).Theadjustmentis

correctwhentheforcebeginstoincreaseandthe

distancebetweenthetopofthehandgripandthe

bottomoftheauger/impellerdrivecontrolleveris1

to2inches(2.5to5cm)asshowninFigure9.

Note:Iftheforcedoesnotnoticeablyincrease,

removethebeltcover(refertostep2ofReplacing

theTractionDriveBelt)andmeasure2inches(5cm)

abovethehandgripatthepointwhereyouremove

theslackfromtheauger/impellerdrivebelt.

5.Toadjustthedistance:

A.Removetheclevispin.

B.Loosenthejamnut.

C.Threadtheclevisupordowntoincreaseor

decreasethedistancebetweenthetopofthe

handgripandthebottomoftheauger/impeller

drivecontrollever(Figure8).

6.Whentheadjustmentiscorrect,installtheclevispin

andsecureitinplacewiththecotterpin(Figure8).

7.Tightenthejamnuttosecuretheclevis(Figure8).

9

Loading...

Loading...