Toro 44751 Service Manual

Form No. 14204SL Rev B

ProPass® 200

Original Instructions (EN)

Revision History

Revision

Date

Description

--

2014

Initial Issue.

A

02/2018

Added revision history.

B

06/2020

Updated Electrical chapter.

©

reproduced by a third party without the express written consent of The Toro Company (and/or the appropriate affiliated company).

THE TORO COMPANY 2020

This document and all information contained herein is the sole property of The Toro Company (and/or its affiliated companies). No

intellectual property rights are granted by the delivery of this document or the disclosure of its content. This document shall not be

Reader Comments

The Toro Company Technical Assistance Center maintains a continuous effort to improve the quality

and usefulness of its publications. To do this effectively, we encourage user feedback.

Please comment on the completeness, accuracy, organization, usability, and readability of this manual

by an e-mail to servicemanuals@toro.com

or Mail to:

Technical Publication Manager, Commercial

The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Phone: +1 952-887-8495

NOTES _

Part No. 14204SL (Rev. B)

Service Manual

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

ProPass 200.

REFER TO THE OPERATOR’S MANUAL FOR OPERATING, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. For reference, insert a copy of the

Operator’s Manual and Parts Catalog for your machine

into Chapter 2 of this service manual. Additional copies

of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com.

The Toro Company reserves the right to change product

specifications or this publication without notice.

ProPass

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the

machine.

200

R

E The Toro Company -- 2014, 2018, 2020

This page is intentionally blank.

ProPass 200

Table Of Contents

Chapter 1 -- Safety

General Safety Instructions 1 -- 2..................

Safety and Instruction Decals 1 -- 4................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Hydraulic System

Specifications 3 -- 2..............................

General Information 3 -- 3........................

Hydraulic Schematics 3 -- 12......................

Hydraulic Flow Diagrams: Standard Hydraulic

Controls 3 -- 14...............................

Hydraulic Flow Diagrams: Electronic Hydraulic

Controls 3 -- 16...............................

Special Tools 3 -- 20.............................

Troubleshooting 3 -- 22...........................

Tes ti ng 3 - - 24...................................

Service and Repairs 3 -- 26.......................

EATON (CHAR--LYNN) S--SERIES GENERAL

PURPOSEMOTORS PARTS andREPAIRMANUAL

EATON (CHAR-- LYNN) R--SERIES GENERAL

PURPOSE GEROLER MOTOR REPAIR

INFORMATION

Chapter 4 -- Electrical System

General Information 4 -- 3........................

Electrical Schematics 4 -- 4.......................

Wire Harness Drawings 4 -- 10....................

Special Tools 4 -- 21.............................

Troubleshooting 4 -- 23...........................

Component Testing 4 -- 25........................

Chapter 5 -- Chassis

General Information 5 -- 3........................

Service and Repairs 5 -- 4........................

Chapter 6 -- Hydraulic Power Pack

Power Pack Engine Specifications 6 -- 2............

Power Pack Hydraulic Specifications 6 -- 3..........

General Information 6 -- 4........................

Electrical System Quick Checks 6 -- 5..............

Adjustments 6 -- 6...............................

Hydraulic Testing 6 -- 8...........................

Service and Repairs 6 -- 12.......................

EATON SERIES 26 GEAR PUMP PARTS and REPAIR

MANUAL

SafetyProduct Records

Hydraulic

Electrical

and Maintenance

System

System

ProPass 200

Chassis

Hydraulic

Power Pack

This page is intentionally blank.

ProPass 200

Chapter 1

Safety

Table of Contents

GENERAL SAFETY INSTRUCTIONS 2............

Before Operating 2............................

While Operating 2............................

Maintenance and Service 3....................

SAFETY AND INSTRUCTION DECALS 4..........

Safety

ProPass 200 Page 1 -- 1 Safety

General Safety Instructions

The ProPass 200 has been tested and certified by

TORO for compliance with existing safety standards

and specifications. Although hazard control and accident prevention partially are dependent upon the design

and configuration of the machine, these factors are also

dependent upon the awareness, concern and proper

training of the personnel involved in the operation, transport, maintenance and storage of the machine. Improper use or maintenance of the machine can result in injury

or death. To reduce the potential for injury or death, comply with the following safety instructions.

Before Operating

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

1. Review and understand the contents of the Operator’s Manuals before starting and operating the machine. Become familiar with the controls and know how

to stop the machine and engine quickly. Additional copies of the Operator’s Manual are available on the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible or

damaged, repair or replace it before operating the machine. Also tighten any loose nuts, bolts or screws to ensure machine is in safe operating condition.

While Operating

1. The operator should be in the operators position

when operating the tow vehicle and ProPass machine.

Stay away from the ProPass when the floor and rear option (twin spinner or side conveyor) system are engaged.

2. Do not run engine that powers the ProPass in a confined area without adequate ventilation. Exhaust fumes

are hazardous and could possibly be deadly.

3. Make sure that the tow vehicle is carefully selected

to assure the best performance and safe operation of

the ProPass machine.

4. Make sure that the operator is familiar with tow vehicle and ProPass operation.

5. Make sure that ProPass is properly secured to tow

vehicle before operating.

7. If ProPass is equipped with a wireless controller, always be in line of sight with the machine when operating,

adjusting or programming the wireless controller.

8. Make sure that the ProPass load is distributing

evenly to prevent shifting of contents.

9. Before leaving the operator’s position of the tow

vehicle:

3. Do not touch engine, muffler or exhaust pipe while

engine is running or soon after it is stopped. These areas

could be hot enough to cause burns.

4. If abnormal vibration is detected, stop operation of

the ProPass immediately and determine source of

vibration. Correct problems before resuming the use of

the machine.

5. While operating, the ProPass may exceed noise levels of 85dB(A) at the operator position. Hearing protection is recommended for prolonged exposure to reduce

the potential of permanent hearing damage.

6. Do not leave the ProPass unattended when it is running.

A. Stop on level ground.

B. Make sure that ProPass floor is stopped and then

disengage spinner system.

C. Ensure that tow vehicle traction lever is in neutral,

set parking brake, stop engine and remove key from

ignition switch.

10.Before disconnecting the ProPass tow behind

chassis from the tow vehicle, park on level surface, ensure that the front tongue jack is in the support position

and chock wheels.

ProPass 200Page 1 -- 2Safety

Maintenance and Service

1. The Operator’s Manual provides information regarding the operation, general maintenance and maintenance intervals for your ProPass machine. Refer to this

publication for additional information when servicing the

machine.

2. Before servicing or making adjustments, position

ProPass machine on a level surface. Engage tow vehicle parking brake, stop engine and remove key from

the ignition switch. If ProPass is equipped with wireless

controller, power off wireless controller. On ProPass

mounted to a tow behind chassis, chock wheels to prevent it from moving.

3. If equipped, press the E--stop button to disable the

ProPass electrical system before working on the machine.Pullthebuttonoutwhenmachineistobereturned

to use.

4. Make sure machine is in safe operating condition by

keeping all nuts, bolts and screws tight.

5. Never store the machine or fuel container inside

where there is an open flame, such as near a water heater or furnace.

6. Make sure all hydraulic line connectors are tight and

all hydraulic hoses and lines are in good condition before applying pressure to the hydraulic system.

7. Keep body and hands away from pin hole leaks in hydraulic lines that eject high pressure hydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Hydraulic fluid accidentally injected into the

skin must be surgically removed within a few hours by

a doctor familiar with this form of injury or gangrene may

result.

8. Before disconnecting any hydraulic component or

performing any work on the hydraulic system, all pressure in system must be relieved. See Relieving Hydraulic System Pressure in the General Information section

of Chapter 3 -- Hydraulic System.

Safety

9. Make sure that electrical power harness from tow vehicle is disconnected before working on the machine’s

electrical system.

10.If major repairs are ever needed or assistance is desired, contact your Authorized Toro Distributor.

11. At the time of manufacture, the machine conformed

to all applicable safety standards. To assure optimum

performance and continued safety certification of the

machine, use genuine Toro replacement parts and ac cessories. Replacement parts and accessories made

by other manufacturers may result in non-conformance

with the safety standards, and the warranty may be

voided.

12.When changing tires or performing other service on

your ProPass machine, use correct hoists and jacks.

Make sure machine is parked on a solid level surface

such as a concrete floor with the hopper empty. Always

chock or block wheels. Use appropriate stands to support the raised machine. If the machine is not properly

supported, the machine may move or fall, which may result in personal injury.

ProPass 200 Page 1 -- 3 Safety

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the ProPass 200. If any decal becomes illegible or damaged, install a new decal. Decal part numbers are listed

in your Parts Catalog.

ProPass 200Page 1 -- 4Safety

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1..............................

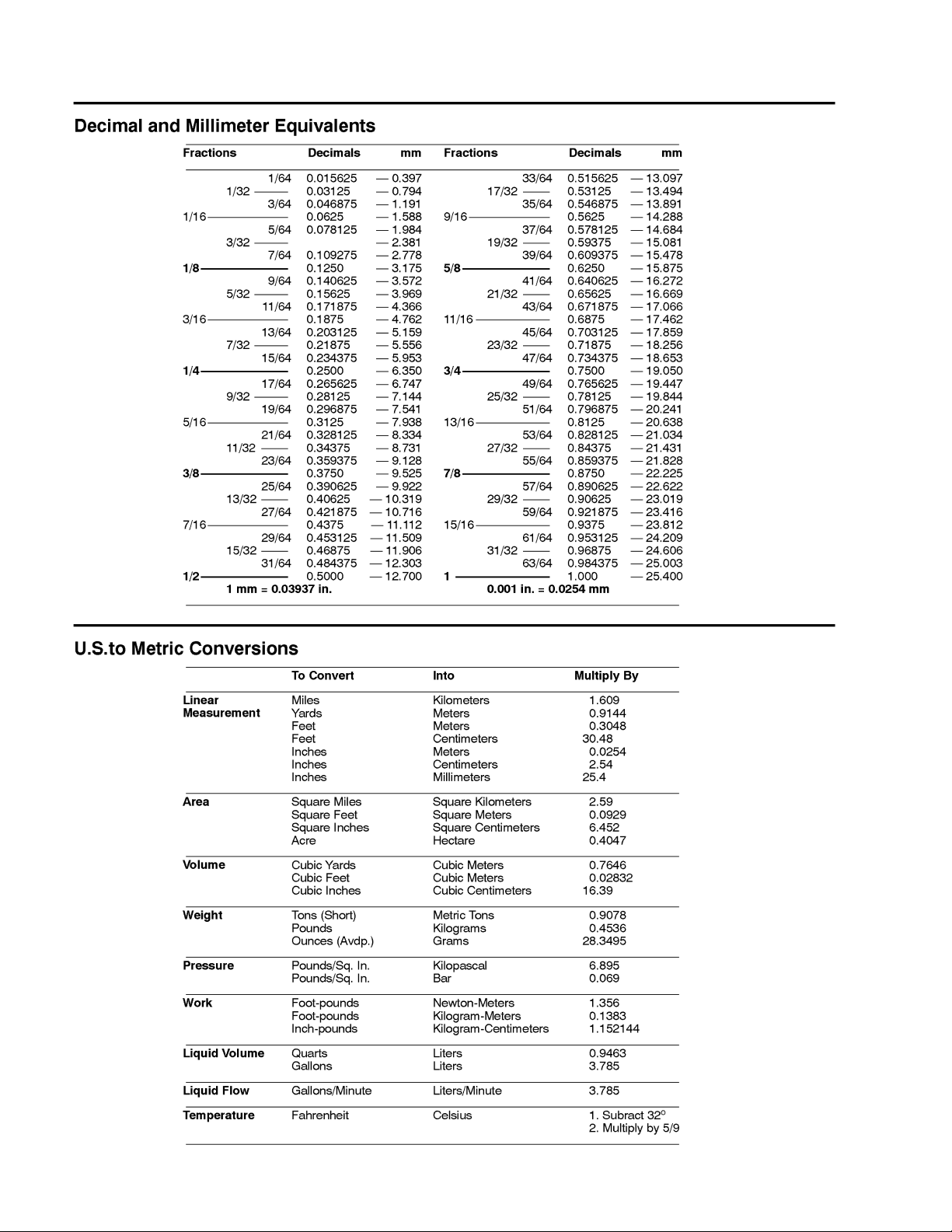

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3...................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners) 5..........

Other Torque Specifications 6..................

Conversion Factors 6.........................

Chapter 2

and Maintenance

Product Records

Product Records

Insert Operator’s Manuals and Parts Catalog for your

ProPass at the end of this chapter. Additionally, insert

Installation Instructions, Operator’s Manuals and Parts

Catalogs for any accessories that have been installed

on your ProPass at the end of this section.

Maintenance

Maintenance procedures and recommended service intervals for your ProPass are covered in the Operator’s

Manual. Refer to this publications when performing regular equipment maintenance. Several maintenance procedures have break--in intervals identified in the

Operator’s Manuals. If machine is equipped with the hydraulic power pack, refer to the Engine Owner’s Manual

for additional engine specific maintenance procedures.

ProPass 200 Page 2 -- 1 Product Records and Maintenance

Equivalents and Conversions

0.09375

ProPass 200Page 2 -- 2Product Records and Maintenance

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

the fastener’s head or similar condition which affects the

installation.

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

thelinesmatchup.

and Maintenance

Product Records

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

Using a Torque Wrench with an Offset Wrench

Use of an offset wrench (e.g. crowfoot wrench) will affect

torque wrench calibration due to the effective change of

torque wrench length. When using a torque wrench with

an offset wrench, multiply the listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: The measured effective length of the torque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

The measured effective length of the torque wrench with

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft--lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft--lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A / B

Torque wrenchOffset wrench

The calculated torque conversion factor for this torque

wrench with this offset wrench would be 18 / 19 = 0.947.

ProPass 200 Page 2 -- 3 Product Records and Maintenance

Figure 3

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Grade 1, 5 &

Thread Size

#6--32UNC

#6--40UNF 17 + 2 192 + 23 25 + 3 282 + 34

#8--32UNC

#8--36UNF 31 + 4 350 + 45 43 + 5 486 + 56

#10--24UNC

#10--32UNF 48 + 5 542 + 56 68 + 7 768 + 79

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130 + 11 3 140 + 15 1582 + 169

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 11 3 11 5 + 12 1299 + 136 160 + 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

8withThin

Height Nuts

in--lb in--lb N--cm in --lb N--cm in --lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

29 + 3 328 + 34 41 + 5 463 + 56

42 + 5 475 + 56 60 + 6 678 + 68

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 11 9 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimum proof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

ProPass 200Page 2 -- 4Product Records and Maintenance

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N --cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N- -cm 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93 + 10 ft--lb 126 + 14 N--m

M16 X 2.0 166 + 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N --m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Stronger Nuts)

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately +

nominal torque value.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

10% of the

and Maintenance

Product Records

ProPass 200 Page 2 -- 5 Product Records and Maintenance

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Typ e A Typ e B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque*

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N --cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft-- lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

* Hole size, material strength, material thickness and fin-

ish must be considered when determining specific

torque values. All torque values are based on non--lubri-

cated fasteners.

ProPass 200Page 2 -- 6Product Records and Maintenance

Table of Contents

Chapter 3

Hydraulic System

SPECIFICATIONS 2............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

ProPass Hydraulic Supply 3....................

Hydraulic Hose Kit (Tow Vehicle to ProPass) 3....

Machine Hydraulic Control 4...................

Rear Option 5................................

Relieving Hydraulic System Pressure 5..........

Hydraulic Hoses 6............................

Hydraulic Hose and Tube Installation (O--Ring

Face Seal Fittings) 6........................

Hydraulic Hose and Tube Installation (JIC Flared

Fittings) 8..................................

Hydraulic O--Ring Face Seal (ORFS) Fitting

Installation 9................................

Hydraulic JIC Flared Fitting Installation 11.........

HYDRAULIC SCHEMATICS 12...................

Standard Hydraulic Controls 12.................

Electronic Hydraulic Controls 13................

HYDRAULIC FLOW DIAGRAMS: STANDARD

HYDRAULIC CONTROLS 14...................

Rear Option Circuit (Twin Spinner or Conveyor) 14

Floor Circuit 14...............................

HYDRAULIC FLOW DIAGRAMS: ELECTRONIC

HYDRAULIC CONTROLS 16...................

Rear Option Circuits (Twin Spinner or Conveyor) 16

Floor Circuit 18...............................

SPECIAL TOOLS 20............................

TROUBLESHOOTING 22........................

TESTING 24...................................

SERVICE AND REPAIRS 26.....................

General Precautions for Removing and

Installing Hydraulic System Components 26....

Check Hydraulic Lines and Hoses 27............

Hydraulic Control (Machines with Standard

Hydraulic Controls) 28.......................

Control Valve Service (Machines with Standard

Hydraulic Controls) 30.......................

Solenoid Valve Assembly (Machines with Standard

Hydraulic Controls) 31.......................

Hydraulic Control (Machines with Electronic

Hydraulic Controls) 32.......................

Hydraulic Control Manifold (Machines with

Electronic Hydraulic Controls) 34..............

Floor Motor 38................................

Floor Motor Service 40........................

Twin Spinner Motors 42........................

Conveyor Motor 44............................

Rear Option Motor Service 46..................

EATON (CHAR--LYNN) S--SERIES GENERAL

PURPOSE MOTORS PARTS and REPAIR MANUAL

EATON (CHAR--LYNN) R--SERIES GENERAL

PURPOSE GEROLER MOTOR REPAIR

INFORMATION

System

Hydraulic

ProPass 200 Page 3 -- 1 Hydraulic System

Specifications

Item Description

Tow Vehicle Hydraulic Supply

Minimum Supply 6 US Gal/Min (23 L/Min) @ 2000 PSI (138 Bar)

Maximum Supply 10 US Gal/Min (38 L/Min) @ 2800 PSI (190 Bar)

Floor Motor Eaton fixed displacement geroler motor

Displacement (per revolution) 22.7 in

Twin Spinner Motors (Rear Option) Eaton fixed displacement geroler motor

Displacement (per revolution) 1.8 in

Conveyor Motor (Rear Option) Eaton fixed displacement geroler motor

Displacement (per revolution) 1.8 in

3

(371 cc)

3

3

NOTE: If tow vehicle provides hydraulic supply,use tow

vehicle hydraulic specifications for information regarding hydraulic flow and relief pressure to the ProPass. If

hydraulic power pack provides hydraulic supply, see

Chapter 6 -- Hydraulic Power Pack Assembly for information regarding hydraulic circuit flow and relief pressure

specifications.

(29 cc)

(29 cc)

ProPass 200Page 3 -- 2Hydraulic System

General Information

Operator’s Manual

The Operator ’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your ProPass machine. Refer to that publication for additional information when servicing the machine.

ProPass Hydraulic Supply

Hydraulic supply for the ProPass machine is either

provided by the tow vehicle or a hydraulic power pack.

If tow vehicle provides hydraulic supply, use tow vehicle

hydraulic specifications for information regarding hydraulic flow and relief pressure to the ProPass. If hydraulic power pack provides hydraulic supply, see

Chapter 6 -- Hydraulic Power Pack Assembly for information regarding hydraulic circuit flow and relief pressure

specifications.

NOTE: See Specifications in this chapter for tow

vehicle hydraulic supply recommendations.

System

Hydraulic

Hydraulic Hose Kit (Tow Vehicle to ProPass)

The hydraulic hose kit used when a ProPass receives its

hydraulic supply from a tow vehicle includes a check

valve in the return hose assembly (item 6 in Figure 1).

If the check valve is removed from the return hose, make

sure that the arrow on the check valve is directed toward

the tow vehicle. Also, when connecting the hydraulic

hoses to the tow vehicle, use the check valve to identify

the return hose for correct installation.

4

3

4

7

6

5

Figure 1

1. Hydraulic hose (supply)

2. Hydraulic hose (return)

3. Dust cap

4. Male coupler

3

5. O--ring

6. Check valve

7. O--ring

1

2

TOW VEHICLE

ProPass 200 Page 3 -- 3 Hydraulic System

Machine Hydraulic Control

ProPass 200 machines use either standard hydraulic

controls or electronic hydraulic controls to allow the operator to change machine settings.

Standard Hydraulic Controls

2

Machines with standard hydraulic controls include

manual hydraulic controls on the front of the ProPass

hopper to adjust hydraulic flow to the floor and rear option (twin spinner or conveyor) motors (Fig. 2). A

pendant electrical control allows the operator to energize the floor and rear option motors from the operator

position of the tow vehicle.

Electronic Hydraulic Controls

Machines with electronic hydraulic controls include a

wireless remote to electrically adjust hydraulic flow to

the floor and rear option (twin spinner or conveyor) motors (Fig. 3). The remote allows initial adjustment of the

floor and rear option motors as well as making adjustments possible while the machine is operating. An

E--Stopbuttononthemachinedisablestheelectrical

system to prevent unexpected machine operation.

If there should be a problem with the wireless remote,

ProPass machines with electronic controls have manual

override adjustments on the driver side of the hydraulic

system that will allow continued operation (Fig. 4). A

control knob is used to adjust floor speed and a flat blade

screwdriver can be used to adjust the rear option speed.

1

1. Floor control

2. Rear option control

2

3

Figure 2

3. Pendant harness

1

3

4

Figure 3

1. Wireless remote

2. E--Stop button

3. Power lead harness

4. Optional power pack

1

2

Figure 4

1. Control knob 2. Screwdriver slot

ProPass 200Page 3 -- 4Hydraulic System

Rear Option

The ProPass includes the twin spinner that is used for

topdressing (Fig. 5). The twin spinner uses two (2) hydraulic motors for operation. The cross conveyor and

swivel is available as an option for delivery of material

from the ProPass hopper (Fig. 6). The conveyor uses

one (1) hydraulic motor for operation.

The ProPass hydraulic system is used to operate either

of these rear options.

Figure 5

System

Hydraulic

Figure 6

Relieving Hydraulic System Pressure

Make sure that the ProPass has electrical power and

CAUTION

Before disconnecting any hydraulic components, operate all hydraulic controls to relieve

system pressure and avoid injury from pressurized hydraulic oil.

Before disconnecting or performing any work on the

ProPass hydraulic system, all pressure in the hydraulic

system must be relieved. Position machine on a level

surface. Turn tow vehicle key switch to OFF and allow

engine to stop. If ProPass is equipped with hydraulic

power pack, make sure that power pack engine is turned

off.

ProPass 200 Page 3 -- 5 Hydraulic System

that controls are operational. With the tow vehicle engine not running, use the pendant control or wireless

controller to energize the hydraulic solenoids for the

floor and rear option (twin spinner or conveyor) motors.

After both hydraulic functions have been energized, turn

tow vehicle key switch OFF and remove key from ignition switch.

Hydraulic Hoses

Hydraulic hoses are subject to extreme conditions such

as pressure differentials during operation and exposure

to weather, sun, chemicals, very warm storage conditions or mishandling during operation and maintenance.

These conditions can cause hose damage and deterioration. Some hoses are more susceptible to these

conditions than others. Inspect all machine hydraulic

hoses frequently for signs of deterioration or damage:

WARNING

Before disconnecting or performing any work on

hydraulic system, relieve all pressure in system

(see Relieving Hydraulic System Pressure in this

section).

Hard, cracked, cut, abraded, charred, leaking or

otherwise damaged hose.

Kinked, crushed, flattened or twisted hose.

Blistered, soft, degraded or loose hose cover.

Cracked, damaged or badly corroded hose fittings.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint (layline) on

the hose. Use two (2) wrenches; hold the hose straight

with one wrench and tighten the hose swivel nut onto the

fitting with the second wrench (see Hydraulic Hose and

Tube Installation in this section). If the hose has an elbow at one end, tighten the swivel nut on that end before

tightening the nut on the straight end of the hose.

For additional hydraulic hose information, refer to Toro

Service Training Book, Hydraulic Hose Servicing (Part

Number 94813SL).

Keep body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to

search for leaks. Hydraulic fluid escaping under

pressure can have sufficient force to penetrate

the skin and cause serious injury. If fluid is injected into the skin, it must be surgically removed within a few hours by a doctor familiar

with this type of injury. Gangrene may result from

such an injury.

Hydraulic Hose and Tube Installation (O--Ring Face Seal Fittings)

NOTE: ProPass machines with serial numbers above

310001000 use O--ring face seal fittings (Fig. 7). Use the

following information when installing hydraulic hoses

and tubes to O--ring face seal fittings.

1. Make sure threads and sealing surfaces of the hose/

tube and the fitting are free of burrs, nicks, scratches or

any foreign material.

2. As a preventative measure against leakage, it is recommended that the face seal O--ring be replaced any

time the connection is opened. Make sure the O--ring is

installed and properly seated in the fitting groove. Lightly

lubricate the O--ring with clean hydraulic oil.

3. Place the hose/tube against the fitting body so that

theflatfaceofthehose/tubesleevefullycontactstheO-ring in the fitting.

1

1. Hydraulic hose/tube

2. Swivel nut

2

Figure 7

3

3. O--ring

4. Fitting body

ProPass 200Page 3 -- 6Hydraulic System

4

4. Thread the hose/tube swivel nut onto the fitting by

hand. While holding the hose/tube with a wrench, use a

torque wrench to tighten the swivel nut to the recommended installation torque shown in Figure 9. This tightening process will require the use of an offset wrench

(e.g. crowfoot wrench). Use of an offset wrench will affect torque wrench calibration due to the effective length

change of the torque wrench. Tightening torque when

using a torque wrench with an offset wrench will be lower

than the listed installation torque (see Using a Torque

Wrench with an Offset Wrench in the Torque Specifications section of Chapter 2 -- Product Records and Maintenance).

C. Useasecondwrenchtotightenthenuttothecorrect Flats From Wrench Resistance (F.F.W.R.). The

markings on the nut and fitting body will verify that the

connection has been properly tightened.

Size F.F.W.R.

4 (1/4 in. nominal hose or tubing) 1/2 to 3/4

6 (3/8 in.) 1/2 to 3/4

8 (1/2 in.) 1/2 to 3/4

10 (5/8 in.) 1/2 to 3/4

12 (3/4 in.) 1/3 to 1/2

16 (1 in.) 1/3 to 1/2

5. If a torque wrench is not available or if space at the

swivel nut prevents use of a torque wrench, an alternate

Mark Nut

and Fitting

Body

Final

Position

method of assembly is the Flats From Wrench Resistance (F.F.W.R.) method (Fig. 8).

A. Using a wrench, tighten the swivel nut onto the fitting until light wrench resistance is reached (approximately 30 in--lb).

B. Mark the swivel nut and fitting body. Hold the

AT WRENCH RESISTANCE

Extend Line

Figure 8

hose/tube with a wrench to prevent it from turning.

Fitting Dash Size Hose/Tube Side Thread Size Installation Torque

4 9/16 -- 18 18to22ft--lb(25to29N--m)

6 11/16 - - 16 27to33ft--lb(37to44N--m)

8 13/16 -- 16 37to47ft--lb(51to63N--m)

10 1--14 60 to 74 ft--lb (82 to 100 N--m)

12 13/16--12 85to105ft--lb(116to142N--m)

16 17/16--12 110to136ft--lb(150to184N--m)

Initial

Position

AFTER TIGHTENING

System

Hydraulic

20 1 11/16 -- 12 140 to 172 ft--lb (190 to 233 N--m)

Figure 9

ProPass 200 Page 3 -- 7 Hydraulic System

Hydraulic Hose and Tube Installation (JIC Flared Fittings)

NOTE: ProPass machines with serial numbers below

310001000 use JIC flared fittings (Fig. 10). Use the following information when installing hydraulic hoses and

tubes to JIC flared fittings.

1. Make sure threads and sealing surfaces of the hose/

tube and the fitting are free of burrs, nicks, scratches or

any foreign material.

2. Thread hose/tube swivel nut onto fitting by hand.

While holding the hose/tube with a wrench, use a torque

wrench to tighten swivel nut to the recommended installation torque shown in Figure 12. If fitting is non--ferrous

material (e.g. brass), use 50% of listed torque values.

This tightening process will require the use of an offset

wrench (e.g. crowfoot wrench) that will affect torque

wrench calibration due to the effective length change of

the torque wrench. Tightening torque when using a

torque wrench with an offset wrench will be lower than

the listed installation torque (see Using a Torque

Wrench with an Offset Wrench in the Torque Specifications section of Chapter 2 -- Product Records and Maintenance).

3. If a torque wrench is not available or if space at the

swivel nut prevents use of a torque wrench, an alternate

method of assembly is the Flats From Wrench Resistance (F.F.W.R.) method (Fig. 11).

Si z e F.F. W. R .

4 (1/4 in. nominal hose or tubing) 1/2 to 3/4

6 (3/8 in.) 1/2 to 3/4

8 (1/2 in.) 1/2 to 3/4

10 (5/8 in.) 1/2 to 3/4

12 (3/4 in.) 1/3 to 1/2

16 (1 in.) 1/3 to 1/2

JIC FLARED FITTING

(ADJUSTABLE TYPE SHOWN)

Figure 10

Mark Nut

and Fitting

Body

Final

Position

A. Using a wrench, tighten the swivel nut onto the fitting until light wrench resistance is reached (approxi-

Extend Line

mately 30 in--lb).

AT WRENCH RESISTANCE

AFTER TIGHTENING

B. Mark the swivel nut and fitting body. Hold the

hose/tube with a wrench to prevent it from turning.

Figure 11

C. Use a second wrench to tighten the nut to the correct Flats From Wrench Resistance (F.F.W.R.). The

markings on the nut and fitting body will verify that the

connection has been properly tightened.

Fitting Dash Size Hose/Tube Side Thread Size Installation Torque

4 7/16 -- 20 10to14ft--lb(14to18N--m)

6 9/16 -- 18 15to21ft--lb(21to28N--m)

8 3/4 -- 16 33to41ft--lb(45to55N--m)

10 7/8 -- 14 43to53ft--lb(59to71N--m)

12 11/16--12 66to82ft--lb(90to111N--m)

14 13/16--12 80 to 98 ft--lb (109 to 132 N--m)

Initial

Position

16 15/16--12 90to110ft--lb(122to149N--m)

Figure 12

ProPass 200Page 3 -- 8Hydraulic System

Hydraulic O--Ring Face Seal (ORFS) Fitting Installation (SAE Straight Thread O--Ring

Fitting into Component Port)

NOTE: ProPass machines with serial numbers above

310001000 use O--ring face seal fittings. Use the following information when installing O--ring face seal fittings.

Non--Adjustable Fitting (Fig. 13)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. As a preventative measure against leakage, it is recommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O --ring with clean hydraulic oil.

Fitting threads should be clean with no lubricant applied.

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

4. Install the fitting into the port. Then, use a torque

wrench and socket to tighten the fitting to the recommended installation torque shown in Figure 14.

NOTE: Use of an offset wrench (e.g. crowfoot wrench)

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be less than the recommended installation torque. See

UsingaTorqueWrenchwithanOffsetWrenchinthe

Torque Specifications section of Chapter 2 -- Product

Records and Maintenance to determine necessary conversion information.

5. If a torque wrench is not available, or if space at the

port prevents use of a torque wrench, an alternate method of assembly is the Flats From Finger Tight (F.F.F.T.)

method.

A. Install the fitting into the port and tighten it down

full length until finger tight.

B. If port material is steel, tighten the fitting to the

listed F.F.F.T. If port material is aluminum, tighten fitting to 60% of listed F.F.F.T.

Si z e F.F.F. T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

Fitting

O--ring

0.25

0.25

0.25

0.25

0.25

0.25

Figure 13

System

Hydraulic

Fitting

Dash Size

Fitting Port Side

Thread Size

Installation Torque Into

Steel Port

Installation Torque Into

Aluminum Port

4 7/16 -- 20 15to19ft--lb(21to25N--m) 9to11ft--lb(13to15N--m)

6 9/16 -- 18 34to42ft--lb(47to56N--m) 20to26ft--lb(28to35N--m)

8 3/4 -- 16 58to72ft--lb(79to97N--m) 35to43ft--lb(48to58N--m)

10 7/8 -- 14 99 to 121 ft--lb (135 to 164 N--m) 60 to 74 ft--lb (82 to 100 N--m)

12 11/16--12 134 to 164 ft--lb (182 to 222 N--m) 81 to 99 ft--lb (110 to 134 N--m)

14 13/16--12 160 to 196 ft--lb (217 to 265 N--m) 96to118ft--lb(131to160N--m)

16 15/16--12 202 to 248 ft--lb (274 to 336 N--m) 121 to 149 ft--lb (165 to 202 N--m)

20 15/8--12 247 to 303 ft--lb (335 to 410 N--m) 149 to 183 ft--lb (202 to 248 N--m)

Figure 14

ProPass 200 Page 3 -- 9 Hydraulic System

Adjustable Fitting (Fig. 15)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. As a preventative measure against leakage, it is recommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O--ring with clean hydraulic oil.

Fitting threads should be clean with no lubricant applied.

4. Turn back the lock nut as far as possible. Make sure

the back up washer is not loose and is pushed up as far

aspossible(Step1inFigure16).

1

2

3

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

5. Install the fitting into the port and tighten finger tight

until the washer contacts the face of the port (Step 2 in

Figure 16).

6. To put the fitting in the desired position, unscrew it by

the required amount, but no more than one full turn

(Step3inFigure16).

7. Hold the fitting in the desired position with a wrench

and use a torque wrench to tighten the fitting to the recommended installation torque shown in Figure 14. This

tightening process will require the use of an offset

wrench (e.g. crowfoot wrench). Use of an offset wrench

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be lower than the listed installation torque (see Using a

Torque Wrench with an Offset Wrench in the Torque

Specifications section of Chapter 2 -- Product Records

and Maintenance).

1. Lock nut

2. Back--up washer

Step 2 Step 4

Figure 15

3. O--ring

Step 3Step 1

Figure 16

8. If a torque wrench is not available, or if space at the

port prevents use of a torque wrench, an alternate method of assembly is the Flats From Finger Tight (F.F.F.T.)

method. Hold the fitting in the desired position with a

wrench and, if port material is steel, tighten the lock nut

with a second wrench to the listed F.F.F.T (Step 4 in Figure 16). If port material is aluminum, tighten fitting to

60% of listed F.F.F.T.

Si z e F. F. F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25

0.25

ProPass 200Page 3 -- 10Hydraulic System

Hydraulic JIC Flared Fitting Installation (JIC Flared Fitting into Component Port)

NOTE: ProPass machines with serial numbers below

310001000 use JIC flared fittings (Fig. 10). Use the following information when installing JIC flared fittings.

When installing a JIC flared fitting into a component port,

follow the same procedures as listed in Hydraulic

O--Ring Face Seal (ORFS) Fitting Installation (SAE

Straight Thread O--Ring Fitting into Component Port)

found earlier in this section. The only difference needed

for installation of JIC flared fittings is the tightening

torque.

Use the following torque values when installing JIC

flared fittings into a steel or aluminum component port.

IMPORTANT: If fitting is non--ferrous material (e.g.

brass fitting), use installation torque for aluminum

port.

JIC FLARED FITTING

(ADJUSTABLE TYPE SHOWN)

Figure 17

Fitting

Dash Size

4 7/16 -- 20 13to17ft--lb(18to23N--m) 7to9ft--lb(10to12N--m)

6 9/16 -- 18 23to29ft--lb(32to39N--m) 11to15ft--lb(15to20N--m)

8 3/4 -- 16 46to58ft--lb(63to78N--m) 23to29ft--lb(32to39N--m)

10 7/8 -- 14 69to85ft--lb(94to115N--m) 35to43ft--lb(48to58N--m)

12 11/16--12 105 to 129 ft--lb (143 to 174 N--m) 53to65ft--lb(72to88N--m)

14 13/16--12 139 to 171 ft--lb (189 to 231 N--m) 70to86ft--lb(95to116N--m)

16 15/16--12 153 to 187 ft--lb (208 to 253 N--m) 76 to 94 ft--lb (103 to 127 N--m)

20 15/8--12 213 to 261 ft--lb (289 to 353 N--m) 107 to 131 ft--lb (145 to 177 N--m)

Fitting Port Side

Thread Size

Installation Torque Into

Steel Port

Figure 18

Installation Torque Into

Aluminum Port

System

Hydraulic

ProPass 200 Page 3 -- 11 Hydraulic System

Hydraulic Schematics

IN

HYDRAULIC

POWER PACK

FLOOR

SOLENOID

VALVE

FLOOR

CONTROL

VALVE

FLOOR

EX CF

MOTOR

IN

OPTION

SOLENOID

VALVE

OPTION

EXCF

CONTROL

VALVE

SPINNER

MOTORS

CONVEYOR

MOTOR

ProPass 200

Hydraulic Schematic

Standard Hydraulic Controls

NOTE: The hydraulic schematic shown above includes

the hydraulic power pack as the hydraulic supply

source. If your ProPass uses hydraulic supply from the

tow vehicle, the vehicle includes the hydraulic pump, relief valve and hydraulic reservoir that are used for the

ProPass.

NOTE: The rear option is either the twin spinner (two

motors) or the cross conveyor (one motor).

All solenoids are shown as

de--energized

NOTE: The hydraulic hose kit used when a ProPass re-

ceives its hydraulic supply from a tow vehicle includes

a check valve in the return hose assembly (see Hydraulic Hose Kit in the General Information section of this

chapter).

ProPass 200Page 3 -- 12Hydraulic System

Loading...

Loading...