Toro ProPass 200, 44701, 44751 Operator's Manual

FormNo.3418-725RevA

ProPass200TopDresserwith

TwinSpinner

ModelNo.44701—SerialNo.401380001andUp

ModelNo.44751—SerialNo.401380001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3418-725*A

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orreproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives,fordetailspleaseseetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

ElectromagneticCompatibility

Domestic:ThisdevicecomplieswithFCCRulesPart15.

Operationissubjecttothefollowingtwoconditions:(1)This

devicemaynotcauseharmfulinterferenceand(2)thisdevice

mustacceptanyinterferencethatmaybereceived,including

interferencethatmaycauseundesirableoperation.

Thisequipmentgeneratesandusesradiofrequencyenergyand

ifnotinstalledandusedproperly,instrictaccordancewiththe

manufacturer'sinstructions,maycauseinterferencetoradio

andtelevisionreception.Ithasbeentypetestedandfoundto

complywithinthelimitsofaFCCClassBcomputingdevicein

accordancewiththespecicationsinSubpartJofPart15of

FCCRules,asstatedabove.However,thereisnoguarantee

thatinterferencewillnotoccurinaparticularinstallation.If

thisequipmentdoescauseinterferencetoradioortelevision

reception,whichcanbedeterminedbyturningtheequipmentoff

andon,theuserisencouragedtotrytocorrecttheinterference

byoneormoreofthefollowingmeasures:Reorientthereceiving

antenna,relocatetheremotecontrolreceiverwithrespecttothe

radio/TVantennaorplugthecontrollerintoadifferentoutletso

thatthecontrollerandradio/TVareondifferentbranchcircuits.If

necessary,theusershouldconsultthedealeroranexperienced

radio/televisiontechnicianforadditionalsuggestions.The

usermayndthefollowingbookletpreparedbytheFederal

CommunicationsCommissionhelpful:"HowtoIdentifyand

ResolveRadio-TVInterferenceProblems".Thisbookletis

availablefromtheU.S.GovernmentPrintingOfce,Washington,

DC20402.StockNo.004-000-00345-4.

FCCID:W7OMRF24J40MDME-Base,

OA3MRF24J40MA-HandHeld

IC:7693A-24J40MDME-Base,7693A-24J40MA-HandHeld

Operationissubjecttothefollowingtwoconditions:(1)this

devicemaynotcauseinterference,and(2)thisdevicemust

acceptanyinterference,includinginterferencethatmaycause

undesiredoperationofthedevice.

JapanElectromagneticCompatibilityCertication

Handheld:

RF2CAN:

MexicoElectromagneticCompatibilityCertication

Handheld:

KoreaElectromagneticCompatibilityCertication(Decal

providedinseparatekit)

Handheld:

RF2CAN:

SingaporeElectromagneticCompatibilityCertication

Handheld:TWM240008_IDA_N4023-15

RF2CAN:

MoroccoElectromagneticCompatibilityCertication

AGREEPARL’ANRTMAROC

NUMEROd’agrement:

Delivred'agrement::

TWM-240005_IDA_N4024-15

MR14078ANRT2017

29/05/2017

Introduction

Thismachineisintendedtobeusedbyprofessional,

hiredoperatorsincommercialapplications.Itis

designedprimarilyformeteringanddispersing

materials,underarangeofmoistureconditions,

withoutcloggingordrasticallyaffectingthedispersion.

Important:Tomaximizethesafety ,performance,

andproperoperationofthismachine,carefully

readandfullyunderstandthecontentsofthis

Operator’sManual.Failingtofollowthese

operatinginstructionsortoreceiveproper

trainingmayresultininjury.Formoreinformation

onsafeoperatingpractices,includingsafetytips

andtrainingmaterials,gotowww.Toro.com.

RF2CAN:

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

ontheproduct.Writethenumbersinthespace

provided.

Contents

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberdecaltoaccesswarranty,parts,andother

productinformation.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................8

1SettingUptheMachineBaseModel

........................................................................9

2InstallingthePowerHarness..........................10

3InstallingtheHopperExtensionKit..................11

4MountingtheHoppertotheT ow

Chassis.........................................................12

5ConnectingtheIntermediateWire

Harness........................................................12

6ConnectingtheOn/OffPendant.....................13

7AssemblingtheHandheldRemote.................13

8MountingtheWirelessRemote......................14

ProductOverview...................................................15

Controls...........................................................15

Specications..................................................17

g237535

Attachments/Accessories.................................17

Operation................................................................18

BeforeOperationSafety...................................18

OperatingCharacteristics.................................18

ConnectingtheMachinetoaTow

Vehicle..........................................................18

TurningtheMachinePowerOn/Off...................19

PreparingtheMachineforOperation................20

DuringOperationSafety...................................23

SlopeSafety.....................................................24

OperatingtheMachine.....................................24

WirelessControllerSafety(Model44751

only)..............................................................25

DisconnectingtheMachinefromaT ow

Vehicle..........................................................25

OperatingtheHydraulicControlsand

Options.........................................................25

OperatingtheFloorandOption.........................31

SettingthePreset1,2,and3Buttons................33

UsingaPresetMode........................................34

g000502

ChoosingaT owVehicle....................................34

LoadingtheHopper..........................................34

UnloadingtheHopper.......................................34

Traveling...........................................................35

AfterOperationSafety......................................35

ParkingtheMachine.........................................35

UsingtheStorageStand...................................36

Maintenance...........................................................38

Pre-MaintenanceSafety...................................38

Lubrication........................................................38

DailyChecks....................................................39

HydraulicSystem.............................................39

MaintainingtheConveyorBeltSystem..............40

WashingtheMachine.......................................41

Storage...................................................................42

Troubleshooting......................................................43

CheckingFaultCodes(EHModels

Only).............................................................43

3

HandheldRemoteMessages(EHModels

Only).............................................................44

Safety

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofboththis

Operator’sManualandtheoperator’smanualof

thetowvehiclebeforeusingthismachine.Ensure

thateveryoneusingthisproductknowshowtouse

thismachineandthetowvehicleandunderstands

thewarnings.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepthemachineasafedistanceawayfrom

bystanderswhileitismoving.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachine,shutofftheengine,engagethe

parkingbrake,removethekey,andwaitforall

movingpartstostopbeforeservicing,fueling,or

uncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

4

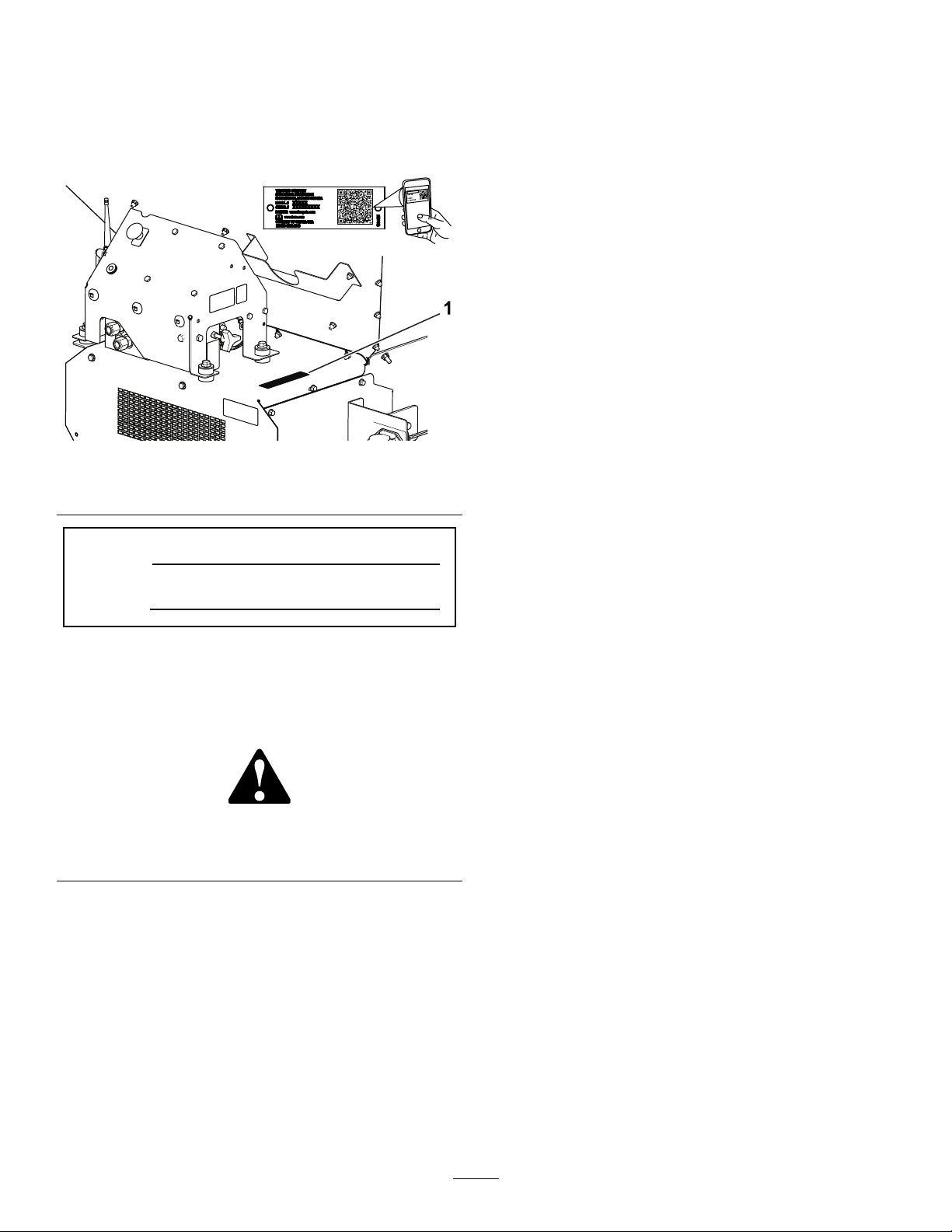

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

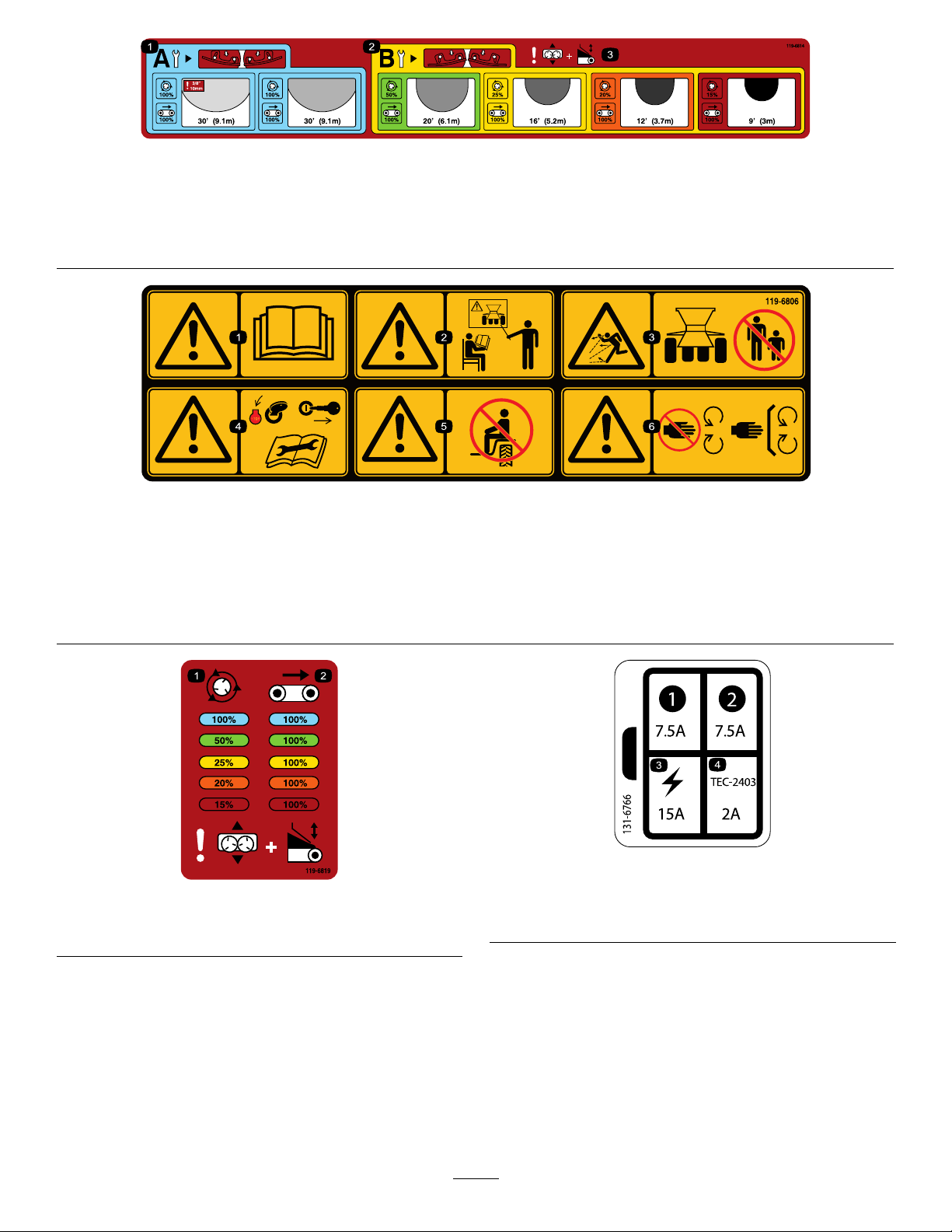

119-6809

1.ReadtheOperator'sManualforinstructionsoncleaning

themachine.

decal119-6809

119-6854

decal119-6854

1.Floorspeed

decal119-6853

119-6853

1.Spinnerspeed

decal115-2047

115-2047

1.Warning—donottouchthehotsurface.

1.Tailgateheightindicator

1.Tailgateadjustment

decal119-6808

119-6808

decal119-0217

119-0217

1.Warning—shutofftheengine;stayawayfrommovingparts;

keepallguardsandshieldsinplace.

decal119-6818

119-6818

5

1.Spinnerspeedadjustment

1.Spinnerspeed

1.Floorspeed

decal119-6810

119-6810

1.ReadtheOperator'sManual.

2.2peoplerequiredtolift.

decal119-6820

119-6820

decal119-6855

119-6855

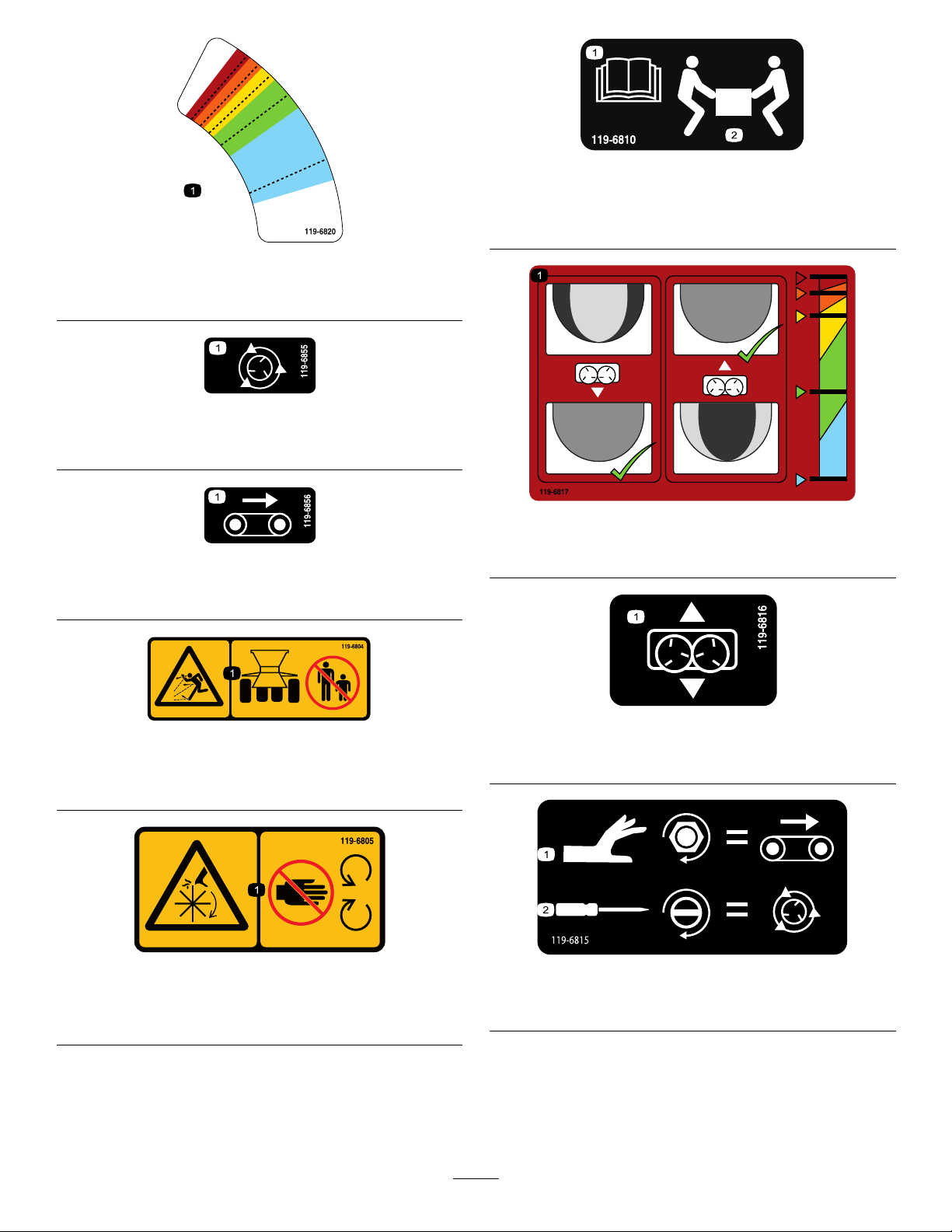

decal119-6817

119-6817

decal119-6856

1.Finetuningspinners

119-6856

119-6804

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

119-6805

1.Cutting/dismembermenthazard,impeller—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

decal119-6804

119-6816

decal119-6816

1.Slideadjustment

decal119-6805

decal119-6815

119-6815

1.Floorspeedadjustment

2.Spinnerspeedadjustment

6

decal119-6814

119-6814

1.Lightspreadspinneradjustmentsettings(refertothe

3.Warning—slideadjustmentandtailgateadjustment.

Operationsectionformoreinformation).

2.Heavyspreadspinneradjustmentsettings(refertothe

Operationsectionformoreinformation).

119-6806

1.Warning—readtheOperator'sManual.4.Warning—shutofftheengine,removetheignitionkey,and

2.Warning—donotoperatethemachineunlessyouaretrained.5.Warning—noridersonthemachine

3.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine.

readtheOperator'sManualbeforeperformingmaintenance

onthemachine.

6.Warning—stayawayfrommovingparts;keepallguardsand

shieldsinplace.

decal119-6806

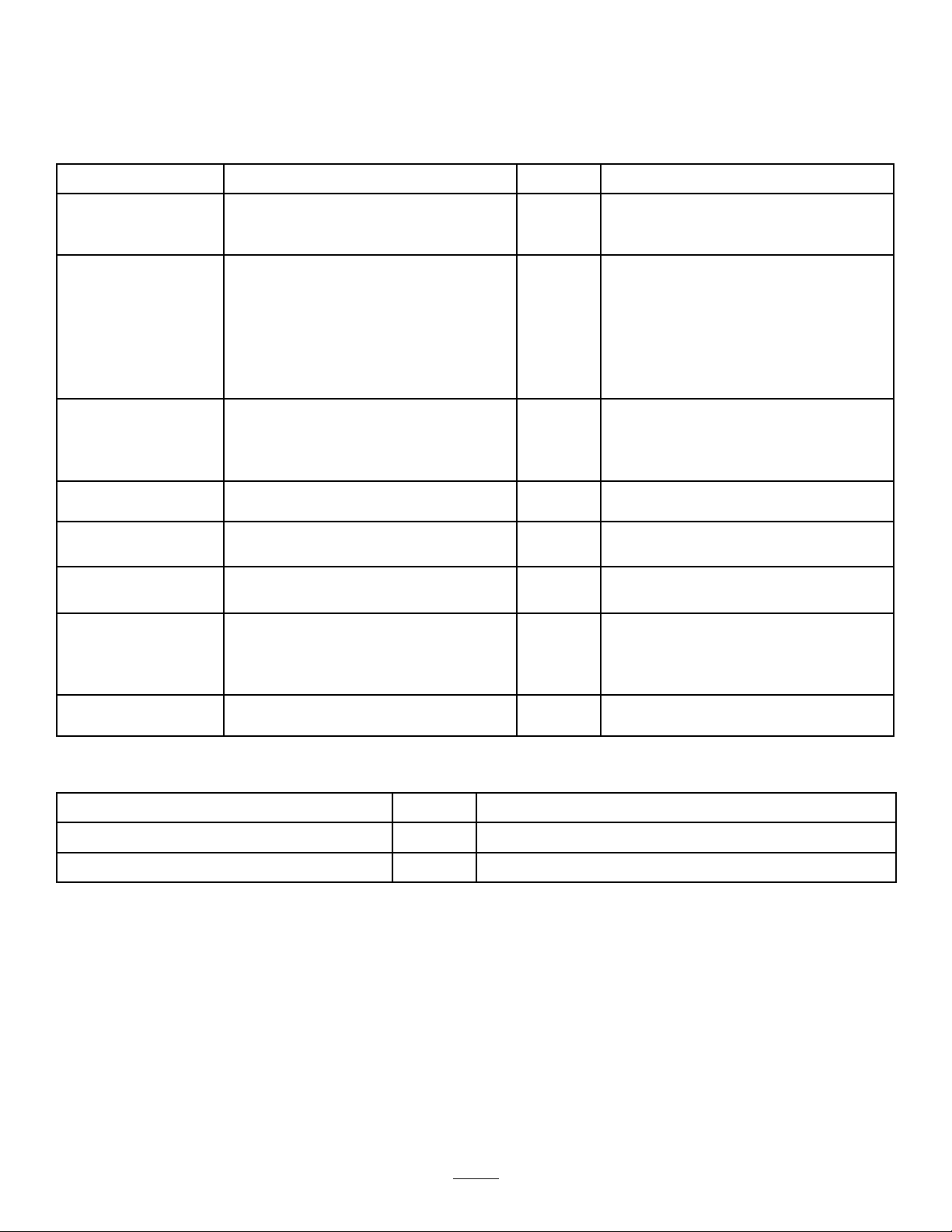

1.Spinnerspeedpercentage

decal131-6766

131-6766

decal119-6819

119-6819

2.Beltspeedpercentage

1.7.5A3.Electricalaccessory—15A

2.7.5A

4.TEC-2403—2A

7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Hopperguard1

Buttonheadbolt(1/4x5/8inch)

Locknut3

Powerharness1

Socketbracket

Socketbracket,heavy

Carriagescrew

Flangenut2

Screw

Flangenut2

Hopperextension(front)

Hopperextension(rear)

Bolt9

Flangenut9

Bolt6

Flangenut6

Intermediatewireharness1

On/offpendant

Handheldremote1

AAbatteries4

Magneticbracket1

Screws,small

Controllermountassembly

Wirelessremoteassembly1

Qty.

Use

3

1

1

2

2

1

1

1

6

1

Setupthemachinebasemodel.

Installthepowerharness.

Installthehopperextensionkit.

Mountthehoppertothetowchassis.

Connecttheintermediatewireharness.

Connecttheon/offpendant(Model

44701only).

Assemblethehandheldremote(Model

44751only).

Mountthewirelessremote(Model

44751only).

MediaandAdditionalParts

Description

Operator’sManual

DeclarationofConformity

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Qty.

1

1Ensureregulatorycompliance.

Readbeforeoperatingthemachine.

8

Use

1

SettingUptheMachine BaseModel

Partsneededforthisprocedure:

1Hopperguard

3

Buttonheadbolt(1/4x5/8inch)

3Locknut

Procedure

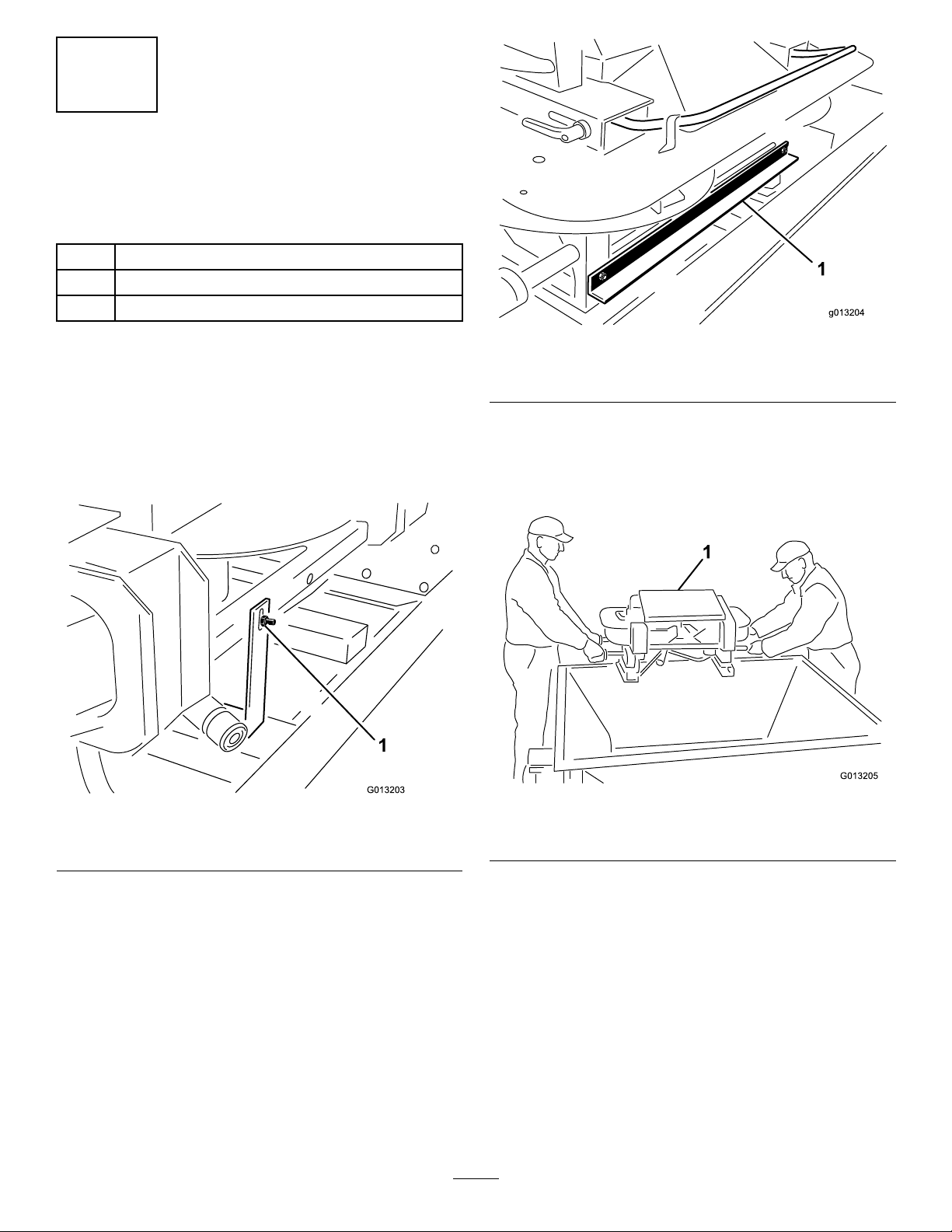

1.Removethebasemodelmachinefromthe

shippingcrate.

2.Attherearofthetwinspinner,removethebolt

andnutattachingthemachineliftingdevice

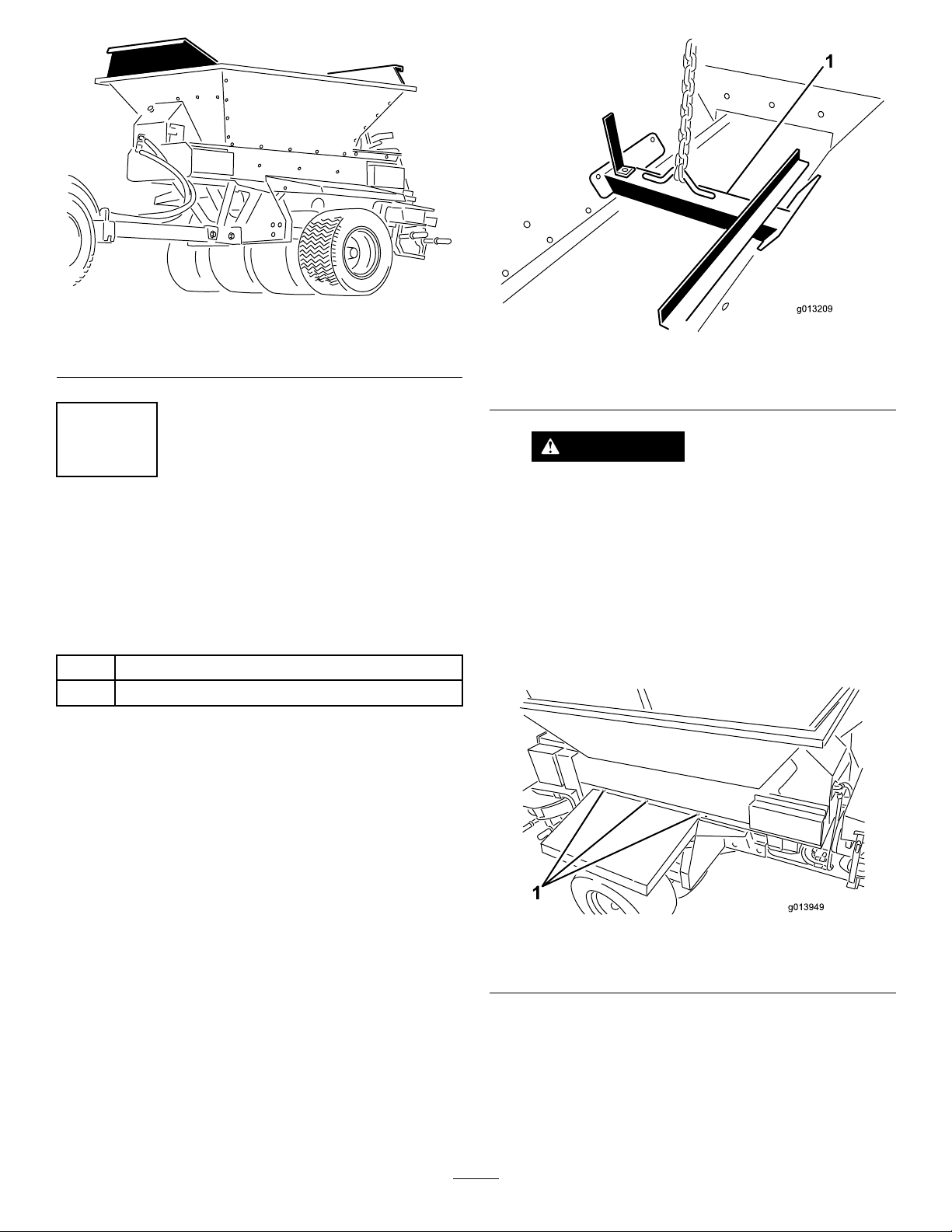

shippingbrackettothetwinspinner(Figure3).

g013204

Figure4

1.Shippingbracket

4.Liftthetwinspinneroutofthehopperusingthe

twinspinneroutergrabhandlesandplacethe

twinspinnerunitontheground(Figure5).

Note:Thissteprequires2people.

Figure3

1.Shippingbracket

3.Atthefrontofthetwinspinner,removethe2

boltsandnutsattachingthemachinelifting

deviceshippingbrackettotheTwinSpinner

(Figure4).

g013203

1.Twinspinner

5.Removethe4screwsfromthelegsofthetwin

spinner.Withthehelpofapartner,liftthetwin

spinnerandremovethepackingstudsand

packingfoam(Figure6).

9

Figure5

g013205

Figure6

1.Packingstudsandfoam

6.Installthehopperguardusingthesupplied

button-headbolts(1/4x5/8inch)andnylon

locknuts(Figure7).

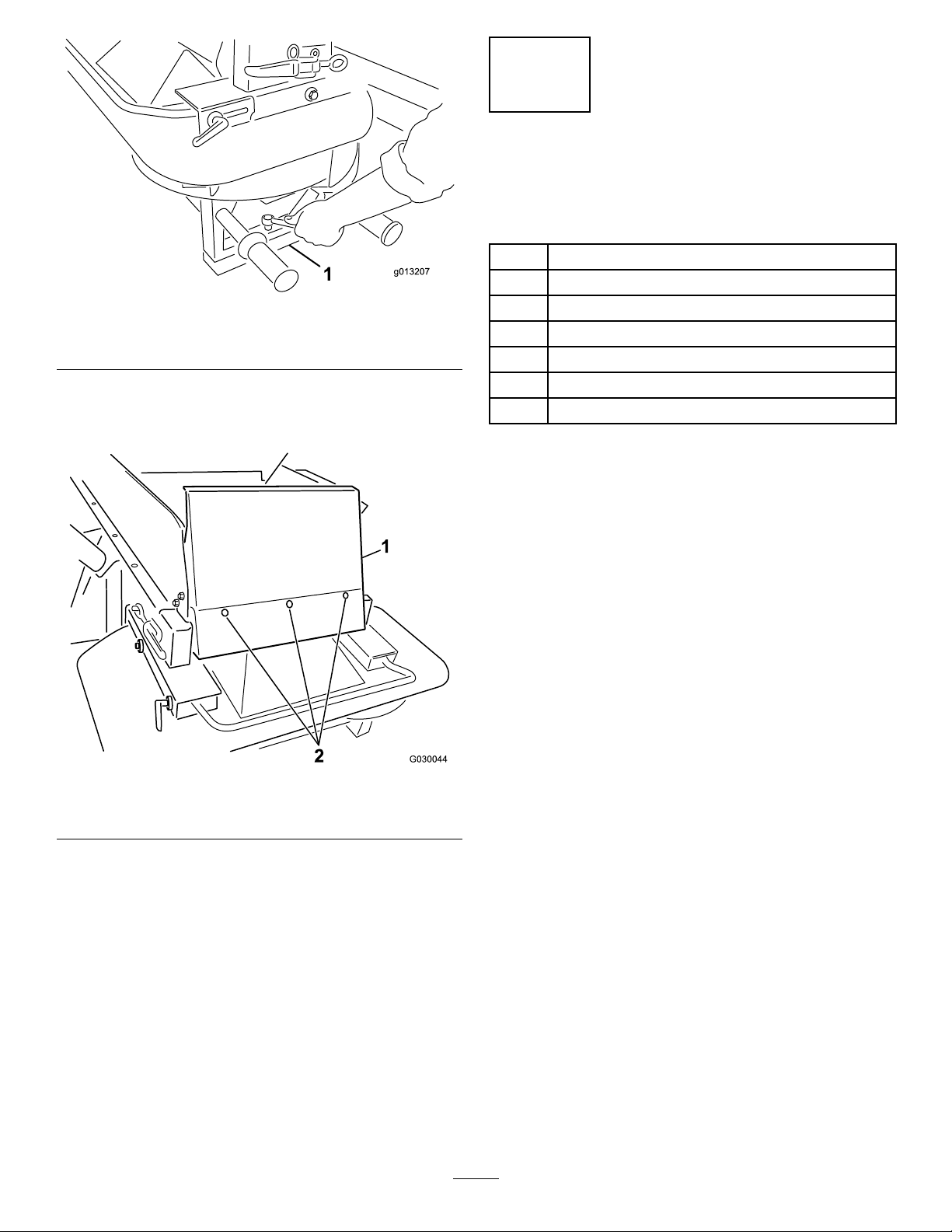

2

InstallingthePower Harness

Partsneededforthisprocedure:

1Powerharness

1

g013207

Procedure

Thetowvehiclepowerharnessprovidestheelectrical

powerrequiredbythecontrolsystemsofthemachine.

Installthisharnessonthevehicleyouplantouse

tooperatethemachine.Ifyouwillusemorethan1

vehiclewiththemachine,purchaseadditionalpower

harnessesfromyourTorodistributor.

Socketbracket

1

Socketbracket,heavy

2

Carriagescrew

2Flangenut

2

Screw

2Flangenut

1.Hopperfrontguard

Figure7

1.Mountthesocketbrackettoaxedpointatthe

rearofthetowvehicleusing1ofthemounting

bracketsprovided(Figure8).

Note:Ensurethatthebracketwillnotcome

incontactwithanythingifthetowvehicleis

equippedwithadumpbox.

g030044

2.Bolts

Important:Ensurethatnoneofthewiring

islooseorinthewayofanymechanical

components.

10

Figure8

3

InstallingtheHopper ExtensionKit

Partsneededforthisprocedure:

1

Hopperextension(front)

1

Hopperextension(rear)

9Bolt

g013261

9Flangenut

1.Socketbracket

2.Routeandsecuretheelectricalwiringfromthe

batterytotheelectricalplugbracket(Figure9).

Figure9

1.Whitewire(brass)3.Nowire(brass)

2.Nowiresilver(silver)4.Blackwire(brass)

3.Feedthewiringthroughthesocketbracketand

installtheblackrubbergrommetoverthewiring

(Figure9).

4.Boltthesockettothesocketbracketusingthe

bolts(1/4inch).

Procedure

1.Removethehopperextensionsfromthebox

andidentifythefrontandtherear(Figure10

andFigure11).

g013263

Figure10

1.Fronthopperextension(showingholeorientation)

g013262

g013264

Figure11

1.Rearhopperextension(showingholeorientation)

2.Usingthehardwareprovided,attachthehopper

extensionstothehopper.Placethenutsonthe

outsideofthehopper.

5.Connecttheredwire(power)tothepositive

postonthebattery,thenconnecttheblackwire

(ground)tothenegativepostonthebattery.

11

Figure12

Hopperextensionkitinstalled

g237533

g013209

Figure13

1.Liftingbracket

4

MountingtheHoppertothe TowChassis

TowChassisCongurationOnly

Partsneededforthisprocedure:

6Bolt

6Flangenut

Procedure

Note:IfyouaremountingtheProPasstopdresser

ontosomethingotherthanthetowchassis,referto

theinstallationinstructionsforyourapplication.

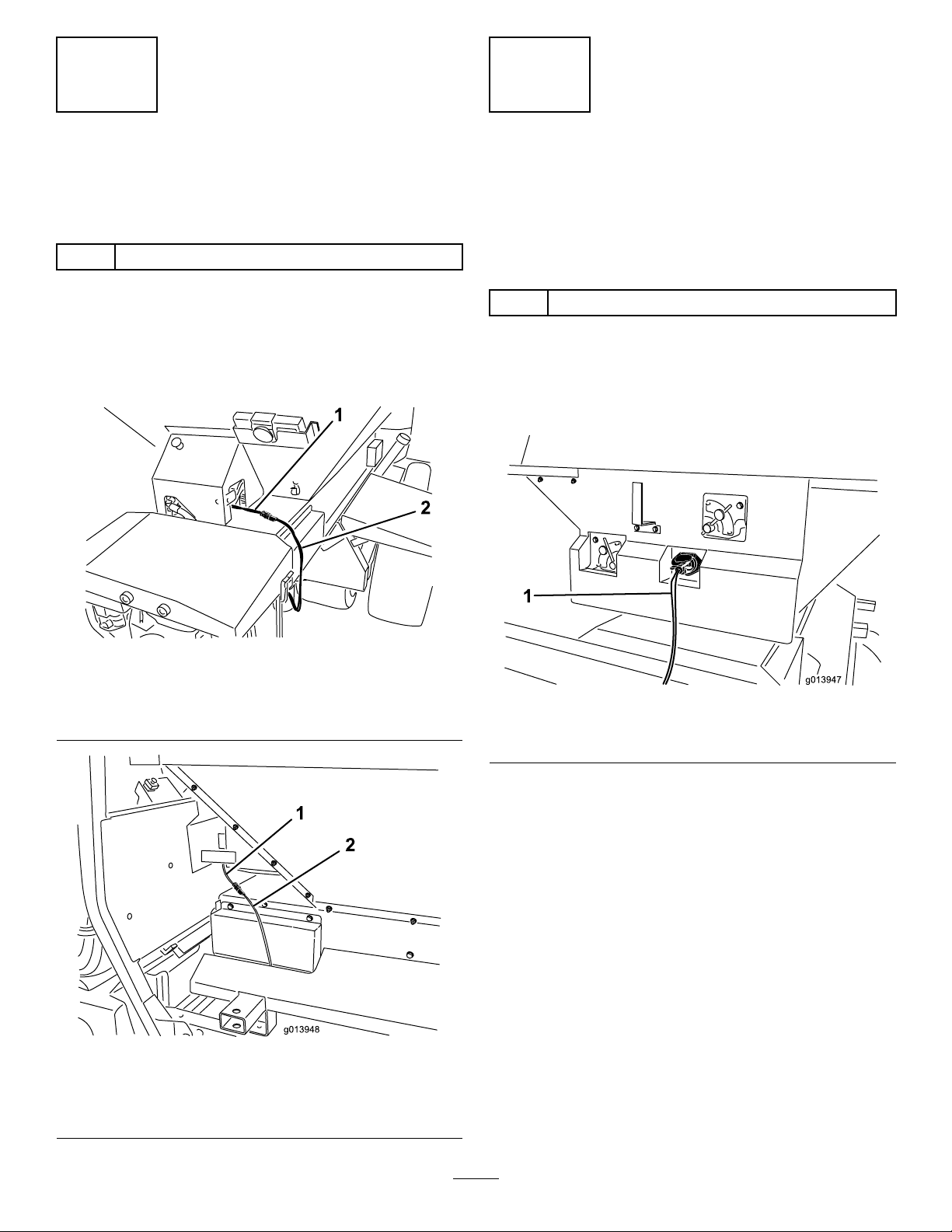

1.Attachaliftingdevicetotheliftingbracketbolted

insidethehopperassembly(Figure13).

WARNING

Donotattempttoliftthebedandhopper

withtheTow-BehindChassis,ProGator,

Workman,orTDCChassisconnected.

Theliftingbracketisnotcapableoflifting

theentiremachine.

2.Usingaliftingmechanism,positionthehopper

overthetowchassis.

3.Lineupthe6mountingholes(3perside)and

installthe5/16x1inchboltsandangenuts.

Figure14

1.Mountinglocations(3eachside)

4.Removetheliftingbracketfromthehoppersides

andinstalltheboltstothehoppersides.

Note:Retaintheliftingbracketforfutureuse;

donotdiscardit.

12

g013949

5

6

Connectingthe

IntermediateWireHarness

Partsneededforthisprocedure:

1Intermediatewireharness

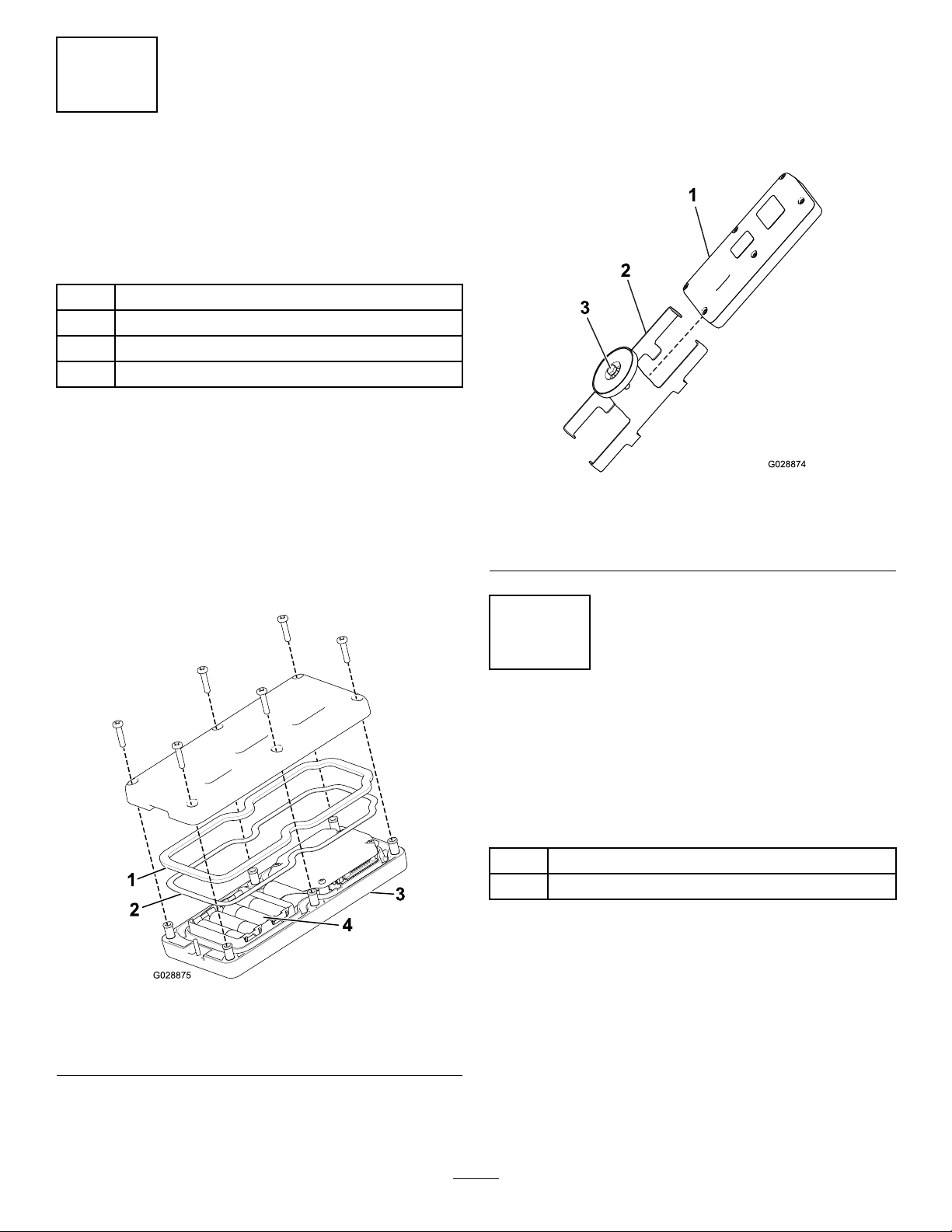

Procedure

Plugtheintermediatewireharnessintothepower

harnessconnectoronthemachine(Figure15or

Figure16).

ConnectingtheOn/Off Pendant

Model44701Only

Partsneededforthisprocedure:

1

On/offpendant

Procedure

Plugtheon/offpendantconnectorintotheconnector

onthemachine(Figure17).

Figure15

Model44751

1.Powerharness2.Intermediatewireharness

Figure16

Model44701

g237534

g013947

Figure17

1.On/offpendant

g013948

1.Powerharness2.Intermediatewireharness

13

4.Securethecoverwith6screws(Figure18)and

torquethemto1.5to1.7N∙m(13to15in-lb).

7

AssemblingtheHandheld

Remote

Model44751Only

Partsneededforthisprocedure:

1Handheldremote

4AAbatteries

1Magneticbracket

6

Screws,small

Procedure

1.Removetherubberbandssecuringtheremote

halvestogether,andremovethebackcover.

2.Installthebatteriesintotheterminalcradle

observingproperpolarity.(Ifthebatteries

areimproperlyinstalled,theunitwillnotbe

damaged,butitwillfailtooperate.)Thecradle

isembossedwithpolaritymarkingsforeach

terminal(Figure18).

5.Installthehandheldremoteintothemagnetic

remotebracket,slidethehalvestogetherto

securetheremote,andtightentheboltinthe

magnet(Figure19).

g028874

Figure19

1.Handheldremote3.Boltinthemagnet

2.Magneticremotebracket

Figure18

1.Rubberseal3.Handheldremote

2.Steelgasket

3.Ensurethatthesteelgasketandrubbersealare

seatedinthechannelintheremoteandsetthe

backcoverinplace(Figure18).

4.4AAbatteries

8

MountingtheWireless Remote

Model44751Only

Partsneededforthisprocedure:

1

Controllermountassembly

1Wirelessremoteassembly

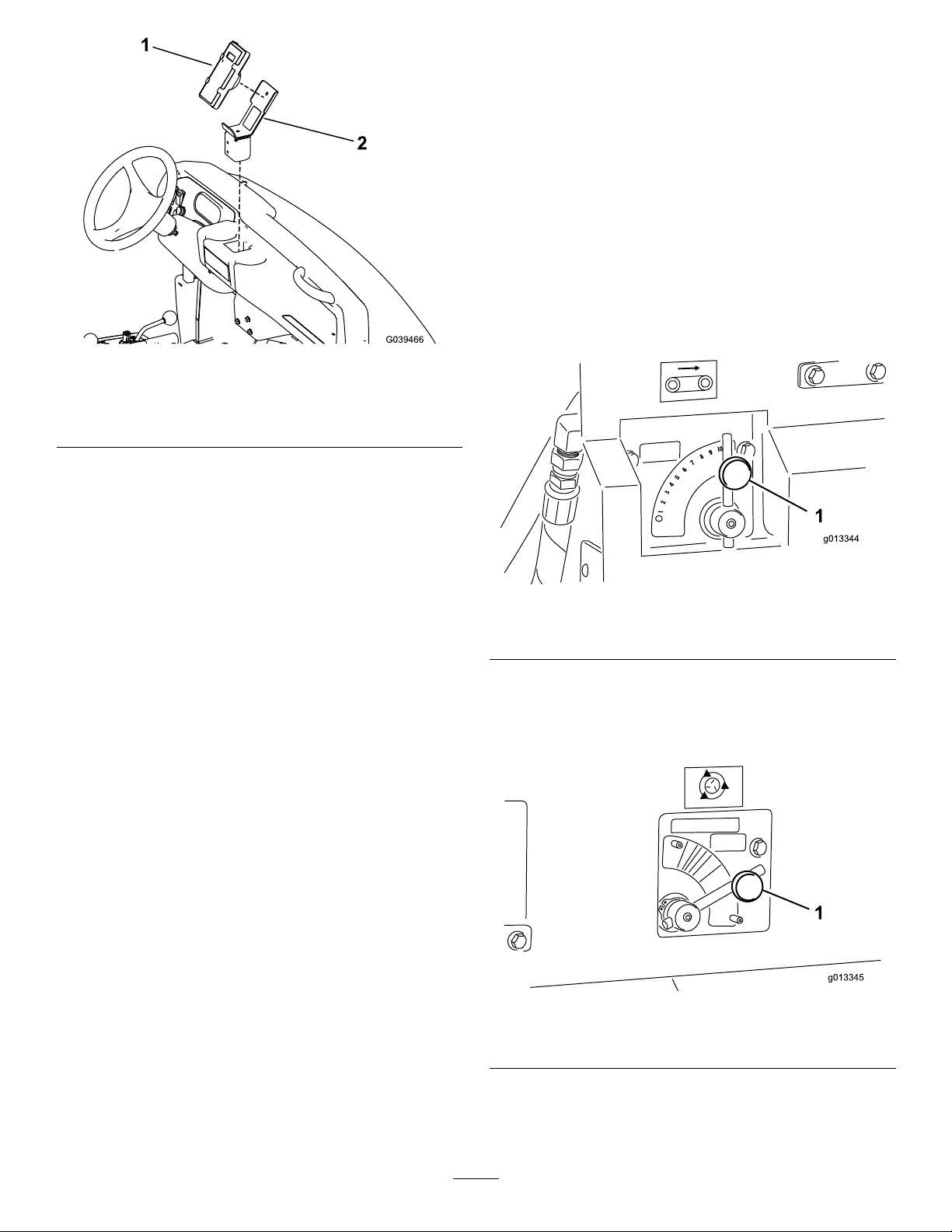

Procedure

g028875

Insertthecontrollermountassemblyintoacupholder

orsimilaropeningonthetowvehicleandusetostore

wirelessremote.Also,thewirelessremotemagnet

willsticktoanymetalcomponent.

14

Figure20

WorkmanHeavyDutyVehicleShown

ProductOverview

Controls

FlowControlValveforFloor

Model44701Only

Ahydraulicowcontrolvalvecontrolsthespeedof

theconveyorbelt.

Thehighestspeedsettingis10andistypicalformost

applicationsfoundontheColor-CodedOperation

Systemdecals.Uselowersettingsforverylight

g030466

applications.

1.Remote

2.Controllermountassembly

g013344

Figure21

1.Floorcontrolvalve

FlowControlValveforOptions

Model44701Only

1.Optioncontrolvalve

15

g013345

Figure22

Loading...

Loading...