Page 1

FormNo.3396-409RevA

MMX-650E-SorMMX-850E-S

MortarMixer

ModelNo.60212—SerialNo.315000001andUp

ModelNo.60218—SerialNo.315000001andUp

ModelNo.60219—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3396-409*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

Introduction

Thismachineisdesignedtomixmortar,plaster,reproong

material,grout,andothersmall-grainedcementproducts.A

vehicleequippedwithanappropriatepintlehitchorballhitch

cantowthemachine..

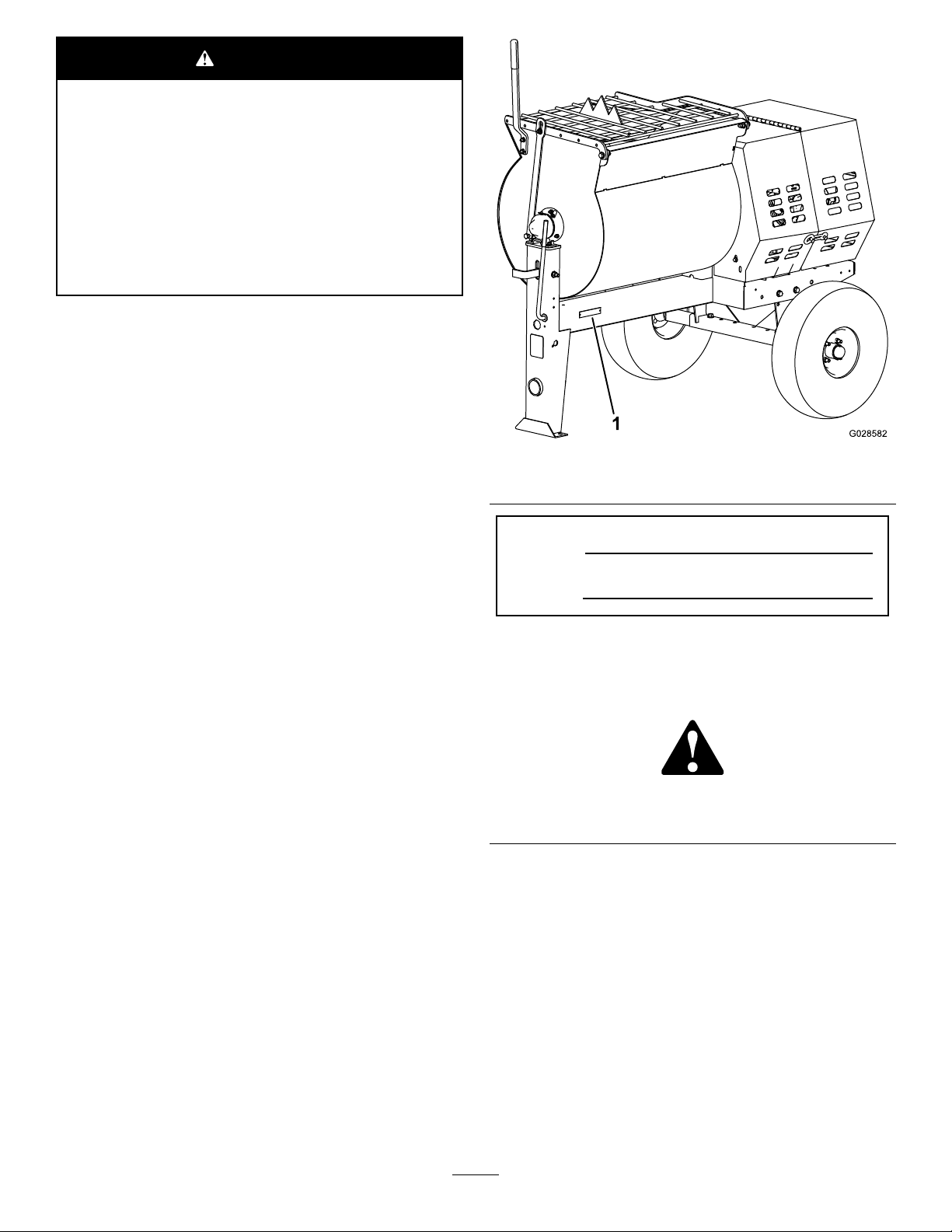

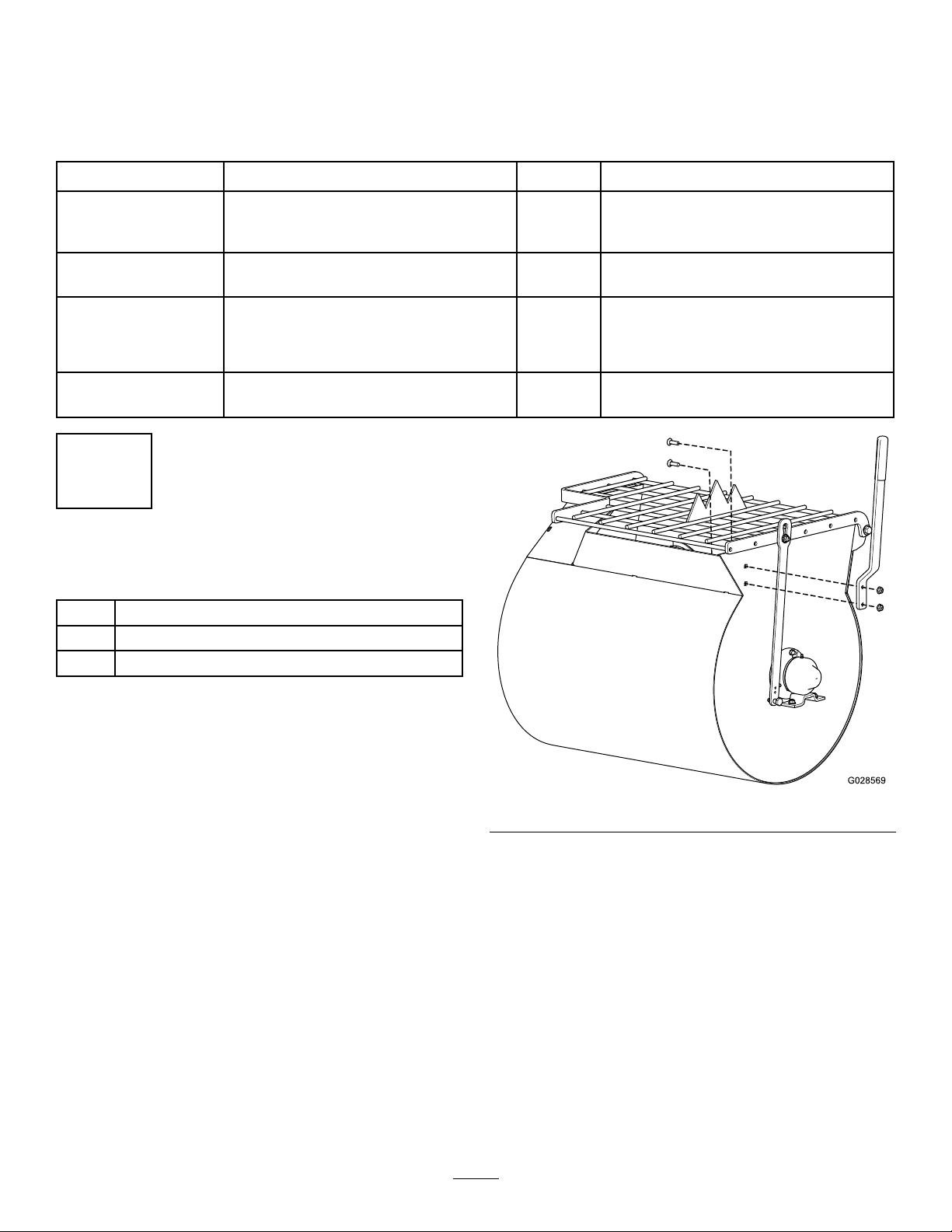

Figure1

1.Modelandserialnumberlocation

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

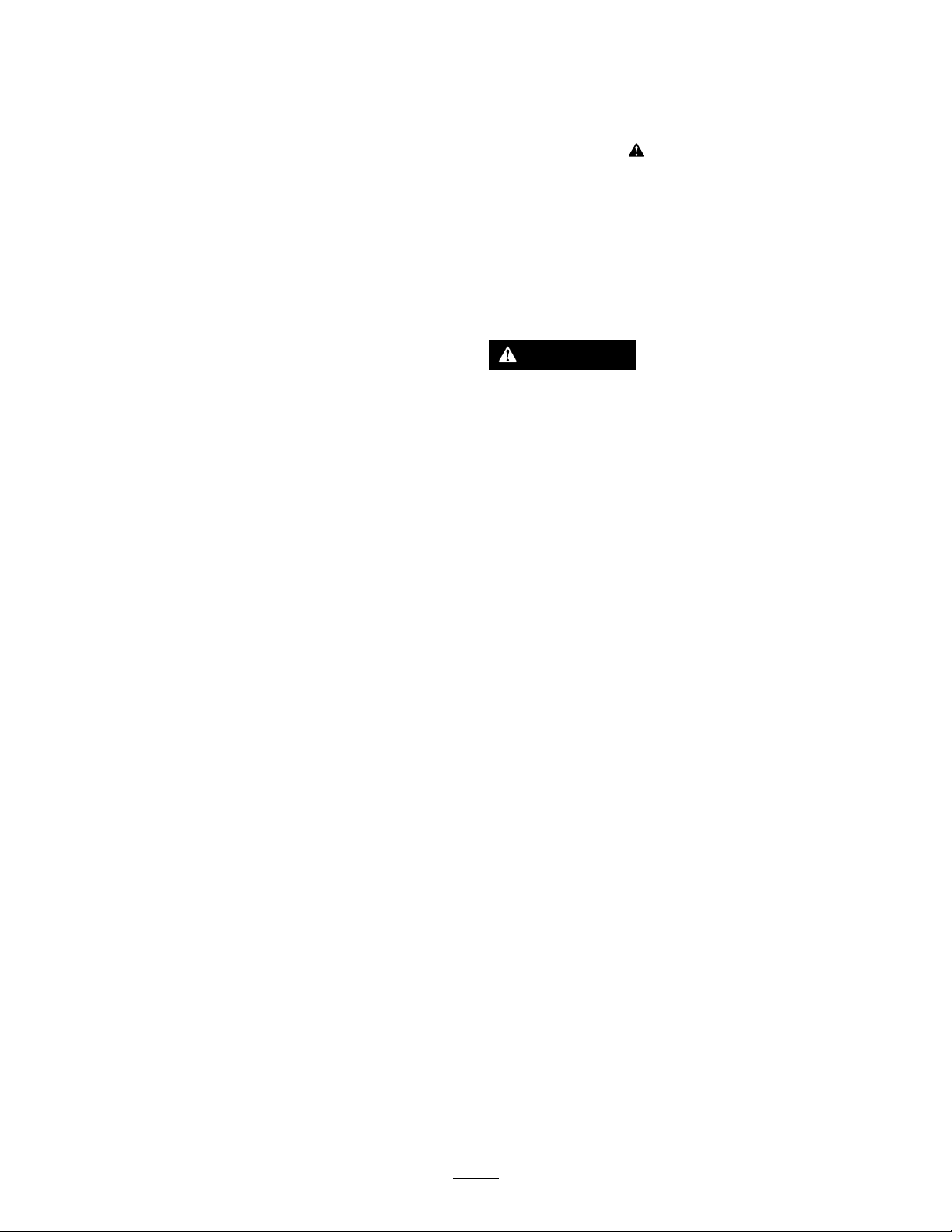

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

TheDOTtireinformationislocatedonthesideofeachtire.

Thisinformationgivesloadandspeedratings.Replacement

tiresshouldhavethesameorbetterratings.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Note:Thevariousmachinesinthismanualhavedifferent

weights;refertoSpecications(page11)toensurethatthe

tiresonyourmachinemeetorexceedtheweightrequirements

ofyourmachine.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................6

Setup............................................................................7

1InstallingtheDumpHandle...................................7

2InstallingtheTowPole..........................................7

3InstallingtheSafetyChain......................................8

4AdjustingtheMixingPaddles..................................9

ProductOverview..........................................................9

Controls...............................................................10

Specications........................................................11

Operation....................................................................12

PreparingtoT owtheMachine..................................12

ExtendingtheAxle.................................................15

TowingtheMachine...............................................16

PreparingtoUsetheMachine...................................16

OpeningandClosingtheCowl.................................17

PoweringtheMachine.............................................17

StartingandStoppingtheMotor...............................19

ControllingthePaddles...........................................19

MixingtheMaterial.................................................19

UsingtheDrum.....................................................20

Maintenance.................................................................22

RecommendedMaintenanceSchedule(s)......................22

PremaintenanceProcedures........................................22

PreparingtheMachineforMaintenance.....................22

RemovingandInstallingtheDividerPlate..................22

Lubrication...............................................................23

LubricatingtheBearingsandSeals............................23

LubricatingtheMotorBearings................................24

LubricatingtheDriveChain.....................................24

BeltMaintenance......................................................25

ServicingtheBelts..................................................25

ReplacingtheBelts.................................................26

AligningthePulleys................................................28

DriveChainMaintenance............................................28

CheckingandAdjustingtheDriveChain....................28

PaddleMaintenance...................................................29

AdjustingthePaddles..............................................29

Cleaning...................................................................31

CleaningtheMachine..............................................31

Storage........................................................................32

StoringtheMachine................................................32

Troubleshooting...........................................................33

Schematics...................................................................34

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

,whichmeans:

Caution

,

W ar ning

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Alwaysfollow

allsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Machiningorhandlingstone,masonry,concrete,

metal,andothermaterialscangeneratedust,mists,

andfumescontainingchemicals,suchassilica,

knowntocauseseriousorfatalinjuryorillness,

suchasrespiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Watershouldbeusedfordust

suppressionwhenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupationaland

tradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyOSHAfor

thematerialbeinghandled.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

,

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriestopeopleordamagetoproperty.

3

Page 4

Towing

Checkwithyourlocalcountyorstatetowingsafetyregulations

beforetowingthemachine.

•Inordertoreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,makesure

thetowingvehicleismechanicallysoundandingood

operatingcondition.

•Turnoffthemotorbeforetransportingthemachine.

•Whentowingwithaballhitch,ensurethattheballhitch

youareusingisthepropersizeforthehitchcoupleron

themachine.

•Whentowingwithapintlehitch,ensurethattheeyeof

thetowpoleisthecorrectdimensionforthepintlehook.

•Inspectthehitchandcouplingforwear.Nevertowthe

machinewithdamagedordefectivehitches,couplings,

chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicleandthe

machine.

•Checkthetiretreadandsidewallfordamageandwear.

•Properlyattachthesafetychainstothetowingvehicle.

•Ensurethatthedirectionalandbrakelightsareworking

properly(ifthemachineisequippedwiththelightkit).

•Ensurethatthedirectional,backup,andbrakelightsof

thetowvehicleareworkingproperly.

•Beforetowing,checktomakecertainyourmachineis

correctlyandsecurelyattachedtothetowingvehicle.

•Ensurethatthesafetychainsareproperlysecuredtothe

vehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhentowing.

•Avoidsuddenstopsandstarts.Thiscancauseskidding,

orjackkning.Smooth,gradualstartsandstopswill

improvetowing.

•Avoidsharpturnstopreventrolling.Towonlywitha

vehiclethathasahitchdesignedfortowing.Donot

attachtowedequipmentexceptatthehitchpoint.

•Donottowthemachinefasterthan88km/h(55mph).

•Usecautionwhenbackingup;useaspotteroutsidethe

vehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Wearpersonalprotectiveequipmentandappropriate

clothingincluding:

–Hardhat

–Respiratorordustmask

–Faceshield

–Safetyglasses

–Hearingprotection

–Safetyshoes

–Longpants

–Shirtwithlongsleevesthataretightatthewrists

–Tight-ttinggloveswithoutdrawstringsorloosecuffs

•Securelonghair,looseclothing,orjewelrythatmayget

tangledinmovingparts.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Ensurethatthemachineisonalevelsurfacebefore

operatingthemachine.

•Chockthetiresofthemachinetopreventunintended

movement.

•Beforeeveryuse:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly(ifthe

machineisequippedwithalightkit).

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

Operation

•Neverrunthemachineinapoorlyventilatedorenclosed

areawithoutproperrespiratoryprotection.Dustfrom

materialsbeingmixedcanbeveryharmfultooperators

andbystanders.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Neverleavearunningmachineunattended.Alwaysstop

themotorandverifythatallmovingpartshavestopped.

•Chockthetireswhenusingthemachine.

•Whennotusingthemachine,chockthetiresorkeepit

attachedtothetowvehicle.

•Keephandsawayfromanymovingparts.Keepfeetaway

fromthetiresandthefrontpost.

•Donotoperatethemachineoutdoorsintherain.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Ensurethattheareaisclearofotherpeopleorpetsbefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverplaceyourhandsoranysolidobjectintothedrum

whenthemachineisinoperation.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Nevermovethemachinewhilethemotorisrunning.

4

Page 5

•Keepthecowlclosedandlatchedduringoperation.

MaintenanceandStorage

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•EnsurethattheON/OFFswitchisintheOFFposition

beforeconnectingthemachinetotheelectricalsource.

•Ifthemixingpaddlesstrikeaforeignobjectorifthe

machineshouldstartmakinganunusualnoiseor

vibration,stopthemotorandemptythedrum.Waitfor

allmovingpartstocometoacompletestopandcool.

Vibrationisgenerallyawarningoftrouble.Inspectfor

cloggingordamage.Cleanandrepairand/orreplace

damagedparts.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonlevelground.

–Stopthemotor.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

–Letthemotorcoolbeforeperformingmaintenance

orstoringthemachine.

–Unplugthemachinebeforemakinganyrepairs.

•Neverlubricate,service,repair,oradjustthemachine

whileitisrunning.

•Keepequipmentmaterialsclearfromthemotor.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththemotor

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Donotmodifytheelectricalconnectorsorwiring.

•Donotconnectthegroundcircuitofthemachinetothe

energizedcircuitoftheelectricalsource.

•Donottamperwithsafetydevices.

•Chockthetireswhenstoringthemachine.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty..

5

Page 6

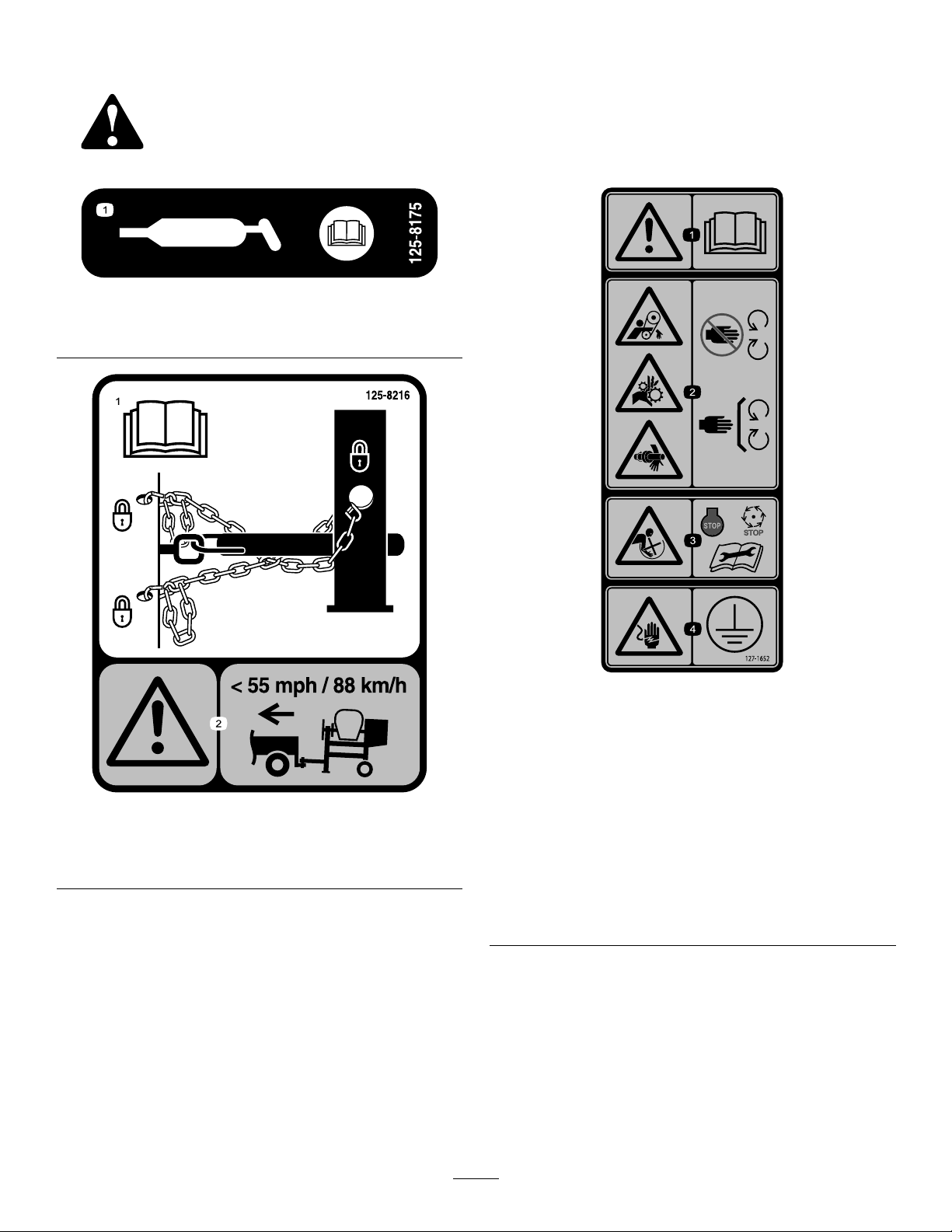

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125–8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

125–8216

2.Warning—limittowing

speedtolessthan55mph

/88km/h.

1.Warning—readthe

Operator’sManual.

2.Handandarm

entanglementatthe

beltdrive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keephandsaway

frommovingparts;keep

allguardsandsafetiesin

place.

127–1652

3.Entanglementhazardat

paddles—stopthemotor

andwaitforallmoving

partstostopbefore

servicingthemachine.

4.Shockhazard—makesure

themachineisgrounded

beforeoperation.

6

Page 7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

1

InstallingtheDumpHandle

Partsneededforthisprocedure:

1Dumphandle

2Bolt

2Nut

Dumphandle1

Bolt2

Nut2

Towpolekit(soldseparately)

Safetychain(soldwithoptionaltowpole

kit)

Connectinglink(soldwithoptionaltow

polekit)

Nopartsrequired

Qty.

Installthedumphandle.

1Installthetowpole.

1

Installthesafetychain.

2

–

Adjustingthemixingpaddles.

Use

InstallingtheDumpHandletotheDrum

1.Cutthecabletiestoremovethedumphandlefrom

theundersideofthegrate.

2.Positionthedumphandlesothattheboltholesalign

withtheboltholesinthedrum(Figure3).

Figure3

3.Insert1carriageboltintothesquareboltholeand

slidethecorrespondingholeofthedrumhandleover

it(Figure3).

4.Installanutontothebolt,andtightenit.

5.Repeatthepreviousstepsfortheremainingcarriage

bolt.

7

Page 8

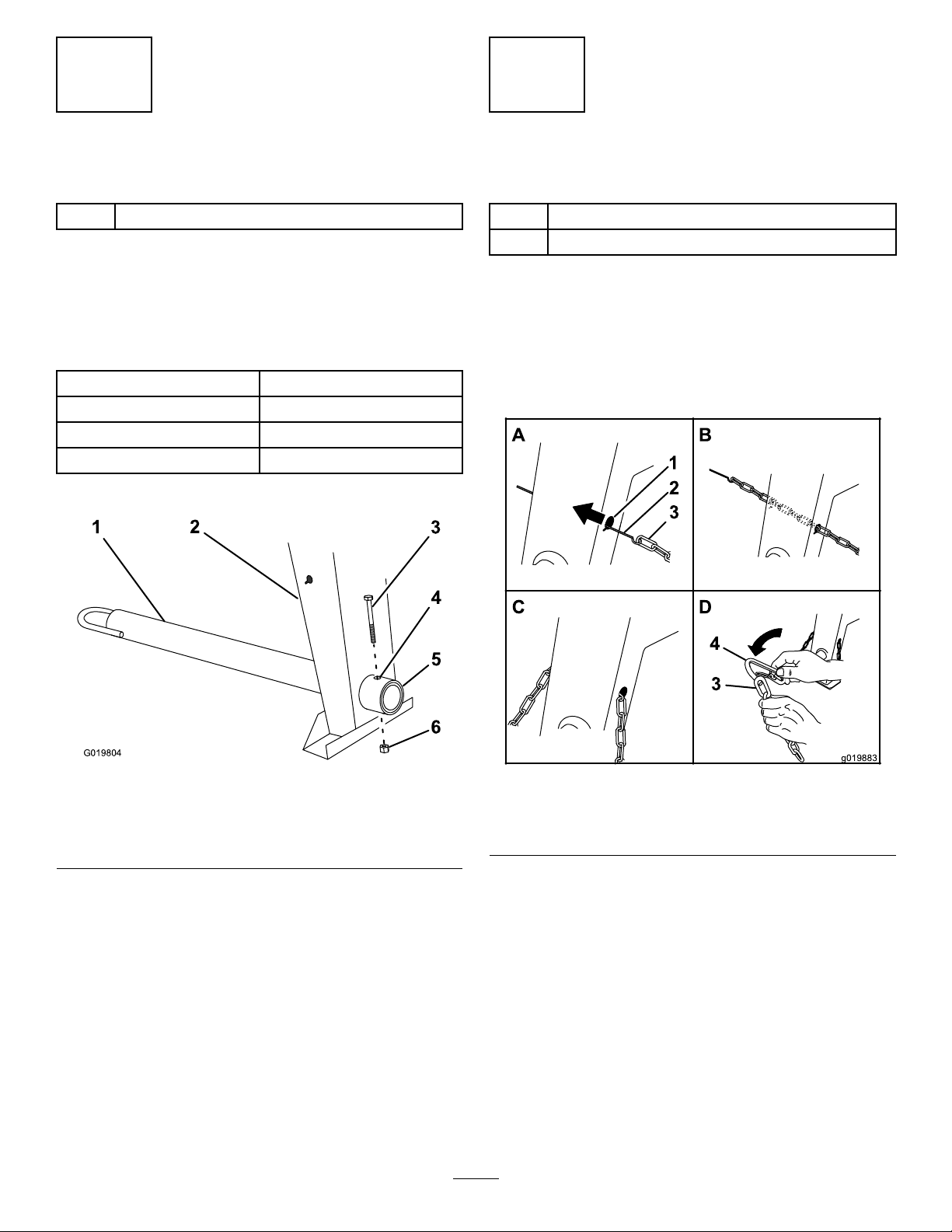

2

5

1

2

4

6

3

G019804

A

B

D

g019883

2

3

4

3

1

3

InstallingtheTowPole

Partsneededforthisprocedure:

1

Towpolekit(soldseparately)

InstallingtheTowPoletotheMachine

Note:Thetowpoleispurchasedseparatelyandincludesthe

nutandboltneededforinstallation.

Themachinehasthefollowingtowpoleoptions:

HitchTypeLength

50mm(2inch)ball—stamped78.7cm(31inches)

50mm(2inch)ball—forged78.7cm(31inches)

Pintle

1.Removetheboltandnutfromthetowpole(Figure4).

78.7cm(31inches)

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain(soldwithoptionaltowpolekit)

2

Connectinglink(soldwithoptionaltowpolekit)

InstallingtheSafetyChain

Note:Thesafetychainispartoftheoptionaltowpolekit.

1.Formahookontheendofabendablepieceofrod

orstiffwire(notincluded),andinsertitthroughboth

keyholesinthefrontpostofthemachine(Figure5A).

Figure4

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

2.Slidethetowpoleforwardandaligntheholeinthe

polewiththeholeintheframetting(Figure4).

3.Inserttheboltthroughtheholesinthettingandthe

pole(Figure4).

4.Threadthenutontotheboltandtightenthemuntil

theyaretightagainsttheframetting(Figure4).

Note:Iftheself-lockingnyloninsertinthelocknut

wearswithuse,replacethenutwithanewGrade5or

Grade8locknut.

5.Frametting

Figure5

1.Keyhole

2.Rodorwire(notincluded)4.Connectinglink

2.Attachthesafetychaintothelengthofrodorwire

(Figure5A).

3.Pulltherod,orwire,andthesafetychainthroughboth

keyholes(Figure5B).

Note:Ensurethatapproximatelyequallengthsof

safetychainextendfromeithersideofthefrontpost.

8

3.Safetychain

Page 9

InstallingtheConnectingLinks

Note:Theconnectinglinksarepartoftheoptionaltowpole

kit.

1.Aligntheconnectinglinktothelastlinkinoneendof

thesafetychain(Figure5D).

2.Inserttheconnectinglinkthroughthechainlinkuntil

theconnectinglinksnapsclosed.

3.Repeatsteps1and2toinstalltheotherconnectinglink

intheotherendofthesafetychain.

4

AdjustingtheMixingPaddles

NoPartsRequired

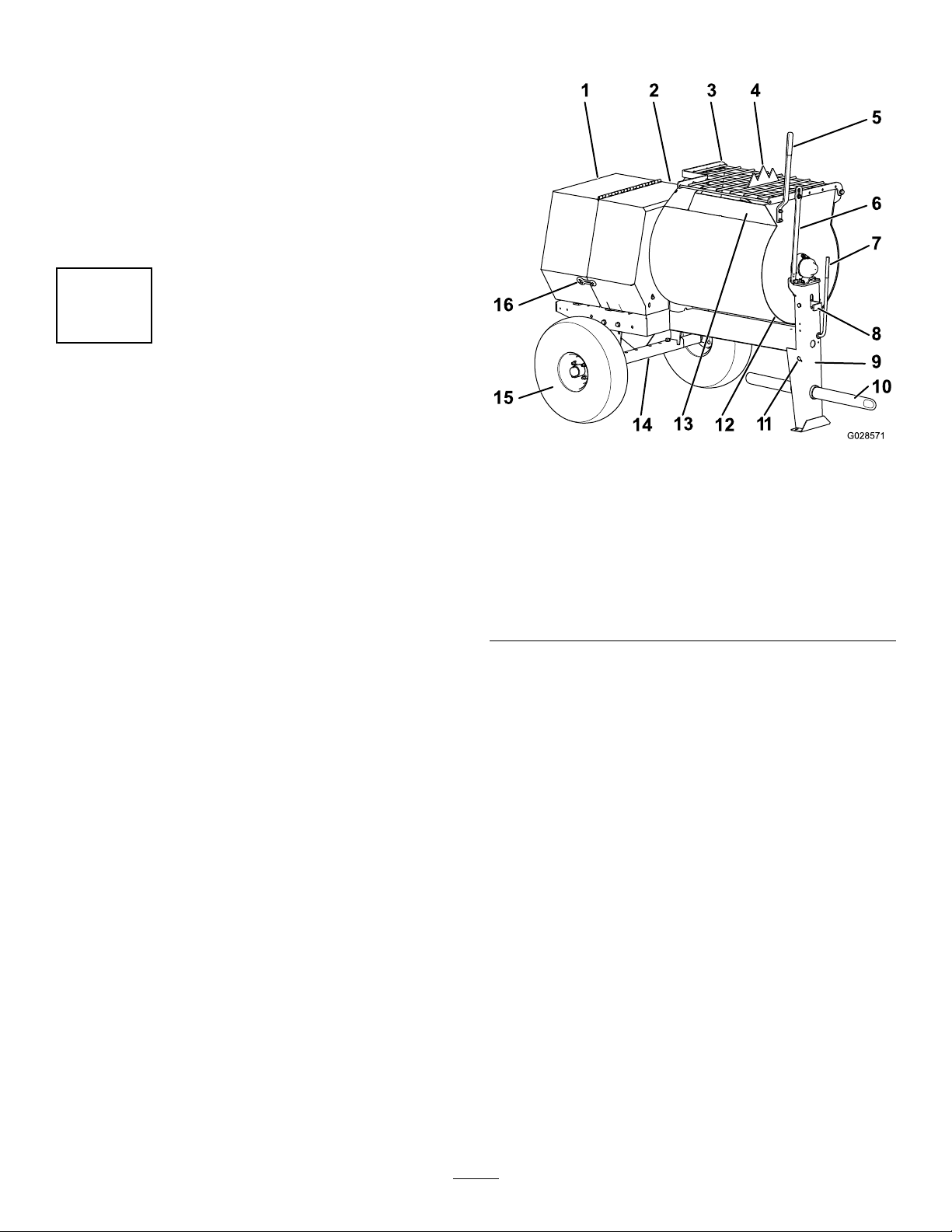

ProductOverview

Procedure

Ifthemixingpaddlesandwipersneedadjustment,adjustthe

paddlesandwipers;refertoAdjustingthePaddles(page29).

Figure6

1.Rearcowl

2.Frontcowl8.Dumplatch14.Axle

3.Grate

4.Bagsplitter10.Towpole

5.Dumphandle

6.Grateliftarm

7.Clutchlever13.Chute

9.Frontpost15.Wheel

11.Safety-chain

keyhole

12.Drum

assembly

16.Cowllatch

9

Page 10

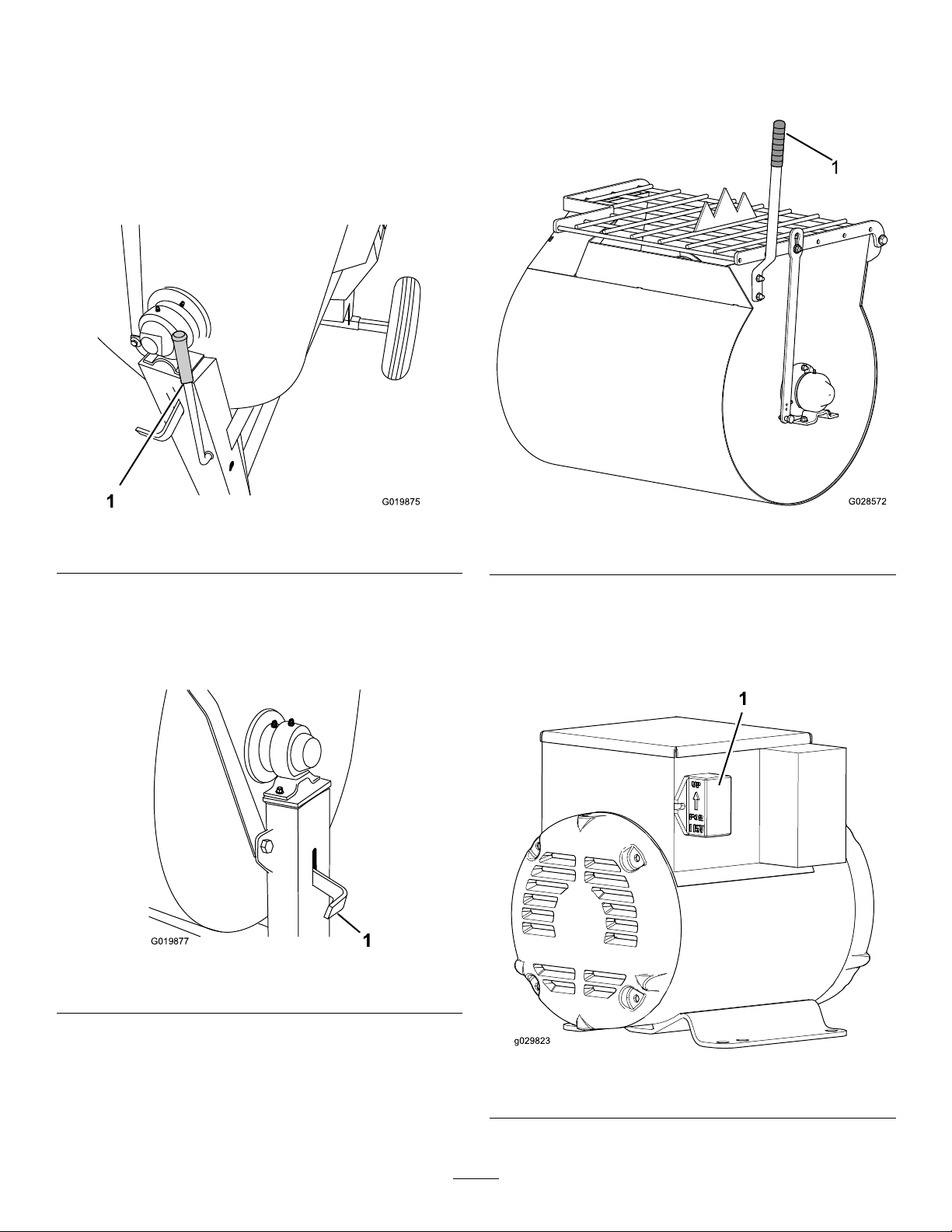

Controls

G019875

1

1

G019877

Becomefamiliarwithallthecontrolsbeforeyoustartthe

motorandoperatethemachine.

ClutchLever

Theclutchleverisusedtoengageanddisengagemotor

powertothepaddles.

DumpHandle

Usethedumphandletorotatethedrumtothedumpposition

andtorotatethedrumtothemixposition(upright).

Figure7

1.Clutchlever

DrumLatch

Thedrumlatchsecuresthedrumtothemixposition(upright)

formixingoperationsandwhentransportingthemachine.

Figure8

Figure9

1.Dumphandle

VoltageBlock

Usethevoltageblocktosettheoperatingvoltageforthe

machine(Figure10).

1.Drumlatch

Figure10

1.V oltageblock

10

Page 11

MotorControls

G022280

3

1

2

g020669

1

Thefollowingmotorcontrolsarefoundonallmodels:

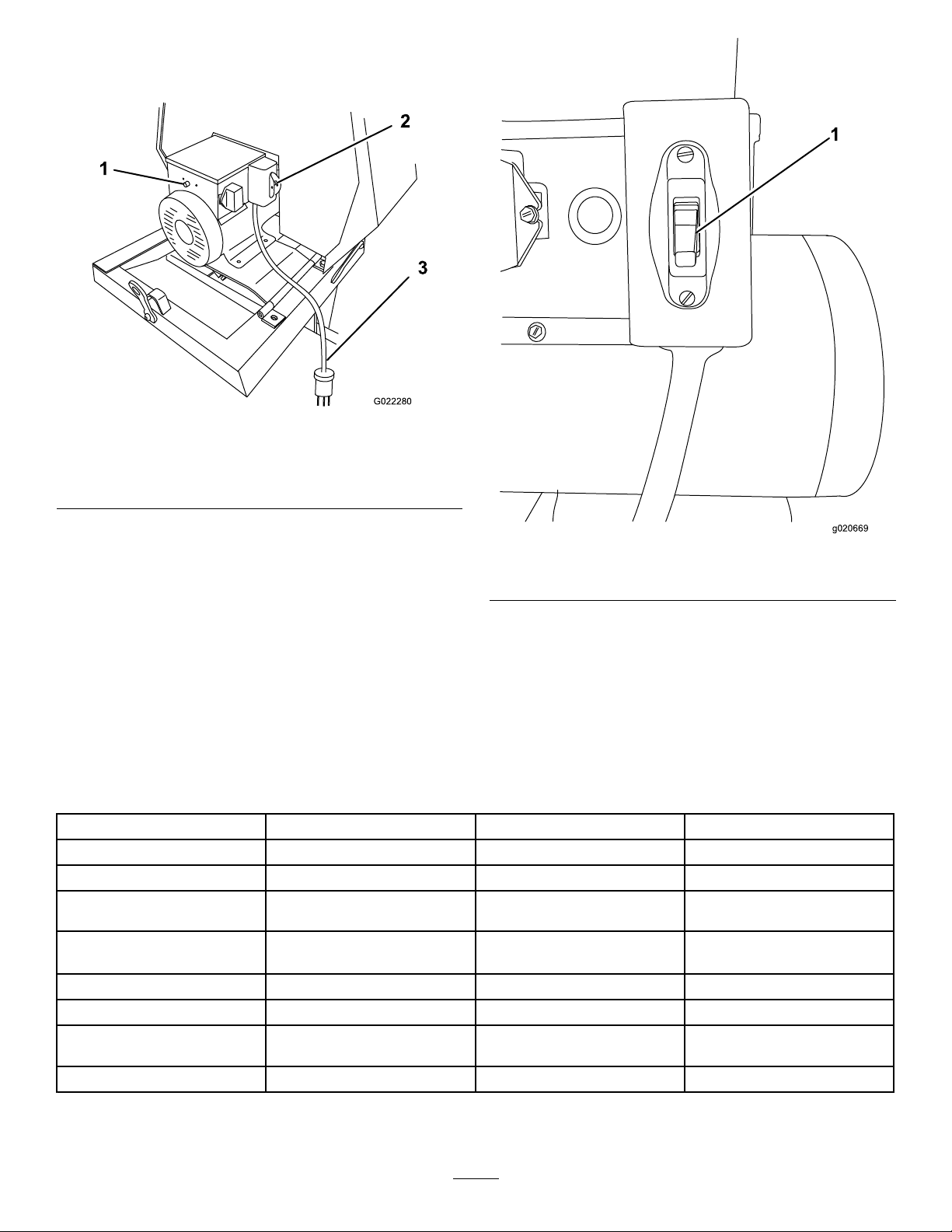

Figure11

1.Thermal-overload

protectorresetbutton

2.ON/OFFswitch

MotorON/OFFSwitch

TheON/OFFswitch(Figure12)allowstheoperatorofthe

3.Powercord

Figure12

1.MotorON/OFFswitch

machinetostartandstopthemotor.Thisswitchislocatedon

thefrontofthemotor.Itismarked(ON)and(OFF).Rotate

theON/OFFswitchtotheONpositiontostartandrunthe

motor.RotatetheON/OFFswitchtotheOFFpositionto

stopthemotor.

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

MachineSpecications

Model602126021860219

BatchCapacity0.17cubicm(6.0cubicft)0.23cubicm(8.0cubicft)0.23cubicm(8.0cubicft)

TotalVolume

Length

(withouttowpole)

Width

0.20cubicm(7.1cubicft)0.25cubicm(9.0cubicft)0.25cubicm(9.0cubicft)

150cm(59inches)168cm(66inches)168cm(66inches)

86cm(34inches)86cm(34inches)86cm(34inches)

Height

Weight

Axle

Motor1.5hpBaldorElectric1.5hpBaldorElectric2hpBaldorElectric

142cm(56inches)142cm(56inches)142cm(56inches)

250kg(550lb)275kg(605lb)275kg(605lb)

86to117cm(34to46inches)

extendable

86to117cm(34to46inches)

extendable

86to117cm(34to46inches)

extendable

11

Page 12

Operation

G019741

G020836

Important:Beforeoperating,removeanydebrisfrom

themachine.Ensurethattheareaisclearofpeople.

CheckingtheTiresandWheels

ServiceInterval:Beforeeachuseordaily—Inspectthetires

andwheels.

WARNING

PreparingtoTowtheMachine

Important:Ensurethatyourtowvehiclehastowing

capacityfortheweightofthemachine.

Important:UseaClass2orlargerreceiver.

Note:Ensurethatyourtowvehiclehastheappropriatehitch

totowthemachine;optionsincludea50mm(2inch)ball

hitchorapintlehitch.

Note:Ifthemachineisequippedwithatrailer-lightkit,

ensurethattheelectricalconnectorofthetowvehicleis

compatiblewiththeelectricalconnectorofthemachine.The

machineusesastandard4-atplug.Ifyourtowvehiclehasa

differenttypeofplug,obtainanadapterfromanautomotive

partsstore.

1.Stopthemotor,unplugthemachine,andemptythe

drum.

2.Ifthedrumhasaccumulatedanywater,dumpthe

drum;refertoDumpingtheDrum(page20),steps1,

3,4,and5.

3.Usingthedumplever,positionthedrumsothatitisin

themixposition(upright)andlocked.

Failuretomaintaincorrecttirepressuremayresult

intirefailureandlossofcontrol,resultingin

propertydamageandseriousinjuryordeath.

•Checkthetirepressurefrequentlytoensure

properination.Ifthetiresarenotinatedto

thecorrectpressure,theywillwearprematurely.

•Inspectthetireconditionbeforetowingand

afteranyoperatingaccident.

TheDOTtireinformationislocatedontheside

ofeachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note:Thevariousmachinesinthismanualhavedifferent

weights;refertoSpecications(page11)toensurethatthe

tiresonyourmachinemeetorexceedtheweightrequirements

ofyourmachine.

1.Visuallyinspectthetiresfordamageandwear(Figure

14andFigure15).

4.Closethecowlandsecurethecowllatches(Figure13).

Figure13

5.Extendtheaxle;refertoExtendingtheAxle(page15).

Figure14

1.Exampleoftirewearcausedbyunderination

Figure15

1.Exampleoftirewearcausedbyoverination

2.Ensurethatthetiresareinatedtothecorrectair

pressure.ThefollowingTireAirPressuretableshows

12

Page 13

theappropriateairpressureforthetiresasinstalledat

1

2

3

4

G021 107

A

B

C

G020359

2

1

thefactory.

Important:Alwayschecktheinformation

ontheactualtiresforthecorrectairpressure

requirement.

Important:Themostcommoncauseoftire

troubleisunder-ination.Maintainfullair

pressure.

TireAirPressure

ModelTirepressure

68012

68018,68019

3.Ensurethatthewheellugnutsaretorquedto108to

122N-m(80to90ft-lb).

Note:Checkthetorqueofthewheellugnutsinitially

andaftertowing.

Note:Torquethelugnutsinthesequenceshownin

Figure16.

Max414kPa(60psi)

Max241kPa(35psi)

HitchingaMachinewithaStampedBall

Coupler

1.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.Oilthe

pivotpointsandslidingsurfacesofthecouplerwith

SAE30motoroil.

2.Openthecouplerlatch(Figure17).

Figure16

Figure17

1.Bail

2.Safetypin

3.Positionthecouplerontopofthehitchball(Figure17).

4.Closethecouplerlatch(Figure17).

5.Openthebailonthesafetypinandinsertthepin

throughtheholeinthelatch(Figure17).

6.Rotatethefreeendofthebailovertheendofthesafety

pinthatisprotrudingthroughthelatch(Figure17).

7.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

13

Page 14

HitchingaMachinewithaForgedBall

A

B

D

G019807

5

1

2

3

4

G019809

Coupler

1.Applyremovablethread-lockingcompoundtothe

threadsofthecouplerbolttopreventthecoupler

handlefromcomingloose(Figure18).

Important:Applythread-lockingcompoundas

neededinthefuture.

HitchingaMachinewithaPintleHitch

TowPole

1.Removethepinfromthepintlehitchandopenit

(Figure19).

Figure18

1.Couplerhandle

2.Coupler

3.Clamp

2.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.

3.Pushthecouplerboltupthroughthecouplerclamp

andthecouplertop,andconnectthecouplerhandleto

thebolt(Figure18).

4.Positionthecouplersothesocketisontopofthehitch

ballandtheclampisundertheball.

5.Turnthecouplerhandleclockwisetothreaditontothe

boltuntilitissecure(Figure18).

Note:Useawrenchtokeeptheboltfromspinning.

6.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

4.Bolt

5.Hitchball

Figure19

2.Positiontheringonthetowpoleontothehookofthe

pintlehitch(Figure19).

3.Closethetopofthepintlehitchandsecureitwiththe

pin(Figure19).

4.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

ConnectingtheSafetyChainstothe

TowVehicle

Connectthesafetychaintothemachineandthetowvehicle

asfollows:

1.Pullthesafetychainthroughtheslotsinthekeyholes

locatedinthefrontpostofthemachine,sothatthere

isjustenoughslackoneachsideforturningaround

cornerswhentowingthemachine(Figure20).

14

Page 15

Note:Stowtheexcesschaininsidethebottomofthe

1

2

3

G021 177

G021 178

1

2

3

frontpostbypushingitintothekeyholesandlatching

theappropriatelinksintothekeyholeslots.

2.Crossbothlengthsofchainunderthetowpole.

Note:Crossingthechainsdecreasesthechancesof

thefrontofthemachinedroppingtothegroundifthe

hitchdoesnotholdtheconnection.

Figure20

1.Connectinglinks3.Chaincrossedundertow

pole

2.Keyholesinfrontpost

ExtendingtheAxle

WARNING

Themachineisnotstablewhentowingitwiththe

axleinthenarrowposition.

Towthemachinewiththeaxleinthewideposition.

Important:Adjusttheaxletothenarrowpositiononly

tomovethemachinethroughanarrowaccesspoint,

suchasthegateofafenceorthedoorwayofabuilding.

PreparingtoChangetheAxleWidth

1.Movethemachinetoaleveljob-sitesurface.

2.Disconnectthemachinefromthetowvehicle.

3.Chockthetires.

4.Ensurethatthedrumisemptyandinthemixposition

(upright).

5.Ensurethatthedrumlatchisengagedandthatthe

drumdoesnotrotatetowardthedumpposition.

AdjustingtheAxleWidth

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

themachineandcauseseriousinjury.

3.Connecteachlengthofchaintothesafetychain

mountingpointonthetowvehiclewiththeconnecting

links(Figure21).

1.Alignajackwithanadequateliftheightandweight

capacityundertheaxle;refertoSpecications(page

11).

2.Liftthemachineuntilthetiresareofftheground.

3.Useajackstandateachsupportpointontherear

frameextension(Figure22).

Usejackstandswhensupportingthemachine.

Figure21

1.Connectinglink3.Chainlink

2.Safetychainmounting

pointontowvehicle

Figure22

1.Supportpoint(2)

15

Page 16

4.Removetheboltsandnutsthatsecuretheinneraxleto

1 2

3

4

3

5

6

5

G020020

theouteraxle(Figure23).

Figure23

1.Wideposition(towing)4.Nut(narrowposition)

2.Narrowposition

3.Nut(wideposition)6.Bolt(narrowposition)

5.Bolt(wideposition)

WARNING

Towingthemachinewithmaterialinthedrum

increasestheriskofahitchmalfunctionandtire

failure.Inaddition,materialcouldbounceoutof

thedrumandhitothervehiclesand/orpeople.

Materialinthedrumincreasestheweight,which

affectsmomentumandbrakingdistance.

Donottowthemachinewithmaterialinthedrum.

•ReviewandunderstandSafeOperatingPractices(page3).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthemachine.

PreparingtoUsetheMachine

•Reviewallofthesafetydecalsonthemachine.

5.Aligntheinneraxletothedesiredpositionasfollows:

•Slideeachsideoftheaxleinwardtothenarrow

position(Figure23).

•Slideeachsideoftheaxleoutwardtothewide

(tow)position(Figure23).

6.Aligntheholesoftheinneraxlewiththeholesofthe

outeraxle.

7.Inserttheboltsthroughtheaxleholes(Figure23).

8.Threadthenutsontothebolts,andtorquethenuts

to87N-m(64ft-lb).

TowingtheMachine

WARNING

Towingthemachineathighspeedincreasesthe

riskofahitchmalfunctionandtirefailure.Higher

speedsalsoincreasethemomentumofthemachine

andbrakingdistance.Ifthemachinebecomes

detachedfromthetowvehicleathighspeed,it

couldcausedamagetoproperty,orinjuryordeath

tobystanders.

Donotexceed88km/h(55mph)whentowingthe

machine.Forpoorroadconditionsorinclement

weather,reducespeedaccordingly.

•Useahard-hat,hearingprotection,ashirtwithlong

sleevesthataretightatthewrists,tight-ttinggloves

withoutdrawstringsorloosecuffs,eyeprotection,and

adustmaskorrespirator.Ameshvisoralonedoes

notprovidesufcienteyeprotection;supplementwith

protectiveglasses.

•Ensurethatyouarefamiliarwiththesafetyregulations

andshutdownproceduresdescribedintheOperator’s

Manual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Ensurethatthepaddlesareinplaceandingood

condition.

•Checkallthegreasettingstoensurethatthemachine

isproperlylubricated.

•Whenpreparingtomixmaterial:

1.Movethemachinetoaleveljob-sitesurface.

2.Removethemachinefromthetowvehicle.

3.Chockthefrontandbackofthetirestoprevent

themachinefrommoving.

4.Ensurethatthedrumisinthemixposition

(upright).

5.Ensurethatthedrumlatchisengagedandthatthe

drumdoesnotrotatetowardthedumpposition.

16

Page 17

OpeningandClosingtheCowl

A

B

D

1

2

3

4

1

g020906

PoweringtheMachine

OpeningtheCowl

1.Atthesideofthemachinewherethefrontcowland

rearcowlmeet,graspthelatchandpullitofffromthe

latchanchorontherearcowl(Figure24).

SettingtheOperatingVoltage

Themachinecanoperatewitha115Vor230Vsupply

voltage.Thevoltageblockdeterminestheoperatingvoltage

ofthemachine().Usethefollowingstepstochangethe

operatingvoltage:

1.Parkthemachineonlevelground.

2.Stopthemotorandunplugthemachine.

3.Removethe2screwssecuringthevoltageblocktothe

motor.

4.Removethevoltageblockfromthemotor,rotatethe

voltageblock180degreesandplugitbackintothe

motor.

5.Securethevoltageplugtothemotorwiththe2screws

thatyoupreviouslyremoved.

Note:Usetheinstructionsonthevoltageblocktodetermine

thevoltageblocksetting.

ConnectingtoaPowerSource

DANGER

Figure24

1.Latch3.Receiver

2.Latchanchor

2.Repeatstep1ontheoppositesideofthemachine.

3.Atthebackofthemachinewheretherearcowlmeets

theframeofthemachine,graspthelatchandpullitoff

fromthelatchanchoronthecowl(Figure24).

4.Rotatetherearcowlupandforwarduntilitisfully

positionedontopofthefrontcowl(Figure24).

4.V -tting

ClosingtheCowl

1.Rotatetherearcowlrearwardanddownuntilthe

receiveratthebottomcenterofthecowlisalignedwith

theV -ttingandushontheframeofthemachine

(Figure24).

2.Atthebackofthemachine,graspthelatchandpullit

ontothelatchanchorontherearcowl.

3.Atthesideofthemachine,graspthelatchandpullit

ontothelatchanchorontherearcowl.

4.Repeatstep3attheoppositesideofthemachine

(Figure24).

Contactwithwaterwhileoperatingtheproduct

couldcauseelectricshock,causinginjuryordeath.

•Donothandletheplugorthemachinewithwet

handsorwhilestandinginwater.

•Useonlyanextensioncordrecommendedfor

outdoorcold-weatheruse.

Important:Checktheextensioncordfrequentlyduring

useforholesorcracksintheinsulation.Donotusea

damagedcord.Donotrunthecordthroughstanding

waterorwetgrass.

Important:Useonlyextensioncordswithterminals

andsocketsforthelive,neutral,andgroundwires.

Important:Connectthemachinetoonlyareceptacle

withlive,neutral,andgroundconnections.

Important:Theconnectingwiresorextensioncord

shouldbeasshortaspossibleandin1piece.

Toreducetheriskofelectricshock,thismachinehasa

polarizedplug(uniquebladeshapesandwidths).Useonly

apolarizedplugandsocketthatiscompliantwithNEMA

specicationsandanextensioncordthatisUL-listed(CSA

certiedinCanada)andrecommendedforoutdooruse.A

polarizedplugwilltinapolarizedcordonly1way .Ifthe

plugdoesnottfullyintothecord,turnthecord.Ifit

stilldoesnott,purchaseanappropriateextensioncord.

Ifyouhaveapolarizedextensioncordandtheextension

cordplugdoesnottfullyintothewallreceptacle,turnthe

17

Page 18

plug.Ifitstilldoesnott,contactaqualiedelectricianto

3

installtheproperoutlet.Donotchangethemachineplugor

extension-cordpluginanyway.

Note:Themachineusesatwist-lockingplug.

PoweringtheMachinewithaPortable

Generator

Whenusingaportablegeneratorasanelectricalsource,

ensurethefollowingpoweroutputspecications:

ExtensionCords

Length

15.2m(50ft)10AWG

22.8m(75ft)10AWG

30.4m(100ft)8AWG

Note:Donotuseanextensioncordover30.4m(100ft)

long.

WireGauge

ModelVoltageAmperesKilowatt

68012

68018

68019

115V/

230V

115V/

230V

115V/

230V

19A/

9.5A

19A/

9.5A

24A/

12A

hour

2.2to2.3

Kw

2.2to2.3

Kw

2.2to2.3

Kw

Frequency/

phase

60Hz/

single

60Hz/

single

60Hz/

single

ResettingtheMotor

Theelectricalmotorforthemachineisequippedwitha

deviceforthermal-overloadprotection.Intheeventthatthe

motorshutsdownautomatically,resetthethermal-overload

protectorasfollows:

1.MovetheON/OFFswitchtotheOFFposition;refer

toFigure12.

2.Disconnecttheelectricalplugforthemachinefromthe

powersource(Figure25).

Figure25

1.Thermal-overload

protectorresetbutton

2.ON/OFFswitch

3.Electricalplug

3.Allowtheelectricmotorofthemachinetocooluntilit

iswarmtothetouchorcooler.

Important:Ensurethatthepaddlesspinfreely.

Checkforstone,masonry,orconcretematerial

betweenthepaddlesandthedrum.

18

Page 19

4.Onthesideofthejunctionboxforthemotor,press

G019873

1

2

theresetbuttonforthethermal-overloadprotector

(Figure25).

5.Connecttheelectricalplugforthemachinetothe

powersource.

6.RotatetheON/OFFswitchtotheONpositionand

ensurethatthemotorstartsnormally.

7.RotatetheON/OFFswitchtotheOFFposition.

StartingandStoppingthe Motor

StartingtheMotor

1.Plugthepowercordintoaproperelectricaloutlet.

2.SwitchtheON/OFFswitchtotheONposition.

3.MovetheclutchlevertotheONposition;referto

ControllingthePaddles(page19)

UsingtheClutchLever

Movetheclutchleverclockwisetoengagetheclutch,and

counterclockwisetodisengagetheclutch(Figure26).

StoppingtheMotor

WARNING

Inanemergencysituation,stopthemotor

immediately.

1.MovetheclutchlevertotheOFFposition;referto

ControllingthePaddles(page19).

2.SwitchtheON/OFFswitchtotheOFFposition;refer

toMotorON/OFFSwitch(page11).

3.Unplugthepowercord.

ControllingthePaddles

DANGER

Thismachineiscapableofamputatinghands.

•Stayintheoperator’spositionwhilethemachine

isrunning.

•Keepallbystandersasafedistancefromthe

machine.

•Stopthemachineimmediatelyifanypeopleor

animalsentertheworkarea.

•Neverplaceanypartofyourbodyintoaposition

thatcausesanunsafeoperatingcondition.

Important:Ensurethatthepaddlesdonotturnwhen

theclutchleverisintheOFFposition.

Usetheclutchlevertocontrolthepowertransmissiontothe

paddlesofthemachine.

Figure26

1.OFFposition2.ONposition

MixingtheMaterial

DANGER

Eyeandskincontactwithconcretematerialsand

breathingthedustinvolvedishazardoustoyour

health.

•Ensurethatthereisadequateairventilation.

•Wearadustmasktopreventinhalationofdust

whileusingthemachine;refertoSafeOperating

Practices(page3).

•Avoiddirectcontactofcementandconcrete

materialswithskinandeyes.

DANGER

Contactwiththemixingpaddlescouldcause

damageorinjury.

Neverputyourhandsinsidethedrumatanytime.

Important:Donotaddmorematerialthanthebatch

capacityofthemachine;refertoSpecications(page11).

Note:Followthemanufacturer’sinstructionsthatareprinted

onthepackagingoftheproductyouareusing.

19

Page 20

MixingaBatchofMaterialinthe

A

B

D

G021 179

Machine

1.Ensurethatthereisnoold,loosematerialinthedrum

thatcancontaminatethebatchofmaterial;referto

CleaningtheDrum(page21)andDumpingtheDrum

(page20),thenreturnthedrumtotheuprightposition.

Note:Ensurethatthedrumisinthemixposition

(upright)andthedrumlatchisengaged.

2.MovetheclutchlevertotheOFFposition;referto

ControllingthePaddles(page19).

3.Startthemotor;refertoStartingtheMotor(page19).

4.MovetheclutchlevertotheONposition;referto

ControllingthePaddles(page19).

5.Addtheingredientsforthebatchasfollows:

A.Pourwaterintothedrumthroughthegratingof

thedrumguard.

B.Addtheplaster,cement,orotherbindingmaterial.

Note:Youcanopenbagsofcement,plaster,and

bindingmaterialsbyloweringthebagontothe

bagsplitter(Figure27).

UsingtheDrum

DANGER

Contactwiththemixingpaddlescouldcause

damageorinjury.

Neverputyourhandsinsidethedrumatanytime.

DumpingtheDrum

Note:Whendumpingabatchofmaterial,leavethemotor

runningandtheclutchintheONpositionsotherotating

paddleshelpdischargethematerial.

1.Alignawheelbarroworsimilarcontainerofadequate

capacityinthepathofthedrumopening.

2.Graspthedumphandlewithyourlefthand(Figure28).

Figure27

C.Ifyouareusingsandand/orotherreinforcing

materials,addthemintothedrum.

6.Allowthepaddlestomixthematerialuntilthe

ingredientshaveauniformappearance.

Note:Ifneeded,addwaterorplaster,cement,or

otherbindingmaterialuntiltheconsistencyofthe

batchiscorrect.

7.Releasethedrumlatchanddumpthedrum;referto

DumpingtheDrum(page20).

Figure28

1.Dumphandle(mix

position)

2.Drumlatch(release

position)

Note:Whendumpingabatchofmaterial,aligna

wheelbarroworasimilarcontainerofadequatecapacity

beneaththechute.

3.Liftthehandleofthedrumlatch(Figure28).

4.Withbothhandsonthedumphandle,rotateit

counterclockwisetodischargethecontentsofthe

drum(Figure28).

Note:Allowthemachinetocompletelydischargethe

contentsofthedrum.

20

3.Drumlatch(locked

position)

4.Dumphandle(dump

position)

Page 21

5.Rotatethedumphandleclockwiseuntilthedrum

latchlocksthedrumintheuprightposition(Figure28).

6.Afterdischargingabatchofmaterial,cleanthedrum;

refertoCleaningtheDrum(page21).

Note:Thisstepwillcleanthepaddlesanddrum

betweenbatchesandpreventdriedmaterialfrom

forming,andcontaminatingthenextbatchofmaterial.

CleaningtheDrum

Important:Donotstrikeonthedrumwithashovel,

hammer,oranyotherdevicetoloosenanyaccumulated

driedmaterials.

1.Stoptherotationofthepaddlesbymovingtheclutch

levertotheOFFposition;refertoControllingthe

Paddles(page19).

2.MovethemotorON/OFFswitchtotheOFFposition;

refertoMotorON/OFFSwitch(page11).

3.Ensurethatthedrumisinthemixposition(upright);

refertoDumpingtheDrum(page20),step5.

4.Spraythemachinewithwatertoremoveany

accumulatedmaterial.

5.Startthemotor;refertoStartingtheMotor(page19).

6.Starttherotationofthepaddlesbymovingtheclutch

levertotheONposition;refertoControllingthe

Paddles(page19).

7.Dumpthedrum;refertoDumpingtheDrum(page

20).

21

Page 22

Maintenance

G021585

Important:Beforeperforminganymaintenanceprocedures,rststopthemotor,wait5minutestoallowallmoving

partstocometoacompletestopandcool,andunplugthepowercord.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Aftertherst10hours

Aftertherst25hours

Beforeeachuseordaily

Aftereachuse

Every40hours

Every50hours

Every6,000hours

Every2years

Premaintenance

Interval

Monthly

MaintenanceProcedure

•Checkthetensionofthedrivechain,andadjustitasneeded.

•Inspectthebeltsandadjustasnecessary .

•Inspectthetiresandwheels.

•Torquethelugnutsto108to122N-m(80to90ft-lb)aftertowing.

•Cleanthedrumbetweenmixingbatchesofmaterial.

•Lubricatethetrunnions.

•Cleanthemachine.

•Lubricatethedrivechainwithanon-stickychainlubricant.

•Inspectthebeltsandadjustasnecessary .

•Checktheclutchoperation.

•Checkthetensionofthedrivechain,andadjustitasneeded.

•Lubricatethemotorbearings.

•Lubricatethepillow-blockbearings.

•Replacethebelts.

RemovingtheDividerPlate

Procedures

PreparingtheMachinefor Maintenance

1.Parkthemachineonalevelsurface.

2.Removethemachinefromthetowvehicle.

3.Chockthetires.

4.Opentherearcowl;refertoOpeningtheCowl(page

17).

5.Turnoffandunplugthemotor;refertoMotor

ON/OFFSwitch(page11).

6.Ensurethatthemotoriscool.

RemovingandInstallingthe DividerPlate

Youneedtoremovethedividerplatetoprovideaccessbefore

performingsomemaintenanceprocedures.

1.Unlatchandopenthecowl;refertoOpeningtheCowl

(page17).

2.Useawrenchtoremovethe4boltsthatsecurethe

dividerplatetothefrontcowl.

Note:Keeptheboltsforinstallingthedividerplate.

Figure29

3.Toremovethedividerplate,liftitupwardandrotateit

counterclockwisesothatitclearsvariouscomponents.

22

Page 23

InstallingtheDividerPlate

G021586

1

3

g021 101

1

2

3

1.Guidethedividerplateintopositionagainstthefront

cowl.

Note:Startwiththedividerplaterotatedslightly

counterclockwise,andthenrotateitclockwisewhile

loweringitintoposition.

Ensurethatthedividerplateisnotbackward.

Figure30

Lubrication

LubricatingtheBearingsand Seals

ServiceInterval:Aftereachuse—Lubricatethetrunnions.

Monthly—Lubricatethepillow-blockbearings.

Note:Thepillow-blockbearingsareinsidethe

cowl—removethedividerplatetoaccessthem;referto

RemovingtheDividerPlate(page22).

Greasetype:#2general-purposelithium-basedgrease.

1.Cleanaroundeachgreasettingwitharagandliftthe

plasticcapoffthegreasetting(Figure31).

2.Aligntheboltholesinthedividerplateandthefront

cowl.

3.Installeachofthe4bolts,andhand-tightenthemto

preventcross-threading.

4.Tightentheboltswithawrenchuntiltheyaresecure.

1.Pillow-blockbearings3.Fronttrunnion

2.Reartrunnion

23

Figure31

Page 24

2.Pumpgreaseintoeachttingasfollows:

G0 2158 8

G021584

1

•Forthepillow-blockbearings,pump1shotof

greaseintoeachtting(Figure31).

•Forthetrunnions,pumpseveralshotsofgrease

intoeachttinguntilitstartstooozeoutofthe

bearinghousing(Figure31).

Important:Pumpgreaseinslowlyandcarefully

topreventdamagetothebearingseals.

3.Wipeupanyexcessgrease.

LubricatingtheMotorBearings

ServiceInterval:Every6,000hours

Greasetype:electric-motorbearinggrease

1.Cleanaroundeachgreasettingwitharag.

2.Pump1or2shotsofgreaseintoeachtting(Figure

32).

Important:Donotover-lubricatethemotor.

LubricatingtheDriveChain

ServiceInterval:Every40hours—Lubricatethedrivechain

withanon-stickychainlubricant.

Applyachainlubricantthatisnon-stickytohelppreventdirt

andabrasiveparticlesfromstickingtothechain.

Figure33

1.Drivechain

Figure32

3.Wipeupanyexcessgrease.

24

Page 25

BeltMaintenance

G019976

1

2

3

1

1

g020662

A.MovetheclutchlevertotheOFFposition;refer

toControllingthePaddles(page19).

ServicingtheBelts

InspectingtheBelts

ServiceInterval:Aftertherst25hours—Inspectthebelts

andadjustasnecessary.

Every40hours—Inspectthebeltsandadjustas

necessary.

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page22).

2.MovetheclutchlevertotheOFFposition;referto

ControllingthePaddles(page19).

3.Examinethebeltsforwearordamage.Ifthebeltsare

wornordamaged,replacethem;refertoReplacingthe

Belts(page26).

4.Examinethepulleysforwear,damage,and

misalignment;refertoAligningthePulleys(page28).

5.Installthedividerplate;refertoInstallingtheDivider

Plate(page23).

AdjustingtheBeltTension

Clutchairgap:2.5to6.5mm(3/32to1/4inch)

1.MovetheclutchlevertotheONposition;referto

ControllingthePaddles(page19).

2.Measuretheairgapbetweenthemotordeckandthe

rollerontheclutch(Figure34).

B.Loosenthenutsandboltsthatsecurethemotor

tothemotordeck(Figure35).

Figure35

1.Nutandbolt

C.Movethemotorpositionasfollows:

•Increasetheairgap—movethemotoraway

fromtheidlerpulley(Figure35).

•Decreasetheairgap—movethemotor

towardtheidlerpulley(Figure35).

D.Alignastraightedgeacrossthemotorpulleyand

theidlerpulley(Figure36).

Figure34

1.Motordeck

2.Clutchroller

3.Ifthemeasuredairgapisnotwithinthespecied

range,adjustthegapasfollows:

3.Clutchairgap:2.5to6.5

mm(3/32to1/4inch)

25

Page 26

3

1

2

4

5

6

7

8

g020663

Figure36

2

1

G021601

2

3

4

1

G021608

Figure37

1.Nut2.Beltguide

4.Sliptheforwardbeltforwardandofftheidlerpulley

(Figure38).

1.Motorpulley

2.Idlerpulley6.Jamnut

3.Belt

4.Beltguide

5.Idlershaft

7.Setscrew

8.Straightedge

E.Ifneeded,pivotthemotoronthemotordeck

untilthemotorpulleyandtheidlerpulleyare

alignedtothestraightedge(Figure36).

F.Tightenthenutsandboltsthatsecurethemotor

tothemotordecktoatorqueof18N-m(13ft-lb).

G.Checktheairgapbetweenthemotordeckand

therollerontheclutch.Iftheairgapisnotwithin

thespeciedrange,repeatstep3untiltheairgap

measurementiswithinthespeciedrange.

H.Installthedividerplate;refertoInstallingthe

DividerPlate(page23).

Important:Ensurethatthepaddlesdonotrotatewhen

theclutchleverisintheOFFposition.

ReplacingtheBelts

Figure38

1.Motorpulley3.Idlerpulley

2.Forwardbelt4.Rearbelt

5.Sliptherearbeltrearwardandofftheidlerpulley

(Figure38).

6.Slipthebeltsoffthemotorpulley.

7.Removethebeltsfromthemachine.

ServiceInterval:Every2years—Replacethebelts.

InstallingtheBelts

1.EnsurethattheclutchleverisintheOFFposition;

refertoControllingthePaddles(page19).

2.Aligntherearbelttothereargrooveinthemotor

pulley.

Note:Donotaligntherearbelttotheidlerpulley .

3.Aligntheforwardbelttotheforwardgrooveofthe

idlerpulley.

26

RemovingtheBelts

1.MovetheclutchlevertotheOFFposition;referto

ControllingthePaddles(page19).

2.Removethedividerplate;refertoRemovingthe

DividerPlate(page22).

3.Removethenutthatsecuresthebeltguidetothe

motor,andremovethebeltguide(Figure37).

Page 27

4.Sliptherearbeltovertheidlerpulleyandalignthebelt

G020666

3 4

5

1

2

totherearpulleygroove.

5.Sliptheforwardbeltoverthemotorpulleyandalign

thebelttotheforwardpulleygroove.

6.Checkthebelttension;refertostep1,step2,andstep

3inAdjustingtheBeltTension(page25).

7.Looselysecurethebeltguidetothemotor(Figure37)

withtheboltthatwasremovedinstep3ofRemoving

theBelts(page26).

8.Adjustthebeltguide;refertoAdjustingtheBeltGuide

(page27).

9.Installthedividerplate;refertoInstallingtheDivider

Plate(page23).

B.Rotatethebeltguideupordownuntilthereis

anairgapof2.5to4.0mm(3/32to5/32inch)

betweentheguideandeachbelt(Figure39).

Important:Thebeltguideshouldnot

contactthebeltswiththeclutchleverinthe

ONposition.

Note:Iftheairgapbetweenthebeltguideand

bothbeltscannotbeattained,then1ofthebelts

istoolong.

C.Tightenthenutthatsecuresthebeltguidetothe

motor(Figure39).

D.Checktheclutchoperation;refertoCheckingthe

ClutchOperation(page27).

AdjustingtheBeltGuide

Note:Toaccessthebeltguide,removethedividerplate;

refertoRemovingtheDividerPlate(page22).

Guideairgap:2.5to4.0mm(3/32to5/32inch)

1.EnsurethattheclutchleverisintheONposition;refer

toControllingthePaddles(page19).

2.Ensurethatthebelttensioniscorrect;referto

AdjustingtheBeltTension(page25).

3.Checkthattheairgapbetweenthebeltguideandthe

beltsis2.5to4.0mm(3/32to5/32inch);referto

Figure39.

5.Installthedividerplate;refertoInstallingtheDivider

Plate(page23).

CheckingtheClutchOperation

ServiceInterval:Every40hours—Checktheclutch

operation.

Important:Thepaddlesmustnotrotateinanempty

drumwhentheclutchleverisintheOFFposition.

1.MovetheclutchlevertotheOFFposition;referto

ControllingthePaddles(page19).

2.Startthemotor;refertoStartingtheMotor(page19).

3.IfthepaddlesrotatewiththeclutchlevertotheOFF

positiondothefollowing:

A.Stopthemotor;refertoStoppingtheMotor

(page19).

B.Checktheairgapbetweenthebeltguideandthe

belts.

Note:Iftheairgapislargerthan4.0mm(5/32

inch),decreasethegapbetweenthebeltguide

andthebelts;refertoAdjustingtheBeltGuide

(page27).

1.Motorpulleys4.Beltguide

2.Belts5.Nut

3.Guideairgap:2.5to4.0

mm(3/32to5/32inch)

4.Iftheairgapisnotwithinthespeciedrange,dothe

following:

A.Loosenthenutthatsecuresthebeltguidetothe

motor(Figure39).

Important:Ensurethatthebeltguideis

towardthemotorpulley.

Figure39

4.Repeatsteps1,2,and3untilthefollowingconditions

aremet:

•TheclutchleverisintheOFFposition.

•Whilethemotorisrunning,thepaddlesdonot

rotateinanemptydrum.

27

Page 28

AligningthePulleys

1

2

3

4

5

6

g020667

G021606

1

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page22).

2.Placeastraightedgeacrossthefaceofthemotorpulley

andtheidlerpulley(Figure40).

DriveChainMaintenance

CheckingandAdjustingthe DriveChain

ServiceInterval:Aftertherst10hours

Every50hours

Thedrivechainshouldhave5to10mm(7/32to13/32inch)

ofexwhenapplying6.8kg(15lb)ofpressureatmid-span.

CheckingtheDrive-ChainTension

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page22).

2.Placeastraightedgealongthechainfrom1sprocket

totheother(Figure41).

Figure40

1.Motorpulley

2.Idlerpulley5.Locknut

3.Straightedge6.Setscrew

Note:Bothpulleysmustbealignedushwiththe

straightedge.

3.Ifthepulleysarenotaligneddothefollowing:

A.MovetheclutchlevertotheOFFposition.

B.Loosenthelocknutsandsetscrewsthatsecurethe

idlerpulleytotheidlershaft(Figure40).

C.Usingasoft-facemallet,taptheidlerpulley

forwardorbackwardalongtheidlershaftuntil

themotorpulleyandtheidlerpulleyarealigned

4.Installthedividerplate;refertoInstallingtheDivider

tothestraightedge(Figure40).

D.Tightenthesetscrewsandlocknutsthatsecurethe

idlerpulleytotheidlershaft(Figure40).

Plate(page23).

4.Idlershaft

Figure41

1.Flexof5to10mm(7/32to13/32inch)

3.Withyournger,pushonthechainwith6.8kg(15lb)

ofpressure,midwaybetweenthesprockets(Figure41).

4.Measurethedistancefromthechaintothestraightedge;

thedistanceshouldbe5to10mm(7/32to13/32

inch).Ifthechaintensionneedsadjustment,referto

AdjustingtheDrive-ChainTension(page28).

5.Installthedividerplate;refertoInstallingtheDivider

Plate(page23).

AdjustingtheDrive-ChainTension

Note:Adjustingthetensionofthedrivechainaffectsthe

tensionofthebelts;adjustthebelttensionafteradjusting

thedrive-chaintension.

1.Removethedividerplate;refertoRemovingthe

DividerPlate(page22).

2.Loosenthenutsandboltsthatsecurethepillow-block

bearingsfortheidlerpulley(Figure42).

28

Page 29

G021602

1

2

3

4

Figure42

1

2

G021605

1.Drivechain

2.Pillow-blockbearings4.Idlerpulley

3.Slidethepillow-blockbearings,alongwiththeidler

pulleyandsmallsprocket,totherighttoincrease

thechaintension,ortothelefttodecreasethechain

tension.

Note:Toslidethepillow-blockbearingstotheleft,

youmustloosenthejamnutandtensionerbolt(Figure

43).Toslidethepillow-blockbearingstotheright,

youmustloosenthemotormountingnutsandbolts

(Figure35).

3.Bolts(4)

PaddleMaintenance

Note:Overtime,youmayneedtoadjustthemixerpaddles

toaccountforwear.

AdjustingthePaddles

AligningtheCircumferentialDrum

Wipers

1.Rotateapaddlefromtheleftrowofpaddlesaround

thedrumandlocateattheinteriorofthedrumthe

smallestdistancebetweenthedrumandthewiperof

thepaddle(Figure44).

2.Marktheinsideoftheinsideofthedrumatthe

locationthatyoudeterminedinstep1.

Figure43

1.T ensionerbolt2.Jamnut

3.Alignthewiperofapaddletothemark.

4.Whenthechainhas5to10mm(7/32to13/32inch)

ofex,tightenthetensionerbolt,thejamnut,andthe

nutsandboltsthatsecurethepillow-blockbearings.

5.Adjustthebelttension;refertoAdjustingtheBelt

Guide(page27).

6.Installthedividerplate;refertoInstallingtheDivider

Plate(page23).

4.Loosenthecarriageboltsandangedlocknutsthat

securethepaddlebladeandwipertothepaddle(Figure

45).

Figure44

29

Page 30

Figure45

1.Wiper4.Paddleblade

2.Distancebetween

paddle-bladeedgeand

wiperedge—3to6mm

(1/8to1/4inch)

3.Wiperbar

5.Carriageboltandanged

locknut

AligningtheEndPaddleWipers

1.Rotatethewiperandxedpaddlearoundtheendplate

ofthedrumandlocatesmallestdistancebetweenthe

drumandthewiperofthepaddle.

2.Marktheinsideoftheendplateatthelocationthatyou

determinedinstep1.

5.Adjustthepositionofthewipersothatthewiper

lightlycontactsthedrumacrossthelengthofthewiper

(Figure46).

Figure46

1.Wiperlightlycontactingthedrumatthesmallestdistance

betweenthedrumandthewiperofthepaddle

6.Adjustthepositionofthepaddlebladesothatthe

outeredgeis3to6mm(1/8to1/4inch)fromthe

outeredgeofthewiper.

Figure47

1.Carriageboltandanged

locknut

2.Closestpointofcontact

3.Drumendplate

3.Alignthewiperofapaddletothemark.

4.Loosenthecarriageboltsandangedlocknutsthat

securethepaddlebladeandwipertothexedpaddle.

(Figure47)

5.Adjustthepositionofthewipersothatthewiperlightly

contactstheendplateacrossthelengthofthewiper.

6.Adjustthepositionofthepaddlebladesothatthe

outeredgeofthebaris3to6mm(1/8to1/4inch)

fromtheouteredgeofthewiper.

7.Torquethecarriageboltsandnutsto19to25N-m

(14to18ft-lb).

8.Repeattheprocedureforthewiperattheendplateon

theotherendofthedrum.

7.Torquethecarriageboltsandnutsto19to25N-m

(14to18ft-lb).

8.Repeatsteps4through7fortheotherpaddleforthat

paddlerow .

9.Repeattheprocedurefortheotherpaddlerows.

30

Page 31

AligningtheAdjustableEndPaddles

1.Aligntheadjustableendpaddletothemarkthatyou

madeinstep2ofAligningtheEndPaddleWipers

(page30).

Cleaning

CleaningtheMachine

2.Loosenthecarriageboltsandangedlocknutsthat

securetheadjustableendpaddletothexedpaddle.

(Figure48)

Figure48

1.Carriageboltandanged

locknut

2.Closestpointofcontact

3.Adjustthepositionoftheadjustableendpaddlesothat

itisasclosetotheendplateaspossible,acrossthe

lengthofthepaddle,withouttouchingendplatewhen

thepaddlesarerotated.

3.Drumendplate

Regularcleaningandwashingwillincreasethelifespanof

themachine.Cleanthemachineaftereachuse,beforethe

dirthardens.

Ensurethatthemotorisunplugged.

Usecarewhenusingahigh-pressuresprayerbecauseitcan

damagewarningdecals,instructionsigns,andthemotor.

Important:Usepressuresprayerstocleanonlythe

drumofthemachine.Cleanofftherestofthemachine

byhandtokeepthemotorfromgettingwet.

Important:Lubricatethetrunnionsaftercleaning;refer

toLubricatingtheBearingsandSeals(page23).

4.Torquethecarriageboltsandnutsto37to45N-m

(27to33ft-lb).

5.Repeattheprocedurefortheadjustableendpaddleat

theendplateontheotherendofthedrum.

31

Page 32

Storage

StoringtheMachine

Forstorageover30days,preparethemachineasfollows:

1.MovetheON/OFFswitchtotheOFFposition,and

unplugthepowercord.

2.Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallythemotor.

Important:Youcanwashthemachinewithmild

detergentandwater.

3.Greasethemachine;refertoLubricatingtheBearings

andSeals(page23)andLubricatingtheDriveChain

(page24).

4.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

5.Paintallscratchedorbaremetalsurfaceswithpaint

fromyourAuthorizedToroDealer.

6.Storethemachineinaclean,drygarageorstoragearea.

7.Coverthemachinetoprotectitandkeepitclean.

32

Page 33

Troubleshooting

Problem

Theelectricmotordoesnotstart.

Themachineishummingexcessively.1.Thecordispluggedintoanincorrect

Themotorisoverheating.

1.Theconnectorforthemachineisnot

pluggedintoapowersource.

2.Thethermal-overloadprotectionforthe

motorsisactivated.

3.Thecurrentprotectorfortheelectrical

sourceisopen.

4.Themachineispluggedintoan

electricalsourcelessthan1 15voltsor

greaterthan230volts.

5.Thepaddlesarejammedinsidethe

drum.

outlet.

1.Themotorisoverloaded.

2.Thereisnotadequateventilation.

3.Themotorisrunningovervoltageor

undervoltage.

PossibleCauseCorrectiveAction

1.Plugtheconnectorintoasocketor

anextensioncordfromanelectrical

source.

2.Resetthethermal-overloadprotector.

3.Resetthecircuitprotector.

4.Connectthemachinetoanelectrical

sourcewiththepropervoltage.

5.Disconnectthemachinefromthe

electricalsource,movetheclutchto

theoffposition,andclearthedebris

fromtheinsideofthedrum.

1.Checktheinputlineconnections.

1.Comparetheactualamps(measured)

withtheratingonthenameplate.

Locateandremovethesourceof

excessivefrictioninthemotororload.

Reducetheload.

2.Checktheexternalcoolingnsfor

excessivedirtbuildupandcleanthe

motor.

3.Checktheinputvoltagetothemotor.

Thebeltslipsorcomesoffthepulleys.

isintheOFFposition.

leverisintheONposition.

Thepaddlesrotateslowlywhentheclutch

leverisintheONposition.

Themixermakesachirpingnoisewhen

mixingmaterial.

1.Thebelttensionisinsufcient.

2.Thebeltisworn.2.Replacethebelt.

3.Thepulley(s)areworn.3.ContactyourAuthorizedService

4.Thepulley(s)aremisaligned.4.Alignthepulley(s).

1.Theclutchleverisnotadjusted

correctly.

2.Thebeltguideisnotadjustedcorrectly.2.Adjustthebeltguide.

1.Theclutchleverisnotadjusted

correctly.

2.Thepaddlesarestuckinthedrum

1.Theclutchleverisnotadjusted

correctly.

1.Thedrivegearismisalignedwiththe

bullgear .

1.Adjustthebelttension.

Dealer.

1.Adjustthebelttension. Thepaddlesrotatewhentheclutchlever

1.Adjustthebelttension. Thepaddlesdonotrotatewhentheclutch

2.Cleanthepaddlesanddrum.

1.Adjustthebelttension.

1.ContactyourAuthorizedService

Dealer.

33

Page 34

Schematics

G021587

ElectricMotorSchematic(Rev.A)

34

Page 35

Notes:

35

Page 36

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

Concrete,

Masonry,and

Compaction

Equipment

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlywarrantyourT oroConcrete,Masonry ,

andCompactionEquipmentProductslistedbelowtobefreefromdefectsin

materialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

ConcreteMixers

•SpindleBearingsLifetime*(originalowneronly)

MortarMixers1year

•DrumBearingsandSealsLifetime*(originalowneronly)

ForwardPlateCompactors

ReversiblePlates1year

RammerCompactors

MudBuggy1year

VibratingTrenchRoller2years

ConcreteSaws

MasonrySaws

PowerTrowels1year

Screeds

ConcreteVibrators

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

*

LifetimeWarranty-Ifthebearing(s)orseal(s)onyourmixerfail,itwillbereplacedunderwarranty ,

atnocostforpartsorlabor.

1year

2years

2years

1year

1year

1year

1year

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow .

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’sanalysis

orwiththeassistanceprovided,contactusat:

SWSCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:800-888-9926

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromT oroandhave

signedtheT oroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,modied,orunapproved

accessories

•Productfailureswhichresultfromfailuretoperformrequired

maintenanceand/oradjustments

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligentorrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

productoperationinclude,butarenotlimitedto,belts,wipers,spark

plugs,tires,lters,gaskets,wearplates,seals,O-rings,drivechains,

clutches.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,or

chemicals,etc.

•Normal“wearandtear”items.Normal“wearandtear”includes,butis

notlimitedto,wornpaintedsurfaces,scratcheddecals,etc.

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0288RevC

Loading...

Loading...