Page 1

Part No. 10178SL

Service Manual

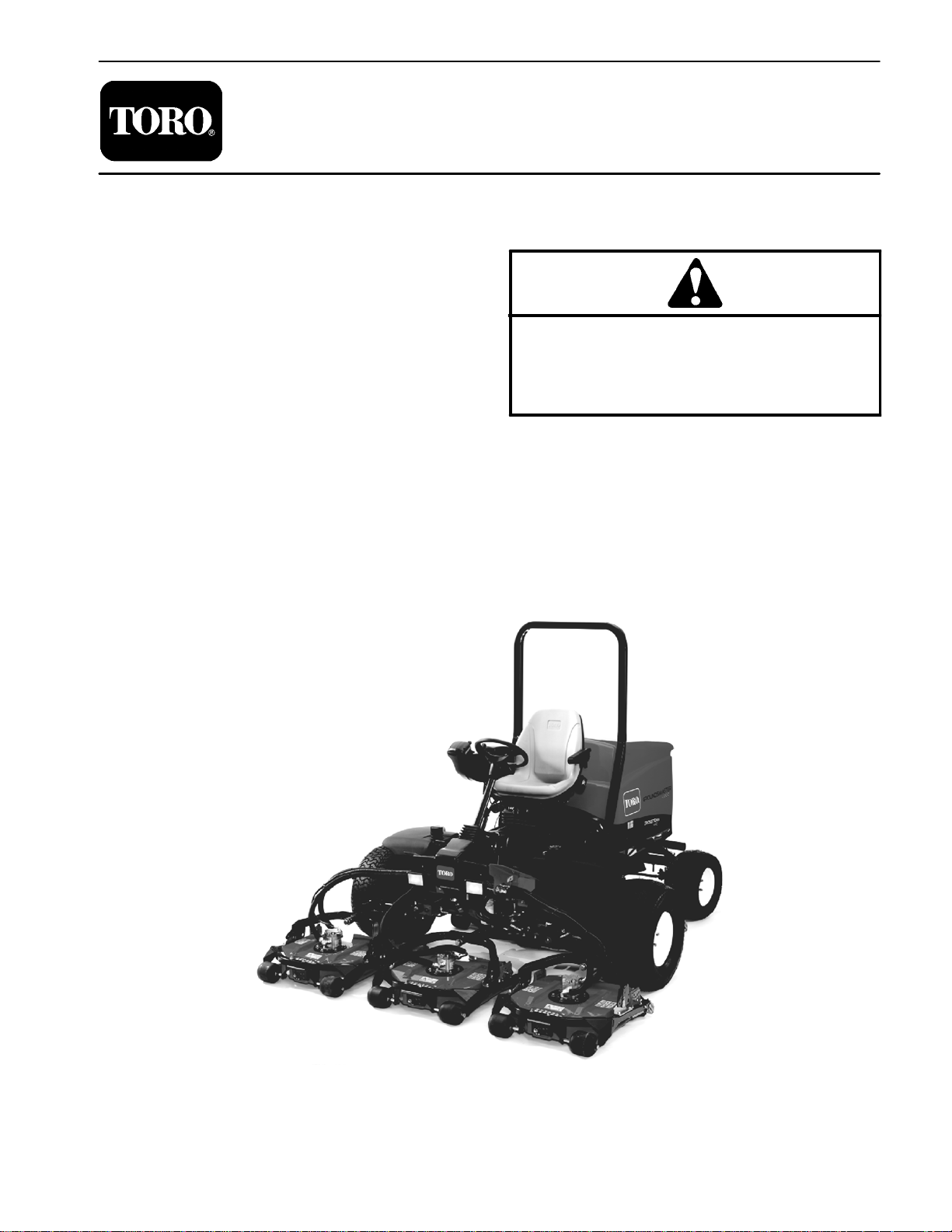

Groundsmaster

Preface

The purposeof thispublication isto providethe service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Groundsmaster 4300--D.

REFER TO THEOPERATOR’S MANUALFOROPERATING, MAINTENANCE AND ADJUSTMENT

INSTRUCTIONS.Spaceis provided in Chapter2 of this

book to insertthe Operator’s Manual and Parts Catalog

for your machine. Additional copies of the Operator’s

Manual and Parts Catalog are available on the internet

at www.Toro.com.

TheToroCompany reservestherightto changeproduct

specifications or this publication without notice.

R

4300--D

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: ANOTE willgive generalinformation about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give importantinstructionswhichmustbefollowed toprevent damage to systems or components on the

machine.

E The Toro Company -- 2010

Page 2

This page is intentionally blank.

Groundsmaster 4300--D

Page 3

Table Of Contents

Chapter 1 -- Safety

Safety Instructions 1 -- 2..........................

Jacking Instructions 1 -- 5.........................

Safety and Instruction Decals 1 -- 6................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Kubota Diesel Engine

General Information 3 -- 1........................

Specifications 3 -- 2..............................

Adjustments 3 -- 3...............................

Service and Repairs 3 -- 4........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

05--E3B SERIES

Chapter 4 -- Hydraulic System

Specifications 4 -- 2..............................

General Information 4 -- 3........................

Hydraulic Schematic 4 -- 9........................

Hydraulic Flow Diagrams 4 -- 10...................

Special Tools 4 -- 22.............................

Troubleshooting 4 -- 26...........................

Testing 4 - - 32...................................

Service and Repairs 4 -- 60.......................

SAUER--DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS REPAIR MANUAL

SAUER--DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS SERVICE INSTRUCTIONS

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

SAUER--DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

TM

SERVICE PROCEDURE

Chapter 5 -- Electrical System

General Information 5 -- 3........................

Special Tools 5 -- 4..............................

Troubleshooting 5 -- 6............................

Electrical System Quick Checks 5 -- 17.............

Adjustments 5 -- 19..............................

Component Testing 5 -- 22........................

Service and Repairs 5 -- 44.......................

Chapter 6 -- Chassis

Specifications 6 -- 2..............................

General Information 6 -- 2........................

Special Tools 6 -- 2..............................

Service and Repairs 6 -- 4........................

Chapter 7 -- Cutting Decks

Specifications 7 -- 2..............................

General Information 7 -- 3........................

Troubleshooting 7 -- 4............................

Special Tools 7 -- 5..............................

Adjustments 7 -- 6...............................

Service and Repairs 7 -- 8........................

Chapter 8 -- Foldout Drawings

Hydraulic Schematic 8 -- 3........................

Electrical Schematic 8 -- 4........................

Wire Harness Drawings 8 -- 6.....................

SafetyProduct Records

and Maintenance

Engine

Kubota Diesel

System

Hydraulic

System

Chassis

Groundsmaster 4300--D

Decks

Cutting Electrical

Foldout

Drawings

Page 4

This page is intentionally blank.

Groundsmaster 4300--D

Page 5

Table of Contents

SAFETY INSTRUCTIONS 2......................

Before Operating 2............................

While Operating 3.............................

Maintenance and Service 4....................

JACKING INSTRUCTIONS 5.....................

SAFETY AND INSTRUCTION DECALS 6..........

Chapter 1

Safety

Safety

Groundmaster 4300--D Page 1 -- 1 Safety

Page 6

Safety Instructions

Your Groundsmastermeetsor exceedssafetystandard

specifications when weights are installed according to

information in the Operator’s Manual. Although hazard

control andaccident preventionare partiallydependent

uponthe design andconfigurationofthe machine, these

factors are also dependent upon the awareness, concern and propertraining ofthe personnelinvolved inthe

operation, transport, maintenance and storage of the

machine. Improper use or maintenanceof the machine

can result in injury or death. To reduce the potential for

injury or death,comply with the following safety instructions.

Before Operating

WARNING

To reduce the potentialfor injuryordeath,comply with the following safety instructions.

1. Review and understand the contents of the Operator’ sManual and OperatorTrainingDVD beforestarting

and operating the machine. Become familiar with the

controls andknow how to stopthe machineand engine

quickly. A replacement Operator’s Manual is available

on the Internet at www.Toro.com.

2. Keep all shields, safetydevicesand decals inplace.

If a shield, safety device or decal is defective, illegible

or damaged, repair or replace it before operating the

machine.

3. Tighten any loose nuts, bolts or screws to ensure

machine is in safe operating condition.

4. Assure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is in

NEUTRAL and PTO switch is OFF (disengaged).

5. Since dieselfuel is highly flammable, handle itcarefully:

A. Store fuel in containers specifically designed for

this purpose.

B. Do not remove machine fuel tank cap while engine is hot or running.

C. Do not smoke while handling fuel.

D. Fill fueltank outdoorsandonlytowithinaninchof

the topof the tank, not thefiller neck.Do not overfill.

E. After refueling machine, install fuel tank andfuel

container caps.

F. Iffuel is spilled,do notattempttostart theengine

but move the machine away from the area of spillage. Avoid creating any source of ignition until fuel

vapors have dissipated. Wipe up any spilled fuel.

Groundsmaster 4300--DPage 1 -- 2Safety

Page 7

While Operating

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Apply the parking brake.

B. Make sure thetraction pedalis in NEUTRALand

the PTO switch is OFF (disengaged).

C. Afterengineisstarted, releaseparking brakeand

keepfoot off tractionpedal. Machinemust not move.

If movement is evident, the traction pedal linkage is

adjusted incorrectly; therefore, shut engine off and

adjust traction pedal linkage until machine does not

move when traction pedal is released (see Operator’ s Manual).

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

4. Do not touch engine, radiator or exhaust system

whileengineisrunningor soonafter it is stopped. These

areas could be hot enough to cause burns.

5. Before getting off the seat:

A. Ensure that traction pedal is in NEUTRAL.

B. Lower and disengage cutting decks and wait for

all movement to stop.

C. Apply parking brake.

D. Stop engine and removekey from ignitionswitch.

6. Anytime the machineis parked (short or long term),

the cuttingdecksshould belowered totheground. This

relieves pressurefrom thehydraulic liftcircuit and eliminates the risk of the cutting decks unexpectedly lowering to the ground.

7. Do not parkon slopesunlesswheels arechockedor

blocked.

Safety

Groundmaster 4300--D Page 1 -- 3 Safety

Page 8

Maintenance and Service

1. Before servicing or making adjustments, lower cutting decks, stop engine, apply parking brake and remove key from the ignition switch.

2. Make suremachineis in safeoperating conditionby

keeping all nuts, bolts and screws tight.

3. Never store the machine or fuel container inside

wherethereisanopenflame, such asneara waterheater or furnace.

4. Makesure all hydraulic line connectorsare tight,and

all hydraulic hoses and lines are in good condition before applying pressure to the hydraulic system.

5. Keepbody andhandsawayfrompinhole leaks inhydrauliclines that ejecthigh pressurehydraulic fluid.Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Fluid accidentally injected into the skin

must be surgically removedwithin a fewhours bya doctor familiar with this form of injury or gangrene may result.

6. Before disconnecting or performing any work on the

hydraulicsystem, allpressurein the system must berelieved by using all of the hydraulic controls (seeRelieving Hydraulic Pressure in the General Information

section of Chapter 4 -- Hydraulic System).

7. Use care when checking or servicing the cutting

decks. Wear gloves and use caution when servicing

them.

8. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Clean

protective screen on machine frequently.

12.Disconnect battery before servicing the machine.

Disconnect negative battery cable first and positive

cablelast. If batteryvoltage is required for troubleshooting or test procedures, temporarily connect the battery.

Reconnect positive battery cable first and negative

cable last.

13.Battery acid is poisonous and can cause burns.

Avoid contactwithskin, eyesand clothing. Protect your

face, eyes and clothing when working with a battery.

14.Battery gases can explode. Keep cigarettes,sparks

and flames away from the battery.

15.When changing attachments, tires or performing

other service, use correct supports, hoists and jacks.

Make sure machine is parked on asolid level floor such

asaconcrete floor. Prior toraising the machine,remove

any attachments that may interfere with the safe and

proper raising of the machine. Always chock or block

wheels. Use jackstandsor appropriate load holdingdevices to support the raised machine. If the machine is

not properly supported, the machine may move or fall,

whichmay result in personal injury (see JackingInstructions in this section).

16.Ifmajor repairs areever needed or assistance is desired, contact an Authorized Toro Distributor.

17.When welding on machine, disconnect all battery

cables toprevent damageto machine electronicequipment. Disconnect negative battery cable first and positive cable last. Also, disconnect the wire harness

connector from the machine controller and disconnect

the terminalconnectorfrom thealternator.Attach welder ground cableno morethantwo (2)feet (0.61meters)

from the welding location.

9. If engine must be runningto performmaintenanceor

to make an adjustment, keep hands, feet, clothing and

other partsof thebody away fromthe cuttingdecksand

other moving parts. Keep bystanders away.

10.Do not overspeed the engine by changing governor

setting. T oassuresafetyandaccuracy,check maximum

engine speed with a tachometer.

1 1.Shut engine off before checking or adding oil to the

crankcase.

18.At the time of manufacture, your Groundsmaster

conformed to thesafety standardsforriding mowers.To

assure optimum performanceand continuedsafetycertification ofthemachine,usegenuine Tororeplacement

parts and accessories. Replacement parts and accessories madeby other manufacturers may result innonconformance with the safety standards, and the

warranty may be voided.

Groundsmaster 4300--DPage 1 -- 4Safety

Page 9

Jacking Instructions

CAUTION

When changing attachments, tiresor performing otherservice, use correctsupports,hoists

and jacks. Make sure machine is parked on a

solid, level surface such as a concrete floor.

Prior to raising machine, remove any attachments that may interfere with the safe and

proper raising of the machine. Always chock

or block wheels. Use jack stands or other appropriate load holding devices to support the

raised machine. If the machine is not properly

supported, the machine may move or fall,

which may result in personal injury.

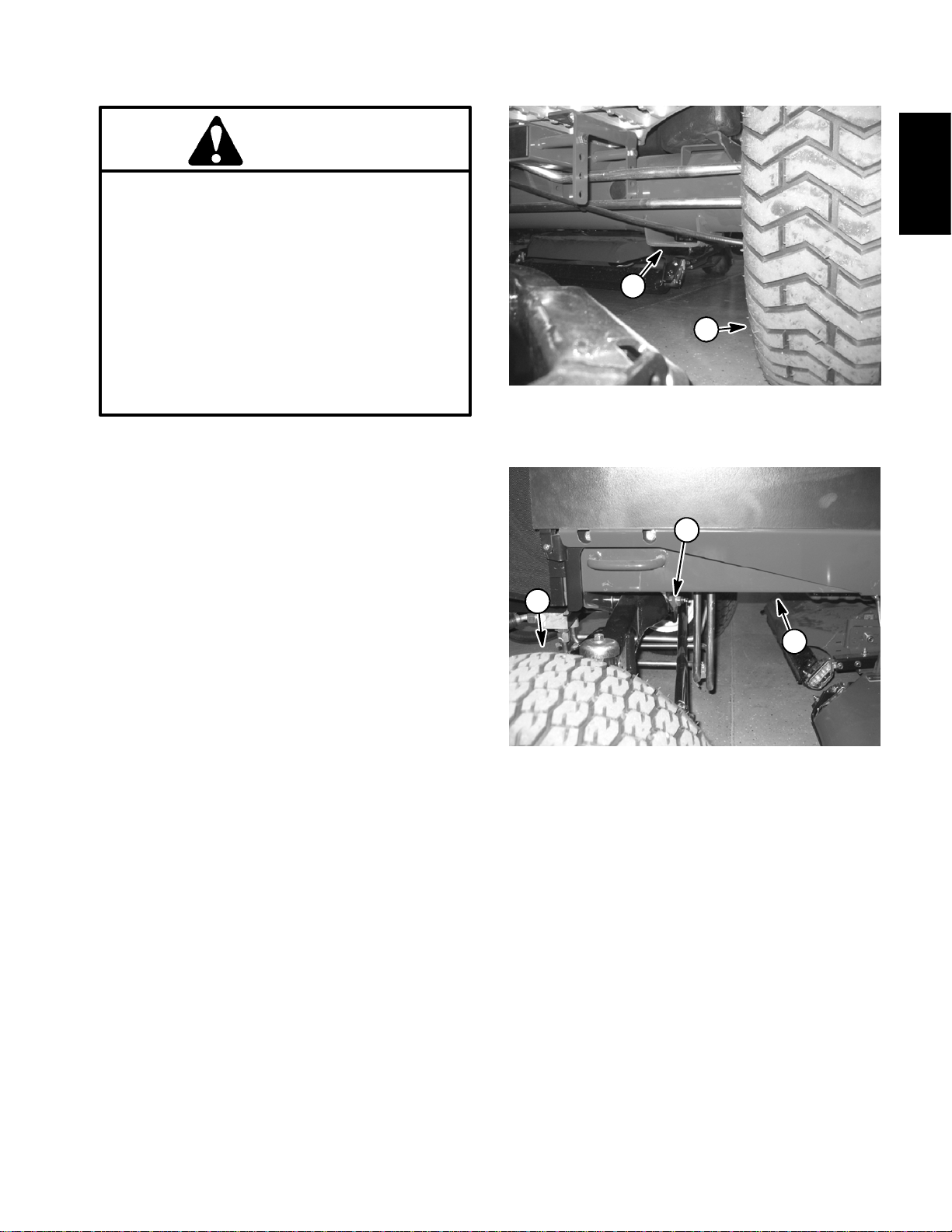

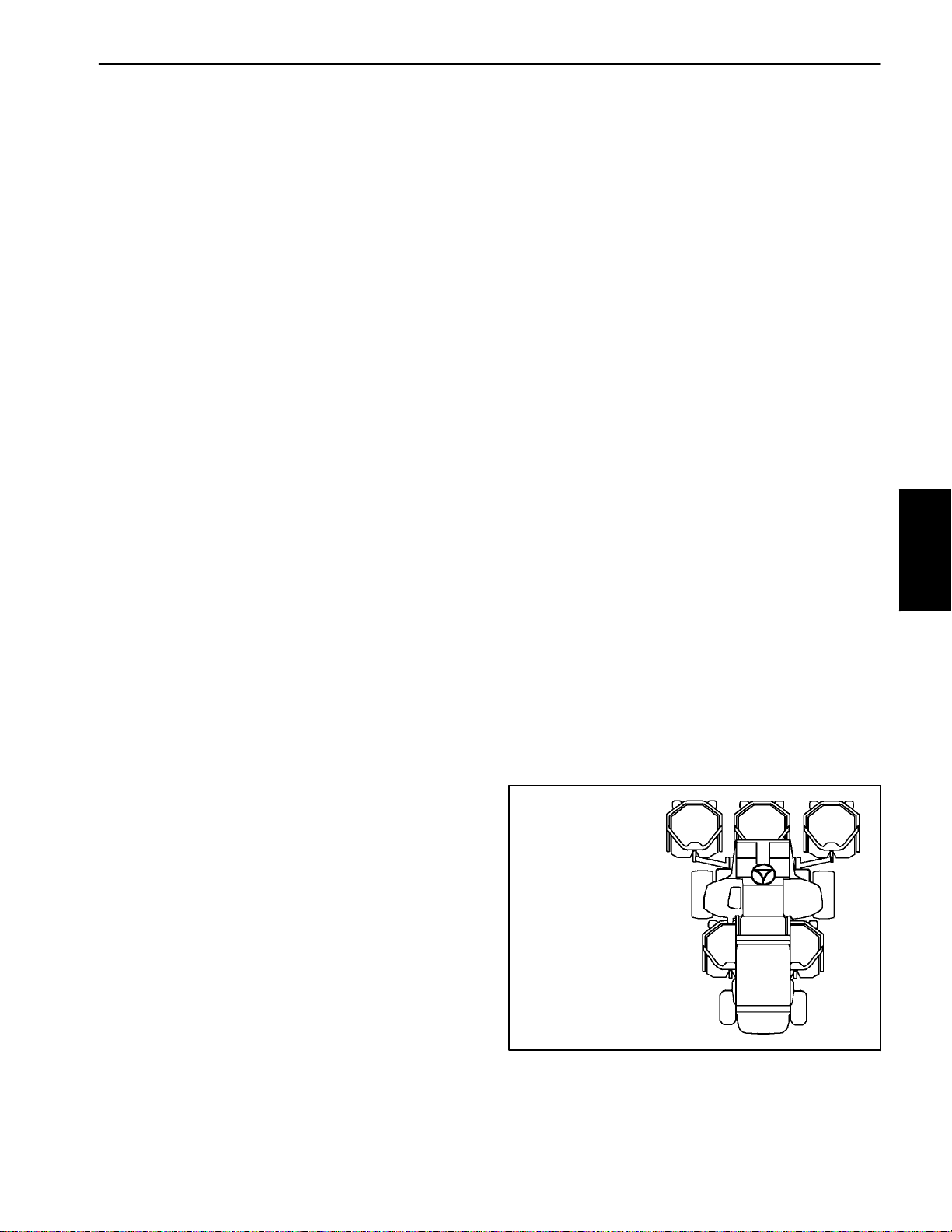

Front End Jacking

1. Applyparking brake and chockboth reartirestoprevent the machine from moving.

2. Position jack securely under the rectangular padon

the frame axle tube, just to the inside of the front wheel

(Fig. 1).

3. Jack front of machine off the ground.

4. Position jackstands under the frame as close to the

wheel as possible to support the machine.

Safety

2

1

Figure 1

1. Front wheel 2. Front jacking point

2

1

3

Rear End Jacking

1. Applyparkingbrakeandchockbothfront tires toprevent the machine from moving.

2. Place jacksecurelyat thecenter of the rear axleunder the axle pivot bracket. Jack rear of machine off the

ground.

3. Position jack stands under the frame to support the

machine.

1. Rear wheel

2. Rear axle pivot bracket

Figure 2

3. Jack stand location

Groundmaster 4300--D Page 1 -- 5 Safety

Page 10

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the traction unit and cutting units of your Groundsmaster. If any decal becomes illegible or damaged, installa

new decal. Part numbers for decals are listed in your

Part Catalog. Order replacement decals from your Authorized Toro Distributor.

Groundsmaster 4300--DPage 1 -- 6Safety

Page 11

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1...............................

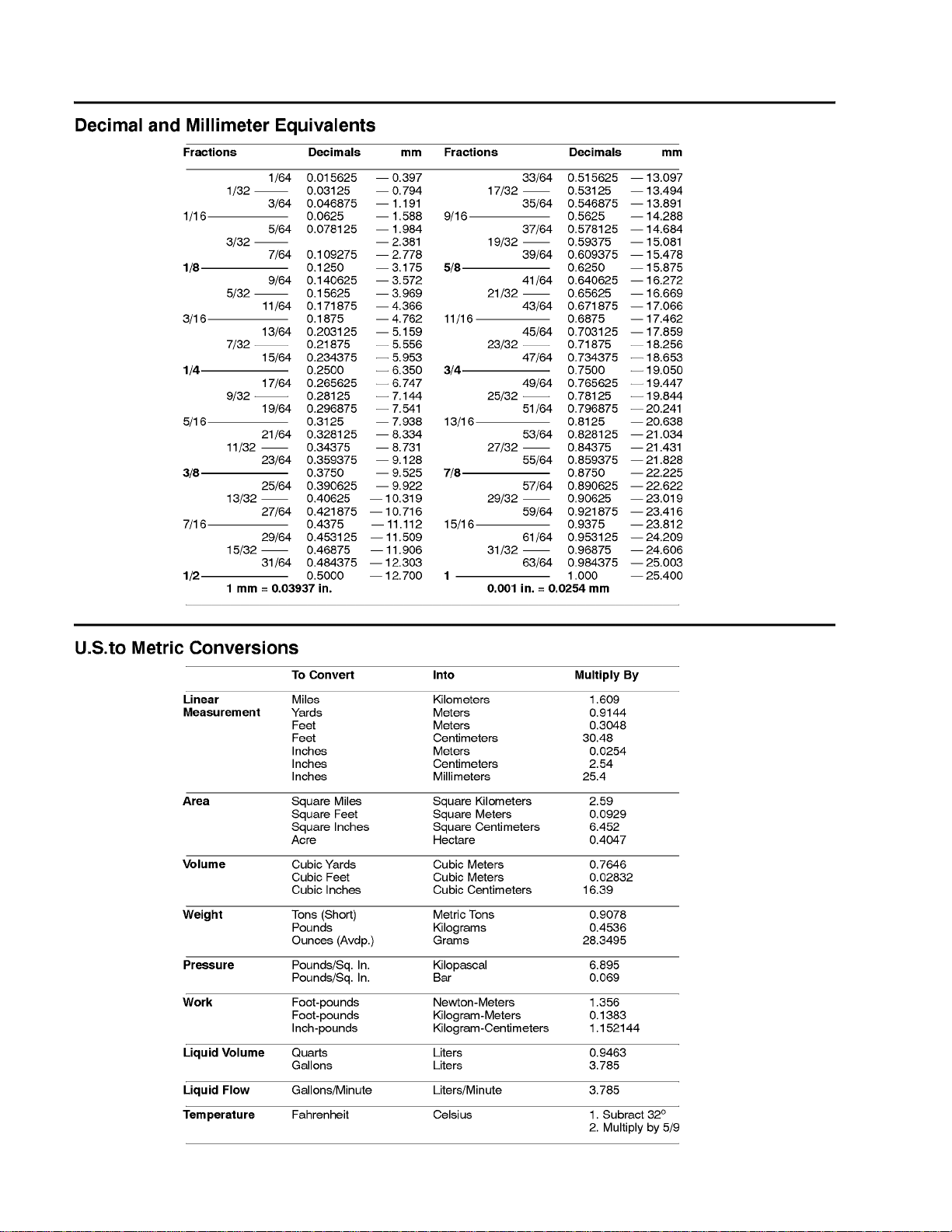

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3....................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Series) 5..............

Other Torque Specifications 6..................

Conversion Factors 6..........................

Chapter 2

Product Records

and Maintenance

Product Records

Insert Operator’s Manual and Parts Catalog for your

Groundsmaster at the end of this chapter. Additionally,

if any optional equipment or accessories have been

installedto your machine, insertthe Installation Instructions, Operator’s Manuals andParts Catalogsfor those

options at the end of this chapter.

Maintenance

Maintenanceprocedures andrecommendedservice intervals for your Groundsmaster areidentified in theOperator’s Manual. Refer to that publication when

performing regular equipment maintenance.

Groundsmaster 4300--D Page 2 -- 1 Product Records and Maintenance

Page 12

Equivalents and Conversions

0.09375

Groundsmaster 4300--DPage 2 -- 2Product Records and Maintenance

Page 13

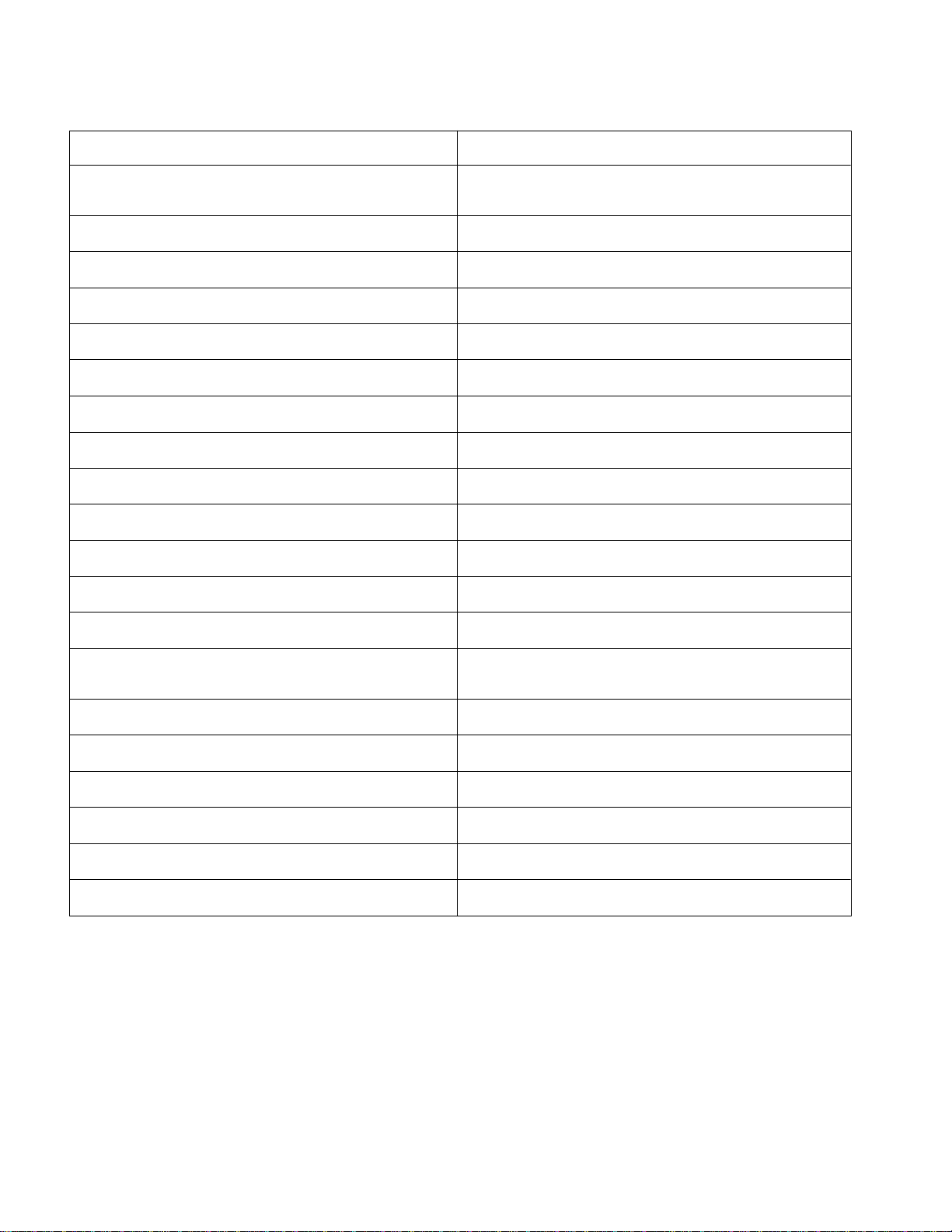

Torque Specifications

Recommended fastener torque values are listed in the

followingtables.Forcriticalapplications,as determined

byToro,eitherthe recommended torque oratorque that

is unique to theapplication isclearly identifiedand specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shallapply to allfasteners which

donot have a specific requirement identified inthis Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence ofa prevailing torquefeature

(e.g. Nylock nut), hardness of the surface underneath

thefastener’sheadorsimilarcondition whichaffectsthe

installation.

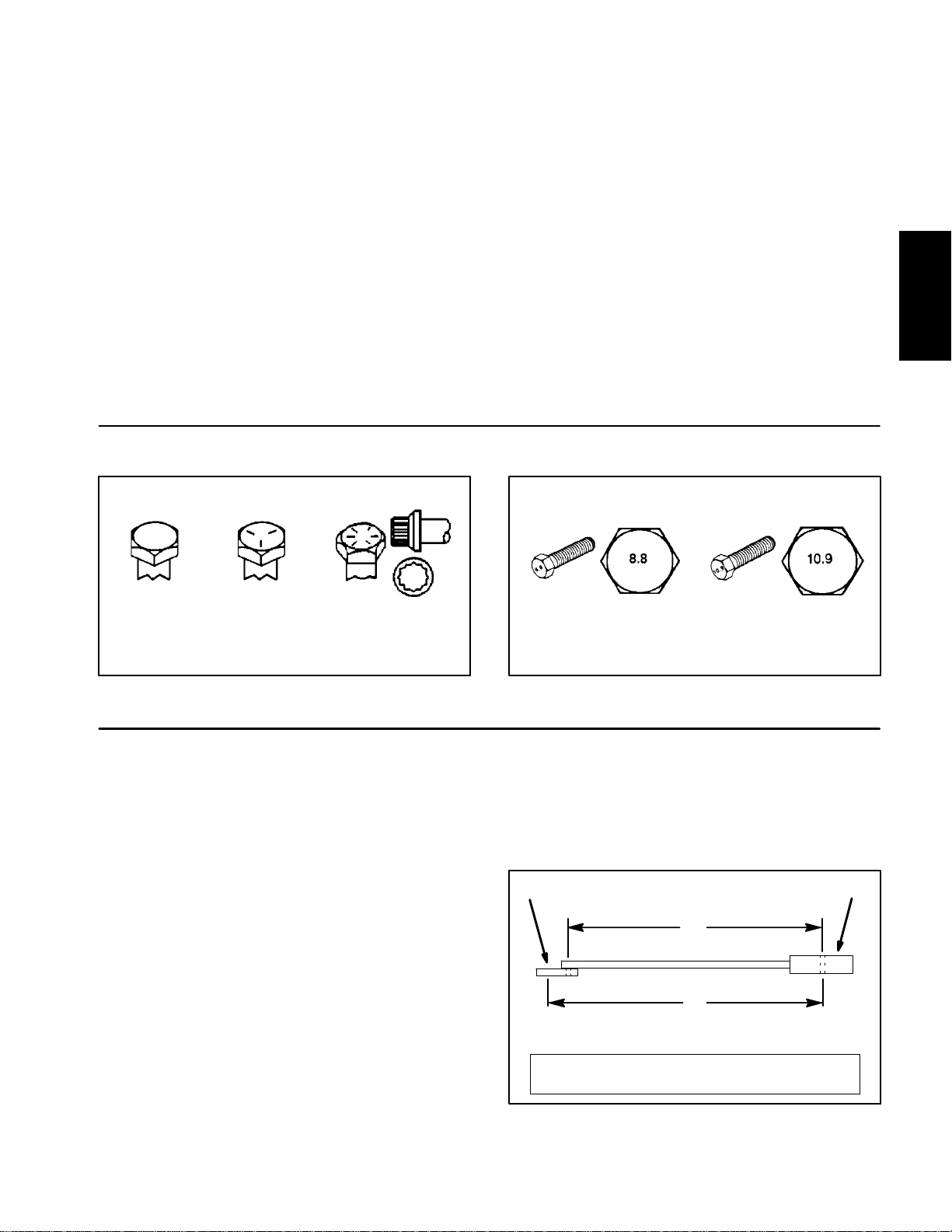

Fastener Identification

Asnoted inthe followingtables,torquevaluesshouldbe

reduced by 25% for lubricated fasteners to achieve

the similarstress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based onthe aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measurethe torque required to tighten the fasteneruntil

the lines match up.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

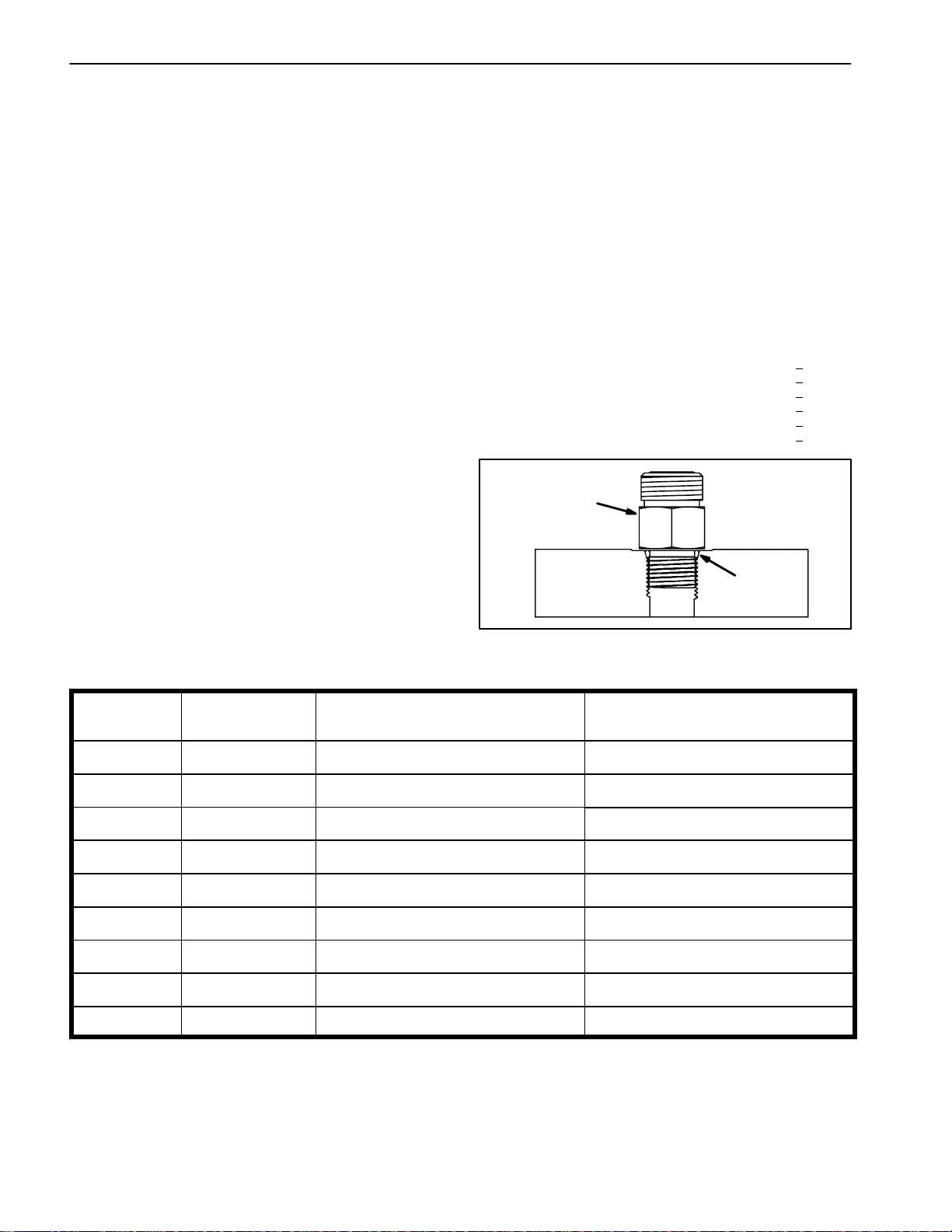

Using a Torque Wrench with an Offset Wrench

Useofanoffsetwrench(e.g.crowfootwrench)willaffect

torquewrenchcalibration due to the effective change of

torquewrench length. When using atorquewrenchwith

an offset wrench, multiplythe listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: Themeasured effectivelength of the torque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

Themeasuredeffectivelengthofthetorquewrenchwith

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft--lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft--lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A/ B

Torque wrenchOffset wrench

The calculated torque conversion factor for this torque

wrenchwiththisoffsetwrench would be 18 / 19 = 0.947.

Groundsmaster 4300--D Page 2 -- 3 Product Records and Maintenance

Figure 3

Page 14

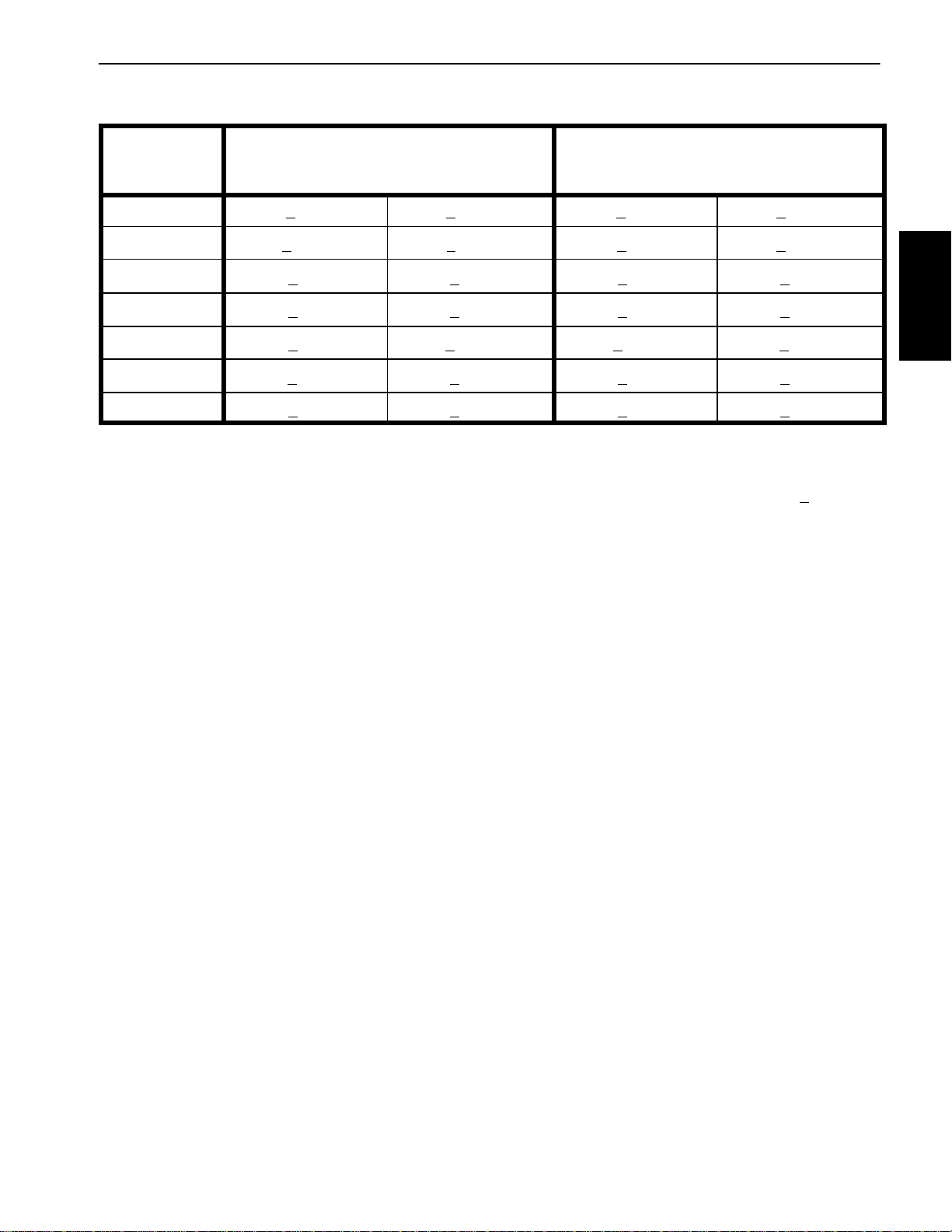

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130+ 113 140 + 15 1582 + 169

1/4 -- 28 UNF 53 +7 65 + 10 734 + 113 115 + 12 1299 + 136 160+ 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 +15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 +17 128 + 17 1446 + 192 225 +25 2542 + 282 325 + 33 3672 +373

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in--lb N--cm in--lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

17 + 2 192 + 23 25 + 3 282 + 34

29 + 3 328 + 34 41 + 5 463 + 56

31 + 4 350 + 45 43 + 5 486 + 56

42 + 5 475 + 56 60 + 6 678 + 68

48 + 5 542 + 56 68 + 7 768 + 79

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 +2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 +3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142+ 15

1/2 -- 20 UNF 32 +4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203+ 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 +10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 +30 407 + 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 +66 904 + 89

NOTE: Reduce torque values listed inthe tableabove

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and8 fasteners arebased on 75%of the minimumproofload specified in SAE J429. The toleranceis

approximately +

10% of the nominal torquevalue. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specifictorque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Groundsmaster 4300--DPage 2 -- 4Product Records and Maintenance

Page 15

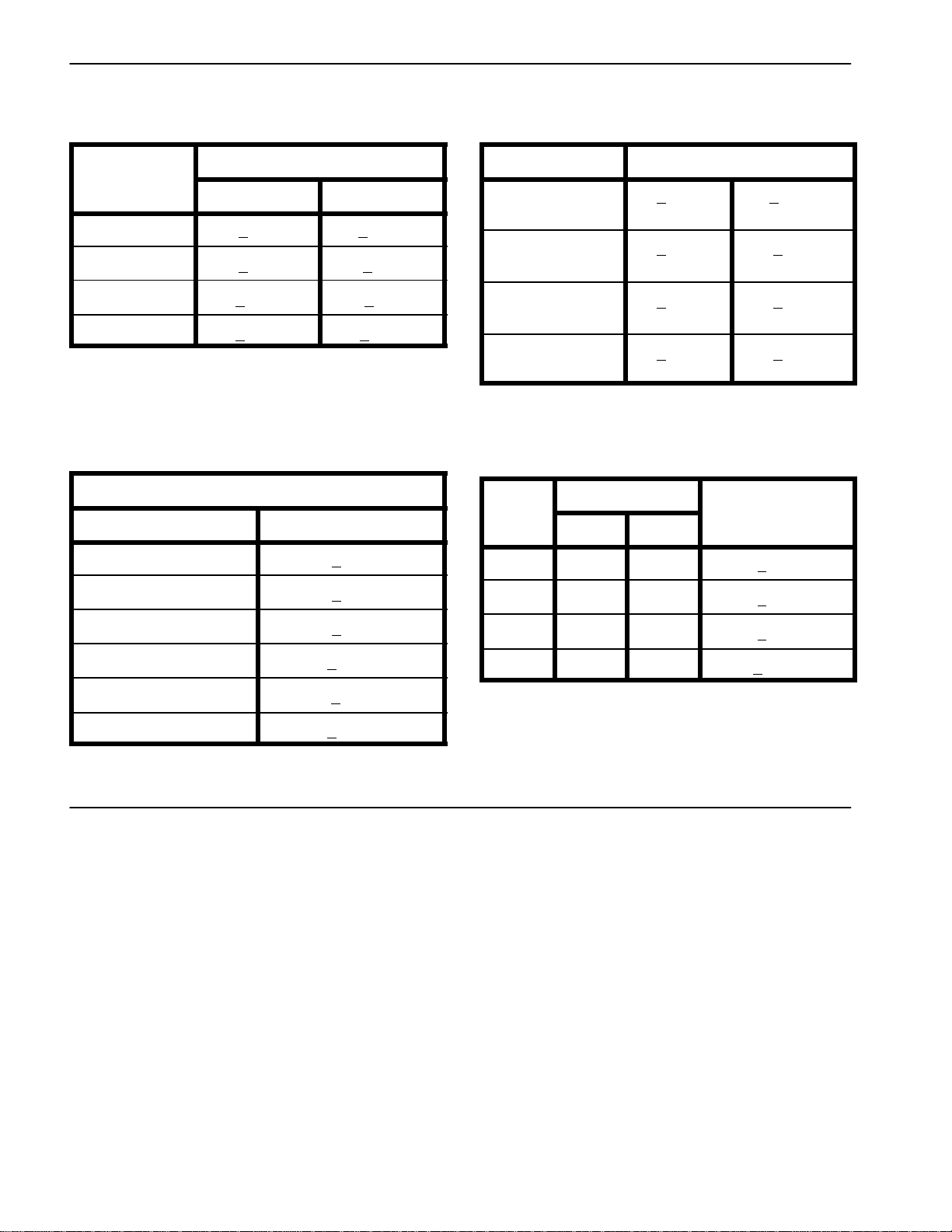

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N--cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N- -cm 133 +14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93 + 10 ft--lb 126+ 14 N--m

M16 X 2.0 166+ 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Reduce torque values listed inthe tableabove

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAEJ1199.Thetoleranceisapproximately+

nominal torque value.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specifictorque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

10%ofthe

Product Records

and Maintenance

Groundsmaster 4300--D Page 2 -- 5 Product Records and Maintenance

Page 16

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

*Holesize,materialstrength,materialthicknessandfinish must be considered when determining specific

torquevalues. Alltorque values arebasedon non--lubricated fasteners.

Groundsmaster 4300--DPage 2 -- 6Product Records and Maintenance

Page 17

Table of Contents

Chapter 3

Kubota Diesel Engine

GENERAL INFORMATION 1.....................

Operator’s Manual 1..........................

Stopping the Engine 1.........................

SPECIFICATIONS 2............................

ADJUSTMENTS 3..............................

Adjust Throttle Control 3.......................

General Information

This Chapter gives information about specifications,

troubleshooting, testing andrepair of the Kubota diesel

engine used in the Groundsmaster 4300--D.

Most repairs and adjustments require tools which are

commonly available in many service shops. The useof

some specialized test equipment isexplained in theengine workshopmanual included at the endof thischapter. However, the cost of the test equipment and the

specialized natureof some repairs may dictate thatthe

work be done at an engine repair facility.

SERVICE AND REPAIRS 4......................

Fuel System 4................................

Air Cleaner 6.................................

Exhaust System 8............................

Radiator 10..................................

Engine 12....................................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

05--E3B SERIES

Service and repair parts for Kubota diesel engines are

suppliedthroughyour local T oroDistributor.If a parts list

is not available, be sure to provide your distributor with

the Toro model and serial number.

Engine

Kubota Diesel

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for the Kubota diesel engine that powers your

Groundsmaster machine. Refer to that publication for

additional information when servicing the machine.

Stopping the Engine

IMPORTANT: The engine used on the Ground smaster 4300--D isturbo--charged. Beforestopping

theengine aftermowing or full load operation,cool

the turbo-charger by allowing the engine to idle at

low speedfor five(5) minutes. Failure to do so may

lead to turbo-charger trouble.

Groundsmaster 4300--D Page 3 -- 1 Kubota Diesel Engine

Page 18

Specifications

Item Description

Make / Designation Kubota V1505--T--E3B, 4--stroke,

Number of Cylinders 4

Bore x Stroke 3.07 in x 3.09 in (78 mm x 78.4 mm)

Total Displacement 91.4 in3(1498 cc)

CompressionRatio 23:1

Firing Order 1 (fan end) -- 3 -- 4 (flywheel end) -- 2

Fuel No. 2--D Diesel Fuel (ASTM D975)

Fuel Injection Pump Bosch MD Type Mini

Fuel Injector Nozzle MiniNozzle (DNOPD)

Fuel Tank Capacity 14 U.S. gallons (53liters)

Governor Centrifugal Mechanical

Low Idle Speed(no load) 1250 to 1350 RPM

High Idle Speed (no load) 3050 to 3250 RPM

Liquid Cooled, OHV, Turbocharged Diesel

Engine Oil API Classification CI--4 or Higher

Oil Pump Gear Driven Trochoid Type

Crankcase Oil Capacity 5.5 U.S. quarts (5.2 liters) with Filter

Cooling System Capacity (including reserve tank) 10 U.S. quarts (9.5 liters)

Starter 12 VDC 1.2 KW

Alternator/Regulator 12 VDC 40 Amp

Engine Dry Weight (approximate) 251 lbs (114 kg)

(see Operator’s Manual for viscosity recommendations)

Groundsmaster 4300--DPage 3 -- 2Kubota Diesel Engine

Page 19

Adjustments

Adjust Throttle Control

Proper throttle operation is dependent upon proper adjustment of throttle control.

NOTE: The throttle cable swivel should be positioned

in the lowest hole in the speed control lever .

2

1. Move throttle control lever on control console to

FAST position.

2. Check position of the engine speed control lever on

fuel injection pump. The speed control lever should be

contacting the high speed screw whenthe throttlecontrol lever is in the FAST position.

3. If necessary,throttle controlcanbeadjustedbylooseningcable clampscrew andrepositioning control cable

until speed control lever contacts high speed screw

when the throttle control lever is in the FAST position.

Tighten cable clamp screw after adjustment has been

completed.

5

1

1. Throttle cable

2. High speed screw

3. Speed control lever

Figure 1

3

4

4. Swivel

5. Cable clamp

Engine

Kubota Diesel

Groundsmaster 4300--D Page 3 -- 3 Kubota Diesel Engine

Page 20

Service and Repairs

Fuel System

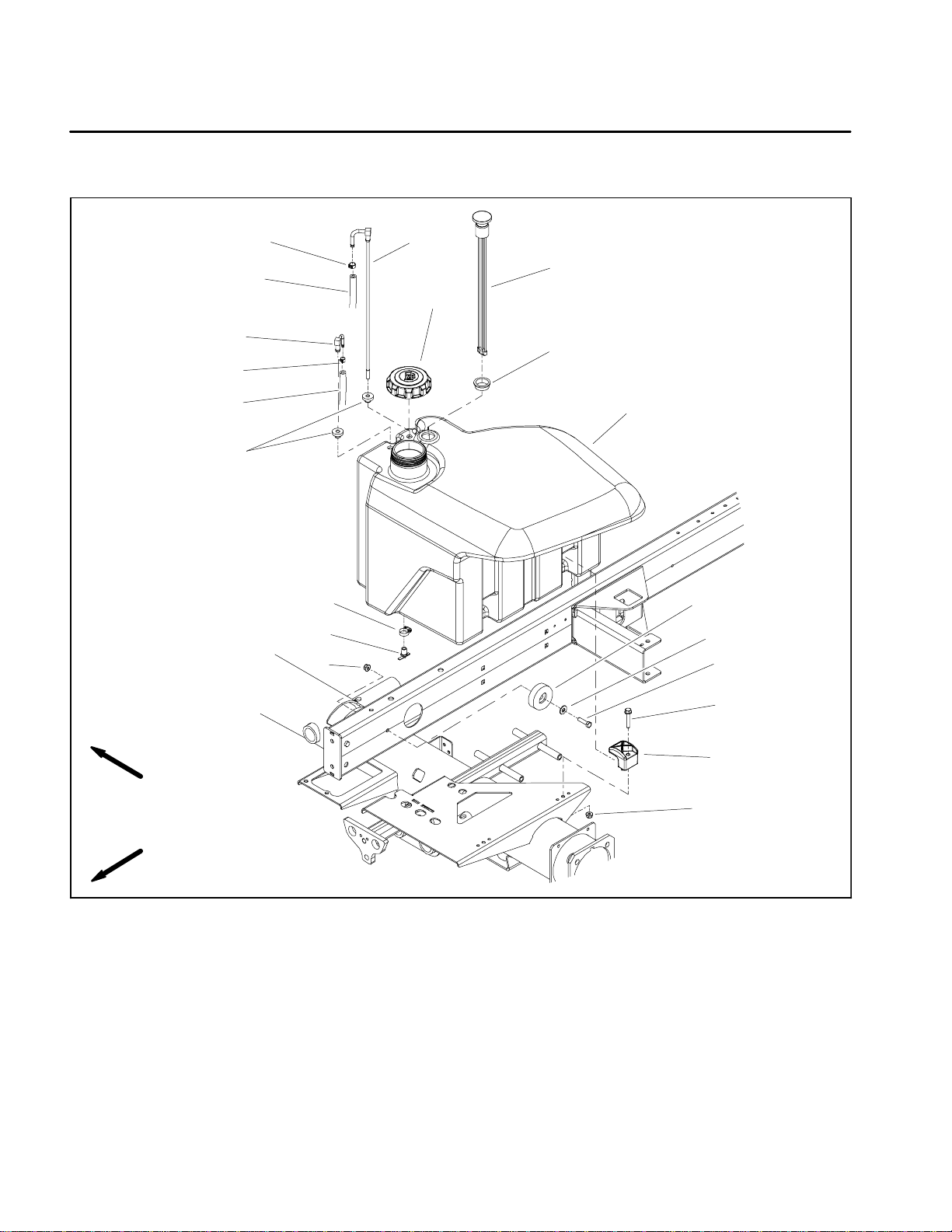

16

8

7

12

15

1

6

11

9

10

2

13

14

4

17

18

19

RIGHT

FRONT

1. Fuel cap

2. Bushing

3. Washer head screw (2 used)

4. Flange nut (3 used)

5. Clamp (2 used)

6. Returnfitting

7. Suction fitting

8. Hose clamp

9. Hose clamp

10. Fuel tank

11. Grommet

12. Fuel gauge

13. Hose clamp

3

5

4

Figure 2

14. Draincock

15. Fuel supply hose

16. Fuel return hose

17. Bumper

18. Flat washer

19. Cap screw

Groundsmaster 4300--DPage 3 -- 4Kubota Diesel Engine

Page 21

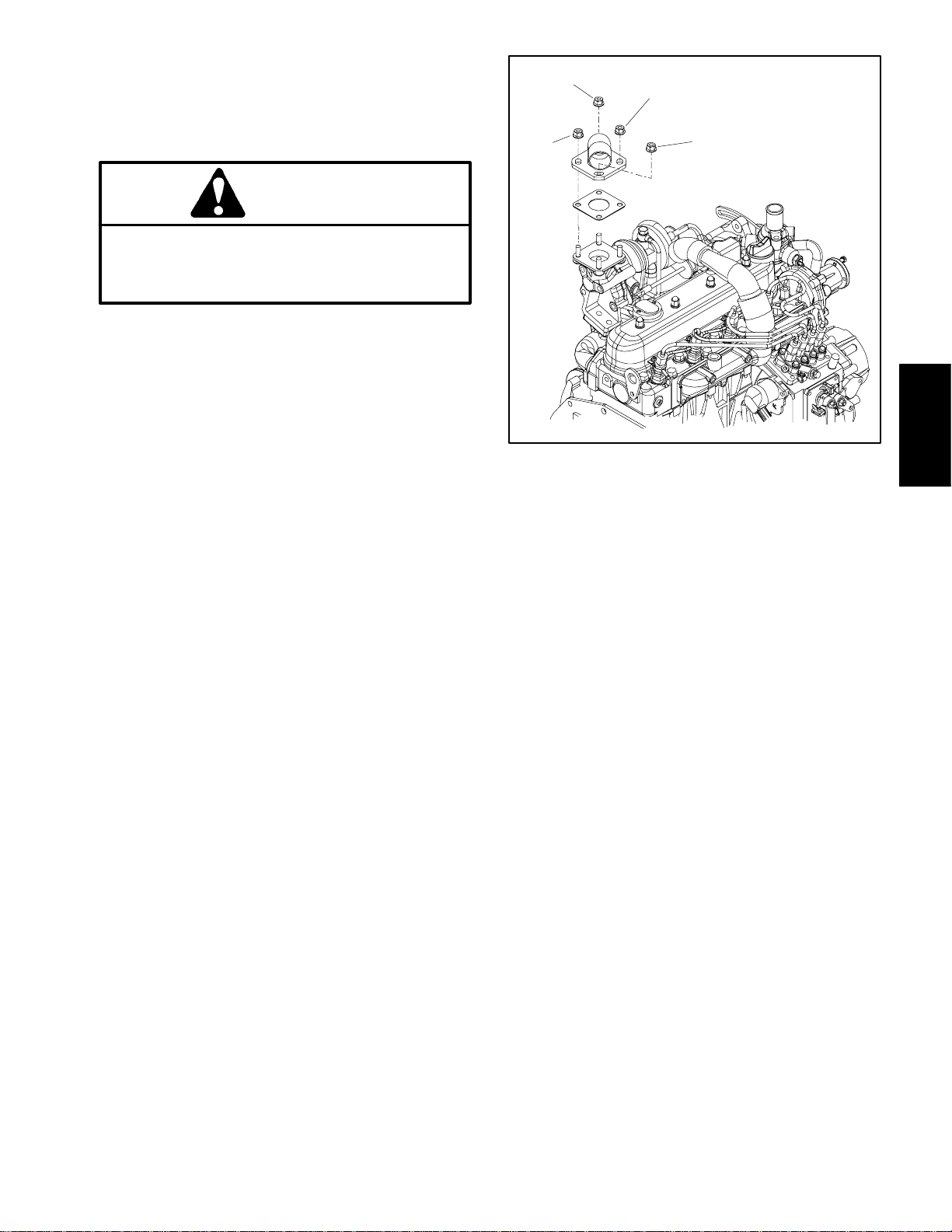

DANGER

Because diesel fuel is highly flammable, use

caution when storing or handling it. Do not

smoke while filling the fuel tank. Do not fill fuel

tankwhile engineis running, whenengineis hot

or when machine is in an enclosed area. Always

fill fuel tankoutsideand wipe up any spilled dieselfuelbefore startingtheengine. Store fuel in a

clean, safety--approved container and keepcontainer cap inplace.Use dieselfuel for theengine

only; not for any other purpose.

3. Opendraincockonbottomoffueltankandallow tank

to fully drain. Close draincock.

NOTE: Before removing fuel hoses from tank fittings,

label hoses for assembly purposes.

4. Loosenhose clampsanddisconnect fuel hoses from

suction (item 7) andreturn (item 6) fittings onthe top of

the fuel tank.

5. Remove fuel tank using Figure 2 as a guide.

Fuel Tank Installation (Fig. 2)

1. Install fuel tank to frame using Figure 2 as a guide.

Check Fuel Hoses and Connections

Check fuel hoses and connections periodically as recommended in theOperator’s Manual. Checkfuelhoses

for deterioration, damage, leakage or loose connections. Replace fuel hoses, clamps and connections as

necessary.

Drain and Clean Fuel Tank

Drain and clean the fuel tank periodically as recommendedinthe Operator’sManual. Also,drainandclean

the fuel tank if the fuel system becomes contaminated

or if the machineis tobestored foran extendedperiod.

To clean fuel tank, flush tank out with clean diesel fuel.

Make sure tank is free of all contaminates and debris.

Fuel Tank Removal (Fig. 2)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Placedrainpanunder fueltank. Make sure that drain

pan is large enough to hold fuel tank contents (see

Specifications in this chapter).

2. Using labels placed during fuel tank removal, correctly connect fuel hoses to suction (item 7) and return

(item 6) fittings on the top of the fuel tank. Secure fuel

hoses with hose clamps.

3. Make sure thatfuel tank draincock is closed.Fillfuel

tank.

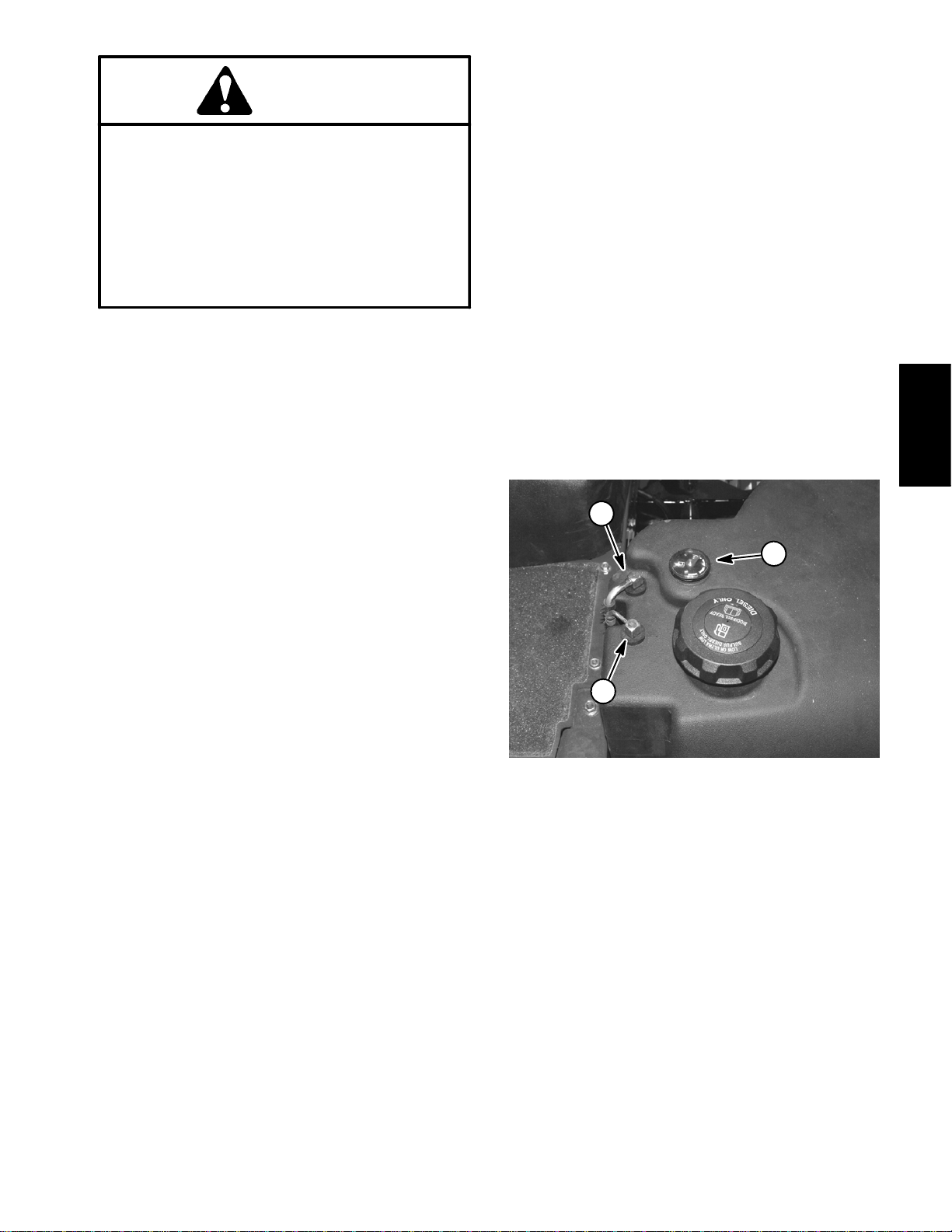

1

3

2

Figure 3

1. Fuel supply hose

2. Fuel return hose

3. Fuel gauge

Engine

Kubota Diesel

Groundsmaster 4300--D Page 3 -- 5 Kubota Diesel Engine

Page 22

Air Cleaner

19

17

14

18

14

8

11

11

7

1

Thread

Sealant

11

6

4

3

16

5

2

12 to 15 in--lb

(1.4 to 1.6 N--m)

RIGHT

FRONT

1. Air cleaner assembly

2. Indicator

3. Adapter

4. Spring

5. Hex nut

6. Bolt

7. Hose

12

13

10

15

12

Figure 4

8. Hose

9. Mount bracket

10. Air cleaner stand

11. Hose clamp (3 used)

12. Flange nut (8used)

13. Cap screw (2 used)

14. Hose clamp (2 used)

12

12

VACUATOR

DIRECTION

9

20

15. Flange head screw (4 used)

16. Air cleaner mountingband

17. Spacer

18. Hose

19. Hose clamp

20. Flange head screw (2 used)

Groundsmaster 4300--DPage 3 -- 6Kubota Diesel Engine

Page 23

Removal (Fig. 4)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parking brake and remove

key from the ignition switch. Raise and support hood.

2. Remove air cleaner components as needed using

Figures 4 as a guide.

3. See Operator’s Manual for air cleaner service and

maintenance procedures.

Installation (Fig. 4)

IMPORTANT: Any leaks in the air filter system will

allowdirt into engineand will causeseriousengine

damage. Make sure that all air cleanercomponents

areingood conditionand areproperlysecured during assembly.

1. Assemble air cleaner system using Figure 4 as a

guide.

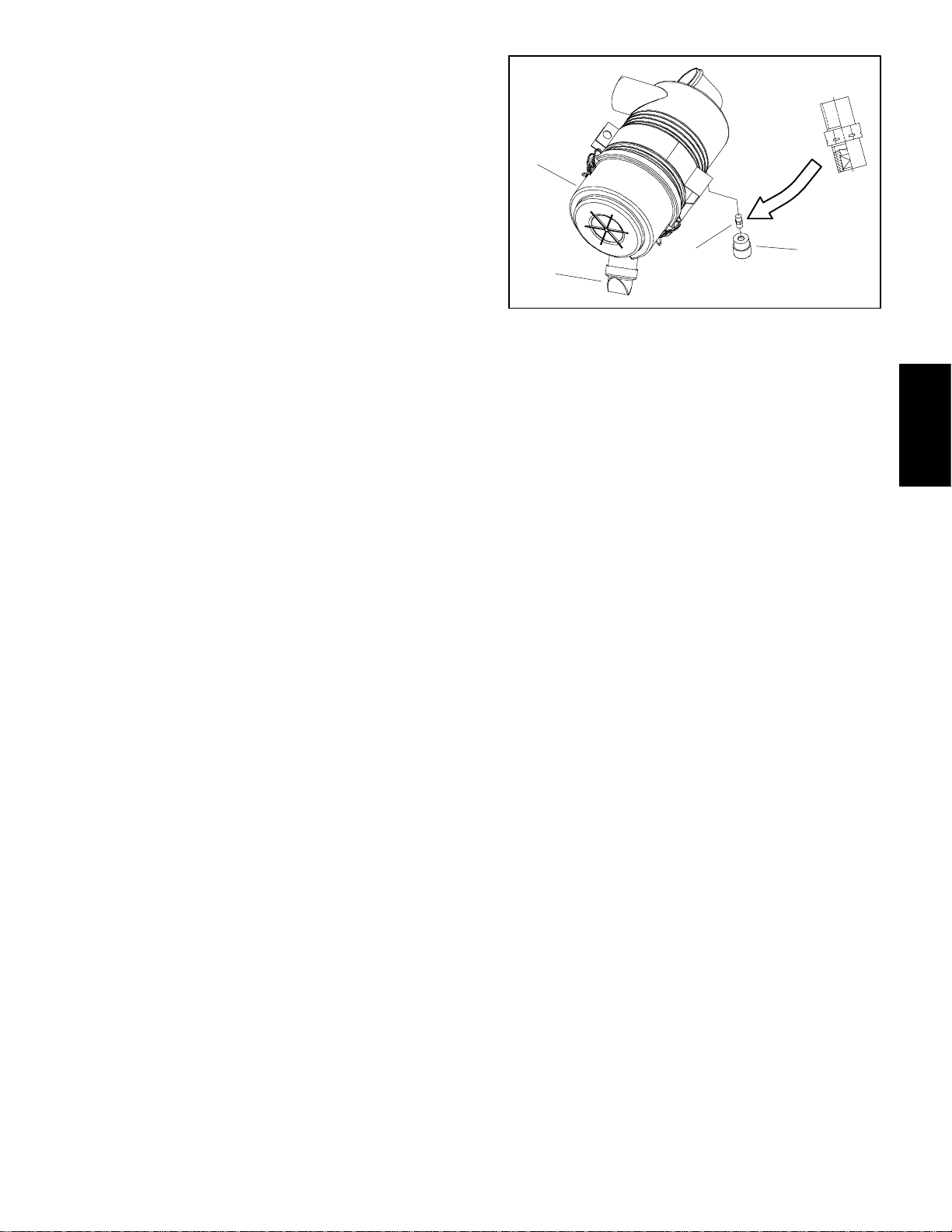

A. If service indicator (item 2) and adapter (item 3)

wereremovedfromaircleanerhousing,applythread

sealant to adapter threads before installing adapter

and indicator to housing. Install adapter so that

groovesinadapter hex andadapterfilter elementare

installed towardservice indicator (Fig.5).Torque indicator from 12 to 15 in--lb (1.4 to 1.6 N--m).

1

4

1. Air cleaner assembly

2. Service indicator

3

Figure 5

3. Adapter

4. Vacuator valve

2

Engine

Kubota Diesel

B. Makesurethatvacuator valve ispointeddownafter assembly.

Groundsmaster 4300--D Page 3 -- 7 Kubota Diesel Engine

Page 24

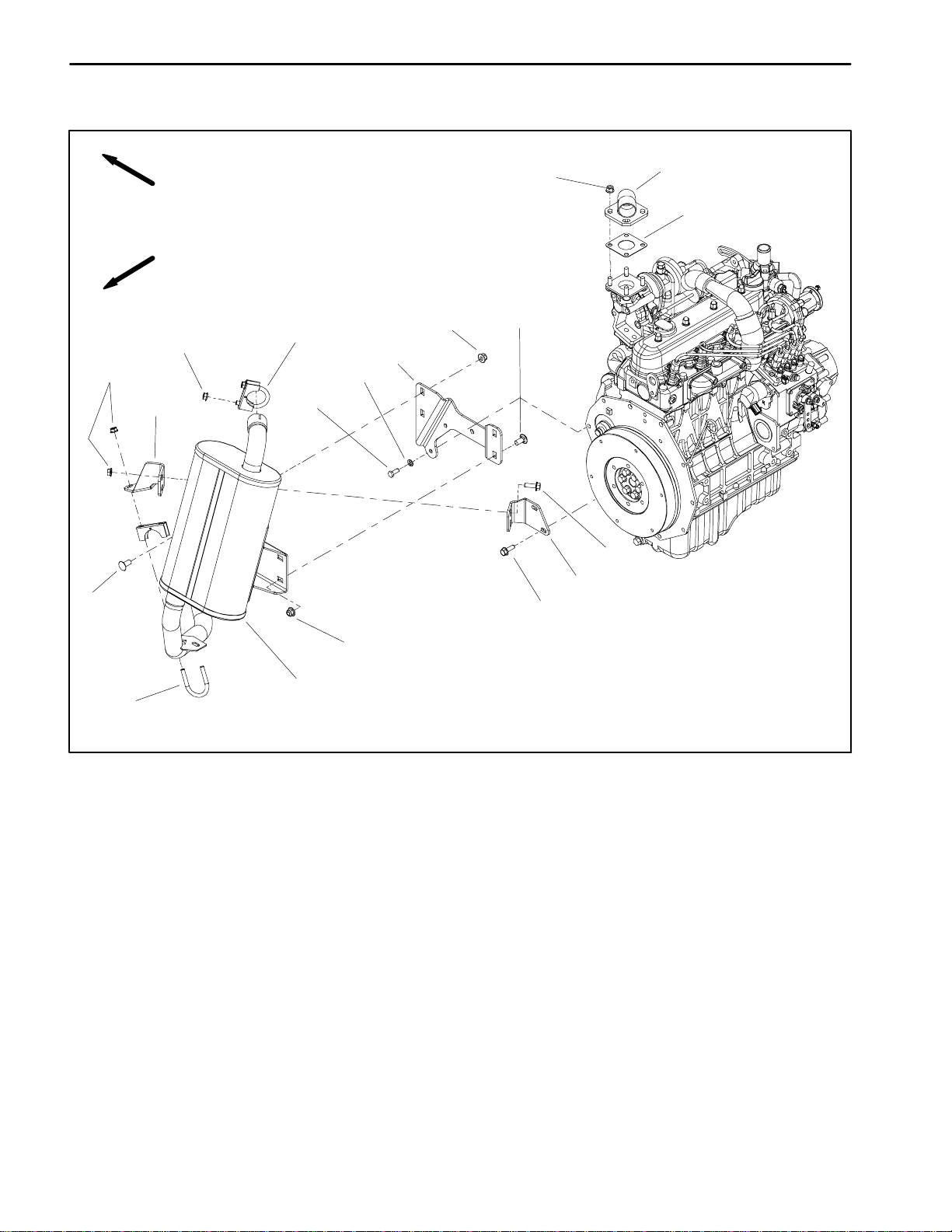

Exhaust System

3

RIGHT

13

1

FRONT

6

10

11

7

12

16

4

2

5

5

8

9

14

17

1. Gasket

2. Lock washer (2 used)

3. Flange nut (4 used)

4. Cap screw (2 used)

5. Carriage screw (4 used)

6. Flange nut (4 used)

6

15

7. Muffler support bracket

8. Flange head screw (2 used)

9. Tail pipe bracket

10. Hex nut (2 used)

11. Upper clamp

12. Flange nut (4used)

Figure 6

13. Exhaust header

14. Flange head screw (2 used)

15. Muffler

16. Tail pipe bracket

17. Lower clamp

Groundsmaster 4300--DPage 3 -- 8Kubota Diesel Engine

Page 25

Removal (Fig. 6)

1. Park machine on a level surface, lower cutting

decks, stop engine, engage parking brake and remove

key from the ignition switch. Raise and support hood.

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before working on the exhaust system.

2. Remove exhaust system using Figure 6 as a guide.

Installation (Fig. 6)

NOTE: Make sure mufflerflange and exhaustmanifold

sealing surfaces arefree of debris or damage that may

prevent a tight seal.

1. Place new muffler gasket on the exhaust manifold.

2. If muffler support bracket (item 7) was removed,secure it to engine with removed fasteners.

3

2

1 (FIRST)

4 (LAST)

Figure 7

Engine

Kubota Diesel

IMPORTANT: Fingertighten all exhaust systemfastenersbeforetightening so that there is no preload

on the exhaust system due to exhaust system assembly.

3. Installexhaust system components to the engineusing Figure 6as aguide. Finger tighten allfasteners until

all exhaust system components have been installed.

4. Tightenexhaust systemfastenersinthefollowingorder:

A. Lift muffler as much as holes in muffler support

bracket (item 7) will allow. Tighten flange nuts (item

6) to secure muffler to support bracket.

B. Tighten flange nuts (item 3) to secure exhaust

header (item 13)toengine flangeusing ordershown

in Figure 7.

C. Tighten hex nuts (item10) tosecureupper clamp

(item 11).

D. If tail pipe bracket(item 9) was removed, tighten

flange head screws (item 14) to secure bracket to

engine.

E. Tighten flange nuts (item 12) to secure lower

clamp (item 17).

F. Tighten fasteners (items 8 and 12) to secure tail

pipe brackets (items 9 and 16).

Groundsmaster 4300--D Page 3 -- 9 Kubota Diesel Engine

Page 26

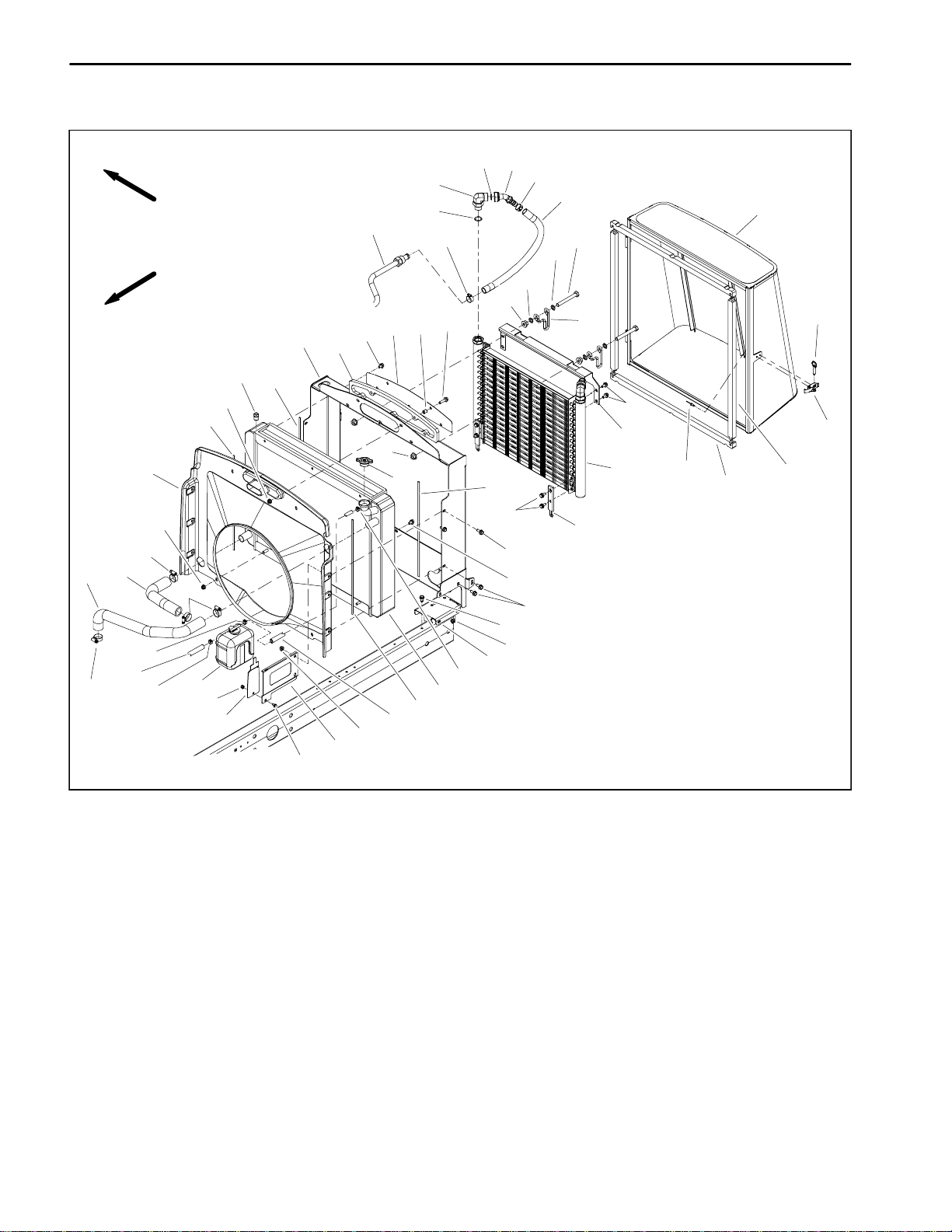

Radiator

RIGHT

FRONT

27

9

41

40

45

35

16

16

28

36

19

20

20

12

22

8

5

15

42

44

43

37

18

46

13

5

12

47

5

17

39

7

29

31

4

11

13

10

26

25

10

2

10

3

2

1

34

23

1. Overflow bottle

2. Hose clamp (3 used)

3. Hose

4. Foam seal (2 used)

5. Foam seal (4 used)

6. Mounting bracket (2 used)

7. Oil cooler

8. Pipe plug

9. Hydraulic fitting (2 used)

10. Hose clamp (4 used)

11. Foam seal (2 used)

12. Flange nut (4used)

13. Flange nut (17used)

14. Oil cooler mount plate (2used)

15. Flange head screw (6 used)

16. Hose clamp (4 used)

33

6

2

21

5

38

13

24

Figure 8

17. Flange head screw (8 used)

18. Clamp (2 used)

19. Cap screw (2 used)

20. Washer (4 used)

21. Radiator

22. Radiator frame

23. Reservoir bracket

24. Reservoir bracket

25. Upper radiator hose

26. Lower radiator hose

27. Fan shroud

28. Hydraulic hose (2 used)

29. Rivet (2 used)

30. Flange head screw (10 used)

31. Draw latch

32. Washer head screw (6 used)

17

14

30

15

30

32

13

33. Flange head screw

34. Lock nut

35. O--ring

36. Screen

37. Intake screen

38. Hose

39. Oil cooler bracket

40. O--ring

41. Hydraulic tube

42. Foam seal

43. Spacer (5 used)

44. Flange head screw (5 used)

45. Hydraulic fitting (2 used)

46. Pin

47. Radiator cap

Groundsmaster 4300--DPage 3 -- 10Kubota Diesel Engine

Page 27

Removal (Fig. 8)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Raise and support the hood.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

10.Carefully pull radiator assembly from the machine.

Plug radiatorand hoseopenings toprevent contamination.

1 1.Inspect all foam seals placed between radiator , fan

shroud and radiator frame. Replace damaged foam

seals.

Installation (Fig. 8)

1. Remove plugs placedin radiatorand hose openings

during the removal procedure.

2. Carefully position radiator assembly to the radiator

support. Position fan shroud to the radiator.

Ethylene--glycol antifreeze is poisonous. Disposeof coolant properly, or storeitin aproperly

labeled container away from children and pets.

3. Drain coolant from radiator.

A. Slowly remove radiator cap from the radiator .

B. Place drain pan below the radiator draincock lo-

cated on the bottom of the radiator. Make sure that

drainpanislargeenough toholdcooling systemcontents (10 U.S. quarts (9.5 liters)).

C. Loosen radiator draincock (threaded in) and allow coolant to drain from radiator.

4. Remove screen from machine.

5. Disconnect radiator hoses (upper and lower) from

the radiator.

6. Loosen hose clampand removeoverflowhose from

radiator fill opening.

7. Remove two (2)flangehead screwsand flangenuts

that secure coolant reservoir and brackets to fan

shroud. Carefully position reservoir and brackets away

from the fan shroud.

8. Remove five (5)flange head screwsand flange nuts

that secure air intake screen (item 37) to machine. Remove screen and foam seal (item 42). Locate and retrieve five (5) spacers (item 43).

3. Securefanshroudandradiatortoradiatorframe with

removed flange head screws and flange nuts. Make

sure that atleast 0.250”(6.4mm)clearanceexistsat all

points between shroud opening and fan.

4. Position coolant reservoir and brackets to the fan

shroud. Secure reservoir to fan shroud and radiator

frame with two(2) flange head screws and flange nuts.

5. Place spacers (item43) into holes infoam seal(item

42). Position foam seal and air intake screen (item 37)

to radiator frame. Secure intakescreen tomachine with

five (5) flange head screws and flange nuts.

6. Connect upper and lower radiator hoses to radiator

and secure with clamps.

7. Connect overflow hose to radiator fill opening and

secure with hose clamp.

8. Makesureradiator draincockisclosed (threaded out

fully).

9. To allow air to escape during radiator filling, remove

pipe plug (item 8) from top of radiator. Fill radiator with

coolant. Make suretoinstallplugonceallairis bled from

radiator.

10.After radiator has been properly filled with coolant,

install radiator cap.

1 1.Lower and secure hood.

Engine

Kubota Diesel

9. Removeflange head screws and flange nuts thatsecure fanshroud andradiator to radiator frame. Position

fan shroud away from the radiator.

Groundsmaster 4300--D Page 3 -- 11 Kubota Diesel Engine

Page 28

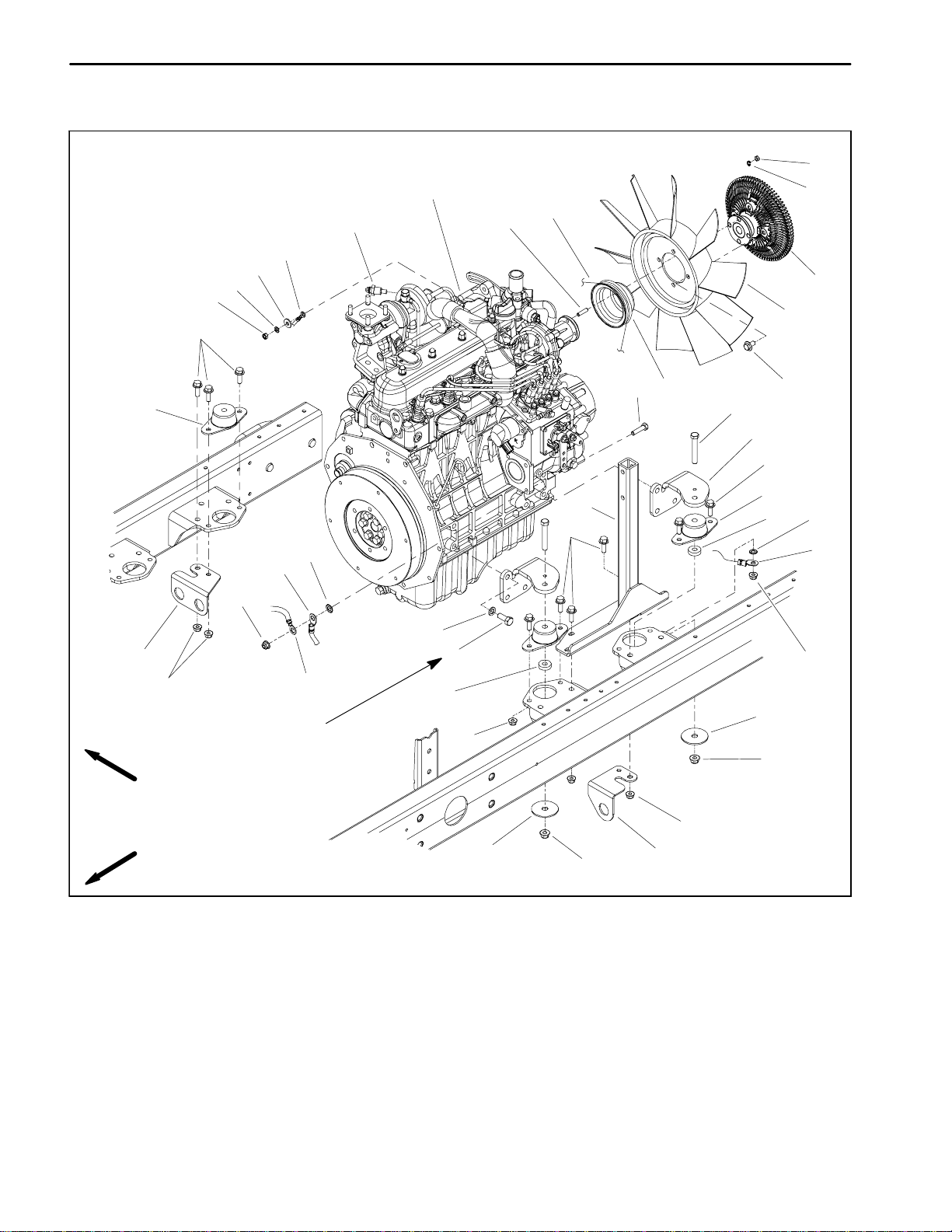

Engine

30

1

15

3

11

16

26

18

19

20

5

10

17

4

29

9

RIGHT

FRONT

13

23

9

32

34 to 42 ft--lb

(47to56N--m)

25

22

21

14

31

7

27

5

24

5

4

22

12

23

2

9

6

9

8

9

6

8

28

1. Engine assembly

2. Cap screw (12 used)

3. Temperature sender

4. Engine mount (4 used)

5. Flange head screw (13 used)

6. Snubbing washer (4 used)

7. Cap screw (4 used)

8. Flange nut (4 used)

9. Flange nut (14 used)

10. Fan clutch

11. Stud (4 used)

Figure 9

12. Lock washer

13. Lock washer

14. Pulley

15. V--belt

16. Lock washer (4 used)

17. Cooling fan

18. Flat washer

19. Spring washer

20. Hex nut

21. Cap screw

22. Spacer (4 used)

23. Negative battery cable

24. Air cleaner stand

25. Lock washer (12 used)

26. Fusible link harness

27. Engine mount (4used)

28. Bracket

29. Bracket

30. Hex nut

31. Flange head screw (4 used)

32. Wire harness ground

Groundsmaster 4300--DPage 3 -- 12Kubota Diesel Engine

Page 29

Removal (Fig. 9)

1. Park machine on a level surface, lower cutting

decks, stop engine and remove key from the ignition

switch. Chockwheelstokeepthemachinefrommoving.

2. Open and support hood.

3. Disconnect negative (--) cable and then positive (+)

cable from the battery.

CAUTION

2

1

3

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Disposeof coolant properly, or storeitin aproperly

labeled container away from children and pets.

4. Drain coolant from radiator (see Radiator Removal

in this section).

5. Remove air cleaner from machine (see Air Cleaner

Removal in this section).

6. Remove exhaust system from machine (see Exhaust System Removal in this section).

7. Remove throttle cable from injector pump (Fig. 10):

A. Remove cap screw that secures throttle cable

end to swivel in speed control lever.

B. Loosen throttle cable clamp and remove cable

from clamp. Slide throttle cable end from swivel.

C. Position throttle cable away from the engine.

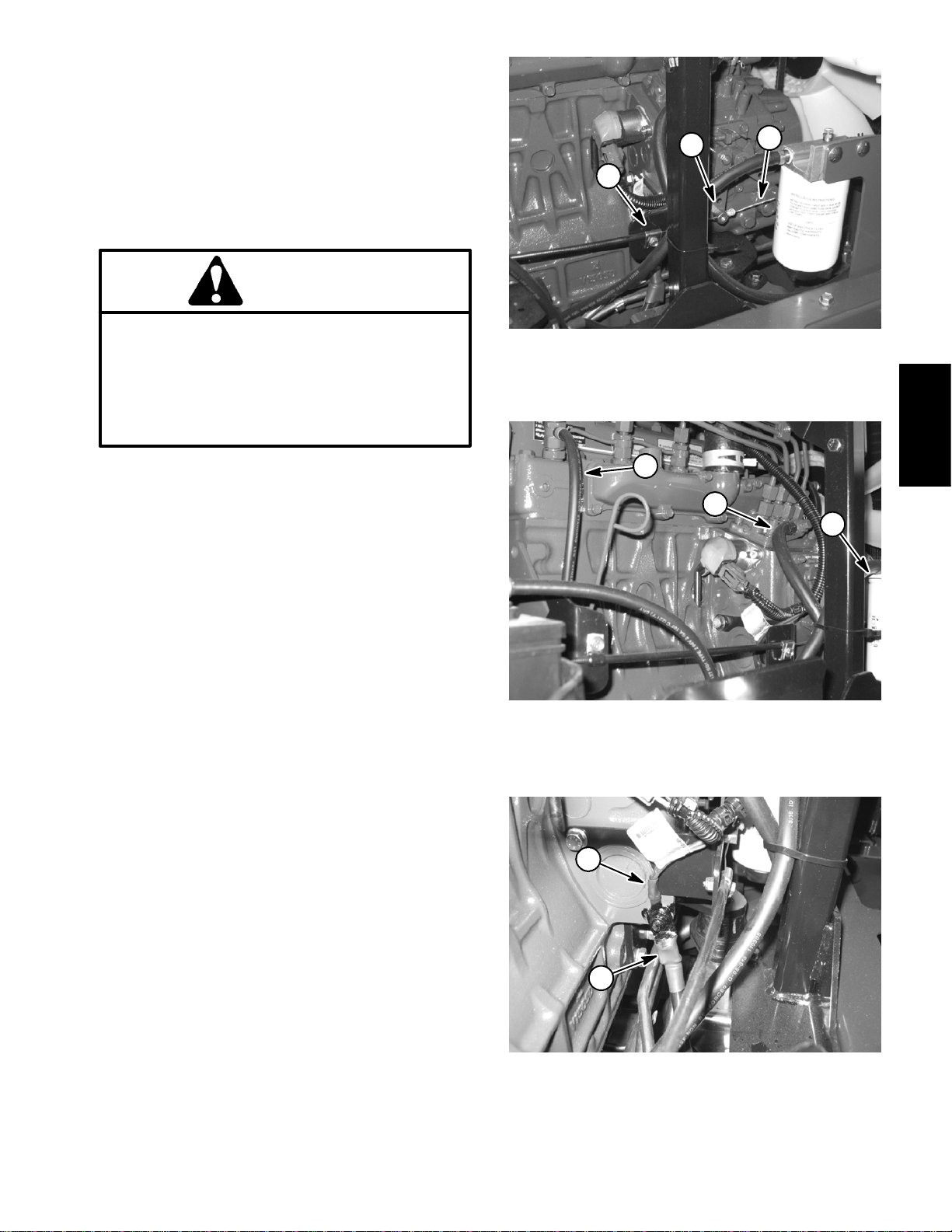

1. Throttle cable end

2. Swivel

1. Fuel return hose

2. Fuel supply hose

Figure 10

1

Figure 11

3. Cable clamp

Engine

Kubota Diesel

2

3

3. Fuel/water filter

8. Disconnect hoses from engine:

A. Loosen clamps and remove upper and lower radiator hoses from the engine.

2

B. At injectorpump, loosenhose clamp anddisconnect supply fuel hose from the injector pump fitting

(Fig. 11).

C. Loosen hose clamp and disconnect fuel return

hose from front injector body (Fig. 11).

1

D. Plug disconnectedhoses andengineopeningsto

preventleakageand contamination.Positiondisconnected hoses away from engine.

1. Negative battery cable 2. Wire harness ground

Figure 12

Groundsmaster 4300--D Page 3 -- 13 Kubota Diesel Engine

Page 30

9. Disconnect hydraulic transmission drive shaft from

engine (see Hydraulic Transmission Drive Shaft Removal in the Service and Repairs section of Chapter 4

-- Hydraulic System). Support driveshaft away fromengine.

Installation (Fig. 9)

1. Locate machine on alevel surface with cuttingdecks

lowered and key removed from the ignition switch.

Chock wheels to keep the machine from moving.

10.Disconnectwireharness connectorsfrom thefollowing engine components:

NOTE: Before disconnectingwire harnessconnectors,

label all electrical leads for assembly purposes.

A. Alternator connector and stud.

B. Oilpressure switchlocatednear theengine oil fil-

ter.

C. Connector, fusible link connector and positive

battery cable from the starter motor.

D. High temperature shut down switch andtemper-

ature sender located on the water pump housing.

E. Fuel stop solenoid on injector pump.

F. Negative battery cable and wire harness ground

from injector pump (Fig. 12).

G. Glow plug strip.

1 1.Remove engine from machine:

2. Make sure that all parts removed from the engine

duringmaintenance or rebuilding are installedtothe engine.

3. If engine brackets were removed from the engine,

secure brackets to engine with lock washers and cap

screws. Torque cap screws from 34 to 42 ft--lb (47 to

56 N--m).

4. Install engine to machine.

A. Attach short sectionof chainbetween lift tabs lo-

cated on each end of the cylinder head

B. Connect a hoist or lift at the center of the short

section of chain. Apply enough tension on the short

chain so that the engine can be supported.

CAUTION

One person should operate hoist or lift while a

second person guides the engine into the machine.

A. Attach short sectionof chainbetween lift tabs located on each end of the cylinder head.

B. Connect a hoist or lift at the center of the short

section of chain. Apply enough tension on the short

chain so that the engine will be supported.

C. Remove fasteners that secure the engine (with

brackets) to the engine mounts.

CAUTION

One person should operate hoist or lift while a

secondpersonguides theengine out of themachine.

IMPORTANT: Make sure to not damage the engine, fuel hoses, hydraulic lines, electrical harness, radiator, battery or other parts while

removing the engine.

D. Raise engine and remove toward front of machine.

IMPORTANT: Make sure to not damage the engine, fuel hoses, hydraulic lines, electrical harness, radiator, battery or other parts while

installing the engine.

C. Lower engine to the machine frame. Make sure

fastener holes of the engine brackets are aligned

with the holes in the engine mounts.

D. Insert cap screw down through each engine

bracket and mount. Place spacer, snubbingwasher

and then flange nut on four (4) cap screws. Tighten

fasteners to secure engine to engine mounts.

5. Connect hydraulic transmissiondrive shaft toengine

(see Hydraulic Transmission Drive Shaft Installation in

the Serviceand Repairssectionof Chapter 4 -- Hydraulic System).

6. Connect all wire harness connectors to correct en-

gine components.

12.Ifnecessary, removeengine brackets(item27)from

engine.

Groundsmaster 4300--DPage 3 -- 14Kubota Diesel Engine

Page 31

7. Remove plugs installed in hoses during disassembly. Connect hoses to the engine:

9. Install aircleaner(see Air CleanerInstallationin this

section).

A. Connect fuel supply and fuel return hoses to engine fittings (Fig. 11). Secure with hose clamps.

B. Connect upper and lower radiator hoses to the

engine. Secure with hose clamps.

8. Connect throttle cable to injector pump (Fig. 10):

A. Route throttle cable to injector pump on engine.

B. Install the throttle cable end into the swivel in

speed control lever. Secure cable end with cap

screw.

C. Position cable under cable clamp.

D. Adjust throttle control (see Adjust Throttle Con-

trol in the Adjustments section of this chapter).

10.Install exhaust system to machine (see Exhaust

System Installation in this section).

1 1.Makesure radiator draincockisclosed (threaded out

fully). Fill radiator with coolant and install radiator cap

(see Radiator Installation in this section).

12.Check engine oil level and adjust if needed.

13.Connectpositive(+) batterycable tothebattery and

then connect negative (--) cable.

14.Bleed fuel system.

15.Close and secure hood.

Engine

Kubota Diesel

Groundsmaster 4300--D Page 3 -- 15 Kubota Diesel Engine

Page 32

This page is intentionally blank.

Groundsmaster 4300--DPage 3 -- 16Kubota Diesel Engine

Page 33

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 2.............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

Check Hydraulic Fluid 3.......................

Towing Machine 3.............................

Hydraulic Hoses 4............................

Hydraulic Hose and Tube Installation 5..........

Hydraulic Fitting Installation 6...................

Relieving Hydraulic System Pressure 8..........

Traction Circuit Component Failure 8............

HYDRAULIC SCHEMATIC 9.....................

HYDRAULIC FLOW DIAGRAMS 10...............

Traction Circuit 10.............................

Mow Circuit 12...............................

Mow Circuit Cutting Deck Blade Braking 14.......

Lift Circuit: Raise Cutting Decks 16..............

Lift Circuit: Lower Cutting Decks 18..............

Steering Circuit 20............................

SPECIAL TOOLS 22............................

TROUBLESHOOTING 26........................

General Hydraulic System Problems 26..........

Traction Circuit Problems 27....................

Mow Circuit Problems 28.......................

Lift Circuit Problems 29........................

Steering Circuit Problems 30...................

TESTING 32...................................

Traction Circuit Relief Valve (R3) and (R4)

Pressure Test 34............................

Traction Circuit Charge Pressure Test 36.........

Gear Pump (P3) Flow Test 38..................

Front Wheel Motor Efficiency Test 40............

Piston (Traction) Pump Flow Test 42.............

Relief Valve (PRV1) and (PRV2) Pressure Test 44.

Gear Pump (P1) and (P2) Flow Test 46..........

Deck Motor Efficiency Test 48..................

Lift Relief Valve (PRV) Pressure Test 50..........

Gear Pump (P4) Flow Test 52..................

Lift Cylinder Internal Leakage Test 54............

Steering Relief Valve (R10) Pressure Test 56.....

Steering Cylinder Internal Leakage Test 58.......

SERVICE AND REPAIRS 60.....................

General Precautions for Removing and Installing

Hydraulic System Components 60.............

Check Hydraulic Lines and Hoses 61............

Flush Hydraulic System 61.....................

Filtering Closed--Loop Traction Circuit 62.........

Hydraulic System Start--up 63..................

Hydraulic Reservoir 64........................

Hydraulic Pump Drive Shaft 66.................

Hydraulic Pump Assembly 68...................

Piston (Traction) Pump Service 72..............

Gear Pump Service 74

Wheel Motors 76........................

Front

Rear Wheel Motors 80.........................

Wheel Motor Service 84.......................

CrossTrax

CrossTrax

Deck Control Manifold 90......................

Deck Control Manifold Service 92...............

Cutting Deck Motor 94.........................

Cutting Deck Motor Service 96..................

Lift Control Manifold 100.......................

Lift Control Manifold Service 102................

Lift Cylinder 104..............................

Lift Cylinder Service 106.......................

Steering Control Valve 108.....................

Steering Control Valve Service 110..............

Steering Cylinder 112..........................

Steering Cylinder Service 114..................

Oil Cooler 116................................

SAUER--DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS REPAIR MANUAL

SAUER--DANFOSS LPV CLOSED CIRCUIT AXIAL

PISTON PUMPS SERVICE INSTRUCTIONS

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

SAUER--DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

TM

AWD Manifold 86..................

TM

AWD Manifold Service 88...........

.........................

TM

SERVICE PROCEDURE

System

Hydraulic

Groundsmaster 4300--D Hydraulic SystemPage 4 -- 1

Page 34

Specifications

Item Description

Piston (Traction) Pump Sauer--Danfoss, LPV Closed Circuit Axial Piston Design

Maximum Pump Displacement (per revolution) 2.14 in

Gear Pump Casappa 4 section, positive displacement gear type pump

Section P1/P2 Displacement (per revolution) 1.03 in

Section P3 Displacement (per revolution) 0.37 in

Section P4 Displacement (per revolution) 0.24 in

Charge Circuit Relief (R5) Pressure 200 PSI (14 bar)

Traction Circuit Relief Pressure

Forward (R3) 3625 PSI (250 bar)

Reverse (R4) 3625PSI (250bar)

Front Wheel Motors Parker orbital rotor motor, TG Series

Displacement (per revolution) 24.7 in

Rear Wheel Motors Parker orbital rotor motor, TL Series

Displacement (per revolution) 18.9 in

Mow Circuit Relief Pressure

Rear Mow Circuit (PRV1) 2500 PSI (175 bar)

Front Mow Circuit (PRV2) 3500 PSI (241 bar)

Cutting Deck Motor Casappa gear motor

Displacement (per revolution) 1.05 in

Cross Over Relief Valve Pressure 1813 PSI (125 bar)

3

(35 cc)

3

(16.84 cc)

3

(6.1 cc)

3

(3.9 cc)

3

(405 cc)

3

(310 cc)

3

(17.16 cc)

Steering Valve Sauer--Danfoss Steering Unit, Type OSPMS

Displacement (per revolution) 6.1 in

Steering Circuit Relief (R10)Pressure 1000 PSI (70 bar)

Lift Circuit Relief (PRV)Pressure 2000 PSI (138 bar)

Hydraulic Filter (Charge and Steering Circuits) Spin--on Cartridge Type with 50 PSI (3.4 bar) Relief in Adapter

Hydraulic Filter (Mow and Lift Circuits) Spin--on Cartridge Type with 50 PSI (3.4 bar) Relief in Adapter

(filter adapter includes filter change indicator)

Hydraulic Oil See Operator’s Manual

Hydraulic Reservoir Capacity 14 U.S. Gallons (53 Liters)

3

(100 cc)

Groundsmaster 4300--DHydraulic System Page 4 -- 2

Page 35

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Groundsmaster 4300--D.Refer to that

publicationfor additionalinformationwhenservicing the

machine.

Check Hydraulic Fluid

The hydraulic system on your Groundsmaster is designedto operate on high qualityhydraulicfluid.Thehydraulic system reservoir holds approximately 14 U.S.

gallons (53 liters) of hydraulic fluid. Check level of hy-

draulicfluid daily.SeeOperator ’sManualfor fluidlevel

checking procedure and hydraulic oil recommendations.

1

Towing Machine

IMPORTANT: If towing limits are exceeded, severe

damage to the piston (traction) pump may occur.

Ifit becomes necessary totoworpush the machine, tow

orpushat a speed below 3 mph(4.8kph),andfora very

shortdistance. If themachineneedsto be moved a considerabledistance, machine should be transported on a

trailer.The piston (traction) pump isequipped with a bypassvalvethatneeds tobeloosenedfortowing orpushing (Fig. 2). Refer to Operator’s Manual for Towing

Procedures.

Figure 1

1. Hydraulic reservoir cap

2

System

Hydraulic

1

Groundsmaster 4300--D Hydraulic SystemPage 4 -- 3

Figure 2

1. Piston (traction) pump 2. Bypass valve

Page 36

Hydraulic Hoses

Hydraulichoses are subject to extreme conditions such

aspressuredifferentialsduring operation and exposure

to weather, sun, chemicals, very warm storage conditionsormishandlingduring operationandmaintenance.

These conditions can causehose damageand deterioration. Some hoses are more susceptible to these

conditions than others. Inspect all machine hydraulic

hoses frequently for signs of deterioration or damage:

WARNING

Beforedisconnectingor performing any work on

hydraulic system, relieve all pressure in system

(seeRelievingHydraulicSystemPressure in this

section).

Hard, cracked, cut, abraded, charred, leaking or

otherwise damaged hose.

Kinked, crushed, flattened or twisted hose.

Blistered, soft, degraded or loose hose cover.

Cracked, damaged or badly corroded hose fittings.

When replacing a hydraulichose, besure that thehose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint (layline) on

the hose. Use two wrenches when tightening a hose;

hold the hose straight with one wrench and tighten the

hose swivelnut ontothe fittingwith thesecond wrench

(see Hydraulic Hose and Tube Installation in this section). If the hose has an elbow at one end, tighten the

swivel nut on that end before tightening the nut on the

straight end of the hose.

For additional hydraulic hose information, refer to Toro

Service Training Book, Hydraulic Hose Servicing (Part

Number 94813SL).

Keepbodyand handsawayfrompinhole leaksor

nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to

search for leaks. Hydraulic fluid escaping under

pressure can have sufficient force to penetrate

the skin and cause serious injury. If fluid is injected into the skin, it must be surgically removed within a few hours by a doctor familiar

withthis typeof injury.Gangrenemay resultfrom

such an injury.

Groundsmaster 4300--DHydraulic System Page 4 -- 4

Page 37

Hydraulic Hose and Tube Installation (O--Ring Face Seal Fitting)

1. Makesure threads and sealing surfacesofthehose/

tube and the fittingare freeof burrs,nicks, scratchesor

any foreign material.

2. Asa preventative measure against leakage,itisrecommended that the face seal O--ring be replaced any

time the connection isopened.Make sure theO--ring is

installedandproperly seatedinthefittinggroove.Lightly

lubricate the O--ring with clean hydraulic oil.

3. Place the hose/tube against the fitting body so that

theflatfaceofthehose/tubesleevefully contactsthe O-ring in the fitting.

4. Thread the swivel nutonto the fittingby hand.While

holding the hose/tube with a wrench, use a torque

wrench to tighten the swivel nut to the recommended

installation torque shown in Figure 5. This tightening

process will require the use of an offset wrench ( e.g.

crowfoot wrench). Use of an offset wrench will affect

torque wrench calibration due to the effective length

change of the torque wrench. Tightening torque when

usingatorquewrenchwithanoffsetwrenchwillbelower

than the listed installation torque (see Using a Torque

Wrench with anOffsetWrench in theTorque Specificationssectionof Chapter 2 -- Product Records andMaintenance).

C. Useasecond wrench totightenthe nuttothe correct FlatsFrom WrenchResistance (F.F.W.R.). The

markingsonthe nutandfittingbodywillverifythatthe

connection has been properly tightened.

Siz e F.F.W.R.

4 (1/4 in. nominal hose or tubing) 1/2 to 3/4

6 (3/8 in.) 1/2to 3/4

8 (1/2 in.) 1/2to 3/4

10 (5/8 in.) 1/2 to 3/4

12 (3/4 in.) 1/3 to 1/2

16 (1 in.) 1/3 to1/2

Swivel Nut

Tube or Hose

O--ring

Fitting Body

Figure 3

System

Hydraulic

5. If a torque wrench is not availableor if space at the

swivelnut prevents use ofatorquewrench, an alternate

method of assembly is the Flats From Wrench Resistance (F.F.W.R.) method (Fig. 4).

Mark Nut

and Fitting

Body

Final

Position

A. Usingawrench,tighten theswivelnut ontothefittinguntillightwrenchresistanceis reached(approxi-

Extend Line

mately 30 in--lb).

B. Mark the swivel nut and fitting body. Hold the

hose/tube with a wrench to prevent it from turning.

AT WRENCH RESISTANCE

Figure 4

Fitting Dash Size Hose/Tube Side Thread Size Installation Torque

4 9/16 -- 18 18to22ft--lb(25to29N--m)

6 11/16 - - 16 27to33ft--lb(37to44N--m)

8 13/16 -- 16 37to47ft--lb(51to63N--m)

10 1--14 60 to 74 ft--lb (82 to 100 N--m)

12 13/16--12 85 to 105 ft--lb (116 to 142 N--m)

Initial

Position

AFTER TIGHTENING

16 17/16--12 110 to 136 ft--lb (150 to 184 N--m)

20 1 11/16 -- 12 140 to 172 ft--lb (190 to 233 N--m)

Figure 5

Groundsmaster 4300--D Hydraulic SystemPage 4 -- 5

Page 38

Hydraulic Fitting Installation (SAE Straight Thread O--Ring Fitting into Component Port)

Non--Adjustable Fitting (Fig. 6)

1. Make sure allthreads and sealingsurfaces offitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. Asa preventative measure against leakage,itisrecommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O--ring with clean hydraulic oil.

Fittingthreadsshouldbecleanwithnolubricantapplied.

IMPORTANT: Before installing fitting into port, determine port material.If fittingis to beinstalled into

an aluminum port, installation torque is reduced.

4. Install the fitting into the port. Then, use a torque

wrench and socket to tighten the fitting to the recommended installation torque shown in Figure 7.

NOTE: Useof an offsetwrench (e.g.crowfoot wrench)

will affect torquewrench calibration due tothe effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be less than the recommendedinstallation torque. See

Using a Torque Wrench with an Offset Wrench in the

Torque Specifications section of Chapter 2 -- Product

Recordsand Maintenancetodetermine necessaryconversion information.

5. If a torquewrench is not available, or if spaceat the

portpreventsuseof atorque wrench,analternate method ofassembly is the Flats From Finger Tight (F.F.F.T.)

method.

A. Install thefitting into the port and tighten it down

full length until finger tight.

B. If port material is steel, tighten the fitting to the

listed F.F.F .T. Ifport material is aluminum,tighten fitting to 60% of listed F.F.F.T.

Siz e F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

Fitting

O--ring

0.25

0.25

0.25

0.25

0.25

0.25

Figure 6

Fitting

Dash Size

Fitting Port Side

Thread Size

Installation Torque Into

Steel Port

Installation Torque Into

Aluminum Port

4 7/16 -- 20 15to19ft--lb(21to25N--m) 9to11ft--lb(13to15N--m)

5 1/2 -- 20 18to22ft--lb(25to29N--m) 11to15ft--lb(15to20N--m)

6 9/16 -- 18 34to42ft--lb(47to56N--m) 20to26ft--lb(28to35N--m)

8 3/4 -- 16 58to72ft--lb(79to97N--m) 35to43ft--lb(48to58N--m)

10 7/8 -- 14 99 to 121 ft--lb (135 to 164 N--m) 60 to 74 ft--lb (82 to 100 N--m)

12 11/16--12 134 to 164 ft--lb (182 to 222 N--m) 81 to 99 ft--lb (110 to 134 N--m)

14 13/16--12 160 to 196 ft--lb (217 to 265 N--m) 96 to 118 ft--lb (131 to 160 N--m)

16 15/16--12 202 to 248 ft--lb (274 to 336 N--m) 121 to 149 ft--lb (165 to 202 N--m)

20 15/8--12 247 to 303 ft--lb (335 to 410 N--m) 149 to 183 ft--lb (202 to 248 N--m)

Figure 7

Groundsmaster 4300--DHydraulic System Page 4 -- 6

Page 39

Adjustable Fitting (Fig. 8)

1. Make sure allthreads and sealingsurfaces offitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. Asa preventative measure against leakage,itisrecommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O--ring with clean hydraulic oil.

Fittingthreadsshouldbecleanwithnolubricantapplied.

4. Turnback thelock nut asfar aspossible. Makesure

the back up washeris notloose and ispushed up asfar

as possible (Step 1 in Figure 9).

IMPORTANT: Before installing fitting into port, determine port material.If fittingis to beinstalled into

an aluminum port, installation torque is reduced.

Lock Nut

Back--up Washer

O--ring

Figure 8

5. Install the fitting intothe port and tighten finger tight

until the washer contactsthe faceof theport ( Step 2 in

Figure 9). Make sure that the fitting does not bottomin

the port during installation.

6. Toput the fitting in thedesiredposition,unscrew it by

the required amount to align fitting with incoming hose

or tube, butno more than one fullturn (Step 3 inFigure

9).

7. Hold the fittingin thedesired position with a wrench

and use a torque wrench to tighten the lock nut to the

recommended installation torque shown in Figure 7.

This tighteningprocess willrequire theuse of an offset

wrench (e.g. crowfoot wrench). Useof an offset wrench

will affect torquewrench calibration due tothe effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be lower thanthe listed installation torque (seeUsing a

Torque Wrench with an Offset Wrench in the Torque

Specifications section of Chapter 2 -- Product Records

and Maintenance).

8. If a torquewrench is not available, or if spaceat the

portpreventsuseof atorque wrench,analternate method ofassembly is the Flats From Finger Tight (F.F.F.T.)

method. Hold the fitting in the desired position with a

wrench and, ifport materialis steel, tightenthe lock nut

witha second wrench to the listedF.F.F.T (Step 4 in Figure9).Ifportmaterialis aluminum, tighten fitting to 60%

of listed F.F.F.T.

Step 3Step 1

Step 2 Step 4

Figure 9

System

Hydraulic

Siz e F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25

0.25

Groundsmaster 4300--D Hydraulic SystemPage 4 -- 7

Page 40

Relieving Hydraulic System Pressure

Beforedisconnectingorperforming any work on the hydraulic system, all pressure in the hydraulic system

mustberelieved.Parkmachineonalevel surface,lower

cutting decks fully, stop engine and engage parking

brake.

To relieve hydraulic pressure in traction circuit, move

tractionpedal to both forward and reversedirections.To

relieve hydraulic pressure in steering circuit, rotate

steering wheel in both directions.

System pressure in cutting circuit is relieved when the

cutting decks are disengaged.

Traction Circuit Component Failure

The traction circuit on Groundsmaster 4300--D machines is a closed loop system that includes the piston

(traction) pump and four (4) wheel motors. Ifa componentinthetractioncircuitshouldfail,debrisandcontamination from the failed component will circulate

throughout the traction circuit. This contamination can

damageother components inthecircuit so itmustbe removed to prevent additional component failure.

The recommended method of removing traction circuit

contamination would be to temporarily install the high

flow hydraulic filter (see Special Tools in this chapter)

intothe circuit. This filter should be used whenconnecting hydraulic test gauges in order to test tractioncircuit

components or after replacing a failed traction circuit

component(e.g. traction(piston)pump or wheelmotor).

The filter will ensure that contaminates are removed

from the closed loop and thus, do notcause additional

component damage.

Once the Toro high flow hydraulic filter kit has been

placedin the circuit, raise and support the machinewith

all wheels off the ground.Then, operate thetraction cir-

To relieve hydraulic pressure in lift circuit, turn ignition

switchtoON(do notstartengine) andfullylower thecutting decks. After decks are fully lowered, turn ignition

switch to OFF and remove key from the switch.

IMPORTANT: If machinewill be serviced on a lift or

atan elevated position,fullylower the cuttingdecks

afterthemachine hasbeenraised to ensure that the

lift cylinders are fully extended. Pressure will be

maintained in the lift cylinders unless they arefully

extended.

cuit to allow oil flowthroughout the circuit. The filterwill

remove contamination from the traction circuit during

operation. Because the Toro high flow filter is bi--directional,the tractioncircuitcan beoperatedin both theforward and reverse direction. The filter should be

removed from the machine after contamination has

been removed from the traction circuit. See Filtering

Closed--LoopTractionCircuitintheServiceandRepairs

section of this chapter for additional information on using the Toro high flow hydraulic filter.

Thealternative tousing theTorohigh flowhydraulicfilter

kit after a traction circuit component failure would beto

disassemble, drain and thoroughly clean all components, tubes and hoses in the tractioncircuit. If any debris remains in the traction circuit and the machine is

operated,thedebriscancauseadditionalcircuit component failure.

NOTE: The traction pump case drain could allow any

debrisinthe tractioncircuittocontaminateother hydraulic circuits on the machine.

Groundsmaster 4300--DHydraulic System Page 4 -- 8

Page 41

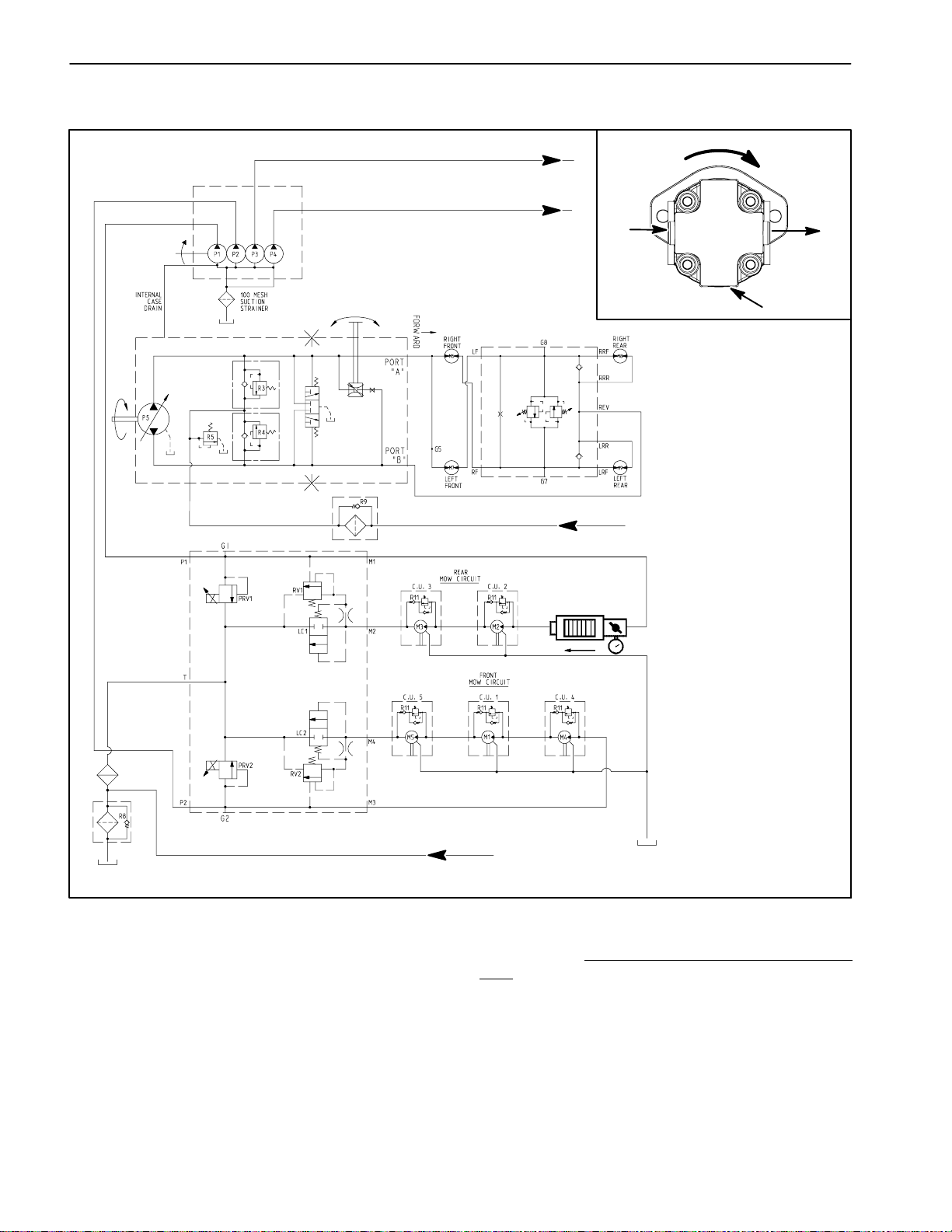

Hydraulic Schematic

CYLINDER

STEERING

VALVE

CONTROL

STEERING

LIFT

CONTROL

MANIFOLD

Hydraulic Schematic

Groundsmaster 4300--D

de--energized

All solenoids are shown as

System

Hydraulic

MANIFOLD

CROSSTRAX

VALVE

BYPASS

GEAR

PUMP

PUMP

PISTON

(TRACTION)

Groundsmaster 4300--D Hydraulic SystemPage 4 -- 9

DECK

CONTROL

MANIFOLD

NOTE: A larger hydraulic schematic is

included in Chapter 8 -- Foldout Drawings

Page 42

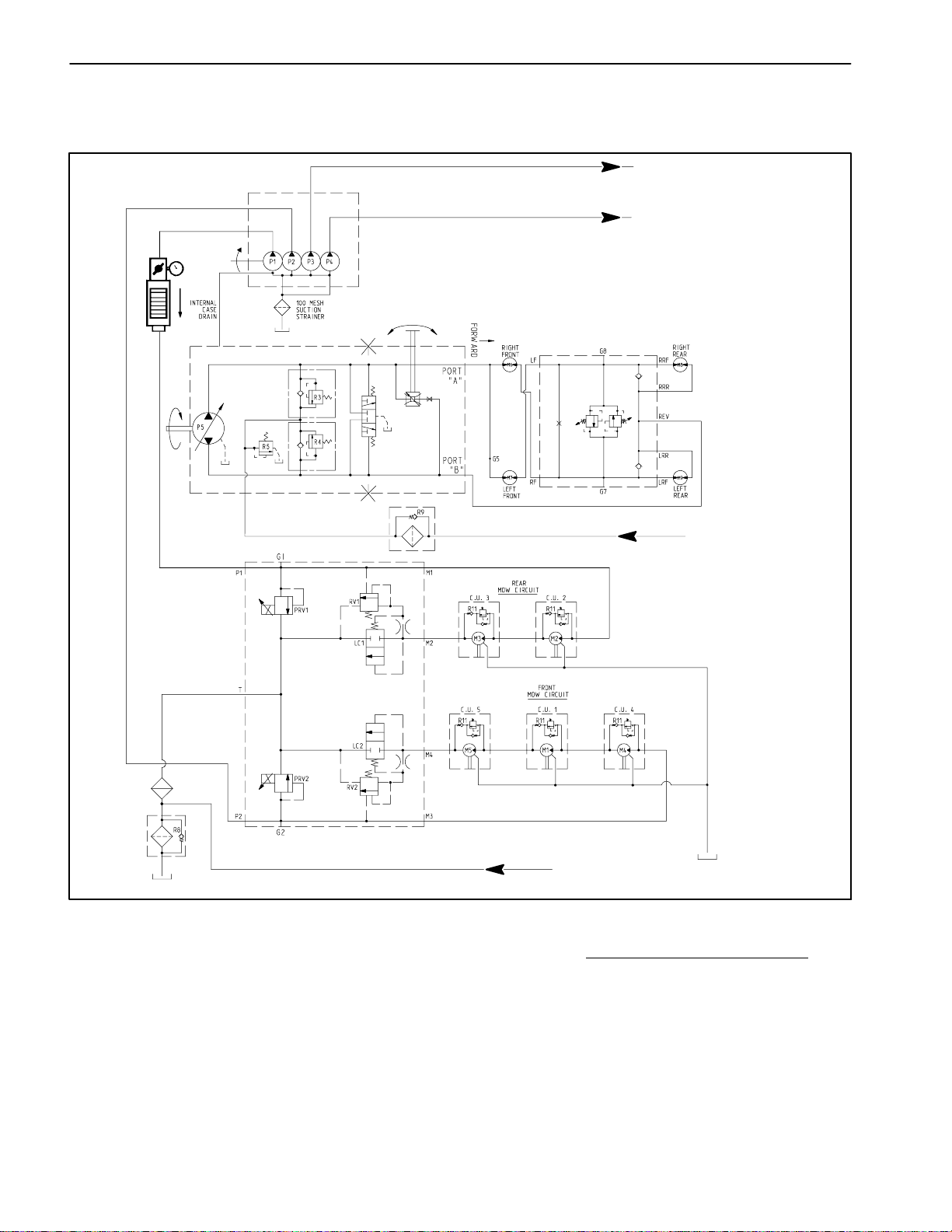

Hydraulic Flow Diagrams

VALVE

CONTROL

STEERING

CYLINDER

STEERING

LIFT

CONTROL

MANIFOLD

Working Pressure

Low Pressure (Charge)

Return or Suction

Flow

Traction Circuit (Forward Shown)

Groundsmaster 4300--D

GEAR

PUMP

BYPASS

MANIFOLD

CROSSTRAX

VALVE

DECK

CONTROL

MANIFOLD

PUMP

PISTON

(TRACTION)

Figure 10

Groundsmaster 4300--DHydraulic System Page 4 -- 10

Page 43

Traction Circuit

The hydraulic traction circuit consists of a variable displacementpistonpump(P5)connectedinaclosedloop,

parallel circuit to four (4) orbital roller vane wheel motors. The traction pump input shaft is rotated by a drive

shaft that is driven from the engine flywheel.

Forward traction circuitpressure can bemeasured at a

test port located in thehydraulic tube that connects the

front wheel motors. Reverse traction circuit pressure

can be measuredat test portsin the AWD control manifold.

Forward Direction (Fig. 10)

Pushing the top ofthe tractionpedal anglesthe traction

pump swash plate to create a flow of oil.This oil flow is

directed to the wheel motors via hydraulic hoses and

tubes to drivethe wheels inthe forward direction.Traction pump flow isdirected tothe frontwheel motorsand

thentotheopposite rearwheelmotors tomaximizetraction. To reduce tire scuffing when turning, traction system pressureis equalized in the AWD control manifold

with an orifice and a bi--directional relief valve. Check

valvesintheAWDmanifold allow the rear wheel motors

toover--runduringtight turns.Forward tractionpressure

is limited to 3625 PSI (250 bar) by the forward traction

relief valve (R3) located in the traction pump.

Oilflowingfromthe w heel motors returns to the variable

displacement pump and is continuously pumped

through the tractioncircuit as long as thetraction pedal

is pushed.

Theangle of the swash platedeterminespumpflowand

ultimatelytractionspeed.Whenthetractionpedalisdepressedasmallamount,asmallswashplaterotationresultsinlowpumpoutputandlowertractionspeed.When

the traction pedal is depressed fully, the pump swash

platerotatesfullytoprovidemaximumpumpoutputand

traction speed.

Gearpump section (P3)suppliesoilflow for thesteering

circuitand also provides aconstant supply ofcharge oil

to the closed loop traction circuit. This charge oil provideslubricationfortractioncircuitcomponentsandalso

replenishes traction circuit oil thatis lost due to internal

leakage in the traction circuit.