Page 1

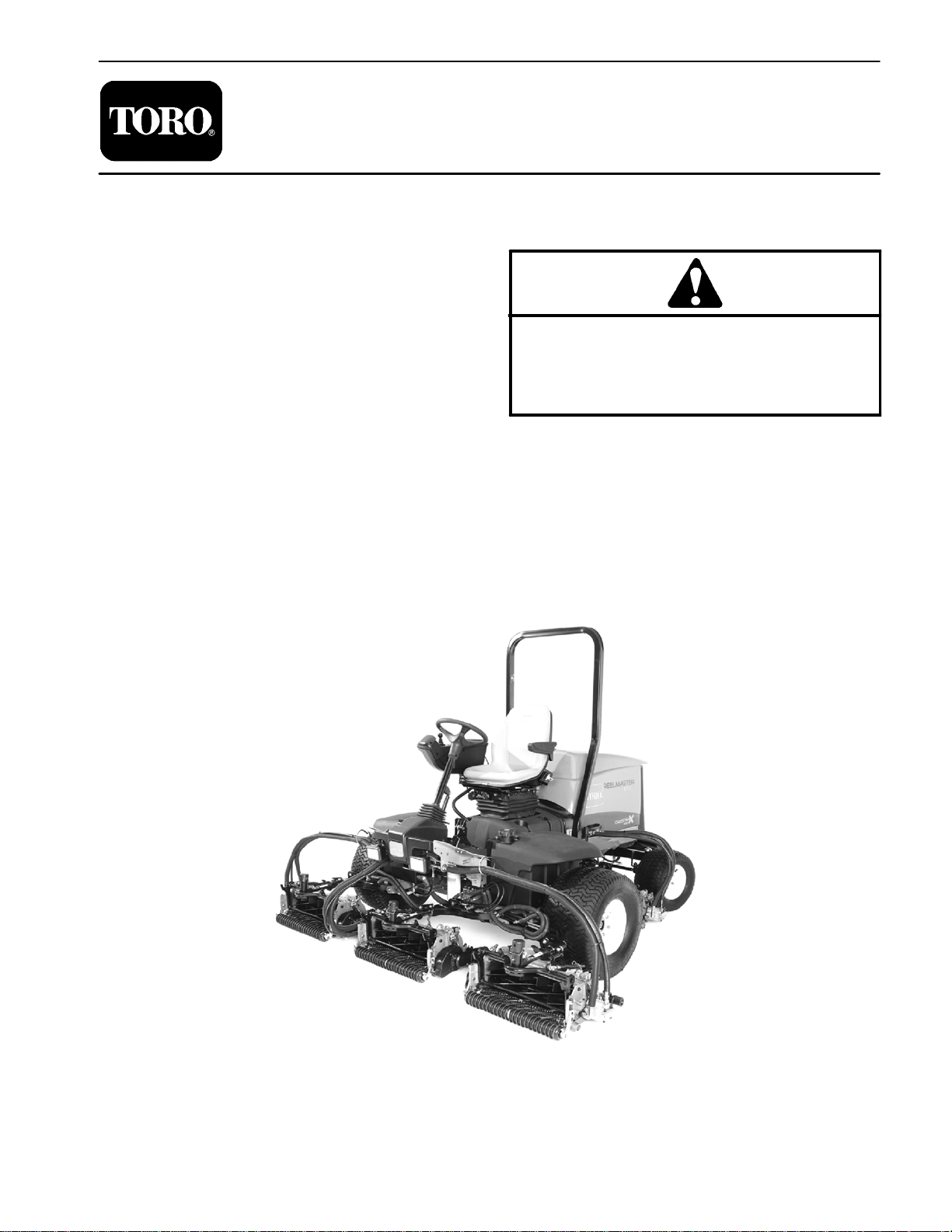

ReelmasterR5210/5410/5510/5610

Preface

The purposeof this publication is to provide theservice

technician with information for troubleshooting, testing,

and repair of major systems and components on the

Reelmaster 5010 series: the 5210, 5410, 5510 and

5610.

REFER TO THE TRACTION UNIT AND CUTTING

UNIT OPERATOR’S MANUALS FOR OPERATING,

MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. Space is provided in Chapter 2 of this book to

insert the Operator’s Manuals and Parts Catalogs for

your machine. Additional copies of the Operator’s

Manual and Parts Catalog are available on the internet

at www.Toro.com.

Part No. 06148SL (Rev. C)

Service Manual

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: ANOTE willgive generalinformation aboutthe

correct operation, maintenance, service, testing or repair of the machine.

TheToroCompanyreserves the right to changeproduct

specifications or this publication without notice.

IMPORTANT: The IMPORTANT notice will give im portantinstructionswhichmust befollowedto prevent damage to systems or components on the

machine.

E The Toro Company -- 2006, 2007, 2009, 2012

Page 2

This page is intentionally blank.

Reelmaster 5010 Series

Page 3

Table Of Contents

SafetyProduct Records

Chapter 1 -- Safety

Safety Instructions 1 -- 2..........................

Jacking Instructions 1 -- 4.........................

Safety and Instruction Decals 1 -- 4................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Kubota Diesel Engine

General Information 3 -- 1........................

Specifications 3 -- 2..............................

Adjustments 3 -- 5...............................

Service and Repairs 3 -- 6........................

KUBOTAWORKSHOPMANUAL:05SERIES DIESEL

ENGINE

Chapter 4 -- Hydraulic System

Specifications 4 -- 2..............................

General Information 4 -- 3........................

Hydraulic Schematics 4 -- 7.......................

Hydraulic Flow Diagrams 4 -- 8....................

Special Tools 4 -- 18.............................

Troubleshooting 4 -- 22...........................

Testing 4 - - 28...................................

Service and Repairs 4 -- 58.......................

SAUER--DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS REPAIR MANUAL

SAUER--DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS SERVICE INSTRUCTIONS

PARKER TORQMOTOR

TM

SERVICE PROCEDURE

(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

EATON DELTA MOTORS PARTS AND REPAIR

MANUAL

SAUER--DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

Chapter 5 -- Electrical System

General Information 5 -- 1........................

Electrical Diagrams 5 -- 1.........................

Special Tools 5 -- 2..............................

Troubleshooting 5 -- 4............................

Electrical System Quick Checks 5 -- 18.............

Adjustments 5 -- 20..............................

Component Testing 5 -- 23........................

Service and Repairs 5 -- 46.......................

Chapter 6 -- Chassis

Specifications 6 -- 2..............................

General Information 6 -- 2........................

Service and Repairs 6 -- 4........................

Chapter 7 -- Cutting Units

Specifications 7 -- 2..............................

General Information 7 -- 3........................

Special Tools 7 -- 4..............................

Factors That Can Affect Cutting Performance 7 -- 8..

Set--Up and Adjustments 7 -- 11...................

Service and Repairs 7 -- 14.......................

Chapter 8 -- Groomer

Grooming Performance 8 -- 2.....................

Troubleshooting 8 -- 3............................

Adjustments 8 -- 4...............................

Service and Repairs 8 -- 5........................

Chapter 9 -- Foldout Drawings

Hydraulic Schematics 9 -- 3.......................

Electrical Schematics 9 -- 5.......................

Electrical Circuit Diagrams 9 -- 7...................

Wire Harness Drawings 9 -- 12....................

Turf Defender

TM

(Optional) Electrical Schematic9 -- 18

and Maintenance

Engine

Kubota Diesel

System

Hydraulic

System

Cutting Electrical

Units

Reelmaster 5010 Series

Rev. C

Groomer Chassis

Foldout

Drawings

Page 4

This page is intentionally blank.

Reelmaster 5010 Series

Page 5

Table of Contents

SAFETY INSTRUCTIONS 2......................

Before Operating 2............................

While Operating 2.............................

Maintenance and Service 3....................

JACKING INSTRUCTIONS 4.....................

SAFETY AND INSTRUCTION DECALS 4..........

Chapter 1

Safety

Safety

Reelmaster 5010 Series Page 1 -- 1 Safety

Rev. B

Page 6

Safety Instructions

Reelmaster machines meet or exceed safety standard

specifications when weights are installed according to

information in the T raction Unit Operator’s Manual. Although hazard control and accident prevention are partially dependent upon the design and configuration of

the machine, these factors are also dependent uponthe

awareness, concern and proper training of the personnel involved in the operation, transport, maintenance

and storage of the machine. Improper use or maintenance of the machine can result in injury or death. To re-

Before Operating

1. Review and understand the contents of the Operator’s Manuals and Operator Training DVD before starting and operating the machine. Become familiar with the

controls and know how to stop the machine and engine

quickly. Additional copies of the Operator’s Manual are

available on the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible

or damaged, repair or replace it before operating the

machine. Also tighten any loose nuts, bolts or screws to

ensure machine is in safe operating condition.

3. Assure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is in

NEUTRAL and PTO switch is OFF (disengaged).

duce the potential for injury or death, comply with the

following safety instructions.

WARNING

To reduce the potential for injury or death,

complywiththefollowingsafetyinstructions.

4. Since diesel fuel is highly flammable, handle it carefully:

A. Store fuel in containers specifically designed for

this purpose.

B. Do not remove machine fuel tank cap while engine is hot or running.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to within an inch of

the top of the tank, not the filler neck. Do not overfill.

E. Replace fuel tank and fuel container caps securely after refueling machine.

F. If fuel is spilled, do not attempt to start the engine

but move the machine away from the area of spillage. Avoid creating any source of ignition until fuel

vapors have dissipated. Wipe up any spilled fuel.

While Operating

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Apply the parking brake.

B. Make sure the traction pedal is in NEUTRAL and

the PTO switch is OFF (disengaged).

C. After engine is started, release parking brake and

keep foot off traction pedal. Machine must not move.

If movement is evident, the traction pedal linkage is

adjusted incorrectly; therefore, shut engine off and

adjust traction pedal linkage until machine does not

move when traction pedal is released (see Traction

Unit Operator’s Manual).

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

4. Do not touch engine, radiator or exhaust system

while engine is running or soon after it is stopped. These

areas could be hot enough to cause burns.

5. Before getting off the seat:

A. Ensure that traction pedal is in NEUTRAL.

B. Lower and disengage cutting units and wait for all

movement to stop.

C. Set parking brake.

D. Stop engine and remove key from ignition switch.

Rev. B

Reelmaster 5010 SeriesPage 1 -- 2Safety

Page 7

6. Anytime the machine is parked (short or long term),

the cutting units should be lowered to the ground. This

relieves pressure from the hydraulic lift circuit and eliminates the risk of the cutting units unexpectedly lowering

to the ground.

Maintenance and Service

7. Do not park on slopes unless wheels are chocked or

blocked.

Safety

1. Before servicing or making adjustments, lower cutting units, stop engine, apply parking brake and remove

key from the ignition switch.

2. Make sure machine is in safe operating condition by

keeping all nuts, bolts and screws tight.

3. Never store the machine or fuel container inside

where there is an open flame, such as near a water heater or furnace.

4. Make sure all hydraulic line connectors are tight, and

all hydraulic hoses and lines are in good condition before applying pressure to the hydraulic system.

5. Keep body and hands away from pin hole leaks in hydraulic lines that eject high pressure hydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury . Fluid accidentally injected into the skin

must be surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result.

6. Before disconnecting or performing any work on the

hydraulic syst em, all pressure in the system must be relieved by using all of the hydraulic controls (see Relieving Hydraulic Pressure in the General Information

section of Chapter 4 -- Hydraulic System).

7. Use care when checking or servicing the cutting

units. Wear gloves and use caution when servicing

them.

8. T o reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Clean

protective screen on machine frequently.

9. If engine must be running to perform maintenance or

to make an adjustment, keep hands, feet, clothing and

other parts of the body away from the cutting units and

other moving parts. Keep bystanders away.

10.Do not overspeed the engine by changing governor

setting. T oassure safety and accuracy, check maximum

engine speed with a tachometer.

1 1.Shut engine off before checking or adding oil to the

crankcase.

12.Disconnect battery before servicing the machine.

Disconnect negative battery cable first and positive

cable last. If battery voltage is required for troubleshooting or test procedures, temporarily connect the battery.

Reconnect positive battery cable first and negative

cable last.

13.Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with a battery.

14.Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

15.When changing attachments, tires or performing

other service, use correct blocks, hoists and jacks.

Make sure machine is parked on a solid level floor such

as a concrete floor. Prior to raising the machine, remove

any attachments that may interfere with the safe and

proper raising of the machine. Always chock or block

wheels. Use jack stands or appropriate load holding devices to support the raised machine. If the machine is

not properly supported, the machine may move or fall,

which may result in personal injury (see Jacking Instructions in this section).

16.If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

17.If welding on the machine is necessary, disconnect

the negative battery cable to prevent electrical system

damage.

18.At the time of manufacture, the machine conformed

to the safety standards for riding mowers. To assure optimum performance and continued safety certification of

the machine, use genuine Toro replacement parts and

accessories. Replacement parts and accessories made

by other manufacturers may result in non-conformance

with the safety standards, and the warranty may be

voided.

Reelmaster 5010 Series Page 1 -- 3 Safety

Page 8

Jacking Instructions

CAUTION

When changing attachments, tires or performing other service, use correct blocks, hoists

and jacks. Make sure machine is parked on a

solid, level surface such as a concrete floor.

Prior to raising machine, remove any attachments that may interfere with the safe and

proper raising of the machine. Always chock

or block wheels. Use jack stands or other appropriate load holding devices to support the

raised machine. If the machine is not properly

supported, the machine may move or fall,

which may result in personal injury.

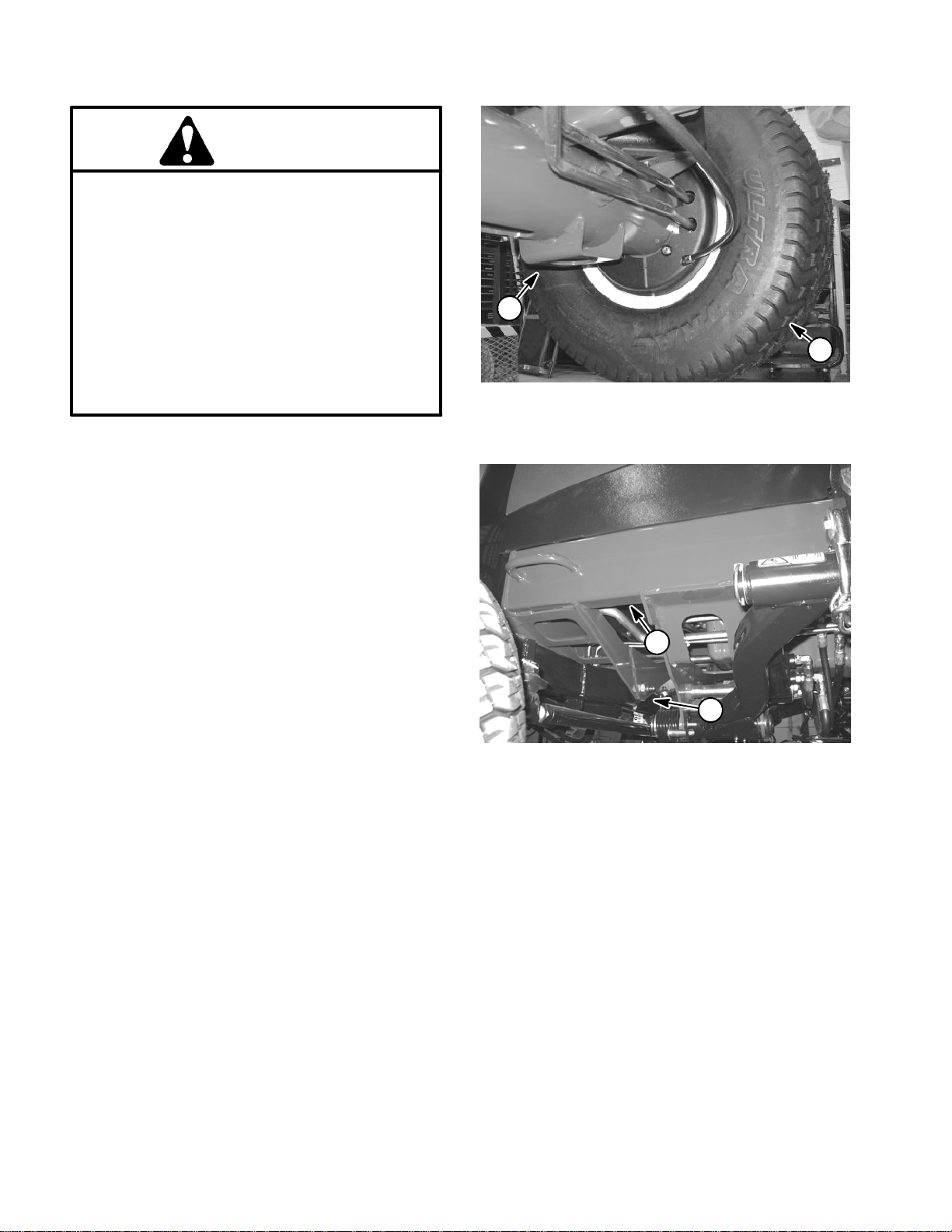

Front End Jacking (Fig. 1)

1. Apply parking brake and chock both rear tires to prevent the machine from moving.

2

1

Figure 1

1. Front wheel 2. Front jacking point

2. Position jack securely under the frame axle tube, just

to the inside of the front wheel.

3. Jack front of machine off the ground.

4. Position jack stands under the frame as close to the

wheel as possible to support the machine.

Rear End Jacking (Fig. 2)

1. Apply parking brake and chock both front tires to prevent the machine from moving.

2. Place jack securely at the center of the rear axle under the axle pivot bracket. Jack rear of machine off the

ground.

3. Position jack stands under the frame to support the

machine.

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the traction unit and the cutting units of yourReelmaster.

If any decal becomes illegible or damaged, install a new

decal. Part numbers for decals are listed in your Part

Catalogs. Order replacement decals from your Authorized Toro Distributor.

2

1

Figure 2

1. Axle center 2. Jack stand location

Rev. B

Reelmaster 5010 SeriesPage 1 -- 4Safety

Page 9

Product Records and Maintenance

Table of Contents

Chapter 2

PRODUCT RECORDS 1.........................

MAINTENANCE 1...............................

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3....................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Series) 5..............

Other Torque Specifications 6..................

Conversion Factors 6..........................

Product Records

Insert Operator’s Manuals and Parts Catalogs for your

Reelmaster at the end of this chapter. Additionally, if any

optional equipment or accessories have been installed

to your machine, insert the Installation Instructions, Operator’s Manuals and Parts Catalogs for those options

at the end of this chapter.

Product Records

and Maintenance

Maintenance

Maintenance procedures and recommended service intervals for your Reelmaster are covered in the Traction

Unit and Cutting Unit Operator’s Manuals. Refer to

those publications when performing regular equipment

maintenance.

Reelmaster 5010 Series Page 2 -- 1 Product Records and Maintenance

Rev. B

Page 10

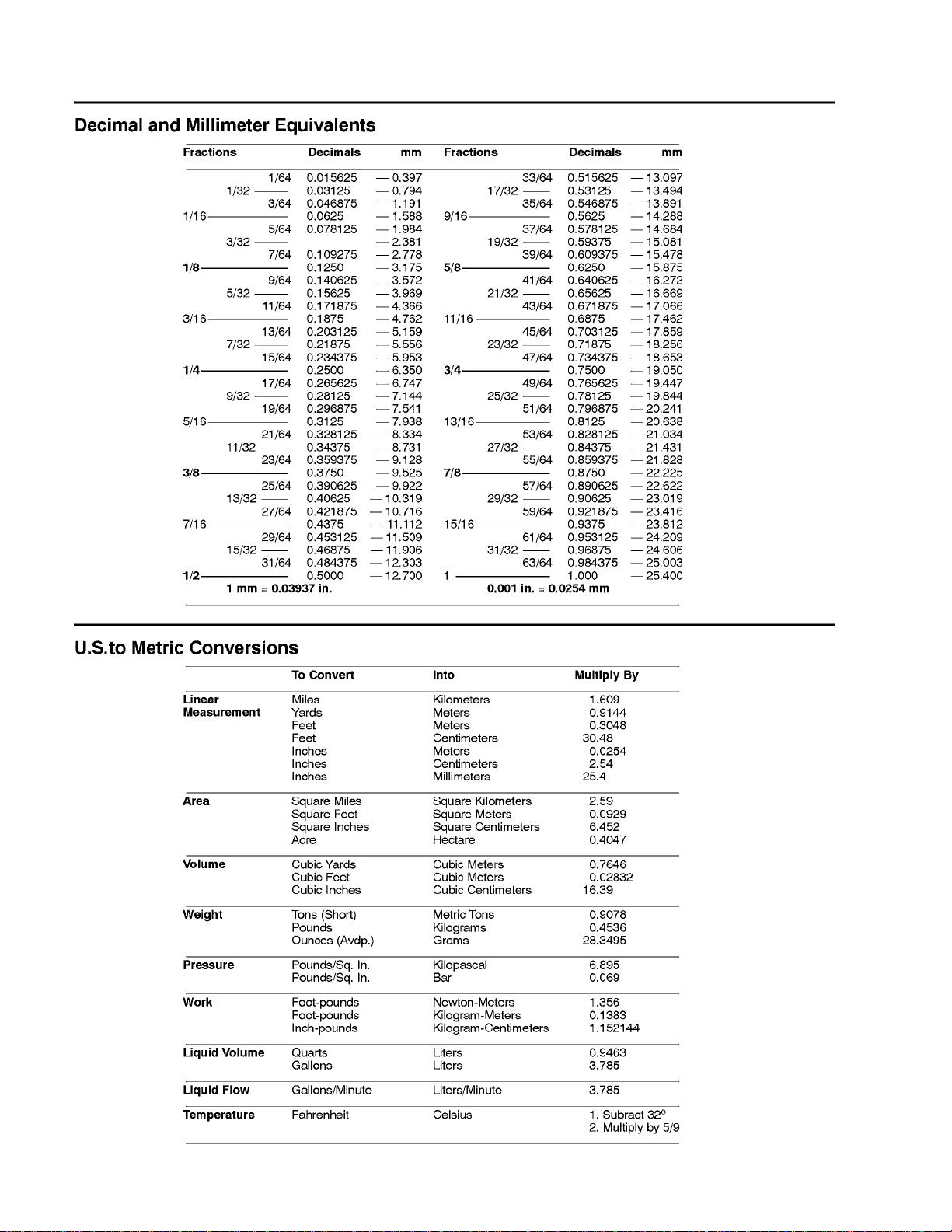

Equivalents and Conversions

0.09375

Reelmaster 5010 SeriesPage 2 -- 2Product Records and Maintenance

Page 11

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners s hall apply to all fasteners which

do not have a specific requirement identified in this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

the fastener’s head or similar condition which affects the

installation.

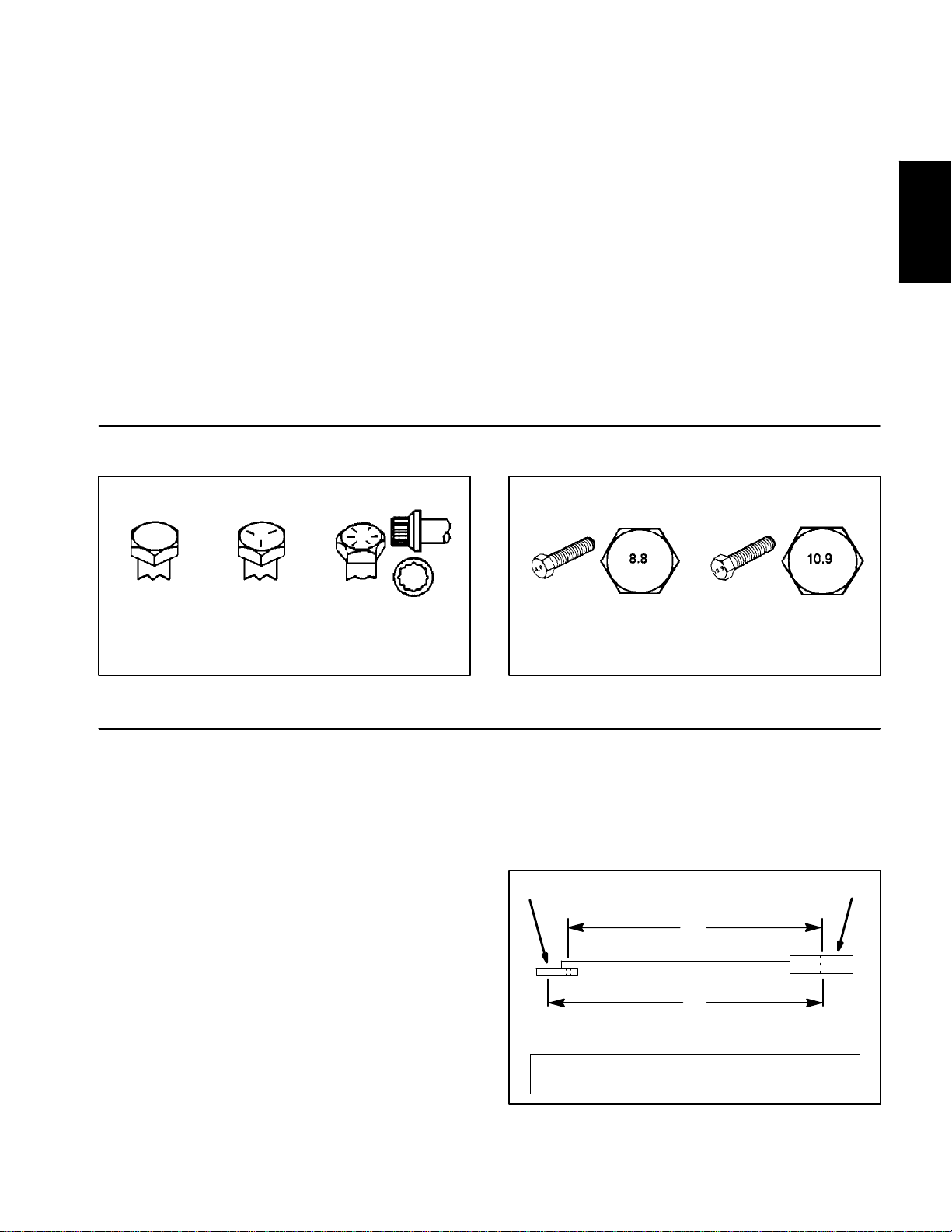

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the s imilar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

the lines match up.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

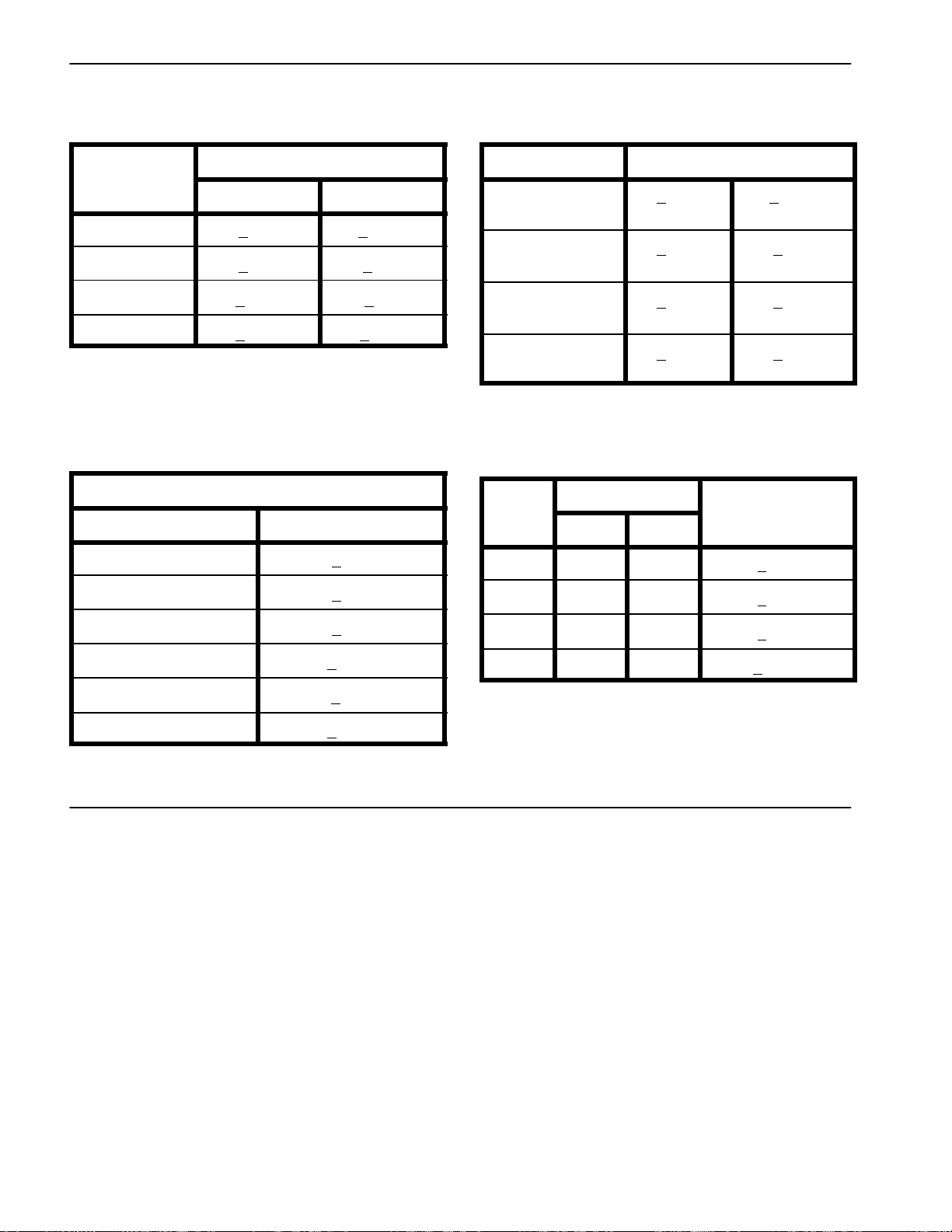

Using a Torque Wrench with an Offset Wrench

Use ofan offset wrench (e.g. crowfoot wrench) will affect

torque wrench calibration due to the effective change of

torque wrench length. When using a torque wrench with

an offset wrench, multiply the listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: The measured effective length of the torque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

The measured effective length of the torque wrench with

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft--lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft--lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A/ B

Torque wrenchOffset wrench

The calculated torque conversion factor for this torque

wrench with this offset wrench would be 18 / 19 = 0.947.

Reelmaster 5010 Series Page 2 -- 3 Product Records and Maintenance

Rev. B

Figure 3

Page 12

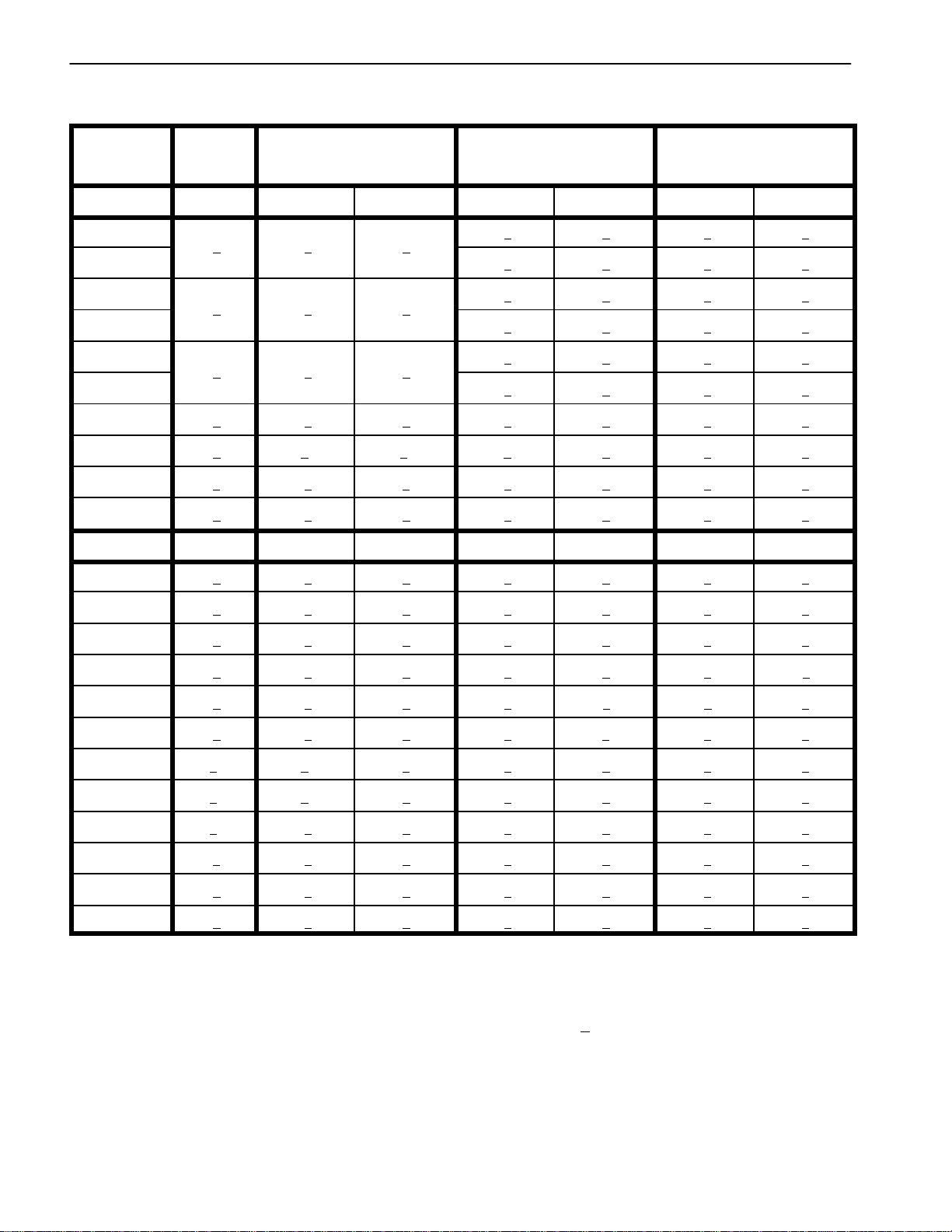

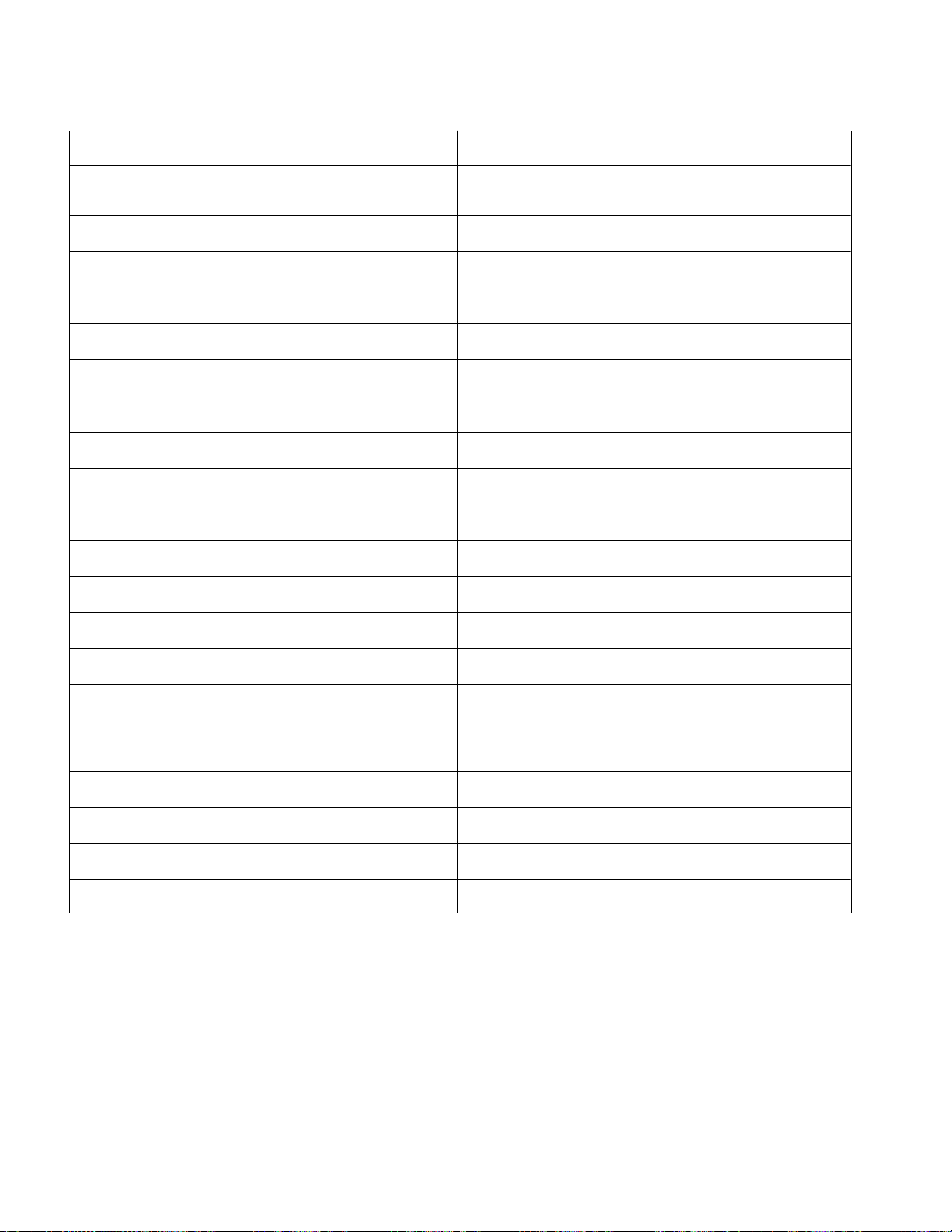

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130 + 113 140 + 15 1582 + 169

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 11 3 11 5 + 12 1299 + 136 160 + 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in--lb N--cm in--lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

17 + 2 192 + 23 25 + 3 282 + 34

29 + 3 328 + 34 41 + 5 463 + 56

31 + 4 350 + 45 43 + 5 486 + 56

42 + 5 475 + 56 60 + 6 678 + 68

48 + 5 542 + 56 68 + 7 768 + 79

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimum proof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Rev. B

Reelmaster 5010 SeriesPage 2 -- 4Product Records and Maintenance

Page 13

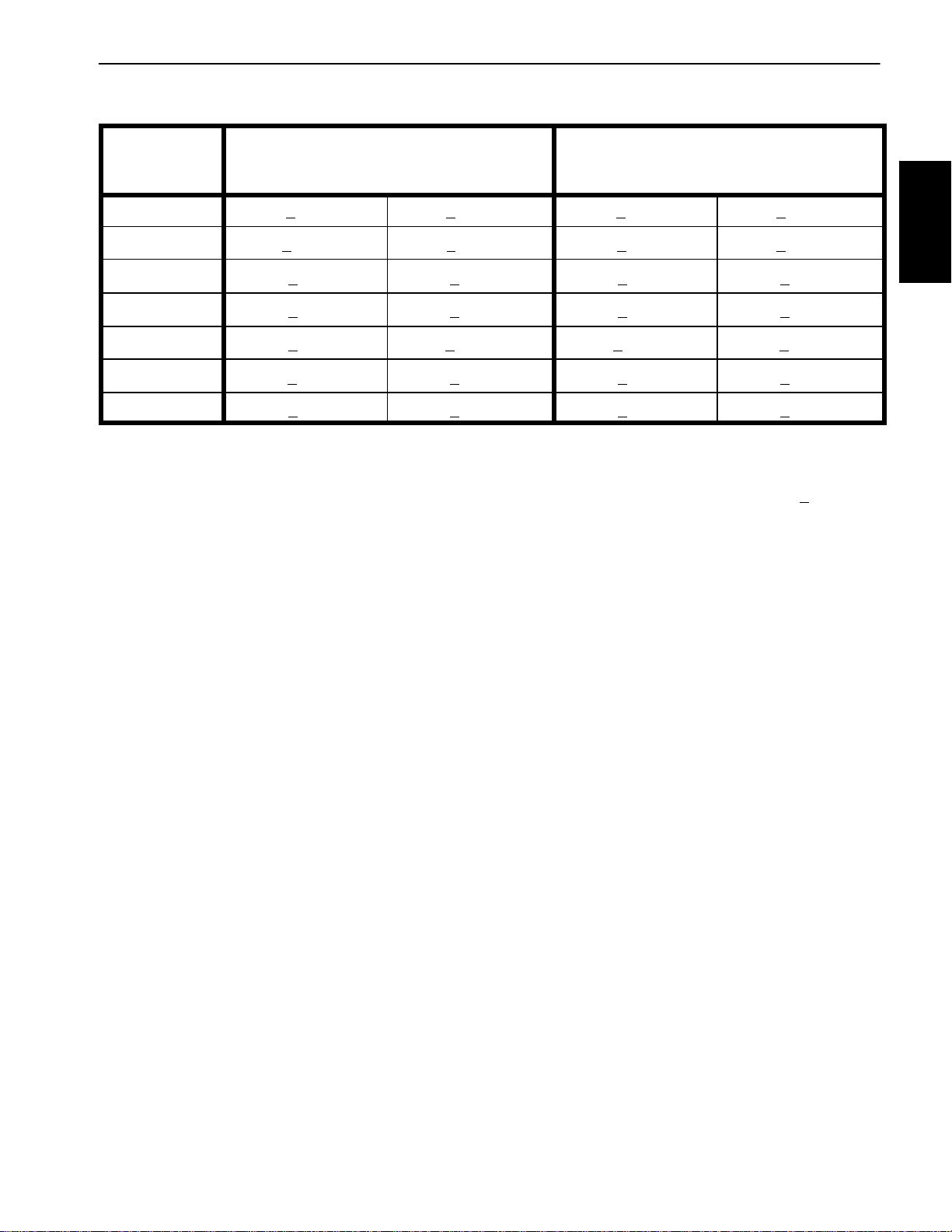

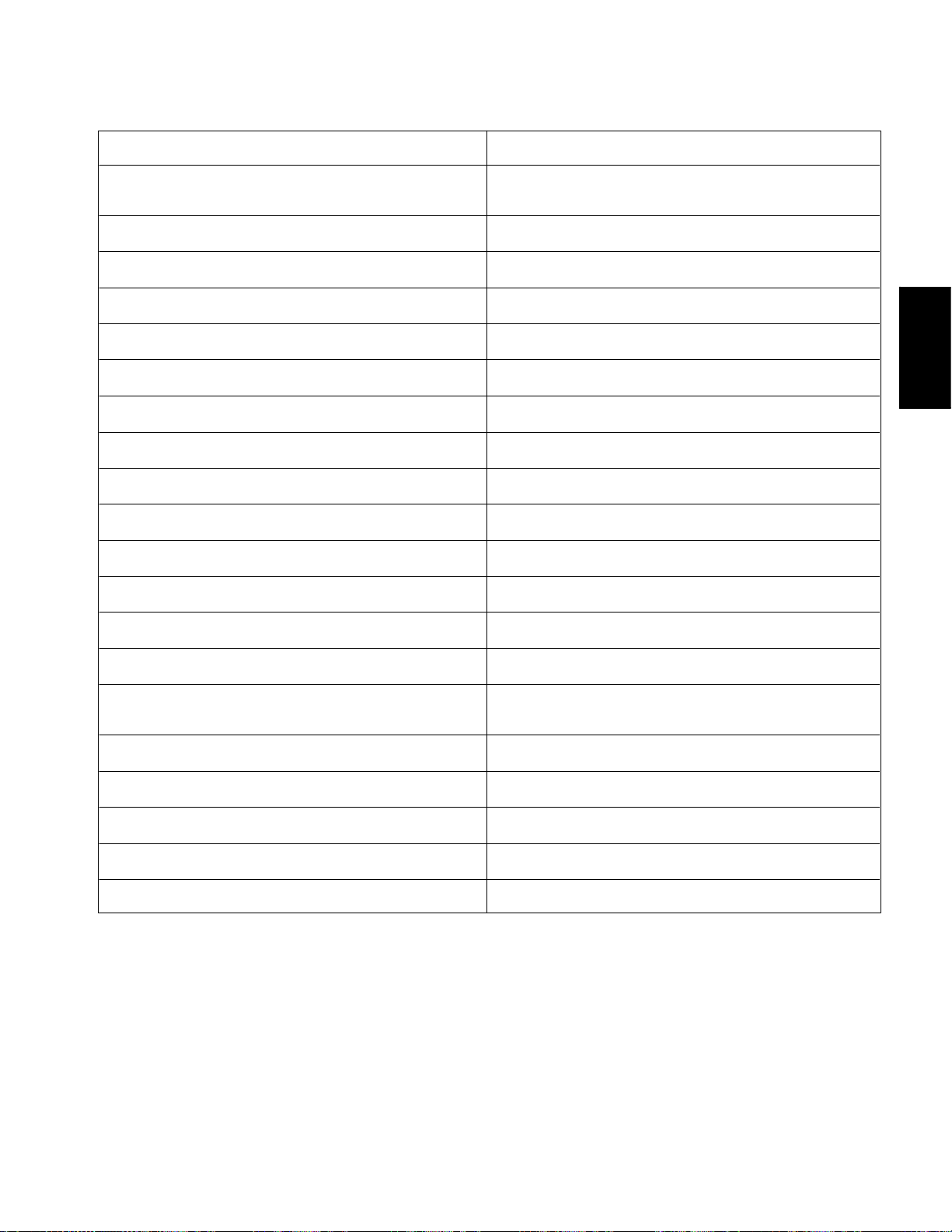

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N--cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N - -c m 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93 + 10 ft--lb 126 + 14 N--m

M16 X 2.0 166 + 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately+

nominal torque value.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

10% ofthe

Product Records

and Maintenance

Reelmaster 5010 Series Page 2 -- 5 Product Records and Maintenance

Page 14

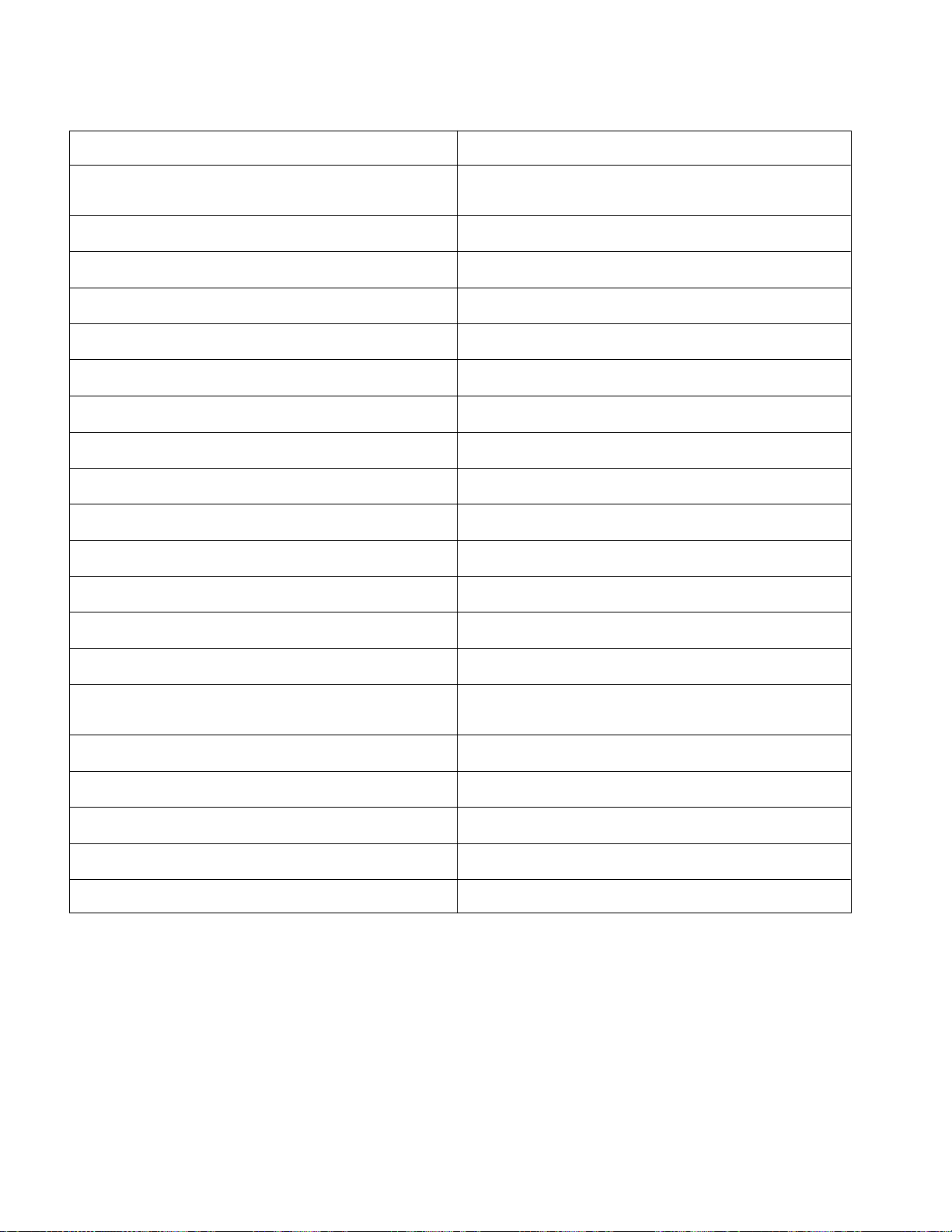

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Typ e B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

* Holesize, material strength, material thickness and finish must be considered when determining specific

torque values. All torque values are based on non--lubricated fasteners.

Reelmaster 5010 SeriesPage 2 -- 6Product Records and Maintenance

Page 15

Table of Contents

Chapter 3

Kubota Diesel Engine

GENERAL INFORMATION 1.....................

Traction Unit Operator’s Manual 1...............

Stopping the Engine (Reelmaster 5610) 1........

SPECIFICATIONS 2............................

Reelmaster 5210 2............................

Reelmaster 5410 and 5510 3...................

Reelmaster 5610 4............................

ADJUSTMENTS 5..............................

Adjust Throttle Control 5.......................

General Information

This Chapter gives information about specifications,

troubleshooting, testing and repair of the Kubota diesel

engine used in the Reelmaster 5010 Series of machines.

Most repairs and adjustments require tools which are

commonly available in many service shops. The use of

some specialized test equipment is explained in the engine service manual included at the end of this chapter.

However, the cost of the test equipment and the specialized nature of some repairs may dictate that the work be

done at an engine repair facility.

SERVICE AND REPAIRS 6......................

Fuel System 6................................

Air Cleaner 8.................................

Exhaust System 10...........................

Radiator 12..................................

Engine 14....................................

KUBOTA WORKSHOP MANUAL: 05 SERIES DIESEL

ENGINE

Service and repair parts for Kubota diesel engines are

supplied through your local Toro Distributor. If a parts list

is not available, be sure to provide your distributor with

the Toro model and serial number.

Engine

Kubota Diesel

Traction Unit Operator’s Manual

The T raction Unit Operator’s Manual provides information regarding the operation, general maintenance and

maintenance intervals for the Kubota diesel engine that

powers your Reelmaster machine. Refer to that publication for additional information when servicing the machine.

Stopping the Engine (Reelmaster 5610)

IMPORTANT: The engine used on the Reelmaster

5610 is turbo--charged. Before stopping the engine

after mowing or full load operation on Reelmaster

5610 machines, cool the turbo-charger by allowing

the engine to idle at low speed for 5 minutes.Failure

to do so may lead to turbo-charger trouble.

Reelmaster 5010 Series Page 3 -- 1 Kubota Diesel Engine

Page 16

Specifications: Reelmaster 5210

Item Description

Make / Designation Kubota D1105, 4-- stroke,

Number of Cylinders 3

Bore x Stroke 3.07” x 3.09” (78 mm x 78.4 mm)

Total Displacement 68.53 in3(1123 cc)

Compression Ratio 22.0:1

Firing Order 1 (fan end) -- 2 -- 3 (flywheel end)

Dry Weight (approximate) 205 lb. (93 kg)

Fuel No. 2--D Diesel Fuel (ASTM D975)

Fuel Injection Pump Bosch MD Type Mini

Fuel Injector Nozzle Mini Nozzle (DNOPD)

Fuel Tank Capacity 14 U.S. Gallons (53 Liters)

Governor Centrifugal Mechanical

Low Idle Speed (no load) 1200 to 1300 RPM

Liquid Cooled, OHV Diesel

High Idle Speed (no load) 3050 to 3250 RPM

Engine Oil API Classification CH--4, CI--4 or Higher

Oil Pump Gear Driven Trochoid Type

Crankcase Oil Capacity 4.0 U.S. Quarts (3.8 Liters) with Filter

Cooling System Capacity (including reserve tank) 5.5 U.S. Quarts (5.2 Liters)

Starter 12 VDC 1.4 KW

Alternator/Regulator 12 VDC 40 Amp

(see Traction Unit Operator’s Manual for viscosity recommendations)

Reelmaster 5010 SeriesPage 3 -- 2Kubota Diesel Engine

Page 17

Specifications: Reelmaster 5410 and 5510

Item Description

Make / Designation Kubota V1505, 4-- stroke,

Liquid Cooled, OHV Diesel

Number of Cylinders 4

Bore x Stroke 3.07” x 3.09” (78 mm x 78.4 mm)

Total Displacement 91.4 in3(1498 cc)

Compression Ratio 21.0:1

Firing Order 1 (fan end) -- 3 -- 4 (flywheel end) -- 2

Dry Weight (approximate) 242 lbs (110 kg)

Fuel No. 2--D Diesel Fuel (ASTM D975)

Fuel Injection Pump Bosch MD Type Mini

Fuel Injector Nozzle Mini Nozzle (DNOPD)

Fuel Tank Capacity 14 U.S. Gallons (53 Liters)

Governor Centrifugal Mechanical

Low Idle Speed (no load) 1200 to 1300 RPM

Engine

Kubota Diesel

High Idle Speed (no load) 3050 to 3250 RPM

Engine Oil API Classification CH--4, CI--4 or Higher

Oil Pump Gear Driven Trochoid Type

Crankcase Oil Capacity 6.3 U.S. Quarts (6 Liters) with Filter

Cooling System Capacity (including reserve tank) 7 U.S. Quarts (6.6 Liters)

Starter 12 VDC 1.4 KW

Alternator/Regulator 12 VDC 40 Amp

(see Traction Unit Operator’s Manual for viscosity recommendations)

Reelmaster 5010 Series Page 3 -- 3 Kubota Diesel Engine

Page 18

Specifications: Reelmaster 5610

Item Description

Make / Designation Kubota V1505, 4-- stroke,

Number of Cylinders 4

Bore x Stroke 3.07” x 3.09“ (78 mm x 78.4 mm)

Total Displacement 91.4 in3(1498 cc)

Compression Ratio 21.0:1

Firing Order 1 (fan end) -- 3 -- 4 (flywheel end) -- 2

Dry Weight (approximate) 251 lbs (114 kg)

Fuel No. 2--D Diesel Fuel (ASTM D975)

Fuel Injection Pump Bosch MD Type Mini

Fuel Injector Nozzle Mini Nozzle (DNOPD)

Fuel Tank Capacity 14 U.S. Gallons (53 Liters)

Governor Centrifugal Mechanical

Low Idle Speed (no load) 1200 to 1300 RPM

Liquid Cooled, OHV, Turbocharged Diesel

High Idle Speed (no load) 3050 to 3250 RPM

Engine Oil API Classification CH--4, CI--4 or Higher

Oil Pump Gear Driven Trochoid Type

Crankcase Oil Capacity 5 U.S. Quarts (4.7 Liters) with Filter

Cooling System Capacity (including reserve tank) 10 U.S. Quarts (9.5 Liters)

Starter 12 VDC 1.4 KW

Alternator/Regulator 12 VDC 40 Amp

(see Traction Unit Operator’s Manual for viscosity recommendations)

Reelmaster 5010 SeriesPage 3 -- 4Kubota Diesel Engine

Page 19

Adjustments

Adjust Throttle Control

Proper throttle operation is dependent upon proper adjustment of throttle control. Make sure throttle control is

operating properly.

NOTE: The throttle cable swivel should be positioned

in the lowest hole in the speed control lever .

1. Move throttle control lever on control console to

FAST position.

2. Check position of the engine speed control lever on

fuel injection pump. The speed control lever should be

contacting the high speed screw when the throttle control lever is in the FAST position.

3. If necessary, throttle control can be adjusted by loosening cable clamp screw and repositioning control cable

until speed control lever contacts high speed screw

when the throttle control lever is in the FAST position.

Tighten cable clamp screw after adjustment has been

completed.

5

1. Throttle cable

2. High speed screw

3. Speed control lever

1

4

Figure 1

2

4. Swivel

5. Cable clamp

Engine

3

Kubota Diesel

Reelmaster 5010 Series Page 3 -- 5 Kubota Diesel Engine

Page 20

Service and Repairs

Fuel System

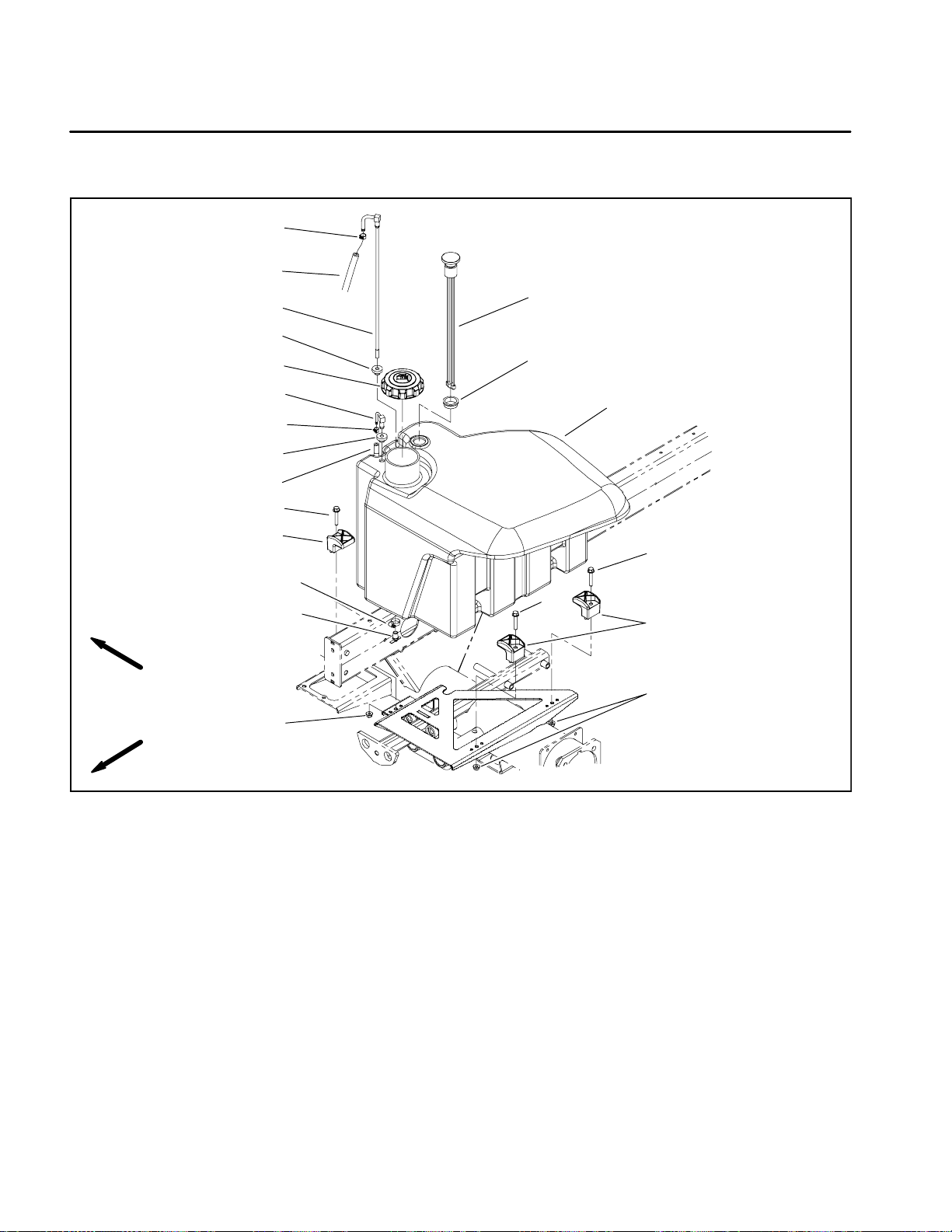

8

15

7

2

1

12

11

RIGHT

FRONT

1. Fuel cap

2. Bushing

3. Washer head screw (3 used)

4. Flange nut (3 used)

5. Clamp (3 used)

6. Return fitting

16

6

9

2

3

5

13

14

4

3

10

3

5

4

Figure 2

7. Suction fitting

8. Hose clamp

9. Hose clamp

10. Fuel tank

11. Grommet

12. Fuel gauge

13. Hose clamp

14. Draincock

15. Fuel hose

16. Return fuel hose

Reelmaster 5010 SeriesPage 3 -- 6Kubota Diesel Engine

Page 21

Fuel Tank Removal (Fig. 2)

DANGER

Because diesel fuel is highly flammable, use

caution when storing or handling it. Do not

smoke while filling the fuel tank. Do not fill fuel

tank while engine is running, when engine is hot

or when machine is in an enclosed area. Always

fill fuel tank outside and wipe up any spilled diesel fuel before starting the engine. Store fuel in a

clean, safety--approved container and keep container cap in place. Use diesel fuel for the engine

only; not for any other purpose.

Check Fuel Lines and Connections

Check fuel lines and connections periodically as recommended in the Traction Unit Operator’s Manual. Check

lines for deterioration, damage, leakage or loose connections. Replace fuel hoses, clamps and connections

as necessary.

Drain and Clean Fuel Tank

Drain and clean the fuel tank periodically as recommended in the Traction Unit Operator’s Manual. Also,

drain and clean the fuel tank if the fuel system becomes

contaminated or if the machine is to be stored for an extended period.

To clean fuel tank, flush tank out with clean diesel fuel.

Make sure tank is free of all contaminates and debris.

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Place drain pan under fuel tank. Make sure that drain

pan is large enough to hold fuel tank contents (see

Specifications in this chapter).

3. Open draincock on bottom of fuel tank and allow tank

to fully drain. Close draincock.

NOTE: Before removing fuel hoses from tank fittings,

label hoses for assembly purposes.

4. Loosen hose clamps and disconnect fuel hoses from

suction (item 7) and return (item 6) fittings on the top of

the fuel tank.

5. Remove fuel tank using Figure 2 as a guide.

Fuel Tank Installation (Fig. 2)

1. Install fuel tank to frame using Figure 2 as a guide.

2. Correctly connect fuel hoses to suction (item 7) and

return (item 6) fittings on the top of the fuel tank. Secure

fuel hoses with hose clamps.

3. Make sure that fuel tank draincock is closed. Fill fuel

tank.

Engine

Kubota Diesel

Reelmaster 5010 Series Page 3 -- 7 Kubota Diesel Engine

Page 22

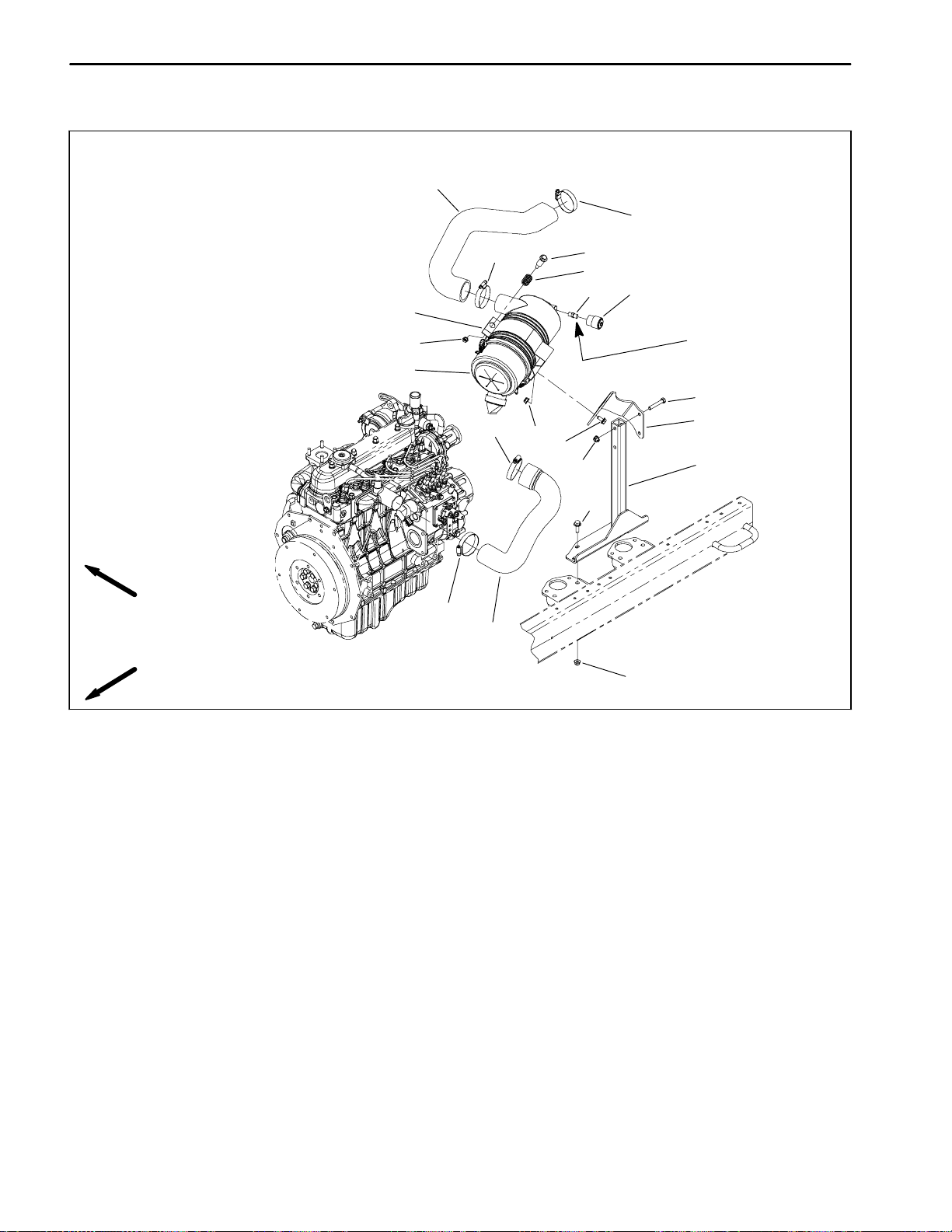

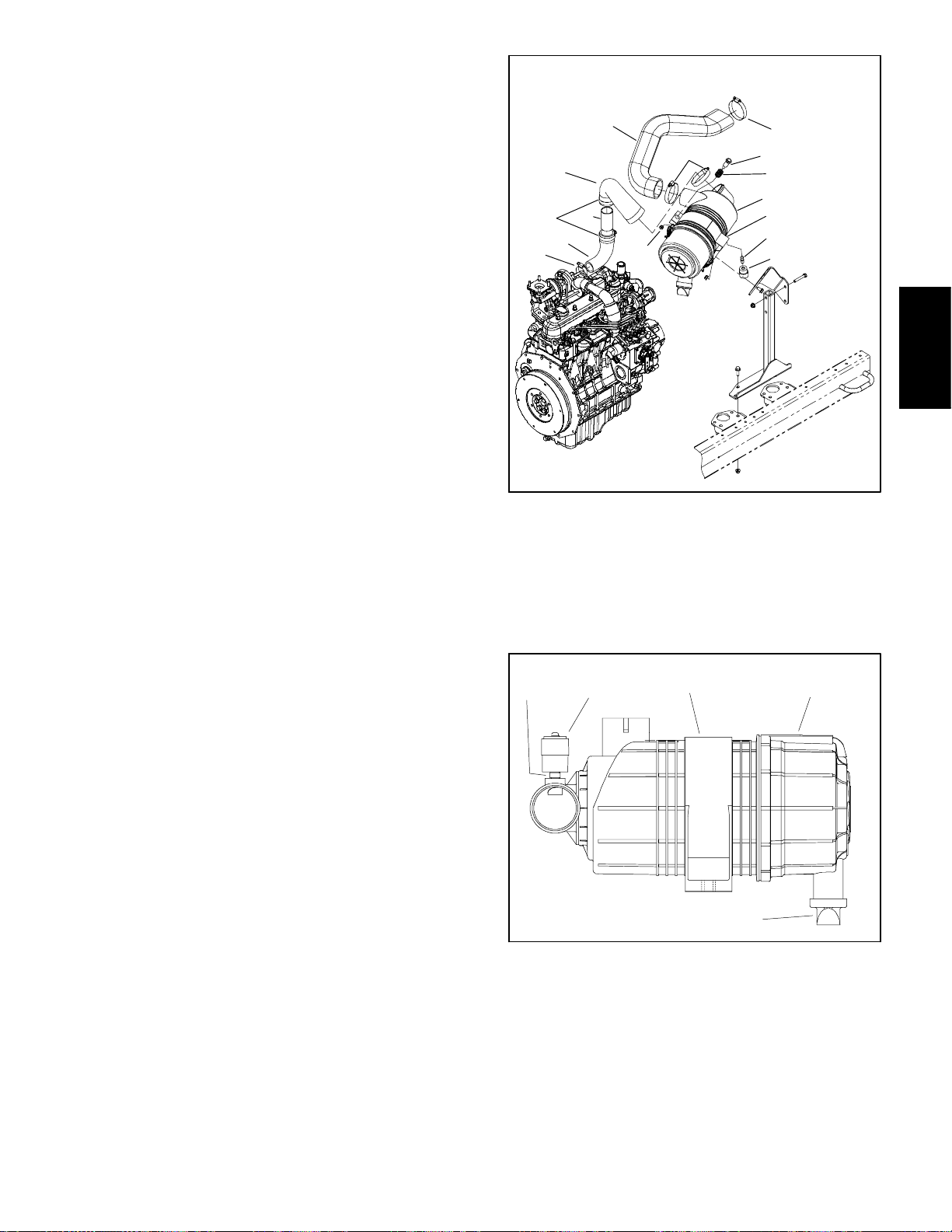

Air Cleaner

REELMASTER 5410--D/5510--D SHOWN

7

11

RIGHT

FRONT

16

11

2

3

4

6

5

THREAD

SEALANT

1

13

11

12

9

15

12

10

14

11

8

12

1. Air cleaner assembly

2. Hex nut

3. Bolt

4. Spring

5. Indicator

6. Adapter

7. Hose

8. Hose

9. Mount bracket

10. Air cleaner stand

11. Ho se cla mp

NOTE: The models in the Reelmaster 5010 Series

have a very similar air cleaner system. The air cleaner

removal and installation procedure is the same for all

models.

Figure 3

12. Flange nut

13. Cap screw (2 used)

14. Flange head screw (4 used)

15. Flange head screw (2 used)

16. Air cleaner mounting band

Reelmaster 5010 SeriesPage 3 -- 8Kubota Diesel Engine

Page 23

Removal (Fig. 3)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch. Raise hood.

2. Remove air cleaner components as needed using

Figures 3, 4 and 5 as guides.

3. See Traction Unit Operator’s Manual for air cleaner

service and maintenance procedures.

Installation (Fig. 3)

IMPORTANT: Any leaks in the air filter system will

allow dirt into engine and will cause serious engine

damage. Make sure that all air cleaner components

arein good condition and are properly secured during assembly.

1. Assemble air cleaner system using Figures 3, 4 and

5 as guides.

A. If indicator and adapter were removed from air

cleaner housing, apply thread sealant to adapter before installing adapter and indicator to housing.

B. Make sure that vacuator valve is pointed down after assembly.

REELMASTER 5610--D

10

9

8

6

7

6

5

Figure 4

1. Air cleaner assembly

2. Mounting band

3. Adapter

4. Indicator

5. Hex nut

6. Hose clamp

7. Hose

11

8. Spacer

9. Hose

10. Hose

11. Ho se cla mp

12. Bolt

13. Spring

11

12

13

1

2

3

4

Engine

Kubota Diesel

4

1. Mounting band

2. Cover

3. Vacuator valve

5

1

Figure 5

2

3

4. Adapter

5. Indicator

Reelmaster 5010 Series Page 3 -- 9 Kubota Diesel Engine

Page 24

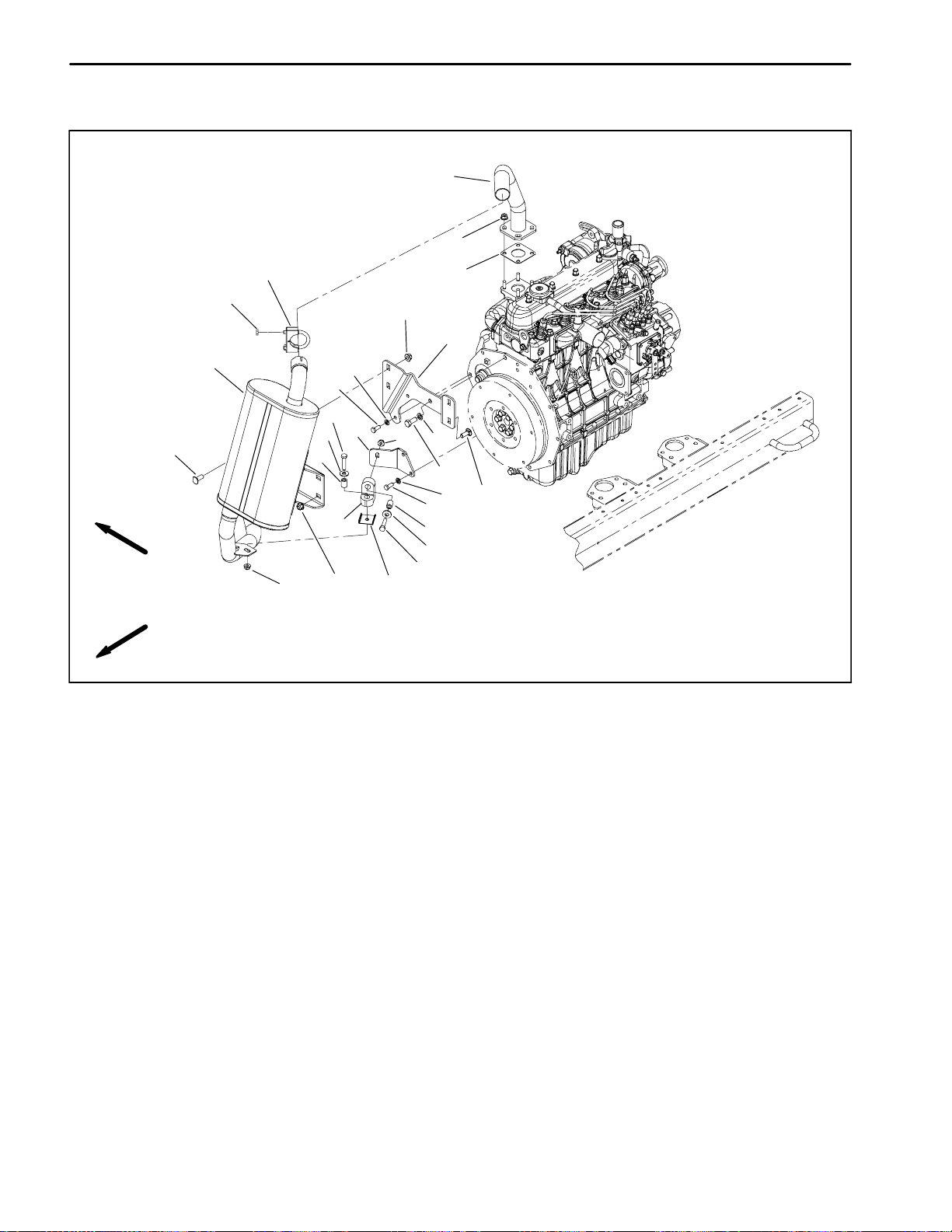

Exhaust System

REELMASTER 5410--D/5510--D SHOWN

17

3

10

20

5

RIGHT

FRONT

1. Gasket

2. Lock washer (4 used)

3. Flange nut (4 used)

4. Cap screw (4 used)

5. Carriage screw (4 used)

6. Flange nut (4 used)

7. Lock washer

11

12

2

4

14

19

13

16

15

6

9

8. Cap screw

9. Isolator plate

10. Hex nut (2 used)

11. Cl amp

12. Flange nut (2 used)

13. Flat washer (2 used)

14. Cap screw (2 used)

6

12

7

8

4

16

13

14

Figure 6

2

1

18

5

15. Rubber hanger

16. Spacer (2 used)

17. Exhaust header

18. Support bracket

19. Tail pipe bracket

20. Muffler

NOTE: The models in the Reelmaster 5010 Series

have a very similar exhaust system. The exhaust system removal and installation procedure is the same for

all models.

Reelmaster 5010 SeriesPage 3 -- 10Kubota Diesel Engine

Page 25

Removal (Fig. 6)

Installation (Fig. 6)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch. Raise hood.

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before working on the exhaust system.

2. Remove exhaust system using Figure 6 as a guide.

NOTE: Make sure muffler flange and exhaust manifold

sealing surfaces are free of debris or damage that may

prevent a tight seal.

1. Place new muffler gasket on the exhaust manifold.

Install exhaust pipe to manifold and secure with four (4)

flange nuts.

IMPORTANT: Finger tighten all exhaust system fasteners before tightening so that there is no preload

on the exhaust system due to exhaust system assembly.

2. Install exhaust system to the engine using Figure 6

as a guide. Finger tighten all fasteners until all exhaust

system components have been installed. Then, fully

tighten fasteners to secure exhaust system.

Engine

Kubota Diesel

Reelmaster 5010 Series Page 3 -- 11 Kubota Diesel Engine

Page 26

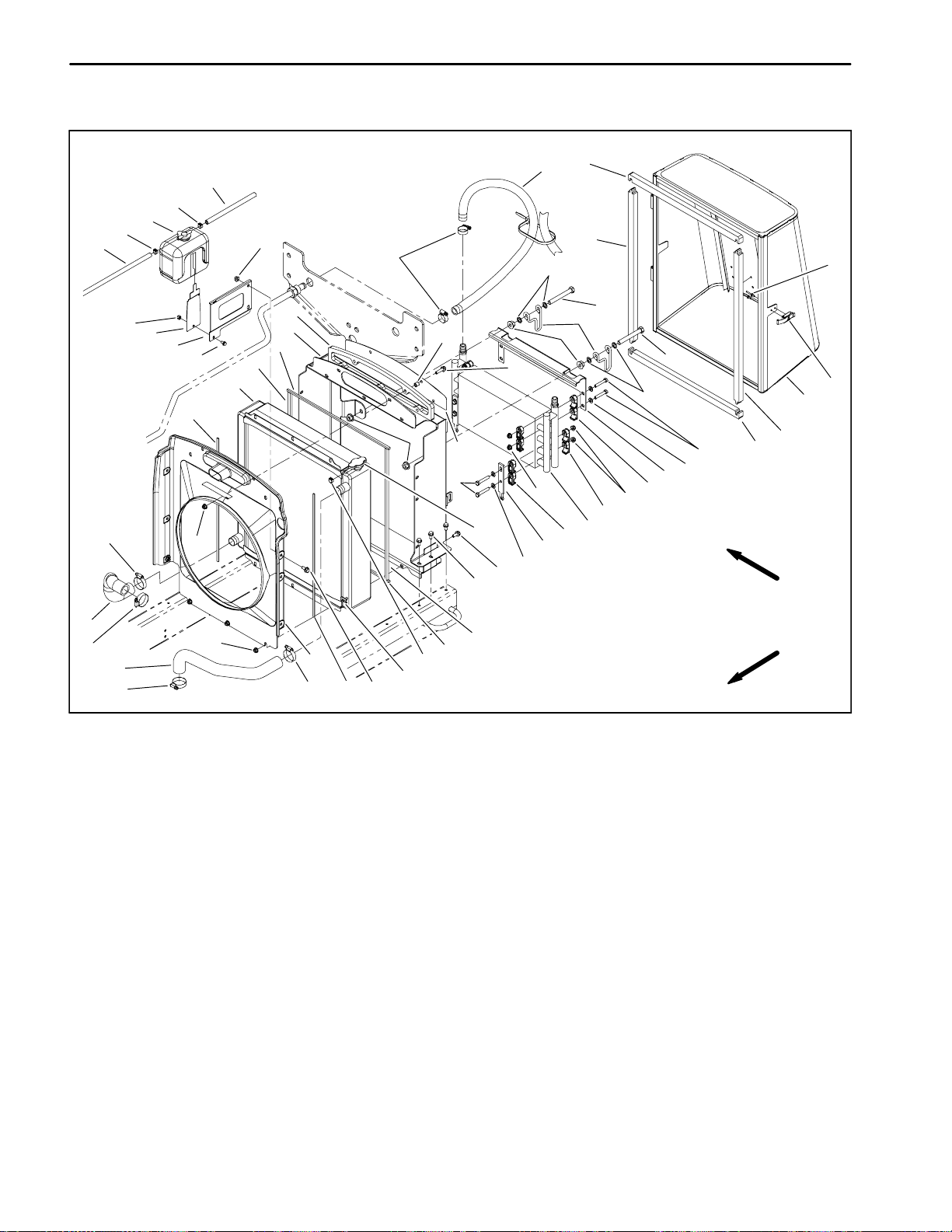

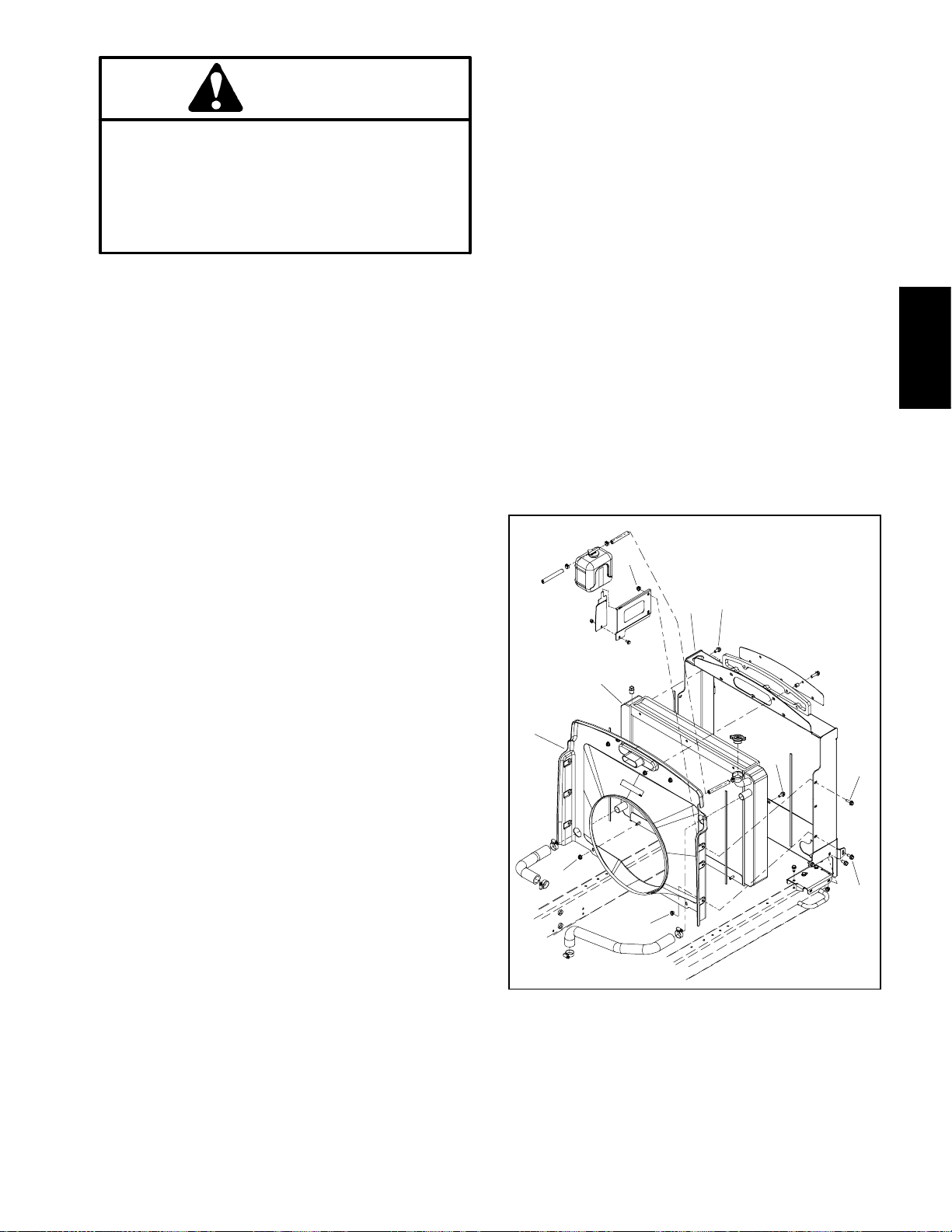

Radiator

2

3

11

28

38

2

1

20

4

29

13

10

34

23

24

33

8

21

5

16

13

26

16

13

25

16

1. Overflow bottle

2. Hose clamp (3 used)

3. Hose

4. Foam seal (2 used)

5. Foam seal (2 used)

6. Foam seal (2 used)

7. Oil cooler

8. Foam seal (2 used)

9. Flat washer (8 used)

10. Hose clamp (4 used)

11. Foam seal (2 used)

12. Flange nut (4 used)

13. Flange nut (22 used)

14. Oil cooler mount plate (2 used)

15. Oil cooler clamp (16 used)

6

22

40

12

27

5

16

30

16. Hose clamp (4 used)

17. Cap screw (4 used)

18. Clamp (2 used)

19. Cap screw (2 used)

20. Washer (4 used)

21. Radiator

22. Radiator frame

23. Reservoir bracket

24. Bracket

25. Hose

26. Hose

27. Fan shroud

28. Hose (2 used)

29. Rivet (2 used)

30. Flange head screw (9 used)

2

41

43

37

17

6

Figure 7

32

8

42

30

44

19

18

12

19

31

20

36

4

11

13

15

35

9

39

15

13

15

7

14

9

RIGHT

FRONT

31. Draw latch

32. Washer head screw (6 used)

33. Flange head screw

34. Lock nut

35. Cap screw (4 used)

36. Screen

37. Intake screen

38. Hose

39. Oil cooler bracket

40. Foam seal

41. Draincock

42. Radiator cap

43. Spacer (5 used)

44. Flange head screw (5 used)

NOTE: Three (3) radiators are used on Reelmaster

5010 series machines. Reelmaster 5410 and 5510 machines use the same radiator. Reelmaster 5210 and

5610 machines use different radiators. All models use

a similar procedure for radiator removal and installation.

Removal (Fig. 7)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Raise the hood.

Reelmaster 5010 SeriesPage 3 -- 12Kubota Diesel Engine

Page 27

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolant properly, or store it in a properly

labeled container away from children and pets.

3. Drain coolant from radiator.

3. Secure fan shroud and radiator to radiator frame with

removed flange head screws and flange nuts. Make

sure that at least .250” (6.4 mm) clearance exists at all

points between shroud opening and fan.

4. Position coolant reservoir and brackets to the fan

shroud. Secure reservoir to fan shroud and radiator

frame with two (2) flange head screws and flange nuts.

5. Place spacers (item 43) into holes in foam seal (item

42). Position foam seal and air intake screen (item 37)

to radiator frame. Secure screen to machine with five (5)

flange head screws and flange nuts.

A. Slowly remove radiator cap from the radiator.

B. Place drain pan below the radiator draincock located on the bottom of the radiator. Make sure that

drain pan is large enough to hold cooling system contents (see Specifications in this Chapter).

C. Loosen draincock and allow coolant to drain from

radiator.

4. Remove screen from machine.

5. Disconnect radiator hoses (upper and lower) from

the radiator.

6. Loosen hose clamp and remove overflow hose from

radiator fill opening.

7. Remove two (2) flange head screws and flange nuts

that secure coolant reservoir and brackets to fan

shroud. Carefully position reservoir and brackets away

from the fan shroud.

8. Remove five (5) flange head screws and flange nuts

that secure air intake screen (item 37) to machine. Remove screen and foam seal (item 42). Locate and retrieve five (5) spacers (item 43).

6. Connect upper and lower radiator hoses to radiator

and secure with clamps.

7. Connect overflow hose to radiator fill opening and

secure with hose clamp.

8. Make sure radiator draincock is closed (threaded out

fully). Fill radiator with coolant.

9. Lower hood. Install screen to rear of machine.

6

1

2

REELMASTER 5610

5

3

5

4

Engine

Kubota Diesel

9. Remove flange head screws and flange nuts that secure fan shroud and radiator to radiator frame. Position

fan shroud away from the radiator.

10.Carefully pull radiator assembly from the machine.

Plug radiator and hose openings to prevent contamination.

6

5

6

1 1.Inspect all foam seals placed between radiator, fan

shroud and radiator frame. Replace damaged foam

seals.

Installation (Fig. 7)

1. Remove plugs placed in radiator and hose openings

1. Radiator (RM 5610)

2. Fan shroud

3. Radiator frame

Figure 8

4. Flange head screw

5. Flange head screw

6. Flange nut

during the removal procedure.

2. Carefully position radiator assembly to the radiator

support. Position fan shroud to the radiator.

Reelmaster 5010 Series Page 3 -- 13 Kubota Diesel Engine

Page 28

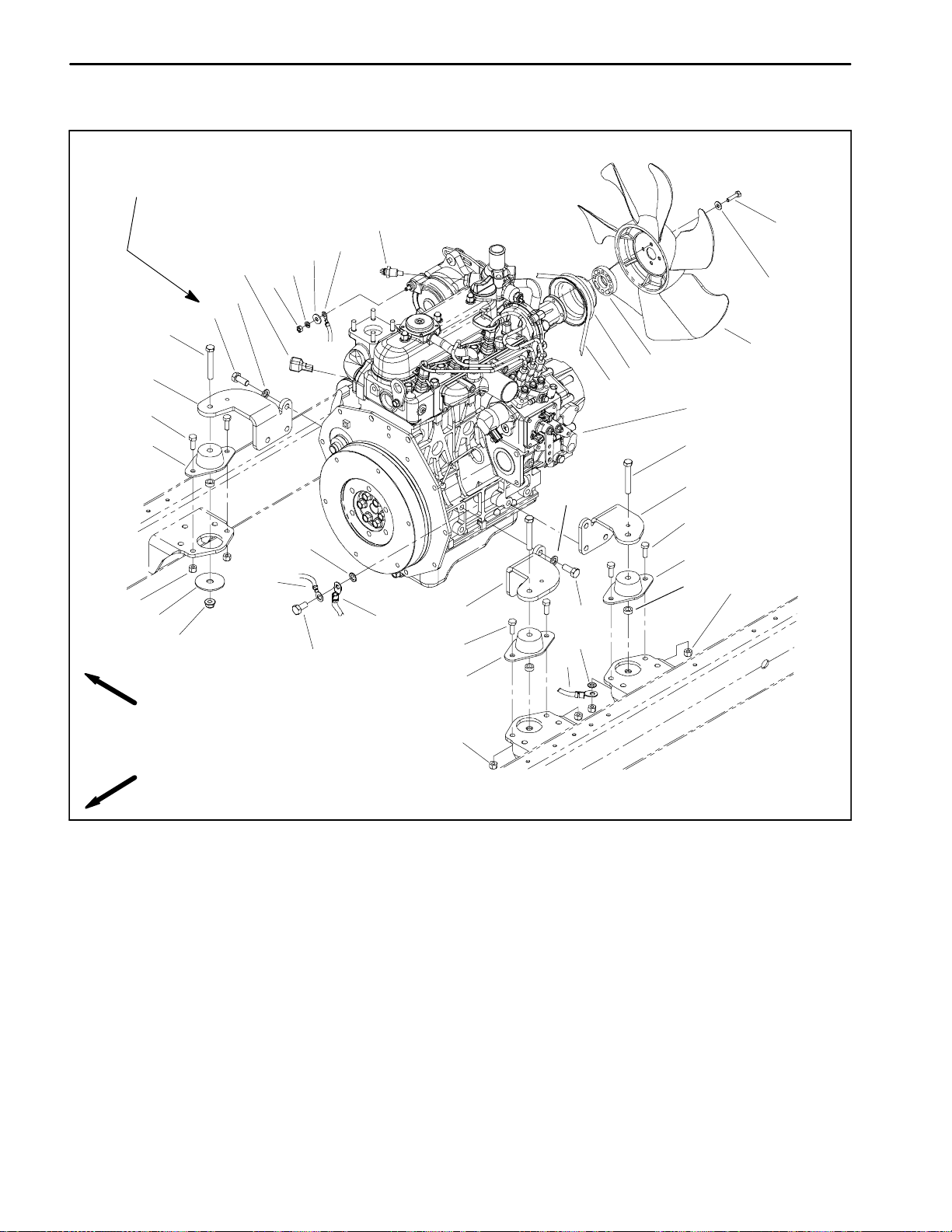

Engine

34 to 42 ft--lb

(47to56N--m)

3

26

11

18

24

25

19

20

16

2

7

17

23

14

10

15

5

4

1

7

23

25

5

13

26

9

6

27

8

21

23

5

2

12

27

4

22

9

4

RIGHT

FRONT

1. Engine assembly

2. Cap screw (12 used)

3. Temperature sender

4. Engine mount (4 used)

5. Cap screw (2 used per mount)

6. Snubbing washer (4 used)

7. Cap screw (4 used)

8. Flange nut (4 used)

9. Lock nut (2 used per mount)

10. Fan spacer

11. Cap screw (4 used)

12. Lock washer

13. Lock washer

14. Pulley

15. V --belt

16. Flat washer (4 used)

17. Cooling fan

18. Flat washer

NOTE: The engine removal and installation procedure

is similar for all models in the Reelmaster 5010 Series.

9

Figure 9

19. Spring washer

20. Hex nut

21. Cap screw

22. Spacer (4 used)

23. Engine bracket (4 used)

24. Diode assembly

25. Lock washer (12 used)

26. Engine wire harness

27. Negative battery cable

Reelmaster 5010 SeriesPage 3 -- 14Kubota Diesel Engine

Page 29

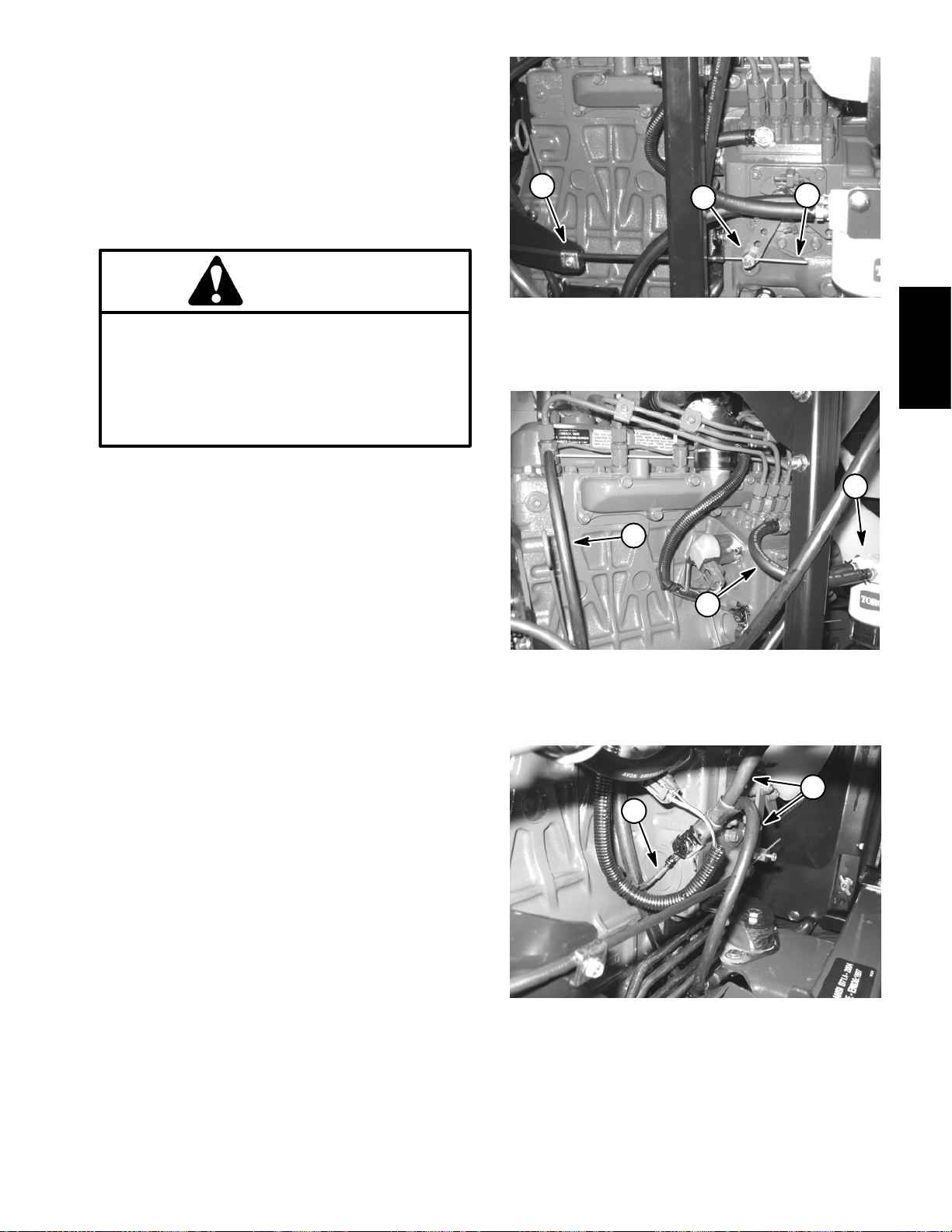

Removal (Fig. 9)

1. Park machine on a level surface, lower cutting units,

stop engine and remove key from the ignition switch.

Chock wheels to keep the machine from moving.

2. Open hood.

3. Disconnect negative (--) and then positive (+) battery

cables from the battery.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolant properly, or store it in a properly

labeled container away from children and pets.

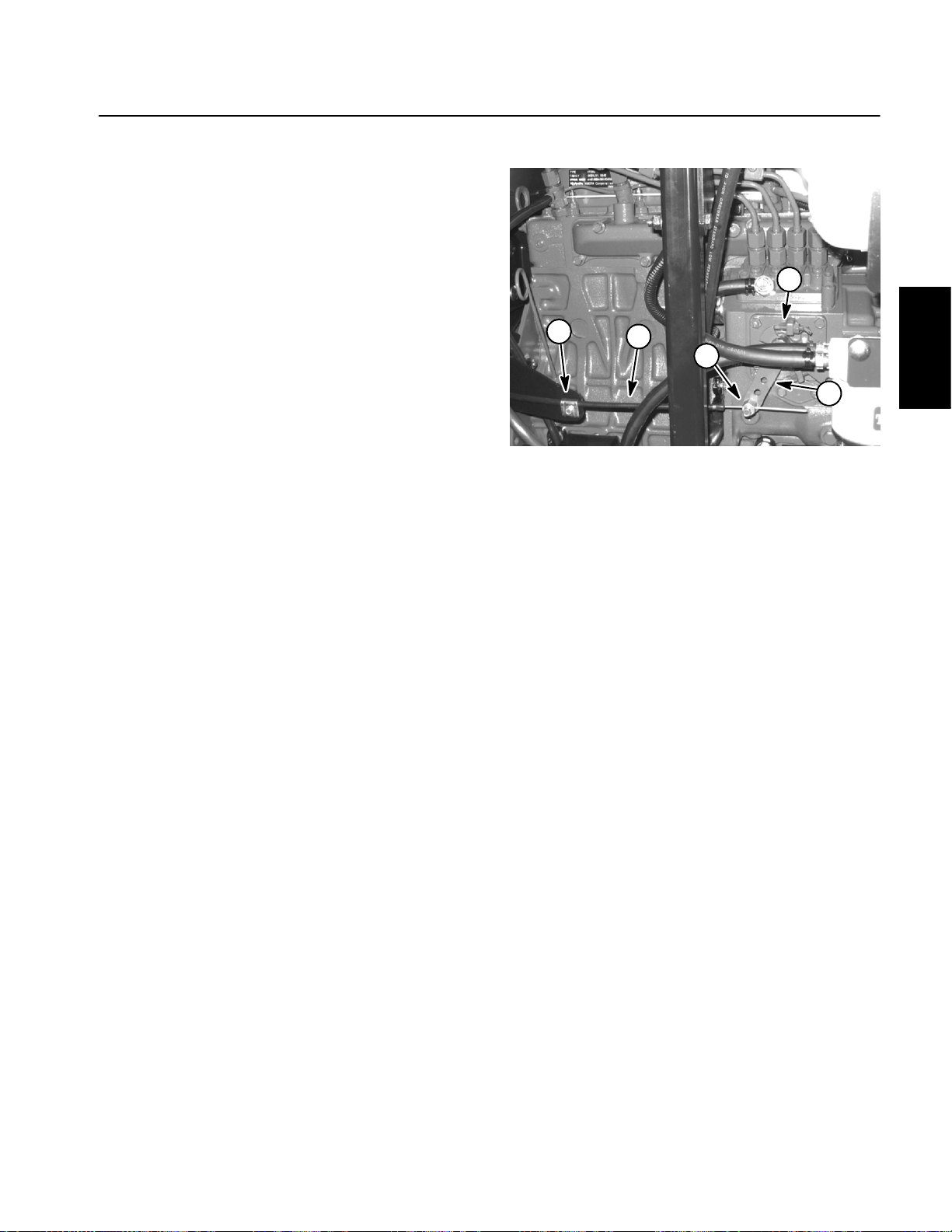

3

1. Throttle cable end

2. Swivel

2

Figure 10

3. Cable clamp

1

Engine

Kubota Diesel

4. Drain coolant from radiator (see Radiator Removal

in this section).

5. Remove air cleaner from machine (see Air Cleaner

Removal in this section).

6. Remove exhaust system from machine (see Exhaust System Removal in this section).

7. Remove throttle cable from injector pump (Fig. 10):

A. Remove cap screw that secures throttle cable

end to swivel in speed control lever.

B. Loosen throttle cable clamp and remove cable

from clamp. Slide throttle cable end from swivel.

C. Position throttle cable away from the engine.

8. Disconnect hoses from engine:

A. Loosen clamps and remove upper and lower radiator hoses from the engine.

B. At injector pump, loosen hose clamp and disconnect supply fuel hose from the injector pump fitting

(Fig. 11).

1. Fuel return hose

2. Fuel supply hose

3

1

2

Figure 11

3. Fuel/water filter

1

2

C. Loosen hose clamp and disconnect fuel return

hose from front injector body (Fig. 11).

D. Plug disconnected hoses and engine openings to

prevent leakage and contamination. Position discon-

1. Negative battery cable 2. Harness ground

Figure 12

nected hoses away from engine.

Reelmaster 5010 Series Page 3 -- 15 Kubota Diesel Engine

Page 30

9. Disconnect hydraulic transmission drive shaft from

engine (see Hydraulic Transmission Drive Shaft Removal in the Service and Repairs section of Chapter 4

-- Hydraulic System). Support drive shaft away from engine.

Installation (Fig. 9)

1. Locate machine on a level surface with cutting units

lowered and key removed from the ignition switch.

Chock wheels to keep the machine from moving.

10.Disconnect wire harness connectors from the following engine components:

NOTE: Before disconnecting wire harness connectors,

label all electrical leads for assembly purposes.

A. Alternator connector and stud.

B. Oil pressure switch located near the engine oil filter.

C. Connector, fusible link connector and positive

battery cable from the starter motor.

D. High temperature shut down switch and temperature sender located on the water pump housing.

E. Fuel stop solenoid on injector pump.

F. Negative battery cable and harness ground from

injector pump (Fig. 12).

G. Glow plug strip.

1 1.Remove engine from machine:

2. Make sure that all parts removed from the engine

during maintenance or rebuilding are installed to the engine.

3. If engine brackets were removed from the engine,

secure brackets to engine with lock washers and cap

screws. Torque cap screws from 34 to 42 ft--lb (47 to

56 N--m).

4. Install engine to machine.

A. Attach short section of chain between lift tabs located on each end of the cylinder head

B. Connect a hoist or chain fall at the center of the

short section of chain. Apply enough tension on the

short chain so that the engine can be supported.

CAUTION

One person should operate lift or hoist while

another other person guides the engine into the

machine.

A. Attach short section of chain between lift tabs located on each end of the cylinder head.

B. Connect a hoist or chain fall at the center of the

short section of chain. Apply enough tension on the

short chain so that the engine will be supported.

C. Remove fasteners that secure the engine (with

brackets) to the engine mounts.

CAUTION

One person should operate lift or hoist while

another person guides the engine out of the machine.

IMPORTANT: Make sure to not damage the engine,

fuel hoses, hydraulic lines, electrical harness, radiator, batteryor other partswhile removing the engine.

D. Raise engine and remove toward front of machine.

IMPORTANT: Make sure to not damage the engine,

fuel hoses, hydraulic lines, electrical harness, radiator, batteryor other parts while installing the engine.

C. Lower engine to the machine frame. Make sure

fastener holes of the engine brackets are aligned

with the holes in the engine mounts.

D. Insert cap screw down through each engine

bracket and mount. Place spacer, snubbing washer

and then flange nut on four (4) cap screws. Tighten

fasteners to secure engine to engine mounts.

5. Connect hydraulic transmission drive shaft to engine

(see Hydraulic Transmission Drive Shaft Installation in

the Service and Repairs section of Chapter 4 -- Hydraulic System).

6. Connect all wire harness connectors to correct engine components.

12.If necessary, remove engine brackets from engine.

Reelmaster 5010 SeriesPage 3 -- 16Kubota Diesel Engine

Page 31

7. Remove plugs installed in hoses during disassembly. Connect hoses to the engine:

9. Install air cleaner (see Air Cleaner Installation in this

section).

A. Connect fuel supply and fuel return hoses to engine fittings (Fig. 11). Secure with hose clamps.

B. Connect upper and lower radiator hoses to the

engine. Secure with hose clamps.

8. Connect throttle cable to injector pump (Fig. 10):

A. Route throttle cable to injector pump on engine.

B. Install the throttle cable end into the swivel in

speed control lever. Secure cable end with cap

screw.

C. Position cable under cable clamp.

D. Adjust throttle control (see Adjust Throttle Control in the Adjustments section of this chapter).

10.Install exhaust system to machine (see Exhaust

System Installation in this section).

1 1.Add coolant to radiator.

12.Check engine oil level and adjust if needed.

13.Connect positive (+) and then negative (--) battery

cables to the battery .

14.Bleed fuel system.

15.Close hood.

Engine

Kubota Diesel

Reelmaster 5010 Series Page 3 -- 17 Kubota Diesel Engine

Page 32

This page is intentionally blank.

Reelmaster 5010 SeriesPage 3 -- 18Kubota Diesel Engine

Page 33

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 2.............................

GENERAL INFORMATION 3.....................

Traction Unit Operator’s Manual 3...............

Check Hydraulic Fluid 3.......................

Towing Traction Unit 3.........................

Hydraulic Hoses 4............................

Hydraulic Fitting Installation 4...................

Relieving Hydraulic System Pressure 6..........

Traction Circuit Component Failure 6............

HYDRAULIC SCHEMATICS 7....................

HYDRAULIC FLOW DIAGRAMS 8................

Traction Circuit 8..............................

Mow Circuit 10...............................

Lift Circuit: Raise Cutting Units 12...............

Lift Circuit: Lower Cutting Units 14...............

Steering Circuit 16............................

SPECIAL TOOLS 18............................

TROUBLESHOOTING 22........................

General Hydraulic System Problems 22..........

Traction Circuit Problems 23....................

Mow Circuit Problems 24.......................

Lift Circuit Problems 25........................

Steering Circuit Problems 26...................

TESTING 28...................................

Traction Circuit Relief Valve (R3) and (R4)

Pressure Test 30............................

Traction Circuit Charge Pressure Test 32.........

Gear Pump (P3) Flow Test 34..................

Front Wheel Motor Efficiency Test 36............

Piston (Traction) Pump Flow Test 38.............

Relief Valve (R1) and (R2) Pressure Test 40......

Gear Pump (P1) and (P2) Flow Test 42..........

Reel Drive Motor Efficiency Test 44..............

Reel Drive Motor Cross--Over Relief Pressure

Test (Reelmaster 5510 and 5610) 46...........

Lift Relief Valve (R6) Pressure Test 48...........

Gear Pump (P4) Flow Test 50..................

Lift Cylinder Internal Leakage Test 52............

Steering Relief Valve (R10) Pressure Test 54.....

Steering Cylinder Internal Leakage Test 56.......

SERVICE AND REPAIRS 58.....................

General Precautions for Removing and Installing

Hydraulic System Components 58.............

Check Hydraulic Lines and Hoses 59............

Flush Hydraulic System 60.....................

Filtering Closed--Loop Traction Circuit 61.........

Hydraulic System Start--up 62..................

Hydraulic Reservoir 64........................

Hydraulic Pump Drive Shaft 66.................

Hydraulic Pump Assembly 68...................

Piston (Traction) Pump Service 72..............

Gear Pump Service 74.........................

Front Wheel Motor 76.........................

Motor

Wheel

Wheel Motor Service (Eaton) 81................

Mow Control Manifold 82.......................

Mow Control Manifold Service 84...............

Lift Control Manifold 88........................

Lift Control Manifold Service 90.................

CrossTrax

CrossTrax

Service 94..................................

Cutting Reel Motor 96.........................

Cutting Reel Motor Service 98..................

Lift Cylinder 102..............................

Lift Cylinder Service 104.......................

Steering Control Valve 106.....................

Steering Control Valve Service 108..............

Steering Cylinder 110..........................

Steering Cylinder Service 112..................

Oil Cooler 114................................

SAUER--DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS REPAIR MANUAL

SAUER--DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS SERVICE INSTRUCTIONS

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

EATON DELTA MOTORS PARTS AND REPAIR

MANUAL

SAUER--DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

Service (Parker) 80................

TM

AWD (Optional Kit) Manifold 92......

TM

AWD (Optional Kit) Manifold

TM

SERVICE PROCEDURE

System

Hydraulic

Reelmaster 5010 Series Hydraulic System (Rev. C)Page 4 -- 1

Page 34

Specifications

Item Description

Piston (Traction) Pump Sauer--Danfoss, LPV Closed Circuit Axial Piston Design

Maximum Pump Displacement (per revolution) 2.14 Cubic Inches (35 cc)

Gear Pump Casappa 4 section, positive displacement gear type pump

Section P1/P2 Displacement (per revolution) (RM 5210 &5410) 0.50 Cubic Inches (8.3 cc)

Section P1/P2 Displacement (per revolution) (RM 5510 &5610) 0.66 Cubic Inches (10.8cc)

Section P3 Displacement (per revolution) (all models) 0.37 Cubic Inches (6.1 cc)

Section P4 Displacement (per revolution) (all models) 0.24 Cubic Inches (3.9 cc)

Charge Circuit Relief (R5) Pressure 200 PSI (14 bar)

Traction Circuit Relief Pressure: Forward (R3) and Reverse (R4) 3625 PSI (250 bar)

Front Wheel Motors (see NOTE below)

Rear Wheel Motors (if equipped)

Mow Circuit Relief Pressure

Rear Mow Circuit (R1) 2500 PSI (172 bar)

Front Mow Circuit (R2) 3500PSI (241 bar)

Cutting Unit Motor (RM 5210 & RM 5410) Sauer--Danfoss gear motor

Displacement (per revolution) 0.73 Cubic Inches (12 cc)

Cutting Unit Motor (RM 5510 & RM 5610) Bosch gear motor

Displacement (per revolution) 1.18 Cubic Inches (19.3 cc)

Cross Over Relief Valve Pressure 1500 PSI (103 bar)

Steering Valve Sauer--Danfoss Steering Unit, Type OSPMS

Steering Circuit Relief (R10)Pressure 1000 PSI (69 bar)

Lift Circuit Relief (R6) Pressure 2000 PSI (138 bar)

Lift Circuit Lower Relief (R7) Pressure 500 PSI (34bar)

Hydraulic Filter (Transmission and Steering Circuits) Spin--on Cartridge Typewith 50 PSI (3.4 bar) Relief in Adapter

Parker orbital rotor motor, TG Series

Eaton geroler motor, Delta Series

Parker orbital rotor motor, TL Series

Hydraulic Filter (Mow and Lift Circuits) Spin--on CartridgeType with 50 PSI (3.4 bar) Reliefin Adapter

Hydraulic Oil See Traction Unit Operator’s Manual

Hydraulic Reservoir Capacity 11U.S. Gallons (41.6 L)

(filter adapter includes filter change indicator)

NOTE: Machines produced with serial number below

311000600 were produced with Parker brand front

wheel motors. Machines with serial number above

311000600wereproduced withEatonbrandfrontwheel

motors. If Parker brand wheel motors have been replaced, thereplacement wheel motors may have been

Eaton brand.

Reelmaster 5010 SeriesHydraulic System (Rev. C) Page 4 -- 2

Page 35

General Information

Traction Unit Operator’s Manual

The Traction Unit Operator’s Manual providesinformation regarding the operation,general maintenance and

maintenance intervals for your Reelmaster machine.

Referto that publication for additional informationwhen

servicing the machine.

Check Hydraulic Fluid

The hydraulic system on Reelmaster 5010 series machines is designed to operate on highquality hydraulic

fluid. The hydraulic system reservoir holds approximately11gallons (41.6 liters)of hydraulic fluid.Check lev-

elofhydraulic fluiddaily.SeeTractionUnitOperator’s

Manualfor fluid level checkingprocedure and hydraulic

oil recommendations.

System

1

Hydraulic

Towing Traction Unit

IMPORTANT: If towing limits are exceeded, severe

damage to the piston (traction) pump may occur.

Ifitbecomesnecessaryto tow or push themachine,tow

orpushataspeedbelow3mph(4.8 kph), and for a very

shortdistance.Ifthemachine needs to bemovedaconsiderabledistance,machineshouldbetransportedona

trailer.Thepiston(traction)pumpisequippedwith a bypassvalvethat needstobeloosened fortowingorpushing (Fig. 2). See Traction Unit Operator’s Manual for

Towing Procedures.

Figure 1

1. Hydraulic reservoir cap

2

1

Figure 2

1. Piston (traction) pump 2. Bypass valve

Reelmaster 5010 Series Hydraulic System (Rev. C)Page 4 -- 3

Page 36

Hydraulic Hoses

Hydraulichoses are subject to extreme conditions such

aspressuredifferentialsduringoperationandexposure

to weather, sun, chemicals, very warm storage conditionsormishandling duringoperationandmaintenance.

Theseconditions cancausedamageorprematuredeterioration. Some hoses are more susceptible to these

conditions than others.Inspectthe hoses frequentlyfor

signs of deterioration or damage.

WARNING

Before disconnecting or performing any work

on hydraulic system, relieve all pressure in

system. Stop engine; lower or support all cutting units.

When replacing a hydraulichose,be sure that thehose

is straight (not twisted) before tightening the fittings.

This can bedone by observingthe imprint onthe hose.

Use two wrenches; hold the hose straight with one

wrench and tighten the hose swivel nut onto the fitting

with the other wrench.

Hydraulic Fitting Installation

O--Ring Face Seal

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches or any foreign material.

2. Make sure the O--ring is installed and properly

seatedinthegroove.ItisrecommendedthattheO--ring

be replaced any time the connection is opened.

3. Lubricate the O--ring with a light coating of oil.

Keepbodyand handsawayfrom pinholeleaks

ornozzles that eject hydraulic fluid under high

pressure. Use paper orcardboard, not hands,

to search for leaks. Hydraulic fluid escaping

under pressure can have sufficient force to

penetrate the skin and cause serious injury. If

fluid is injected into the skin, it must be surgically removed within a few hours by a doctor

familiar with thistype of injury. Gangrenemay

result from such an injury.

Nut

Sleeve

Seal

Body

4. Put the tube and nut squarely into position on the

facesealendofthe fitting and tighten the nut until finger

tight.

5. Mark the nut and fitting body. Hold the body with a

wrench.Useanotherwrenchtotightenthe nuttothecorrect Flats FromFingerTight(F.F.F.T.). Themarkings on

thenutand fittingbodywillverifythattheconnectionhas

been tightened.

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 0.75 +

6(3/8in.) 0.75+

8(1/2in.) 0.75+

10 (5/8 in.) 1.00 +

12 (3/4 in.) 0.75 +

16 (1 in.) 0.75 +

0.25

0.25

0.25

0.25

0.25

0.25

Figure 3

Final

Position

Mark Nut

and Body

Extend Line

Initial

Position

Finger Tight After ProperTightening

Figure 4

Reelmaster 5010 SeriesHydraulic System (Rev. C) Page 4 -- 4

Page 37

SAE Straight Thread O--Ring Port -- Non--adjustable

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches or any foreign material.

2. Always replace theO--ring sealwhen this typeoffitting shows signs of leakage.

3. Lubricate the O--ring with a light coating of oil.

O--Ring

4. Install thefitting into the port and tighten it down full

length until finger tight.

5. Tighten the fitting to the correct Flats From Finger

Tight (F.F.F.T.).

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25

0.25

SAE Straight Thread O--Ring Port -- Adjustable

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches or any foreign material.

2. Always replace theO--ring sealwhen this typeoffitting shows signs of leakage.

3. Lubricate the O--ring with a light coating of oil.

4. Turn back the jamnut as faras possible. Makesure

the back up washerisnotloose and is pushedupasfar

as possible (Step 1).

Figure 5

Lock Nut

Back--up Washer

O--Ring

System

Hydraulic

5. Install the fitting into the port and tighten finger tight

until the washer contacts the face of the port (Step 2).

6. Toputthefittinginthedesired position, unscrew itby

the required amount, but no more than one full turn

(Step 3).

7. Hold thefitting in the desired positionwith awrench

and turn the jam nutwith anotherwrench to the correct

Flats From Finger Tight (F.F.F.T.) (Step 4).

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25

0.25

Reelmaster 5010 Series Hydraulic System (Rev. C)Page 4 -- 5

Figure 6

Step 3Step 1

Step 2 Step 4

Figure 7

Page 38

Relieving Hydraulic System Pressure

Beforedisconnectingorperforming any work on the hydraulic system, all pressure in the hydraulic system

mustbe relieved.Parkmachineonalevelsurface,lower

cutting units fully, stop engine and engage parking

brake.

To relieve hydraulic pressure in traction circuit, move

tractionpedaltobothforwardandreverse directions. To

relieve hydraulic pressure in steering circuit, rotate

steering wheel in both directions.

Traction Circuit Component Failure

The traction circuit on Reelmaster 5010 series machines is a closed loop system that includes the piston

(traction) pump andtwo (2) wheel motors (4wheel motors on machines equipped with optional CrossTrax

AWD kit). If a component in the traction circuit should

fail,debrisandcontaminationfromthefailedcomponent

will circulate throughout the traction circuit. This contamination can damageothercomponents in thecircuit

so it mustberemoved to preventadditionalcomponent

failure.

If acomponent failure occurs in the traction circuit,it is

recommended that the entire traction circuit be disassembled,drainedandthoroughlycleanedtoensure that

all contamination is removed fromthe circuit.If any debrisremainsinthetractioncircuitandthe machine isoperated, the debris can cause additional component

failure.

TM

To relieve hydraulic pressure in lift circuit, start engine

and fully lower thecuttingunits. Turn key switch toOFF

and remove key from the ignition switch.

System pressure in cutting circuit is relieved when the

cutting units are disengaged.

Oncethefilter hasbeenplacedin thecircuit,operatethe

tractioncircuittoallow oilflowthroughthecircuit. Thefilter will remove contamination from the traction circuit

during circuit operation.The filter canbe removed from

the machine after contamination has been removed

from the traction circuit.

IMPORTANT: When operatingthetraction system with

the highpressure filter installed, make sure that flow is

always directed through the filter before entering a replaced component (e.g. do notpress the traction pedal

in the reverse direction if the filter is placed for forward

direction flow). If flow is reversed, debris from the filter

will re--enter the traction circuit.

NOTE: The traction pump case drain could allow tractioncircuitcontaminationtocontaminateotherhydraulic

circuits on the machine.

An alternative method of removing traction circuit contamination would be to temporarily install a high pressurehydraulicoilfilter(seeSpecialTools)intothecircuit.

Thefiltershouldbeusedwhenconnectinghydraulictest

gaugesinordertotesttractioncircuitcomponentsorafter replacing a failed traction circuit component (e.g.

traction(piston)pumporwheelmotor).Thefilterwillensure that contaminates are removed from the closed

loopandthus,donotcauseadditionalcomponentdamage.

Reelmaster 5010 SeriesHydraulic System (Rev. C) Page 4 -- 6

Page 39

Hydraulic Schematics

The hydraulic schematics for Reelmaster 5010 series

machines are located inChapter9 -- Foldout Drawings.

System

Hydraulic

Reelmaster 5010 Series Hydraulic System (Rev. C)Page 4 -- 7

Page 40

Hydraulic Flow Diagrams

IN

P

V1

R10

T

OUT

FRONT

C5 L

C1

C1 L

C4

C4 L

CV4

SV1

G4

SV2

SVRV

P4

CV1

C5

RIGHT

FRONT

C2/3

CV5

CV23

R7

T

SV3

C2/3 L

LIFT

CONTROL

MANIFOLD

LEFT

FRONT

CENTER

CONTROL

STEERING

L

R

VALVE

STEERING

CYLINDER

RIGHT

REAR

LEFT

REAR

Working Pressure

Traction Circuit (Forward Shown)

Reelmaster 5010 (5510/5610 Shown)

Low Pressure (Charge)

Return or Suction

Flow

RH

B

A

M7

M6

B

A

LH

G5

A

EXTERNAL CASE DRAIN

P3 P4

100 MESH

SUCTION

P2

P1

STRAINER

WHEEL

MOTORS

TRACTION

FORWARD

R3

B

R5 R4

REAR MOW CIRCUIT

G6

R9

G1

M3

C.U. 3

R11

M2

C.U. 2

OR1

R11

M1

BKLP1

MR1

OR4

CV

OR3

FC1

EP1

MSV2

MSV1

R1

P1

T

FRONT MOW CIRCUIT

BKLP2

MR2

FC2

EP2

R2

P2

M5

C.U. 5C.U. 1C.U. 4

R11

M1

R11R11

M4

M2

MOW

CONTROL

MANIFOLD

OR2

G2

P5

CASE

DRAIN

INTERNAL

R8

Figure 8

Reelmaster 5010 SeriesHydraulic System (Rev. C) Page 4 -- 8

Page 41

Traction Circuit

The hydraulic traction circuit consists of a variable displacementpistonpump(P5)connectedinaclosedloop,

parallelcircuittotwo(2)orbital rollervanewheelmotors.

The traction pumpinput shaft isrotated by a driveshaft

that is driven from the engine flywheel.

Traction circuit pressure (forward and reverse) can be

measured at test ports located in the hydraulic tubes

that connect the front wheel motors.

Forward Direction (Fig. 8)

Pushing the top ofthetraction pedal anglesthetraction

pump swash plate to create a flow of oil.This oil flow is

directed to the wheel motors via hydraulic hoses and

tubes to drive the wheels in the forward direction. Forward traction pressure is limited to 3625 PSI (250 bar)

by the forward traction relief valve (R3) located in the

traction pump.

Oilflowingfromthewheelmotorsreturnstothevariable

displacement pump and is continuously pumped

through the tractioncircuit as long as thetraction pedal

is pushed.

Theangleoftheswashplate determines pump flow and

ultimatelytractionspeed.Whenthetractionpedalisdepressedasmallamount,asmallswashplaterotationr esultsinlowpumpoutputandlowertractionspeed.When

the traction pedal is depressed fully, the pump swash

platerotatesfullytoprovidemaximumpumpoutputand

traction speed.

Gearpumpsection(P3)supplies oil flowforthesteering

circuitand also provides aconstantsupplyof charge oil

to the closed loop traction circuit. This charge oil provideslubrication fortractioncircuitcomponentsandalso

replenishes traction circuit oil thatis lost due to internal

leakage in the traction circuit.

Reverse Direction

The traction circuitoperates essentially the same inreverse as it does in the forward direction. However, the

flow through thecircuitis reversed. Pushingthe bottom

of the traction pedal rotates the traction pump swash

plate to create a flow of oil. This oil is directed to the

wheel motors to drive the wheels in the reverse direction. Reverse traction pressure is limited to 3625 PSI

(250bar)bythereversetractionreliefvalve(R4)located

in the traction pump.

Oil flowing from the wheelmotorsreturns to the traction

pump and is continuously pumped through the closed

loop traction circuit as long as the traction pedal is

pushed.

Thecharge circuit and flushingvalve(R10)function the

same in reverse as they do in the forward direction.

TM

CrossTrax

On machines equipped with the optional CrossTrax

AWD (Optional)

TM

AWD kit, four wheel motors are used (Fig. 9). Traction

pump flow is directed tothe front tiresand theopposite

rear tires to maximize traction. To reduce tire scuffing

when turning, traction system pressure is equalized in

theAWDmanifold withanorificeandabi--directionalrelief valve. Check valves in the AWD manifold allow the

rear wheel motors to over run during tightturns.

CrossTrax AWD Hydraulic Schematic

TM

G5

System

Hydraulic

Gearpump(P3)takesitssuction from the hydraulic reservoir.Charge pump flow is directed to the low pressure

side of the closedlooptractioncircuit. Charge pressure

is limited by the charge relief valve (R5) located in the

tractionpump.Thecharge relief pressureis200PSI(14

bar).

The piston pump (P5) includes a flushing valve (R10)

thatbleedsoffasmall amount of hydraulic fluid for coolingoftheclosedlooptractioncircuit.Thechargesystem

replenishesoilthatisbled from the traction circuitbythe

flushing valve.

Reelmaster 5010 Series Hydraulic System (Rev. C)Page 4 -- 9

Figure 9

Page 42

IN

P

L

V1

R10

T

OUT

CONTROL

STEERING

FRONT

CENTER

C1 L

C4

C4 L

CV4

SV1

G4

SV2

SVRV

P4

C5 L

C1

C5

RIGHT