Toro 51641 Service Manual

TC1000 GAS TRIMMER, MODEL 51641

Table of Contents – Page 1 of 3

ABOUT THIS MANUAL

SAFETY INSTRUCTIONS

FOR YOUR SAFETY

MAINTENANCE

MAINTENANCE - AIR CLEANER

MAINTENANCE - MUFFLER

MAINTENANCE - SPARK PLUG

MAINTENANCE - FUEL FILTER

MAINTENANCE - COOLING SYSTEM

MAINTENANCE - TRIMMER IMPLEMENT

MAINTENANCE - FLEX SHAFT

MAINTENANCE - PREPARATION FOR STORAGE

SPECIFICATIONS

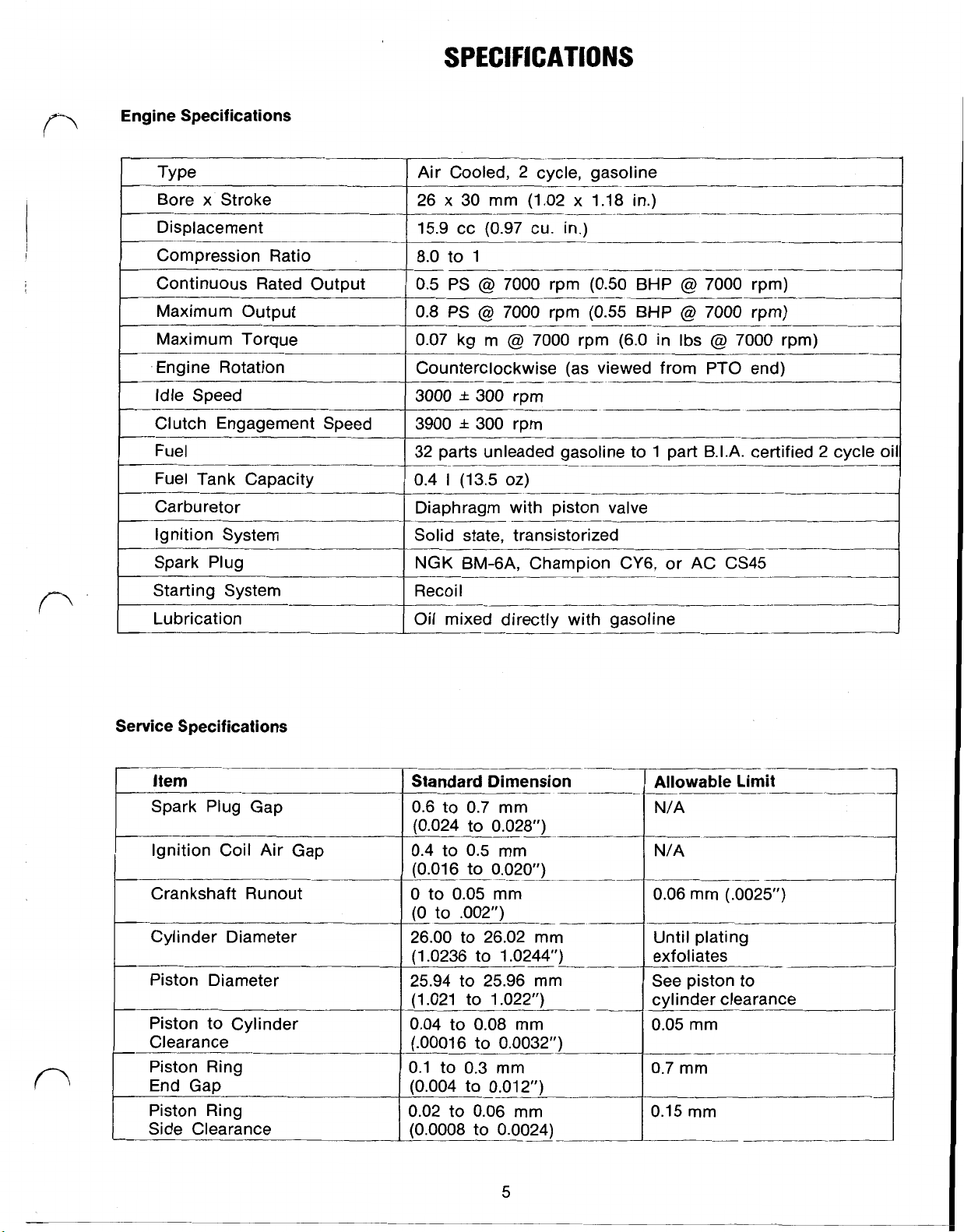

ENGINE SPECIFICAT IONS

SERVICE SPECIFICATIONS

SPECIFICATIONS

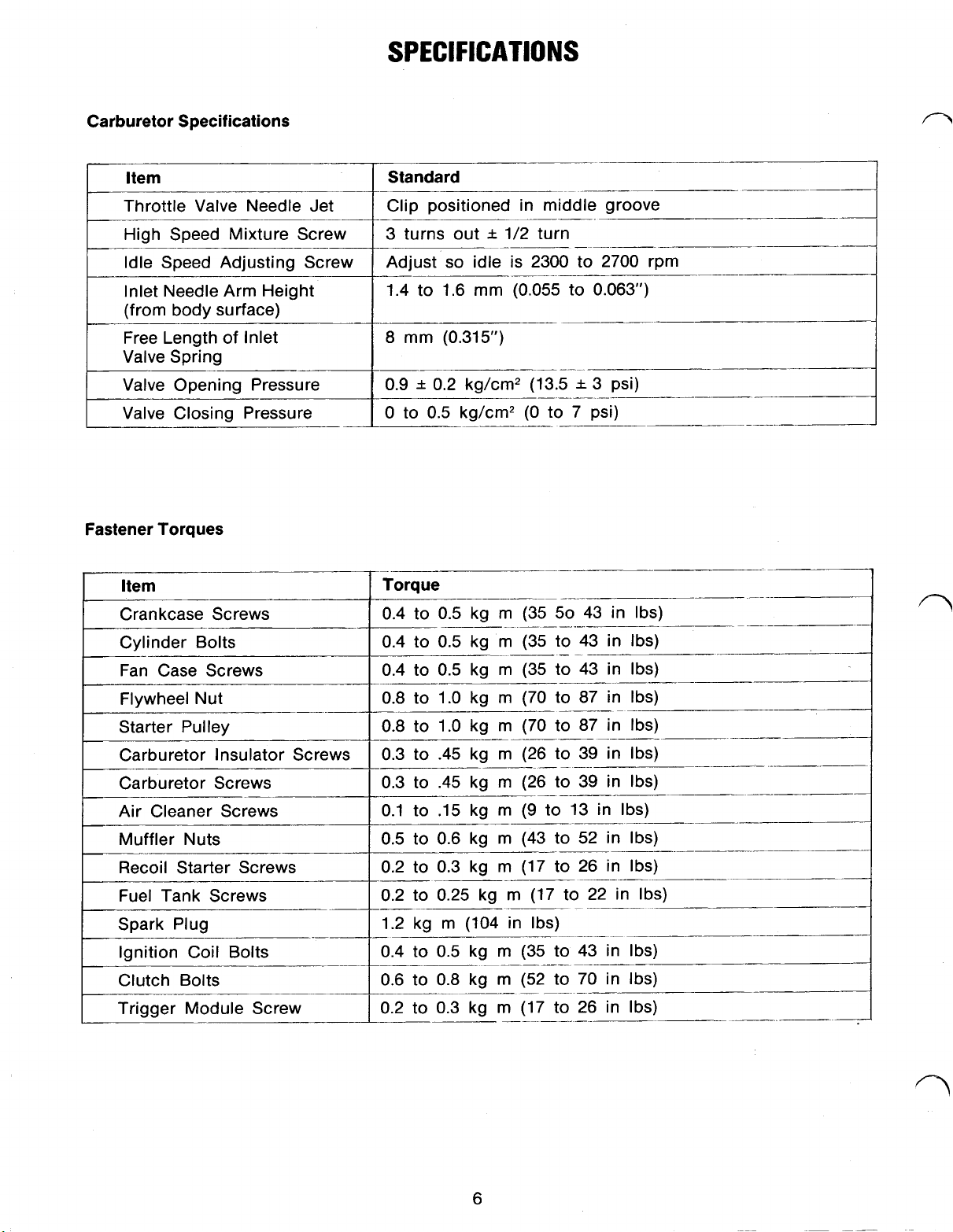

CARBURETOR SPECIFICATIONS

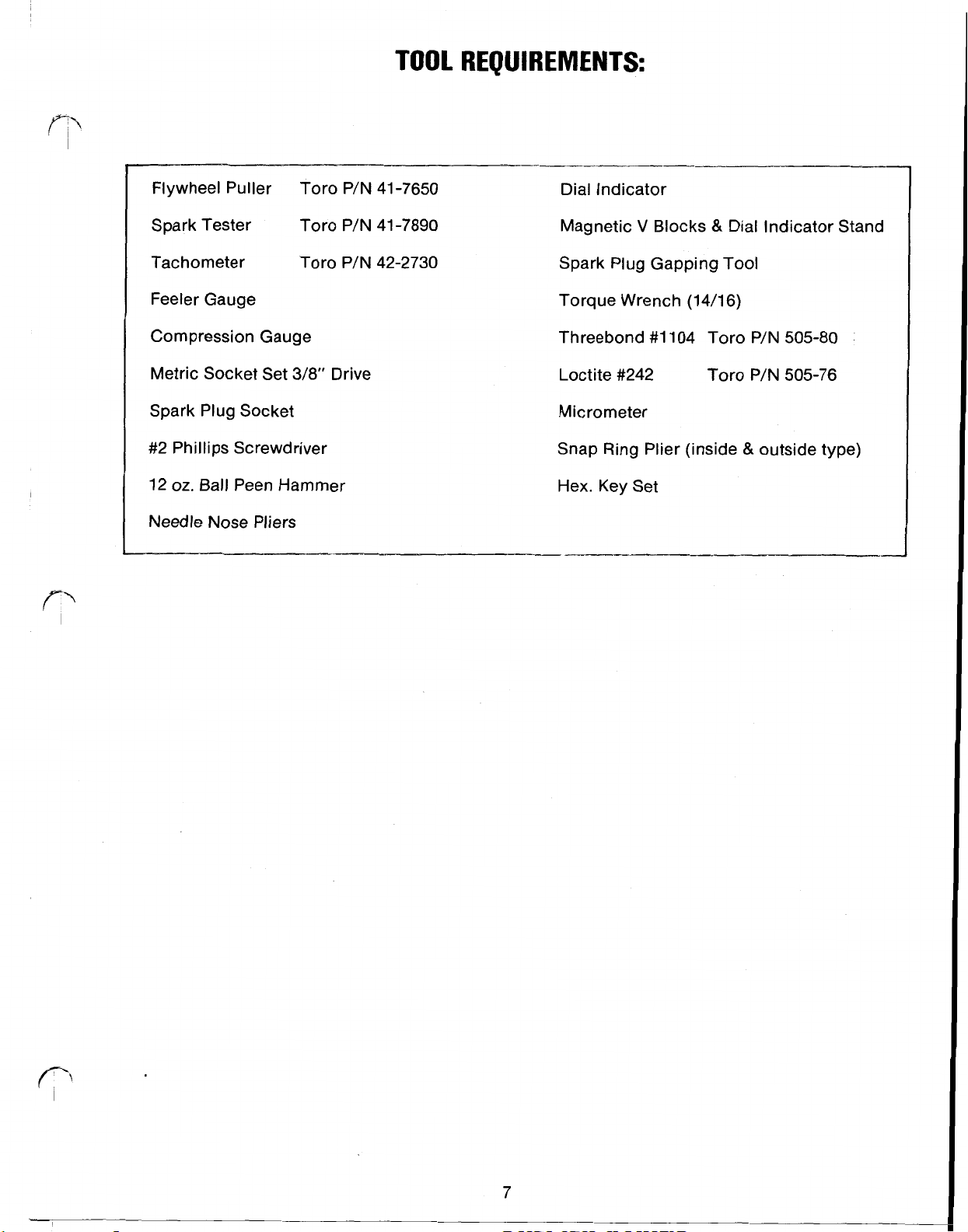

TOOL REQUIREMENTS:

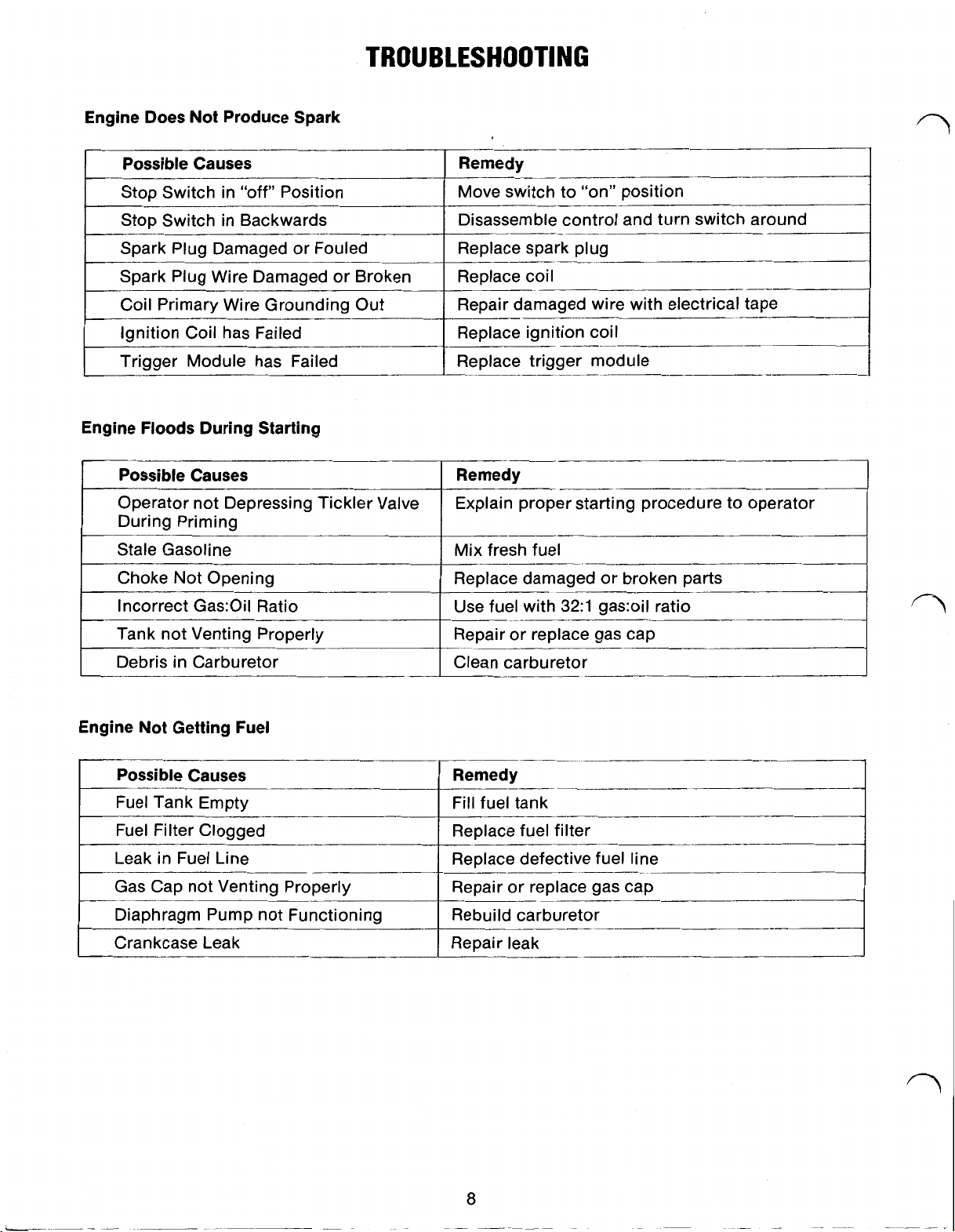

TROUBLESHOOTING

ENGINE DOES NOT PRODUCE SPARK

ENGINE FLOODS DURING STARTING

ENGINE NOT GETTING FUEL

TROUBLESHOOTING

ENGINE LACKS POWER

ENGINE HAS LOW COMPRESSION

ENGINE BACKFIRES (INDICATED BY BURNT AIR CLEANER ELEMENT)

SECTION 1 CARBURETOR

CARBURETOR OPERATION

CARBURETOR OPERATION - THE DIAPHRAGM PUMP

CARBURETOR OPERATION - FUEL METERING & MIXING

CARBURETOR OPERATION - THE PRIMER SYSTEM

CARBURETOR - REMOVAL

CARBURETOR - DISASSEMBLY

CARBURETOR - REASSEMBLY

CARBURETOR - INSTALLATION

CARBURETOR ADJUSTMENT - IDLE SPEED

CARBURETOR ADJUSTMENT - MIXTURE

CARBURETOR ADJUSTMENT - THROTTLE VALVE

TC1000 GAS TRIMMER, MODEL 51641

Table of Contents – Page 2 of 3

SECTION 2 FUEL SYSTEM

FUEL TANK - FUEL TANK - REMOVAL

FUEL TANK - INSTALLATION

PRIMER PUMP - PRIMER PUMP - PROPER USE

PRIMER PUMP - OPERATION

PRIMER PUMP - DISASSEMBLY

PRIMER PUMP INSPECTION

PRIMER PUMP REASSEMBLY

FUEL PICKUP TUBE AND FILTER SERVICE

FUEL CAP - FUEL CAP - OPERATION

FUEL CAP - DISASSEMBLY

FUEL CAP - INSPECTION

FUEL CAP - REASSEMBLY

SECTION 3 IGNITION

IGNITION OPERATION

IGNITION OPERATION - FLYWHEEL

IGNITION OPERATION - IGNITION COIL

IGNITION OPERATION - TRIGGER MODULE

IGNITION OPERATION - SPARK PLUG

AIR GAP ADJUSTMENT

AIR GAP ADJUSTMENT - PREPARATION

AIR GAP ADJUSTMENT - REASSEMBLY

COIL - COIL - REMOVAL

COIL - INSTALLATION

SECTION 4 RECOIL STARTER

RECOIL STARTER - OPERATION

RECOIL STARTER - REMOVAL

RECOIL STARTER - INSTALLATION

RECOIL STARTER - REEL DISASSEMBLY

RECOIL STARTER - REEL REASSEMBLY

RECOIL STARTER - STARTER PULLEY DISASSEMBLY

RECOIL STARTER - STARTER PULLEY REASSEMBLY

SECTION 5 CLUTCH AND FLYWHEEL

CLUTCH SHOES AND FLYWHEEL - OPERATION

CLUTCH SHOES AND FLYWHEEL - INSPECTION

CLUTCH SHOES AND FLYWHEEL - REMOVAL

CLUTCH SHOES AND FLYWHEEL - REASSEMBLY

CLUTCH DRUM AND CLUTCH HOUSING - CLUTCH DRUM AND CLUTCH HOUSING -

CLUTCH DRUM AND CLUTCH HOUSING - REASSEMBLY

SECTION 6 ENGINE

ENGINE - OPERATION

ENGINE - REMOVAL FROM DRIVE TUBE

ENGINE - DISASSEMBLY

ENGINE - CLEANING AFTER DISASSEMBLY

TC1000 GAS TRIMMER, MODEL 51641

Table of Contents – Page 3 of 3

SECTION 6 ENGINE - Continued

ENGINE - INSPECTION

ENGINE - REASSEMBLY

ENGINE - INSTALLATION ON DRIVE TUBE

SECTION 7 CONTROLS

CONTROL AND GRIP - REMOVAL FROM DRIVE TUBE

CONTROL AND GRIP - INSTALLATION ON DRIVE TUBE

SECTION 8 HANDLE

HANDLE - REMOVAL FROM DRIVE TUBE

HANDLE - INSTALLATION ON DRIVE TUBE

HANDLE - ADJUSTMENT

SECTION 9 SHIELD

SHIELD - KNIFE REPLACEMENT

SHIELD - REMOVAL FROM DRIVE TUBE

SHIELD - INSTALLATION ON DRIVE TUBE

SECTION 10 CUTTER HEAD BEARINGS

CUTTER HEAD BEARINGS - REMOVAL

CUTTER HEAD BEARINGS - INSTALLATION

SECTION 11 FLEXIBLE DRIVE SHAFT

FLEXIBLE DRIVE SHAFT - REMOVAL

FLEXIBLE DRIVE SHAFT - SERVICE

FLEXIBLE DRIFT SHAFT - INSTALLATION

SECTION 12 DRIVE TUBE

DRIVE TUBE - REMOVAL

DRIVE TUBE - SERVICE

DRIVE TUBE - INSTALLATION

SECTION 13 TAP AND TRIM HEAD

TAP AND TRIM SPOOL - TAP AND TRIM SPOOL - REMOVAL

TAP AND TRIM SPOOL - LINE REPLACEMENT

TAP AND TRIM SPOOL - REMOVAL

TAP AND TRIM HEAD - TA P AND TRIM HEAD - DISASSEMBLY

TAP AND TRIM HEAD - INSPECTION

TAP AND TRIM HEAD - REASSEMBLY

SECTION 14 FLEX BLADE

FLEX BLADE - REMOVAL FROM DRIVE SHAFT

FLEX BLADE - INSTALLATION ON DRIVE TUBE

SECTION 15 ACCESSORIES

STANDARD AND DELUXE HARNESS - ASSEMBLY

ABOUT

THIS

MANUAL

This Service Manual was written expressly for the

Powered Trimmer. The Tor0 Company had made every effort to make the

information in this manual complete and correct.

This manual was written with the service technician in mind. It

so

that information used most often is up front. As a result, you will find

reference information on safety, maintenance, specifications, special tools

and troubleshooting all in the front third of the manual.

Disassembly, inspection and reassembly procedures are covered in the last

two-thirds of the manual and are grouped by component.

each common repair with its own section or sub-section. For example, you

will find that air gap adjustment and ignition coil replacement are called out

separately.

And, because certain components are often difficult to troubleshoot without

a good understanding of how they work, we have included some

component theory. This information can be found at the beginning of most

service procedure sections.

We

are hopeful that you will find this manual a valuable addition to your

shop. If you should come across any errors or

regarding this manual, please contact us at the following address:

The Tor0 Company

8111 Lyndale Avenue South

Minneapolis, MN, USA

TOR0

if

you have any questions

55420

TClOOO Gas

is

organized

We

tried to cover

The Tor0 Company reserves the right to change product specifications or

this manual without notice.

The Tor0 Company gratefully acknowledges the assistance of Mitsubishi

Heavy Industries, Ltd. in the production of this manual.

COPYRIGHT RIGHTS

Tor0 Company

MINNEAPOLIS,

MN

55420

RESERVED

1987

U.S.A.

Reference Information

For Your Safety 1

TABLE

OF

CONTENTS

Page

Maintenance

Specifications

Tool

Requirements 7

Troubleshooting

Service Procedures

Section 1

Carburetor

operation

removal 13

disassembly 13

reassembly 15

installation 17

adjustment 17

2

5

8

Page

10

I

Section

2

Fuel System

Fuel Tank

removal 19

installation 19

Primer Pump

properuse 19

operation 19

disassembly

inspection

reassembly

Fuel Pickup Tube and Filter

service

Fuel Cap

operation 21

disassembly

inspection

reassembly

20

20

20

21

22

22

22

Service Procedures

j

Section 3

(continued)

Ignition

operation 23

air gap adjustment 25

coil removal 26

coil installation 26

Page

Section 4

Section

Section 6

5

Recoil Starter

Recoil Starter

operation 27

removal 27

installation 27

reel disassembly 27

reel reassembly 28

starter pulley disassembly 29

starter pulley reassembly 29

Clutch

Clutch Shoes and Flywheel

operation 30

inspection 30

removal

reassembly 31

Clutch Drum and Clutch Housing

disassembly 31

reassembly 31

Engine

operation 32

removal from drive tube 34

disassembly 35

cleaning after disassembly 36

inspection 37

reassembly 38

installation on drive tube 39

30

Section 7

Section 8

Section 9

Controls

Control and Grip

removal from drive tube 40

installation on drive tube 40

Handle

removal from drive tube 41

installation on drive tube 41

adjustment 41

Shield

knife replacement 42

removal from drive tube 42

installation on drive tube 42

Service Procedures

(continued)

I

Section 10

Section 11

Section 12

Section 13

Cutter Head Bearings

removal

installation

Flexible Drive Shaft

removal

installation

Drive Tube

removal

service

installation

Tap and Trim@ Head

Tap and Trim@ Spool

Tap and Trim@ Head

.....................................................

..................................................

..................................................

.....................................................

......................................................

..................................................

removal

line replacement

installation

disassembly

inspection

reassembly

.................................................

...........................................

........................................

..............................................

.............................................

..............................................

.............................................

Page

43

43

44

44

45

45

45

46

46

46

47

47

47

Section 14

Section 15

Flex Blade

removal from drive shaft 48

installation on drive tube

Accessories

Standard and Deluxe Harness

assembly

....................................................

......................................

48

49

PERSONAL SAFETY

INSTRUCTION Read

the instruction because it

has to

Failure to comply with

the instruction may result

or death.

SAFETY

do

with the safety.

in

personal injury

INSTRUCTIONS

This manual is intended as a service and repair

manual only. The safety instructions provided in

this manual are for the troubleshooting and

service of the product only. The individual

Operator's Manual will contain safety information

on

the operation of the TC1000.

Operator's Manuals with complete operational

safety instructions are available through:

The Toro Company

Publications Department

8111

Lyndale Avenue South

Minneapolis, MN

55420

U.S.A.

FOR

Avoid possible explosions

Store fuel in a container designed for gasoline

and never smoke while working around gasoline.

Avoid fires

Never allow the trimmer engine closer than one

meter (three feet) to any combustible material.

Avoid accidental misuse of fuel

Always store fuel in a container designed for

gasoline that is properly labeled.

Avoid falls

Always wipe up spilled fuel or oil.

Avoid asphyxiation

Never operate an engine in a confined area

without proper ventilation.

. .

. .

.

.

. . .

.

. .

YOUR

SAFETY

gas

.

trimmer.

Avoid unexpected starting of the engine

Always disconnect the spark plug wire before

attempting any cleaning, adjustment or repair.

Avoid contact with a moving cutter head.

Always stay clear

engine is running. The clutch is a mechanical

device which could fail.

the cutter head from turning.

Avoid blindness

Always wear eye protection when repairing or

running a gas trimmer.

Avoid hearing

Wear ear protection when running a

. . .

loss

of

the cutter head when the

Do

not rely on it to keep

. .

.

. .

.

.

1

MAINTENANCE

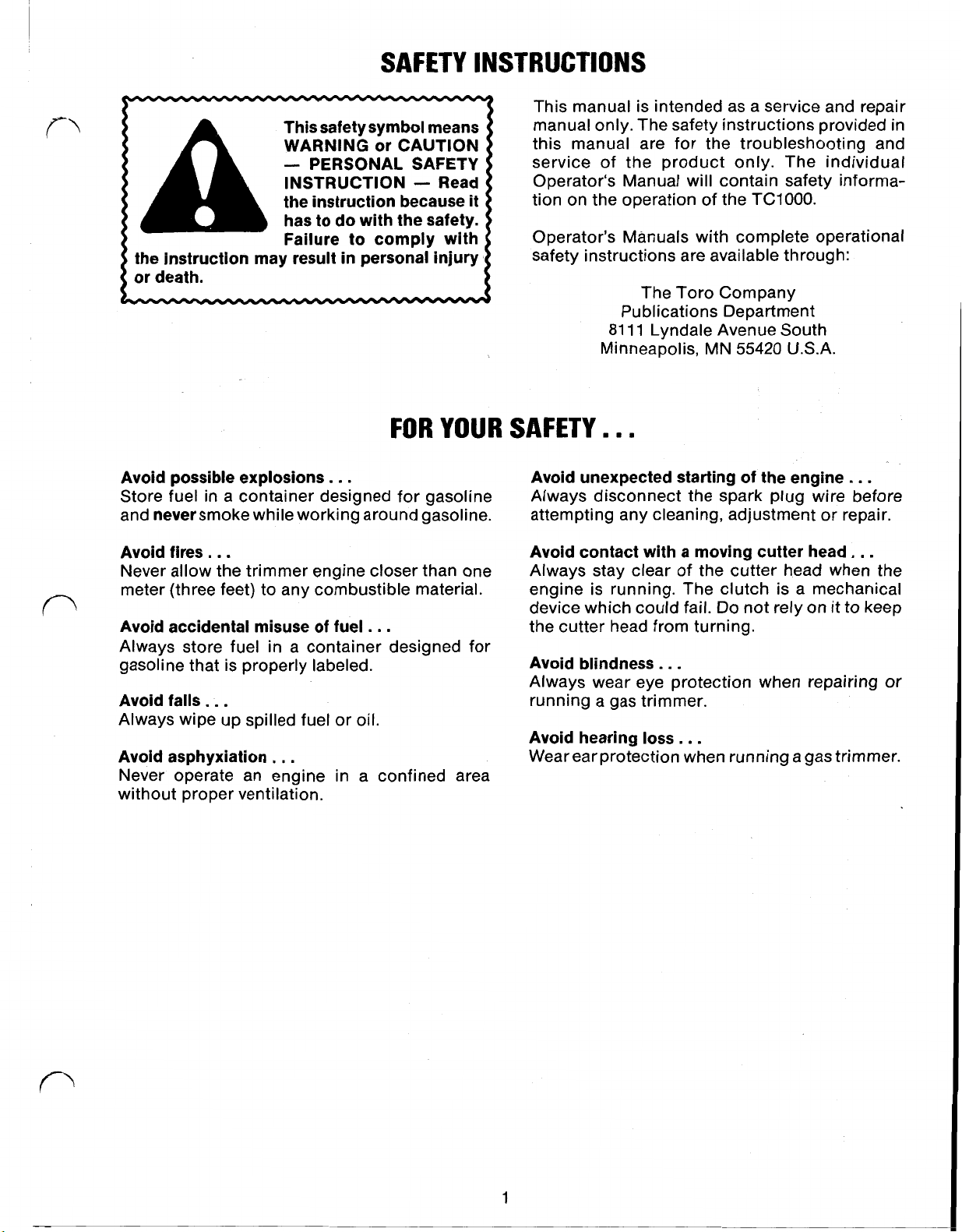

Maintenance

Air

Cleaner

Servicing of the air cleaner is recommended

afterevery25 hours of operation or more often in

very dusty conditions.

See Fig.

AIR

1.

FILTER GRID

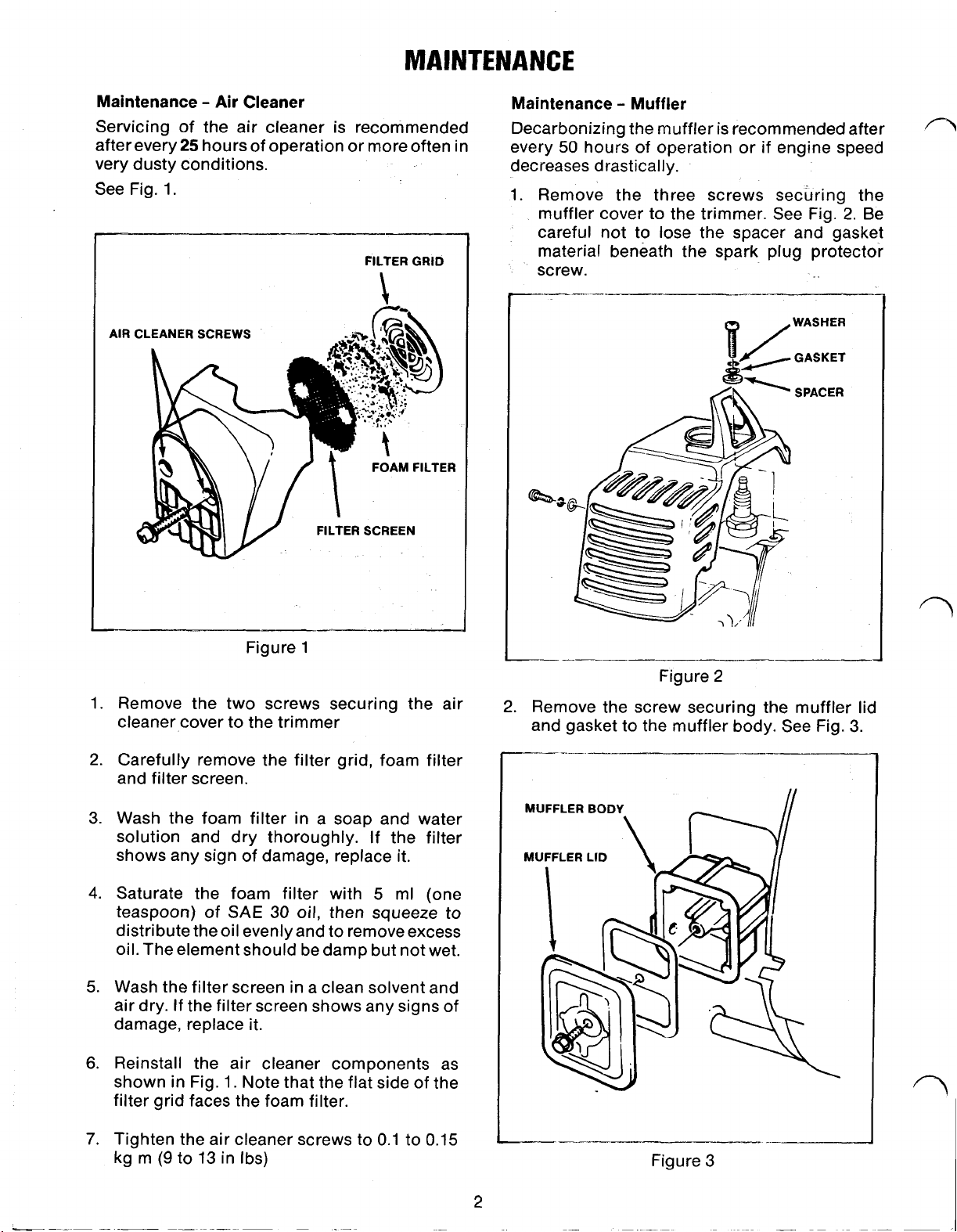

Maintenance Muffler

Decarbonizing the muffler

every

50

hours of operation or if engine speed

is

recommended after

decreases drastically.

1.

Remove the three screws securing the

muffler cover to the trimmer. See Fig.

careful not to

lose

the spacer and gasket

material beneath the spark plug protector

screw.

SPACER

2.

Be

Figure

1.

Remove the two screws securing the air

1

cleaner cover to the trimmer

2.

Carefully remove the filter grid, foam filter

and filter screen.

3.

Wash the foam filter in a soap and water

solution and dry thoroughly.

If

the filter

shows any sign of damage, replace it.

4.

Saturate the foam filter with

SAE

30

teaspoon) of

oil, then squeeze to

5

ml (one

distribute the oil evenly and to remove excess

oil. The element should be damp but not wet.

5.

Wash the filter screen in a clean solvent and

air dry.

If

the filter screen shows any signs of

damage, replace it.

6.

Reinstall the air cleaner components as

shown in Fig.

1.

Note that the flat side of the

filter grid faces the foam filter.

Figure

2.

Remove the screw securing the muffler

2

and gasket to the muffler body. See Fig.

MUFFLER

MUFFLER

BOD

LID

lid

3.

7.

Tighten the air cleaner screws to

kg m

(9

to

13

in Ibs)

0.1

to

0.15

2

P\

Maintenance Muffler (cont'd)

3.

Rotate the engine crankshaft until the piston

totally covers the exhaust port. Clean the

exhaust port area by using a clean flat piece

of hardwood. Remove all loose particles.

IMPORTANT Use extreme care when cleaning the exhaust port. Stay clear of the piston

so

it will not be damaged.

4. Clean any carbon buildup inside the muffler

body.

5.

Make sure the muffler gasket is still useable

(replace

muffler body and muffler lid to trimmer.

6. Reinstall muffler cover and tighten all fasteners securely. Be sure to install the spacer

underneath the spark plug protector as

shown in Figure 2.

if

necessary) and install gasket,

pickup tube above the filter. Pull the filter and

hose out the fuel tank opening. See Fig. 4.

r'l

Maintenance Spark Plug

The TC1000 uses an

equivalent. Correct gap is 0.6-0.7 mm (0.024-

0.028"). The recommended servicing interval for

the spark plug is 25 hours of operation.

1. Stop the engine and pull off the spark plug

wire.

2. Clean around the spark plug and remove the

spark plug from the engine using a 19mm

(3/4 inch) socket.

IMPORTANT: Replace a cracked, fouled

dirty spark plug.

clean electrodes because engine damage

could result from grit entering the cylinder.

3. Set the plug gap to 0.6-0.7mm (0.24-0.28").

4. Reinstall the plug and gasket in the engine.

Tighten to 1.2 kg m (104 in Ibs).

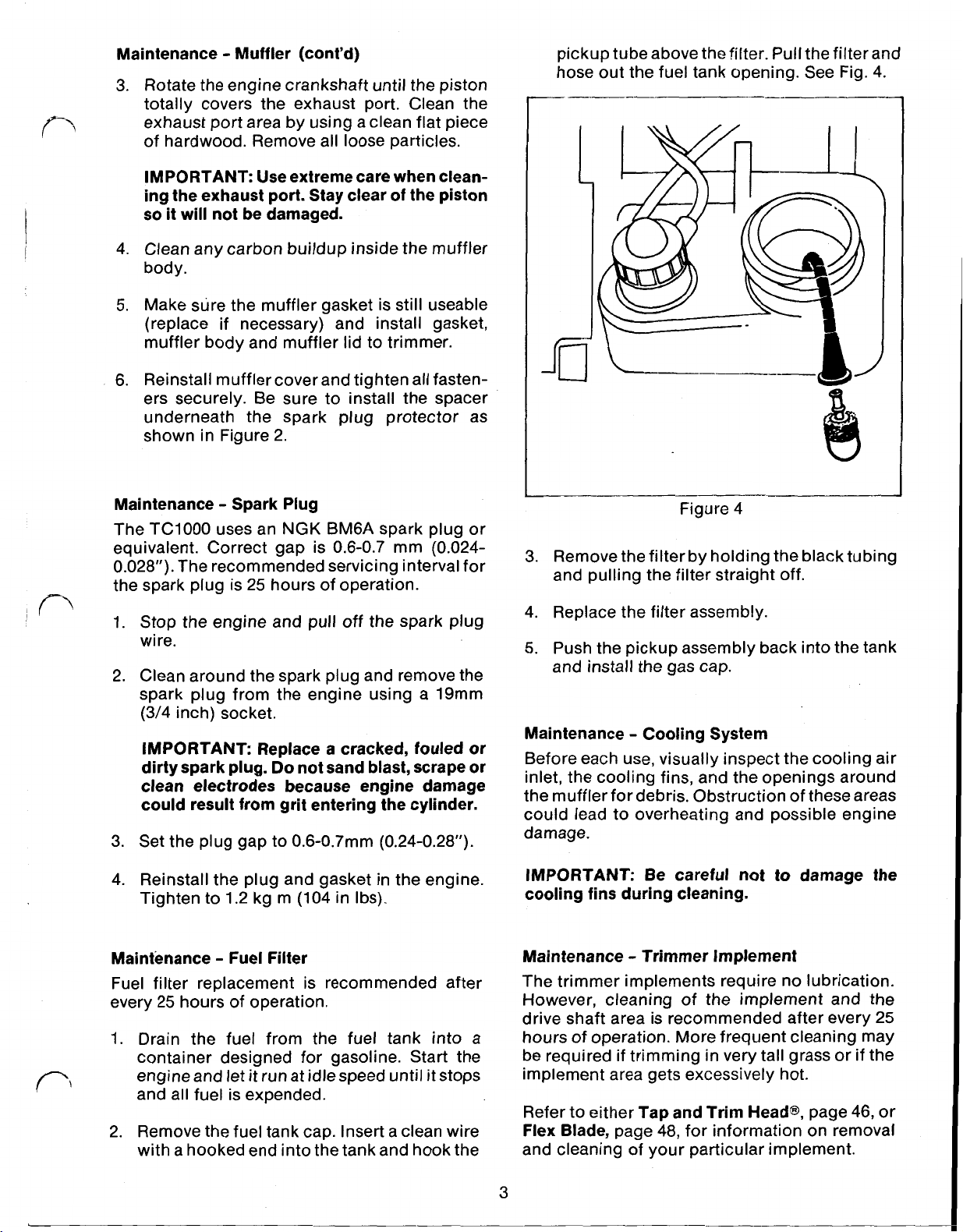

Maintenance Fuel Filter

Fuel filter replacement is recommended after

every 25 hours of operation.

1.

Drain the fuel from the fuel tank into a

container designed for gasoline. Start the

engineand let it run at idlespeed until it stops

and all fuel is expended.

2. Remove the fuel tank cap. Insert a clean wire

with a hooked end into the tank and hook the

NGK

BM6A spark plug or

Do

not sand blast, scrape

or

or

Figure 4

3. Remove the filter by holding the black tubing

and pulling the filter straight off.

4.

Replace the filter assembly.

5.

Push the pickup assembly back into the tank

and install the gas cap.

Maintenance Cooling System

Before each use, visually inspect the cooling air

inlet, the cooling fins, and the openings around

the muffler for debris. Obstruction of these areas

could lead to overheating and possible engine

damage.

IMPORTANT: Be careful not

cooling fins during cleaning.

Maintenance Trimmer Implement

The trimmer implements require no lubrication.

However, cleaning

drive shaft area is recommended after every 25

hours of operation. More frequent cleaning may

be required

implement area gets excessively hot.

Refer to either

Flex Blade,

and cleaning of your particular implement.

if

trimming in very tall grass or

page 48, for information on removal

of

the implement and the

Tap and Trim Head@,

to

damage

page 46, or

if

the

the

3

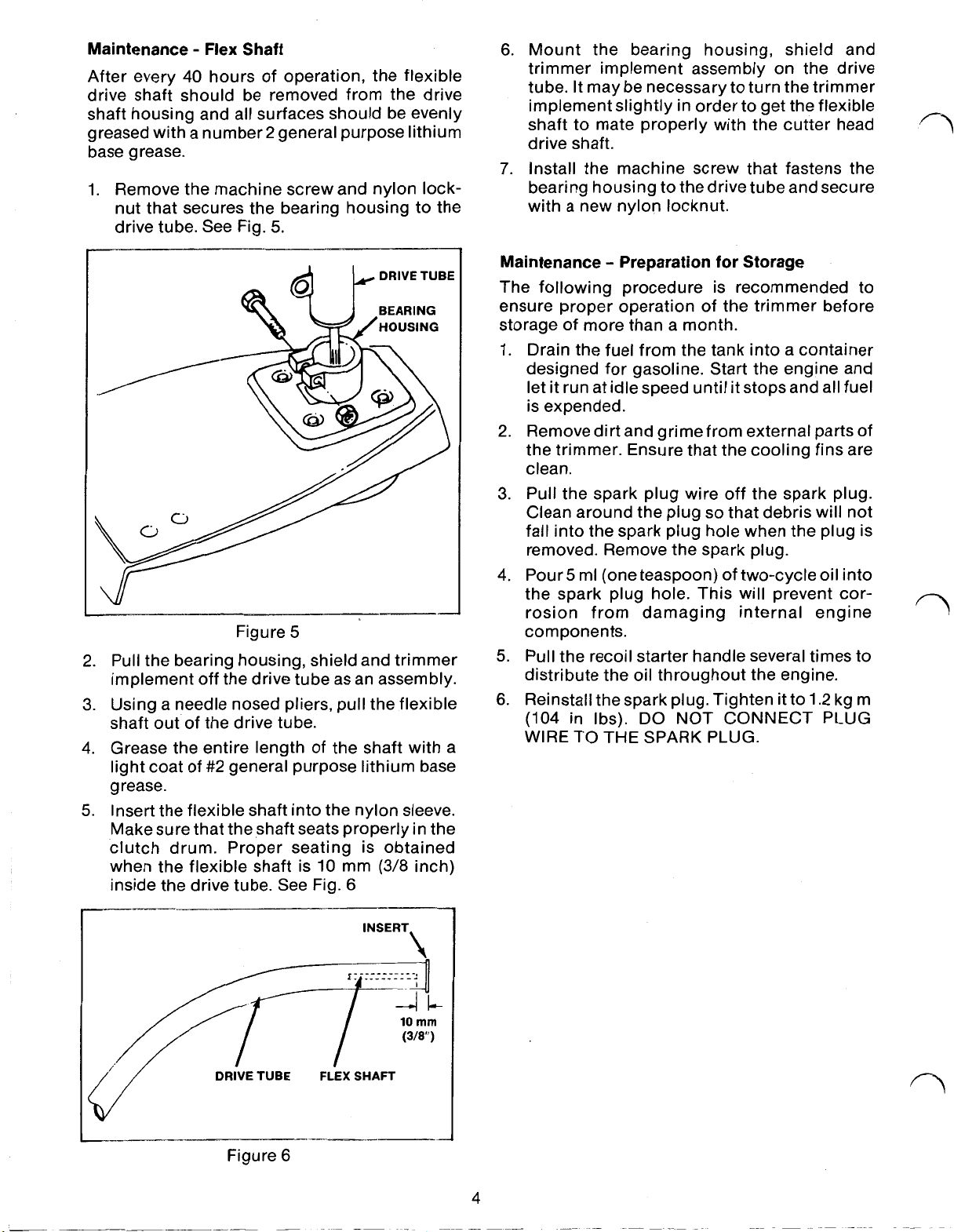

Maintenance Flex Shaft

After every 40 hours of operation, the flexible

drive shaft should be removed from the drive

shaft housing and all surfaces should be evenly

greased with a number 2 general purpose lithium

base grease.

1. Remove the machine screw and nylon locknut that secures the bearing housing to the

drive tube. See Fig.

5.

Figure

5

2. Pull the bearing housing, shield and trimmer

implement off the drive tube as an assembly.

3.

Using a needle nosed pliers, pull the flexible

shaft out of the drive tube.

4. Grease the entire length of the shaft with a

light coat of #2 general purpose lithium base

grease.

5.

Insert the flexible shaft into the nylon sleeve.

Make sure that the shaft seats properly in the

clutch drum. Proper seating is obtained

when the flexible shaft is 10 mm

inside the drive tube. See Fig.

6

(3/8

inch)

6.

Mount the bearing housing, shield and

trimmer implement assembly on the drive

tube. It may be necessary to turn the trimmer

implement slightly in order to get the flexible

shaft to mate properly with the cutter head

drive shaft.

7.

Install the machine screw that fastens the

bearing housing to the drive tube and secure

with a new nylon locknut.

Maintenance Preparation for Storage

The following procedure is recommended to

ensure proper operation of the trimmer before

storage of more than a month.

1. Drain the fuel from the tank into a container

designed for gasoline. Start the engine and

let it run at idle speed until it stops and all fuel

is expended.

2. Remove dirt and grime from external parts of

the trimmer. Ensure that the cooling fins are

clean.

3.

Pull the spark plug wire off the spark plug.

Clean around the plug

so

that debris will not

fall into the spark plug hole when the plug is

removed. Remove the spark plug.

4. Pour 5 ml (one teaspoon) of two-cycle oil into

the spark plug hole. This will prevent corrosion from damaging internal engine

components.

5.

Pull the recoil starter handle several times to

distribute the oil throughout the engine.

6.

Reinstall the spark plug. Tighten it to 1.2 kg m

(104 in Ibs). DO NOT CONNECT PLUG

WIRE

TO THE SPARK PLUG.

DRIVE

Figure

TUBE

6

FLEX

SHAFT

4

Engine Specifications

SPECIFICATIONS

Type

Bore x Stroke

Displacement

Compression Ratio

Continuous Rated Output

Maximum Output

Maximum Torque

Engine Rotation

Idle Speed

Clutch Engagement Speed

Fuel

Fuel Tank Capacity

Carburetor

Ignition System

Spark Plug

Starting System

Lubrication

Air Cooled, 2 cycle, gasoline

x

30 mm (1.02 x 1.18 in.)

26

15.9 cc

.________--

(0.97

cu. in.)

8.0 to 1

0.5

PS

@

7000

rpm

(0.50

BHP

@

7000

rpm)

0.8

PS

@

7000

rpm

0.07

kg m

@

7000

Counterclockwise

3000

300

rpm

(0.55

rpm (6.0 in Ibs

(as

BHP

@

7000

rpm)

@

_______.___-

7000

viewed from PTO end)

rpm)

3900 300 rpm

32 parts unleaded gasoline to 1 part B.I.A. certified 2 cycle

0.4

I

(13.5

02)

.__-

Diaphragm with piston valve

Solid state, transistorized

NGK BM-6A, Champion

CY6,

or AC

CS45

Recoil

Oil mixed directly with gasoline

oil

Service Specifications

I

Item

Spark Plug Gap

Ignition Coil Air Gap

Crankshaft Runout

Cylinder Diameter

Piston Diameter

Piston to Cylinder

Clearance

Piston Ring

Piston Ring

Side Clearance

Standard Dimension

0.6 to

0.7

mm

(0.024 to 0.028")

0.5

0.4 to

mm

(0.016 to 0.020")

0

to

0.05

mm

(0

to .002")

26.00 to 26.02 mm

(1.0236 to 1.0244")

______-

25.94 to 25.96 mm

(1.021 to 1.022")

0.04 to 0.08 mm

(.00016 to 0.0032")

0.1 to 0.3 mm

(0.004 to 0.012")

0.02 to 0.06 mm

(0.0008 to 0.0024)

__-

__-

Allowable Limit

N/A

N/A

0.06 mm (.0025")

Until plating

exfoliates

See piston to

cylinder clearance

0.05

mm

0.7

mm

0.15 mm

5

Carburetor Specifications

SPECIFICATIONS

Item

Throttle Valve Needle Jet

High Speed Mixture Screw

Idle Speed Adjusting Screw

Inlet Needle Arm Height

(from body surface)

Valve Spring

Valve Opening Pressure

Valve Closing Pressure

Fastener Torques

Standard

Clip positioned in middle groove

3 turns out 1/2 turn

Adjust

__-

1.4

so

idle is 2300 to 2700 rpm

to 1.6 mm

(0.055

to 0.063")

TOOL

Flywheel Puller Toro P/N 41-7650 Dial Indicator

REQUIREMENTS

Spark Tester Toro P/N 41-7890 Magnetic

Tachometer Toro P/N 42-2730 Spark Plug Gapping

Feeler Gauge Torque Wrench (14/16)

Compression Gauge Threebond #1104 Toro P/N

Metric Socket Set

Spark Plug Socket Micrometer

#2 Phillips Screwdriver Snap Ring Plier (inside

12

oz.

Ball Peen Hammer Hex. Key Set

Needle Nose Pliers

3/8"

Drive Loctite #242 Toro P/N 505-76

V

Blocks

&.

Dial Indicator Stand

Tool

505-80

&

outside type)

7

Engine Does Not Produce Spark

Engine Floods During Starting

TROUBLESHOOTING

control and turn switch around

eplace trigger module

Possible Causes

Operator not Depressing Tickler Valve

During Priming

Stale Gasoline Mix fresh fuel

Choke Not Opening Replace damaged

Incorrect Gas:Oil Ratio

Tank not Venting Properly

Debris in Carburetor

Engine Not Getting Fuel

Possible Causes

Fuel Tank Empty

Fuel Filter Clogged

Gas Cap not Venting Properly

Diaphragm Pump not Functioning

Remedy

Explain proper starting procedure to operator

Use fuel with

Repair

Clean carburetor

Remedy

Fill fuel tank

Replace fuel filter

Replace defective fuel line

Repair or replace gas cap

Rebuild carburetor

or

or

broken parts

32.1

gasoil ratio

replace gas cap

Crankcase Leak

Repair leak

_____-

TROUBLESHOOTING

Engine Lacks Power

Possible Causes Remedy

Grass Wound around Trimmer Head Clean trimmer head

Gas:Oil Ratio

Stale Fuel

Carburetor Improperly Adjusted Adjust carburetor

Flywheel Key Sheared or Missing

Low Compression

Engine Has Low Compression

Possible Causes Remedy

Insufficient Oil in Fuel

Piston Rings Excessively Worn

Air Leak in Lower Crankcase Replace lower crankcase seals

Air Leak in Cylinder Mounting Area

Air Leak at Spark Plug

;s,”

;3;h;;;pi

Replace flywheel key

“Low

See

Use fuel with gasoil ratio

Rebuild engine

Replace gasket and tighten mounting bolts

Replace defective plug or cylinder

I

ratio

Compression”

I

I

I

Engine Backfires

Possible Causes

Muffler and Exhaust Port Plugged

with Carbon

Sheared or Missing Flywheel Key

Operator Constantly Revving Engine

(indicated by burnt air cleaner element)

Decarbonize muffler and exhaust ports

Replace flywheel key

Educate Operator

I

__.-

9

SECTION

1

Carburetor Operation

The carburetor for the TC1000 is a diaphragm

style carburetor. It uses alternating pulses from

the crankcase to pump fuel from the fuel tank to

the carburetor.

To adequately describe the function of the car-

buretor, it is necessary to break its operation

down into three systems:

-The Diaphragm Pump

Fuel Metering and Mixing System

The Primer System

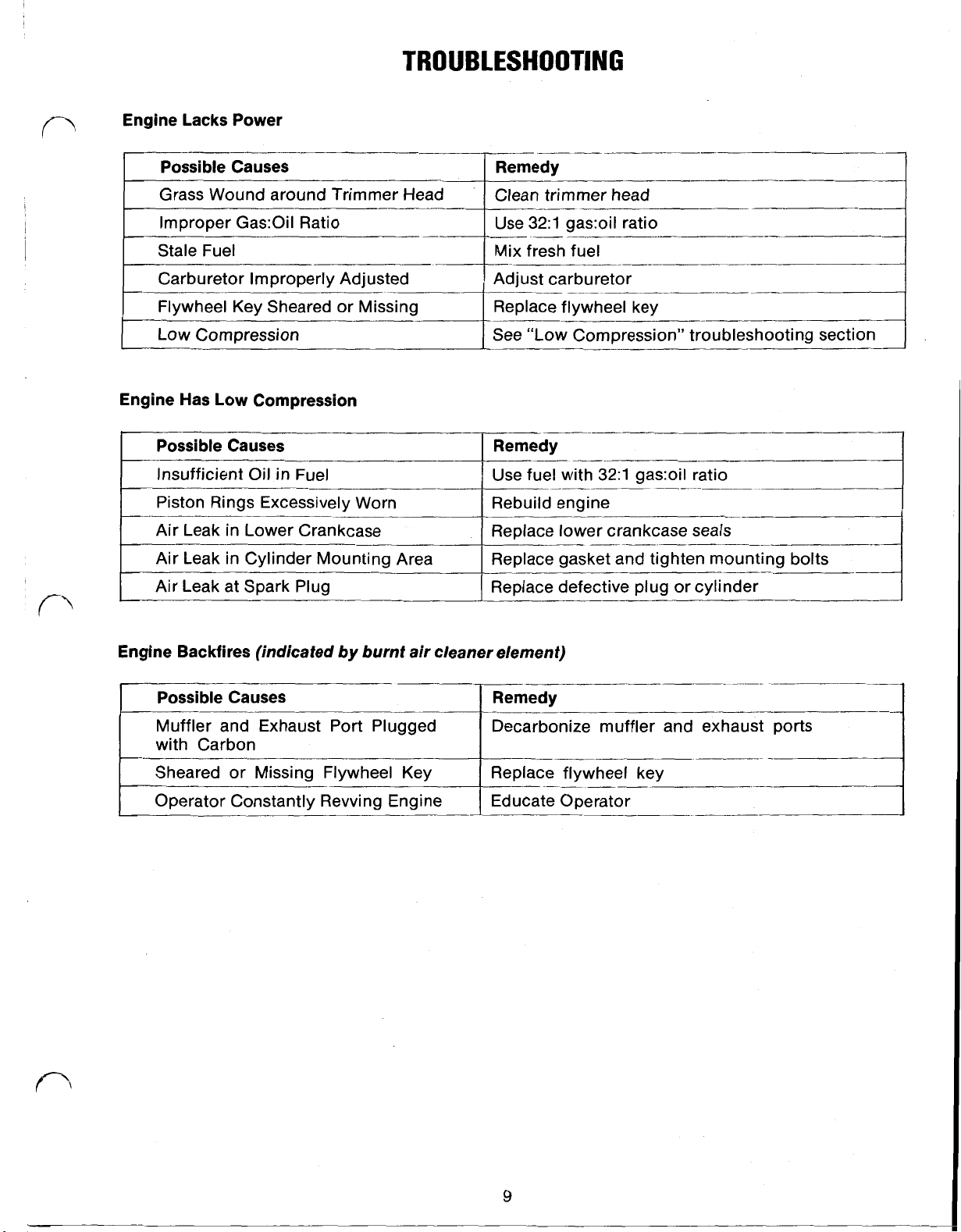

Carburetor Operation The Diaphragm Pump

The diaphragm pump requires alternating positive and negative air pressures working upon it in

order to fluctuate and perform a pumping

function. The source of the positive and negative

pressures is the lower crankcase where these

pressures are alternately being created by the up

and down movement of the piston.

Transfer of these pressure pulses is accomplished by a passage which leads from the lower

crankcase, to a point just below the intake port.

See Fig.

7.

PULSE

PASSAGE

PULSE PASSAGE PULSE HOLE

Figure

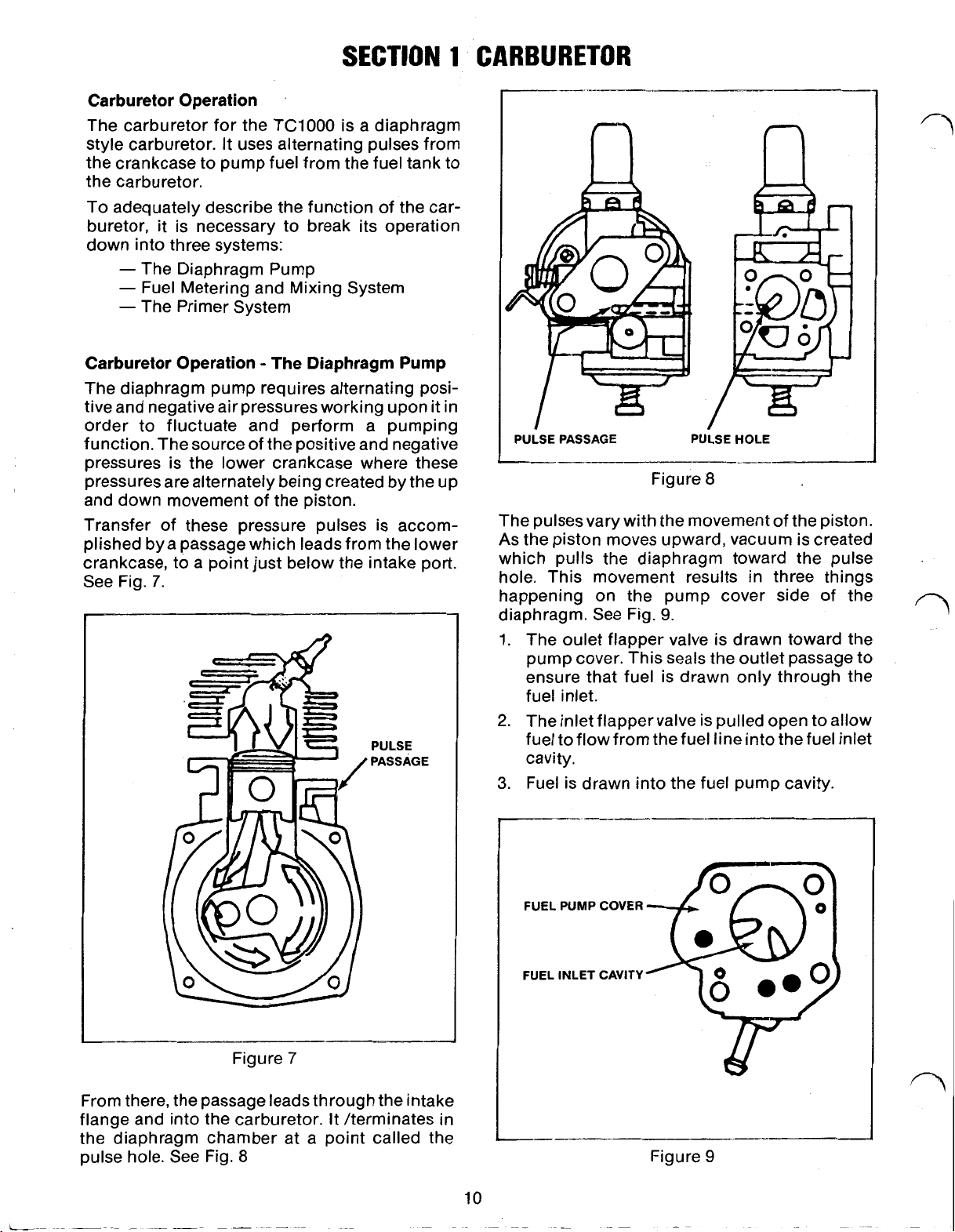

The pulses

As

the piston moves upward, vacuum is created

vary

with the movement of the piston.

8

which pulls the diaphragm toward the pulse

hole. This movement results in three things

happening on the pump cover side of the

diaphragm. See Fig.

1.

The outlet flapper valve is drawn toward the

9.

pump cover. This seals the outlet passage to

ensure that fuel is drawn only through the

fuel inlet.

2.

The inlet flapper valve is pulled open to allow

fuel toflowfrom thefuel line

into

thefuel inlet

cavity.

3.

Fuel is drawn into the fuel pump cavity.

Figure

7

From there, the passage leads through the intake

flange and into the carburetor. It /terminates in

the diaphragm chamber at a point called the

pulse hole. See Fig.

8

10

FUEL PUMP

FUEL INLET

COVER

CAVITY

Figure

._I

9

Loading...

Loading...