Page 1

TC3, 4, 5000 GAS TRIMMER, MODELS 51643, 51644, 51645

Table of Contents – Page 1 of 4

ABOUT THIS MANUAL

SAFETY INFORMATION

FOR YOUR SAFETY...

SPECIFICATION

TOOL REQUIREMENTS:

TROUBLESHOOTING

MAINTENANCE

MAINTENANCE - AIR CLEANER

MAINTENANCE - MUFFLER

MAINTENANCE - SPARK PLUG

MAINTENANCE - FUEL FILTER

MAINTENANCE - COOLING SYSTEM

MAINTENANCE - TRIMMER IMPLEMENT

MAINTENANCE - PREPARATION FOR STORAGE

MAINTENANCE - GEARBOX LUBRICATION

SECTION 1 CARBURETOR

CARBURETOR OPERATION

CARBURETOR OPERATION - THE DIAPHRAGM PUMP

CARBURETOR OPERATION - FUEL METERING & MIXING

CARBURETOR OPERATION - THE PRIMER SYSTEM

CARBURETOR - REMOVAL

CARBURETOR - DISASSEMBLY

CARBURETOR - REASSEMBLY

CARBURETOR - INSTALLATION

CARBURETOR ADJUSTMENT - IDLE SPEED

CARBURETOR ADJUSTMENT - MIXTURE

CARBURETOR ADJUSTMENT - THROTTLE VALVE

SECTION 2 FUEL SYSTEM

FUEL TANK - FUEL TANK - REMOVAL

FUEL TANK - INSTALLATION

PRIMER PUMP - PRIMER PUMP - PROPER USE

PRIMER PUMP - OPERATION

PRIMER PUMP - DISASSEMBLY

PRIMER PUMP - INSPECTION

PRIMER PUMP - REASSEMBLY

FUEL PICKUP TUBE AND FILTER - SERVICE

FUEL CAP - FUEL CAP - OPERATION

Page 2

TC3, 4, 5000 GAS TRIMMER, MODELS 51643, 51644, 51645

Table of Contents – Page 2 of 4

SECTION 2 FUEL SYSTEM - Continued

FUEL CAP - DISASSEMBLY

FUEL CAP - INSPECTION

FUEL CAP - REASSEMBLY

SECTION 3 IGNITION

IGNITION OPERATION

IGNITION OPERATION - FLYWHEEL

IGNITION OPERATION - IGNITION COIL

IGNITION OPERATION - TRIGGER MODULE

IGNITION OPERATION - SPARK PLUG

AIR GAP ADJUSTMENT

TC3000/TC4000 AIR GAP ADJUSTMENT - PREPARATION

TC3000/TC4000 AIR GAP ADJUSTMENT

TC3000/TC4000 AIR GAP ADJUSTMENT - REASSEMBLY

TC5000 AIR GAP ADJUSTMENT - PREPARATION

TC5000 AIR GAP ADJUSTM ENT

TC5000 AIR GAP ADJUSTMENT - REASSEMBLY

COIL - COIL - REMOVAL

COIL - INSTALLATION

SECTION 4 RECOIL STARTER

RECOIL STARTER - OPERATION

RECOIL MECHANISM - REMOVAL

RECOIL MECHANISM - DISASSEMBLY

RECOIL MECHANISM - REASSEMBLY

RECOIL MECHANISM - INSTALLATION

STARTER PULLEY - REMOVAL

STARTER PULLEY - INSTALLATION

SECTION 5 CLUTCH SHOES AND FLYWHEEL

CLUTCH SHOES AND FLYWHEEL - OPERATION

CLUTCH SHOES AND FLYWHEEL - DISASSEMBLY

CLUTCH SHOES AND FLYWHEEL - INSPECTION

CLUTCH SHOES AND FLYWHEEL - REMOVAL

CLUTCH SHOES AND FLYWHEEL - REASSEMBLY

CLUTCH DRUM AND CLUTCH HOUSING - CLUTCH DRUM AND CLUTCH HOUSING -

CLUTCH DRUM AND CLUTCH HOUSING - REASSEMBLY

ISOLATION MOUNT (TC4000 AND TC5000 ONLY) - ISOLATION MOUNT -

ISOLATION MOUNT - DISASSEMBLY

ISOLATION MOUNT - REASSEMBLY

SECTION 6 ENGINE

ENGINE - OPERATION

ENGINE - REMOVAL FROM DRIVE TUBE

Page 3

TC3, 4, 5000 GAS TRIMMER, MODELS 51643, 51644, 51645

Table of Contents – Page 3 of 4

SECTION 6 ENGINE - Continued

ENGINE - DISASSEMBLY

ENGINE - CLEANING AFTER DISASSEMBLY

ENGINE - INSPECTION

ENGINE - REASSEMBLY

ENGINE - INSTALLATION ON DRIVE TUBE

SECTION 7 CONTROLS

CONTROL - DISASSEMBLY

CONTROL - REASSEMBLY

GRIP - REMOVAL

GRIP - INSTALLATION

SECTION 8 HANDLE

TC3000 HANDLE - REMOVAL FROM DRIVE TUBE

TC3000 HANDLE - INSTALLATION ON DRIVE TUBE

TC3000 HANDLE - ADJUSTMENT

TC4000 HANDLE - REMOVAL FROM TUBE

TC4000 HANDLE - INSTALLATION ON DRIVE TUBE

TC4000 HANDLE - ADJUSTMENT

TC5000 HANDLE - REMOVAL FROM DRIVE TUBE.

TC5000 HANDLE - INSTALLATION ON DRIVE TUBE

TC5000 HANDLE - ADJUSTMENT

SECTION 9 SHIELD

SHIELD - REMOVAL FROM DRIVE TUBE

SHIELD - INSTALLATION ON DRIVE TUBE

SHIELD - MOUNTING CUTTER KNIFE ON SHIELD

SECTION 10 GEARBOX

GEARBOX - REMOVAL

GEARBOX - INSTALLATION ON DRIVE TUBE

GEARBOX - SEAL REMOVAL

GEARBOX - SEAL INSTALLATION

SECTION 11 DRIVE SHAFT AND TUBE

DRIVE SHAFT - DRIVE SHAFT - REMOVAL

DRIVE SHAFT - INSTALLATION

DRIVE TUBE - DRIVE TUBE - REMOVAL

DRIVE TUBE - INSTALLATION

SECTION 12 LEECO MANUAL FEED HEAD

LEECO MANUAL FEED HEAD - SPOOL REMOVAL

LEECO MANUAL FEED HEAD - LINE REPLACEMENT

LEECO MANUAL FEED HEAD - SPOOL INSTALLATION

Page 4

TC3, 4, 5000 GAS TRIMMER, MODELS 51643, 51644, 51645

Table of Contents – Page 4 of 4

SECTION 12 LEECO MANUAL FEED HEAD - Continued

LEECO MANUAL FEED HEAD - DISASSEMBLY

LEECO MANUAL FEED HEAD - INSPECTION

LEECO MANUAL FEED HEAD - REASSEMBLY

SECTION 13 KAAZ MANUAL FEED HEAD

KAAZ MANUAL FEED HEAD - DISASSEMBLY

KAAZ MANUAL FEED HEAD - LINE REPLACEMENT

KAAZ MANUAL FEED HEAD - REASSEMBLY

SECTION 14 PLASTIC FIXED LINE HEAD

PLASTIC FIXED LINE HEAD - LINE REPLACEMENT

PLASTIC FIXED LINE HEAD - REMOVAL

SECTION 15 METAL FIXED LINE HEAD

METAL FIXED LINE HEAD - LINE REPLACEMENT

METAL FIXED LINE HEAD - REMOVAL

METAL FIXED LINE HEAD - INSTALLATION

SECTION 16 TAP AND TRIM HEAD

TAP AND TRIM LINE REPLACEMENT - TAP AND TRIM SPOOL -

TAP AND TRIM SPOOL - LINE REPLACEMENT

TAP AND TRIM SPOOL - INSTALLATION

TAP AND TRIM HEAD - DISASSEMBLY

TAP AND TRIM HEAD - INSPECTION

TAP AND TRIM HEAD - REASSEMBLY

SECTION 17 METAL BLADES

METAL BLADE - REMOVAL

METAL BLADE - INSTALLATION

SECTION 18 HARNESSES

STANDARD AND DELUXE HARNESS - ASSEMBLY

SECTION 19 SPARK ARREST O R MUFFL ER

SPARK ARRESTOR MUFFLER - REMOVAL

SPARK ARRESTOR MUFFLER - INSTALLATION

SPARK ARRESTOR MUFFLER - MAINTENANCE

Page 5

Page 6

ABOUT

This Service Manual was written expressly for the Tor0 TC3000, TC4000 and

TC5000 Gas Powered Trimmers. The Tor0 Company had made every effort to

make the information

in

this manual complete and correct.

THIS

MANUAL

This manual was written with the service technician

that information used most often is

information on safety, maintenance, specifications, special tools and

troubleshooting all

Disassembly, inspection and reassembly procedures are covered

two-thirds of the manual and are grouped by component. We tried to cover each

common repair with its own section or sub-section. For example, you will find

that air gap adjustment and ignition coil replacement are called out separately.

And, because certain components are often difficult to troubleshoot without a

good

understanding of how they work, we have included some component theory.

This information can be found of the beginning of most service procedure

sections.

We are hopeful that you will find this manual a valuable addition to your shop. If

you should come across any errors or if you have any questions regarding this

manual, please contact us at the following address:

in

the front third of

81

11

Bloomington, MN, USA 55420

up

front. As a result, you will find reference

the

manual.

The Tor0 Company

Lyndale Avenue South

in

mind.

It

is organized

in

so

the last

The Tor0 Company reserves the right to change product specifications or this

manual without notice.

The Tor0 Company gratefully acknowledges the assistance of Mitsubishi Heavy

Industries, Ltd.

in

the production of this manual.

COPYRIGHT@ ALL RIGHTS RESERVED

(C)

The Toro Company

MINNEAPOLIS,

MN

1987

55420 -USA

Page 7

Reference Information

Safety Information

Specifications 2

Tool Requirements

TABLE OF CONTENTS

Page

1

5

Service Procedures

Section

Section 2 Fuel System

1

Troubleshooting

Maintenance

Carburetor Page

operation 11

removal

disassembly 14

reassembly 16

installation 18

adjustment 18

Fuel Tank

removal 20

installation 20

6

8

14

Primer Pump

properuse 21

operation

disassembly 22

inspection 22

reassembly 22

Fuel Pickup Tube and Filter

service 23

Fuel Cap

operation 23

disassembly 24

inspection 24

reassembly 24

21

Page 8

Service Procedures (cont'd)

TABLE

OF

CONTENTS

Page

Section

5

operation

airgapadjustment

coilremoval

coil installation

Recoil Starter

Recoil Mechanism

operation

removal

disassembly

reassembly

installation

Starter Pulley

removal

installation

Clutch and lsomount

Clutch Shoes and Flywheel

operation

disassembly

inspection

25

27

28

29

30

30

30

31

32

33

33

34

34

34

Section

6

removal

reassembly

Clutch Drum and Housing

disassembly

reassembly

lsomount

Engine

(TC4000

operation

disassembly

reassembly

operation

removal

disassembly

cleaning after disassembly

inspection

and TC5000 only)

from

drive tube

35

35

35

35

36

37

37

38

40

41

42

43

Page 9

Service Procedures (cont’d)

Section 6 Engine (cont’d)) Page

TABLE

OF

CONTENTS

Section

Section

8

7

reassembly

installation on drive tube.

Control and Grip

Control

disassembly 46

reassembly

Grip

removal

installation

Handle

TC3000

removal from drive tube 48

Installation on drive tube. 48

adjustment

TC4000

removal from drive tube

installation on drive tube.

adjustment.

44

45

48

48

49

Section

Section

9

10

TC5000

removal from drive tube

installation on drive tube.

adjustment.

Shield

removal from drive tube

installation on drive tube.

mounting cutter knife on shield

Gearbox

removal from drive tube

installation on drive tube.

sealremoval

sealinstallation

49

50

50

52

52

53

54

54

Page 10

Service Procedures (cont’d)

Drive Shaft

Drive

TABLE

removal 56

installation 56

Tube

removal 56

installation 57

OF

CONTENTS

Section

Section

Section 14 Plastic Fixed Line Head

12

13

Leeco@ Manual Line Feed Head

sped

removal 58

linereplacement 58

installation 58

Head

disassembly 59

inspection 59

reassembly 59

Kaaz@ Manual Line Feed Head

head disassembly 61

linereplacement 61

headreassembly 62

linereplacement

headremoval 63

headinstallation 64

63

Section 15 Metal Fixed Line Head

linereplacement

headremoval

headinstallation

Section 16 Tap and Trim@ Head

Spool

removal 67

linereplacement 67

installation 67

65

65

66

Page 11

Service Procedures (cont’d)

TABLE

OF

CONTENTS

Section

Section 17

Section 18

Section 19

Tap and Trim@ Head (cont’d)

Head

disassembly 68

inspection 68

reassembly 68

Metal Blades

removal 69

installation 69

Harnesses

assembly

Spark Arrestor Muffler

removal 71

installation 71

maintenance 71

Page 16

70

Page 12

SAFETY INFORMATION

This manual is intended

this safety symbol manual only. The safety instructions provided

means WARNING

CAUTION product only. The individual Operator’s Manual will

A

INSTRUCTION Read the instruction TC3000.

because

Failure to comply with the instruction

may result

PERSONAL SAFETY contain safety information on the operation of the

it

has to do

in

personal injury

with

or

FOR

or

safety.

death.

YOUR SAFE

manual are for the troubleshooting and service of the

Operator’s Manuals with complete operational safety

instructions are available through:

as

TC4000.

Minneapolis,

or TC5000.

The Tor0 Company

Publications Department

81

11

Lyndale Avenue South

MN

TY...

a service and repair

55430

U.S.A.

in

this

I----

Avoid possible explosions Avoid unexpected starting of the engine

Store fuel in a container designed for gasoline and Always disconnect the spark plug wire before

never smoke while working around gasoline. attempting any cleaning, adjustment or repair.

Avoid fires Avoid contact with a moving cutter head

Never allow the trimmer engine closer than one meter Always stay clear of the cutter head when the engine

(three feet) to any combustible material. is running. The clutch is a mechanical device which

Avoid accidental misuse of fuel

Always store fuel in an approved container that is

properly labeled.

Avoid falls

Always wipe up spilled fuel or oil.

Avoid asphyxiation

Never operate an engine

proper ventilation.

in

a confined area without

could fail. Do not rely on

from turning.

Avoid blindness

Always wear eye protection when repairing or

running a gas trimmer.

Avoid hearing

Wear ear protection when running a gas trimmer.

loss

it

to keep the cutter head

1

Page 13

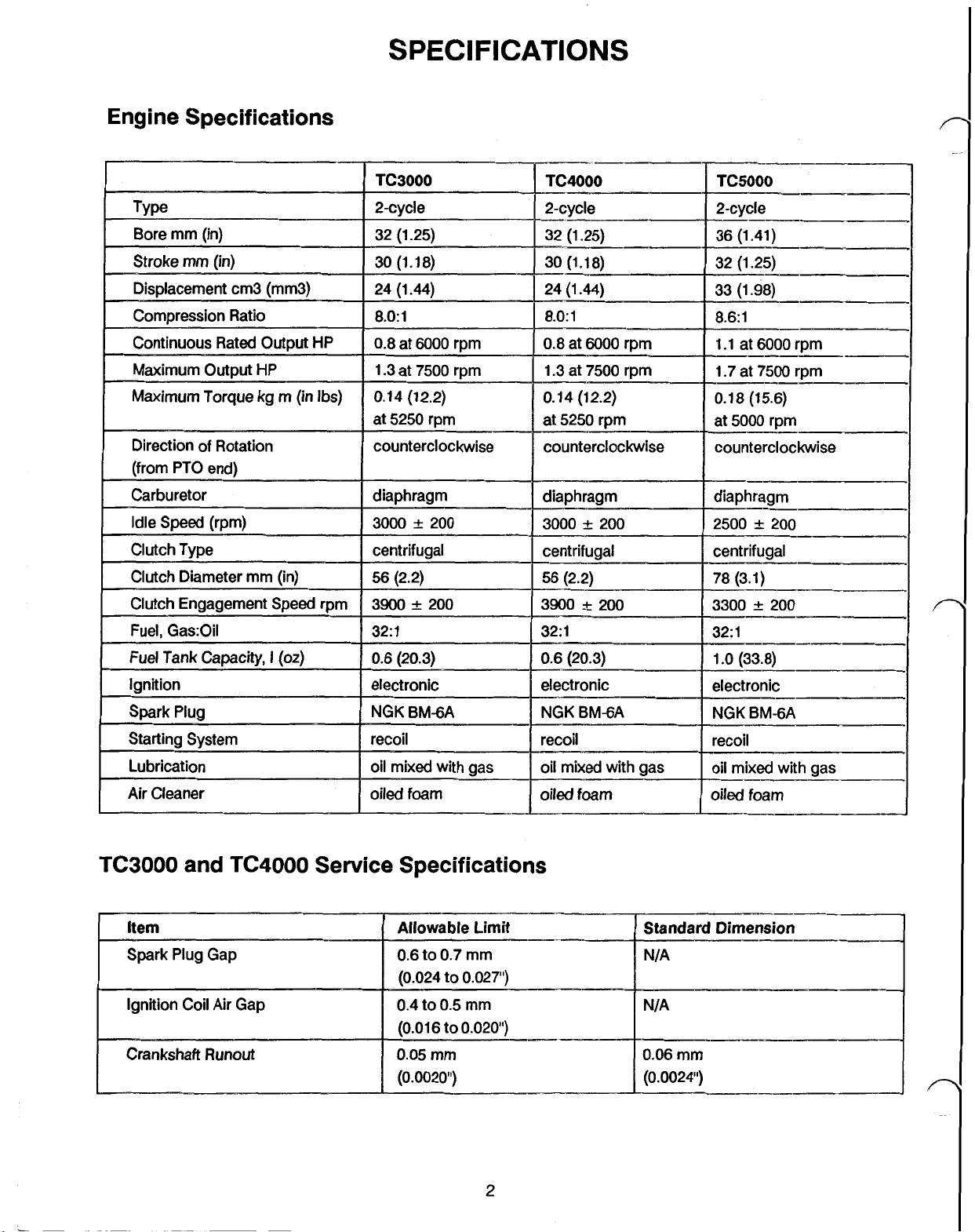

Engine Specifications

SPECIFICATIONS

TC3000

and

TC4000

Service Specifications

2

Page 14

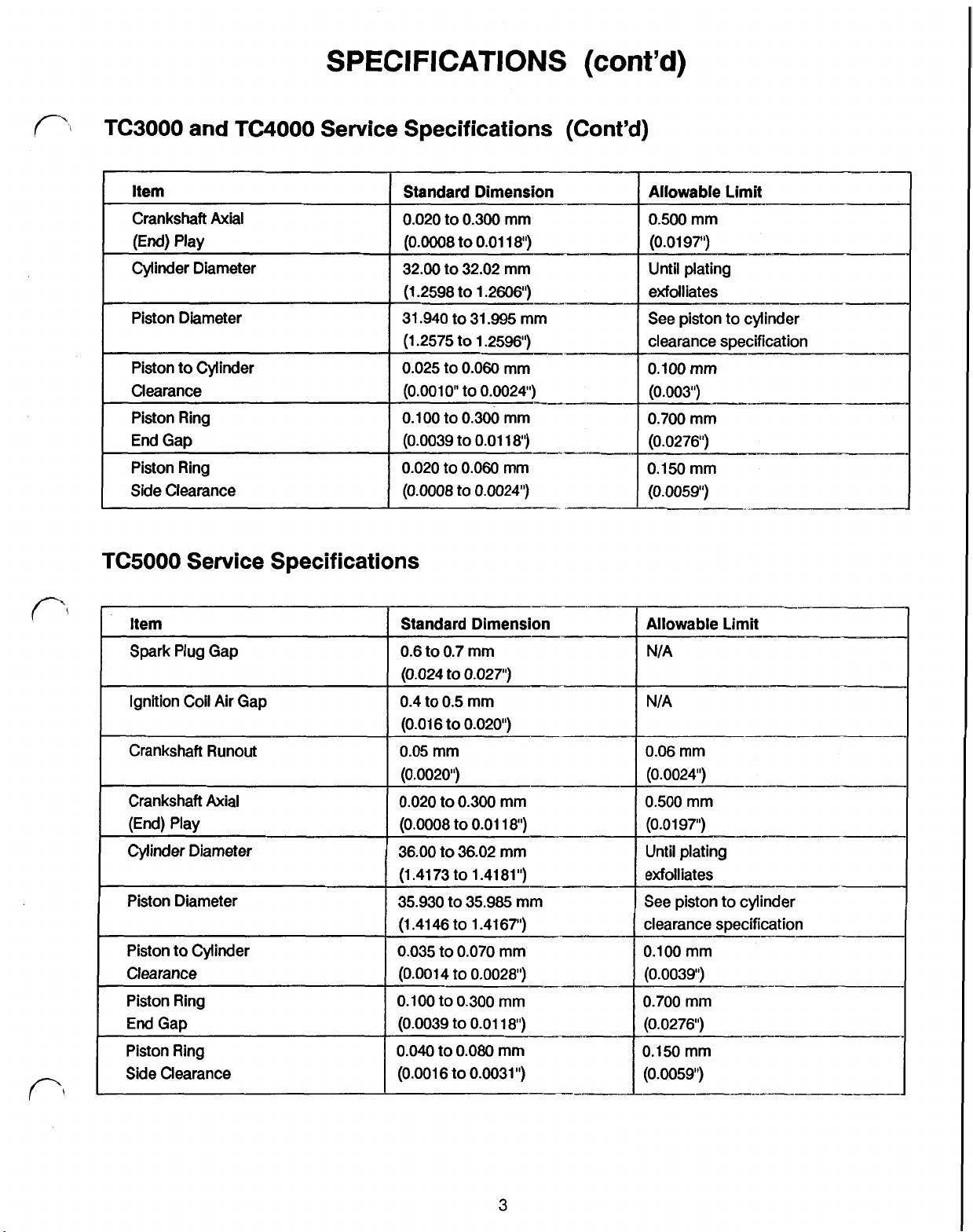

SPECIFICATIONS

(cont'd)

TC3000 and TC4000 Service Specifications (Cont'd)

Piston Ring

Side

Clearance

0.020

(0.0008

TC5000 Service Specifications

to

to

0.060

0.0024")

mm

0.150

mm

.

(0.0059")

3

Page 15

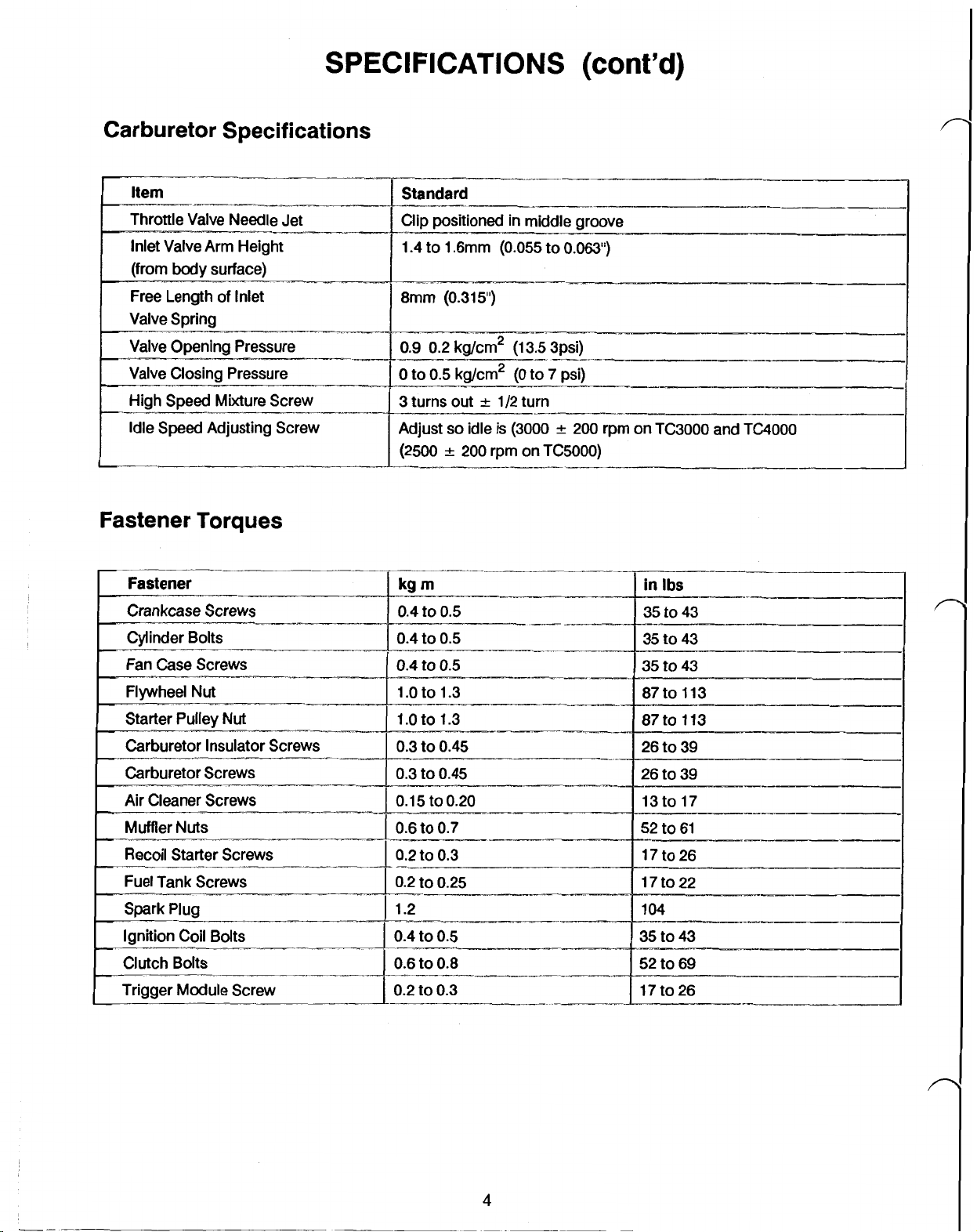

SPECIFICATIONS

Carburetor Specifications

Item Standard

Throttle Valve Needle Jet

1.4

to 1.6mm

(0.055

(cont'd)

to

0.W')

Idle Speed Adjusting Screw Adjust

Fastener Torques

Fastener

Crankcase Screws

(2500

kgm

0.4

to

so

0.5

idle

200

is

rpm

(3000

on

200

TCSOOO)

rpm on TC3000 and

in

Ibs

35 to 43

TC4000

Page 16

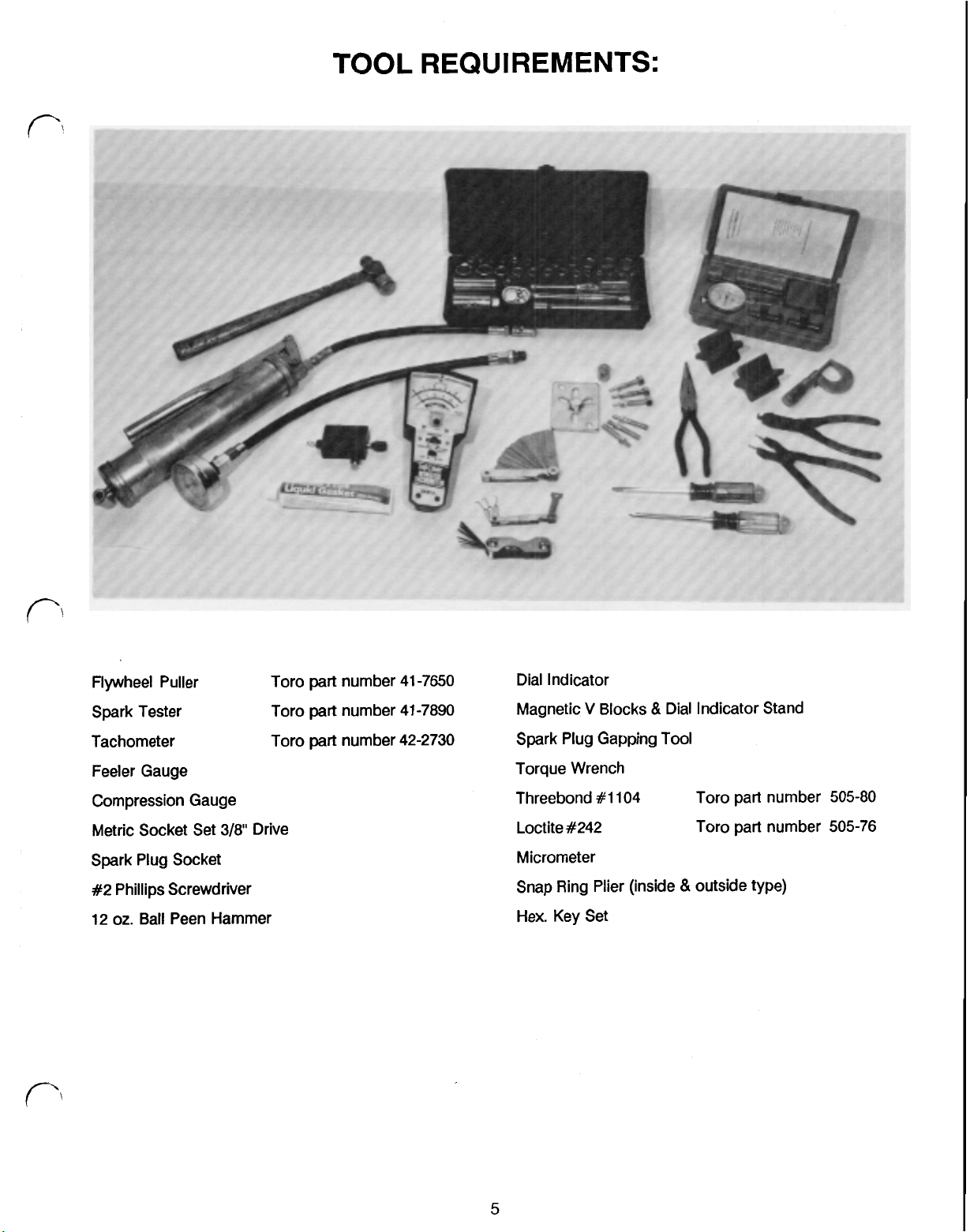

TOOL

REQUIREMENTS:

Flywheel Puller Tor0 part number 41-7650 Dial Indicator

V

Spark Tester Tor0 part number41-7890

Tachometer

Feeler Gauge

Compression Gauge

Metric Socket Set

Spark Plug Socket

#2 Phillips Screwdriver

12

oz.

Ball Peen Hammer

3/8”

Tor0

Drive

part number 42-2730

Magnetic

Spark Plug Gapping

Torque Wrench

Threebond #1104 Tor0 part number

Loctite #242 Tor0 part number

Micrometer

Snap Ring Plier (inside

Hex. Key Set

Blocks & Dial Indicator Stand

Tool

&

outside type)

505-80

505-76

5

Page 17

TROUBLESHOOTING

Engine Does Not Produce Spark

Engine

Floods

During Starting

Engine Not Getting Fuel

crankcase

leak

Page 18

TROUBLESHOOTING

Engine Lacks Power

Engine Has Low Compression

(cont’d)

Remedy

Engine Backfires (indicated by burnt air cleaner element)

Trimmer Vibrates Excessively

I

7

Page 19

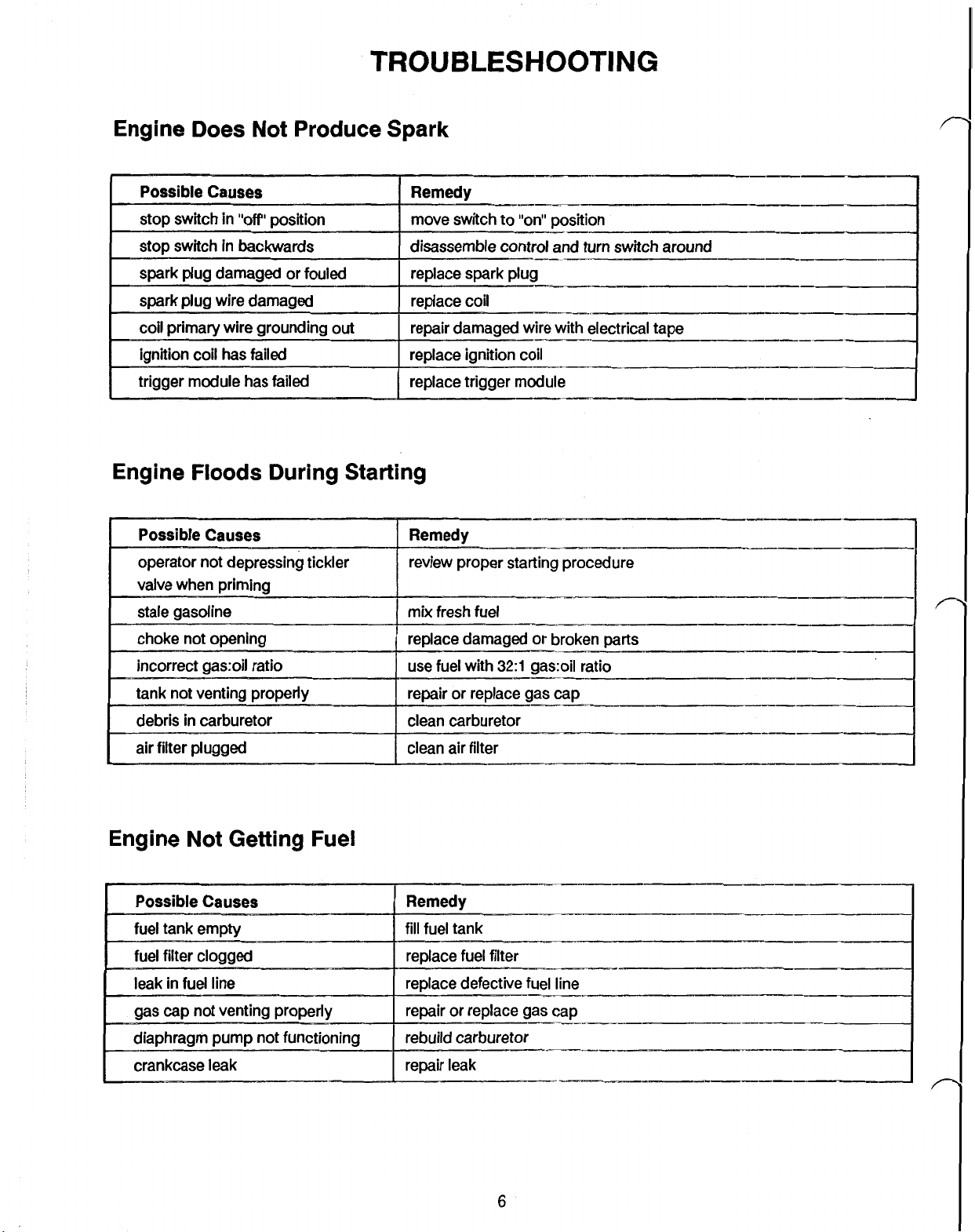

Maintenance

Air

Cleaner

Servicing of the air cleaner is recommended after every

25

hours of operation or more often in very dusty

conditions.

See

Figure

1.

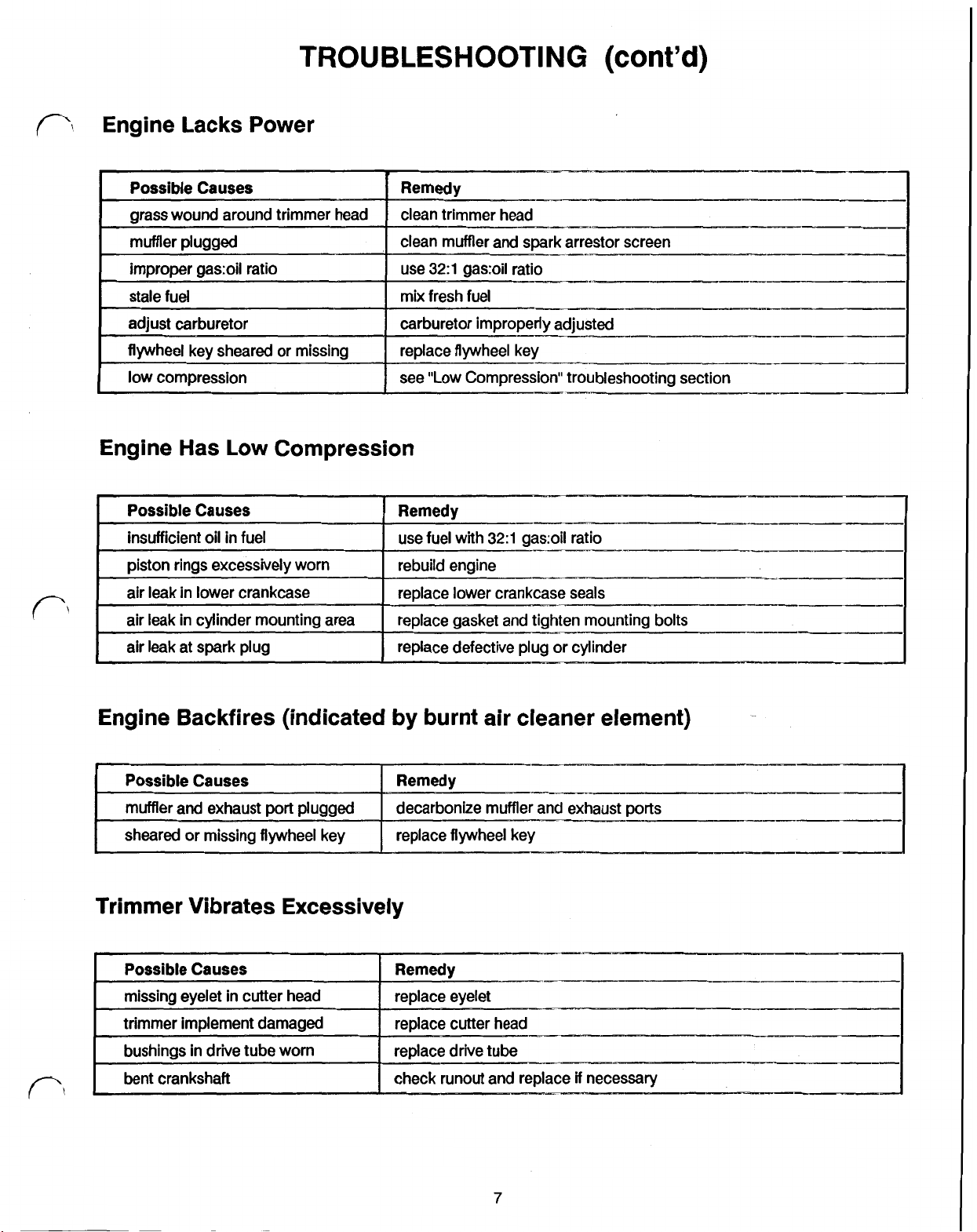

Maintenance Muffler

Decarbonizing the muffler is recommended after every

50

hours of operation or

drastically. See Figure

if

engine speed decreases

2.

AIR

1.

Remove the

FILTER

FILTER SCREEN

Figure

two

screws securing the air cleaner

1

GRID

FOAM FILTER

cover to the trimmer

Carefully remove the filter grid, foam filter and filter

2.

screen.

Figure

1.

Remove the three screws securing the muffler

2

cover to the trimmer.

2.

Remove the

two

nuts securing the muffler to the

engine.

3.

Rotate the engine crankshaft until the piston totally

covers the exhaust port. Clean the exhaust port

area by using a clean flat piece of hard wood.

Remove all loose particles.

Wash the foam filter in a soap and water solution

3.

and dry thoroughly.

damage replace

4.

Saturate the foam filter with 5ml (one teaspoon) of

SAE

30

oil, then squeeze to distribute the oil evenly

If

the filter shows any sign of

it.

and to remove excess oil. The element should be

damp but not wet.

Wash the filter screen in a clean solvent and air dry.

5.

If

the filter screen shows any signs of damage,

replace

Reinstall the air cleaner components as shown in

6.

Figure

it.

1.

Note that the flat side of the filter grid

faces the foam filter.

Tighten the air cleaner screws to

7.

(13

to

17.5

in Ibs)

0.15

to

0.20

kg m

8

IMPORTANT

the exhaust port. Stay clear

will

not be damaged.

4.

Inspect the inside of the muffler for excessive

carbon buildup.

Use extreme care

If

carbon buildup appears to be

when

of

the piston

cleaning

restricting the exhaust flow, replace the muffler.

Otherwise, clean the muffler by holding

it

vice grips and heating with a propane torch. Once

hot, break the carbon loose by hitting the muffler

on

a

hard surface. Ensure that the muffler is

completely free

of

all carbon particles before

reinstalling.

5.

Reinstall muffler using a new muffler gasket and

tighten all fasteners securely.

6.

Reinstall

the

muffler cover as shown in Figure

so

with a

1.

it

Page 20

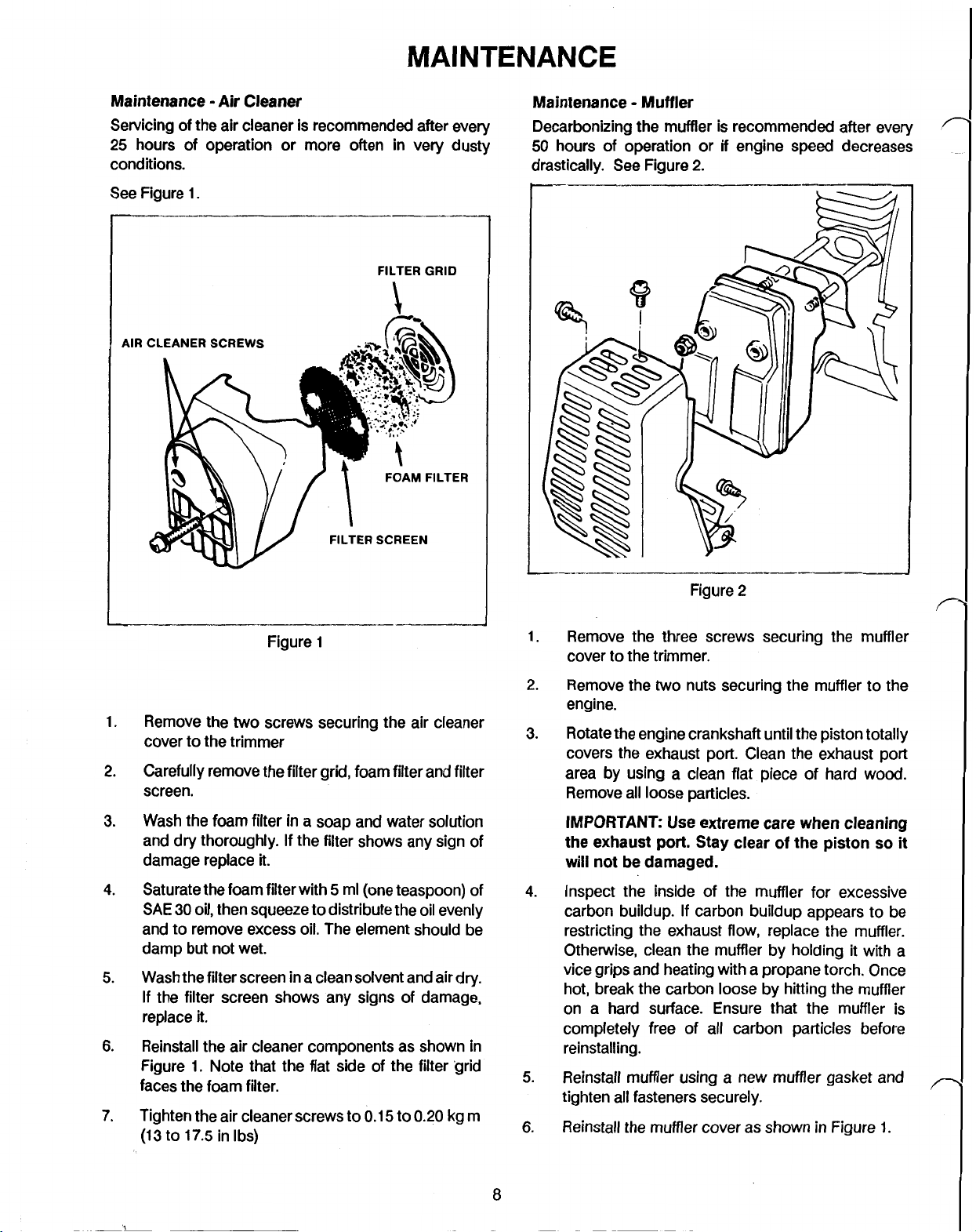

Maintenance Spark Plug

The TC3000,

BMGA spark plug or the equivalent. Correct gap is

mm

(0.024-0.028”).

for the spark plug is

1.

Stop the engine and pull

2.

Clean around the spark plug and remove the spark

plug from

IMPORTANT: Replace

spark plug.

TC4000

and the TC5000 each use an

The recommended servicing interval

25

hours of operation.

off

the spark plug wire.

the

engine using a 19mm

a

cracked, fouled or dirty

Do

not sand blast, scrape or clean

(3/4")

NGK

0.6-0.7

socket.

electrodes because engine damage could

result

from

grit entering the cylinder.

3.

Set the plug gap to 0.6-0.7mm

Figure

3.

I3

(.024-.028”)

.024

(0.6

0.7

See

.028"

mm)

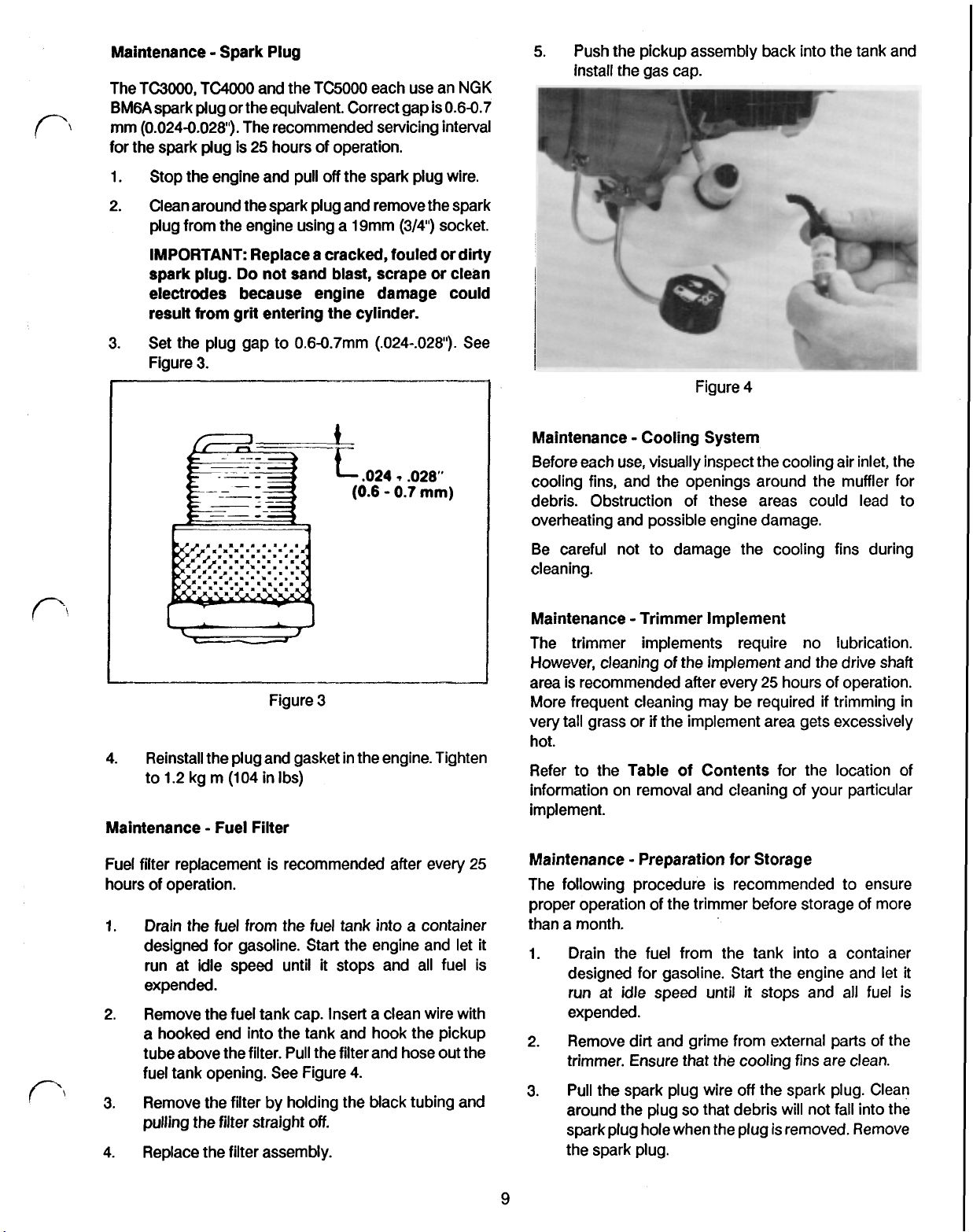

5.

Push the pickup assembly back into the tank and

install the gas cap.

Figure

4

Maintenance Cooling System

Before each use, visually inspect the cooling air inlet, the

cooling fins, and the openings around the muffler for

debris. Obstruction of these areas could lead

to

overheating and possible engine damage.

Figure

Reinstall the plug and gasket in the engine. Tighten

4.

to

1.2

kg m

(1

04

in Ibs)

3

Maintenance Fuel Filter

Fuel filter replacement is recommended after every

hours of operation.

1. Drain the fuel from the fuel tank into a container

designed for gasoline. Start the engine and

run at idle speed until

it

stops and all fuel is

expended.

2.

Remove the fuel tank cap. Insert a clean wire with

a

hooked end into the tank and hook the pickup

tube above the filter. Pull the filter and hose

fuel tank opening. See Figure

3.

Remove the filter by holding the black tubing and

pulling the filter straight

4.

Replace the filter assembly.

4.

off.

out

let

the

25

to

Be careful not

damage the cooling fins during

cleaning.

Maintenance Trimmer Implement

The trimmer implements require no lubrication.

However, cleaning of the implement and the drive shaft

area is recommended after every

More frequent cleaning may be required

very tall grass or

if

the implement area gets excessively

25

hours of operation.

if

trimming in

hot.

to

the

Refer

Table

of

Contents for the location of

information on removal and cleaning of your particular

implement.

Maintenance Preparation

for

Storage

The following procedure is recommended to ensure

proper operation of the trimmer before storage of more

than a month.

it

1.

Drain

the

fuel from the tank into a container

designed for gasoline. Start the engine and

run at idle speed until

it

stops and all fuel

let

it

is

expended.

2.

Remove dirt and grime from external parts of the

trimmer. Ensure that the cooling fins are clean.

3.

Pull

the spark plug wire off the spark plug. Clean

so

around the plug

that debris will not fall into the

sparkplug hole when the plug is removed. Remove

the spark plug.

9

Page 21

Maintenance Preparation for Storage (cont’d)

4.

Pour 5ml (one teaspoon) of two-cycle oil into the

spark plug hole This will prevent corrosion from

damaging internal engine components.

5. Pull the recoil starter handle several times to

distribute the oil throughout the engine.

6.

Reinstall

in Ibs).

the

spark plug. Tighten

DO

NOT CONNECT

it

PLUG

to

WIRE

1.2

kg m

TO

(104

THE

SPARK PLUG.

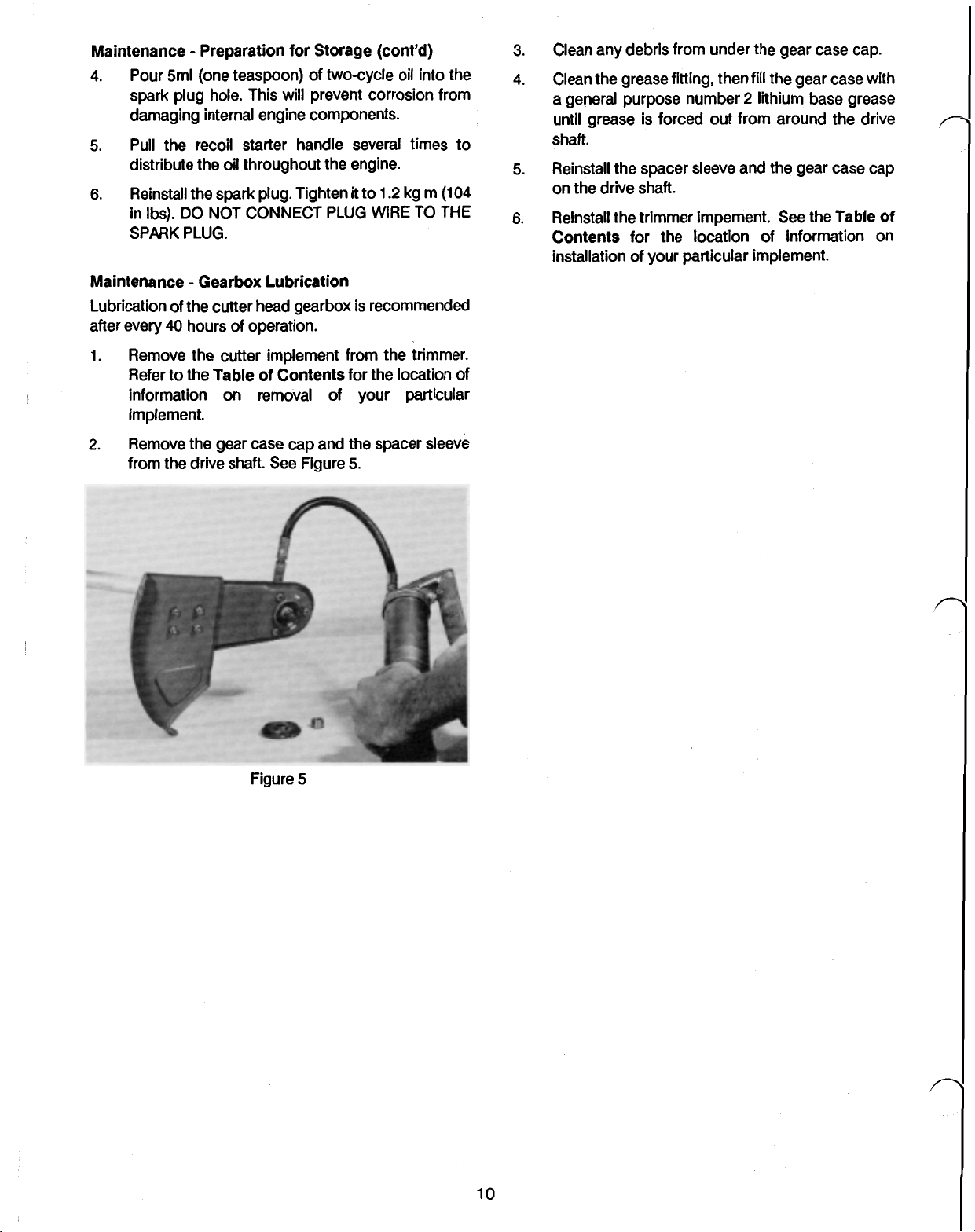

Maintenance Gearbox Lubrication

Lubrication of

after every

1.

Remove the cutter implement from the trimmer.

Refer to the Table

the

cutter head gearbox is recommended

40

hours of operation.

of

Contents for the location of

information on removal of your particular

implement.

2.

Remove the gear case cap and the spacer sleeve

from the drive shaft. See Figure

5.

3.

Clean any debris from under the gear case cap.

4.

Clean the grease fitting, then fill

a general purpose number

the

2

lithium base grease

until grease is forced out from around the drive

Shaft.

5. Reinstall the spacer sleeve and

the

on the drive shaft.

6.

Reinstall the trimmer implement See the Table

Contents for the location of information on

installation of your particular implement.

gear case with

gear case cap

of

Figure

5

10

Page 22

SECTION

Carburetor Operation

The carburetor used on the TC3000, TC4000 and the

TC5000 is a diaphragm style carburetor.

alternating pulses from the crankcase to pump fuel from

the fuel tank to the carburetor.

It

1

uses

CARBURETOR

n

To adequately describe the function

is necessary to break its operation down into three

systems:

The Diaphragm Pump

Fuel Metering and Mixing System

The Primer System

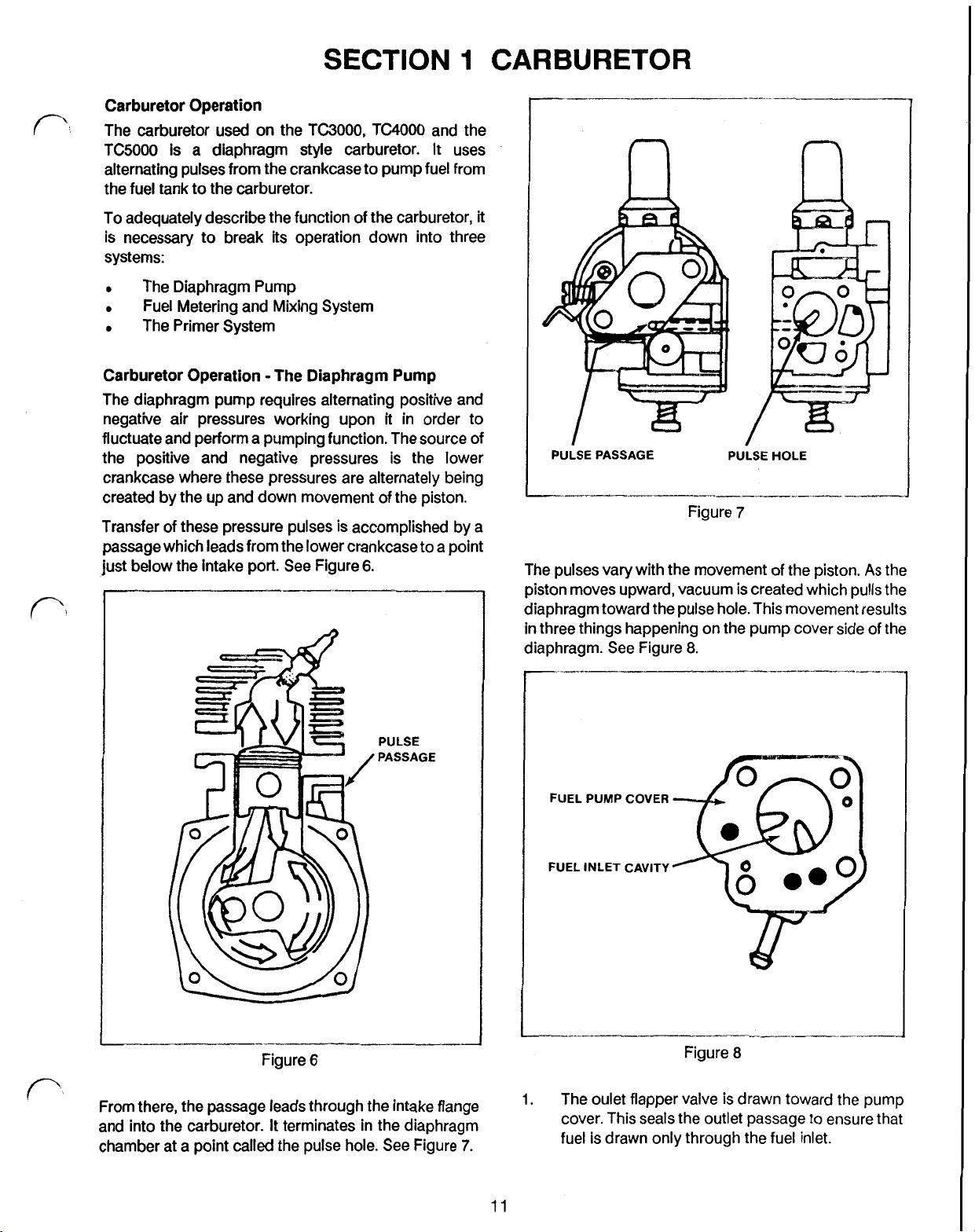

Carburetor Operation The Diaphragm Pump

The diaphragm pump requires alternating positive and

negative air pressures working upon

fluctuate and perform a pumping function. The source of

the positive and negative pressures is the lower

crankcase where these pressures are alternately being

created by the up and down movement of the piston.

Transfer of these pressure pulses is accomplished by a

passage which leads from the lower crankcase to a point

just below the intake port. See Figure

of

the carburetor,

it

in order to

6.

it

PULSE PASSAGE

The pulses vary with the movement of the piston.

piston moves upward, vacuum is created which pulls the

diaphragm toward the pulse hole. This movement results

in

three things happening on the pump cover side of the

diaphragm. See Figure

Figure

8.

PULSE

7

HOLE

As

the

PULSE

PASSAGE

Figure

From there, the passage leads through the intake flange

and into the carburetor. It terminates in the diaphragm

chamber at a point called the pulse hole. See Figure

6

7.

FUEL

PUMP

COVER

FUEL

INLET

CAVITY

Figure

8

1.

The oulet flapper valve

cover. This seals the outlet passage to ensure that

fuel is drawn only through the fuel inlet.

is

drawn toward the pump

11

Page 23

Carburetor Operation

The

Diaphragm Pump

(cont’d)

2.

The inlet flapper valve is pulled open to allow fuel

to flow from the fuel line and into the fuel inlet

cavity.

3.

Fuel is drawn into the fuel pump cavity.

As

the piston moves downward, another sequence

occurs which pumps the fuel from the pump cavity

into

the

the main diaphragm cavity. See Figure

9.

FUEL PUMP CAVITY

INLET

NEEDLE

Figure

1.

The exhaust stroke sends a positive pressure pulse

9

to the pump diaphragm which pushes the

diaphragm toward the pump cover.

2.

The positive pressure in the fuel pump cavity seals

the inlet flapper valve to prevent fuel from being

forced back into the fuel line.

3.

The outlet flapper valve is pushed open.

4.

Fuel is forced out of

the

pump cavity and past the

inlet needle.

I

MAIN

DIAPHRAGM

CAVITY INLET

Figure

10

NEEDLE

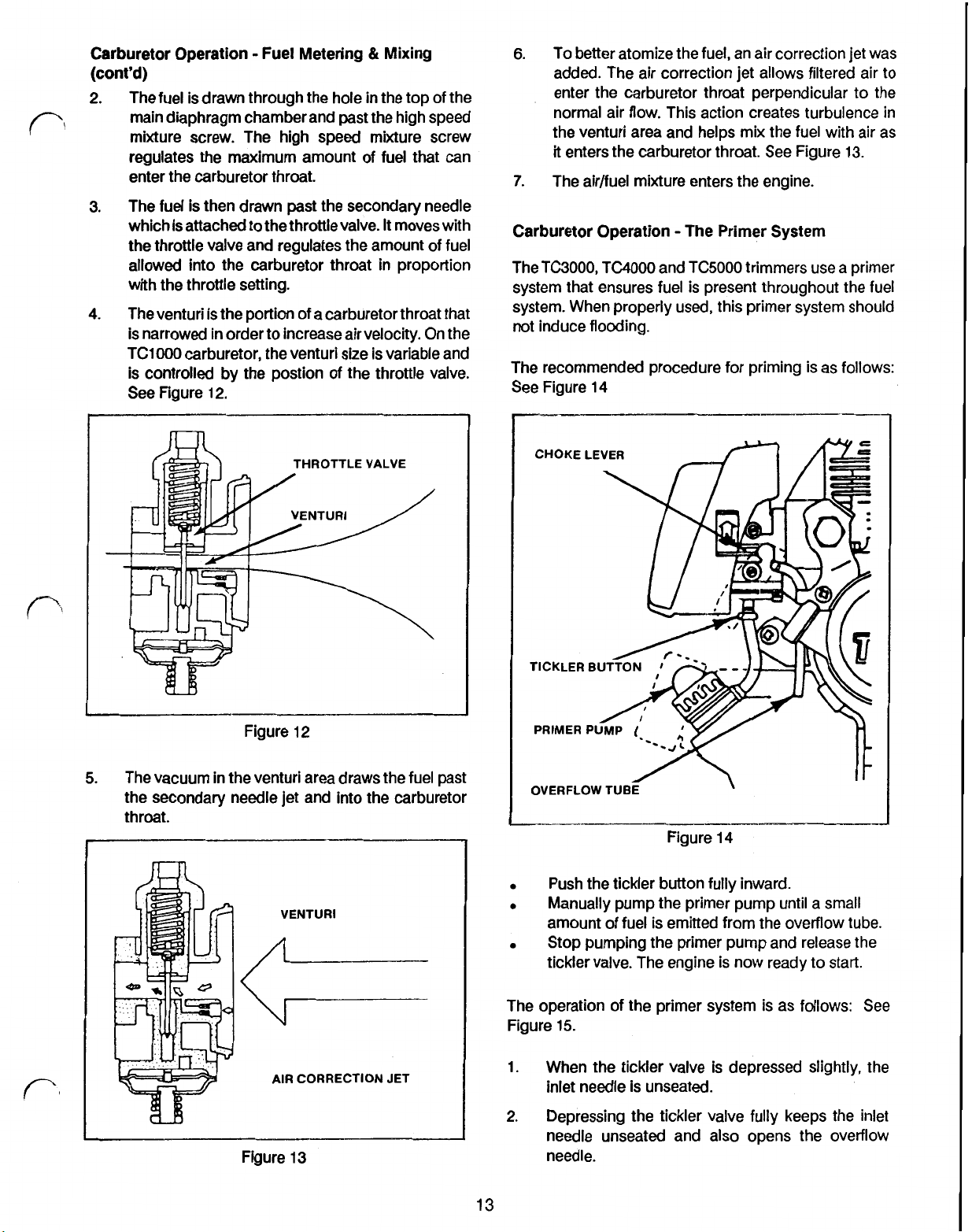

Carburetor Operation Fuel Metering Mixing

With the main diaphragm filled with fuel, the carburetor

meters the amount going into the engine by using the

high speed mixture screw and the needle

entering the intake port

with air to further atomize

of

the engine, the fuel is mixed

it

and increase its

jet.

Before

combustibility.

The metering and mixing operation is described below:

See Figure

11.

n

THROTTLE VALVE

SECONDARY

NEEDLE JET

NOTE:

The inlet needle is spring loaded in the

closed position. The spring pressure is very slight

and is easily overcome by the force of the fuel

coming through the passage.

5.

The fuel enters the main diaphragm cavity.

Figure

NOTE:

reservoir

10.

The main diaphragm serves only as a

so

that fuel can be properly metered

before entering the venturi. It does not do any

pumping of fuel during normal operation.

6.

Once the positive pressure is gone, the needle

valve is reseated. This allows fuel to

be

drawn from

the sealed main diaphragm cavity and into the

carburetor throat on the intake stroke.

See

12

HIGH SPEED

MIXTURE screw

CAVITY

Figure

1.

On the intake stroke, vacuum in the carburetor

11

throat draws fuel from the main diaphragm cavity.

Note that as the intake stroke begins, the main

diaphragm cavity is filled with fuel and that the

diaphragm is bowed toward the cover.

Page 24

Carburetor Operation Fuel Metering & Mixing

(cont’d)

2.

The fuel is drawn through the hole in the top of the

main diaphragm chamber and past the high speed

mixture screw. The high speed mixture screw

regulates the maximum amount of fuel

that

enter the carburetor throat.

3. The fuel is then drawn past the secondary needle

which is attached to the throttlevalve.

It

moves with

the throttle valve and regulates the amount of fuel

allowed into the carburetor throat in proportion

with the throttle setting.

4. The

venturi

is the portion of a carburetor throat that

is narrowed in order to increase air velocity. On the

TC1000 carburetor, the venturi size is variable and

is controlled by the postion

See Figure

12.

of

the throttle valve.

can

6.

To better atomize the fuel, an air correction

jet

was

added. The air correction jet allows filtered air to

enter the carburetor throat perpendicular to the

normal air flow. This action creates turbulence in

the

venturi area and helps mix the fuel with air as

it

enters the carburetor throat.

7.

The air/fuel mixture enters the engine.

See

Figure 13.

Carburetor Operation The Primer System

The TC3000, TC4000 and TC5000 trimmers use a primer

system that ensures fuel is present throughout the fuel

system. When properly used, this primer system should

not induce flooding.

The recommended procedure for priming is as follows:

See Figure

14

THROTTLE

VALVE

Figure 12

5.

The vacuum in the venturi area draws the fuel past

the secondary needle jet and into the carburetor

throat.

VENTURI

CHOKE

OVERFLOW

LEVER

TUBE

\

Figure 14

Push the tickler button fully inward.

Manually pump the primer pump until a small

amount of fuel is emitted from the overflow tube.

Stop pumping the primer pump and release the

tickler valve. The engine is now ready to start.

AIR

CORRECTION

Figure 13

JET

The operation

Figure 15.

1.

2.

13

of

the primer system is as follows:

When the tickler valve is depressed slightly, the

inlet needle is unseated.

Depressing the tickler valve fully keeps the inlet

needle unseated and also opens the overflow

needle.

See

Page 25

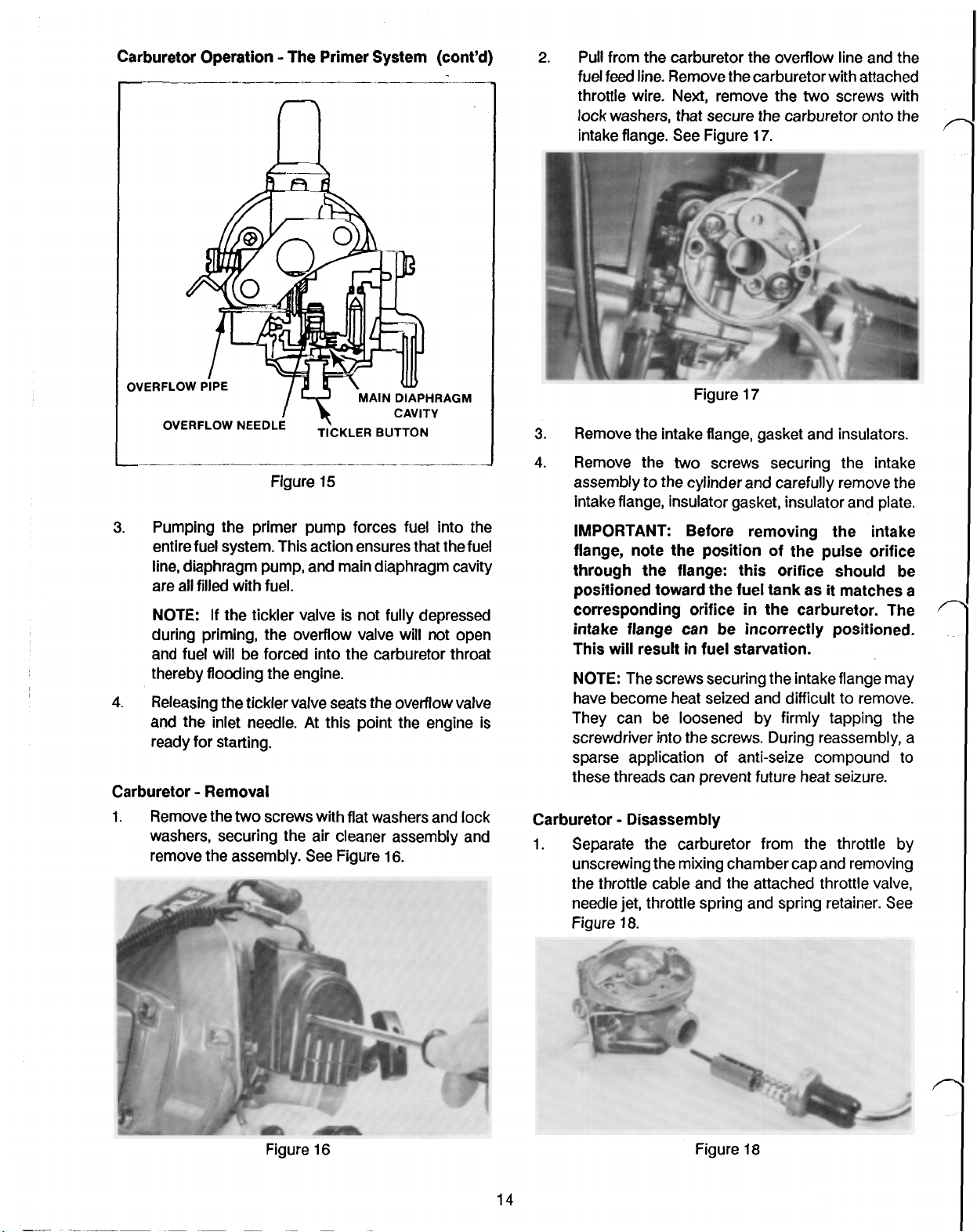

Carburetor Operation The Primer System (cont’d)

2.

Pull from the carburetor the overflow line and the

fuel feed line. Remove the carburetor with attached

throttle wire. Next, remove

the

two

screws with

lock washers, that secure the carburetor onto the

intake flange. See Figure

17.

MAIN

DIAPHRAGM

CAVITY

OVERFLOW

3.

Pumping the primer pump forces fuel into the

NEEDLE

Figure

TICKLER

15

BUTTON

entire fuel system. This action ensures that the fuel

line, diaphragm pump, and main diaphragm cavity

are all filled with fuel.

NOTE: If the tickler valve is not fully depressed

during priming, the overflow valve will not open

and fuel will be forced into the carburetor throat

thereby flooding the engine.

4.

Releasing the tickler valve seats the overflow valve

and the inlet needle. At this point the engine is

ready for starting.

Carburetor Removal

1.

Remove the

two

screws with flat washers and lock

washers, securing the air cleaner assembly and

remove the assembly. See Figure

16.

Figure

3.

Remove the intake flange, gasket and insulators.

4.

Remove the

assembly

two

to

the cylinder and carefully remove the

17

screws securing the intake

intake flange, insulator gasket, insulator and plate.

IMPORTANT: Before removing the intake

flange, note the position of the pulse orifice

through the flange: this orifice should be

positioned toward the fuel tank as

corresponding orifice

in

the carburetor. The

it

matches a

intake flange can be incorrectly positioned.

This will result

NOTE:

The screws securing the intake flange may

in

fuel starvation.

have become heat seized and difficult to remove.

They can be loosened by firmly tapping the

screwdriver into the screws. During reassembly, a

sparse application of anti-seize compound to

these threads can prevent future heat seizure.

Carburetor Disassembly

1.

Separate the carburetor from the throttle by

unscrewing the mixing chamber cap and removing

the throttle cable and the attached throttle valve,

needle jet, throttle spring and spring retainer. See

Figure

18.

Figure

16

14

Figure

18

Page 26

Carburetor Disassembly (cont'd)

2.

Remove the fuel pump by removing

the

with lock washers securing the pump cover then

lifting

off

the pump diaphragm and pump cover

gasket.

NOTE:

The gasket and the diaphragm are

extremely thin and may stick together giving

appearance of one piece. Remember that the

pump diaphragm seals against the pump cover

and that the gasket seals against the carburetor

body. See Figure 19.

4

screws

the

NOTE:

Before removing inlet needle pieces,

inspect inlet needle arm height using a depth

micrometer. The correct height is

(.055

to

.062”)

See Figure 21.

INLET NEEDLE

1.4

ARM

HEIGHT

INLET NEEDLE

Figure 21

to 1.6 mm

Figure 19

Remove the four screws with lock washers

3.

securing the main diaphragm cover assembly to

lift

off

the carburetor. Carefully

the main diaphragm

cover assembly.

NOTE:

The main diaphragm assembly and the

main diaphragm packing are thin and may stick

together giving the appearance of one piece, not

two.

Remember that the main diaphragm gasket

seals against the carburetor body. See Figure 20.

Remove the inlet needle pieces from the

carburetor by removing the inlet needle pin set

screw and carefully lifting out the inlet needle arm

with inlet needle pin, the inlet valve spring and the

inlet needle valve. See Figure 22.

INLET NEEDLE

ARM AND

PIN

Figure 20

15

Figure 22

5.

Remove the throttle adjusting screw, throttle

adjusting screw spring and the high speed mixture

screw. See Figure

23.

Page 27

Carburetor Disassembly (cont’d)

E-CLIP

GROOVES

SECONDARY NEEDLE

Figure

23

Figure

2.

Position the needle with the retainer clip into the

25

throttle valve.

3.

Install the special washer and spring clip as shown

in Figure

26.

Push the needle assembly into the

throttle valve and line up the slots in the special

washer and the throttle valve.

Carburetor Reassembly

IMPORTANT

good condition.

1.

Install the

placement

Make certain all parts are clean and

Do

not use worn or damaged parts.

E

clip on the throttle valve. Nominal

of

the E clip is in the middle groove. The

upper groove will yield a leaner mixture and the

lower groove yields a richer mixture.

25.

See

in

Figure

Figure

4.

Slide the throttle spring on the throttle cable and

26

position the throttle cable into its groove in the

throttle valve.

5.

Install the throttle adjusting screw with the

adjusting screw spring into the carburetor.

6.

Install the high speed mixture screw. Gently seat

the screw, then back out approximately three

turns to give a nominal setting.

full

Page 28

Carburetor Reassembly

7.

Replace the inlet needle pieces by installing the

inlet

needle, the

(cont’d)

inlet

needle spring, the inlet needle

arm and secure with the screw. See Figure

/--

SCREW

27.

OVERFLOW

VALVE

INLET

NEEDLE

ARM

INLET

NEEDLE

PIN

INLET

NEEDLE

9.

Replace the main diaphragm parts by installing the

main diaphragm gasket against the carburetor, the

main diaphragm assembly upon the main

diaphragm gasket, the main diaphragm cover

upon the main diaphragm assembly. When

installing the main diaphragm assembly, position

the shaft of the pin toward the inlet needle arm, not

toward the tickler button.

NOTE:

Sealant is not recommended on these

gasket surfaces.

Secure these pieces with four screws with lock

washers. See Figure

29.

CARBURETOR

Figure

27

BODY

Make certain the spring is securely seated in the

inlet needle arm and that the inlet arm positively

engages the inlet valve.

I

8.

Using the carburetor body surface as reference,

check the inlet valve height. Inlet valve height can

be checked with a height gauge or with an

accurate depth gauge. See Figure

28.

Carburetor Inlet Needle Valve Height

1.4

to

1.6

mm

(.055

to

.063”)

Figure

INLET

NEEDLE

ARM

HEIGHT

Replace the fuel diaphragm pump parts by

10.

29

installing the pump cover gasket against the

carburetor, the pumpdiaphragm against the pump

cover gasket, the pump cover against the pump

INLET

NEEDLE

diaphragm and securing these pieces with four

screws with lock washers. See Figure

30.

SPRING

17

NOTE:

Sealant is not recommended on these

gasket surfaces.

Install the throttle cable with attached throttle parts

11.

into the carburetor and secure by tightening the

throttle fitting.

The carburetor is completely reassembled and

ready for installation to the intake flange.

Page 29

Carburetor Reassembly (cont’d)

3.

Ensure that the throttle cable is positioned as

shown in Figure 32 to prevent throttle cable

damage.

Figure 30

Carburetor

I.

Install the intake flange with gaskets and heat

Installation

shield making certain that the pulse hole is not

obstructed by any of the intake components.

Secure by tightening the screws to .3 to

(26 to 38 in Ibs). See Figure 31.

The proper order for installing the intake

components is:

gasket

heat shield

gasket

intake flange

.45

kg m

CORRECT

ROUTING

Figure 32

4.

Attach the fuel feed line and the overflow line to the

carburetor.

5.

Place the air cleaner steel net, element and grid

into the air cleaner cover and install the assembled

air cleaner onto the carburetor. Secure with the

screws with lock washers and flat washers.

Carburetor Adjustment Idle Speed

CAUTION:

head whenever engine

Stay

clear

of

cutter

is

running.

two

Figure 31

2. Place the carburetor gasket on the intake flange

making sure that the pulse hole is not obstructed.

Install the carburetor.

Tighten the screws to .3 to

.45

kg m, (26 to 38 in

Ibs.)

1. With the engine running at operating temperature,

the choke fully opened and,

no

load applied to the

engine, turn the idle speed adjusting screw to

achieve an idle in the range specified below.

TC3000

3000

&

TC4000

200 rpm

TC5000

2500

200

rpm

See Figure 33.

Figure 33

n

18

Page 30

Carburetor Adjustment Mixture

A

1.

The

controls the fuel flow requirements during the

engine's optimum demand. With the engine

running at operating temperature, the choke fully

opened and, no load applied to the engine, turn the

high speed mixture screw to obtain the highest

RPM.

from fully closed.

Turning the screw clockwise will make the air/fuel

mixture lean (less fuel/more air).

Turning the screw counterclockwise will make the

air/fuel mixture rich (more fuel/less air).

IMPORTANT: Turning the high speed mixture

screw

CAUTION:

head whenever engine is

running.

high

speed mixture screw (see Figure

This should be approximately2 to 3 turns

in

too tightly may damage the tip.

stay

clear

of

cutter

34)

out

throttle valve should travel to the top

carburetor opening when the trigger is in

throttle position.

3.

To adjust, loosen the jam nut on throttle cable and

rotate the turnbuckle to increase or decrease the

travel of the throttle valve. See Figure

--

TURNBUCKLE

JAM

NUT

34.

of

the

full

Carburetor Adjustment Throttle Valve

CAUTION: Stay clear

head whenever engine is

running.

1.

Remove

to the trimmer and remove the air cleaner as an

assembly.

2.

Squeeze the throttle trigger and note the travel

throttle valve in the carburetor opening. The

two

screws securing the air cleaner cover

of

cutter

Figure

4.

Tighten the jam nut and check the adjustment.

5.

Reinstall the air cleaner cover assembly and

secure using the

lock washers.

two

34

screws with flat washers and

of

6.

Check the idle speed and adjust

to

Carburetor Adjustment

if

necessary.

Idle

Speed, page

Refer

18.

19

Page 31

SECTION 2 FUEL SYSTEM

FUEL TANK

Fuel Tank Removal

I.

Loosen the

hex screws that retain the fuel tank guard. Remove

the fuel tank guard. See Figure 35.

two

locknuts and the corresponding

Figure

35

3. Remove the fuel tank.

if

4. The bracket can be removed,

removing the single machine screw retaining

the crankcase.

5.

The strap can be removed,

backing out the four Phillips fan housing screws

approximately 3/16' each. This will provide

sufficient clearance to remove the strap.

IMPORTANT:

fan housing screws unless absolutely

necessary as loosening them

ignition coil air gap.

necessary,

before running engine.

Fuel Tank Installation

1. With the fan housing loosely secured to the

crankcase, slip the fuel tank strap into its slot on

the underside of the engine. Tighten evenly the four

Phillips screws retaining the fan housing to the

crankcase to .4 to

Figure 37.

(TC5000

do

not forget to reset the air gap

only)

If

removal of the strap is

.5

kg m (35 to 43

necessary, by

if

necessary, by

Do

not loosen the

will

affect the

in

Ibs). See

it

to

2.

Loosen the locknut on the fuel tank strap screw

then turn the screw counterclockwise until the strip

is free from the bracket. See Figure 36.

Figure 36

Figure 37

NOTE:

loosened, the

See

2.

Fasten the strap bracket to the underside of the

crankcase using the single machine screw.

3. Start the fuel tank strap screw into the strap bracket

and turn clockwise until the tank is seated on all

four pads.

locknut.

(TC5000

TC5000

only) If the fan housing was

air

gap must be reset before starting.

Air Gap Adjustment, page

DO

NOT OVERTIGHTEN. Tighten the

28.

Page 32

Fuel Tank Installation (cont’d)

4. Slide the fuel tank guard into the lower fan housing

and tighten the

the

two

corresponding locknuts.

5.

Slide the retaining ring onto the fuel line, then push

two

hex screws retaining

it.

Tighten

the line onto the fitting near the primer bulb. Slide

the retainer ring down, over the fitting, to secure

the line. See Figure 38.

Push the tickler button fully inward.

Manually pump the primer pump until a small

amount of fuel is emitted from the overflow tube.

Stop pumping the primer pump and release the

tickler valve. The engine is now ready to start.

Primer Pump Operation

The primer system on the TC3000, TC4000 and

is

used

on cold starts only and ensures that fuel is

present throughout the entire fuel system.

TC5000

It

relies on

manual pumping action to draw fuel into the primer and

to pump

The primer pump uses a

it

into the fuel line and the carburetor.

two

step operation to pump fuel

to the carburetor. Pushing on the primer diaphragm does

the following: See Figure 40.

INLET CHECK BALL

OUTLET CHECK BALL

Figure 38

PRIMER PUMP

Primer Pump Proper Use

Proper operation of the primer system is as follows:

See

Figure 39.

CHOKE LEVER

VALVE CUSHION

Figure 40

1. The inlet check ball seats.

2.

The outlet valve is pushed against the porousvalve

cushion to allow fuel or air (whatever is in the

primer diaphragm) to pass into the fuel line and

carburetor.

Releasing the primer diaphragm allows

back

to

its

original shape which results in the

following: See Figure 41.

FUEL FLOW

\

\

VALVE CUSHION CHECK BALL

VALVE CUSHION

it

to come

OUTLET

OVERFLOW

TUBE

\

Figure 39

21

INLET CHECK BALL

~--~-

Figure 41

1.

The vacuum produced

by

the diaphragm seals the

outlet check valve. This prevents fuel from being

drawn from the fuel line.

Page 33

Primer Pump Operation (cont'd)

2.

The inlet valve

is

drawn toward the porous valve

cushion which allows fuel to be drawn from the

pickup line inside the tank. This action fills the

primer diaphragm with fuel and readies

next pump.

Primer Pump Disassembly

1.

Pull

the primer pump from the tank and remove the

fuel line. The primer pump is press fit into the fuel

tank. See Figure

42.

it

for the

Figure 42

2.

Unscrew the rubber cap/button from the pump.

See Figure

43.

Figure

44

Primer Pump Inspection

1.

Inspect the disassembled primer pump for

contamination or damaged parts.

2. Clean thoroughly in a mild soap and water solution.

3.

If

the primer pump is suspect after inspection, the

entire primer pump assembly should be replaced.

Primer Pump Reassembly

1.

Before reassembling, familiarize yourself with the

configuration of the parts

properly installed.

GASKET

E

See

\

Figure

to

ensure they are

45.

VALVE SEATE

n

3.

Carefully

cushion, and

lift

Figure

out

the top valve seat with the valve

two

43

ball

valves. See Figure

4. Insert a thin, non-puncturing punch through the

hole in the bottom of the pump and carefully push

out

gasket

A,

valve seat A with valve cushion, and

gasket B.

44

22

PUMP

BODY

Figure

Gasket

“B”

has

two

sizes of fuel orifices one

large and one small.

Gasket

"A"

has one size of fuel orifices both

large.

45

Page 34

Primer Pump Reassembly (cont'd)

Valve seat

through the seat.

Valve seat

partially cut into the seat.

Gasket

pump. Gasket

outside.

Reassemble parts into the pump body. Position

2.

gasket

nozzle of the pump body.

Place valve seat

3.

"A"

has a locating notch that is cut

"B"

has

"A"

and valve seat

"B”

B

so

the

small fuel orifice is toward the outlet

a locating notch that is

"A"

are inside the

and valve seat

A

with valve seats up, on gasket

"B”

B.

Push one valve cushion into valve seat

4.

covers the double holed fuel orifice.

Place gasket

5.

A

on valve seat

A.

are to the

A

so

these elements and the fuel strainer located inside

the pickup weight. Clean or replace as necessary.

Reassemble the pickup assembly making sure that

3.

the

pickup tube fits snugly on the top of the fiber

filter element.

If pickup tube removal is desired,

4.

removed by removing the primer pump as

described under Primer Pump Disassembly,

page

22.

Remove the fuel pickup tube by pulling

5.

tank. It is also pressed in.

Inspect the pickup tube for cracks or punctures

6.

and replace

it

Reinstall the fuel pickup tube by lightly coating the

7.

barbed end with

the proper tank orifice.

if

necessary.

two

cycle oil and pressing

it

can be

it

out of the

it

into

Drop the

6.

in valve seat

7.

Place one valve cushion into valve seat

covers the double-holed fuel orifice.

Set valve seat

8.

body with assembled parts.

Secure all parts by screwing the rubber cap/button

9.

on the pump body.

Reinstall the pump into the tank opening and

10.

attach the fuel line.

Fuel Pickup Tube and Filter Service

1.

The fuel filter on the pickup tube can be inspected

without removing the pickup assembly by "fishing"

the filter out through the filter hole.

two

ball valves through gasket A to seat

A.

B

B

with valve cushion into the pump

See

so

Figure 46.

that

FUEL CAP

it

Fuel Cap Operation

The fuel tank cap on the TC3000, TC4000 and TC5000

somewhat complex due to the requirements of the

application. The cap must vent in order to prevent a

vacuum or pressure buildup within the tank but must also

prevent leakage of fuel.

The cap accomplishes the above by using a system of

valves which work under different conditions. When the

tank is under pressure, the following occurs:

47.

UMBRELLA VALVE

PACKING

'I

ORIFICE

See

is

Figure

2.

Pull the pickup weight from the end of the tube and

remove

the

fiber filter elements. Inspect both of

23

Figure 47

1.

The pressure passes through the packing orifice

so

that

it

can act upon the umbrella valve.

2.

The pressure passes through the

in

the valve holder and lifts the umbrella portion of

the umbrella valve

3.

Pressure passes into the top of the gas cap and

isemitted to the atmosphere through the slits in the

threads of the gas cap.

off

its seat.

two

small orifices

Page 35

Fuel Cap Operation (cont’d)

When a vacuum occurs within the tank, the following

occurs: See Figure

48.

Fuel Cap Inspection

1.

It

is important that the fuel cap properly vents the

tank. Inspect the gasket to ensure that the hole at

the rounded end is unobstructed.

2.

Check the

two

small pressure outlet holes in the

holder to ensure that they are open.

3.

The stem of the umbrella valve allows air into the

tank to compensate for the fuel being used by the

engine. Ensure that

it

will open and close by

holding the flat end lengthwise between your

thumbs and squeezing. See Figure

50.

UMBRELLA

Figure

1.

Atmospheric pressure enters the top of the gas cap

through the slits

2.

Because a vacuum in the tank means that higher

in

48

the gas cap threads.

VALVE

pressure is present outside the tank than within,

the higher pressure passes down the stem of the

umbrella valve and forces

3.

The higher pressure passes through the packing

the

stem orifice open.

orifice and enters the fuel tank thereby equalizing

the pressure.

Fuel Cap Disassembly

1.

Remove the fuel cap from the tank.

2.

Pry the gasket, holder and breather valve out of the

tank cap. See Figure 49.

4.

Clean all fuel cap parts thoroughly.

Fuel Cap Reassembly

1.

Position the holder inside the gasket, then screw

this assembly into the fuel cap until

in the top of the fuel cap.

it

is fully seated

3.

Clean these parts thoroughly.

Figure 49

2.

Reinstall the cap on the fuel tank.

Page 36

SECTION

IGNITION

3

Ignition Operation

The firing of the spark plug at the proper time is the

culmination of a number of components working

together. In the TC3000,

components used are:

Flywheel

Ignition Coil

Trigger Module

Spark plug

See Figure

51.

TC4000,

SPARK PLUG,

and TC5000 the

flywheel magnets to cut through the coils to generate

electricity. See Figure

52

IGNITION

COIL

Low voltage is produced in the primary coil which

to

low to produce a spark at the spark plug.

The secondary coil serves

produced in the primary. To accomplish this, the

secondary coil must have many more windings than the

primary. The higher the ratio between the primary coil

a

Figure

The following describes the function of each of the above

components.

Ignition Operation Flywheel

The flywheel is connected directly to the crankshaft and

turns at the same speed as the engine. Imbedded in the

flywheel are three magnets. These magnets rotate past

the coil to generate electricity.

Imbedded in the opposite side of the flywheel is a steel

counterweight which offsets the weight of the three

magnets.

It

is not magnetic.

TRIGGER

51

MODULE

windings to secondary coil windings, the greater the

voltage amplification will be.

However, even though the secondary coil in the TClOOO

has considerably many more windings than the primary,

the voltage produced is still not high enough to produce

spark across the spark plug electrodes. To further

amplify the voltage, the trigger module is used

Ignition Operation Trigger Module

The trigger module amplifies the voltage in the

secondary coil by breaking the primary circuit just as the

primary voltage reaches its peak. This breaking of the

primary circuit results

field surrounding the primary coil. The collapse of the

primary magnetic field induces a large voltage surge in

the secondary which is sufficient to produce a spark

across the spark plug electrodes.

is

sent

the trigger module. The primary voltage is much too

to

amplify the voltage

in

a rapid collapse of the magnetic

Ignition Operation Ignition Coil

It

The ignition coil is actually a transformer.

close to the flywheel to allow the magnetic field of the

is positioned

Before getting into the actual electronics used inside the

trigger module,

of the voltage waveform produced by the flywheel

magnets moving by the ignition coil.

it

is important to have an understanding

See

Figure

53.

25

Page 37

lgnition Operation Trigger Module (cont'd)

The following is the process the trigger module uses to

break the primary circuit to produce spark:

55

See

Figure

PRIMARY VOLTAGE WAVEFORM

Figure

53

As

the magnets rotate past the coil, voltage is produced.

This voltage, when uninterrupted, is first positive, then

negative as the magnet passes by the coil. This effect is

caused by the

Explanation of the trigger module also requires an

understanding of the

I

two

opposing poles of the magnet.

NPN

transistor. See Figure

C

(Collector)

54.

I

E

(Emitter)

Figure

1.

The magnet passes by the coil and induces an

alternating voltage.

2.

As

the voltage begins to increase, (approximately

point "a"

and current flows from point

through

3.

Current

current

that

in

Figure

R3,

R4,

and Tr2. See Figure

Figure

l1

flowing through Tr2 induces a larger

12.

Note that current

l2

is much larger. See Figure

53)

transistor

55

56

l1

Tr2

"C'

is

very

57.

is

turned on

to

point

56.

small and

"D"

NPN-type

Figure

A

transistor

requires across the base and emitter (points B and E in

Figure

turned on,

above. At

current,

current

l1.

Thus, the transistor functions

allows a small current to control a large one.

has

a certain minimum voltage that

54

above) before

it

allows a small current,

the

same time, the transistor allows a large

12,

to

flow from point C to

l2

will vary in proportion to the smaller current,

54

it

will "turn on". Once

l1,

to flow as shown

E.

The magnitude of

as

an amplifier in that

it

has

MTI

unit Ignition

it

it

4.

When the voltage

in "Figure

is

at the point

53,

Tr1 is still in the

coil

Spark

"a"

level as denoted

off

mode

Ground

plug

26

Page 38

Ignition

5.

Operation Trigger Module (cont'd)

and allows no current

l3

or l4

to

flow.

As the voltage produced in the primary coil

reaches

its

negative peak (point

"b

in

Figure 53),

transistor Tr1 is turned on and allows small current

l3

and large current l4 to

MTI

unit Ignition

flow.

See Figure 58.

coil

TERMINAL NUT

METAL SHELL

Ground

Spark

plug

Figure

6.

When transistor Tr1 turns on, nearly all of the

58

current flow through R4 and Tr2 is diverted through

path l4 since

in

drop

Off.

7.

When Tr2 turns off, current

it

is the path of least resistance. This

current I1 results

in

transistor Tr2 turning

l2

drops rapidly and

causes the magnetic field surrounding the primary

in

coil to rapidly collapse. This

voltage surge

to

produce a spark across the spark plug.

in

the secondary which is sufficient

Another task the trigger module performs is

turn causes a

to

limit the

maximum revolutions per minute that the engine will

attain.

It

does this by means of the ITDC (ignition timing

delay circuit) which can also be seen

in

Figure 55.

This circuit senses the engine speed, and, as it

approaches 10,000 rpm,

it

delays the turning on of

transistor Tr1 slightly. This retards the timing and

prevents the engine from further acceleration.

CENTER LEG INSULATOR

ELECTRODE

GROUND ELECTRODE GAP

Figure

59

The other important area is the insulator. The insulator

prevents arcing from taking place in another portion of

the plug, away from the electrodes. Because of the

extremely high voltage present, even a slight crack or

fouling of the head insulator can result in arcing and a

malfunction of the plug.

AIR GAP ADJUSTMENT

The space between the coil and the flywheel magnets is

called the "air gap". Because the coil mounting holes are

oversized, air gap on the TC3000, TC4000, and TC5000

is adjustable.

It

is important

to

set

it

to the proper

specification to ensure strong spark and proper timing.

TC3000/TC4000 Air Gap Adjustment Preparation

1.

For convenience, remove the engine from

the

drive

tube as described under Engine Removal from

Drive Tube, page 40.

2.

With the recoil assembly on a hard flat surface, use

an impact wrench to remove the four fan housing

screws. Remove the fan housing.

Ignition Operation Spark Plug

The spark plug is used to ignite the air/fuel mixture by

producing a spark just before the piston reaches top

dead center.

shown

There are two critical areas important

in

Figure

A

spark plug

56.

is

typically constructed as

to

proper spark

TC3000/TC4000 Air Gap Adjustment

NOTE: If coil performance is suspect, check the air gap

with a feeler gauge prior

mounting screws.

0.020').

1. Loosen the

plug function. The first is that the electrodes are properly

gapped and are clean. This ensures that a strong spark

will be present and that

it

occurs at the proper time.

Excessive gap or fouling can delay firing enough to

cause a

loss

of power or stalling.

27

to

loosening

It

should be 0.4

two

coil mounting screws. Position a

to

the

0.5 mm

two

(0.016

coil

to

feeler gauge between the coil and the flywheel near

one of the coil mounting screws and tighten.

Repeat this procedure for the other end of the coil.

Air gap adjustment is now complete. See Figure

60.

Page 39

TC3000/TC4000 Air Gap Adjustment (cont'd)

Figure

60

Figure 61

TC300O/TC4000 Air Gap Adjustment Reassembly

1. Install the fan housing. Tighten the screws to

0.5

kg m

(35

to

43

in Ibs).

2.

Install the plastic fan housing cover using three

i

Phillips screws.

3.

Mount the engine on the drive tube as described

in Engine Installation on Drive Tube, page

0.4

to

45.

TC5000 Air Gap Adjustment Preparation

1. Remove the carburetor

Carburetor Removal, page

2.

Remove the three screws securing the muffler

cover and remove the cover.

as

described under

14.

Also

Figure 62

remove the

muffler at this time. TC5000 Air Gap Adjustment Reassembly

3.

Remove the screw securing the cylinder Cover to

the cylinder. Remove the cover.

1. Install the cylinder cover. Make sure that the coil

wire and grommet are properly positioned in the

cylinder cover slot.

2. Install the muffler and muffler cover.

TC5000 Air Gap Adjustment

1. The coil on the TC5000 is mounted to the inside

of

3.

Install the carburetor as described in Section

under Carburetor Installation, page 18.

the fan housing. The two coil mounting screws are

located near the base of the cylinder. Loosen both

coil mounting screws. See Figure 61

2.

Insert a feeler gauge between the coil and the

flywheel near one of the coil mounting screws. See

Figure 62. When the correct gap is achieved,

tighten the screw with an

8

mm open end wrench. described under Engine Removal from Drive

Repeat this procedure for the other coil mounting

Coil Removal

1.

Remove the engine from the drive tube as

Tube,

screw. This completes the air gap adjustment. 2. Remove the muffler cover and the cylinder cover.

28

page

I

40.

Page 40

Coil Removal (cont'd) Coil Installation

3.

Remove the fuel tank as described under Fuel

20,

Tank Removal, page

to gain access to screws. Be sure to install the rubber insulating

ignition wiring.

4.

Pull

out

the

two

male connectors leading into the

female connector found beneath the carburetor.

5.

Position the engine assembly

so

that the recoil

1.

Install the trigger module using

gasket beneath

2.

Install the coil with the proper air gap by following

the procedure found under heading:

ADJUSTMENT,

housing is resting on a hard, flat surface. Remove

the four Phillips head screws retaining the fan

housing with an impact wrench and

housing. (The

fan housing

TC5000

so

be careful not to damage any wires

has the coil mounted in the

lift

off

the fan

while removing the housing.)

6.

Remove the trigger module and gasket. See Figure

63.

it.

See Figure

page

27.

63.

two

machine

AIR

GAP

Figure

63

29

Page 41

SECTION

4

RECOIL STARTER

Recoil Starter Operation

An

exploded view of the recoil assembly used on the

TC3000, TC4000 and the TC5000 is shown below. See

Figure

64.

STARTER RETURN REEL

PULLEY CLOCKSPRING

FRICTION

The recoil mechanism shown in Figure

follows:

The operator pulls the rope which

it

reel spinning. As the reel turns,

in

the recoil housing. The clock spring rewinds the rope

once the

“T”

handle is released.

winds up a clock spring

64

in

turn results

functions as

in

the

starter pulley and

When the reel stops turning, the starter pawl is forced

back into

spring.

Recoil Mechanism Removal

1.

Recoil Mechanism Disassembly

1.

its

Remove the three (TC3000 and TC4000) or four

(TC5000) screws retaining the recoil housing to the

crankcase and remove the recoil starter unit.

N0TE: There

starter housing.

during removal from the crankcase.

Pull

out a loop of starter rope approximately

(12

inches) and tie a tight slip knot to keep

rewinding. This loop will provide

necessary to untie the knot from the

See Figure

in

turn, forces the engine to turn over.

normal retracted position by the return

is

no spring tension against

It

should not fly

off

nor unwind

the

“T”

the

recoil

30

it

slack

handle.

from

66.

cm

Note that the pawl pivots

kept in its normally retracted position by the return

spring. See Figure

As

the reel begins to turn, the pawl turns with

it

is

in contact with the friction plate which does not

rotate. This contact between the pawl and the friction

plate forces the pawl outward

65.

in

the recoil reel and that

Figure

65

so

that

it.

However,

it

engages the

it

is

Figure

Once the

rope to slowly retract into the recoil housing.

2.

Remove the bind screw.

protection and leather gloves are

recommended

recoil housing.

3. Gently

friction spring, and pawl.

“T”

handle has been removed, allow the

CAUTION: Once the

screw is removed,

for the recoil spring to fly out of

the recoil housing. Eye

during

lift

off

as an assembly the friction plate,

66

bind

it

is possible

servicing of the

30

Page 42

Recoil Mechanism Disassembly (cont'd)

CAUTION:

plate and reel components

carefully as jerking them out

may cause the recoil spring to

come out of the recoil housing.

4.

Remove the return spring.

remove the friction

See

Figure 67.

CAUTION:

wire surrounding the spring

A

the

personal injury.

until the spring is installed in

the recoil housing. Removing

wire prematurely may result

Do

not remove

the

in

Figure 67

5.

Gently

pliers.

A

6. Untie the knot in the recoil rope and remove the

rope from the recoil reel.

7.

If

by carefully turning the recoil housing over (spring

side down) and rapping

sure to stay clear of the spring when performing

this operation.

IMPORTANT

unless

unsprung, the spring should be replaced.

lift

out the recoil reel with a needle nose

CAUTION:

from the recoil starter case, the

spring may fly

it

is necessary to remove the recoil spring, do

Do not remove

it

is

If the reel is jerked

out

of

position.

it

on a hard flat surface. Be

the

recoil spring

absolutely necessary. Once

so

Figure 68

2.

Insert one end of the recoil rope into the

appropriate hole in the recoil reel.

knot in that end of the rope and

the hole making sure that no portion

protrudes

out

of

the recess.

See

Figure 69.

Tie

pull

a single

it

down into

of

the rope

loop

Recoil Mechanism Reassembly

1.

If

the recoil spring was removed during

it

disassembly, replace

the spring with the wire on

as

shown in Figure

with a

it

68.

new

one. Position

into the recoil housing

31

Figure 69

3.

Position the spring in the starter case

spring's inner end is approximately

from the shaft. This distance ensures that the reel

hook will engage the spring.

See

3

mm

Figure

so

(1/8

70.

that the

inch)

Page 43

Recoil Mechanism Reassembly (cont'd)

reel back and forth slightly in order

to

properly mate.

6.

Insert the

in Figure

pawl

return spring into position as shown

72.

to

get the parts

NOTE:

If

the spring jumped

out

of the recoil

housing, the recoil spring should be replaced.

4.

Wind

counterclockwise

side of the reel

the recoil rope onto the reel in a

direction (as viewed from the

without

the knot

in

it).

Hook the end

of the rope in the slot provided in one of the reel

flanges. Leave about

Figure

71.

15

cm

(6

inches) of rope.

See

Figure 72

7.

Place the friction plate, friction plate spring and

pawl onto the recoil reel as an assembly. Make sure

that the end of the

pawl

return spring is properly

positioned on the outside of the pawl then install

the bind screw. Tighten

to

0.8

to

1.O

kg m (70

to

in Ibs).

Prewind the spring approximately one and one half

8.

turns in a counterclockwise direction then slip the

end of the rope through the hole in the recoil

housing.

Pull about 30 cm (12 inches) of rope

9.

recoil and

tie

a tight slip knot in

it.

out

of the

This will keep the

recoil rope from retracting into the housing during

'7"

installation of the

Slide the

10.

“T”

handle then the metal reinforcement

handle.

onto the recoil rope. Secure by tying a knot in the

end of the rope then inserting

top of the

Release the slip knot be giving

11.

“T”

handle.

it

into the

if

a sharp

slot

tug.

in the

80

Figure

5.

Position the recoil spring

spring is about

to

ensure proper engagement

6.

Line up the end of the recoil spring with the

3mm

the reel and install the reel.

71

so

(1/8

inch) from the center post

It

may help to rock the

that

with

the end of the

the reel.

slot

in

Recoil Mechanism Installation

1.

Position the recoil starter gasket on the crankcase

and install the recoil starter. Tighten all retaining

so

screws evenly

as not to damage the recoil

housing.

NOTE:

The recoil housing is self-centering and

requires no special centering procedure.

Page 44

Starter Pulley Removal

1.

Remove the recoil starter as described under

Recoil Mechanism Removal, page

2.

Remove the starter pulley nut by turning

counterclockwise. See Figure

73.

30.

it

3.

The starter pulley is threaded onto the crankshaft

and is removed by turning

it

counterclockwise.

the engine turns while trying to remove

piece

of

and

tap to loosen.

wood on one

of

the starter pulley ratchets

Starter Pulley Installation

1.

Thread the starter pulley onto the crankshaft.

2.

Install the flywheel nut, tightening to

(87

to

113

m

3.

Install the recoil starter as described under Recoil

in Ibs).

Mechanism Installation.

1.O

it,

place a

to

1.3

If

kg

I

i

33

Page 45

SECTION 5 CLUTCH SHOES AND FLYWHEEL

Clutch Shoes and Flywheel Operation

74.

200

TC4000

parts

rpm

The TC3000,

clutch. The clutch

spring. These

in Figure

Operation of the clutch is as follows:

1.

When the trimmer engine speed is less than

spring holds the

clutch drum.

and TC5000 use a centrifugal type

is

constructed of two shoes and a

are fastened to the flywheel as shown

Figure

74

(3300

200

rpm on the TC5000) the

two

clutch shoes in, away from the

3900

3.

Remove the fan housing.

IMPORTANT: (TCSOOO only). The coil

mounted to the inside of the fan housing on

TC5000.

lead,

only, and swing

in

a

Clutch Shoes and Flywheel Inspection

1.

Inspect the clutch pads for even wear.

the clutch shoes for evidence of cracking.

2.

Inspect the clutch drum (found in the fan housing)

for roundness and even wear.

3.