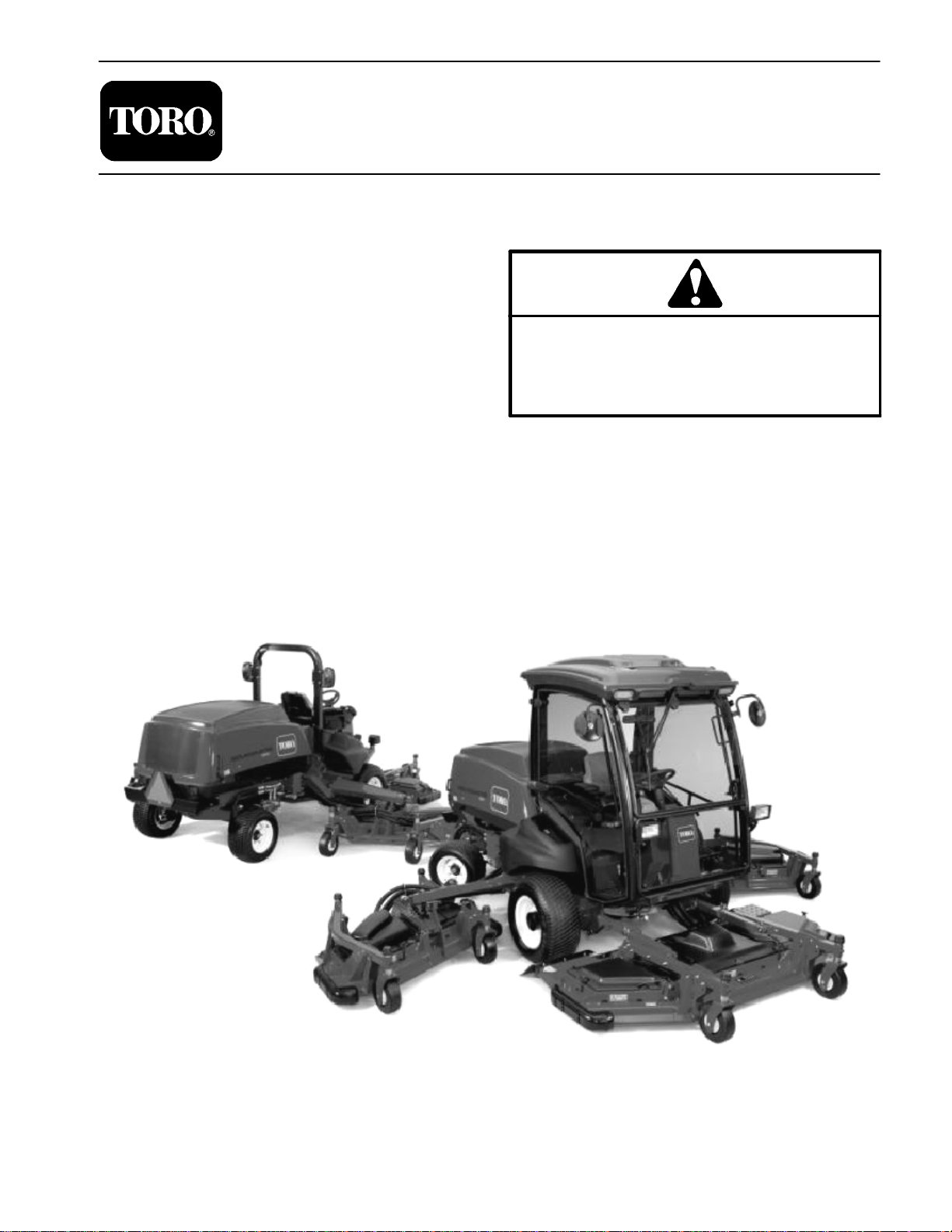

Page 1

Part No. 08159SL

Service Manual

Groundsmaster

Preface

The purposeof this publication is to provide theservice

technician with information for troubleshooting, testing,

and repair of major systems and components on the

Groundsmaster 5900 and 5910.

REFER TO THE OPERATOR’S MANUALS FOR OPERATING, MAINTENANCE AND ADJUSTMENT

INSTRUCTIONS. For reference, insert a copy of the

Operator’s Manual and Parts Catalog for yourmachine

into Chapter 2 of this service manual. Additional copies

of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com.

TheToroCompanyreserves the right to changeproduct

specifications or this publication without notice.

R

5900 & 5910

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: ANOTE willgive generalinformation aboutthe

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give importantinstructionswhichmust befollowedto prevent damage to systems or components on the

machine.

E The Toro Company -- 2009

Page 2

This page is intentionally blank.

Groundsmaster 5900/5910

Page 3

Table Of Contents

Chapter 1 -- Safety

General Safety Instructions 1 -- 2..................

Jacking Instructions 1 -- 5.........................

Safety and Instruction Decals 1 -- 6................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Diesel Engine

General Information 3 -- 2........................

Engine Specifications 3 -- 4.......................

Engine Fastener Torque Specifications 3 -- 5........

Adjustments 3 -- 7...............................

Service and Repairs 3 -- 8........................

Chapter 4 -- Hydraulic System

Specifications 4 -- 2..............................

General Information 4 -- 3........................

Hydraulic Schematic 4 -- 11.......................

Hydraulic Flow Diagrams 4 -- 12...................

Special Tools 4 -- 30.............................

Troubleshooting 4 -- 33...........................

Testing 4 - - 38...................................

Adjustments 4 -- 60..............................

Service and Repairs 4 -- 61.......................

SAUERDANFOSSDSERIESGEARPUMPSEALKIT

SERVICE INSTRUCTION BULLETIN

REXROTH VARIABLE PUMP A10VG REPAIR IN-

STRUCTIONS

REXROTHVARIABLEPUMPA10VG REPAIRMANU-

AL

EATON REPAIR INFORMATION: MODEL 74318 and

74348 PISTON MOTORS

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

EATON PARTS AND REPAIR INFORMATION: 5

SERIES STEERING CONTROL UNITS

TM

SERVICE PROCEDURE

Chapter 5 -- Electrical System

General Information 5 -- 2........................

Electrical Drawings 5 -- 3.........................

Special Tools 5 -- 4..............................

Troubleshooting 5 -- 6............................

Info Center Display 5 -- 11........................

Electrical System Quick Checks 5 -- 28.............

Adjustments 5 -- 30..............................

Component Testing 5 -- 32........................

Service and Repairs 5 -- 63.......................

Chapter 6 -- Axles, Planetaries and Brakes

Specifications 6 -- 2..............................

General Information 6 -- 3........................

Service and Repairs 6 -- 4........................

Chapter 7 -- Chassis

General Information 7 -- 1........................

Service and Repairs 7 -- 2........................

Chapter 8 -- Cutting Decks

Specifications 8 -- 2..............................

Troubleshooting 8 -- 3............................

General Information 8 -- 4........................

Service and Repairs 8 -- 6........................

SafetyProduct Records

Diesel

Hydraulic

Electrical

Axles, Planetaries

and Maintenance

Engine

System

System

and Brakes

Groundsmaster 5900/5910

Cutting Decks Chassis

Page 4

This page is intentionally blank.

Groundsmaster 5900/5910

Page 5

Table Of Contents (Continued)

Chapter 9 -- Operator Cab

General Information 9 -- 2........................

Service and Repairs 9 -- 3........................

ICE COMPRESSOR SERVICE MANUAL

Chapter 10 -- Foldout Drawings

Hydraulic Schematic 10 -- 3.......................

Electrical Schematics 10 -- 4......................

Wire Harness Drawings 10 -- 10..................

Cab

OperatorFoldout

Drawings

Groundsmaster 5900/5910

Page 6

This page is intentionally blank.

Groundsmaster 5900/5910

Page 7

Chapter 1

Table of Contents

GENERAL SAFETY INSTRUCTIONS 2............

Before Operating 2............................

While Operating 3.............................

Maintenance and Service 4....................

JACKING INSTRUCTIONS 5.....................

Jacking the Front End 5........................

Jacking the Rear End 5........................

SAFETY AND INSTRUCTION DECALS 6..........

Safety

Safety

Groundsmaster 5900/5910 Page 1 -- 1 Safety

Page 8

General Safety Instructions

TheGroundsmaster 5900 and 5910 are testedand certified by Toro for compliance with existing safety standards and specifications. Although hazard control and

accident prevention partially are dependent upon the

design and configuration of the machine, these factors

are also dependent upon the awareness, concern and

proper training of the personnel involved in the operation, transport, maintenance and storage of the machine.Improperuseormaintenance of themachinecan

resultininjuryordeath. Toreduce the potentialforinjury

or death, comply with the following safety instructions.

Before Operating

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

1. Review and understand the contents of the Operator’s Manual and Operator’s DVD before starting and

operating the machine. Become familiar with the controls and know how to stop the machine and engine

quickly. Additionalcopies ofthe Operator’s Manual are

available on the internet at www.Toro.com.

2. Keep all shields, safetydevicesanddecals in place.

Ifashield,safetydeviceordecalisdefective,illegibleor

damaged, repair or replace it before operating the machine.Alsotightenany loose nuts,boltsorscrewstoensure machine is in safe operating condition.

3. Assure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is in

NEUTRAL and PTO switch is OFF (disengaged).

4. Since diesel fuel is flammable, handle it carefully:

A. Use an approved fuel container.

B. Donotremove fueltankcapwhile engineishotor

running.

C. Do not smoke while handling fuel.

D. Fillfueltankoutdoorsandonly towithinaninchof

the top of the tank, not the filler neck.Do notoverfill

fuel tank.

E. Wipe up any spilled fuel.

Groundsmaster 5900/5910Page 1 -- 2Safety

Page 9

While Operating

1. Sit onthe seatwhen starting and operating the machine.

2. Before starting the engine:

A. Engage the parking brake.

B. Makesurethetractionpedalis intheneutralposi-

tion and the PTO switch is OFF (disengaged).

C. Afterengineisstarted, releaseparkingbrakeand

keepfootofftractionpedal.Machinemustnot move.

Ifmovementisevident,the traction pedal isadjusted

incorrectly;therefore,shutengineoffandadjusttraction system until machinedoesnotmove when traction pedal is released.

3. Do not run engine in a confined area without ade-

quate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

4. Do not touch engine, radiator or exhaust system

whileengineis runningorsoonafteritis stopped.These

areas could be hot enough to cause burns.

5. Before getting off the seat:

A. Ensure that traction pedal is in the neutral posi-

tion.

B. Apply parking brake.

C. Lower the cutting decks fully to the ground. This

relieves pressure from the lift circuit and eliminates

the risk of the cutting decks accidentallylowering to

the ground.

D. Disengage cutting decks and wait for cutting

blades to stop completely.

E. Allow engineto run at low idle speed for at least

five (5)minutes after full load operation to allow the

turbocharger to cool.

F. Stopengineandremovekeyfromswitch.Waitfor

all machine movement to stop.

6. Do not park machine on slopes unless wheels are

chocked or blocked.

Safety

Groundsmaster 5900/5910 Page 1 -- 3 Safety

Page 10

Maintenance and Service

1. Before servicing or making machine adjustments,

lower cutting decks, stop engine, apply parking brake

and remove key from the ignition switch.

2. Make sure machine isinsafeoperating condition by

keeping all nuts, bolts and screws tight.

3. Shut engine off before checking or adding oil to the

engine crankcase.

4. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt.Clean

protective screen on machine frequently.

5. Never store the machine or fuel container inside

wherethereisanopenflame,suchasnearawaterheater or furnace.

6. Do not overspeed the engineby changing governor

setting.Toassuresafetyandaccuracy,checkmaximum

engine speed.

7. Disconnect batteries before servicing the machine.

Disconnect negative battery cables first and positive

cables last. If battery voltage is required for troubleshooting or test procedures, temporarily connect the

batteries. Reconnect positive battery cables first and

negative cables last.

8. Battery acid is poisonous and can cause burns.

Avoidcontact with skin,eyesand clothing. Protect your

face, eyes and clothing when working with a battery.

9. Battery gases canexplode. Keep cigarettes,sparks

and flames away from the battery.

10.When changing attachments, tires or performing

otherservicethatrequiresthemachine toberaised,use

correct jacks, hoists and supports.Make suremachine

is parked on a solid level surface such as a concrete

floor. Prior to raising the machine, remove any attachmentsthatmayinterferewiththe safeandproperraising

ofthemachine.Always chockorblockwheels.Uses uitable jack stands to support the raised machine. If the

machine is not properly supported by jack stands, the

machinemay move or fall,which mayresultinpersonal

injury (see Jacking Instructions in this chapter).

11.Make sureallhydrauliclineconnectorsare tight,and

all hydraulic hoses and lines are in good condition before applying pressure to the system.

12.Keepbodyandhandsawayfrompinholeleaksinhydrauliclinesthatejecthighpressurehydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Fluid accidentally injected into the skin

mustbesurgicallyremovedwithinafewhoursby a doctor familiar with this form of injury or gangrene may result.

13.Before disconnectingorperforming any work onthe

hydraulic system, all pressure in system must be relieved by stopping engine and lowering the cutting

decks to the ground.

14.Make sure all engine fuel system connectors and

components are correctly installed, and all fuel hoses

are in good condition before starting engine.

15.Keep bodyandhandsawayfrom leaksinenginefuel

injectionlines.Usecardboard or papertofindhighpressurefuelleaksiftheymayexist.Leakingfuelunderpressure can penetrate skin and cause injury.

16.If enginemustberunningtoperformmaintenance or

an adjustment, keep hands, feet, clothing and other

parts of the body away from cutting decks and other

moving parts. Keep bystanders away.

17.At the time ofmanufacture, the machine conformed

tothesafetystandardsfor riding mowers. Toassureoptimumperformanceandcontinued safety certificationof

the machine, use genuine Toro replacement parts and

accessories.Replacementpartsandaccessoriesmade

by other manufacturers mayresultin non-conformance

with the safety standards, and the warranty may be

voided.

18.When welding on machine, disconnect all battery

cables to preventdamageto machine electronicequipment. Disconnect negative battery cable first and positive cable last. Disconnect and remove engine

electronic control module (ECM) from engine before

welding on the machine. Also, attach welder ground

cable no more than two (2) feet (0.61 meters) from the

welding location.

19.If major repairsareeverneededor assistance is desired, contact an Authorized Toro Distributor.

Groundsmaster 5900/5910Page 1 -- 4Safety

Page 11

Jacking Instructions

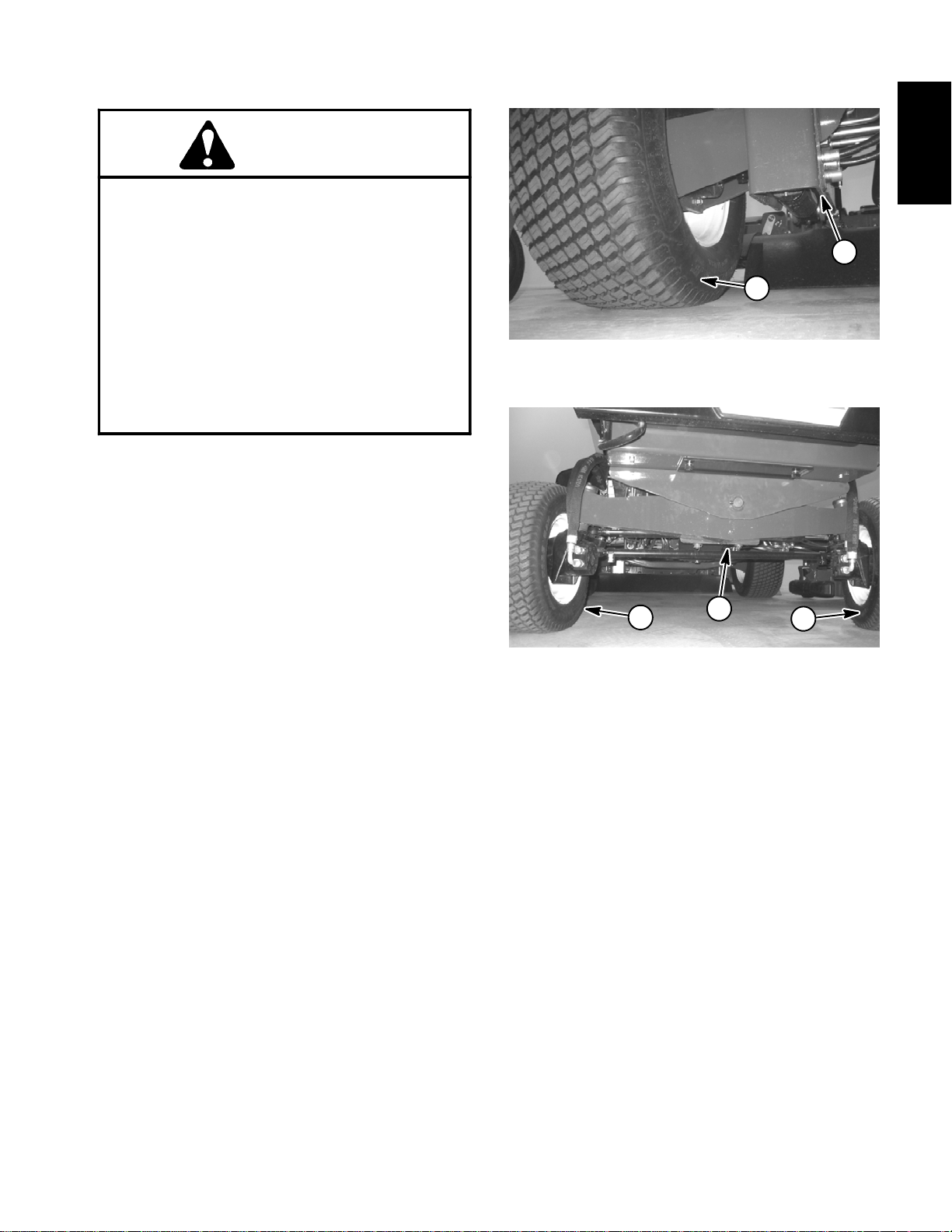

CAUTION

When changing attachments, tires or performingotherservice thatrequiresthemachine tobe

raised,usecorrect jacks,hoistsandsupportsto

raise and support the machine. Make sure machineisparkedonasolid levelsurfacesuch asa

concretefloor.Prior to raising machine, remove

anyattachmentsthatmay interfere with thesafe

and proper raising of the machine. Always

chock or block wheels. Use appropriate jack

stands to support the raised machine. Ifthemachine is not properly supportedby jack stands,

the machine may moveor fall, which may result

in personal injury.

Jacking the Front End (Fig. 1)

1. Chock both rear tires to prevent the machine from

moving.

2. Position jack securely under the frame, just to the inside ofthe fronttire. Makesure thatjack does not contact hydraulic lift cylinder.

3. Position appropriate jackstands under theframeas

close to the front wheel as possible to support the machine.

Jacking the Rear End (Fig. 2)

2

Figure 1

1. Frame jacking point 2. Front tire

2

Figure 2

1. Rear axle jacking point 2. Rear tire

1

Safety

1

2

1. Applyparkingbrakeandchockbothfronttires toprevent the machine from moving.

2. Place jack securely under the center of rear axle.

Jack rear of machine off the ground.

3. Use appropriate jack stands under the rear axle to

support the machine.

Groundsmaster 5900/5910 Page 1 -- 5 Safety

Page 12

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

your Groundsmaster. If any decal becomes illegible or

damaged, install a new decal. Decal part numbers are

listed in your Parts Catalog.

Groundsmaster 5900/5910Page 1 -- 6Safety

Page 13

Product Records and Maintenance

Table of Contents

Chapter 2

PRODUCT RECORDS 1.........................

MAINTENANCE 1...............................

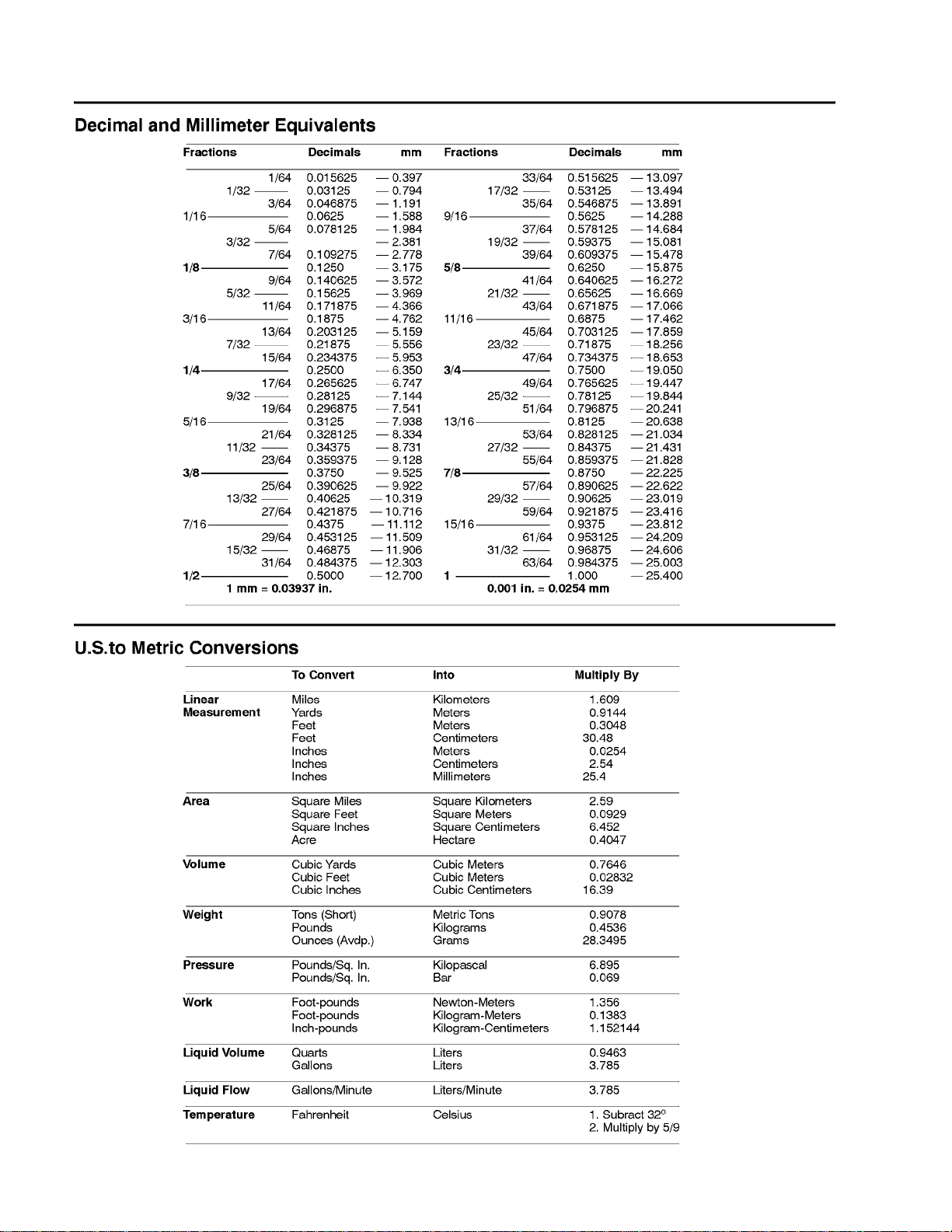

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3....................

Fastener Identification 3.......................

Product Records

Insert Operator’s Manuals and Parts Catalogs for your

Groundsmaster at the end of this chapter. Additionally,

if any optional equipment or accessories have been

installedto your machine, inserttheInstallationInstructions, Operator’s Manuals andPartsCatalogs for those

options at the end of this chapter.

Maintenance

Maintenanceproceduresand recommended serviceintervalsforyourGroundsmasterarecoveredintheOperator’s Manuals. Refer to this publication when

performing regular equipment maintenance.

Standard Torque for Dry, Zinc Plated, and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated, and

Steel Fasteners (Metric) 5....................

Other Torque Specifications 6..................

Conversion Factors 6..........................

Product Records

and Maintenance

Groundsmaster 5900/5910 Page 2 -- 1 Product Records and Maintenance

Page 14

Equivalents and Conversions

0.09375

Groundsmaster 5900/5910Page 2 -- 2Product Records and Maintenance

Page 15

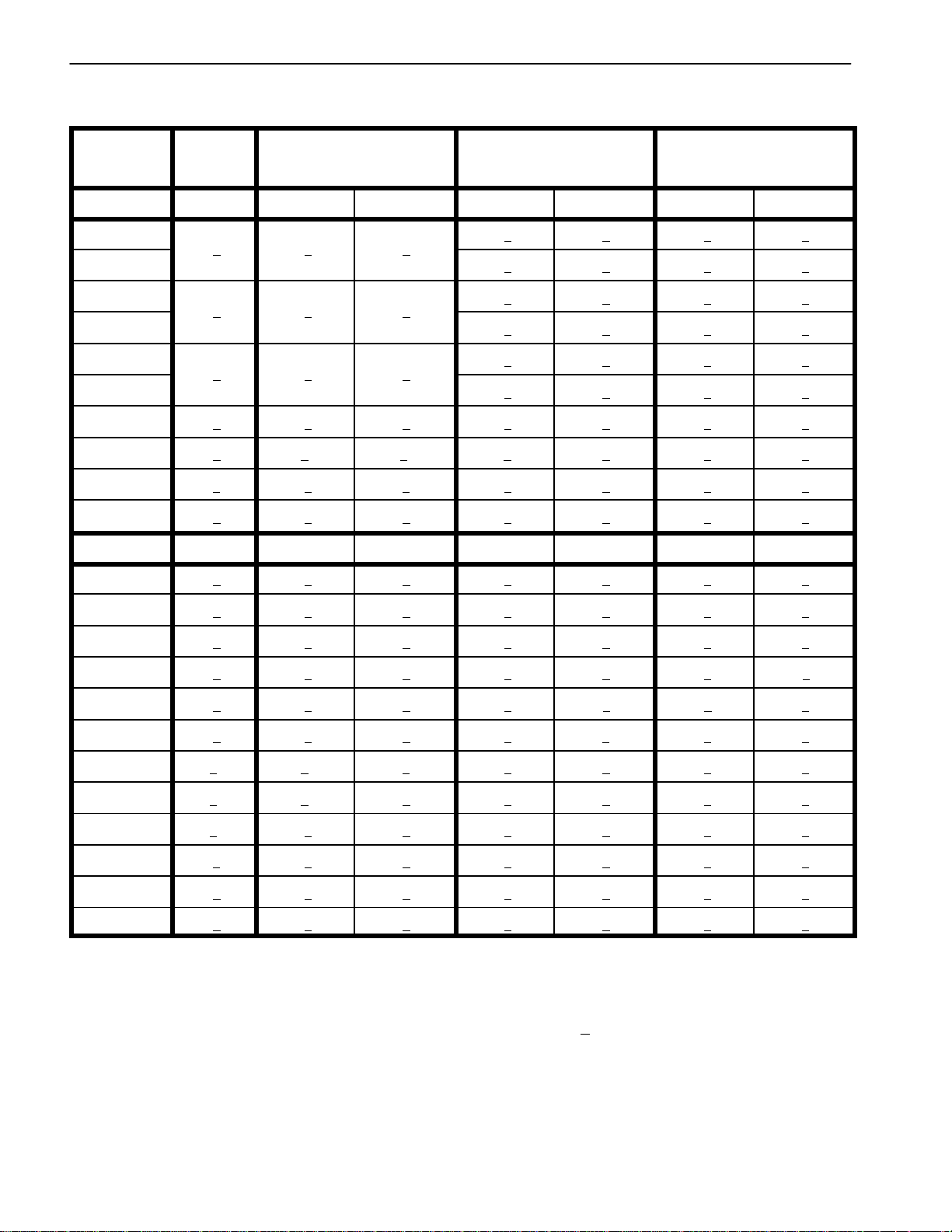

Torque Specifications

Recommended fastener torque values are listed in the

followingtables.Forcriticalapplications,asdetermined

byToro, eithertherecommendedtorqueora torque that

is unique to theapplicationis clearly identifiedandspecified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shallapply to all fastenerswhich

donot have a specific requirement identified inthis Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presenceof a prevailingtorque feature

(e.g. Nylock nut), hardness of the surface underneath

thefastener’sheadorsimilarconditionwhichaffectsthe

installation.

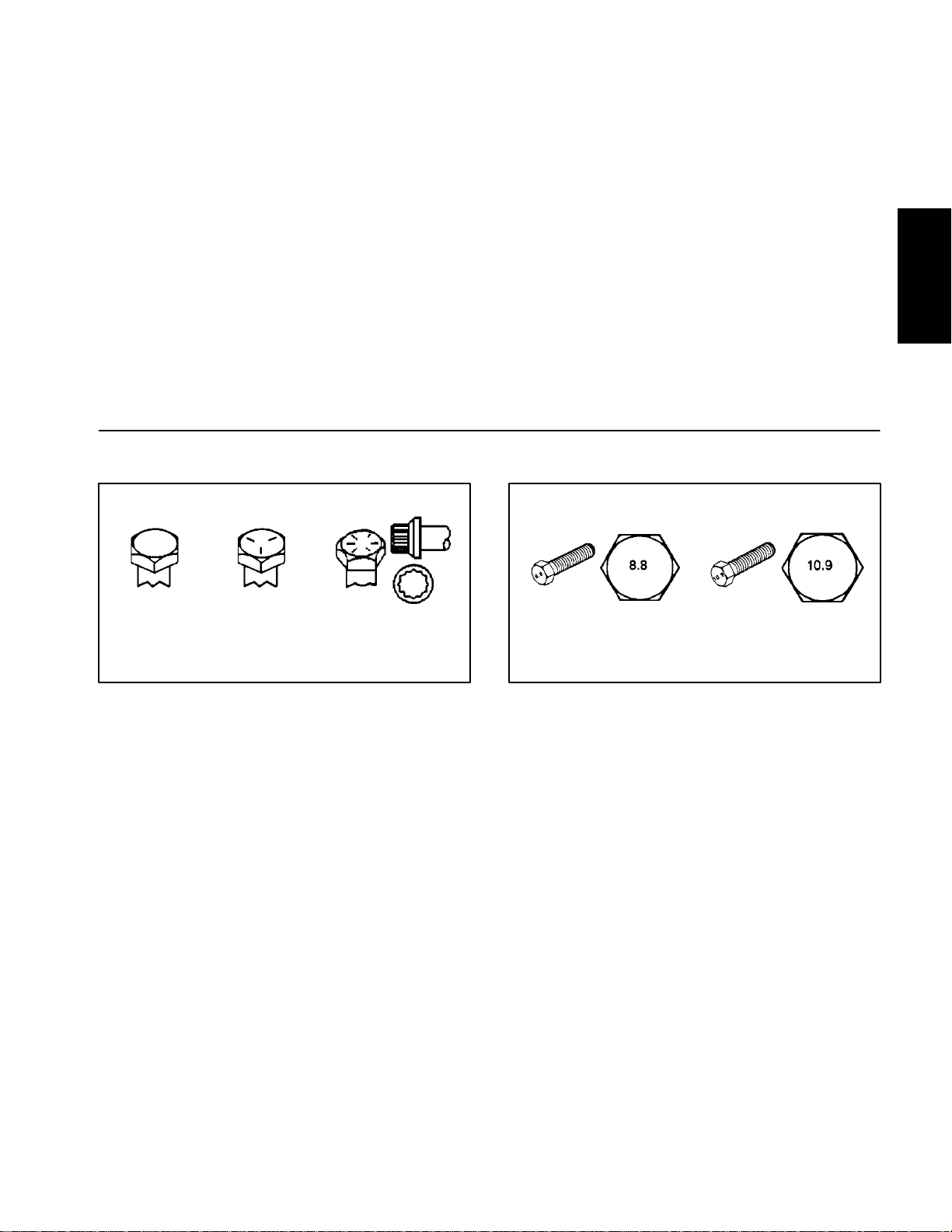

Fastener Identification

Asnotedin thefollowingtables,torque valuesshouldbe

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torquevalues may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based onthe aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measurethetorquerequiredtotightenthefastener until

the lines match up.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

Groundsmaster 5900/5910 Page 2 -- 3 Product Records and Maintenance

Page 16

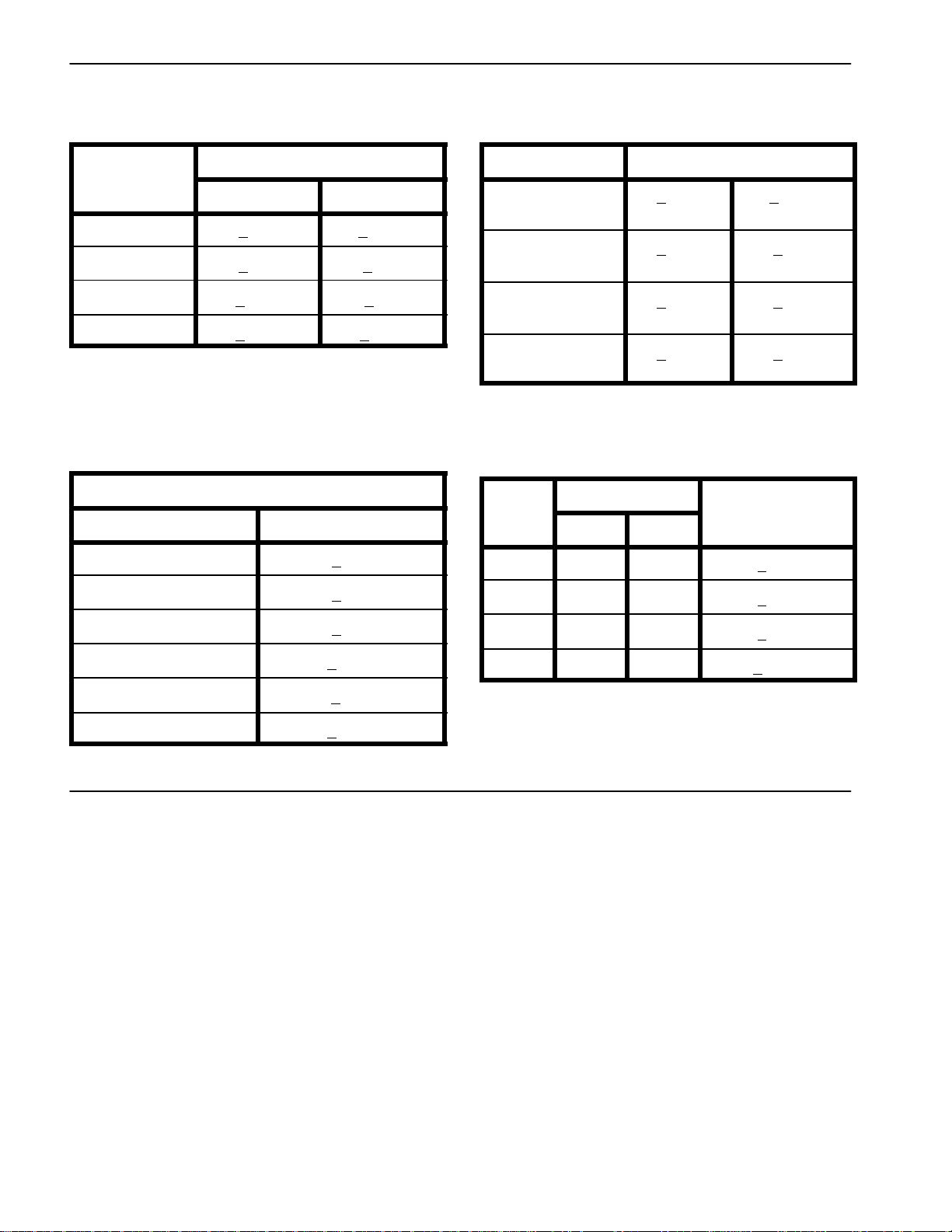

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130 + 113 140 + 15 1582 + 169

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 113 115 + 12 1299 + 136 160 + 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 -- 16 UNC 16 + 2 16 + 2 22+ 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in--lb N--cm in--lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 56

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

17 + 2 192 + 23 25 + 3 282 + 34

29 + 3 328 + 34 41 + 5 463 + 56

31 + 4 350 + 45 43 + 5 486 + 56

42 + 5 475 + 56 60 + 6 678 + 68

48 + 5 542 + 56 68 + 7 768 + 79

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 +2 24 +3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 +7 95 +9

7/16 -- 20 UNF 29 +3 29 + 3 39 + 4 55 + 6 75 + 8 77 +8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 +11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 +7 72 +9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 +10 95 + 15 129 + 20 170 + 18 230 + 24 240 +24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 +37 375 + 38 508 + 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 +43 569 + 58

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed inthe tableabove

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and8 fasteners arebased on 75%of the minimumproofload specified in SAE J429. The toleranceis

approximately +

10% of the nominal torquevalue. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specifictorque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Groundsmaster 5900/5910Page 2 -- 4Product Records and Maintenance

Page 17

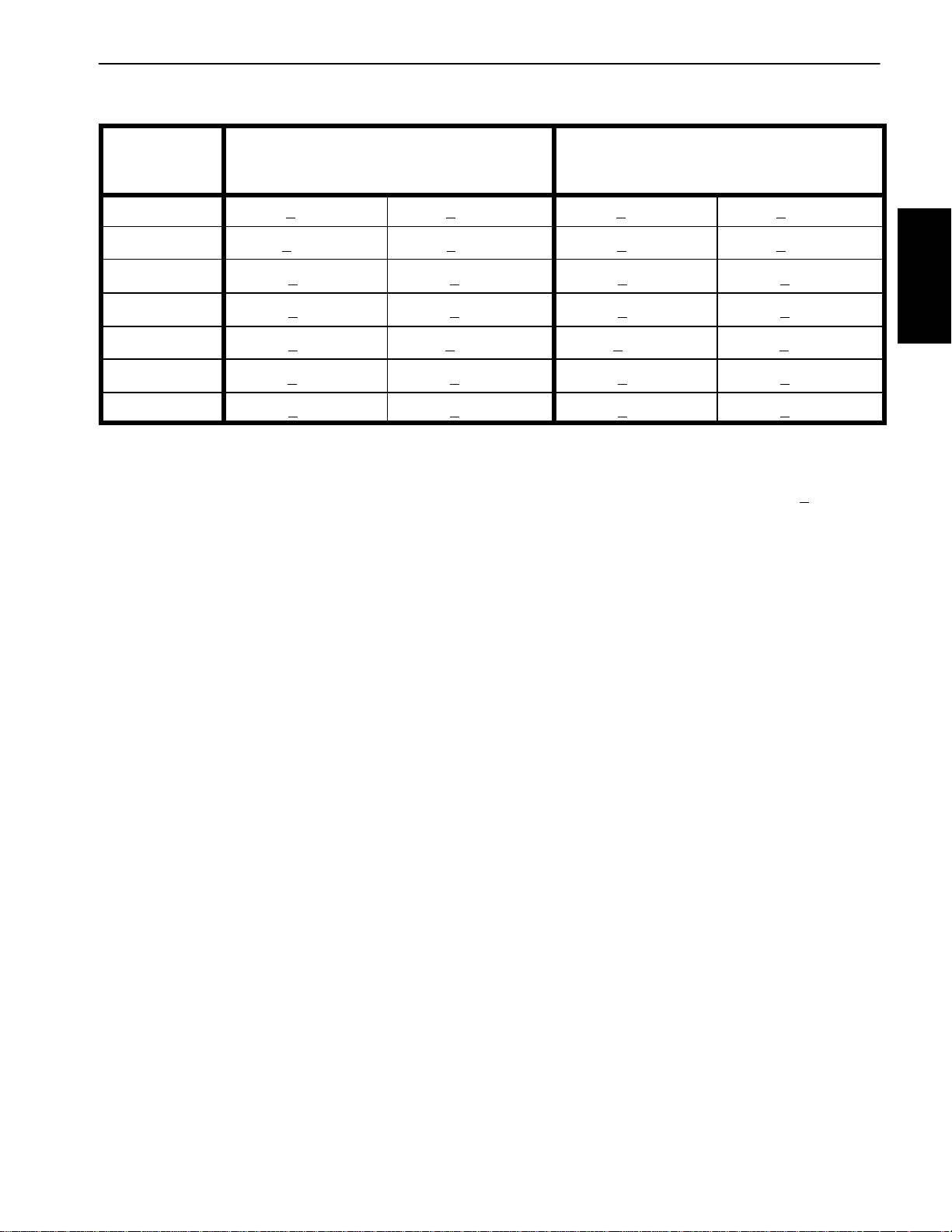

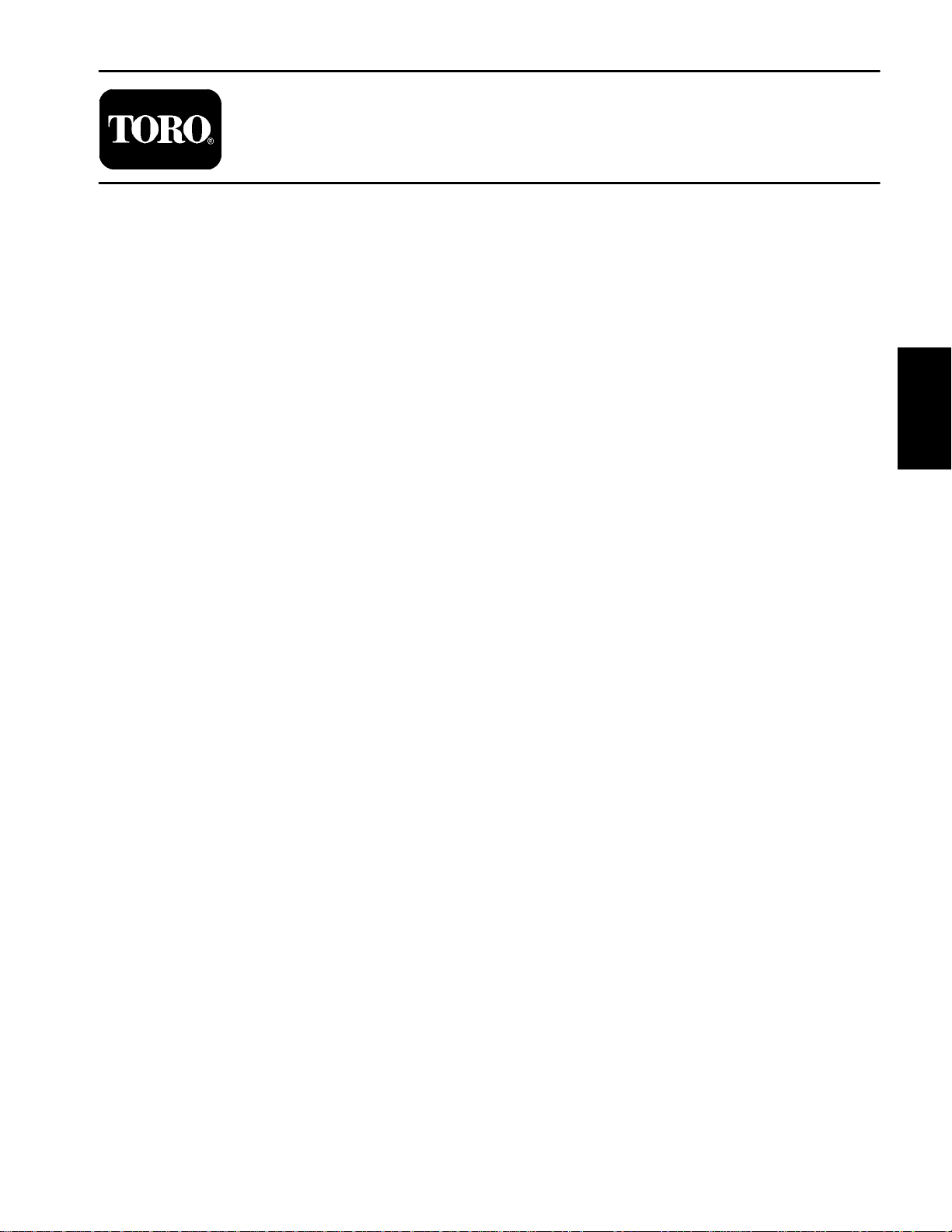

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N--cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N- -cm 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93+ 10 ft--lb 126 + 14 N--m

M16 X 2.0 166 + 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Reduce torque values listed inthe tableabove

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specifictorque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAEJ1199.Thetoleranceis approximately+

nominal torque value.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

10%ofthe

Product Records

and Maintenance

Groundsmaster 5900/5910 Page 2 -- 5 Product Records and Maintenance

Page 18

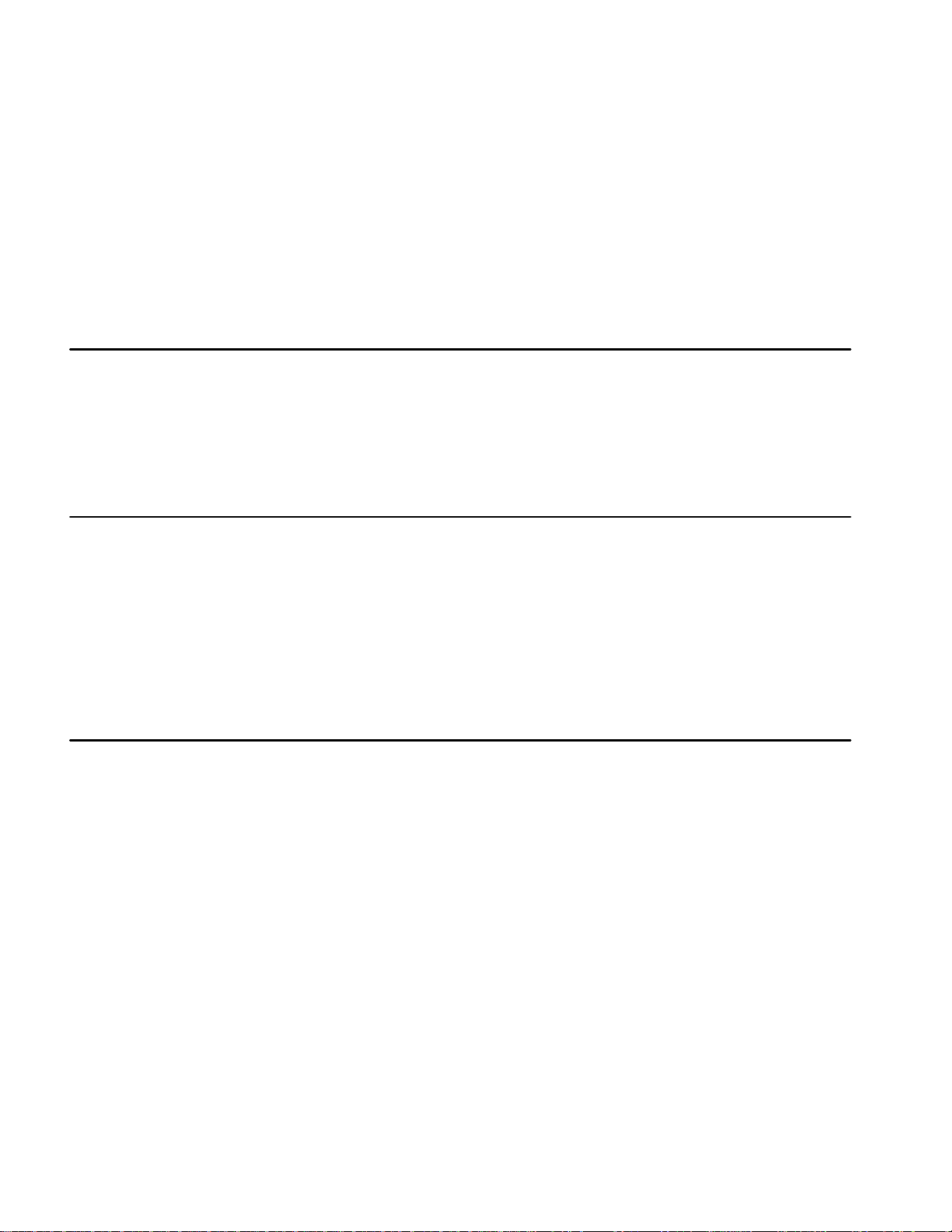

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

*Holesize,materialstrength,materialthicknessandfinish must be considered when determining specific

torquevalues.All torquevaluesarebasedon non--lubricated fasteners.

Groundsmaster 5900/5910Page 2 -- 6Product Records and Maintenance

Page 19

Table of Contents

GENERAL INFORMATION 2.....................

Operator’s Manual 2..........................

Engine Identification 2.........................

Engine Electronic Control Module (ECM) 2.......

Stopping the Engine 3.........................

Fuel Injection System 3........................

ENGINE SPECIFICATIONS 4....................

ENGINE FASTENER TORQUE SPECIFICATIONS 5

ADJUSTMENTS 7..............................

Valve Clearance 7............................

SERVICE AND REPAIRS 8......................

Air Filter System 8............................

Exhaust System 10...........................

Turbocharger 12..............................

Fuel System 14...............................

Check Fuel Lines and Connections 14..........

Drain and Clean Fuel Tank 14.................

Fuel Tank Removal 15.......................

Fuel Tank Installation 15......................

Chapter 3

Diesel Engine

Radiator 16..................................

Alternator 18.................................

Starter Motor 20..............................

Valve Cover 22...............................

Engine Breather System 24....................

Thermostat 26................................

Water Pump 28...............................

Front Cover 30...............................

Oil Pan 34...................................

Engine 36....................................

Engine Removal 36..........................

Engine Installation 38........................

Flywheel Coupling Assembly 40................

Diesel

Engine

Groundsmaster 5900/5910 Page 3 -- 1 Diesel Engine

Page 20

General Information

This Chapter gives information about specifications of

the Cummins B3.3 diesel engine used in the Groundsmaster 5900 and 5910. Additionally, some engine repairproceduresaredescribedinthismanual.Described

adjustments and repairs require tools which are commonly available in many service shops.

Some service and repair parts for the engine in your

Groundsmaster are supplied through your Authorized

Toro Distributor. Bepreparedto provide your distributor

with the Toro model andserial number ofyourmachine

to obtain parts.

Operator’s Manual

The Operator’s Manualprovides informationregarding

the operation, general maintenance and maintenance

intervals for your Groundsmaster machine.Refertothe

Operator’s Manualfor additional information when servicing the machine.

Engine Identification

Detailedinformationonengine troubleshooting, testing,

disassembly and reassembly is identified in the Cummins Service Manual that is available from Cummins.

The use of some specialized tools and test equipment

is explained in the CumminsServiceManual.However,

the specialized natureof some engine repairs maydictate that the work be done at an engine repair facility.

The engine dataplate located near the startermotor includes the engine serial number and control parts list

number. The fuel injection dataplate is located on the

fuel injection pump. The ECM dataplate is on the electroniccontrolmoduleattachedtotheflywheelend of the

engine. These engine identification tags will assist in

identifying the correct partsand serviceinformation for

the Cummins engine in your Groundsmaster.

Engine Electronic Control Module (ECM)

TheCumminsenginethat isusedintheGroundsmaster

5900 and 5910 uses an electronic control module

(ECM) for engine management and also to communicatewiththeTECcontrollersandtheoperator Info Center on the machine. All engine ECM electrical

connectors should be plugged intothecontrollerbefore

themachineignitionswitch ismovedfromtheOFF position to either the ON or START position. If the engine

ECM is to be disconnected for any reason, make sure

thattheignitionswitch isintheOFFposition with thekey

removed before disconnecting the ECM. Also, to preventpossiblemoduledamagewhenweldingon the machine,disconnectandremovetheengineECM from the

engine before welding.

Groundsmaster 5900/5910Page 3 -- 2Diesel Engine

Page 21

Stopping the Engine

IMPORTANT: Before stopping the engine after

mowing or full load operation, allow the engine to

runatlowidlespeedfor five (5) minutes.Thiswillallow the turbocharger and internal engine components to adequately cool down.Failuretoallow this

cooldown period may lead to premature turbocharger and engine failure.

Fuel Injection System

The engine fuelinjection system operatesat high pressures during engine operation. Do not loosen any fuel

system components, fittings or hoses while the engine

is running.

Keepbodyandhandsawayfromleaksinenginefuel injection lines.Use cardboard or paper to find high pressure fuel leaks if they may exist. Leaking fuel under

pressure can penetrate skin and cause injury.

Diesel

Engine

Groundsmaster 5900/5910 Page 3 -- 3 Diesel Engine

Page 22

Engine Specifications

Item Description

Make / Designation Cummins, 4--Cycle, 4 Cylinder,

Bore 3.74 in (95.0 mm)

Stroke 4.53 in (115 mm)

Total Displacement 201 in3(3300 cc)

Firing Order 1 (Closest to Engine Pulley) -- 2 -- 4 -- 3

Direction of Rotation Clockwise (Viewed from EnginePulley)

Compression Ratio 17:1

ValveClearance

Intake 0.014” (0.35 mm)

Exhaust 0.020” (0.50 mm)

Fuel Diesel or Biodiesel (up to B20) with Low/Ultra Low Sulfur Content

Fuel TankCapacity 35 U.S. gallons (132 liters)

Fuel Injection Pump Zexel Rotary Type VE Pump

Injection Nozzle Closed Nozzle, Hole Type

Liquid Cooled, Turbocharged, Diesel Engine

Governor Electronic

Low Idle (no load) 1350 RPM

High Idle (no load) 2750 RPM

Oil Pump Geroter Type

Engine Oil API CH--4 or CI--4 (see Operator’s Manual for Viscosity)

Crankcase Oil Capacity 8.5 U.S.quarts (8.0 liters) with Filter

Starter 12 VDC, 2.2 kW

Alternator/Regulator 12 VDC, 120 AMP

Coolant Capacity

GM 5900 (without cab) 13.5 U.S. quarts (12.8 liters)

GM 5910 (with cab) 18 U.S. quarts (17 liters)

Engine Dry Weight 606 U.S. pounds (275 kg)

Groundsmaster 5900/5910Page 3 -- 4Diesel Engine

Page 23

Engine Fastener Torque Specifications

Item Description

Alternator Adjusting Cap Screw 23 ft--lb (31 N--m)

Alternator Mounting Bracket Cap Screw (2 used) 23 ft--lb (31 N--m)

Alternator Mounting Cap Screw 49 ft--lb (66N--m)

Crankshaft Pulley Bolt 274 ft--lb (372 N--m)

Exhaust Manifold Flange Head Screw (8 used) 33 ft--lb (45 N--m)

Front Cover Flange Head Screw (16 used) 14 ft--lb (19 N--m)

Oil Drain Plug 38 ft--lb (51 N--m)

Oil Pan Flange Head Screw (24 used) 24 to 38 ft--lb (32 to 51 N--m)

Oil Suction Tube Flange Head Screw (2 used) 14 ft--lb (19 N--m)

Starter Mounting Flange Head Screw (2 used) 32 ft--lb (43 N--m)

Thermostat Housing Flange Head Screw (2 used) 14 ft--lb (19 N--m)

Turbocharger Mounting Nut (4 used) 22 ft--lb (30 N--m)

Turbocharger Oil Drain Line Cap Screw (2 used) 18 ft--lb (24 N--m)

Turbocharger Oil Supply Line Banjo Bolt 18 ft--lb (24 N--m)

ValveAdjustment Nut (rocker arm) 29to36ft--lb(39to49N--m)

ValveCover Nut (3 used) 80 in--lb (9 N--m)

Water Pump Pulley Flange Head Screw (4 used) 23 ft--lb (31 N--m)

Diesel

Engine

Groundsmaster 5900/5910 Page 3 -- 5 Diesel Engine

Page 24

This page is intentionally blank.

Groundsmaster 5900/5910Page 3 -- 6Diesel Engine

Page 25

Adjustments

Valve Clearance

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood.

3. Remove valve cover from engine (see Valve Cover

RemovalintheServiceandRepairssectionofthischapter).

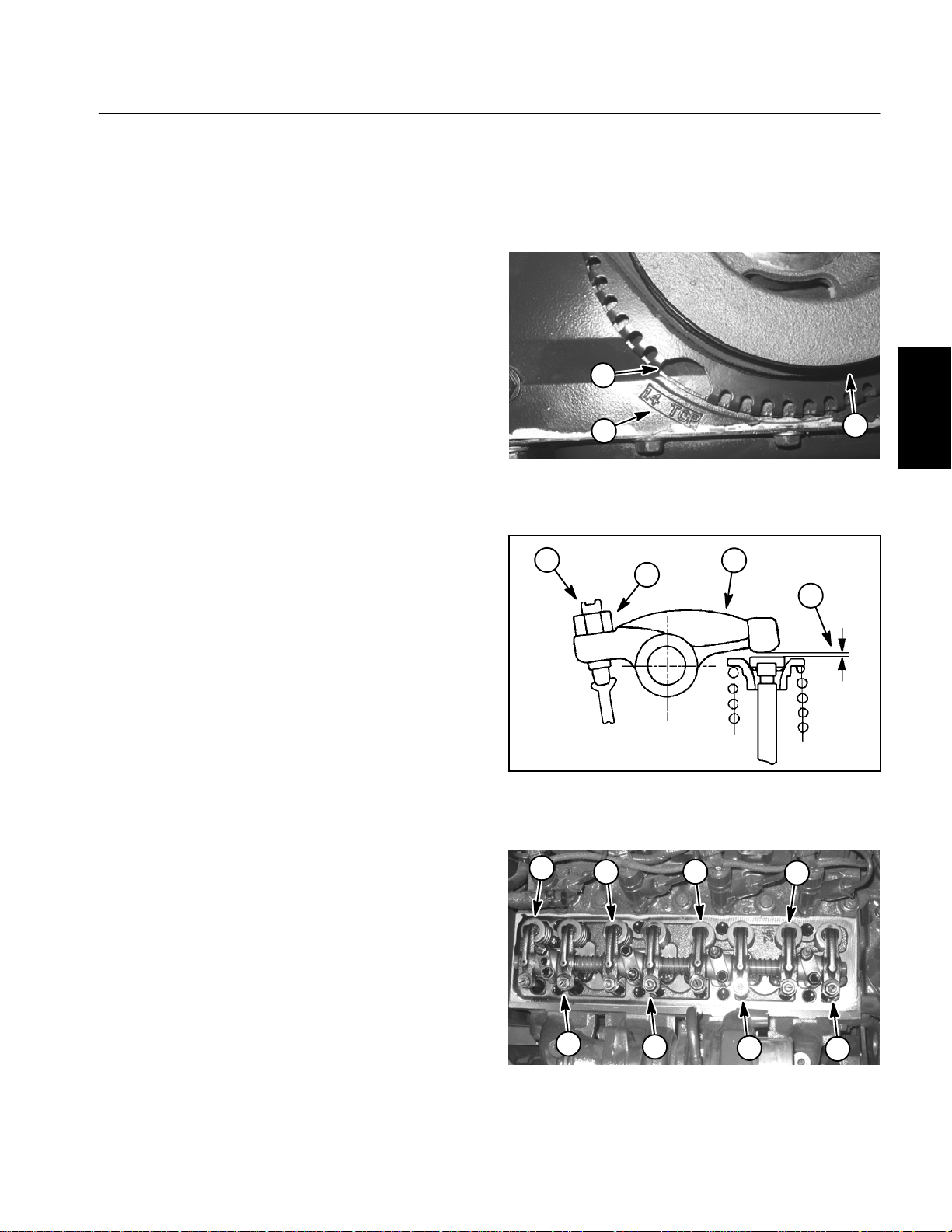

4. Position engine crankshaft so cylinder #1 is at top

deadcenter(TDC)attheendofthecompression stroke:

A. While watching the movement of the cylinder #4

intakevalve,rotate enginecrankshaftinnormal rotation direction (clockwise). When the cylinder #4 intakevalve starts to open,cylinder#1is approaching

TDC at the end of the compression stroke.

B. Continue rotating the crankshaft in the normal

rotation direction (clockwise) until the cutout in the

tone wheel attached to the back of the crankshaft

pulleyalignswith“1.4TOP”castinenginefrontcover

(Fig. 1).

5. Inthiscrankshaftposition,adjustvalve clearance for

intakevalvesforcylinders#1and#3andexhaustvalves

for cylinders #1 and #2 (Fig. 2 and 3).

8. Installvalvecovertoengine(seeValveCoverInstallationintheServiceandRepairssectionofthis chapter).

9. Lower and secure hood.

2

3

1

Figure 1

1. Crankshaft pulley

2. Tone wheel cutout

2

3. TDC indicator

3

1

4

Diesel

Engine

A. Loosenthelock nutontherocker armadjustment

screw.

B. Insert correct feeler gauge between the valve

stem and the rocker arm. Intake valve clearance

specification is 0.014” (0.35 mm). Exhaust valve

clearance specification is 0.020” (0.50 mm).

C. Adjust screw until aslightdragisfeltonthefeeler

gauge.

D. Hold adjustment screw in position and tighten

lock nut to secure valve clearance adjustment.

Torque lock nut from29 to 36 ft--lb (39 to 49 N--m).

E. After tightening lock nut, re--check valve clearance.

6. Rotate crankshaft in the normal rotation direction

(clockwise) one complete revolution. The tone wheel

cutout should again be aligned with “1.4 TOP”.

7. Inthiscrankshaftposition,adjustvalve clearance for

intakevalvesforcylinders#2and#4andexhaustvalves

for cylinders #3 and #4. Follow procedureunder step5

above.

1. Lock nut

2. Adjustment screw

8

6

7

1. #1 intake

2. #1 exhaust

3. #2 intake

4. #2 exhaust

Figure 2

5

Figure 3

3. Rocker arm

4. Valve clearance

4

3

5. #3 intake

6. #3 exhaust

7. #4 intake

8. #4 exhaust

2

1

Groundsmaster 5900/5910 Page 3 -- 7 Diesel Engine

Page 26

Service and Repairs

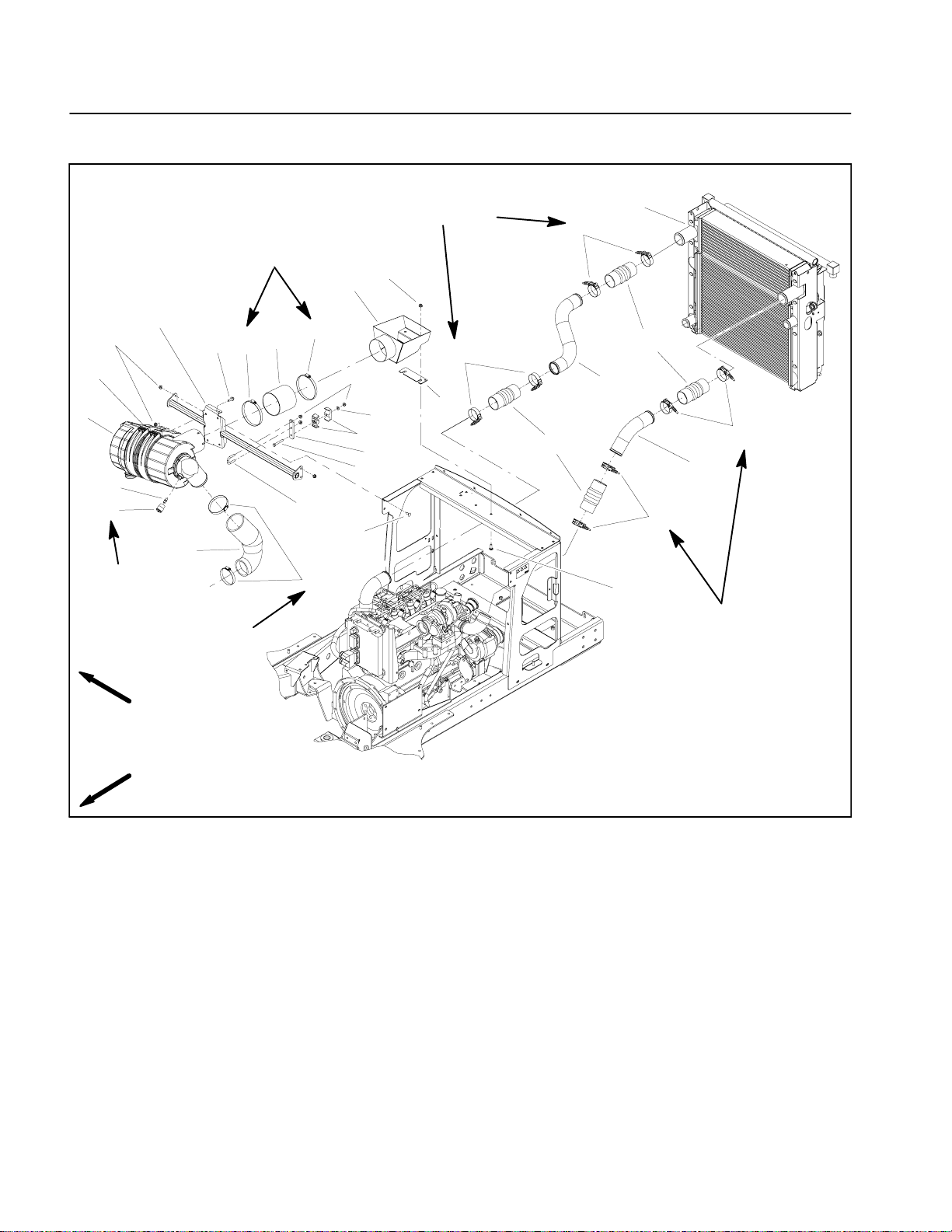

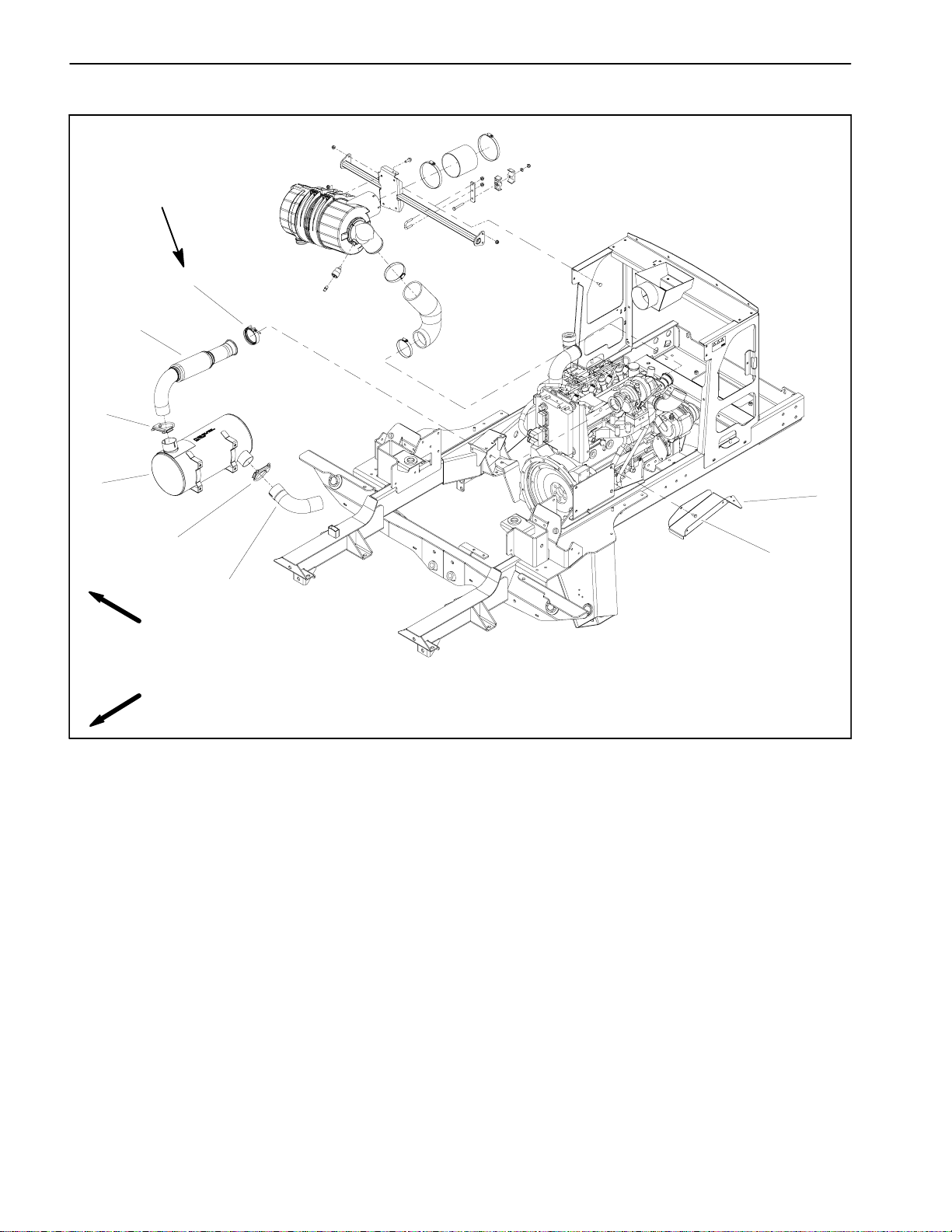

Air Filter System

5

6

7

8

9

12 to 15 in--lb

(1.4 to 1.6 N--m)

4

3

11

45 to 55 in--lb

(5.1 to 6.2 N--m)

45 to 55 in--lb

(5.1 to 6.2 N--m)

2

1

12

10

24

50 to 70 in--lb

(5.7 to 7.9 N--m)

3

19

23

1

21

20

19

22

17

15

13

14

16

19

25

21

19

18

26

50 to 70 in--lb

(5.7 to 7.9 N--m)

RIGHT

FRONT

1. Clamp

2. Air hose

3. Flange head screw (6 used)

4. Air cleaner mount

5. Flange nut (8 used)

6. Air cleaner mounting band (2 used)

7. Air cleaner assembly

8. Adapter

9. Service indicator

Figure 4

10. Worm clamp

11. Intake tube

12. U--bolt

13. Cap screw

14. Mount plate

15. Tube clamp

16. Flat washer

17. Flange nut (3 used)

18. Carriage screw (4 used)

19. Hose clamp (8 used)

20. Tube

21. Air intake tube (4 used)

22. Tube

23. Radiator assembly

24. Airbox

25. Spacer plate (as needed)

26. Carriage screw (2 used)

Groundsmaster 5900/5910Page 3 -- 8Diesel Engine

Page 27

Removal (Fig. 4)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood to allow access to engine.

3. Remove air cleaner components as needed using

Figure 4 as a guide.

4. Inspect all tubes andclampsfor evidence of wearor

damage. Replace components as needed.

NOTE: If charge air cooler in radiator assembly needs

to be serviced (Fig. 5), refer to Radiator Removal and

Installation in this section.

Installation (Fig. 4)

IMPORTANT: Any leaks in the air filter system will

causeseriousenginedamage.Makesurethatallair

cleaner components are in good condition and are

properly secured during installation.

5

6

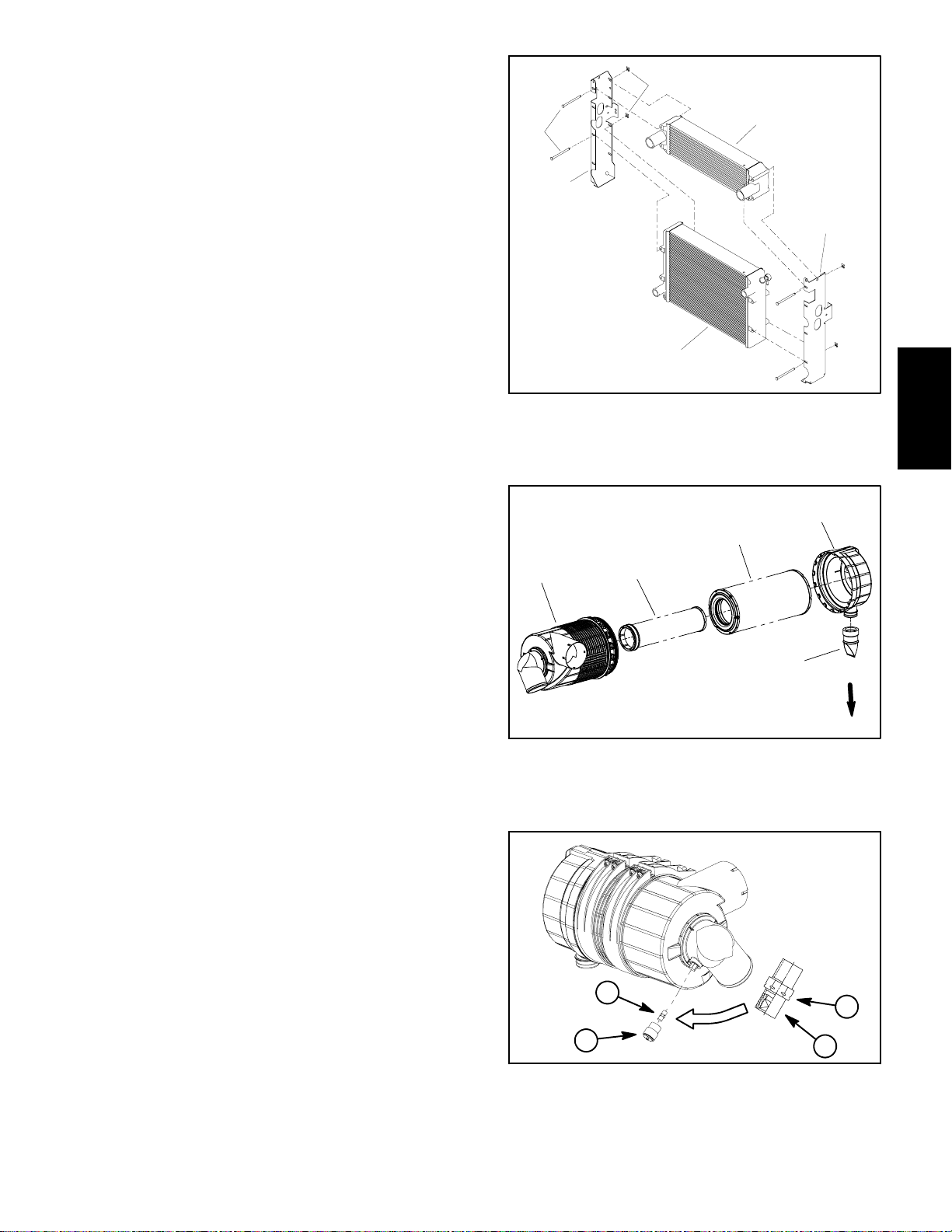

1. Radiator

2. LH cooler bracket

3. Charge air cooler

4

1

Figure 5

3

2

4. Pin clip (8 used)

5. Pin (8 used)

6. RH cooler bracket

Diesel

Engine

1. Assemble air cleaner system using Figure 4 as a

guide.

A. Verify that tabs in air cleaner mounting bands

mesh fully with slots in air cleaner body.

B. Position hose clamps (item 1)so thatthere is no

interference with hood foam when hood is closed.

C. Torque hose clamps (items 1 and 10)from 45 to

55 in--lb (5.1 to 6.2 N--m).

D. Torquehoseclamps(item 19)from50to70 in--lb

(5.7 to 7.9 N--m).

E. Make sure that air cleaner vacuator valve is

pointed down after assembly (Fig. 6).

F. If service indicator (item 8) and adapter (item 9)

wereremovedfromaircleanerhousing,applythread

sealant toadapter threads before installing adapter

and indicator to housing. Install adapter so that

groovesinadapterhexand adapterfilterelementare

installed toward service indicator(Fig.7). Torque indicator from 12 to 15 in--lb (1.4 to 1.6 N--m).

1

1. Air cleaner housing

2. Safety filter

3. Filter element

2

4

3

5

VACUATOR

VALVE

DIRECTION

Figure 6

4. Cover

5. Vacuator valve

2. Apply chalk onairboxlip, lower hoodandcheckthat

hood makes a continuoussealaround airbox (item 24).

If necessary, use shim(s) (item 25) to adjustlocation of

1

4

airbox for proper sealing with hood.

2

3. Lower and secure hood.

3

Figure 7

1. Adapter

2. Service indicator

3. Adapter filter element

4. Adapter grooves

Groundsmaster 5900/5910 Page 3 -- 9 Diesel Engine

Page 28

Exhaust System

50 to 70 in--lb

(5.7 to 7.9 N--m)

1

2

3

4

3

RIGHT

FRONT

1. Exhaust clamp

2. Exhaust tube

3. Muffler clamp (2 used)

7

6

5

Figure 8

4. Muffler

5. Tailpipe

6. Flange head screw (4 used)

7. Heat shield

Groundsmaster 5900/5910Page 3 -- 10Diesel Engine

Page 29

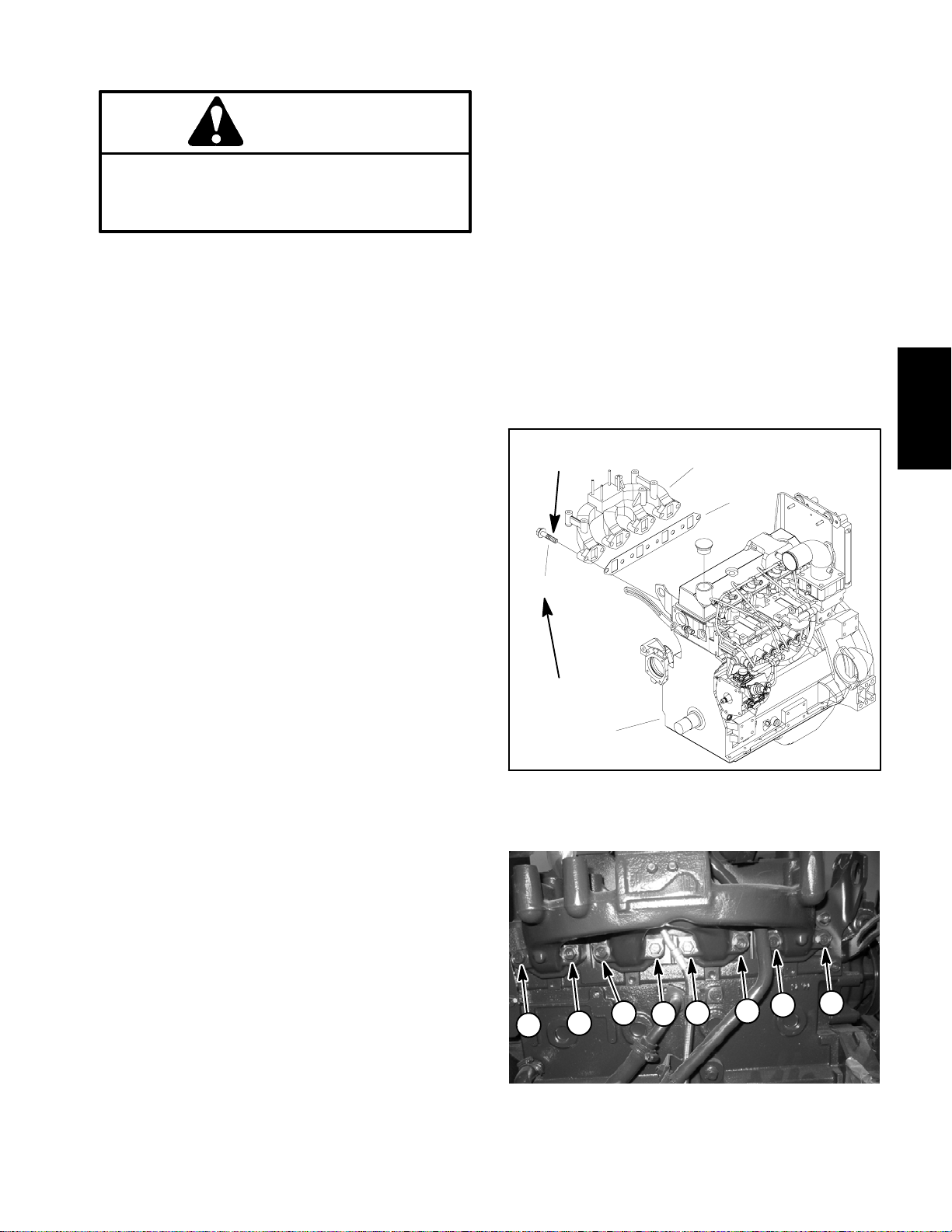

Removal (Fig. 8)

CAUTION

B. Position new manifold gasket and exhaust manifoldtocylinderheadand secure witheight(8)flange

head screws. Tighten the screws in the sequence

shown in Figure 10. Torque screws 33 ft--lb (45

N--m).

The engine and exhaust system may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before working on the exhaust system.

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood to allow access to exhaust

system.

3. Remove sidepanel from right side offrame to allow

easier access to exhaust system components.

4. Removemufflerand/orexhausttubefromtheengine

as necessary using Figure 8 as a guide.

5. If necessary, remove exhaust manifold from engine

(Fig. 9):

A. Remove turbocharger from exhaust manifold

(see Turbocharger Removal in this section).

B. Support exhaust manifold to prevent it from falling.

C. Secure turbocharger to exhaust manifold (see

Turbocharger Installation in this section).

3. Install muffler and/orexhaust tube to the engineusing Figure 8 as a guide. Torque exhaustclamp (item1)

from 50 to 70 in--lb (5.7 to 7.9 N--m).

4. After exhaust system assembly, check that tailpipe

is approximately parallel to the ground. Loosen clamp

and adjust tailpipe if necessary.

5. Install and secure side panel to right side of frame.

6. Lower and secure hood.

Antiseize

lubricant

4

1

2

Diesel

Engine

C. Removeeight(8)flangehead screwsthatsecure

exhaustmanifoldtocylinderhead.Removemanifold

from engine.

D. Remove and discard manifold gasket. Clean

mating surfaces of cylinder head and manifold.

6. Ifexhaustopeningsaretobeleftopenfor any length

oftime,coveropeningstopreventanymaterialfromfalling into openings.

Installation (Fig. 8)

NOTE: Makesure all exhaust systemsealingsurfaces

are free of debris or damage that may prevent a tight

seal.

1. Removeallcoversandplugsthatwereplacedduring

removal to prevent contamination entry.

2. Installexhaustmanifoldtoengineifremoved(Fig.9):

A. Apply antiseize lubricant to threads of flange

head screws used to secure exhaust manifold.

33 ft--lb

(45 N--m)

3

1. Exhaust manifold

2. Manifold gasket

4

8

6

Figure 9

1

2

Figure 10

3. Engine

4. Flange screw (8 used)

5

3

7

Groundsmaster 5900/5910 Page 3 -- 11 Diesel Engine

Page 30

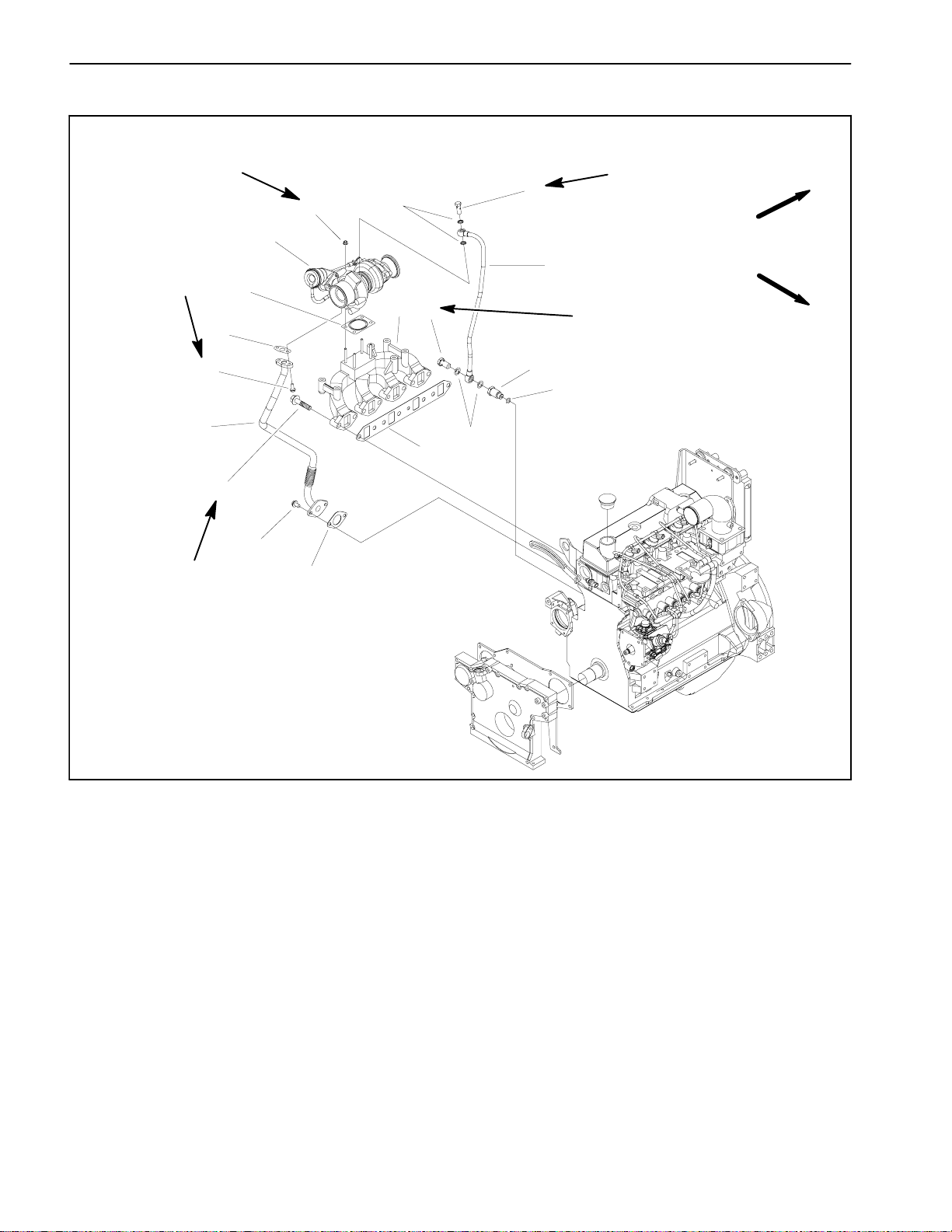

Turbocharger

22 ft--lb

(30 N--m)

18 ft--lb

(24 N--m)

33 ft--lb

(45 N--m)

15

16

17

14

18

13

18 ft--lb

2

4

1

5

6

7

3

(24 N--m)

FRONT

RIGHT

18 ft--lb

(24 N--m)

9

10

8

11

12

1. Turbocharger assembly

2. Flange nut (4 used)

3. Banjo bolt

4. Sealing washer

5. Oil supply tube

6. Exhaust manifold

7. Banjo bolt

Figure 11

8. Sealing washer

9. Coupling

10. O--ring

11. Exhaust manifold gasket

12. Gasket

13. Flange head screw(2 used)

14. Flange head screw(8 used)

15. Oil drain tube

16. Flange head screw(2 used)

17. Gasket

18. Turbocharger gasket

Groundsmaster 5900/5910Page 3 -- 12Diesel Engine

Page 31

Removal (Fig. 11)

CAUTION

9. Carefully lift turbocharger from exhaust manifold.

10.Cover engine, air cleaner and turbocharger openings to prevent any material from falling into openings.

Also, plug openings in oil supply and drain lines.

The engine and exhaust system may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before working on the

turbocharger.

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood to allow access to engine.

3. Thoroughly clean turbochargerareatoprevent contaminants from entering engine.

4. Loosen clamps that secure exhaust tube to turbocharger outletand muffler inlet. Remove exhaust tube.

5. Loosen clamps that secure air intake tube to turbocharger inlet and air cleaner outlet. Remove air intake

tube.

6. Remove two (2) cap screws that secure oil drainline

to turbocharger. Separateoil drainline fromturbocharger.

7. Remove banjo bolt that secures oil supply line to

turbocharger. Separate oil supply line from turbocharger.

8. Removefour(4)nuts thatsecureturbochargertoexhaust manifold.

Installation (Fig. 11)

NOTE: Makesuremufflerflangeand exhaust manifold

sealing surfaces are free ofdebris or damage that may

prevent a tight seal.

1. Install newgaskets if original gasket wasdamaged.

2. Removeallcoversandplugsthatwereplacedtoprevent contamination entry.

3. Position turbocharger to exhaust manifold and secure with four (4) nuts. Torque nuts 22 ft--lb (30 N--m).

4. Positionoildrainlinetoturbochargerandsecurewith

two (2) cap screws. Torque screws 18 ft--lb (24 N--m).

5. Pour clean engine oil into oil supply line port to ensure turbocharger lubrication on start--up.

6. Position oil supply line to turbocharger and secure

with banjo bolt. Torque banjo bolt 18 ft--lb (24 N--m).

7. Fit air intake tube to turbochargerinletandaircleaner outlet. Secure intake tube with clamps.

8. Fit exhaust tube to turbocharger outlet and muffler

inlet. Secure exhaust tube with clamps.

9. Lower and secure hood.

Diesel

Engine

Groundsmaster 5900/5910 Page 3 -- 13 Diesel Engine

Page 32

Fuel Tank

RIGHT

11

10

12

14

13

19

17

18

16

15

1

2

20

21

3

5

22

21

4

9

21

6

5

7

8

FRONT

1. Fitting cover

2. Screw (3 used)

3. Fuel supply standpipe

4. Fuel return standpipe

5. Bushing (2 used)

6. Elbow fitting

7. Bushing

8. Fuel tank

9. Fuel hose (2 used)

10. Flange nut (2 used)

11. Tank hold down

12. Flange head screw(2 used)

13. Clamp (2 used)

14. Cap

15. Plug (4 used)

DANGER

Becausedieselfuelishighly flammable,usecaution when storing or handling it. Do not smoke

while filling the fuel tank. Do not fill fuel tank

while engine is running, hot or when machine is

in an enclosedarea. Always fill fueltank outside

and wipe up any spilled diesel fuel before starting the engine. Store fuel in a clean, safety--approved container and keep cap in place. Use diesel fuelas an engine fuel only; not for any other

purpose.

Figure 12

16. Gasket

17. Fuel sender

18. Lock washer (5 used)

19. Screw (5 used)

20. Fuel hose

21. Worm clamp (3 used)

22. Fuel hose

Check Fuel Lines and Connections

Checkfuellinesand connections periodically asrecommendedintheOperator’s Manual. Check lines for deterioration,damage, leaks or loose connections.Replace

hoses, clamps and connections as necessary.

Drain and Clean Fuel Tank

Drain and clean the fuel tank periodically as recommendedintheOperator’sManual.Also,drain and clean

the fuel tank if the fuel system becomes contaminated

or if themachineis to bestoredfor an extendedperiod.

To clean fuel tank, flush tank out with clean diesel fuel.

Make sure tank is free of contaminates and debris.

Groundsmaster 5900/5910Page 3 -- 14Diesel Engine

Page 33

Fuel Tank Removal (Fig. 12)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Chock rear wheels and jack up front of machine.

Support machine on jack stands. Remove front, left

wheel to allow fuel tank removal.

3. Useafueltransferpumptoremovefuelfromthefuel

tank and into a suitable container.

4. Removethree(3) socketheadscrews thatsecurefitting cover (item 1) to fuel tank. Remove fitting cover.

5. Disconnect power (blue/red) and ground (black)

wires from the fuel sender on the fuel tank (Fig. 13).

5. Using labels placed during tank removal, correctly

connect fuel hoses to thefuel supply standpipe, the return standpipe andthevent elbow fitting.Secure hoses

with hose clamps.

6. Connect electrical wiring to the fuel sender.

A. Connect blue/red wireto the centerterminal and

black wire to any of the screws that secure the fuel

sender to the fuel tank.

B. Apply skin--over grease (ToroPartNo.505--165)

to the wire terminal connections.

7. Position fitting cover to fuel tank and secure with

three (3) socket head screws.

6. Labelfuelhosestoassure properassembly.Disconnect fuel hosesfrom the fuelsupply standpipe (item 3),

the return standpipe (item 4) and the vent elbow fitting

(item 6) in top of tank (Fig. 13).

7. Route fuel lines from under clamps (item 13) that

route fuel lines from standpipes. If necessary, remove

plugs and clamps from top of tank.

8. Remove two (2) flange head screws and lock nuts

that secure tankhold down (item11) to frame.Remove

tank hold down.

9. Slide fuel tank from left side of machine to remove

tank.

10.If necessary, remove standpipes, elbow bushings

and fuel sender from fuel tank.

Fuel Tank Installation (Fig. 12)

1. If removed, install standpipes, elbow bushings and

fuel sender into fuel tank.

2. Install fuel tank from left side of machine.

WARNING

Failure to maintain proper torque couldresultin

failureorlossof wheel andmayresultin personal injury.

8. Install front, left wheel assembly.

9. Lower machine to ground. Torque wheel lug nuts in

a crossing pattern from70 to 90 ft--lb (95 to 122N--m).

10.Fill fuel tank.

4

5

1

6

2

3

Diesel

Engine

3. Position tank hold down (item 11) to fuel tank and

machine frame. Secure hold down with two (2) flange

head screws and lock nuts.

1. Sender power wire

2. Sender ground wire

3. Fuel sender

Figure 13

4. Fuel supply hose

5. Return fuel hose

6. Vent hose

4. Route fuel supplyand return hosesunder clamps in

top of tank.

Groundsmaster 5900/5910 Page 3 -- 15 Diesel Engine

Page 34

Radiator

Thread Sealant

RIGHT

FRONT

29

50 to 70 in--lb

(5.7 to 7.9 N--m)

14

33

15

38

33

25

31

13

21

34

39

37

6

35

25

31

1

24

26

33

32

28

30

2

23

26

2

3

36

4

5

31

25

27

8

6

7

10

22

31

25

18

11

9

10

12

15

14

16

20

17

19

50 to 70 in--lb

(5.7 to 7.9 N--m)

40

1. Radiator assembly

2. Flange nut (4 used)

3. Support plate (2 used)

4. Flange nut (4 used)

5. Rubber pad (4 used)

6. Hose clamp (3 used)

7. Upper radiator hose

8. Overflow hose

9. Hose clamp

10. Worm clamp (5 used)

11. Barb fitting

12. Drain cock fitting

13. Fan shroud

14. Air intake tube (4 used)

15. Hose clamp (8 used)

16. Tube

17. Coolant reservoir

18. Grommet (2 used)

19. Lock nut (2 used)

20. Hose

21. Cap screw (4 used)

22. Hose

23. Radiator cap

24. Support rod

25. Flat washer (10 used)

26. Flange nut (4 used)

27. Hose sleeve

Removal (Fig. 14)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise andsupport hoodto allow access to radiator.

Figure 14

28. Cap screw (2 used)

29. Tube

30. Washer (4 used)

31. Flange nut (14 used)

32. Clamp (2 used)

33. Carriage screw (14 used)

34. Lower radiator hose

35. Fan motor bracket

36. Fitting

37. Coolant level sensor

38. Cap screw (2 used)

39. Reservoir cap

40. Flat washer (2 used)

3. Rotate clamps that secure oil cooler to radiator

frame. Tilt oil cooler toward rear of machine.

4. Loosenhoseclampsanddisconnect airintaketubes

(item14) from the charge air cooler.

5. Disconnectwireharnessconnectorfromcoolantlevel sensor on right side of radiator.

Groundsmaster 5900/5910Page 3 -- 16Diesel Engine

Page 35

CAUTION

6. Connect air intake tubes (item14) to the charge air

cooler and secure with hose clamps. Torque clamps

from 50 to 70 in--lb (5.7 to 7.9 N--m).

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolantproperly, orstore it in aproperly

labeled container away from children and pets.

6. Drain radiatorinto a suitable container using the radiator drain. The radiator drain is located near the hydraulic 4WD manifold (Fig. 15).

7. Loosenhoseclampsand disconnect upper and lower coolant hoses (item 6) from the radiator.

8. Loosen hose clampthat secures coolant drainhose

tofitting(item 36)onbottomofradiator.Removecoolant

drain hose assembly from radiator.

9. Disconnectreservoirhose(item22)fromtheradiator

vent tube.

10.Detach radiator from the fan shroud and support by

removingtwo(2) carriagescrews(item33),flatwashers

and flange nuts.

7. Connect wire harness connector to coolant level

sensor on right side of radiator.

8. Install coolant drain hose assemblytoradiatorfitting

and secure with hose clamp.

9. Connectreservoirhose(item22)totheradiator vent

tube and secure with hose clamp.

10.Make sure radiator drain is closed. Fill radiatorwith

coolant.

11.Secure oil cooler to radiator frame.

12.Run engine and check for any coolant leaks.

13.Lower and secure hood.

3

1

Diesel

Engine

11.Tilt radiator and charge air cooler assembly toward

rearof machine and carefully lift assembly fromthe machine.

12.Plug all radiator and hoseopenings to prevent contamination.

13.Inspect rubber pads (item 5) at bottom of radiator.

Replace pads if worn or damaged.

14.Disassemble radiator and charge air cooler assembly as needed using Figure 16 as a guide.

Installation (Fig. 14)

1. Assemble radiator and charge air cooler assembly

as needed using Figure 14 as a guide. Apply thread

sealant to coolant level sensor if it was removed.

2. Remove plugs from radiator and hoses placed during the removal procedure.

3. Carefully lower radiator and charge air cooler assembly into the machine.

4. Attach radiator to the fan shroud and support with

two (2) carriage screws, flat washers and flange nuts.

1. Radiator hose

2. Radiator drain

5

6

2

Figure 15

3. Air intake tube

4

3

2

1

5. Connect upper and lower coolant hoses (item 6) to

the radiator. Secure hoses with hose clamps.

1. Radiator

2. LH cooler bracket

3. Charge air cooler

Figure 16

4. Pin clip (8 used)

5. Pin (8 used)

6. RH cooler bracket

Groundsmaster 5900/5910 Page 3 -- 17 Diesel Engine

Page 36

Alternator

FRONT

23 ft--lb

(31 N--m)

RIGHT

49 ft--lb

(66 N--m)

3

11

5

1

12

6

7

8

10

13

4

4

9

2

1. Alternator

2. Front cover

3. Belt

4. Bevel washer (2 used)

5. Flange head screw

Figure 17

6. Flat washer

7. Hex nut

8. Flange head screw (2 used)

9. Alternator bracket

10. Cap screw

11. Water pump

12. Adjusting bracket

13. Alternator bracket

Groundsmaster 5900/5910Page 3 -- 18Diesel Engine

Page 37

Removal (Fig. 17)

Installation (Fig. 17)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood to allow access to engine.

3. Remove battery accesspanel. Disconnect negative

battery cable first and then positive battery cable (see

Battery Removal in the Service and Repairs section of

Chapter 5 -- Electrical System).

4. Loosen flange head screw (item 5) that secures alternator to adjusting bracket. Rotate alternator toward

enginetoloosendrivebelt.Removebeltfromalternator

pulley.

5. Inspect drive belt for glazing or damage. Replace

belt if necessary.

6. For assemblypurposes, labelall wires that connect

toalternator.Disconnect wiresfromalternatorterminals

and position wires away from alternator.

7. Support alternator to prevent it from shifting or falling.

1. Position alternator to engine brackets.

2. Secure alternator to mounting brackets and adjust-

ingbracketwithremovedfastenersandwashers.Donot

fully tighten fasteners.

3. Place drivebelt on alternator pulley. Rotate alterna-

tor away from engine to properly tension drive belt.

4. Tighten screws to secure alternator. Torque cap

screw at mounting bracket (item 10) to 49 ft--lb (66

N--m). Torque flange head screw at adjusting bracket

(item 5) to 23 ft--lb (31 N--m).

5. Using labels placed during alternator removal, cor-

rectly connect all wires to alternator terminals.

6. Connectpositivebatterycable topositivebatteryter-

minal.Then,connectnegativebatterycable tonegative

battery terminal (see Battery Installation in the Service

and Repairs section of Chapter 5 -- Electrical System).

Install battery access panel.

7. Lower and secure hood.

Diesel

Engine

8. Remove flange head screw andflat washer thatsecure alternator to adjusting bracket (item 12). Remove

cap screw, two (2) bevel washers and hex nut that secure alternator to mounting brackets (items 9 and 13).

9. Carefully remove alternator from engine and machine.

Groundsmaster 5900/5910 Page 3 -- 19 Diesel Engine

Page 38

Starter Motor

32 ft--lb

(43 N--m)

FRONT

RIGHT

1

2

3

Figure 18

1. Engine 2. Starter motor 3. Flange head screw (2 used)

Groundsmaster 5900/5910Page 3 -- 20Diesel Engine

Page 39

Removal (Fig. 18)

Installation (Fig. 18)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood to allow access to engine.

3. Remove battery accesspanel. Disconnect negative

battery cable first and then positive battery cable (see

Battery Removal in the Service and Repairs section of

Chapter 5 -- Electrical System).

4. Label all wires that connect to starter for assembly

purposes. Disconnect wiresfrom starter terminals.and

position away from starter (Fig. 19).

A. Removenutand lockwasherthatsecurecableto

starter stud. Remove cable from starter stud.

B. Loosen screw used to secure harness blue wire

to starter solenoid. Unplug wire from starter.

5. Support starter to prevent it from shifting or falling.

6. Remove two (2) flange head screws that secure

starter to engine.

1. Position starter to engine housing.

2. Secure starter to engine with two (2) flange head

screws. Torque screws 32 ft--lb (43 N--m).

3. Using labels placed during removal, correctly con-

nect and secure removed wires to starter terminals.

4. Connectpositivebatterycable topositivebatteryter-

minal.Then,connectnegativebatterycable tonegative

battery terminal (see Battery Installation in the Service

and Repairs section of Chapter 5 -- Electrical System).

Install battery access panel.

5. Lower and secure hood.

2

1

3

Diesel

Engine

7. Carefully remove starter from engine and machine.

1. Starter stud

2. Starter solenoid

Figure 19

3. Screw

Groundsmaster 5900/5910 Page 3 -- 21 Diesel Engine

Page 40

V alve Cover

80 in--lb

(9 N--m)

3

4

2

5

FRONT

RIGHT

6

7

1

1. Engine

2. Valve cover

3. Lock nut (3 used)

Figure 20

4. Flat washer (3 used)

5. Isolation washer (3 used)

6. Oil fill cap

7. Valve cover gasket

Groundsmaster 5900/5910Page 3 -- 22Diesel Engine

Page 41

Removal (Fig. 20)

Installation (Fig. 20)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood to allow access to engine.

3. Thoroughly clean valve cover and cylinder head to

prevent contaminant entry into engine.

4. Remove crankcase breather tube from valve cover

(see Engine Breather Removal in this section).

5. Removethree(3)locknuts, flatwashersandisolator

washers.

6. Remove valve cover from cylinder head. Remove

and discard valve cover gasket.

1. Position new gasket and valve cover to cylinder

head.

2. Secure valve cover to cylinder head with three (3)

isolatorwashers,flatwashersandlocknuts.Torquelock

nuts 80 in--lb (9 N--m).

3. Connectcrankcasebreathertubetovalve cover and

secure with hose clamp (see Engine Breather Installation in this section).

4. Check engine oil level and add oil if necessary.

5. Lower and secure hood.

Diesel

Engine

Groundsmaster 5900/5910 Page 3 -- 23 Diesel Engine

Page 42

Engine Breather System

FRONT

RIGHT

15

16

15

14

12

11

13

10

17

12

8

7

9

6

5

4

2

3

1

1. Hose

2. Hose clamp

3. Spacer

4. Breather mount plate

5. Cap screw (2 used)

6. Breather

Figure 21

7. Breather outlet hose

8. Latch plate

9. Hose clamp

10. Breather inlet hose

11. Hose clamp

12. Hose clamp

13. Breather hose

14. Hose barb

15. Hose

16. Check valve

17. Worm clamp

Groundsmaster 5900/5910Page 3 -- 24Diesel Engine

Page 43

Removal (Fig. 21)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood to allow access to engine.

3. Clean breather components before removal to prevent contaminant entry into breather system.

4. Remove breather components as necessary using

Figure 21 as a guide.

Installation (Fig. 21)

1. Install removed breather components using Figure

21 as a guide. If removed, make sure that check valve

(item 16) is installed with black side toward the engine

oil pan (Fig. 22).

2. Lower and secure hood.

FROM BREATHER

1

2

TOWARD ENGINE

Figure 22

1. Base (gray) 2. Cover (black)

Diesel

Engine

Groundsmaster 5900/5910 Page 3 -- 25 Diesel Engine

Page 44

Thermostat

1. Water pump

2. Seal

6

5

4

3

2

14 ft--lb

(19 N--m)

1

Figure 23

3. Thermostat

4. Gasket

5. Thermostat housing

6. Flange head screw (2 used)

Removal (Fig. 23)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood to allow access to engine.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolantproperly, orstore it in aproperly

labeled container away from children and pets.

3. Draincoolantfrom radiatorandengine (seeRadiator

Removal in this section).

4. Remove upper coolant hose from thermostat housing.

5. Removetwo(2)flangeheadscrewsthatsecurethermostat housing to water pump. Remove thermostat

housing.

6. Removethermostatand sealfromwater pumphousing.

7. Clean gasket surfaces of pump and thermostat

housing.

8. Inspect thermostat sealing areas in pump housing.

Thoroughly clean sealing surfaces if any corrosion or

debris buildup is evident.

Thermostat Testing

1. Remove the thermostat (see Water Pump, Hose,

Pipe and Thermostat Removal and Installation).

2. Suspendthethermostat andathermometerinacontainerofwater(Fig. 24). Foraccuratetestresults,donot

allowthethermostator thermometer to contact the container.

Groundsmaster 5900/5910Page 3 -- 26Diesel Engine

Page 45

3. Slowly heat the waterandstir water to allowuniform

watertemperature.Noteandrecord the temperaturefor

the following:

A. The thermostat should start to open at 180

o

C).

(82

o

F

B. The thermostat should be fully open (0.315” (8

o

mm) lift) at 203

F(95oC).

4. If the thermostat fails to open,only partiallyopensor

sticks, it should be replaced.

Installation (Fig. 23)

1. Installseal andthermostatintowaterpumphousing.

2. Position thermostat gasket and housing to water

pump housing. Secure thermostat housingwith two (2)

flange head screws. Torque screws 14 ft--lb (19 N--m).

3. Installuppercoolanthoseto thermostathousingand

secure with hose clamp.

4. Fill cooling system with coolant.

5. Run engine and check for any coolant leaks.

6. Lower and secure hood.

Figure 24

Diesel

Engine

Groundsmaster 5900/5910 Page 3 -- 27 Diesel Engine

Page 46

Water Pump

FRONT

RIGHT

23 ft--lb

(31 N--m)

3

14 ft--lb

(19 N--m)

8

14

5

11

6

13

10

4

1

7

9

12

2

1. Flange head screw (4 used)

2. Water pump pulley

3. Belt

4. Flange head screw

5. Flange head screw (2 used)

Figure 25

6. O--ring

7. Gasket

8. Thermostat housing

9. Flange head screw (3 used)

10. Water pump

11. Thermostat

12. Front cover

13. Seal

14. Gasket

Groundsmaster 5900/5910Page 3 -- 28Diesel Engine

Page 47

Removal (Fig. 25)

Installation (Fig. 25)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2. Raise and support hood to allow access to engine.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolantproperly, orstore it in aproperly

labeled container away from children and pets.

3. Draincoolantfrom radiatorandengine (seeRadiator

Removal in this section).

4. Disconnect wire harness connector from temperature sensor on water pump housing (Fig. 26).

5. Remove upper andlower radiator hoses from water

pump.

1. Make sure that gasket surfaces on engine, water

pump and thermostat housing are thoroughly cleaned.

2. PositionnewO--ringandgaskettowaterpumphous-

ing.

3. Secure water pump to engine with four (4) cap

screws.

4. Ifpulleywas removedfromwaterpumpshaft,secure

pulley with four (4) cap screws. Torque cap screws 23

ft--lb (31 N--m).

5. If thermostatwas removedfrom waterpump, install

thermostat to water pump (see Thermostat Installation

in this section).

6. Install upper and lower radiator hoses to water

pump. Secure hoses with hose clamps.

7. On Groundsmaster 5910 machines:

A. Install and secure cab heater hoses to water

pump.

B. Install and adjust A/C compressor drive belt.

Diesel

Engine

6. On Groundsmaster 5910 machines:

A. Remove cab heater hoses from water pump.

B. Remove A/C compressor drive belt.

7. Remove alternator and drive belt from engine (see

Alternator Removal in this section).

8. Removefour(4)capscrewsthatsecurewaterpump

to engine.

9. Carefully remove water pump from engine.

10.Remove and discard O--ring and gasket from be-

tween water pump and engine.

11.If necessary, remove thermostat from water pump

(see Thermostat Removal in this section). Make sure

that gasket surfaces on water pump and thermostat

housing are thoroughly cleaned.

12.If necessary, remove pulley from water pump.

A. Removefour(4)capscrewsthatsecurepulleyto

pump shaft.

8. Connect wire harness connector to temperature

sensor on water pump (Fig. 26).

9. Install alternator and drive belt toengine (seeAlternator Installation in this section). Adjust drive belt.

10.Fill cooling system with coolant.

11.Run engine and check for any coolant leaks.

12.Lower and secure hood.

1

2

Figure 26

1. Water pump 2. Temperature sensor

B. Pull pulley from pump shaft.

Groundsmaster 5900/5910 Page 3 -- 29 Diesel Engine

Page 48

Front Cover

FRONT

RIGHT

49 ft--lb

(66 N--m)

10

15

14

23 ft--lb

(31 N--m)

5

6

12

7

8

13

4

4

9

3

1

1. Belt

2. Front cover

3. Water pump pulley

4. Bevel washer (2 used)

5. Flange head screw

6. Flat washer

7. Hex nut

11

18

274 ft--lb

(372 N--m)

19

Figure 27

8. Flange head screw (2 used)

9. Alternator bracket

10. Water pump assembly

11. Crankshaft pulley with tone wheel

12. Adjusting bracket

13. Alternator bracket

17

16

2

24 ft--lb

(32 N--m)

14. Cap screw

15. Alternator

16. Flange head screw

17. Oil pan

18. Mounting plate

19. Cap screw

Groundsmaster 5900/5910Page 3 -- 30Diesel Engine

Page 49

Removal (Fig. 27)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parkingbrake andremove

key from the ignition switch.

2

4

2. Raise and support hood to allow access to engine.

3. Loosen screws that secure alternator to mounting

brackets and rotate alternator toward engine to loosen

drive belt. Remove belt frommachine.

4. On Groundsmaster 5910 machines, remove A/C

compressor drive belt.

5. Removeelectricalcomponents fromfrontcover(Fig.

28):

A. Remove screws that secure electrical harness

clamps to front cover.

B. Removescrewsthat securecrankshaftandcam-

shaft position sensors to front cover.

C. Carefullypulltwo(2)sensorsfromfront cover.In-

spect O--rings onsensors andreplace if necessary.

D. Position wire harness and sensors away from

front cover.

6. Remove five (5) flange head screws that secure oil

pantofrontcover (see Oil Pan Removal in this section).

4

3

1. Crankshaft sensor

2. Camshaft sensor

3. Tone wheel

6

Figure 28

5

5

4. Harness clamp

5. Crankshaft pulley

1

4

1

Diesel

Engine

7. Remove lock nutandthrustwasher that securerear

axlepivotshaft to frame. Slide pivot shaft towardrearof

machine toallow clearance for engine pulley bolt to be

removed (see Rear Axle Removal in the Service and

Repairs section of Chapter 6-- Axles, Planetaries and

Brakes).

8. Remove crankshaft pulley (Fig. 28):

IMPORTANT: When removing crankshaft pulley,

take care to not damage tone wheelthat is secured

to back of pulley.

A. Useappropriateholding tool topreventthepulley

and engine crankshaft from rotating.

B. Loosen and remove cap screw and mounting

plate that secure pulley to crankshaft.

C. Slide pulley fromcrankshaft.Locate and retrieve

woodruff key from crankshaft.

IMPORTANT: Three (3) different lengths of flange

head screws are used to secure the front cover. To

assist with assembly, note location of screws as

they are removed.

4

14 ft--lb

(19 N--m)

3

2

Figure 29

1. Front cover

2. Flange head screw

3. Flange head screw

4. Oil seal

5. Alternator bracket

6. Flange head screw

9. Removesixteen(16) flangeheadscrewsthatsecure

frontcovertoengine(Fig.29).R otate alternator bracket

away from front cover.

10.Carefully remove front cover from engine.

11.Removesealfromfrontcovertakingcaretonotdamage seal bore in cover.

12.Thoroughly clean all removed components. Make

surethat all sealant is removedfromfrontcoversealing

surfaces.

13.Inspectcrankshaftsurfaceinoilsealareaforanyevidenceof wear or damage.Repairorreplacecrankshaft

if necessary.

Groundsmaster 5900/5910 Page 3 -- 31 Diesel Engine

Page 50

Installation (Fig. 27)

1. Make sure that mounting surfaces on engine, front

cover and oil pan are thoroughly cleaned.

9. Secure electrical components to front cover (Fig.

28):

A. Positionwireharness and sensors to front cover.

2. Fill 50% of theseallip space with grease.UseCummins seal installer tool #3164900 (or equivalent) to

install new oil seal into front cover.

3. ApplyCumminssealant#3164067(or equivalent),to

the front cover mounting surfaces. Make sure to apply

sealant to all engine and oil pan mating surfaces.

4. Carefully install front cover to engine taking care to

not damage the oil seal during assembly.

5. Rotate alternator bracket to front cover.

6. Usingnotestakenduringfrontcoverremovaltoidentify correct screw location, securefront cover to engine

withsixteen(16)flange head screws. Torquescrews14

ft--lb (19 N--m).

7. Secureoilpantofrontcoverwithfive(5)flangehead

screws. Torque screws 14 ft--lb (19 N--m).

8. Install crankshaft pulley:

IMPORTANT: When installing crankshaft pulley,

take care to not damage tone wheelthat is secured

to back of pulley.

A. Place woodruff key into crankshaft slot.

B. Carefully slide pulley onto crankshaft making

suretonotdamageoil sealinfrontcover.Also,make

sure to align keyslot in pulley with woodruff key in

crankshaft.

B. Apply a light film of clean oil to crankshaft and

camshaft position sensorsO-- rings. Carefully install

sensors into front cover and secure with screws.

C. Secure electrical harness clamps to front cover.

10.Secure rearaxlepivot shaft to frame(seeRear Axle

Removal in theServiceand Repairs section ofChapter

6-- Axles, Planetaries and Brakes).

A. Slide axle pivot shaft toward front of machine.

Make sure that that roll pin on pivot shaft is positioned in frame reliefs.

B. Installthrustwasher and locknutontopivotshaft.

C. Tightenlocknut to eliminate any axialmovement

of rear axle.Makesure that axlecanstill pivot freely

after lock nut is tightened.

11.Position drivebelttocrankshaft, water pump andal-

ternator pulleys. Tension belt and tighten alternator

mountingscrews (see Alternator Installation in thissection).

12.On Groundsmaster 5910 machines, install and ad-

just A/C compressor drive belt.

13.Check engine oil level and adjust if necessary.

14.Start engine and check for any oil leakage.

15.Lower and secure hood.

C. Install mounting plate (item 18) and cap screw

(item 19) to pulley and crankshaft.

D. Using an appropriate holding tool to prevent the

pulley and engine crankshaft from rotating, torque

cap screw 274 ft--lb (372 N--m).

Groundsmaster 5900/5910Page 3 -- 32Diesel Engine

Page 51

This page is intentionally blank.

Diesel

Engine

Groundsmaster 5900/5910 Page 3 -- 33 Diesel Engine

Page 52

Oil Pan

14 ft--lb

(19 N--m)

FRONT

RIGHT

1

3

8

7

2

14 ft--lb

(19 N--m)

3

38 ft--lb

(51 N--m)

1. O--ring

2. Flat washer

3. Flange head screw (2 used)

5

6

Figure 30