Page 1

16” & 18” Gas

Trimmer

Model No. 51903 — 790000001 & Up

Model No. 51904 — 790000001 & Up

Model No. 51906 — 790000001 & Up

Model No. 51907 — 790000001 & Up

16” & 18” Gas

FORM NO. 3319–144 REV A

Coupe-Herbe

Modèle No. 51903 — 790000001 et suivants

Modèle No. 51904 — 790000001 et suivants

Modèle No. 51906 — 790000001 et suivants

Modèle No. 51907 — 790000001 et suivants

16” & 18” Gas

Recortadora

Modelos N. 51903 — 790000001 y siguientes

Modelos N. 51904 — 790000001 y siguientes

Modelos N. 51906 — 790000001 y siguientes

Modelos N. 51907 — 790000001 y siguientes

Operator ’s Manual

Manuel de l’Utilisateur

Manual del Usuario

Page 2

WARNING:

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects,

or other reproductive harm.

AVERTISSEMENT:

Les gaz d’échappement du moteur de ce

produit contiennent des produits

chimiques reconnus dans l’état de

Californie comme cancérigènes,

responsables de malformations

congénitales, ou comme nocifs à l’égard

des fonctions de la reproduction.

ADVERTENCIA:

El escape del motor de esta herramienta

contiene productos químicos que según

la información del Estado de California

producen cáncer, defectos congénitos u

otros riesgos reproductivos.

Page 3

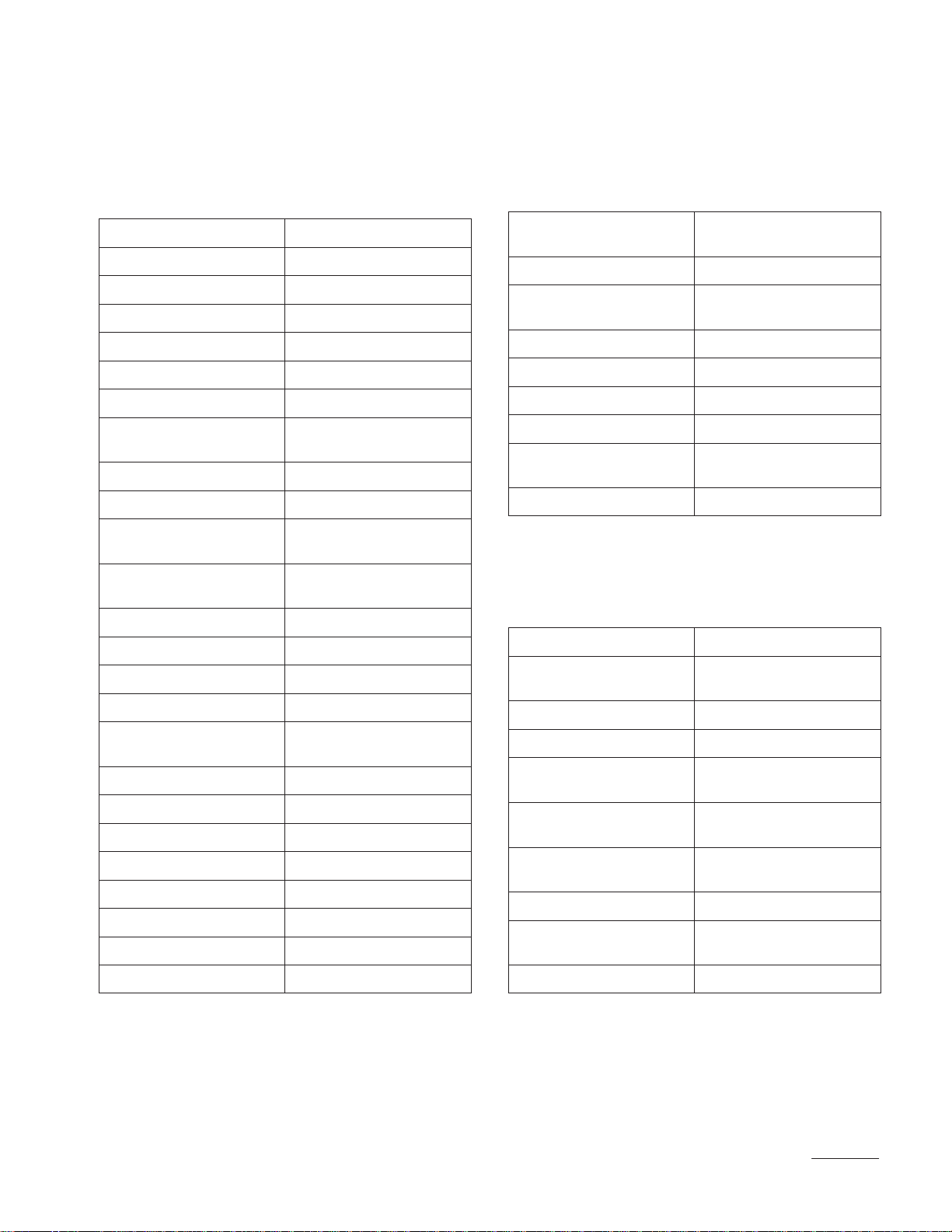

Figures–Figuras

1

1

English

1. Model and serial number decal location

Français

1. Emplacement des numéros de modèle et de série

3

4

Español

1. Ubicación de la calcomanía con el modelo y el número de serie

2

Printed in USA

The Toro Company – 1996, Rev. 1997

All Rights Reserved

i

Page 4

5

7

8

6

ii

Page 5

9

10

m-2912

2

11

1

English

1. Screw

2. Full choke position

3. Choke lever

Français

1. Vis

2. Position entièrement

fermée

3. Levier du starter

Español

1. Tornillo

2. Posición de obturación

total

3. Palanca del obturador

3

4

5

4. Run position

5. Partial choke position

4. Position de marche

5. Position partiellement

fermée

4. Posición de

funcionamiento

5. Posición de obturación

parcial

1

English

1. Primer bulb

Français

1. Pompe d’amorçage

Español

1. Perilla de cebado

1

iii

Page 6

12

1

2

English

1. Starter rope 2. Throttle trigger

Français

1. Corde du lanceur 2. Gâchette de commande

des gaz

Español

1. Cuerda de arranque 2. Gatillo del acelerador

14

15

13

English

1. Stand

Français

1. Support

Español

1. Soporte

1

iv

Page 7

16

17

18

19

20

v

Page 8

21

22

24

25

23

26

1

English

1. Air filter

Français

1. Filtre à air

Español

1. Filtro de aire

vi

Page 9

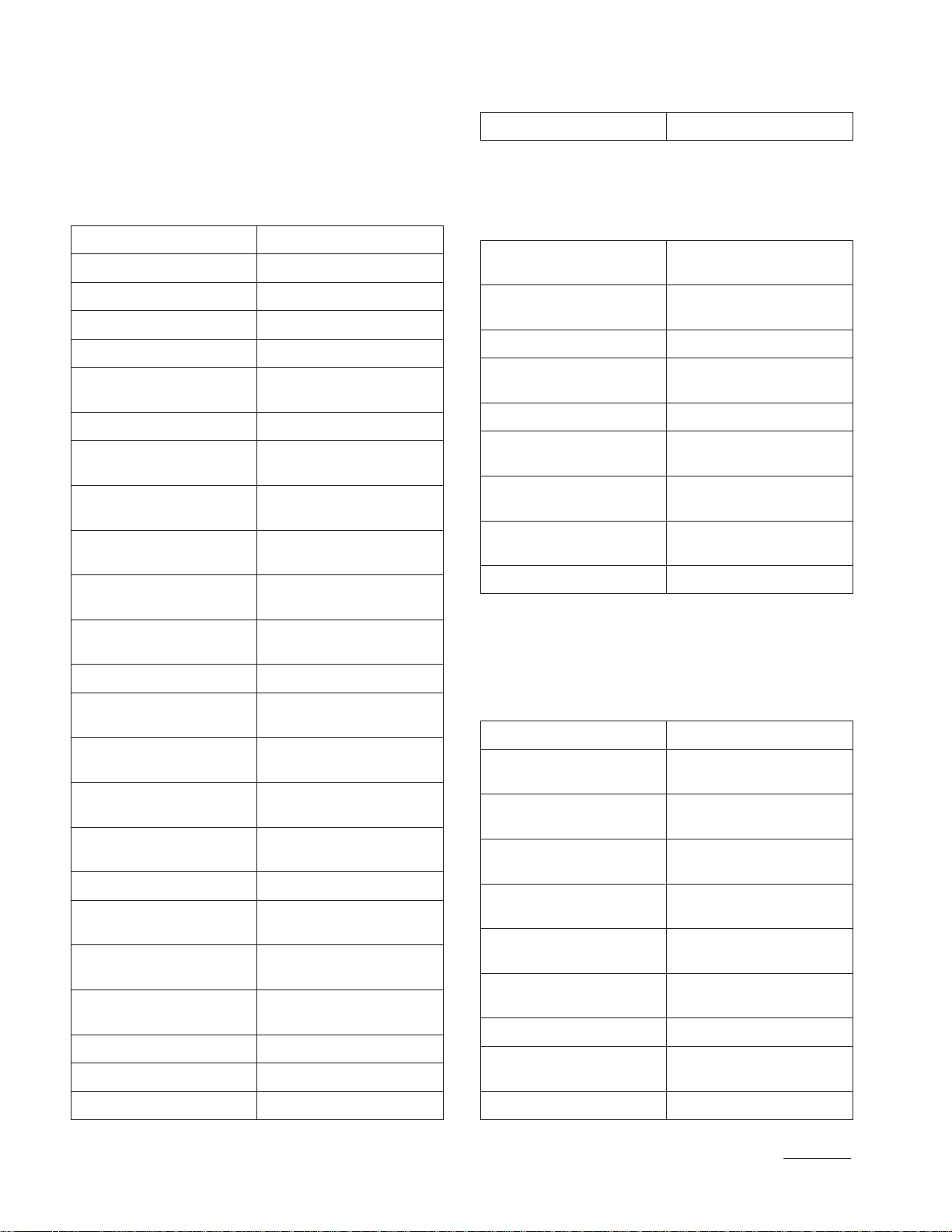

27

1

30

2

3

4

28

29

English

WALBRO CARBURETOR

1. Throttle lever

2. Idle speed screw

Français

CARBURATEUR WALBRO

1. Levier d’accélérateur

2. Vis de régime de ralenti

3. Pointeau de richesse de

haut régime

Español

CARBURADOR WALBRO

1. Palanca del acelerador

2. Tornillo de ajuste de la

velocidad en ralentí

3. Aguja de ajuste de la

mezcla de alta velocidad

3. High speed mixture

needle

4. Idle speed mixture needle

4. Pointeau de richesse de

ralenti

4. Aguja de ajuste de la

mezcla de velocidad en

ralentí

vii

Page 10

1

31 32

2

3

4

English

ZAMA CARBURETOR

1. Throttle lever

2. Idle speed screw

Français

CARBURATEUR ZAMA

1. Levier d’accélérateur

2. Vis de régime de ralenti

3. Pointeau de richesse de

haut régime

Español

3. High speed mixture

needle

4. Idle speed mixture needle

4. Pointeau de richesse de

ralenti

.020 in

(0.5 mm)

1

33

CARBURADOR ZAMA

1. Palanca del acelerador

2. Tornillo de ajuste de la

velocidad en ralentí

3. Aguja de ajuste de la

mezcla de alta velocidad

4. Aguja de ajuste de la

mezcla de velocidad en

ralentí

English

1. Muffler mounting bolts

Français

1. Boulons de montage du silencieux

Español

1. Pernos de montaje del silenciador

viii

Page 11

34 35

1

1

English

1. Inlet port

Français

1. Ouverture d’entrée

Español

1. Orificio de admisión

English

1. Muffler gasket

Français

1. Joint du silencieux

Español

1. Junta del silenciador

ix

Page 12

Contents

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fueling And Before Operating 2. . . . . . . . . .

While Operating 3. . . . . . . . . . . . . . . . . . . . .

Maintenance And Storage 3. . . . . . . . . . . . .

Safety and Instruction Decals 4. . . . . . . . . . .

Symbol Glossary 4. . . . . . . . . . . . . . . . . . . .

Assembly 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing The D-handle 5. . . . . . . . . . . . . . .

Installing The String Guard 5. . . . . . . . . . . .

Before Starting 5. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil And Fuel 5. . . . . . . . . . . . . . . . . . . . . . .

Mixing Oil And Fuel 7. . . . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting/Stopping 7. . . . . . . . . . . . . . . . . . . .

Adjusting The Trimming Line Length 8. . . .

Page

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied

with your new product, so feel free to contact your

local Authorized Service Dealer for help with service,

genuine Toro parts, or other information you may

require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. You will find the model and serial number

decal located in a unique place on the product

(Fig. 1).

For your convenience, write the product model and

serial numbers in the space below.

Decorative Trimming 8. . . . . . . . . . . . . . . . .

Maintenance 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Schedule 8. . . . . . . . . . . . . . . .

Line Installation 8. . . . . . . . . . . . . . . . . . . . .

Installing A Prewound Reel 9. . . . . . . . . . . .

Air Filter Maintenance 10. . . . . . . . . . . . . . . .

Carburetor Adjustment 10. . . . . . . . . . . . . . . .

Replacing The Spark Plug 11. . . . . . . . . . . . .

Inspecting/Cleaning The Muffler 12. . . . . . . .

Cleaning 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 13. . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Shaft & Cutting Head 14. . . . . . . . . . .

Cold Engine Torque Specifications 14. . . . . .

California Emission Control Warranty Statement 15

Warranty 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model No.

Serial No.

Read this manual carefully to learn how to operate

and maintain your product correctly. Reading this

manual will help you and others avoid personal injury

and damage to the product. Although Toro designs,

produces and markets safe, state-of-the-art products,

you are responsible for using the product properly

and safely. You are also responsible for training

persons who you allow to use the product about safe

operation.

The Toro warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

EN–1

Page 13

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

Fueling And Before Operating

1. Gasoline is extremely flammable and its vapors

can explode if ignited. Always stop the engine

and allow it to cool before filling the fuel tank.

Do not smoke while filling the fuel tank. Keep

sparks and open flames away from the area.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

Safety

Note: For users on U. S. Forest Land and

in the states of California, Maine,

Oregon and Washington. All U.S.

Forest Land and the state of California

(Public Resources Codes 4442 and

4443), Oregon and Washington

require, by law that certain internal

combustion engines operated on forest

brush and/or grass-covered areas be

equipped with a spark arrestor,

maintained in effective working order,

or the engine be constructed, equipped

and maintained for the prevention of

fire. Check with your state or local

authorities for regulations pertaining to

these requirements. Failure to follow

these requirements could subject you

to liability or a fine. This unit is not

factory equipped with a spark

arrestor. If these items are required in

your area, ask your dealer to install the

Optional Accessory Part #180030

Spark Arrestor Kit.

2. Store gasoline and fuel only in containers

designed and approved for the storage of such

materials.

3. Pressure can build up in the fuel tank. Loosen

the fuel tank cap slowly to relieve any pressure

in the tank.

4. Add fuel in a clean, well-ventilated area. Wipe

up any spilled fuel immediately. If fuel has been

spilled, allow it to dry completely before starting

the engine.

5. Move the trimmer at least 10 ft (3 m) from the

fueling point before starting the engine.

6. Thoroughly inspect the trimmer for loose or

damaged parts before each use. Do not use until

adjustments or repairs are made.

7. Avoid accidental starting. Be in the starting

position whenever pulling the starting rope.

8. Keep all bystanders, especially children, and pets

at least 33 ft (10 m) away from the area.

9. Carefully inspect the areas to be cut. Remove all

debris that could become entangled in the string

or blade. Also remove any objects that could be

thrown during cutting.

10. Before starting, make sure the string head is not

in contact with anything.

11. Always remain alert. To prevent injury to

yourself and others, do not operate this trimmer

if you are fatigued.

12. Do not operate the unit while under the influence

of drugs, alcohol or medication.

EN–2

Page 14

While Operating

1. Wear safety glasses or goggles at all times when

operating this trimmer.

2. Dress properly. Do not operate this trimmer

when barefoot or wearing open sandals. Always

wear sturdy, rubber-soled footwear. The use of

gloves, ear/hearing protection and long pants are

recommended.

3. Do not wear loose fitting clothing or articles

such as scarves, strings, chains, ties, etc. because

they could get drawn into the air intake. Also

make sure long hair does not get drawn into the

air intake.

4. Keep hands, face, and feet away from all moving

parts. Do not attempt to touch or stop the string

when it is rotating.

5. Do not touch the muffler or cylinder. These parts

get extremely hot from operation and remain hot

for a short time after the equipment is turned off.

9. Use the right tool. Do not use this trimmer for

any job except that for which it is intended.

10. Do not force the tool at a rate faster than the rate

at which it is able to cut effectively.

11. Do not overreach. Keep proper footing and

balance at all times.

12. Do not operate the engine faster than the speed

necessary to cut, trim or edge. Do not run the

engine at high speed when not cutting.

13. The string guard must be in place at all times

while operating the trimmer.

14. Do not extend the trimming line beyond the

length specified in this manual.

15. Always stop the engine when cutting is delayed

or when walking from one cutting location to

another.

6. Always hold the trimmer with both hands when

operating. Keep a firm grip on both the front and

rear handles or grips.

7. Operate this trimmer only in a well-ventilated

area -outdoors. Carbon monoxide exhaust fumes

can be lethal in a confined area.

8. If the unit strikes or becomes entangled with a

foreign object, stop the engine immediately and

check for damage. Repair any damage before

further operation is attempted. Do not operate

the trimmer with loose or damaged parts.

Maintenance And Storage

1. Use only genuine Toro replacement parts when

servicing this trimmer. These parts are available

from your authorized dealer. The use of

non-standard parts, or other accessories or

attachments not approved for this trimmer, could

result in serious injury to the user or damage to

the trimmer and void your warranty.

2. Lock up and store the trimmer in an appropriate

and dry location to prevent unauthorized use and

damage. Keep unit out of the reach of children.

EN–3

Page 15

Safety and Instruction Decals

(

)

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

ON ENGINE

(Part No. 92-3332)

ON GAS TANK

Part No. 92-3334

Symbol Glossary

ON BOOM

(Part No. 92-3328)

Hot surface

Stay a safe distance

from the machine

Read operator’s

manual

Fuel Oil

Wear eye and hearing

protection

Thrown or flying

objects–Whole body

exposure

For service

information, call:

1–800–237–2654

EN–4

Page 16

Assembly

Note: Failure to follow these assembly

instructions may cause flex shaft

failure.

Model 51906

1. Slide the string guard onto the guard mount

above the string head assembly. Align the screw

holes in the string guard with the screw holes in

the string assembly (Fig. 6).

Installing The D-handle

1. Push the D-handle down over the boom (Fig. 2).

2. Install the bolt, washer and wing nut and tighten

(Fig. 2).

Installing The String Guard

POTENTIAL HAZARD

• Foreign objects can be thrown by trimmer.

WHAT CAN HAPPEN

• Contact with thrown objects can cause

personal injury.

HOW TO AVOID THE HAZARD

• Never operate the trimmer without the

string guard in place.

Model 51903

1. Place the string guard onto the boom above the

clamp assembly (Fig. 3).

2. Place the three hex nuts into the recessed holes

on top of the guard (Fig. 7).

3. Install the screws into the holes from the bottom

of the guard. Tighten the screws (Fig. 8).

Before Starting

Oil And Fuel

THIS ENGINE IS CERTIFIED TO OPERATE

ON UNLEADED GAS AND OIL MIXTURE.

Note: BE SURE TO READ THESE

INSTRUCTIONS CAREFULLY

BEFORE ATTEMPTING TO START

OR OPERATE THIS UNIT. Using old

or improper oil or fuel, or improperly

mixing the oil and fuel can cause

engine damage. This type of damage

will void the engine warranty.

2. Push the string guard down to the top of the

string head assembly and then rotate the string

guard to the proper position (Fig. 4). The string

guard is in the correct position when the string

guard points toward the engine, and the holes in

the string guard line up with the holes in the top

of the string head assembly.

3. Install the screws with a Phillips screwdriver

(Fig. 5).

EN–5

Page 17

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

POTENTIAL HAZARD

• Gasoline/oil mixture contains petroleum

distillate.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AVOID THE HAZARD

• Use a funnel and fill the fuel tank outdoors,

in an open area, when the engine is cold.

Wipe up any gasoline that spills.

• Do not fill the fuel tank completely full.

Add gasoline to the fuel tank until the level

is 1/4” to 1/2” (6 mm to 13 mm) below the

bottom of the filler neck. This empty space

in the tank allows gasoline to expand.

• Never smoke when handling gasoline, and

stay away from an open flame or where

gasoline fumes may be ignited by a spark.

• Store gasoline in an approved container

and keep it out of the reach of children.

• Never buy more than a 30-day supply of

gasoline.

Recommended Oil Type

WHAT CAN HAPPEN

• Gasoline/oil mixture can be harmful or

fatal if swallowed. It can also irritate your

skin.

HOW TO AVOID THE HAZARD

• Do not drink gasoline/oil mixture.

• Avoid prolonged contact with skin. Wash

thoroughly after handling.

• Do not reuse oil bottle.

IMPORTANT: If gasoline/oil mixture is

swallowed, do not induce vomiting. CALL

PHYSICIAN IMMEDIATELY.

Recommended Fuel Type

Use clean, fresh, unleaded gasoline that is less than

60 days old.

Note: Alcohol blended fuel absorbs moisture

(water). As little as 1% moisture in the

fuel can cause fuel and oil to separate

and form acids when stored.

An 8oz. (0.24 liter) bottle of 2-cycle engine oil is

included with your product.

TORO 2-cycle oil is recommended for this outdoor

power tool. If another brand of 2-cycle oil is used,

make sure it is high quality oil, formulated for

2-cycle, air-cooled engines.

If this type of fuel must be used, use

fresh fuel, (less than 60 days old) and

mix according to the mixing

instructions.

Definition Of Blended Fuels

Today’s fuels are often a blend of gasoline and one or

more oxygenates such as ethanol, methanol or MTBE

(ether).

Use Of Blended Fuels

If you choose to use a blended fuel or its use is

unavoidable, the following precautions are

recommended.

EN–6

Page 18

1. Always use fresh fuel mix per your operator’s

manual.

2. Use the special additive STA-BIL or an

equivalent.

3. Always agitate the fuel mix before fueling the

unit.

4. Drain the tank and run the engine dry before

storing the unit.

Use Of Fuel Additives

The use of fuel additive, such as STA-BIL Gas

Stabilizer or an equivalent, will inhibit corrosion and

minimize the formation of gum deposit. Add 0.8 oz

(23 ml) per gallon of fuel per instructions on

container. NEVER add fuel additives directly to the

unit’s fuel tank. Using a fuel additive can keep fuel

fresh for up to six (6) months.

POTENTIAL HAZARD

• Gasoline contains gasses that can build up

pressure inside a gas tank.

WHAT CAN HAPPEN

• Fuel can be sprayed on you when removing

gas cap.

HOW TO AVOID THE HAZARD

• Remove fuel cap slowly to avoid injury

from fuel spray.

Operation

Starting/Stopping

1. Mix oil with gas and fill fuel tank with fuel/oil

mixture — Per instructions on page 7.

Mixing Oil And Fuel

Note: For proper engine operation and

maximum reliability, pay strict

attention to the oil and fuel mixing

instructions on the 2-cycle oil

container. Use a 32:1 fuel/oil ratio

when you use 2-cycle oil. Using

improperly mixed fuel can severely

damage the engine.

Thoroughly mix the proper ratio of 2-cycle engine oil

with unleaded gasoline in a separate fuel can, 32:1.

Do not mix them directly in the engine fuel tank. See

the following table for specific gas and oil mixing

ratios.

32:1 GAS/OIL Mixing Chart

Gasoline Oil

1 US gallon 4.0 oz.

(3.8 liters) (118 ml)

1 liter 30 ml

2. Fully press and release the primer bulb 5 to 7

times. See Fig. 10 for the primer bulb location.

3. Place the choke lever in the full “choke”

position. See Fig. 11.

4. With the unit on the ground, squeeze the throttle

trigger fully and pull the starter rope briskly

(Fig. 12) until the engine sounds like it wants to

run. (Normally 2 to 5 pulls).

5. Place the choke lever in the “partial” choke

position (Fig. 11). Pull the starter rope briskly 1

to 3 times to start the engine (Fig. 12).

6. If the engine does not start, repeat steps 3

through 5.

7. After the engine warms up for 5 to 10 seconds,

place the choke lever in the “run” position

(Fig. 11).

8. To stop the engine, hold the kill switch in the

“off” position until the engine stops (Fig. 9).

EN–7

Page 19

Note: When storing the unit or when setting

unit down between uses, place the unit

flat on the floor so it sits on its stand

instead of hanging it by the guard or

the cutting head (Fig. 13).

Note: Always keep the trimming line fully

extended. Line release becomes more

difficult as cutting line becomes

shorter.

Each time the head is bumped, about 1 inch

(25.4 mm) of trimming line is released. A blade in the

weed guard will cut the line to the proper length if

excess line is released.

Adjusting The Trimming Line

Length

Your trimmer is equipped with a bump head that

allows the operator to release more trimming line

without stopping the engine. To release additional

line, lightly tap the trimming head on the ground

(Fig. 14 – Model 51903, Fig. 15 – Model 51906)

while operating the trimmer at high speed.

For best results, tap the head on bare ground or hard

soil. If line release is attempted in tall grass, the

engine may stall.

Decorative Trimming

Decorative trimming is accomplished by removing all

vegetation around trees, posts, fences, etc.

(Fig. 16 – Model 51903, Fig. 17 – Model 51906).

Maintenance

Maintenance Schedule

These required maintenance procedures should be performed at the frequency stated in the table to ensure that

your unit continues to meet the 1995 California emission regulations. They should also be included as part of any

seasonal tune-up.

Frequency Maintenance Required Refer to:

Before starting engine Fill fuel tank with correct oil and fuel mixture. Page 7

Every 10 hours Clean and re-oil air filter. Page 10

Every 25 hours Inspect and clean muffler. Page 12

Every 50 hours Check spark plug condition and gap. Page 11

Line Installation

The trimming line may be replaced by two different

methods — rewinding the existing reel or installing a

prewound reel.

Rewinding The Existing Reel

To rewind the existing reel you must:

1. Check for the correct line size.

2. Remove the existing reel and spring.

3. Wind the existing reel with the new line.

4. Reinstall the existing reel and spring.

EN–8

Page 20

The Correct Line To Use

POTENTIAL HAZARD

• Use of improper line could cause line to

break and be thrown in operator’s or

bystander’s direction.

WHAT CAN HAPPEN

• Use of improper line could result in serious

personal injury.

Winding The Existing Reel

1. Take approximately 25 ft (7.6 m) of new

trimming line, loop it into two equal lengths.

Insert each end of the line through one of the two

holes in the inner reel (Fig. 22). Pull the line so

that the loop is as small as possible.

2. Wind the lines, in even and tight layers, onto the

reel (Fig. 23). Wind the line in the direction

indicated on the inner reel. Be sure not to

overlap the two ends of the line.

HOW TO AVOID THE HAZARD

• Use only Toro approved replacement

monofilament line.

• Do not use any type of wire or other

string–like substance. Do not use

metal-reinforced line.

It is very important to use the correct size line. A line

with a diameter of .080 inches (2.03 mm) must be

used. The engine may overheat and fail if you use

a larger line.

Removing The Existing Reel

1. Stop engine and wait for all moving parts to

stop. Pull wire off spark plug.

2. Hold the outer spool with one hand and unscrew

the Bump Knob counterclockwise (Fig. 18).

Inspect the captured bolt inside the Bump Knob

to make sure it moves freely. Replace the Bump

Knob if it is damaged.

Note: Place your index finger between the

two lines to stop the lines from

overlapping.

Note: Failure to wind the line in the direction

indicated will cause the bump head to

operate incorrectly.

3. Insert the ends of the line into the two holding

slots (Fig. 24).

Reinstalling The Reel

1. Insert the ends of the line through the eyelets in

the outer spool (Fig. 25), then grasp the ends and

pull firmly to release the line from the holding

slots in the spool.

2. Hold the inner reel in place and install the Bump

Knob in the clockwise direction (see Fig. 18).

Line installation is now complete.

3. Remove the inner reel (Fig. 19).

4. Use a clean cloth to clean the inner surface of the

outer spool (Fig. 20).

Note: Always clean the inner reel, outer

spool, and shaft before reassembling

the bump head.

5. Check the indexing teeth on the inner reel and

outer spool for wear (Fig. 21). If necessary,

deburr or replace the reel and spool.

EN–9

Installing A Prewound Reel

1. Follow the instructions in THE CORRECT

LINE TO USE.

2. Follow the instructions in REMOVING THE

EXISTING REEL.

3. Follow the instructions in REINSTALLING

THE REEL.

Page 21

Air Filter Maintenance

Note: CLEAN AND RE-OIL THE AIR

FILTER EVERY 10 HOURS OF

OPERATION. Your unit’s air filter is

one of the most important areas to

maintain. If it is not maintained, you

will void the warranty. Before

cleaning, make sure the unit is turned

off.

The condition of the air filter is important to the

operation of the trimmer. A dirty air filter will restrict

the air flow, which upsets the fuel-air mixture in the

carburetor. The resulting symptoms are often

mistaken for an out-of-adjustment carburetor.

Therefore, check the condition of the air filter

before adjusting the carburetor. Refer to Air Filter

Maintenance.

If the following conditions are experienced, it may be

necessary to adjust the carburetor:

1. Remove the screws on each side of the

carburetor/air filter cover assembly. Remove the

air filter cover (Fig. 11).

Note: The choke lever must be in the

“CHOKE” position to remove and

install the air filter cover.

2. Remove the air filter (Fig. 26).

3. Wash the filter in detergent and water (Fig. 27).

Rinse the filter thoroughly and allow it to dry.

4. Apply enough clean SAE 30 oil to saturate the

filter (Fig. 28).

5. Squeeze the filter to spread the oil (Fig. 29).

6. Reinstall the filter (see Fig. 26), air filter cover

and screws (see Fig. 11).

Note: If the unit is operated without the

carburetor/air filter cover assembled,

you will void the warranty.

Carburetor Adjustment

• The engine will not idle

• The engine hesitates or stalls on acceleration

• The loss of engine power that is not corrected by

cleaning the air filter and muffler

Note: Careless adjustments can seriously

damage your unit.

Adjusting the Carburetor

1. Clean the air filter if it is dirty. Refer to Air

Filter Maintenance.

2. Make the initial settings with the engine stopped.

These initial settings should allow you to start

and warm up the unit before making the final

adjustments.

Initial Idle Speed Setting

A. For Walbro carburetors: Back the idle

speed screw (Fig. 30) out

(counterclockwise) until it does not contact

the carburetor throttle lever. Then turn the

screw in (clockwise) until it just begins to

move the throttle lever; then continue

turning 2 full turns.

This unit is equipped with a diaphragm-type

carburetor that has been carefully calibrated at the

factory. In most cases, no further adjustment is

required.

Note: To meet the 1995 California emission

regulations, the carburetor has

adjustment needle limiter caps to

restrict the amount of adjustment.

B. For Zama carburetors: Back the idle speed

screw (Fig. 31) out (counterclockwise)

until it does not contact the throttle valve

located inside of the carburetor. This is

accomplished by carefully watching for the

movement of the throttle lever to stop. Then

turn the screw in (clockwise) until it just

begins to move the throttle lever, then

continue turning 1 1/2 turns.

EN–10

Page 22

3. Initial High Speed Mixture and Idle Speed

Mixture Needle Settings: Turn both the high

speed mixture and idle speed mixture needles

out (counterclockwise) until the limiter caps

stop.

B. Squeeze the throttle trigger. If the engine

falters or hesitates as it accelerates, turn the

idle speed mixture needle (Figs. 30 and 31)

out (counterclockwise) 1/16 turn at a time

until the engine accelerates rapidly.

C. If the idle speed changes significantly

because of Steps a and b, readjust the idle

speed screw (refer to Step 2).

POTENTIAL HAZARD

• Engine must be running to make some

carburetor adjustments.

• When engine is running, cutting head is

rotating and other parts are moving.

WHAT CAN HAPPEN

• Contact with rotating cutting head or other

moving parts could cause serious personal

injury or death.

HOW TO AVOID THE HAZARD

• Keep hands, feet and clothing away from

cutting head and other moving parts.

• Keep all bystanders and pets away from

unit while making carburetor adjustments.

4. Start the engine and let it run for a minute.

5. Release the throttle trigger and let the engine

idle. If the engine stops, turn the idle speed

screw (Figs. 30 and 31) in (clockwise) 1/8 turn

at a time (as required) until the engine idles.

Note: Forcing the limiter caps with a

screwdriver will damage the needle

tips and the seat in the carburetor body.

7. Final High Speed Mixture Needle

Adjustment:

A. High speed mixture needle adjustment is

not recommended without a precision high

speed tachometer.

B. The factory presets the high speed mixture

needle at 1-1/4 turns out from the closed

position. Your unit should perform well at

this setting. If additional adjustment of the

high speed mixture needle is required,

contact your local authorized service dealer.

Note: If the limiter caps are removed at any

time, your unit will no longer meet the

1995 California emission regulations

and you will void the warranty.

Note: If the carburetor adjustments do not

help the unit to run properly, contact

your authorized service dealer.

Replacing The Spark Plug

Use a Champion RDJ7Y spark plug (or equivalent).

Correct air gap is 0.020 in (0.5 mm). Remove plug

after every 50 hours of operation and check its

condition.

6. Final Idle Speed Screw and Idle Speed

Mixture Needle Settings: Adjust the idle speed

screw and idle speed mixture needle for

smoothest engine idle.

A. Turn the idle speed mixture needle (Figs. 30

and 31) in (clockwise) until you hear the

fastest idle; then turn the needle out

(counterclockwise) 1/8 turn.

EN–11

1. Stop the engine and pull the wire off of the spark

plug.

2. Clean around the spark plug and remove it from

the cylinder head.

Note: Replace a cracked, fouled or dirty

spark plug. Do not sand blast, scrape

or clean electrodes because the engine

could be damaged by grit entering the

cylinder.

Page 23

3. Set the air gap at 0.020 in (0.5 mm) using a wire

feeler gauge (Fig. 32). Install a correctly gapped

spark plug into the cylinder head. Torque to

110-120 in•lb (12.3-13.5 N•m).

Muffler Reassembly

1. Install a new gasket. Make sure the arrow

stamped into the gasket is to your right. Tuck the

tab (with the arrow) between the cylinder and

plastic shroud (Fig. 35).

Inspecting/Cleaning The

Muffler

The muffler should be removed every 25 hours of

operation to inspect for excessive carbon build-up.

Excessive deposits around the exhaust ports or

exhaust holes will cause poor engine performance.

Use the following procedure to remove, inspect, clean

and reinstall the muffler.

POTENTIAL HAZARD

• Muffler surface becomes hot when trimmer

is in operation and remains hot for some

time after the engine is shut off.

WHAT CAN HAPPEN

• Contact with hot muffler surfaces could

cause a burn.

2. Install the muffler with the muffler mounting

bolts (see Fig. 33) and torque the bolts to 80-90

in•lb (9-10.1 N•m).

Cleaning

POTENTIAL HAZARD

• When engine is running, cutting head is

rotating and other parts are moving.

WHAT CAN HAPPEN

• Contact with rotating cutting head or other

moving parts could cause serious personal

injury or death.

HOW TO AVOID THE HAZARD

• Always turn off your trimmer before you

clean or perform any maintenance on it.

HOW TO AVOID THE HAZARD

• Make sure the muffler is cool before

inspecting and cleaning it.

1. Remove the muffler mounting bolts (Fig. 33).

2. Remove the muffler (with heat shield) and

gasket. Discard the old gasket.

Inspection And Cleaning

1. Check the inlet port of the muffler and outlet

port of the cylinder for excessive carbon deposits

(Fig. 34). Clean as required.

2. Inspect the muffler mounting holes for

elongation. Replace the muffler if the holes are

elongated.

Use a small brush to clean off the outside of the

trimmer. Do not use strong detergents on plastic

housing or handle. They can be damaged by

household cleaners that contain aromatic oils such as

pine and lemon, and by solvents such as kerosene.

Wipe off any moisture with a soft cloth.

Storage

If the trimmer will be stored for an extended period of

time, use the following storage procedure.

1. Drain all fuel from the fuel tank and drain into a

container with the same 2-cycle fuel mixture. Do

not use fuel that has been stored for more

than 60 days. Dispose of the old fuel/oil mix in

a safe manner and use a fresh mix.

EN–12

Page 24

2. Start the engine and allow it to run until it stalls.

g

This ensures that all fuel has been drained from

the carburetor.

3. Allow the engine to cool. Remove the spark plug

and put approximately 1 oz (30 ml) of any high

quality motor oil or 2-cycle oil into the cylinder.

Pull the starter rope slowly to distribute the oil.

Reinstall the spark plug.

Note: Remove the spark plug and drain all of

Troubleshooting

Problem Cause Action

the oil from the cylinder before

attempting to start the trimmer after

storage.

4. Thoroughly clean the unit and inspect for any

loose or damaged parts. Repair or replace

damaged parts and tighten loose screws, nuts or

bolts.

The unit is now ready for storage.

5. Store the trimmer in a dry, well-ventilated area

out of the reach of children.

Engine Will Not Start

Engine Will Not Idle Cutting head bound with grass Stop engine and clean cutting head

Engine Will Not Accelerate Carburetor misadjusted Adjust carburetor

Engine Lacks Power or Stalls When

Cutting

Cutting Head Will Not Advance Line Cutting head out of line Refill with new cutting line

Empty fuel tank Fill fuel tank

Primer bulb wasn’t pushed enough Press primer bulb fully and slowly

5-7 times

Engine flooded Use starting procedure WITHOUT

USING CHOKE

Throttle wire has come loose Tighten throttle wire

Dirty air filter Clean or replace air filter

No oil in fuel Add oil to fuel

Inner reel bound up Replace inner reel

Cutting head dirty Clean reel and spool

Indexing teeth worn or burred Replace reel and spool

Line welded Disassemble, remove the welded

section and rewind the line

Line twisted when refilled Disassemble and rewind reel

Not enough line is exposed Push the Bump Knob and pull out

102 mm (4 in) of line until the line is

outside of the cutting head

If further assistance is required, contact your local authorized Toro service dealer.

EN–13

Page 25

Specifications

Engine

Engine Type Air-Cooled, 2-Cycle

Stroke 1.25 in (31.75 mm)

Displacement 31 cc (1.9 cu. in)

Bore 1.37 in (34.79 mm)

Clutch Type None

Operating RPM 7000 rpm

Ignition Type Electronic

CD Module Air Gap 0.10-0.15 in

(0.254-0.381 mm)

Piston Ring Width 0.046 in (1.16 mm)

Piston Ring End Gap# 0.085 in (2.159 mm)

Piston Ring Side Clear-

ance

Average Compression 90 to 120 lbs.

Spark Plug Champion RDJ7Y

Spark Plug Gap 0.020 in (0.5 mm)

Lubrication Fuel/Oil Mixture

Fuel/Oil Ratio 32:1

Carburetor Diaphragm, All-Posi-

Starter Auto Rewind

Muffler Baffled with Guard

Throttle Manual, Spring Return

Fuel Tank Capacity 18 oz (530 ml)

Bearings Needle and Ball

Crankshaft Cantilevered

Connecting Rod Stamped Steel

0.005 in max.

(0.127 mm)

(41-55 kg)

tion

Drive Shaft & Cutting Head

Drive Shaft Chrome Vanadium,

1/4”

Drive Shaft Housing Steel Tube

Operating Weight Approx. 10.5 lbs

(4.73 kg)

Throttle Control Finger-Tip Trigger

Shoulder Strap Optional

Line Spool Bump Line Releaser

Line Spool Diameter 3 in (76.2 mm)

Trimming Line Diame-

ter

Cutting Path Diameter 18 in (45.7 cm)

0.080 in (2.03 mm)

Cold Engine Torque

Specifications

Cylinder Bolts 120 in•lb (13.5 N•m)

Muffler Bolts 80-90 in•lb

(9-10.1 N•m)

Carburetor Mount Bolts 15 in•lb (1.67 N•m)

Shroud Mounting Bolts 120 in•lb (13.5 N•m)

Module Mounting

Screws

Starter Housing

Screws

Air Cleaner Cover

Screws

Flywheel Nut 150 in•lb (16.9 N•m)

Spark Plug 110-120 in•lb

28 in•lb (3.2 N•m)

40 in•lb (4.5 N•m)

40 in•lb (4.5 N•m)

(12.3-13.5 N•m)

Fuel Tank HD Polyethylene

Reed Screw 15 in•lb (1.67 N•m)

EN–14

Page 26

California Emission

Control Warranty

Statement

Your Warranty Rights And

Obligations

engine, but Toro cannot deny warranty solely for

the lack of receipts or for your failure to ensure

the performance of all scheduled maintenance.

• As the lawn and garden equipment engine

owner, you should however be aware that Toro

may deny you warranty coverage if your lawn

and garden equipment engine or a part has failed

due to abuse, neglect, improper maintenance or

unapproved modifications.

The California Air Resources Board and Toro are

pleased to explain the emission control system

warranty on your 1995 lawn and garden equipment

engine. In California, new lawn and garden

equipment engines must be designed, built and

equipped to meet the State’s stringent anti-smog

standards. Toro must warrant the emission control

system on your lawn and garden equipment engine

for the periods of time listed below provided there

has been no abuse, neglect or improper maintenance

of your lawn and garden equipment engine.

Your emission control system may include parts such

as the carburetor or fuel injection system, the ignition

system, and catalytic converter. Also included may be

hoses, belts, connectors and other emission-related

assemblies.

Where a warrantable condition exists, Toro will repair

your lawn and garden equipment engine at no cost to

you including diagnosis, parts and labor.

The 1995 and later utility and lawn and garden

equipment engines are warranted for two years. If any

emission-related part on your engine is defective, the

part will be repaired or replaced by Toro.

• You are responsible for presenting your lawn and

garden equipment engine to a Toro Authorized

Service Dealer as soon as a problem exists. The

warranty repairs should be completed in a

reasonable amount of time, not to exceed 30

days.

If you have any questions regarding your warranty

rights and responsibilities, you should call

1–800–237–2654.

Manufacturer’s Warranty Coverage:

• The warranty period begins on the date the

engine or equipment is delivered to the retail

purchaser.

• The manufacturer warrants to the initial owner

and each subsequent purchaser, that the engine is

free from defects in material and workmanship

which cause the failure of a warranted part for a

period of two years.

• Repair or replacement of warranted part will be

performed at no charge to the owner at an

Authorized Toro Service Dealer. For the nearest

location, please contact Toro at:

1–800–237–2654.

Owner’s Warranty Responsibilities:

• As the lawn and garden equipment engine

owner, you are responsible for the

performance of the required maintenance

listed in your operator’s manual. Toro

recommends that you retain all receipts covering

maintenance on your lawn and garden equipment

EN–15

• Any warranted part which is not scheduled for

replacement, as required maintenance which is

scheduled only for regular inspection to the

effect of “Repair or replace as necessary” is

warranted for the warranty period. Any

warranted part which is scheduled for

replacement as required maintenance will be

warranted for the period of time up to the first

scheduled replacement print for that part.

Page 27

• The owner will not be charged for diagnostic

labor which leads to the determination that a

warranted part is defective, if the diagnostic

work is performed at an Authorized Toro Service

Dealer.

• The manufacturer is liable for damages to other

engine components caused by the failure of a

warranted part still under warranty.

• Failures caused by abuse, neglect or improper

maintenance are not covered under warranty.

• In order to file a claim, go to your nearest

Authorized Toro Service Dealer. Warranty

services or repairs will be provided at all

Authorized Toro Service Dealers.

• Any manufacturer approved replacement part

may be used in the performance of any warranty

maintenance or repair of emission related parts

and will be provided without charge to the

owner. Any replacement part that is equivalent in

performance or durability may be used in

non-warranty maintenance or repair and will not

reduce the warranty obligations of the

manufacturer.

• The use of add-on or modified parts can be

grounds for disallowing a warranty claim. The

manufacturer is not liable to cover failures or

warranted parts caused by the use of add-on or

modified parts.

• The following components are included in the

emission related warranty of the engine, air

filter, carburetor, primer, fuel lines, fuel pick

up/fuel filter, ignition module, spark plug and

muffler.

EN–16

Page 28

Hand Held

Gas Products

THE TORO TOTAL COVERAGE

GUARANTEE

A Full Warranty

(Limited Warranty for Commercial Use)

What Is Covered By This Express Warranty?

The Toro Company promises to repair any TORO Product

used for normal residential purposes* if defective in materials

or workmanship. The following time periods apply from the

date of purchase:

• TORO Hand Held Gas Products

with Model Numbers of 51911,

51916, 51918 and 58452 3 year full warranty. . . . . . . . . .

• All other TORO Hand Held

Gas Products 2 year full warranty. . . . . . . . . . . . . . . . . . . .

The cost of parts and labor is included, but the customer

pays the transportation costs.

*Normal residential purposes means use of the product on

the same lot as your home. Use at more than one location is

considered commercial use and the commercial use warranty would apply.

What Products Are Covered By This Warranty?

This warranty applies to all TORO Hand Held Gas Powered

Trimmers, Blowers/Vacs, Cultivators and Brushcutters. All

other TORO gas powered or electric powered products are

covered by separate warranty statements.

How About Commercial Use?

Toro Consumer Products used for commercial, institutional

or rental use are warranted against defects in material or

workmanship. The following time period applies from the

date of purchase:

• TORO Hand Held Gas Products

used Commercially 45 day limited warranty. . . . . . . . . . . .

Repair by an Authorized Toro Dealer is your sole remedy

under this warranty.

How Do You Get Warranty Service?

Should you feel your TORO Product requires warranty service, contact the retailer who sold you the product or any

Authorized TORO Service Dealer or TORO Master Service

Dealer. The Yellow Pages of your telephone directory is a

good reference source. The dealer will either arrange service

at his/her dealership or recommend another Authorized Service Dealer who may be more convenient. You may need

proof of purchase (copy of registration card, sales receipt,

etc.) for warranty validation.

If for any reason you are dissatisfied with the Service Dealer’s analysis of the defect in materials or workmanship or if

you need a referral to a TORO Service Dealer, please feel

free to contact us at the following address:

Toro Customer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420–1196

612–888–8801

800–237–2654

30 Day Satisfaction Guarantee

If for any reason you are not satisfied with your TORO Hand

Held Gas Product within the first 30 days of residential use,

you may return the product to the retail outlet where purchased. The retailer will offer the purchaser the option of either a refund of the original purchase price or credit for the full

value toward the purchase of a similar TORO Hand Held Gas

Product. All refund or credit arrangements must be made

through the retailer who originally sold you the TORO Hand

Held Gas Product.

What Must You Do To Keep The Warranty

In Effect?

You must maintain your TORO Product by following the maintenance procedures described in the operator’s manual. Such

routine maintenance, whether performed by a dealer or by

you, is at your expense.

What Does This Warranty Not Cover?

and

How Does Your State Law Relate To This Warranty?

There is no other express warranty. This express warranty

does not cover:

• Cost of regular maintenance service or parts, such as filters, fuel, lubricants, tune–up parts, blade sharpening or

cable/linkage adjustments.

• Any product or part which has been altered or misused or

required replacement or repair due to accidents or lack of

proper maintenance.

• Repairs necessary due to improper fuel, contaminants in

the fuel system, or failure to properly prepare the fuel system prior to any period of non–use over three months.

• Pickup and delivery charges.

All repairs covered by this warranty must be performed by an

Authorized TORO Service Dealer using Toro approved replacement parts.

The Toro Company is not liable for indirect, incidental or

consequential damages in connection with the use of the

TORO Products covered by this warranty, including any

cost or expense of providing substitute equipment or service during reasonable periods of malfunction or non–

use pending completion of repairs under this warranty.

Some states do not allow exclusions of incidental or consequential damages, so the above exclusion may not apply to you.

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

COUNTRIES OTHER THAN THE UNITED STATES AND CANADA

Customers who have purchased TORO products exported from the United States or Canada should contact their TORO

Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied

with your Distributor’s service or have difficulty obtaining guarantee information, contact the TORO importer. If all other

remedies fail, you may contact us at The Toro Company.

Page 29

Contenido

Introducción

Página

Introducción 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seguridad 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repostado y antes de comenzar la tarea 2. . .

Durante el funcionamiento 3. . . . . . . . . . . . .

Mantenimiento y almacenamiento 3. . . . . . .

Calcomanías de seguridad e instrucciones 4

Glosario de símbolos 5. . . . . . . . . . . . . . . . .

Montaje 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instalación de la manija D 6. . . . . . . . . . . . .

Instalación de la protección del cordel 6. . . .

Antes de comenzar 6. . . . . . . . . . . . . . . . . . . . . . .

Aceite y combustible 6. . . . . . . . . . . . . . . . .

Mezcla del aceite y el combustible 8. . . . . .

Funcionamiento 8. . . . . . . . . . . . . . . . . . . . . . . . .

Arranque/Parada 8. . . . . . . . . . . . . . . . . . . . .

Ajuste de la longitud de la línea de recorte 9

Recorte decorativo 9. . . . . . . . . . . . . . . . . . .

Mantenimiento 10. . . . . . . . . . . . . . . . . . . . . . . . . .

Programa de mantenimiento 10. . . . . . . . . . .

Instalación de la línea 10. . . . . . . . . . . . . . . . .

Instalación de un carrete rebobinado

previamente 11. . . . . . . . . . . . . . . . . . . . . . .

Mantenimiento del filtro de aire 11. . . . . . . . .

Ajuste del carburador 12. . . . . . . . . . . . . . . . .

Reemplazo de las bujías 13. . . . . . . . . . . . . . .

Inspección/Limpieza del silenciador 14. . . . .

Limpieza 14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Almacenamiento 15. . . . . . . . . . . . . . . . . . . . . . . .

Localización de averías 16. . . . . . . . . . . . . . . . . . .

Especificaciones técnicas 17. . . . . . . . . . . . . . . . . .

Motor 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Eje impulsor y cabeza de corte 17. . . . . . . . . .

Especificaciones del par de apriete del

motor frío 18. . . . . . . . . . . . . . . . . . . . . . . . .

Garantía de control de emisiones en California 19.

Garantía 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gracias por comprar un producto Toro.

Todo el personal de Toro queremos que esté

totalmente satisfecho con su nuevo producto. Por ello

le rogamos que se ponga en contacto con su

concesionario local autorizado, que dispone de piezas

de repuesto Toro genuinas y le podrá ayudar con los

problemas técnicos y asistirle en todo momento.

Siempre que se comunique con el Concesionario de

Servicio Autorizado o con la fábrica, tenga a mano

los números de modelo y serie del producto. Estos

números ayudarán al Concesionario de Servicio o al

Representante de Servicio a proporcionarle una

información precisa acerca de su producto

determinado. Encontrará la calcomanía con los

números de modelo y serie en un lugar especial en el

producto (Fig. 1).

Para su comodidad, anote a continuación el modelo y

el número de serie de su producto.

No. del modelo:

No. de serie:

Lea este manual detenidamente para aprender a

utilizar y mantener correctamente su producto. La

lectura de este manual le ayudará a Vd. y a otros a

evitar lesiones corporales y daños a la máquina.

Aunque Toro diseña, fabrica y comercializa productos

seguros y de la más alta calidad, Vd. es el responsable

de utilizar el producto de forma segura y adecuada.

Vd. también es el responsable de instruir a las

personas a las que tiene intención de dejar utilizar la

máquina, para que la usen según las normas de

seguridad.

A lo largo de este manual, Toro ha incluido avisos

que identifican peligros potenciales y mensajes de

seguridad especiales que le ayudarán a Vd. y a otros a

evitar las lesiones corporales, incluso la muerte. Las

palabras utilizadas para indicar estos mensajes e

ES–1

Page 30

identificar el nivel de riesgo son PELIGRO,

ADVERTENCIA y CUIDADO. No obstante, sin

importar el nivel de riesgo, sea extremadamente

cuidadoso.

PELIGRO señala una situación extremadamente

arriesgada que causará lesiones graves, incluso la

muerte, si no se siguen las precauciones indicadas.

Si en su área es necesario el uso de

estos accesorios, póngase en contacto

con su concesionario para que instale

el kit del supresor de chispas, n° de

ref. 180030, de la sección Accesorios

opcionales.

ADVERTENCIA señala un riesgo que puede causar

lesiones graves, incluso la muerte, si no se siguen las

instrucciones indicadas.

CUIDADO señala un riesgo que puede causar

lesiones leves o moderadas si no se siguen las

instrucciones indicadas.

También se utilizan otras dos palabras para resaltar

cierto tipo de información. “Importante” llama la

atención sobre informaciones técnicas especiales y

“Nota” hace hincapié sobre informaciones generales

que es conveniente resaltar.

Seguridad

Nota: Para los usuarios que habiten en los

bosques de EE.UU., y en los estados

de California, Maine, Oregon y

Washington. Todos los bosques de

EE.UU. y el estado de California

(Código de Recursos Públicos 4442 y

4443), Oregon y Washington

requieren, por ley, que ciertos motores

de combustión interna utilizados en las

zonas cubiertas de bosque y/o de

hierba estén equipados con un supresor

de chispas, se mantengan en perfecto

estado de funcionamiento o que el

motor hay sido fabricado, equipado y

mantenido para evitar los incendios.

Consulte a las autoridades estatales y

locales para obtener información

relativa a estos requisitos. El

incumplimiento de estos requisitos

puede hacerle merecedor de una multa

o responsable de los posibles daños.

Esta unidad no viene equipada de

fábrica con un supresor de chispas.

Repostado y antes de

comenzar la tarea

1. La gasolina es extremadamente inflamable y, si

se inflama, sus vapores pueden explotar. Pare

siempre el motor y espere a que enfría antes de

llenar el depósito de combustible. No fume

mientras reposta. Manténgase alejado de chispas

y de llamas desnudas.

2. Almacene la gasolina y el combustible sólo en

recipientes diseñados y aprobados para estos

materiales.

3. En el depósito de combustible puede producirse

un aumento de presión. Afloje lentamente la tapa

del depósito para liberar la presión que pudiera

haber en el mismo.

4. Añada el combustible en un área bien ventilada.

Limpie inmediatamente el combustible

derramado. Si se ha derramado combustible,

espere a que seque completamente antes de

poner en marcha el motor.

5. Antes de poner en marcha el motor, separe la

recortadora al menos 3 m del punto de

repostado.

6. Inspeccione minuciosamente la recortadora en

busca de piezas flojas o dañadas antes de cada

utilización. No la utilice hasta que se hayan

efectuado todas las reparaciones.

7. Evite los arranques accidentales. Colóquese en el

punto donde desea comenzar a trabajar antes de

halar la cuerda de arranque.

8. Mantenga a los espectadores, especialmente los

niños, y a los animales domésticos, a una

distancia mínima de 10 m del área de trabajo.

ES–2

Page 31

9. Inspeccione cuidadosamente el área que se va a

cortar. Elimine toda la suciedad que pudiera

enredarse en el cordel o en la cuchilla. Retire

también los objetos que pudieran ser lanzados

durante el proceso de corte.

10. Antes de comenzar, cerciórese de que la cabeza

del cordel no esté en contacto con ningún objeto.

11. Permanezca siempre alerta. Para evitar lesionarse

o lesionar a otras personas, no opere la

recortadora si está cansado.

7. Opere esta recortadora solamente en exteriores

bien ventilados. Los vapores de monóxido de

carbono de los gases de escape en un área

confinada pueden ser mortales.

8. Si golpea o se enreda con un objeto extraño, pare

inmediatamente el motor y compruebe si se han

producido daños.Si golpea o se enreda con un

objeto extraño, pare inmediatamente el motor y

compruebe si se han producido daños. Repare

los daños antes de volver a utilizar la

recortadora. No haga funcionar la recortadora

con piezas flojas o deterioradas.

12. No opere la unidad si está bajo los efectos de

drogas, alcohol o medicamentos.

Durante el funcionamiento

1. Mientras utilice la recortadora, lleve siempre

gafas de seguridad.

2. Vístase adecuadamente. No opere la recortadora

descalzo o con sandalias. Utilice siempre calzado

resistente y con suela de goma. Se recomienda el

uso de guantes, pantalones largos y protección

en los oídos.

3. No utilice ropas sueltas o accesorios tales como

bufandas, cordones, cadenas, corbatas, etc., ya

que la admisión de aire podría tirar de ellos.

Cerciórese también de que el cabellos largo no se

introduzca en la admisión de aire.

4. Mantenga las manos, la cara y los pies lejos de

las piezas móviles. No intente tocar o parar el

cordel cuando esté girando.

9. Utilice la herramienta adecuada. Utilice la

recortadora sólo para la tarea para la cual ha sido

diseñada .

10. No fuerce la máquina a una velocidad superior a

la que resulte eficaz para el corte.

11. No intente recortar hierba que esté fuera de su

alcance. Mantenga siempre el equilibrio y los

pies firmemente en el suelo.

12. No haga funcionar el motor a una velocidad

superior a la necesaria para el corte, recorte o

ribeteado. No haga funcionar el motor a un

régimen elevado cuando no esté cortando la

hierba..

13. La protección del cordel debe estar colocada

siempre que la recortadora esté funcionando.

14. No extienda la línea de recorte más allá de la

longitud especificada en el presente manual.

15. Pare siempre que el motor cuando deje de cortar

o cuando se traslade de una zona de corte a otra.

Mantenimiento y

5. No toque el silenciador o el cilindro. Estas

piezas se calientan considerablemente y

permanecen calientes cierto tiempo después de

haber apagado el equipo.

6. Sujete siempre la recortadora con ambas manos,

mientras esté en funcionamiento. Sujete

firmemente tanto la manija delantera como la

trasera.

almacenamiento

1. Cuando repare esta recortadora, utilice

únicamente piezas de repuesto originales de

Toro. Puede conseguir estas piezas en su

concesionario autorizado. El uso de piezas que

no sean estándar u otros accesorios o aperos no

aprobados para esta recortadora, podrían causar

lesiones serias al usuario o daños a la

recortadora, e invalidar su garantía.

ES–3

Page 32

2. Guarde bajo llave y almacene la recortadora en

un local apropiado para evitar que sea utilizada

por personal no autorizado. Mantenga la unidad

fuera del alcance de los niños.

Calcomanías de seguridad e instrucciones

Las calcomanías de seguridad e instrucciones están colocadas en un lugar

fácilmente visible por el operador y lejos de las piezas potencialmente peligrosas.

Reemplace cualquier calcomanía dañada o despegada.

EN EL MOTOR

(N° de ref. 92-3332)

EN LA PLUMA

(N° de ref. 92-3328)

EN EL DEPÓSITO DE COMBUSTIBLE

(N° de ref. 92-3334)

ES–4

Page 33

Glosario de símbolos

Superficie caliente

Mantenerse a una

distancia segura de la

máquina

Leer el manual del

operador

Combustible Aceite

Utilizar protección

ocular y en los oídos

Objetos volantes –

Todo el cuerpo está

expuesto

Para obtener

información de

servicio, llame al:

1–800–237–2654

ES–5

Page 34

Montaje

Nota: Si no se respetan estas instrucciones,

puede producirse el fallo del eje de

flexión.

Instalación de la manija D

1. Empuje hacia abajo la manija D sobre el plumón

(Fig. 2).

2. Instale el perno, la arandela y la tuerca de

mariposa y apriételos (Fig. 2).

la protección del cordel apunte hacia el motor, y

sus orificios estén alineados con los orificios de

la parte superior del conjunto de la cabeza del

cordel.

3. Enrosque los tornillos con un destornillador

Phillips (Fig. 5).

Modelo 51906

1. Coloque la protección del cordel sobre la

montura de protección, por encima del conjunto

de la cabeza del cordel. Alinee los orificios para

tornillos de la protección del cordel con los

orificios para tornillos del conjunto del cordel

(Fig. 6).

Instalación de la protección

del cordel

PELIGRO POTENCIAL

• La recortadora puede arrojar objetos

extraños.

LO QUE PUEDE SUCEDER

• El contacto con los objetos lanzados puede

causar lesiones personales.

COMO EVITAR EL PELIGRO

• Nunca opere la cortadora sin las

protecciones del cordel colocadas.

Modelo 51903

1. Coloque la protección del cordel sobre el

plumón, por encima del montaje de la abrazadera

(Fig. 3).

2. Empuje la protección del cordel hacia la parte

superior del conjunto de la cabeza del cordel y

después gírela hasta colocarla correctamente

(Fig. 4). Se alcanza la posición correcta cuando

2. Coloque las tres tuercas hexagonales en los

orificios rebajados de la parte superior de la

protección (Fig. 7).

3. Instale los tornillos en los orificios de la parte

inferior de la protección. Apriete los tornillos

(Fig. 8).

Antes de comenzar

Aceite y combustible

ESTE MOTOR ESTÁ CERTIFICADO PARA

FUNCIONAR CON UNA MEZCLA DE

GASOLINA SIN PLOMO Y ACEITE.

Nota: CERCIÓRESE DE LEER

CUIDADOSAMENTE ESTAS

INSTRUCCIONES ANTES DE

INTENTAR ARRANCAR O HACER

FUNCIONAR ESTA UNIDAD. El uso

de aceite o combustible viejo o

inadecuado puede causar daños al

motor. Este tipo de daños invalidará la

garantía del motor.

ES–6

Page 35

PELIGRO POTENCIAL

• En ciertas condiciones, la gasolina es

extremadamente inflamable y altamente

explosiva.

LO QUE PUEDE SUCEDER

• Un incendio o una explosión causados por

gasolina pueden quemar al operador y

otras personas y causar daños materiales.

COMO EVITAR EL PELIGRO

• Utilice un embudo y llene el depósito de

combustible en el exterior, en un área

abierta y con el motor frío. Limpie la

gasolina derramada.

• No llene completamente el depósito de

gasolina. Añada gasolina hasta que el nivel

alcance desde 6 mm a 13 mm (1/4 a

1/2 pulgada) por debajo de la parte inferior

del cuello de llenado. Este espacio vacío en

el depósito permite la dilatación de la

gasolina.

• No fume nunca mientras maneja la

gasolina y manténgase alejado de llamas

desnudas o de lugares donde una chispa

pueda inflamar los vapores de la gasolina.

• Almacene la gasolina en un recipiente

homologado y manténgalo fuera del alcance

de los niños.

• No compre nunca una provisión de gasolina

para más de 30 días.

PELIGRO POTENCIAL

• La mezcla de gasolina/aceite contiene

destilados de petróleo.

LO QUE PUEDE SUCEDER

• La mezcla de gasolina/aceite puede ser

nociva o incluso mortal si se ingiere.

También puede irritar la piel.

COMO EVITAR EL PELIGRO

• No beba la mezcla de gasolina/aceite

• Evite un contacto prolongado con la piel.

Lávese cuidadosamente después de

manipular la mezcla.

• No vuelva a utilizar la botella de aceite.

IMPORTANT: Si se ingiere la mezcla de

gasolina/aceite, no induzca el vómito.

LLAME INMEDIATAMENTE A UN

MEDICO.

Tipo de combustible recomendado

Utilice gasolina sin plomo, fresca y limpia con

menos de 60 días de antigüedad.

Nota: EL combustible mezclado con alcohol

absorbe humedad (agua). Una cantidad

de 1% de humedad en el combustible

puede causar la separación del

combustible y del aceite y formar

ácidos durante el período de

almacenamiento.

Tipo de aceite recomendado

Con su producto se incluye una botella de 0,24 litros

de aceite de motor de 2 ciclos.

El aceite de 2 tiempos TORO está recomendado para

esta herramienta de exteriores. Si se utiliza un aceite

de 2 tiempos de cualquier otra marca, cerciórese de

que se trata de un aceite de alta calidad, formulado

para los motores de 2 tiempos refrigerados por aire.

Si fuera necesario utilizar este tipo de

combustible, utilice combustible

fresco, (menos de 60 días de

antigüedad) y mézclelo siguiendo las

instrucciones.

Definición de combustibles mezclados

Los combustibles de hoy en día suelen consistir en

mezclas de gasolina y uno o más compuestos

oxigenados, tales como el etanol, metanol o MTBE

(éter).

ES–7

Page 36

Utilización de combustibles mezclados

Si decide utilizar un combustible mezclado o su

utilización resulta inevitables, se recomienda tomar

las siguientes precauciones.

1. Utilice siempre una mezcla fresca de

combustibles según las indicaciones de su

manual del operario.

Mezcle cuidadosamente la proporción correcta de

aceite de motor de 2 tiempos con gasolina sin plomo

en un bidón de gasolina diferente, en una relación

32:1. No los mezcle directamente en el depósito de

combustible. Consulte en el cuadro siguiente las

relaciones de mezclado de aceite y de gasolina.

Cuadro de mezclado GASOLINA/ACEITE 32:1

2. Utilice el aditivo especial STA-BIL o un

equivalente.

3. Agite siempre la mezcla de combustible antes de

proceder al repostado.

4. Antes de almacenar la unidad, vacíe el depósito

y haga funcionar el motor hasta que se pare por

falta de gasolina.

Utilización de aditivos de combustible

El uso de un aditivo de combustible, del tipo del

Estabilizador de Gasolina STA-BIL o un

equivalente, inhibirá la corrosión y minimizará la

formación de depósitos gomosos. Añada 23 ml por

galón de combustible, siguiendo las instrucciones del

recipiente. NUNCA agregue aditivos de combustible

en el depósito de la máquina. El uso de un aditivo

puede mantener el combustible fresco por un

período de hasta 6 (seis) meses.

Gasolina Aceite

1 galón EE.UU. 4,0 oz.

(3,8 litros) (118 ml)

1 litro 30 ml

PELIGRO POTENCIAL

• La gasolina contiene gases que pueden

hacer aumentar la presión dentro del

depósito de combustible.

LO QUE PUEDE SUCEDER

• Cuando retire la tapa del depósito, el

combustible puede salir del depósito,

rociándole.

COMO EVITAR EL PELIGRO

• Retire lentamente la tapa del depósito para

evitar la lesiones producidas por la

pulverización de combustible.

Mezcla del aceite y el

combustible

Nota: Para mantener el motor en óptimas

condiciones y obtener un rendimiento

máximo, preste especial atención a las

instrucciones para el mezclado de

aceite y de combustible que aparecen

en el recipiente del aceite de 2 tiempos.

Utilice una relación de combustible/

aceite de 32:1 cuando utilice un aceite

de 2 tiempos. El uso de un combustible

incorrectamente mezclado puede dañar

seriamente al motor.

ES–8

Funcionamiento

Arranque/Parada

1. Mezcle la gasolina y el aceite y llene el depósito

de combustible con la mezcla resultante —

Según las instrucciones de la página 7.

2. Apriete a fondo y suelte la pera de cebado de 5 a

7 veces. Vea la Fig. 10 para localizar la pera de

cebado.

3. Coloque a fondo la palanca del obturador en la

posición “obturador’. Vea la Fig. 11.

Page 37

4. Con la unidad en el suelo, apriete completamente

el gatillo del acelerador y hale con fuerza la

cuerda de arranque (Fig. 12) hasta que suene

como si el motor quisiera arrancar.

(Normalmente de 2 a 5 haladas).

5. Coloque la palanca del obturador en la posición

“parcial” (Fig. 11). Hale con fuerza la cuerda de

arranque de 1 a 3 veces para poner en marcha el

motor (Fig. 12).

6. Si el motor no se pone en marcha, repita los

pasos del 3 al 5.

7. Después de que el motor se caliente durante 5 a

10 segundos, coloque la palanca del obturador en

la posición “funcionamiento” (Fig. 11).

Ajuste de la longitud de la

línea de recorte

Su recortadora está equipada con un tope que permite

al operario soltar más línea de recorte sin necesidad

de parar el motor. Para soltar una cantidad adicional

de línea, golpee ligeramente en el suelo la cabeza de

recorte (Fig. 14 – Modelo 51903, Fig. 15 –

Modelo 51906) mientras hace funcionar la

recortadora a alta velocidad.

Nota: Mantenga siempre la línea de recorte

completamente extendida. Se hace más

difícil soltar línea a medida que ésta se

hace más corta.

Cada vez que se golpea la cabeza, se liberan

aproximadamente 25,4 mm (1 pulgada) de línea de

recorte. Si se soltara una cantidad excesiva, una

cuchilla situada en el protector de maleza se encarga

de cortar la línea a la longitud adecuada.

8. Para detener el motor, mantenga el interruptor de

parar en la posición “OFF” hasta que se detenga

el mismo (Fig. 9).

Nota: Cuando almacene la unidad o cuando

la deje en el suelo entre tareas,

colóquela de forma que descanse sobre

su soporte, en vez de colgarla de la

protección o de la cabeza de corte

(Fig. 13).

Para obtener mejores resultados, golpee la cabeza

sobre un suelo desnudo o duro. Si se intenta soltar

línea mientras se trabaja en hierba de gran altura, el

motor puede calarse.

Recorte decorativo

El recorte decorativo se consigue retirando toda la

vegetación que se encuentra alrededor de los árboles,

los postes, las vallas, etc.

(Fig. 16 – Modelo 51903, Fig. 17 – Modelo 51906).

ES–9

Page 38

Mantenimiento

Programa de mantenimiento

Estos procedimientos de mantenimiento deben efectuarse a los intervalos indicados en el cuadro para garantizar

que su unidad cumpla con los requisitos de la regulación de emisiones del estado de California de 1995. También

deben formar parte de cualquier revisión estacional.

Frecuencia Mantenimiento necesario Consulte:

Antes de poner en

marcha el motor

Cada 10 horas Limpiar y engrasar el filtro de aire. Página 10

Cada 25 horas Inspeccionar y limpiar el silenciador. Página 12

Cada 50 horas Revisar el estado de la bujía y de la separación entre

Instalación de la línea

La línea de recorte puede reemplazarse de dos formas

distintas — rebobinando el carrete ya colocado o

instalando un carrete enrollado previamente.

Llene el depósito de combustible con la mezcla adecuada de aceite y de combustible.

los electrodos.

Qué línea debe utilizarse

PELIGRO POTENCIAL

Página 7

Página 11

• El uso de una línea incorrecta puede

Rebobinado del carrete ya colocado

Para rebobinar el carrete ya colocado:

provocar su ruptura y su lanzamiento en

dirección del operador o los espectadores.

LO QUE PUEDE SUCEDER

• El uso de una línea incorrecta puede causar

1. Compruebe que está utilizando el tamaño de

línea correcto.

2. Desmonte el carrete y el muelle colocados.

3. Rebobine el carrete con la línea nueva.

4. Vuelva a instalar el carrete y el muelle.

serias lesiones.

COMO EVITAR EL PELIGRO

• Utilice únicamente líneas de repuesto de un

solo filamento aprobadas por Toro.

• No utilice ningún tipo de cable u otros

materiales parecidos al cordel. No utilice

líneas con refuerzo metálico.

ES–10

Es muy importante utilizar el tamaño de línea

correcto. Se debe utilizar una línea con un diámetro

de 2,03 mm (0,08 pulgadas). Si se utiliza una línea

de mayor diámetro el motor podría recalentarse.

Desmontaje del carrete ya colocado

1. Pare el motor y espere a que todas las piezas

móviles se detengan. Saque el cable de la bujía.

Page 39

2. Sujete la bobina exterior con una mano y

desenrosque la perilla de tope en sentido

contrario a las agujas del reloj (Fig. 18).

Compruebe que el perno aprisionado dentro de la

perilla se mueve libremente. Reemplace la

perilla si estuviera dañada.

3. Desmonte el carrete interior (Fig. 19).

4. Utilice un paño limpio para limpiar la superficie

interior de la bobina exterior (Fig. 20).

Instalación del carrete

1. Introduzca los extremos de la línea a través de

los ojales de la bobina exterior (Fig. 25), después

agarre los extremos y tire firmemente para soltar

la línea de las ranuras de sujeción de la bobina.