Page 1

Form No. 3314-405 Rev A

Twin Bagger Grass Catcher

Rear Engine Rider and Lawn Tractor Attachment

Model No. 59184

Installation Instructions

Setup

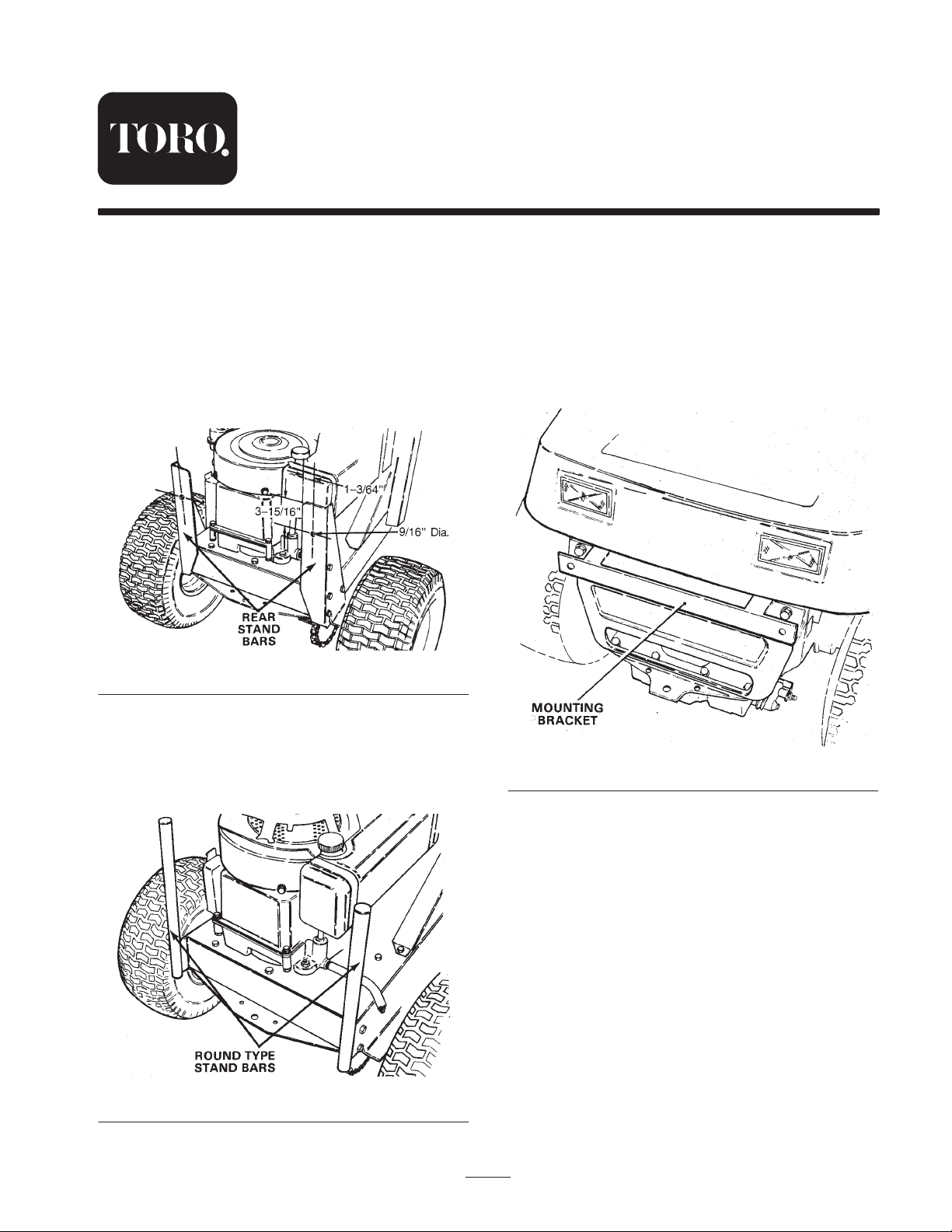

Updating the Stand Bars

(Rear Engine Riders Only)

Note: Step 1 pertains to riders with serial numbers

6000001 through 6999999, while step 2 is for riders with

serial number prior to 6000001.

1. Using dimensions shown in Figure 1, locate and drill a

9/16 in. diameter hole in each rear stand bar.

Figure 1

Installing the Mounting Bracket

(Lawn Tractors Only)

Note: Step 1 pertains to tractors with serial numbers

7000001 and Up while step 2 pertains to tractors with

serial number prior to 7000001.

1. Secure mounting bracket (supplied with tractor) to rear

frame with 2 capscrews (5/16 x 3/4 in.) and locknuts

(Fig. 3).

2. If rider is equipped with round type stand bars (Fig. 2),

they must be replaced with new ones, Toro Part No.

56-7440 (right-hand) and 56-7450 (left-hand). Stand

bars may be purchased from your local authorized

Toro dealer.

Figure 2

2001 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Figure 3

2. Mounting bracket, Toro Part No. 61-9730, must be

purchased from your local authorized Toro dealer.

After bracket is obtained, install it as instructed in

step 1.

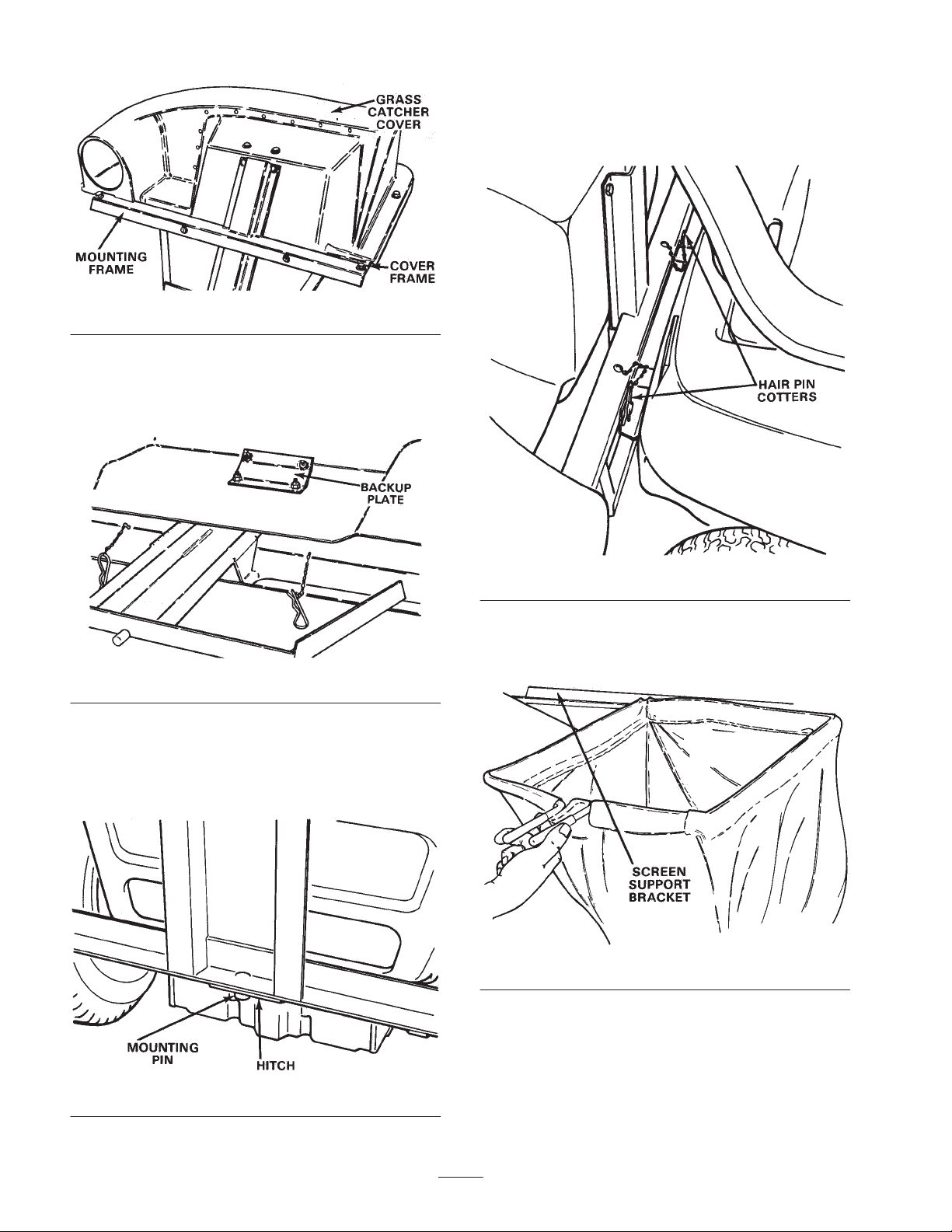

Assembling the Mounting Frame to the

Grass Catcher Cover

1. Loosely secure mounting frame to grass catcher cover

with backup plate, 4 capscrews (5/16 x 1 in.), flat

washers, and locknuts (Fig. 4 and 5). Position the

washers on the outside of the grass catcher cover with

the backup plate inside the cover.

All Rights Reserved

1

Printed in the USA

Page 2

Figure 4

2. Secure mounting frame to grass catcher cover frame

with 2 capscrews (3/8 x 1 in.), flat washers, and

locknuts (Fig. 5). Position the washers on the top side

of the assembly. Tighten all mounting fasteners.

2. Rotate grass catcher up so mounting pins line up with

mounting holes in tractor mounting bracket or rider

stand bars. Push pins through holes and retain with

hairpin cotters (Fig. 7).

Figure 5

Installing the Grass Catcher and Bags

1. Slide grass catcher mounting pin into mounting hole in

hitch (Fig. 6).

Figure 7

3. Slide grass bag under bag frame cover, positioning

front edge of bag rod into screen support bracket on

bag frame (Fig. 8).

Figure 8

4. Lift rear of bag up to bag cover. Squeeze bag handles,

allowing them to be positioned in bag frame brackets.

Release bag handles, locking them in brackets (Fig. 9).

Figure 6

2

Page 3

Figure 9

Figure 11

Note: Plastic lawn bags may be inserted inside cloth bags

to aid in disposal of grass clippings.

To ease in the installation of plastic bags, insert bag

handles into frame brackets from the rear as shown in

Figure 10, and insert plastic bags.

Figure 10

3. After chute assembly and duct are assembled, slide

duct onto grass catcher.

4. Slide chute assembly under deflector. Hook rear chute

bracket around pivot post on deck. Slide front of chute

into locking position with mating part of hinge lock.

Insert locking pin (Fig. 12).

Figure 12

Note: Support bracket on chute assembly must hook

behind pivot post on deck.

Assembling and Installing the Chute

Assembly and Duct

1. Secure retainer to duct with barbed clip and spacer

fastener (Fig. 11).

2. Slide duct onto chute assembly, aligning duct retainer

with chute knob. Hook retainer onto knob, securing

assemblies (Fig. 11).

Operation

Bagging Conditions

To ensure efficient operation of the grass catcher, the

operating characteristics must be understood. In addition

to cutting turf uniformly, the blade also generates

high-velocity air currents. These air currents help propel

grass clippings from under the mower housing, through

the duct, and into the grass bags. However, certain

conditions may cause the rear grass catching system to

malfunction.

One condition that may cause a “conveying” malfunction

from the mower housing to the grass bags is when the

mower housing is set too low. Since air is required to

3

Page 4

propel grass clippings, there must be a source for this air.

And if the source is obstructed, conveying will be

inefficient. Thus, the height-of-cut must not be set too

low, because grass surrounding the mower housing will

prevent air from getting under the housing and entering

the conveying system.

A second condition that may cause a malfunction is when

excessively long and heavy grass clippings cannot be

propelled into the grass bags. Even though the supply of

air may be acceptable for efficient conveying, some grass

clippings may fall from the main air stream to the bottom

of the duct. This starts a progressive buildup of grass

clippings in the duct, discharge chute, and against the

inside of the mower housing. The chute and duct may

even plug. Therefore, to ensure efficient grass collecting,

experiment with different heights-of-cut until satisfaction

is obtained.

Another condition affecting conveying is moisture. If the

turf is wet from watering, morning dew, or internal

moisture content, the system may malfunction. Therefore,

to ensure efficiency, cut the grass when it is dry. Since dry

grass has some moisture content, clippings may stick to

the duct, discharge chute, and on the inside of the mower

housing. This slight buildup is normal, but the duct,

discharge chute, and housing must be cleaned to prevent

undesirable buildup of clippings.

• Overlap swaths to produce an even cutting pattern and

to minimize the load on the engine. Make sure grass

clippings move continuously through the duct.

• Empty the grass bags and do not let clippings “back

fill” into the duct. To empty bags, shift into Neutral,

move blade control to Disengage position, rotate

ignition key to Off, and set parking brake. Slide grass

bags under grass bag cover, positioning front edge of

bag rod into screen support bracket on bag frame. Lift

rear of bag up to bag cover. Squeeze bag handles,

allowing them to be positioned in bag frame brackets.

Release bag handles, locking them in brackets.

• While operating, glance frequently at the duct. If grass

clippings are not moving through the duct, there may

be an obstruction in the duct or discharge chute. The

obstruction can usually be cleared by moving gear

shift to neutral, raising mower housing to highest

position, and slapping the side of the installed clear

duct, near the obstruction. If the obstruction does not

pass into the grass bags when duct is slapped, move

blade control into Disengage position, rotate ignition

key to Off, and set parking brake. Then remove duct

and clear any obstruction from the duct or discharge

chute with a stick or similar object. After obstruction

is removed, install duct, restart engine, and continue

grass collecting.

When cutting in dry, dusty conditions, lower throttle speed

and shift gear selector to higher gear to maintain ground

speed.

A final condition to consider is ground speed. As the

engine overloads (slows down), air velocity decreases.

Therefore, ground speed of the rider must be slow enough

to allow all grass clippings to move continuously from

under the housing, through the duct, and into the grass

bag.

Warning

Do not operate mower without the grass deflector

or entire grass catcher in place.

Bagging Tips

• To ensure maximum air currents in the system, move

throttle to Fast and gear shift to first gear, which is the

slowest ground speed.

• Do not collect grass when it is wet or too long.

However, wet grass can be cut with the grass deflector

installed. Several hours later, pick up the dry grass

clippings with complete grass catcher installed.

• After using the grass catcher, remove mulch from

inside of hopper cover, duct, discharge chute, and from

underside of mower housing. If grass clippings remain

on inside of these parts, a malfunction will likely

result. To retain translucency, remove grass and dirt

stains from inside of duct by washing it with soap and

water. Keep the blade sharp to ensure good grooming

and conveying results.

Warning

The bags are made of material that will catch the

majority of foreign objects, such as small stones

that may be thrown into them. However, under

normal usage, this material is subject to

deterioration and wear.

• Check the bags frequently for deterioration and

wear.

• If bags are worn, replace them with a genuine

Toro part.

• Cut the grass often, especially when the turf growth is

rapid. High heights-of-cut produce good grooming

results. If shorter turf is desired, cut the grass again.

4

Loading...

Loading...