Page 1

ProLine

121cc Two-cycle

FORM NO. 3318–918

Vertical Shaft Engine

Part No. 61–8062 – 790001 & Up

Operator’s Manual

IMPORTANT: Read this manual carefully. It contains information about your

safety and the safety of others. Also become familiar with the controls and

their proper use before you operate the product.

Page 2

Introduction

We want you to be completely satisfied with your

new product, so feel free to contact your local

Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model of your

product. This number will help the Service Dealer or

Service Representative provide exact information

about your specific product.

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

Printed in USA

The Toro Company – 1996

All Rights Reserved

Page 3

Contents

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 2. . . . . . . . . . . . . . . . . . . . . .

General Engine Specifications 3. . . . . . . . . .

Engine Feature Locations 3. . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Rope Configuration for

Zone-start Applications 4. . . . . . . . . . . . . .

Starter Rope Configuration for

Non-zone-start Applications 4. . . . . . . . . .

Installing the Spark Plug Protector 5. . . . . .

Kill Switch Wire 5. . . . . . . . . . . . . . . . . . . .

Fuel Line 5. . . . . . . . . . . . . . . . . . . . . . . . . .

For European Applications 5. . . . . . . . . . . .

Operation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Approved Oils and Mixing Ratios 6. . . . . . .

Mixing Gasoline and Oil 7. . . . . . . . . . . . . .

Filling the Fuel Tank 8. . . . . . . . . . . . . . . . .

Starting the Engine 8. . . . . . . . . . . . . . . . . . .

Page

Page

Maintenance 9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 9. . . . . . . . . . . . . . . .

Before Performing Any Maintenance 9. . . .

Servicing the Air Cleaner 10. . . . . . . . . . . . . .

Replacing the Spark Plug 11. . . . . . . . . . . . . .

Cleaning the Cooling System 11. . . . . . . . . .

Cleaning the Muffler Pipe

and Exhaust Port 12. . . . . . . . . . . . . . . . . . .

Draining the Gasoline 13. . . . . . . . . . . . . . . .

Storage 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Carburetor 13. . . . . . . . . . . . . .

1

Page 4

Specifications

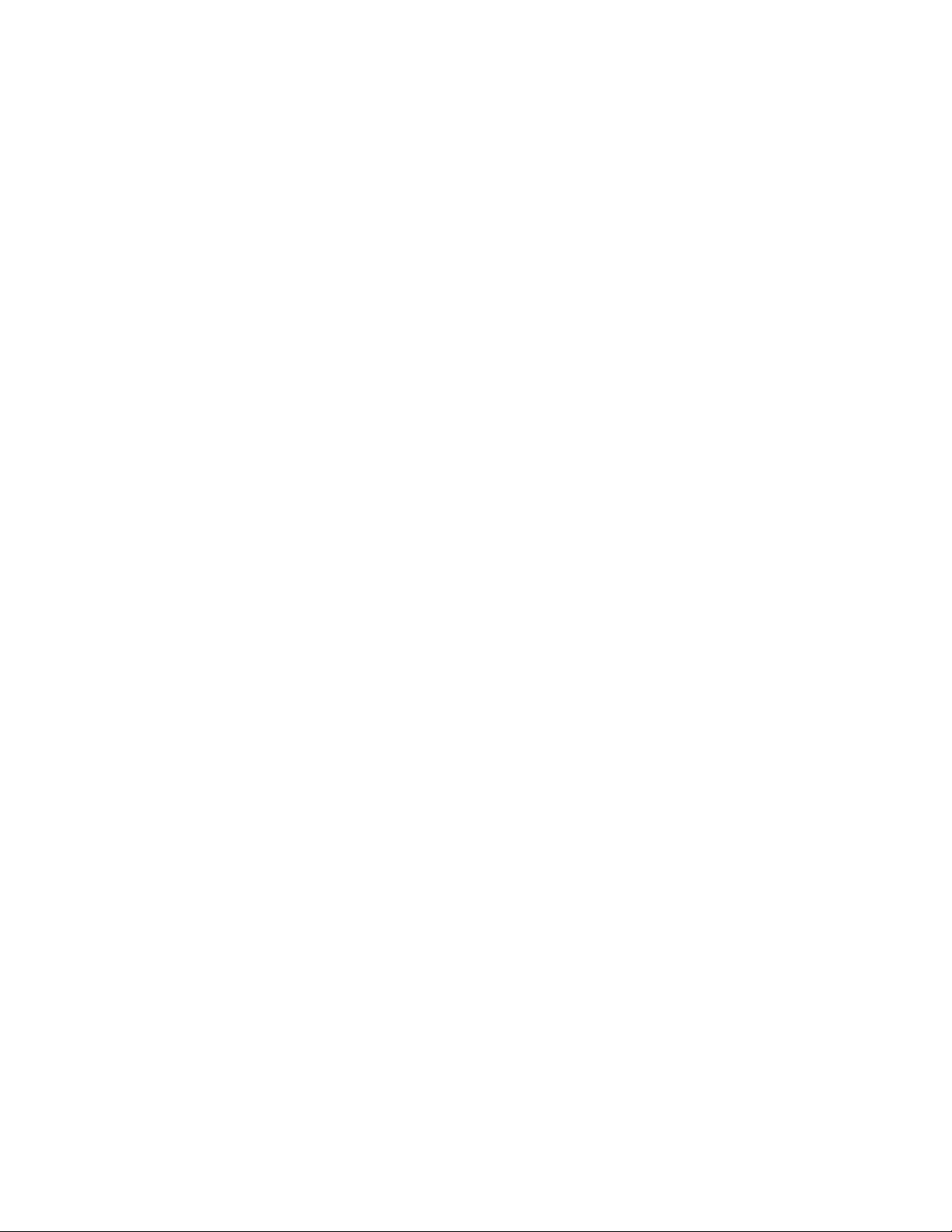

Technical Data

(Dimensions in Inches)

*

Front View

Front

*Specifications subject to change without notice.

Rotation

Crankshaft

Figure 1

2

Page 5

Specifications

General Engine Specifications

Engine Type Air-cooled, Two-cycle,. . . . . . . . . . .

3rd Port Induction, Vertical Shaft

Displacement 121 cc. . . . . . . . . . . . . . . . . . . . . . . .

Bore x Stroke 2.283” x 1.811”. . . . . . . . . . . . . . . .

(58 mm x 46 mm)

Ignition System Solid State. . . . . . . . . . . . . . . . . . .

Spark Plug NGK BPMR4A. . . . . . . . . . . . . . . . . .

0.032” (0.8 mm) gap

Governor Mechanical Flyweight. . . . . . . . . . . . . . .

No Load Governor Setting 3000 RPM ± 150. . . .

Main Bearings Ball Bearing. . . . . . . . . . . . . . . . . .

Rod Bearings Caged Needle Bearing. . . . . . . . . . .

Lubrication System Pre-mixed with Fuel. . . . . . .

Air Cleaner Semi-dry, Urethane Foam. . . . . . . . . .

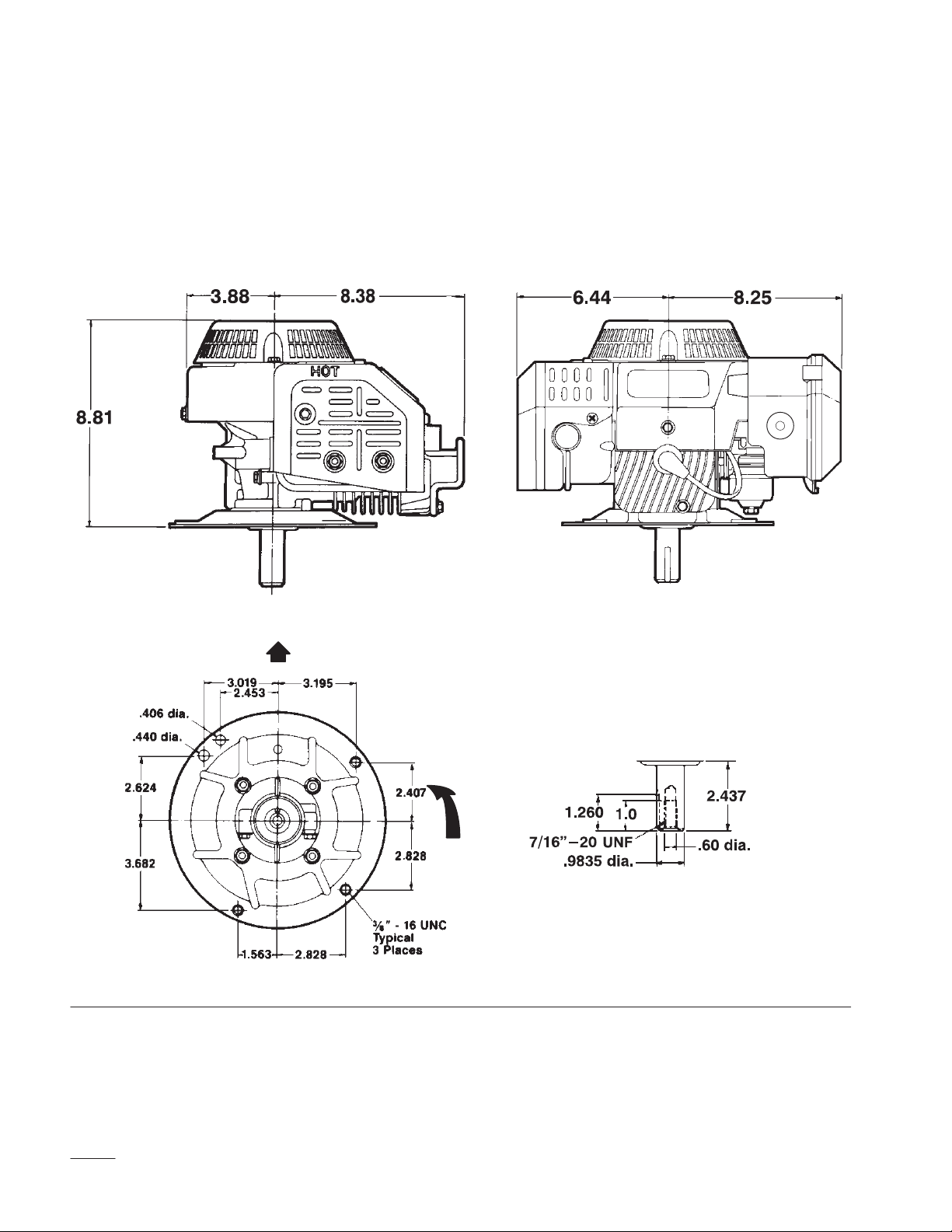

Engine Feature Locations

2

1

3

4

1. Muffler

2. Air Slots in Recoil Housing

3. Muffler Guard Extension

(European requirement

only)

5

6

Figure 2

4. Spark Plug Protector

5. Spark Plug and Wire

6. Primer

7. Air Cleaner

7

Throttle Travel 1.50” (38 mm). . . . . . . . . . . . . . . .

PTO Diameter 1” (25 mm). . . . . . . . . . . . . . . . . . .

PTO Length 2.437” (62 mm). . . . . . . . . . . . . . . . .

Mounting Bolt Size .375” (9.5 mm). . . . . . . . . . .

Direction of Rotation Counterclockwise. . . . . . . .

Dry Weight 20 lbs (9 kg). . . . . . . . . . . . . . . . . . . . .

3

Page 6

Installation

Check the position of the recoil start on the engine

being replaced. Note that this replacement engine is

assembled for zone-start blade applications.

Starter Rope Configuration for

Zone-start Applications

1. Insert the starter rope into the rope guide

(Fig. 3).

1

2

Starter Rope Configuration for

Non-zone-start Applications

1. Remove the recoil assembly (Fig 4).

2. Rotate the recoil assembly 90 degrees clockwise,

then reassemble the recoil assembly to the

engine (Fig 4).

1

m–2705

Figure 3

1. Rope Guide (typical) 2. Starter Rope

2. Fasten the rope stop to the starter rope to within

2-1/2” (64 mm) of the recoil assembly.

Figure 4

1. Recoil Assembly

3. Remove the rope stop and starter handle from

the starter rope.

4. Remove approximately 28” (71 cm) of the starter

rope, then reattach the starter handle.

5. Attach the recoil decal to the recoil assembly so

the decal reads from the front of the engine.

4

Page 7

Installation

Installing the Spark Plug

Protector

Fasten the spark plug protector to the engine using

the self-tapping screws provided with the engine

(Fig 2).

1

2

3

Figure 5

1. Self-tapping Screw (2)

2. Muffler Guard Extension

(European requirement

only)

3. Spark Plug Protector

For European Applications

• A muffler guard extension is attached to the

muffler. This is a European safety requirement

and is not necessary for USA applications

(Fig. 2).

• A fuel decal is provided to be affixed over the

existing fuel decal. USA purchasers may discard

this decal.

Kill Switch Wire

Connect the kill switch wire to the equipment

according to the equipment manufacturer’s

instructions.

Fuel Line

You may have to cut the fuel line to fit your particular

application.

5

Page 8

Operation

Approved Oils and Mixing

Ratios

Your two-cycle engine requires a mixture of gasoline

and oil. Failure to use the correct oils and mixture

will result in serious engine damage.

For simplicity and best engine performance, mix the

contents of one 5.2-ounce bottle of Toro Two-cycle

Oil with two gallons of fresh, unleaded regular

gasoline. Leaded regular gasoline can be used if

unleaded regular is not available.

Toro Two-cycle Oil is specially formulated to

provide superior lubrication, make starting easy and

prolong engine life. Regular use of Toro Two-cycle

Oil will help keep your engine clean, and will help

reduce spark plug fouling, piston ring sticking and

pre-ignition. Toro Two-cycle Oil will also minimize

varnish buildup, combustion chamber deposits and

exhaust port blockage.

You can also use Toro “Easy Mix” Two-cycle Oil

(one 3.2-ounce bottle mixed per gallon of gasoline for

a 40:1 ratio) in this Toro two-cycle engine.

If Toro Two-cycle Oil or Toro “Easy Mix”

Two-cycle Oil is not available, mix two gallons of

gasoline and 5.2 ounces of another high grade

two-cycle oil that has the NMMA or BIA–TCW

certification printed on the label.

Note: Substitute oils may produce more

exhaust smoke, may require increased

engine service (more frequent spark

plug changes and exhaust port/cylinder

decarbonizing), and could reduce

engine life.

IMPORTANT: NEVER USE AUTOMOTIVE

OIL (i.e. SAE 30, 10W30 etc.), OR THE

WRONG MIX RATIO BECAUSE ENGINE

DAMAGE MAY OCCUR. If engine failure

occurs and it has been determined that Toro

Two-cycle Oil was not used, the failure may

not be covered the Toro warranty.

Toro recommends that Toro Stabilizer/Conditioner

be used regularly during operation and storage. Toro

Stabilizer/Conditioner cleans the engine during

operation and prevents gum-like varnish deposits

from forming in the engine during storage.

DO NOT USE FUEL ADDITIVES OTHER

THAN THOSE MANUFACTURED FOR FUEL

STABILIZATION DURING STORAGE, SUCH

AS TORO STABILIZER/CONDITIONER OR A

SIMILAR PRODUCT. TORO’S

STABILIZER/CONDITIONER IS A

PETROLEUM DISTILLATE BASED

CONDITIONER/STABILIZER. TORO DOES

NOT RECOMMEND STABILIZERS WITH AN

ALCOHOL BASE SUCH AS ETHANOL,

METHANOL OR ISOPROPYL. STABILIZERS

SHOULD NOT BE USED TO TRY TO

ENHANCE THE POWER OR PERFORMANCE

OF MACHINE.

6

Page 9

Operation

Mixing Gasoline and Oil

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AVOID THE HAZARD

• Use a funnel and fill the fuel tank outdoors,

in an open area, when the engine is cold.

Wipe up any gasoline that spills.

• Do not fill the fuel tank completely full.

Add gasoline to the fuel tank until the level

is 1/4” to 1/2” (6 mm to 13 mm) below the

bottom of the filler neck. This empty space

in the tank allows gasoline to expand.

• Never smoke when handling gasoline, and

stay away from an open flame or where

gasoline fumes may be ignited by a spark.

• Store gasoline in an approved container

and keep it out of the reach of children.

• Never buy more than a 30-day supply of

gasoline.

Do not use gasoline that has been stored in an

approved container from one season to the next. Use

clean, fresh lead-free gasoline with an octane rating of

85 or higher. Purchase only the quantity of gasoline

that can be used in 30 days to ensure freshness. Use

of lead-free gasoline results in fewer combustion

chamber deposits and longer spark plug life. Leaded

gasoline may be used if lead-free is not available.

Mix the contents of one 5.2-ounce bottle of Toro

Two-cycle Oil with two gallons of fresh, unleaded

regular gasoline as follows:.

1. Pour one gallon of gasoline into an approved

gasoline container, then add one 5.2-ounce bottle

of Toro Two-cycle Oil.

2. Install the cap on the gasoline container and

shake to mix the oil and gasoline thoroughly

(Fig. 6).

3. Slowly remove the cap, then add the remaining

gasoline.

Note: Do not mix gasoline and oil in the

engine fuel tank. Oil that is at room

temperature mixes more easily and

thoroughly than cold oil.

1682

Figure 6

Note: NEVER USE METHANOL,

GASOLINE CONTAINING

METHANOL, GASOHOL

CONTAINING MORE THAN 10%

ETHANOL, PREMIUM GASOLINE

OR WHITE GAS BECAUSE

ENGINE FUEL SYSTEM COULD

BE DAMAGED.

7

Page 10

Operation

Filling the Fuel Tank

1. Pull the spark plug wire off of the spark plug

(Fig. 7).

2. Clean around the fuel cap before removing the

cap.

3. Remove the fuel tank cap and fill the fuel tank

with the gasoline/oil mix to within 1/4 inch

(6 mm) of the top of the tank, not into the filler

neck. DO NOT OVERFILL THE TANK.

4. Reinstall the fuel tank cap securely and wipe up

any spilled fuel.

5. Reconnect the spark plug wire to the spark plug

(Fig. 7).

Starting the Engine

POTENTIAL HAZARD

• Clothing and body parts can get caught in

moving parts on the engine and equipment.

WHAT CAN HAPPEN

• Contact with moving parts on the engine

and equipment could cause serious

personal injury.

HOW TO AVOID THE HAZARD

• Stay away from moving parts on the engine

and equipment.

• Ensure that the equipment is in neutral,

and disengage all clutches, belts and chains.

If the engine is remotely controlled, refer to the

equipment manufacturer’s starting and operating

instructions for control positions which correspond to

the Toro engine’s starting and operating positions.

1

1. Spark Plug Wire

2. Spark Plug

1. Make sure the spark plug wire is connected to

spark plug (Fig. 7).

2. Cover the hole in the center of the primer with

your thumb and push once. An additional prime

may be necessary in extremely cold temperatures

(Fig. 7).

2

3

Note: The choke and primer are usually not

necessary when starting a warm

Figure 7

3. Primer

3. Pull the recoil starter.

engine.

4. To stop the engine, move the remote control on

the equipment to the setting specified by the

equipment manufacturer.

8

Page 11

Maintenance

Service Interval Chart

Each

Service Operation

Service Air Cleaner X

Remove and Check/Replace Spark Plug X

Clean Cooling System X

Clean Muffler Pipe and Exhaust Port X

Drain Gasoline X

Use25Hours75Hours

Storage

Service

Before Performing Any

Maintenance

POTENTIAL HAZARD

• If you leave the wire on the spark plug,

someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of engine could

seriously injure you or other bystanders.

Stop the engine and pull the spark plug wire off of the

spark plug (Fig. 7).

Notes

Clean more

frequently in

dusty or dirty

conditions

HOW TO AVOID THE HAZARD

• Pull wire off spark plug before performing

any maintenance. Also push wire aside so it

does not accidentally contact spark plug.

1

2

Figure 8

1. Spark Plug 2. Spark Plug Wire

9

Page 12

Maintenance

Servicing the Air Cleaner

Normally clean the air cleaner after every 25

operating hours. More frequent cleaning is required

when the engine is operated in dusty or dirty

conditions.

1. Make sure the spark plug wire is disconnected

from the spark plug (Fig. 9).

3

1

2. Lift the tab at the top of the air cleaner and pivot

the air cleaner cover down. Clean the cover

thoroughly (Fig. 9).

3. If the outside of the foam element is dirty,

remove it from the air cleaner body and clean it

thoroughly as follows:

A. Wash the foam element in a solution of

liquid soap and warm water. Squeeze the

element to remove the dirt.

IMPORTANT: Do not twist the foam element

as the foam may tear.

B. Rinse the element thoroughly in clear water.

C. Dry the element by wrapping it in a clean

rag. Squeeze the rag and element to dry the

element.

D. Saturate the element with engine oil.

Squeeze the element to remove any excess

oil, and to distribute the oil thoroughly. A

damp element is desirable.

2

1. Spark Plug

2. Spark Plug Wire

4

Figure 9

3. Foam Element

4. Air Cleaner Cover

4. Reinstall the foam element and air cleaner cover

(Fig. 9).

IMPORTANT: Do not operate the engine

without the air cleaner element installed or

extreme engine wear and damage will likely

result.

10

Page 13

Maintenance

Replacing the Spark Plug

Use an NGK BPMR4A spark plug or equivalent. The

correct air gap is 0.032” (0.8 mm). Remove the plug

after every 25 operating hours and check its

condition.

1. Stop the engine and pull the spark plug wire off

of the spark plug.

2. Clean around the spark plug and remove the plug

from the cylinder head.

IMPORTANT: Replace a cracked, fouled or

dirty spark plug. Do not sandblast, scrape or

clean the electrodes because engine damage

could result from grit entering the cylinder.

3. Set the air gap to 0.032” (0.8 mm) (Fig. 10).

4. Reinstall the correctly gapped spark plug and

gasket seal. Tighten the plug firmly to 10 ft-lb

(13.6 Nm).

Cleaning the Cooling System

Cleaning the cooling system ensures correct cooling,

best engine performance and maximum engine life.

1. Clean any dirt and chaff from the cylinder,

cylinder head fins, and from around the

carburetor and linkage (Fig. 2).

2. Remove any debris from around the air intake

slots on the recoil housing (Fig. 2).

1

.032”

(0.8 mm)

2

Figure 11

1. Air Slots in Recoil Housing 2. Cylinder Head FIns

986

Figure 10

11

Page 14

Maintenance

Cleaning the Muffler Pipe and

Exhaust Port

POTENTIAL HAZARD

• Muffler and engine surfaces become hot

during operation.

WHAT CAN HAPPEN

• Contact with hot muffler and engine

surfaces could cause a burn.

HOW TO AVOID THE HAZARD

• Clean the muffler and exhaust port only

after the engine and muffler are cool.

Clean the end of the muffler pipe and the exhaust port

every 75 hours of operation.

1. Use a hardwood scraper to remove the carbon

from the end of the muffler pipe (Fig. 12).

3. Remove the hex head screw, then remove the

muffler from the engine (Fig. 12).

4. Make sure the spark plug wire is off of the spark

plug, then slowly pull the starter rope until the

piston covers the exhaust port (Fig. 13).

5. Clean the carbon from the exhaust port with a

flat, hardwood scraper (Fig. 13).

IMPORTANT: Do not use a metal scraper or

similar object to clean the exhaust port. This

can damage the piston or cylinder.

1

2. Remove the Phillips screw, two hex nuts and

lock washers and remove the muffler cover and

attached muffler cover extension from the engine

(Fig. 12).

1

2

Figure 12

1. Hex Head Screw

2. Hex Nut and Lock

Washer (2)

4

3

3. Muffler Cover

4. Muffler Pipe

5. Phillips Screw

3

2

Figure 13

1. Spark Plug

2. Exhaust Port

3. Spark Plug Wire

6. Check the muffler gasket and replace it if worn

5

or damaged.

7. Reinstall the muffler onto the engine, then

reinstall and tighten the hex head screw

(Fig. 12).

8. Reinstall the muffler cover and muffler cover

extension onto the muffler, then reinstall and

tighten the Phillips screw, and the two lock

washers and hex nuts (Fig. 12).

12

Page 15

Maintenance

Draining the Gasoline

POTENTIAL HAZARD

• If gasoline is spilled on a hot engine, it

could ignite.

WHAT CAN HAPPEN

• Contact with burning gasoline could cause

serious personal injury.

HOW TO AVOID THE HAZARD

• Drain gasoline from a cold engine only.

1. Shut off the engine and allow it to cool.

IMPORTANT: Drain gasoline from a cold

engine only.

2. Make sure the spark plug wire is off of the spark

plug. Remove the cap from the fuel tank and use

a pump-type syphon to drain the fuel into a clean

gas can.

Note: This is the only procedure

recommended for draining fuel.

Storage

For long-term storage, either drain the gasoline from

the fuel tank or use a fuel additive before storing. To

drain the gasoline, refer to Draining the Gasoline

above.

If You Leave the Gasoline in the Tank

Fuel can be left in the gas tank only if a fuel additive

such as Toro’s Stabilizer/Conditioner is added to the

gasoline and run through the engine before storing.

Toro’s Stabilizer/Conditioner is a petroleum distillate

based stabilizer/conditioner. Toro does not

recommend stabilizers with an alcohol base such as

ethanol, methanol or isopropyl. Use the fuel additive

in the recommended quantities as specified on the

container. Under normal conditions, fuel additives

remain effective in the fuel for six to eight months.

Coating the Inside of the Cylinder

1. Remove the spark plug and pour two

tablespoons of engine oil into the spark plug

hole in the cylinder.

2. Pull the starter rope slowly to coat the inside of

the cylinder.

3. Reinstall the spark plug and tighten to 10 ft-lbs

(13.6 Nm). DO NOT REINSTALL THE

SPARK PLUG WIRE ONTO THE SPARK

PLUG.

4. Slowly pull the starter rope until resistance is felt

due to compression pressure, then stop. Release

the starter rope tension slowly to prevent the

engine from reversing due to compression

pressure. This position closes both the intake and

exhaust ports to prevent cylinder bore corrosion.

Adjusting the Carburetor

If You Drain the Gasoline

1. After the fuel is drained, start the engine and let

it idle until all the fuel is consumed and the

engine stops.

2. Repeat the starting procedure two more times to

ensure that all the gas is removed from the

engine. If the gasoline is not drained, gum-like

varnish deposits will form and cause poor engine

operation, even starting problems.

The carburetor has been set at the factory and

normally won’t require any further adjustment.

However, when operating the engine at altitudes 5000

feet above sea level and higher, the carburetor jets

may have to be changed. Contact your Authorized

Toro Service Dealer for assistance.

13

Page 16

Walk

Mowers

THE TORO PERFORMANCE

WARRANTY

A Full Warranty

(Limited Warranty for Commercial Use)

What Is Covered By This Express Warranty?

The Toro Company promises to repair any TORO Product

used for normal residential purposes* if defective in materials

or workmanship or if it stops functioning due to the failure of a

component. The following time periods apply from the date of

purchase:

Super Recycler Walk Mowers 5 year full warranty.

All Others 2 year full warranty. . . . . . . . . . . . . . . . . . .

The cost of parts and labor is included, but the customer pays

the transportation costs.

What Products Are Covered By This Warranty?

This warranty applies to all gasoline powered consumer walk

power mowers. Riding products and wide area walk behind

mowers are covered by separate warranty statements.

How About Commercial Use?

TORO Consumer Products used for commercial, institutional

or rental use are warranted against defects in material or

workmanship. Components failing due to normal wear are not

covered by this warranty. The following time periods apply

from the date of purchase:

Products Warranty Period

Engine Entire Unit

21" Commercial Duty

Walk Mowers

With GTS 150 Engine 2 year limited 1 year limited. . . .

Without GTS 150 Engine 1 year limited 1 year limited.

All Others 45 day limited 45 day limited. . . . . . . . . . . . . .

How Do You Get Warranty Service?

Should you feel your TORO Product requires warranty ser

vice, contact the dealer who sold you the product or any Au

thorized TORO Service Dealer or TORO Master Service Deal

er. The Yellow Pages of your telephone directory is a good

reference source. The dealer will either arrange service at

his/her dealership or recommend another Authorized Service

Dealer who may be more convenient. You may need proof of

purchase (copy of registration card, sales receipt, etc.) for

warranty validation.

What Must You Do To Keep The Warranty In Effect?

You must maintain your TORO Product by following the main

tenance procedures described in the operator's manual. Such

routine maintenance, whether performed by a dealer or by

you, is at your expense.

What Does This Warranty Not Cover?

and

How Does Your State Law Relate To This Warranty?

There is no other express warranty except the TORO Starting

Guarantee on GTS Engines. This express warranty does not

cover:

Cost of regular maintenance service or parts, such as filters,

fuel, lubricants, oil changes, spark plugs, blade sharpening,

blade worn out, cable/linkage adjustments or brake and clutch

adjustments.

Any product or part which has been altered or misused or

required replacement or repair due to accidents or lack of

proper maintenance.

Repairs necessary due to improper fuel, contaminants in the

fuel system, or failure to properly prepare the fuel system prior

to any period of non-use over three months.

Pickup and delivery charges.

All repairs covered by this warranty must be performed by an

Authorized TORO Service Dealer using Toro approved replace

ment parts.

Repair by an Authorized TORO Service Dealer is your sole

remedy under this warranty.

The Toro Company is not liable for indirect, incidental or

consequential damages in connection with the use of the

TORO Products covered by this warranty, including any

cost or expense of providing substitute equipment or ser

vice during reasonable periods of malfunction or non-use

pending completion of repairs under this warranty. Some

states do not allow exclusions of incidental or consequen

tial damages, so the above exclusion may not apply to

you.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

If for any reason you are dissatisfied with the Service Dealer's

analysis of the defect in materials or workmanship or if you

need a referral to a TORO Service Dealer, please feel free to

contact us at the following address:

Toro Customer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

612-888-8801

800-348-2424

* Normal residential purposes means mowing the lawn on

the same lot as your home. Use at more than one location

is considered commercial use and the commercial use

warranty would apply.

COUNTRIES OTHER THAN THE UNITED STATES OR CANADA

Customers who have purchased TORO products exported from the United States or Canada should contact their TORO Dis

tributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with

your Distributor's service or have difficulty obtaining guarantee information, contact the TORO importer. If all other remedies

fail, you may contact us at The Toro Company.

Loading...

Loading...