Page 1

TUBE FRAME GENERATOR

Table of Contents – Page 1 of 3

PREFACE

SAFETY INSTRUCTIONS

FOR YOUR SAFETY

IDENTIFICATION

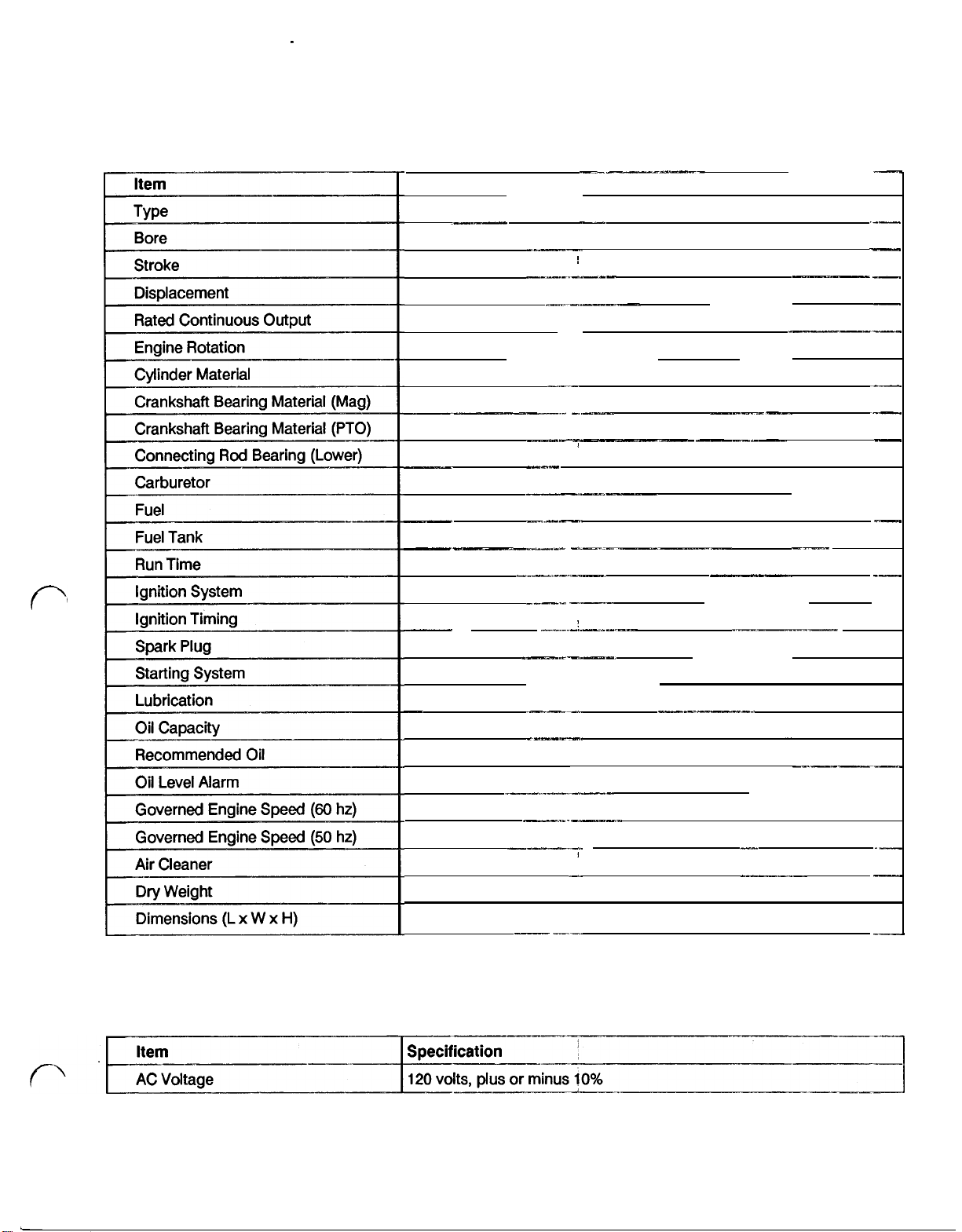

T1200 SPECIFICATIONS

MODEL 62012 PRODUCT SPECIFICATIONS

MODEL 62012 GENERATOR SPECIFICATIONS

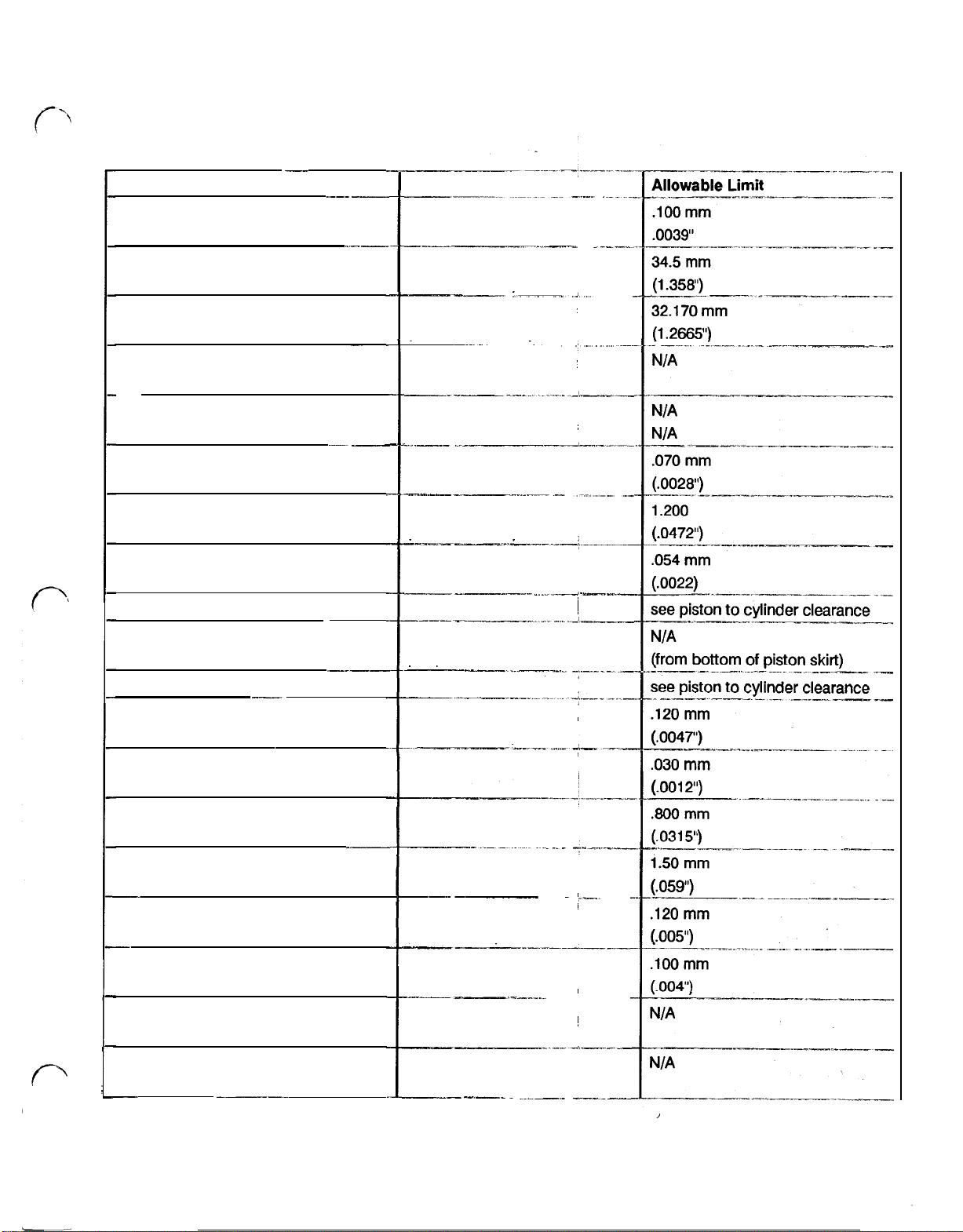

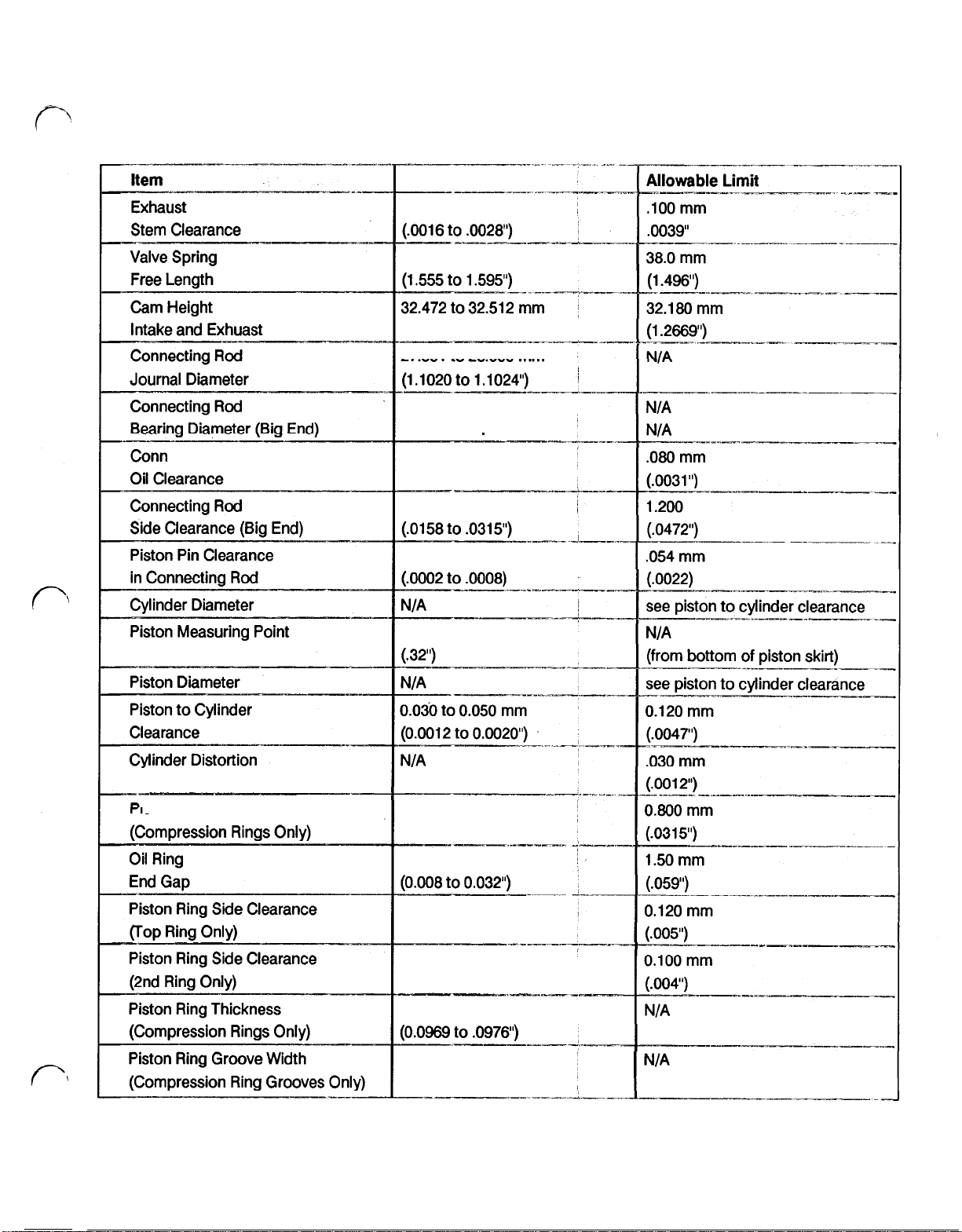

MODEL 62012 ENGINE SERVICE SPECIFICATIONS

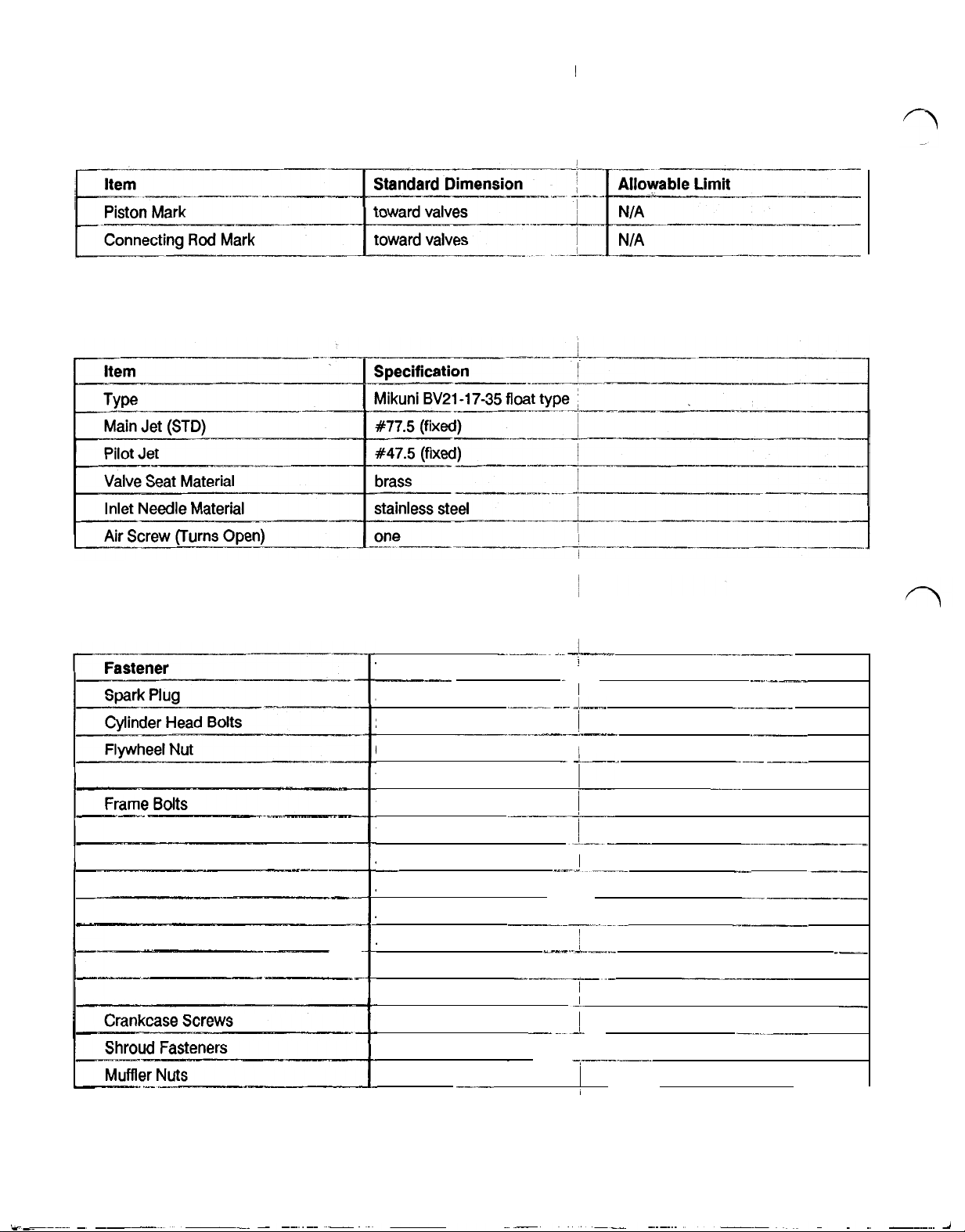

MODEL 62012 CARBURETOR SPECIFICATIONS

MODEL 62012 FASTENER TORQUES

T1800 SPECIFICATIONS

MODEL 62018 PRODUCT SPECIFICATIONS

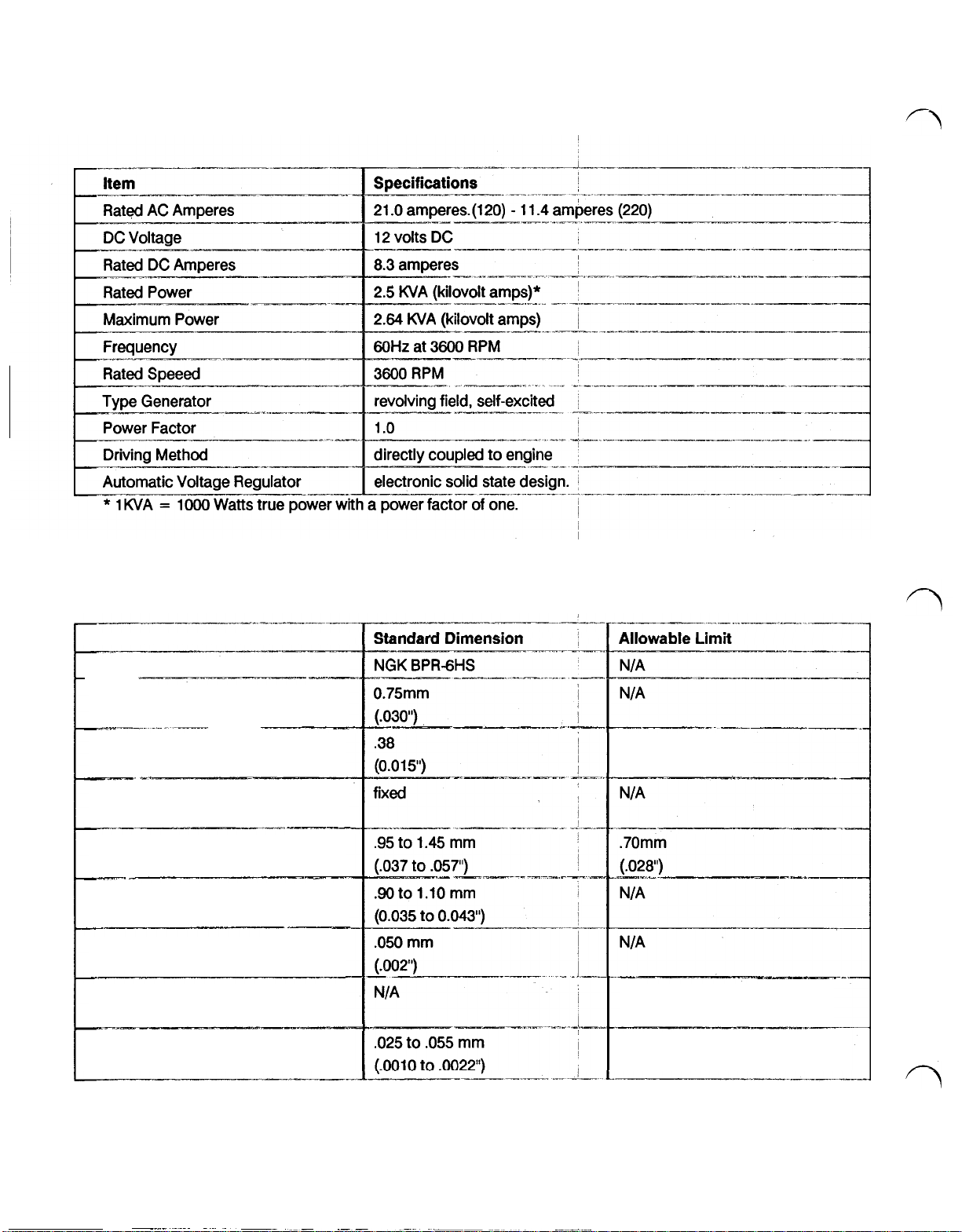

MODEL 62018 GENERATOR SPECIFICATIONS

MODEL 62018 ENGINE SERVICE SPECIFICATIONS

MODEL 62018 CARBURETOR SPECIFICATIONS

MODEL 62018 FASTENER TORQUES

T2500 & T2500D SPECIFICATIONS

MODELS 62025 & 62027 PRODUCT SPECIFICATIONS

MODEL 62025 & 62027 GENERATOR SPECIFICATIONS

MODELS 62025 & 62027 ENGINE SERVICE SPECIFICATIONS

MODELS 62025 & 62027 CARBURETOR SPECIFICATIONS

MODELS 62025 & 62027 FASTENER TORQUES

T3000 & T3000D SPECIFICATIONS

MODELS 62030 & 62032 PRODUCT SPECIFICATIONS

MODEL 62030 & 62032 GENERATOR SPECIFICATIONS

MODELS 62030 & 62032 ENGINE SERVICE SPECIFICATIONS

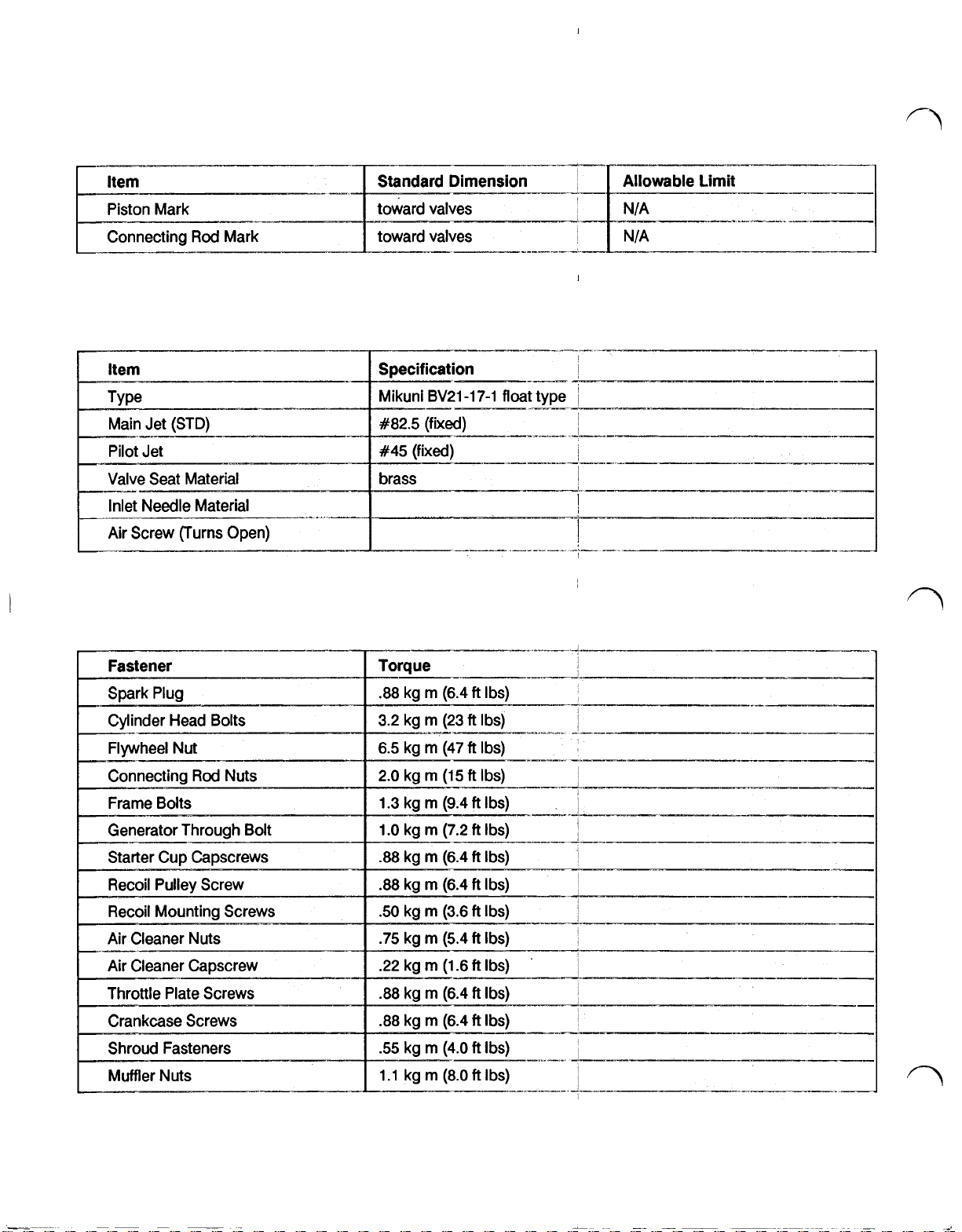

MODELS 62030 & 62032 CARBURETOR SPECIFICATIONS

MODELS 62030 & 62032 FASTENER TORQUES

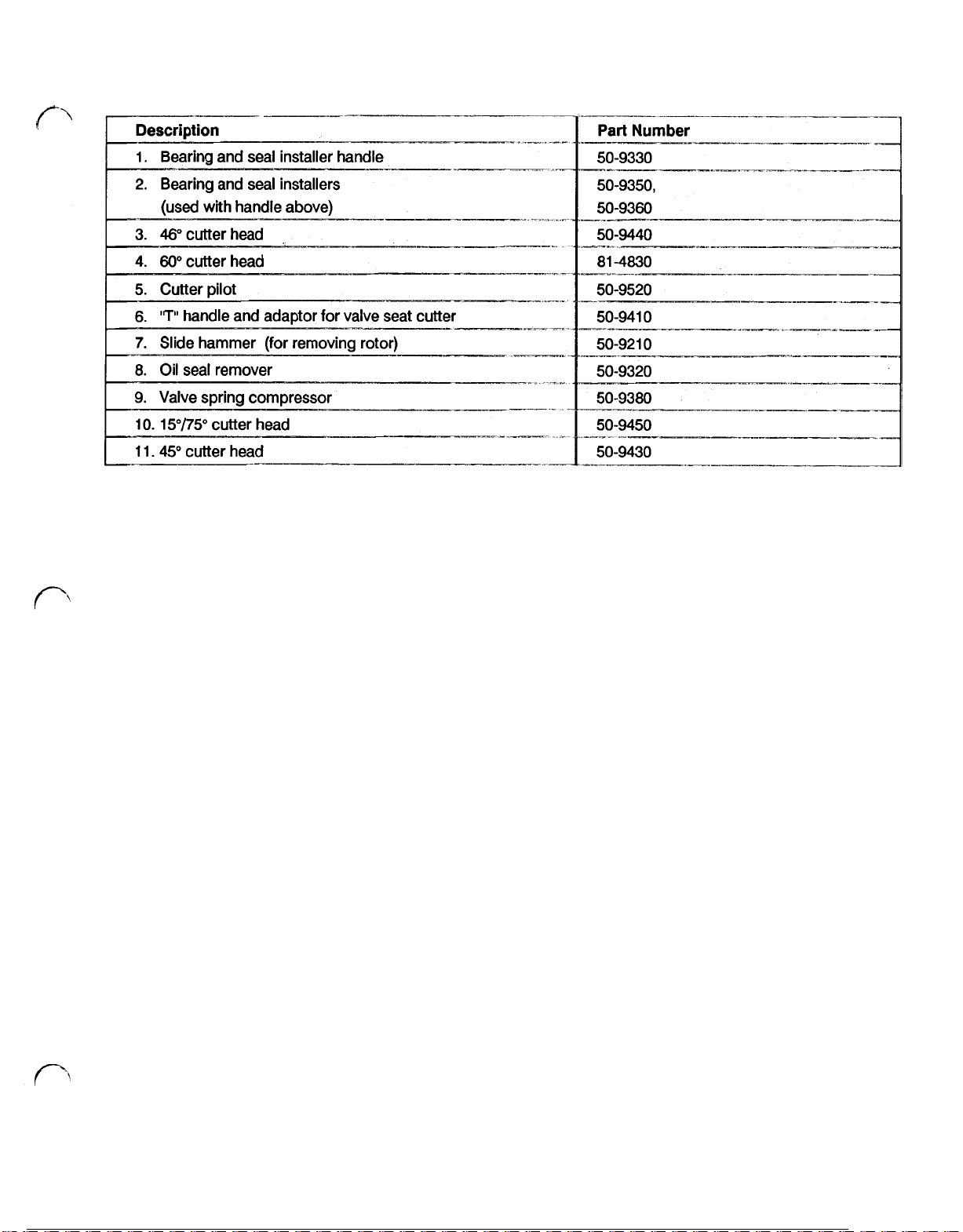

SPECIAL TOOLS

TROUBLESHOOTING

ENGINE DOES NOT PRODUCE SPARK

ENGINE FLOODS DURING STARTING

ENGINE DOES NOT GET FUEL DURING STARTING

ENGINE DIFFICULT TO START

ENGINE LACKS POWER

ENGINE KNOCKS

Page 2

TUBE FRAME GENERATOR

Table of Contents – Page 2 of 3

TROUBLESHOOTING - Continued

ENGINE MISSES UNDER LOAD

ENGINE OVERHEATS

ENGINE SURGES OR RUNS UNEVENLY

ENGINE VIBRATES EXCESSIVELY

ENGINE USES EXCESSIVE OIL OR SMOKES

MAINTENANCE

MAINTENANCE - AIR CLEANER

MAINTENANCE - SPARK PLUG

MAINTENANCE - CHANGING OIL

MAINTENANCE - FUEL SEDIMENT BOWL

MAINTENANCE - FREQUENCY ADJUSTMENT

MAINTENANCE - VALVE CLEARANCE

MAINTENANCE - VALVE CLEARANCE INSPECTION

MAINTENANCE - VALVE CLEARANCE ADJUSTMENT

MAINTENANCE - DECARBONING SPARK ARRESTER

MAINTENANCE - STORAGE

SECTION 1 CARBURETOR

CARBURETOR - OPERATION

CARBURETOR - REMOVAL

CARBURETOR - DISASSEMBLY

CARBURETOR - SERVICE

CARBURETOR - REASSEMBLY

CARBURETOR - INSTALLATION

SECTION 2 FUEL SYSTEM

FUEL TANK AND STRAINER

FUEL TANK AND STRAINER - REMOVAL

FUEL TANK AND STRAINER - INSTALLATION

FUEL TANK CAP

FUEL TANK CAP - SERVICE

FUEL SHUTOFF AND SEDIMENT BOWL

FUEL SHUTOFF AND SEDIMENT BOWL - REMOVAL

FUEL SHUTOFF AND SEDIMENT BOWL - SERVICE

FUEL SHUTOFF AND SEDIMENT BOWL - INSTALLATION

SECTION 3 IGNITON SYSTEM

IGNITION OPERATION

IGNITION OPERATION - FLYWHEEL

IGNITION OPERATION - IGNITION COIL

IGNITION OPERATION - TRIGGER CIRCUIT

IGNITION OPERATION - SPARK PLUG

IGNITION COIL - TESTING

Page 3

TUBE FRAME GENERATOR

Table of Contents – Page 3 of 3

SECTION 3 IGNITON SYSTEM - Continued

IGNITION COIL - REMOVAL

IGNITION COIL - INSTALLATION

SPARK PLUG

SPARK PLUG - REMOVAL

SPARK PLUG - INSTALLATION

SECTION 4 RECOIL STARTER

RECOIL STARTER - REMOVAL

RECOIL STARTER - DISASSEMBLY

RECOIL STARTER - REASSEMBLY

RECOIL STARTER - INSTALLATION

SECTION 5 LOW OIL SHUTDOWN

LOW OIL SHUTDOWN CIRCUIT - PURPOSE

LOW OIL SHUTDOWN CIRCUIT - OPERATION

LOW OIL SHUTDOWN CIRCUIT - TESTING

LOW OIL SHUTDOWN SWITCH - REMOVAL

LOW OIL SHUTDOWN SWITCH - INSTALLATION

SECTION 6 ENGINE

ENGINE - DISASSEMBLY

ENGINE - CLEANING AFTER DISASSEMBLY

ENGINE - INSPECTION

ENGINE - REASSEMBLY

SECTION 7 GENERATOR

DEFINITION OF TERMS

GENERATOR OPERATION

GENERATOR TESTING

GENERATOR SERVICE

TROUBLESHOOTING

SECTION 8 CONTROL PANEL

CONTROL PANEL- DISASSEMBLY

SECTION 9 SCHEMATICS

SCHEMATICS

Page 4

Page 5

PREFACE

This Service and Overhaul Manual was written expressly for the Tor0 T1200, T1800,

T2500 and T3000 electric generators. This manual will cover both single and dual

voltage models of the T2500 and T3000 generator.

The Tor0 Company has made every effort to make this Service Manual a useful and

lasting addition to every Service Facility. To assure proper and effective repairs, and

to provide optimum performance for the life

this manual carefully, referencing

This manual contains a brief section on electrical theory which is essential to

understanding generator operation, troubleshooting and maintenance The

complete manual also provides the service technician with a working guideline of

maintenance, troubleshooting, test, repair and overhaul procedures.

The Toro Company reserves the right to change product specifications or this manual

without notice.

The Tor0 Company gratefully acknowledges the assistance provided by the Suzuki

Motor Company in the writing

it

as necessary when generator service is required.

of

this manual.

of

the machine, you are urged to read

COPYRIGHT®©

©The Tor0 Company

Minneapolis,

ALL

RIGHTS

MN

55420

RESERVED

1988

USA

Page 6

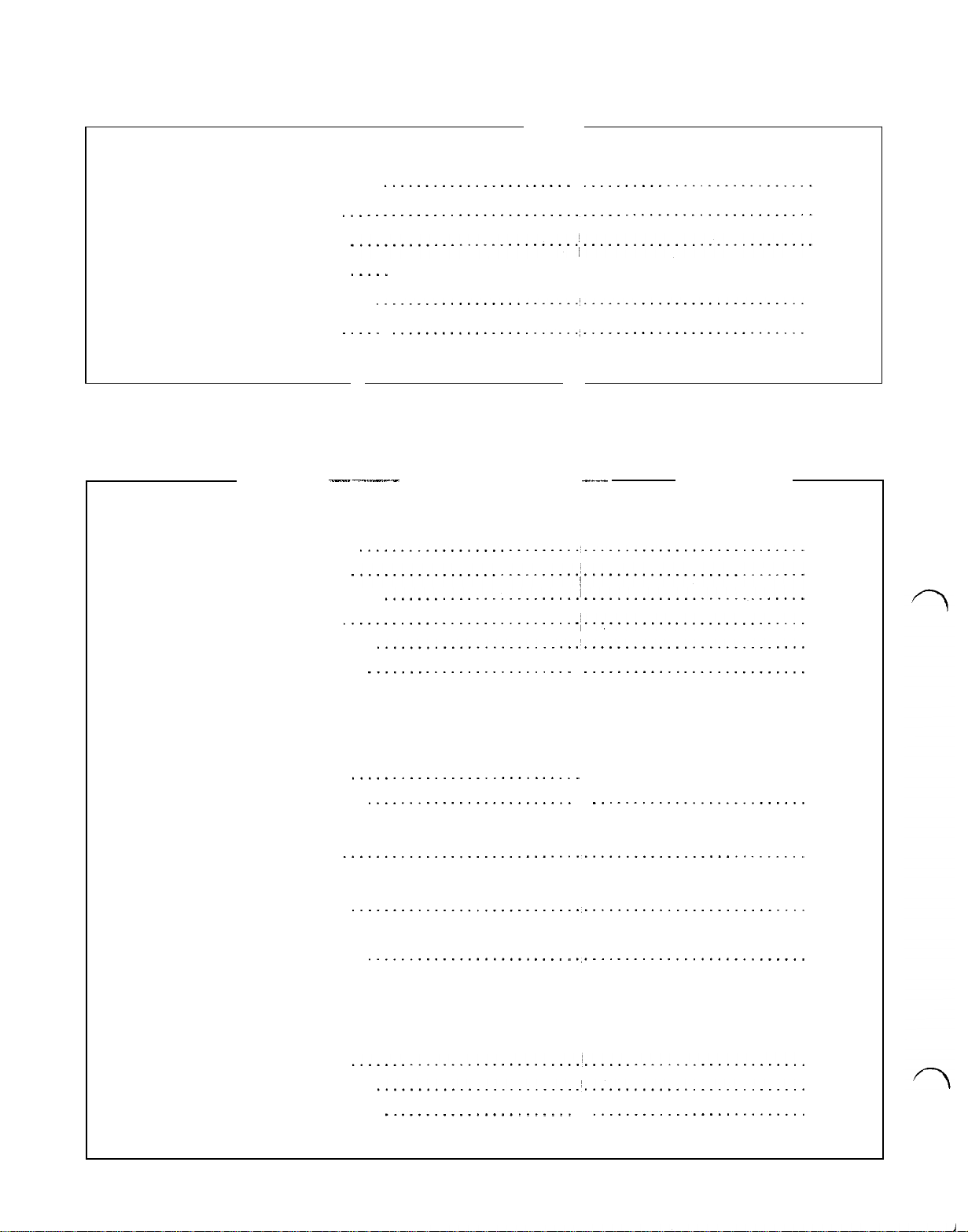

Reference Information

TABLE

OF

C

O

N

T

E

N

T

S

Page

Service Procedures

Section One Carburetor

Safety Instructions

Identification

Specifications 3

Special Tools 19

Troubleshooting*

Maintenance 24

*

For generating troubleshooting information, see Section

I

7,

page

74.

i

operation

removal 30

disassembly

service 31

reassembly 3 1

installation 31

i

1

2

20

Page

29

30

Section Two Fuel System

Fuel Tank and Strainer

removal 33

installation 33

Fuel Tank Cap

service 33

Fuel Shutoff and Sediment

removal 34

service 34

installation

Section Three Ignition System

Ignition Operation

flywheel 36

ignitioncoil 36

trigger circuit 36

sparkplug 37

Bowl

35

Page 7

TABLE

Service Procedures (cont'd)

OF

CONTENTS

I

(cont'd)

Section Three

Section Four

Section Five

Ignition System (cont'd)

Ignition Coil

removal

installation

Spark Plug

removal

installation

Recoil Starter

removal

disassembly

reassembly

installation

Low

Oil

Shutdown

Low

Oil

Shutdown Circuit

purpose

operation

testing

Low Oil Shutdown Switch

removal

installation

Page

38

39

I

40

40

41

41

42

43

44

44

44

I

45

45

Section Six

Section Seven

Engine

disassembly

cleaning after disassembly

inspection

reassembly

Generator

Definition

Generator Operation

of

Terms

exciter coil and permanent magnet

AVR and rotor coil

stator coil and receptacles

generatingprocess

automatic voltage regulator

45

51

51

55

64

65

65

66

66

66

Page 8

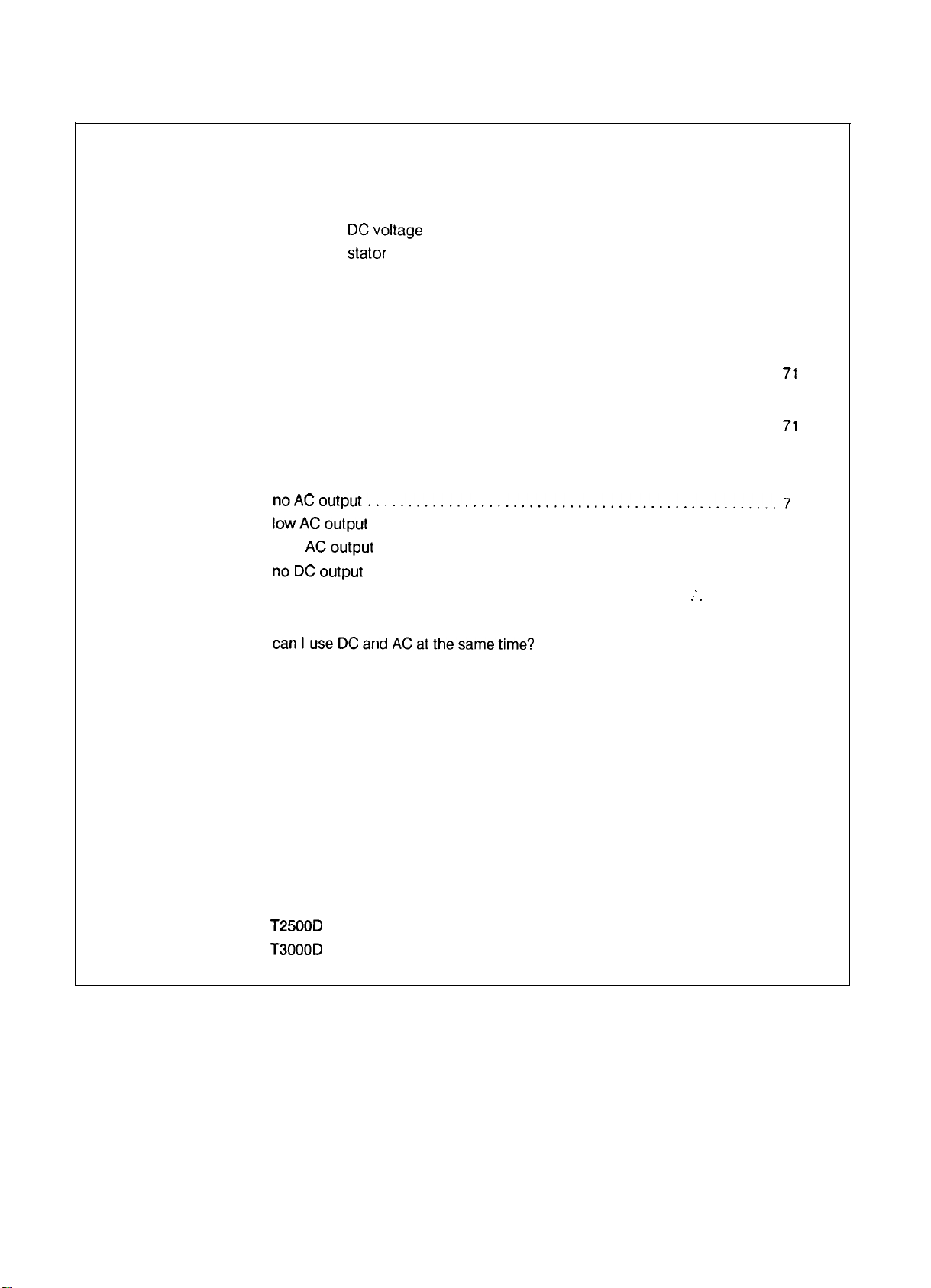

TABLE OF CONTENTS (cont’d)

Service Procedures (cont’d)

Section Seven

Generator (cont’d)

Generator Testing

measuring AC voltage

measuring DCvoltage

measuring stator coil resistance

measuring rotor coil resistance

measuring exciter coil resistance.

sensor circuit continuity

DC circuit diodes

brush inspection ................................................

Generator Service

disassembly ...................................................

reassembly

Troubleshooting

noACoutput...................................................7

IowACoutput

high

ACoutput

noDCoutput

engine labors heavily

low output on dual voltage generators

canIuseDCandACatthesametime?

...........................................

...........................................

...................................

....................................

..................................

..........................................

...............................................

....................................................

..................................................

.................................................

...................................................

;‘.

.................................

..............................

.............................

.........

Page

68

68

68

69

69

70

70

71

71

72

4

74

75

75

76

76

76

Section Eight Control Panel

disassembly ...................................................

inspection .....................................................

reassembly

Section Nine

Schematic Diagram

T1200

T1800

T2500..

T3000

T2500D

T3000D

....................................................

.........................................................

.........................................................

.......................................................

.........................................................

.......................................................

.......................................................

77

77

77

78

78

79

79

80

80

Page 9

SAFETY

This safety symbol

means WARNING

AND/OR CAUTION

PERSONAL SAFETY

INSTRUCTION Read the instruction

because

Failure to comply with

may result in personal injury or death.

it

has to do with safety.

the

instruction

INSTRUCTIONS

This manual is intended to be a service and repair

manual only The safety instructions provided in this

manual are for the troubleshooting and service of the

product only. Individual Operator's Manuals will

contain safety information for the operation of the

generators that are described is this manual.

Operator's Manuals with complete operational safety

instructions are available through:

The Toro Company

Publications Department

81

11

Lyndale Avenue South

~Minneapolis,

MN

55420

U.S.A.

FOR

Mishandling gasoline and oil can be deadly.

Gasoline is explosive and should never be

exposed to a flame or spark. Do not smoke

while working around gasoline.

Avoid the accidental misuse of gasoline by

always using a storage container designed for

gasoline.

Avoid fire hazards by operating the generator

no closer

combustible material.

When decarboning the muffler, burning

pieces of carbon may be discharged. Make

sure there is no combustible material in

area.

Spilled oil or gasoline can present a fire

hazard or cause injury through falls. Always

remove spilled oil or gasoline.

than

one meter, (three feet) to any

YOUR

the

SAFETY

Engine exhaust fumes can cause death. Never

operate an engine in a confined area or

without venting the exhaust fumes to

outside atmosphere.

a

in

or

the

spark plug.

line.

generator

operation

You can be killed by the electricity

produces. While a generator is

never/ touch any portion of your body to

exposed or uninsulated terminals

Make sure that the engine will not accidentally

start while completing a service procedure by

pulling

Electrical line workers can be electricuted by

backfeeding electricity. Never connect a

generator to your house wiring without using

a

generator from

the

spark plug wire

double throw switch to separate the

the

incoming

off

the

wiring.

1

Page 10

IDENTIFICATION

Each Tor0 whole good is assigned a model and serial number. ,The model number has five digits and

In

indicates the size and style of the product.

serial number which serves to differentiate products with the same model number. The serial number has

seven digits, the first of which identifies the year of manufacture (ie.

built

in

1986.)

addition to the model number, each product also has a unique

6000386

indicates that the product was

These numbers are printed on a decal that

the decal located on the lower cross brace of the tube frame under the engine end of the generator. On

1986

and newer units, the decal can be

decal in correspondence or when replacement parts are needed.

An engine number

service information, please include the engine number.

is

also located on the block of the engine. When filing warranty claims or requesting

is

found

about

1

"

behind the

high and 3"wide. Units built

gas

tank. Always refer to specific numbers

in

1984

and

1985

have

on

the

2

i

Page 11

TI200

Model 62012 Product Specifications

SPECIFICATIONS

Model 62012 Generator Specifications

3

Page 12

TI200

SPECIFICATION$

Model 62012 Generator Specifications (cont'd)

*

1

KVA

=

1000

Watts true power with a power factor of one.

(cont'd)

I

Model 62012 Engine Service Specifications

Standard Dimension

Spark

Plug

Spark Plug Gap

Ignition Coil Air Gap

(External Mount)

Width of Valve

Seat Contact

Intake Guide to Valve

Stem Clearance

NGK BPR-6HS

.75mm

(.030")

.38

(.015”)

fixed

1.OO

to

1.40

mm

(.039

to

.055”)

.80

to

1.OO

mm

(.032

to

.040")

.050

mm

(.002”)

NIA

.025

to

.055

mm

(,0010

to

.0022")

Allowable Limit

NIA

NIA

!

N/A

NIA

.030

mm

(.0012")

.080

mm

.0032

"

Page 13

TI200

SPECIFICATIONS

(cont'd)

Model

62012

Stem Clearance

Bearing Diameter (Big End)

Side Clearance (Big End)

Engine Service Specifications (cont'd)

35.5

to

25.990

.005

to

36.5

to

26.000

.025

mm

mm

mm

Cylinder Distortion

5

Page 14

TI200

SPECIFICATIONS

(cont'd)

Model

Model

62012

62012

Engine Service

Carburetor

Specifications

Specifications

(cont'd)

Model

62012

Fastener

Torques

Torque

.88

2.0

6.5 kg

.7

kg

1.3

1.O

.88

.88

50

.75 kg

.22

.88

.88

55

kg m (6.4

kg m (14.5

m

(47

ft

m

(5.0

ft

kg m (9.4

kg

m

(7.2

kg m (6.4

kg m (6.4

kg

m

(3.6

m

(5.4

kg

m

(1.6

kg m (6.4

kg m (6.4

kg m (4.0

ft

Ibs)

ft

ft

ft

ft

ft

ft

ft

ft

ft

ft

Ibs)

ft

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

i

I

!

!

1.1

kg

m

(8.0

ft

6

Ibs)

i

Page 15

TI800

SPECIFICATIONS

Model

62018

Product Specifications

Specification

air cooled 4-stroke, side valve

66

mm (2.60")

56

mm (2.20”)

191.6 cc (11.69 cu. in.)

2.8 kilowatt (3.8

counterclockwise (as viewed from

aluminum with

ball

ball

plain

float

unleaded regular gasoline

7.00

liters (1.84 gal.)

5.0

hours at rated load

I

-

-

-

HP) @ 3600 rpm

-

~

cast

iron liner

-

PTO

end)

-

-I---

_

___I___

_

_

_

I

Model

6201

transistorized

25°

BTDC

NGK

BPR-6HS

recoil

splash

.7 liters (23.7 oz)

detergent

float type

3600 rpm

3000

rpm

oiled foam type element

40

kg

(88.5

54.1

x 33.7 x48.5 cm (21.3 x 13.3 x 19.1 in)

8

Generator Specifications

@

3600 rpm

SAE

10W30 or' 30,

Ibs)

-

~~

I

--------_-

API

rating of

-

____

SC,

SD,

-~-

I

__

SE,

_

_I_

or

-

-

_

-

SF

_

_

___I_

-

7

Page 16

TI

800

SPECIFICATIONS

Model 6201 8 Generator Specifications (cont'd)

Specification

12.5 amperes.

12 volts DC

8.3

Amperes

1.5

KVA

(kilovolt amps)*

Maximum Power

1.8

KVA

60Hz at

3600

RPM

(kilovolt amps)

3600

RPM

(cont'd)

i

revolving field, self

1

.o

-

excited

directly coupled to engine

Automatic Voltage Regulator

*

1

KVA

=

1000

Watts true power with

electronic solid state design.

a

power factor of one.

Model 6201 8 Engine Service Specifications

Item

Spark Plug

Spark Plug Gap

Ignition Coil Air Gap

(External Mount)

Ignition Coil Air Gap

(Internal Mount)

Valve

Margin

NGK

BPR-6HS

75

mm

(.030")

1.35

to

(.053

to .073")

1.85

mm

!

Width

of

Valve

Seat Contact

Valve

I

Lash

-

Valve Head Runout (Both)

_

I

-

Intake Guide to Valve

Stem Clearance

_____-_

.80

to

1

.OO

mm

(.032

to

.039')

.050

mm

(.002”)

N/A

,025 to

(.0010

.055

to .0022")

mm

8

_._

I

-

Page 17

TI

800

SPECIFICATIONS

(cont'd)

Model

62018

Item

Exhaust Guide to Valve

Stem Clearance

Valve Spring

Free Length

Cam Height

Intake and Exhuast

Connecting

Journal Diameter

Connecting

Bearing Diameter (Big End)

Connecting

Oil Clearance

Connecting

Side Clearance (Big End)

Piston Pin Clearance

in Connecting

Cylinder Diameter

Piston Measuring Point

Engine Service Specifications (cont'd)

Rod

Rod

Rod

Journal

Rod

Rod

Standard Dimension

.035

to

.065

mm

(.0014

to

.0026')

to

36.5

35.5

(1.398

32.465

(1.2781

25.990

(1.0232

26.005

(1.0238

.005

to

(.0002

.200

to

(.0079

to

.006

(.0002

mm

to

1.437")

to

32.505

to

1.2797")

to

26.000

to

1.0236')

to

26.01

5

to

1.0242")

..025

mm

to

.OOlO”)

.900

to

.0354')

.019

mm

to

.0008)

mm

mm

mm

N/A

15

mm

(59')

I

~-.

-

Piston Diameter

Piston to Cylinder

Clearance

Cylinder Distortion

Piston Ring End Gap

(Compression Rings Only)

Oil Ring

End Gap

Piston Ring Side Clearance

(Top Ring Only)

Piston Ring Side Clearance

(2nd Ring Only)

Piston Ring Thickness

(Compression Rings Only)

Piston Ring Groove Width

(Compression Ring Grooves Only)

NIA

.045

to

(.0018

NIA

.200

to

(.0079

.20

to

(.008

to

.020

to

(.001

to

.020

to

(.001

to

to

1.97

(.0776

to

2.01

(.0791

.065

to

.0026')

.400

to

.0158')

.40

mm

.016')

.060

.003')

.060

.003")

1.99

to

.0783")

2.03

to

.0799")

mm

mm

mm

mm

-_._---

mm

mm

9

Page 18

TI800 SPECIFICATIONS

(cont'd)

Model 62018 Engine Service Specifications (cont'd)

Model 62018 Carburetor Specifications

Item

#75 (fixed)

#40

(fixed)

I

Main Jet

Pilot Jet

(STD)

Model 62018 Fastener Torques

Fastener

Spark Plug

Cylinder Head Bolts

Flywheel

Connecting

Nut

Rod

Nuts

Frame Bolts

Torque

.88

kg

2.0

kg

6.5 kg

.70 kg

1.3 kg

rn

rn

rn

rn

rn

(6.4

(15

(47

(5.1

(9.4

ft

ft

ft

ft

ft

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

I

I

I

i

-

.I

I

_

-

..~

-

~

-

-

Generator Through Bolt

Starter

CUP

Capscrews

Recoil Pulley Screw

Recoil Mounting Screws

Air Cleaner

Nuts

Air Cleaner Capscrew

Throttle Plate Screws

Crankcase Screws

Shroud Fasteners

Muffler

Nuts

1.O

kg

rn

(7.2

.88

kg m (6.4

.88

kg m (6.4

.50

kg

rn

(3.6

.75 kg

rn

(5.4

.22

kg

rn

(1.6

.88

kg

rn

(6.4

.88

kg

rn

(6.4

.55

kg m (4.0

-

1.05 kg m (7.6

ft

Ibs)

ft

Ibs)

ft

Ibs)

ft

Ibs)

ft

Ibs)

ft

Ibs)

ft

Ibs)

ft

Ibs)

ft

lbs)

ft

io

-

Ibs)

-

---.___.___

I

_I_

-

I

-

-

~

-

_

-

-~______

-

Page 19

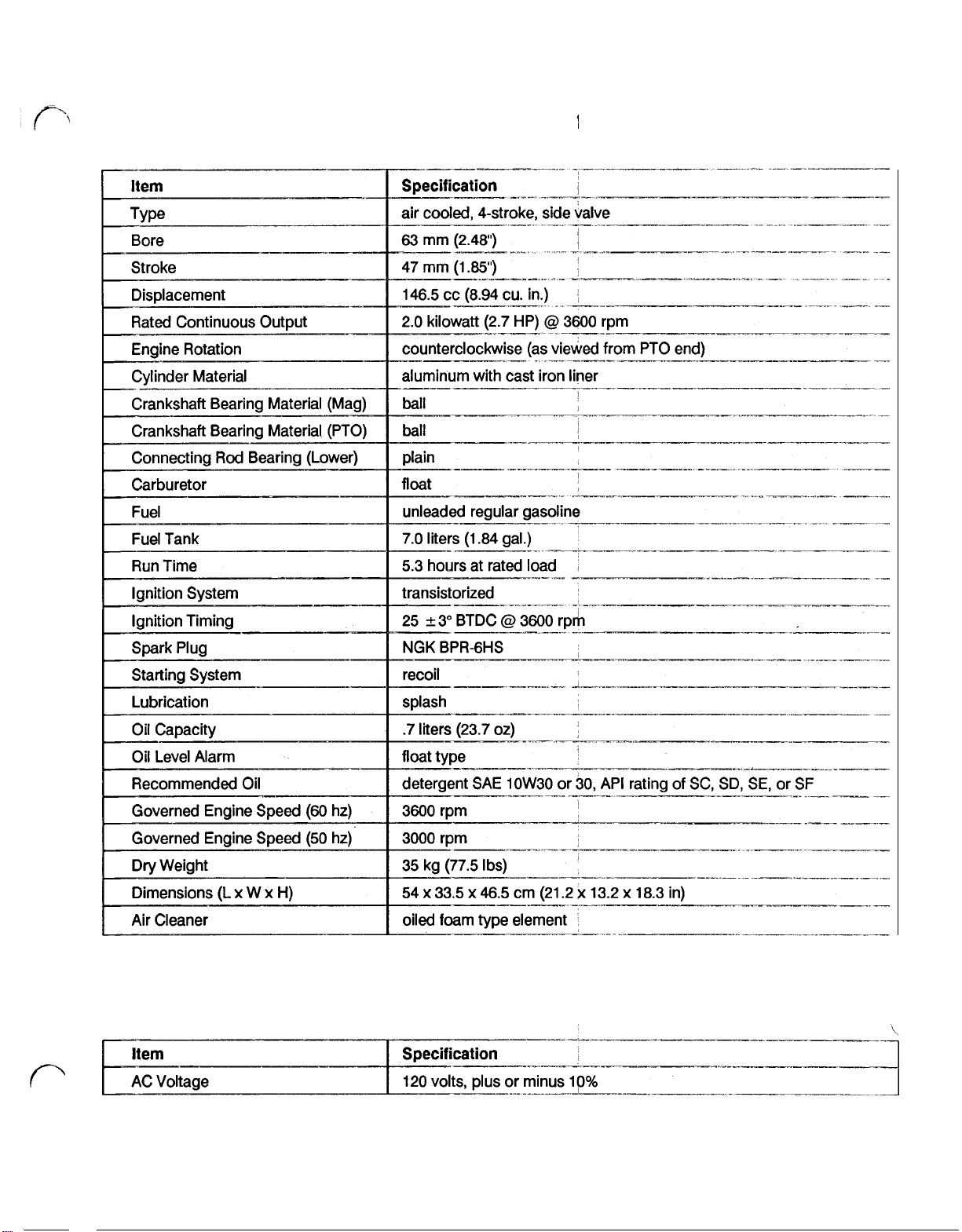

T2500 & T2500D

SPECIFICATIONS

Models

62025 & 62027

Item

Type

Bore

Stroke

Displacement

Rated Continuous Output

Engine Rotation

Cylinder Material

Crankshaft Bearing Material (Mag)

Crankshaft Bearing Material (PTO)

Connecting

Rod

Bearing (Lower)

Carburetor

Fuel

Fuel Tank

Run Time

Ignition System

Product Specifications

Specification

air

cooled,

72 mm (2.83

62 mm (2.44

4-stroke, side' valve

"

)

"

)

252.4 cc (15.40 cu. in.)

3.7 kilowatt

(5.0

counterclockwise (as viewed from PTO end)

aluminum with cast iron Sleeve

ball

ball

plain

float

unleaded regular gasoline

11

.O

liters (2.91 gal.)

5.0

hours at rated load

-

transistorized

I

_I-

HP) at 3600 rpm

___

_._

----__

~

-

I

Ignition Timing

Spark Plug

Starting System

Lubrication

Oil Capacity

Oil Level Alarm

Recommended Oil

Governed Engine Speed

Governed Engine Speed

Air Cleaner

Dry Weight

Dimensions (L

Model

62025 & 62027

x

Item

W

x

H)

@

25° BTDC

3600 rpm

NGK BPR-6HS

recoil

splash

.O

liters (33.8

1

oz)

float type

SAE

10W30or'30,

(60

(50

hz)

hz)

detergent

3600

rpm

3000

rpm

oiled foam type element

52.8 kg (1 16.5 Ibs)

56.6

x

36.3 x 53.6 cm (22.6 x 14.3 x 21.1 in)

Generator Specifications

Specification

I

i

API

rating of SC, SD, SE, or SF

I

-..-_-

-

I

-

AC Voltage

120

-

220 volts, plus or minus 10%

Page 20

T2500 & T2500D SPECIFICATIONS

Models 62025 & 62027 Generator Specifications :(cont'd)

(cont'd)

Models 62025

Item

Spark Plug

Spark Plug Gap

"

___I-

Ignition Coil Air Gap

(External Mount)

Ignition Coil Air Gap

(Internal Mount)

Valve

Margin

Width of Valve

Seat Contact

Valve

Lash

Valve Head Runout (Both)

&

62027 Engine Service Specifications

N/A

.030

mm

(.0012”)

Intake Guide to Valve

Stem Clearance

12

.080

mm

.0032

"

Page 21

T2500 & T2500D SPECIFICATIONS

(cont'd)

Models

ecting

62025 & 62027

Guide

to

Valve

Rod

Journal

Engine Service Specifications (cont'd)

Standard

.040

39.5

(1.2784

27.991

28.013

(1

.1029

.013

(.0005

.400

.006

to

to

40.5

to

to

to

.036”

to

to

.800

to

.019

.070

to

28.000

28.027

to

.0014")

Dimension

mm

mm

1.2800')

mm

mm

1 1

034")

mm

mm

iston Ring End Gap

8.0

mm

0.200

to

(0.0079

0.20

to

0.030

to

(0.001

to

0.020

to

(0.001

to

to

2.46

2.51

to

(.0988

to

0.400

mm

to

0.01

58')

0.80

mm

0.070

mm

0.003')

0.060

mm

0.003")

2.48

mm

2.53

mm

.0996”)

13

Page 22

T2500

&

T2500D

SPECIFICATIONS

(cont'd)

Models

Models

62025 & 62027

62025 & 62027

Engine Service Specifications (cont'd)

Carburetor Specifications

Models

Connecting

Generator Through

Starter Cup Capscrews

Recoil Pulley Screw

Recoil Mounting Screws

Air Cleaner Nuts

Air Cleaner Capscrew

Throttle Plate Screws

62025 & 62027

Rod

Nuts

Bolt

Fastener Torques

Torque

.88

;__-

kg m (6.4

2.5

kg m (19

6.5

kg m (47

1.8 kg

1.3 kg

1.O

kg m (7.3

.88

kg m (6.4

.88

kg m (6.4

.50

kg m (3.6

.75 kg m (5.4

.22 kg

.88

kg m (6.4

.88

kg m (6.4

.55

kg m (4.0

1.1 kg

m

m

m

m

(13

(9.0

(1.6

(8.0

ft

ft

ft

ft

ft

ft

ft

ft

ft

ft

ft

ft

ft

ft

ft

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

Ibs)

-__I.

-~.-

-

I

i

i

i

I

-

I

__-

-

__

-

14

Page 23

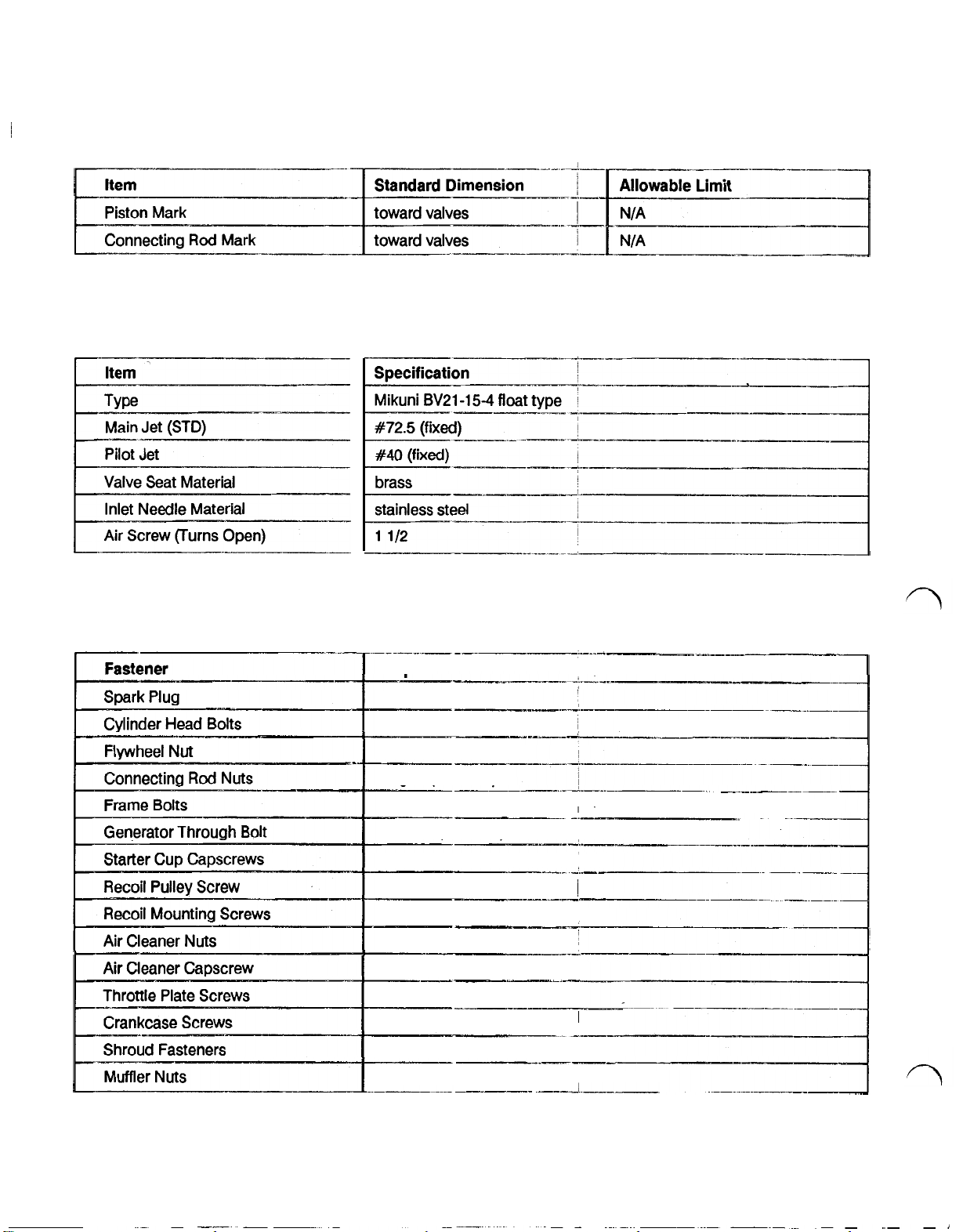

T3000

Models 62030 & 62032 Product Specifications

&

T3000D

SPECIFICATIONS

Model 62030

&

62032 Generator specifications

15

Page 24

T3000 & T3000D

SPECIFICATIONS

Models 62030 & 62032 Generator Specifications' (cont'd)

(cont'd)

Models 62030

Ignition Coil Air Gap

Ignition Coil Air Gap

Width

of Valve

Valve Head Runout

&

62032 Engine Service Specifications

Standard Dimension

NGK

BPR-6HS

.75mm

(.030')

.38

(.015”)

fixed

.95

to

1.45 mm

to

to

1.10 mm

to

mm

.057")

.043")

(.037

.90

(.035

.050

(.002”)

(Both)

N/A

i

!

i

!

i

I

i

i

I

N/A

N/A

N/A

.030

mm

(.0012”)

I

.025

(.0010

to

to

.055

mm

.0022")

.080 mm

.0032”

16

Page 25

T3000

&

T3000D

SPECIFICATIONS

(cont'd)

Models 62030 & 62032 Engine Service Specifications (cont'd)

Exhaust Guide to Valve

Rod

ecting

Journal

.040

to

(.0016

to

to

39.5

(1.555

to

32.472

(1.2784

27.991

(1.1020

28.01 3

(1.1029

.013

to

(.0005

to

.400

to

(.0158

to

to

.006

(.0002

to

NIA

8.0

mm

(.32")

.070

mm

.0028')

40.5

mm

1.595")

to

32.51 2

to

1.2800”)

to

28.000

to

1.1024")

to

28.027

to

1.1034")

.036

"

.0014')

.800

.0315")

.019

mm

.0008)

mm

mm

mm

mm

I

i

Piston

Ring

End

Gap

NIA

.030

to

.050

(.0012

to

.0020”)

NIA

.20

to

.40

mm

(.008

to

.Ol6”)

to

.80

.20

(.008

.030

(.001

.020

(.001

2.46

(.0969

2.51

(.0988

mm

to

.032")

to

.070

to

.0003”)

to

.060

to

.003")

to

2.48

to

.0976')

to

2.53

to

.0996”)

mm

mm

mm

mm

mm

!

-

,.~

-

17

Page 26

T3000 & T3000D

SPECIFICATIONS

(cont'd)

Models 62030 & 62032 Engine Service Specifications (cont'd)

Models 62030

&

62032 Carburetor Specifications

stainless

1

1/4

steel

Models 62030 & 62032 Fastener Torques

18

Page 27

SPECIAL TOOLS

19

Page 28

TROUBLESHOOTING

Engine Does Not Produce Spark

Possible Causes

engine switch in “off’ position

spark plug fouled or damaged

spark plug wire damaged

ignition coil primary wire grounding out

ignition coil has failed

Engine Floods During Starting

Possible Causes

no spark

stale gasoline

I

engine overchoked

choke not opening

I

1

leaking needle/seat

water in fuel

I

plugged air filter

Remedy

I

move switch to “on” position

replace spark plug

replace coil

repair damaged wire with electrical tape

replace ignition coil

Remedy

see “Engine Does Not Produce Spark’

troubleshooting section above

fill tank with fresh unleaded gasoline

open choke, close fuel shutoff valve

and turn over until engine fires

replace damaged parts

I

1

clean carburetor and pressure check

1

drain tank and fill with fresh gasoline

clean air filter

I

I

I

I

I

Engine Does Not Get Fuel During Starting

Possible Causes

fuel shutoff closed

fuel tank empty

plugged fuel line or filter

fuel cap not venting properly

r-~---

* For generating troubleshooting information, see Section 7, page 74.

20

Remedy

open fuel shutoff valve

fill fuel tank with fresh unleaded gasoline

clean or replace plugged component

repair or replace fuel cap

I

I

Page 29

TROUBLESHOOTING

(cont'd)

Engine Difficult

I

engine not getting fuel

engine

Engine Lacks

Possible

choke partially closed

has

low compression compare compression to compression of

Power

Causes

to

Start

Remedy

see "Engine Does Not Produce Spark”

troubleshooting section (page

see "Engine Does Not

Starting

see "Engine Floods During Starting

troubleshooting section (page

new unit

Remedy

open choke

adjust carburetor

"

troubleshooting section (page

--

repair as necessary

Get

8)

Fuel During

"

8)

8)

lack

of

lubrication

Engine Knocks

replace flywheel key

fill crankcase with proper lubricant

clean or replace air cleaner

grind valves and set valve lash

see

"

Generator Troubleshooting Guide",

page

74

compare compression to new unit

and overhaul

Remedy

.__^_.--

clean carbon from combustion chamber

replace damaged or worn parts

tighten flywheel nut

-

-

__

tighten rotor bolt

replace key

___

if

necessary

-

-

_I-

__

-

*

For generating troubleshooting information, see Section

21

7,

page

74.

Page 30

TROUBLESHOOTING

Engine Misses Under Load

Engine Overheats

(cont’d)

Engine Surges or Runs Unevenly

*

For generating troubleshooting information, see Section

7,

page

74.

22

Page 31

TROUBLESHOOTING

Engine Vibrates Excessively

(cont'd)

Engine Uses Excessive

*

For generating troubleshooting information, see Section

Oil

or

Smokes

7,

page

replace damaged

tighten engine mounting bolts

Remedy

set engine to proper speed

drain excess oil

ensure that cap does not pass oil or air

replace damaged or worn parts

overhaul engine

74.

parts

23

Page 32

MAINTENANCE

Maintenance

The air cleaner should be serviced every

Maintenance may have to be completed as often as

every 25 hours

or dusty conditions.

1. Shut the generator off and close the fuel shutoff

valve.

2. Remove the thumb screw retaining the air cleaner

cover. See Figure 1.

Remove the dust cup, baffel, foam element and

3.

element holder.

4.

Wash the element in soap and water or

made for cleaning air cleaner elements.

Air

Cleaner

50

hours.

if

the generator is being operated in dirty

Figure

1

a

solvent

Maintenance

The spark plug is the ignition source for

in the combustion chamber of the engine. The engine

will not run properly

replaced

cleaned;

spark plug cleaners will leave grit on the plug that can

cause rapid :engine wear.

Type:

Substitute: Champion L92Y/L92YC

Maintenance Changing Oil

Tor0 generators are shipped without oil.

generator until you have added the correct amount of

Service Classification

Oil change frequency:

I

1. Stop the engine and remove the spark plug wire

from the spark plug.

2.

Remove the oil

3.

Position and drain pan under the engine and

remove the drain plug.

Spark

a8

required. Spark plugs should not be

if

the plug is fouled or dirty, replace

Plug

the

if

the spark plug is not inspected and

NGK BP-

5HS

I

.6-.7mm (.024-.028')

-

Every 100 hours

-

105 Kg-cm (80-120

70

-

lbs)

in

Do

not start the

see spec. on page

30

summer

20 fall, spring

10 winter

MS,

SC,

SD,

SE

fill

After the first

every

plug.

See

50

Figure 2.

20

hrs. thereafter.

fuel air mix

it.

Abrasive

_

-

3

hrs. and

~_~..~~

5.

Squeeze the element dry

Saturate the element with

6.

then squeeze the excess oil out of the element.

Note: an element that is too heavily saturated with

oil may restrict air flow and cause a rich running

condition for the engine.

7.

Reinstall the element holder, foam element, baffel

and dust cup.

Secure the air cleaner cover with the single

8.

mounting screw.

Make sure the breather hose is properly connected

9.

to the body of the air cleaner.

of

the cleaning solution.

30

weight motor oil and

24

Page 33

5.

Maintenance - Changing Oil (cont’d)

4.

Reinstall the drain plug and dispose of the used oil

at a proper waste oil disposal site.

r

‘,

5.

Fill the crankcase with oil. See the Specification

Section on page 3 for the proper quantity. When

replacing the oil it will be helpful to tilt the generator

back about

the filler neck without spilling. See Figure 3.

100-15’,

-__1_

this will allow the oil to enter

-----

t

Empty the fuel bowl and clean it of any debris.

6.

The filter screen is located in the head of the bowl

and may be removed and cleaned at this time. See

Figure 4.

7.8.On reinstallation make sure the screen is properly

seated to prevent unfiltered fuel from entering the

carburetor.

Reinstall the sediment bowl and tighten the plastic

collar.

9.

Turn the fuel valve back on and visually check for

leaks.

SCREEN

r

----.

Figure 3

.-----l_l___

\

Maintenance - Fuel Sediment Bowl

The

T1200 - T3000

sediment bowl and strainer that will filter debris from the

fuel and will trap water before the fuel reaches the

carburetor. The sediment bowl should be cleaned at

least once a season.

Cleaning the fuel sediment bowl will require working with

gasoline.

presence of gasoline. Always keep gasoline in

a container designed for the storage of

flammable liquids.

1.

Stop the engine and remove the spark plug wire.

2.

Close the fuel shutoff valve.

3.

Prepare a drain pan to catch a small amount of

gasoline that may be spilled or released when the

fuel bowl is removed.

4.

Unscrew the plastic’collar retaining the fuel bowl

and pull the fuel bowl off the head assembly.

generators are equipped with a fuel

CAUTION: Misuse of gasoline

can cause death. Do not work

with gasoline around open

flames. Do not smoke in the

10.

Return the valve to the “off’ position when the

cleaning and inspection are complete.

Maintenance - Frequency Adjustment

All Toro generators including the T1200 designed to run at a speed of 3600 rpm. The frequency

of the

el,ectricity

speed) 60 cycles of alternating current per second

(6OHz); ,This

revolutions per second or 3600 rpm.

~~~~~~~~~~-~~

1.

Check the engine oil level.

2.

Disconnect any load that may be connected to the

generator.

3.

Start the generator.

4.

5.

/

Connect a load to the generator that is similar to

the load the generator is normally under when

used by the customer.

Adjust the speed of the engine with the speed

adjustment screw to 3600 rpm. The speed adjust-

produced is (controlled by the engine

is, of course, the same as 60 engine

T300O

are

Page 34

Maintenance Frequency Adjustment (cont'd)

ment screw is located behind the air cleaner and

connects

6.

With the engine at 3600 rpm the

front of the generator will resonate. (some models

are not equipped with a frequency meter.) See

Figure

to

the governor arm.

5.

60Hz

MENT

reed on the

SCREW

closing completely and the valve clearance will have

be adjusted.

.05-.15

for both intake and

exhaust valves.

Adjustment Frequency: Every

I

Maintenance Valve Clearance Inspection

1.

Stop /the generator and remove the spark plug

wire.

Close the fuel shutoff valve.

2.

Remove the single screw retaining the air cleaner

3.

to

bracket

Remove the two screws retaining the air cleaner

4.

assembly

5.

Pull

Remove the two screws retaining the breather

6.

assembly

the engine block.

to

the carburetor.

the breather hose

off

mm

(.002-.006”)

300

hrs

the breather assembly.

to

I

7.

The speed of the engine may also be set using a

variety of tachometers. Once the engine speed is

adjusted

be set at

Maintenance Valve Clearance

The

T1200

The valves are opened and closed with solid cam

followers. If the clearance between the end of the valve

stem and the cam follower is

close. The clearance is factory set at

(.002-.006'”).

face may wear causing the valve stem and follower

clearance

degrades after many hours of use, the valves may not be

to

3600

rpm the electrical frequency will

60

Hz.

T3000 generators use side valve engines.

too

small the valve may not

.05-.15

After many hours of use the valve seat and

to

decrease. If the performance of the engine

mm

Remove the breather assembly. Take note of how

7.

the gaskets and reed plate are installed.

Measure the valve clearance with the engine cold

8.

and on top dead center (TDC) of the compression

stroke. See Figure

To determine TDC; remove the spark plug and

place: a clean wooden dowel

opening

Rotate the engine until both valves are closed

(watch the cam followers

When both valves

reaches the highest point

of the

with more accuracy by using a depth reading dial

indicator.

so

the dowel rests on the top of the piston.

compression

6.

Figure

6

in

the spark plug

in

the breather opening.)

stop

moving as the dowel

in

its

travel you have TDC

stroke. TDC can be determined

26

Page 35

Maintenance Valve Clearance Inspection (cont'd)

9.

The correct clearance is .05-.15 mm (.002-.006'”).

If the clearance is not within tolerance, the valves

must be removed from the engine and the

approprlate

amount

of material ground

off

the stem

of the valve.

Maintenance Valve Clearance Adjustment

1.

Follow steps

2.

Remove the fuel hose from the carburetor.

3. Remove

front control panel. See Figure

1

7

as described above.

two

hair pin clips from the bottom of the

7.

Remove the valves.

9.

After the valves are removed the ends of the stems

10.

should be ground to provide

the

required

clearance.

11.

Check the condition

face. Recondition the face and seat

12.

Reinstall the valves and keepers.

Reinstall the head of the engine. Consult the

13.

of

the valve seat and valve

if

necessary.

Specification Section for correct head bolt torque.

14.

Replace the metal shield over the cylinder head of

the engine. This shroud is part of the cooling

system and must be properly installed.

Remount the fuel tank with the four hair pin clips.

15.

Install the fuel hose on the carburetor.

16.

1

7.

Reinstall the spark plug wire.

Maintenance Decarboning Spark Arrester

All

Toro generators are fitted with spark arresting

mufflers.'

If

the spark arrester is not serviced, the ability

of the engine to exhaust will be restricted and the

performance of the generator will drop.

4.

Remove

two

gasoline tank. See Figure

Figure

hair pin clips from the bottom of the

7

8.

I

Figure

5.

Lift

the tank and front panel assembly forward and

away from the head of the engine.

6.

Remove the screws retaining the metal shield on

the head of the engine (three screws on the T1200,

T1800

and four on the T2500, T3000).

7.

Remove the screws retaining the head of the

engine.

8.

Use a valve spring compressor to remove the valve

keepers.

8

Decarboning

Interval: 100 hrs

1.

Stop the engine.

2.

Remove the spark plug wire.

3. Remove the

Figure

4.

Remove the single screw retaining the spark

9.

two

spark arrester clean

Figure

9

out

-__^_-

arrester tube in the end of the exhaust pipe and pull

the tube out of the pipe. See Figure

5.

Take the generator to a well ventilated area that is

9

free of combustible material.

6.

Start the generator and tap on the side of the muf

bolts.

above.

See

-

27

Page 36

Maintenance Decarboning Spark Arrester (cont'd)

fler to dislodge any carbon build up within the

spark arrester.

CAUTION: Exhaust fumes can

cause death. Operate the

generator only

ventilated area.

CAUTION: The muffler will

cause burns if

7.

Allow the muffler to cool. Remove any remaining

carbon from the clean out ports and the exhaust

discharge opening.

8.

Reinstall the muffier clean out bolts.

10.

Reinstall the spark arrester.

Maintenance Storage

If

the generator is not going to be used for a period of

three months or more the following long term storage

procedures should

1.

Drain all gasoline from the fuel tank into a container

designed for storing flammable liquids.

be

completed:

In

it

is touched.

a well

CAUTION: Misuse of gasoline

can cause

while working with gasoline.

Never expose gasoline to open

flame or fire.

working

while'

2.

Start

the generator and run the remaining fuel out

of the

carburetor.

Turn the engine over

3.

feel the resistance of compression; this will

indicate that both valves are in'

sealing the cylinder.

4.

Drain :the existing engine oil and refill the engine

with fresh oil.

5.

Remove the spark plug and pour one or

tablespoons of

plug.

6.

Service the air cleaner element. See the

instructions on page

maintenance

7.

Check the tightness of all fasteners.

8.

cover the generator and put

Always

with gasoline.

with

oil

into the cylinder and replace the

death.

use

the recoil starter until you

24

Never smoke

proper ventilation

the

closed position

on air cleaner

it

away for storage.

two

28

Page 37

SECTION

1

CARBURETOR

Carburetor Operation

The carburetor receives fuel from the gasoline tank and

mixes

it

with air in the right proportions to provide a

highly combustible mixture to the engine.

As

the piston moves up on the compression stroke, a

partial vacuum is created within the engine crankcase,

causing the greater atmospheric pressure to force air to

flowthrough the carburetor into the cylinder. Thevelocity

of the air increases as

it

flows through the carburetor

venturi and the air pressure is reduced at this point to

less than atmospheric pressure. The low pressure in the

venturi of the carburetor causes atmospheric pressure

to push raw fuel from the float bowl into the air stream in

the throat of the carburetor, where

it

breaks up into a fine

spray, or becomes atomized, and mixes with the air

stream.

See

Figure

Atmospheric

Pressure

10.

,Venturi

from the float bowl. This fuel premixes with the incoming

is

air, then

See Figure

discharged into the intake port of the engine.

12.

Pilot System

Pilot Jet

,Pilot Air Fitting

COLD

START

Figure

11

Carburetor

Bore

Float Bowl

To

Engine

When starting the engine an extra rich mixture is

is

required. The choke plate

provide an approximate

closed by the operator to

8:l

ratio of fuel to air for this rich

mixture. Closing the choke plate further reduces the air

pressure in the venturi to increase the fuel pushed into

the carburetor throat. In this condition fuel also flows

from the float bowl through the pilot system ports as well

as the main discharge tube to achieve the proper starting

mixture.

See

Figure

11.

Fuel atomization becomes more efficient, due to heat,

once the engine has reached normal operating

temperature. As a result the engine does not require the

rich mixture

it

did for starting and the choke plate must

be moved to the open position. The engine speed is now

regulated by the throttle plate. In no load conditions a

small portion of the fuel may be drawn from the main

fuel

discharge tube, however the primary

from the pilot circuit. Air passing through the pilot

the pilot air fitting draws fuel

out

supply is drawn

jet

from

of the pilot jet orifice

Pilot System /Pilot Jet

Fitting

NO

LOAD

Figure

12

As the throttle plate is opened to compensate for engine

load, the main discharge tube becomes the main source

of fuel. Opening the throttle plate increases the flow of

air through the venturi and strengthens the low pressure

area at the main discharge tube. Fuel discharge

increases at the main discharge tube as it decreases

from the pilot system. Air is drawn from the air correction

jet

through holes along the length of the main discharge

tube. This premixes air with the fuel before

it

enters the

29

Page 38

Carburetor Operation (cont'd)

carburetor throat for more efficient atomizing of the fuel.

See

Figure

Throttle

Main

Plate

Discharge

Tube

13.

Float

,Pilot System

UNDER

Correction Jet

LOAD

7.

Slide /the carburetor off

its

studs and disconnect

the governor link rod.

8.

There will be a small amount of gasoline in the bowl

of the carburetor. Drain this gasoline into a

suitable container by opening the drain screw on

the bottom of the carburetor.

CAUTION: Mishandling

gasoline can cause death.

Always work with gasoline in a

well ventilated area free

Do

flame or sparks.

not smoke around

gasoline

Carburetor Disassembly

1.

Remove the carburetor bowl nut.

necessary to remove the drain screw.

15.

of

It

See

open

is not

Figure

Figure

13

Carburetor Removal

1.

Stop the generator and remove the spark plug

wire.

2.

Close the fuel shutoff valve.

3.

Remove the single screw retaining the air cleaner

body to the engine block.

4..

Remove the'

two

screws retaining the air cleaner to

the carburetor.

5.

Remove the fuel inlet hose.

6.

Remove the two nuts retaining the carburetor to

the

engine. See Figure

14.

Figure

15

Figure

14

30

2.

The main

jet

is threaded into the carburetor bowl

nut. The float and inlet needle may be removed by

pulling out the float hinge pin. Note: one end of the

hinge'

pin

is flattened slightly. The pin must be

removed from this end. See Figure

3.

The pilot jet may be removed from the top of the

16.

carburetor and can be cleaned or replaced. Fuel

flows through the small opening in the end of the

Page 39

Carburetor Disassembly (cont'd)

jet and air enters through the holes in the side. The

opening on the top of the jet is a drilling passage

and is plugged.

The pilot screw controls air in the pilot circuit.

should be open 1 to 1 Figure

17.

1/2

turns on all engines. See

t

FLAT

CAUTION: Be sure

safety glasses when using

compressed air. Use pressure

It

3.

If

it

is

suspected that the seat is leaking, the

carburetor can be pressure tested after

cleaned. Use Toro Pressure tester, Number

41-7910.

(7

should be completed with the carburetor turned

upside down

See Figure

the 'needle and try the test again. If the carburetor

fails again, the seat is bad and the carburetor must

be replaced

If

psi) for at least

of no more than

the seat is good,

10

so

the seat holds the needle closed.

18.

If

the pressure leaks down, replace

it

will hold

seconds. This procedure

40

to

PSI.

it

has been

.5

wear

kg/cm

2

Figure

PILOT

Figure

Carburetor Service

1.

The metallic body of the carburetor may be

cleaned in carburetor cleaner. Plastic parts may

be damaged by some carburetor cleaners.

16

17

Figure

Carburetor Reassembly

1.

Replace the main nozzle and bowl gasket.

2.

Install the pilot jet and pilot screw. Refer to Figure

17.

The pilot screw should be open 1 to 1 -

3.

Hook the inlet needle into the float and secure the

float and needle in place with the hinge pin.

Figure

Remount the bowl and gasket.

4.

Carburetor Installation

19.

18

1/2

turns.

See

Carburetor passages may be cleaned

compressed air.

2.

Replace any components that show wear or

damage. The inlet needle is replaceable but the

seat is not.

out

with

31

1.

Mount one gasket, one spacer and one additional

gasket on the carburetor mounting studs.

2.

Connect the tension spring from the governor arm

to the throttle shaft.

Page 40

Carburetor Installation (cont’d)

3.

Connect the governor link rod. See Figure 20.

5.

Straighten the governor arm

allow

connection

of

if

the linkage rod to the

carburetor.

6.

lnstail the carburetor mounting nuts.

7.

Connect the fuel inlet hose.

8.

If

the

~governor

arm has been removed to provide

additional working clearance, make sure

correctly reset.

it

has been bent to

it

is

Figure 19

I

Figure 20

4.

Install the carburetor on the mounting studs.

FLAT

The governor shaft

is

turned

full

counterclockwise

while; the governor holds the throttle plate wide

open.

The governor spring connects in the upper hole

of

the governor arm. See Figure 21.

I

i

Figure 21

14. Remount the air cleaner body to the carburetor

with

two

screws.

15. Secure the air cleaner bracket to the engine block.

Carburetor reinstallation is now complete.

32

Page 41

SECTION

FUEL TANK AND STRAINER

See the Specification Section for

fuel tank and approximate running time under full load.

The required fuel is regular unleaded gasoline.

Fuel Tank and Strainer Removal

1. Shut off the generator.

2. Drain the fuel tank. Remove the line on the inlet side

of the fuel shutoff valve. See Figure 22.

the

capacity of each

2

FUEL

8.

SYSTEM

Examine the fuel tank for debris and wash the tank

with a cleaning solvent

if

necessary.

NOTE:

liquids available to receive the gasoline from the

tank.

flame or sparks. Do not smoke around

gasoline.

Have a container suitable for flammable

Figure 22

CAUTION: Mishandling

gasoline can cause death.

Always work with gasoline in a

well ventilated area free of open

Fuel Tank and Strainer Installation

1.

Install the fuel tank on the front panel.

2. Reset the fuel tank

frame and install the hairpin clips.

3. Connect the fuel hose to the fitting on the shutoff

valve and sediment bowl.

distorted

4. Install the fuel strainer and tank cap.

FUEL

TANK

The fuel tank cap is an important

of the fuel system.

must do:

It

must allow atmospheric pressure into the tank and

must allow any buildup of pressure out of the tank. The

cap also' has to keep fuel in the tank.

it

CAP

It

must keep debris, water, etc., out of the tank.

and

front panel on the generator

If

the clamp is bent or

should be replaced.

but

often ignored part

It

has several important jobs that

it

it

Remove the fuel tank cap.

3.

4.

Pull

the fuel strainer out of the tank.

Examine the fuel strainer for debris and wash it out

5.

in a suitable solvent.

Removethe four hairpin clips retaining the fuel tank

6.

and front panel to the frame of the generator.

7.

Lift

the fuel tank away from the engine and remove

the

five

screws retaining fuel tank to the front panel.

The fuel tank is now separate from the generator.

See

Figure 23.

Fuel Tank Cap Service

1.

Examine the condition of the cap. Look for

distortion or bending.

2.

Examine the gasket. The gasket should indicate an

even seal for a full 360 degrees. The gasket part

number is 53

See

Figure 24.

3.

Make sure the cap is venting properly.

be, able to force air through the cap from the inside

out and the outside in. Replace the cap

not vent properly.

33

-

1420 for T1200 -:T3000 generators.

You

should

if

it

does

Page 42

Fuel Tank Cap Service (cont'd)

Fuel Shutoff and Sediment Bowl Removal

Drain the fuel tank. Removethe line on the inlet side

1.

of

the fuel shutoff valve. See Figure

22

on page

33.

A

STRAINER

NOTE:

liquids available to receive the gasoline from the

tank.

flame or sparks. Do not smoke around

gasoline.

2.

Disconnect the outlet hose from the fuel shutoff

valve.

Fuel Shutoff and Sediment Bowl Service

1.

Complete service of the valve may be

accomplished without removing the valve from

mounting bracket.

2.

Remove the sediment bowl by unscrewing the

collar around the

Have a container suitable for flammable

CAUTION: Mishandling

gasoline can cause death.

Always work with gasoline in a

i

well ventilated area free of open

bowl.

See Figure

26.

its

Figure

24

4.

Install the cap and make sure the tabs on the cap

pull

it

fully against the tank as

FUEL SHUTOFF AND SEDIMENT BOWL

The

T1200

valve and sediment bowl. The valve is mounted to the

tube frame under the fuel tank. See Figure 25.

T3000

generators use a combined shutoff

it

is turned in place.

Figure

3.

Take:

note

that there is a filter screen in the head of

the valve that may be cleaned or replaced as

required. The

See Figure

part

27.

26

number of the screen is

50-3770.

Figure

25

34

4.

The valve may be serviced by removing the set

screw on the side of the valve. Use care, as the

valve stem is under spring pressure and must be

restrained as the set screw is loosened.

Page 43

Fuel

Shutoff

and Sediment

Bowl

Service (cont'd)

6.

When the stem and valve cylinder are removed, the

be

valve may

solvent.

cleaned in a nonflammable cleaning

Figure

27

5.

After the valve stem is removed, the plastic valve

cylinder may be withdrawn with a needle nose

pliers.

SCREEN

Fuel Shutoff and Sediment

1.

Reassemble the valve by inserting the valve

cylinder and stem in the body of the valve. Make

sure the cylinder and hole

up 'with the handle of the valve stem. Restriction

of

fuel flow may occur

indexed correctly.

2.

Install the valve stem retaining screw. Make sure

the valve is free to turn.

likely that the end of the retaining screw is not

located in the slot on the side

The slot is there to limit the rotation

about

90

degrees.

Fasten the valve to its mounting plate with

3.

screws.

4.

Install the inlet and outlet hoses to the valve.

Bowl

If

Installation

in

the

valve

if

the

two

parts

the valve will not turn

of

the valve stem.

of

cylinder lines

are not

it

is

the valve to

two

35

Page 44

SECTION

IGNITION

SYSTEM

IGNITION OPERATION

The firing of the spark plug at the proper time is the

culmination of a number of components working

together. In the T1200 T3000 generator, the

components used are:

Flywheel

Ignition coil

Trigger circuit (molded into the ignition coil)

Spark plug

See

Figure

28.

secondary coil must have many more windings than the

primary. The higher the ratio between the primary coil

to secondary coil windings, the greater the voltage

amplification will be.

Figure 28

The following describes the function of each of the above

components.

Ignition Operation Flywheel

The engine flywheel is the generating force for the

ignition system.

Imbedded in the flywheel are permanent magnets. These

magnets rotate past the coil to generate electricity.

Imbedded in the opposite side of the flywheel is a steel

counterweight which offsets the weight of the three

magnets.

Ignition Operation Ignition Coil

The ignition coil is actually a transformer. It is positioned

close to the flywheel to allow the magnetic field of the

flywheel magnets to cut through the coils to generate

electricity. See Figure

Low voltage is produced in the primary coil which is sent

to the trigger circuit. This voltage would be much too low

to produce a spark at the spark plug.

It

is not magnetic.

29.

I

Figure 29

Even though the secondary coil has considerably many

more windings than the primary, the voltage produced

is still not high enough to produce sparkacross the spark

plug electrodes To further amplify the voltage, the

trigger circuit is used.

Ignition Operation Trigger Circuit

The trigger circuit amplifies the voltage in the secondary

coil by breaking the primary circuit just as the primary

its

voltage reaches

circuit results in a rapid collapse

surrounding g the primary coil. The collapse of the primary

magnetic field induces a large voltage surge in the

secondary' which is sufficient to produce a spark across

the spark plug electrodes.

Before getting into the actual electronics used inside the

trigger circuit,

of the voltage waveform produced by the flywheel

magnets moving by the ignition coil.

As

the magnets rotate past the coil, voltage is produced.

This voltage,' when uninterrupted, is first positive, then

negative as the magnet passes by the coil. This effect is

caused by the two opposing poles

peak. This breaking of the primary

of

the magnetic field

it

is important to have an understanding

See

Figure 30.

of

the magnet.

The secondary coil serves to amplify the voltage

produced in the primary. To accomplish this, the

Explanation of the trigger circuit also requires an

understanding of the

NPN

transistor. See Figure 31.

36

Page 45

Ignition Operation Trigger Circuit (cont'd)

3.

Current

current,

12

that

I1

flowing through Tr2 induces a larger

l2.

Note that current

is much larger.

MTI

unit Ignition coil

See

I1

is very small and

Figure

34.

PRIMARY

B

VOLTAGE

Figure

(Base)

30

WAVEFORM

C

(Collector)

E

(Emitter)

NPN-type

Figure

31

A

transistor has a certain minimum voltage that

requires across the base and emitter (points B and E in

it

the Figure above) before

turned on

above.

current,

current

11.

Thus, the transistor functions as an amplifier in that it

it

allows a small current,

At

the same time the transistor allows a large

12,

to flow from point C to

12

will vary in proportion to the smaller current,

will "turn on". Once

11.

to flow as shown

E.

The magnitude of

allows a small current to control a large one.

it

has

!

MTI unit Ignition coil

Figure

Figure

MTI unit Ignition

it

4.

When the voltage is at the point "a" level as denoted

above in Figure

30,

allows no current

MTI

unit Ignition

32

33

Trl is still in the

13

or

14

to flow.

coil

"

off'

See

coil

Ground

Spark plug

mode and

Figure

35.

The following is the process the trigger circuit uses to

break the primary circuit to produce spark:

1.

The magnet passes by the coil and induces an

alternating voltage.

2.

As

the voltage begins to increase (approximately

point

"a"

in Figure

and current flows from point

R3, R4,

and Tr2.

See

Figure

32.

30),

transistor Tr2 is turned on

"c"

to point "d" through

See

Figure

33.

Spark plug.

37

Page 46

Ignition Operation Trigger Circuit (cont'd)

5.

As the voltage produced in the primary coil

“b”

reaches its negative peak (point

transistor Trl is turned on and allows small current

13

and large current

6.

When transistor Trl turns on, nearly all of the

current flow through

14

path

drop in current

Off.

7.

When Tr2 turns

causes the magnetic field surrounding the primary

coil to rapidly collapse. This in turn causes a

voltage surge in the secondary which is sufficient

to produce a spark across the spark plug.

Ignition Operation

The spark plug is used to ignite the air fuel mixture by

producing a spark just before the piston reaches top

dead center.

shown in Figure

since

A

spark plug is typically constructed as

36.

14

to flow.

R4

and Tr2 is diverted through

it

is the path of least resistance. This

I1

results in transistor Tr2 turning

off,

current

-

Spark Plug

12

in Figure

drops rapidly and

30),

Excessive gap or fouling can delay firing enough to

loss

cause a

The other important area is the insulator. The insulator

prevents arcing from taking place in another portion of

the plug, away from the electrodes. Because

extremely high voltage present, even a slight crack or

fouling of

malfunction of the plug.

IGNITION

Ignition Coil Testing

The operation of the ignition coil should be tested before

.the product' is disassembled.

1.

Shut

appliances that may be plugged into the generator.

2.

Remove the rubber spark plug cover and remove

the sp'ark plug.

Inspect the spark plug and ensure that

3.

condition. Make sure there are no particles

bridging the spark gap.

of power or stalling.

the

head insulator can result in arcing and a

COIL

off

the fuel supply valve and disconnect any

it

is in good

of

the

HEAD INSULATOR

COPPER

LEG

CORE

INSULATOR

4.

Ground the body of the plug on the side of the

engine. Turn the ignition switch on. Pull the starter

cord and watch for a spark at the gap of the plug.

5.

If

there is a strong spark, the ignition module is

intact and working properly.

6.

If

there is a lack of spark, check the oil level in the

engine. The engine uses a low oil shut down device

will

that

low. For operation of the low oil level shut down

device, see Low Oil Shutdown, page

7.

If

connected to the low oil shut down module.

Access to the yellow wire may be obtained by

removing the single screw that retains a wlre

connector bracket on the front crossframe of the

generator.

the wire.

prevent the engine from starting

the

oil

level is normal, disconnect the yellow wire

See

Figure

37

for the exact location

44.

if

the oils

of

GROUND

There are

plug function. The first is that the electrodes are properly

gapped and are clean. This ensures that

will be present and that it occurs

ELECTRODE

Figure

36

two

critical areas important to proper spark

a

strong spark

at

the proper time.

GAP

38

Page 47

Ignition Coil Testing (cont'd)

8. Insulate the wire from ground and attempt to start

the generator.

If

the

ignition has spark the low oil

shut down circuit is at fault. See the section on the

low oil shutdown circuit, page 44.

9

If

the ignition has no spark with the low oil shut

down circuit disconnected the fault is with the

Ignition circuitry and the coil may have to

be

removed. See the section on coil removal below.

Ignition Coil Removal

Stop the generator and remove the spark plug

1.

wire.

Close the fuel shutoff valve.

2.

10. Unplug the black ignition kill wire and and the entire

coil may be removed.

3.

Remove

the

four screws retaining blower housing

of the generator.

Pull

4.

some slack

in

the spark plug wire and remove

the blower housing.

On the T1200 and T1800 the coil is now exposed

5.

and may be removed after unplugging the ignition

kill wire.

T1200 and T1800 generators built in 1983 and all

6.

T2500 and T3000 generators have the ignition coil

mounted on the engine block behind the flywheel.

The flywheel magnets are located on an internal

counterbore in the flywheel. The flywheel must be

removed to expose the ignition coil.

Remove the flywheel nut and the three screws

7

retaining the starter cup.

See

Figure 38.

40

Figure

Ignition

1.

Coil

Installation

Mount the ignition coil on the engine block. On the

T1200 and T1800 an air gap

of

.381 mm (.015")

should be set between the coil and flywheel. On

the T2500 and T3000 and 1983 models

and T1800 that have ignition coils that are mounted

on the engine block behind the flywheel, the

ignition coil location is fixed and no adjustment is

possible

of

T1200

Figure 38

8. Use a puller or remover to remove the flywheel.

See

the section on special tools on page 19, for the

part

correct tool and

number. See Figure 39.

9. The ignition on T2500 and T3000 generators is now

exposed. See Figure

40.

39

2.

Route and secure the spark plug wire in the wire

retainer on the back of the engine block.

On models with internal ignition coils, remount the

3.

flywheel. Make sure the taper on the flywheel and

the taper on the crankshaft are clean. Torque the

flywheel nut to

kg m (43

50

6.0

7.0

engines. See Figure 41.

Remount the blower housing with the recoil starter

4.

attached.

ft

Ibs) on all

Page 48

Ignition

5.

Coil

Installation (cont'd)

Reconnect the Ignition kill wire.

gap on the electrodes of the plug is

.028").

.6

.7

mm (.024

SPARK PLUG

Figure 41

Spark Plug

1. Stop the engine and remove the rubber dust cover.

2. Remove the spark plug wire.

3.

Clean debris from around the spark plug

does not

removed

4. Remove the plug with a 19 mm (3/4”) wrench.

5.

Spark 'plugs should not

cleaners and reused. Grit

the plug and cause engine damage. Dirty spark

plugs

Spark Plug Installation

1.

Use an

spark plug.

2.

Set the plug gap to

3.

Install the plug with a 19 mm

use a release agent

4. Torque the plug to

Removal

fall

into the engine when the plug

Should be replaced.

NGK

BP-5HS

or Champion L92Y

.6

or

oil on the threads

1.2

kg m (8.5

be

cleaned by abrasive

will

eventually fall out of

.7

mm (.024 .028")

(3/4')

wrench.

of

ft

Ibs).

so

dirt

or

L92YC

Do

not

the plug.

is

NGK

The correct spark plug is an

substitute is a Champion L92Y or L92YC. The correct

BP-5HS.

An acceptable

5.

Replace the spark plug wire.

6.

Reinstall the rubber dust cover.

40

Page 49

SECTION 4 RECOIL STARTER

Recoil Starter Removal

1.

Turn

off