Page 1

Toro® Groundsmaster® 4500-D

Quality Design For A Quality Cut

T.Map

TM

Improve Irrigation Control

Factory Service School

Education Program Earns An A

+

Operator Training

ProCore®Operator Video

Toro

®

Greensmaster®FlexTM21

Exceeding Expectations

Options & Attachments

Toro®Debris Blowers

1

Issue No. 4, February 2002 Information From Toro to Help YOU and YOUR Course

INSIDE THIS ISSUE

2

4

6

8

10

14

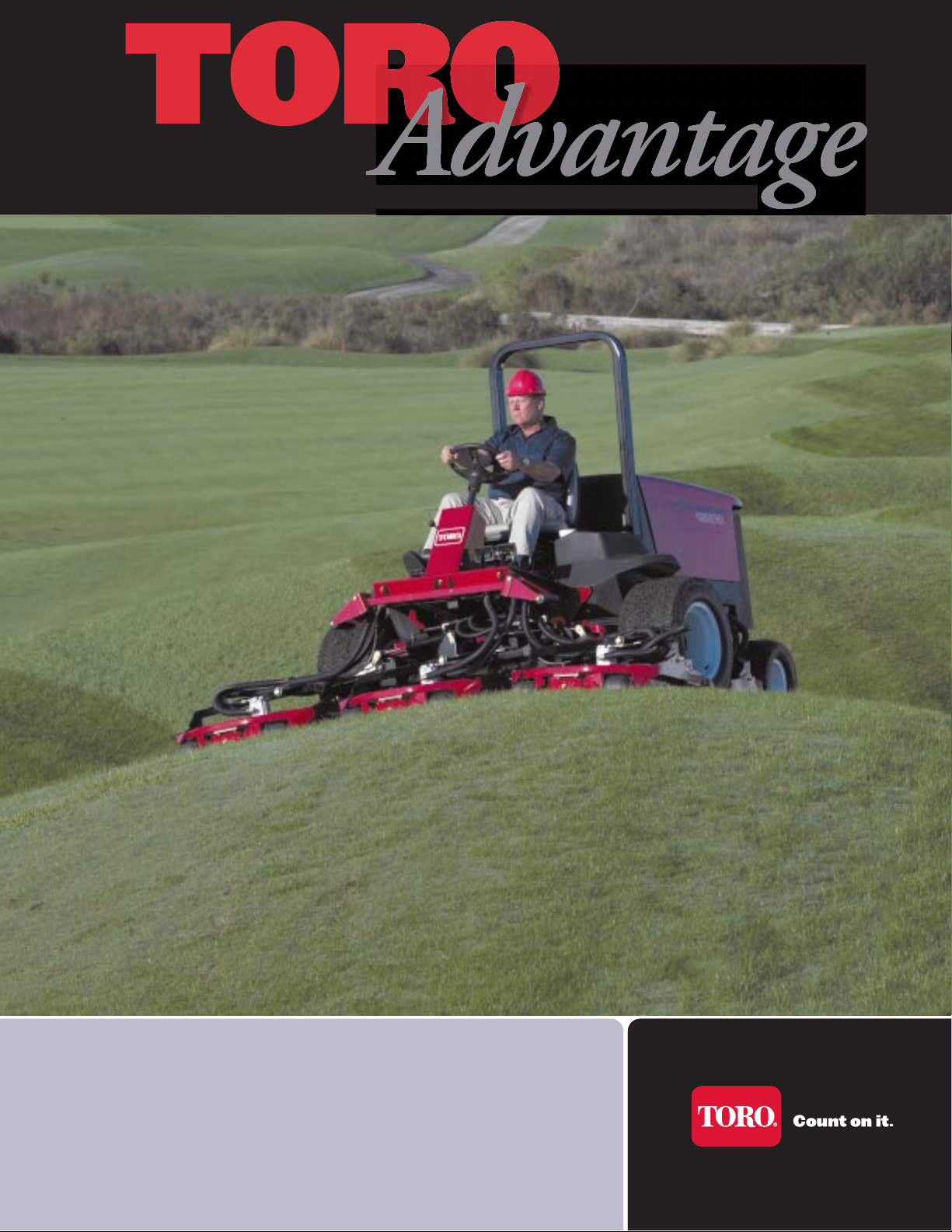

Introducing the New

Toro

®

Groundsmaster®4500-D

Page 2

T

oro has done it again! In

response to superintendents’

needs for more productive

rotaries that help them improve their

quality of cut, Toro

announces yet another

breakthrough mower.

Introducing the Toro

Groundsmaster®4500-D,

the latest addition to

our family of groundfollowing rotary mowers.

Featuring Toro’s

exclusive Contour

TM

Plus cutting technology,

the Groundsmaster

4500-D has five freefloating decks that follow the contour of the

terrain so you can get a

championship-quality

cut on undulating

surfaces.

Better yet, the decks

on the 4500 deliver a

wide nine foot cut (2.74

meters) to give you a

big boost in productivity. Also, with its 60-HP

Kubota®turbo charged

engine, full-time bidirectional four-wheel

drive and superior traction, the 4500

promises you a better cut in demanding

places, like roughs and slopes.

Power, versatility, productivity… could

you ask for more? Actually, yes, which is

why we built the Groundsmaster 4500-D

for easier maintenance, user-friendly

design, better striping capabilities, operator comfort, a quieter engine and more.

Real-World Proven

“I’m convinced it’s the best rotary

mower out there,” says Bryan Miller.

Miller is Golf Course Superintendent

at the Georgian Resort in Villa Rica,

Georgia, an 18-hole, Tom Fazio-designed

course near Atlanta. Last year, they

decided to replace their reel mowers with

rotaries in the rough areas. “We had

undulations wreaking havoc on the

mower, or it would scalp the edges,”

Miller says. So, he called Toro.

“They discussed this new mower, but

told me it was still in development,” he

recalls. “I told them if that machine was

everything it’s made out to be, we’d love

to get it here.” He arranged for a demonstration of the prototype 4500, and liked

what he saw.

“This is a great innovation,” he adds.

“I think the quality of cut during difficult times to mow is going to be even

better than reel mowers—like in heavy

grass, heavy dew or debris. It’s going to

allow us to mow these areas like we want

to and maintain the quality.”

“It didn’t bog down a bit,” agrees Jeff

Connell, another superintendent who

has had personal experience with the

4500. “It has an extreme amount of

horsepower, so you don’t have to worry

about going through thicker grass or wet

grass. With that four-wheel drive, it also

didn’t slip or make any kind of tire ruts

or spins anywhere.”

Connell is the superintendent at the

Columbia Country Club in Columbia,

South Carolina, a 27-hole private facility

designed by Ellis Maples. Presently

undergoing a major renovation, the

physical layout of the course had created

particular equipment needs.

“We mow close to 100 acres,” he says,

“and we were just not getting all the way

around the golf course as many times as we

needed to. Also, we’ve got a lot of bunker

faces that kind of go down. It seemed we

couldn’t get in without scalping.”

Last spring, Connell was invited to a

demonstration of the Groundsmaster

4500-D. He was quickly impressed.

“The biggest thing I liked about it was

the solid roller on the back and the antiscalp rollers on the front,” he says. “You

could actually mow over the top of a

bunker face and not get any kind of

scalping whatsoever. The nice thing

about the solid roller in the back is that

The New Toro

®

Groundsmaster

®

Productivity And A Quality Cut For Demanding Turf

2

The Toro®Groundsmaster®4500-D has five ContourTMPlus cutting decks that follow

the contour of the terrain for exceptional quality of cut on undulating surfaces.

Page 3

4500-D

you get a nice even cut. You know, the

ground is not totally level out there, but

having this solid roller all the way across,

it’s a lot more uniform.”

Although it has a wide cutting ability,

the Groundsmaster 4500-D is remarkably versatile. It can zip through roughs

and then do great mowing on trim areas

as well.

“It gives you a large piece of equipment that acts

like a small one,”

Connell adds. “It

cuts a large

swath, but in the

fashion and

closeness of a

smaller piece of

equipment. It

acts as a trim

mower; it does

both jobs at the

same time.”

“There’s nothing

like it in this size category,” explains Tim

Koch, Toro’s Marketing Manager of

Groundsmaster Products. “It has incredible power for a nine-foot machine, with

117 foot-pounds of torque

available. The hydraulic parallel traction system gives

superb traction, and it’s truly

very strong. That means better ability to maneuver on

hills.

“What this machine is

really about is undulating

terrain and superior cutting,”

Koch says. “It’s being able to

mow in rough areas with a

rotary product.

“These features all combine

to produce a fantastic quality

of cut,” he emphasizes.

Better for Everybody

In addition to its superior

quality of cut on undulating

ground, the Groundsmaster

4500-D is more enjoyable to

operate and maintain. Among

its popular features are easy

serviceability and accessibility:

the decks can be raised or

removed quickly, and in

almost no time, the exterior

enclosures can be pulled off without

tools, so technicians can get at everything

right away.

Even with all that horsepower and

torque, the engine speed on the

Groundsmaster 4500 is quite low—just

2600 rpm.

Combined with

a variable

clutch on the

engine-cooling

fan, that means

much lower

sound levels.

“The engine

provides many

benefits in

addition to

more power

and torque, slowing

the engine down to 2600 rpm results in

a quieter operation,” Koch points out.

Other unique features include a large

operator platform and easy-to-reach deck

levers. There is even a cup holder and

extra space available for a water cooler

and other storage.

Just the Beginning

With shipments starting in early Spring

2002, the Groundsmaster 4500-D is sure

to be popular with any superintendent

who wants more power, more control and

a better cut on undulating terrain. But

that’s not all.

Also shipping in the Spring of 2002,

the even larger 4700-D features seven

free-floating cutting decks, which produce an amazing swath 12.5 feet (3.8

meters) wide! Designed for rough mowing, it will be a real productivity booster.

And because it’s from Toro, you know

it’ll perform.

All things considered, Toro

Groundsmaster mowers are taking precision cutting to a whole new level… especially on ground that isn’t.

3

“I’m convinced it’s the best rotary

mower out there.”

– Bryan Miller

The Georgian Resort, Villa Rica, Georgia.

Jeff Connell (inset) is the golf course superintendent at Columbia Country Club in Columbia,

South Carolina, a 27-hole private facility. The layout of the course is particularly suited for the

Toro

®

Groundsmaster®4500-D.

Page 4

T

oro has made irrigation management easier by making it

more advanced. Building on

our history of innovations and leadership

in irrigation systems, we consistently

incorporate the appropriate technology

into our products.

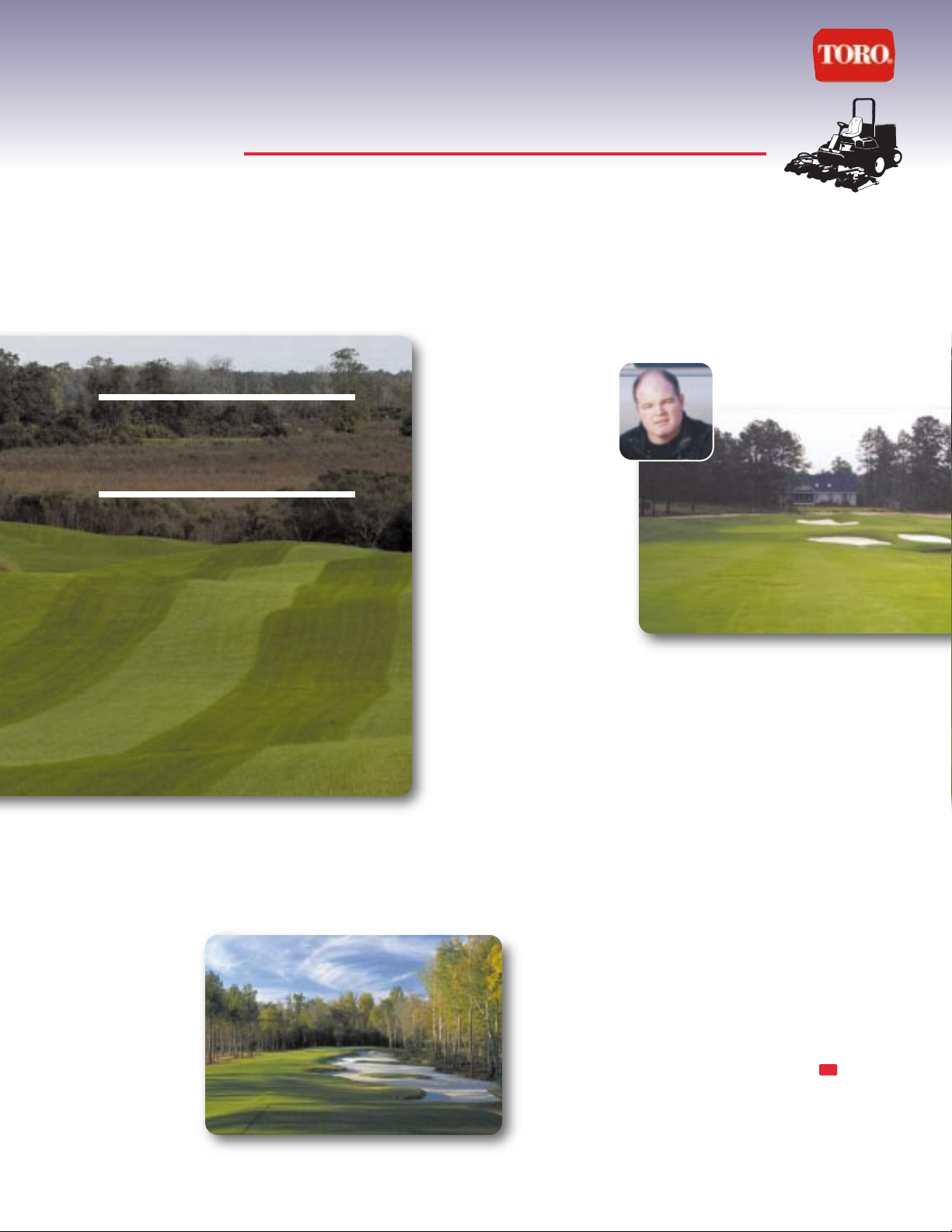

The development of Toro’s PC-based

SitePro®central control system gave

superintendents an amazing way to

improve irrigation management and stay

informed. As good as SitePro is, those

capabilities can be taken to an even higher level.

With Toro’s T.MapTM, included in the

SitePro software, you can create a precise

graphic representation of your golf

course. T.Map puts a new world of

resource management right at your fingertips, because you can use it to make

instantaneous system adjustments with a

click of your mouse.

T.Map’s advanced technology interacts

with the SitePro control system database

to create dynamic graphic displays of

your golf course. Using comprehensive

interactive site maps on your computer

screen, you can accurately locate irriga-

tion elements such as

sprinklers, pipes,

sensors, pump stations, electrical lines,

valves and

wire splices.

T.Map also

shows you

the precise,

in-scale locations of physical features on

your course, such as greens, bunkers, cart

paths and so on, right down to individual trees.

With T.Map software, you simply pull

up real-time screens indicating areas in

question, and then click on the map

symbols to adjust sprinkler run times,

engage rain holds, initiate starts and

syringes, and more. Field-status monitors

tell you which satellites and sprinklers are

running and which are on hold, and alert

you to any problems.

You can also use SitePro

and T.Map to display simulations of projected water flow,

measure areas and distances,

issue work orders, help in

event planning and many

other tasks.

Control is Just a

Click Away

“With T.Map, you are

looking at your course on the

screen, just as it is physically

in the real world,” explains

Aivars Jurkis, Toro’s Senior

Customer Support and

Technical Advisor. “You get a

picture of your course with

all these dots on it to show

the irrigation stations. You

just click on the ones you

want.” It’s that simple.

“The SitePro

engine runs the irrigation system.

T.Map just allows

you to view the setup a lot more

graphically,” adds

Bill Thornton,

Toro’s Western

Regional Sales

Manager. “That

helps especially

when the

operator

isn’t a

computer

expert.”

“For example let’s say there’s a spot

that’s dry on the golf course, and you

want to give it more water,” Jurkis

explains. “Just click on the head there.

T.Map will ask you how long it should

4

T.Map

TM

Software

Picture This: Improve Irrigation Control With T.Map

TM

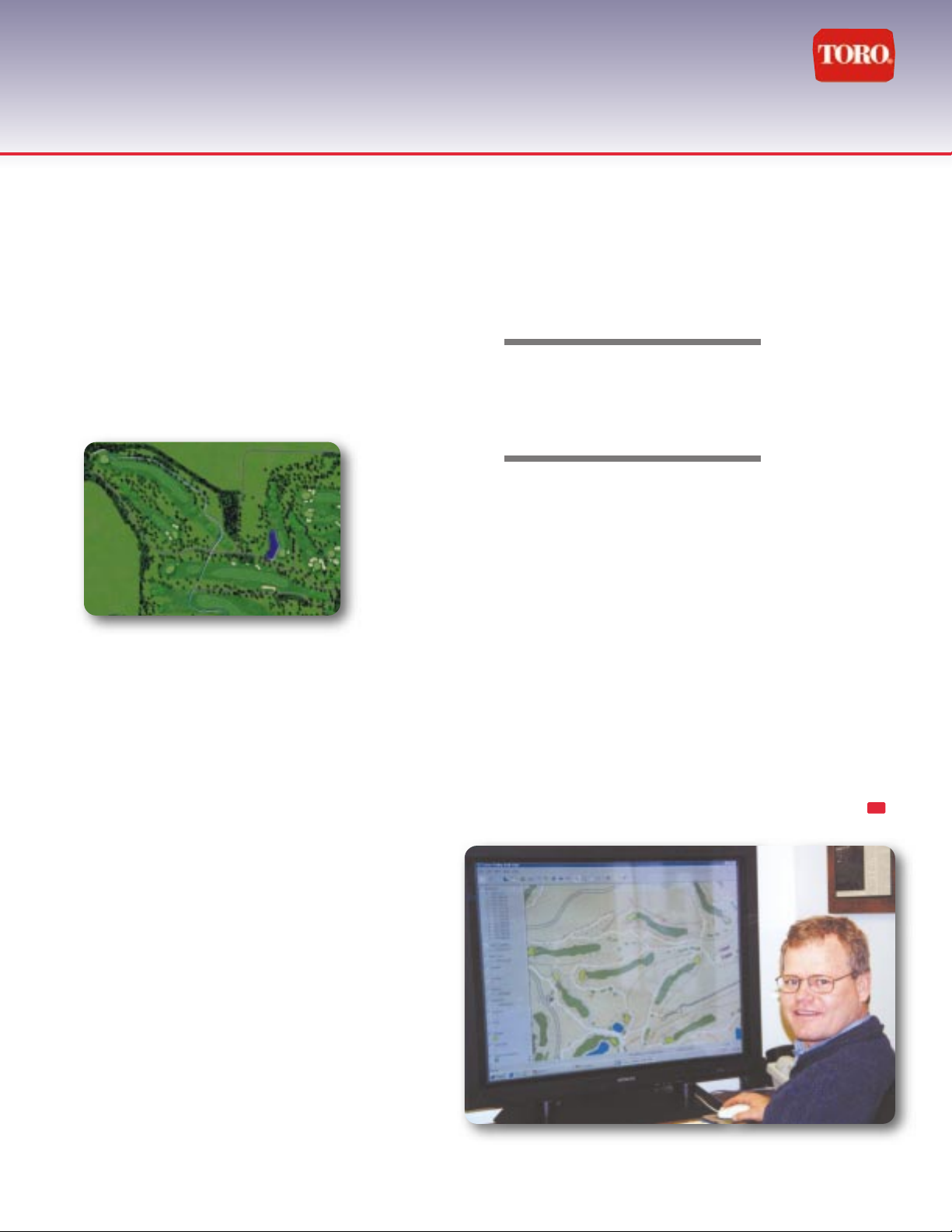

Tom Walker is the golf course superintendent at the Inverness Club in Toledo,

Ohio. He credits the T.Map

TM

system for providing flexibility and efficiency.

Page 5

run; enter how long you want, and it will

automatically turn it on. You don’t need

to know the satellite station number or

any of that, because it looks it up for

you.”

“It’s just a great, great benefit,” says

Tom Walker, Golf Course Superintendent

at The Inverness Club in Toledo, Ohio.

“The ability to change the time of certain sprinklers, to take your mouse and

loop around a few heads and put them

on hold for one day, two days, whatever,

it’s wonderful.”

Built in 1903, The Inverness has hosted many major tournaments, including

four U.S. Opens. It typically ranks

among the best-groomed courses in

America, so Walker has high standards to

uphold. He feels that SitePro and T.Map

have helped him a lot.

“There’s so much flexibility,” he adds.

“Not only is it an excellent irrigation

package, it also gave me an accurate map

of the golf course. I can use it for charting square footages, charting out holes,

locating drain lines, even trees,” he says.

“As far as saving me time and getting the

job done better, it’s just wonderful.”

Easy Installation

When T.Map is installed, whether with

new or existing SitePro software, it

requires a designer or consultant to provide an AutoCAD image of the golf

course—from a survey, GPS program,

aerial photos or even drawn freehand.

GPS isn’t required for T.Map, but it does

improve accuracy.

The AutoCAD data is then converted

into T.Map-shaped files and layered

color-coded images.

“What the data conversion does is to

look at all this

course info, create

what it needs to

create, and saves it

in a zip file,”

explains Toro’s

Jurkis. “That one

file is all you need.

Tell SitePro to do a File Open, and there

it will be.”

When setting up the initial AutoCAD

image, which most new courses already

have, you can determine how detailed

you want it to be.

Everything You’re Looking For

“It’s unlimited what you can do,” says

Steve Glossinger, Golf Course Manager

at Caves Valley Golf Club in Baltimore,

Maryland. “We put in all the surfaces,

contour lines, fairways, bunkers, trees,

even paths and buildings. We did just

about everything on the property.”

Caves Valley, site of this year’s Senior

Open, has relied on computerized irrigation control for several years, but T.Map

is a big improvement, Glossinger feels.

“I didn’t

know it was

going to be

this good,

quite

frankly,” he

says. “It’s

friendlier; I

picked up on

it quicker. It

has everything superintendents

are looking

for. With this

system, you

really see

your golf

course and

where your

heads are and what you’re running. After

this,” he adds, “you wonder how you

survived with the old system. It’s that

good.”

At Caves Valley, T.Map does much

more than irrigation. “You can see

your whole

course,”

Glossinger says,

“so we use it as a

tool to implement

strategies. For

example, we were getting ready to put up

corporate tents, but instead of going

down there and doing all that measuring,

with a couple clicks on the screen we

knew how many tents would fit.”

The advantages of SitePro and T.Map

are just starting to be discovered—water

conservation, irrigation troubleshooting,

locating trees for removal, determining

square footage of greens and bunkers,

measuring for paving estimates—and the

list goes on. Better yet, it’s easy to get

introduced to the program and quickly

benefit from it.

“You don’t need technical savvy to run

this,” says Walker. “You just point your

mouse at something and click. It’s 100

times simpler than programming a VCR.”

5

Golf Course Manager of Caves Valley Golf Club Steve Glossinger uses a 40 inch (101.6

cm), flat panel display with his T.Map

TM

system.

“As far as saving me time and

getting the job done better, it’s

just wonderful.”

– Tom Walker

Toro’s T.MapTMsystem provides an accurate

graphical representation of the golf course to

simplify irrigation management.

Page 6

6

B

eing a leader in the equipment industry requires more

than great equipment. We

depend heavily on the people who

operate and service our equipment.

That’s why we have a long-standing

commitment to training and education,

to help ensure that customers are as

comfortable and knowledgeable about

equipment as they can be.

One of the many popular things we

offer in our training spectrum is Toro’s

Customer Factory Service Education

Program, or as it’s more commonly

known, “Factory Service School.” Our

Factory Service School is a three-day

session held at Toro’s Training Center

in Bloomington, Minnesota, including

a visit to our assembly facility at

Tomah, Wisconsin. Designed primarily

for technicians, the guests at Factory

Service School attend a variety of helpful seminars that address issues of concern to them and the industry. They

also get unique

opportunities to

meet other technical professionals

from around the

country and

exchange ideas.

Created over 20

years ago to provide training for

distributors, Toro’s

Factory Service

Schools have since

been expanded to

include technicians

from golf courses, sports facilities and

municipalities. Currently Toro offers

these end-user Factory Service School

sessions about five times a year.

Useful Information

The Factory Service School program

usually starts on a Sunday night with a

welcoming get-acquainted reception.

Then over the next three days, “students” of Factory Service School attend

informational tours, presentations and

hands-on sessions addressing such help-

ful topics as cutting unit adjustments,

hydraulics, electrical systems, equipment maintenance, diagnostics and

troubleshooting.

“It was very informative,” says Rick

Paré, Equipment Manager at Eagle

Crest Resort in Redmond, Oregon. He

attended Factory Service School this

past September. “Training is beneficial

for everybody. You always like to see

new updates and new innovations that

are coming along. The mere fact that

greens are so fast and are cut so short

now, we’ve got to be on our toes all the

time.”

In addition to the training classes

and seminars themselves, Paré enjoyed

the chance to swap notes and tips with

the technicians he met there.

“One person’s attitude on how to

maintain a piece of equipment differs

from another’s,” he adds. “Whenever

you get together with a bunch of technicians or superintendents, you always

talk about what

works for you and

what doesn’t.”

“When you hear

someone else with

a situation similar

to yours, it helps,”

agrees Michael

Koopman, another

technician who

attended Factory

Service School last

year. Koopman is

the Equipment

Manager at Old

Collier Golf Club in Naples, Florida.

“It was geared more for education,

but they gave us the option of giving

our feedback,” he says about Factory

Service School. “I think one of the best

things—and something that people are

really interested in—is when they

brought the engineers in and asked if

we had any questions for them. That

was on Monday, the first day. Then, if

they couldn’t answer a question, they

said they would get back to us before

we left for home on Wednesday.

“One thing I’ll say,” he adds, “is that

they didn’t run away from someone

who said, ‘Hey, I have a problem with

something.’ They listen to what the

people have to say.”

The chance to meet with Toro engineers and ask them specific questions

has always been one of the most popular features at Factory Service School.

The technicians in attendance know

their equipment better than anyone,

and Toro appreciates the opportunity to

get first-hand input from people who

put the machines through their paces

every day.

“They asked us if we had any problems, or if we had any questions we

wanted answered,” Paré says. “I thought

that was good; they were very straightforward.”

Customer-Focused

Given the wide range of products

Toro represents, part of the challenge

with any type of training is to make

sure it’s relevant to a particular customer, to give him or her the information they need most.

“We have two different types of

schools we offer to our customers,”

explains Jim Peterson, Toro’s Education

and Learning Manager in the

Commercial Products Division. “One

has a golf focus and the other has a

grounds focus. So the technical information we provide is specific to the

needs of the technician,” he says.

Factory Service School

Toro’s Customer Factory Service Education Program Earns An A+

Toro’s Factory Service School gives equipment managers and technicians hands-on instruction on how

to properly service Toro equipment.

Technicians benefit greatly from the interaction with Toro employees and peers at the

Factory School.

Page 7

“For a golf school, we would concentrate on products used on greens and

fairways, and those things of particular

interest in a golf setting for that group

of customers,” Peterson says. “For

example, golf school might focus more

on reel-type cutting units. Some of the

most lively discussions we have at any

golf school will surround the subject of

reel-type cutting units.”

Tailoring the presentation material to

keep it pertinent and interesting is vital

when your goal is to offer truly useful

material to those in attendance. Toro

firmly believes in the value of making

information available to the people who

need it. We also believe in putting that

information to good use.

“At the end of the day, merely learn-

ing is not the goal; behavior change is

the goal, and learning is how we get

there,” Peterson says. “We want to

make sure that whenever we get into a

certain topic or subject, that the participant is able to make that leap, where

they’ve learned something new and now

they can take that and use it. We want

them to be able to do something more

efficiently, or do it in a new way that

improves their skills and abilities as a

service technician,” he says.

“Helping them to personally grow in

their occupation is what this is really all

about,” Peterson adds, “and it’s going to

benefit everybody if we can do that.”

Next Session Sept. 16–18

An upcoming Toro Factory Service

School is scheduled for September

16–18, 2002. Some of the planned topics for the program include an introduction to the ACE System to aid in

troubleshooting, and a seminar called

“Cutting System Dynamics,” which

addresses the design, set-up and adjustment of cutting units. The cost of

attending is $600 US per person, which

includes three nights’ lodging, meals,

local transportation and all classroom

materials.

If you would like to attend a Factory

Service School, or want to obtain more

information about it, please contact

your local Toro distributor.

“I’m glad that I went, and I would

love to go again,” says Paré. “There’s

still a lot to learn.”

7

TOROfor

you

R

ick Paré and Mike

Koopman both have good

things to say about their

trips to Toro’s Factory School, but their

experiences there will undoubtedly be

forever fixed in their memories for other

reasons: they were attending their sessions on Tuesday, September 11, when

the horrible terrorist attacks hit America.

“We were going through the plant, in

the special operations area, and that’s

when we heard about the plane crashes,”

recalls Paré. “So it got cut short, and we

didn’t get to see everything we would

have liked to, but they did the best they

could with the situation the way it was.”

“I was scheduled to fly out on

Thursday, but didn’t end up leaving until

Saturday,” adds Koopman. “We had to

stay all those extra nights, but Toro said,

‘Don’t worry, we’ll take care of it.’ On

Tuesday, I’m sure those Toro guys would

have liked to go home to their families,

too, but they stayed there with us. They

could have just sent us back to the hotel

for two or three days, but I don’t think

that crossed their minds,” he says. “I was

impressed with that.”

Paré was actually able to head back

home to Oregon shortly after the attacks,

but it required some fortunate coincidences.

“On September 11th, the airlines were

shut down,” he explains, “but my wife

got me connected with a salesman from

her company who was in Minneapolis

for a convention. He happened to run

into another guy from our area and a

friend of his from Boise. He told me,

‘I’ve got room for one more,’ so I hitchhiked a ride home with them. It was 30

hours… not the way I wanted to see the

country,” he says.

“But I feel so strongly about the Toro

program and wanting to return, that I

would hitchhike back!”

A Memorable Trip Becomes Truly Unforgettable

Michael Koopman upholds high standards

for the quality of his maintenance facility.

The equipment facility at Old Collier Golf

Club, Naples, Florida.

Michael Koopman services almost exclusively Toro Equipment at Old Collier Golf Club.

Page 8

ProCore®Operator Video Teaches Proper Techniques

Operator

Training

W

hen you don’t do a

particular job every-

day, it’s always a good

idea to refresh your skills before

jumping into the task. With that in

mind, Toro recently released the

Toro®ProCore®Operator Training

Video (Part No. 01087SV) to help

sharpen your skills.

Recorded in both English and

Spanish, the video covers the initial

set-up and operation of the ProCore

series of aerators. These aerators

cover a lot of ground so any missteps can slow you down. Taking the

time to view this short video before

aerating is useful for new operators

as well as a nice refresher for seasoned operators. The operator’s

manual should also be read in its

entirety to ensure safe and proper

operation.

Some basic tips for good

aeration:

Make sure everything is level

from the start. Mount the aerator

on a level surface and check the

machine to see that it is level before

beginning operation.

Pay close attention to the Power

Take Off (PTO) shaft. The PTO

cannot be too long or it will damage

the shaft or gearbox. It may need to

be changed by the equipment technician.

Use the best settings. The aerator

should be set to lift about 4 inches

(10 cm) off the ground during operation. Adjust the aerator to a 4degree forward angle for the best

holes. NEVER angle the aerator

rearward or damage may occur to

the machine or turf.

Get the right tines and set the

penetration. There are a variety of

tines to choose from. The depth

chart in the operator’s manual has a

guide to tines and proper settings.

Set the tine depth the same on both

sides of the aerator. If tine depth is

changed, recheck the aerator angle

to ensure it is still 4 degrees.

Practice using the aerator. Before

actually aerating the course, find a

clear area and practice stopping and

starting and raising and lowering

the aerator. Be

sure to mark all

obstacles on the

course to avoid

things like irrigation heads and

electrical wires.

Any debris like

rocks that will

damage the aerator should also be

removed.

Start correctly.

To begin aerating,

use a low tractor

engine rpm in an

appropriate gear.

Set the speed

between .6 and

2.5 miles per

hour (.97 and

4.02 kmh). As

you begin and the

tractor moves forward, fully lower

the 3-point linkage and increase the engine speed

until you reach 540 rpm on the

PTO. The machine must be on the

ground when set at 540 rpm. The

aerator may be damaged if the tines

are not working in the turf when

operated at full speed.

Use the right front tractor wheel

as a site guide. The right front trac-

tor wheel should be used as a site

guide to maintain equal lateral hole

spacing with the previous pass. This

will allow you to use the offset of

the aerator to stay off the area you

already aerated.

Stop correctly. When finished

aerating, lower the engine rpm, raise

the aerator, depress the clutch on

the tractor with your foot and stop

the PTO.

Always stop for people. If anyone

comes near the area of operation,

move off the area you’re aerating and

stop the machine until the area is

clear. Since tines are pummeling the

surface of the turf, a tine may break

and fly off or debris may fly out

from the aerator. Always be aware of

any people around you.

The new ProCore

®

Operator

Training Video is available from

your local distributor. Other new

operator training videos available

include: the Groundsmaster®3500

(Part No. 00061SV), Groundsmaster

®

4000 (Part No. 01085SV), and the

Greensmaster®FlexTM21 (Part No.

01086SV). Each video is $16 US.

8

Page 9

9

En el video vídeo de ProCore se explican las técnicas correctas de operación

Capacitación

de Operadores

C

uando un operador deja de

hacer un trabajo particular

todos los días, es recomendable que repase lo que sabe de ese trabajo

antes de volver a realizarlo. Pensando en

esto, Toro preparó recientemente el video

vídeo de capac-

itación de operadores del

equipo Toro

®

ProCore

®

(número de

catálogo

01087SV) para

ayudar a los

operadores a

mejorar sus

habilidades.

Está narrado

en inglés y

español, y

cubre la

preparación inicial y la

operación de

los aireadores

de la serie

ProCore. Estos

aireadores

cubren una

gran extensión

de terreno y

cualquier paso

incorrecto puede

retrasar el trabajo. Será muy útil dedicar

el tiempo necesario para ver este breve

videovídeo antes del de hacer trabajos de

aireación tanto en el caso de operadores

nuevos como de operadores experimentados que necesiten una buena repasada.

Debe leerse completamente el manual de

instrucciones para asegurar la operación

segura y correcta.

Sugerencias básicas para una

buena aireación:

Asegúrese de que todo el equipo esté

nivelado desde el principio. Monte el

aireador en sobre una superficie nivelada

y revise la máquina para asegurarse de

que esté nivelada antes de comenzar la

operación.

Ponga especial atención al eje de la

toma de fuerza (PTO). La toma de

fuerza no debe ser demasiado larga

porque podría dañar el eje o la caja de

engranajes. Quizá Es posible que deba ser

cambiada por un técnico especializado.

Use las los mejores regulacione-

sajustes. El aireador debe ser ajustado

para elevarse unos 10 centímetros del

suelo durante la operación. Ajuste las

puntas a un ángulo de 4 grados para que

hagan bien los agujeros. NUNCA ajuste

el aireador a un ángulo hacia la parte

trasera porque podría dañar la máquina o

el césped.

Use las puntas correctas y ajuste la

penetración. Hay diversas puntas entre

las que puede escoger. La tabla de profundidad en el manual de instrucciones

tiene una guía de puntas y ajustes correctos. Ajuste la profundidad de las puntas

al mismo nivel en ambos lados del

aireador. Si cambia la profundidad de las

puntas, vuelva a revisar el ángulo del

aireador para asegurarse de que todavía

esté en a 4 grados.

Practique usando el aireador. Antes

de empezar la aireación del campo,

busque una zona despejada y practique

parando parar y arrancandoarrancar, elevando elevar y bajando bajar el aireador.

Recuerde marcar todos los obstáculos en

el campo para evitar daños a objetos

como cabezales de irrigación y cables

eléctricos. Debe quitar los objetos que

puedan dañar el aireador, tales como

rocas.

Arranque correctamente. Para

empezar la aireación, use una marcha

lenta del motor del tractor. Ajuste la

velocidad entre 0.97 y 4.02 kph (0.6 a

2.5 mph). A medida que comience a

avanzar con el tractor, baje completamente el acoplamiento de tres puntos y

aumente la velocidad del motor hasta

alcanzar 540 rpm en la toma de fuerza.

La máquina debe estar en el suelo cuando la ajuste a 540 rpm. El aireador puede

dañarse si las agujas puntas no están trabajando en el césped cuando opera a alta

velocidad.

Use la rueda delantera derecha del

tractor como guía. La rueda delantera

derecha del tractor debe usarse como

guía para mantener el mismo espacio lateral entre agujeros después de cada pasada. Esto le permitirá mantenerse fuera

del área en que ya trabajó.

Detenga correctamente la máquina.

Cuando termine de airear, baje reduzca la

velocidad del motor, eleve el aireador,

oprima el embrague del tractor con el pie

y pare la toma de fuerza.

Siempre pare cuando vea gente. Si

alguien se acerca al área donde opera,

apártese del área y pare la máquina hasta

que la gente se aleje. Como las puntas

golpean con fuerza la superficie del

césped, una de ellas podría romperse y

salir lanzada o podría golpear un objeto

que también saldría lanzado del aireador.

Siempre esté alerta por si hay gente a su

alrededor.

El nuevo videovídeo de capacitación

de operadores de ProCore está disponible

en su distribuidora local. Hay otros

videovídeos de capacitación de operadores nuevos, incluyendo los siguientes:

Cortadora Groundsmaster

®

3500 (No. de

catálogo 00061SV), Cortadora

Groundsmaster®4000 (No. de catálogo

01085SV), y Cortadora Greensmaster

®

Flex™21 (No. de catálogo 01086SV).

Cada cinta de videovídeo cuesta $16

dólares.

Page 10

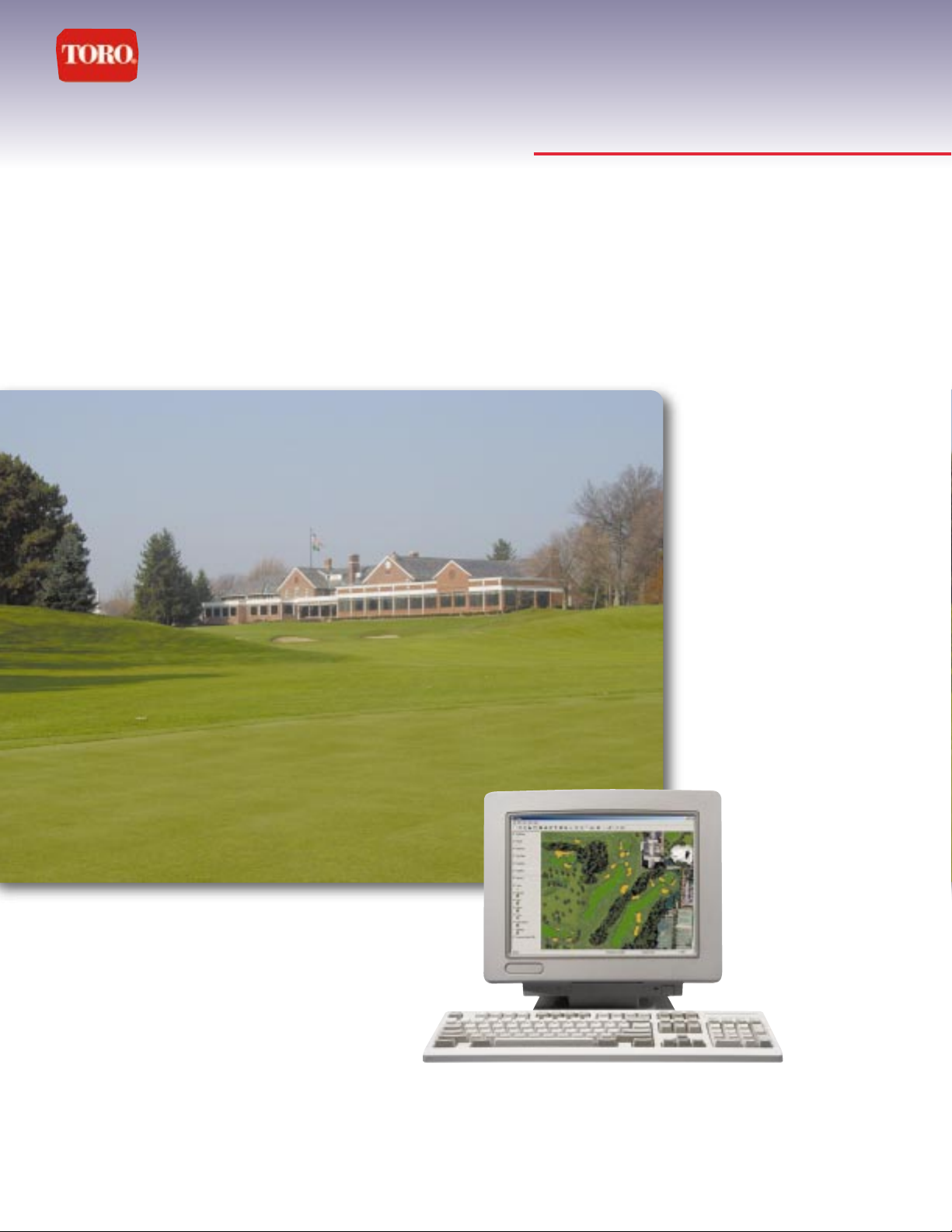

W

hen Toro introduced the

Greensmaster®FlexTM21 a

year ago, the industry had

never seen a greens mower like it.

The Flex 21 had been conceived and

designed based on specific requests and

input from real-world equipment users.

Toro engineers had gone out and

talked to superintendents, oper-

ators and technicians, all with

the golfer in mind, about

what they needed in a better walk mower.

That kind of guid-

ance and recommen-

dations led to the

many special fea-

tures of the

Flex 21,

most notably its unique flexible cutting

unit, which is essential for undulating

greens and the new Ultra Dwarf grasses.

The cutting unit not only flexes from side

to side around the bedknife centerline,

but also forward and backward around

the reel centerline.

The flexible cutting unit is separate

from the traction unit so it ensures a

superior cut and less scalping than any

other mower. This innovative development allows for crisp, tight mowing at the

height you want, even on the most challenging greens.

“We developed this product based on

customers’ needs and concerns,” says Jerry

Goman, lead engineer for the Flex 21.

“We were hearing more and more about

new grass cultivars and lower height of

cut, combined with undulations and

movements in the green. There was a

need for this machine.”

Tremendously Positive

Response

“It surpassed what I thought it would

do,” says superintendent Mitchell

Wilkerson. “What they promised it would

be able to do, it has.”

Wilkerson is a Certified Golf Course

Superintendent at the 36-hole Moss Creek

Country Club of Hilton Head, South

Carolina. Last year, he was in the market

for new equipment, and had some specific

needs in mind.

“One of our problems was that we have

Super Dwarf Champion on our north

course, and we have a lot of undulations

on our greens,” he says. “At the height we

were mowing, with any little movement

we would just scalp it.”

Wilkerson had been told about the Flex

21 and arranged for a test with Toro. He

was immediately convinced. “That made

me a believer. It was just everything they

said it was.” Wilkerson reports.

His new mowers went right into action

and immediately made a difference. “On

the Super Dwarfs, it was like night and

day,” Wilkerson says. “On the undulations, we didn’t see any bruising or scalping. It was pretty dramatic.”

“It was a no-brainer for me when I saw

the difference it made,” agrees Steve

Nelson, Superintendent at Mississippi

Dunes Golf Links in Cottage Grove,

Minnesota.

“There are severe undulations on the

greens here,” Nelson explains. “My slopes

are so severe, for walk mowing there are

some greens I could only mow in certain

directions.”

Nelson had tried several different types

of greens mowers, but nothing was satisfactory. “I was still getting the scalping,”

he adds. Then he heard about the new

Flex 21 and was able to borrow one from

a friend to try it.

“When I took it out there, I could see

what it can do,” he says. “It was nice

because I had every other brand out there,

and it was easy to see the difference. I didn’t get the scalping the other mowers did.”

Cutting Shorter

With the Flex 21, Nelson was then able

to improve the putting surface of his

greens. “We wanted to start stepping

them down,” he says. “Once I saw that

the scalping wasn’t there, I knew I could

start taking them lower, and start getting

the quality and speed we needed.”

Mitch Fossey is another superintendent

Toro®Greensmaster®Flex

TM

21

Exceeding Expectations

10

Toro’s Greensmaster®FlexTM21 greens mower

offers several substantial benefits to superintendents, operators and technicians.

Page 11

who was looking for a closer cut. Fossey is

the superintendent at Troy Burne Golf

Club in Hudson, Wisconsin, a new course

with very undulating greens.

“We were having a lot of problems getting good quality cuts on our greens,” he

explains, “because they’re brand new

greens on 100% pure sand base. We just

couldn’t get a mower to cut short enough

for us without damaging or scalping the

grass. They built them with some big rolls

through the middle, and some pretty

severe dips.”

Fossey made calls to find out if someone could provide an answer to his problems. He met with a Toro representative,

who told him about the new Flex 21

mower, which was then still at the

prototype stage.

“We ended up being a test facility,”

Fossey explains. “We actually ran the prototypes on that machine. We helped Toro

in the fine-tuning process.”

At the end of the testing period, Fossey

bought the club their own Flex 21s.

High Praise

“It is the best walking greens mower I

have ever used,” Fossey adds, “and I’ve

been in the business for twenty years and

used a lot of different ones. If someone is

going to walk mow, this is what they

should walk mow with!”

Other superintendents have had similar

great things to say about the Flex 21. In

addition to excellent close-cutting without

scalping, they’re pleased with the

machine’s improved operating and maintenance features.

All controls are easily reachable from

the operator position. The clutch and reel

engage from hand controls. The reel

clutch and the traction clutch have been

incorporated into a single multi-function

control lever and all controls have been

assimilated into the gearbox.

Technicians appreciate the Flex 21’s ease

of maintenance. No grease zerks means it

never has to be greased, and will keep

grease off your greens. All you really need

to check are the height of cut and bedknife adjustments. The Flex 21 has an

exclusive bedbar geometry that keeps the

bedknife aligned for the life of the mower.

When the reel wears, the bedbar geometry

remains constant to maintain a consistently aggressive, even cut with minimized

maintenance.

The Flex 21 was also designed for easy

removal of the cutting unit. Simply take

out two bolts, and the cutting unit comes

off quickly for grinding or replacement.

Golfers will notice the Flex 21 too,

because it gives them a good-playing

green with faster, more predictable ball

roll.

“I’ve had several people call and ask me

if I’d recommend a Flex 21,” says Fossey,

“and I tell them I recommend it 150%.”

“There is nothing else out there like the

Flex 21,” agrees Mitchell Wilkerson. “I

have total confidence in it.”

11

Moss Creek Country Club, Hilton Head, South Carolina, is

a 36-hole golf course with very distinctive architecture.

The Toro

®

FlexTM21 mower was a perfect fit for

the undulating greens of Troy Burne Golf Club,

a dazzling new course in Hudson, Wisconsin.

Page 12

12

W

hen Toro engineers aren’t

busy developing better

products for you, they

work on ways to make those products

easier to use.

Here are several new tools that were

created to make servicing of Toro golf

sprinklers faster and simpler than ever.

These particular items were designed for

Toro 800S Series golf irrigation systems,

but all of them are downward compatible

to be equally effective with the 600 and

700 Series sprinklers.

Universal Riser Hold-up Tool

Now it’s much

simpler to

replace a sprinkler nozzle. This

versatile little

gadget slips

neatly into place

to hold up the riser while you’re working

beneath it. Multi-directional for use on

both 700 and 800S Series sprinklers, the

hold-up tool is like having another hand.

It replaces part no. 995-55.

1.5'' Valve Insertion Tool

This extremely helpful device has been

upgraded for more

efficient use, especially by providing

improved retention

of the snap ring

during valve installation. This new

insertion tool

replaces part no.

995-10.

However, if you currently have the

existing Toro Valve Insertion Tool #99510, you can also just modify and

improve it yourself with our new 1.5''

(3.81 cm) Valve Insertion Upgrade Kit

(Part No. 102-2063).

5/8'' Nutdriver

Here’s another handy tool you shouldn’t

be without. This new 5/8'' (1.5875 cm)

nutdriver is a big help for removal and

installation of all 800S Series main nozzles.

Snap-Ring Pliers

Talk about making

the job a snap! This

durable, long-handled set of pliers

provides an ideal

grip and reach for

easier removal of a

sprinkler’s valve snap

ring, as well as the

new removable rock

screen. This tool replaces

part no. 995-07.

T

oro’s line of rotary mowers

will provide excellent quality

of cut providing they are serviced correctly and consistently. Regular

scheduled maintenance will reduce problems associated with equipment wear and

tear and ultimately reduce costly

repairs. The following guide-

lines will ensure peak

performance of

your rotary

mowers.

Service Recommendations:

4 Check mower blades daily.

4 Grease gauge wheel pivots daily.

4 Grease gauge wheel axle daily.

4 Torque blades every 50 hrs.

4 Grease spindle bearings every 50 hrs.

4 Check drive belt tension every 50 hrs.

4 Check gearbox oil every 50 hrs.

4 Change gearbox oil every 250 hrs.

Irrigation Tools You Shouldn’t be Without

Rotary Mower Tips

For Smooth Operation

Snap-Ring Pliers (Part

No. 995-100).

Universal Riser Hold-up

Tool (Part No. 102-0336).

1.5'' Valve Insertion Tool

(Part No. 995-101).

Page 13

R

otary mowers cut grass by

the blade’s cutting surface

impacting against the grass

stems at a high velocity. To ensure good

quality of cut, the cutting edge of the

blade must be kept in a sharp condition.

A dull blade will produce a ragged cut

and will require an excessive amount of

engine horsepower to rotate the blade

through the grass. The most common

causes for rotary mowers not giving a

good quality of cut are due to dull cutting edges and/or bent blades. Whenever

a blade is removed for sharpening:

1. Check the blades to ensure that it is not

bent and has the correct attitude in relation to the housing and ground surface.

2. The blade must be sharpened correctly.

3. Check blade balance each time the blade

is sharpened.

4. When installing the blade, tighten the

blade retaining bolt or nut to the correct

torque so it will not loosen during operation.

If blade is allowed to wear, a slot will

form between the sail and flat part of the

blade (see figure 1).

Eventually a piece of the sail may

break off and be thrown from under the

housing, possibly resulting in serious

injury to yourself or a bystander.

Sharpening Process

Before sharpening the blade, check to

make sure it is straight. Lay the blade on

a flat surface to check.

Do not try to straighten a blade that is

bent, and never weld a broken or cracked

blade. Always use a new Toro blade to

ensure continued safety certification of

the product.

When sharpening the blade, grind the

top surface only, trying to maintain the

angle of the original cutting edge. Do

not grind the bottom surface or a chisel

shape will result (see figure 2). The lowest portion on the blade that contacts the

grass must be the cutting edge or the

grass will not be cleanly cut and excessive

horsepower will be required.

To prevent possible personal injury,

wear a face shield or safety glasses when

grinding or sharpening is being done.

After the blade has been sharpened,

check the balance. This can best be done

by using a blade balancer tool. A bal-

anced blade will stay in a horizontal position on the balancer. A blade that is not

balanced will settle to the heavy side. If

the blade is not balanced, grind some

metal off the heavy end of the blade.

Blade Bolt Torque

When installing blades, be sure to

tighten the blade retaining bolt to the

proper torque. Do not use an air or electric wrench to apply the final torque. To

prevent loosening or damaged threads,

always use a standard torque wrench to

apply the final torque (see figure 3).

Check blade retaining bolt torque any

time a blade has hit a solid object.

13

Technician

tips

Inspecting and Sharpening

Rotary Mower Blades

Customer Care Available at www.toro.com/golf

DO NOT grind bottom of cutting edge.

This will cause poor quality of cut and

demand higher horsepower.

Grind top side of cutting edge only.

Ideal angle for cutting edge is 30º.

INCORRECT This will cause poor quality

of cut and high horsepower requirement.

CORRECT

CORRECT

FLAT PART

OF BLADE

SAIL

SLOT

FORMED

SAIL

WEAR

SAIL

INCORRECT Bent lades will cause poor quality

of cut and demand higher horsepower.

Figure 1

Figure 2

Figure 3

Page 14

14

T

oro has a commitment to

helping you have a better-

looking golf course, and sometimes it means providing you with equipment that goes beyond the mowing and

growing of turfgrass.

Our versatile line of options and

attachments includes several handy

debris blowers which you can conveniently use to remove grass clippings,

leaves, twigs, pine needles and other

debris off of your fairways, cart paths

and other surfaces.

Toro offers different sizes of blowers to

fit a variety of uses and applications.

That’s especially true since Toro recently

acquired the well-respected Goossen line

of debris blower products, now enabling

us to offer you an even wider range of

options and choices.

Whichever of our debris blowers you

select, though, it will give you a much

more efficient way of keeping your

course neater and cleaner. Instead of relying on a lot of manual labor and backpack blowers, a Toro debris blower can

simply be towed behind a tractor, or for

the more compact self-contained units,

behind a utility vehicle. In any case, a

Toro debris blower enables you to clean

up large areas in a short time, with just

one operator.

Toro debris blowers offer you bi-directional air chutes as standard equipment.

That means you can blow debris from

either side of the unit, and then simply

turn the chute to send the airflow 180

º

in the opposite direction. That’s important because it allows you to immediately

make additional passes at an area without

having to drive all the way back around,

and still blow the debris to one side.

Other standard features

on Toro debris

blowers

include heavyduty construction on a 1/4''

(.64 cm) steel

frame, plus

skid plates and

rear rollers to

help protect

your turfgrass.

Whatever

your golf

course’s particular situation

calls for, there’s

sure to be a Toro blower that’s just right

for you.

Toro®Debris Blower 400

This compact unit goes anywhere a

tow vehicle can. It generates an air discharge of 6000 cubic feet (170 cubic

meters) per minute (cfm) and a windspeed of 140 mph (225 kmh). Airflow

direction is easily changed from the operator’s seat. Solid, durable construction

promises years of trouble-free service.

Toro®Debris Blower 600

When you want to quickly clear large

areas of debris, use this Toro blower to

create a incredibly powerful wind force

of over 9000 cfm (255 cmm) at a velocity

of 153 mph (246 kmh). The rugged 600

Series includes a second rear roller to provide even more protection for your turf.

BL-3000 Debris Blower

This versatile self-powered unit (Model

No. BL3000PT) packs a lot of force,

with 6170 cfm (174.7 cmm) of airflow

at a velocity of 145 mph (233 kmh).

This hitch-mounted blower is easily

towed behind any utility vehicle. Airflow

can easily be changed from the operator’s

seat with the electric control kit.

You know what it’s like to have

unwanted leaves, pine needles or other

natural debris detracting from the beauty

and playability of your course. So trust a

hard-working Toro debris blower unit to

keep your turf looking better… with a

lot less time and labor.

Also now available from Toro is

Goossen Industries’ powerful line of

Versa-Vac and Mid-Vac products. These

machines will help you maintain high

quality turfgrass and become more productive at cleaning up your course. For

more information on Toro’s new blower

and vacuum products, talk to your Toro

distributor.

14

&

Options

Attachments

Toro®Debris Blowers

An Easy Way To A Cleaner Course

Toro®Debris Blower 600 (Model No. 44536).

Toro

®

Debris Blower 400 (Model No. 44523)

Toro’s new debris blower products allow quick

and powerful clean-up of golf course areas.

Page 15

15

Innovation Drives Year of Solid Performance

New And Upgraded Products Introduced At GCSAA In Orlando

D

id you happen to invest in a

Toro® Greensmaster® Flex

TM

21

in 2001? How about a

Groundsmaster®3500-D? These are two

of our innovative products that helped

lead Toro to a year of profitability amid

economic and world turmoil.

Beyond delivering products that help

make your job easier, what does it mean

for you when Toro turns a profit when

the economic odds are stacked against it?

More new products, upgrades and

enhancements to existing products.

New Toro Products

Introduced at the 2002

GCSAA Conference and Show

n The 800S Series Sprinklers offer the

ultimate in performance, reliability,

and durability at the lowest cost of

ownership. The new Spike-Gaurd

TM

solenoid offers more than twice the

surge protection than the other sprinklers.

n 720G Series Sprinklers–Toro captured

the strength and performance of a

golf sprinkler in a small-diameter

body that’s ideal for tee boxes,

approaches and other block system

areas with special requirements. Fully

adjustable for optimal performance

with MultiMatrx

®

adjustable flow

nozzles and the TruJectory feature.

n Smart OSMAC–Now give your E-

OSMAC and OSMAC RDR narrowband satellites standalone capability!

Simple satellite programming with

the use of a laptop, the Smart

OSMAC User Interface software and

a serial cable.

n Groundsmaster®4500-D/4700-D–

These powerful rotaries will stripe

rough and trim areas with productive

9-ft. and 12.5-ft. cutting swaths.

n Greensmaster®3150–The most often

relied on riding greens mower from

Toro gets a new look. It has the same

great features you’ve trusted for years,

but now your operators get additional

comfort from easier joystick control,

plus added safety with the ability to

exit the machine from either side and

optional Roll Over Protection System

(ROPS). The redesigned hydraulics

control leaks better and provide

dynamic braking and suspension traction control.

n Multi Pro®5600–Toro’s latest concept

in spraying is expanded into a

machine with a 300-gallon tank. The

Multi Pro series now has faster reaction time—it’s instantaneous—and

more accurate spray control from the

Pro ControlTMsprayer system.

n Workman®3000/4000 Series Heavy

Duty Vehicles–Ten years after Toro

changed the definition of how a heavy

duty vehicle should perform, the original Workman gets a boost with up to

25 percent more horsepower. It’s available in three engine configurations.

n Reelmaster®2000-D–With a new

engine and greater operator comforts,

this new triplex mower offers excellent performance at a real value.

Upgrades, Accessories and

Attachments for Existing

Toro Products

n New Reelmaster®5000 and 6000

series fairway mowers can now be fit-

ted with powered rear roller brushes

for grass clipping dispersion.

n A new adjustable height-of-cut kit

allows for a higher cut—up to 1-3/8

inches—on Reelmaster®5200-D and

5400-D mowers.

n Improved verticutters are available for

the Reelmaster®3100-D, 5500-D

and all 6000 series Reelmasters.

n Hydraulic hose replacement kits

prepackage all the components

you’ll need to service your Reelmaster

®

5000 and 6000 series mowers.

n The redesigned Workman includes an

optional high flow hydraulics kit for

added hydraulic power. Also watch

for new Workman attachments to be

introduced in 2002 including a

Vicon® Spreader.

n Outfit your Flex 21 any way you

want with optional light kits and specialized bedknives, groomers, brushes

and rollers to meet your needs.

n Debris Products–A host of new debris

products are now available under the

Toro brand, following the acquisition

of Goossen Products. Look for the

Toro Versa-Vac and several new blowers for your debris management needs.

The Toro®Groundsmaster®3500-D was introduced

in 2001.

Introduced last year, Toro’s Greensmaster

®

FlexTM21 can be customized for your course

conditions.

Page 16

We Appreciate Your Feedback

Bulk Rate

U.S.Postage

PAID

St. Louis, MO

Permit #1977

If you have any questions, comments or suggestions, contact toroadvantage@toro.com or

fax 952.887.8693. Send us your ideas for future topics or tell us what you think about this

issue. We hope to hear from you soon.

Send Address Changes to:

Canyon Communications, 1630 S. Stapley Dr., Suite 117, Mesa, AZ 85204 or toroadvantage@toro.com

©2002 The Toro Company, 8111 Lyndale Ave. S., Bloomington, MN 55420-1196

T

oro commercial turf equipment and irrigation systems can now be

acquired in one easy step with Toro Financing. Offered in partnership

with GE Capital Vendor Financial Services, Toro Financing makes

obtaining the products you want even easier.

You can choose the solution that best meets your needs:

n Conditional Sales Contracts

n Leases

n Seasonal Skip Payment Plans

n Municipal Financing and Leasing

Irrigation systems including pipe, wire and labor costs can be financed by courses

with the required credit rating using conditional sales contracts.

“We’re excited to be bringing financial solutions to a new marketplace and are

committed to providing flexible options to organizations managing landscapes with

Toro equipment and irrigation systems,” said Jim Kelly, Senior Vice President

/General Manager of GE Capital Vendor Financial Services. “We’re bringing our

superior customer service, vast resources and financial expertise to Toro Financing to

help Toro better serve their customers.”

“We’re pleased to be able to extend these financial offerings to irrigation systems,”

said Bill Hughes, Vice President/General Manager at Toro. “A golf course can renovate its irrigation system and get equipment to for its fleet in one transaction from

one manufacturer. That’s unprecedented.”

Initially, Toro Financing will be available to golf courses, municipalities, schools,

universities, sports organizations and others who purchase commercial turf maintenance equipment and irrigation systems in the United States.

Introducing Toro Financing

Enhanced Financial Solutions for Acquiring Equipment

and Irrigation Systems

New Services

www.toro.com

Loading...

Loading...