Toro 56006, 56015, 56022, 56027, 56033 Service Manual

...

FOOTE 3 & 6-SPEED TRANSMISSION REPAIR MANUAL, FICHE WH 5 BLUE

Table of Contents – Page 1 of 2

FOREWORD

SPECIFICATIONS

3-SPEED - DESCRIPTION:

LUBRICATION:

TOLERANCES:

TORQUE VALUE:

6-SPEED DESCRIPTION:

LUBRICATION:

TOLERANCES:

TORQUE VALUES:

TROUBLESHOOTING GUIDE

SHIFTING DIFFICULT

NOISY

JUMPS OUT OF GEAR OR GEAR DOES NOT ENGAGE COMPLETELY

BRAKE NOT EFFECTIVE (6-SPEED)

3-SPEED TRANSMISSION

INTERLOCK SWITCH - DISASSEMBLY

REASSEMBLY

OVERHAUL - DISASSEMBLY

SHIFT FORKS

OUTPUT SHAFT

DRIVE SHAFT

INPUT SHAFT (BEVEL PINION ASSEMBLY)

CLEANING AND INSPECTION

OVERHAUL - REASSEMBLY - INPUT SHAFT

DRIVE SHAFT

OUTPUT SHAFT

SHIFT FORKS

WHEEL HORSE 225287/225608 3-SPEED TRANSMISSION

PARTS LIST -- 3-SPEED TRANSMISSION

FOOTE 3 & 6-SPEED TRANSMISSION REPAIR MANUAL, FICHE WH 5 BLUE

Table of Contents – Page 2 of 2

6-SPEED TRANSMISSION

DISASSEMBLY

BRAKE AND SHIFT LEVER

DRIVE SHAFT

INTERMEDIATE SHAFT

DIFFERENTIAL & AXLES

REVERSE IDLER & SHIFT FORKS

HI-LO SHIFT & INPUT SHAFT

CLEANING AND INSPECTION

REASSEMBLY

INPUT SHAFT

HI-LO SHIFT

SHIFT FORKS

REVERSE IDLER

INTERMEDIATE SHAFT

DIFFERENTIAL & AXLES

DRIVE SHAFT

LUBRICATION

BRAKE

SHIFT LEVER

INPUT SHAFT END PLAY

PARTS LIST -- 6-SPEED TRANSMISSION

WHEEL HORSE 107972/108282 6-SPEED TRANSMISSION

PARTS LIST -- 6-SPEED TRANSMISSION

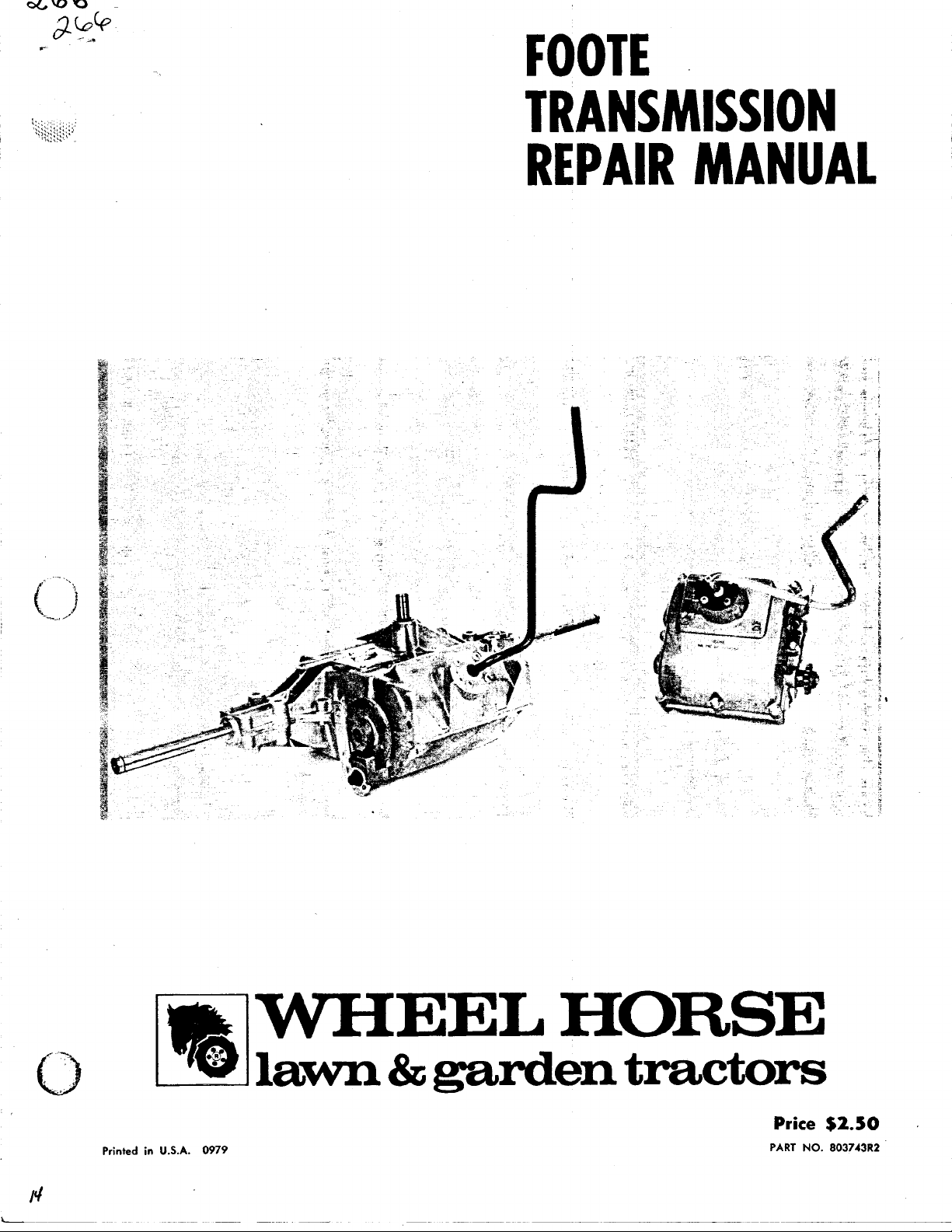

FOOTE

TRANSMISSION

REPAIR

MANUAL

Printed in

U.S.A.

0979

WHEEL

HORSE

Price

PART

NO.

$2.50

803743R2

.

FOREWORD

This

service and repair manual has been compiled to provide

authorized Wheel Horse service personnel with the proper procedures

and techniques for servicing Foote mechanical transmissions as used

in Wheel Horse equipment.

The

following index

all of the sections first to gain a proper understanding of the mechanical

transmission.

The

transmission

strict cleanliness control during all stages

a small amount

the components.

of

lists

all areas covered.

is

a sophisticated piece

of

dirt or other. contamination can severely damage

It

is

advisable to read

of

machinery. Maintain

service and repair. Even

SPECIFICATIONS

TROUBLESHOOTING GUIDE

3-SPEED

TRANSMISSION

INTERLOCK SWITCH

Disassembly

Reassembly

OVERHAUL DISASSEMBLY

Shift Forks

Output Shaft

Drive Shaft

Input Shaft

Cleaning

and Inspection

OVERHAUL REASSEMBLY

Input Shaft

.................................

Driveshaft

Output Shaft

Shift

Forks

EXPLODED VIEW

PARTS

6-SPEED TRANSMISSION

LIST

DISASSEMBLY

Brake and Shift

Driveshaft

Intermediate Shaft

Differential and Axles

Reverse

Idler and Shift Forks

Hi-Lo Shift and Input Shaft

Cleaning

and

inspection

REASSEMBLY

Input Shaft

Hi-Lo Shift

Shift

Forks

Reverse

Idler

Intermediate Shaft

Differential and Axles

Drive Shaft

Lubrication

Brake

Shift Lever

Input Shaft

End

EXPLODED VIEW

PARTS

LIST

Lever

Play

1-9

1-2

1

1-2

2-4

3

3

3

4

4

4-7

5

5

5-6

6-7

a

9

10-1

8

10-12

10

10

11

11

11

11

12

12-15

12

12

12

13

13

13

14

14

14

15

15

17

16 &18

3-SPEED

6-SPEED

DESCRIPTION:

Foote Model

Transmission; three speeds, with reverse

2010-55

or

2010-65

LUBRICATION:

Main Case

grease*

Interlock switch cavity, nylon seat for

light coating, Lubriplate

12

oz

(350

gm),

DS-ES

Shell

TOLERANCES:

Bevel Gear/Pinion backlash

Drive shaft end play

Output shaft end play

Input shaft end play

0-.015

0-.015

in.

0-.012

.010-.020

in.

TORQUE VALUE:

Housing bolts

80-90

in. Ibs.

(9.2-10.4

Sliding Gear

Darina

shift

lever

switch lubricant.

in.

(.4

(.4

mm)

(.3

mm)

in.

(.25-.50

Nm)

"0"

mm)

mm)

DESCRIPTION:

Foote Model

speeds, with reverse

4000-5

Sliding Gear Transmission; six

LUBRICATION:

Main Case

grease

Input Shaft Needle Bearings, Axle Cavities pack

with Exxon Unirex

24

oz.

(700

gm) Shell Darina

*

N-3

grease**

TOLERANCES:

Drive Shaft End Play

Intermediate Shaft End Play

(5.7

mm)

Input Shaft End Play

Axle Shafts Shim for minimum end play without

binding

Brake Air Gap

TORQUE

Housing Case Bolts

Housing Center Support Bolt

Reverse Idler Shaft Bolt

Brake Shoulder Bolt

Shift Fork Screws Back

VALUES:

(11.7-12.8

(9.2-10.4

Apply Loctite

Brake Shoulder Bolt and Shift Fork Screws

Nm)

Nm)

.020-.030

.010-.020

.020

in.

(.5

80-90

80-90

200-250

off

271

(Red) to threads of

in.

.020-.030

in.

mm)

in. Ibs.

100-110

in. Ibs.

in.

lbs.

turn from

(5.7

mm)

in.

(.3-.5

mm)

(9.2-10.4

in. Ibs.

(23.3-29

snug

"0"

Nm)

Nm)

-"--

*Available through Foote

**Available through Foote

Co.

distribution system in

Co.

distribution system in

For name of nearest distributor contact:

Fredrickstown, Ohio

SHIFTING DIFFICULT

Clutch not releasing completely.

Worn shift linkage.

Shifts being made under load or without using

clutch.

Shift forks or shift lever bent.

Broke dragging (6-Speed)

NOISY

Gears worn or damaged.

Improper bevel gear/pinion backlash.

Bearings worn or damaged.

16

oz.

5

oz.

J.

B.

Foote Foundry

P.0.

Box

236

Phone614-694-2055

JUMPS OUT OF GEAR OR GEAR DOES

ENGAGE COMPLETELY

BRAKE

(460

(150

Co.

gm) can order

gm) tube order

P/N

P/N

1866

2801

43019

GUIDE

NOT

Lugs on clutch collars worn or damaged.

Shift forks or shift lever bent.

Detent balls or springs broken or damaged.

Part of vehicle interfering with full travel of shift

lever.

Hi-Lo shift fork broken (6-Speed).

NOT

EFFECTIVE

Friction pucks worn.

Brake air gap too large.

Bent or damaged brake linkage.

Shoulder bolt loose.

(6-Speed)

3-SPEED

TRANSMISSION

INTERLOCK

SWITCH

DISASSEMBLY

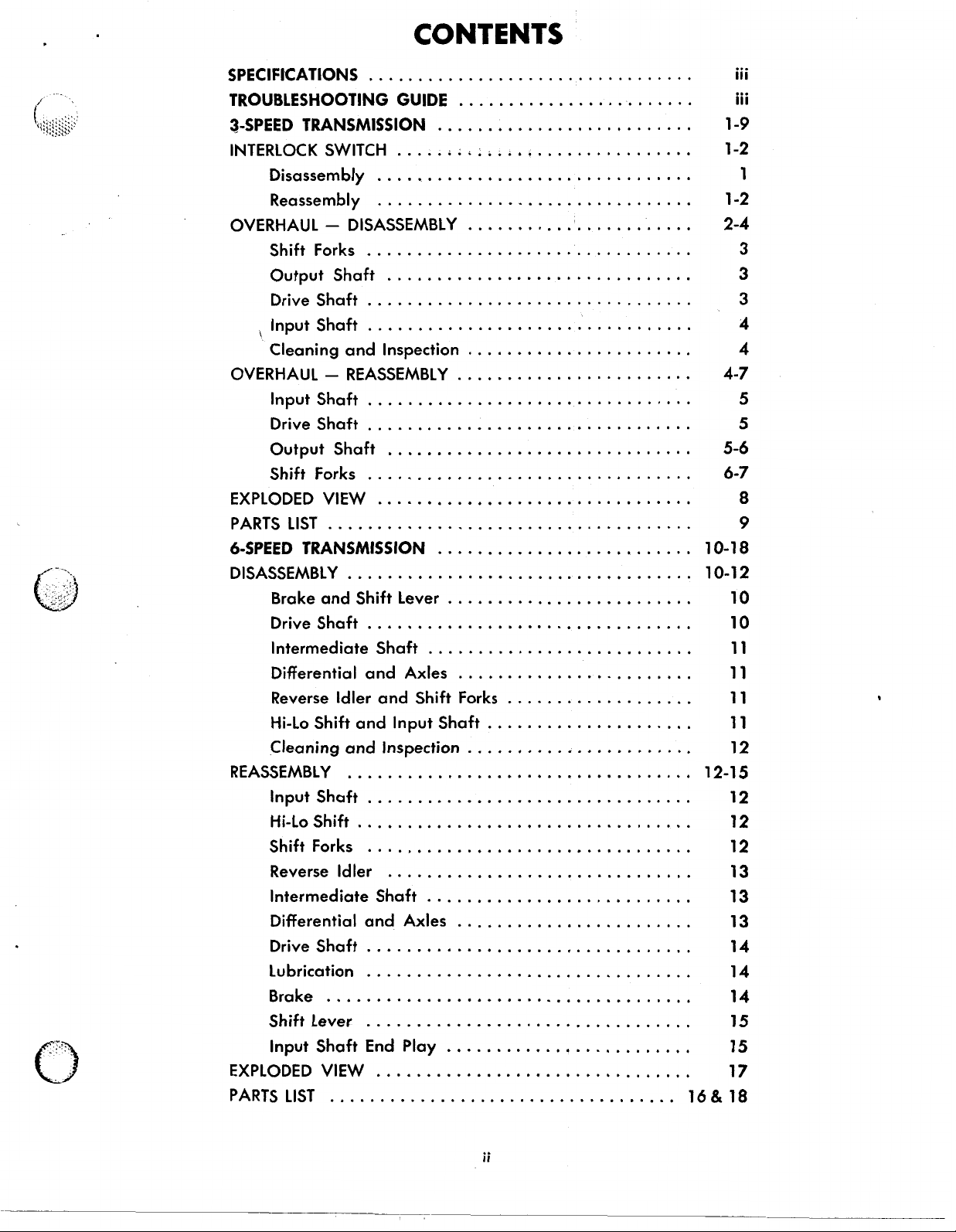

The

main components of the neutral interlock

switch are contained under the nylon cover that

retains the shift stick at the top of the transmission

1).

(Fig.

FIG.

1.

Foote 3-Speed transmission

To

service

neutral

Remove the four Phillips head screws securing the

nylon cover (Fig.

the

switch, shift

If

in the vehicle disconnect electrical wiring.

the

transmission into

2).

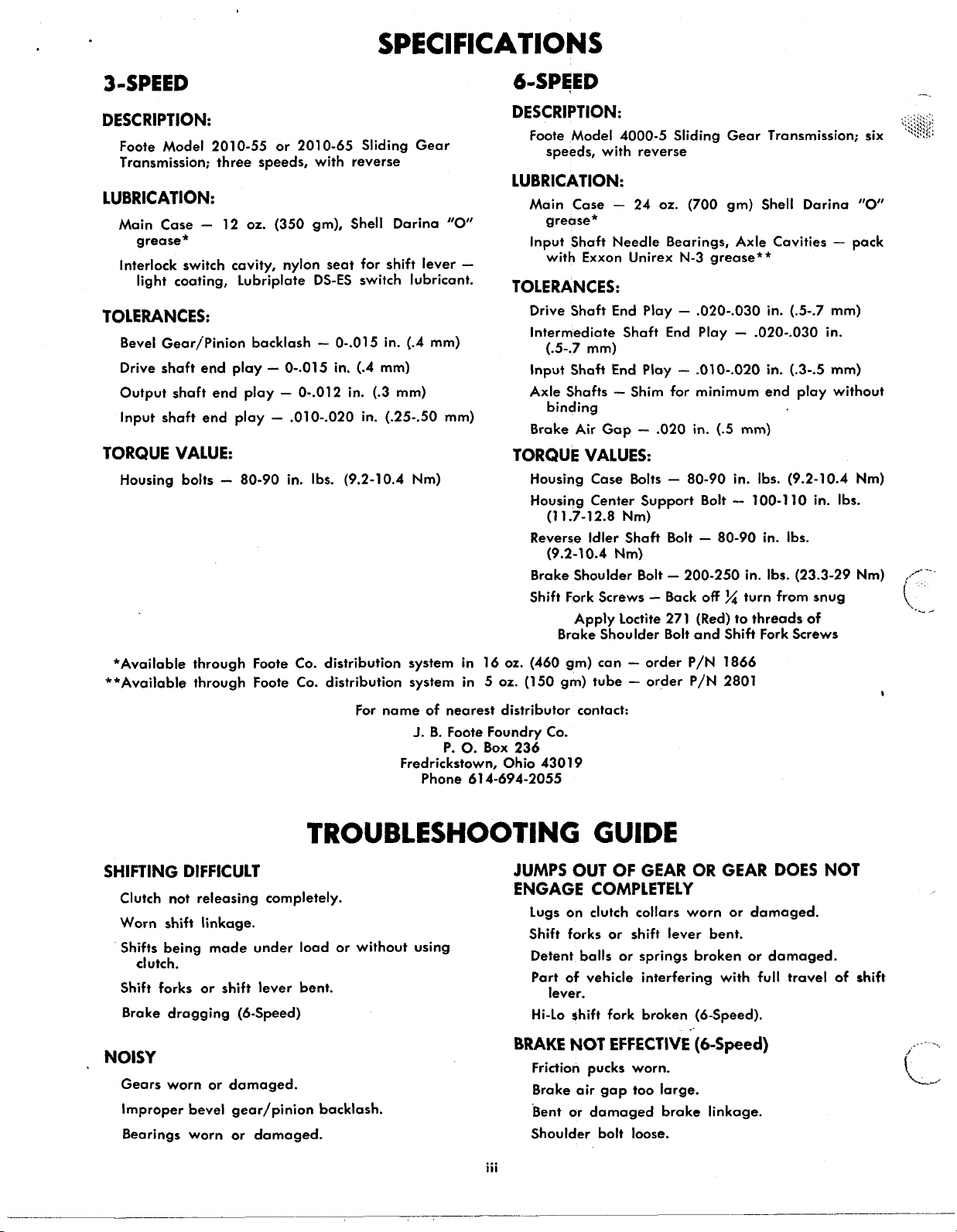

FIG.

3.

Interlock Switch Components

REASSEMBLY

fo

reassemble, drop the detent ball into the hole.

Next, replace the detent pin, with the hollowed side

toward

cant to

able contact bar, spring and housing assembly

bar faces outward.

Compress the contact bar, spring and housing and

install the contact plate

bottom (Fig.

the

ball. Apply a light coating of switch lubri-

the

interlock switch cavity. Install the move-

Be

sure the bar

so

the rivets are toward the

slides

4).

$0

the

freely.

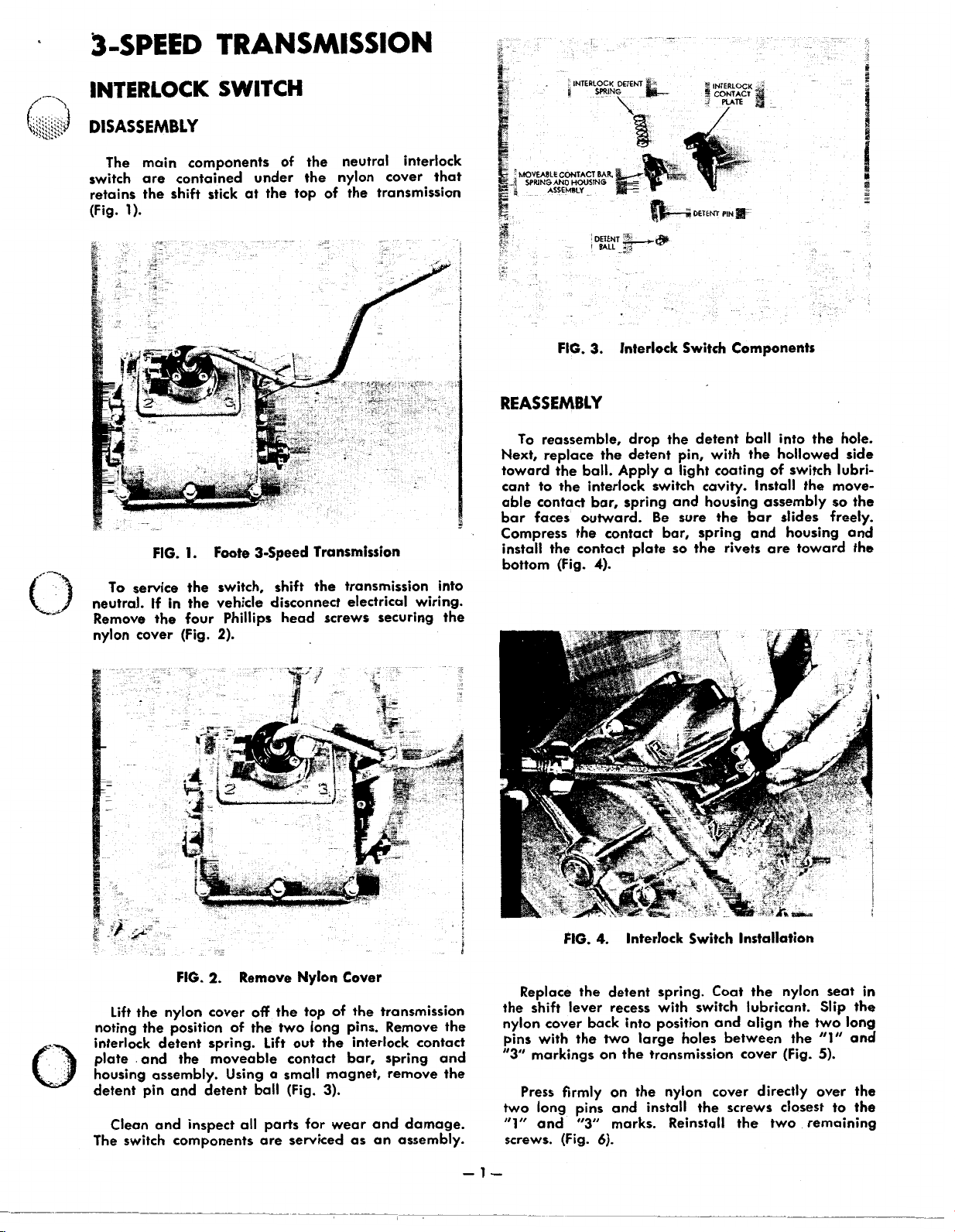

FIG.

2.

Remove Nylon Cover

lift

the nylon cover

noting the position of the

interlock detent spring.

plate .and the moveable contact bar, spring and

housing assembly. Using a small magnet, remove the

detent pin and detent ball (Fig.

Clean and inspect all parts for wear and damage.

The

switch components are serviced as an assembly.

off

the top of

two

lift

out the interlock contact

the

long pins. Remove the

3).

transmission

FIG.

4.

E

Replace

the

shift lever recess with switch lubricant. Slip the

nylon cover back into position and align the two long

pins with the two large holes between the

"3"

markings on the transmission cover (Fig.

Press

two

"1"

screws. (Fig.

the

firmly on the nylon cover directly over the

long pins and install

and

"3"

Interlock Switch Installation

detent spring. Coat the nylon seat in

the

marks. Reinstall the two remaining

screws closest to the

6).

-1-

"1"

5).

and

FIG.

5.

Align Detent Pins

FIG.

6.

Replace Nylon Cover

Check

mission in the neutral position. Continuity should

exist with the transmission in neutral only. Reconnect

the switch wiring and test for proper operation with

the

should only be possible with the shift lever in neutral.

the two leads for continuity with the trans-

transmission in each gear. Starting the engine

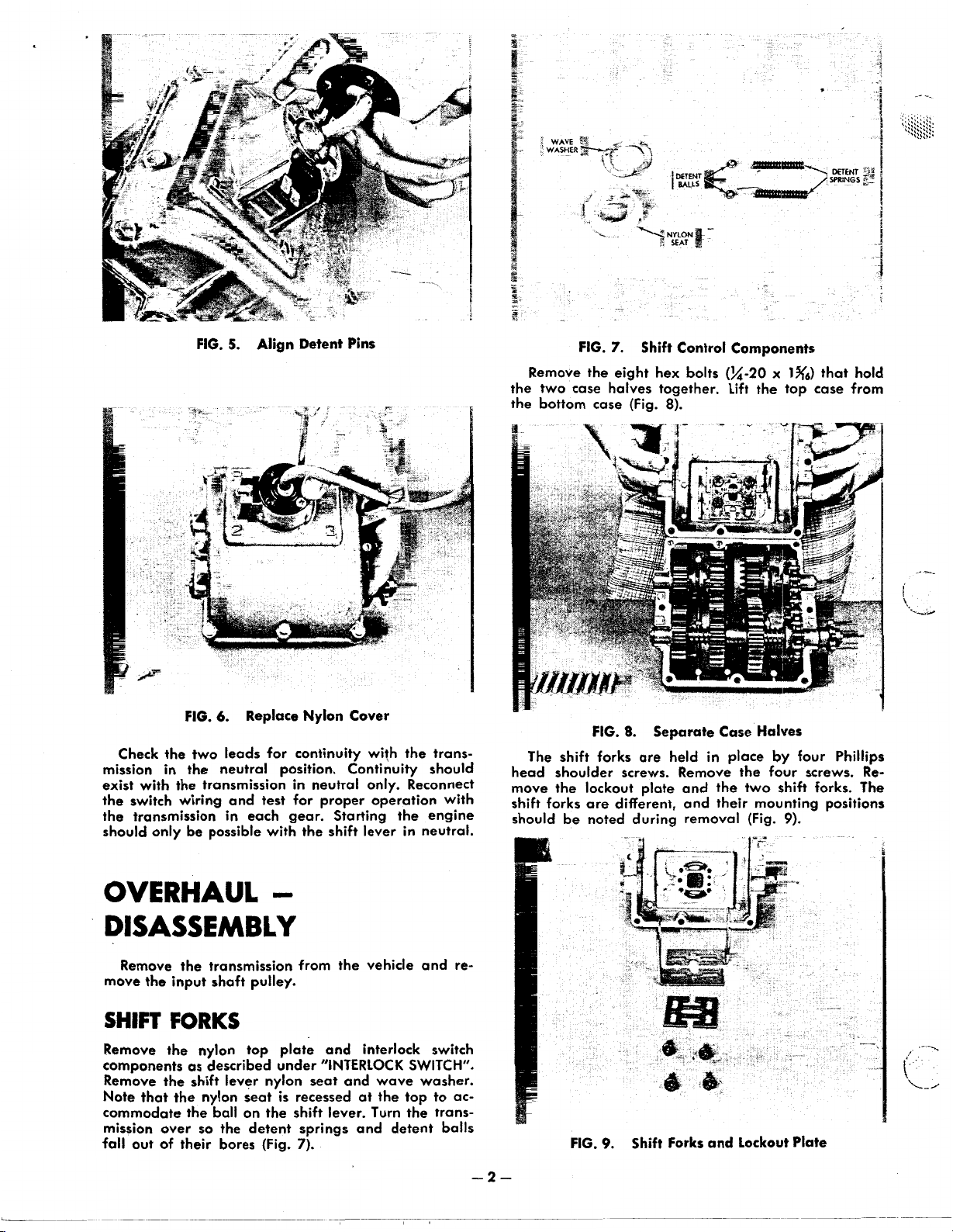

FIG.

7.

Shift Control Components

the

Remove

the

two case halves together.

the bottom case (Fig.

The

shift forks are held in place by four

head shoulder screws. Remove

move the lockout plate and

shift forks are different, and their mounting positions

should be noted during removal (Fig.

eight hex bolts

FIG.

8.

Separate Case Halves

8).

(1/4-20

the

x

Lift

the top case from

the

four screws.

two

shift

9).

1 5/16

that hold

forks. The

Phillips

Re-

OVERHAUL

DiSASSEMBLY

Remove the transmission from the vehicle and re-

move the input shaft pulley.

SHIFT

Remove the nylon top plate and interlock switch

components as described under "INTERLOCK SWITCH".

Remove the shift lever nylon seat and wave washer.

Note that the nylon seat

commodate the ball on the shift lever. Turn the trans-

mission over

fall out of their bores (Fig.

FORKS

so

the detent springs and detent balls

is

recessed at the top to ac-

7).

-2-

FIG.

9.

Shift Forks and Lockout Plate

Loading...

Loading...