Page 1

Form No. 3329-634

Trimmer/Brushcutter

Model No. 51930—230000001 & Up

Model No. 51932—230000001 & Up

Model No. 51934—230000001 & Up

Model No. 51930A—230000001 & Up

Model No. 51932A—230000001 & Up

Model No. 51934A—230000001 & Up

Model No. 51936—230000001 & Up

Model No. 51938—230000001 & Up

Model No. 51940—230000001 & Up

If you have questions concerning your

trimmer or brushcutter, please call us

STOP

at 1-866-574-9242 (US) or

1-866-574-9243 (Canadá).

Operator’s Manual

WARNING:

To reduce the risk of injury, the user must read and understand the operator’s manual. Save this manual.

English (EN), French (F), and Spanish (ES)

Page 2

P

STO

READ THIS INFORMATION

Before you use your new trimmer/brushcutter, read the following

helpful hints to get you started.

Fueling

DANGER:

Gasoline is extremely flammable and explosive. A

fire or explosion from gasoline will burn you and

others.

1. Obtain a clean container that is approved for use with gasoline.

gallon of 87-octane, unleaded

2. Mix all of the 2-cycle oil provided with 1

gasoline.

3. Fill the trimmer’s gas tank carefully.

Cold Starting vs. Warm Starting

US

When you restart the trimmer/brushcutter and you are not sure whether the

engine is still warm, set the choke lever to B (Choke Open) and pull the starter

cord. If the engine does not start within 5 pulls, refer to “To Start a Cold Engine”

later in this manual.

Flooded Engine

Will the engine start? If not, it may be flooded. Relax, this is easy to correct. Set

the choke lever to B (Choke Open). Squeeze the trigger and pull the starter cord

quickly for 10 to 12 pulls. If the engine does not start, refer to “Troubleshooting”

later in this manual or call toll free at

(Canada)

.

For questions concerning your trimmer/

brushcutter, call us toll free at

1-866-574-9242.

L

L

CA

1-866-574-9242

1-866-574-9242 (US) or 1-866-574-9243

WARNING:

California to cause cancer, birth defects, or other reproductive harm.

© The Toro Company-2003 Printed in USA

8111 Lyndale Ave., Bloomington, MN 55420, USA All rights reserved

The engine exhaust from this product contains chemicals known to the State of

Page 3

Table of Contents

Introduction................................................................................................................................................................ 4

Safety Rules ................................................................................................................................................................. 5

Symbols....................................................................................................................................................................... 6

Product Labels............................................................................................................................................................. 7

Specifications............................................................................................................................................................... 8

Applications................................................................................................................................................................. 8

Features ....................................................................................................................................................................... 9

Unpacking................................................................................................................................................................. 11

Assembly ...................................................................................................................................................................12

Connecting the Attachment to the Upper Shaft.................................................................................................. 12

Removing the Attachment from the Upper Shaft ................................................................................................12

Attaching the Front Handle ................................................................................................................................ 12

Attaching the Shoulder Strap .............................................................................................................................. 12

Attaching the Grass Deflector..............................................................................................................................13

Converting from Brushcutter to Trimmer ...........................................................................................................14

Converting from Trimmer to Brushcutter ...........................................................................................................15

Operation.................................................................................................................................................................. 16

Mixing the Fuel................................................................................................................................................... 16

Filling the Tank................................................................................................................................................... 16

Starting the Product............................................................................................................................................ 17

Stopping the Product .......................................................................................................................................... 17

Operating the Trimmer ....................................................................................................................................... 18

Operating the Brushcutter .................................................................................................................................. 19

Maintenance.............................................................................................................................................................. 20

Emissions Maintenance Schedule........................................................................................................................ 20

Cleaning the Product .......................................................................................................................................... 20

Servicing the Product.......................................................................................................................................... 20

Replacing the Cutting Line ................................................................................................................................. 20

Replacing the Spool ............................................................................................................................................21

Checking the Fuel Cap........................................................................................................................................ 22

Cleaning the Air Filter ........................................................................................................................................22

Cleaning the Spark Arrester................................................................................................................................. 22

Replacing the Spark Plug.....................................................................................................................................23

Storing the Product............................................................................................................................................. 23

Transporting the Product .................................................................................................................................... 23

Troubleshooting......................................................................................................................................................... 24

Warranty ................................................................................................................................................................... 26

Table of Contents 3

Page 4

Introduction

Thank you for purchasing a Toro product.

We would like for you to be completely satisfied with your new product, so feel free to contact an authorized service

dealer for help with service, genuine Toro parts, or other information you may require.

Whenever you contact an authorized service dealer, always know the model and serial numbers of the product. These

numbers will help the service representative provide exact information about your specific product. You will find the

model and serial number decal located on the motor housing.

For your convenience, write the product model and serial numbers in the space below.

Model No.

Serial No.

Read this manual carefully to learn how to operate and maintain your product correctly. Reading this manual will help

you and others avoid personal injury and damage to the product. Although Toro designs, produces, and markets safe,

state-of-the-art products, you are responsible for using the product properly and safely. You are also responsible for

training persons you allow to use the product about safe operation.

The Toro warning system in this manual identifies potential hazards and has special safety messages that help you and

others avoid personal injury, even death. DANGER, WARNING, and CAUTION are signal words that identify the

level of hazard. However, regardless of the hazard, be extremely careful. Two other words, “Important” and “Note,”

highlight information.

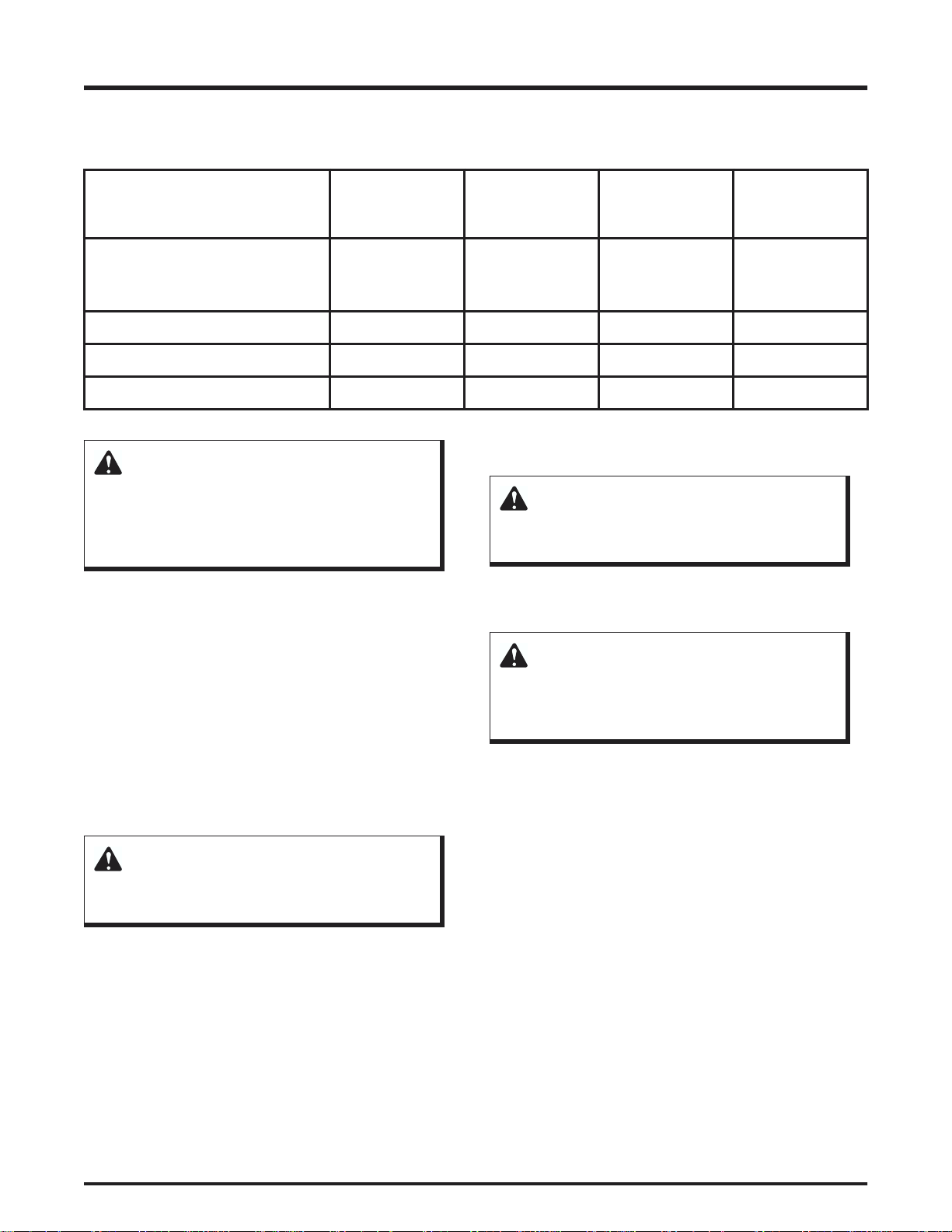

Signal Word Explanation

DANGER

WARNING

CAUTION

Important

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert against unsafe practices that may cause property

damage.

Advises you of important information or instructions vital to the operation or maintenance

of the equipment.

Note

4 Introduction

Advises you of additional information concerning the operation or maintenance of the

equipment.

Page 5

Safety Rules

WARNING:

Read and understand all instructions. Failure to follow all instructions may result in serious personal injury as well

as damage to the product.

This product has been designed and manufactured to

meet or exceed the requirements of the current version of

ANSI B175.3, safety requirements for gasoline-powered

string trimmers and brushcutters.

Physical Condition of the Operator. Do not

■

operate this product when tired, ill, or under the

influence of alcohol, drugs, or medication.

■

Clothing Requirements. Always wear long heavy

pants, boots, and gloves. Do not wear loose clothing,

jewelry, short pants, sandals, or go barefoot. Secure

hair so that it is above shoulder level to avoid

entanglement in moving parts.

Protective Accessories Requirements. Wear eye

■

protection marked to comply with ANSI Z87.1

standards when operating this product. Wear hearing

protection during extended periods of operation.

Condition of Trimmer Before Use. Inspect the

■

product before each use. Replace damaged parts.

Check for fuel leaks. Make sure all fasteners are in

place and secure. Replace cutting attachment parts

that are cracked, chipped, or damaged in any way.

Make sure the cutting attachment is properly

installed and securely fastened. Be sure the cutting

attachment shield is properly attached, and in the

position recommended by the manufacturer. Use

only flexible, non-metallic line recommended by the

manufacturer. For example, never use wire or wirerope, which can break off and become a dangerous

projectile.

■

Proper Stance. Keep firm footing and balance. Do

not overreach. Keep the cutting attachment below

waist level. Keep all parts of your body away from the

rotating cutting attachment and hot surfaces.

■

Exhaust Gases. Never start or run the product inside

a closed room or building; breathing exhaust fumes

can cause illness or death.

Fueling. Mix and pour fuel outdoors where there are

■

no sparks and flames. Slowly remove the fuel cap

only after stopping the engine. Do not smoke while

fueling or mixing fuel. Wipe spilled fuel from the

product. Move at least 30 ft. (9 m) away from the

fueling source and site before starting the engine.

■

Work Area. Clear the area to be cut before each use.

Remove all objects, such as rocks, broken glass, nails,

wire, or string, that can be thrown or become

entangled in the cutting attachment. Clear the area

of children, bystanders, and pets. At a minimum,

keep all children, bystanders, and pets outside a 50

ft. (15 m) radius. Because there still may be a risk of

injury to bystanders from thrown objects, bystanders

should be encouraged to wear eye protection. If you

are approached while operating the product, stop the

engine and the cutting attachment.

■

Dangerous Environments. To avoid falling, do not

use the product in damp or wet locations.

Controlling the Product. During carburetor

■

adjustments the cutting attachment may spin.

Therefore, you should wear protective equipment

and observe all safety instructions when adjusting the

carburetor. For products equipped with a clutch, be

sure the cutting attachment stops turning when the

engine idles. When the product is turned off, make

sure the cutting attachment has stopped before

setting down the product.

■

Use the Right Product. Use the product for the

intended purpose only.

Condition of Brushcutter Before Use. The handles

■

shall be mounted according to the manufacturer’s

instructions. Do not attach any blade to a product

without proper installation of all required parts.

Failure to use the proper parts can cause the blade to

fly off and seriously injure the operator and/or

bystanders. Discard blades that are bent, warped,

cracked, broken, or damaged in any way.

Use the Right Equipment. Always use the barrier

■

bar on the front handle and the shoulder strap with

the brushcutter.

■

Blade Thrust. Blade thrust may occur when the

spinning blade contacts an object that it does not

immediately cut. A blade thrust can be violent

enough to cause the product and/or operator to be

propelled in any direction, and possibly lose control

of the product. Blade thrust can occur without

warning if the blade snags, stalls, or binds. This is

more likely to occur in areas where it is difficult to

see the material being cut.

Stopping the Product. A coasting blade can cause

■

injury while it continues to spin after the engine is

stopped or throttle is released. Maintain proper

control until the blade has completely stopped

rotating.

Safety Rules 5

Page 6

Important: This engine is equipped with a spark arrester muffler. It is a violation of California Public Resource Code

Section 4442 to use or operate this engine without a spark arrester muffler on any forest-covered, brush-covered, or

grass-covered land. Other states or federal areas may have similar laws.

This spark ignition system complies with Canadian ICES-002.

Save these instructions. Refer to them frequently and use them to instruct others who may use this product. If you

loan someone this product, loan these instructions also.

Save These Instructions

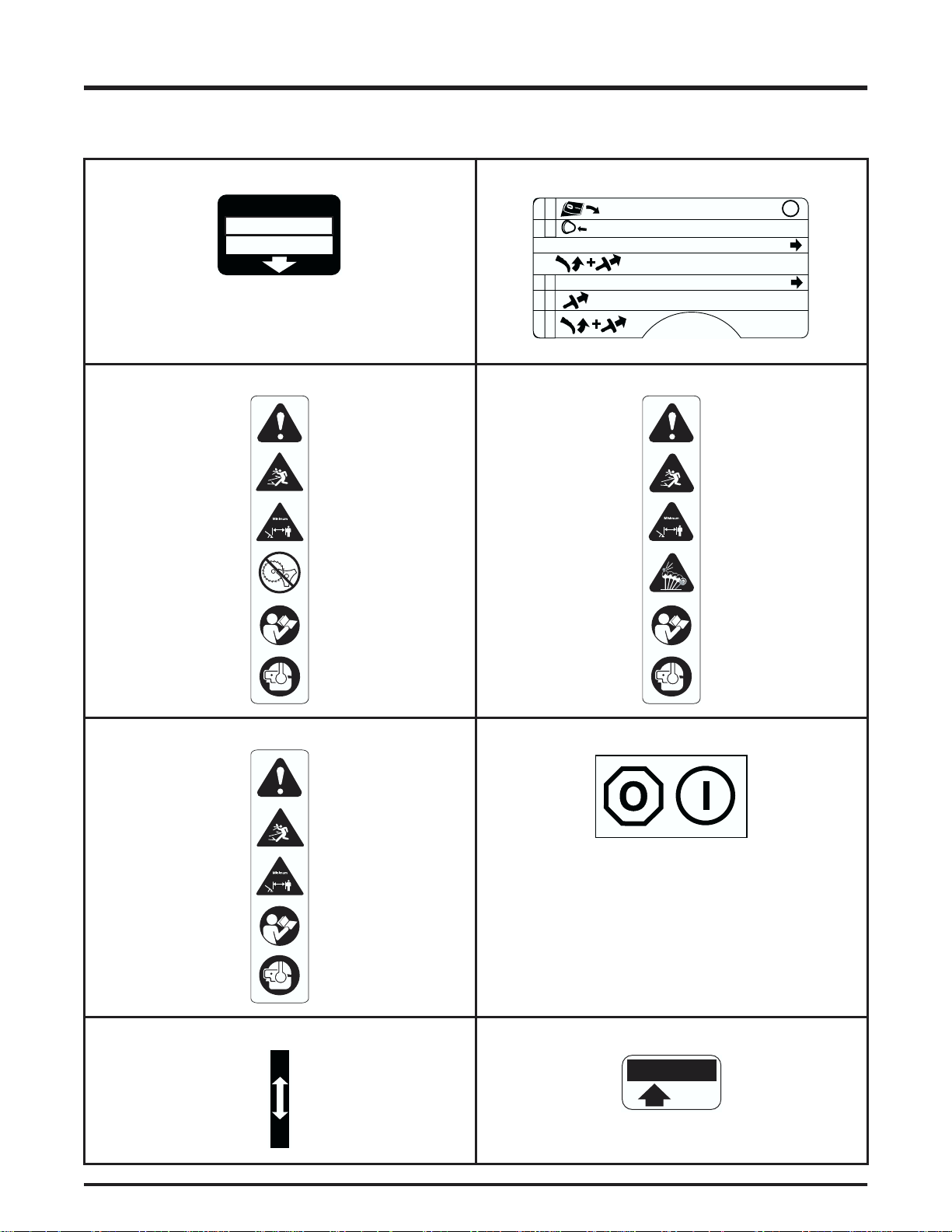

Symbols

The following symbols are located on the product. Please study them and learn their meaning. Proper interpretation of

these symbols allows you to operate the product better and safer.

Symbol Name Explanation

Safety Alert Indicates danger, warning, or caution. Attention is required in

order to avoid serious personal injury. May be used in conjunction

with other symbols or pictographs.

Thrown Objects Thrown objects can cause severe injury. Wear protective clothing

and boots.

Keep Bystanders Away Keep all bystanders, especially children and pets, at least 50 feet

(15 m) from the operating area.

Blade Thrust Beware of blade thrust. Blade thrust is the sudden sideways, for-

ward, or backward motion of the product that may occur when the

blade jams or catches on an object such as a sapling or a tree

stump.

No Blade Do not install any type of blade on Model No. 51930 or 51936

and Model No. 51932 or 51938. Use only flexible, non-metallic

line recommended by the manufacturer.

Read Operator’s Manual Read the operator’s manual before starting or operating this prod-

uct. Failure to follow operating instructions and safety precautions

in the operator’s manual can result in serious injury.

Eye and Ear Protection Thrown objects can cause severe eye injury. Wear eye protection

marked to comply with ANSI Z87.1 standards when operating

this product. Wear hearing protection during extended periods of

operation.

Gasoline and Oil Use unleaded gasoline intended for motor vehicle use with an

octane rating of 87 ([R + M] / 2) or higher.This product is powered by a 2-cycle engine and requires pre-mixing gasoline and 2cycle oil.

6 Symbols

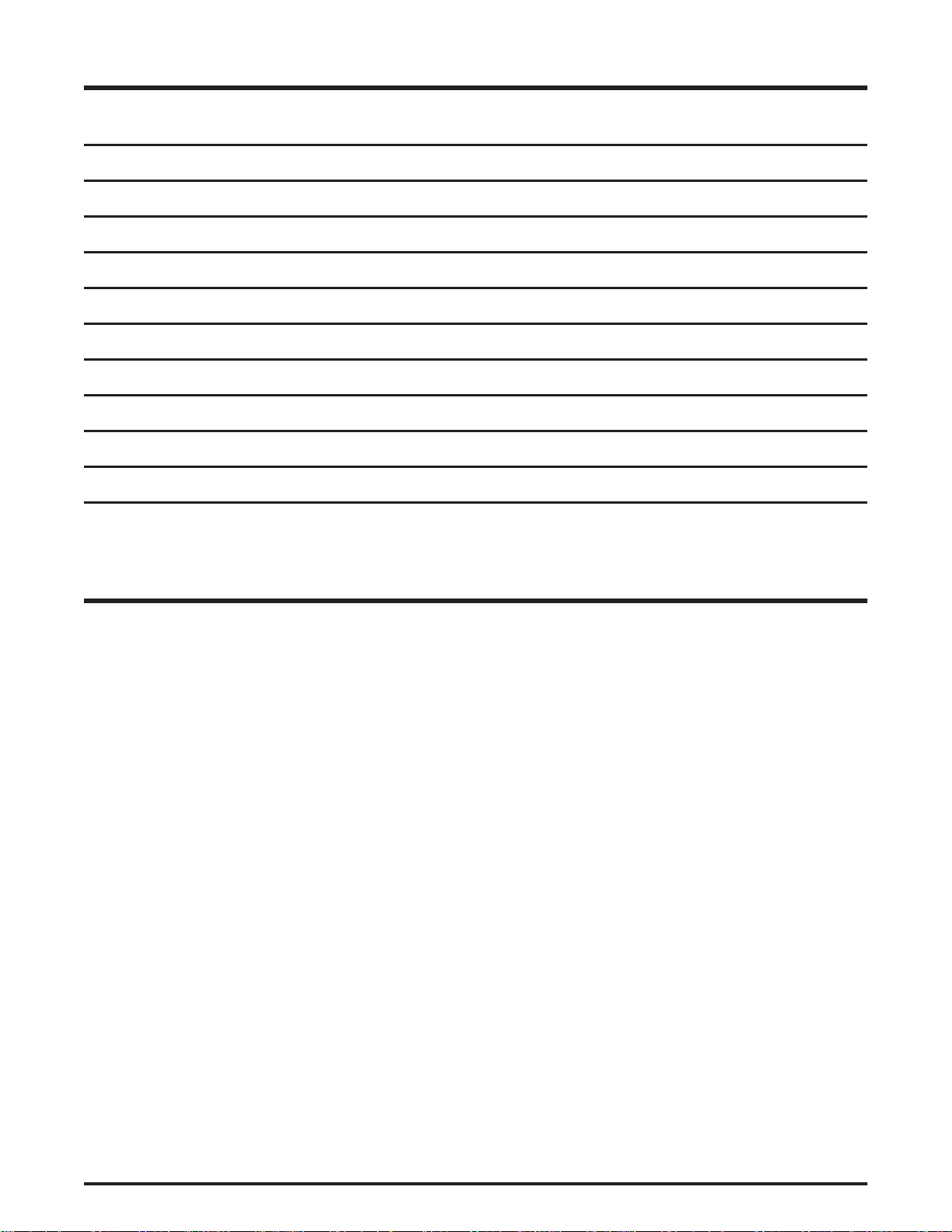

Page 7

ON

OFF

Product Labels

Product labels and instructions are easily visible to the operator and are located near any area of potential danger.

Replace damaged or lost labels.

Part No. 983647-001 Part No. 983648-001

To Start

Cold Engine

Warm Engine

1

1

2

2

Choke Position A

3

4

5

3

Choke Position B

4

6

Part No. 984032-001 Part No. 985102-001

50' 15m

set SWITCH to ON

Push bulb x 8

Set lever to A

Squeeze trigger Pull rope ONLY 3 times

Move to B

Repeat until run

Repeat until run

50' 15m

I

Part No. 984105-001 Part No. 984240-001

50' 15m

Part No. 983780-001 Part No. 983961-001 (Shoulder Strap)

A

CHOKE CLOSED

QUICK RELEASE

PULL

B

CHOKE OPEN

Product Labels 7

Page 8

Specifications

Name Specification

Engine 25.4 cc Full Crank

Durability 300 hours

Cutting Width

Model Nos. 51930 & 51936 17 in.

Model Nos. 51932 & 51938 18 in.

Model Nos. 51934 & 51940 8 in. for brushcutter, 18 in. for trimmer

Line Size .095 in.

Weight

Model Nos. 51930 & 51936 12-1/2 lbs.

Model Nos. 51932 & 51938 13-1/2 lbs.

Model Nos. 51934 & 51940 13-1/2 lbs.

Applications

Use this product for the following applications:

■

Cutting grass, weeds, and light undergrowth (all models)

■

Edging along sideways and driveways (all models)

Cutting pulpy weeds, vines, and light brush (Model Nos. 51934 & 51940)

■

8 Specifications

Page 9

Features

Before using the product, familiarize yourself with all

operating features and safety requirements. However, do

not let familiarity with the product make you careless.

WARNING:

Exercise caution when using the product.

Careless actions, for even a fraction of a second,

can result in serious personal injury.

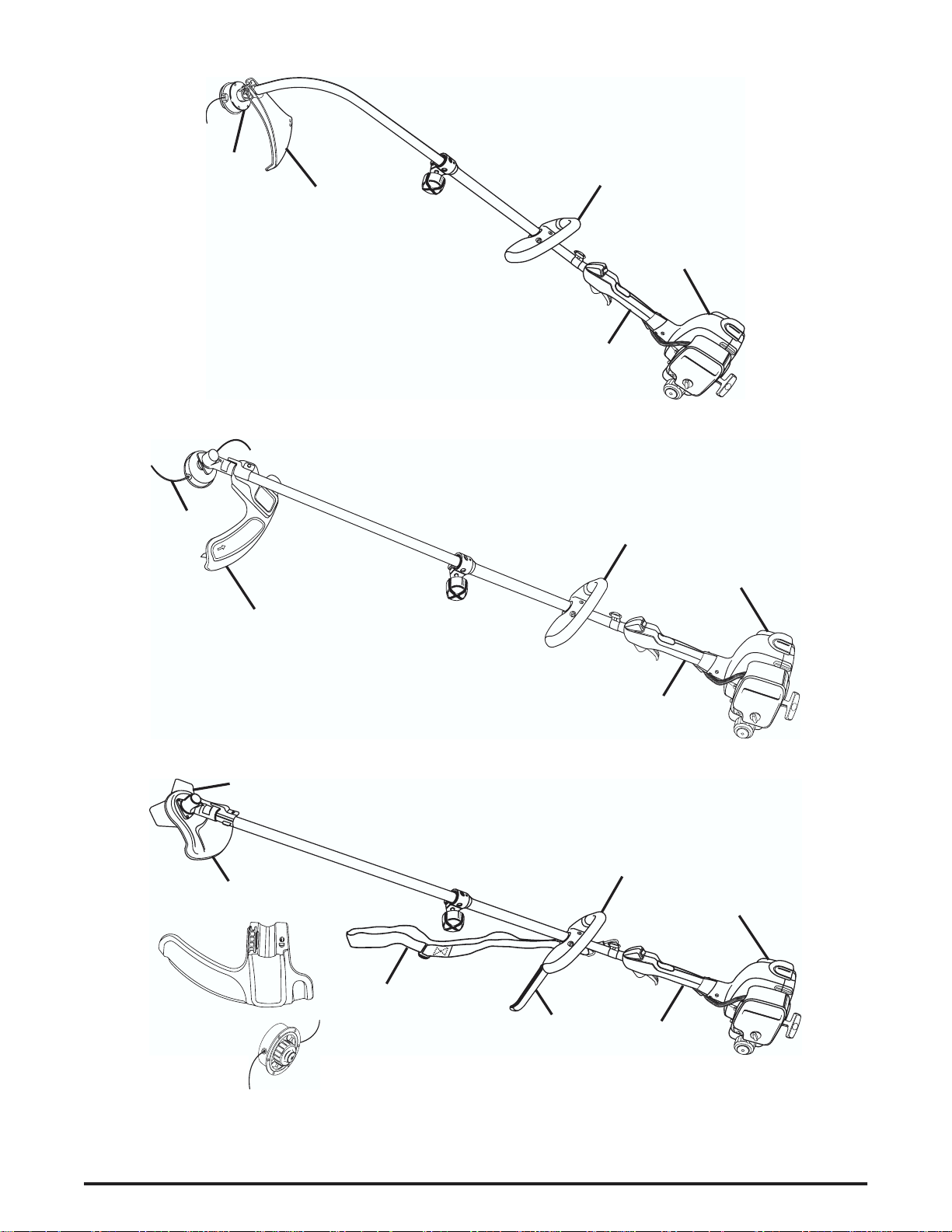

Your new product is equipped with the following features. See Figure 1.

Common Features

Engine

The engine is powerful and easy to start. It is effectively

counterbalanced, which allows for less vibration and

more durability.

Dual Line

The dual line permits more efficient cutting than a single

line.

Grass Deflector

The grass deflector helps protect you from flying debris.

Ergonomic Design

The design of the product provides for easy handling. It

is designed for comfort and ease of grasp when operating

in different positions and at different angles.

Brushcutter Features

(Model Nos. 51934 & 51940)

Blade

The Tri-Arc™ blade allows you to brushcut weeds, vines

and light brush.

Brushcutter Guard

The brushcutter guard helps protect you from the blade

and from flying debris.

Shoulder Strap

The brushcutter includes a shoulder strap that helps support the product.

Barrier Bar

The handle on the brushcutter contains a barrier bar that

restrains the operator in position and maintains a proper

distance between the operator and the blade.

WARNING:

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to serious personal injury.

Curved Shaft Trimmer Feature

(Model Nos. 51930 & 51936)

Grass Barrier

The grass barrier keeps grass from getting wrapped

around the drive shaft.

Features 9

Page 10

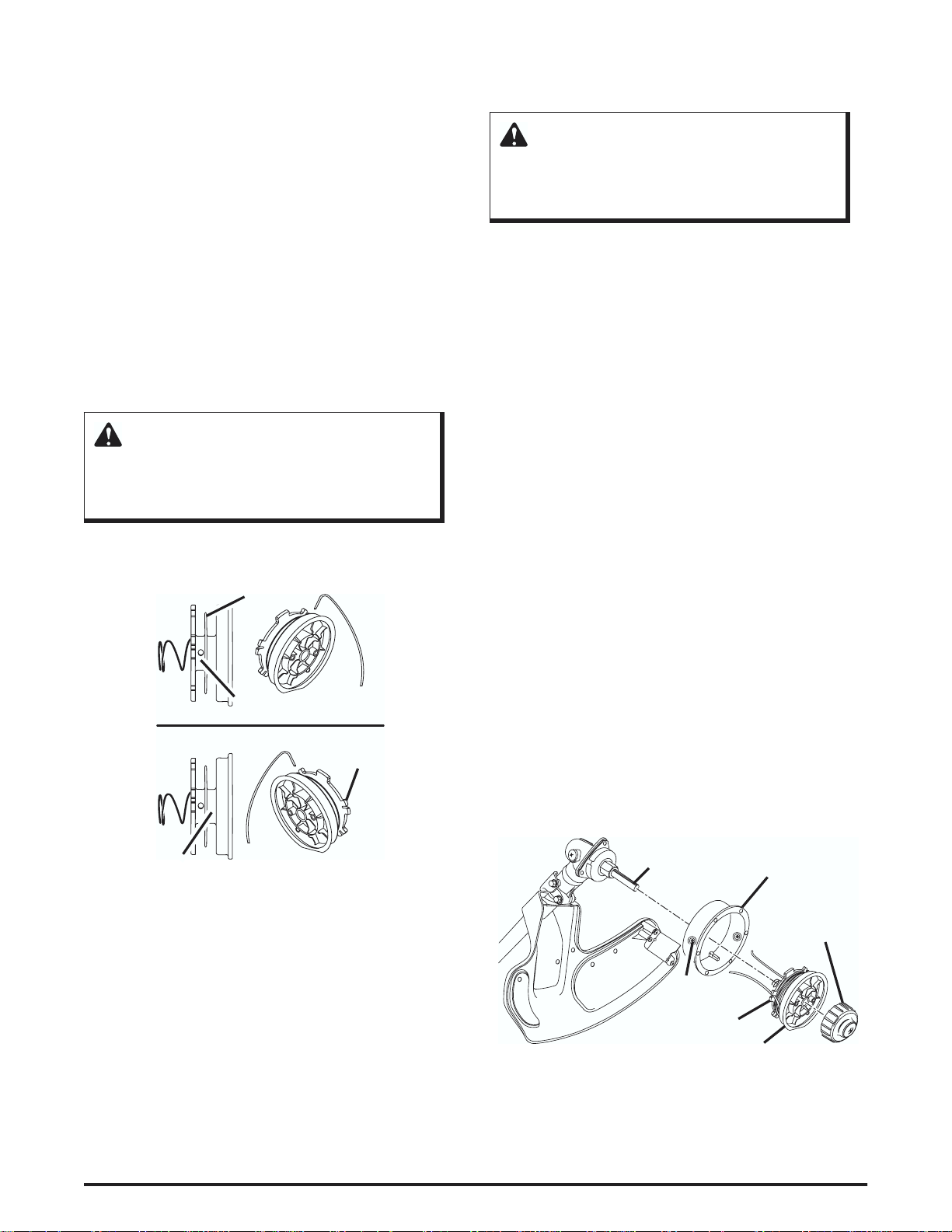

Curved Shaft Trimmer

(Model Nos. 51930 & 51936)

Grass

Barrier

Dual Line

Front Handle

Curved Shaft

Grass Deflector

Engine

Trigger

Handle

Straight Shaft Trimmer

(Model Nos. 51932 & 51938)

Front Handle

Engine

Straight Shaft

Grass Deflector

Blade

Brushcutter

Guard

Brushcutter

(Model Nos. 51934 & 51940)

Shoulder Strap

Barrier

Bar

Trigger

Handle

Front Handle

Engine

Trigger

Handle

Figure 1

10 Features

Page 11

Unpacking

Instructions

■

Carefully remove the product from the box.

Inspect the product carefully to make sure no

■

breakage or damage occurred during shipping.

■

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product.

If any parts are damaged or missing, please call

■

toll free 1-866-574-9242 (US) or 1-866-574-9243

(Canada) for assistance.

WARNING:

If any parts are missing, do not operate the

product until the missing parts are replaced.

Failure to do so could result in serious personal

injury.

Packing List

Upper shaft (Power head) (1)

Attachment shaft (Cutting head) (1)

Handle (1)

Curved shaft grass deflector (1) (Model Nos. 51930 &

51936)

Straight shaft grass deflector (1) (Model Nos. 51932 &

51938 and Model Nos. 51934 & 51940)

Grass barrier (Model Nos. 51930 & 51936)

Hex head cap screw - 1/4-20 x 2 in. (1)

(Model Nos. 51930 & 51936)

Lock washer (1) (Model Nos. 51930 & 51936)

Flat washer (1) (Model Nos. 51930 & 51936)

Wing nut (1) (Model Nos. 51930 & 51936)

Hex nut (Model Nos. 51930 & 51936)

Oil

Head locking tool (1) (Model Nos. 51934 & 51940)

Shoulder strap (1) (Model Nos. 51934 & 51940)

Storage cap

Unpacking 11

Page 12

Assembly

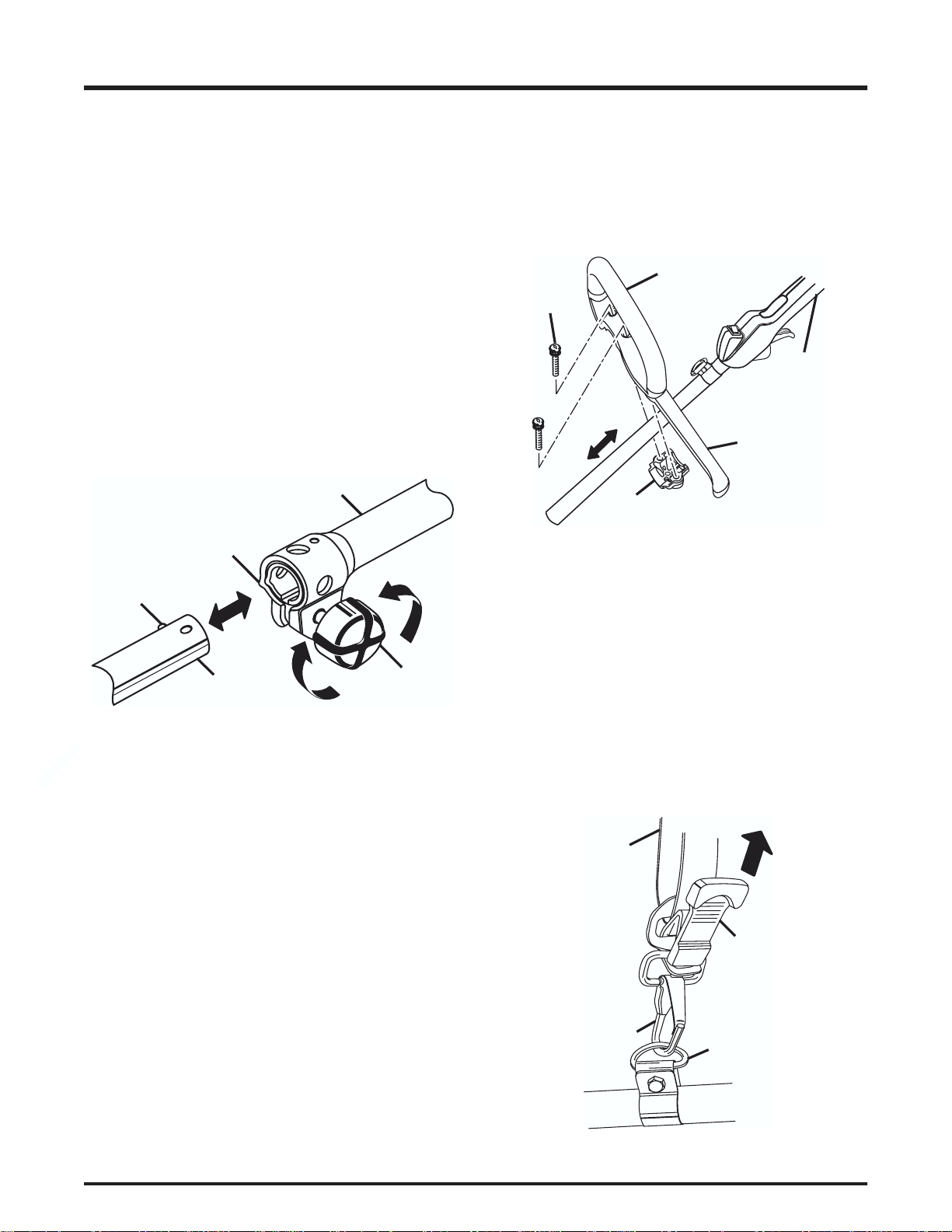

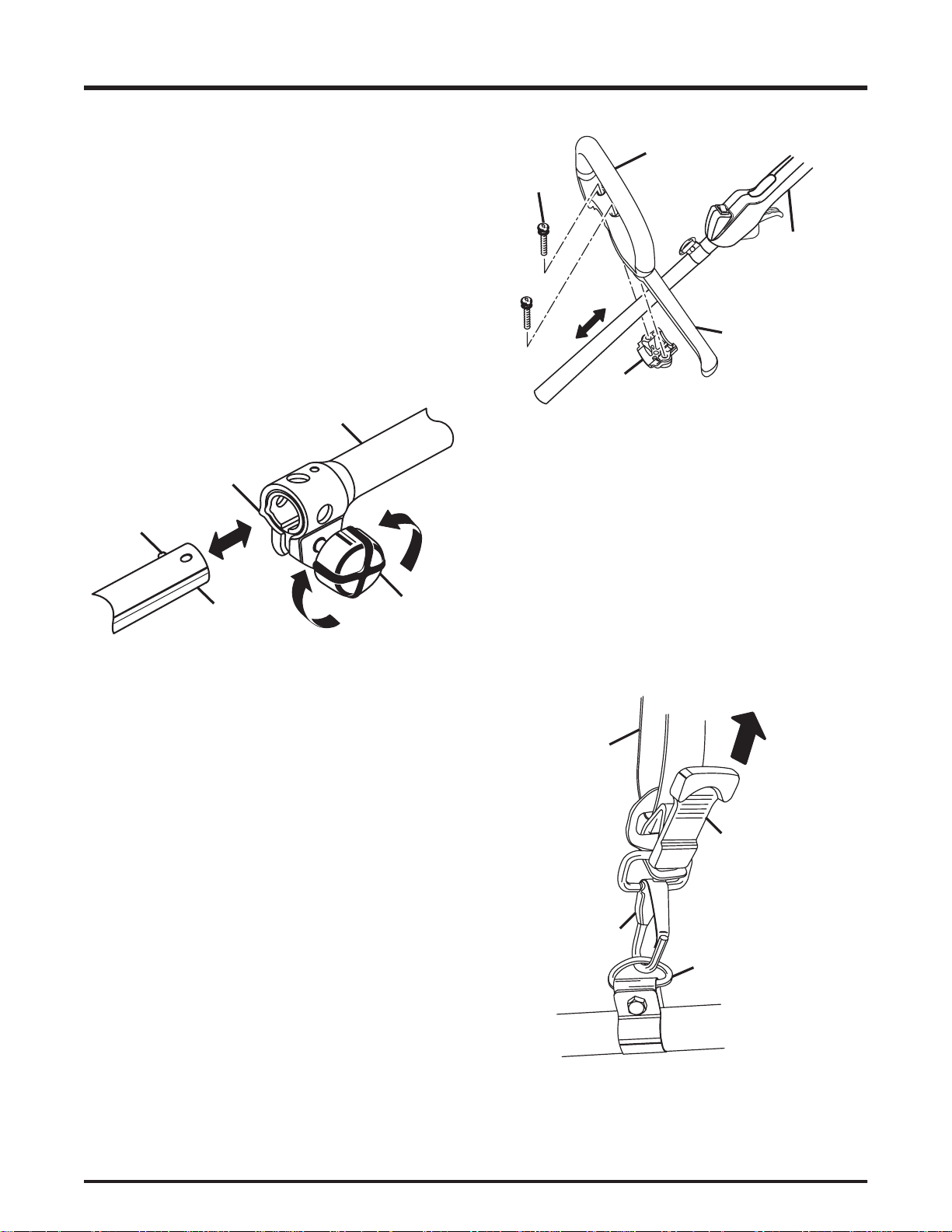

Connecting the Attachment to the Upper

Shaft

See Figure 2.

Follow these steps to connect the attachment to the

upper shaft.

1.

Loosen the knob by turning it counterclockwise.

2. Remove the end cap from the attachment shaft.

3. Align the button on the attachment shaft with the

guide recess on the upper shaft.

4. Slide the attachment shaft into the upper shaft until

the attachment shaft clicks into place.

Note: You may need to turn the attachment shaft to

properly align the two shafts.

5. Tighten the knob securely by turning it clockwise.

Upper Shaft

Guide

Recess

Button

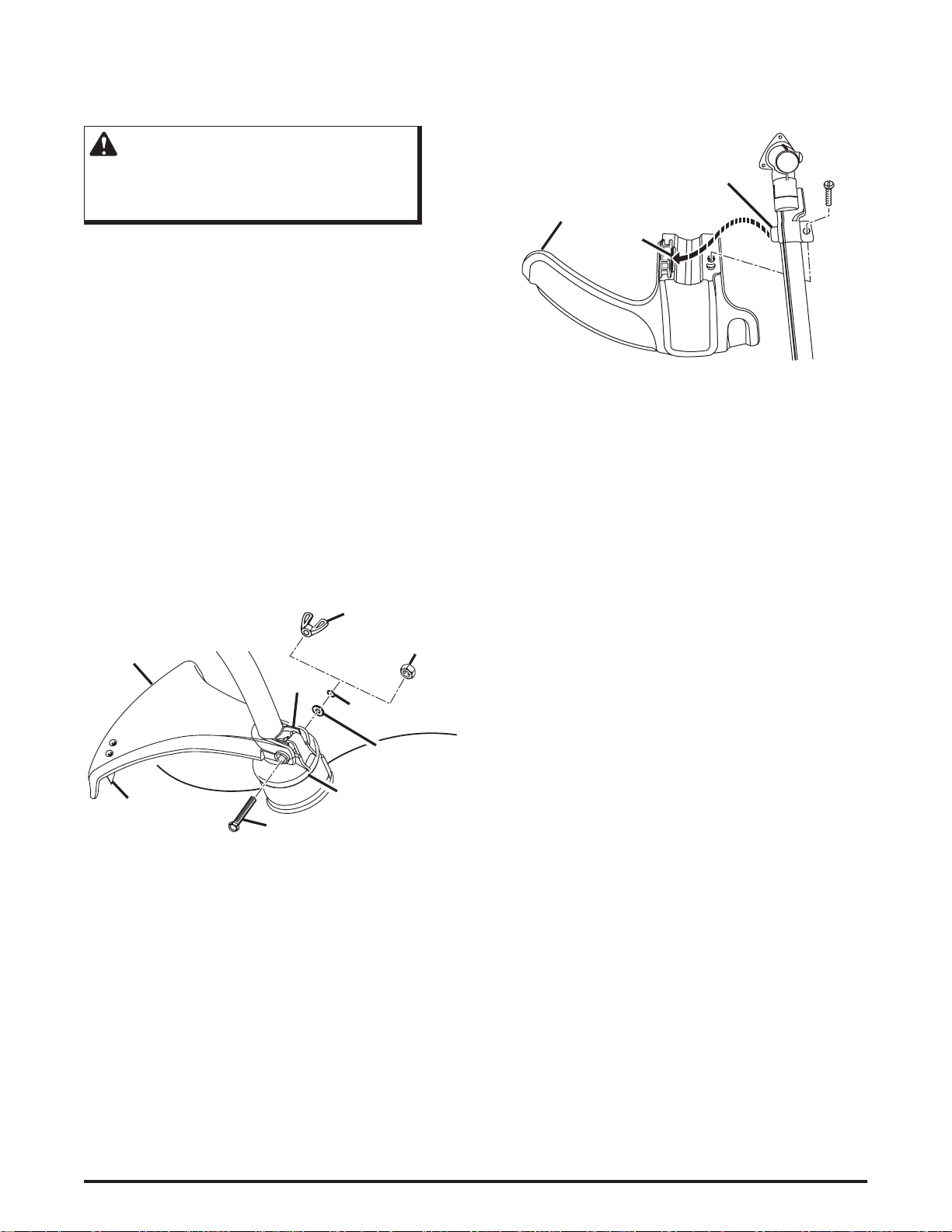

3. Place the handle along the upper shaft to a position

that allows for comfortable operation.

4. Place the handle support on the bottom of the tube

on the opposite side of the front handle.

5. Secure the handle with the slotted Torx™ screws.

.

Slotted

Torx

Screw

Handle

Support

Front

Handle

Trigger

Handle

Barrier

Bar

(Model Nos.

51934 &

51940)

Figure 3

Attaching the Shoulder Strap

Model Nos. 51934 & 51940

See Figure 4.

Attachment

Shaft

Knob

Figure 2

Removing the Attachment from the Upper

Shaft

See Figure 2.

Follow these steps to remove the attachment from the

upper shaft.

1. Loosen the knob by turning it counterclockwise.

2. Push the button while pulling out the attachment.

Attaching the Front Handle

See Figure 3.

Follow these steps to attach the front handle.

1. Remove the slotted Torx™ screws to separate the

handle from the handle support.

2. Press the handle onto the top of the upper shaft, no

less than 10 in. (25.4 cm) from the center of the trigger handle, angling the handle toward the trigger

handle.

Follow these steps to attach the shoulder strap.

1. Connect the latch on the strap to the hanger bracket.

2. Adjust the strap to a comfortable position.

Note: To quickly release the product from the shoul-

der strap, sharply pull the quick release tab.

Strap

Quick

Release

Tab

Latch

Hanger

Bracket

Figure 4

12 Assembly

Page 13

Attaching the Grass Deflector

Attaching the grass deflector differs depending on the

type of trimmer: curved shaft or straight shaft.

WARNING:

The line cutting blade on the grass deflector is

sharp. Avoid contact with the blade. Failure to

avoid contact can result in serious personal injury.

Note: To protect the operator, always be sure to attach

the grass deflector.

To Attach the Curved Shaft Grass Deflector

Model Nos. 51934 & 51940

See Figure 5.

Follow these steps to attach the curved shaft grass deflector.

1. Press the grass deflector onto the bottom of the

curved shaft as shown.

2. Lift the grass barrier up slightly.

3. Insert the hex head cap screw through the grass

deflector, bracket, and grass barrier.

3. Align the screw hole in the mounting bracket with

the screw hole in the grass deflector.

4. Insert the slotted hex head screw through the mount-

ing bracket and into the grass deflector.

5. Tighten the screw securely.

Tab

Straight Shaft

Grass Deflector

Slot

Figure 6

4. Place the flat washer and lock washer on the hex head

cap screw.

5. Place the wing nut or hex nut on the hex head cap

screw and turn clockwise to secure.

Wing

Curved Shaft

Grass Deflector

Bracket

Line

Cutting

Blade

To Attach the Straight Shaft Grass Deflector

Model Nos. 51932 & 51938 and Model Nos. 51934 &

51940

Hex Head

Cap Screw

Nut

Lock

Washer

Flat

Washer

Grass

Barrier

Hex

Nut

Figure 5

See Figure 6.

Follow these steps to attach the straight shaft grass deflector.

1. Remove the slotted hex head screw from the grass

deflector.

2. Insert the tab on the mounting bracket in the slot on

the grass deflector.

Assembly 13

Page 14

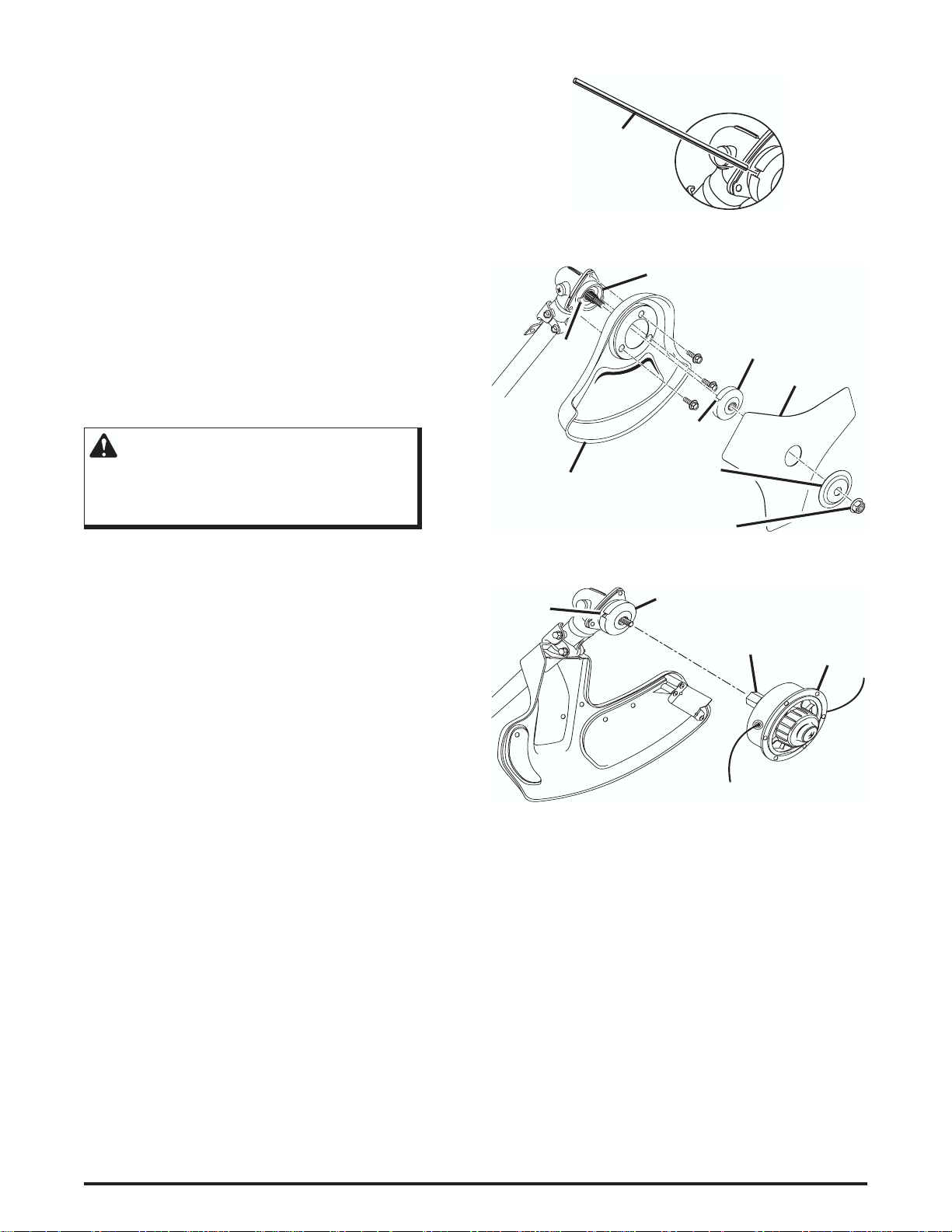

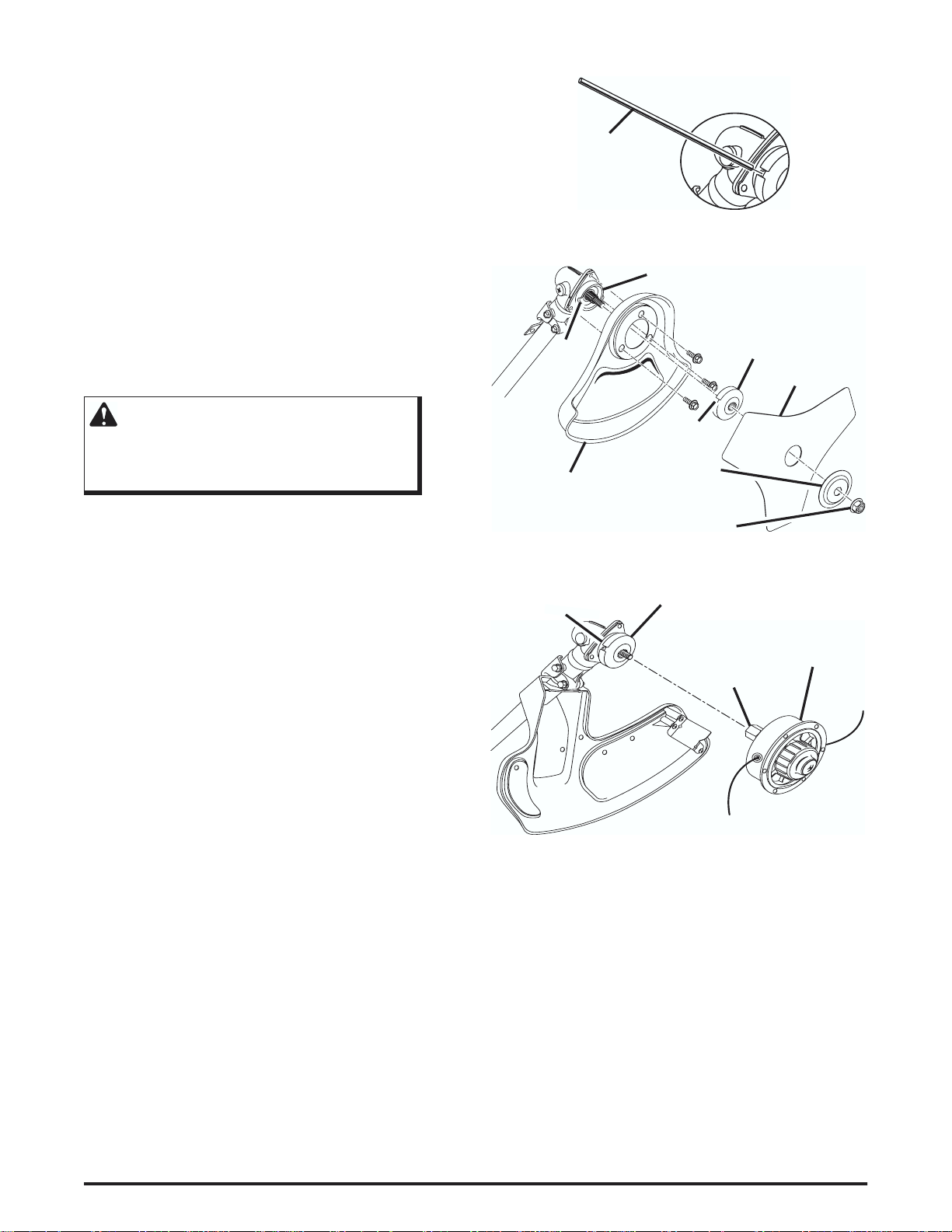

Converting from Brushcutter to Trimmer

Gear Head

Guard

Cupped

Washer

Flanged

Washer

Blade

Blade Nut

Slot

Slot

Brushcutter

Drive

Shaft

Flanged Washer

Gear

Head

Trimmer

Head

Assembly

Model Nos. 51934 & 51940

To convert from the brushcutter to the trimmer, remove

the blade, remove the brushcutter guard, attach the grass

deflector, and install the trimmer head assembly.

To Remove the Blade and Brushcutter Guard

See Figure 7 and Figure 8.

Head

Locking

Tool

Follow these steps to remove the blade and brushcutter

guard.

1. Align the slot in the flanged washer with the slot in

the gear head.

2. Place the head locking tool through the slot in the

flanged washer and gear head.

3. Remove the blade nut by turning it clockwise (left-

handed threads).

4. Remove the cupped washer and the blade.

WARNING:

Be careful when handling the blade. It is sharp.

Failure to heed this warning can result in serious

personal injury.

5. Remove the flanged washer from the gear shaft and

retain it for the trimmer head assembly installation.

6. Remove the three screws securing the brushcutter

guard.

7. Remove the brushcutter guard.

Note: Store the brushcutter parts together for future

use.

Figure 7

Figure 8

To Attach the Grass Deflector

Refer to “To Attach the Straight Shaft Grass Deflector”

earlier in this manual.

To Install the Trimmer Head Assembly

See Figure 9.

Follow these steps to install the trimmer head assembly.

1. Align the slot in the flanged washer with the slot in

Figure 9

the gear head.

2. Insert the head locking tool through the flanged

washer and gear head.

3. Install the drive shaft and trimmer head assembly

onto the gear shaft by turning the drive shaft counterclockwise (left-handed threads).

4. Tighten the drive shaft securely.

14 Assembly

Page 15

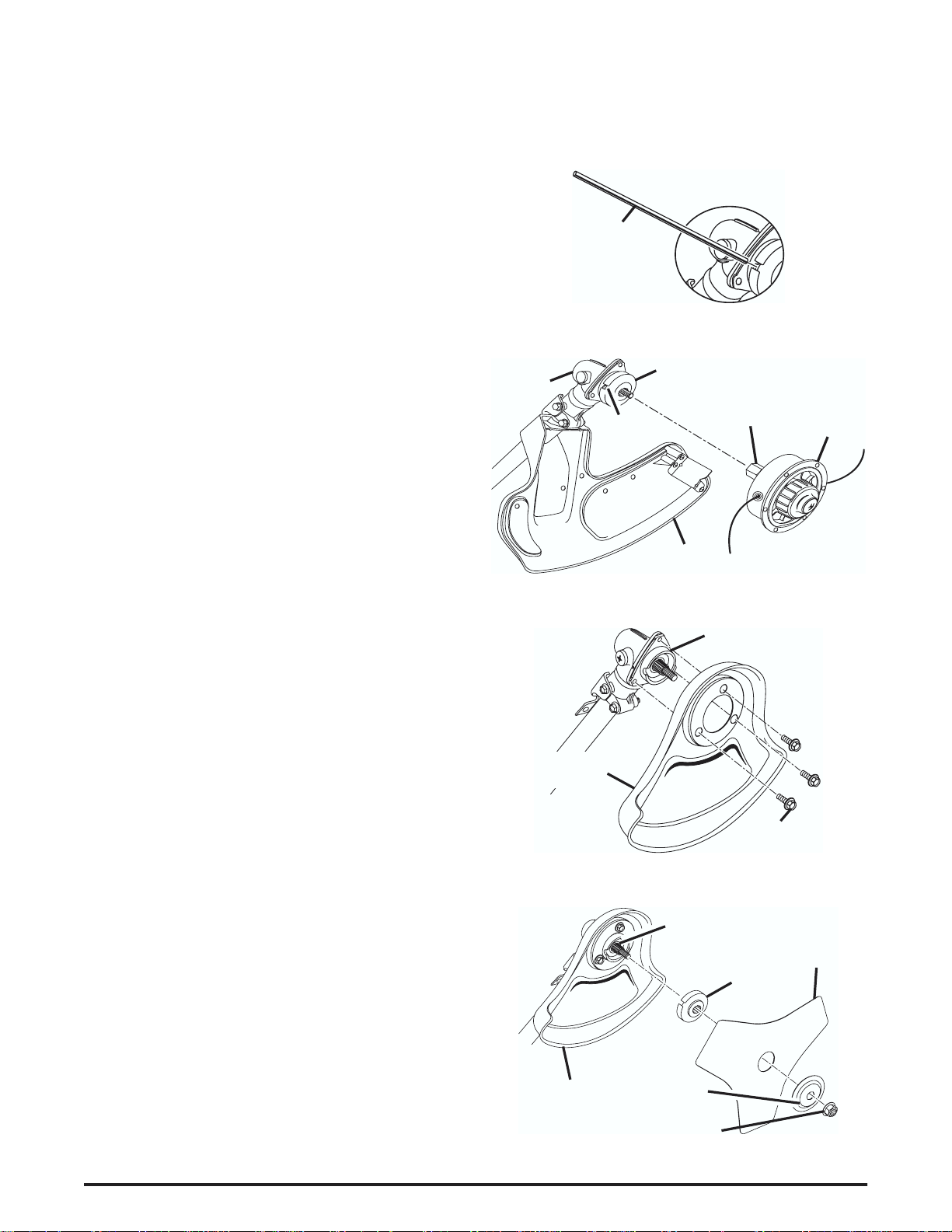

Converting from Trimmer to Brushcutter

Drive

Shaft

Flanged Washer

Gear

Head

Trimmer

Head

Assembly

Slot

Grass Deflector

Straight Shaft

Model Nos. 51934 & 51940

To convert from the trimmer to the brushcutter, remove

the trimmer head assembly, remove the grass deflector,

attach the brushcutter guard, and install the blade.

To Remove the Trimmer Head Assembly and Grass

Deflector

See Figure 10 and Figure 11.

Follow these steps to remove the trimmer head assembly

and grass deflector.

1. Align the slot in the flanged washer with the slot in

the gear head.

2. Insert the head locking tool through the flanged

washer and gear head.

3. Remove the drive shaft and trimmer head assembly

by turning the drive shaft clockwise (left-handed

threads).

4. Remove the flanged washer and retain it for the blade

installation.

5. Remove the screw securing the grass deflector.

6. Remove the grass deflector.

6. Install the blade nut by turning it counterclockwise

(left-handed threads).

7. Tighten the blade nut and torque to 120 in.lb. mini-

mum (finger tight plus 1/2 turn).

Head

Locking

Tool

Figure 10

Note: Store the trimmer head assembly parts

together for future use.

To Attach the Brushcutter Guard

See Figure 12.

Note: To protect the operator, always be sure to attach

the brushcutter guard.

Follow these steps to attach the brushcutter guard.

1. Place the guard onto the gear head as shown.

2. Insert the three hex head screws from the bottom

through the guard into the gear head.

3. Tighten the screws securely and torque to

40-50 in.lb.

To Install the Blade

See Figure 13.

Follow these steps to install the blade.

1. Place flanged washer over the gear shaft with the hol-

low side toward the brushcutter guard.

2. Center the blade on the flanged washer, making sure

the blade fits flat and the raised hub goes through the

hole in the blade.

3. Install the cupped washer with the raised center away

from the blade.

4. Place the blade nut onto the gear shaft.

5. Insert the head locking tool through the flanged

washer and gear head.

Brushcutter

Guard

Brushcutter

Guard

Gear Shaft

Cupped

Washer

Blade Nut

Gear Head

Hex Head

Screw

Flanged

Washer

Figure 11

Figure 12

Blade

Figure 13

Assembly 15

Page 16

Operation

Mixing the Fuel

DANGER:

Gasoline is extremely flammable and explosive. A

fire or explosion from gasoline will burn you and

others.

This product is powered by a 2-cycle engine and requires

pre-mixing gasoline and 2-cycle oil. The oil mix should

be 50:1, using oil that meets or exceeds JASO-FC specifications.

Follow these steps to mix the fuel.

1. Obtain a clean container that is approved for use

with gasoline.

2. Mix the 2-cycle engine oil provided with unleaded

gasoline in the container, according to the instructions on the oil carton.

Important: This engine is certified to operate on

unleaded gasoline intended for automotive use with an

octane rating of 87 ([R + M] / 2) or higher. Do not use

automotive oil or 2-cycle outboard oil. Store the container out of the reach of children.

50:1 Gasoline to Oil Mixing Chart

Gasoline Oil

1/2 US gallon 1.3 oz.

1 US gallon 2.6 oz.

2 US gallons 5.2 oz.

1 liter 20 ml

Filling the Tank

WARNING:

Always stop the engine before filling the tank.

Never add fuel to a machine with a running or hot

engine. Move at least 30 ft. (9 m) away from the

refueling site before starting the engine. Do not

smoke while filling the tank.

Follow these steps to fill the tank.

1. Clean the surface around the fuel cap to prevent con-

tamination.

2. Loosen the fuel cap by turning it counterclockwise.

3. Pour the fuel mixture carefully into the tank.

4. Clean and inspect the gasket.

Note: Replace the fuel cap if the gasket is damaged.

5. Install the fuel cap and tighten it by turning it clock-

wise.

WARNING:

Check for fuel leaks. If you find any leaks, correct

the problem before using the product.

6. Wipe spilled fuel from the product.

7. Move at least 30 ft. (9 m) away before starting the

product.

Note: It is normal for the engine to emit smoke during use.

2 liters 40 ml

3 liters 60 ml

4 liters 80 ml

5 liters 100 ml

+ =

16 Operation

Page 17

WARNING:

The product may throw objects during

operation, causing injury to the operator or to

bystanders. Always wear suitable eye protection,

long heavy pants, and boots while operating the

product.

Starting the Product

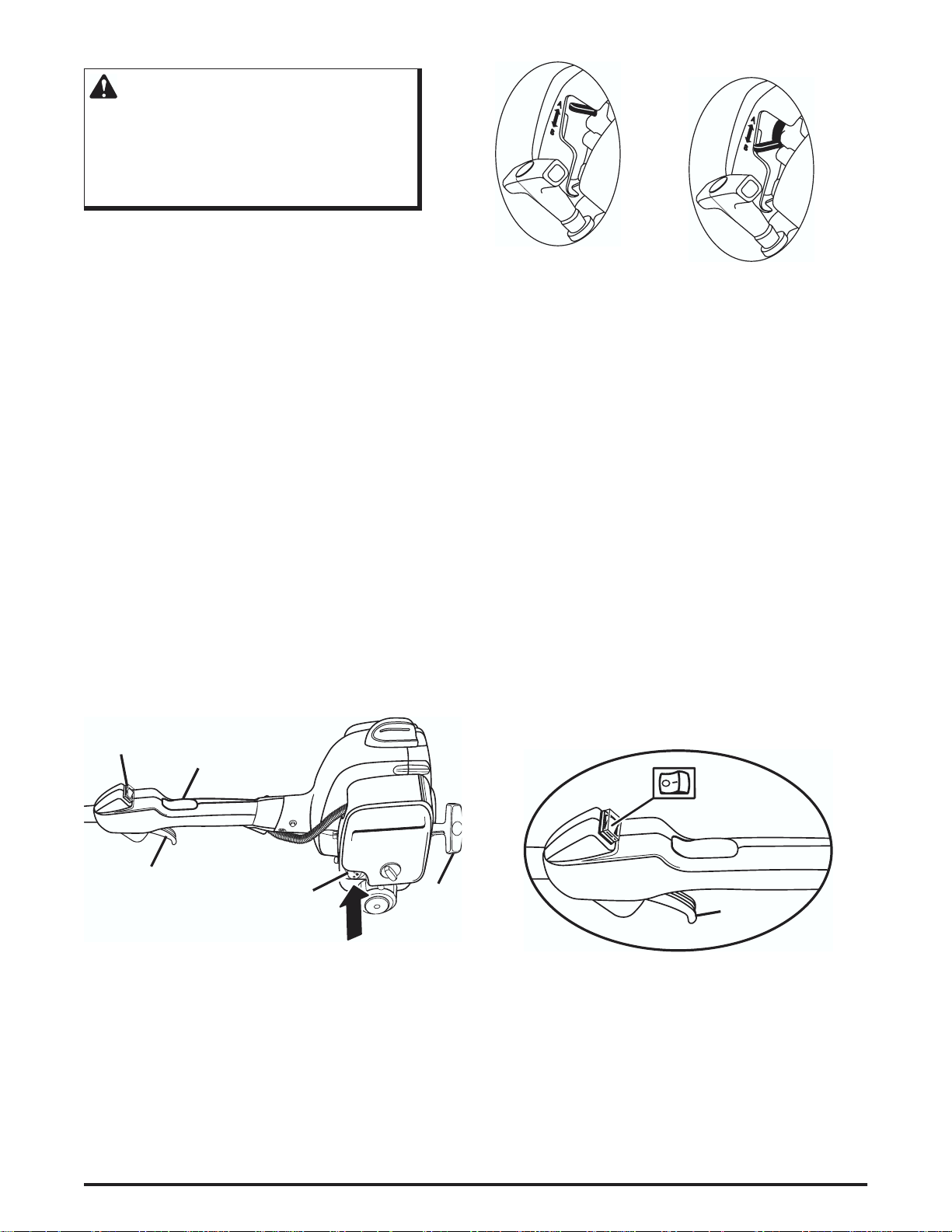

See Figure 14a, Figure 14b, and Figure 15.

Starting the product differs depending on whether the

engine is cold or warm. Refer to the label on the air filter

cover.

To Start a Cold Engine

Follow these steps to start a cold engine.

1. Lay the product on a flat, bare surface.

2. Toggle the switch to the I (ON) position.

3. Push the primer bulb approximately eight times.

4. Set the choke lever to A (Choke Closed).

5. Press the lock-off button and squeeze the trigger.

6. Pull the starter cord three times.

7. Set the choke lever to B (Choke Open).

8. Press the lock-off button and squeeze the trigger.

9. Pull the starter cord.

Note: If the product starts, let it run for 30 seconds

before using it. If the product does not start, repeat

the previous steps.

Set Choke to A

Set Choke to B

Figure 14b

To Start a Warm Engine

Follow these steps to start a warm engine.

1. Lay the product on a flat, bare surface.

2. Toggle the switch to the I (ON) position.

3. Push the primer bulb up to eight times.

4. Set the choke lever to B (Choke Open).

5. Do not squeeze the trigger.

6. Pull the starter cord.

Note: If the product does not start, repeat the previ-

ous steps.

Stopping the Product

See Figure 15.

Follow these steps to stop the product.

1. Release the trigger.

2. Toggle the switch to the O (OFF) position.

Switch

Trigger

Lock-off

Button

Primer

Bulb

Starter

Cord

Figure 14a

Switch

Trigger

Figure 15

Operation 17

Page 18

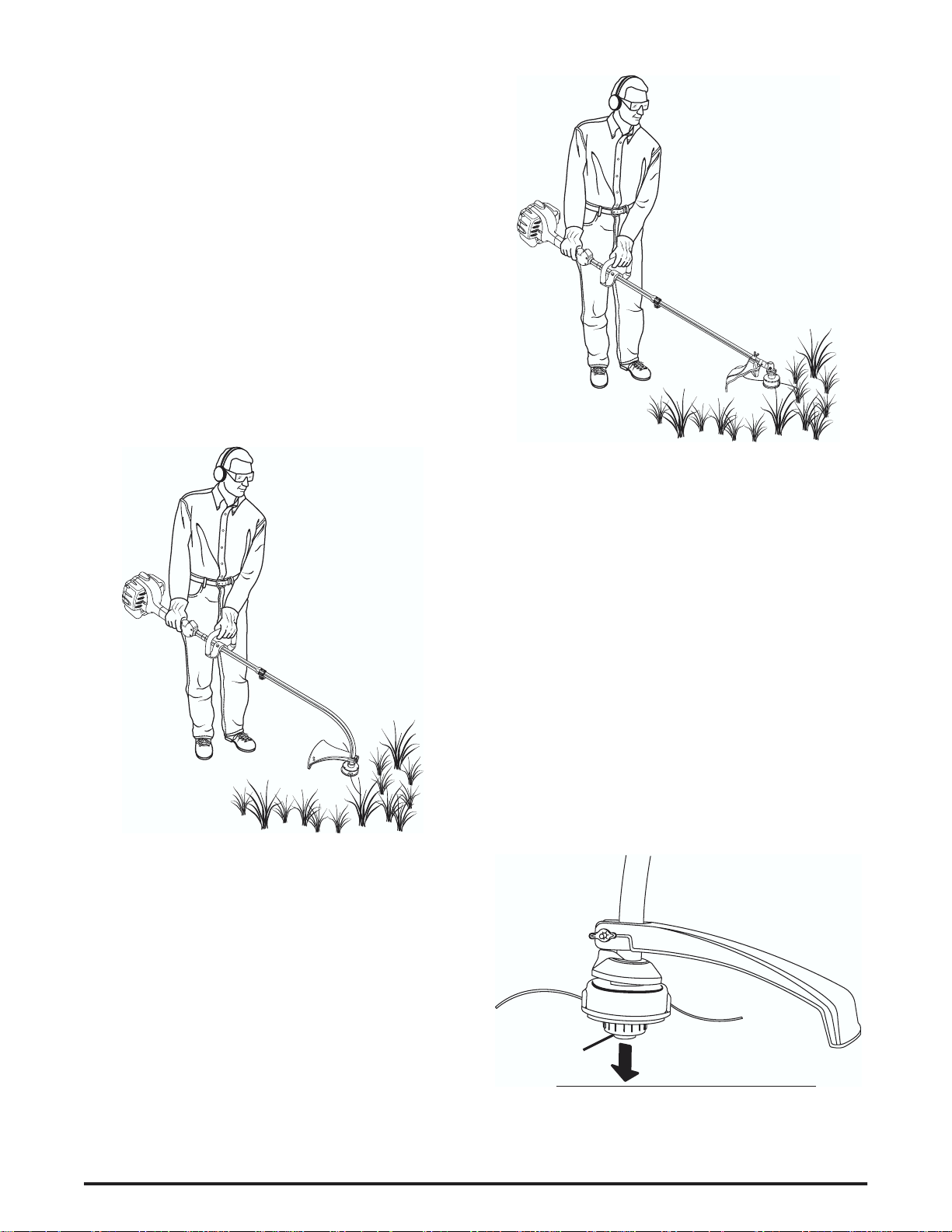

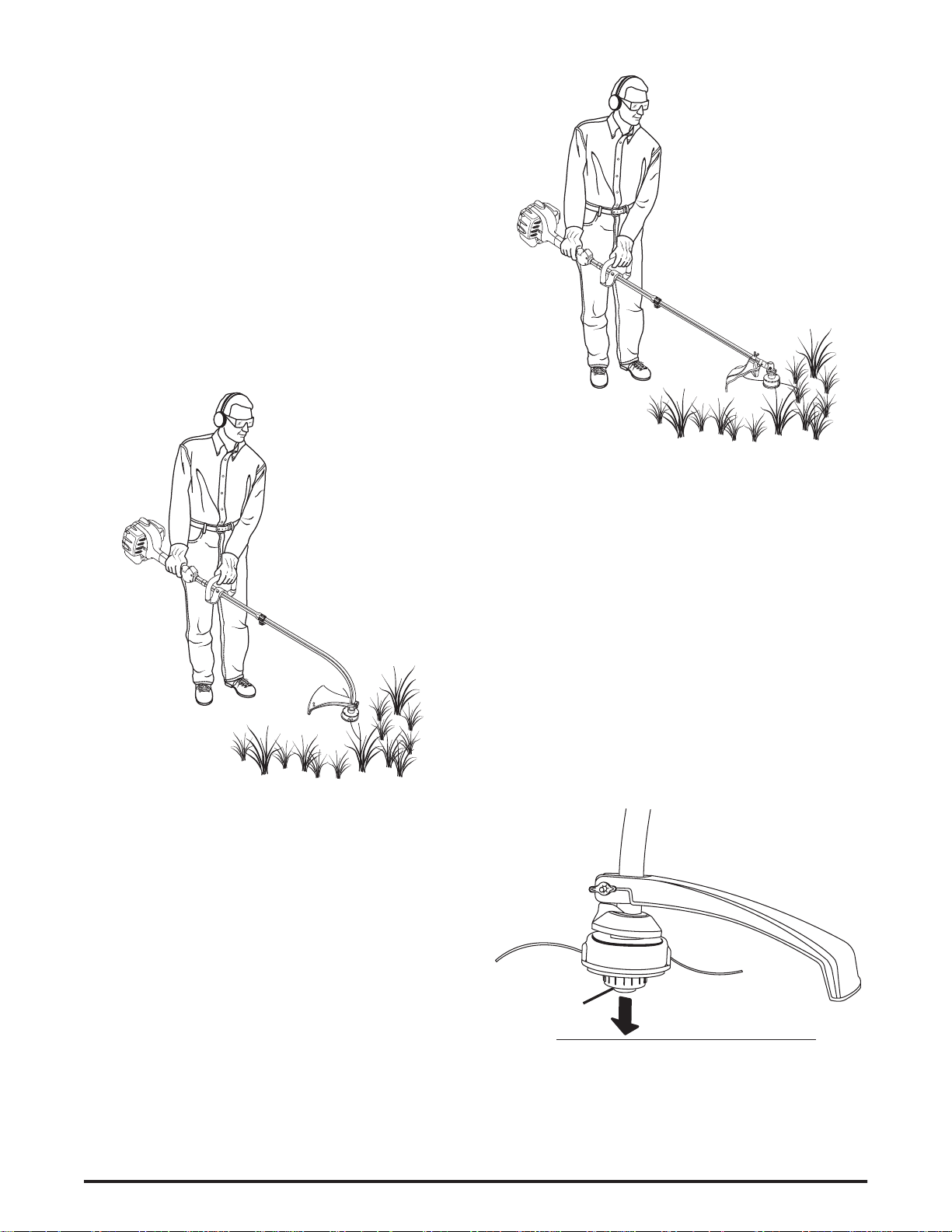

Operating the Trimmer

Retaining

Cap

Operating the trimmer differs, depending on whether

you are using the curved shaft trimmer or the straight

shaft trimmer.

To Operate the Curved Shaft Trimmer

(Model Nos. 51930 & 51936)

See Figure 16a.

Follow these steps to operate the curved shaft trimmer.

1. Start the trimmer.

2. Hold the trimmer at waist level with your right hand

on the trigger handle and your left hand on the front

handle.

3. Place the product on the right side of your body with

the engine behind and away from your body.

4. Trim grass and weeds in a right-to-left motion with

the line parallel to the ground.

Figure 16b

To Advance the Cutting Line

See Figure 16c.

Figure 16a

To Operate the Straight Shaft Trimmer

(Model Nos. 51932 & 51938)

See Figure 16b.

Follow these steps to operate the straight shaft trimmer.

1. Start the trimmer.

2. Hold the trimmer at waist level with your right hand

on the trigger handle and your left hand on the front

handle.

Follow these steps to advance the cutting line.

1. Start the trimmer.

2. Tap the retaining cap lightly on the ground while the

motor is running. The line will only advance with

the engine at full throttle. Do not hold the retain-

ing cap on the ground.

Note: The line cutting blade on the grass deflector will

cut the line to the proper length.

Note: To help prevent line tangle, tap only once to

lengthen the line. If additional line is required, wait a few

seconds before retapping the retaining cap. Do not allow

the line to wear too short. Keep the cutting line at full

length.

3. Place the product on the right side of your body with

the engine behind and away from your body.

4. Trim grass and weeds in a left-to-right motion with

Figure 16c

the line parallel to the ground.

18 Operation

Page 19

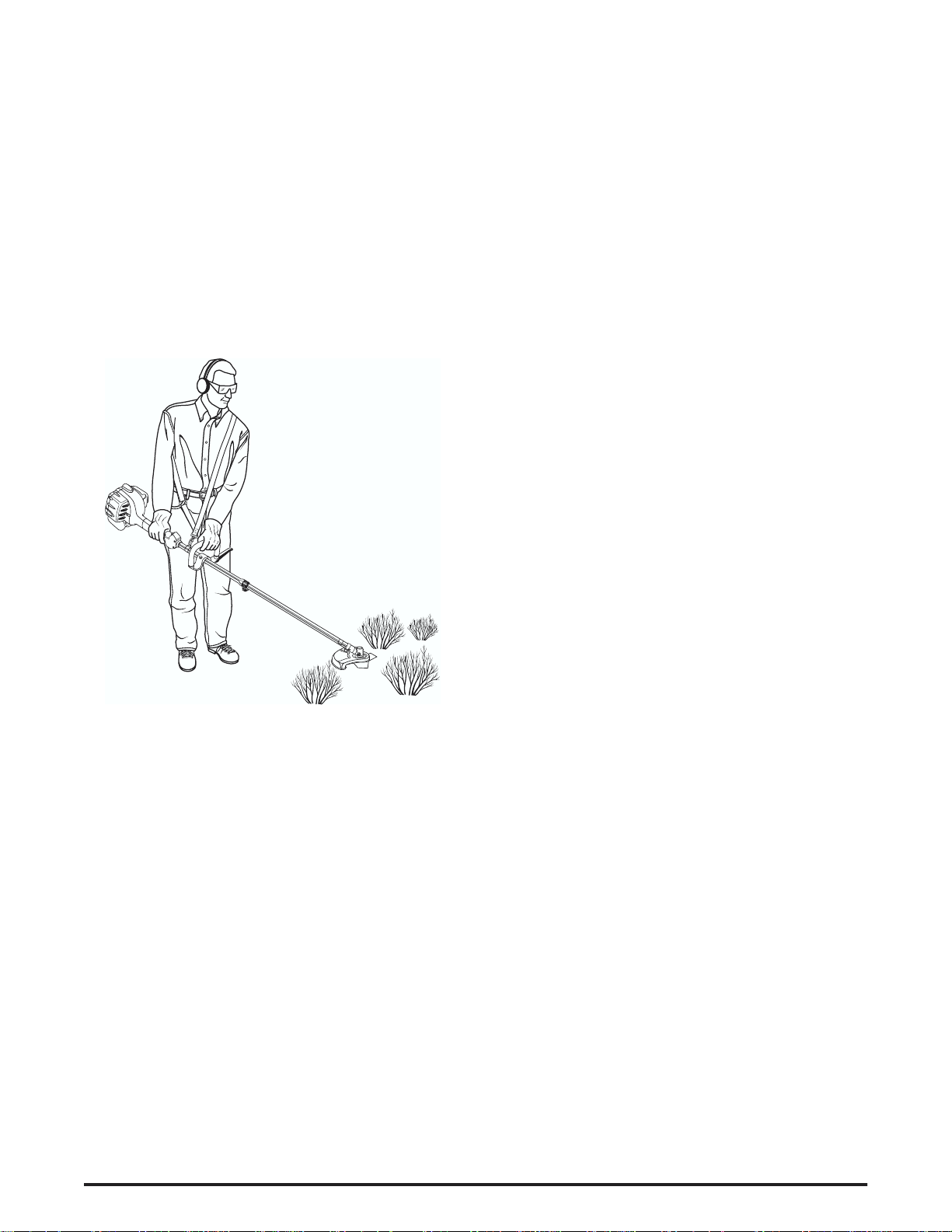

Operating the Brushcutter

(Model Nos. 51934 & 51940)

See Figure 17.

Follow these steps to operate the brushcutter.

1. Start the brushcutter.

2. Hold the brushcutter at waist level with your right

hand (arm extended) on the trigger handle and your

left hand on the front handle.

3. Place the product on the right side of your body with

the engine behind and away from your body.

4. Brushcut weeds and vines in a right-to-left motion

with the blade parallel to the ground.

Figure 17

Operation 19

Page 20

Maintenance

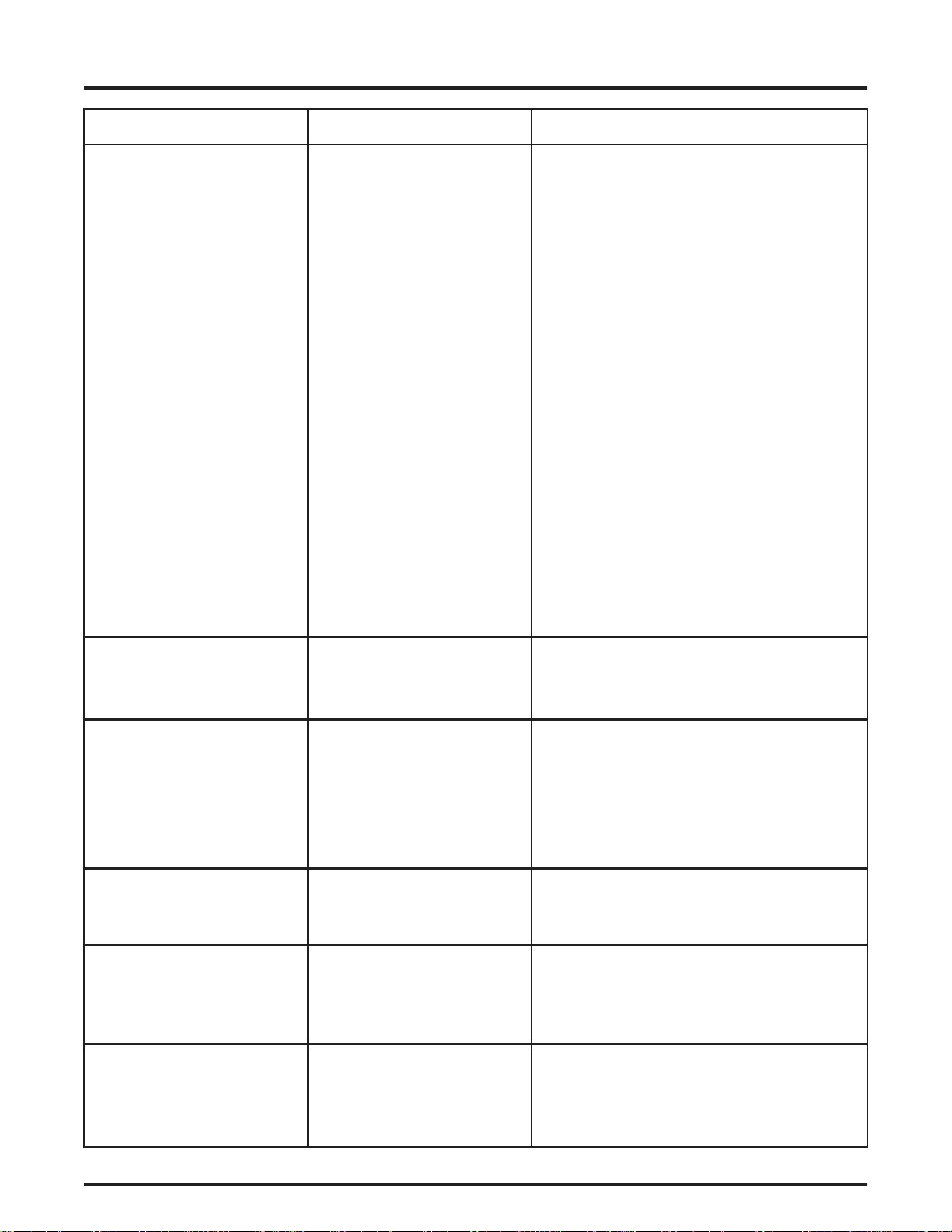

Emissions Maintenance Schedule

Maintenance, replacement, or repair of the emission control device and systems may be performed by any nonroad engine repair establishment or individual.

Emission Part Inspect before

each use

Clean every 5

hours

Replace every

25 hours or

yearly

Clean every 25

hours or yearly

Fuel Tank Assembly (Includes

X

Fuel Lines, Fuel Cap, and Fuel

Filter)

Air Filter X X

Spark Arrester X

Spark Plug X

Replacing the Cutting Line

WARNING:

When replacing parts other than engine or

emissions parts, Use only Toro replacement parts.

Use of any other parts may create a hazard or cause

product damage.

See Figure 18 and Figure 19.

WARNING:

Use of line other than the proper monofilament

cutting line could cause personal injury.

Follow these steps to replace the cutting line.

Cleaning the Product

Stop the trimmer.

■

Stop the product before cleaning.

Clean the exterior of the product with a damp cloth.

■

■

Avoid using solvents when cleaning plastic parts.

Most plastics are susceptible to damage from various

types of commercial solvents and may be damaged by

their use.

■

Wipe or scrape the trimmer head and spool area

when they accumulate dirt or clippings.

Scrape debris away from air intake vents on both

■

sides of the motor housing.

CAUTION:

Keeping air intake vents free of grass and debris

prevents motor overheating and possible failure.

Note: Depending on the type of fuel used, the type

and amount of oil used, and/or your operating conditions, the exhaust port and muffler may become

blocked with carbon deposits. If you notice a power

loss with your gas powered tool, you may need to

remove these deposits to restore performance. We

highly recommended that only qualified service technicians perform this service.

Servicing the Product

■

Check and tighten all fasteners. If any part is

damaged or lost, repair it or replace it.

1.

WARNING:

Make sure the trimmer head stops rotating.

Contact with a rotating trimmer head could cause

personal injury.

2.

Remove the spark plug boot. See Figure 22.

Remove the retaining cap.

3.

4.

Remove the empty spool.

Clean the trimmer head thoroughly. Inspect the

5.

trimmer head for any damaged or worn parts.

Hold the spool with the spring positioned upward.

6.

7.

Insert the end of the new line into the hole in the

upper threaded area of the spool.

Wind the line around the spool as indicated by the

8.

arrows on the top of the spool until the line reaches

the edge of the spool. Do not wind the line beyond

the edge of the inner ring.

9.

Secure the line temporarily by pushing it into one of

the slotted tabs on the spool.

Measure six inches of line from the slotted tab and

10.

cut the line at that point.

20 Maintenance

Page 21

11. Repeat the process for the lower threaded area of the

Retaining

Cap

Spool

Trimmer

Head

Drive

Shaft

Eyelet

Slotted

Tab

spool, winding the line and securing it in the slotted

tab opposite the first secured line.

Follow these steps to replace the spool.

1. Stop the trimmer.

12. Insert the lines into the eyelets on the trimmer head.

13. Place the spool on the drive shaft.

Note: To install the spool, you may need to rotate it

slightly. If the line should tangle or break at the eyelet, remove the spool, refeed the line through the eyelets, and reassemble the spool on the trimmer.

14. Release the lines from the tabs by sharply pulling

each line.

15. Push down on the spool to reveal the threads inside

the drive shaft.

16. Thread the retaining cap on the drive shaft.

17. Secure the retaining cap.

WARNING:

An improperly installed retaining cap or spool

could fly off the trimmer. Contact with a thrown

retaining cap or spool could cause personal injury.

18. Replace the spark plug boot. See Figure 22.

Inner Ring

WARNING:

Make sure the trimmer head stops rotating when

you release the trigger. Contact with a rotating

trimmer head could cause personal injury.

2. Remove the spark plug boot. See Figure 22.

3. Remove the retaining cap by turning as indicated by

the arrow on the cap.

4. Remove the empty spool.

5. Clean the trimmer head thoroughly. Inspect the

trimmer head for any damaged or worn parts.

6. Remove the lines from the slotted tabs on the spool

and unwind approximately six inches.

7. Secure the lines temporarily by pushing them into

the slotted tabs on the spool.

8. Insert the lines of the new spool into the eyelets on

the trimmer head.

9. Place the spool on the drive shaft.

Note: To install the spool, you may need to rotate it

slightly.

Note: If the line should tangle or break at the eyelet,

remove the spool, refeed the line through the eyelets,

and reassemble the spool on the trimmer.

Upper

Threaded Area

Slotted

Tab

Lower

Threaded Area

Figure 18

Replacing the Spool

See Figure 19.

Note: For best performance, use only Toro spools (Part

No. 88046). The spool may wear during normal use of

the line advance feature and may require occasional

replacement. Replacement spools are available through

your Toro retailer.

10. Release the lines from the tabs by sharply pulling

each line.

11. Push down on the spool to reveal the drive shaft.

12. Thread the retaining cap on the drive shaft.

13. Secure the retaining cap.

14. Replace the spark plug boot. See Figure 22.

Figure 19

Maintenance 21

Page 22

Checking the Fuel Cap

WARNING:

A leaking fuel cap is a fire hazard and must be

replaced immediately.

The fuel cap contains a non-serviceable filter and check

valve. A clogged fuel filter causes poor engine performance. If performance improves when the fuel cap is

loosened, the check valve may be faulty or the filter may

be clogged. Replace the fuel cap if necessary.

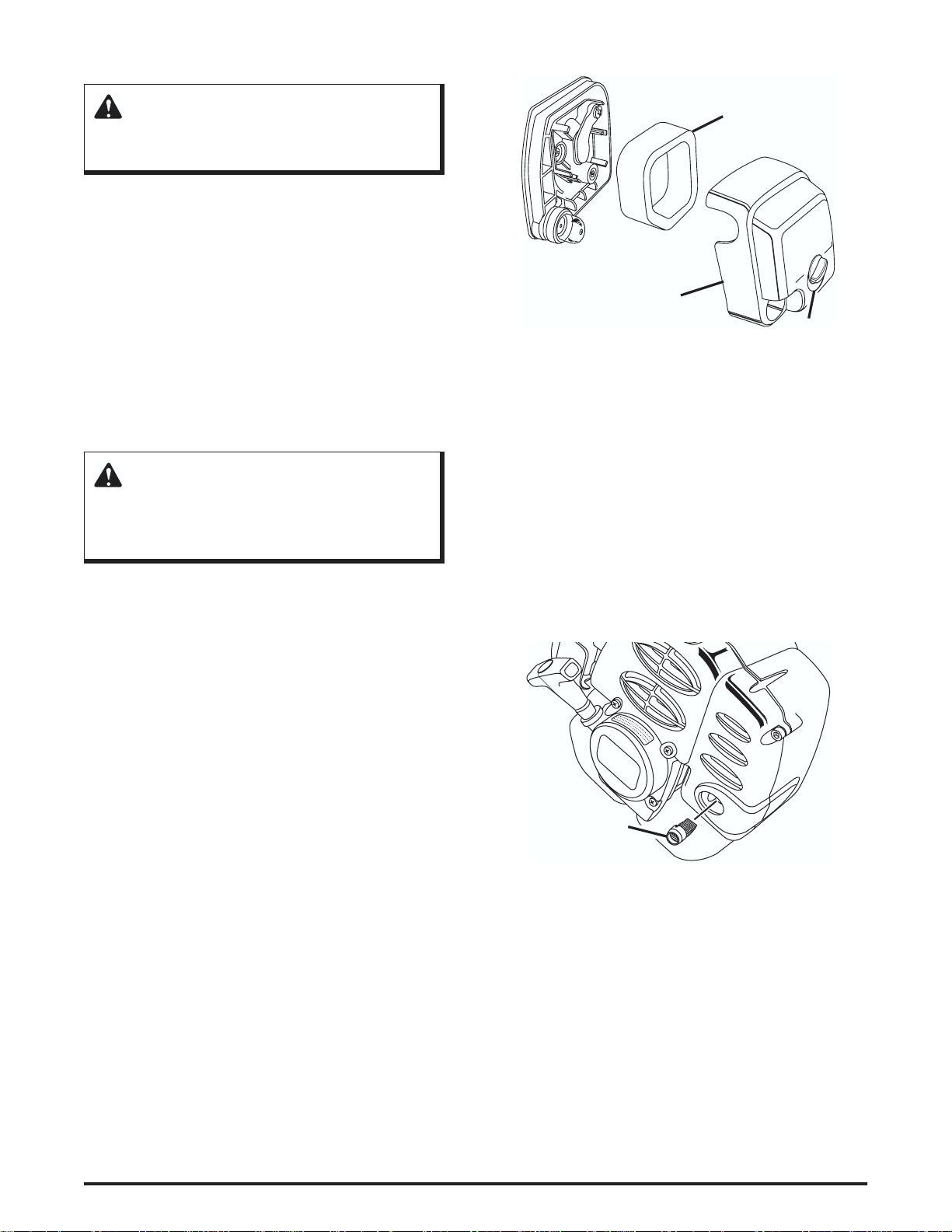

Cleaning the Air Filter

See Figure 20 and Figure 22.

Clean the air filter as indicated by the maintenance

schedule.

Follow these steps to clean the air filter.

1. Stop the trimmer.

WARNING:

Make sure the trimmer head stops rotating when

you release the trigger. Contact with a rotating

trimmer head could cause personal injury.

2. Remove the spark plug boot.

3. Loosen the air filter cover by turning the knob coun-

terclockwise.

Air

Filter

Air

Filter

Cover

Knob

Figure 20

Cleaning the Spark Arrester

See Figure 21.

Follow these steps to clean the spark arrester.

1. Locate the spark arrester through the hole on the

muffler-side engine cover.

2. Remove the spark arrester by pulling it out with nee-

dle-nosed pliers.

3. Clean the spark arrester with a small wire brush.

4. Replace the spark arrester.

4. Remove the air filter cover.

5. Remove the air filter.

6. Clean the air filter with warm soapy water.

7. Rinse the air filter and let it dry completely.

8. Work two drops of oil into the air filter.

9. Replace the air filter (fits only one way).

10. Replace the air filter cover.

11. Tighten the air filter cover by turning the knob

clockwise.

12. Replace the spark plug boot.

Note: Replace the air filter (Part No. 88048) as indi-

cated by the maintenance schedule.

Spark

Arrester

Figure 21

22 Maintenance

Page 23

Replacing the Spark Plug

See Figure 22.

Model Nos. 51930, 51932, & 51934 use a NGK

BPMR7A or Champion RCJ-6Y spark plug.

Model Nos. 51930A, 51932A, 51934A, 51936, 51938,

& 51940 use a NGK CMR7A spark plug. Use an exact

replacement and replace annually.

Follow these steps to replace the spark plug.

1. Remove the spark plug boot.

2. Loosen the spark plug by turning it counterclockwise

with a socket.

3. Remove the spark plug.

4. Hand thread the new spark plug, turning it clock-

wise.

5. For Model Nos. 51930, 51932: Tighten with a

socket and torque to 170 in.lb. minimum, 190 in.lb.

maximum. Do not over tighten.

Storing the Product

Storing the product differs depending on the amount of

time it will be in storage.

Note: If the product includes another attachment, place

the storage cap on the end of the attachment shaft and

hang it up to store.

To Store the Product Short Term

Follow these steps to store the product short term.

1. Clean all foreign material from the product.

2. Store the product in a well-ventilated place that is

inaccessible to children.

To Store the Product Long Term

If you do not intend to use the product for more than

one month, follow the storage procedures below.

Follow these steps to store the product long term.

1. Drain all of the fuel from the tank into a container

approved for gasoline.

6. For Model Nos. 51930A, 51932A, 51934A, 51936,

51938, & 51940: Tighten with a socket and torque

to 87 in.lb. minimum, 104 in.lb. maximum. Do not

over tighten.

CAUTION:

Be careful not to cross-thread the spark plug. Crossthreading will seriously damage the product.

Spark Plug Boot

Spark

Plug

2. Run the engine until it stops.

3. Clean all foreign material from the product.

4. Store the product in a well-ventilated place that is

inaccessible to children.

Note: Keep the product away from corrosive agents

such as garden chemicals and de-icing salts.

Important: Abide by all federal and local regulations for the safe storage and handling of gasoline.

Transporting the Product

Follow these steps to transport the product.

1. Drain the fuel mixture into a container that is

approved for use with gasoline.

2. Carry the product by the front handle.

3. Secure the product in your vehicle or on a trailer.

Figure 22

Maintenance 23

Page 24

Troubleshooting

Problem Possible Cause Solution

Engine will not start 1. Switch set to the O (OFF)

position.

2. No spark

3. No fuel

4. Flooded engine

5. Starter cord pulls harder now

then when new

1. Set switch to the I (ON) position.

2. Remove the spark plug. Reattach the spark

plug cap and lay the spark plug on the metal

cylinder. Pull the starter cord and watch for a

spark at the spark plug tip. If there is no spark,

repeat the test with a new spark plug.

3. Push primer bulb until the bulb is full of fuel.

If the bulb does not fill, the primary fuel

delivery system is blocked. If the primer bulb

fills, the engine may be flooded. (See next

item.)

4. Remove the spark plug. Turn the product so

that the spark plug hole is aimed at the

ground. Make sure the choke lever is set to B

and pull the starter cord 10 to 14 times. This

clears excess fuel from the engine. Clean and

reinstall the spark plug. With the trigger fully

depressed, pull the starter cord 3 times. If the

engine does not start, set the choke lever to A

and follow normal starting instructions. If the

engine still fails to start, repeat the procedure

with a new spark plug.

5. Contact an authorized service dealer.

Engine does not reach full speed

and emits excessive smoke

Line will not advance when

using automatic line lengthening

Retaining cap hard to turn when

using automatic line lengthening

Grass wraps around the trimmer

head assembly and the attachment shaft

Oil drips from muffler 1. Operating the product at

1. Check oil fuel mixture

2. Air filter is dirty

3. Spark arrestor screen is dirty

1. Line welded to itself

2. Not enough line on the

spool

3. Line worn too short

4. Line tangled on spool

5. Engine speed too slow

Screw threads are dirty or damaged

1. Cutting tall grass at ground

level

2. Operating the product at

part throttle

part throttle

2. Check oil/fuel mixture

3. Air filter is dirty

1. Use fresh fuel and the correct 2-cycle oil mix.

2. Clean the air filter.

3. Clean the spark arrester.

1. Lubricate with silicone spray.

2. Install more line.

3. Pull line while alternately pressing down on

and releasing the retaining cap.

4. Remove line from spool and rewind.

5. Advance line at full throttle.

Clean the threads and lubricate with grease. If

this does not solve the problem, replace the

retaining cap.

1. Cut tall grass from the top down.

2. Operate the product at full throttle.

1. Operate the product at full throttle.

2. Use fresh fuel and the correct 2-cycle oil mix.

3. Clean the air filter.

24 Troubleshooting

Page 25

Notes

Notes 25

Page 26

Warranty

OWT Industries, Inc.

Gas Trimmer Products

Limited Warranty

OWT INDUSTRIES, INC. warrants to the original retail purchaser that this Gas Trimmer Product is free from defects in material

and workmanship and agrees to repair or replace, at our option, any defective Product free of charge within these time periods from

the date of purchase:

Two years for Gas Trimmer Products, if the Product is used for personal, family, or household use;

■

90 days, if Gas Trimmer Products are used for any other purpose, such as commercial or rental.

■

■ Two years for emissions control systems on Gas Trimmer Products used for any purpose, as provided below.

Except as provided in the Emission Control Warranty Statement, this warranty extends to the original retail purchaser only and

commences on the date of original retail purchase.

Instructions for Obtaining Warranty Service

Any part of the Product manufactured or supplied by OWT Industries, Inc. and found in the reasonable judgement of OWT,

Industries, Inc. to be defective in material or workmanship will be repaired or replaced by an authorized service dealer for this product without charge for parts and labor. To locate your nearest authorized service dealer for this product, contact us at Toll free 1866-574-9242 US and Toll free 1-866-574-9243 Canada

The Product including any defective part must be returned to an Authorized Service Dealer for this product within the warranty

period. The expense of delivering the Gas Trimmer Product to the service dealer for warranty work and the expense of returning it

back to the owner after repair or replacement will be paid for by the owner. OWT Industries. Inc.’s responsibility in respect to

claims is limited to making the required repairs or replacements and no claim of breach of warranty shall be cause for cancellation

or rescission of the contract of sale of any Product. Proof of purchase will be required by the dealer to substantiate any warranty

claim. All warranty work must be performed by a service dealer authorized by OWT Industries, Inc. to service this product.

This warranty does not cover any Gas Trimmer Product that has been subject to misuse, neglect, negligence, or accident, or that has

been operated in any way contrary to the operating instructions as specified in the Operator’s Manual. This warranty does not

apply to any damage to the Gas Trimmer Product that is the result of improper maintenance or to any Gas Trimmer Product that

has been altered or modified so as to adversely affect the products operation, performance or durability or that has been altered or

modified so as to change its intended use. The warranty does not extend to repairs made necessary by normal wear or by the use of

parts or accessories which are either incompatible with the Gas Trimmer Product or adversely affect its operation, performance or

durability.

In addition, this warranty does not cover the following (except to the extent covered by the emissions control warranty set forth

below):

A. Tune-ups – Spark Plugs, Carburetor Adjustments, Filters

B. Wear Items – Bump Knobs, Outer Spools, Cutting Line, Inner Reels, Starter

Pulley, Starter Ropes, Drive Belts

OWT Industries, Inc. reserves the right to change or improve the design of any Gas Trimmer Product without assuming any obliga-

tion to modify any product previously manufactured.

ALL IMPLIED WARRANTIES ARE LIMITED IN DURATION TO THE STATED WARRANTY PERIOD. ACCORD-

INGLY, ANY SUCH IMPLIED WARRANTIES INCLUDING MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE, ARE DISCLAIMED IN THEIR ENTIRETY AFTER THE EXPIRATION OF THE APPROPRIATE TWO-YEAR OR NINETY DAY WARRANTY PERIOD. OWT INDUSTRIES INC.’S OBLIGATION UNDER

THIS WARRANTY IS STRICTLY AND EXCLUSIVELY LIMITED TO THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS AND OWT DOES NOT ASSUME OR AUTHORIZE ANYONE TO ASSUME FOR THEM ANY OTHER

OBLIGATION. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

OWT INDUSTRIES INC. ASSUMES NO RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL OR OTHER

DAMAGES INCLUDING, BUT NOT LIMITED TO EXPENSE OF RETURNING THE GAS TRIMMER PRODUCT TO

A GAS TRIMMER AUTHORIZED SERVICE DEALER AND EXPENSE OF DELIVERING IT BACK TO THE OWNER,

MECHANIC’S TRAVEL TIME, TELEPHONE OR TELEGRAM CHARGES, RENTAL OF A LIKE PRODUCT DURING

THE TIME WARRANTY SERVICE IS BEING PERFORMED, TRAVEL, LOSS OR DAMAGE TO PERSONAL PROPERTY,

LOSS OF REVENUE, LOSS OF USE OF THE PRODUCT, LOSS OF TIME, OR INCONVENIENCE. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

This warranty gives you specific legal rights, and you may also have other rights, which vary, from state to state.

This product is manufactured under license from The Toro Company by OWT Industries, Inc.

26 Warranty

Page 27

FEDERAL AND CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

OWT Industries, Inc. specifically warrants the emissions control system of this Gas Trimmer Product in accordance with the California and Federal legal requirements described below:

OWT Industries, Inc. warrants to the original retail purchasers and subsequent purchasers that the nonroad engine

included with this product has been designed, built and equipped, at the time of sale, to comply with applicable EPA

regulations, and that the engine is free from defects in material and workmanship that would cause it to fail to conform

with the applicable regulations for its warranty period.

The following CARB statement only applies to model numbers 51936, 51938, and 51940.

The California Air Resources Board (CARB), and OWT Industries, Inc. are pleased to explain the Emission Control

System Warranty on your nonroad or small off-road engine. In California, new small off-road engines must be

designed, built and equipped to meet the state's stringent anti-smog standards. OWT Industries, Inc. must (and

does) warrant the emission control system on your nonroad or small off-road engine for the period of time listed

above provided there has been no abuse, neglect, or improper maintenance of your nonroad or small off-road engine.

Your emission control system may include parts such as the carburetor or fuel injection system, the ignition system,

the catalytic converter. Also included may be hoses, belts, and connectors and other emission related assemblies.

Where a warrantable condition exists, OWT Industries, Inc. will repair your nonroad or small off-road engine at no

cost to you, including diagnosis (if the diagnostic work is performed at an authorized dealer), parts, and labor.

Manufacturer's Warranty Coverage

The 1995 and later small off-road engines are warranted for two years in California from original date of purchase. If any emis-

sion-related part on your engine is defective, the part will be repaired or replaced by OWT Industries, Inc. free of charge.

Owner’s Warranty Responsibilities

As the non-road or small off-road engine owner, you are responsible for the performance of the required maintenance listed in

your owner's manual. OWT Industries, Inc. recommends that you retain all receipts covering maintenance on your non-road or

small off-road engine, but OWT Industries, Inc. cannot deny warranty solely for the lack of receipts or for your failure to ensure

the performance of all scheduled maintenance.

As the non-road or small off-road engine owner, you should however, be aware that OWT Industries, Inc. may deny you warranty

coverage if your non-road or small off-road engine or a part has faild due to abuse, neglect, improper maintenance or unapproved

modifications.

You are responsible for presenting your nonroad or small off-road engine to an OWT Industries, Inc distribution center or autho-

rized service center as soon as a problem exists. The warranty repairs should be completed in a reasonable amount of time, not to

exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should contact an OWT Industries, Inc., Cus-

tomer Representative at 1-866-574-9242 (US) or 1-866-574-9243 (Canada)

Emission-related warranted parts for this product include: Carburetor, Spark Plug, Ignition, Air Filter and Fuel Filter.

Maintenance Reqirements

The owner is responsible for the performance of the required maintenance as defined by OWT Industries, Inc. in the owner's manual.

Limitations

The Emission Control Systems Warranty shall not cover any of the following:

(a) repair or replacement required because of misuse or neglect, lack of required maintenance, repairs improperly performed or

replacements not conforming to OWT Industries, Inc. specifications that adversely affect performance and/or durability, and

alterations or modifications not recommended or approved in writing by OWT Industries, Inc., and

(b) replacement of parts and other services and adjustments necessary for required maintenance at and after the first scheduled

replacement point.

The Emissions Compliance Period referred to on the Emissions Compliance label indicates the number of operating hours for

which the engine has been shown to meet Federal emission requirements. Category C=50 hours, B=125 hours, and A=300 hours.

Page 28

Customer Service Information

If your product requires service or maintenance, contact your nearest authorized service dealer.

free at 1-866-574-9242 (US) or 1-866-574-9243 (Canada).

To locate your nearest authorized service dealer for this product, contact us toll

OWT Industries, Inc.

P.O. Box 35

Highway 8

Pickens, SC 29671

USA

983000-115

Page 29

Forme No. 3329-634

Taille-bordures / débroussailleuse

No. de modèle 51930 —230000001 et plus

No. de modèle 51932 —230000001 et plus

No. de modèle 51934 —230000001 et plus

No. de modèle 51930 A —230000001 et plus

No. de modèle 51932 A—230000001 et plus

No. de modèle 51934 A —230000001 et plus

No. de modèle 51936 —230000001 et plus

No. de modèle 51938 —230000001 et plus

No. de modèle 51940 —230000001 et plus

STOP

Pour toute question concernant le

taille-bordures ou la débroussailleuse,

nous appeler au :

1-866-574-9242 (États-Unis) ou le

1-866-574-9243 (Canada).

Manuel d’utilisation

AVERTISSEMENT :

Pour réduire les risques de blessures, l’utilisateur doit lire et veiller à bien comprendre le manuel d’utilisation.

Conserver ce manuel.

Anglais (AN), français (FR) et espagnol (ES)

Page 30

P

INFORMATIONS IMPORTANTES

Avant d’utiliser ce taille-bordures / débroussailleuse pour la première fois,

STO

lire les conseils utiles ci-dessous.

Approvisionnement en carburant

DANGER :

L’essence est extrêmement inflammable et explosive.

Un incendie ou une explosion d’essence infligerait des

brûlures à l’opérateur et aux autres personnes

présentes.

1. Se procurer un bidon ou jerrycan approuvé pour l’essence.

2. Mélanger la totalité du flacon d’huile moteur 2 à 4 litres (1 États-Unis gallon)

d’essence sans plomb à 87 octanes.

3. Remplir le réservoir du taille-bordures avec précaution.

Démarrage à froid et à chaud

En cas d’incertitude en ce qui concerne la température du moteur avant de le relancer,

mettre le volet de départ en position B (volet de départ ouvert) et tirer le cordon du

lanceur. Si le moteur ne démarre pas après 5 tractions du cordon, consulter la section

« Démarrage d’un moteur froid », plus loin dans ce manuel.

Moteur noyé

Le moteur démarre-t-il ? S’il ne démarre pas, il peut être noyé. Ne pas s’inquiéter, ce

problème peut facilement être corrigé. Mettre le levier du volet de départ en position

(volet de départ ouvert). Appuyer sur la gâchette et tirer le cordon du lanceur rapidement

10 à 12 fois. Si le moteur ne démarre toujours pas, consulter la section « Dépannage »,

plus loin dans ce manuel ou appeler gratuitement le 1-866-574-9242 (États-Unis) ou le

1-866-574-9243 (Canada).

B

Pour toute question concernant le

taille-bordures / débroussailleuse, nous

contacter gratuitement

au 1-866-574-9242.

AVERTISSEMENT :

chimiques connus de l’Etat de Californie pour causer le cancer, des malformations congénitales et d’autres

troubles de l’appareil reproducteur.

© The Toro Company-2003 Imprimé aux États-Unis

8111 Lyndale Ave., Bloomington, MN 55420, USA Tous droits réservés

Les gaz d’échappement de ce produit contiennent des produits

2

Page 31

Table des matières

Introduction................................................................................................................................................................ 4

Règles de sécurité ........................................................................................................................................................ 5

Symboles ..................................................................................................................................................................... 6

Étiquettes du produit................................................................................................................................................... 7

Fiche technique ........................................................................................................................................................... 8

Applications................................................................................................................................................................. 8

Caractéristiques ...........................................................................................................................................................9

Déballage................................................................................................................................................................... 11

Assemblage ................................................................................................................................................................ 12

Montage de l’accessoire sur l’arbre supérieur ..........................................................................................................................12

Retrait de l’accessoire de l’arbre supérieur..............................................................................................................................12

Installation de la poignée avant..............................................................................................................................................12

Installation de la bandoulière.................................................................................................................................................12

Installation du déflecteur d’herbe...........................................................................................................................................13

Conversion de débroussailleuse en taille-bordures .................................................................................................................14

Conversion de taille-bordures en débroussailleuse .................................................................................................................15

Utilisation.................................................................................................................................................................. 16

Mélange du carburant ...........................................................................................................................................................16

Remplissage du réservoir........................................................................................................................................................16

Démarrage.............................................................................................................................................................................17

Arrêt .....................................................................................................................................................................................17

Utilisation du taille-bordures.................................................................................................................................................18

Utilisation de la débroussailleuse............................................................................................................................................19

Maintenance.............................................................................................................................................................. 20

Programme d’entretien du système antipollution

Nettoyage

Maintenance

Remplacement de la ligne de coupe

Remplacement de la bobine

Vérification du bouchon du réservoir de carburant

Nettoyage du filtre à air

Nettoyage de l’écran pare-étincelles

Remplacement de la bougie

Remisage

Transporter l’outil

............................................................................................................................................................. 20

......................................................................................................................................................... 20

.......................................................................................................................... 20

.................................................................................................................................... 21

.......................................................................................................................................... 22

......................................................................................................................... 22

..................................................................................................................................... 23

.............................................................................................................................................................. 23

.................................................................................................................................................. 23

Dépannage ................................................................................................................................................................24

Garantie ....................................................................................................................................................................26

....................................................................................................... 20

.................................................................................................... 22

Table des matières 3

Page 32

Introduction

Merci d’avoir acheté un produit Toro.

Nous tenons à ce que vous soyez entièrement satisfait de votre nouveau produit. N’hésitez donc pas à contacter un concessionnaire

réparateur agréé pour tout ce qui concerne l’entretien et le dépannage, la commande de pièces détachées ou tout renseignement qui

pourrait vous être utile.

Lors de tout contact avec un concessionnaire agréé, veiller à disposer des numéros de modèle et de série du produit. Ces numéros

aideront le représentant de service à fournir des informations exactes sur le produit particulier. L’autocollant des numéros de modèle

et de série est apposé sur le boîtier du moteur.

Par commodité, noter le numéro de série dans l’espace ci-dessous.

No. de modèle.

No. de série.

Lire ce manuel attentivement pour apprendre à utiliser et entretenir le produit correctement. La lecture de ce manuel aidera à

protéger l’opérateur et les autres personnes présentes contre les risques de blessures et à éviter des dommages au produit. Bien que les

outils conçus, fabriqués et commercialisé par Toro soient des produits de la plus haute qualité, étudiés pour offrir une sécurité maximum, il incombe à leurs propriétaires de les utiliser correctement et en toute sécurité. Il incombe également au propriétaire de

l’outil d’instruire les personnes, autorisées à l’utiliser, au sujet de la sécurité d’utilisation.

Tout au long de ce manuel, Toro utilise un système d’identification des dangers potentiels et des messages de sécurité destinés à

permettre à l’opérateur et aux personnes présentes d’éviter des risques de blessures graves, voire mortelles. Les termes « DANGER »,

« AVERTISSEMENT » et « ATTENTION » sont utilisés pour indiquer le niveau de risque. Toutefois, quel que soit le niveau de

risque, la plus extrême prudence est de rigueur. Deux autres termes, « Important » et « Remarque », sont destinés à attirer l’attention

sur des informations importantes.

Terme signal Explication

DANGER

AVERTISSEMENT

ATTENTION

Important

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée, aura pour conséquences des

blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner des

blessures graves.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, aura pour conséquences

des blessures légères ou de gravité modérée. Ce terme peut également être employé pour avertir

l’utilisateur de pratiques dangereuses pouvant causer des dommages matériels.

Un message intitulé « Important » contient des informations ou instructions vitales pour l’utilisation

ou l’entretien du matériel.

Remarque

4 Introduction

Une remarque contient des informations ou instructions complémentaires concernant l’utilisation ou

l’entretien du matériel.

Page 33

Règles de sécurité

AVERTISSEMENT :

Lire et veiller à bien comprendre toutes les instructions . Le non respect de toutes les instructions ci-dessous peut entraîner des

blessures graves et des dommages au produit.

Ce produit a été conçu et fabriqué pour être conforme ou

supérieur aux exigences de sécurité pour taille-bordures et

débroussailleuses de la norme ANSI B175.3 actuellement

en vigueur.

■

Condition physique de l’opérateur .Ne pas utiliser ce

produit en état de fatigue ou sous l’influence de l’alcool, de

drogues ou de médicaments.

■

Vêtements. Toujours porter des pantalons longs, des

chaussures de travail et des gants. Ne pas porter de

vêtements amples, bijoux, shorts, sandales et ne pas

travailler pieds nus. Attacher les cheveux longs pour les

maintenir au-dessus des épaules, afin qu’ils ne se prennent

pas dans les pièces en mouvement.

■

Accessoires de protection. Toujours porter une

protection oculaire certifiée conforme à la norme ANSI

Z87.1. lors de l’utilisation de ce produit. Porter une

protection auditive durant les périodes d’utilisation

prolongée.

■

État du taille-bordures avant utilisation. Inspecter

l’outil avant chaque utilisation. Remplacer les pièces

endommagées. S’assurer de l’absence de fuites de

carburant. S’assurer que toutes les pièces de boulonnerie

sont en place et bien serrées. Remplacer toutes les pièces de

l’accessoire de coupe qui sont fendues, brisées ou

endommagées de quelque façon que ce soit. S’assurer que