Page 1

Part No. 15212SL

Service Manual

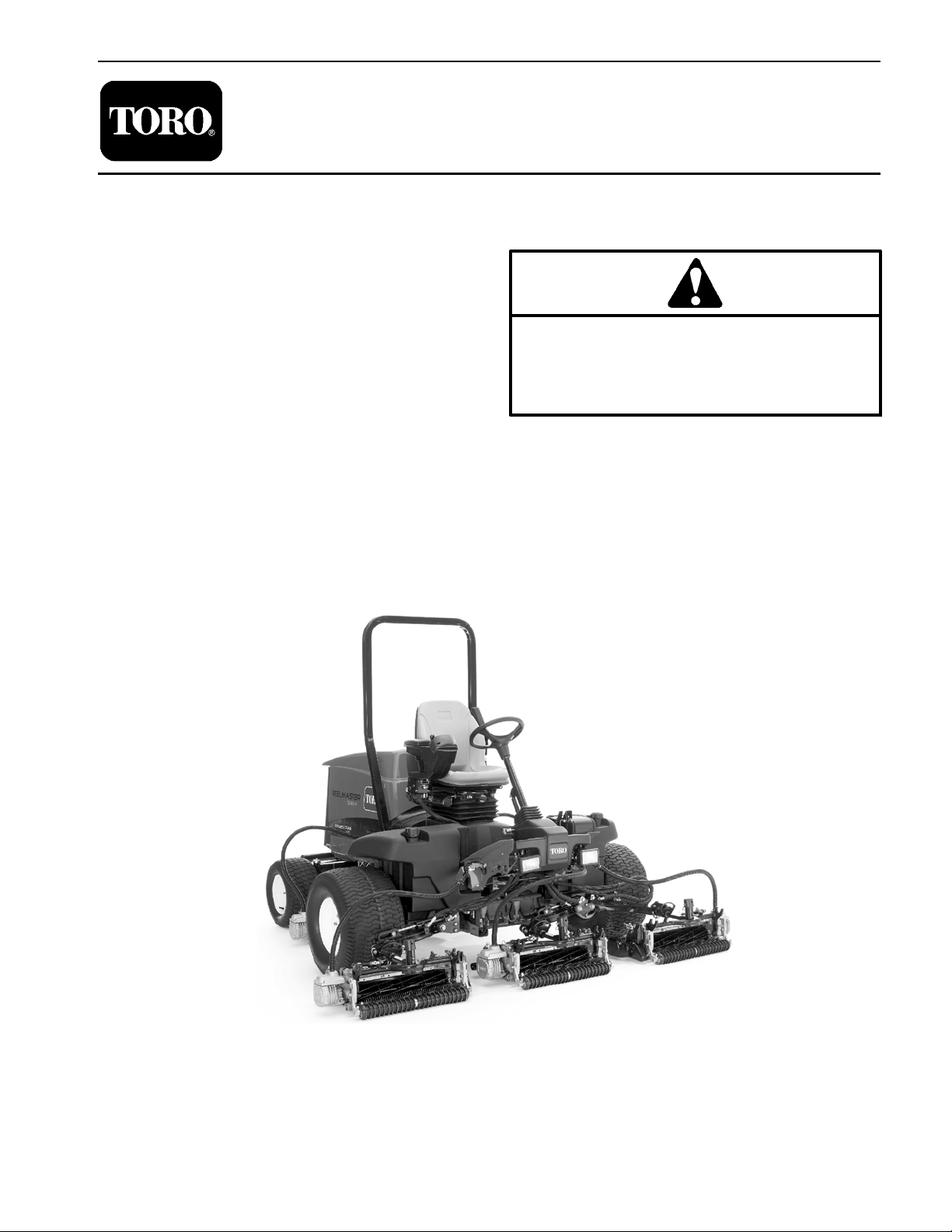

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Reelmaster 5010- H (Hybrid).

REFER TO THE TRACTION UNIT AND CUTTING

UNIT OPERATOR’S MANUALS FOR OPERATING,

MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. Space is provided in Chapter 2 of this book to

insert the Operator’s Manuals and Parts Catalogs for

your machine. Additional copies of the Operator’s

Manual and Parts Catalog are available on the internet

at www.Toro.com.

The Toro Company reserves the right to change product

specifications or this publication without notice.

Reelmaster

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the

machine.

R

5010- H

E The Toro Company - 2015

Page 2

This page is intentionally blank.

Reelmaster 5010- H

Page 3

Table Of Contents

Chapter 1 - Safety

Safety Instructions 1 - 2..........................

Jacking Instructions 1 - 5.........................

Safety and Instruction Decals 1 - 6................

Chapter 2 - Product Records and Maintenance

Product Records 2 - 1...........................

Maintenance 2 - 1...............................

Equivalents and Conversions 2 - 2................

Torque Specifications 2 - 3.......................

Chapter 3 - Kubota Diesel Engine

Specifications 3 - 2..............................

General Information 3 - 3........................

Service and Repairs 3 - 4........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

05- E4B SERIES

Chapter 4 - Hydraulic System

Specifications 4 - 2..............................

General Information 4 - 3........................

Hydraulic Schematic 4 - 10.......................

Hydraulic Flow Diagrams 4 - 12...................

Special Tools 4 - 20.............................

Troubleshooting 4 - 25...........................

Testing 4 - 30...................................

Service and Repairs 4 - 52.......................

SAUER- DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS REPAIR MANUAL

SAUER- DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS SERVICE INSTRUCTIONS

EATON DELTA MOTORS PARTS AND REPAIR

MANUAL

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

SAUER- DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

TM

SERVICE PROCEDURE

Chapter 5 - Electrical System

General Information 5 - 2........................

Electrical System Operation 5 - 4.................

Special Tools 5 - 6..............................

InfoCenter Display 5 - 10.........................

Troubleshooting 5 - 18...........................

Electrical System Quick Checks 5 - 40.............

Adjustments 5 - 42..............................

Component Testing 5 - 46........................

Service and Repairs 5 - 77.......................

Chapter 6 - Chassis

Specifications 6 - 2..............................

General Information 6 - 2........................

Special Tools 6 - 3..............................

Service and Repairs 6 - 4........................

Chapter 7 - Cutting Units

Specifications 7 - 2..............................

General Information 7 - 3........................

Special Tools 7 - 4..............................

Factors That Can Affect Cutting Performance 7 - 8..

Set- Up and Adjustments 7 - 12...................

Service and Repairs 7 - 14.......................

SafetyProduct Records

and Maintenance

Engine

Kubota Diesel

System

Hydraulic

System

Chassis

Reelmaster 5010- H

Cutting Electrical

Units

Page 4

This page is intentionally blank.

Reelmaster 5010- H

Page 5

Table Of Contents (Continued)

Chapter 8 - Groomer

General Information 8 - 2........................

Special Tools 8 - 3..............................

Grooming Performance 8 - 4.....................

Troubleshooting 8 - 5............................

Adjustments 8 - 7...............................

Service and Repairs 8 - 8........................

Chapter 9 - Foldout Drawings

Electrical Drawing Designations 9 - 2..............

Hydraulic Schematic 9 - 3........................

Electrical Schematic 9 - 4........................

Wire Harness Drawings 9 - 6.....................

GroomerFoldout

Drawings

Reelmaster 5010- H

Page 6

This page is intentionally blank.

Reelmaster 5010- H

Page 7

Table of Contents

SAFETY INSTRUCTIONS 2......................

Before Operating 2............................

While Operating 3.............................

Maintenance and Service 4....................

JACKING INSTRUCTIONS 5.....................

SAFETY AND INSTRUCTION DECALS 6..........

Chapter 1

Safety

Safety

Reelmaster 5010- H Page 1 - 1 Safety

Page 8

Safety Instructions

Reelmaster machines meet or exceed safety standard

specifications when weights are installed according to

information in the Traction Unit Operator’s Manual. Although hazard control and accident prevention are partially dependent upon the design and configuration of

the machine, these factors are also dependent uponthe

awareness, concern and proper training of the personnel involved in the operation, transport, maintenance

and storage of the machine. Improper use or maintenance of the machine can result in injury or death. To reduce the potential for injury or death, comply with the

following safety instructions.

Before Operating

WARNING

To reduce the potential for injury or death, comply with the following safety instructions.

1. Review and understand the contents of the Operator’ s Manuals and Operator Training DVD before starting and operating the machine. Become familiar withthe

controls and know how to stop the machine and engine

quickly. Additional copies of the Operator’s Manual are

available on the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible

or damaged, repair or replace it before operating the

machine. Also tighten any loose nuts, bolts or screws to

ensure machine is in safe operating condition.

3. Assure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is in

NEUTRAL and Enable/Disable switch is OFF (disabled).

4. Since fuel is flammable, handle it carefully:

A. Store fuel in containers specifically designed for

this purpose.

B. Do not remove machine fuel tank cap while engine is hot or running.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to within an inch of

the top of the tank, not the filler neck. Do not overfill.

E. Replace fueltank and fuel container caps securely after refueling machine.

F. If fuel is spilled, do not attempt to start the engine

but move the machine away from the area of spillage. Avoid creating any source of ignition until fuel

vapors have dissipated. Wipe up any spilled fuel.

Reelmaster 5010- HPage 1 - 2Safety

Page 9

While Operating

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Apply the parking brake.

B. Make sure the traction pedal is in NEUTRAL, the

Enable/Disable switch is in the disabled position and

the engine speed switch is in the mid- speed position.

C. Turn the ignition switch to the ON/PREHEAT position to energize the glow plugs. After allowing the

glow plugs to preheat, turn the switch to the START

position. Release the switch to the ON/PREHEAT

position when the engine starts.

D. After engine is started, release parking brake and

keep foot off traction pedal. Machine must not move.

If movement is evident, the traction pedal linkage is

adjusted incorrectly; therefore, shut engine off and

adjust traction pedal linkage until machine does not

move when traction pedal is released (see T raction

Unit Operator’s Manual).

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

4. Do not touch engine, radiator, exhaust system or hydraulic components while engine is running or soonafter

it is stopped. These areas could be hot enough to cause

burns.

5. Before getting off the seat:

A. Ensure that traction pedal is in NEUTRAL.

B. Lower and disengage cutting units. Wait for all

movement to stop.

C. Apply parking brake.

D. Move the engine speed switch to the low idle position and allow the engine to reach low idle speed.

E. Stop engine and remove key from ignition switch.

6. Anytime the machine is parked (short or long term),

the cutting units should be lowered to the ground. This

relieves pressure from the hydraulic lift circuit and eliminates the risk of the cutting units unexpectedly lowering

to the ground.

7. Do not park on slopes unless wheels are chocked or

blocked.

Safety

Reelmaster 5010- H Page 1 - 3 Safety

Page 10

Maintenance and Service

1. Before servicing or making adjustments, lower cutting units, apply parking brake, stop engine and remove

key from the ignition switch.

2. Make sure machine is in safe operating condition by

keeping all nuts, bolts and screws tight.

3. Never store the machine or fuel container inside

where there is an open flame, such as near a water heater or furnace.

4. Make sure all hydraulic line connectors are tight, and

all hydraulic hoses and lines are in good condition before applying pressure to the hydraulic system.

5. Keep body and hands away from pin hole leaks in hydraulic lines that eject high pressure hydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Fluid accidentally injected into the skin

must be surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result.

6. Before disconnecting or performing any work on the

hydraulic system, all pressure in the system must be relieved by using all of the hydraulic controls with the engine not running (see Relieving Hydraulic Pressure in

the General Information section of Chapter 4 - Hydraulic System).

7. Use care when checking or servicing the cutting

units. Wear appropriate gloves and use caution when

servicing them.

8. T o reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Clean

protective screen on machine frequently.

13.Before installing, removing or working on 48 VDC

system components (e.g. cutting units, motor/generator), separatesystem components from the 48 VDC battery pack by unplugging the 48 VDC battery disconnect

(see 48 VDC Battery Disconnect in the General Information section of Chapter 5 - Electrical System). Plug

the connector back in before operating the machine.

14.Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with a battery.

15.Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

16.When changing tires, attachments or performing

other service, use correct jacks, hoists and supports.

Make sure machine is parked on a solid level floor such

as a concrete floor. Prior to raising the machine, remove

any attachments that may interfere with the safe and

proper raising of the machine. Always chock or block

wheels. Use jack stands or appropriate load holding devices to support the raised machine. If the machine is

not properly supported, the machine may move or fall,

which may result in personal injury (see Jacking Instructions in this section).

17.If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

18.When welding on machine, disconnect battery

cables to prevent damage to machine electronic equipment. Disconnect negative battery cable first and positive cable last. Also, disconnect wire harness connector

from the TEC controller and disconnect the terminal

connector from the alternator. Attach welder ground

cable no more than two (2) feet (0.6 meters) from the

welding location.

9. If engine must be running to perform maintenance or

to make an adjustment, keep hands, feet, clothing and

other parts of the body away from the cutting units and

other moving parts. Keep bystanders away.

10.To assure safety and accuracy, check maximum engine speed.

1 1.Shut engine off before checking or adding oil to the

engine crankcase.

12.Disconnect 12 VDC battery located at the rear of the

machine before servicing themachine. Disconnect negative battery cable first and positive cable last. If battery

voltage is required for troubleshooting or test procedures, temporarily connect the battery. Reconnect positive battery cable first and negative cable last.

19.Make sure to dispose of potentially harmful waste

(e.g. fuel, oil, engine coolant, filters, batteries) in an environmentally safe manner. Follow all local codes and

regulations when recycling or disposing of waste.

20.At the time of manufacture, the machine conformed

to the safety standards for riding mowers. To assure optimum performance and continued safety certification of

the machine, use genuine Toro replacement parts and

accessories. Replacement parts and accessories made

by other manufacturers may result in non-conformance

with the safety standards, and the warranty may be

voided.

Reelmaster 5010- HPage 1 - 4Safety

Page 11

Jacking Instructions

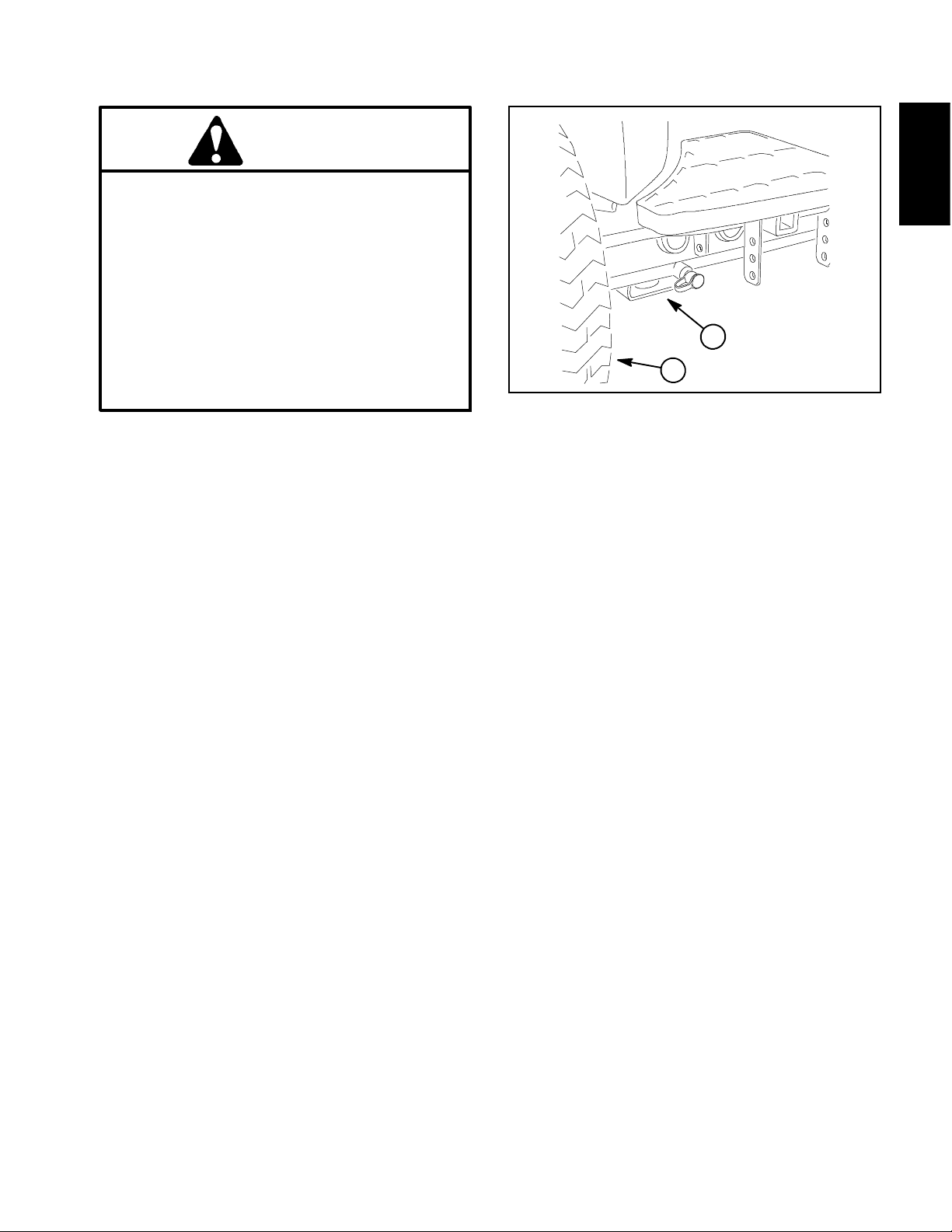

CAUTION

When changing tires, attachments or performing other service, use correct hoists, jacks and

jack stands. Make sure machine is parked on a

solid, level surface such as a concrete floor.

Prior to raising machine, remove any attachmentsthat may interfere with the safeand proper raising of the machine. Always chock or

block wheels. Use jack stands or other appropriate load holding devices to support the

raised machine. If the machine is not properly

supported, the machine may move or fall,

which may result in personal injury.

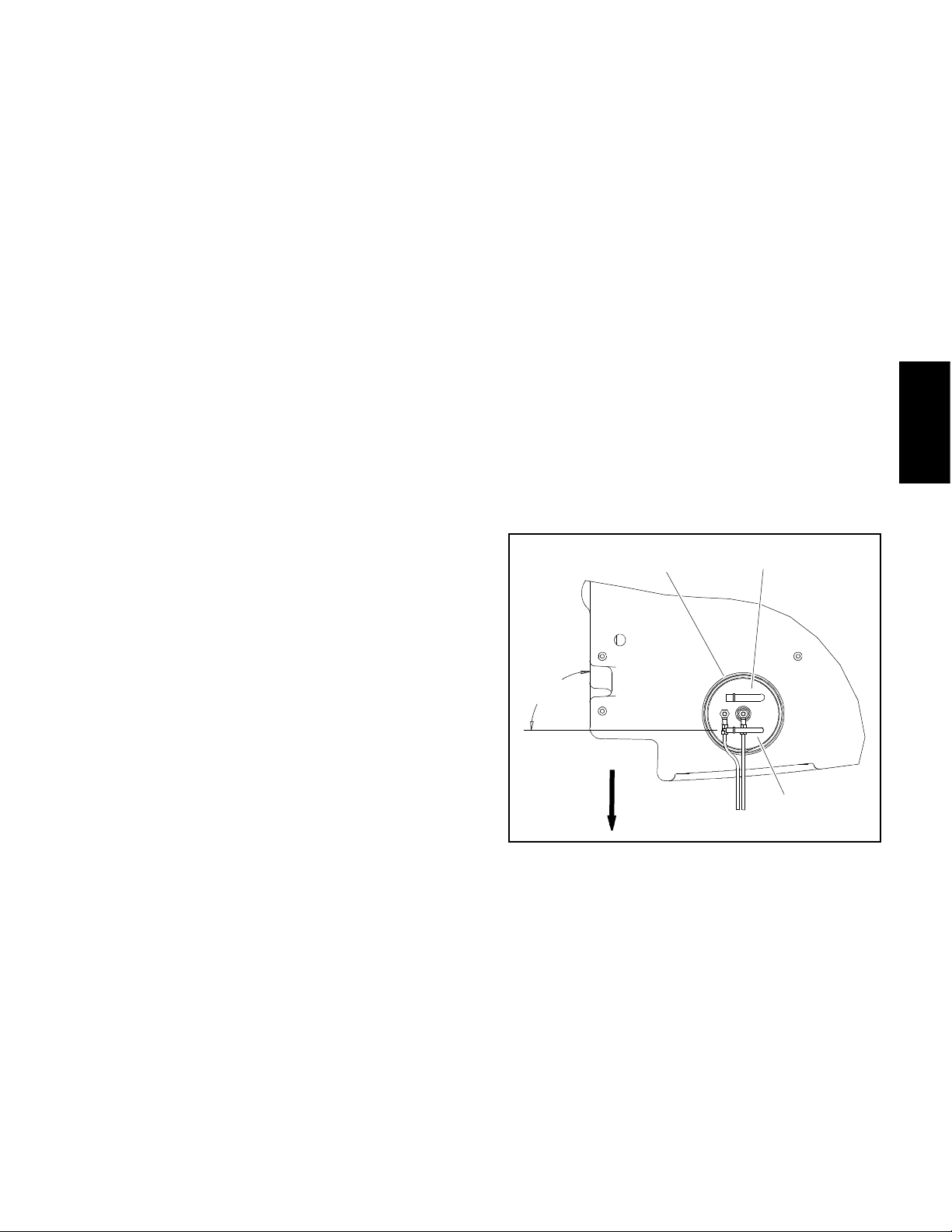

Front End Jacking (Fig. 1)

1. Apply parking brake and chock both rear tires to prevent the machine from moving.

2. Position jack securely below the rectangular pad under the frame axle tube, just to the inside of the front

wheel.

3. Jack front of machine off the ground.

4. Position jack stands under the frame as close to the

raised wheel as possible to support the machine.

Safety

2

1

Figure 1

1. Front wheel 2. Front jacking point

Rear End Jacking

1. Apply parking brake and chock both front tires to prevent the machine from moving.

2. Place jack securely at the center of the rear axle under the axle pivot bracket. Jack rear of machine off the

ground.

3. T o support the raised machine, position jack stands

under the frame rail next to the axle support bracket.

Reelmaster 5010- H Page 1 - 5 Safety

Page 12

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the traction unit and the cutting units of yourReelmaster.

If any decal becomes illegible or damaged, install a new

decal. Part numbers for decals are listed in your Part

Catalogs. Order replacement decals from your Authorized Toro Distributor.

Reelmaster 5010- HPage 1 - 6Safety

Page 13

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1..............................

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3...................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Series) 5..............

Other Torque Specifications 6..................

Conversion Factors 6.........................

Chapter 2

Product Records

and Maintenance

Product Records

Insert Operator’s Manual and Parts Catalog for your

Reelmaster at the end of this chapter. Refer to Operator’s Manual for recommended maintenance intervals.

Additionally, insert Installation Instructions, Operator’s

Manuals and Parts Catalogs for any accessories that

have been installed on your Reelmaster at the end of

this section.

Maintenance

Maintenance procedures and recommended service intervals for your Reelmaster are covered in the Operator’s Manual. Refer to that publication when performing

regular equipment maintenance. Several maintenance

procedures have break- in intervals identified in the Operator’s Manual. Refer to the Engine Operator’s Manual

for additional engine specific maintenance procedures.

Reelmaster 5010- H Page 2 - 1 Product Records and Maintenance

Page 14

Equivalents and Conversions

0.09375

Reelmaster 5010- HPage 2 - 2Product Records and Maintenance

Page 15

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

the fastener’s head or similar condition which affects the

installation.

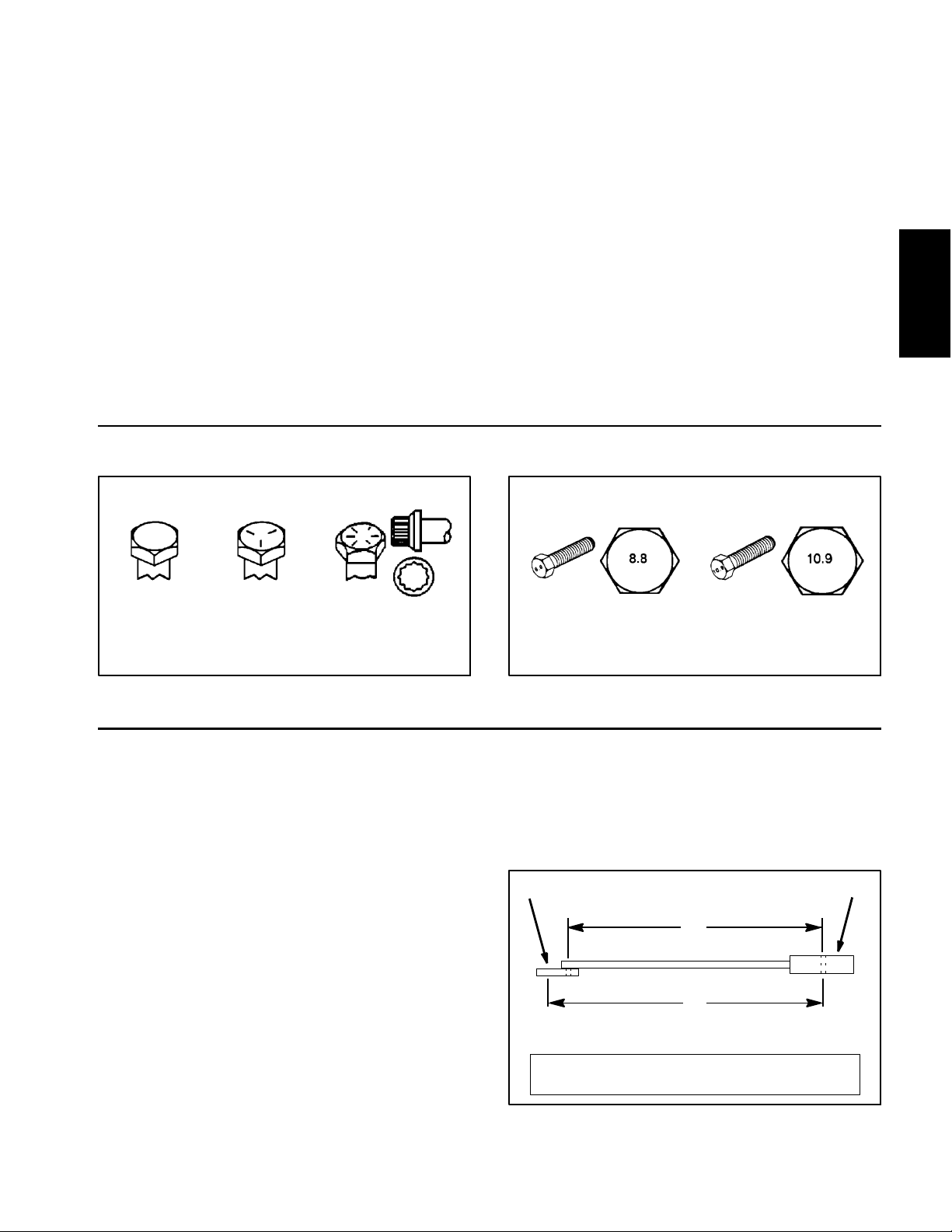

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

the lines match up.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

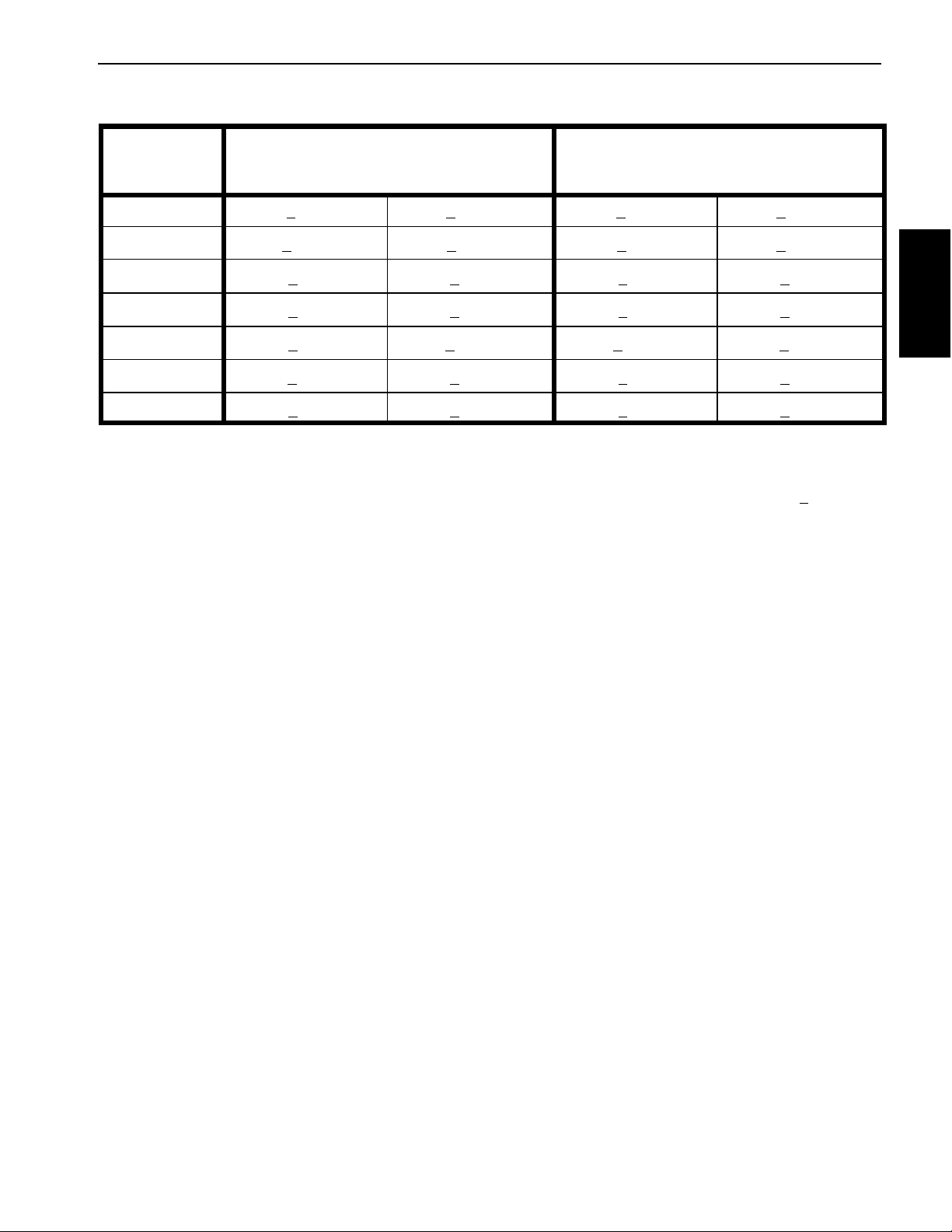

Using a Torque Wrench with an Offset Wrench

Use of an offset wrench (e.g. crowfoot wrench) will affect

torque wrench calibration due to the effective change of

torque wrench length. When using a torque wrench with

an offset wrench, multiply the listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: Themeasuredeffectivelengthofthetorque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

Themeasuredeffectivelengthofthetorquewrenchwith

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft- lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft- lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A / B

T orque wrenchOffset wrench

Thecalculatedtorqueconversionfactorforthistorque

wrench with this offset wrench would be 18 / 19 = 0.947.

Reelmaster 5010- H Page 2 - 3 Product Records and Maintenance

Figure 3

Page 16

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

#6- 32UNC

#6- 40UNF 17 + 2 192 + 23 25 + 3 282 + 34

#8- 32UNC

#8- 36UNF 31 + 4 350 + 45 43 + 5 486 + 56

# 10 - 24 UNC

#10- 32UNF 48 + 5 542 + 56 68 + 7 768 + 79

1/4 - 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130 + 113 140 + 15 1582 + 169

1/4 - 28 UNF 53 + 7 65 + 10 734 + 11 3 115 + 12 1299 + 136 160 + 17 1808 + 192

5/16 - 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 - 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 - 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in- lb in- lb N- cm in- lb N- cm in- lb N- cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft- lb ft- lb N- m ft- lb N- m ft- lb N- m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

29 + 3 328 + 34 41 + 5 463 + 56

42 + 5 475 + 56 60 + 6 678 + 68

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 - 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 - 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 - 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 - 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 - 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 - 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 - 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 - 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 - 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 - 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 - 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimum proof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Reelmaster 5010- HPage 2 - 4Product Records and Maintenance

Page 17

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size

M5 X 0.8 57 + 6in-lb 644 + 68 N- cm 78 + 8in-lb 881 + 90 N- cm

M6 X 1.0 96 + 10 in- lb 1085 + 11 3 N - cm 133 + 14 in- lb 1503 + 158 N- cm

M8 X 1.25 19 + 2ft-lb 26 + 3N-m 28 + 3ft-lb 38 + 4N-m

M10 X 1.5 38 + 4ft-lb 52 + 5N-m 54 + 6ft-lb 73 + 8N-m

M12 X 1.75 66 + 7ft-lb 90 + 10 N- m 93 + 10 ft- lb 126 + 14 N- m

M16 X 2.0 166 + 17 ft- lb 225 + 23 N- m 229 + 23 ft- lb 310 + 31 N- m

M20 X 2.5 325 + 33 ft- lb 440 + 45 N- m 450 + 46 ft- lb 610 + 62 N- m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Stronger Nuts)

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately +

nominal torque value.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

10% of the

Product Records

and Maintenance

Reelmaster 5010- H Page 2 - 5 Product Records and Maintenance

Page 18

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 - 20 UNC 140 + 20 in- lb 73 + 12 in- lb

5/16 - 18 UNC 215 + 35 in- lb 145 + 20 in- lb

3/8 - 16 UNC 35 + 10 ft- lb 18 + 3ft-lb

1/2 - 13 UNC 75 + 15 ft- lb 50 + 10 ft- lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 + 5in-lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non- lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in-lb

Threads per Inch

Typ e A Type B

Recommended Torque**

65 + 10 ft- lb 88 + 14 N- m

80 + 10 ft- lb 108 + 14 N- m

80 + 10 ft- lb 108 + 14 N- m

80 + 10 ft- lb 108 + 14 N- m

Baseline Torque*

No. 8 - 32 UNC 30 + 5in-lb

No. 10 - 24 UNC 38 + 7in-lb

1/4 - 20 UNC 85 + 15 in- lb

5/16 - 18 UNC 110 + 20 in- lb

3/8 - 16 UNC 200 + 100 in- lb

Conversion Factors

in-lbX11.2985=N-cm N-cmX0.08851=in-lb

ft- lb X 1.3558 = N- m N- m X 0.7376 = ft- lb

No. 8 15 18 30 + 5in-lb

No. 10 12 16 38 + 7in-lb

No. 12 11 14 85 + 15 in- lb

* Hole size, material strength, material thickness and finish must be considered when determining specific

torque values. All torque values are based on non- lubricated fasteners.

Reelmaster 5010- HPage 2 - 6Product Records and Maintenance

Page 19

Table of Contents

SPECIFICATIONS 2............................

GENERAL INFORMATION 3.....................

Traction Unit Operator’s Manual 3...............

Kubota Workshop Manual 3....................

48 VDC Battery Disconnect 3...................

SERVICE AND REPAIRS 4......................

Air Cleaner Assembly 4........................

Exhaust System 6............................

Fuel System 8................................

Radiator Assembly 10.........................

Engine 14....................................

Engine Bellhousing Assembly 18................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

05- E4B SERIES

Chapter 3

Kubota Diesel Engine

Engine

Kubota Diesel

Reelmaster 5010- H Page 3 - 1 Kubota Diesel Engine

Page 20

Specifications

Item Description

Make / Designation Kubota Model D1105- E4B: 4- Cycle, 3 Cylinder,

Number of Cylinders 3

Bore x Stroke 3.07” x 3.09” (78 mm x 78.4 mm)

Total Displacement 68.5 in3(1123 cc)

Firing Order 1 (fan end) - 2 - 3 (flywheel end)

Direction of Rotation Counterclockwise (viewed from flywheel)

Fuel Diesel or Biodiesel (up to B20) Fuel with

Fuel Injection Pump Bosch MD Type Mini Pump

Injection Nozzles Mini Nozzle (DNOPD)

Fuel Tank Capacity 14 U.S. Gallons (53 Liters)

Governor All Speed Mechanical

Low Idle Speed (no load) 1400 RPM

Water Cooled, Tier 4 Diesel Engine

Low or Ultra Low Sulfur Content

High Idle Speed (no load) 3000 RPM

Engine Oil API CH- 4, CI- 4 or higher

Engine Oil V iscosity See Traction Unit Operator’s Manual

Oil Pump Gear Driven Trochoid Type

Crankcase Oil Capacity 3.5 U.S. Quarts (3.3 Liters) with Filter

Cooling System Capacity (including reserve tank) 5.5 U.S. Quarts (5.2 Liters)

Starter 12 VDC 1.4 KW

Alternator/Regulator 12 VDC 40 Amp

Dry Weight (approximate) 205 lb. (93 kg)

NOTE: The Kubota engine used in your Reelmaster is

equipped with a mechanical governor as listed above.

During normal machine operation however, engine

speed control is electronically managed by the machine

TEC controller, the 48 VDC motor/generator controller

and the engine mounted fuel actuator. These three (3)

machine components determine engine/generator

speed during use and modify fuel settings at the fuel actuator as necessary to maintain appropriate engine

speed based on load.

Reelmaster 5010- HPage 3 - 2Kubota Diesel Engine

Page 21

General Information

This Chapter gives information about specifications,

troubleshooting, testing and repair of the Kubota diesel

engine used in Reelmaster 5010- H machines.

Most repairs and adjustments require tools which are

commonly available in many service shops. The use of

some specialized test equipment is explained in the engine Kubota Workshop Manual included at the end of

this chapter . However, the cost of the test equipment

and the specialized nature of some repairs may dictate

that the work be done at an engine repair facility.

Traction Unit Operator’s Manual

The T raction Unit Operator’ s Manual provides information regarding the operation, general maintenance and

maintenance intervals for the Kubota diesel engine that

powers your Reelmaster machine. The Kubota Operator’s Manual includes information specific to the engine

used in your Reelmaster. Refer to these publications for

additional information when servicing the machine.

Kubota Workshop Manual

Service and repair parts for Kubota diesel engines are

supplied through your local Toro Distributor . If an engine

parts list is not available, be sure to provide your distributor with the Toro model and serial number.

Engine

Kubota Diesel

The engine that powers your Reelmaster machine is a

Kubota model D1105- E4B (Tier 4 compliant). The Kubota Workshop Manual, Diesel Engine, 05- E4B Series is

available for this engine. Make sure that the correct engine manual is used when servicing the engine on your

Reelmaster.

48 VDC Battery Disconnect

CAUTION

Before installing, removing or servicing components in the 48 VDC system (e.g. cutting unit motors, motor/generator), separate the 48 VDC battery disconnect. This will prevent unexpected

operation of 48 VDC system components.

The 48 VDC battery disconnect is attached to the right

frame rail under the operator seat (Fig. 1). Unplug the

disconnect to make sure that 48 VDC components do

not operate unexpectedly. Apply dielectric grease to the

contact surfaces of the battery disconnect and plug the

battery disconnect back in after service to the 48 VDC

system is completed.

1

1. RH frame rail 2. 48V battery disconnect

2

Figure 1

FRONT

Reelmaster 5010- H Page 3 - 3 Kubota Diesel Engine

Page 22

Service and Repairs

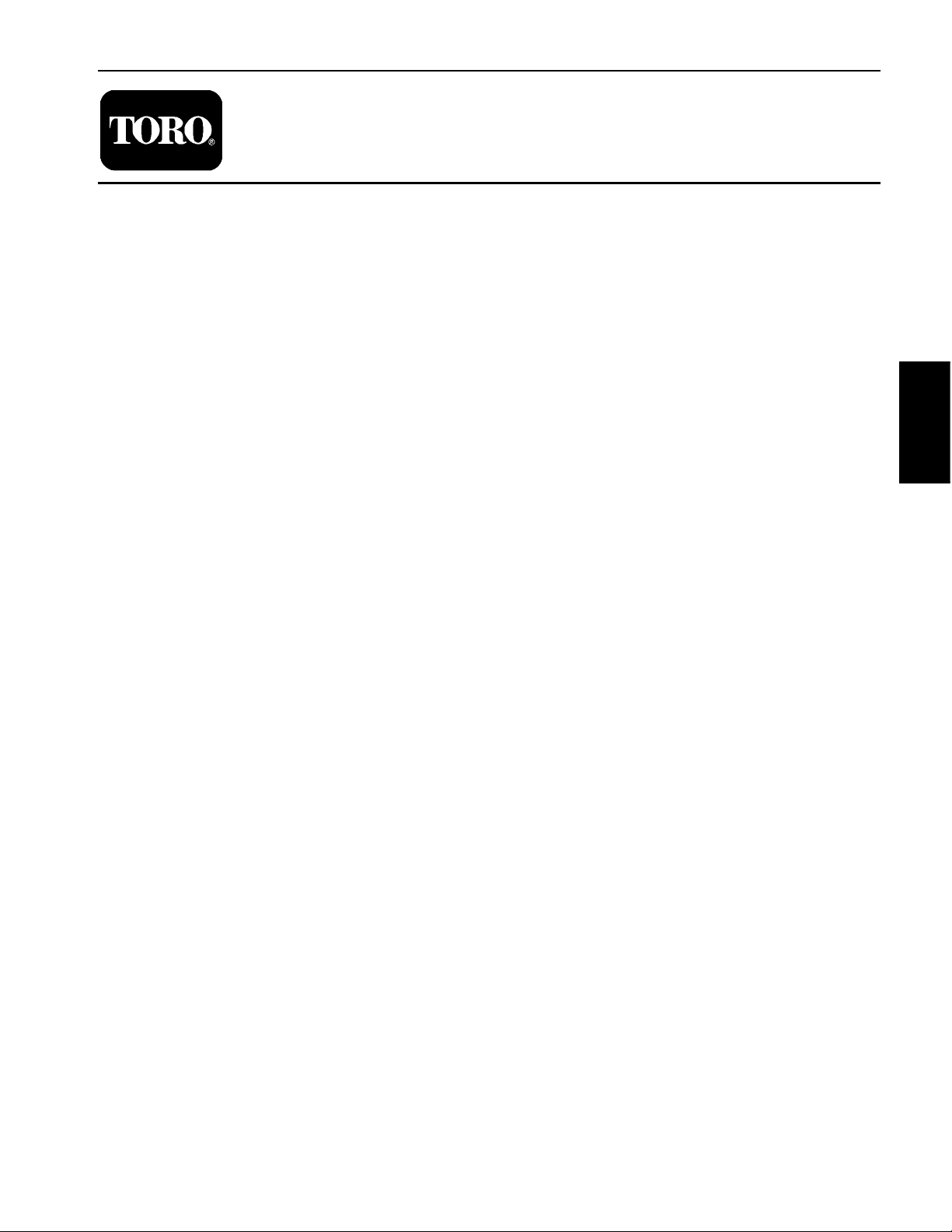

Air Cleaner Assembly

3

5

3

7

1

10

8

9

11

12

13

14

6

2

3

12

16

17

15

30 to 40 in- lb

(3.4 to 4.5 N- m)

Thread

Sealant

3

4

30 to 40 in- lb

(3.4 to 4.5 N- m)

RIGHT

FRONT

1. Diesel engine

2. Air cleaner assembly

3. Hose clamp (4 used)

4. Air intake hose

5. Air intake hose

6. Service indicator

Figure 2

7. Indicator adapter

8. Shoulder bolt

9. Nut

10. Compression spring

11. Air cle aner mounting band

12. Flange nut (6 used)

12

13. Flange head screw (2 used)

14. Cap screw (2 used)

15. Flange head screw (2 used)

16. Air cleaner bracket

17. Air cleaner stand

Reelmaster 5010- HPage 3 - 4Kubota Diesel Engine

Page 23

Removal (Fig. 2)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch. Raise and support hood.

2. Remove air cleaner components as needed using

Figure 2 as a guide.

12 to 15 in- lb

(1.4 to 1.6 N- m)

2

3. See Traction Unit Operator’s Manual for air cleaner

service and maintenance procedures.

Installation (Fig. 2)

IMPORTANT: Any leaks in the air filter system will

allow dirt into engine and will cause serious engine

damage. Make sure that all air cleaner components

arein good condition and are properly secured during assembly.

1. Assemble air cleaner system using Figure 2 as a

guide.

A. If service indicator (item 6 in Fig. 2) and adapter

(item 7 in Fig. 2) were removed from air cleaner

housing, apply thread sealant to adapter threads before installing adapter and indicator to housing.

Install adapter so that grooves in adapter hex and

adapter filter element are installed toward service indicator (shown in Fig. 3). Torque indicator from 12 to

15 in- lb (1.4 to 1.6 N- m).

B. Make sure that evacuator valve on air cleaner assembly is pointed down after assembly.

1

1. Air cleaner assembly

2. Service indicator

3

Thread

Sealant

Engine

Kubota Diesel

4

Figure 3

3. Indicator adapter

4. Evacuator valve

C. T orque hose clamps from 30 to 40 in- lb (3.4 to

4.5 N- m).

2. After air cleaner has been properly installed, lower

and secure hood.

Reelmaster 5010- H Page 3 - 5 Kubota Diesel Engine

Page 24

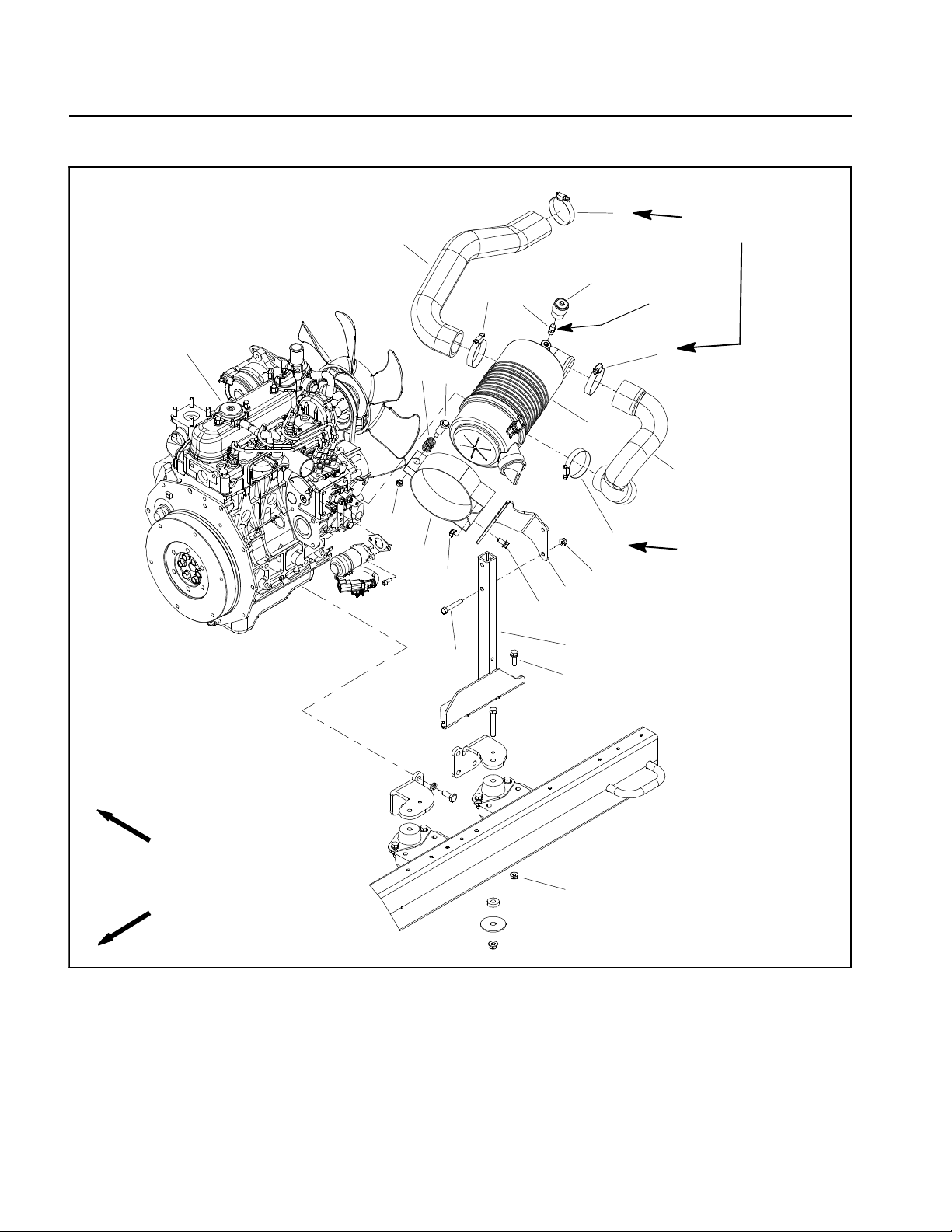

Exhaust System

11

12

13

14

15

16

RIGHT

FRONT

17

5

3

4

9

14

2

1

8

6

7

10

1. Diesel engine

2. Exhaust muffler

3. Clamp

4. Hex nut (2 used)

5. Flange nut (4 used)

6. Carriage bolt (4 used)

Figure 4

7. Bellhousing

8. Tailpipe bracket

9. Flange head screw

10. Flange nut

11. Exhaust header

12. Flange nut (4 used)

13. Exhaust gasket

14. Flange head screw (6 used)

15. Muffler guard

16. Washer head screw (2 used)

17. Muffler bracket

Reelmaster 5010- HPage 3 - 6Kubota Diesel Engine

Page 25

Removal (Fig. 4)

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before working on the exhaust system.

1. Raise and support hood to gain access to exhaust

system. Allow engine and exhaust system to cool before

doing any disassembly of exhaust system components.

2. Remove exhaust system components from the engine as necessary using Figure 4 as a guide. Discard exhaust gasket (item 13) if exhaust header (item 11) was

removed.

Installation (Fig. 4)

IMPORTANT: If exhaust studs were removed from

engine cylinder head, thoroughly clean threads in

head and apply Loctite #277 (or equivalent) to stud

threads before installing studs into head.

3. Adjust muffler guard (item 15) on frame so there is

⅜” (9.5 mm) clearance between exhaust tailpipe and

guard in all directions.

4. After all exhaust components have been installed,

lower and secure hood.

D

C

B

A

Engine

Kubota Diesel

E

NOTE: Make sure that all exhaust system flanges and

sealing surfaces are free of debris or damage that may

prevent a tight seal.

1. Install new exhaust gasket (item 13) if gasket was

removed. Do not use any type of gasket sealant on gasket or flange surfaces.

2. Install all removed exhaust system components using Figure 4 as a guide. Hand tighten exhaust system

fasteners and after all exhaust system components

have been installed, fully tighten the fasteners as shown

in Figure 5:

A. Tighten flange head screws that secure muffler

bracket to engine bellhousing.

B. Tighten carriage screws and flange nuts that secure exhaust muffler to muffler bracket.

C. Tighten flange nuts that secure exhaust header

to engine exhaust manifold.

D. Tighten clamp that secures exhaust muffler to exhaust header.

F

Figure 5

E. Tighten flange head screw and flange nut that secures exhaust muffler to tailpipe bracket.

F. Tighten flange head screws that secure tailpipe

bracket to engine bellhousing.

Reelmaster 5010- H Page 3 - 7 Kubota Diesel Engine

Page 26

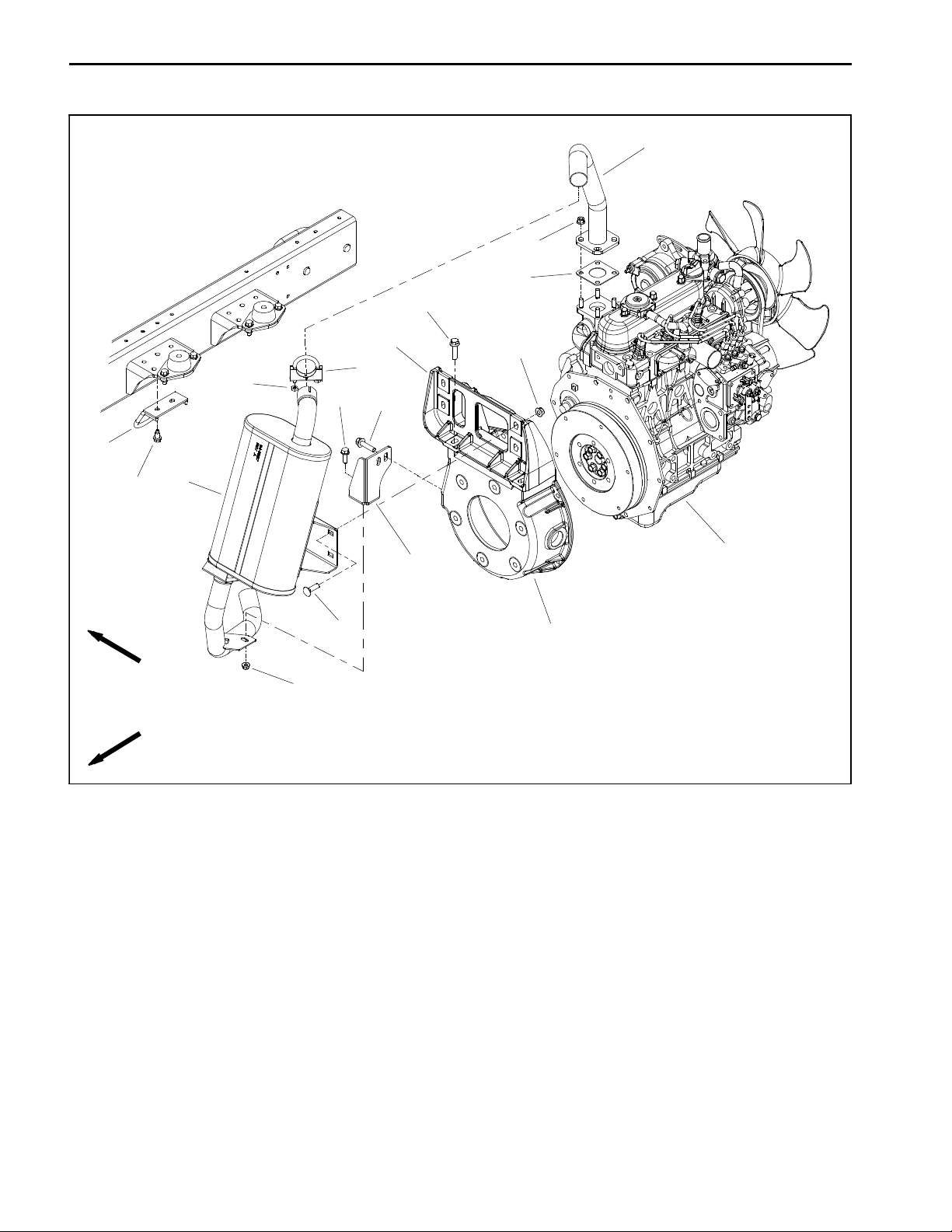

Fuel System

RIGHT

FRONT

9

12

17

16

15

18

7

6

8

19

12

4

3

5

3

14

20

2

1

11

10

1. Fuel tank

2. Fuel tank cap

3. Screw (7 used)

4. Strap

5. Sender cover

6. Hose clamp

7. Fuel supply hose

8. Hose clamp

9. Fuel return hose

10. Clamp (2 used)

11. Flange head screw (2 used)

12. Flange nut (3 used)

13. Draincock

14. Hose clamp

DANGER

Because diesel fuel is flammable, use caution

when storing or handling it. Do not smoke while

filling the fuel tank. Do not fill fuel tank while engine is running, when engine is hot or when machine is in an enclosed area. Always fill fuel tank

outside and wipe up any spilled diesel fuel before starting the engine. Store fuel in a clean,

safety- approved container and keep container

cap in place. Use diesel fuel for the engine only;

not for any other purpose.

13

Figure 6

15. Cap screw

16. Flat washer

17. Bumper

18. Fuel sender cap

19. Fuel sender

20. Gasket

Check Fuel Lines and Connections

Check fuel lines and connections periodically as recommended in the Traction Unit Operator’s Manual. Check

lines for deterioration, damage, leakage or loose connections. Replace fuel hoses, clamps and connections

as necessary.

Drain and Clean Fuel Tank

Drain and clean the fuel tank periodically as recommended in the Traction Unit Operator’s Manual. Also,

drain and clean the fuel tank if the fuel system becomes

contaminated or if the machine is to be stored for an extended period.

Reelmaster 5010- HPage 3 - 8Kubota Diesel Engine

Page 27

IMPORTANT: Follow all local codes and regulations when recycling or disposing waste fuel.

To clean fuel tank, flush tank out with clean diesel fuel.

Make sure tank is free of all contaminates and debris.

Fuel Tank Installation (Fig. 6)

1. Install fuel tank to frame using Figure 6 as a guide.

Secure fuel hoses with cable ties as noted during fuel

tank removal.

Priming the Fuel System

The fuel system needs to be primed before starting the

engine for the first time, after running out of fuel or after

fuel system maintenance (e.g. draining the filter/water

separator, replacing a fuel hose). To prime the fuel system, make sure that the fuel tank has fuelin it. Then,turn

the ignition key to the RUN position for ten (10) to fifteen

(15) seconds which allows the fuel pump to prime the

fuel system. DO NOT use the engine starter motor to

crank the engine in order to prime the fuel system.

Fuel Tank Removal (Fig. 6)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Place drain pan under fuel tank. Make sure that drain

pan is large enough to hold fuel tank contents (see

Specifications in this chapter).

3. Open draincock on bottom of fuel tank and allow tank

to fully drain. Close draincock.

4. Disconnect wire harness connection from the fuel

sender (item 19).

A. If fuel sender was removed from fuel tank, make

sure that fuel fittings on sender are orientated at 90

from right side of tank as shown in Figure 7. Also, to

prevent damage to fuel sender during assembly,

make sure that fuel sender does not turn as sender

cap is tightened.

2. Correctly connect supply (item 7) and return (item 9)

fuel hoses to fittings on the top of thefuel sender. Secure

fuel hoses with hose clamps.

3. Secure wire harness connector to fuel sender.

4. Make sure that fuel tank draincock is closed. Fill fuel

tank with clean fuel.

5. Prime the fuel system (see above).

6. Before returning machine to operation, make sure

that no fuel leaks exist.

1

2

o

Engine

Kubota Diesel

NOTE: Before removing fuel hoses from tank fittings,

label hoses for assembly purposes.

IMPORTANT: T o prevent damage to fuel hoses, numerous cable ties are used to secure hoses to machine components. Take note of all cable ties that

are removed from machine during fuel tank removal

so they can be properly replaced during tank installation.

5. Loosen hose clamps and carefully disconnect supply (item 7) and return (item 9) fuel hoses from fittings

on the top of the fuel sender.

6. Remove fuel tank using Figure 6 as a guide.

IMPORTANT: If fuel sender is removed from fuel

tank, note orientation of fittings for assembly purposes (Fig. 7).

o

90

FRONT

1. Fuel sender

2. Fuel supply fitting

3

Figure 7

3. Fuel return fitting

Reelmaster 5010- H Page 3 - 9 Kubota Diesel Engine

Page 28

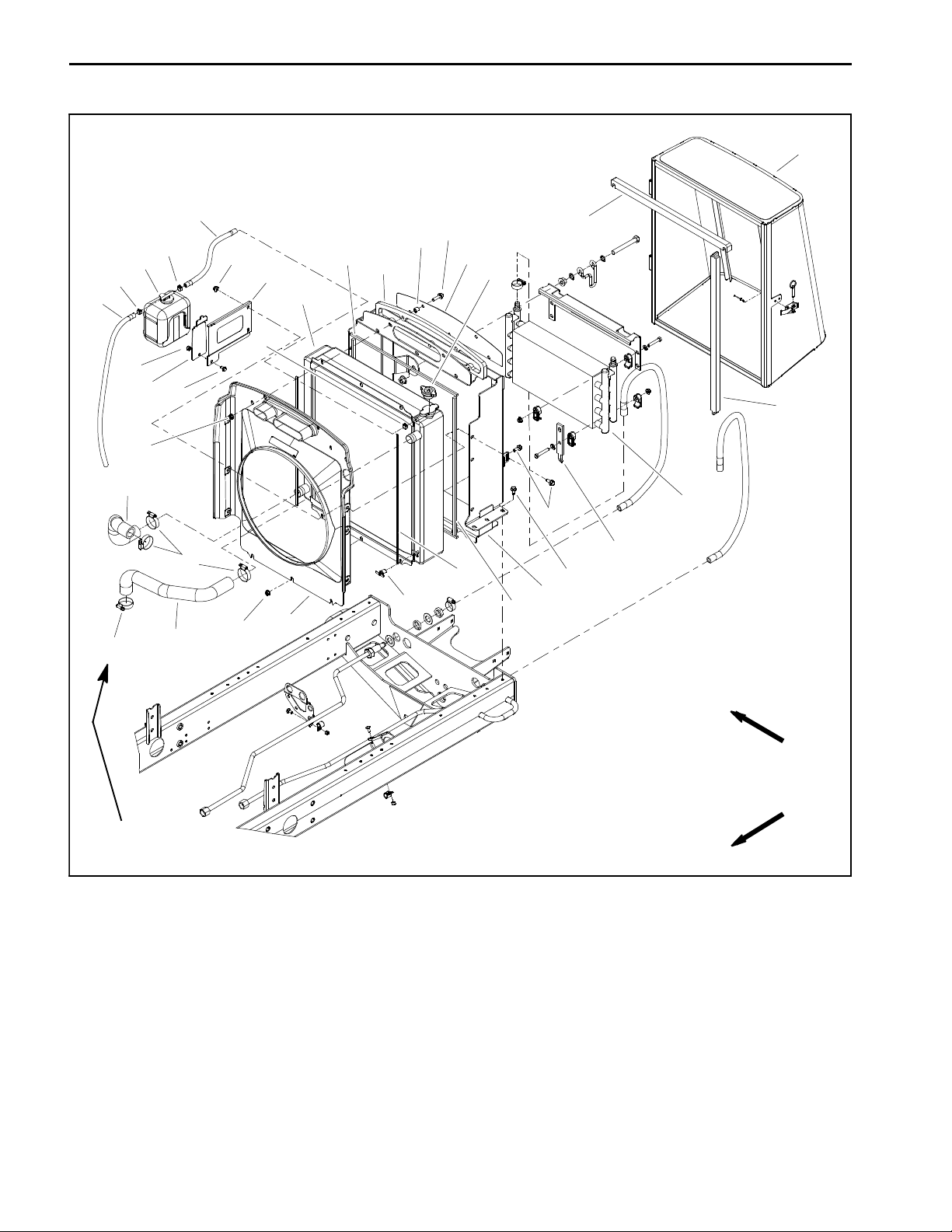

Radiator Assembly

11

6

14

12

13

15

9

2

1

2

10

21

3

28

18

8

2

26

20

25

4

10

23

5

27

7

17

16

24

7

22

10

29

31

19

30

30 to 40 in- lb

(3.4 to 4.5 N- m)

1. Coolant reservoir

2. Hose clamp (3 used)

3. Hose

4. Foam seal (2 used)

5. Oil cooler

6. Hose

7. Hose clamp (4 used)

8. Foam seal (2 used)

9. Radiator cap

10. Flange nut (14 used)

11. Rear screen

Figure 8

12. Foam seal

13. Spacer (5 used)

14. Flange head screw (5 used)

15. Air intake screen

16. Draincock

17. Foam seal (2 used)

18. Radiator

19. Radiator frame

20. Reservoir bracket

21. Reservoir bracket

RIGHT

FRONT

22. Upper radiator hose

23. Lower radiator hose

24. Fan shroud

25. Flange head screw

26. Lock nut

27. Flange head screw (9 used)

28. Foam seal (2 used)

29. Foam seal (2 used)

30. Mount plate (2 used)

31. Washer head screw (6 used)

Reelmaster 5010- HPage 3 - 10Kubota Diesel Engine

Page 29

Removal (Fig. 8)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Unlatch rear screen, lift screen from hinges and remove screen from machine.

3. Remove 12 volt battery from rear of machine to ease

oil cooler removal (see 12 VDC Battery Service in the

Service and Repairs section of Chapter 5 - Electrical

System).

4. Rotate clamps that secure oil cooler to radiator

frame. Carefully lift and remove oil cooler from radiator

frame. Position and support oil cooler away from the radiator.

5. Raise and support the hood.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

30 to 40 in- lb

(3.4 to 4.5 N- m)

RIGHT

FRONT

2

1. Fan shroud

2. Air cleaner intake hose

3. Hose clamp

3

4

30 to 40 in- lb

(3.4 to 4.5 N- m)

Figure 9

4. Generator intake hose

5. Hose clamp

1

5

Engine

Kubota Diesel

Ethylene- glycol antifreeze is poisonous. Dispose of coolant properly, orstore it in a properly

labeled container away from children and pets.

6. Drain radiator into a suitable container either by using the draincock (item 16) on the left side of the radiator

or by disconnecting the lower radiator hose from the radiator. Make sure that drain container is large enough to

hold cooling system contents (see Specifications in this

Chapter).

IMPORTANT: Follow all local codes and regulations when recycling or disposing engine coolant.

7. Disconnect air cleaner and motor/generator intake

hoses from fan shroud (Fig. 9).

8. Disconnect radiator hoses (upper and lower) from

the radiator.

9. At rear of radiator frame, carefully cut the upright

foam seals (item 4) at the junction of the radiator frame

and the machine frame. This will allow the radiator frame

to be removed from the machine without removing the

foam seal from the radiator and machine frames.

10.Remove six (6) washer head screws (item 31) that

secure the radiator frame (item 19) to the frame.

1 1.Carefully raise radiator assembly (radiator, fan

shroud, coolant reservoir and radiator frame) from the

machine.

12.Plug radiator and hose openings to prevent contamination.

13.Disassemble radiator assembly as needed using

Figure 8 as a guide.

Installation (Fig. 8)

1. Inspect all foam seals placed between radiator, fan

shroud and radiator frame. Replace damaged foam

seals.

2. Remove plugs placed in radiator and hose openings

during the removal procedure.

3. Install all removed components to radiator frame using Figure 8 as a guide.

4. Carefully lower radiator assembly with radiator, fan

shroud, coolant reservoir and radiator frame to the machine frame.

5. Secure the radiator frame (item 19) to the frame with

six (6) washer head screws (item 31).

6. Make sure that at least 0.250” (6.4 mm) clearance

exists at all points between fan shroud opening and fan.

7. Connect upper and lower radiator hoses to radiator

and secure with hose clamps. Torque hose clamps from

30 to 40 in- lb (3.4 to 4.5 N- m).

Reelmaster 5010- H Page 3 - 11 Kubota Diesel Engine

Page 30

8. Connect air cleaner and motor/generator intake

hoses to fan shroud and secure with hose clamps (Fig.

9). Torque hose clamps from 30 to 40 in- lb (3.4 to 4.5

N- m).

9. Make sure radiator draincock is closed (threadedout

fully).

12.Carefully position and install oil cooler to radiator

frame. Rotate clamps to secure oil cooler to radiator

frame.

13.Install 12 volt battery (see 12 VDC Battery Service

in the Serviceand Repairs sectionof Chapter5 - Electrical System).

10.Fill radiator and coolant reservoir with coolant.

1 1.Lower and secure hood.

14.Install and latch rear screen.

Reelmaster 5010- HPage 3 - 12Kubota Diesel Engine

Page 31

This page is intentionally blank.

Engine

Kubota Diesel

Reelmaster 5010- H Page 3 - 13 Kubota Diesel Engine

Page 32

Engine

34

33

11

26

45

30 to 40 in- lb

(3.4 to 4.5 N- m)

22

Thread

Sealant

18

14

25

35

22

16

23

22

19

32

12

46

44

24

27

3

44

15

1

17

6

42

41

40

29

37

36

39

30

43

2

7

31

28

22

7

20

21

3

5

9

13

10

7

RIGHT

FRONT

1. Diesel engine

2. Cap screw (12 used)

3. Flange head screw (4 used)

4. Snubbing washer (4 used)

5. Cap screw (4 used)

6. Flange nut (8 used)

7. Flange nut (8 used)

8. Spacer (4 used)

9. Lock washer (12 used)

10. Engine mount (2 used)

11. RH engine mount

12. Exhaust gasket

13. Bellhousing

14. Flange nut (4 used)

15. Tailpipe bracket

16. Service indicator

34 to 42 ft- lb

(47to56N-m)

Figure 10

17. Air cleaner assembly

18. Air intake hose

19. Air intake hose

20. Air cleaner bracket

21. Air cleaner stand

22. Hose clamp (4 used)

23. Indicator adapter

24. Muffler bracket

25. Exhaust header

26. Exhaust muffler

27. Clamp

28. Flange head screw (2 used)

29. Nut

30. Air cle aner mounting band

31. Cap screw (2 used)

38

7

8

4

6

32. Compression spring

33. Muffler guard

34. Washer head screw (2 used)

35. Temperature sender

36. Socket head screw (2 used)

37. Fuel actuator

38. LH engine mount

39. Extension spring

40. Throttle spring bracket

41. Cap screw

42. Cap screw

43. Fuel actuator gasket

44. Flange head screw (6 used)

45. Carriage bolt (4 used)

46. Shoulder bolt

Reelmaster 5010- HPage 3 - 14Kubota Diesel Engine

Page 33

Engine Removal (Fig. 10)

1. Park machine on a level surface, lower cutting units,

stop engine and remove key from the ignition switch.

Chock wheels to keep the machine from moving.

2. Disconnect negative (- ) and then positive (+) battery

cables from the12 volt battery at the rear of the machine

(see 12 VDC Battery Service in the Service and Repairs

section of Chapter 5 - Electrical System).

FRONT

2

4

1

2

3. Open and support hood.

4. Separate system components from the 48 VDC battery pack by unplugging the 48 VDC battery disconnect.

(see 48 VDC Battery Disconnect in the General Information section of this chapter). This will prevent unexpected 48 VDC system component operation.

5. Remove air cleaner from machine (see Air Cleaner

Assembly in this section).

6. Remove exhaust muffler from machine (see Exhaust System in this section).

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene- glycol antifreeze is poisonous. Dispose of coolant properly, orstore it in a properly

labeled container away from children and pets.

1. Fuel supply hose

2. Hose clamp

3. Fuel return hose

1

2

3

5

Figure 11

4. Hose clamp

5. Separator

Engine

Kubota Diesel

3

4

7. Drain radiator into a suitable container either by using the draincock on the left side of the radiator or by disconnecting the lower radiator hose from the radiator.

1. Fuel actuator

2. Fuel actuator connector

Figure 12

3. Wire harness ground

4. Negative battery cable

Make sure that drain container is large enough to hold

cooling system contents (see Specifications in this

Chapter).

IMPORTANT: Follow all local codes and regula-

2

tions when recycling or disposing engine coolant.

8. Disconnect hoses from engine:

2

A. Loosen clamps and remove upper and lower radiator hoses from the engine.

B. Disconnect fuel supply and return hoses from en-

3

1

4

gine (Fig. 11).

5

C. Plug disconnected hoses and engine openings to

prevent leakage and contamination. Positiondisconnected hoses away from engine.

Figure 13

1. Engine mount (4 used)

2. Screw (2 per mount)

3. Nut (2 per mount)

3

4. Lock washer

5. Ground cable

Reelmaster 5010- H Page 3 - 15 Kubota Diesel Engine

Page 34

9. Disconnect hydraulic pump drive shaft from 48 VDC

motor/generator (see Hydraulic Pump Drive Shaft in the

Service and Repairs section of Chapter 4 - Hydraulic

System). Position and support drive shaft away from

motor/generator and engine.

IMPORTANT: T o prevent damage to electrical wire

harness, numerous cable ties are used to secure

harness to machine components. Take note of all

cable ties that are removed from machine during

engine removal so they can be properly replaced

during engine installation.

10.Note location of cable ties used to secure wire harness to the machine for assembly purposes. Disconnect

wires and/or electrical connections from the following

engine electrical components:

IMPORTANT: Make sure to not damage the engine,

fuel hoses, hydraulic lines, electrical harness, radiator or other parts while removing the engine.

13.Carefully raise engine from machine moving it toward thefront of the machine and away from radiator assembly.

14.If necessary, remove engine mount brackets from

engine.

15.If necessary, remove engine mounts from machine

frame (Fig. 13). Note that front engine mount on left side

of machine has the negative battery cable ground connection secured with one of the mount bolts. If removed,

make sure to locate lock washer that should be installed

between the cable connection and the frame.

A. The wire harness connectors from the alternator,

temperature sender, oil pressure switch, starter motor solenoid and fuel actuator.

B. The wire harness ring terminals from the alternator and glow plug bus.

C. The positive battery cable and fusible link harness from the engine starter motor.

D. The negative battery cable and wire harness

ground at the engine block under the fuel actuator

(Fig. 12).

E. The wire harness connector from the 48 VDC

motor/generator assembly.

CAUTION

Make sure that hoist or lift used to remove engine assembly can properly support engine and

attached components. Engine assembly weighs

approximately 280 pounds (127 kg).

1 1.Connect suitable lift or hoist to the lift brackets on

each end of the engine cylinder head.

12.Remove flange nuts, rebound washers, spacers and

cap screws that secure the engine mount brackets to

the engine mounts.

16.If necessary, remove 48 VDC motor/generator from

engine (see 48 VDC Motor/Generator Assembly in the

Service and Repairs section of Chapter 5 - Electrical

System).

Engine Installation (Fig. 10)

1. Locate machine on a level surface with cutting units

lowered and key removed from the ignition switch.

Chock wheels to keep the machine from moving.

2. Make sure that all parts removed from the engine

during maintenance or rebuilding are installed to the engine.

3. If engine mount brackets were removed from the engine, secure brackets to engine with lock washers and

cap screws. Torque cap screws from 34 to 42 ft- lb (47

to 56 N- m).

4. If removed, install 48 VDC motor/generator and bellhousing assembly to engine (see 48 VDC Motor/Generator Assembly in the Service and Repairs section of

Chapter 5 - Electrical System).

5. If removed, secure engine mounts to frame machine

frame (Fig. 13). Make sure that negative battery cable

ground connection is secured withlock washer between

the cableconnection and theframe if front engine mount

on left side of machine was removed.

6. Connect suitable lift or hoist to the engine lift brackets.

CAUTION

One person should operate hoist or lift while a

second person guides the engine out of the machine.

Reelmaster 5010- HPage 3 - 16Kubota Diesel Engine

Page 35

CAUTION

One person should operate lift or hoist while a

second person guides the engine into the machine.

12.Install air cleaner (see Air Cleaner Assembly in this

section).

13.Install exhaust muffler to machine (see Exhaust System in this section). Make sure that exhaust tube has ⅜”

(9.5 mm) clearance with guard in all directions after assembly.

IMPORTANT: Make sure to not damage the engine,

fuel hoses, hydraulic lines, electrical harness, radiator or other parts while installing the engine.

7. Carefully lower engine to the mounts secured to the

machine frame. Make sure fastener holes of the engine

mount brackets are aligned with the holes in the engine

mounts.

8. Insert cap screw down through each engine mount

bracket and mount. Place spacer, snubbing washer and

then flange nut on four (4) cap screws. Tighten fasteners

to secure engine to engine mounts.

9. Connect hydraulic pump drive shaft to motor/generator output shaft (see Hydraulic Pump Drive Shaft in the

Service and Repairs section of Chapter 4 - Hydraulic

System).

10.Connect all wire harness connectors to correct engine components. Secure wire harness to the machine

with cable ties in locations noted during engine removal.

1 1.Remove plugs installed in fuel and coolant hoses

and engine openings during disassembly. Connect

hoses to the engine:

14.Make sure radiator draincock isclosed (threaded out

fully). Fill radiator and coolant reservoir with coolant.

15.Check engine oil level and adjust if needed.

16.Check and adjust oil level in hydraulic reservoir as

needed.

17.Plug the 48 VDC battery disconnect back in.

18.Close and secure hood.

19.Connect positive (+) and then negative (- ) battery

cables to the 12 volt battery (see 12 VDC Battery Service in the Service and Repairs section of Chapter 5 Electrical System).

20.Prime the fuel system (see Fuel System in t his section).

21.Start engine and operate hydraulic controls to properly fill hydraulic system (see Charge Hydraulic System

in the Service and Repairs section of Chapter 4 - Hydraulic System).

Engine

Kubota Diesel

A. Connect fuel supply and fuel return hoses to engine fittings (Fig. 11). Secure fuel hoses with hose

clamps.

B. Connect upper and lower radiator hoses to the

engine. Secure hoses with hose clamps. Torque

hose clamps from 30 to 40 in- lb (3.4 to 4.5 N- m).

Reelmaster 5010- H Page 3 - 17 Kubota Diesel Engine

Page 36

Engine Bellhousing Assembly

20

50 to 60 ft- lb

(68to81N-m)

1

Antiseize

Lubricant

2

19

16

18

7

9

8

5

4

17

11

15

Antiseize

Lubricant

14

3

6

10

12

13

25 to 31 ft- lb

(34to42N-m)

RIGHT

FRONT

1. Diesel engine

2. Motor/generator assembly

3. Flange head screw

4. Collar

5. Coupler hub

6. Woodruff key

7. Bellhousing

8. Cap screw (2 used)

9. Flat washer (2 used)

10. Flange head screw (7 used)

11. Flange nut (2 used)

12. R - clamp (for generator wire harness)

13. Clamp (for fuel return hose)

14. Caplug

The 48 VDC motor/generator is attached to the engine

bellhousing with six (6) flange head screws. Access to

these screws requires the bellhousing and motor/generator to be removed from the engine as an assembly. For

recommended procedures to remove the bellhousing

and motor/generator assembly from the engine, see 48

VDC Motor/Generator Assembly in the Service and Repairs section of Chapter 5 - Electrical System.

Figure 14

15. Flange head screw (6 used)

16. Dowel pin (2 used)

17. Coupler flange

18. Socket head screw (3 used)

19. Muffler bracket

20. Flange head screw (4 used)

Reelmaster 5010- HPage 3 - 18Kubota Diesel Engine

Page 37

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 2............................

GENERAL INFORMATION 3.....................

Traction Unit Operator’s Manual 3..............

48 VDC Battery Disconnect 3..................

Check Hydraulic Fluid 3.......................

Towing Traction Unit 4.........................

Hydraulic Hoses 4............................

Hydraulic Hose and Tube Installation 5..........

Hydraulic Fitting Installation 6..................

Relieving Hydraulic System Pressure 8..........

Traction Circuit Component Failure 8............

HYDRAULIC SCHEMATIC 10....................

HYDRAULIC FLOW DIAGRAMS 12...............

Traction Circuit 12............................

Lift Circuit: Raise Cutting Units 14...............

Lift Circuit: Lower Cutting Units 16..............

Steering Circuit 18............................

SPECIAL TOOLS 20............................

TROUBLESHOOTING 25........................

General Hydraulic System Problems 25..........

Traction Circuit Problems 26...................

Lift Circuit Problems 27........................

Steering Circuit Problems 28...................

TESTING 30...................................

Traction Circuit Relief Valve (R3) and (R4)

Pressure Test 32............................

Traction Circuit Charge Pressure Test 34.........

Gear Pump (P2) Flow Test 36..................

Front Wheel Motor Efficiency Test 38............

Piston (Traction) Pump Flow Test 40............

Lift Relief Valve (SVRV) Pressure Test 42........

Gear Pump (P1) Flow Test 44..................

Lift Cylinder Internal Leakage Test 46............

Steering Relief Valve (R10) Pressure Test 48.....

Steering Cylinder Internal Leakage Test 50.......

SERVICE AND REPAIRS 52.....................

General Precautions for Removing and Installing

Hydraulic System Components 52.............

Check Hydraulic Lines and Hoses 53............

Flush Hydraulic System 54.....................

Filtering Closed- Loop Traction Circuit 55........

Hydraulic System Start- up 56..................

Hydraulic Reservoir 58........................

Piston (Traction) Pump Control Assembly 60.....

Hydraulic Pump Assembly 62..................

Piston (Traction) Pump Service 66..............

Gear Pump Service 68........................

Hydraulic Pump Drive Shaft 70.................

Hydraulic Pump Drive Shaft Cross and

Bearing Service 72..........................

Front Wheel Motors 74........................

Front Wheel Motor Service 76

Rear Wheel Motors (Machines with Optional

CrossTrax

Rear Wheel Motor Service (Machines with Optional

CrossTrax

Control Manifold Cartridge Valve Service 81......

Lift Control Manifold 82........................

Lift Control Manifold Service 84.................

CrossTrax

Optional CrossTrax

CrossTrax

with Optional CrossTrax

Lift Cylinders 90..............................

Lift Cylinder Service 92........................

Steering Control Valve 94......................

Steering Control Valve Service 96...............

Steering Cylinder 98..........................

Steering Cylinder Service 100..................

Hydraulic Oil Cooler 102.......................

SAUER- DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS REPAIR MANUAL

SAUER- DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS SERVICE INSTRUCTIONS

EATON DELTA MOTORS PARTS AND REPAIR

MANUAL

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

SAUER- DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

TM

Kit) 78.........................

TM

Kit) 80.........................

TM

AWD Manifold (Machines with

TM

AWD Manifold Service (Machines

..................

TM

Kit) 86.................

TM

Kit) 88.............

TM

SERVICE PROCEDURE

System

Hydraulic

Reelmaster 5010- H Hydraulic SystemPage 4 - 1

Page 38

Specifications

Item Description

Piston (Traction) Pump Closed Circuit Axial Piston Design

Maximum Pump Displacement (per revolution) 2.14 Cubic Inches (35 cc)

Gear Pump 2 Section, Positive Displacement Gear Type Pump

Section P1 Displacement (per revolution) (all models) 0.24 Cubic Inches (3.96 cc)

Section P2 Displacement (per revolution) (all models) 0.40 Cubic Inches (6.61 cc)

Charge Circuit Relief (R5) Pressure 200PSI(14bar)

Traction Circuit Relief Pressure: Forward (R3) and Reverse (R4) 3625 PSI (250 bar)

Front Wheel Motors Geroler Motor

Displacement (per revolution) 24.7 in

Rear Wheel Motors (if equipped) Rotor Motor

Displacement (per revolution) 19.0 in

Steering Valve Hydrostatic Steering Unit, Open Center

Displacement (per revolution) 6.1 in

Steering Circuit Relief (R10) Pressure 1000 PSI (70 bar)

Lift Circuit Relief (SVRV) Pressure 2000 PSI (138 bar)

Lift Circuit Lower Relief (R7) Pressure 500PSI(35bar)

Hydraulic Filter (Steering Circuit) Spin- on Cartridge Type with 25 PSI (1.7 bar) Relief in Adapter

Hydraulic Oil See Traction Unit Operator’s Manual

Hydraulic Reservoir Capacity 11 U.S. Gallons (41.6 L)

3

(405 cc)

3

(310 cc)

3

(100 cc)

Reelmaster 5010- HHydraulic System Page 4 - 2

Page 39

General Information

Traction Unit Operator’s Manual

The Traction Unit Operator’s Manual provides information regarding the operation, general maintenance and

maintenance intervals for your Reelmaster m achine.

Refer to that publication for additional information when

servicing the machine.

48 VDC Battery Disconnect

CAUTION

Before installing, removing or servicing components in the 48 VDC system (e.g. cutting unit motors, motor/generator), separate the 48 VDC battery disconnect. This will prevent unexpected

operation of 48 VDC system components.

The 48 VDC battery disconnect is attached to the r ight

frame rail under the operator seat (Fig. 1). Unplug the

disconnect to make sure that 48 VDC components do

not operate unexpectedly. Apply dielectric grease to the

contact surfaces of the battery disconnect and plug the

battery disconnect back in after service to the 48 VDC

system is completed.

FRONT

1

1. RH frame rail 2. 48V battery disconnect

2

Figure 1

System

Hydraulic

Check Hydraulic Fluid

The hydraulic system on Reelmaster 5010- H machines

is designed to operate on high quality hydraulic fluid.

The hydraulic system reservoir holds approximately 11

gallons (41.6 liters) of hydraulic fluid. Check level of hy-

draulic fluid daily. See Traction Unit Operator’s Manual for fluid level checking procedure and hydraulic oil

recommendations.

Reelmaster 5010- H Hydraulic SystemPage 4 - 3

1

2

Figure 2

1. Hydraulic reservoir 2. Cap with dipstick

Page 40

Towing Traction Unit

IMPORTANT: If towing limits are exceeded, severe

damage to the piston (traction) pump may occur.

If it becomes necessary to tow or push the machine, tow

or push at a speed below 3 mph (4.8 kph), and for a very

short distance. If the machine needs to be moved a considerable distance, machine should be transported on a

trailer. The piston (tracti on)pumpisequippedwithabypass valve that needs to be loosened for towing or pushing (Fig. 3). See Traction Unit Operator’s Manual for

Towing Procedures.

Hydraulic Hoses

Hydraulic hoses are subject to extreme conditions such

as pressure differentials during operation and exposure

to weather, sun, chemicals, very warm storage conditions or mishandling during operation and maintenance.

These conditions can cause hose damage and deterioration. Some hoses are more susceptible to these

conditions than others. Inspect all machine hydraulic

hoses frequently for signs of deterioration or damage:

1

2

Figure 3

1. Piston (traction) pump 2. Bypass valve

WARNING

Before disconnecting or performing any work on

hydraulic system, relieve all pressure in system

(see Relieving Hydraulic System Pressure in this

section).

Hard, cracked, cut, abraded, charred, leaking or

otherwise damaged hose.

Kinked, crushed, flattened or twisted hose.

Blistered, soft, degraded or loose hose cover.

Cracked, damaged or badly corroded hose fittings.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint (layline) on

the hose. Use two wrenches when tightening a hose;

hold the hose straight with one wrench and tighten the

hose swivel nut onto the fitting with the second wrench

(see Hydraulic Hose and Tube Installation in this section). If the hose has an elbow at one end, tighten the

swivel nut on that end before tightening the nut on the

straight end of the hose.

For additional hydraulic hose information, refer to Toro

Service Training Book, Hydraulic Hose Servicing (Part

Number 94813SL).

Keep body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to

search for leaks. Hydraulic fluid escaping under

pressure can have sufficient force to penetrate

the skin and cause serious injury. If fluid is injected into the skin, it must be surgically removed within a few hours by a doctor familiar

with this type of injury. Gangrene may result from

such an injury.

Reelmaster 5010- HHydraulic System Page 4 - 4

Page 41

Hydraulic Hose and Tube Installation (O- Ring Face Seal Fitting)

1. Make sure threads and sealing surfaces of the hose/

tube and the fitting are free of burrs, nicks, scratches or

any foreign material.

2. As a preventative measure against leakage, it is recommended that the face seal O - ring be replaced any

time the connection is opened. Make sure the O - ring is

installed and properly seated in the fitting groove. Lightly

lubricate the O- ring with clean hydraulic oil.

3. Place the hose/tube against the fitting body so that

the flat face of the hose/tube sleeve fully contacts the Oring in the fitting.

4. Thread the swivel nut onto the fitting by hand. While

holding the hose/tube with a wrench, use a torque

wrench to tighten the swivel nut to the recommended

installation torque shown in Figure 6. This tightening

process will require the use of an offset wrench (e.g.

crowfoot wrench). Use of an offset wrench will affect

torque wrench calibration due to the effective length

change of the torque wrench. Tightening torque when

usingatorquewrenchwithanoffsetwrenchwillbelower

than the listed installation torque (see Using a Torque

Wrench with an Offset Wrench in the Torque Specifications section of Chapter 2 - Product Records and Maintenance).

C. Useasecondwrenchtotightenthenuttothecorrect Flats From Wrench Resistance (F.F.W.R.). The

markings on the nut and fitting body will verify that the

connection has been properly tightened.

Siz e F.F.W .R.

4 (1/4 in. nominal hose or tubing) 1/2 to 3/4

6 (3/8 in.) 1/2 to 3/4

8 (1/2 in.) 1/2 to 3/4

10 (5/8 in.) 1/2 to 3/4

12 (3/4 in.) 1/3 to 1/2

16 (1 in.) 1/3 to 1/2

Swivel Nut

Tub e or Hose

O- ring

Fitting Body

Figure 4

System

Hydraulic

5. If a torque wrench is not available or if space at the

swivel nut prevents use of a torque wrench, an alternate

method of assembly is the Flats From Wrench Resist-

Mark Nut

and Fitting

Body

Final

Position

ance (F.F.W.R.) method (Fig. 2).

A. Using a wrench, tighten the swivel nut onto the fitting until light wrench resistance is reached (approximately 30 in- lb).

B. Mark the swivel nut and fitting body. Hold the

hose/tube with a wrench to prevent it from turning.

AT WRENCH RESISTANCE

Extend Line

Figure 5

Fitting Dash Size Hose/Tube Side Thread Size Installation Torque

4 9/16 - 18 18 to 22 ft- lb (25 to 29 N- m)

6 11/ 16 - 1 6 27 to 33 ft- lb (37 to 44 N- m)

8 13/16 - 16 37 to 47 ft- lb (51 to 63 N- m)

10 1- 14 60 to 74 ft- lb (82 to 100 N- m)

12 13/16- 12 85 to 105 ft- lb (116 to 142 N- m)

16 17/16- 12 110to136ft-lb(150to184N-m)

Initial

Position

AFTER TIGHTENING

20 1 11/16 - 12 140 to 172 ft- lb (190 to 233 N- m)

Figure 6

Reelmaster 5010- H Hydraulic SystemPage 4 - 5

Page 42

Hydraulic Fitting Installation (SAE Straight Thread O- Ring Fitting into Component Port)

Non- Adjustable Fitting (Fig. 7)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. As a preventative measure against leakage, it is recommended that the O- ring be replaced any time the

connection is opened.

3. Lightly lubricate the O- ring with clean hydraulic oil.

Fitting threads should be clean with no lubricant applied.

IMPORTANT: Before installing fitting into port, determine port material. If fittingistobeinstalledinto

an aluminum port, installation torque is reduced.

4. Install the fitting into the port. Then, use a torque

wrench and socket to tighten the fitting to the recommended installation torque shown in Figure 8.

NOTE: Useofanoffsetwrench(e.g.crowfootwrench)

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be less than the recommended installation torque. See

UsingaTorqueWrenchwithanOffsetWrenchinthe

Torque Specifications section of Chapter 2 - Product

Records and Maintenance to determine necessary conversion information.

5. If a torque wrench is not available, or if space at the

port prevents use of a torque wrench, an alternate method of assembly is the Flats From Finger Tight (F.F.F.T.)

method.

A. Install the fitting into the port and tighten it down

full length until finger tight.

B. If port material is steel, tighten the fitting to the

listed F.F.F.T. If port material is aluminum, tighten fitting to 60% of listed F.F.F.T.

Siz e F.F.F. T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6 (3/8 in.) 1.50 +

8 (1/2 in.) 1.50 +

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

Fitting

O- ring

0.25

0.25

0.25

0.25

0.25

0.25

Figure 7

Fitting

Dash Size

Fitting Port Side

Thread Size

Installation Torque Into

Steel Port

Installation Torque Into

Aluminum Port

4 7/16 - 20 15 to 19 ft- lb (21 to 25 N- m) 9to11ft-lb(13to15N-m)

5 1/2 - 20 18 to 22 ft- lb (25 to 29 N- m) 11 to 15 ft- lb (15 to 20 N- m)

6 9/16 - 18 34 to 42 ft- lb (47 to 56 N- m) 20 to 26 ft- lb (28 to 35 N- m)

8 3/4 - 16 58 to 72 ft- lb (79 to 97 N- m) 35 to 43 ft- lb (48 to 58 N- m)