Page 1

AC-1 ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 2

ABOUT THIS MANUAL

GENERAL INFORMATION

ENGINE SPECIFICAT IONS

FUEL AND LUBRICATION

IGNITION

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS (CONT)

SAFETY WARNINGS AND NOTES

PRODUCT IDENTIFICATION NUMBERS

OIL AND FUEL RECOMMENDATIONS

STARTING/STOPPING INSTRUCTIONS

SERVICE/MAINTENANCE INSTRUCTIONS

STORAGE INSTRUCTIONS

TROUBLESHOOTING

ENGINE FAILS TO START

ENGINE STARVES ON ACCELERATION

ENGINE IS HARD TO START

ENGINE STALLS

ENGINE FIRES INTERMITTENTLY

ENGINE DOES NOT PRODUCE MAXIMUM POWER

CARBURETOR FLOODS

ENGINE STOPS AFTER RUNNING BRIEFLY

ENGINE WILL NOT IDLE

ENGINE BACKFIRES OR MISFIRES

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STOPS DURING OPERATION

ENGINE VIBRATES EXCESSIVELY

ENGINE USES EXCESSIVE AMOUNT OF OIL

STARTER ROPE IS DIFFICULT TO PULL OR ENGINE LOCKS

DISASSEMBLY

TYPICAL DISASSEMBLY SEQUENCE

REMOVE MAJOR COMPONENTS

DISASSEMBLE ENG IN E

INSPECTION AND REPAIR

CARBURETOR DISA SSEMBLY AND REASSEMBLY

STARTER DISASSEMBLY AND REASSEMBLY

BREATHER DISASSEMBLY AND REASSEMBLY

SPARK ARRESTER SCR EEN

PISTON/CONNECTING ROD DISASSEMBLY & ASSEMBLY

PISTON/CONNECTING ROD DISASSEMBLY & ASSEMBLY

CYLINDER HEAD INSPECTION & REPAIR

Page 2

AC-1 ENGINE SERVICE MANUAL

Table of Contents – Page 2 of 2

INSPECTION AND REPAIR - Continued

CRANKCASE INSPECTION & REPAIR

MAJOR COMPONENTS INSPECTION & REPAIR

REASSEMBLY

TYPICAL ASSEMBL Y SEQU E NCE

ENGINE REASSEMBLY

INSTALL AIR FILTER BASE, AIR FILTER AND AIR FILTER COVER

ASSEMBLE HANDLE

ASSEMBLE COV ERS

Page 3

Page 4

ABOUT THIS MANUAL

This Service Manual was written expressly for the Toro AC-1 Four Stroke Engine. The Toro Company has made

every effort to make the information in this manual complete and correct. We are hopeful you' find this manual a

If

valuable addition to your service shop.

please contact us at the following address:

you have any questions or comments regarding the information inside,

The Toro Company

Consumer Service Training Department.

81

11

Lyndale Avenue South

!

Bloomington, MN

55420

The Toro Company reserves the right to change product specifications or this manual without notice.

Copyright@

1996

The Toro Company

All

Rights Reserved

Page 5

General Information

.........................

B

Troubleshooting

Disassembly

Inspection and Repair ......................

Reassembly

.........................

..............................

...........................

.#

..

.,

..

.,

..

4

5

Page 6

Table

Of

Contents

Engine Specifications

Fuel and Lubrication

ignition

Torque Specifications

Safety Warnings And Notes

Product Identification Numbers

Oil And Fuel Recommendations

Starting/stopping Instructions

Service/maintenance Instructions

......................................

Recommended Oil Type

Checking the Oil

Changing the Oil

Recommended Fuel Type

Definition of Blended Fuels

Use of Blended Fuels

Use of Fuel Additives

To Start the Engine

To Stop the Engine

Air Filter

..................................

...............................

...............................

...............................

..............................

.............................

............................

............................

...........................

..........................

.........................

..........................

.........................

.........................

.

...........................

...........................

...........................

........................

1-3

1-4

1-4

1-4

1-6

1-7

1-7

1-7

1-8

1-9

1-9

1-9

1-9

1-9

1-10

1-10

1-11

1-11

1-11

Spark Plug

Carburetor Adjustment

Definition of Optimum Setting for Idle Speed Mixture and

High Speed Mixture Adjustments

Rocker Arm to Valve Clearance Adjustment

Spark Arrester Screen

Storage instructions

To Reactivate Unit for Service

Special Tools

...................................

................................

..........................

.....................

...............

..........................

...............................

.......................

1-12

1-12

1-15

1-15

1-16

1-17

1-17

1-18

1

-2

Page 7

j

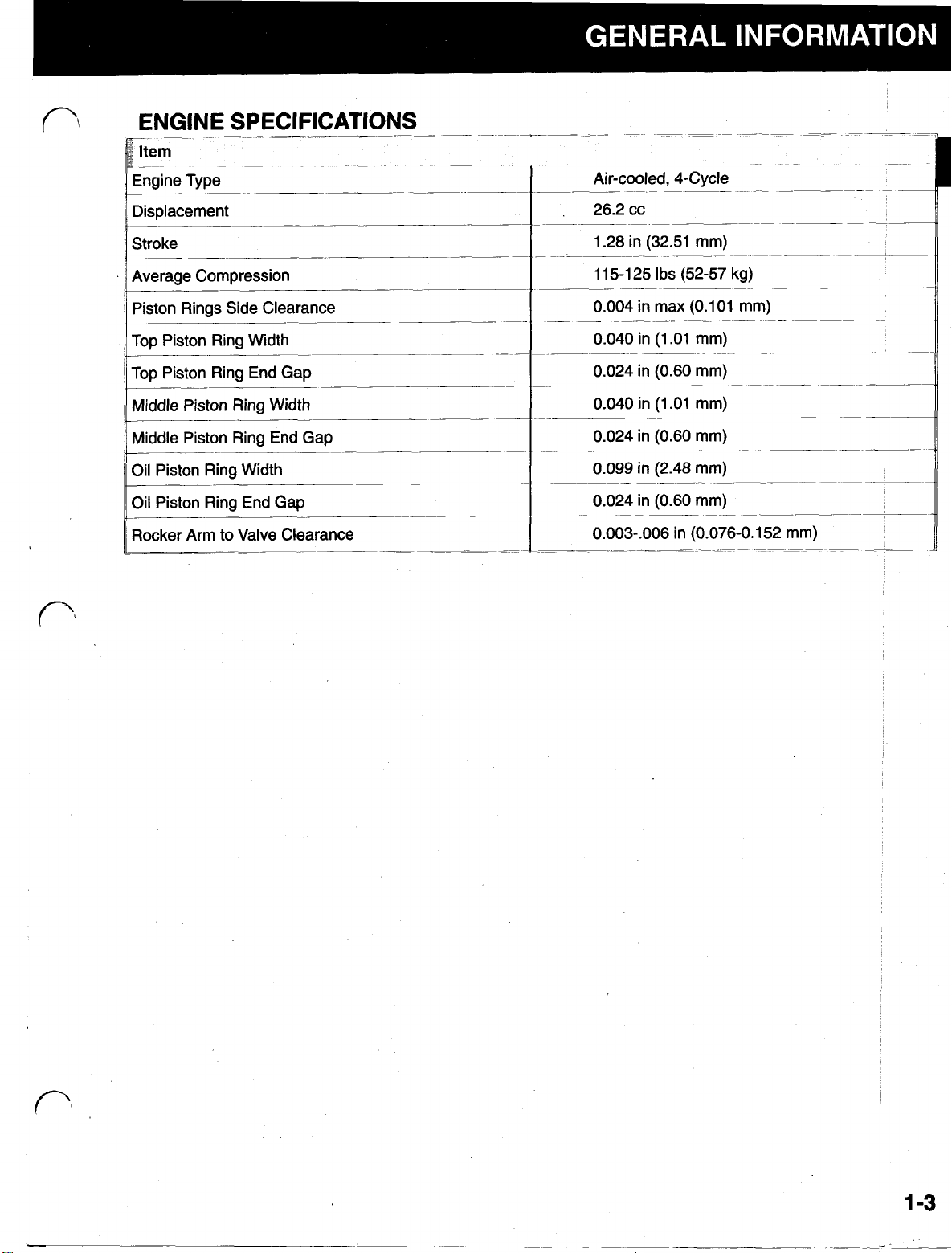

Item

B

Engine Type

___

Displacement

~~

~~

~

~~

Air-cooled, 4-Cycle

Stroke

~__~

Average Compression

Piston Rings Side Clearance

~~-~___

Top Piston Ring Width

Top Piston Ring End Gap

Middle Piston Ring Width

_____~.

Middle Piston Ring End Gap

-

~ ~~

Oil Piston Ring Width

Oil Piston Ring End Gap

~____

Rocker Arm to Valve Clearance

~~~

~-

-~

~__

-

__~

__~_____--

_-

~~

-

_-

~~~

~

~-

~~

-~

~

__

~~

~~

1

-3

Page 8

11

Approx Fuel Tank Capacity

TORQUE SPECIFICATIONS

18

oz

(530

ml)

tem

Carburetor/Air Filter Base Plate Mounting Screws

~~~~~

Carburetor Mount Insulator Screws

~~

Clutch Housing/Drum Assembly Screws

_.

~ . ~

_~~_~~~-_____-~_--

-

--~__

~

~ ~~ ~

-

Clutch Rotor

Cylinder Head Hex Nuts

Cylinder Screws

Spark Plug

~

-.

~

-

-

.

-.

..

_.._..____

. .___

Rear Engine Cover Screw

Front Engine Cover Screws

~

.

.

.

~~

~~

__

~~

-

-

1-4

Page 9

Page 10

SAFETY WARNINGS AND NOTES

WARNING: Hot Surfaces!

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols and the

explanations with them, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper accident prevention measures. Some general warnings

follow.

WARNING: Spring Under Tension!

The rope starter on these engines contains a flat wire

spring that is under tension. Wear eye and hand protection when replacing worn or broken spring, in case it

should uncoil as it is handled. Allow spring tension to

be completely relieved and make sure pulley disen-

.

gages from spring before removing the pulley retain-

ers, pulley, and starter spring from housing.

,

WARNING: Electrical Shock!

Never touch electrical wires or components while the

engine is running. They can be sources of electrical

shock.

The muffler, cylinder, crankcase, trimmer cutting head,

and other engine surfaces get extremely hot from operation. These surfaces remain hot for a short period

of time after the engine is stopped. To prevent severe

burns, allow the engine to cool completely before servicing.

I

WARNING: Explosive Fuel!

Gasoline may be present in the fuel tank, carburetor,

fuel lines, or crankcase. Gasoline is extremely flammable and its vapors can explode

if

ignited. Keep sparks,

flames, and other sources of ignition away from the engine.

Do

not smoke while servicing the engine. Never

use gasoline as a cleaning agent.

in

not

well-

fill

the fuel

~

Store gasoline only in approved containers,

ventilated, unoccupied buildings, away from sparks,

flames, or other sources of ignition.

Do

tank while the engine is hot or running, since spilled

fuel could ignite

sparks from ignition.

spilled fuel.

if

it comes in contact with hot parts

Do

not start the engine near

Do

not smoke while handling gasoline or

or

filling the fuel tank.

i

.

WARNING: Cracked Or Broken Flywheel Fins

Can Become Projectiles!

Be careful not to crack or break any flywheel cooling

fins. They could fly

off

during operation.

If

cooling fin:

are cracked or broken, replace the flywheel.

1

-6

Page 11

PRODUCT IDENTIFICATION

NUMBERS

When ordering parts, or in any communication involving an engine or product, always give the:

Model Number, and

Serial Number

NOTE:

BEFORE Attempting TO START

THIS UNIT. Using old oil or fuel can cause engine

damage. This type of damage will void the engine

warranty

READ

THESE INSTRUCTIONS

CAREFULLY

OR

OPERATE

These numbers are located on a decal (or decals) affixed to the unit (Figure 1-1). The identification de-

will be located on the metal boom. The actual

location will vary depending on the type of product.

Figure 1-1. Product Identification Decal

1.0762.005

.

OIL AND FUEL

RECOMMENDATIONS

Recommended Oil Type

Toro 4-cycle oil is recommended for use in this engine

(Figure 1-2).

high

quality SAE

troleum Institute) service class SG,

Using the proper type and weight of oil in the oil pan is

extremely important. Check the oil before each use

and change the oil regularly. Failure to use the correct

oil, or using dirty oil, can cause premature engine

wear and failure.

If

another brand 4-cycle oil is used, use a

30

weight oil of API (American Pe-

SF,

SH.

TORO,

FOUR-CYCLE

ENGINE

OIL

,.

WARNING: Explosive Fuel!

Gasoline

can explode if ignited. Store gasoline only in ap-

proved containers, in well-ventilated, unoccupied

buildings, away from sparks or flames. Do not fill

the fuel tank while the engine is hot or running,

since spilled fuel could ignite if

with hot parts or sparks from Ignition. Do not start

the engine near spilled fuel. Do not smoke while

handling gasoline. Never use gasoline as a cleaning agent.

Is

extremely flammable and its vapors

it

comes

in

contact

I--------

Figure 1-2. Recommended Oil Type.

3.6051.002

1

-7

Page 12

Checking the

Oil

The importance of checking and maintaining the

proper oil level in the oil pan cannot be overempha-

sized. Check the oil

1.

Make sure the engine is stopped, level and is cool

so

the oil has had time to. drain into the oil pan

(Figure

1-3

BEFORE EACH USE

as follows:

for straight shaft units or Figure

1-4

for curved shaft units).

1-3.

Figure

Figure

2.

To keep dirt, grass clippings, etc. out of the engine,

clean the area around the oil

Level Engine - Straight Shaft Unit.

1-4.

Level Engine - Curved Shaft Unit.

fill

plug before remov-

3.6051.020

3.6051.004

ing it.

3.

Remove the oil

into the crankcase. Thread the oil

fill

plug; wipe the oil

off.

Reinsert it

fill

plug into the

oil pan.

4.

Remove the oil

(Figure

1-5).

fill

plug and check the oil level

Figure

1-5.

Removing Oil Fill Plug.

2.6051.005

The oil level should be up to the top of the dipstick

(Figure

1-5).

Full

(3.40z/lOOml)

Add Oil

L

Figure

5.

1-6.

Oil Level

If

the oil level is low, add the oil to the top

the dipstick (see Figure

3.6051.006

1-6).

Always check the

of

level with the dipstick before adding more oil.

1

-8

Page 13

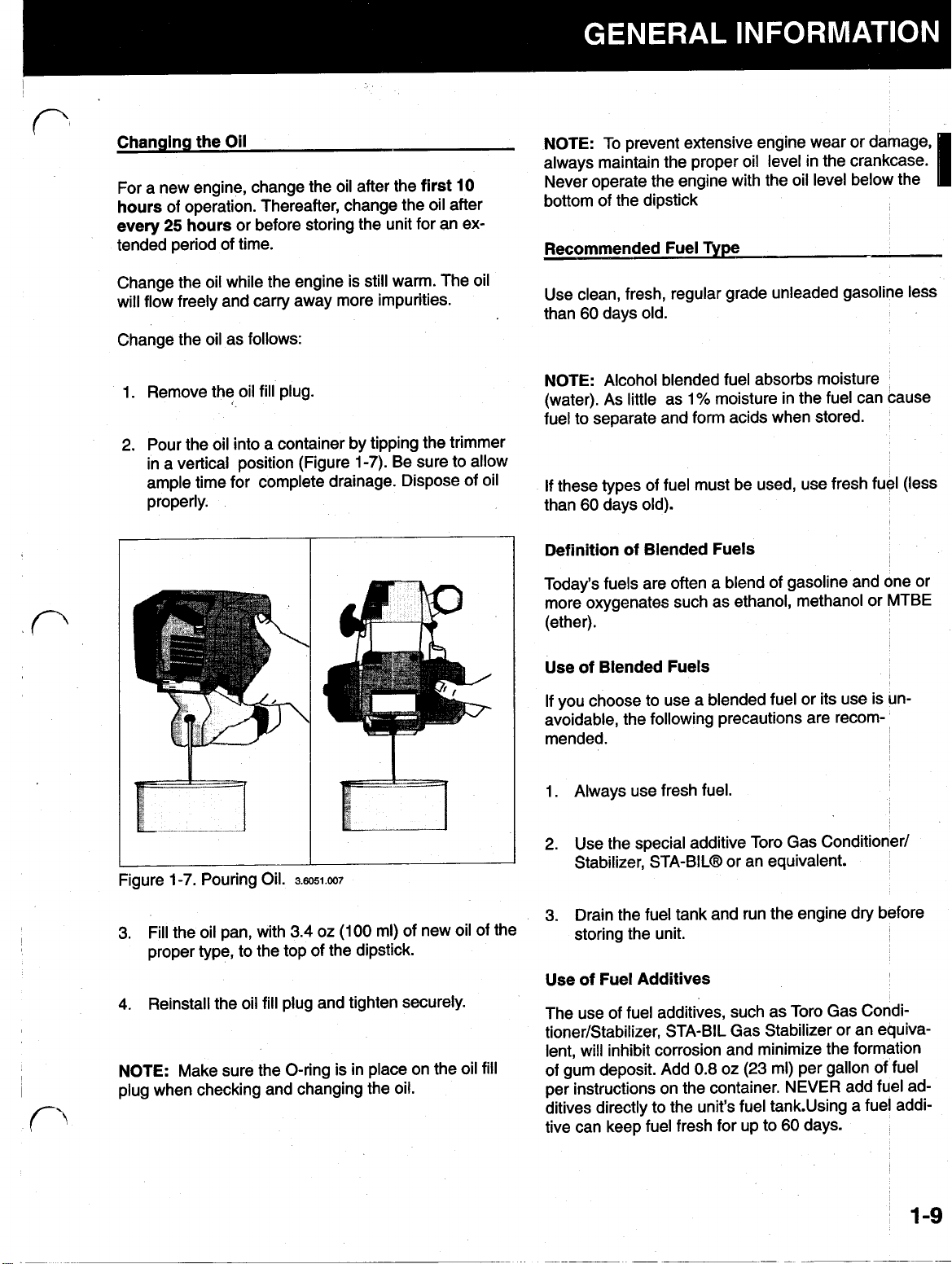

Changing the Oil

For a new engine, change the oil after the

hours

every

of operation. Thereafter, change the oil after

25

hours

or before storing the unit for an ex-

tended period of time.

first

10

NOTE:

To prevent extensive engine wear or damage,

always maintain the proper oil level in the crankcase.

Never operate the engine with the oil level below the

bottom of the dipstick

Recommended Fuel Type

Change the oil while the engine is still warm. The oil

will flow freely and carry away more impurities.

Change the oil as follows:

1.

Remove the oil

2. Pour the oil into a container by

in a vertical position (Figure

fill

plug.

tipping the trimmer

tipping

7).

Be sure to allow

1-7

ample time for complete drainage. Dispose of oil

properly.

Use clean, fresh, regular grade unleaded gasoline less

than

60

days old.

NOTE:

(water). As little as

Alcohol blended fuel absorbs moisture

1

%

moisture in the fuel can cause

fuel to separate and form acids when stored.

If

these types of fuel must be used, use fresh fuel (less

than

60

days old).

Definition

of

Blended Fuels

Today's fuels are often a blend of gasoline and one Or

more oxygenates such as ethanol, methanol or MTBE

(ether).

Use of Blended Fuels

If

you choose to use a blended fuel or its use is un-

avoidable, the following precautions are recom-

mended.

1-7.

Figure

Pouring Oil.

3. Fill the oil pan, with 3.4 oz

3.6051.007

(100

ml) of new oil of the

proper type, to the top of the dipstick.

4.

Reinstall the oil

NOTE:

Make sure the O-ring is in place on the oil

fill

plug and tighten securely.

plug when checking and changing the oil.

fill

1.

Always use fresh fuel.

2. Use the special additive Toro Gas Conditioner/

Stabilizer, STA-BIL

(R)

or an equivalent.

3. Drain the fuel tank and run the engine dry before

storing the unit.

Use of Fuel Additives

The use of fuel additives, such as Toro Gas Conditioner/Stabilizer, STA-BIL Gas Stabilizer or an equiva-

lent, will inhibit corrosion and minimize the formation

of gum deposit. Add

0.8

oz (23 ml) per gallon of fuel

per instructions on the container. NEVER add fuel ad-

ditives directly to the unit's fuel tank. Using a fuel addi-

60

tive can keep fuel fresh for up to

days.

1-9

Page 14

STARTING/STOPPING

INSTRUCTIONS

To

Start

the Engine

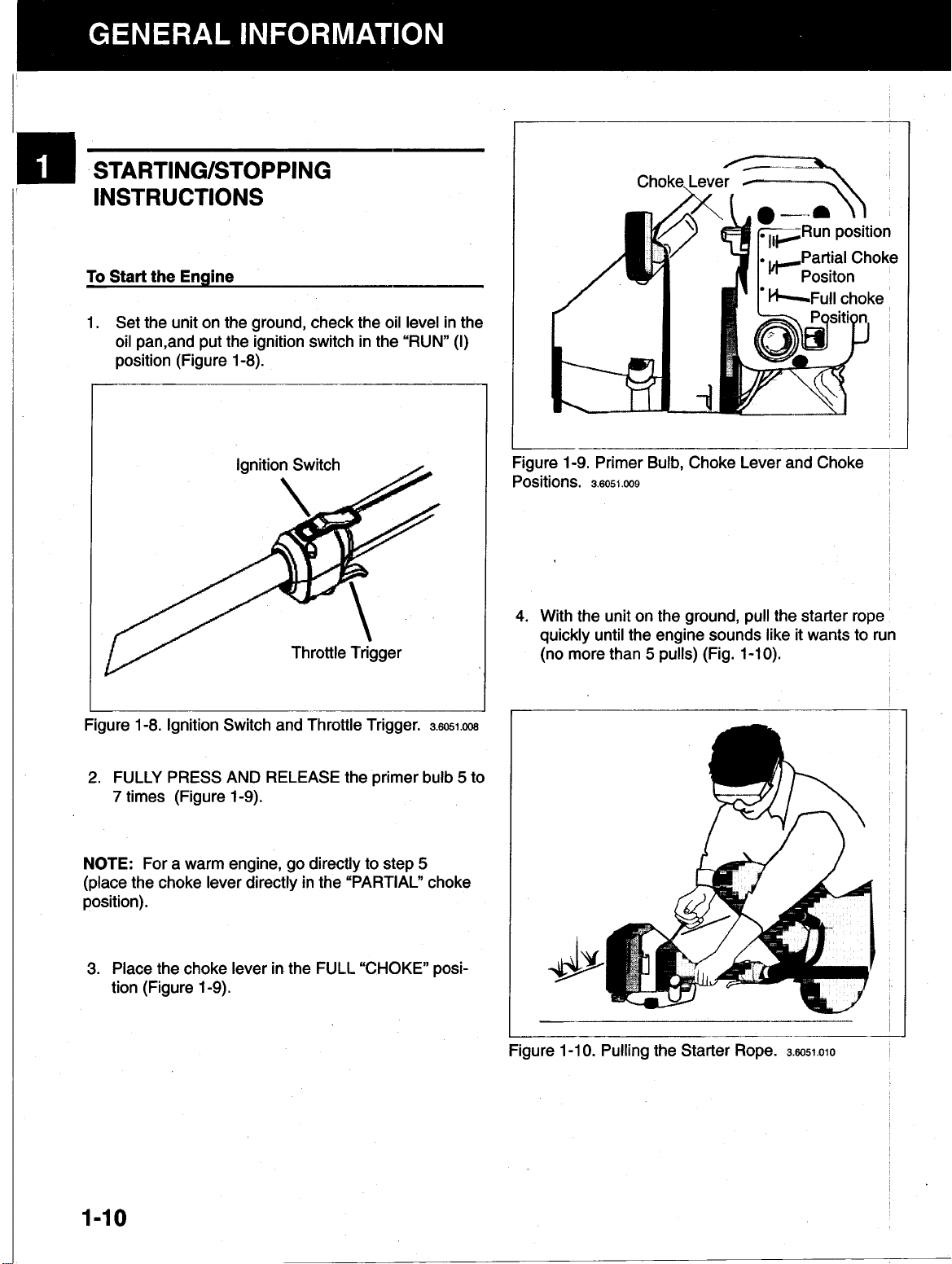

1.

Set the unit on the ground, check the oil level in the

oil pan, and put the ignition switch in the “RUN”

position (Figure 1-8).

---Run position

Partial Choke

choke

(I)

Figure 1-8. Ignition Switch and Throttle Trigger.

2.

FULLY PRESS AND RELEASE the primer bulb 5 to

7

times (Figure 1-9).

NOTE:

For a warm engine, go directly to step

3.6051.008

5

(place the choke lever directly in the “PARTIAL” choke

position).

Figure

Positions.

1-9.

Primer Bulb, Choke Lever and Choke

3.6051.009

4.

With the unit on the ground, pull the starter rope

quickly until the engine sounds like it wants to run

5

(no more than

pulls) (Fig. 1-10).

,

3.

Place the choke lever

tion (Figure 1-9).

1-10

in

the FULL “CHOKE” posi-

Figure 1-1

0.

Pulling the Starter Rope.

3.6051.010

Page 15

5.

Place the choke lever in the “PARTIAL” choke position (see Figure 1-9 on page 1.4). Pull the starter

rope quickly until the engine starts (no more than

5

pulls).

6.

If

the engine does not start, repeat steps 2 to 8.

7.

Run the engine for

lever fully squeezed (see Figure 1

30

seconds, with the throttle

-6),

to warm up.

Place the choke lever in the “RUN” position

(Figure 1-9).

2.

Wash the air filter in detergent and water

(Figure 1-11). Rinse the air filter thoroughly in

clean water and allow

it

to dry.

NOTE:

In colder weather, run the engine for 2 to

3

minutes to warm up.

To

Stop the Engine

Place the ignition switch in the “STOP position (see

Figure 1-8).

SERVICE / MAINTENANCE

INSTRUCTIONS

Air Filter

NOTE:

CLEAN AND

EVERY 10 HOURS

one of the most important areas to maintain.

maintained as follows, poor engine performance and

severe engine damage can result.

1. Remove the three

filter cover assembly. Remove the air filter cover

and air filter. Refer to

RE-OIL

OF

(3)

THE

AIR

FILTER

OPERATION. The air filter is

screws on the carburetor/air

Part

3

-

Engine

Disassembly

\

If

it is not

L

Figure 1-1 1. Washing Air Filter Element.

3.

Apply clean SAE

Figure 1-1

2.

Oiling Air Filter Element.

30

oil to the air filter (Figure 1-12).

3.6051.012

3.6051.011’

I

I

4. Squeeze the air filter to ensure that the oil is spread

throughout the entire filter (Figure 1-13).

1-11

Page 16

L

Figure 1-13. Squeezing Excess Oil from Air Filter

Element.

5.

Spark Plug

3.6051.013

Reinstall the air filter in the carburetor/air filter

base. Refer to

Part

5

-

Engine Reassembly

NOTE:

Do not clean the spark plug in a machine

~

which uses abrasive grit. Some grit could remain on

the spark plug and enter the engine causing extensive

damage.

4. Check the spark plug gap using a wire feeler gauge.

Set the gap to

5.

Reinstall the spark plug and torque to

(1 1.3-1 2.3

0.025 in

N-m).

(0.635

mm)(Figure 1-14).

100-110 in-lb

Use a Champion RDZ19H spark plug. Every 50

hours

of operation, remove the spark plug, check its condition, and reset the gap or replace with a new plug as

necessary. Allow the engine to cool before removing

the spark plug.

WARNING: Electrical Shock!

Never touch electrical wires or components while the

engine is running. They can be sources of electrical

shock.

1. Before removing the spark plug, clean the area

around the base of the spark plug to keep dirt and

debris out of the engine.

2.

Disconnect the spark plug wire and remove the

spark plug from engine.

3.

Inspect the spark plug for carbon buildup and clean

if

necessary. Replace the plug

if

reuse is questionable.

if

it is badly burnt or

Figure 1-14. Spark Plug Gap.

Carburetor Adjustment

3.6051.014

-

These engines are equipped with a diaphragm-type

carburetor. The carburetor has been carefully cali-

~

brated at the factory. In most cases, no further adjustment will be required.

The condition of the air filter is very important to the

(

eration of the trimmer. A dirty air filter will restrict the

air flow to the carburetor. This in turn upsets the fuelair mixture in the carburetor. The resulting symptoms

are often mistaken for an out-of-adjustment carburetor

Therefore, check the condition of the air filter before

adjusting the carburetor. Refer to “Air Filter“ Service/Maintenance Instructions.

I-

1-12

-

Page 17

If

the following conditions are experienced, it may be

necessary to adjust the carburetor.

The engine will not idle

The engine hesitates or stalls on acceleration.

The

loss

of engine power, which is not corrected

by cleaning the air filter, muffler, spark arrester

screen or adjusting the rocker arm to valve

clearance

The engine operates in an erratic or fuel-rich

condition

NOTE:

Follow these carburetor adjustment procedures carefully. An incorrectly adjusted carburetor can

cause severe engine damage.

407000001-Use the following carburetor adjustment

instructions:

1.

Initial Idle Speed Setting:

Turn the idle speed

screw until it stops.

2.

Initial High Speed Mixture and Idle

ture Settings:

and idle mixture needles

Turn both the high speed mixture

in (clockwise)

Speed

until they

Mix-

are lightly seated.

3.

Turn the needles

following number

out

of

turns:

the

High Speed Mixture Needle: 1 turn

Idle Speed Mixture Needle:

1

turn

Make sure the unit is fully assembled before

making carburetor adjustments.

For trimmers

and

brushcutters, make sure

the boom, cutting head, and line guard are installed

and the cutting line is extended to its full cutting length.

The carburetor has three basic adjustments: the idle

speed adjustment, the idle speed mixture adjustment,

and the high speed mixture adjustment (Figure 1-15).

Mixture Needle

NOTE:

Turn the high speed mixture and idle mixture

needles finger-tight. Do not force the needles with a

screwdriver as this can damage the tips of the needles

and the seats in the carburetor body.

4. Start the engine and let it run for

3

to 5 minutes

with the throttle lever fully squeezed.

5.

Release the throttle trigger and let the engine idle.

Turn the idle speed screw

until the speed decreases and the bump

wise)

out (counterclock-

head stops rotating.

6.

Final Idle Speed and Mixture Adjustments:

Adjust the idle speed screw and idle speed mixture needle for the smoothest engine idle using

Do

the following procedure.

not squeeze throttle

trigger when adjusting the idle speed screw and

idle speed mixture needle.

a. Set the idle speed mixture needle

at the optimum setting

(Figure 1-16). See “Definition of Optimum

Setting” on page

1-1

5.

Figure

1-1

5.

Carburetor Adjustments.

3.6051.015

1-13

Page 18

b

b. Squeeze the throttle trigger.

falters or hesitates as

idle speed mixture needle

wise) 1/16 turn at a time

celerates rapidly.

it

If

the engine

accelerates, turn the

out (counterclock-

until the engine ac-

3.

Turn the needles

following number of turns:

High Speed Mixture Needle: 1 1/8 turns

out (counterclockwise)

the

c.

If

the idle speed has changed significantly because of steps a. and b. above, readjust the

idle speed screw.

7.

Final High Speed Mixture Setting:

Adjust the high speed mixture needle as follows:

a. Squeeze the throttle trigger and

run the unit at high speed for

b. While squeezing the throttle trigger fully, set

the high speed mixture needle at the optimum

setting. See “Definition of Optimum Setting”

on page 1-1 5.

NOTE:

must be the last adjustment made

the idle speed mixture needle is adjusted, the high

speed mixture needle must be readjusted.

8.

For Units with Engine Serial Number 407000001

and Greater-Use

ment instructions:

The high speed mixture needle adjustment

Make sure the air filter cover is reinstalled securely

before placing the unit back into service.

the following carburetor adjust-

3

to 5 minutes.

on

the carburetor.

Idle Speed Mixture Needle1 1/8 turns

NOTE:

mixture needles using finger pressure. Forcing the mixture needles will damage the tips of the needles and

the seats in the carburetor body.

4.

5.

6.

If

NOTE:

justment is made, no more high speed mixture needle

adjustments to the carburetor are necessary.

Seat the high speed mixture and idle speed

Start the engine and let it run for 3 to 5 minutes

with the throttle lever fully squeezed.

Release the throttle trigger and let the engine idle.

If

the engine stops, turn the idle speed screw

(clockwise) 1/8 turn

the engine idles.

Final High Speed Mixture Needle Adjustment:

a. While squeezing the throttle trigger fully, set

the high speed mixture needle at the optimum

setting. See “Definition of Optimum Setting”.

After the final high speed mixture needle ad-

at a time (as required) until

in

~

1.

Initial Idle Speed Setting:

screw (Figure 1-15)

it

does not contact

Then turn the screw

gins

to move the throttle lever; then continue turn-

ing

2

full turns.

2.

Initial High Speed Mixture and idle Speed

Mixture Settings:

ture and idle speed mixture needles

wise)

until they are

out (counterclockwise)

the carburetor throttle lever.

in (clockwise)

Turn both the high speed mix-

lightly seated.

Back the idle speed

1-14

until it

just be-

in (clock-

until

7.

Final Idle

Adjustments:

idle speed mixture needle for the smoothest engine idle using the following procedure. Do not

squeeze the throttle trigger when adjusting the idle

speed screw and idle speed mixture needle.

a. Set the idle speed mixture needle at the

b. Turn the idle speed mixture needle

Speed

optimum setting (Figure 1-16). See “Definition’

of Optimum Setting”.

(counterclockwise) 1/8 turn

of optimum.The engine should idle and accelerate smoothly.

and Idle Speed Mixture

Adjust the idle speed screw and

out

to the rich side

’

~

~

~

Page 19

8.

Final Idle Speed Adjustment:

speed by turning the idle speed screw

wise)

or

out (counterclockwise)

head does not rotate.

Do

Adjust the idle

in (clock-

until the cutting

not squeeze the throttle

trigger when adjusting the idle speed screw.

9.

Make sure the air filter cover is reinstalled securely

before placing the unit back into service.

Definition of Optimum Setting for Idle Speed

Mixture and High Speed Mixture Adjustments

Always set the idle speed mixture needle and high

speed mixture needle at the optimum setting. To find

the optimum setting, use the following procedure.

1. Turn the adjusting needle

out (counterclockwise)

from the preliminary setting until the engine speed

decreases (rich). Note the position of the needle.

2.

Turn the adjusting needle

in (clockwise).

The engine speed may increase as the needle is turned

in (lean). Note the position of the needle.

Rocker Arm to Valve Clearance Adjustment

50

hours

Every

of operation, remove the rocker

arm

cover and check the rocker arm to valve clearance.

1.

Remove the four

(4)

screws from the engine cover.

Remove the engine cover. Remove the rocker arm

cover. Refer to

2.

Position the crankshaft

Part

3

-

Engine Disassembly.

so

that the piston is at the

top of the compression stroke (both rocker arms

are free and loose).

3.

Measure the clearance between the valve stems

and rocker arms, using a

1-17).

flat

feeler gauge (Figure

3.

Set the adjusting needle

midway

and the lean settings (Figure 1-16).

Adjust to

Midpoint

Figure 1-16. Optimum Setting.

3.6051.016

between the rich

Lean

I

Figure 1-17. Measuring the Rocker Arm to Valve

Clearance.

3.6051.017

The recommended rocker arm to valve clearance for

both the intake and exhaust is

(.076

mm-,152 mm).

.003-.006

in

Page 20

4.

If

the clearance is not within specification, adjust as

follows:

Spark Arrester Screen

b

To

the adjusting nut counterclockwise.

To

the adjusting nut

5.

a. Turn the adjusting nut (Figure 1-18), using a

5/16 in (8 mm) wrench or nut driver.

increase the rocker arm to valve clearance,

decrease the rocker arm to valve clearance,

clockwise.

b. Recheck the clearance with a flatfeeler gauge

and readjust as necessary (see Figure 1-1

Reinstall the rocker arm cover, using a new gasket.

Torque the rocker arm cover screw to

(2.2-3.4 N.m).

20-30 in-lb

turn

turn

7).

This unit is equipped with a spark arrester screen.

50

hours

Every

screen for debris and/or deposits.

WARNING: Hot Surfaces!

Make sure the muffler is cool before checking the

spark arrester screen to prevent injury.

1. Remove the spark arrester cover screw and cover

(Figure 1-1

of operation, check the spark arrester

9).

Figure 1-18. Adjusting Nuts.

6. Install the breather hose to the air filter base.

7.

Reinstall the engine cover and screws. Refer to

Part

5

-

Engine Reassembly.

Torque the top screws to

Torque the front screw to

Torque the rear screw with washer to

4.0

Nom).

2.6051.018

15-20 in-lb (1.7-2.2 Nom).

20-25 in-lb (2.2-2.8 Nom).

30-35 in-lb (3.5-

1-16

Figure 1-1

2.

3.

4.

9.

Spark Arrester Screen.

Push the spark arrester screen out of the cover.

Inspect the spark arrester screen.

If

the screen is clean, reinstall the screen,

cover and screw.

replace it.

Torque the screw to

If

the screen is plugged,

15-20 in-lb (1.7-2.2 N-m).

3.6051.019

Page 21

STORAGE

WARNING: Explosive Fuel!

Gasoline is extremely flammable and its vapors can

explode if ignited. Store gasoline only in approved containers, in well-ventilated, unoccupied buildings, away

from sparks or flames. Do not

the engine is hot or running, since spilled fuel could

if

ignite

from ignition. Do not start the engine near spilled fuel.

Do not smoke while handling gasoline. Never use

gasoline as a cleaning agent.

1.

2.

3.

it comes in contact with hot parts or sparks

Drain all fuel from the fuel tank.

that has been stored for more than

Start the engine and run it until it stalls. This

ensures that all fuel has been drained from the

carburetor.

Drain the oil from the crankcase and add fresh oil

(3.4

oz

to lubricate the engine.

INSTRUCTIONS

fill

the fuel tank while

Do

not use fuel

60

/100

ml). Pull the starter rope a few times

days.

Figure

To

1.

2.

3.

1-21.

Storing a Curved Shaft Unit.

Reactivate Unit for Service

Remove the spark plug and drain the oil from the

cylinder by slowly pulling the starter rope.

Reinstall the spark plug.

Refuel the unit with fresh gasoline. Start engine in

accordance with the

Starting Instructions.

3.6051.021

4.

Allow the engine to cool. Remove the spark

plug and put several drops of any

30

quality SAE

Petroleum Institute) service class SG,

into the cylinder. Pull the starter rope slowly to dis-

tribute the oil. Reinstall the spark plug.

5.

Clean the unit and inspect for any loose or

damaged parts. Repair or replace damaged parts

and tighten loose screws, nuts, or bolts.

6.

Store the unit in a 'dry, well ventilated area. Place

unit

the

for straight shaft units or Figure

shaft units).

flat on the floor or on a table (Figure

weight oil of API (American

high

1-21

SF,

for curved

SH

1-20

Figure

1-20.

Storing a Straight Shaft Unit.

3.6051.020

Page 22

~

Special

Tools

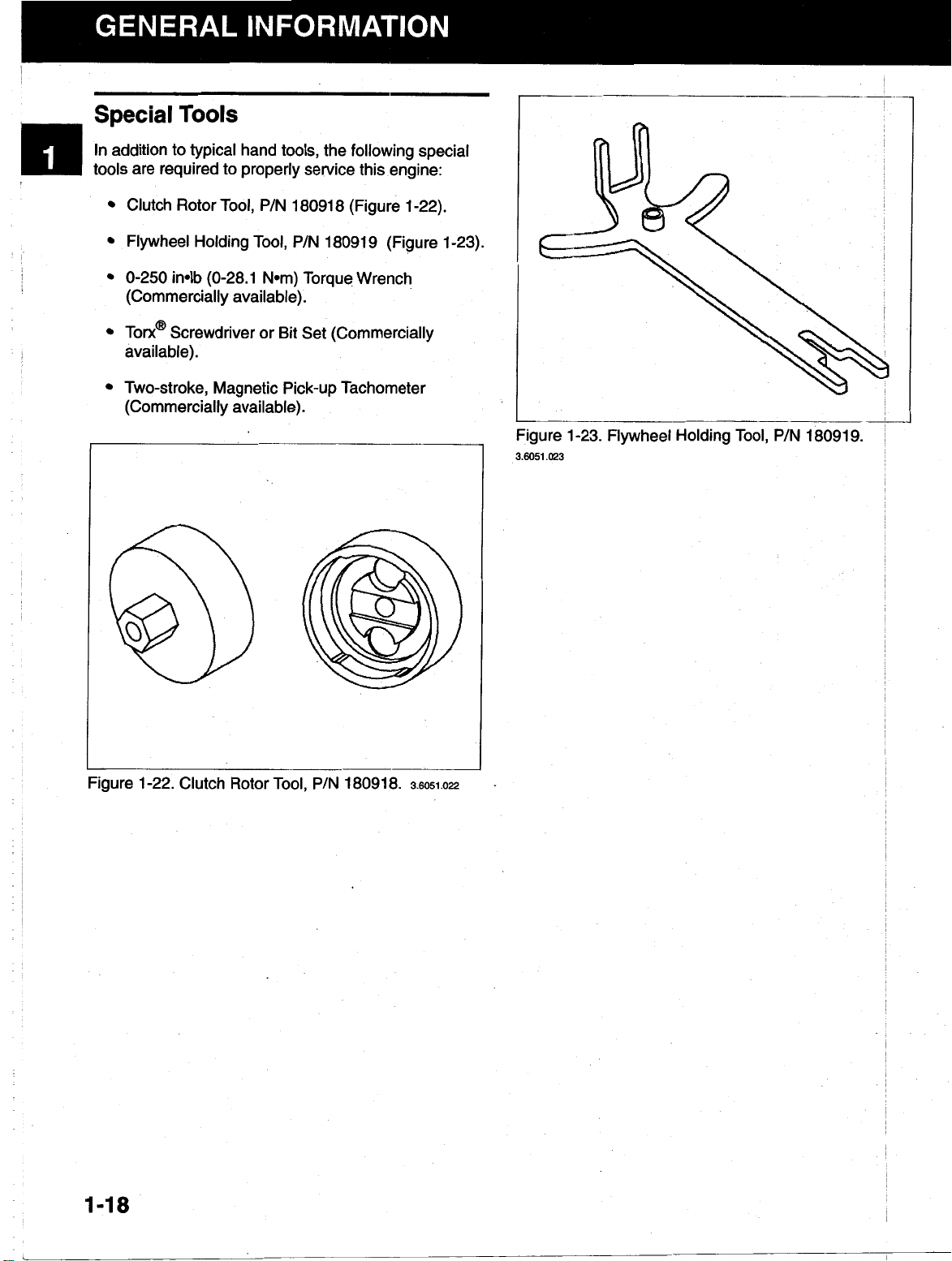

In addition to typical hand tools, the following special

tools are required to properly service this engine:

Clutch Rotor

Flywheel Holding

Tool,

P/N 180918 (Figure 1-22).

Tool,

P/N 180919 (Figure 1-23).

0-250 in-lb (0-28.1 N.m) Torque Wrench

(Commercially available).

Toro (R)

Screwdriver or Bit Set (Commercially

available).

Two-stroke, Magnetic Pick-up Tachometer

(Commercially available).

Figure 1-23. Flywheel Holding Tool, P/N 18091 9.

3.6051

.023

Figure 1-22. Clutch Rotor

1-1

8

Tool,

P/N 180918.

3.6051.022

Page 23

General Information

.

...........................

.

Troubleshooting

Disassembly

Inspection and Repair

Reassembly

......

......

. .

.

...........................

...........................

............................

2.

5

2-1

Page 24

Table

Of

Contents

Engine Fails

Engine Starves On Acceleration

Engine

Engine Stalls

Engine Fires Intermittently

Engine Does Not Produce Maximum Power

Carburetor

Engine Stops After Running Briefly

Engine Will Not Idle

Engine Backfires

Engine Will Not Accelerate

Engine Lacks Power Or Stops During Operation

Engine Vibrates Excessively

Engine Uses Excessive Amount Of Oil

Starter Rope

Is

Hard

To

Start

...............................

.........................

To

Start

..............................

....................................

.............................

Floods

.................................

........................

................................

Or

Misfires

...........................

............................

...........................

......................

Is

Difficult

To

Pull Or Engine Locks

...................

2-8

.................

.................

2-8

2-9

2-9

2-9

2-3

2-4

2-4

2.5

2-5

2-6

2-6

2-7

2-7

2-7

2-2

Page 25

c’

When difficulties occur, be sure to check for simple

causes which, at first, may seem too obvious to be

considered.

A

starting problem, for example, could be

caused by an empty fuel tank.

The following table lists some common causes of

operating troubles and the possible causes and

remedies.

I

-

Engine Fails

__

~-

;Possible

L-

Ignition switch in STOP

-~

~_~~~___

~-

~~ ~

Cause

To

.-

~~

_____

Start

~-

_

~.

(0)

position

_

.

~~ ~

-

-

___

~~

~-__

Out of fuel or water in fuel

~~

-___

Dirty or plugged air filter

Loose spark plug lead wire

__~____~

-

.-

~

Fouled, improperly gapped or broken spark plug

__~._

Plugged fuel tank cap vent

Plugged or waterlogged fuel filter

-

~_____~

Improperly adjusted carburetor

____-

Plugged muffler

-

Faulty primer or primer/fuel lines improperly installed

~.

-

-.

Plugged fuel line

Faulty carburetor diaphragm

____

Plugged spark arrester screen

Faulty fuel pump diaphragm

-

~.

_____

~~

.__

~-

-

_____

__

-

Plugged carburetor/fuel pump passages

&

Incorrect air gap between flywheel

ignition module

__

Faulty ignition module

Low

compression

_________~.~

.~

Rocker arm to valve clearance is out of adjustment

_~_____~_

___.

~~ ~~

~.__________

-

~-

~ ~~

-

i

~~ ~ ~

-~

~~~ ~~ ~

~

~-

__

-

__

~~

-_

Remedy

Place switch in

~

RUN

(I)

position

-~~

Drain tank and blow out fuel lines to remove water

Refuel tank with fresh fuel

-_

Clean or replace air filter

Reconnect lead wire

.~____

____

~

___~~

~-____

Clean or replace spark plug; set gap to 0.025 inch

(0.635

Clean fuel tank cap vent

Replace fuel filter

Adjust carburetor

mm)

__

~-

~-

~.-~____-~

~~

__

-~

~-

__

__~-

.-

~-

Clean or replace muffler

Correctly install primer/fuel lines or replace primer

~

____~.._~_.________

Blow out fuel line

Replace diaphragm

~~

Clean or replace spark arrester screen

Replace pump diaphragm

~~~ ~

Clean out passages

__

~.

~~~

-.

~~

.~

~~

~-

~

Set ignition module air gap to

0.008-0.01

-

Replace ignition module

_~_____

Replace piston rings or cylinder

_

2

in (0.201

.-

~~~~

-0.305

__

mm)

~-

--

Adjust rocker arm to valve clearance

___

~ ~~~

~

_

_~_

~_ _~

~-

~-

~ ~

__

-

~ ~~ ~

__

-~

8.

~~ ~

~-

~__

____

~-

~

I-

____

__

I

_~

~-

__

2-3

Page 26

1

8

Engine

possible

.

Cause

Is

Hard

To

~___~~

Start

~~

Fouled, improperly gapped or broken spark plug

Plugged or waterlogged fuel filter

___.

-

Improperly adjusted carburetor

Clogged muffler

~~

Faulty primer or primer/fuel lines improperly installed

~~

Incorrect air gap between flywheel and ignition module

-

Faulty ignition module

Plugged spark arrester screen

~-

.~

~

Rocker arm to valve clearance is out of adjustment

Worn or improperly adjusted carburetor jet needle

Faulty carburetor diaphragm

Faulty fuel pump diaphragm

~~

-

~~

__

__

..

~

.~

-

~~

-

~

-

~.

_____~~~

_____

~

-~

~

________

Low compression

_

-~

~~~~ ~

.

~~~

___

~ ~~ - ~

Remedy

-

~~

~ ~ ~~ ~

Clean or replace spark plug;

~~

set gap to 0.025 inch

~~~

Replace fuel filter

Adjust carburetor

Clean or replace muffler

_-

-

_

~~____~-~

~ ~~ ~ ~~~

~

-~

~

(0.635

mm).

~

Correctly install primer/fuel lines or

replace primer

~-

Set ignition module air gap to

0.008-0.01 2 in (0.201

Replace ignition module

___~_~~

Clean or replace spark arrester screen

_____~

_____~

~-

~_

Adjust rocker arm to valve clearance

_

Adjust or replace needle

~

Replace carburetor diaphragm

_

-

Replace fuel pump diaphragm

..

~ ~ ~

~~

~~~~~

_

~~ ~

~_-

-0.305

~~

_

~~~ ~ ~

_~

mm)

~ ~

___________~~~

Replace piston rings or cylinder

~

.

_-

~~~

___~_~_____~_~

-.

.

~

-

-

~-

.~

~

.~

~

_

~~

I

~

-

,

___

~ ~

~

~

_____

2-4

Page 27

Engine Stalls

Plugged fuel tank cap vent

Improperly adjusted carburetor

Plugged muffler

Plugged spark arrester screen

Plugged fuel line

-

Faulty ignition module

___-

-

__~

~-

~

-~

.~___

~

-_

Clean or replace spark plug; set gap to

0.025

inch

-

-.

~~

(0.635

Clean fuel tank cap vent

Adjust carburetor

mm)

~

_.

_.

~-

__

_.

Clean or replace muffler

~

~-

~~ ~~

Clean or replace spark arrester screen

Blow

out fuel line

Replace ignition module

____

~

~

~-

~-

~

--~

~-

~

-~

__

-___

~

~

--

-

__~

~-

Engine Fires Intermittently

Fouled, improperly gapped or broken spark plug

____-

incorrect air gap between flywheel and ignition module

improperly adjusted carburetor

~ ~

-~

Faulty ignition module

-

~

__---

Remedy

~ ~~

Clean or replace spark plug; set gap to

0.025

inch

--

~

(0.635

mm).

-~___

Set ignition module air gap to

0.008-0.01

~~

Adjust carburetor

Replace ignition module

~-

~ ~~~

2

in

______~

____

--

(0.201

-.

-

~ ~~ ~

-0.305

~-

__

mm))

-

2-5

,

Page 28

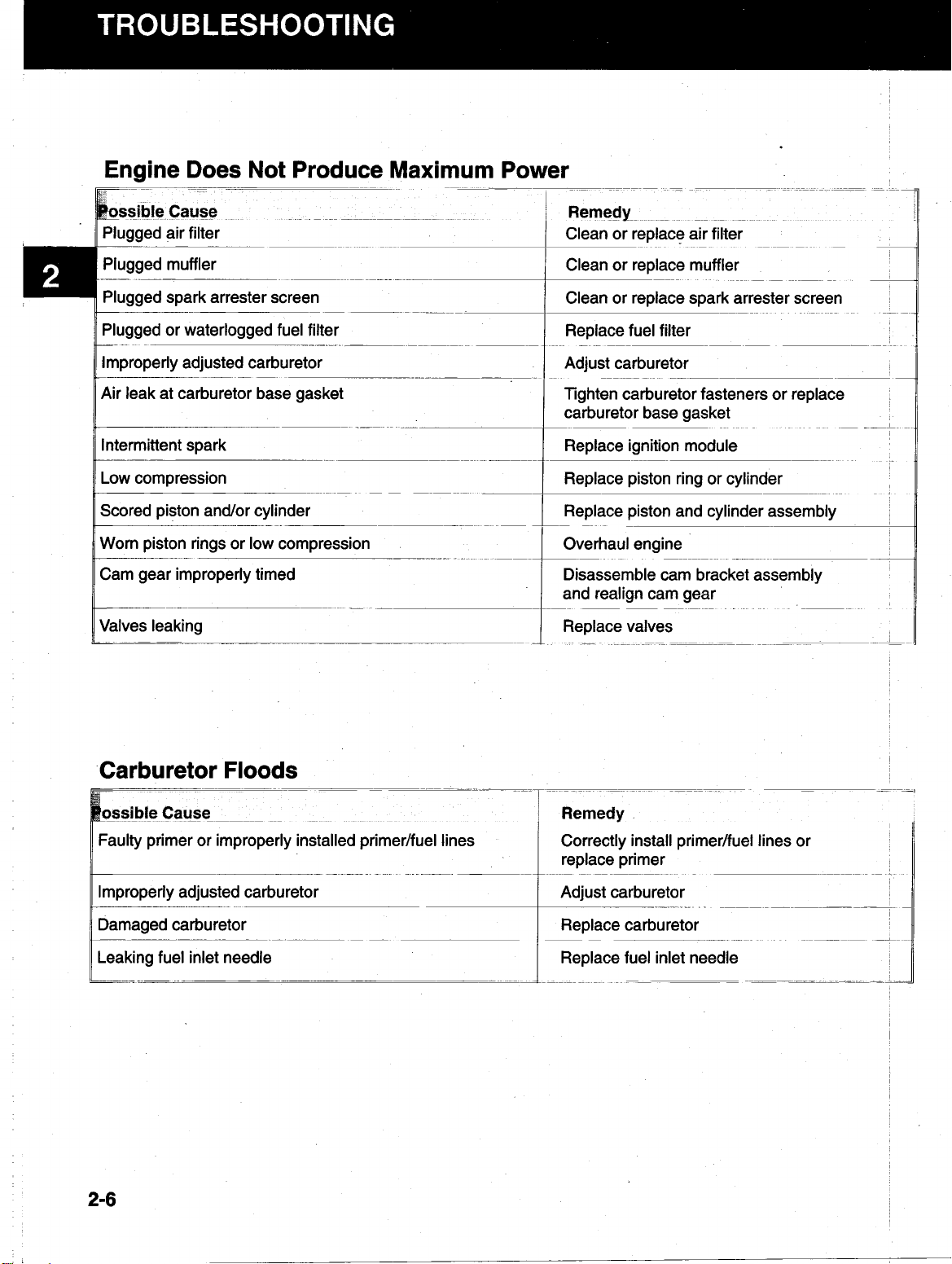

Engine Does Not Produce Maximum Power

Plugged muffler

Plugged spark arrester screen

Plugged or waterlogged fuel filter

-.

..

~

~ ~ ~~~ ~

~~ ~~~~ ~ ~~~

Improperly adjusted carburetor

Air leak at carburetor base gasket

Intermittent spark

Low compression

Scored piston and/or cylinder

._

~ ~~ ~

~p

~ ~

..

-

.

.

Worn piston rings or low compression

Cam gear improperly timed

Valves leaking

~~~

~_~

~.

~~

~ _ ~

__

~

Carburetor

Floods

pp~_~

~~~ ~~~

ulty primer or improperly installed primer/fuel lines

_. . .

.

.. . ...

~

11

Damaged carburetor

Leaking fuel inlet needle

11

~.

2-6

~~~

~~~~ ~

I

Remedy

.

. .

~_

Page 29

Engine

_~_____.

possible Cause

i

Stops

~__~~

~~~~

After Running Briefly

-~

~ ~~

Partially plugged fuel tank cap vent

Dirty or plugged air filter

Water in fuel

________

~~

Air leak at carburetor base gasket

Dirty carburetor fuel inlet needle or passage

~~

__

Faulty carburetor diaphragm

_______~~

-~

-~__

~

~~

~~___~~~__

Clean or replace air filter

~.

~~

__

Drain tank and blow out lines

~~~~

~~__

Tighten carburetor mounting fasteners or

replace carburetor base gaskets

-

-~

~~ ~

__~_

Replace fuel inlet needle or clean out carburetor

_-.___~.________

~~.~~_____~-

~___~~-~

Replace diaphragm

~

~~

~-

Losing compression

Engine

Possible g Cause

__~

Improperly adjusted carburetor

___~~________

Dirty or plugged air filter Clean or replace air filter

Faulty carburetor diaphragm Replace carburetor diaphragm

Faulty carburetor inlet seat gasket Replace carburetor inlet seat gasket

Will

~ ~

Not

Idle

~ ~~ ~~ ~~ ~~

~___

~______________~

Leaking crankshaft seal Replace crankshaft seal

Scored cylinder or low compression

____

i

~~1

-_

~ ~ ~

-

.-~.____._~

-$

.__~__

I

I

Replace piston rings or gaskets or

overhaul engine

___________-__

~~~ ~

~-

Remedy

~~ ~~~ ~~ ~~~ ~~

Adjust carburetor

~~

~~

________

__

~~

~~-.

-~

~ ~

-

.~

-

~__

~____-~

~-

~

~-

~

-

Overhaul engine

--

~-

~-

__

~

Engine Backfires Or Misfires

possible Cause

~

~

~-

~

Fouled, improperly gapped or broken spark plug

.

.___

Shorted ignition module leads

Rocker arm to valve clearance is out of adjustment

-

Weak valve spring

,__-

~~

-

~. _____.~~

~ ~

___~

~~

~

~-

~~

Check for loose or bare wires or loose

assembly and corrector replace ignition module

Adjust rocker arm to valve clearance

-_

-

-~

~___

-

Replace valve spring

~~~~ ~

2-7

Page 30

Plugged muffler Clean or replace muffler

~

__~~

~___~

Plugged spark arrester screen

Carburetor diaphragm gasket leaking

~~

~~__

.

~~__

0.025

inch(0.635 mm)

~

Clean or replace spark arrester screen

~~

.~

~~ ~

.

~~ ~ ~ ~~~~~ ~

Replace gasket

-

~~

Faulty primer bulb causing flooding

Dirty or plugged air filter

Plugged muffler

Plugged spark arrester screen

~-

Rocker arm to valve clearance is out of adjustment

Scored cylinder or low compression (below

. . .

. .

.

-

~

.-.~

-

~~~~~~

~

__~~

~~ ~~~ ~

~

-~

.

~~~____

~~ ~~

~___

~

90

~

psi)

Replace primer bulb

.-

-_

Clean or replace air filter

-

Clean or replace muffler

.

Clean or replace spark arrester screen

-

~

Adjust rocker arm to valve clearance

~~~__

~____._____~~

~~

.-

~ ~ ~~~~ ~ ~ ~

~~~~ ~ ~ ~ ~~

__~

~

~

~-

-

-~

~~ ~~~ ~

~~ ~~

I

..

Overhaul engine

2-8

Page 31

I

Oil

fill

plug loose or O-ring is leaking oil

-~

Breather housing plugged or damaged,

___-

..~~

Gaskets damaged or gasket surfaces nicked

-

Valve guides worn excessively

__

..

Cylinder wall worn or glazed

Piston rings and grooves worn excessively

.

.____.

-.

..

Piston fit undersized

~

Starter Rope

Oil

accumulated in combustion chamber

Is

Difficult

To

Pull Or Engine Locks

Replace O-ring and tighten oil

I

~~

Replace

breather housing assembly

__~

fill

plug

smooth gasket surfaces;

~

...

1

Replace cylinder head assembly

~

use new gaskets

~.

Replaced cylinder

piston rings and/or piston

,

1

Measure

-~

~~ ~~~~ ~

~~__-

1.

Remove the spark plug

2.

Drain the oil from the spark plug opening

and replace piston

__~

~~

~____

~~

__~

__

~

~__.~

~_i~~

if

necessary

~ ~~~

3.

Pull the starter rope several times to

remove any excess oil from the cylinder

excess oil with a dry cloth

5.

Reinstall the spark plug

2-9

Page 32

General Information

. .

.........

Troubleshooting

Disassembly

Inspection and Repair

Reassembly

....

.....

.....

.

.

.

.

.........

.........

.

.

.........

..........

3

3-1

Page 33

Table

Of

Contents

Typical Disassembly Sequence

Remove Major Components

Remove Engine

Remove The Spark Plug Wire And Spark Plug

Remove Upper Handle

Remove Lower Handle

Remove Air Filter

Remove Air Filter Base. Primer Bulb And

Carburetor

Remove Primer Bulb

Remove Engine Cover

Remove Carburetor Mount Insulator

Remove Intake Baffle

Remove Muffler

Remove Clutch

Remove Starter Module Assembly

..............................

.................................

...............................

..............................

..........................

...........................

..............

..........................

..........................

.............................

...........................

..........................

...................

...........................

....................

3-3

3-4

3-4

3-4

3-4

3-5

3-6

3-6

3-7

3-8

3-8

3-9

3-9

3-10

3-12

Remove Fuel Tank Bracket And Fuel Tank

Fuel Tank And Lines Disassembly And Reassembly

Fuel Line and Filter Removal

Fuel Line and Filter Installation

Disassemble .Engine

Remove Fan Housing

Remove Muffler Baffle

Remove Ignition Module

Remove Rocker Arm Assembly

Remove Cylinder Head. Valve Assembly And

Cylinder

Remove Piston/Connecting rod

Remove Cam Bracket Assembly

Remove Oil Pan

Remove Seal

..................................

................

...........

.......................

......................

...............................

...........................

...........................

.........................

......................

.......................

.....................

..............................

...............................

3-13

3-13

3-13

3-13

3-14

3-14

3-14

3-14

3-15

3-17

3-18

3-19

3-19

3-19

3-2

Page 34

Typical Disassembly Sequence

7.

Remove Engine Cover

This section covers the disassembly of major internal

engine components.

covers the disassembly, reassembly, inspection and repair of the subassemblies of the engine components.

Clean all parts thoroughly as the component parts are

disassembled. Only clean parts can accurately be inspected and gauged for wear or damage. There are

many commercially available cleaners that will quickly

remove oil and grime from engine parts. When such a

cleaner is used, follow the manufacturer's instructions

and safety precautions carefully. Particular attention

should be given to commercial cleaners compatibility'

with plastic parts.

Make sure that the cleaner is wiped

and not allowed to air dry

residue on parts which can affect engine lubrication.

The following sequence is suggested for complete engine disassembly. This procedure can be varied toaccommodate individual requirements for disassembly.

Refer to the appropriate parts manual to ensure the

correct replacement parts are ordered.

Part 4 lnspection and Repair

off

of engine parts

as

some cleaners leave a

8. Remove Carburetor Mount Insulator

9. Remove Intake Baffle

10. Remove Muffler

11. Remove Clutch

12. Remove Starter Module Assembly

13. Remove Fuel Tank Bracket and Fuel Tank

14. Fuel Tank Lines Disassembly and Reassembly

15. Remove Fan Housing

16. Remove Muffler Baffle

17. Remove Ignition Module

18. Remove Flywheel

19. Remove Rocker Arm Assembly

20. Remove Cylinder Head, Valve Assembly and

Cylinder

1. Drain Fuel from Tank and Oil from Oil Pan

2. Remove Spark Plug Wire and Spark Plug

3. Remove Engine from Equipment

4.

Remove Lower Handle

5.

Remove Air Filter

6. Remove Air Filter Base, Primer Bulb and

Carburetor

21. Remove Piston/Connecting Rod

22. Remove Cam Bracket Assembly

23. Remove Oil Pan

24. Remove Seal

NOTE:

necessary to make the desired repairs.

Only disassemble the engine to the extent

3-3

Page 35

REMOVE

Remove Engine

1.

Drain all fuel from the fuel tank.

MAJOR

COMPONENTS

3

2. Start the engine and allow it to run until it stalls.

low the engine to cool.

3.

Drain the oil from the oil pan.

Remove The Spark

1.

Disconnect the spark plug wire from the spark

plug. Remove the spark plug

Plug

Wire And Spark

Plug

.

Al-

2.6051.005

Remove Upper Handle

NOTE:

be removed with a T-25 Toro

1.

All

screws are T-25 Toro

Remove the six

(6)

screws from the upper handle.

3-4

(R)

screws and can

(R)

screwdriver.

5

Page 36

I

REMOVE

(cont.)

I

2.

Separate the

the

rear of the handle, next to the screw boss

MAJOR

two

two

halves apart with a screwdriver at the

COMPONENTS

halves

of

the handle by prying

.

NOTE:

handle, making removal

2.6047.026

Remove

-

1.

2.

The anti-vibration isolator

of

the halves difficult.

Lower

Remove the retainer screw, which holds the

switch and throttle trigger assembly in the handle. The trigger can now be removed from the

cable and the switch lifted

cated in the lower handle.

Remove the throttle cable and lead wires from

the lower handle.

Handle

is

wedged into the

off

the

two

pins

lo-

3

3

E

3.

Press down on the lower handle at the rear, near

the isolator. This will dislodge the isolator from

the lower handle, allowing the handle to be re-

.

moved.

NOTE:

handle slightly loosen the screws on the fuel tank

bracket and pull the fuel tank and bracket away from

the lower handle.

NOTE:

the location

and throttle cable location.

If

you have difficulty removing the lower

When removing the lower handle note

of

the anti-rotation cap screw, lead wires

I

3-5

Page 37

REMOVE MAJOR COMPONENTS

(cont.)

Remove Air Filter

1.

Remove the three

cover. Remove the air filter cover

(3)

screws securing the air filter

).

3

NOTE:

position to remove and install the air filter cover.

2.

The choke lever should be in the "PARTIAL"

Remove the air filter element from the air filter

.

The element is held in place by eight

base

pins.

(8)

Remove Air Filter Base, Primer Bulb And

Carburetor

1.

Remove the three

base, primer bulb and carburetor to the carbure-

tor mount insulator

(3)

screws securing the air filter

).

3-6

2.6047.

Page 38

REMOVE

MAJOR

COMPONENTS

(cont.)

2.

Remove the Z-bend of the throttle cable from the

hole in the carburetor throttle lever

.

NOTE:

the top of the throttle lever.

3.

4.

5.

6.

The Z-bend is located in the third hole from

Remove the carburetor and the

Dicard the gaskets.

Remove the fuel line from the carburetor fuel inlet

fitting.

Remove the fuel line from the fuel outlet fitting on

carburetor (to primer bulb).

Remove the throttle cable from the carburetor

mount insulator.

two

(2)

gaskets.

Remove Primer

1.

Remove the fuel lines from the fittings on the

primer bulb.

2.

Squeeze the mounting tabs on the back of the

bulb and pull the bulb out from the front of the

air filter base.

3.

Inspect the check valves in the primer bulb for fuel

leakage. To do this inspection, place your finger

over the long fitting on the back of the primer

.

bulb and press the front of the bulb.

collapses and air comes out through the short fit-

ting, replace the primer bulb.

Inspect the primer bulb for flexibility and cuts or

tears. Replace the primer bulb

Bulb

If

the bulb

if

necessary

3-7

Page 39

REMOVE MAJOR COMPONENTS

(cont.)

Remove Engine Cover

1.

Remove the rear engine cover screw

2.

Remove the

cover and the screw from the front of the cover.

Lift the cover up and

two

(2)

screws from the top of the

off

of the engine.

-

3.6047.035

Remove Carburetor Mount Insulator

1.

Remove the

two

(2)

screws securing the

carburetor mount insulator to the crankcase.

3-8

3.6047.037

Page 40

REMOVE

MAJOR

COMPONENTS

(cont.)

2.

Remove the carburetor mount insulator and

carburetor mount insulator gasket.

3.

Remove the

carburetor mount insulator.

two

(2)

hex nuts on the back of the

2.6047.039

NOTE: For Units Prior to Engine Serial

4050000001-The hex nuts were not retained. Be

careful not to lose them.

Remove Intake Baffle

1.

Remove the intake baffle from the cylinder

Number

3

-

Remove muffler

1.

Remove the three

I

(3)

muffler mounting bolts

3-9

Page 41

REMOVE

MAJOR COMPONENTS

(cont.)

2

Remove the muffler and muffler gasket. Discard

the old gasket.

NOTE:

time.

NOTE:

scrapers. Always use wood or plastic scrapers.

Remove

1.

For units that take attachments, remove the spring.

The muffler baffle cannot be removed at this

Do

not scrape the gasket surfaces with metal

Clutch

Remove the three

housing/drum assembly to the fan housing.

move the clutch housing/drum assembly

(3)

screws securing the clutch

Re-

2.

Remove the isolator, which

clutch cover and the starter module

assembly.

3-1

0

is

located between the

2.6047.043

Page 42

REMOVE MAJOR

COMPONENTS

(cont.)

I

3.

With the starter pawls on the flywheel positioned

at the top (12 o'clock) and bottom

stall flywheel holding tool, P/N 18091 9.

4.

Lift the starter assembly until

rotor. At 9 o'clock on the fan housing, roll the flywheel holding tool into the flywheel until the

head of the cap screw on the bottom of the tool

fits into the screw hole of the fan housing.

(6

o'clock), in-

it

contacts the clutch

5.

Holding the flywheel holding tool in place, postion

the clutch rotor tool (P/N 180918) over the rotor.

Page 43

REMOVE

MAJOR

COMPONENTS

(cont.)

6.

Using a

rotor tool counterclockwise to remove the clutch

rotor.

7.

Remove the clutch rotor and washer.

3/4

inch socket wrench, turn the clutch

-~

2.6047.M

Remove Starter Module Assembly

1.

Remove the

rope eyelet bracket. Remove the starter module

assembly.

3-1

2

two

(2)

screws securing the starter

Page 44

REMOVE MAJOR

(cont.)

COMPONENTS

Remove Fuel Tank Bracket And Fuel Tank

1.

Remove the

bracket.

2.

Remove the fuel tank bracket and fuel tank.

3.

Remove the rubber fuel tank pad.

two

(2)

screws from the fuel tank

'

3

Fuel Tank And Lines Disassembly And

Reassembly

Fuel Line and Filter Removal

This unit has

clear line provides normal fuel flow. The blue line

provides a return line for excess fuel flow during the

primer operation.

1.

Push the fuel line into the fuel tank until you can

pull the filter out of the tank neck.

two

fuel lines to the fuel tank. The

2.

If

the fuel filter is dirty or clogged, replace it with a

new fuel line assembly.

Fuel Line and Filter Installation

1.

Insert a piece of trimmer line through the hole in

the rear side of the fuel tank to the filler opening.

Slide the fuel line over the trimmer line.

2.

Guide the fuel line through the hole in the tank

with the trimmer line.

3.

Working through the filler neck, insert the fuel line

with the fuel filter attached through the hole in

the rear of the tank.

4.

Work the fuel line from outside of tank, pulling until

the filter lays on the bottom of the tank or

inches

(1

52

mm) of line are exposed.

6

3-1

3

Page 45

DISASSEMBLE ENGINE

Remove Fan Housing

1.

Remove the four

housing to the crankcase. Remove the fan hous-

ing.

2.

Disconnect the switch lead wires.

Remove Muffler Baffle

1.

Remove the muffler baffle.

(4)

screws securing the fan

53

Remove Ignition Module

1.

Remove the

two

(2)

screws securing the ignition

module to the crankcase. Remove the ignition

module.

3-1

4

Page 46

DISASSEMBLE ENGINE

(cont.)

WARNING:

CRACKED

OR

BROKEN COOLING

FINS ARE A HAZARD! Be careful not to crack or

off

break any cooling fins. They could fly

eration.

If

cooling fins are cracked or broken, re-

during op-

place the flywheel.

1.

Remove the spacer from the crankshaft.

2.

Using a plastic-faced mallet, tap and pull the fly-

~

wheel until it breaks free from the crankshaft.

3.

Remove the flywheel from the crankshaft.

4.

Remove the flywheel key from the crankshaft.

~

I

Remove Rocker Arm Assembly

1.

Remove the rocker arm cover screw. Remove

rocker arm cover and gasket.

I

3.6047.058

I

3-1

5

Page 47

DISASSEMBLE ENGINE

2.

Remove the rocker adjusting nuts, rocker arm

pivots and rocker arms.

(cont.)

Adjusting Nut

Arm

NOTE:

disassembling the rocker arm assembly.

3.

I

4.

Always match intake and exhaust parts when

Remove the

guides.

Remove the four

washers.

two

(2)

push rods from the push rod

(4)

cylinder hex nuts and

Rocker Arm

5.

Remove the push rod guides from the cylinder

studs.

3-1

6

2.6060.060

2.6047.061

Page 48

DISASSEMBLE ENGINE

Remove Cylinder Head, Valve assembly And

Cylinder

1.

Lift the cylinder head

the cylinder head gasket.

2.

Remove the two

from the cylinder head.

off

of the cylinder. Remove

(2)

valves and valve retainers

(cont.)

NOTE:

down on the valve retainers with your fingers and

rock them to the side.

3.

NOTE:

necessary.

NOTE:

should not be removed from the cylinder head,

To

make removal of the valves easier, push

Remove the

The valves cannot be ground. Replace

The rocker box is factory assembled and

two

(2)

valve springs.

Page 49

I

DISASSEMBLE

I

4.

Remove the two

cylinder.

ENGINE

(2)

cylinder screws from the

(cont.)

5.

Remove the cylinder and cylinder gasket from the

crankcase.

NOTE:

To

Do

not scrape the gasket from the cylinder.

remove the gasket, soak the cylinder with solvent.

L

2.6047.065

2.6047.066

Remove

1.

Piston/connecting

rod

Remove the piston/connecting rod from the crankcase. Grasp the piston/connecting rod, slide it to

the rear and twist slightly. No tool

3-1

8

is

required.

Page 50

DISASSEMBLE

-

Remove Cam Bracket Assembly

1.

Remove the

assembly. Remove the cam bracket assembly.

two

ENGINE

(2)

screws from the cam bracket

(cont.)

Remove

1.

Remove Seal

NOTE:

he crankcase.

1.

Oil

Pan

Remove the six

move the oil pan.

Remove the seal only

Remove the seal from the flywheel side

crankcase, using a seal puller or flathead screw-

driver.

(6)

screws from the oil pan. Re-

if

oil

is leaking from

Of

the

NOTE:

crankcase.

Do

not remove the crankshaft from th6

3-1

9

Page 51

General Information ...............

*.

.

I.

Troubleshooting

Disassembly

Inspection and Repair

Reassembly

.................

..................

...................

.............

..

..

.

..

..

..

..

..

..

Page 52

//

!!

l1

Table

Carburetor Disassembly And Reassembly

Carburetor Disassembly

Fuel Metering Side

Fuel Pump Side

Carburetor Inspection and Cleaning

Carburetor Reassembly

Fuel Metering Side

Fuel Pump Side

Final Carburetor Adjustment

Adding Starter Spring Tension

Starter Disassembly

Starter Inspection and Service

Starter Reassembly

Breather Disassembly And Reassembly

Breather Hose Function Test

.............................

..............................

..............................

..............................

............................

............................

Of

.........................

..........................

........

.......................

Contents

....................

...................

i

..............

......................

......................

.....................

4-3

4-3

4-4

4-5

4-5

4-6

4-6

4-9

4-9

4-10

4-11

4-12

4-13

4-15

4-16

I

~

I

~

I

~

Reassembly

Spark Arrester Screen

Piston/Connecting Rod Disassembly & Assembly

Piston Inspection and Repair

Connecting Rod Inspection and Repair

Reassembly

Cylinder Head Inspection & Repair

Cylinder Inspection and Repair

Valve Assembly. Inspection and Repair

Crankcase Inspection and Repair

Crankcase Inspection

Cam Bracket Disassembly and Inspection

Cam Bracket Reassembly

Major Component Inspection

Fuel Tank and Cap Inspection

Clutch Inspection 4-22

Muffler Inspection and Cleaning

................................

..............................

.......................

..................

................................

........................

......................

..................

.....................

............................

........................

&

Repair

......................

.......................

.............................

......................

4-16

4-16

................

................

..

4-17

4-17

4-18

4-18

4-19

4-19

4-20

4-20

4-20

4-21

4-21

4-22

4-22

4-22

4-2

Flywheel Inspection and Repair

......................

4-23

Page 53

I

This section covers the disassembly, reassembly, inspection and repair of the subassemblies of the major internal

engine components.

Clean all parts thoroughly as the component parts are disassembled. Only clean parts can accurately be in-

spected and gauged for wear or damage. There are many commercially available cleaners that will quickly re-

move oil and grime from engine parts. When such a cleaner is used, follow the manufacturer’s instructions and

safety precautions carefully. Particular attention should be given to commercial cleaners compatibility with plastic

parts.

is

wiped

off

Make sure that the cleaner

of the engine parts and not allowed to air dry as some cleaners leave a

residue on parts which can affect engine lubrication.

CARBURETOR DISASSEMBLY’

AND REASSEMBLY

Carburetor

The fast idle starting system consists

Disassembly

of

a throttle

cam, which is activated by a choke cam. When the

cams are in the choke position, it

is

not necessary

to

squeeze the throttle fully when starting, which reduces the likelihood of flooding.

1.

Inspect throttle and choke cams for wear

age. Replace,

2.

Remove the high speed mixture

(L)

ture

if

necessary.

adjusting needles and springs.

(H)

or

dam-

and idle mix-

-

~

4-3

Page 54

2.

Remove the fuel metering diaphragm and gasket.

2.6047.074

NOTE:

These components are under spring

tension. Remove them carefully to prevent

sure the spring is not stretched.

4-4

loss.

Make

Page 55

CARBURETOR DISASSEMBLY

AND REASSEMBLY

(cont.)

...

Fuel Pump Side

1.

Remove the idle speed adjusting screw and spring

from the fuel pump cover.

2.

Remove the fuel pump cover screw and cover

,

Idle Speed

Adjusting Screw

ring

3.

Remove the spring, fuel pump cover gasket

pump diaphragm from the fuel pump cover.

NOTE:

throttle plate, throttle lever, choke lever, welch plugs,

fuel inlet screen, etc. is not recommended.

/-

NOTE:

do not use drill bits or wire to clean fuel ports and

passages.

Further disassembly to remove the

To prevent damage to the carburetor body,

I

4

and

Carburetor Inspection and Cleaning

Two carburetor service kits are available: a gasket/diaphragm kit and a carburetor repair kit.

The gasket/diaphragm kit contains the fuel metering

cover gasket, fuel metering diaphragm, fuel pump

cover gasket, and fuel pump diaphragm.

The carburetor repair kit contains the gaskets and

diaphragms included in the gasket/diaphragm kit

plus fuel inlet needle and spring, fuel metering

lever, metering lever hinge pin, the fuel inlet screen

Page 56

CARBURETOR DISASSEMBLY AND

REASSEMBLY

Refer to the appropriate parts manual for service kit part

numbers.

1.

Inspect the tips of the high speed mixture needle,

idle speed mixture needle, and fuel inlet needle

for wear or damage. Replace the needles

essary.

(cont.)

if

nec-

Inspect Here

4

2.

Gaskets and diaphragms eventually deteriorate

and become stiff with age and use.

practice to replace gaskets and diaphragms for

each repair. However,

and flexible, you do not need to replace it, un-

less a complete carburetor rebuild is being per-

formed.

3.

Clean the metering cover, pump cover, carburetor

body and filter screen with carburetor cleaner.

Blow out all passages with compressed air.

Carburetor Reassembly

Fuel Metering Side

1.

Install the fuel inlet needle, fuel metering lever

spring, metering lever and metering lever hinge

pin. Secure the hinge pin in carburetor body with

the hinge pin screw.

if

the diaphragm is

It

is good

soft

I I

1

4-6

2.6047.078

Page 57

CARBURETOR DISASSEMBLY

AND REASSEMBLY(cont.)

2.

Place a straight edge across the carburetor body.

Use a

wire

feeler gauge to measure the distance

between the straight edge and the top of the fuel

metering lever.

DEPRESS

HERE

HIGH

THEN

NEEDLE

HERE

PUSH

LOW

3.6047.079

The fuel metering lever should be

in.

(1.52-1.78

If

the lever is adjusted too high, the engine will

run rich.

gine will run lean. Poor acceleration and erratic

operation may also be noted.

mm)

below the straight edge.

If

the lever is adjusted too low, the en-

0.060-0.070

2.6047.081

3.

Install the metering cover gasket (next to carburetor body) and metering diaphragm. Make sure

the larger circular plate of diaphragm is towards

the metering lever.

Page 58

CARBURETOR DISASSEMBLY AND

REASSEMBLY(cont.)

4.

Make sure there are no wrinkles in the metering

diaphragm. Install the metering cover and

screws. Tighten the screws securely.

5.

Install the high speed mixture (H) and idle mixture

(L)

adjusting needles and springs.

2.6047.082

.Turn both needles

lightly

are

seated.

out (counterclockwise)

in (clockwise)

until they

Then turn the needles

the following

number of turns:

For Units with Engine Serial Number Prior to

407000001

High Speed Mixture Needle:

Idle Speed Mixture Needle:

1 turn

1 turn

For Units with Engine Serial Number 407000001 and

Greater-

High Speed Mixture Needle:

Idle Speed Mixture Needle:

NOTE:

needles

Turn the high speed mixture and idle mixture

finger-tight.

Do

not force the needles with a

1 1/8 turns

1

1/8

turns

screwdriver because this can damage the tips of the needles and the seats in the carburetor body.

Idle speed

2.6047.083

.

3.6051.015

4-8

Page 59

CARBURETOR DISASSEMBLY’

AND REASSEMBLY

Fuel Pump Side

-

1.

Install the fuel pump diaphragm (next to

carburetor body) and gasket.

2.

Install the spring, fuel pump cover, and cover

screw. Tighten the screw securely.

(cont.)

-

~

~

2.6047.0

3.

If

necessary, install the idle speed adjusting screw

and spring.

For Units with Engine Serial Number

and Greaterwise)

until it

tinue turning

Turn the adjusting screw

just

touches

2

full turns.

the throttle lever; then con-

Final Carburetor Adjustment

407000001

in