FormNo.3432-306RevE

ProLineCommercialWalk-Behind

Mower

with36in,48in,54in,or60inCuttingUnit

ModelNo.44409—SerialNo.400000000andUp

ModelNo.44410—SerialNo.400000000andUp

ModelNo.44423—SerialNo.400000000andUp

ModelNo.44424—SerialNo.400000000andUp

ModelNo.44427—SerialNo.400000000andUp

ModelNo.44430—SerialNo.400000000andUp

ModelNo.44436—SerialNo.400000000andUp

ModelNo.44448—SerialNo.400000000andUp

ModelNo.44454—SerialNo.400000000andUp

ModelNo.44460—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3432-306*

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Visitwww.Toro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g291703

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Thisrotary-bladelawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Usingthisproductforpurposesotherthan

itsintendedusecouldprovedangeroustoyouand

bystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

g000502

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

ProductOverview.....................................................8

Controls.............................................................8

Specications....................................................9

Attachments/Accessories...................................9

BeforeOperation.................................................10

BeforeOperationSafety...................................10

AddingFuel......................................................10

UsingtheSafety-InterlockSystem.....................11

PerformingDailyMaintenance..........................12

DuringOperation.................................................12

DuringOperationSafety...................................12

OperatingtheParkingBrake.............................13

StartingtheEngine...........................................14

ShuttingOfftheEngine.....................................14

OperatingtheMower-Blade-ControlSwitch

(PTO)............................................................15

DrivingtheMachine..........................................16

UsingtheAdjustableReferenceBar.................17

SideDischargingorMulchingGrass.................17

AdjustingtheHeightofCut...............................18

AdjustingtheAnti-ScalpRollers........................19

AfterOperation....................................................19

AfterOperationSafety......................................19

UsingtheFuel-ShutoffValve.............................19

PushingtheMachinebyHand..........................20

TransportingtheMachine.................................20

Maintenance...........................................................22

MaintenanceSafety..........................................22

RecommendedMaintenanceSchedule(s)...........22

Pre-MaintenanceProcedures..............................23

RemovingtheMowerDeckGuard....................23

Lubrication..........................................................24

GreasingtheMachine.......................................24

GreasingtheFrontCasterPivots......................24

GreasingtheCasterWheelBearings................24

EngineMaintenance...........................................25

EngineSafety...................................................25

ServicingtheAirCleaner..................................25

ServicingtheEngineOil....................................27

ServicingtheSparkPlug...................................30

FuelSystemMaintenance...................................31

DrainingtheFuelT ank......................................31

ReplacingtheFuelFilter...................................32

ElectricalSystemMaintenance...........................33

ElectricalSystemSafety..................................33

ServicingtheBattery.........................................33

ServicingtheFuses..........................................34

DriveSystemMaintenance..................................35

CheckingtheTirePressure...............................35

CheckingtheWheel-LugNuts..........................35

AdjustingtheNeutralTraction...........................35

AdjustingtheTracking......................................35

AdjustingtheCaster-PivotBearings.................36

ServicingtheCasterWheelsand

Bearings........................................................36

CoolingSystemMaintenance..............................37

CleaningtheAir-IntakeScreen.........................37

CleaningtheCoolingSystem............................37

BrakeMaintenance.............................................38

TestingtheParkingBrake.................................38

AdjustingtheParkingBrake..............................38

BeltMaintenance................................................39

InspectingtheBelts..........................................39

ReplacingtheMower-DeckBelt........................39

AdjustingtheIdlerPulleyArm...........................41

ReplacingtheTransmissionBelt.......................41

ControlsSystemMaintenance.............................43

AdjustingtheMotion-ControlLevers.................43

HydraulicSystemMaintenance...........................44

HydraulicSystemSafety...................................44

HydraulicSystemSpecications.......................44

CheckingtheHydraulicFluidLevel...................44

ChangingtheHydraulicFluidand

Filters............................................................44

BleedingtheHydraulicSystem.........................46

MowerDeckMaintenance....................................47

BladeSafety.....................................................47

ServicingtheCuttingBlades.............................47

LevelingtheMowerDeck..................................49

ReplacingtheGrassDeector..........................50

Cleaning..............................................................52

CleaningundertheMower................................52

DisposingofWaste...........................................52

Storage...................................................................53

StorageSafety..................................................53

CleaningandStoringtheMachine....................53

Troubleshooting......................................................54

Schematics.............................................................56

3

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2017.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

•Read,understand,andfollowtheinstructions

andwarningsinthisOperator’sManualandon

themachineandattachmentsbeforestartingthe

engine.

•Donotputyourhandsorfeetnearmovingpartsof

orunderthemachine.Keepclearofanydischarge

opening.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepbystandersandchildrenoutoftheoperating

area.Donotallowchildrentooperatethemachine.

Allowonlypeoplewhoareresponsible,trained,

familiarwiththeinstructions,andphysically

capabletooperatethemachine.

•Stopthemachine,shutofftheengine,remove

theignitionkey(ifequipped),andwaitforall

movingpartstostopbeforeservicing,fueling,or

uncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

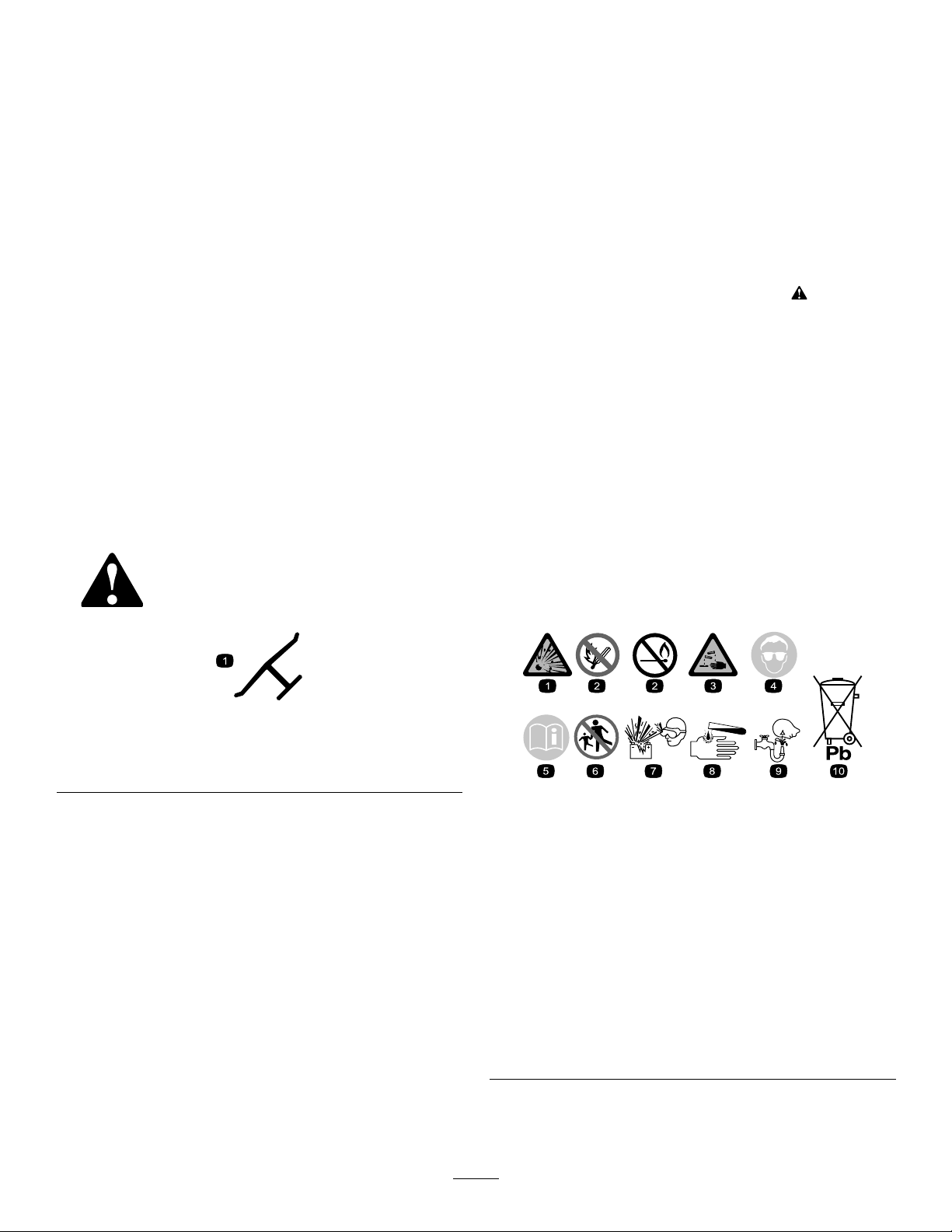

Manufacturer'sMark

1.Thismarkindicatesthatthebladeisidentiedasapart

fromtheoriginalmachinemanufacturer.

decaloemmarkt

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard6.Keepbystandersaway

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

fromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

4

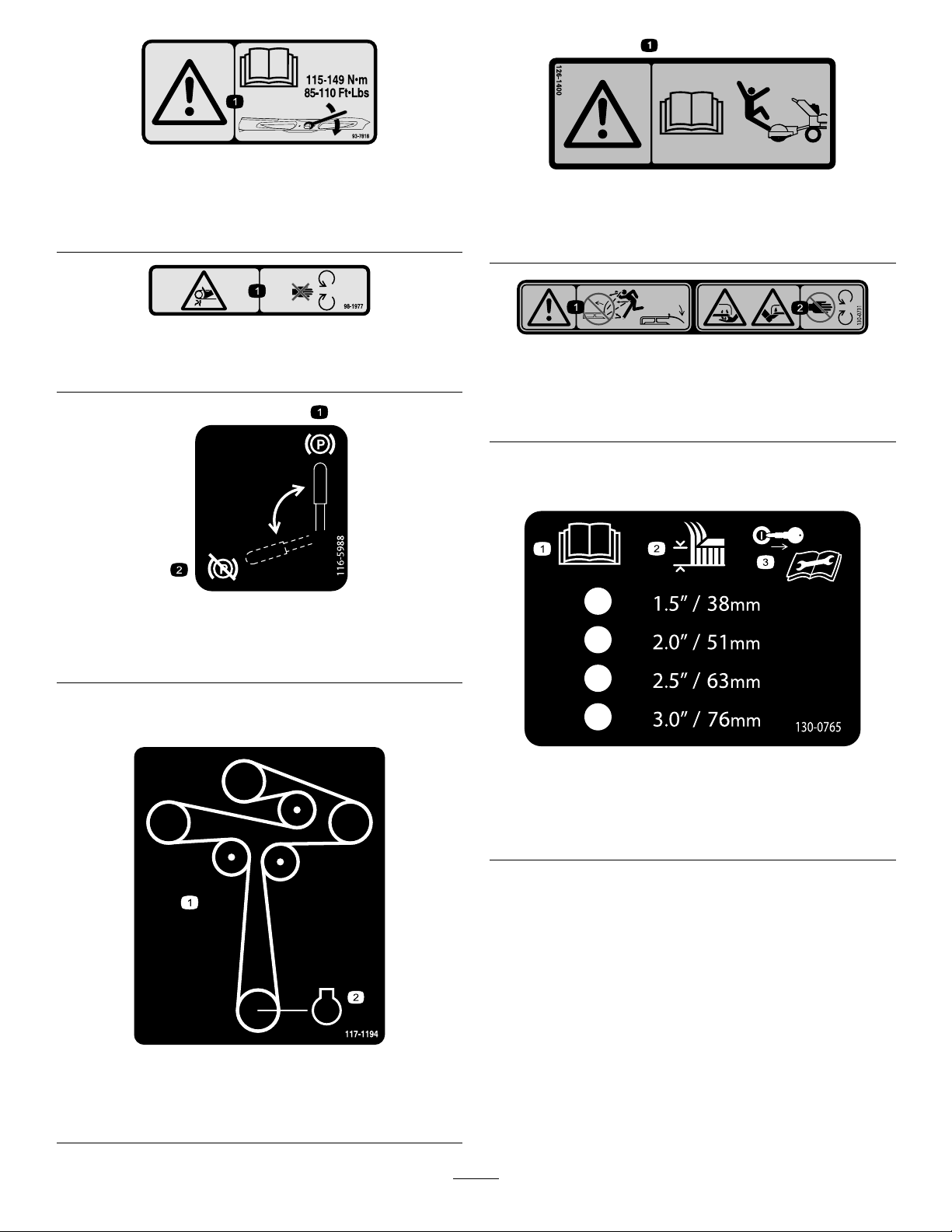

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to1 10

ft-lb).

98-1977

1.Entanglementhazard,belt—stayawayfrommovingparts.

116-5988

decal93-7818

decal126-1400

126-1400

1.Warning—readtheOperator’sManualforinformationabout

attachments;certainattachmentscancauseyoutofall.

decal98-1977

decal130-0731

130-0731

1.Warning—thrownobject

hazard;keepthedeector

shieldinplace.

2.Cuttinghazardofhandor

foot,mowerblade—keep

awayfrommovingparts.

Decal130-0765isfor122cm(48-inch),137cm

(54-inch),and152cm(60-inch)modelsonly.

decal116-5988

1.Parkingbrake—engaged2.Parking

brake—disengaged

Decal117-1 194isfor122cm(48-inch),137cm

(54-inch),and152cm(60-inch)modelsonly.

117-1194

decal117-1 194

1.ReadtheOperator's

Manual.

2.Height-of-cutselection

decal130-0765

130-0765

3.Removethekeybefore

performingmaintenance.

1.Beltrouting

2.Engine

5

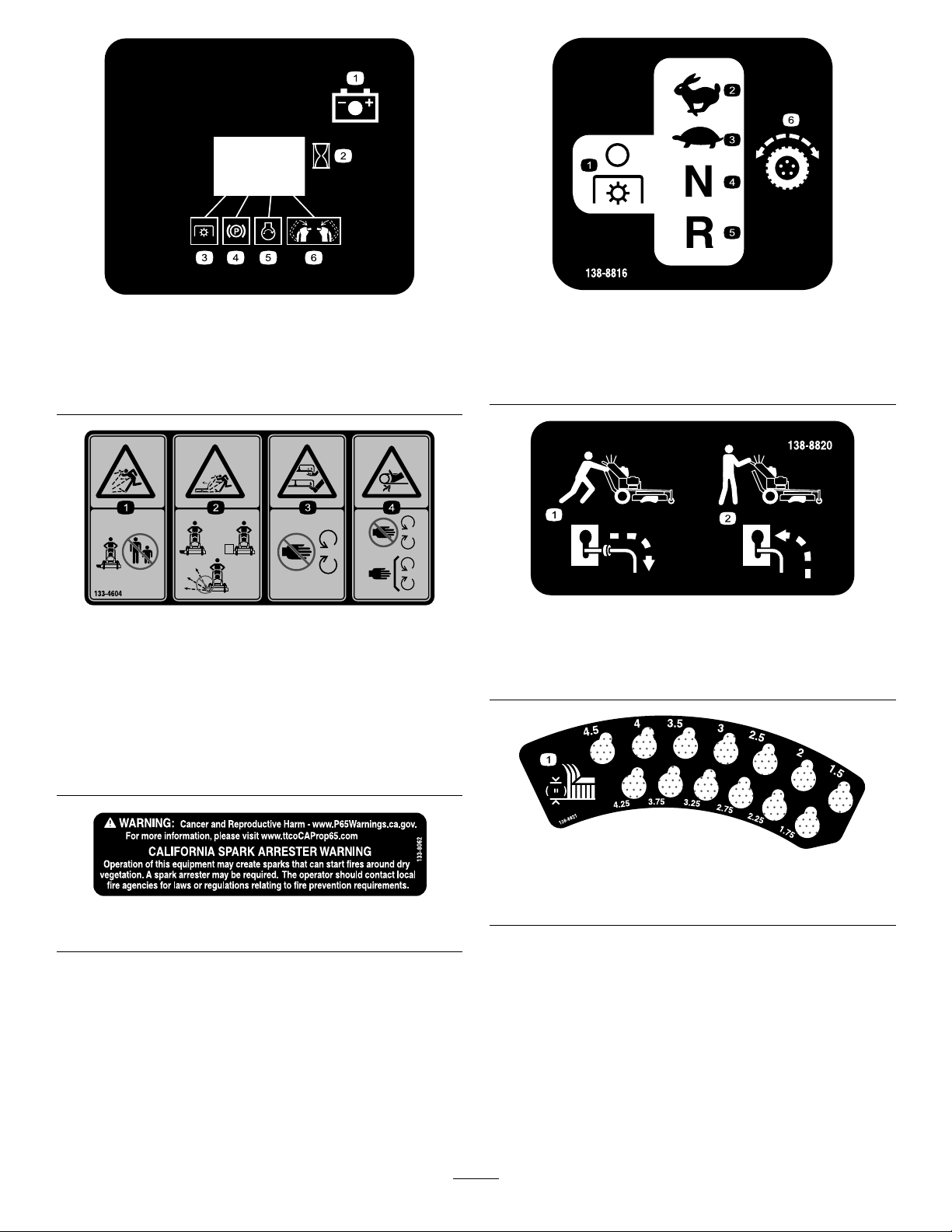

131-3536

1.Battery4.Parkingbrake

2.Time5.Engine—start

3.Powertakeoff(PTO)

6.Engagethehandlebars.

decal131-3536

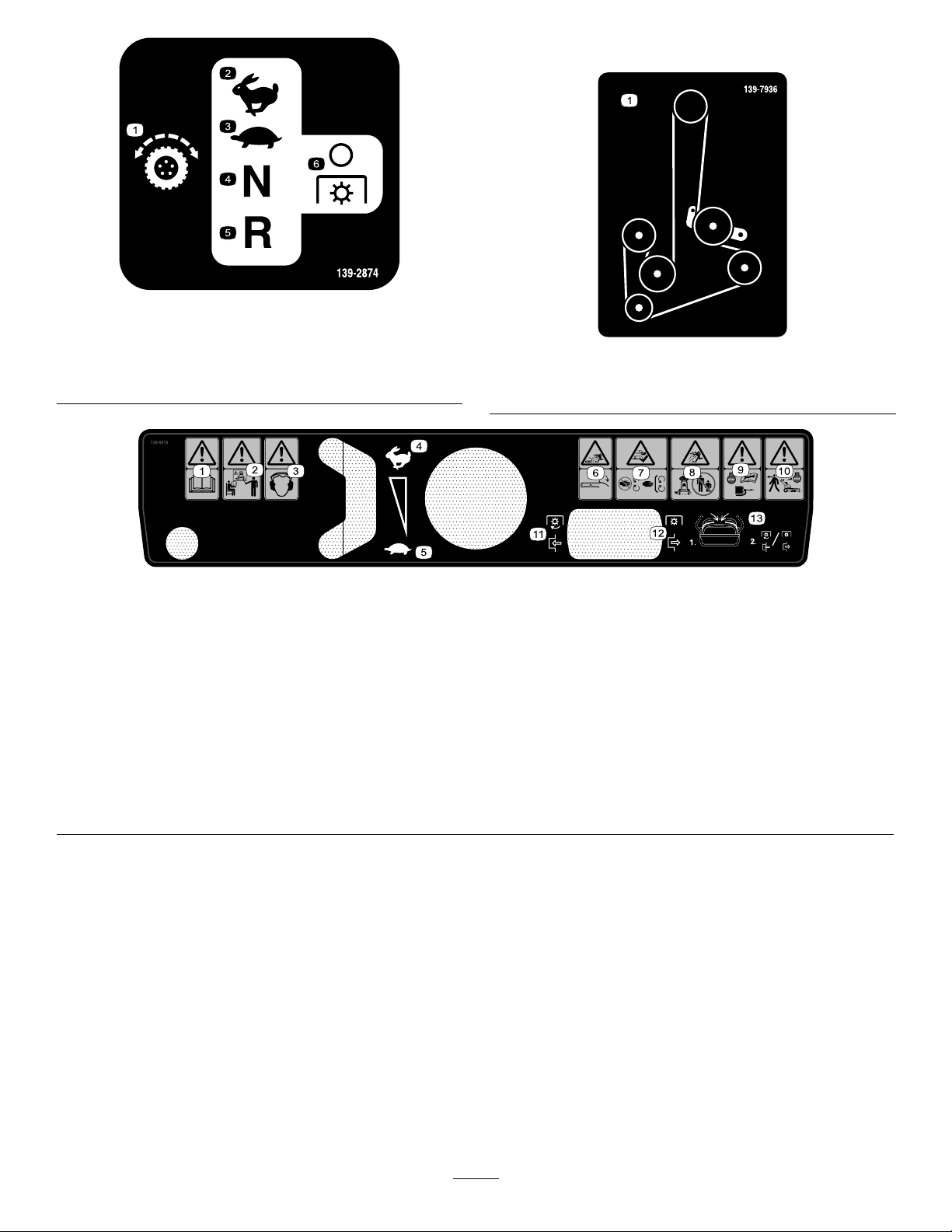

1.PTO—disengage

138-8816

4.Neutral

decal138-8816

2.Fast5.Reverse

3.Slow

6.Tractioncontrols

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

opendeector—only

operatethemachinewith

adeectororagrass

collector.

133-4604

3.Severinghazardofhand

4.Entanglement

133-8062

decal133-4604

orfoot—keepawayfrom

movingparts.

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

decal133-8062

1.Disengagethehydrostatic

drivetopushthemachine.

1.Heightofcut

decal138-8820

138-8820

2.Engagethehydrostatic

drivetooperatethe

machine.

decal138-8821

138-8821

6

Decal139-7936isfor91cm(36-inch)modelsonly.

decal139-2874

139-2874

1.Tractioncontrols4.Neutral

2.Fast5.Reverse

3.Slow6.PTO—disengage

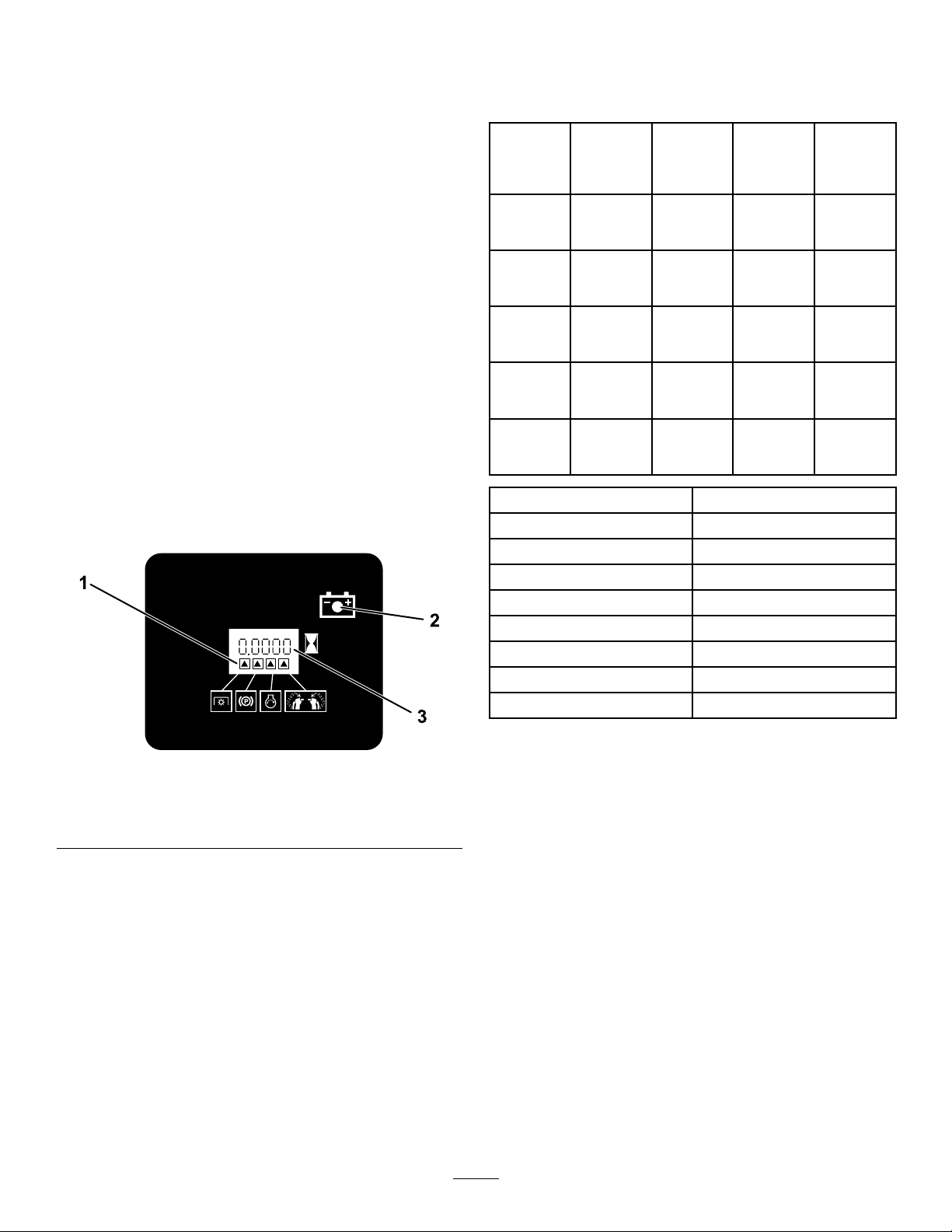

1.Warning—readtheOperator’sManual.

2.Warning—alloperatorsshouldbetrainedbeforeoperating

themachine.

3.Warning—wearhearingprotection.

4.Fast

5.Slow12.PTO—disengage

6.Thrownobjecthazard—lowerthedeectorbeforeusingthe

machine.

7.Cutting/dismembermenthazardofhandandfoot;mower

blade—stayawayfrommovingparts;keepallguardsand

shieldsinplace.

decal139-7936

139-7936

1.Beltrouting

decal138-8818

138-8818

8.Thrownobjecthazard—keepbystandersaway .

9.Warning—shutofftheengine,disconnectthesparkplug,and

readtheOperator’sManualbeforeperformingmaintenance.

10.Warning—shutofftheenginebeforeleavingthemachine.

11.PTO—engage

13.MovethetractioncontrolleverstotheNeutralposition;

engageordisengagethePTO.

7

ProductOverview

Figure3

1.Sidedischarge5.Controlpanel

2.Height-of-cutlever

3.Engine7.Mowerdeck

4.Fueltank8.Anti-scalproller

6.Parking-brakelever

Controls

ControlPanel

g299386

g299567

1.Parking-brakelever

2.Adjustablereferencebar

3.Leftmotion-controllever

4.Hourmeter10.Throttlecontrol

5.Referencebaradjustment

lever

6.Rightmotion-controllever

Figure4

7.Rearreferencebar

8.Blade-controlswitch

(PTO)

9.Keyswitch

11.Chokecontrol

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure4).

Blade-ControlSwitch(Power

Takeoff)

Theblade-controlswitch,representedbya

power-takeoff(PTO)symbol,engagesand

disengagespowertothemowerblades(Figure4).

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingor

storingthemachine.

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andST ART.

8

Choke

Specications

Usethechoketostartacoldengine.

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure4).

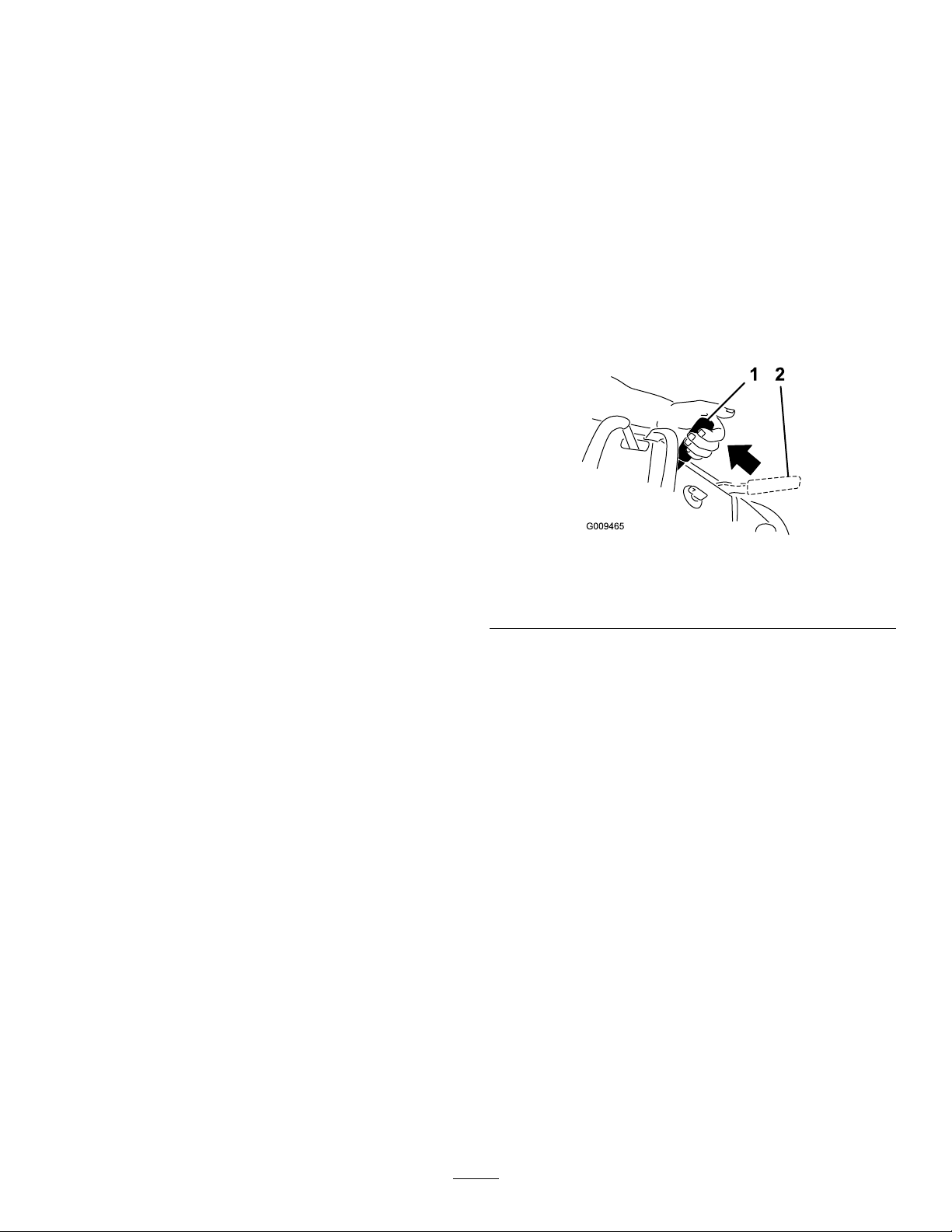

Safety-InterlockIndicators

Therearesymbolsonthehourmeterthatindicate

withablacktrianglethattheinterlockcomponentis

positionedcorrectly(Figure5).

Battery-IndicatorLight

IfyouturnthekeyswitchtotheONpositionfora

fewseconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed(Figure5).

Thebatterylightturnsonwhenthekeyswitchis

turnedonandwhenthechargeisbelowthecorrect

operatinglevel(Figure5).

Specicationsanddesignaresubjecttochange

withoutnotice.

Cutting

width

Widthwith

deector

down

Widthwith

deector

up

Height114

Length196

44409

44410

44423

44424

44427

44430

44448

44454

91cm

(36-inch)

Mower

Deck

91cm(36

inches)

130

cm(51

inches)

94cm(37

inches)

cm(45

inches)

cm(77

inches)

122cm

(48-inch)

Mower

Deck

122

cm(48

inches)

160

cm(63

inches)

124

cm(49

inches)

117

cm(46

inches)

203

cm(80

inches)

Weight

265kg(585lb)

263kg(580lb)

292kg(644lb)

290kg(639lb)

294kg(648lb)

314kg(693lb)

303kg(669lb)

315kg(695lb)

137cm

(54-inch)

Mower

Deck

137

cm(54

inches)

175

cm(69

inches)

140

cm(55

inches)

117

cm(46

inches)

203

cm(80

inches)

152cm

(60-inch)

Mower

Deck

152

cm(60

inches)

191

cm(75

inches)

155

cm(61

inches)

117

cm(46

inches)

211

cm(83

inches)

Figure5

1.Safety-interlockindicators

2.Batterylight

3.Hourmeter

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection(Figure4).

ReferenceBarAdjustmentLever

Usetheadjustmentlevertochangethepositionofthe

adjustablereferencebar(Figure4).

g216020

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

9

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Donotallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alwaysshutoffthemachine,removetheignition

key(ifequipped),waitforallmovingpartstostop,

andallowthemachinetocoolbeforeadjusting,

servicing,cleaning,orstoringit.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andsafetyprotectivedevicesare

attachedandfunctioningproperly.Donotoperate

themachineunlesstheyarefunctioningproperly .

•Inspecttheareawhereyouwillusethemachine,

andremoveallobjectsthatcouldinterferewith

theoperationofthemachineorthatthemachine

couldthrow.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.

•Beforeusing,alwaysvisuallyinspecttoseethat

theblades,bladeboltsandmowerdeckarenot

wornordamaged.Replacewornordamaged

bladesandboltsinsetstopreservebalance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatingasourceofignitionuntilthefuel

vaporshavedissipated.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromthevehicle

beforelling.

•Removeequipmentfromthetruckortrailerand

refuelitontheground.Ifthisisnotpossible,refuel

suchequipmentwithaportablecontainerrather

thanfromafuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineroperatingatalltimesuntilfueling

iscomplete.

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothetank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshlongerwhenusedasdirectedby

thefuel-stabilizermanufacturer

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

10

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

FillingtheFuelTank

Figure6

g031282

Figure7

1.Thetriangleslightupwhentheinterlockcomponentsare

g302021

inthecorrectposition.

TestingtheSafety-Interlock

UsingtheSafety-Interlock

System

WARNING

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtoprevent

PTOfromengagingunlessyoudothefollowing:

•Moveeithermotion-controllevertothecenter,

unlockedposition.

•PullthePTOswitchtotheONposition.

Thesafety-interlocksystemisdesignedtostop

theblades/attachmentifyoumoveorreleaseboth

motion-controlleversoutward.

Thehourmeterhassymbolstonotifytheuser

wheneachinterlockcomponentisinthecorrect

position.Whenthecomponentisinthecorrect

position,atrianglelightsupinthecorresponding

square(Figure7).

System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.

Note:Ifthesafetysystemdoesnotoperateas

describedbelow,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately.

1.Engagetheparkingbrakeandstarttheengine.

2.Movethemotion-controlleverstothecenter,

unlockedposition.

Note:Theengineshouldshutoff.

3.Starttheengineanddisengagetheparking

brake.Donotmovethemotion-controllevers.

Note:Theengineshouldidle5secondsand

thenshutoff.

4.Engagetheparkingbrakeandstarttheengine.

5.PresstheONpositionforthePTOswitch.

Note:Themowerbladesshouldnotengage.

6.Disengagetheparkingbrake.

7.Holdeithermotion-controlleverinthecenter

positionandpresstheONpositionforthePTO

switch.

Note:Themowerbladesshouldengage.

8.Releasethemotion-controllever.

Note:Theengineshouldidle5secondsand

thenshutoff.

9.Engagetheparkingbrakeandstarttheengine.

10.Disengagetheparkingbrake.

11.Holdeithermotion-controllevertothecenter

positionandpresstheONpositionforthePTO

switch.

11

Note:Themowerbladesshouldengage.

12.PresstheOFFpositionforthePTOswitch.

Note:Themowerbladesshoulddisengage.

13.PresstheONpositionforthePTOswitch.

Note:Themowerbladesshouldengage.

14.Engagetheparkingbrake.

Note:Themowerbladesshoulddisengageand

theengineshouldshutoff.

15.PresstheONpositionforthePTOswitch.

16.Trystartingtheengine.

Note:Theengineshouldnotcrank.

PerformingDaily

Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page22).

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Keepbystandersoutoftheoperatingarea.Stop

themachineifanyoneentersthearea.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

•Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.Avoidmowingin

wetconditions.

•Keepyourhandsandfeetawayfromthecutting

unit.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Useextremecarewhenapproachingblind

corners,shrubs,trees,orotherobjectsthatmay

blockyourview.

•Disengagethedrivetothecuttingunitandengage

theparkingbrakebeforeadjustingtheheightof

cut.

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,which

islethalifinhaled.

•Donotleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(includingto

emptythecatchersortounclogthecuttingunits),

dothefollowing:

–Parkthemachineonlevelground.

–Disengagethecuttingunitandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutoffthemachineandremovetheignition

key(ifequipped).

–Waitforallmovingpartstostop.

–Shutoffthemachineanddisengagethedrive

tothecuttingunitinthefollowingsituations:

◊Beforefueling

◊Beforeclearingblockages

◊Beforechecking,cleaning,ormaintaining

thecuttingunit

◊Afterstrikingaforeignobjectorifan

abnormalvibrationoccurs.Inspectthe

cuttingunitfordamageandmakerepairs

beforestartingandoperatingthemachine

◊Beforeleavingtheoperatingposition

–Useonlyaccessoriesandattachments

approvedbyTheToro®Company .

–Besureofyourfootingwhileusingthis

machine,especiallywhenbackingup.Walk;

donotrun.

–Neveroperatewiththedischargedeector

raised,removedoraltered,unlessyouare

usingagrasscatcher.

–Nevercarrypassengersonthemachine.

–Donotdirectthedischargematerialtoward

anyone.Avoiddischargingmaterialagainst

awallorobstruction;materialmayricochet

towardyou.Stoptheblade(s)whencrossing

gravelsurfaces.

–Starttheenginecarefullyaccordingto

instructionsandwithyourfeetwellawayfrom

12

theblade(s)andnotinfrontofthedischarge

chute.

–Useextremecautionwhenreversingorpulling

themachinetowardyou.

–Stopthebladeifyoumusttransportthe

machinetoandfromthemowingareaand

whencrossingsurfacesotherthangrass.

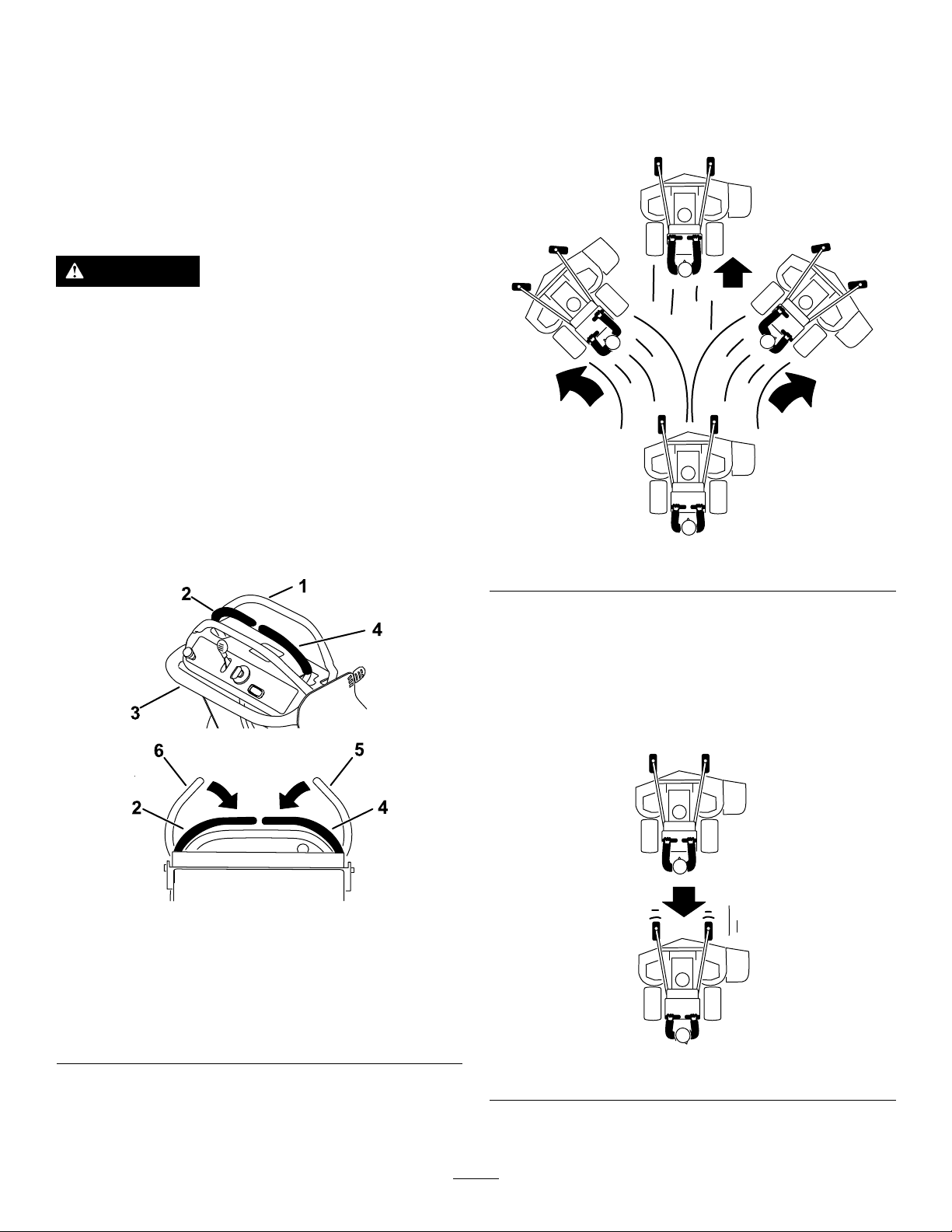

OperatingtheParking

Brake

Alwaysengagetheparkingbrakewhenyoushut

offthemachineorleavetheoperatorposition.

Beforeeachuse,checktheparkingbrakeforproper

operation.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Youareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.Beforeusingthemachine

onaslope,dothefollowing:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Operateacrossslopes,neverupanddown.Avoid

operationonexcessivelysteeporwetslopes.

Poorfootingcouldcauseaslip-and-fallaccident.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,water,orotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distancebetweenthemachineandanyhazard.

Useahandheldtooltooperateintheseareas.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocks,orotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Ifyoulosecontrolofthemachine,stepawayfrom

thedirectionoftravelofthemachine.

•Alwayskeepthemachineingearwhengoing

downslopes.Donotcoastdownhill(applicable

onlytogear-driveunits).

Pulltheparking-brakeleverrearwardtoengageit

(Figure8).

Pushtheparking-brakeleverforwardtodisengageit.

Note:Theengineshutsoffifyoumovethe

motion-controlleverswhiletheparkingbrakeis

engagedorifthemachineidlesfor5secondswhile

theparkingbrakeisdisengaged.

g009465

Figure8

1.Parkingbrake—engaged2.Parking

brake—disengaged

13

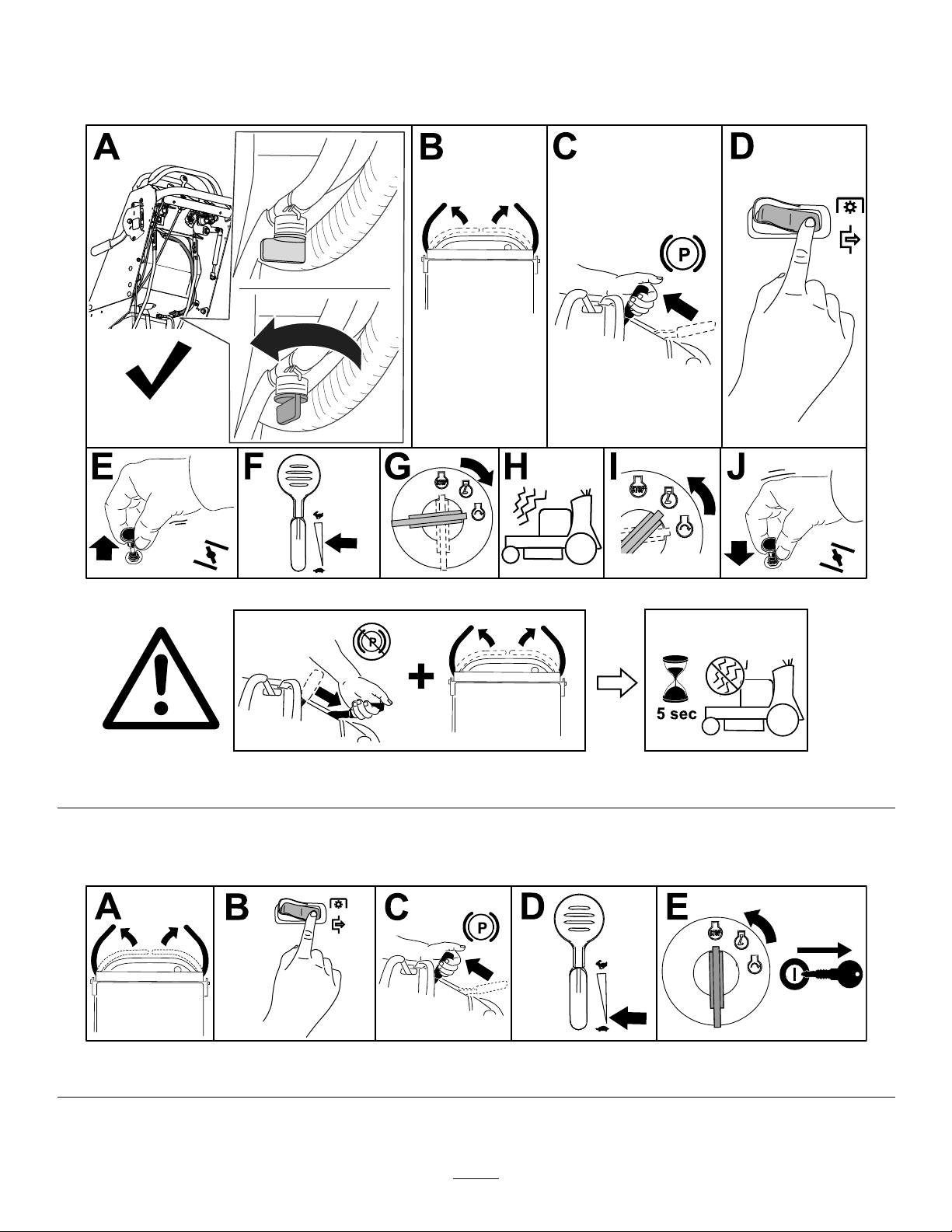

StartingtheEngine

Note:Ifyoureleasethemotion-controlleversanddonotengagetheparkingbrake,theenginewillshutoff

after5seconds.

ShuttingOfftheEngine

g292627

Figure9

g289750

Figure10

14

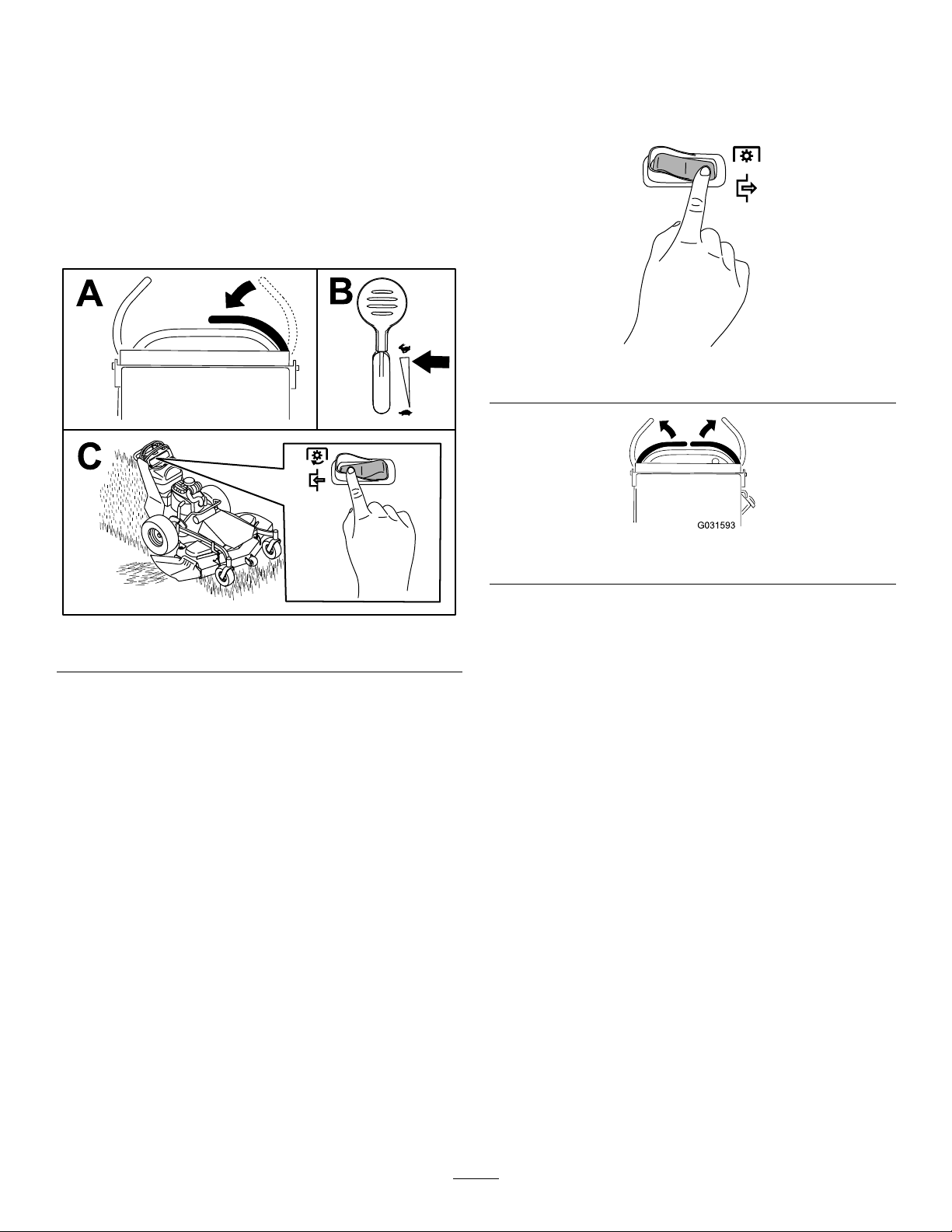

Operatingthe

Mower-Blade-Control

Switch(PTO)

Usetheblade-controlswitch(PTO)inconjunctionwith

themotion-controlleverstoengageanddisengage

themowerblades.

EngagingtheMowerBlades(PTO)

DisengagingtheMowerBlades

(PTO)

Figure12andFigure13show2waystodisengage

themowerblades.

g299432

Figure12

Figure11

g031593

Figure13

g299433

15

DrivingtheMachine

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.

Note:Theengineshutsoffifyoumovethe

motion-controlleverswhiletheparkingbrakeis

engagedorifthemachineidlesfor5secondswhile

theparkingbrakeisdisengaged.

CAUTION

Themachinecanspinveryrapidly,andyou

maylosecontrolofthemachine,causing

personalinjurytoyouanddamagetothe

machine.

Slowdownthemachinebeforemakingsharp

turns.

DrivingForward

1.Disengagetheparkingbrake;refertoOperating

theParkingBrake(page13).

Note:Thefartheryoumovethemotion-control

leversineitherdirection,thefasterthemachine

movesinthatdirection.

Note:T ostop,movethemotion-controllevers

backtotheNEUTRALposition.

2.Movethemotion-controlleversdowntothe

NEUTRALposition.

Figure14

1.Frontreferencebar

2.Leftcontrolleverin

NEUTRALposition

3.Rearreferencebar6.Leftcontrolleverwhen

4.Rightcontrolleverin

NEUTRALposition

5.Rightcontrolleverwhen

released

released

3.Slowlypushthemotion-controlleversforward

(Figure15).

g303736

Figure15

DrivingBackward

1.Movebothmotion-controlleverstotheNEUTRAL

position.

2.Slowlypullthemotion-controlleversrearward

(Figure16).

g299431

g303735

Figure16

16

UsingtheAdjustable

ReferenceBar

Usetheadjustmentlevertochangethepositionof

theadjustablereferencebarandlimitthemaximum

forwardspeed(Figure17).

Movethelevertotheupperpositiontodecreasethe

maximumspeed;movethelevertothelowerposition

toincreasethemaximumspeed.

Figure17

SideDischargingor

g299434

MulchingGrass

Thismowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandbystandersareexposedto

bladecontactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

cancauseseriousinjuryordeath.

•Neverremovethegrassdeectorfromthe

mowerdeck,becausethegrassdeector

routesmaterialdowntowardtheturf.If

thegrassdeectorisdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mowerdeck.

•Nevertrytoclearthedischargeareaor

mowerbladesbeforeyoudisengagethe

mowerblades.Turntheignitionkeyto

theOFFposition.Removethekeyand

disconnectthespark-plugwires.

17

AdjustingtheHeightofCut

Youcanadjusttheheightofcutfrom38to114mm(1-1/2to4-1/2inches)in6mm(1/4inch)increments.

Figure18

g303747

18

AdjustingtheAnti-Scalp

Rollers

AfterOperation

Modelswitha122cm(48inch),

137cm(54inch),or152cm(60

inch)DeckOnly

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftheanti-scalprollers.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethenutandboltpositiontheanti-scalp

rollersandinstallthenutandbolt.

4.Ensurethatthespacersandbushingsare

installed(Figure19).

AfterOperationSafety

GeneralSafety

•Alwaysshutoffthemachine,removetheignition

key(ifequipped),waitforallmovingpartstostop,

andallowthemachinetocoolbeforeadjusting,

servicing,cleaning,orstoringit.

•Cleangrassanddebrisfromthemachinetohelp

preventres.Cleanupoilorfuelspills.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Usefull-widthrampsforloadingthemachineinto

atrailerortruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Directbothfrontandrear

strapsdownandoutwardfromthemachine.

UsingtheFuel-Shutoff

Figure19

1.Bushing4.Bolt

2.Anti-scalproller5.Nut

3.Spacer

Valve

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage(Figure20).

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

g301976

g299483

Figure20

1.OFFposition2.ONposition

19

PushingtheMachineby

OperatingtheMachine

Hand

Important:Alwayspushthemachinebyhand.

Donottowthemachine,becausetowingmay

damageit.

Important:Donotstartoroperatethemachine

withthebypassvalvesopen.Damagetosystem

mayoccur.

PushingtheMachine

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Locatethebypassleversontheframeonboth

sidesoftheengine.

4.Movethebypassleversrearwardthroughthe

keyholeanddowntolocktheminplace(Figure

21).

Note:Dothisforeachlever.

Movethebypassleversforwardthroughthekeyhole

anddowntolocktheminplaceasshowninFigure21.

Note:Dothisforeachlever.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway .

5.Disengagetheparkingbrake.

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure22).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Ensurethatthelengthoframpisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.

g303749

Figure21

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

6.Whennished,engagetheparkingbrake.

3.Leverpositionforpushing

themachine

20

Figure23

g299488

1.Full-widthrampinstowed

position

2.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

LoadingtheMachine

WARNING

Figure22

3.H=heightofthetraileror

truckbedtotheground

4.Trailer

1.Backthemachineupthe

ramp.

2.Walkthemachinedown

theramp.

5.Shutofftheengine,removethekey,andengage

theparkingbrake.

6.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumperwithstraps,chains,

cable,orropes(Figure24).Refertolocal

g229507

regulationsfortie-downrequirements.

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Backthemachineuptherampandwalkit

forwarddowntheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakesand

lights.

3.Lowertheramp(Figure22).

4.Backthemachineuptheramp(Figure23).

1.Reartie-downloop

2.Fronttie-downloopfor

122,137,and152cm(48,

54,and60inch)machines

g328545

Figure24

3.Tiedownthefrontcaster

framefor91cm(36inch)

machines.

21

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

MaintenanceSafety

•Beforeadjusting,cleaning,servicing,orleaving

themachine,dothefollowing:

–Parkthemachineonalevelsurface.

–Movethethrottleswitchtothelow-idleposition.

–Disengagethecuttingunits.

–Ensurethatthetransmissionisinneutral.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keepyourhands,feet,

clothing,andanypartsofthebodyawayfromthe

RecommendedMaintenanceSchedule(s)

cuttingunit,attachments,andanymovingparts.

Keepbystandersaway.

•Keepallpartsingoodworkingcondition.Replace

allworn,damaged,ormissingpartsanddecals.

Keepallfastenerstighttoensurethatthemachine

isinsafeworkingcondition.

•Checkthegrasscatchercomponentsfrequently

andreplacethemwhentheyarewornordamaged.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufer,coolingscreen,andtheengineto

helppreventres.Cleanupoilorfuelspills.

•Checkthebrakeoperationfrequently .Adjustand

servicethebrakeasneeded.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•T oensuresafe,optimalperformanceofthe

machine,useonlygenuineT ororeplacement

parts.Replacementpartsmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Changethehydraulic-systemltersanduid.

•Checkthewheel-lugnuts.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Cleanthegrassanddebrisfromtheair-intakescreen.

•Testtheparkingbrake.

•Inspecttheblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemowerdeck.

•Greasethecasterwheelbearings.

•Cleanthefoamair-cleanerelement—standardaircleanersonly.

•Checkthebeltsforwearorcracks.

•Checkthepaperair-cleanerelement—standardaircleanersonly.

•Checkthehydraulicuid.

•Changetheengineoil.

•Check,cleanandgapthesparkplug.

•Checkthebattery.

•Checkandcleantheengine-coolingnsandshrouds.

Every200hours

•Replacethepaperair-cleanerelement—standardaircleanersonly.

•Changetheengine-oillter.

22

MaintenanceService

Every250hours

Interval

MaintenanceProcedure

•Replacetheprimaryairlter(moreoftenindirtyordustyconditions)—heavy-duty

aircleanersonly .

•Checkthesafetyairlter(moreoftenindirtyordustyconditions)—heavy-dutyair

cleanersonly.

Every300hours

Every500hours

Every800hours

Yearly

•Checkandadjustthevalveclearance.ContactanAuthorizedServiceDealer.

•Replacethesafetyairlter(moreoftenindirtyordustyconditions)—heavy-duty

aircleanersonly .

•Adjustthecaster-pivotbearing.

•Aftertheinitialchange—changethehydraulic-systemltersanduidwhenusing

Toro®HYPR-OIL™500uid.(Changeitmoreoftenunderdirtyordustyconditions)

•Replacethefuellter.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Checkthemowerdeckidlerarmforwear.

•Inspectthebladeboltsandcurvedwashers.Replaceifdamaged.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Shutofftheengineandremovethekeyfromtheswitchbeforeyouperformanymaintenance.

Pre-Maintenance

Procedures

RemovingtheMowerDeck

Guard

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Unlatchthe2rubberlatchesfromthescrews

andremovethedeckcover(Figure25).

g302738

Figure25

23

Lubrication

GreasingtheCasterWheel

Bearings

GreasingtheMachine

Greasethemachinemoreoftenindirtyordusty

conditions.

GreaseType:No.2lithiumormolybdenumgrease

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

Note:Scrapeanypaintoffthefrontofthe

tting(s).

4.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

5.Wipeupanyexcessgrease.

GreasingtheFrontCaster

ServiceInterval:Every25hours—Greasethecaster

wheelbearings.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure26)witharag.

Note:Scrapeanypaintoffthefrontofthe

tting(s).

Pivots

ServiceInterval:Yearly

Greasetype:Lithiumormolybdenumgrease

1.Removethedustcapandadjustthecaster

pivots;refertoAdjustingtheCaster-Pivot

Bearings(page36).

Note:Keepthedustcapoffuntilyouhave

nishedgreasingthecasterpivots.

2.Removethehexplug.

3.Threadagreasettingintothehole.

4.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

5.Removethegreasettingfromthehole.

6.Installthehexpluganddustcap.

g301977

Figure26

1.Frontcastergreasetting

4.Connectagreaseguntoeachtting(Figure26).

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

24

EngineMaintenance

EngineSafety

•Donotchangethegovernorspeedoroverspeed

theengine.

•Runtheenginedryorremovethefuelwithahand

pump;neversiphonthefuel.Ifyoumustdrainthe

fueltank,doitoutdoors.

ServicingtheAirCleaner

RefertoFigure27toidentifytheaircleanerforyour

engine.

4.Unscrewthecoverknobsandremovethe

air-cleanercover(Figure28).

5.Unscrewthehoseclampandremovethe

air-cleanerassembly(Figure28).

6.Carefullypullthefoamelementoffthepaper

element(Figure28).

g012619

Figure28

Figure27

1.Standardaircleaner

2.Heavy-dutyaircleaner

ServicingaStandardAirCleaner

ServiceInterval:Every25hours—Cleanthefoam

air-cleanerelement—standardair

cleanersonly.

Every50hours—Checkthepaperair-cleaner

element—standardaircleanersonly.

Every200hours—Replacethepaperair-cleaner

element—standardaircleanersonly.

Note:Servicetheaircleanermorefrequently(every

fewoperatinghours)iftheoperatingconditionsare

extremelydustyorsandy.

Important:Donotapplyoiltothefoamorpaper

element.

RemovingtheFoamandPaperElements

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleantheareaaroundtheaircleanertoprevent

dirtfromenteringtheengineandcausing

damage(Figure28).

g302948

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

CleaningtheFoamAir-CleanerElement

1.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifit

istornorworn.

ServicingthePaperAir-CleanerElement

Important:Donotcleanthepaperlter,replace

it(Figure28).

1.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.

2.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperair-cleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

air-cleanerelement(Figure28).

2.Placetheair-cleanerassemblyontotheair

cleanerbaseandsecureitwiththe2wingnuts

(Figure28).

25

3.Placetheair-cleanercoverintopositionand

tightenthecoverknob(Figure28).

ServicingaHeavyDutyAirCleaner

ServiceInterval:Every250hours—Replacethe

primaryairlter(moreoftenindirty

ordustyconditions)—heavy-dutyair

cleanersonly.

Every250hours—Checkthesafety

airlter(moreoftenindirtyordusty

conditions)—heavy-dutyaircleanersonly.

Every500hours—Replacethesafety

airlter(moreoftenindirtyordusty

conditions)—heavy-dutyaircleanersonly.

Note:Servicetheaircleanermorefrequentlyif

operatingconditionsareextremelydustyorsandy .

RemovingtheFilters

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure29).

6.Removethesafetylteronlytoreplaceit.

InspectingtheFilters

1.Inspectthesafetylter.Ifitisdirty ,replaceboth

thesafetyandprimarylters.

Important:Donotattempttocleanthe

safetylter.Ifthesafetylterisdirty,then

theprimarylterisdamaged.

2.Inspecttheprimarylterfordamagebylooking

intothelterwhileshiningabrightlightonthe

outsideofthelter.Iftheprimarylterisdirty,

bent,ordamaged,replaceit.

Note:Holesinthelterappearasbrightspots.

Donotcleantheprimarylter.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandthe

coverinstalled.

1.Ifyouareinstallingnewlters,checkeachlter

forshippingdamage.

Note:Donotuseadamagedlter.

2.Ifyouarereplacingtheinnerlter,carefullyslide

itintothelterbody(Figure29).

3.Carefullyslidetheprimarylteroverthesafety

lter(Figure29).

Figure29

1.Air-cleanerbody4.Air-cleanercover

2.Primarylter5.Safetylter

3.Latch

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutofthe

air-cleanerbody(Figure29).

Note:Ensurethattheprimarylterisfully

seatedbypushingontheouterrimwhile

installingit.

Important:Donotpressonthesoft,inside

areaofthelter.

4.Installtheair-cleanercoverandsecurethe

latches(Figure29).

g001883

Note:Avoidknockingthelterintothesideof

thebody.

26

ServicingtheEngineOil

Engine-OilSpecications

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

Model44409,44410,44423,44424,and44427

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,

orSL)

EngineOilCapacity:1.5L(51oz)withoutlter;

1.7L(57oz)withlter

Viscosity:Refertothetablebelow.

Figure30

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothingand

otherbodypartsawaythemuferandother

hotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecause

theenginemaybedamaged.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Checktheengine-oillevelasshownin(Figure

g303164

32).

Model44430,44448,and44454

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,

orSL)

EngineOilCapacity:1.8L(61oz)withoutlter;

2.0L(68oz)withlter

Viscosity:Refertothetablebelow.

Figure31

g037096

27

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every100hours

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoil

g299569

drainscompletely.

2.DisengagethePTOandengagetheparking

brake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.ChangetheengineoilasshowninFigure33.

Figure32

g311705

28

g299570

g235264

Figure34

6.Starttheengineanddrivetoaatarea.

7.Checktheoillevelagain.

ChangingtheEngine-OilFilter

ServiceInterval:Every200hours

Figure33

5.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

34).

Note:Changetheengine-oilltermorefrequently

whenoperatingconditionsareextremelydustyor

sandy.

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page28).

2.Changetheengine-oillter(Figure35).

g036784

29

ServicingtheSparkPlug

ServiceInterval:Every100hours

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

g299569

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

Type:NGK®BPR4ESorequivalent

Airgap:0.75mm(0.03inch)

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.RemovethesparkplugasshowninFigure36.

Figure35

Note:Ensurethattheoil-ltergaskettouches

theengine,thenrotatethelteranextra3/4turn.

3.Fillthecrankcasewiththepropertypeofnew

oil;refertoEngine-OilSpecications(page27).

g299598

g027477

g027478

Figure36

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

30

Figure37

InstallingtheSparkPlug

FuelSystem

Maintenance

DANGER

Incertainconditions,fuelisextremely

g027479

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

RefertoFuelSafety(page10)foracomplete

listoffuelrelatedprecautions.

DrainingtheFuelTank

Note:Useasyphonpumptodrainfuelfromthetank.

Youcanpurchaseasyphonpumpatahardwarestore.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyou,others,and

candamageproperty .

Figure38

•Performanyfuel-relatedmaintenance

whentheengineiscold.Dothisoutdoors

inanopenarea.Wipeupanyfuelthat

spills.

g027661

•Neversmokewhendrainingfuel,andstay

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(Figure39).

4.Removethefuelcap.

5.Insertasyphonpumpintothefueltank.

6.Usingthesyphonpump,drainthefuelintoa

cleanfuelcan(Figure39).

7.Wipeupanyspilledfuel.

31

Figure39

1.Fuelcap

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Y early(whichever

comesrst)

Donotinstalladirtylterifitisremovedfromthefuel

line.

Note:Wipeupanyspilledfuel.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Closethefuel-shutoffvalve;refertoUsingthe

Fuel-ShutoffValve(page19).

4.ReplacethefuellterasshowninFigure40.

g300374

g029685

Figure40

32

ElectricalSystem

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

fourpartswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

WARNING

Incorrectlyremovingthecablesfrom

batterycoulddamagethemachineand

cables,causingsparks.Sparkscan

causethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative

(black)batterycablebefore

disconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

4.Slidetherubbercoveroffthepositive(red)

cable.

5.Disconnectthepositive(red)cablefromthe

batterypost(Figure41).

Note:Retainallfasteners.

6.Removethebatteryhold-down(Figure41),and

liftthebatteryfromthetray.

Voltage:12V

RemovingtheBattery

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Disconnectthenegative(black)groundcable

fromthebatterypost(Figure41).

Note:Retainallfasteners.

WARNING

Batteryterminalsormetaltools

couldshortagainstmetalmachine

components,causingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Whenremovingorinstallingthe

battery,donotallowthebattery

terminalstotouchanymetalpartsof

themachine.

g299658

Figure41

1.Battery4.Terminalboot

2.Positive(+)batterypost5.Negative(–)batterypost

3.Bolt,washer,andnut6.Batteryhold-down

•Donotallowmetaltoolstoshort

betweenthebatteryterminalsand

metalpartsofthemachine.

33

ChargingtheBattery

ServicingtheFuses

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.260specicgravity).Thisisespecially

importanttopreventbatterydamagewhenthe

temperatureisbelow0°C(32°F).

1.Removethebatteryfromthemachine;referto

RemovingtheBattery(page33).

2.Connecta3to4Abatterychargertothebattery

posts.Chargethebatteryatarateof3to4A

for4to8hours(12V).

Note:Donotoverchargethebattery.

3.Whenthebatteryisfullycharged,unplugthe

chargerfromtheelectricaloutlet,anddisconnect

thechargerleadsfromthebatteryposts(Figure

42).

4.Installthebattery;refertoInstallingtheBattery

(page34).

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Pulloutthefusetoremoveorreplaceit.

Figure42

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetray(Figure41).

2.Usingthefastenerspreviouslyremoved,install

thepositive(red)batterycabletothepositive

(+)batteryterminal.

3.Usingthefastenerspreviouslyremoved,install

thenegativebatterycabletothenegative(-)

batteryterminal.

4.Slidetheredterminalbootontothepositive

(red)batterypost.

5.Securethebatterywiththehold-down(Figure

41).

g299668

Figure43

1.Mainfuse(15A)2.Chargingfuse(25A)

g000538

34

DriveSystem

Maintenance

CheckingtheTirePressure

Figure44

g300244

g300245

Figure45

1.Nut2.Lowercontrolrod

5.Startthemachineandmovethethrottlecontrol

totheFASTposition.

6.Tondtheneutralposition,movethelower

g300243

controlrodupordownuntilthetirestopsrotating

(Figure45).

7.Tightenthenut(Figure45).

CheckingtheWheel-Lug

Nuts

ServiceInterval:Aftertherst100hours—Checkthe

wheel-lugnuts.

Checkandtorquethewheel-lugnutsto115to142

N∙m(85to105ft-lb).

AdjustingtheNeutral

Traction

Ifthemachinecreepswhilethemotion-controllevers

areinneutral,adjusttheneutraltraction.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetherearofthemachineontojackstands

highenoughtoraisethedrivewheelsoffthe

ground.

4.Loosenthenutforcontrol-rodassembly(Figure

45).

Important:Ensurethattheroddoesnot

move;otherwise,youmayneedtoadjustthe

rodagain.

8.Repeatfortheotherlever.

Note:Y oumayneedtoadjustthetrackingafter

adjustingtheneutraltraction;refertoAdjustingthe

Tracking(page35).

AdjustingtheTracking

Ifyoupushbothmotion-controlleversforwardfull

speedacrossaat,levelsurfaceandthemachine

pullsto1side,adjustthetrackingasfollows.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.RotatetheadjustmentscrewshowninFigure45

toincreaseordecreasethespeedforthatlever.

Note:Rotatethescrewclockwisetodecrease

thespeed;rotateitcounterclockwisetoincrease

thespeed.

Ifthemachinepullstotheleft,decreasethe

speedfortherightleverorincreasethespeed

fortheleftlever.

35

Ifthemachinepullstotheright,decreasethe

speedfortheleftleverorincreasethespeed

fortherightlever.

4.Tightenthelocknutuntilthespringwashersare

at,andthenbackoffa1/4turntoproperlyset

thepreloadonthebearings(Figure47).

Important:Makesurethatthespring

washersareinstalledcorrectlyasshownin

Figure47.

5.Installthedustcap(Figure47).

Figure46

1.Adjustmentscrew

4.Startthemachineanddriveforwardacrossa

at,levelsurfacewiththemotion-controllevers

fullyforwardtocheckifthemachinetracks

straight.Repeattheprocedureasneeded.

AdjustingtheCaster-Pivot

Bearings

122cm(48inch),137cm(54inch),

and152cm(60inch)Machines

Only

ServiceInterval:Every500hours/Y early(whichever

comesrst)

Note:Youdonotneedtoadjustthecaster-pivot

bearingsfor91cm(36inch)machines.

g299908

g001297

Figure47

1.Springwashers

2.Locknut

3.Dustcap

ServicingtheCaster

WheelsandBearings

Thecasterwheelsrotateonarollerbearingsupported

byaspannerbushing.Ifthebearingiskeptwell

lubricated,wearwillbeminimal.Failuretokeepthe

bearingwelllubricatedcausesrapidwear.Awobbly

casterwheelusuallyindicatesawornbearing.

1.Removethelocknutandwheelboltholdingthe

casterwheeltothecasterfork(Figure48).

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethedustcapfromthecasterandtighten

thelocknut(Figure47).

36

Figure48

1.Locknut4.Rollerbearing

2.Bushing

3.Spannerbushing

2.Remove1bushing,thenpullthespanner

bushingandrollerbearingoutofthewheelhub

(Figure48).

3.Removetheotherbushingfromthewheelhub

andcleananygreaseanddirtfromthewheel

hub(Figure48).

4.Inspecttherollerbearing,bushings,spanner

bushingandtheinsideofthewheelhubforwear.

5.Casterwheel

6.Wheelbolt

Note:Replaceanydamagedorwornparts

(Figure48).

5.Place1bushingintothewheelhub(Figure48).

6.Greasetherollerbearingandspannerbushing,

andslidethemintothewheelhub(Figure48).

CoolingSystem

Maintenance

CleaningtheAir-Intake

Screen

Removeanybuildupofgrass,dirt,orotherdebris

fromthecylinderandcylinderheadcoolingns,

theair-intakescreenontheywheelend,andthe

carburetor-governorleversandlinkage.Thishelps

ensureadequatecoolingandcorrectenginespeedto

reducethepossibilityofoverheatingormechanical

damagetotheengine.

g009453

CleaningtheCooling

System

ServiceInterval:Beforeeachuseordaily

Every100hours/Yearly(whichevercomesrst)

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheair-intakescreen,recoilstarter,and

fanhousing(Figure49).

4.Cleanthedebrisandgrassfromtheengine

parts.

5.Installtheair-intakescreen,recoilstarter,and

fanhousing(Figure49).

7.Placethesecondbushingintothewheelhub

(Figure48).

8.Installthecasterwheelintothecasterforkand

secureitwiththewheelboltandlocknut(Figure

48).

9.Tightenthelocknutuntilthespannerbushing

bottomsagainsttheinsideofthecasterforks

(Figure48).

10.Greasethettingonthecasterwheel.

37

Figure49

1.Air-intakescreen4.Bolt

2.Fanhousing5.Nut

3.Recoilstarter

BrakeMaintenance

TestingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

Beforeeachuse,testtheparkingbrakeonbotha

levelsurfaceandslope.

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.Iftheparkingbrake

doesnotholdsecurely ,adjustit.

1.DisengagethePTOandengagetheparking

brake

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

g001472

3.Disengagetheparkingbrake.

4.Engagethebrakeleverandensurethatthe

machinedoesnotmove.

5.Adjustthebrakeifneeded.

AdjustingtheParking

Brake

1.Parkthemachineonalevelsurfaceand

disengagethePTO.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasetheparkingbrake.

4.Loosentheboltonthecableclampontheleft

sideofthemachine(Figure50).

Figure50

1.Cable

2.Cableclamp

5.Pulldownonthecablesuntiltheyaretight.

6.Tightenthenut.

38

3.Boltandnut

g031396

7.Checktheparkingbrakefunction;referto

TestingtheParkingBrake(page38).

BeltMaintenance

InspectingtheBelts

ServiceInterval:Every25hours—Checkthebelts

forwearorcracks.

Replacethebeltifitisworn.Thesignsofawornbelt

includesquealingwhilethebeltisrotating;theblades

slippingwhilecuttinggrass;andfrayededges,burn

marks,andcracksonthebelt.

ReplacingtheMower-Deck

Belt

WARNING

Thespringisundertensionwheninstalled

andcancausepersonalinjury.

Becarefulwhenremovingthebelt.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.For91cm(36-inch)decks,loosenthe2bolts

forbothpulleycoversandslidethecoversoff

(Figure51).

Figure51

g303050

1.Cover2.Screw(2)

4.For122cm(48-inch),137cm(54-inch),and

152cm(60-inch)decks,loosenthe4screws

forbothpulleycoversandremovethecovers

(Figure52).

39

Figure54

48in,54in,and60inMowerDecks

g299742

Figure52

1.Cover2.Screw(4)

5.Usingaspring-removaltool(T oroPartNo.

92-5771),removetheidlerspringfromthedeck

hooktoremovetensionontheidlerpulley,and

rollthebeltoffthepulleys(Figure53orFigure

54).

g298962

1.Idlerpulley

2.Clutchpulley5.Spring-removaltool

3.Mowerbelt

4.Spring

6.Routethenewbeltaroundtheclutchpulleyand

mowerpulleys(Figure53orFigure54).

7.Installtheidlerspringtothedeckhook(Figure

53orFigure54).

8.Checkthelengthofthespring.Ifitislessthan

15.2cm(6inches),adjusttheidlerpulleyarm;

proceedtostep4inAdjustingtheIdlerPulley

Arm(page41).

9.Installthepulleycovers(Figure51orFigure52).

Figure53

36inMowerDecks

1.Idlerpulley

2.Clutchpulley5.Spring-removaltool

3.Mowerbelt

4.Spring

g299741

40

AdjustingtheIdlerPulley

Arm

ServiceInterval:Yearly—Checkthemowerdeck

idlerarmforwear.

Ifthelengthofthespringislessthan15.2cm(6

inches)oriftheidlerpulleyarmcontactstheidlerstop

showninFigure55,adjusttheidlerpulleyarm.

g302008

Figure56

122cm(48-inch)deckshown

Figure55

122cm(48-inch)deckshown

1.Springlengthatleast15.2

cm(6inches)

2.Nut4.Idlerstop

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethedeckguards;refertoRemovingthe

MowerDeckGuard(page23)

4.Loosenthenutontheidlerpulley(Figure55).

5.Adjustthepulleyintheslotasneeded(Figure

56).

3.Idlerpulley

1.Idlerarm

2.Slot4.Slidepulleytotherightfor

g302009

6.Tightenthenut(Figure55).

7.Installthedeckguard;refertoRemovingthe

MowerDeckGuard(page23).

3.Slidepulleytotheleftfor

wornbelt.

newbelt

ReplacingtheTransmission

Belt

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethemower-deckbeltfromtheclutch

pulley;refertoReplacingtheMower-DeckBelt

(page39).

4.Removetheclutchpulley(Figure57).

Slidethepulleytotheleftoftheslotforaworn

beltorifthespringlengthismorethan15.2cm

(6inches).

Slidethepulleytotherightoftheslotforanew

beltorifthespringlengthislessthan15.2cm

(6inches)

41

1.Clutchpulley

2.Washer

Figure57

g300384

Figure59

1.Belt2.Idlerpulley

g300383

9.Installthespringtothespringanchor.Usethe

3.Bolt

driveratchettoapplytensiontothespringto

allowthebelttopassoverthelipoftheidler

pulley(Figure58).

5.Insertadriveratchetinthesquareholeofthe

idlerarmtoreleasethebelttension(Figure58).

Figure58

1.Spring3.Squarehole

2.Idlerpulley

6.Removethebelt(Figure59).

7.Slowlyreleasethedrivertoreleasethespring

tension.Removethespringfromtheanchoron

theframe,ifneeded.

8.Installthenewbelt,routingitaroundthepulleys

asshowninFigure59.

10.Releasethetensioninthespringtoapply

tensiontothebelt.

11.Checkthatthebeltisseatedproperlyinallthe

pulleys.

12.Installtheclutchpulley(Figure57).T orquethe

boltto68to81N∙m(50to60ft-lb).

13.Installthemower-deckbelttotheclutchpulley;

refertoReplacingtheMower-DeckBelt(page

39).

g303781

42

ControlsSystem

Maintenance

Adjustingthe

Motion-ControlLevers

Ifthemotion-controlleversdonotalignhorizontally ,

adjustthemotion-controllevers.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Pushthemotion-controlleversdowntothe

operatingposition.

g303793

Figure61

1.Nut3.Bailswitch

2.Cam4.Theatofthecam.

6.Adjustthecamuntilitalignswiththeother

motion-controlleverandtightenthenutforthe

cam(Figure61).

Figure60

1.Leftmotion-controlleverin

operatingposition

2.Rightmotion-controllever

inneutralposition

4.Checkthehorizontalalignmentofthe

motion-controllevers(Figure60).

5.Loosenthenutholdingthecamforthe

motion-controlleveryouareadjusting(Figure

61).

3.Checkthehorizontal

alignmenthere.

4.Rightmotion-controllever

inoperatingposition

Note:Movingthecamclockwiselowersthe

lever;movingthecamcounterclockwiseraises

g300386

thelever.

Important:Donotrotatetheatofthecam

pastvertical.Theoperator-presencecontrol

switchshouldnevercontacttheatofthe

cam(Figure61).

43

HydraulicSystem

Maintenance

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

HydraulicSystem

Specications

HydraulicFluidType:T oro®HYPR-OIL™500

hydraulicuid

HydraulicSystemFluidCapacity:4.7L(159oz)

Important:Usetheuidspecied.Otheruids

coulddamagethesystem.

CheckingtheHydraulic

FluidLevel

ServiceInterval:Every50hours

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Allthemachinetocoolcompletely.

4.Checktheuidlevelonthesideofthehydraulic

tank(Figure62).Continuetheprocedureifthe

levelisbelowthecoldlllevel.

Figure62

ChangingtheHydraulic

FluidandFilters

ServiceInterval:Aftertherst50hours—Changethe

hydraulic-systemltersanduid.

Every500hours—Aftertheinitial

change—changethehydraulic-system

ltersanduidwhenusingT oro

500uid.(Changeitmoreoftenunderdirtyor

dustyconditions)

Toreplacethehydraulicuid,theltersneedtobe

removed.Replacebothatthesametime;referto

HydraulicSystemSpecications(page44)foruid

specications.

®

HYPR-OIL

g300398

™

5.Cleantheareaaroundthecapofthehydraulic

tank(Figure62).

6.Removethecapfromthellerneckandadd

uidtothereservoiruntilitreachesthecoldll

level(Figure62).

7.Installthecaponthetank(Figure62).

RemovingtheFiltersandDraining

theFluid

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

44

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Important:Donotallowdirttoenterthe

hydraulicsystem,orcontaminationmay

occur.

3.Allowtheenginetocool.

4.Removethe2boltsandnutsfromthetransaxle

guards(Figure63).

Figure63

1.Shortcarriagebolt

2.Nut(5/16inch)

3.Transaxleguard

5.Pivottheguardsdown.

6.Locatethelterandguardsoneach

transaxle-drivesystem(Figure64).

9.Placeadrainpanbelowtheltertocatchthe

uidthatdrainswhenthelterandventplugs

areremoved.

10.Locateandremovetheventplugoneach

transmission

11.Unscrewtheltertoremoveit,andallowthe

uidtodrainfromthedrivesystem.

12.Repeatthisprocedureforbothlters.

InstallingtheHydraulicFilters

1.Applyathincoatofhydraulicuidonthesurface

oftherubbersealofeachlter.

g303851

2.Turnthelterclockwiseuntiltherubberseal

contactsthelteradapter,thentightenthelter

anadditional3/4to1fullturn.

7.Removethe3screwssecuringthelterguard

andremovetheguard(Figure64).

Figure64

Rightsideshown

1.Transaxledrive

2.Filter5.Ventplug

3.Filterguard

4.Screws

8.Carefullycleantheareaaroundthelters.

g010254

g027477

Figure65

3.Repeatfortheoppositelter.

4.Installthelterguardsovereachlterthatyou

previouslyremoved(Figure64).

5.Usethe3screwstosecurethelterguards

(Figure64).

45

AddingHydraulicFluid