Page 1

N-28 ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 1

GENERAL INFORMATION

SPECIFICATIONS AND TORQUES

SAFETY WARNINGS AND NOTES

PRODUCT IDENTIFICATION NUMBERS

STARTING/STOPPING INSTRUCTIONS

SERVICE/MAINTENANCE INSTRUCTIONS

STORAGE INSTRUCTIONS

TROUBLESHOOTING

ENGINE FAILS TO START

ENGINE STARVES ON ACCELERATION

ENGINE IS HARD TO START

ENGINE STALLS

ENGINE FIRES INTERMITTENTLY

ENGINE DOES NOT PRODUCE MAXIMUM POWER

CARBURETOR FLOODS

ENGINE STOPS AFTER RUNNING BRIEFLY

ENGINE WILL NOT IDLE

ENGINE BACKFIRES OR MISFIRES

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STOPS DURING OPERATION

DISASSEMBLY, INSPECTION, & REPAIR

TYPICAL DISASSEMBLY SEQUENCE

MAJOR COMPONENTS (CONT.)

ENGINE

REASSEMBLY

TYPICAL DISASSEMBLY SEQUENCE

ENGINE

MAJOR COMPONENTS

Page 2

GENERAL INFORMATION

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting ..............................

Disassembly, Inspection, and Repair ...................

Reassembly ................................

1

2

3

4

1 - 1

Page 3

GENERAL INFORMATION

1

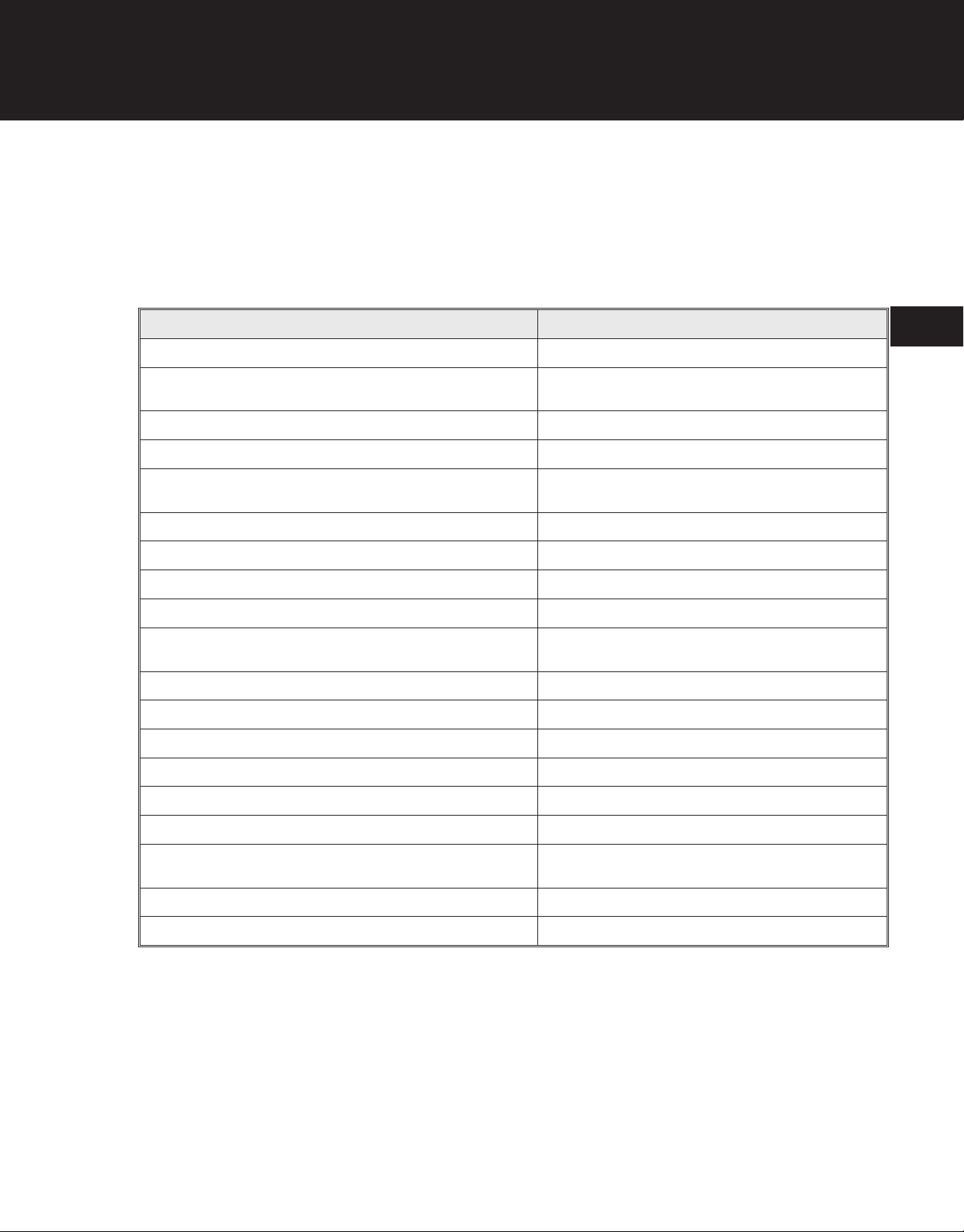

SPECIFICATIONS AND TORQUES

Engine - All N28 Engines . . . . . . . . . . . . . . . . . . . . . . 1-4

Engine - Units with Serial Number 102084332 to 302010968 . . . 1-4

Engine - Units with Serial Number 302010969 and Greater . . . . 1-3

Fuel and Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Carburetor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Carburetor Units with Serial Number 102084332 to 302010968 . . 1-5

Table Of Contents

Carburetor Spacer . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Clutch Standard N28 Engines . . . . . . . . . . . . . . . . . . . . 1-5

Clutch Professional N28 Engines . . . . . . . . . . . . . . . . . . 1-5

Crankcase and Cylinder . . . . . . . . . . . . . . . . . . . . . . . 1-5

Drive Housing (Boom) Professional N28 Units . . . . . . . . . . . 1-5

Engine/Styling Cover . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Flex Drive Housing (Boom) - Standard N28 Units . . . . . . . . . . 1-5

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Ignition Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Starter/Starter Housing . . . . . . . . . . . . . . . . . . . . . . . 1-5

1- 2

Page 4

GENERAL INFORMATION

Safety Warnings and Notes . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Product Identification Numbers . . . . . . . . . . . . . . . . . . . . . . 1-7

Engine Serial Number Significance . . . . . . . . . . . . . . . . . 1-7

Oil and Fuel Recommendations . . . . . . . . . . . . . . . . . . . . . . 1-7

Recommended Oil Type . . . . . . . . . . . . . . . . . . . . . . 1-7

Recommended Fuel Type . . . . . . . . . . . . . . . . . . . . . 1-7

Use of Blended Fuels . . . . . . . . . . . . . . . . . . . . . . . 1-8

Problems with Blended Fuels . . . . . . . . . . . . . . . . . . . . 1-8

Gasohol Use May Require Carburetor Adjustments . . . . . . . . 1-8

Use of Fuel Additives . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Fuel and Oil Mixing Instructions . . . . . . . . . . . . . . . . . . 1-8

Starting/Stopping Instructions . . . . . . . . . . . . . . . . . . . . . . . 1-9

To Start the Engine . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1

To Stop the Engine . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Service/Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . 1-10

Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Carburetor Adjustment . . . . . . . . . . . . . . . . . . . . . . . 1-11

Governed Carburetor Check . . . . . . . . . . . . . . . . . . . . 1-12

Storage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Storage for 45 to 60 Days . . . . . . . . . . . . . . . . . . . . . 1-13

Storage for More Than 60 Days . . . . . . . . . . . . . . . . . . 1-13

Reactivate Unit for Service . . . . . . . . . . . . . . . . . . . . . 1-13

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

1 - 3

Page 5

GENERAL INFORMATION

SPECIFICATIONS AND TORQUES

1

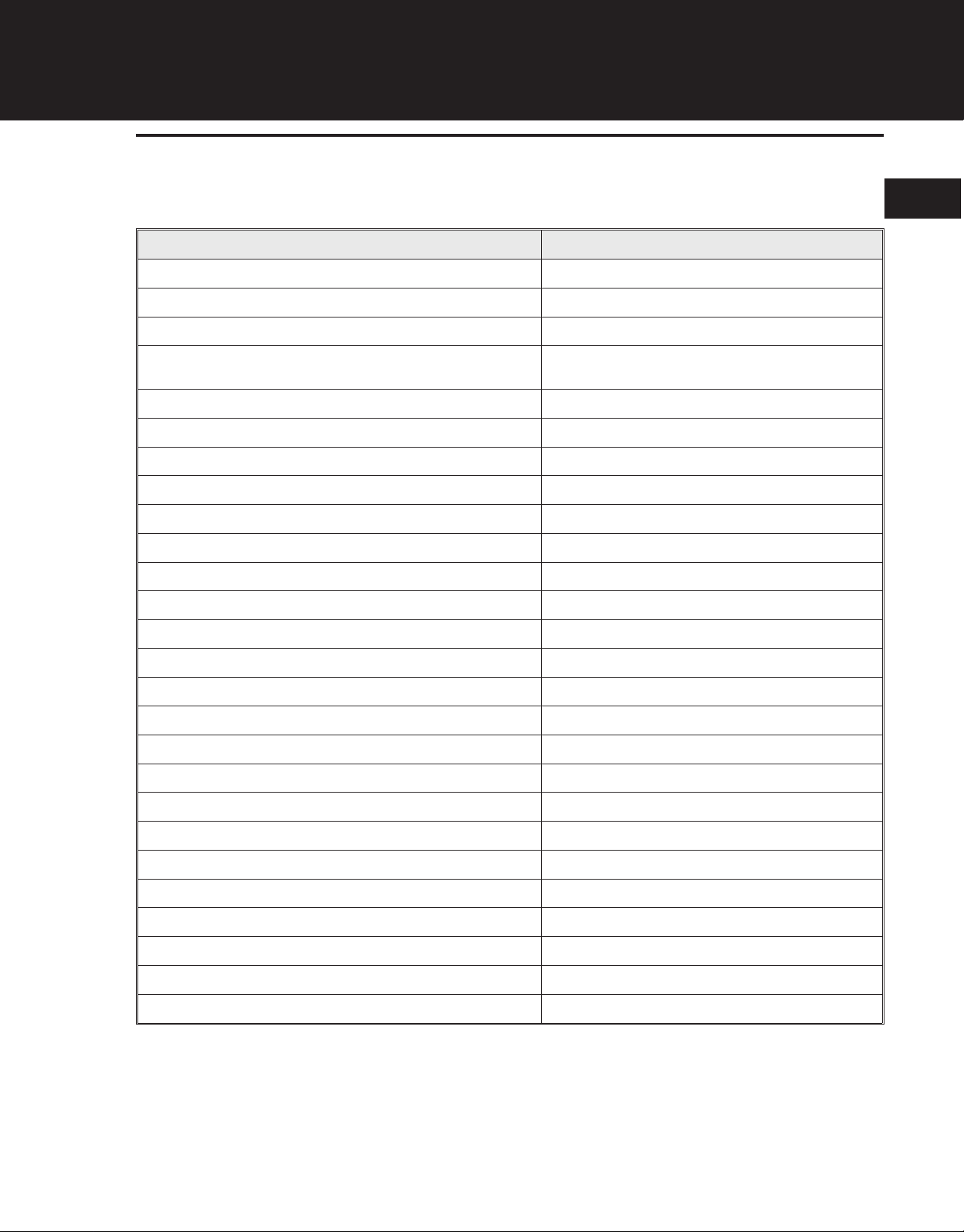

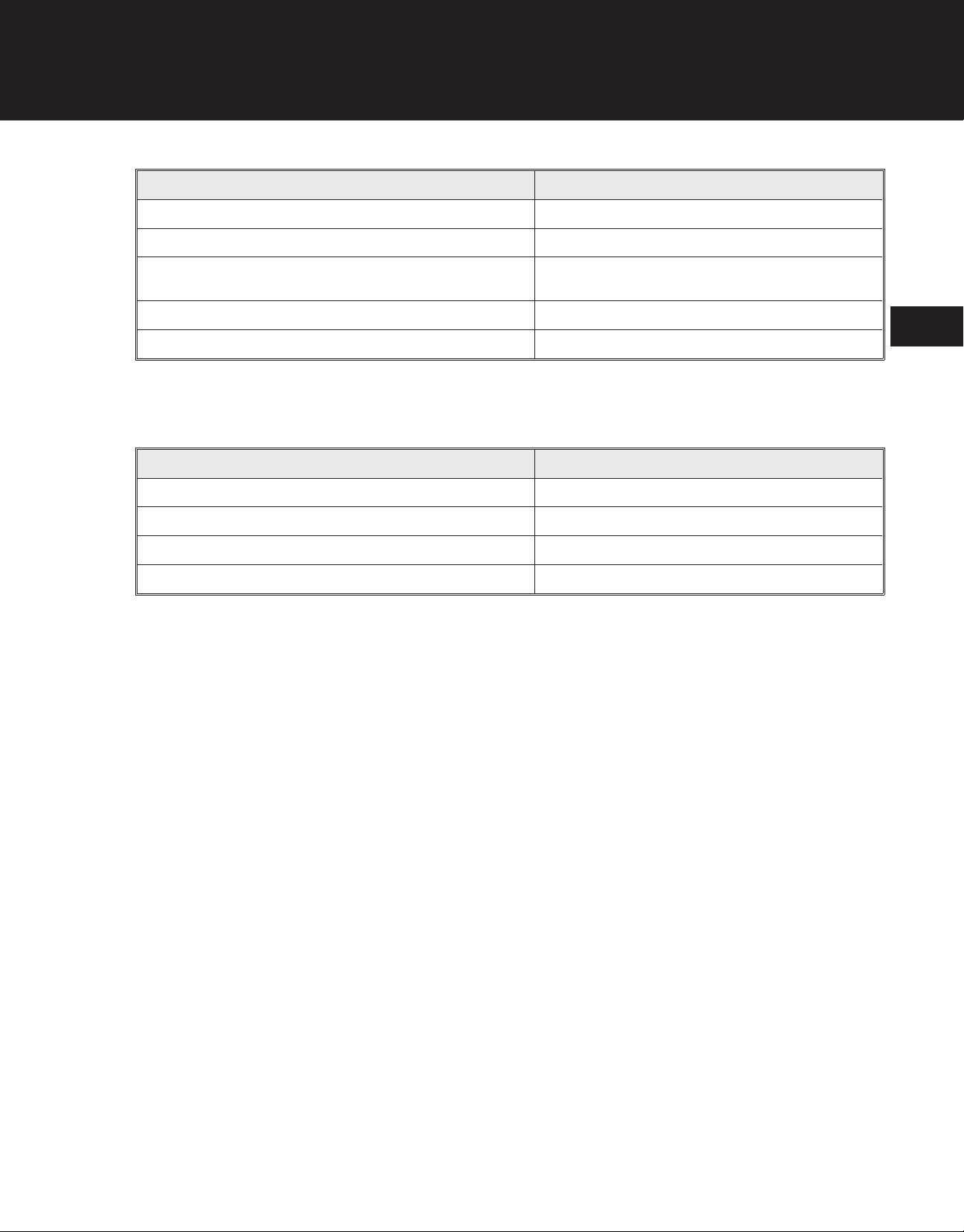

Engine Specifications

Item

Engine Type Air-cooled. 2-cycle, Third Port

Displacement 1.7 cu. in. (28.5 cc)

Bore 1.31 in. (33.27 mm) 1.31 in. (33.27 mm)

Stroke 1.28 in. (32.51 mm) 1.28 in. (32.51 mm)

Average Compression 115-125 lbs. (52-57 kg)

Piston Ring(s) Side Clearance 0.004 in. max (0.101 mm)

Piston Ring Width (S/N 102084332 to 302010968) 0.060 in. (1.6 mm)

Piston Ring Width (S/N 302010969 and Greater) 0.046 in. (1.14 mm)

Piston Ring End Gap (S/N 102084332 to 302010968) 0.072 in. (1.8 mm)

Piston Ring End Gap (S/N 302010969 and Greater) 0.057 in. (1.45 mm)

Fuel and Lubrication

Item

Lubrication Fuel/Oil Mixture

Fuel/Oil Ratio 32:1

Approx. Fuel Tank Capacity 18 oz. (530 ml)

Ignition

Item

Ignition Type Electronic

Ignition Module Air Gap 0.010-0.015 in. (0.254-0.381 mm)

Spark Plug Type Champion® RDJ7Y

Spark Plug Gap 0.018-0.023 in. (0.45 to 0.58 mm)

1- 4

Page 6

SPECIFICATIONS AND TORQUES (cont.)

GENERAL INFORMATION

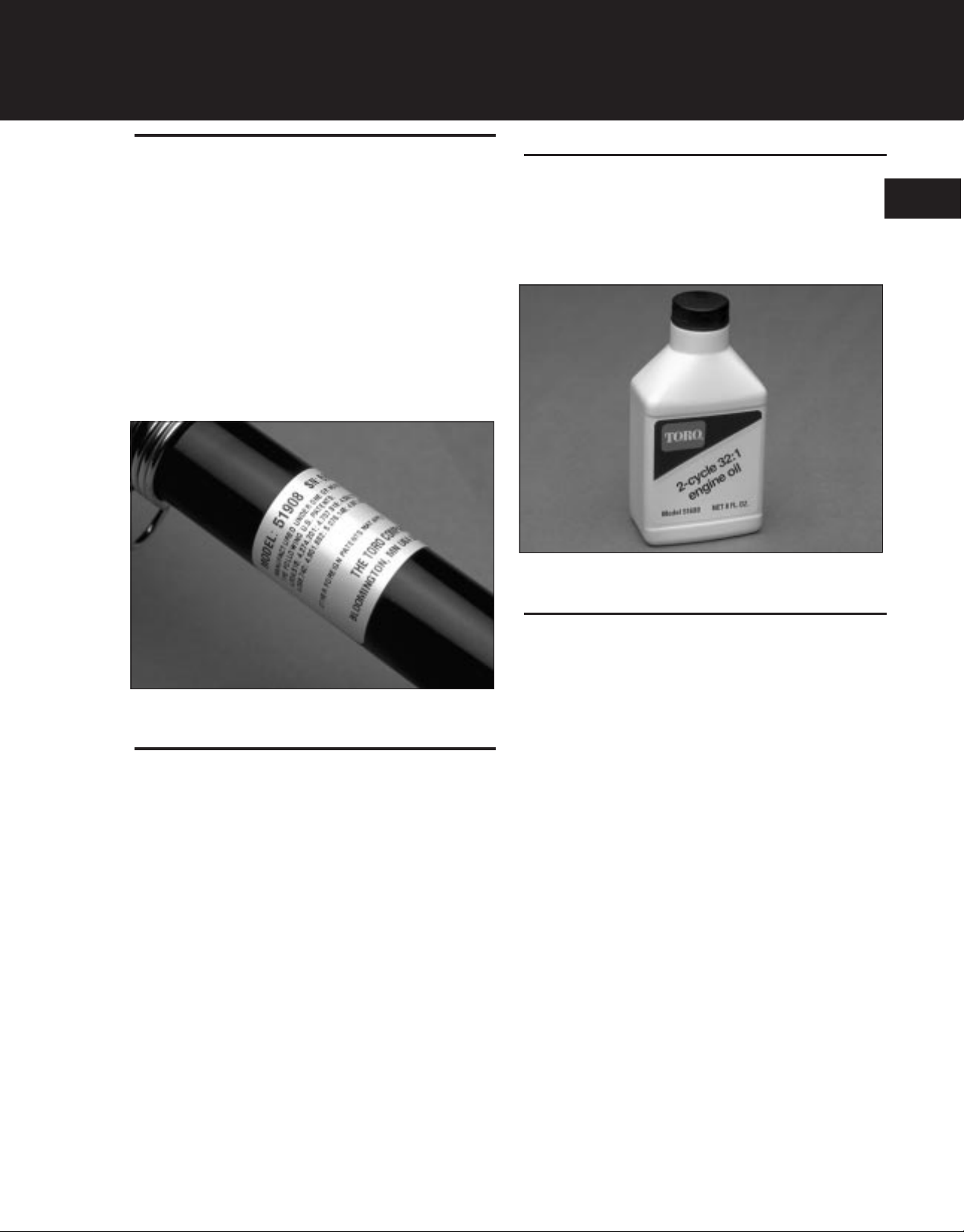

Torque Specifications

Item

Air Filter Cover Mounting Screws 18-22 in•lb (2.0-2.5 N•m)

Carburetor/Choke Plate Mounting Screws (Initial Torque) 13-17 in•lb (1.5-1.9 N•m)

Carburetor/Choke Plate Mounting Screws (Retorque) 23-27 in•lb (2.6-3.0 N•m)

Throttle Wire Swivel Screw (S/N 102084332 to

302010968)

Carburetor Spacer Screws 55-65 in•lb (6.2-7.3 N•m)

Clutch Cover Mounting Screws 35-40 in•lb (3.9-4.5 N•m)

Clutch Rotor 150-160 in•lb (16.9-18.0 N•m)

Clutch Housing/Drum Assembly Screws 35-40 in•lb (3.9-4.5 N•m)

Clutch Rotor 130-150 in•lb (14.6-16.8 N•m)

Clutch Bolts 60-80 in•lb (6.7-9.0 N•m)

Crankcase (Cylinder) Mounting Screws 50-60 in•lb (5.6-6.7 N•m)

Crankcase Cover Mounting Screws 55-65 in•lb (6.2-7.3 N•m)

Spark Plug 100-120 in•lb (11.2-13.5 N•m)

9-12 in•lb (1.0-1.4 N•m)

1

Boom Clamp Screw 70-80 in•lb (7.9-9.0 N•m)

Anti-Rotation Screw 15-20 in•lb (1.7-2.3 N•m)

Rear Engine Cover to Starter Housing Screw 50-60 in•lb (5.6-6.7 N•m)

Rear Engine Cover to Crankcase Screw 35-40 in•lb (3.9-4.5 N•m)

Engine Styling Cover 35-40 in•lb (3.9-4.5 N•m)

Boom Clamp Nut 70-80 in•lb (7.9-9.0 N•m)

Anti-Rotation Screw 15-20 in•lb (1.7-2.3 N•m)

Fuel Tank Bracket Screws 50-60 in•lb (5.6-6.7 N•m)

Ignition Module Mounting Screws 25-35 in•lb (2.8-3.9 N•m)

Muffler Exhaust Tube Screws 15-25 in•lb (1.7-2.8 N•m)

Muffler Mounting Screws 80-90 in•lb (9.0-10.1 N•m)

Starter Housing Screws 35-40 in•lb (3.9-4.5 N•m)

Starter Pulley Retainer Screw 20-30 in•lb (2.3-3.4 N•m)

1 - 5

Page 7

GENERAL INFORMATION

SAFETY WARNINGS AND NOTES

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols and

1

the explanations with them deserve your careful

attention and understanding. The safety warnings do

not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes

for proper accident prevention measures.

WARNING: For Your Safety

Highlights instructions which failure to obey can result

in personal injury.

NOTE: Advises of information which may be useful

while performing maintenance or repair of the

equipment. Also highlights instructions which failure to

obey can result in damage to parts or equipment.

WARNING: Spring Under Tension!

The rope starter on these engines contains a flat wire

spring that is under tension. Wear eye and hand

protection when replacing worn or broken spring, in

case it should uncoil as it is handled. Allow spring

tension to be completely relieved and make sure

pulley disengages from spring before removing the

pulley retainer(s), pulley, and starter spring from

housing.

WARNING: Explosive Fuel!

Gasoline may be present in the fuel tank, carburetor,

fuel line, or crankcase. Gasoline is extremely

flammable and its vapors can explode if ignited. Keep

sparks, flames, and other sources of ignition away

from the engine. Do not smoke while servicing the

engine. Never use gasoline as a cleaning agent.

Store gasoline only in approved containers in

well-ventilated, unoccupied buildings away from

sparks, flames, or other sources of ignition. Do not fill

the fuel tank while the engine is hot or running, since

spilled fuel could ignite if it comes in contact with hot

parts or sparks from ignition. Do not start the engine

near spilled fuel. Do not smoke while handling

gasoline or filling the fuel tank.

WARNING: Cracked or Broken FLYWHEEL

Cooling Fins Are A Hazard!

Be careful not to crack or break any flywheel cooling

fins. They could fly off during operation. If cooling fins

are cracked or broken, replace the flywheel.

WARNING: Electrical Shock!

Never touch electrical wires or components while the

engine is running. They can be sources of electrical

shock.

WARNING: HOT SURFACES!

The muffler, cylinder, crankcase, trimmer cutting head,

and other engine surfaces get extremely hot from

operation. These surfaces remain hot for a short

period of time after the engine is stopped. To prevent

severe burns, allow the engine to cool completely

before servicing.

1- 6

Page 8

GENERAL INFORMATION

PRODUCT IDENTIFICATION

NUMBERS

When ordering parts, or in any communication

involving an engine or product, always give the:

• Model Number and

• Serial Number

These numbers are located on a decal (or decals)

affixed to the unit (Figure 1-1). The identification

decal(s) will be located on the engine, metal boom, or

plastic housing. The actual location will vary

depending on the type of product.

Recommended Oil Type

Toro 2-cycle oil is recommended for use in these

engines (Figure 1-2). If another brand of 2-cycle oil is

used, use a high quality oil that is formulated for small

2-cycle air-cooled engines.

Figure 1-2. Recommended Oil Type.

1

Figure 1-1. Product Identification Decal.

OIL AND FUEL

RECOMMENDATIONS

WARNING: Explosive Fuel!

Gasoline is extremely flammable and its vapors can

explode if ignited. Store gasoline only in approved

containers in well-ventilated, unoccupied buildings

away from sparks or flames. Do not fill the tank while

the engine is hot or running, since spilled fuel could

ignite if it comes in contact with hot parts or sparks

from ignition. Do not start the engine near spilled fuel.

Do not smoke while handling gasoline. Never use

gasoline as a cleaning agent.

NOTE: READ THESE INSTRUCTIONS CAREFULLY

BEFORE ATTEMPTING TO START OR OPERATE

THIS UNIT. Using old oil or fuel or improperly mixing

the oil and fuel can cause engine damage. This type

of damage will void the engine warranty.

Recommended Fuel Type

Use clean fresh, regular grade unleaded gasoline.

NOTE: Alcohol blended fuel absorbs moisture (water).

As little as 1% moisture in the fuel can cause fuel and

oil to separate and form acids when stored.

If these types of fuel must be used, use fresh fuel (less

than 60 days old) and mix according to the instructions

in this section.

1 - 7

Page 9

GENERAL INFORMATION

Use of Blended Fuels

1

If you choose to use a blended fuel or its use is

unavoidable, the following precautions are

recommended:

1. Always use fresh fuel mixed according to the

instructions in this section.

2. Use the special additive Alcohol Protector® (by

Gold Eagle) or equivalent to inhibit corrosion and

reduce oil/fuel separation (mix as directed).

3. Always agitate the fuel mix before fueling unit.

4. Drain the fuel tank and run engine dry before storing

unit.

Problems with Blended Fuels

Some problems associated with blended fuels include:

• Vapor lock

Use of Fuel Additives

The use of fuel additives such as Toro Gas

Stabilizer/Conditioner, STA-BIL® Gas Stabilizer, or an

equivalent, will minimize the formation of fuel gum

deposits. Such an additive should only be used when

fuel/oil mix is prepared. Add 0.4 oz. (11 ml) per gallon

of gasoline or mix per instructions on container.

NEVER add fuel additives directly to the unit fuel tank.

Fuel and Oil Mixing Instructions

NOTE: For proper engine operation and maximum

reliability, pay strict attention to these fuel and oil

mixing instructions. Use a 32:1 fuel/oil ratio when

using Toro or IDC 2-cycle oil. Using improperly mixed

fuel can severely damage the engine. Never mix the

gasoline and oil in the fuel tank of the unit.

Use the following procedures to ensure complete

mixing:

1. Put a small amount of fresh gasoline into a clean

one U.S. gallon (3.785 liter) fuel can.

• Poor warm restart

• Poor performance at high altitudes

• Corrosion of fuel system components

If any of these symptoms occur, switch to regular,

unleaded gasoline.

Gasohol Use May Require Carburetor Adjustments

These engines are lubricated by oil mixed with fuel.

Using blended fuel may alter the air/fuel ratio causing

a lean mix (less fuel, more air).

If this condition is not corrected by adjusting the

carburetor, engine damage due to poor lubrication can

result.

2. Add 4-oz. (118 ml) of Toro 2-cycle engine oil.

3. Fill the remainder of the fuel can with gasoline.

4. Screw the fuel can cap on tightly and SHAKE THE

CAN VIGOROUSLY FOR 30 SECONDS.

1- 8

Page 10

GENERAL INFORMATION

STARTING/STOPPING

INSTRUCTIONS

To Start the Engine

1. Make sure the switch is in the “START” or “ON”

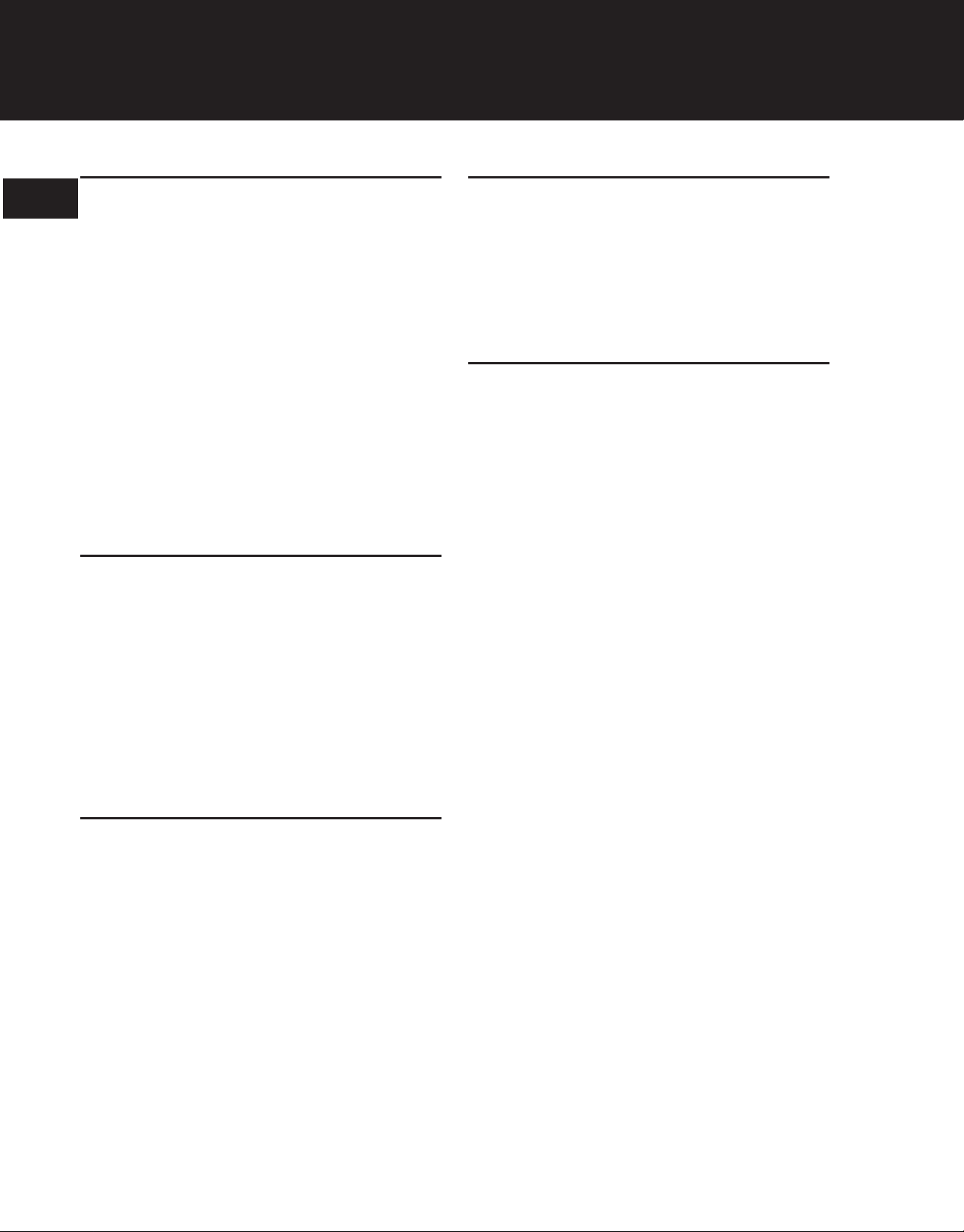

position (Figure 1-3).

Figure 1-3. Typical Ignition Switch.

2. FULLY PRESS AND RELEASE the primer bulb 5 to

7 times (Figure 1-4).

3.6069.003.

5. Squeeze the throttle trigger to “FULL THROTTLE”

(Figure 1-5). Hold or lock the throttle in this

position.

Figure 1-5. Typical Throttle Control.

6. Pull the starter rope BRISKLY until you hear the

engine sound like it wants to run (normally 2 to 5

pulls).

7. Place the choke lever in the “PARTIAL” choke

position (Figure 1-4).

3.6069.005

1

3. Place the choke lever in the FULL “CHOKE” position

(Figure 1-4).

Primer Bulb

Choke Lever

Figure 1-4. Primer Bulb and Choke Lever.

4. Place the unit in the starting position with the

trimmer cutting head away from yourself and

others.

3.6069.004

8 Pull the starter rope BRISKLY 1 to 3 pulls to start

the engine.

9. If the engine does not start, repeat steps 1

through 8.

10. After the engine warms up for 5 to 10 seconds,

place the choke lever in the “RUN” position.

To Stop the Engine

Place the ignition switch in the “OFF” or “STOP”

position (see Figure 1-3).

1 - 9

Page 11

GENERAL INFORMATION

SERVICE/MAINTENANCE

INSTRUCTIONS

1

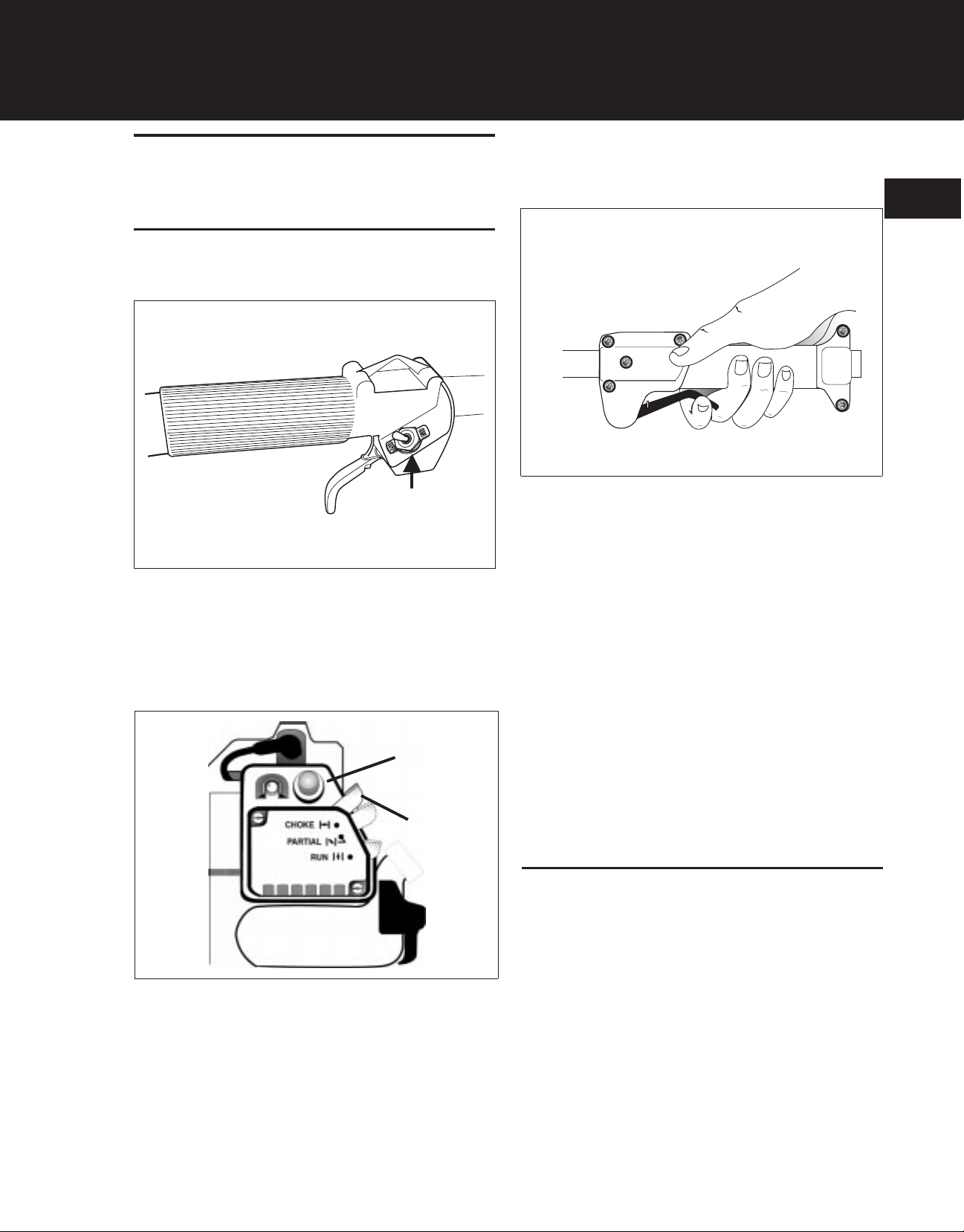

Air Filter

NOTE: CLEAN AND RE-OIL THE AIR FILTER

EVERY 10 HOURS OF OPERATION. The air filter is

one of the most important areas to maintain. If it is not

maintained as follows, severe engine damage can

result:

1 Remove the air filter from the carburetor/air filter

cover assembly. Refer to Part 3 - Engine

Disassembly.

Figure 1-7. Oiling Air Filter Element.

3.6069.008

2. Wash the air filter in detergent and water

(Figure 1-6). Rinse the air filter thoroughly in clean

water and allow it to dry.

Figure 1-6. Washing Air Filter Element.

3. Apply clean SAE 30 oil to the air filter (Figure 1-7).

3.6069.006

4. Squeeze the air filter to ensure that the oil is spread

throughout the entire filter (Figure 1-8).

Figure 1-8. Squeezing Excess Oil from Air

Filter Element.

5. Reinstall the air filter in the carburetor/air filter cover

assembly. Refer to Part 4 - Engine Assembly.

3.6069.008

1 - 10

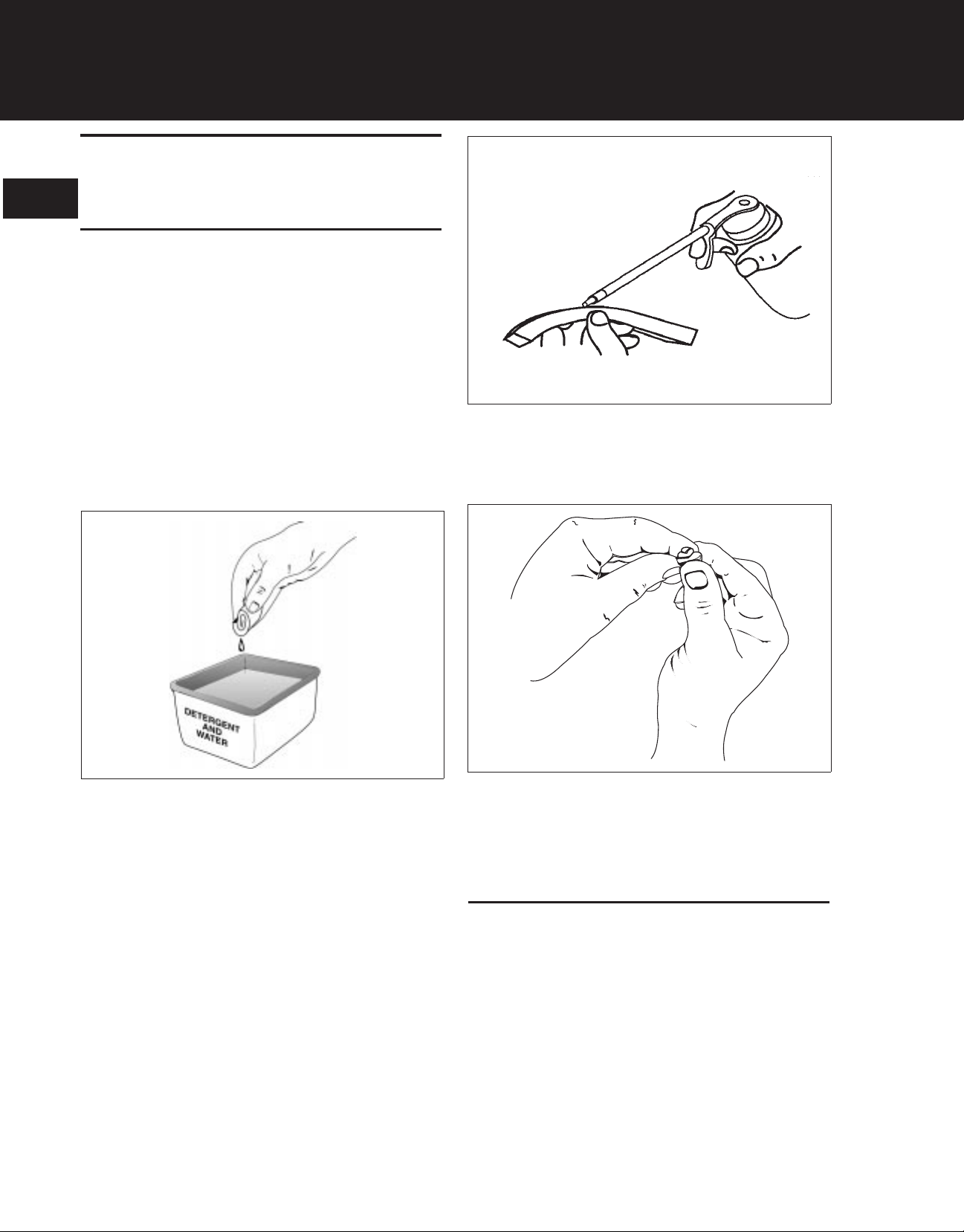

Spark Plug

Every 50 hours of operation remove the spark plug,

check its condition, and reset the gap or replace with a

new plug as necessary.

WARNING: Electrical Shock!

Page 12

Never touch electrical wires or components while the

engine is running. They can be sources of electrical

shock.

GENERAL INFORMATION

Carburetor Adjustment

1. Before removing the spark plug, clean the area

around the base of the spark plug to keep dirt and

debris out of the engine.

2. Disconnect the spark plug wire and remove the

spark plug from engine.

3. Inspect the spark plug for carbon buildup and clean

if necessary. Replace the plug if it is badly burnt or

if reuse is questionable.

NOTE: Do not clean the spark plug in a machine

which uses abrasive grit. Some grit could remain

on the spark plug and enter the engine causing

extensive damage.

4. Check the spark plug gap using a wire feeler gauge.

Set the gap to 0.018-0.023 inch (0.45 to 0.58 mm)

(Figure 1-9).

5. Reinstall the spark plug and torque to 100-120 in•lb

(11.3 - 13.5 N•m).

These engines are equipped with a diaphragm-type

carburetor. The carburetor has been carefully

calibrated at the factory. In most cases, no further

adjustment will be required.

The condition of the air filter is very important to the

operation of the trimmer. A dirty air filter will restrict the

air flow to the carburetor. This, in turn, upsets the

fuel-air mixture in the carburetor. The resulting

symptoms are often mistaken for an out-of-adjustment

carburetor. Therefore, check the condition of the air

filter before adjusting the carburetor. Refer to “Air

Filter” Service/Maintenance Instructions.

If the following conditions are experienced, it may be

necessary to adjust the carburetor:

• The engine will not idle.

• The engine hesitates or stalls on acceleration.

• The loss of engine power, which is not corrected

by cleaning the air filter.

• The engine operates in an erratic or fuel-rich

condition (indicated by excessive exhaust smoke

from the muffler).

NOTE: Follow these carburetor adjustment

procedures carefully. An incorrectly adjusted

carburetor can cause severe engine damage.

1

0.018 - 0.023 in.

(0.45 - 0.58 mm)

Figure 1-9. Spark Plug Gap.

Make sure the unit is fully assembled before making

carburetor adjustments.

For trimmers and brushcutters, make sure the boom,

cutting head, and line guard are installed and the

cutting line is extended to its full cutting length.

The carburetor has three basic adjustments: idle

speed adjustment, idle mixture adjustment, and high

speed mixture adjustment (Figure 1-10).

3.6069.009

1-11

Page 13

GENERAL INFORMATION

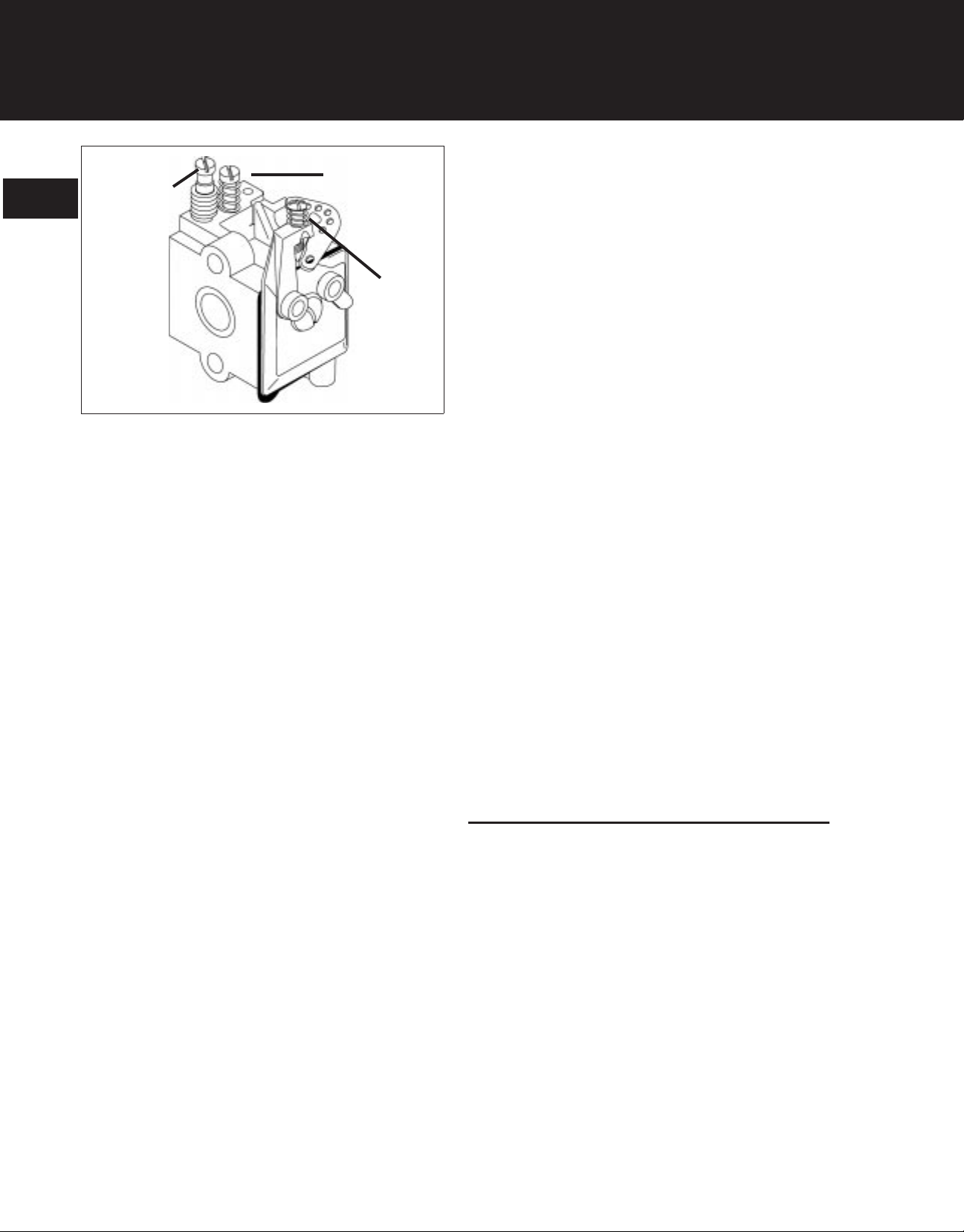

(H) High

Speed

1

Mixture

Figure 1-10. Carburetor Adjustments.

1. Initial Idle Speed Setting: Turn idle speed screw

counterclockwise until it does not touch the throttle

lever. Now turn the screw clockwise until it just

touches the throttle lever; then continue turning 2

full turns.

(L) Idle Mixture

Needle

Idle

Speed

Screw

3.6069.010

5. Final High Speed Mixture Setting: Squeeze the

throttle trigger to the FULL (WIDE OPEN)

THROTTLE position. Turn the high speed mixture

needle clockwise or counterclockwise to set the

high speed RPM: 6,800 to 7,200.

6. Release the throttle trigger and let the engine idle.

If the engine stops, turn the idle speed screw

clockwise 1/8 turn at a time until the engine idles.

7. Final Idle Mixture and Idle Speed Settings: Adjust

the the idle mixture and idle speed as follows:

a. Turn the idle mixture needle clockwise until the

fastest idle RPM is reached; then turn the

needle counterclockwise 1/8 turn.

b. Squeeze the throttle trigger. If the engine falters

or hesitates as it accelerates, turn the idle

mixture needle counterclockwise 1/16 turn at

a time until the engine accelerates rapidly.

2. If so equipped, remove the rubber cap from the

high speed mixture adjustment needle.

3. Initial High Speed Mixture and Idle Mixture Settings:

Turn both the high speed mixture and idle mixture

needles clockwise until they are lightly seated.

Then turn the needles counterclockwise the

following number of turns:

High Speed Mixture Needle : 1¼ turns

Idle Mixture Needle: 1¼ turns

NOTE: Turn the high speed mixture and idle

mixture needles finger-tight. Do not force the

needles with a screw driver as this can damage

the tips of the needles and the seats in the

carburetor body.

4. Start engine and allow it to warm up for 3 to 5

minutes.

NOTE: For the following steps, use a magnetic

pick-up 2-cycle engine tachometer to monitor

engine speed.

c. If the idle speed has changed significantly

because of steps a. and b. above, readjust the

idle speed screw.

The recommended idle speed for all products is

3,000 to 3,200 RPM.

8. Make sure the air filter cover is reinstalled securely

before placing the unit back into service.

Governed Carburetor Check

Some units are equipped with fuel-governed

carburetors. If so equipped, and after adjusting the

carburetor, check the operation of the governor on

trimmers and brush cutters as follows:

1. Clip or wind the cutting line so it is inside the cutting

head (not extended to its full cutting length).

2. Start the engine and run it at FULL (WIDE OPEN)

THROTTLE.

The maximum high speed RPM should not exceed

8,800 RPM.

1 - 12

Page 14

GENERAL INFORMATION

3. If the high speed RPM exceeds 8,800 RPM, the

governor assembly in the carburetor must be

cleaned or replaced and the carburetor readjusted.

STORAGE INSTRUCTIONS

WARNING: Explosive Fuel!

Gasoline is extremely flammable and its vapors can

explode if ignited. Store gasoline only in approved

containers in well-ventilated, unoccupied buildings

away from sparks or flames. Do not fill the fuel tank

while the engine is hot or running, since spilled fuel

could ignite if it comes in contact with hot parts or

sparks from ignition. Do not start the engine near

spilled fuel. Do not smoke while handling gasoline.

Never use gasoline as a cleaning agent.

Storage for 45 to 60 Days

Use the following storage procedure for equipment or

fuel that will be stored for more than 45 days and less

than 60 days:

Equipment - Empty the fuel tank and run the unit until

the fuel system is empty. When starting the unit after

storage, refill the fuel tank with freshly mixed gasoline

and oil.

Fuel - Do not use fuel that has been stored for more

than 60 days. Dispose the old fuel in a safe manner

and use a fresh mix.

5. Store the unit in a dry, well ventilated area.

To Reactive Unit for Service

1. Remove the spark plug and drain the oil from the

cylinder by slowly pulling the starter rope.

2. Reinstall the spark plug.

3. Refuel the unit with a fresh gasoline/oil mixture.

Start engine in accordance with the Starting

Instructions.

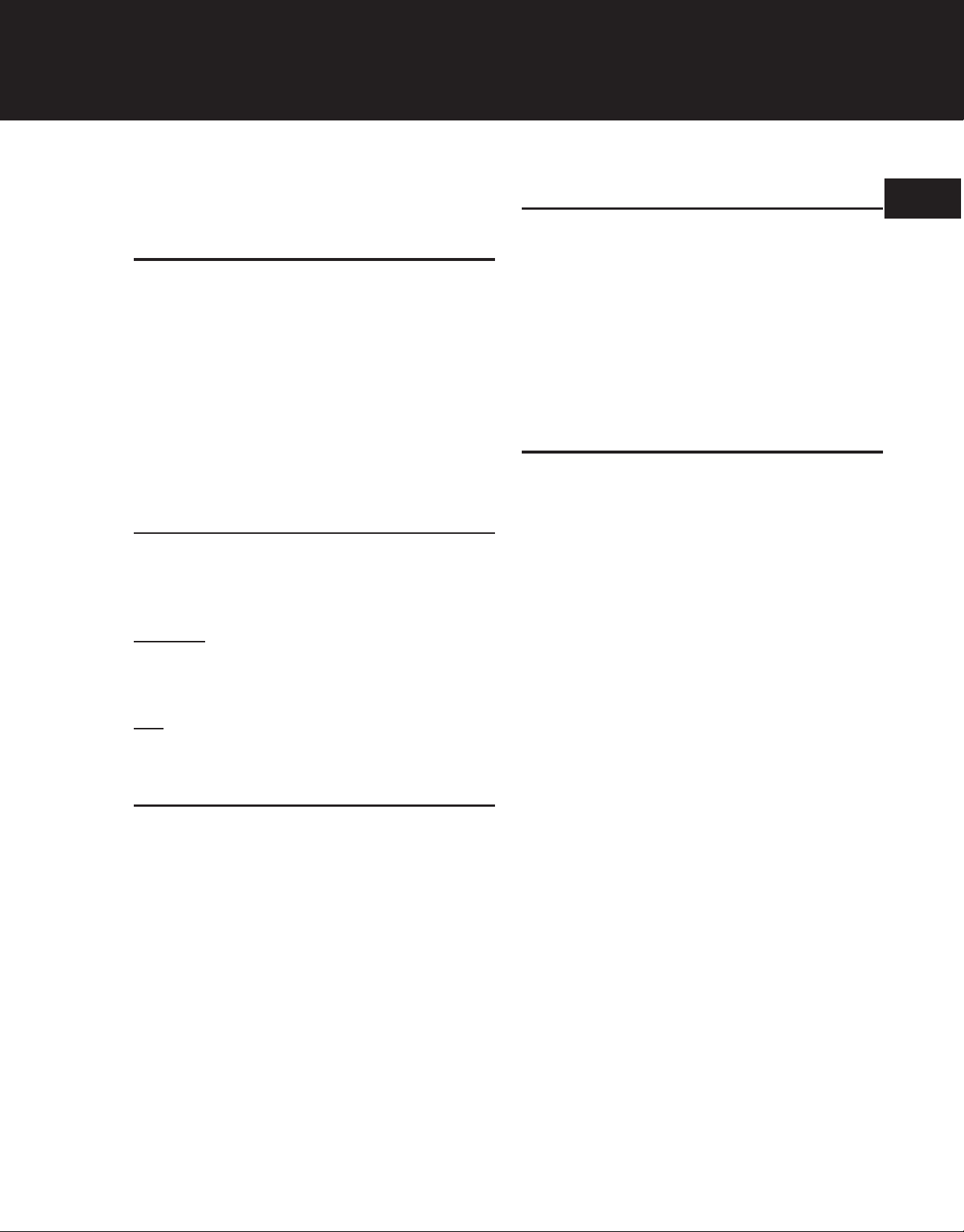

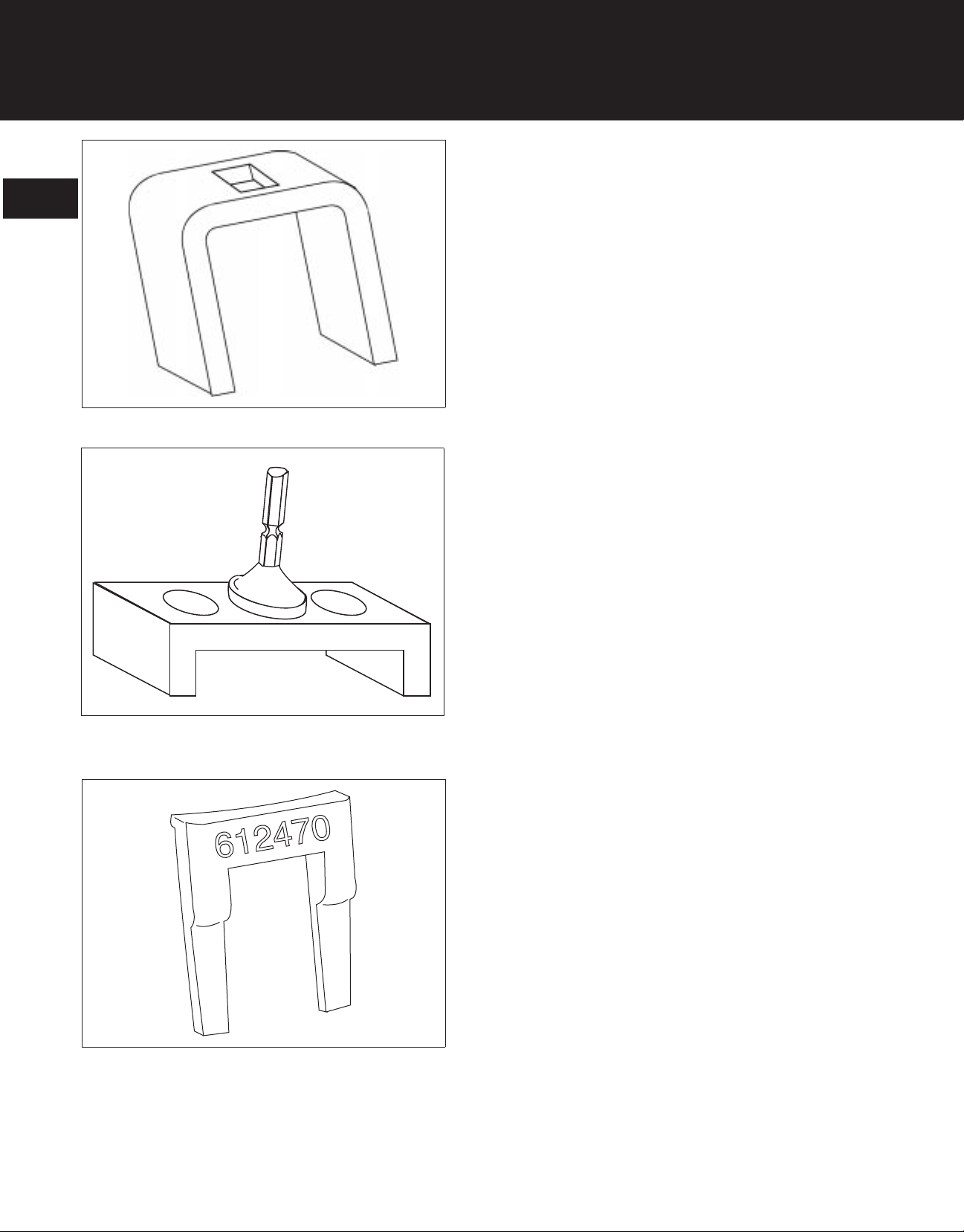

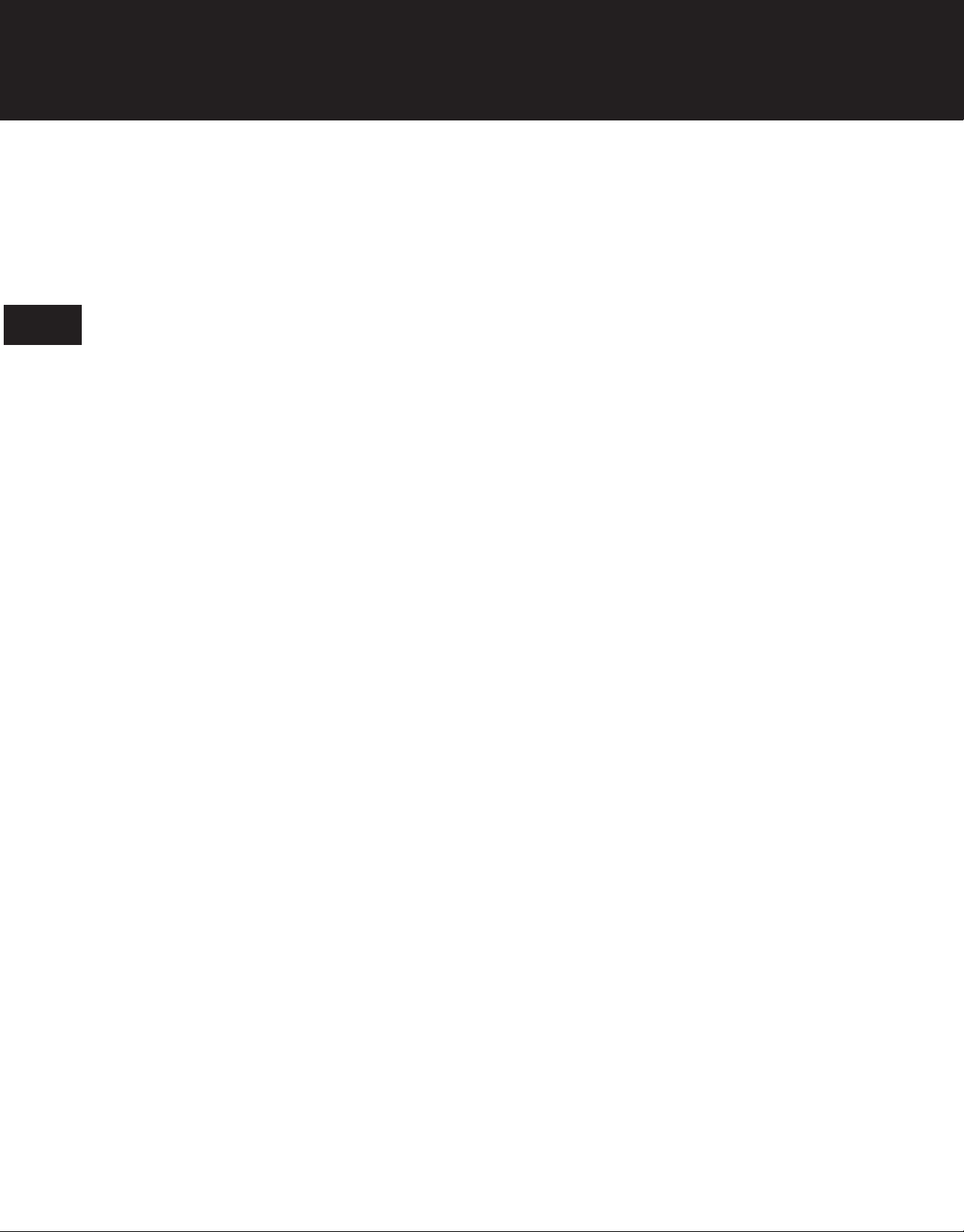

SPECIAL TOOLS

In addition to typical hand tools, the following special

tools are required to properly service these engines:

• Clutch Tool, (Standard N28 Engines) P/N 147337

(Figure 1-11).

• Clutch Tool, (Professional N28 Engines)

(Figure 1 -12).

• Flywheel Holder, P/N 612470 (Figure 1- 13).

• 0-250 in•lb (0-28.1 N•m) Torque Wrench

(commercially available).

• Torx® Screwdriver or Bit Set (commercially

available).

1

Storage for More Than 60 Days

1. Drain all fuel from the fuel tank into an approved

fuel container.

2. Start the engine and run it until it stalls.

3. Allow the engine to cool. Remove the spark plug

and put about 1 oz. (39 ml) of any high quality

motor or 2-cycle oil into the cylinder. Pull the

starter rope slowly to distribute the oil. Reinstall

the spark plug.

4. Clean the unit and inspect for any loose or

damaged parts. Repair or replace damaged parts

and tighten loose screws, nuts, or bolts.

• Two-stroke, Magnetic Pick-up Tachometer

(commercially available).

• Arbor or Hydraulic Press (commercially available).

• Bearing and Seal Pullers (commercially available).

• Hex Wrench Clutch Rotor Tool, P/N 180918.

• Flywheel Holding Tool, P/N 180918.

• 0-250 in•lb (0-28.1 N•m) Torque Wrench

(commercially available).

• Torx® Screwdriver or Bit Set (commercially

available).

• Two-stroke, Magnetic Pick-up Tachometer

(commercially available).

1 - 13

Page 15

GENERAL INFORMATION

1

Figure 1-11. Clutch Tool P/N 147337.

Figure 1-12. Clutch Tool for Professional

N28 Engines.

3.6069.011

3.6069.012

Figure 1-13. Flywheel Holder, P/N 612470.

1 - 14

3.6069.013

Page 16

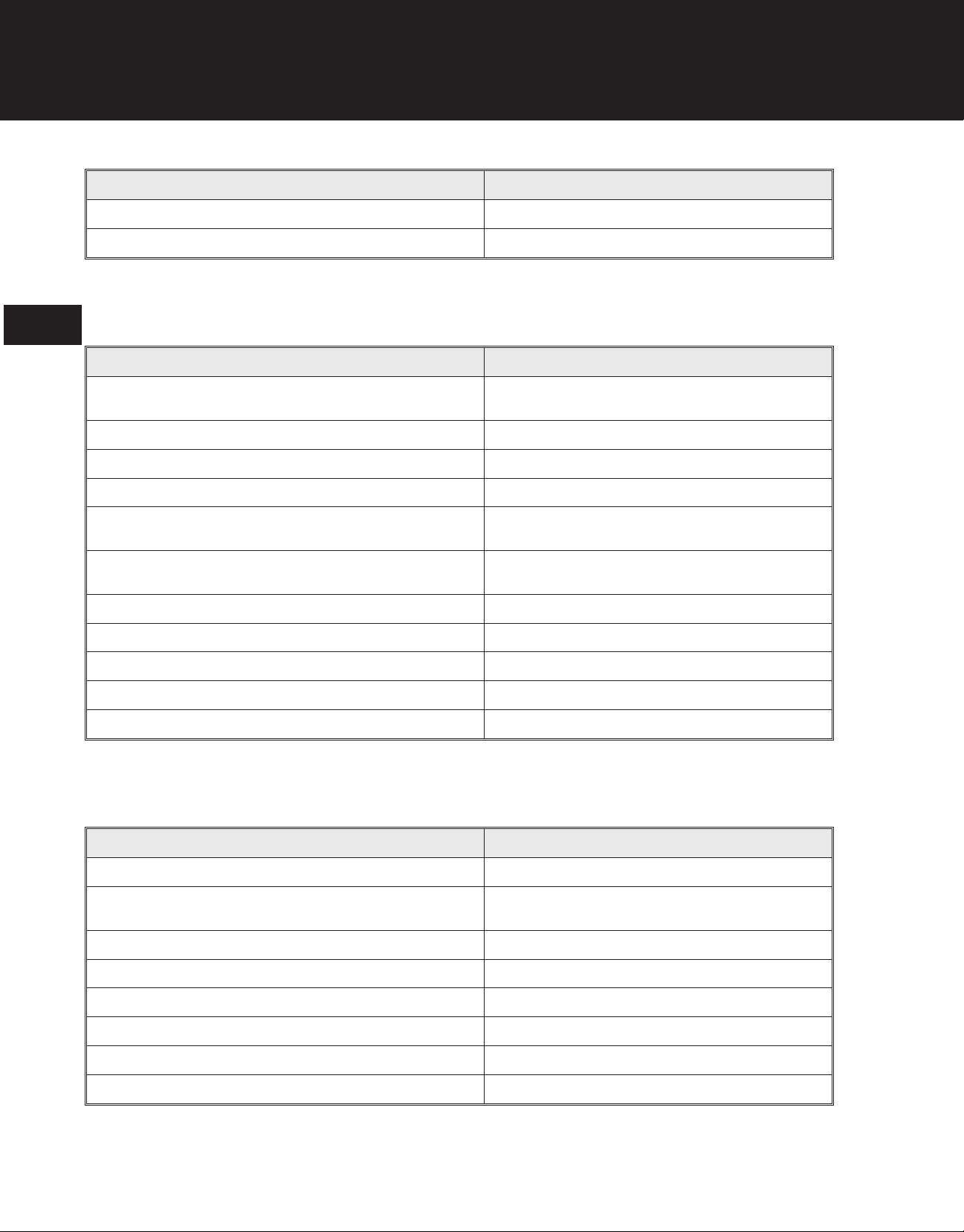

TROUBLESHOOTING

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting .............................

Disassembly, Inspection, and Repair ...................

Reassembly ................................

1

2

3

4

2 - 1

Page 17

TROUBLESHOOTING

Engine Fails to Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Engine Starves on Acceleration . . . . . . . . . . . . . . . . . . . . . . 2-4

Engine is Hard to Start . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Table of Contents

2

Engine Stalls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Engine Fires Intermittently . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Engine Does Not Produce Maximum Power . . . . . . . . . . . . . . . . 2-5

Carburetor Floods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Engine Stops After Running Briefly . . . . . . . . . . . . . . . . . . . . . 2-6

Engine Will Not Idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Engine Backfires or Misfires . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Engine Will Not Accelerate . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Engine Lacks Power or Stops During Operation . . . . . . . . . . . . . . 2-7

2- 2

Page 18

TROUBLESHOOTING

When difficulties occur, be sure to check for simple causes which, at first, may seem too obvious to beconsidered.

A starting problem, for example, could be caused by an empty fuel tank.

The following table lists some common causes of operating troubles and the possible causes and remedies.

Engine Fails to Start

Possible Cause Remedy

Ignition switch OFF Turn switch ON

Out of fuel or water in fuel Drain tank and blow out fuel lines to remove

water. Refuel tank with fresh fuel mixture.

Dirty or plugged air filter Clean or replace air filter

Loose spark plug lead wire Reconnect lead wire

Fouled, improperly gapped, or broken spark plug Clean or replace spark plug; set gap to

0.018-0.023 inch (0.45 to 0.58 mm)

Plugged fuel tank cap vent Clean fuel tank cap vent

Plugged or waterlogged fuel filter Replace fuel filter

Improperly adjusted carburetor Adjust carburetor

Plugged muffler Clean or replace muffler

Faulty primer or primer/fuel lines improperly installed Correctly install primer/fuel lines or

replace primer

Incorrect fuel mixture Drain tank; refill with correct fuel mixture

Plugged fuel line Blow out fuel line

Faulty carburetor diaphragm Replace diaphragm

2

Plugged fuel pump filter screen Clean or replace filter screen

Faulty fuel pump diaphragm Replace pump diaphragm

Plugged carburetor/fuel pump passages Clean out passages

Incorrect air gap between flywheel and ignition Set ignition module air gap to

(0.010-0.015 in (0.254-0.381 mm)

Faulty ignition module Replace ignition module

Low compression Replace piston ring(s) or cylinder

2 - 3

Page 19

TROUBLESHOOTING

Engine Starves on Acceleration

Possible Cause Remedy

Plugged fuel filter Replace fuel filter

Improperly adjusted carburetor Adjust carburetor about 1/8 turn

2

Engine is Hard to Start

Possible Cause Remedy

Fouled, improperly gapped, or broken spark plug Clean or replace spark plug; set gap to

0.018-0.023 in. (0.45 to 0.58 mm)

Plugged or waterlogged fuel filter Replace fuel filter

Improperly adjusted carburetor Adjust carburetor

Clogged muffler Clean or replace muffler

Faulty primer or primer/fuel lines improperly installed Correctly install primer/fuel lines or

replace primer

Incorrect air gap between flywheel and ignition module Set ignition module air gap to

0.010-0.015 inch (0.254-0.381 mm)

Faulty ignition module Replace ignition module

Worn or improperly adjusted carburetor jet needle Adjust or replace needle

Faulty carburetor diaphragm Replace carburetor diaphragm

Faulty fuel pump diaphragm Replace fuel pump diaphragm

Low compression Replace piston ring or cylinder

Engine Stalls

Possible Cause Remedy

Dirty or plugged air filter Clean or replace air filter

Fouled, improperly gapped, or broken spark plug Clean or replace spark plug; set gap to

0.018-0.023 in. (0.45 to 0.58 mm)

Plugged fuel tank cap vent Clean fuel tank cap vent

Incorrect fuel mixture Drain tank; refill with correct fuel mixture

Improperly adjusted carburetor Adjust carburetor

Plugged muffler Clean or replace muffler

Plugged fuel line Blow out fuel line

Faulty ignition module Replace ignition module

2- 4

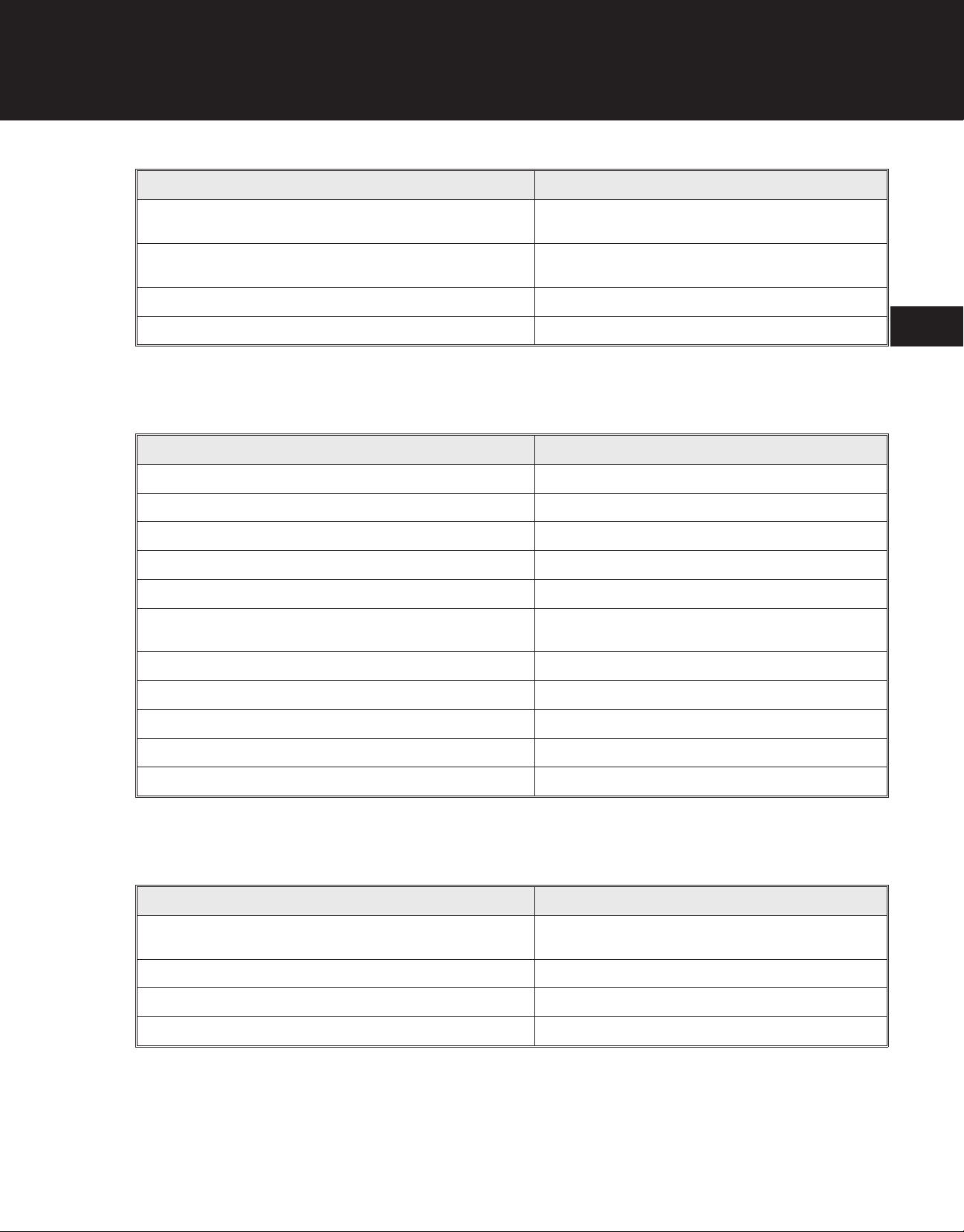

Page 20

TROUBLESHOOTING

Engine Fires Intermittently

Possible Cause Remedy

Fouled, improperly gapped, or broken spark plug Clean or replace spark plug; set gap to

0.018-0.023 in. (0.45 to 0.58 mm)

Incorrect air gap between flywheel and ignition module Set ignition module air gap to

0.010-0.015 inch (0.254-0.381 mm)

Faulty ignition module Replace ignition module

Incorrect fuel mixture Drain tank; refill with correct fuel mixture

Engine Does Not Produce Maximum Power

Possible Cause Remedy

Plugged air filter Clean or replace filter

Incorrect fuel mixture Drain tank; refill with correct fuel mixture

Plugged muffler Clean or replace muffler

Plugged or waterlogged fuel filter Replace fuel filter

Improperly adjusted carburetor Adjust carburetor

Air leak at carburetor base gasket Tighten carburetor fasteners or replace

carburetor base gasket

Intermittent spark Replace ignition module

Low compression Replace piston ring or cylinder

Leaking crankcase seals Replace crankcase seals

Scored piston and/or cylinder Replace piston cylinder assembly

2

Worn piston rings or low compression Overhaul engine

Carburetor Floods

Possible Cause Remedy

Faulty primer or improperly installed primer/fuel lines Correctly install primer/fuel lines or

replace primer

Improperly adjusted carburetor Adjust carburetor

Damaged carburetor Replace carburetor

Leaking fuel inlet needle Replace fuel inlet needle

2 - 5

Page 21

TROUBLESHOOTING

Engine Stops After Running Briefly

Possible Cause Remedy

Partially plugged fuel tank cap vent Clean fuel tank cap vent

Dirty or plugged air filter Clean or replace air filter

Water in fuel mixture Drain tank and blow out lines

Air leak at carburetor base gasket Tighten carburetor mounting fasteners

or replace carburetor base gaskets

2

Dirty carburetor fuel inlet needle or passage Replace fuel inlet needle or clean out

carburetor

Faulty carburetor diaphragm Replace diaphragm

Losing compression Replace piston ring or gaskets or

overhaul engine

Engine Will Not Idle

Possible Cause Remedy

Improperly adjusted carburetor Adjust carburetor

Faulty carburetor diaphragm Replace carburetor diaphragm

Faulty carburetor inlet seat gasket Replace carburetor inlet seat gasket

Leaking crankshaft seals Replace crankshaft seals

Scored cylinder or low compression Overhaul engine

Engine Backfires or Misfires

Possible Cause Remedy

Improper or contaminated fuel mix Drain tank; refill with fresh fuel mixture

Fouled, improperly gapped, or broken spark plug Clean or replace spark plug; set gap to

0.018-0.023 in. (0.45 to 0.58 mm)

Shorted ignition module leads Check for loose or bare wires or loose

assembly and correct or replace ignition

module.

2- 6

Page 22

TROUBLESHOOTING

Engine Will Not Accelerate

Possible Cause Remedy

Carburetor improperly adjusted Adjust carburetor

Air filter clogged Clean or replace air filter

Spark plug fouled Clean or replace spark plug; set gap to

0.018-0.023 in. (0.45 to 0.58 mm)

Plugged muffler Clean or replace muffler

Carburetor diaphragm gasket leaking Replace gasket

Engine Lacks Power or Stops During Operation

Possible Cause Remedy

Faulty primer causing flooding Replace primer

2

Dirty or plugged air filter Clean or replace air filter

Plugged muffler Clean or replace muffler

Scored cylinder or low compression (below 90 psi) Overhaul engine

2 - 7

Page 23

This Page Intentionally Left Blankl

2- 8

Page 24

DISASSEMBLY, INSPECTION, & REPAIR

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting ..............................

Disassembly, Inspection, and Repair ..................

Reassembly ................................

1

2

3

4

3 - 1

Page 25

DISASSEMBLY, INSPECTION, & REPAIR

Table Of Contents

Typical Disassembly Sequence . . . . . . . . . . . . . . . . . . . . . . 3-4

Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Drain Fuel From Tank . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Remove Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Standard N28 Engines . . . . . . . . . . . . . . . . . . . . . 3-5

Professional N28 Engines . . . . . . . . . . . . . . . . . . . 3-6

Remove Styling Cover . . . . . . . . . . . . . . . . . . . . . . . 3-7

Remove Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3

Remove Choke/Carburetor . . . . . . . . . . . . . . . . . . . . . 3-8

Remove Primer Bulb . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Carburetor Disassembly . . . . . . . . . . . . . . . . . . . . . . . 3-9

Fuel Metering Side . . . . . . . . . . . . . . . . . . . . . . . 3-9

Fuel Pump Side . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Carburetor Inspection and Cleaning . . . . . . . . . . . . . . . . . 3-11

Carburetor Reassembly . . . . . . . . . . . . . . . . . . . . . . . 3-12

Fuel Metering Side . . . . . . . . . . . . . . . . . . . . . . . 3-12

Fuel Pump Side . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Final Carburetor Adjustment . . . . . . . . . . . . . . . . . . . . 3-15

Remove Carburetor Spacer . . . . . . . . . . . . . . . . . . . . . 3-15

Remove Rear Engine Cover . . . . . . . . . . . . . . . . . . . . 3-16

Remove Fuel Tank Bracket, Fuel Tank, and Heat Shield . . . . . . 3-16

Fuel Tank and Lines, Disassembly, Inspection, and Reassembly . 3-16

Fuel Tank and Cap . . . . . . . . . . . . . . . . . . . . . . . 3-16

Fuel Line and Filter Removal . . . . . . . . . . . . . . . . . 3-17

Fuel Line and Filter Installation . . . . . . . . . . . . . . . . 3-17

3- 2

Remove Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Exhaust Exit Tube Removal . . . . . . . . . . . . . . . . . . 3-18

Page 26

DISASSEMBLY, INSPECTION, & REPAIR

Muffler Inspection and Cleaning . . . . . . . . . . . . . . . . . . 3-18

Muffler Reassembly . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Remove Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Standard N28 Engines . . . . . . . . . . . . . . . . . . . . 3-19

Professional N28 Engines . . . . . . . . . . . . . . . . . . 3-20

Clutch Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Remove Starter Housing . . . . . . . . . . . . . . . . . . . . . . 3-21

Starter Disassembly, Repair, and Reassembly . . . . . . . . . . . 3-22

Adding Starter Spring Tension . . . . . . . . . . . . . . . . 3-22

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Inspection and Service . . . . . . . . . . . . . . . . . . . . 3-24

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Remove Ignition Module . . . . . . . . . . . . . . . . . . . . . . 3-27

Remove Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

FIywheel Inspection and Repair . . . . . . . . . . . . . . . . . . 3-28

Remove Spark Plug, Cylinder, and Piston/Connecting

Rod Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Cylinder and Piston Inspection . . . . . . . . . . . . . . . . . . . 3-31

Crankshaft and Crankcase Disassembly . . . . . . . . . . . . . . 3-31

Crankcase Inspection . . . . . . . . . . . . . . . . . . . . . . . 3-33

Crankcase Reassembly . . . . . . . . . . . . . . . . . . . . . . 3-33

3

3 - 3

Page 27

DISASSEMBLY, INSPECTION, & REPAIR

Typical Disassembly Sequence

The following sequence is suggested for complete

engine disassembly, inspection, and repair. This

procedure can be varied to accommodate individual

requirements for disassembly and repair.

Clean all parts thoroughly as the engine is

disassembled. Only clean parts can accurately be

inspected and gauged for wear or damage. There are

many commercially available cleaners that will quickly

remove oil and grime from engine parts. When such a

cleaner is used, follow the manufacturer’s instructions

and safety precautions carefully. Particular attention

should be given to commercial cleaners compatibility

with plastic parts.

Make sure that the cleaner is wiped off of engine parts

3

and not allowed to air dry as some cleaners leave a

residue on parts which can affect engine lubrication.

Refer to the appropriate parts manual to ensure the

correct replacement parts are ordered.

1. Drain Fuel from Tank*

7. Remove Rear Engine Cover

8. Remove Fuel Tank Bracket, Fuel Tank, and Heat

Shield

9. Remove Muffler*

10. Remove Clutch

11. Remove Starter Housing

12. Remove Ignition Module

13. Remove Flywheel

14. Remove Spark Plug*, Cylinder, and Piston/

Connecting Rod

15. Remove Crankshaft; Disassemble Crankcase

2. Remove Engine from Equipment

3. Remove Styling Cover

4. Remove Air Filter*

5. Remove Choke/Carburetor*

6. Remove Carburetor Spacer

* On some units, these can be removed and

reinstalled without removing the engine from its

normal operating installation.

NOTE: Only disassemble the engine to the extent

necessary to make the desired repairs.

3- 4

Page 28

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

Drain Fuel From Tank

WARNING:

EXPLOSIVE FUEL

WARNING: Explosive Fuel!

Gasoline may be present in the fuel tank,

carburetor, fuel lines, and crankcase. Gasoline is

extremely flammable, and its vapors can

explode if ignited. Keep sparks, flames, and

other sources of ignition away from the engine.

Do not smoke while servicing the engine. Never

use gasoline as a cleaning agent.

3

1. Drain all fuel from the fuel tank and drain into a

suitable container for storing a 2-cycle fuel

mixture.

2. Start the engine and allow it to run until it stalls.

Allow the engine to cool.

2.0415.011

2.6071.015

Remove Engine

Standard N28 Engines

Remove the engine from the equipment as follows:

1. If necessary, remove the air filter cover and base

before the throttle cable is removed from the

carburetor throttle lever.

2 For units with serial number 102084332 to

302010968 - loosen the screw securing the

throttle cable in the swivel on carburetor throttle

lever. Remove the throttle cable from the swivel.

3 - 5

Page 29

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

3. For units with serial number 302010969 and

greater, remove the Z-bend of throttle cable

from the hole in the carburetor throttle lever.

4. Disconnect the lead wires from the ignition switch.

NOTE: The location of the lead wires and the

removal instructions will vary from model to model.

3

2.6071.016

5. Remove the anti-rotation screw from the drive

housing.

6. Loosen clamp nut and bolt.

7. Remove engine from the drive housing (boom).

Professional N28 Engines

Remove the engine from the equipment as follows:

1. If necessary, remove the air filter cover and base

before the throttle cable is removed from the

carburetor throttle lever.

Anti-Rotation

Screw

Drive Housing

Clamp

3.6071.017

2. Remove the throttle cable from the hole in

carburetor throttle lever.

3- 6

3.6069.004

Page 30

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

3. Disconnect the lead wires from the ignition

switch.

NOTE: The location of the lead wires and the

removal instructions will vary from model to model.

3.6069.003

3

Clamp

Screw

Anti-Rotation

Screw

4. Remove the anti-rotation screw from the clutch

housing/drum assembly.

5. Loosen clamp screw.

6. Remove engine from the drive housing (boom).

3.6071.016

Remove Styling Cover

Units with a professional N28 engine are equipped

with an engine styling cover. To remove the styling

cover:

2.6071.018

1. Remove the screws securing the styling cover.

Remove the cover.

3 - 7

Page 31

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

Remove Air Filter

Use the following procedures to remove the air filter

cover and element. Service the element as

instructed in Part 1 - General Information.

1. Remove the screws securing the air filter cover.

Remove the air filter cover assembly from the

air filter base.

3

3.6071.019

2. Remove the air filter element from the air filter

cover.

Remove Choke/Carburetor

1. Remove the screws securing the choke

components, air filter base, and carburetor to

the carburetor spacer.

2. Remove the flat washers, wavy washer, choke

lever and choke plate, and spacers.

3.6071.020

3- 8

2.6071.021

Page 32

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

3. Remove the fuel line from the carburetor fuel inlet

fitting.

4. Remove the fuel line from the fuel outlet fitting on

carburetor (to primer bulb).

Fuel Inlet

Fitting

Fuel Outlet

Fitting

5. Remove the carburetor and carburetor gasket.

2.6071.024

3

Remove Primer Bulb

1. Remove the fuel lines from the fittings on primer

bulb.

2. Squeeze the mounting tabs on the back of the

bulb, and pull the bulb out from the front of the

air filter base.

Inspect the primer bulb for flexibility and cuts or

tears. Replace the primer bulb if necessary.

2.6071.022

2.6071.023

Carburetor Disassembly

Fuel Metering Side

1. Remove the high speed mixture (H) and idle

mixture (L) adjusting needles and springs.

3 - 9

Page 33

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

2. Remove the fuel metering cover screws and

cover.

3

2.6071.024

3. Remove the fuel metering diaphragm and gasket.

4. Remove the screw securing the metering lever

hinge pin in carburetor body.

Remove the metering lever, hinge pin, metering

lever spring, and fuel inlet needle.

NOTE: These components are under spring tension.

Remove them carefully to prevent loss. Make sure

the spring is not stretched.

2.6071.025

3 - 10

2.6071.026

Page 34

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

Fuel pump Side

1. Remove the idle speed adjusting screw and

spring from fuel pump cover.

2. Remove the fuel pump cover screw and cover.

2.6047.027

3

2.6071.028

3. Remove the fuel pump cover gasket and pump

diaphragm.

NOTE: Further disassembly to remove the throttle

plate, throttle lever, welch plugs, fuel inlet screen,

etc., is not recommended.

Carburetor Inspection And Cleaning

Two carburetor service kits are available: a gasket/

diaphragm kit and a carburetor repair kit.

The gasket/diaphragm kit contains the fuel metering

cover gasket, fuel metering diaphragm, fuel pump

cover gasket, and fuel pump diaphragm.

2.6277.138

The carburetor repair kit contains the gaskets and

diaphragms included in the gasket/diaphragm kit

plus the high speed mixture needle and spring, idle

mixture needle and spring, fuel inlet needle and

spring, fuel metering lever, metering lever hinge pin,

the fuel inlet screen and welch plugs. Refer to the

appropriate parts manual for service kit part

numbers.

3-11

Page 35

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

1. Inspect the tips of the high speed mixture needle,

idle mixture needle, and fuel inlet needle for

wear or damage. Replace the needles if

necessary.

3

3.6179.165

2. Gaskets and diaphragms eventually deteriorate

and become stiff with age and use. It is good

practice to replace gaskets and diaphragms for

each repair. However, if the diaphragm is soft

and flexible, you do not need to replace it unless

a complete carburetor rebuild is being

performed.

3. Clean the metering cover, pump cover, carburetor

body, and filter screen with carburetor cleaner.

Blow out all passages with compressed air.

NOTE: To prevent damage to the carburetor body,

do not use drill bits or wire to clean fuel ports and

passages.

Carburetor Reassembly

Fuel Metering Side

2.6060.152

1. Install the fuel inlet needle, fuel metering lever

spring, metering lever, and metering lever hinge

pin. Secure the hinge pin in carburetor body with

the hinge pin screw.

3 - 12

2.6071.026

Page 36

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

2. Place a straight edge across the carburetor body.

Use a wire feeler gauge to measure the

distance between the the straight edge and the

top of the fuel metering lever.

The fuel metering lever should be 0.060-0.070 in.

(1.52-1.78 mm) below the straight edge.

2.6071.029

3

DEPRESS

HERE

HIGH

THEN PUSH

NEEDLE

HERE

PR Y UP HERE

LOW

Adjust the metering lever.

If the lever is adjusted too high, the engine will

run rich. If the lever is adjusted too low, the

engine will run lean. Poor acceleration and

erratic operation may also be noted.

3.6071.031

3. Install the metering cover gasket (next to

carburetor body) and metering diaphragm. Make

sure the larger circular plate of diaphragm is

towards the metering lever.

3.6071.032

3 - 13

Page 37

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

4. Make sure there are no wrinkles in the metering

diaphragm. Install the metering cover and

screws. Tighten the the screws securely.

3

2.6071.033

5. Install the high speed mixture (H) and idle mixture

(L) adjusting needles and springs.

Turn both needles clockwise until they are lightly

seated. Then turn the needles counterclockwise

the following number of turns:

High Speed Mixture Screw: 1¼ turns

Idle Mixture Screw: 1¼ turns

NOTE: Turn the high speed mixture and idle mixture

needles finger-tight. Do not force the needles with a

screwdriver as this can damage the tips of the

needles and the seats in the carburetor body.

Fuel Pump Side

2.6071.034

1. Install the fuel pump diaphragm (next to carburetor

body) and gasket.

.

3 - 14

2.6071.035

Page 38

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

2. Install the fuel pump cover and cover screw.

Tighten the screw securely.

3. If necessary, install the idle speed adjusting

screw and spring.

Turn the adjusting screw clockwise until it just

touches the throttle lever; then continue turning

2 full turns.

2.6071.036

3

3.6069.010

Final Carburetor Adjustment

Make final adjustments to the carburetor when the

unit is fully reassembled. Refer to “Carburetor

Adjustment” in Part 1 - General Information.

Remove Carburetor Spacer

1. Remove the two (2) screws securing the

carburetor spacer to the crankcase.

2. Remove the carburetor spacer and carburetor

spacer gasket.

2.6071.037

3. If necessary, remove the two (2) hex nuts on the

back of the carburetor spacer.

3 - 15

Page 39

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

Remove Rear Engine Cover

1. Remove the two (2) screws securing the rear

cover to the starter housing and crankcase.

2. Remove the rear engine cover.

3

2.6071.039

Remove Fuel Tank Bracket, Fuel Tank, and Heat

Shield

1. Remove the two (2) screws from the fuel tank

bracket.

2. Remove the bracket, fuel tank, and heat shield.

3. Remove the rubber fuel tank mounting pads.

Fuel Tank and Lines, Disassembly, Inspection

and Reassembly

Fuel Tank and Cap

1. Inspect the fuel tank for cracks, rubbing, or

chaffed spots. Replace the tank if necessary.

2.6071.040

2. Inspect the rubber fuel tank mounting pads (on

either side of the tank) for condition. Replace

the mounts if necessary.

3. Inspect the fuel tank cap for cracks, damaged

vent valve, or other visible signs of damage.

Replace the cap if necessary.

3 - 16

2.6078.085

Page 40

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

Fuel Line and Filter Removal

This unit has two fuel lines to the fuel tank. The

clear line provides normal fuel flow. The blue line

provides a return line for excess fuel flow during the

primer operation. The blue (primer) line is removed/

installed in the same manner as the fuel line except

it does not have a fuel filter.

To remove the fuel lines and fuel filter:

1. Push the fuel fitting, fuel filter, and fuel line out of

the fuel tank through the tank neck.

2.6071.041

3

2.6078.086

2. If the fuel filter is dirty or clogged, replace it with a

new fuel line assembly.

Fuel Line and Filter Installation

1. Insert a piece of trimmer line through the hole in

the bottom of fuel tank to the filler opening. Slide

the fuel line over trimmer line.

2. Working through the filler neck, insert the fuel line

with the fuel filter and fitting attached through

the hole in the bottom of tank.

2.6078.087

3. Work the fuel line from outside of tank, pulling

until the filter lays on the bottom of the tank.

3 - 17

Page 41

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

Remove Muffler

1. Remove the muffler mounting bolts.

2. Remove the muffler and gasket. Discard the old

gasket.

3

3.6071.045

Exhaust Exit Tube Removal

1. Remove the screws securing the exhaust exit tube

to the muffler body.

2. Remove the exhaust exit tube and gasket.

Muffler Inspection and Cleaning

The muffler should be removed periodically to

inspect for excessive carbon build-up. Excessive

deposits around the exhaust ports or exhaust exit

holes will cause poor engine performance.

2.6071.043

1. Check the inlet port of muffler for excessive

carbon deposits. Clean as required.

3 - 18

2.6071.046

Page 42

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

2. Inspect the baffle inside muffler for carbon

build-up. Clean baffle by scraping carbon as

required. Use a piece of wire to clear

obstructions from the small holes in baffle.

3. Inspect the muffler mounting holes for elongation.

Replace the muffler if the holes are elongated.

3.6071.045

3

2.6071.043

Muffler Reassembly

1. Install a new gasket and the exhaust exit tube.

Secure the tube with two (2) screws.

Torque the screws to 15-25 in•lb (1.7-2.8 N•m).

Remove Clutch

Standard N28 Engines

1. Remove the four (4) screws securing the clutch

cover to starter housing. Remove the clutch

cover.

2.6071.046

3 - 19

Page 43

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

Clutch Tool

2. Install flywheel holder, P/N 612470 or 180919.

3. Using clutch tool, P/N 147337 or 180918, remove

the clutch rotor.

4. Remove the spacer sleeve from crankshaft.

3

Flywheel Holder

2.6071.047

Professional N28 Engines

1. Remove the four (4) screws securing the clutch

housing/drum assembly to starter housing.

Remove the clutch housing/drum assembly.

2. Install flywheel holder, P/N 612470 or 180919.

3. Remove the two (2) clutch shoe bolts and

washers.

2.6071.048

3 - 20

2.6071.049

Page 44

Clutch Tool

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

4. Using the clutch tool for professional N28

engines, remove the clutch rotor.

5. Remove the spacer sleeve from crankshaft.

2.6071.050

3

2.6078.088

Clutch Inspection

1. Check the clutch rotor, shoes, and spring for

wear or damage. Replace if necessary.

Remove Starter Housing

1. If necessary, disconnect the spark plug wire from

spark plug and remove the spark plug.

2. Remove the screws securing the starter housing.

Remove the starter housing.

2.6071.051

3 - 21

Page 45

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

Starter Disassembly, Repalr, and Reassembly

WARNING: Sprlng under tension!

The rope starter on these engines contains a flat

wire spring that is under tension. Wear eye and

hand protection when replacing worn or broken

spring, in case it should uncoil as it is handled. Allow

spring tension to be completely relieved and make

sure pulley disengages from spring before removing

the pulley retainer, pulley, and starter spring from

housing.

3

2.6060.153

Adding Starter Spring Tension

If the rope pull handle does not fully return against

the starter housing, the spring may need another

turn of tension. Additional tension can be added

without disassembling the starter.

To add spring tension:

1. Pull the rope out a short distance and hold the

pulley from turning.

2. Wind one or more extra turns of rope onto the

pulley.

NOTE: If necessary, loosen the pulley retainer

screw while holding the pulley down to provide

clearance between the retainer and pulley. Torque

the retainer screw to 20-30 in•lb (2.3-3.4 N•m) after

additional rope is wound onto pulley.

2.6071.052

3 - 22

2.6071.053

Page 46

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

3. Pull the rope out to its full length and let it return

until the pull handle rests against the starter

housing.

NOTE: Do not add any more tension than is

necessary to make the pull handle return against the

starter housing. Adding excessive spring tension

can cause the spring to break.

If spring pressure is weak and adjustment will not

enable the pull handle to return against the starter

housing, replace the spring.

2.6078.089

3

2.6071.053

Disassembly

1. Relieve the spring tension by removing the pull

handle and allow the pulley to slowly unwind

inside the starter housing. Make sure the spring

tension is fully relieved before proceeding.

2. Remove screw and pulley retainer.

3. Remove the starter pulley from the starter

housing .

2.6071.054

3 - 23

Page 47

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

4. If necessary, carefully remove the starter spring

from the starter housing using a needle-nose

pliers.

NOTE: Once the starter spring is removed from the

starter housing, a service replacement spring

(prewound and contained in a spring retainer)

should be used to reassemble the starter.

Reinstallation of the old starter spring is not

recommended.

3

2.6071.055

5. Remove the starter rope from the pulley.

6. Remove the rope guide bushing from the starter

housing.

Inspection and Service

1. Inspect the starter rope for wear or frays. Replace

the rope if necessary.

2. Inspect the starter pulley for worn pawl

engagement teeth. Also check for wear on the

surface of pulley that is in contact with the

starter spring.

2.6071.056

3. Make sure old grease and dirt are cleaned from

all starter components before reassembling.

3 - 24

2.6047.092

Page 48

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

Reassembly

1. Install the starter spring into the starter housing

as follows:

a. Orient the replacement starter spring so the

spring windings are clockwise (the open end

of spring hook is to the left).

2.6071.057

3

2.6071.058

b. Grasp the spring near the spring hook with a

needle-nose pliers and carefully remove the

spring retainer.

c. Place the spring into the starter housing.

Make sure the spring hook is installed over

the post in the starter housing.

d. Make sure the spring windings are laying flat

against the starter housing around the entire

circumference of the spring. Hold the spring

in this position and carefully release the

needle-nose pliers holding the spring.

2.6071.059

3 - 25

Page 49

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

2. Insert the rope through the hole in starter pulley.

Tie a single knot in the rope approximately

0.5 in. (12.7 mm) from the end.

3. Pull the rope tight, pulling the knot into the pocket

in the pulley. Using a screwdriver, or similar tool,

push the end of the rope into the slot in the

pulley.

3

2.6071.060

4. Hold the pulley with the pawl engagement teeth

towards you. Wrap the rope around the pulley in

the clockwise direction. Make sure all of the

rope is wound onto the pulley.

5. Apply a small amount of grease (Mobilgrease®

HP or equivalent) to the post in starter housing,

spring, and backside of pulley.

6. Install the rope guide bushing into the starter

housing.

7. Install the pulley/rope assembly into the starter

housing. Rotate the pulley slightly until the

spring hooks onto the pulley, and the pulley

drops into place.

Post

2.6071.056

8. Route rope through the guide bushing in the

starter housing.

Install the pull handle on the rope and secure it

with a single knot.

3 - 26

2.6071.062

Page 50

DISASSEMBLY, INSPECTION, & REPAIR

MAJOR COMPONENTS (cont.)

9. Install the pulley retainer and screw. Torque the

screws to 20-30 in•lb (2.3-3.4 N•m).

10. Pull the rope out to its full length and let it return.

Check the spring tension and adjust as

necessary. Refer to “Adding Starter Spring

Tension” above.

2.6071.053

ENGINE

3

2.6071.064

Remove Ignition Module

1. Make sure the spark plug wire and the lead

wires to the ignition module are disconnected.

2. Remove the screws securing the ignition module

to the cylinder. Remove the ignition module.

Remove Flywheel

WARNING: CRACKED OR BROKEN COOLING

FINS ARE A HAZARD!

Be careful not to crack or break any cooling fins.

They could fly off during operation. If cooling fins are

cracked or broken, replace the flywheel.

2.6071.065

1. Using a plastic-faced mallet, tap and pull

flywheel until it breaks free from the crankshaft.

3 - 27

Page 51

DISASSEMBLY, INSPECTION, & REPAIR

ENGINE (cont.)

2. Remove the flywheel from the crankshaft.

3. Remove the flywheel key from crankshaft.

3

2.6071.066

Flywheel Inspection and Repair

Inspect the flywheel for the following conditions:

• Missing, broken, or cracked fins.

• Oval shaped pawl pin holes.

• Broken, damaged or missing springs, pawls, or

pawl pins. Freedom of movement of pawls.

• Evidence that the Starter Pawl Repair Kit has

been installed (holes in bottom of the flywheel

below pawl pins).

• Other signs of fatigue, wear, or damage to the

flywheel.

Starter Pawl Repair Kit, P/N 180142, is available to

repair the flywheel. This kit contains 2 pawl pins

(oversized*), 2 pawl springs, and 2 pawls. To install

the kit, an arbor press, 0.228 in (5.79 mm) drill and

drill press are required. Installation instructions are

provided in the kit.

2.6060.161

CONTENTS OF KIT

#180142

2 Starter Pawl Pins

(oversized)

2 Starter Pawl Springs

*NOTE: The pawl pins in this kit are oversized.

Once this kit is installed, the flywheel cannot be

repaired a second time.

For all other damage, replace the flywheel.

3 - 28

2 Starter Pawls

2.6078.093

Page 52

DISASSEMBLY, INSPECTION, & REPAIR

ENGINE (cont.)

Remove Spark Plug, Cylinder, and Piston

Connecting Rod Assembly

1. Remove the spark plug from cylinder.

Service the spark plug as instructed in Part 1 General Information.

2.6071.067

3

2.6071.068

2. Remove the four (4) screws securing the

crankcase cover to crankcase. Remove the

crankcase cover and gasket.

3. Remove the four (4) cylinder mounting screws.

2.6071.069

3 - 29

Page 53

DISASSEMBLY, INSPECTION, & REPAIR

ENGINE (cont.)

4. Remove the connecting rod from crankshaft.

5. Remove the cylinder with piston/connecting rod

assembly from the crankcase as a unit. Remove

the cylinder gasket.

3

2.6071.070

6. Remove the piston/connecting rod assembly from

the cylinder.

NOTE: Units with serial number 102084332 to

302010968 have one (1) piston ring. Units with

serial number 302010969 and greater have two (2)

piston rings.

7. Remove the piston ring(s) from the piston.

NOTE: Do not disassemble the piston/connecting

rod further.

2.6071.071

3 - 30

2.6071.072

Page 54

DISASSEMBLY, INSPECTION, & REPAIR

ENGINE (cont.)

Cylinder and Piston Inspection

1. Inspect the cylinder, piston, and piston ring(s) for

wear and damage. Refer to the specifications

and tolerances in Part 1 - General Information.

Replace the cylinder, piston, or piston ring(s) if

necessary.

2.6078.090

3

2.6071.073

2. Install the piston ring(s) into the ring groove(s) in

piston, and check the side clearance of piston

ring(s). The maximum side clearance is

0.004 inch (0.101 mm). Replace the ring(s) and

piston if necessary.

NOTE: Units with one (1 ) piston ring have a piston

ring width of 0.060 inch (1.6 mm) minimum.

Units with two (2) piston rings have a piston ring

width of 0.047 inch (1.14 mm) minimum.

3. Inspect the ring groove(s) on piston for carbon

deposits. Clean the ring groove(s) thoroughly.

Crankshaft and Crankcase Disassembly

NOTE: Crankcase disassembly and reassembly

requires the use of an arbor press and suitable drift

punches and bearing supports. If these are not

available, do not attempt to repair the crankcase

assembly. Refer to the appropriate parts manual to

order a complete crankcase/crankshaft assembly.

2.6071.074

1. Using an arbor press, press the crankshaft and

thrust washer out of the crankcase.

3 - 31

Page 55

DISASSEMBLY, INSPECTION, & REPAIR

ENGINE (cont.)

2. Remove the outer (sealed) bearing from the

flywheel side of the crankcase using a bearing

puller.

3

2.6071.075

3. Remove the inner (unsealed) bearing from the

inside of the crankcase.

4. Remove the snap rings securing the inner seal in

crankcase.

2.6071.076

Snap Rings

3 - 32

2.6071.077

Page 56

DISASSEMBLY, INSPECTION, & REPAIR

ENGINE (cont.)

5. Remove the inner seal from crankcase.

2.6071.078

3

2.6071.076

Crankcase Inspection

1. Inspect the crankcase for nicks, cracks, and

deformation. Replace if necessary.

2. Inspect the crankshaft for nicks, cracks,

roundness, and deformation. Replace if

necessary.

Crankcase Reassembly

NOTE: To prevent bearing damage, make sure

bearings are fully supported on both the inner and

outer races during all pressing operations. Make

sure the inner surface of crankcase and mating

surfaces of bearings and seal are clean, dry, and

free from grease and oil.

2.6071.077

1. Install outer snap ring (nearest flywheel).

3 - 33

Page 57

DISASSEMBLY, INSPECTION, & REPAIR

ENGINE (cont.)

2. Make sure the race of the outer (sealed) bearing

is packed with grease. If necessary, apply a

small amount of a high quality grade 2 lithium

based (or equivalent) bearing grease to the

bearing. Keep the grease off of the inner and

outer bearing surfaces that mate against the

crankcase and crankshaft.

3. Press the outer (sealed) bearing into the

crankcase until it is flush with the crankcase

surface. Make sure the rubber seal is to the

outside.

3

4. Press the inner seal into the crankcase to a depth

of 0.400 in. (10.2 mm). Make sure the lips of the

inner seal face away from the outer bearing.

Outer (Sealed)

Bearing

2.6071.079

Lightly lubricate the lips of the inner seal with

2-cycle engine oil.

5. Install the inner snap ring (nearest crank cheek).

6. Install the thrust washer onto the crankshaft.

7. Press the inner (unsealed) bearing onto the

crankshaft until it makes light contact with the

thrust washer.

2.6071.080

Bearing Support

3 - 34

2.6071.081

Page 58

Crankshaft/Bearing

DISASSEMBLY, INSPECTION, & REPAIR

ENGINE (cont.)

8. Press the crankshaft/bearing assembly into the

crankcase until the bearing is flush with the

inner surface of the crankcase.

2.6071.082

3

2.6071.083

9. Check the clearance between the inner surface of

the crankcase and the crankshaft counterweight

at several points.

Recommended clearance is 0.030 in.

(0.762 mm). Adjust the location of the

crankshaft/bearing if necessary.

3 - 35

Page 59

This Page Intentionally Left Blank

3 - 36

Page 60

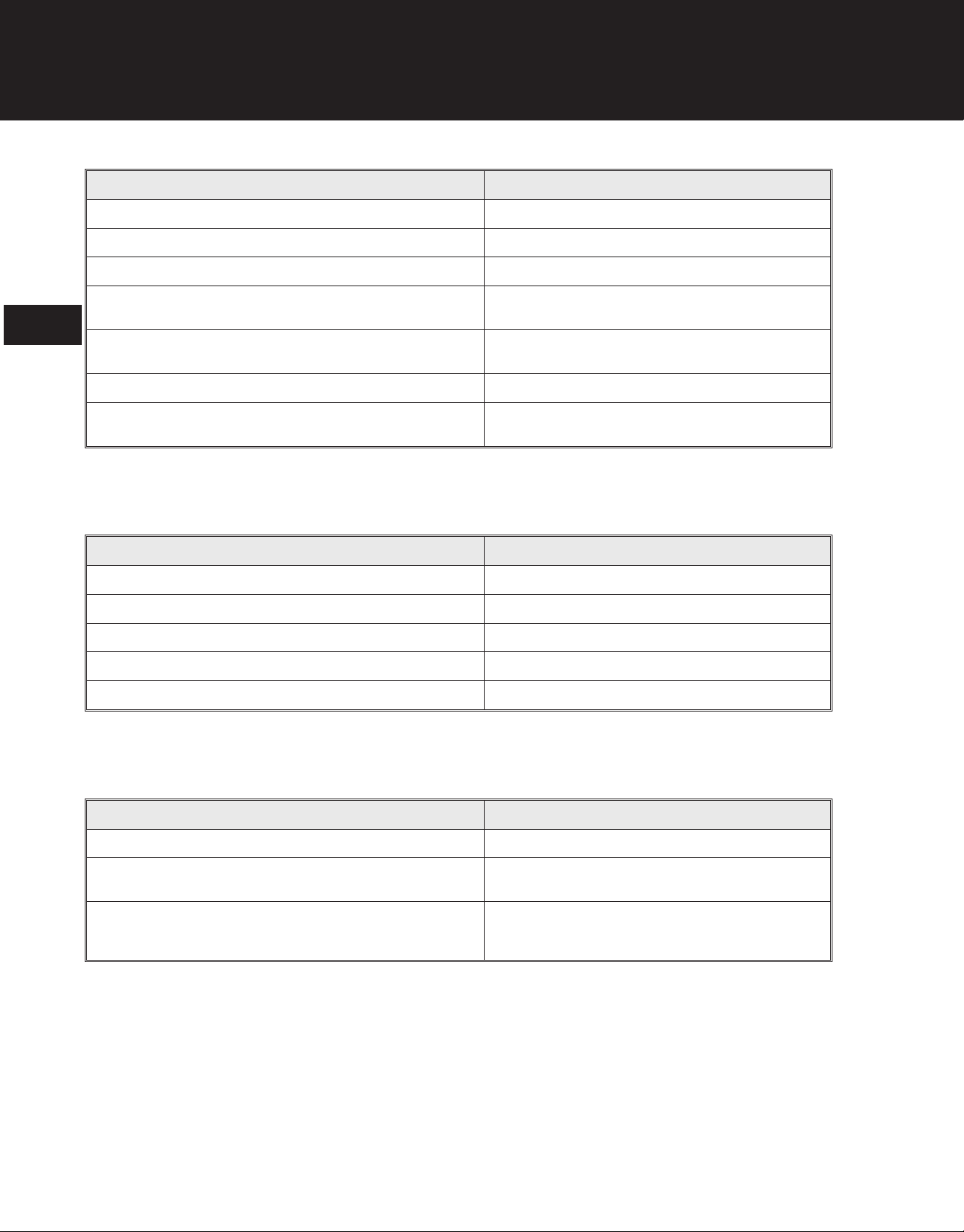

REASSEMBLY

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting .............................

Disassembly, Inspection, and Repair ..................

Reassembly ...............................

1

2

3

4

4 - 1

Page 61

REASSEMBLY

Typical Assembly Sequence . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Install Piston/Connecting Rod . . . . . . . . . . . . . . . . . . . . 4-4

Install Cylinder To Crankcase . . . . . . . . . . . . . . . . . . . . 4-5

Install Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Install Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Install Ignition Module . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Table Of Contents

4

Install Starter Housing . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Install Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Standard N28 Engines . . . . . . . . . . . . . . . . . . . . . 4-9

Professional N28 Engines . . . . . . . . . . . . . . . . . . . 4-10

Install Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Install Carburetor Spacer . . . . . . . . . . . . . . . . . . . . . . 4-11

Install Heat Shield, Fuel Tank, and Bracket . . . . . . . . . . . . . 4-12

Install Rear Engine Cover . . . . . . . . . . . . . . . . . . . . . . 4-12

Install Primer Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Install Carburetor, Choke, and Connect Fuel Lines . . . . . . . . . 4-13

Install Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Install Styling Cover . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Install Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Standard N28 Engines . . . . . . . . . . . . . . . . . . . . . 4-14

Professional N28 Engines . . . . . . . . . . . . . . . . . . . 4-16

4- 2

Prepare the Unit for Operation . . . . . . . . . . . . . . . . . . . . 4-17

Page 62

Typical Disassembly Sequence

REASSEMBLY

The following sequence is suggested for complete

engine REASSEMBLY. This procedure assumes that

all components are new or have been reconditioned

and all component subassembly work has been

completed. This procedure can be varied to

accommodate individual requirements for assembly

and repair.

NOTE: Make sure the engine is assembled using all

specified torque values and clearances. Failure to

observe specifications can cause severe engine wear

or damage.

Always use new gaskets.

1. Install Piston/Connecting Rod

2. Install Cylinder to Crankcase

3. Install Spark Plug

4. Install Flew

7. Install Clutch

8. Install Muffler*

9. Install Carburetor Spacer*

10. Install Heat Shield, Fuel Tank, and Bracket

11. Install Rear Engine Cover

12. Install Carburetor and Choke; Connect Fuel Lines*

13. Install Air Filter*

14. Install Styling Cover

15. Install Engine

4

16. Prepare the Unit for Operation

5. Install Ignition Module

6. Install Starter Housing

* On some units, these can be removed and

reinstalled without removing the engine from its normal

operating installation.

4 - 3

Page 63

REASSEMBLY

ENGINE

Install Piston/Connecting Rod

For units with one (1) piston ring, use the following

instructions

1. If necessary, install the piston ring onto the piston.

Make sure the ring end gap is located over the

anti-rotation pin in the piston ring groove.

2.6071.072

4

2. Lubricate the piston and piston ring with 2-cycle

engine oil. Compress the piston ring and insert

the piston into the cylinder.

3. Position the piston ring anti-rotation pin/end gap

so it faces away from the exhaust port of

cylinder.

NOTE: With the exhaust port on the right and intake

port on the left, the text on the piston rod should

face towards you.

2.6071.071

4- 4

2.6078.095

Page 64

2.6078.096

REASSEMBLY

ENGINE (cont.)

For units with two (2) piston rings, use the following

instructions.

1. If necessary, install the piston rings onto the piston.

2. Make sure the ring end gaps are located over the

anti-rotation in the piston ring grooves.

Spark Plug

Port

2.6071.071

3. Lubricate the piston and piston rings with 2-cycle

engine oil. Compress the piston rings and insert

the piston into the cylinder.

NOTE: With the exhaust port on the right and intake

port on the left, the text on the piston rod should

face towards you.

Install Cylinder to Crankcase

1. Put a new cylinder gasket on the cylinder.

2. Position the cylinder so the spark plug port is on

the left side of the cylinder.

4

2.6071.070

3. Lubricate the pin on crankshaft counterweight

with 2-cycle engine oil. Slip the connecting rod

bearing over the pin.

4 - 5

Page 65

REASSEMBLY

ENGINE (cont.)

4. Secure the crankcase to the cylinder with four (4)

screws.

Torque the screws to 50-60 in•lb (5.6-6.8 N•m).

2.6071.069

5. Install a new crankcase cover gasket, the

4

crankcase cover, and attaching screws.

Torque the screws to 55-65 in•lb (6.2-7.3 N•m).

Install Spark Plug

1. Make sure the spark plug gap is set to

0.018-0.023 inch (0.045 to 0.058 mm) using a

wire feeler gauge.

2. Install the spark plug into cylinder and torque to

100-120 in•lb (11.2-13.5 N•m).

2.6071.068

4- 6

2.6071.067

Page 66

2.6071.066

REASSEMBLY

MAJOR COMPONENTS

Install Flywheel

WARNING: Cracked or Broken Cooling Fins Are

A Hazard!

Be careful not to crank or break any cooling fins.

They could fly off during operation. If cooling fins are

cracked or broken, replace the flywheel.

1. Install the crankshaft key into the key way on

crankshaft.

2.6078.097

4

2. Position the flywheel so that the key slot in the

flywheel aligns with the crankshaft key. Place

the flywheel onto the crankshaft.

Install Ignition Module

1. Install the ignition module ground lead tab

terminal and module fastening screws.

2.6078.098

4 - 7

Page 67

REASSEMBLY

MAJOR COMPONENTS (cont.)

2. Move the ignition module away from the flywheel

as far as possible. Tighten the fastening screws

slightly