Toro 4502, 8603, 4503, 8602 Service Manual

SCAMP AND UTILITY MODELS

SERVICING

4502, 4503, 8602, 8603

WITH

“F”

SERIES ENGINES

SELF-PROPELLED BELT DRIVE

Adjustments

and

servicing of the Scamp and

Utility self-propelled mowers are very different

from

all

previous models of self-propelled

mowers.

SAFETY WARNING

BEFORE

ANY

ADJUSTMENTS OR

REPAIRS ARE ATTEMPTED, DIS-

CONNECT

AND

REMOVE SPARK

PLUG TO PREVENT STARTING.

INSTALLING CONTROL

ROD

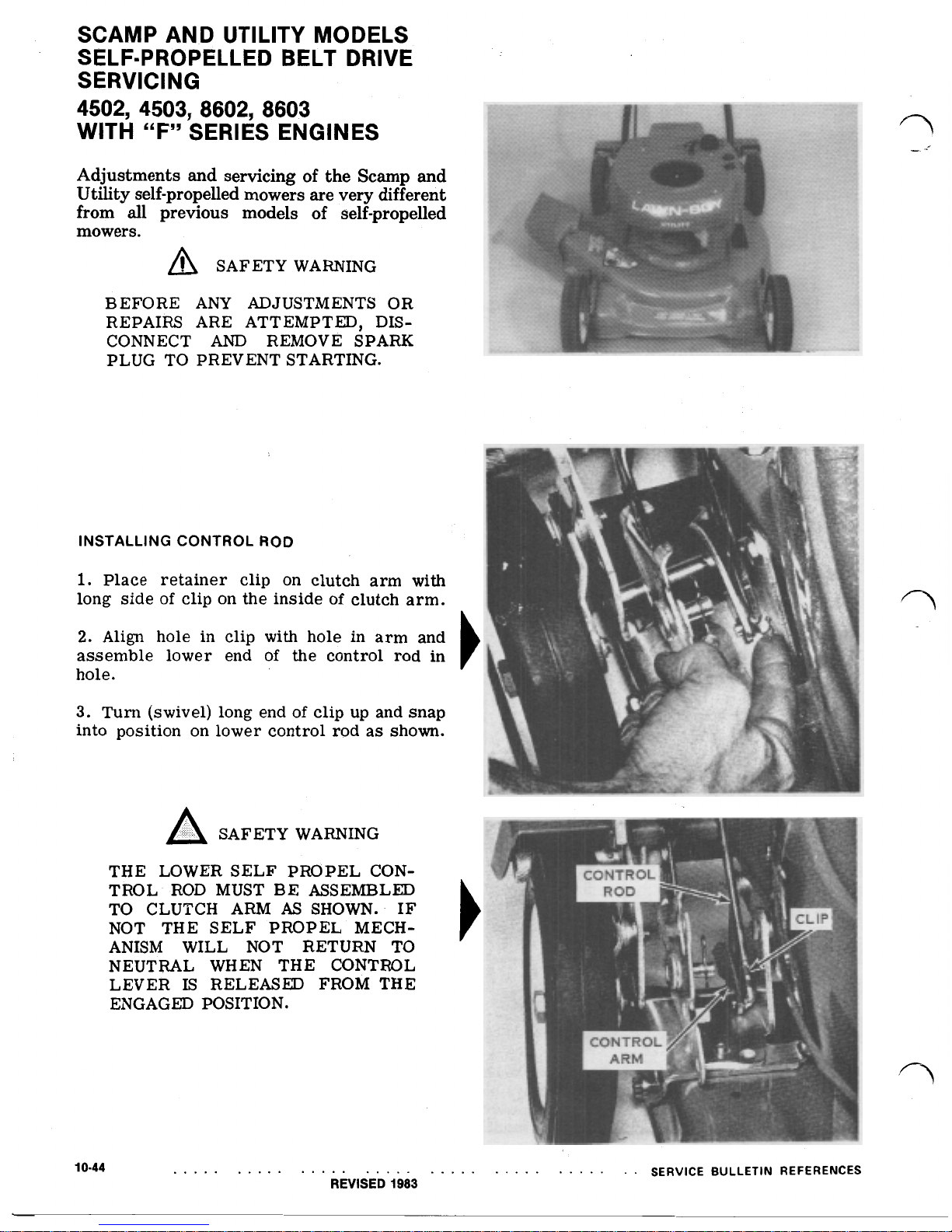

1.

Place retainer clip on clutch arm

with

long side

of

clip on the inside

of

clutch arm.

2.

Align

hole in

clip

with

hole in arm and

assemble lower end

of

the control

rod

in

hole.

3.

Turn (swivel) long end

of

clip up and snap

into position on lower control rod as shown.

SAFETY WARNING

THE LOWER SELF PROPEL CONTROL ROD MUST

BE

ASSEMBLED

TO CLUTCH ARM

AS

SHOWN. IF

NOT THE SELF PROPEL MECHANISM WILL NOT RETURN TO

NEUTRAL WHEN THE CONTROL

LEVER IS RELEASED FROM THE

ENGAGED POSITION.

10-44

REVISED

1983

SERVICE BULLETIN REFERENCES

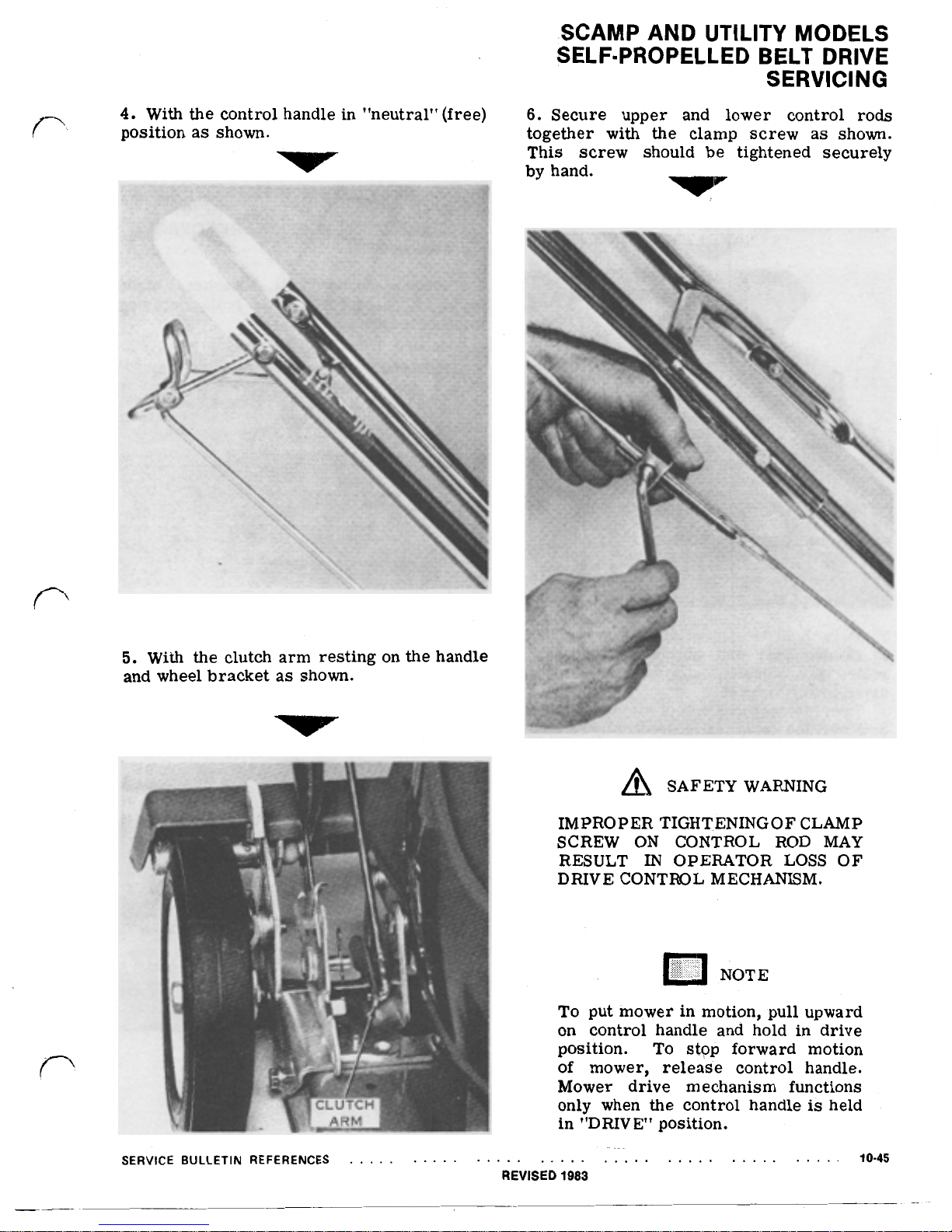

4.

With

the control handle in "neutral" (free)

position as shown.

SCAMP AND UTILITY MODELS

SERVICING

6.

Secure upper and lower control rods

together with the clamp screw as shown.

This screw should be tightened securely

SELF=PROPELLED BELT DRIVE

by hand.

5.

With

the clutch arm resting on the handle

and wheel bracket as shown.

SAFETY WARNING

IMPROPER TIGHT.ENING OF CLAMP

SCREW ON CONTROL ROD MAY

RESULT

IN

OPERATOR LOSS OF

DRIVE CONTROL MECHANISM.

NOTE

To

put mower in motion, pull upward

on control handle and hold in drive

position. To stop forward motion

of

mower, release control handle.

Mower drive mechanism functions

only when the control handle

is

held

in "DRIVE" position.

!

SCAMP AND UTILITY MODELS

SERVICING

SELF-PROPELLED BELT DRIVE

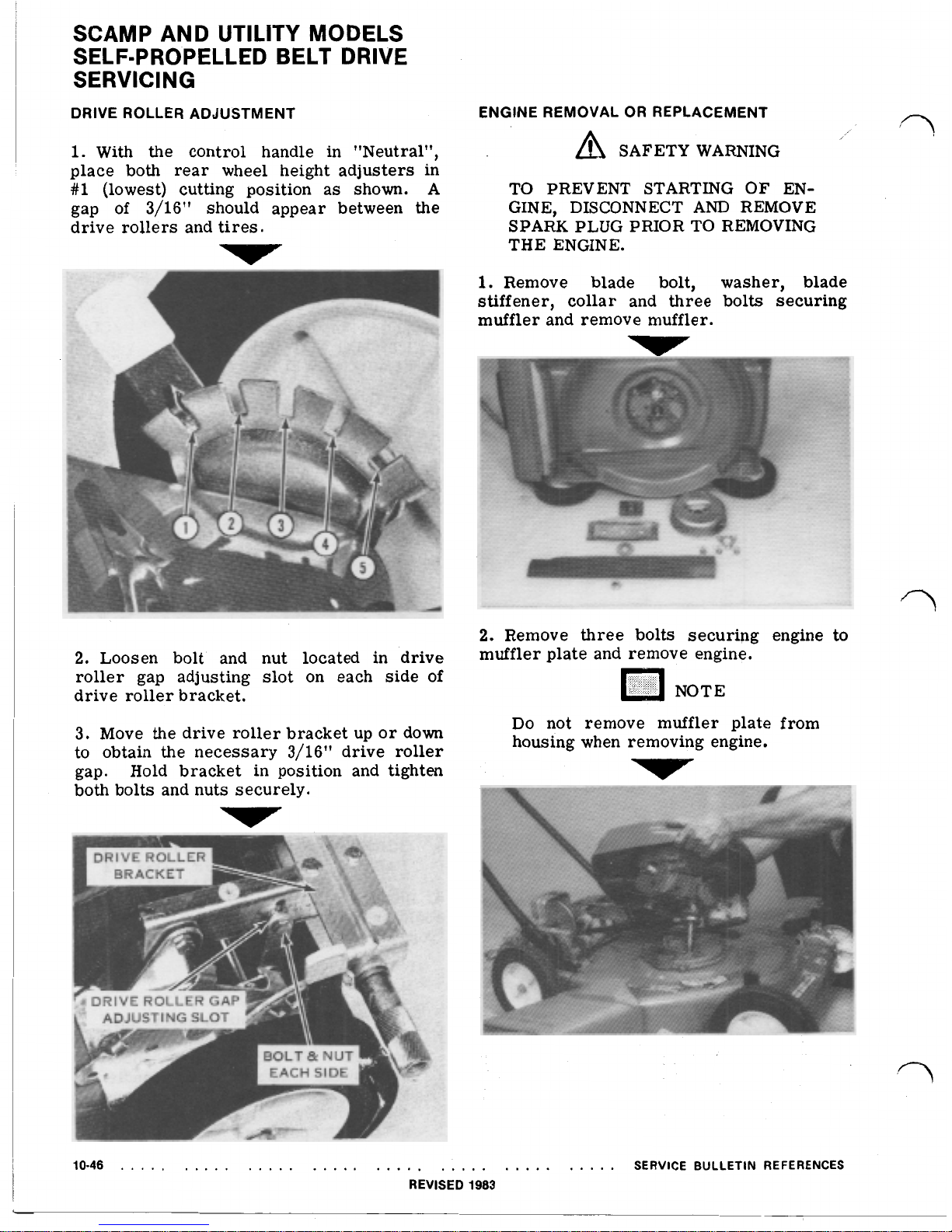

DRIVE ROLLER ADJUSTMENT

1.

With the control handle in "Neutral",

place both rear wheel height adjusters in

#1

(lowest) cutting position as shown.

A

gap of 3/16" should appear between the

drive rollers and tires.

2.

Loosen bolt and nut located in drive

roller gap adjusting slot on each side of

drive roller bracket.

3. Move the drive roller bracket up or down

to obtain the necessary 3/16'' drive roller

gap. Hold bracket

in

position and tighten

both bolts and nuts securely.

ENGINE REMOVAL

OR

REPLACEMENT

SAFETY WARNING

TO PREVENT STARTING OF ENGINE, DISCONNECT

AND

REMOVE

SPARK PLUG PRIOR TO REMOVING

THE ENGINE.

1.

Remove blade bolt, washer, blade

stiffener, collar and three bolts securing

muffler and remove muffler.

n

2.

Remove

three

bolts securing engine to

muffler plate and remove engine.

Do not remove muffler plate from

housing when removing engine.

10-46

SERVICE BULLETIN REFERENCES

REVISED

1983

Loading...

Loading...