Toro 51950, 51970, 51990 Operator's Manual

Operator’s Manual

Trimmer/Brushcutter

English (EN), French (FR), and Spanish (ES)

English (EN), French (FR), and Spanish (ES)

WARNING:

Form No. 3353-567 Rev A

Before you use your new trimmer/brushcutter, read the following help-

re or explosion from gasoline will burn you and

2.

Mix all of the 2-cycle oil provided with 1 US gallon of 87-octane, unleaded

Fill the trimmer’s gas tank carefully.

When you restart the trimmer/brushcutter and you are not sure whether the engine is still warm, set

the choke lever to

(Choke Open) and pull the starter cord. If the engine does not start within 5

pulls, refer to “To Start a Cold Engine” later in this manual.

Will the engine start? If not, it may be ooded. Relax, this is easy to correct. Set the choke lever to

(Choke Open). Squeeze the trigger and pull the starter cord quickly for 10 to 12 pulls.

If the engine does not start, refer to “Troubleshooting” later in this manual or call toll-free at

WARNING:

Printed in USA

All rights reserved

All rights reserved

1-866-574-9242

CALL

trimmer/brushcutter, call us toll free at

3

Table of Contents

Introduction

Product Labels

Features

Product Speci cations

Assembly

Unpacking

Removing the Attachment from the Upper Shaft

Attaching the Front Handle

Attaching the Shoulder Strap

Attaching the Grass De ector

Applications

Mixing the Fuel

Filling the Tank

20

Maintenance

21

Emissions Maintenance Schedule

21

Replacing the Cutting Line

Replacing the Spool

23

23

Replacing the Spark Arrester

23

Replacing the Spark Plug

24

25

Warranty

26-27

Table of Contents

4

We would like for you to be completely satis ed with your new product, so feel free to contact an authorized service dealer

Whenever you contact an authorized service dealer, always know the model and serial numbers of the product. These num-

bers will help the service representative provide exact information about your speci c product. You will nd the model and

For your convenience, write the product model and serial numbers in the space below.

Serial No.

Read this manual carefully to learn how to operate and maintain your product correctly. Reading this manual will help you

However, regardless of the hazard, be extremely careful. Two other words, “Important” and “Note,” highlight information.

Signal Word

Indicates an imminently hazardous situation which, if not avoided, will result in death or

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or

Indicates a potentially hazardous situation which, if not avoided, may result in minor

property damage.

Advises you of important information or instructions vital to the operation or maintenance

Advises you of additional information concerning the operation or maintenance of the

5

meet or exceed the requirements of the current version of

ANSI B175.3, safety requirements for gasoline-powered

Physical Condition of the Operator.

Do not operate

this product when tired, ill, or under the in uence of

Always wear long heavy

pants, boots, and gloves. Do not wear loose cloth-

Protective Accessories Requirements.

Wear eye

protection marked to comply with ANSI Z87.1

protection during extended periods of operation.

Inspect the

product before each use. Replace damaged parts.

parts that are cracked, chipped, or damaged in any

way. Make sure the cutting attachment is properly

position recommended by the manufacturer. Use

manufacturer. For example, never use wire or wire-

rope, which can break off and become a dangerous

projectile.

Proper Stance.

Keep rm footing and balance. Do

not overreach. Keep the cutting attachment below

waist level. Keep all parts of your body away from

the rotating cutting attachment and hot surfaces.

Exhaust Gases.

Never start or run the product inside

Fueling.

Mix and pour fuel outdoors where there are

no sparks and ames. Slowly remove the fuel cap

product. Move at least 30 ft. (9 m) away from the

Work Area.

use. Remove all objects, such as rocks, broken glass,

nails, wire, or string, that can be thrown or become

WARNING:

Read and understand all instructions. Failure to follow all instructions may result in serious personal injury

keep all children, bystanders, and pets outside a 50

Dangerous Environments.

use the product in damp or wet locations.

During carburetor adjust-

ments the cutting attachment may spin. Therefore,

you should wear protective equipment and observe

tor. For products equipped with a clutch, be sure the

the product.

Use the Right Product.

Use the product for the

without proper installation of all required parts. Fail-

ure to use the proper parts can cause the blade to y

broken, or damaged in any way.

Use the Right Equipment.

Always use the barrier

bar on the front handle and the shoulder strap with

the brushcutter.

Blade Thrust.

Blade thrust may occur when the

mediately cut. A blade thrust can be violent enough

to cause the product and/or operator to be propelled

product. Blade thrust can occur without warning if

the blade snags, stalls, or binds. This is more likely

to occur in areas where it is dif cult to see the mate-

rial being cut.

A coasting blade can cause

trol until the blade has completely stopped rotating.

Safety Rules

6

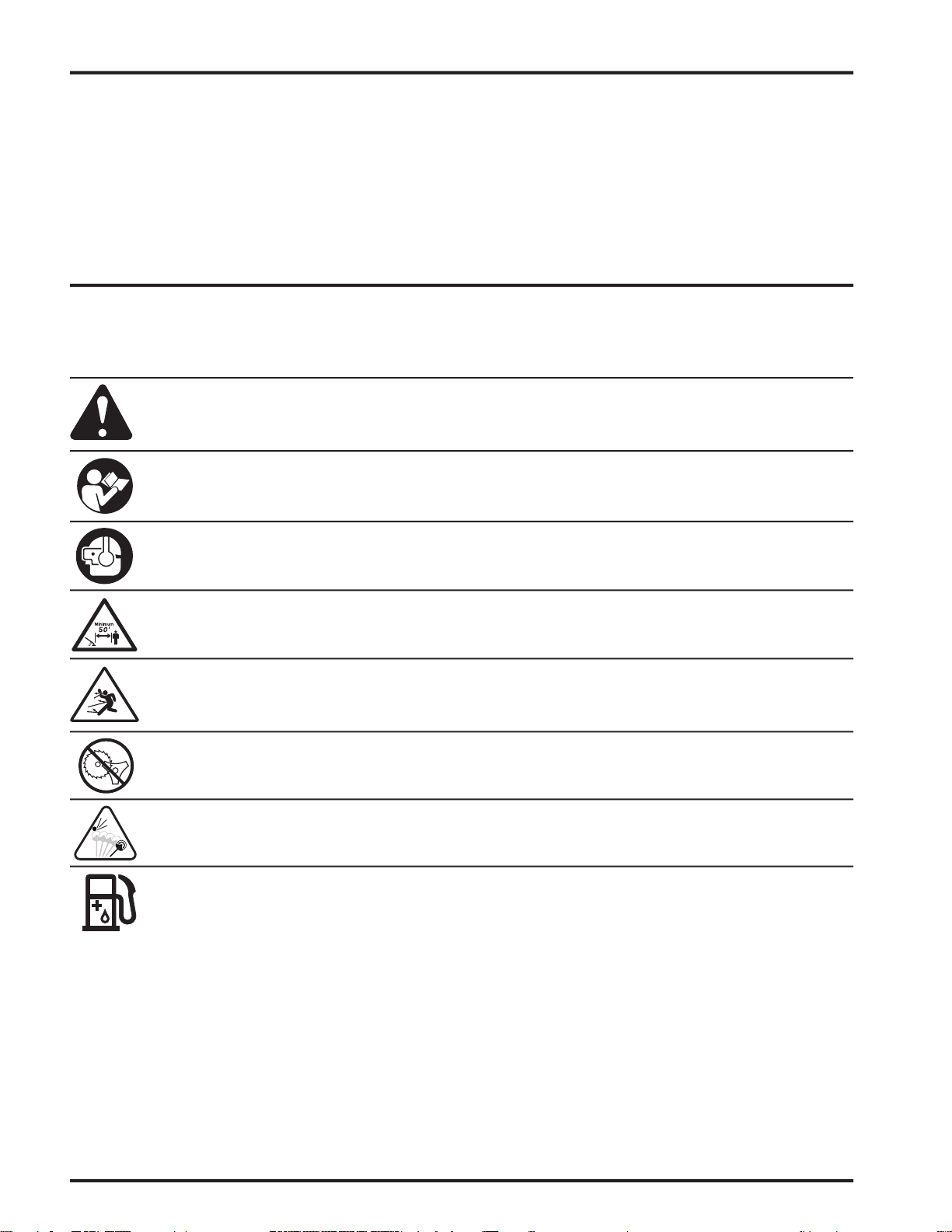

Symbols

4442 to use or operate this engine without a spark arrester muf er on any forest-covered, brush-covered, or grass-

Refer to them frequently and use them to instruct others who may use this product. If you

Symbol

Precautions that involve your safety.

Read the Operator’s Manual

Read the operator’s manual before starting or operating this product.

Failure to follow operating instructions and safety precautions in the

Wear Eye and Hearing Protection

Wear eye protection which is marked to comply with ANSI Z87.1 as

well as hearing protection when operating this equipment.

Keep Bystanders Away

Keep all bystanders at least 50 feet (15 m) away.

Richochet

property damage.

No Blade

Do not install or ues any type of blade on a product displaying this

Blade Thrust

Beware of blade thrust. Products authorized for blade use will

Use unleaded gasoline intended for motor vehicle use with an octane

rating of 87 ([R + M] / 2) or higher. This product is powered by a

2-cycle engine and requires pre-mixing gasoline and 2-cycle oil.

Symbols

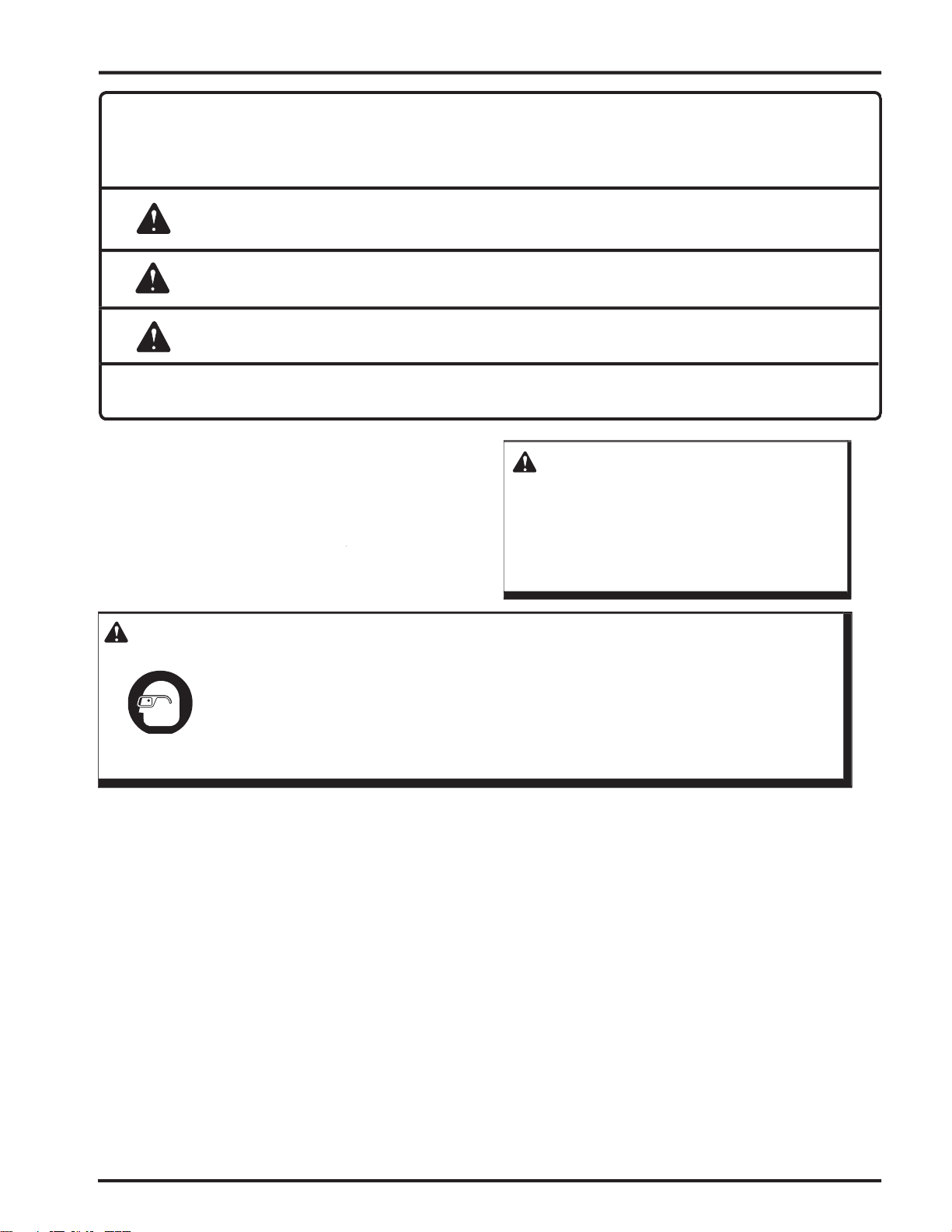

The following signal words and meanings are intended to explain the levels of risk associated with

this product.

SYMBOL

SIGNAL

Indicates an imminently hazardous situation, which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

Indicates a potentially hazardous situation, which, if not avoided, may result

SERVICE

be performed only by a quali ed service tech ni cian. For

AU THO RIZED SERVICE CENTER

for repair. When

WARNING:

to use this product until you read thoroughly and

un der stand completely the op er a tor’s manual. Save

this op er a tor’s manual and review fre quent ly for

may use this prod uct.

needed. We recommend Wide Vision Safety Mask for use over eyeglasses or standard

with ANSI Z87.1.

WARNING:

WARNING:

8

Product labels and instructions are easily visible to the operator and are located near any area of potential danger.

Replace damaged or lost labels

Part No. 983961-001 (Shoulder Strap)

Part No. 983647-001

Part No. 983648-001

Part No. 984032-001

Part No. 985102-001

Part No. 984105-001

Part No. 984240-001

Part No. 983780-001

50' 15m

50' 15m

50' 15m

9

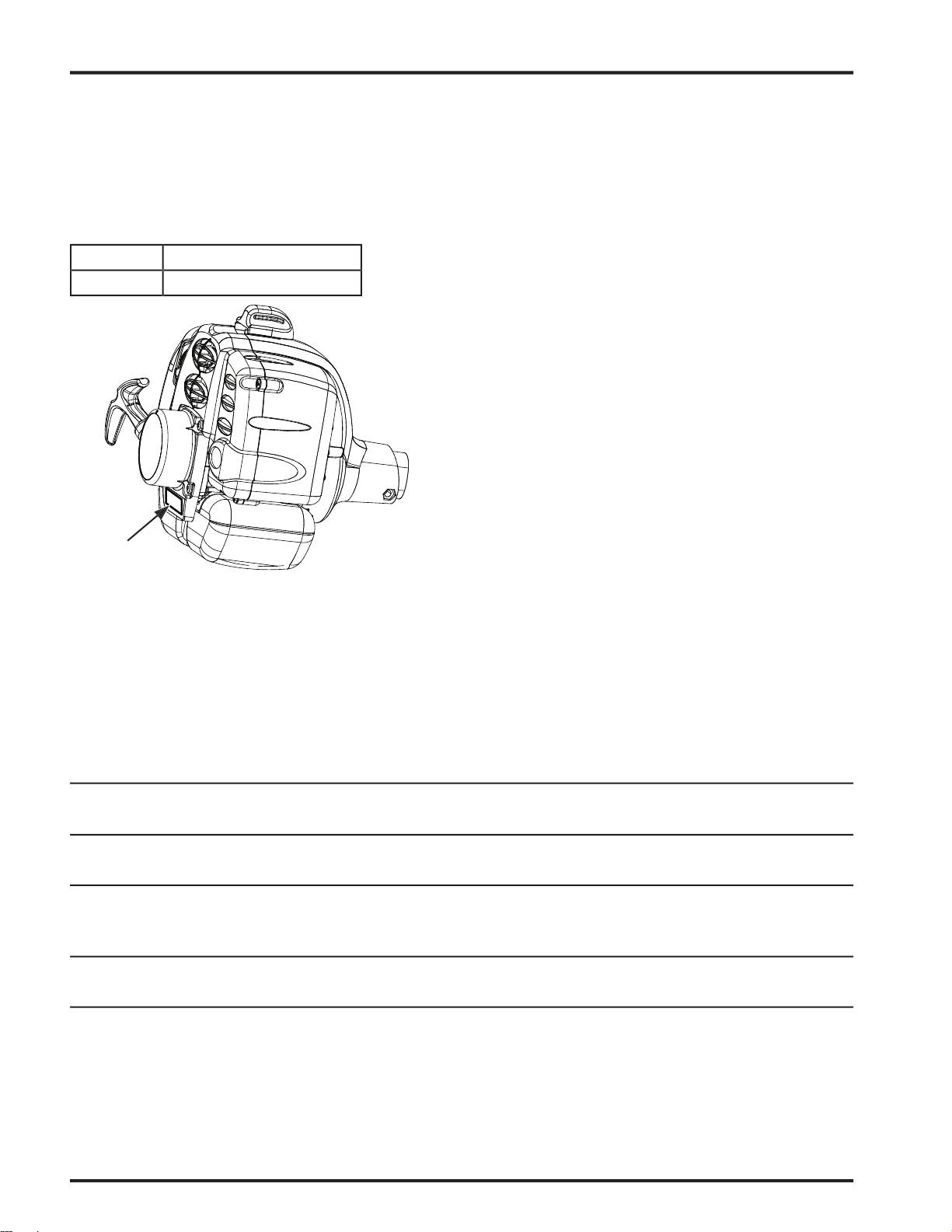

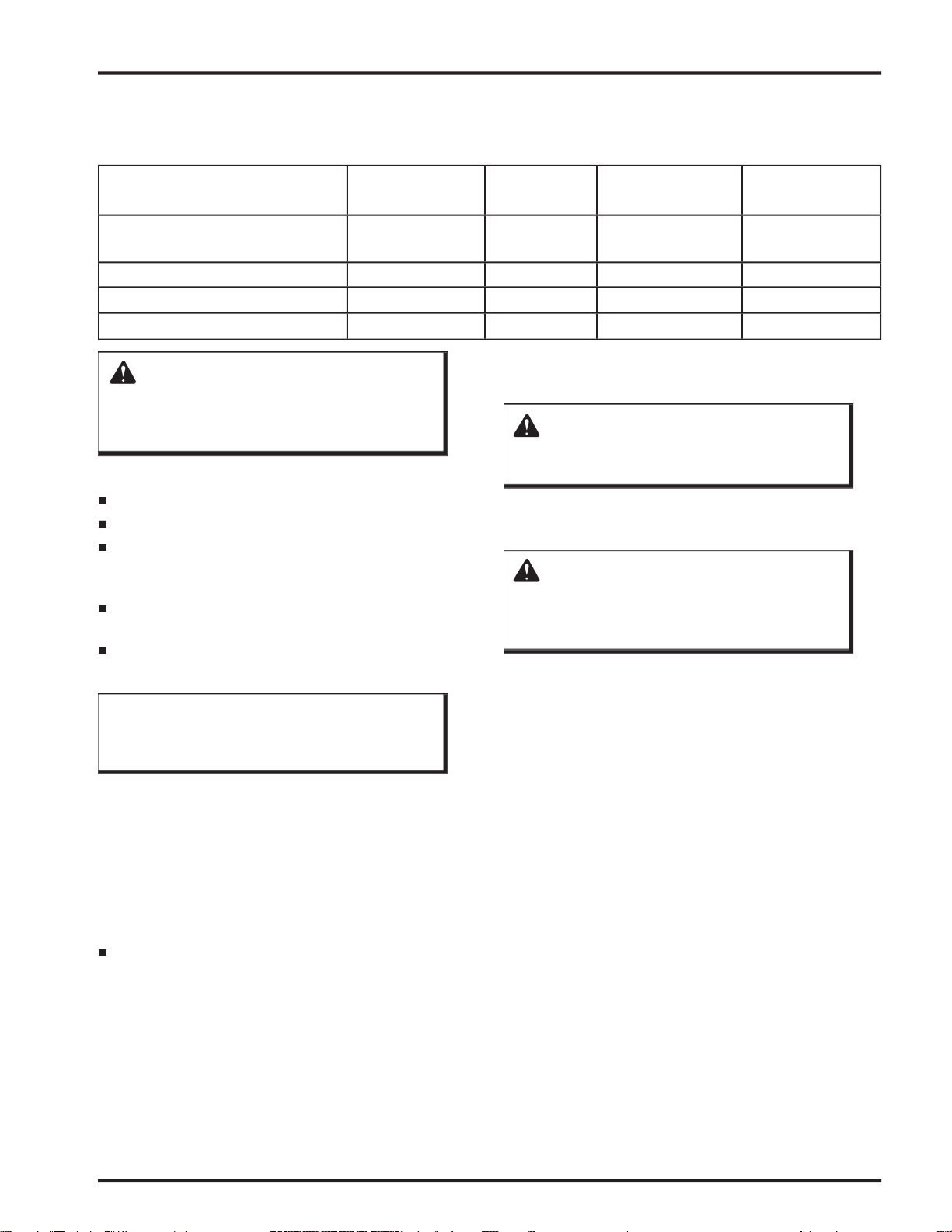

Specification

Engine

25.4 cc Full Crank

Model No. 51950

Model No. 51970

Model No. 51990

Line Size

Weight

Model No. 51950

Model No. 51970

Model No. 51990

Specifications

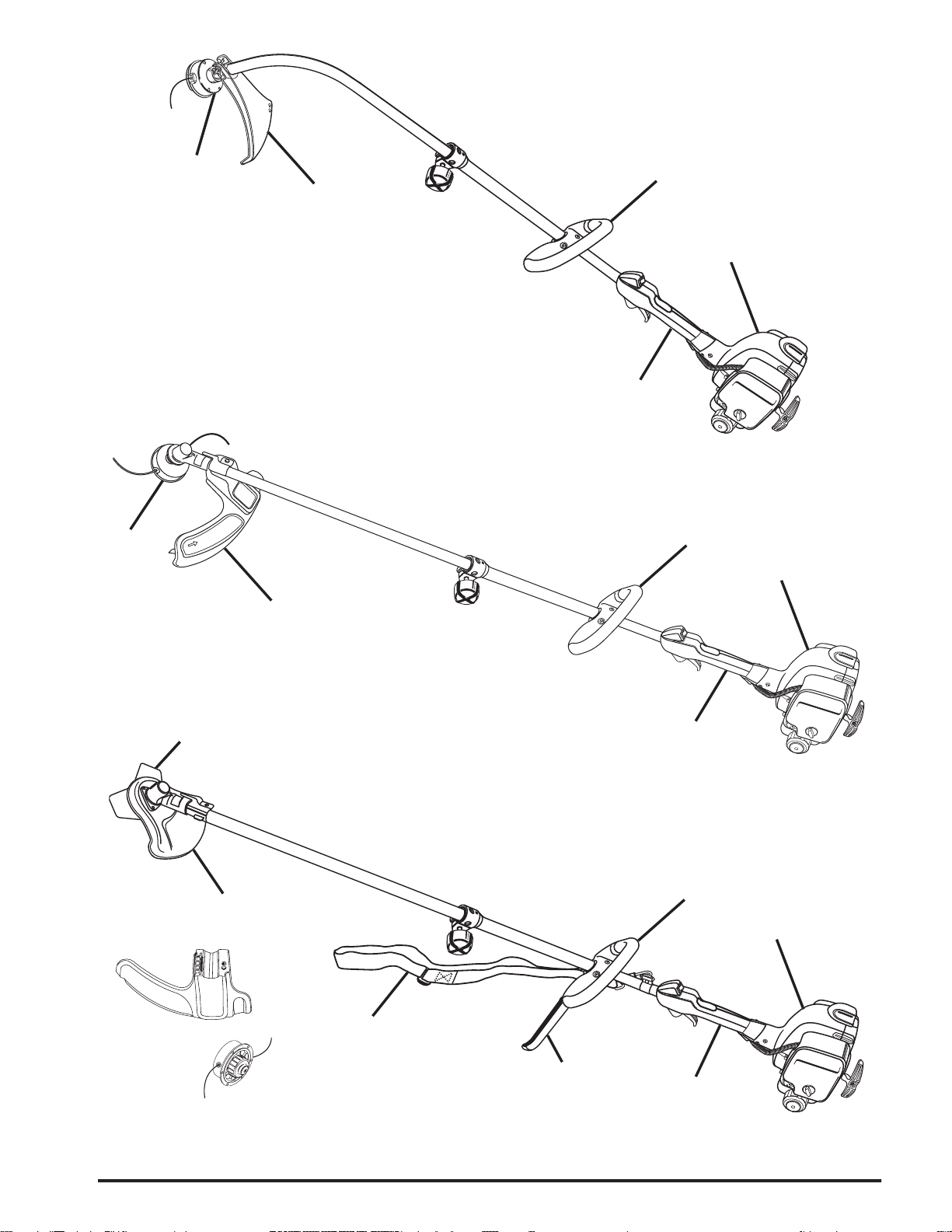

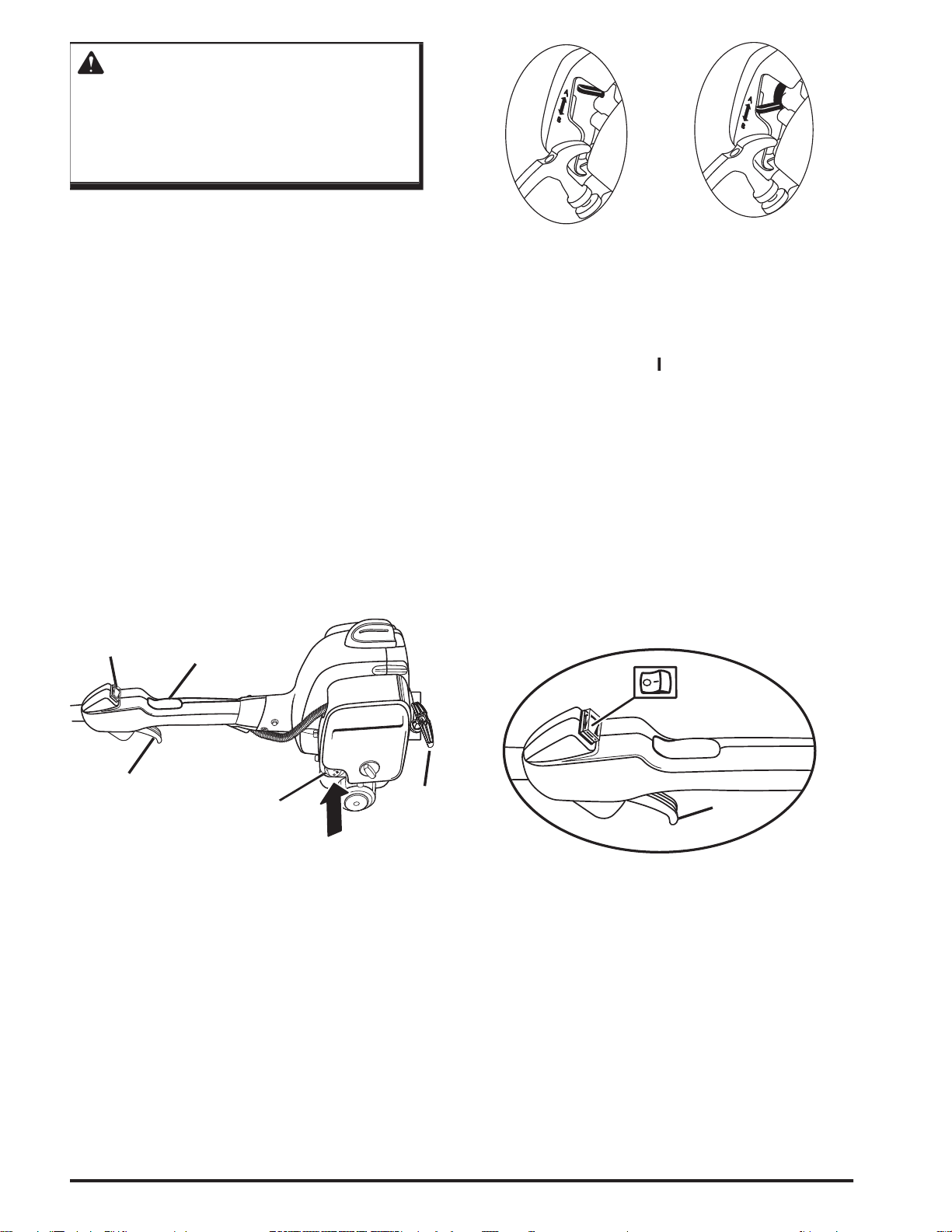

See Figure 1.

Before attempting to use this product, familiarize yourself

with all operating features and safety rules.

the drive shaft.

Shoulder Strap

the product.

restrains the operator in position and maintains a proper

Shoulder

Strap

Trigger

Trigger

Trigger

Straight Shaft

Inspect the product carefully to make sure no breakage

Do not discard the packing material until you have

product.

If any parts are damaged or missing, please call toll free

Upper shaft (Power head) (1)

Attachment shaft (Cutting head) (1)

Handle (1)

Lock washer (1) (Model No. 51950)

Flat washer (1) (Model No. 51950)

Wing nut (1) (Model No. 51950)

Head locking tool (1) (Model No. 51990)

Assembly

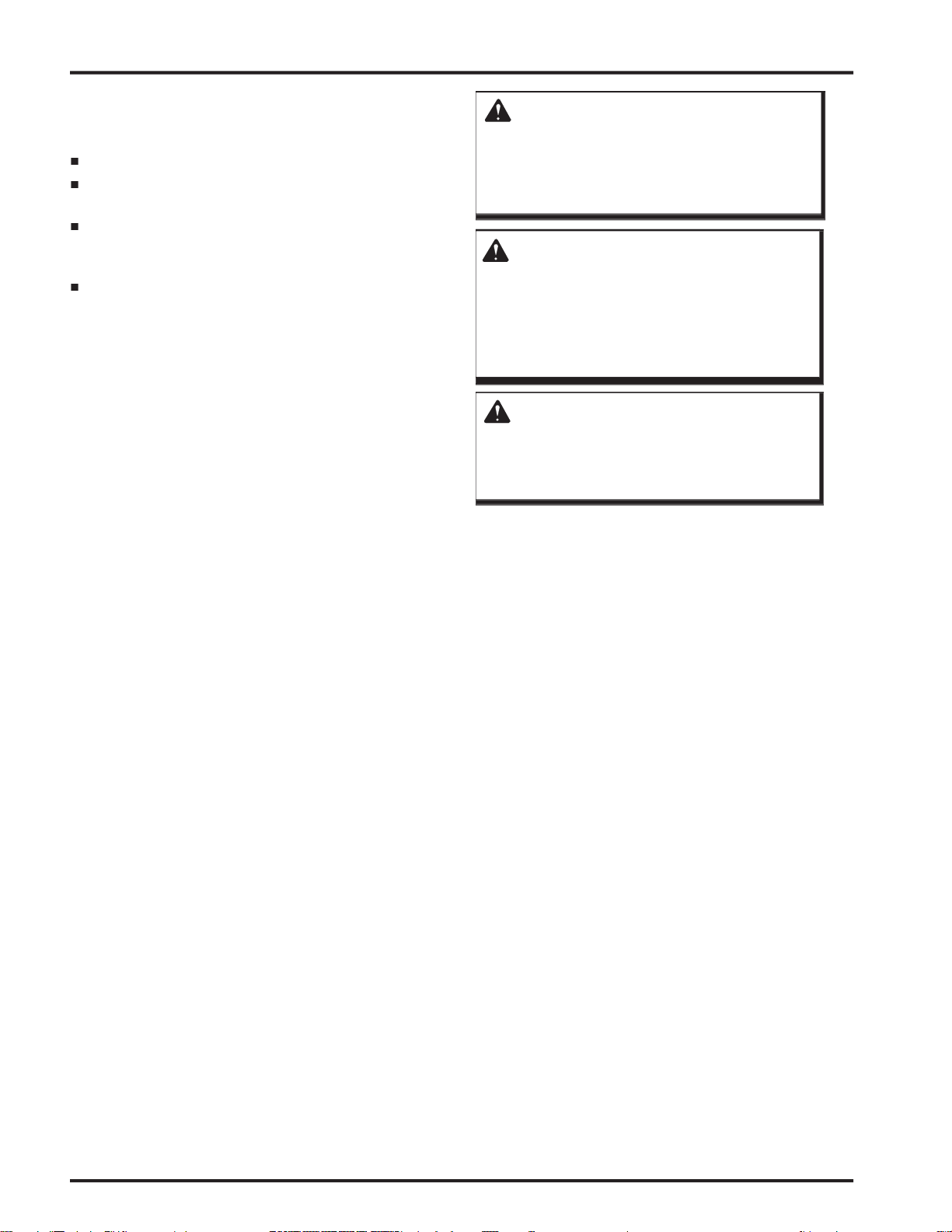

WARNING:

product until the missing parts are replaced.

Failure to do so could result in serious personal

WARNING:

Do not attempt to modify this tool or create

tool. Any such alteration or modi cation is

misuse and could result in a hazardous condition

WARNING:

Do not start trimmer until assembly is complete.

Failure to comply could result in accidental

Assembly

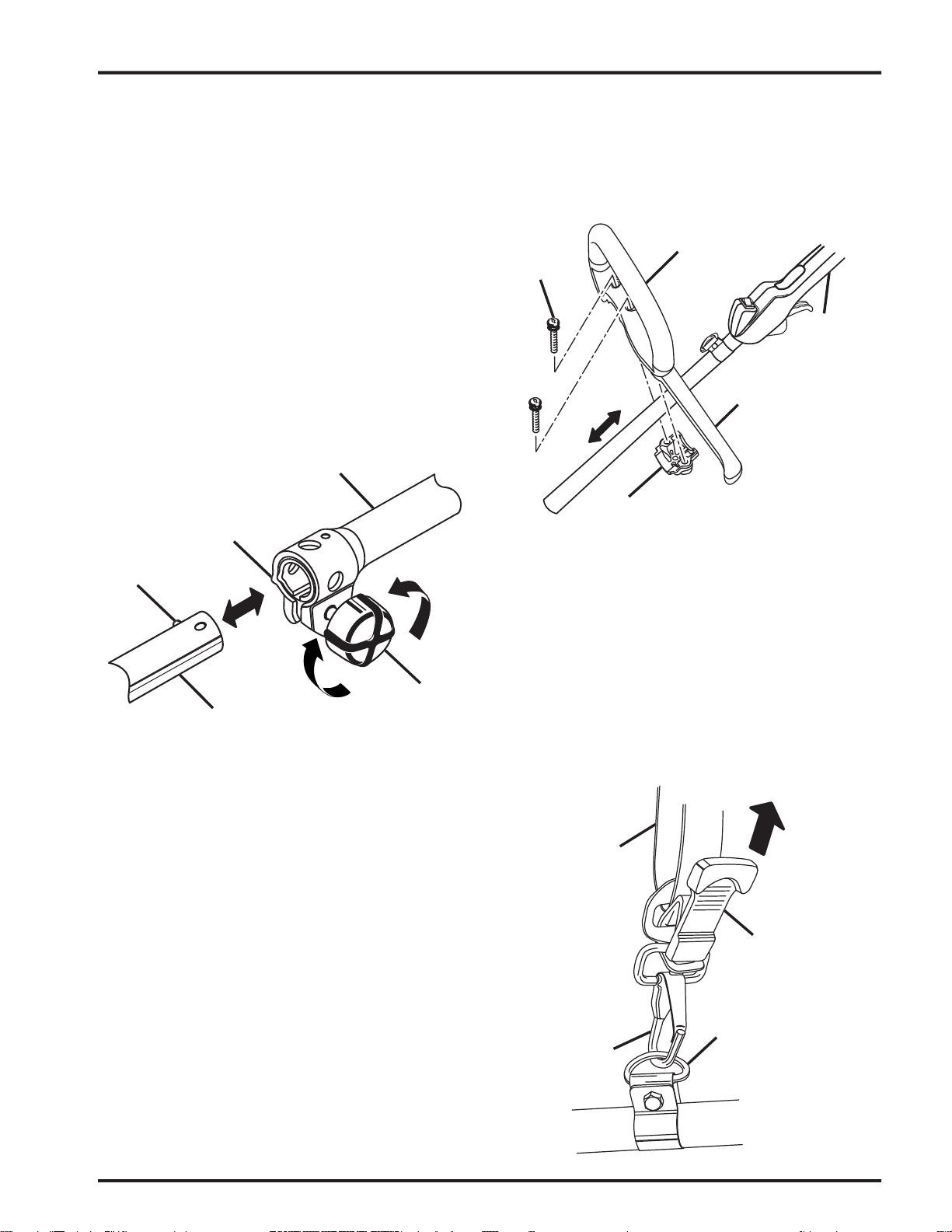

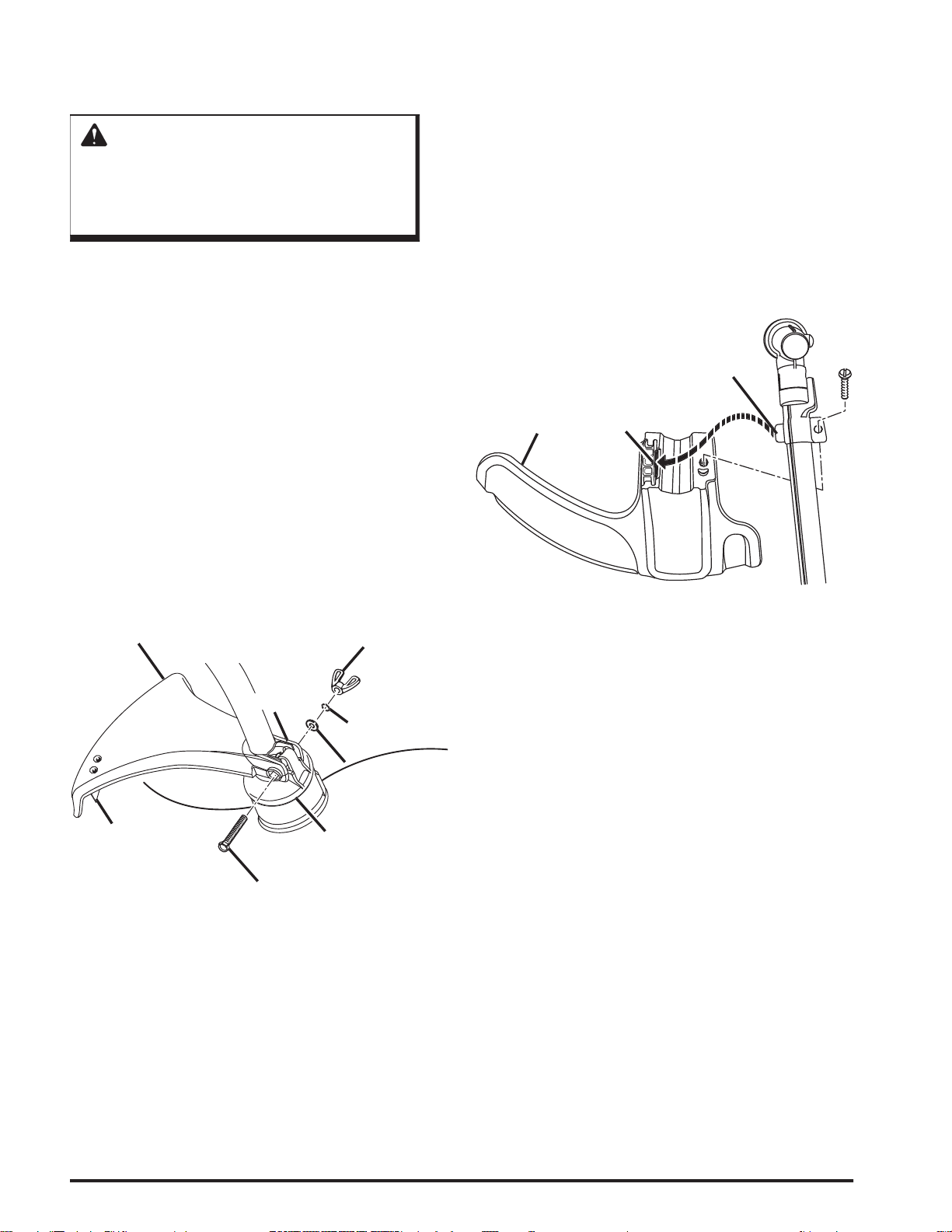

See Figure 2.

Follow these steps to connect the attachment to the upper

Loosen the knob by turning it counterclockwise.

Remove the end cap from the attachment shaft.

3.

Align the button on the attachment shaft with the guide

recess on the upper shaft.

You may need to turn the attachment shaft to

properly align the two shafts.

5.

See Figure 2.

Follow these steps to remove the attachment from the upper

Loosen the knob by turning it counterclockwise.

Push the button while pulling out the attachment.

Attaching the Front Handle

See Figure 3.

Follow these steps to attach the front handle.

Remove the slotted Torx™ screws to separate the

handle from the handle support.

2.

Press the handle onto the top of the upper shaft, no

handle, angling the handle toward the trigger handle.

3.

Place the handle along the upper shaft to a position that

Place the handle support on the bottom of the tube on

the opposite side of the front handle.

5.

Attaching the Shoulder Strap

See Figure 4.

Follow these steps to attach the shoulder strap.

2.

Adjust the strap to a comfortable position.

To quickly release the product from the shoulder

Assembly

Attachment

Shaft

Shaft

Slotted

Torx

Screw

Trigger

51990

Support

Strap

Tab

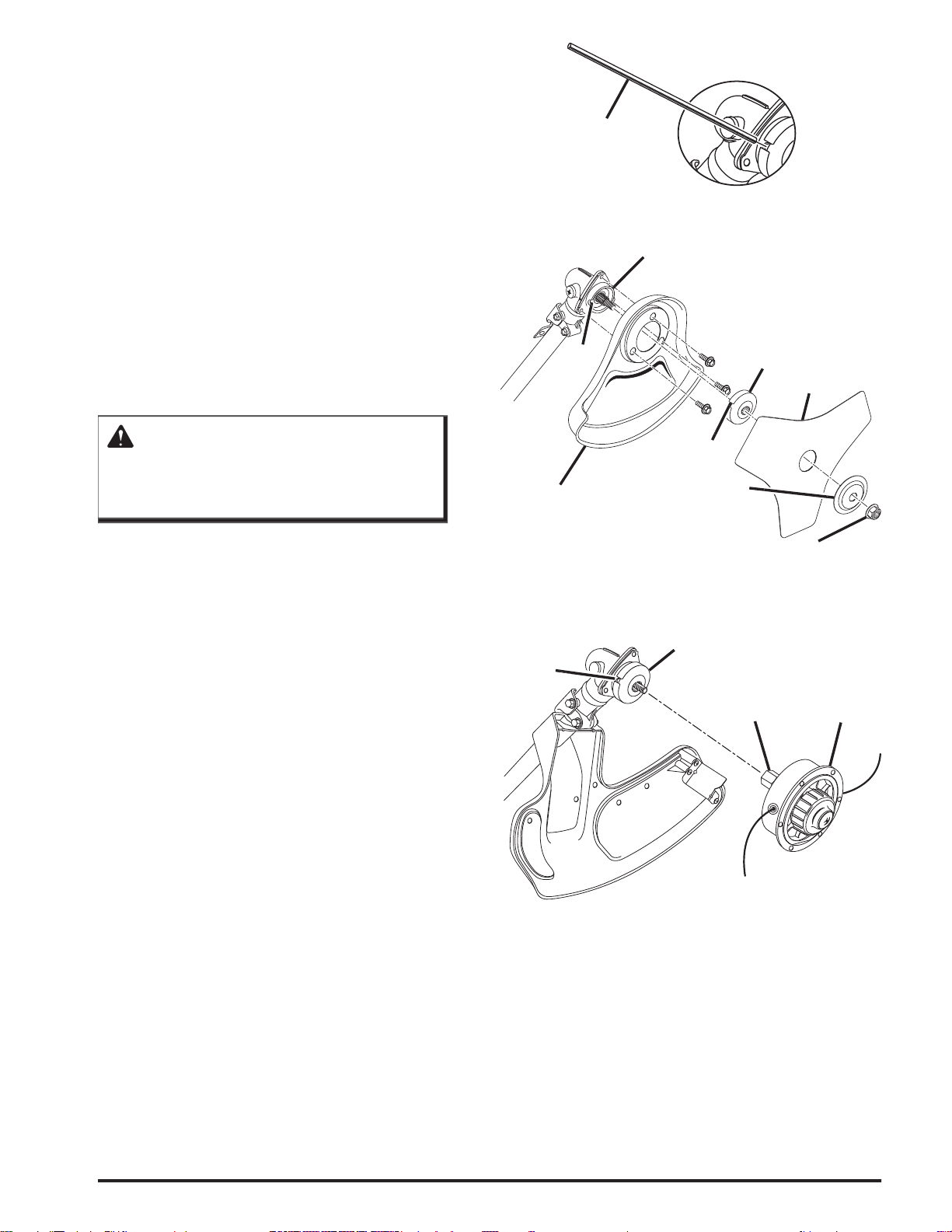

Attaching the Grass Deflector

Attaching the grass de ector differs depending on the type

WARNING:

to avoid contact can result in serious personal

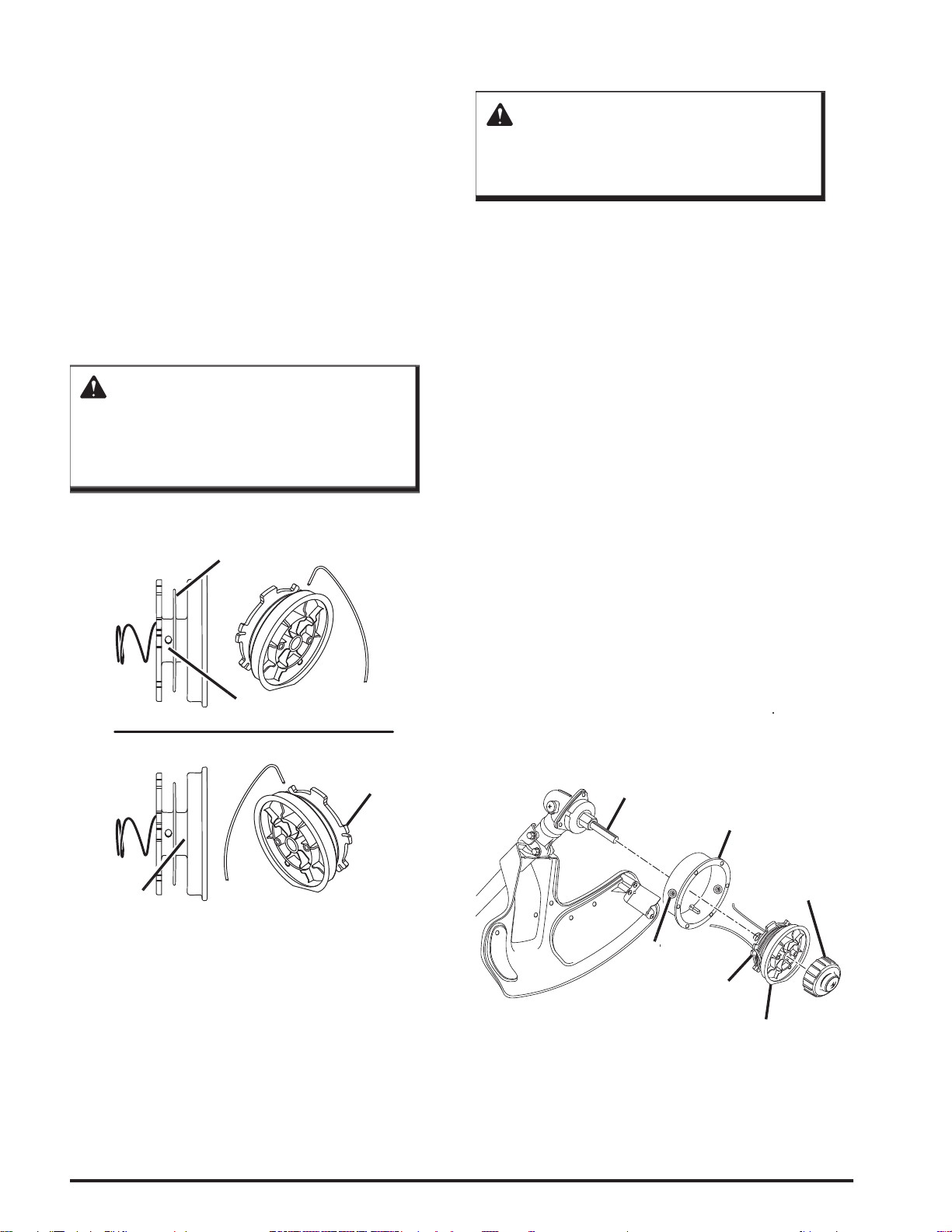

To Attach the Curved Shaft Grass Deflector

See Figure 5.

Follow these steps to attach the curved shaft grass de ector.

Press the grass de ector onto the bottom of the curved

Lift the grass barrier up slightly.

3.

Insert the hex head cap screw through the grass de ec-

tor, bracket, and grass barrier.

Place the at washer and lock washer on the hex head

5.

Place the wing nut or hex nut on the hex head cap screw

To Attach the Straight Shaft Grass Deflector

See Figure 6.

Follow these steps to attach the straight shaft grass de ector.

Remove the slotted hex head screw from the grass

2.

Insert the tab on the mounting bracket in the slot on the

3.

Align the screw hole in the mounting bracket with the

4.

Insert the slotted hex head screw through the mounting

bracket and into the grass de ector.

5.

Assembly

Wing

Straight Shaft

Washer

Washer

Tab

Slot

Trimmer

blade, remove the brushcutter guard, attach the grass de ec-

tor, and install the trimmer head assembly.

To Remove the Blade and Brushcutter Guard

See Figure 7 and Figure 8.

Follow these steps to remove the blade and brushcutter

Align the slot in the anged washer with the slot in the

Place the head locking tool through the slot in the

anged washer and gear head.

3.

Remove the blade nut by turning it clockwise (left-

handed threads).

4.

Remove the cupped washer and the blade.

WARNING:

Be careful when handling the blade. It is sharp.

Failure to heed this warning can result in serious

personal injury.

5.

Remove the anged washer from the gear shaft and

retain it for the trimmer head assembly installation.

6.

Remove the three screws securing the brushcutter

Remove the brushcutter guard.

use.

To Attach the Grass Deflector

Refer to “To Attach the Straight Shaft Grass De ector”

To Install the Trimmer Head Assembly

See Figure 9.

Follow these steps to install the trimmer head assembly.

Align the slot in the anged washer with the slot in the

2.

Insert the head locking tool through the anged washer

3.

Install the drive shaft and trimmer head assembly onto

the gear shaft by turning the drive shaft counterclock-

wise (left-handed threads).

Assembly

Tool

Slot

Washer

Slot

Washer

Trimmer

Assembly

Shaft

Washer

trimmer head assembly, remove the grass de ector, attach

the brushcutter guard, and install the blade.

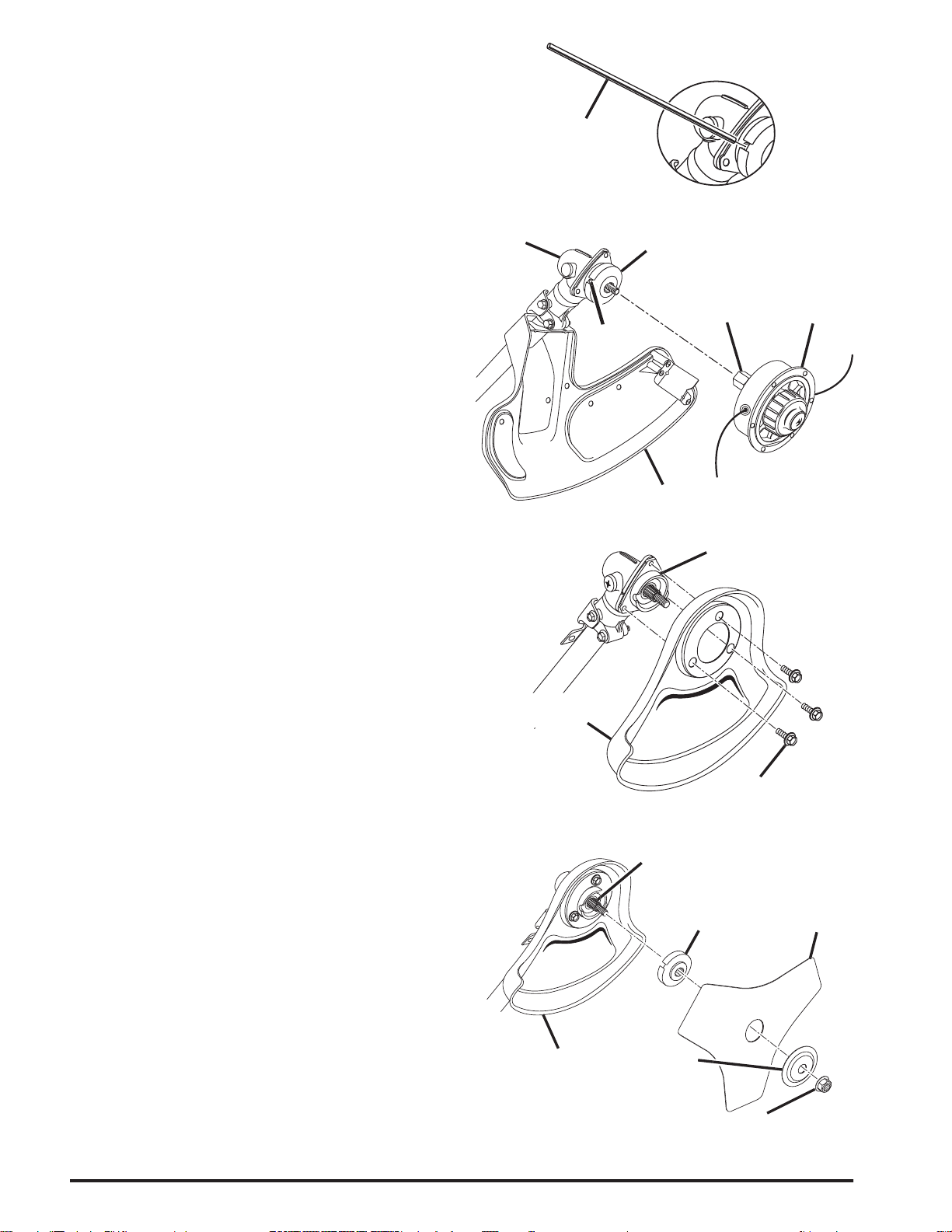

To Remove the Trimmer Head Assembly and Grass

See Figures 10 and 11.

Follow these steps to remove the trimmer head assembly

Align the slot in the anged washer with the slot in the

Insert the head locking tool through the anged washer

3.

Remove the drive shaft and trimmer head assembly by

turning the drive shaft clockwise (left-handed threads).

Remove the anged washer and retain it for the blade

5.

Remove the screw securing the grass de ector.

6.

Remove the grass de ector.

To Attach the Brushcutter Guard

See Figure 12.

brushcutter guard.

Follow these steps to attach the brushcutter guard.

Place the guard onto the gear head as shown.

Insert the three hex head screws from the bottom

through the guard into the gear head.

3.

To Install the Blade

See Figure 13.

Follow these steps to install the blade.

Place anged washer over the gear shaft with the

hollow side toward the brushcutter guard.

blade ts at and the raised hub goes through the hole

3.

Install the cupped washer with the raised center away

4.

Place the blade nut onto the gear shaft.

5.

Insert the head locking tool through the anged washer

6.

Install the blade nut by turning it counterclockwise

Assembly

Tool

Trimmer

Assembly

Shaft

Washer

Straight Shaft

Slot

Screw

Washer

Washer

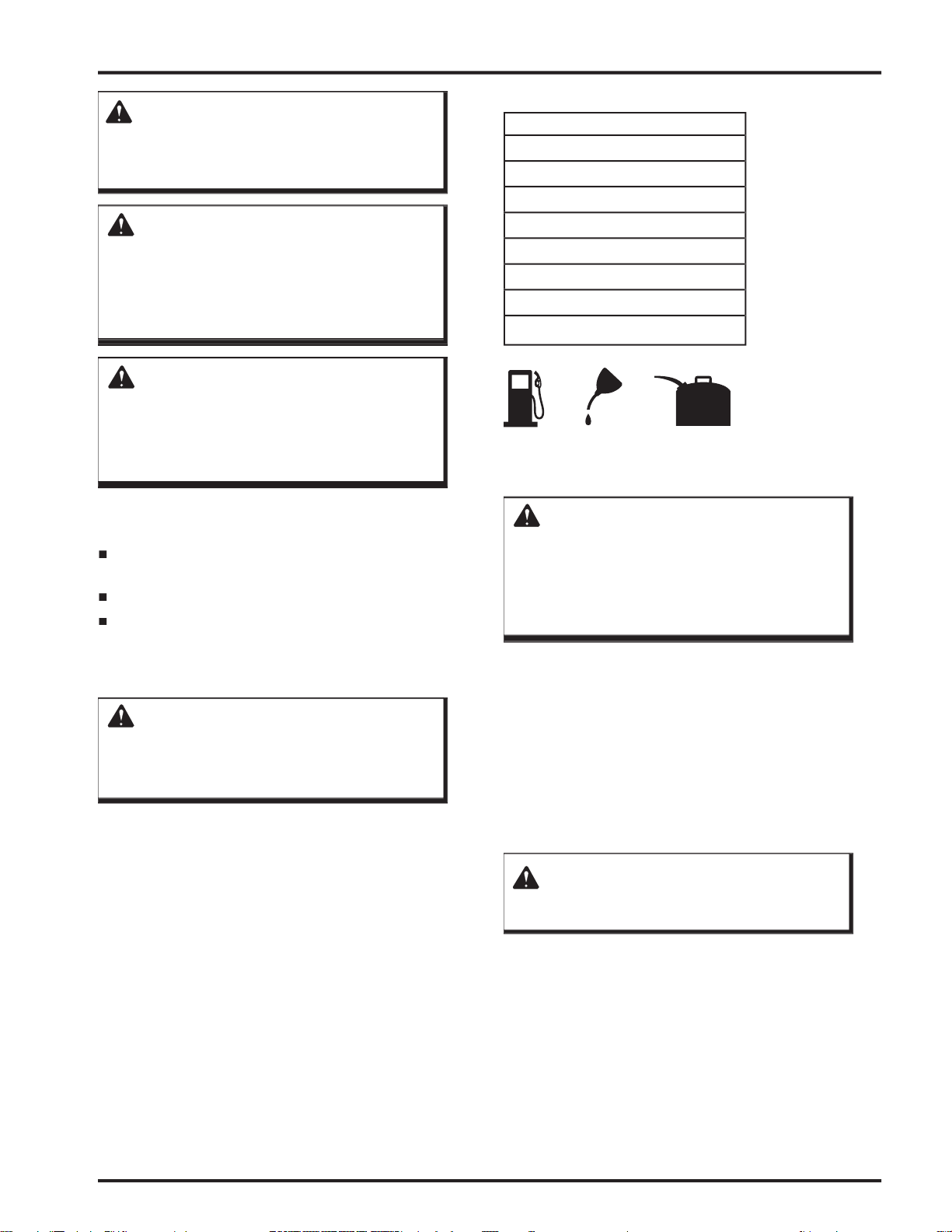

A re or explosion from gasoline will burn you

mixing gasoline and 2-cycle oil. The oil mix should be 50:1,

using oil that meets or exceeds JASO-FC speci cations.

Follow these steps to mix the fuel.

Mix the 2-cycle engine oil provided with unleaded

2-cycle outboard oil. Store the container out of the reach of

WARNING:

Always stop the engine before lling the tank.

Never add fuel to a machine with a running or

hot engine. Move at least 30 ft. (9 m) away from

the refueling site before starting the engine. Do

not smoke while lling the tank.

Follow these steps to ll the tank.

tamination.

Loosen the fuel cap by turning it counterclockwise.

3.

Pour the fuel mixture carefully into the tank.

Replace the fuel cap if the gasket is damaged.

5.

Install the fuel cap and tighten it by turning it clock-

wise.

WARNING:

the problem before using the product.

6.

Wipe spilled fuel from the product.

Move at least 30 ft. (9 m) away before starting the

product.

It is normal for the engine to emit smoke during

use.

WARNING:

Do not allow familiarity with tools to make you

WARNING:

Always wear safety goggles or safety glasses

with side shields when operating power tools.

Failure to do so could result in objects being

thrown into your eyes resulting in possible seri-

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this tool.

Applications

Use this product for the following applications:

Edging along sidewalks and driveways (all models)

50:1 Gasoline to Oil Mixing Chart

2.6 oz.

2 US gallons

20 ml

2 liters

40 ml

4 liters

=

WARNING:

tion, causing injury to the operator or to by-

product.

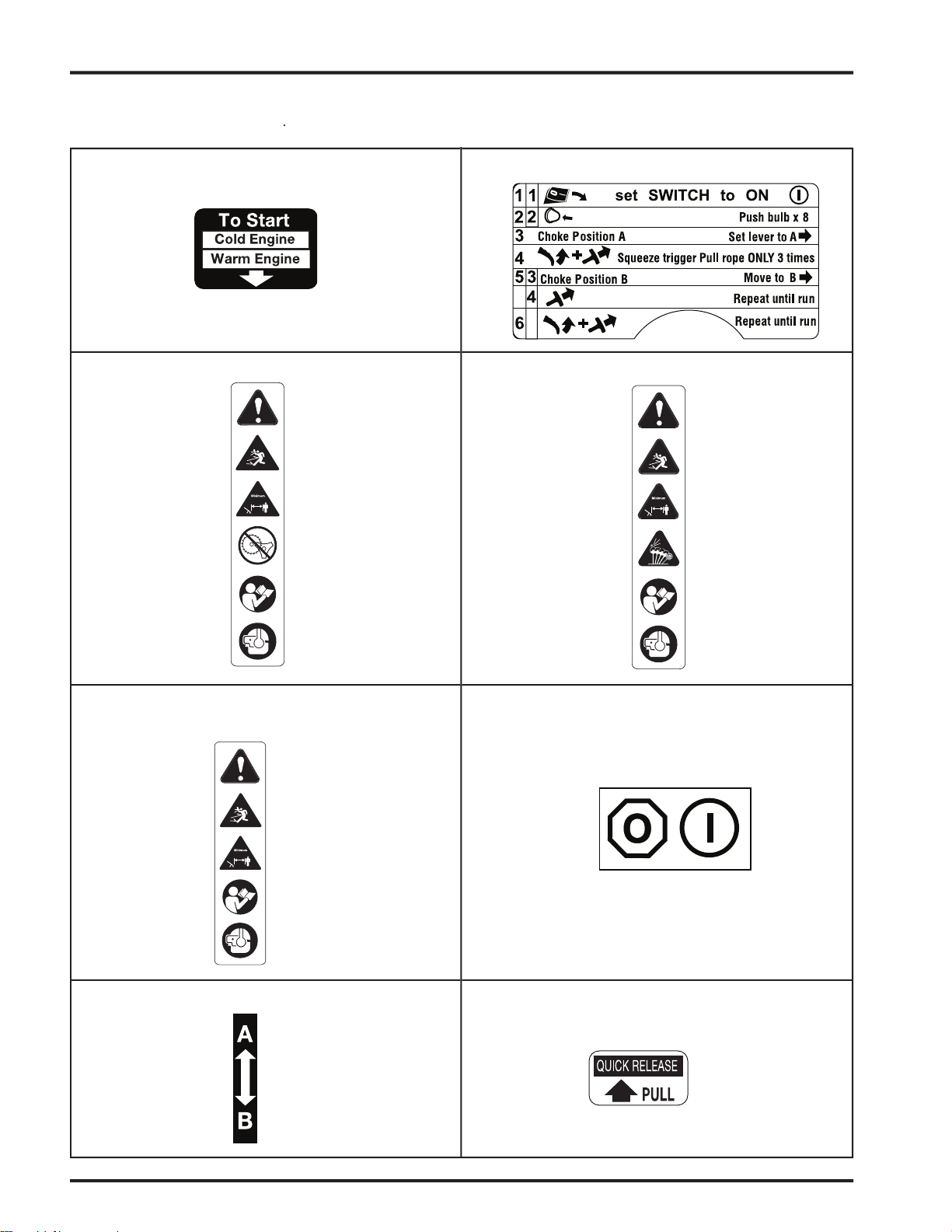

See Figure 14a, Figure 14b, and Figure 15.

To Start a Cold Engine

Follow these steps to start a cold engine.

Lay the product on a at, bare surface.

3.

Push the primer bulb approximately eight times.

5.

Press the lock-off button and squeeze the trigger.

6.

Pull the starter cord three times.

(Choke Open).

8.

Press the lock-off button and squeeze the trigger.

9.

Pull the starter cord.

If the product starts, let it run for 30 seconds

before using it. If the product does not start, repeat the

previous steps.

To Start a Warm Engine

Follow these steps to start a warm engine.

Lay the product on a at, bare surface.

2.

3.

Push the primer bulb up to eight times.

(Choke Open).

5.

Do not squeeze the trigger.

6.

Pull the starter cord.

If the product does not start, repeat the previous

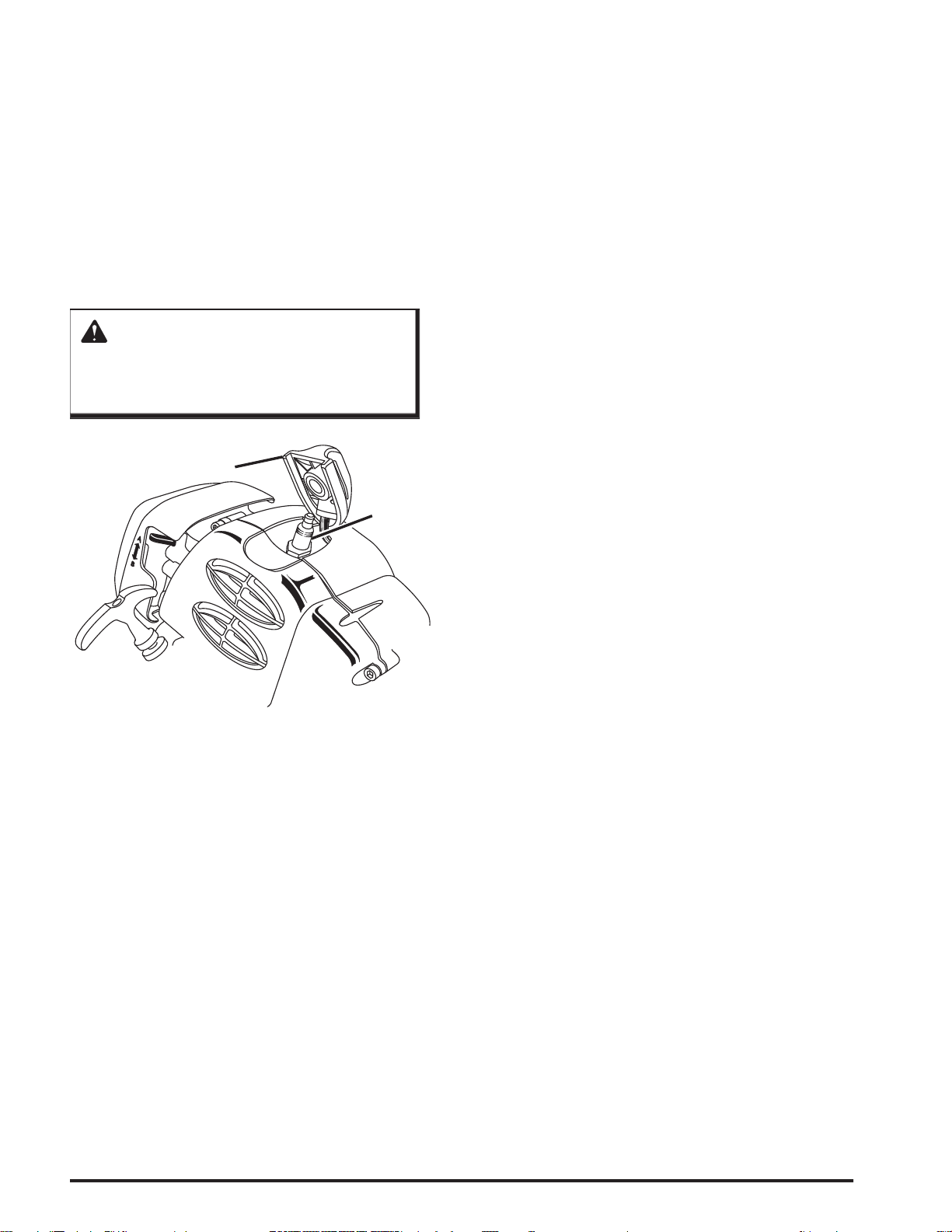

Stopping the Product

See Figure 15.

Follow these steps to stop the product.

Release the trigger.

(OFF) position.

Switch

Starter

Trigger

Trigger

Switch

Set Choke to A

Set Choke to B

using the curved shaft trimmer or the straight shaft trimmer.

WARNING:

Always hold the string trimmer away from the

body, keeping clearance between the body and

the product. Any contact with the housing or

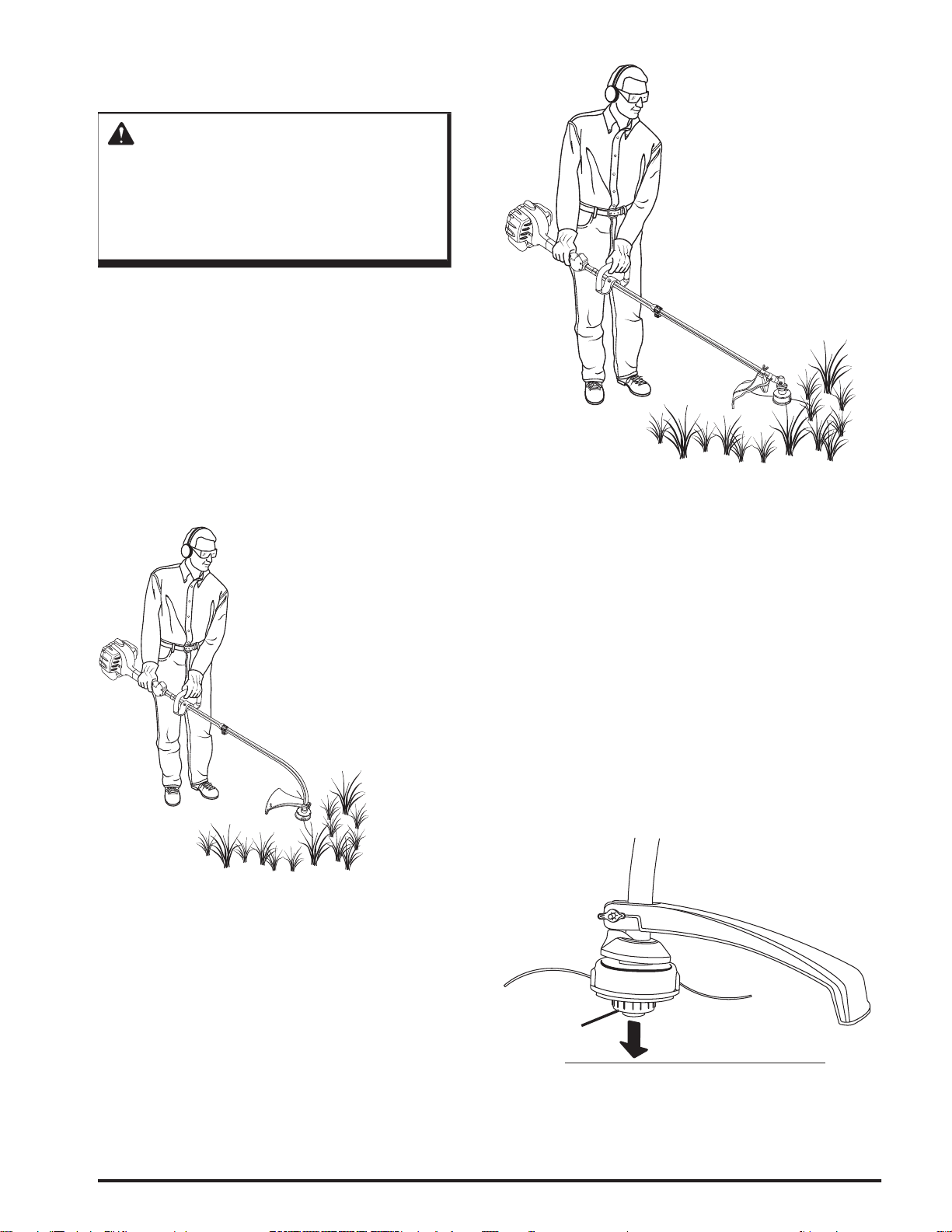

To Operate the Curved Shaft Trimmer

See Figure 16a.

Follow these steps to operate the curved shaft trimmer.

Hold the trimmer at waist level with your right hand

handle.

3.

Place the product on the right side of your body with

the engine behind and away from your body.

4.

To Operate the Straight Shaft Trimmer

See Figure 16b.

Follow these steps to operate the straight shaft trimmer.

Hold the trimmer at waist level with your right hand

handle.

3.

Place the product on the right side of your body with

the engine behind and away from your body.

To Advance the Cutting Line

See Figure 16c.

Follow these steps to advance the cutting line.

2.

motor is running. The line will only advance with the

Do not hold the retaining cap

20

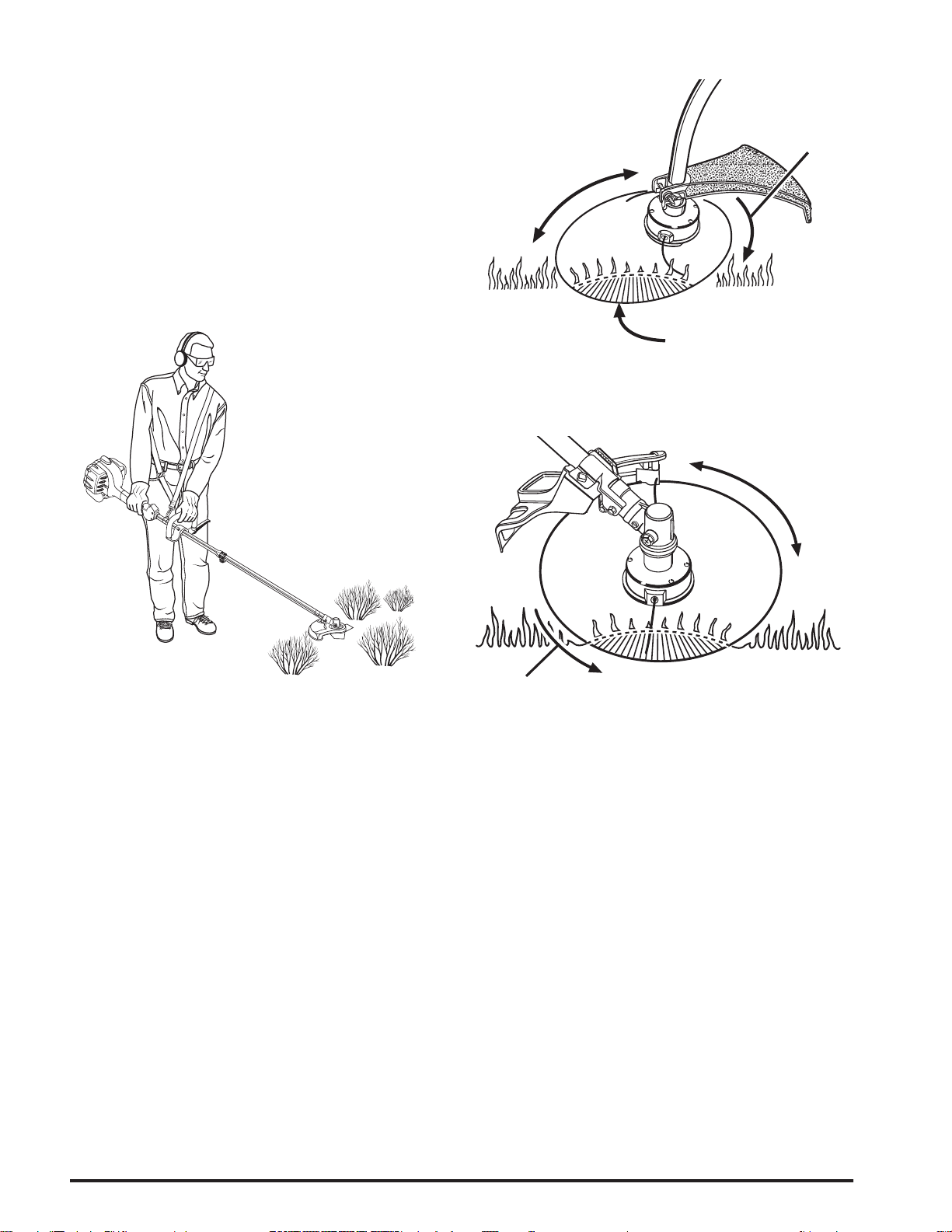

See Figure 17.

Follow these steps to operate the brushcutter.

Hold the brushcutter at waist level with your right hand

3.

Place the product on the right side of your body with

the engine behind and away from your body.

4.

Brushcut weeds and vines in a right-to-left motion with

the blade parallel to the ground.

See Figures 18 and 19.

Avoid hot surfaces by always keeping the tool away

Figures 16a, 16b and 17.)

Keep the trimmer tilted toward the area being cut; this

3.

passing the unit from left to right. This will avoid

throwing debris at the operator. Avoid cutting in the

4.

Use the tip of string to do the cutting; do not force

5.

Wire and picket fences cause extra string wear, even

breakage. Stone and brick walls, curbs and wood may

wear string rapidly.

6.

Avoid trees and shrubs. Tree bark, wood moldings, sid-

Straight Shaft Trimmer

Area

Area

Maintenance, replacement, or repair of the emission control device and systems may be performed by any non-

5 hours

X

X

X

Fuel Tank Assembly (Includes Fuel

Lines, Fuel Cap, and Fuel Filter)

Air Filter

WARNING:

Use only Toro replacement parts when servicing

this product. Use of any other parts may create a

hazard or cause product damage.

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

Wipe or scrape the trimmer head and spool area when

they accumulate dirt or clippings.

Keeping air intake vents free of grass and debris

prevents motor overheating and possible failure.

Depending on the type of fuel used, the type and

the exhaust port and muf er may become blocked with

See Figures 20 and 21.

WARNING:

Use of line other than the proper mono lament

Follow these steps to replace the cutting line.

WARNING:

Make sure the trimmer head stops rotating.

Contact with a rotating trimmer head could

2.

Remove the spark plug boot.

See Figure 24.

3.

Remove the retaining cap.

4.

Remove the empty spool.

5.

head for any damaged or worn parts.

6.

Hold the spool with the spring positioned upward.

Insert the end of the new line into the hole in the upper

threaded area of the spool.

8.

Wind the line around the spool as indicated by the ar-

rows on the top of the spool until the line reaches the

Do not wind the line beyond the

9.

Measure six inches of line from the slotted tab and cut

the line at that point.

22

See Figure 21.

For best performance, use only Toro spools (Part No.

AR04118). The spool may wear during normal use of the

ment. Replacement spools are available through your Toro

retailer.

Repeat the process for the lower threaded area of the

Insert the lines into the eyelets on the trimmer head.

Place the spool on the drive shaft.

Note: To install the spool, you may need to rotate it

remove the spool, refeed the line through the eyelets,

Release the lines from the tabs by sharply pulling each

Push down on the spool to reveal the threads inside the

WARNING:

An improperly installed retaining cap or spool

retaining cap or spool could cause personal

Replace the spark plug boot.

See Figure 24.

Threaded Area

Slotted

Tab

Threaded Area

Follow these steps to replace the spool.

WARNING:

Make sure the trimmer head stops rotating when

you release the trigger. Contact with a rotating

trimmer head could cause personal injury.

2.

Remove the spark plug boot.

See Figure 24.

3.

Remove the retaining cap by turning as indicated by the

4.

Remove the empty spool.

5.

head for any damaged or worn parts.

6.

Remove the lines from the slotted tabs on the spool and

unwind approximately six inches.

8.

Insert the lines of the new spool into the eyelets on the

trimmer head.

9.

Place the spool on the drive shaft.

If the line should tangle or break at the eyelet,

remove the spool, refeed the line through the eyelets,

Release the lines from the tabs by sharply pulling each

Push down on the spool to reveal the drive shaft.

Replace the spark plug boot.

See Figure 24

Trimmer

Shaft

Spool

Slotted

Tab

23

Air Filter

Air

WARNING:

A leaking fuel cap is a re hazard and must be

replaced immediately.

valve. A clogged fuel lter causes poor engine performance.

If performance improves when the fuel cap is loosened,

the check valve may be faulty or the lter may be clogged.

Replace the fuel cap if necessary.

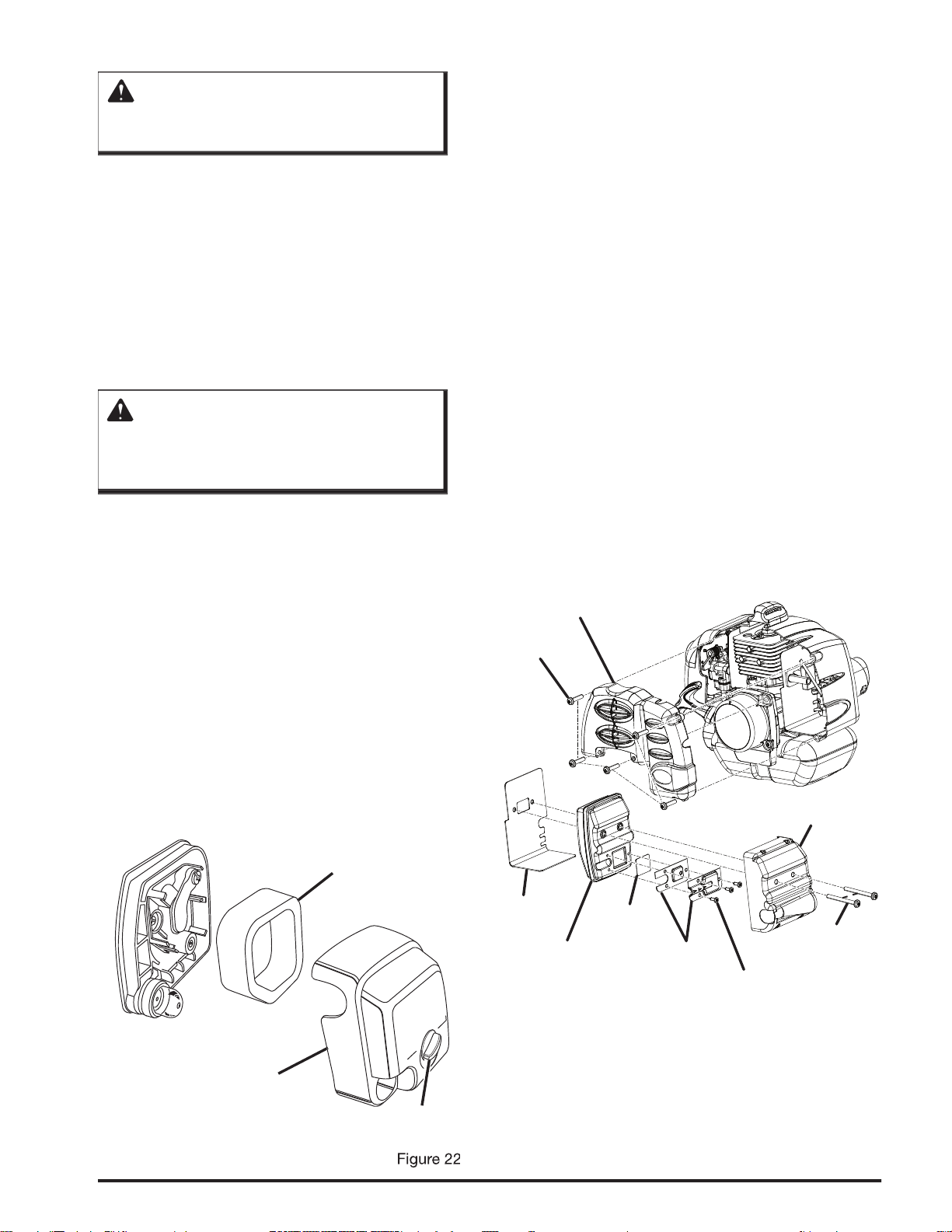

See Figure 22 and Figure 23.

Follow these steps to clean the air lter.

WARNING:

Make sure the trimmer head stops rotating when

you release the trigger. Contact with a rotating

trimmer head could cause personal injury.

2.

Remove the spark plug boot.

3.

Loosen the air lter cover by turning the knob counter-

4.

Remove the air lter cover.

5.

Remove the air lter.

6.

Rinse the air lter and let it dry completely.

8.

Work two drops of oil into the air lter.

9.

Replace the air lter ( ts only one way).

Replace the air lter cover.

wise.

Replace the spark plug boot.

Replace the air lter (Part No. 88048) as indi-

See Figure 23.

use. If replacement is necessary, use Toro part number

To replace the spark arrester:

Remove the ve screws that hold the cover.

Removing these screws requires the use of a T20

Remove the cover.

3.

Remove the muf er assembly and muf er gasket. It

may be necessary to work the muf er assembly free

Remove the three screws that hold the plates on the

muf er.

5.

Remove the spark arrester.

6.

Replace the old spark arrester with the new one.

Reassemble the muf er by reinstalling the plates and

tightening the three screws.

8.

Reassemble the muf er and muf er cover and attach to

the muf er gasket with the two screws.

9.

Reinsert the muf er assembly.

Reinstall the cover on the tool and fasten with the ve

Do not overtighten screws.

Spark

Arrester

Screw(s)

Screw(s)

Screw(s)

24

See Figure 24.

All model numbers included in this manual use an

NGK BPMR7A or Champion RCJ-6Y spark plug. Use an

Remove the spark plug boot.

Loosen the spark plug by turning it counterclockwise

with a socket.

3.

Remove the spark plug.

Hand thread the new spark plug, turning it clockwise.

5.

mum, 190 in.lb. maximum.

Do not over tighten.

Be careful not to cross-thread the spark plug.

product.

Note: If the product includes another attachment, place the

to store.

To Store the Product Short Term

Follow these steps to store the product short term.

To Store the Product Long Term

If you do not intend to use the product for more than one

month, follow the storage procedures below.

Follow these steps to store the product long term.

Drain all of the fuel from the tank into a container ap-

proved for gasoline.

2.

Run the engine until it stops.

3.

Keep the product away from corrosive agents

Abide by all federal and local regulations

Transporting the Product

Follow these steps to transport the product.

Drain the fuel mixture into a container that is approved

2.

3.

Spark

Spark Plug Boot

25

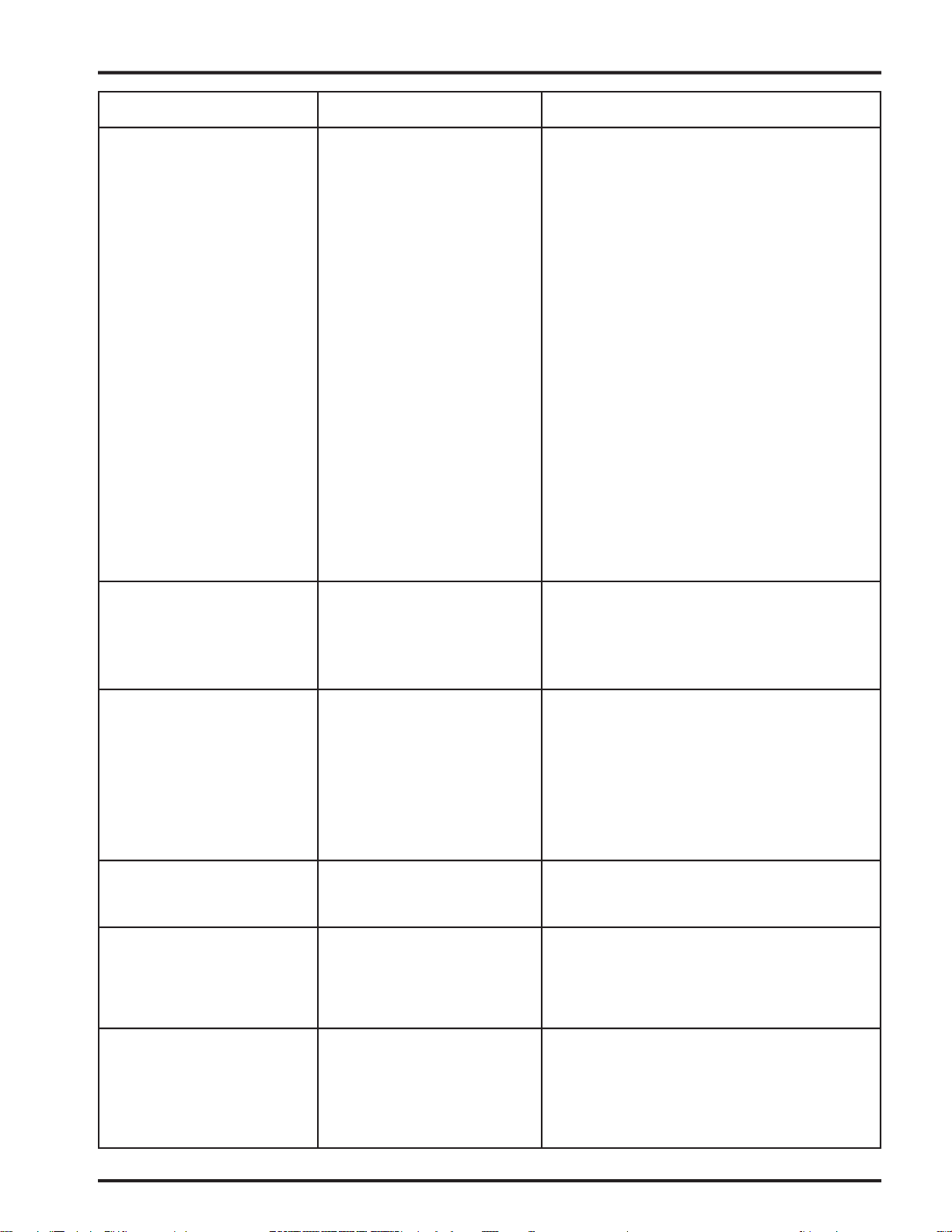

Engine will not start

Engine does not reach full speed

Line will not advance when us-

Retaining cap hard to turn when

using automatic line lengthening

mer head assembly and the

2.

Remove the spark plug. Reattach the spark

plug cap and lay the spark plug on the metal

repeat the test with a new spark plug.

Push primer bulb until the bulb is full of fuel.

If the bulb does not ll, the primary fuel deliv-

the engine may be ooded. (See next item.)

4.

Remove the spark plug. Turn the product

reinstall the spark plug. With the trigger fully

A

with a new spark plug.

Use fresh fuel and the correct 2-cycle oil mix.

2.

Lubricate with silicone spray.

2.

Install more line.

Pull line while alternately pressing down on

4.

Remove line from spool and rewind.

Advance line at full throttle.

2.

2.

Use fresh fuel and the correct 2-cycle oil mix.

position.

2.

No spark

No fuel

4.

Flooded engine

then when new

2.

Air lter is dirty

Line welded to itself

2.

Not enough line on the spool

Line worn too short

4.

Line tangled on spool

Engine speed too slow

damaged

2.

throttle

throttle

2.

Air lter is dirty

Solution

Troubleshooting

Troubleshooting

26

Warranty

terial and workmanship and agrees to repair or replace, at our option, any defective Product free of charge within these time

periods from the date of purchase:

Except as provided in the Emission Control Warranty Statement, this warranty extends to the original retail purchaser only

Any part of the Product manufactured or supplied by OWT Industries, Inc. and found in the reasonable judgement of OWT,

Industries, Inc. to be defective in material or workmanship will be repaired or replaced by an authorized service dealer for

this product without charge for parts and labor. To locate your nearest authorized service dealer for this product, contact us

ranty period. The expense of delivering the Gas Trimmer Product to the service dealer for warranty work and the expense of

returning it back to the owner after repair or replacement will be paid for by the owner. OWT Industries. Inc.’s responsibil-

Inc. to service this product.

that has been operated in any way contrary to the operating instructions as speci ed in the Operator’s Manual. This warranty

Product that has been altered or modi ed so as to adversely affect the products operation, performance or durability or that

has been altered or modi ed so as to change its intended use. The warranty does not extend to repairs made necessary by

normal wear or by the use of parts or accessories which are either incompatible with the Gas Trimmer Product or adversely

In addition, this warranty does not cover the following (except to the extent covered by the emissions control warranty set

A. Tune-ups – Spark Plugs, Carburetor Adjustments, Filters

B. Wear Items – Bump Knobs, Outer Spools, Cutting Line, Inner Reels, Starter Pulley, Starter Ropes, Drive Belts

ALL IMPLIED WARRANTIES ARE LIMITED IN DURATION TO THE STATED WARRANTY PERIOD. ACCORD-

INGLY, ANY SUCH IMPLIED WARRANTIES INCLUDING MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE, ARE DISCLAIMED IN THEIR ENTIRETY AFTER THE EXPIRATION OF THE APPRO-

PRIATE TWO-YEAR OR NINETY DAY WARRANTY PERIOD. OWT INDUSTRIES INC.’S OBLIGATION UNDER

DAMAGES INCLUDING, BUT NOT LIMITED TO EXPENSE OF RETURNING THE GAS TRIMMER PRODUCT TO

A GAS TRIMMER AUTHORIZED SERVICE DEALER AND EXPENSE OF DELIVERING IT BACK TO THE OWNER,

MECHANIC’S TRAVEL TIME, TELEPHONE OR TELEGRAM CHARGES, RENTAL OF A LIKE PRODUCT DURING

ERTY, LOSS OF REVENUE, LOSS OF USE OF THE PRODUCT, LOSS OF TIME, OR INCONVENIENCE. SOME

Warranty

Loading...

Loading...