Toro 41594, Multi-Pro 5800 Operator's Manual

FormNo.3391-858RevB

Multi-Pro5800TurfSprayer

ModelNo.41594—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3391-858*B

TheMulti-Pro

®

turfsprayerisadedicatedturfspray

applicationvehicleandisintendedtobeusedbyprofessional,

hiredoperatorsincommercialapplications.Itisprimarily

designedforsprayingonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

orotherreproductiveharm.

tocausecancer,birthdefects,orother

reproductiveharm.

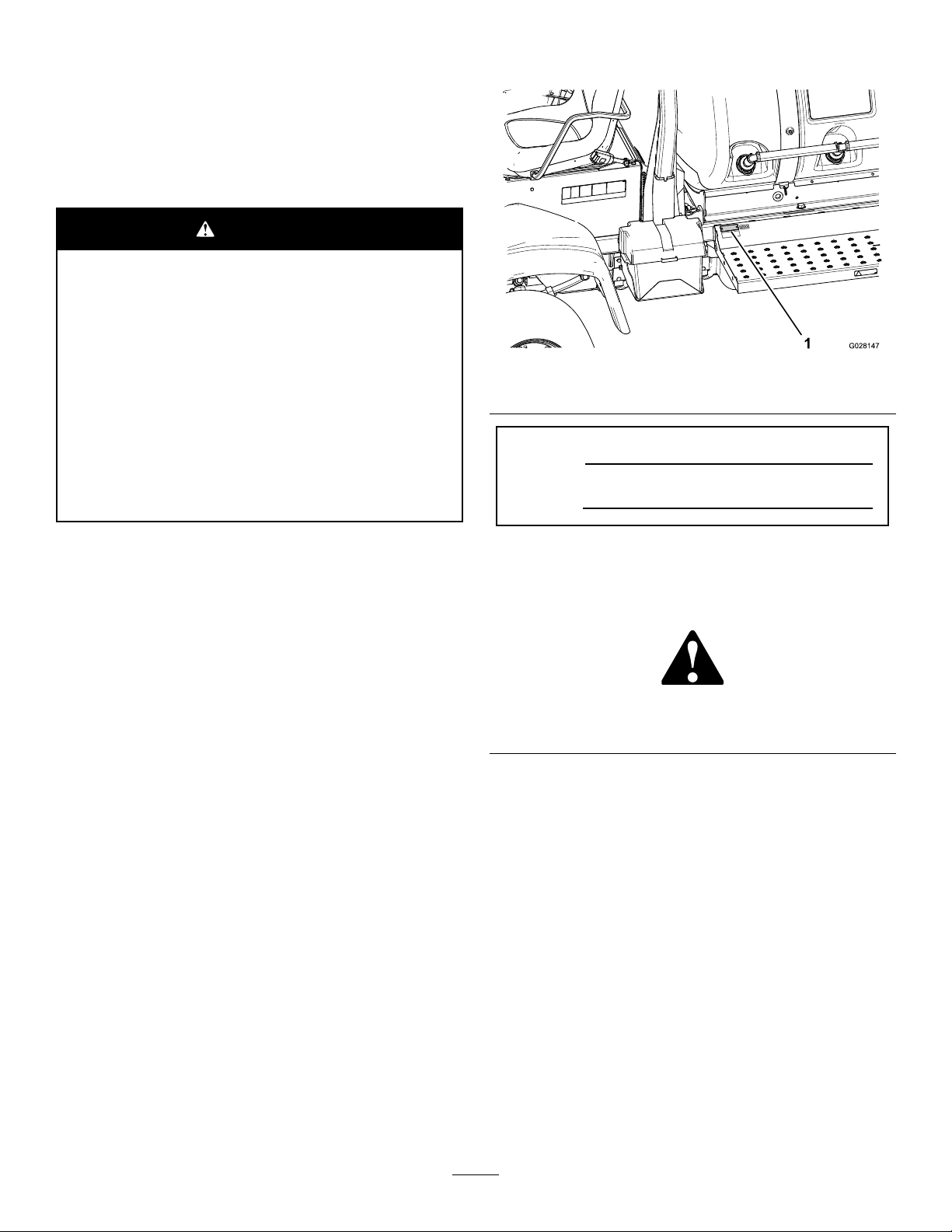

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationinthis

manualcanhelpyouandothersavoidinjuryandproduct

damage.AlthoughTorodesignsandproducessafeproducts,

youareresponsibleforoperatingtheproductproperlyand

safely.YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndingadealer,or

toregisteryourproduct.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ChemicalSafety.......................................................5

WhileOperating......................................................6

Maintenance...........................................................7

SoundPower..........................................................8

SoundPressure.......................................................8

Hand-ArmVibration...............................................8

WholeBodyVibration.............................................8

SafetyandInstructionalDecals.................................8

Setup...........................................................................14

1CheckingtheBoomHingeSprings.........................14

2RemovingtheShippingBumper.............................15

ProductOverview.........................................................16

Controls...............................................................17

VehicleControls.................................................17

Specications........................................................21

Operation....................................................................22

ThinkSafetyFirst...................................................22

PerformingPre-StartingChecks...............................22

PreparingtoDrivetheMachine................................22

UsingtheInfoCenter..............................................26

PreparingtoUsetheSprayer....................................29

OperatingtheMachine............................................30

BreakinginaNewSprayer.......................................31

OperatingtheSprayer.............................................31

FillingtheFreshWaterTank....................................31

FillingtheSprayTank..............................................31

OperatingtheBooms..............................................32

Spraying................................................................32

TurfCarePrecautionswhileOperatinginStationary

Modes...............................................................33

SprayingTips.........................................................33

UncloggingaNozzle..............................................33

SelectingaNozzle..................................................33

CleaningtheSprayer...............................................33

CalibratingtheSectionValves...................................34

AgitationBypassValveKnobPosition.......................35

CalibratingtheAgitationBypassValve.......................35

Pump....................................................................36

TransportingtheSprayer.........................................36

TowingtheSprayer.................................................36

Maintenance.................................................................38

RecommendedMaintenanceSchedule(s)......................38

DailyMaintenanceChecklist....................................39

NotationforAreasofConcern.................................39

PremaintenanceProcedures........................................40

JackingtheSprayerUp............................................40

AccessingtheEngine..............................................40

Lubrication...............................................................42

GreasingtheSprayer...............................................42

GreasingtheBoomHinges......................................42

GreasingtheActuatorRodBearings..........................42

EngineMaintenance..................................................43

CheckingtheAirCleaner.........................................43

ServicingtheEngineOil..........................................44

CheckingthePCVValve..........................................46

FuelSystemMaintenance...........................................46

CheckingtheFuelLineandConnections...................46

ServicingtheFuelFilter...........................................46

DrainingtheFuelTank...........................................48

BleedingtheFuelSystem.........................................49

ElectricalSystemMaintenance....................................49

ReplacingtheFuses................................................49

ServicingtheBattery...............................................49

DriveSystemMaintenance.........................................51

InspectingtheWheels/Tires....................................51

ChangingthePlanetaryGearboxFluid.......................51

AdjustingtheFrontWheelToe-in.............................52

CoolingSystemMaintenance......................................53

ServicingtheCoolingSystem...................................53

BrakeMaintenance....................................................54

AdjustingtheBrakes...............................................54

BeltMaintenance......................................................55

ServicingtheAlternatorBelt....................................55

HydraulicSystemMaintenance....................................55

HydraulicFluidSpecication...................................55

ServicingtheHydraulicOil......................................56

SprayerSystemMaintenance........................................58

InspectingtheHoses..............................................58

ChangingthePressureFilter....................................58

InspectingtheSprayerPump....................................59

AdjustingtheActuators...........................................59

InspectingtheNylonPivotBushings.........................60

Cleaning...................................................................60

CleaningtheRadiatorCoolingFins...........................60

CleaningtheSprayerValves.....................................60

Storage........................................................................70

Troubleshooting...........................................................71

Schematics...................................................................74

3

Safety

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

ThemachinemeetstherequirementsofSAEJ2258.

SafeOperatingPractices

Important:Important:Themachineisdesigned

primarilyasanoff-roadvehicleandisnotintendedfor

extensiveuseonpublicroads.Whenusingthemachine

onpublicroads,followalltrafcregulationsanduse

anyadditionalaccessoriesthatmayberequiredbylaw,

suchaslights,turnsignals,slowmovingvehicle(SMV)

sign,andothersasrequired.

TheMulti-Pro5800TurfSprayerwasdesignedandtestedto

offersafeservicewhenoperatedandmaintainedproperly.

Althoughhazardcontrolandaccidentpreventionpartiallyare

dependentuponthedesignandcongurationofthemachine,

thesefactorsarealsodependentupontheawareness,concern,

andpropertrainingofthepersonnelinvolvedintheoperation,

maintenanceandstorageofthemachine.Improperuseor

maintenanceofthemachinecanresultininjuryordeath.

NotalloftheattachmentsthatadapttotheMulti-Pro5800

TurfSprayerarecoveredinthismanual.Seethespecic

Operator’sManualprovidedwitheachattachmentfor

additionalsafetyinstructions.Readthesemanuals.

Toreducethepotentialforinjuryordeath,complywiththe

followingsafetyinstructions:

Supervisor'sResponsibilities

•Makesurethatoperatorsarethoroughlytrainedand

familiarwiththeOperator'sManual,engineowner’smanual,

andalllabelsonthesprayer.

•Establishyourownspecialproceduresandworkrules

forunusualoperatingconditions(e.g.slopestoosteep

forsprayeroperation).

Note:Localregulationsmayrestricttheageofthe

operator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,ordamagetoproperty.

BeforeOperating

•Operatethemachineonlyafterreadingandunderstanding

thecontentsofthismanual.

•Neverallowchildrentooperatethesprayer.

•Neverallowotheradultstooperatethesprayerwithout

rstreadingandunderstandingtheOperator'sManual.

Onlytrainedandauthorizedpersonsshouldoperatethis

sprayer.Makesurethatalloperatorsarephysicallyand

mentallycapableofoperatingthesprayer.

•Thissprayerisdesignedtocarryonlyyou,theoperator

andonepassengerintheseatprovidedbythe

manufacturer.Nevercarryanyadditionalpassengerson

thesprayer.

•Neveroperatethesprayerwhenundertheinuence

ofdrugsoralcohol.Evenprescriptiondrugsandcold

medicinescancausedrowsiness.

•Donotdrivethesprayerwhenyouaretired.Besureto

takeoccasionalbreaks.Itisveryimportantthatyoustay

alertatalltimes.

•Becomefamiliarwiththecontrolsandknowhowtostop

theenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.Ifa

shield,safetydevice,ordecalismalfunctioning,illegible,

ordamaged,repairorreplaceitbeforeoperatingthe

machine.

•Wearappropriateclothing;includingsafetyglasses,long

pants,substantialslip-resistantfootwearorrubberboots,

gloves,andhearingprotection.Tiebacklonghair.Do

notwearjewelry.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Training

•ReadtheOperator'sManualandothertrainingmaterial

beforeoperatingthemachine.

Note:Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neveruntrainedpeopleoperateorservicetheequipment.

Wearhearingprotectionwhenoperatingthis

machine.

•Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besuretodrive

cautiously,usetheheadlights,andevenconsideradding

additionallights.

•Beextremelycarefulwhenoperatingaroundpeople.

Alwaysbeawareofwherebystandersmightbelocated

andkeepthemawayfromtheworkarea.

•Beforeoperatingthesprayer,alwayscheckthedesignated

areasofthesprayerthatarestatedinthePre-Starting

4

ChecksintheOperationsection.Ifthemachinedoes

notfunctioncorrectlyorisdamagedinanyway ,donot

usethesprayer.Makesurethattheproblemiscorrected

beforethesprayerorattachmentisoperated.

•Makesuretheoperatorandpassengerareaiscleanand

freefromchemicalresidueanddebrisbuildup.

•Ensurethatalluidlineconnectorsaretightandallhoses

areingoodconditionbeforeapplyingpressuretothe

system.

Note:Donotusethesprayerifitisleakingordamaged.

•Sincefuelishighlyammable,handleitcarefully.

–Useanapprovedfuelcontainer.

–Donotremovethecapfromthefueltankwhenthe

engineishotorrunning.Allowtheenginetocool

beforefuelingthemachine.

–Donotsmokewhilehandlingfuel.

–Fillthefueltankofthemachineoutdoors.

–Fillthefueltankofthemachinetoabout25mm(1

inch)belowthetopofthetank(thebottomofthe

llerneck).Donotoverllthefueltank.

ChemicalSafety

WARNING

Chemicalsubstancesusedinthespreader-sprayer

systemmaybehazardousandtoxictoyou,

bystanders,animals,plants,soilsorotherproperty.

•Carefullyreadandfollowthechemicalwarning

labelsandMaterialSafetyDataSheets(MSDS)

forallchemicalsusedandprotectyourself

accordingtothechemicalmanufacturer's

recommendations.Ensurethataslittleskin

aspossibleisexposedwhileusingchemicals.

UseappropriatePersonalProtectiveEquipment

(PPE)toguardagainstpersonalcontactwith

chemicals,suchas:

–safetyglasses,goggles,and/orfaceshield

–respiratororltermask

–chemicalresistantgloves

–rubberbootsorothersubstantialfootwear

–hearingprotection

–Wipeupanyspilledfuel.

–cleanchangeofclothes,soap,anddisposable

towels,tobekepton-hand,intheeventof

achemicalspill.

•Keepinmindthattheremaybemorethan

onechemicalused,andinformationoneach

chemicalshouldbeassessed.

•Refusetooperateorworkonthesprayerifthis

informationisnotavailable!

•Beforeworkingonasprayersystem,make

surethatthesystemhasbeentriplerinsedand

neutralizedaccordingtotherecommendations

ofthechemicalmanufacturer(s)andallofthe

valveshavebeencycled3times.

•Verifythereisanadequatesupplyofcleanwater

andsoapnearby,andimmediatelywashoffany

chemicalsthatcontactyou.

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer'sinstructionsfor

thesafeapplicationofthechemical.Donotexceed

recommendedsystemapplicationpressure.

•Donotll,calibrate,orcleantheunitwhenpeople,

especiallychildren,orpetsareinthearea.

•Handlechemicalsinawellventilatedarea.

•Havecleanwateravailableespeciallywhenllingthe

spraytank.

•Donoteat,drink,orsmokewhileworkingwithchemicals.

5

•Donotcleanspraynozzlesbyblowingthroughthemor

placinginmouth.

•Alwayswashyourhandsandotherexposedareasassoon

aspossibleafteryounishworkingwithchemicals.

•Keepchemicalsintheiroriginalpackagesandstoredin

asafelocation.

•Properlydisposeofunusedchemicalsandchemical

containersasinstructedbythechemicalmanufacturer

andyourlocalcodes.

•Chemicalsandfumesaredangerous;neverenterthetank

orplaceyourheadoverorintheopeningofatank.

•Followalllocal,state,federalregulationsforspreading

orsprayingchemicals.

–Watchoutfortrafcwhenyouarenearorcrossing

roads.Alwaysyieldtherightofwaytopedestrians

andothervehicles.Thissprayerisnotdesignedfor

useonstreetsorhighways.Alwayssignalyourturns

orstopearlyenoughsothatotherpeopleknowwhat

youplantodo.Obeyalltrafcrulesandregulations.

–Theelectricalandexhaustsystemsofthesprayercan

producesparkscapableofignitingexplosivematerials.

Neveroperatethesprayerinornearanareawhere

thereisdustorfumesintheairwhichareexplosive.

–Ifyouareeverunsureaboutsafeoperation,stop

workandaskyoursupervisor.

•Donottouchtheengineormuferwhiletheengineis

runningorsoonafterithasstopped.Theseareasmaybe

hotenoughtocauseburns.

WhileOperating

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Theoperator(andpassenger)shouldremainseated

wheneverthesprayerisinmotion.Theoperatorshould

keepbothhandsonthesteeringwheelwheneverpossible.

Keepyourarmsandlegswithinthesprayerbodyatall

times.

•Alwayswatchoutforandavoidlowoverhangssuchas

treelimbs,doorjambs,andoverheadwalkways.Make

surethereisenoughroomoverheadtoeasilyclearthe

sprayerandyourhead.

•Failuretooperatethesprayersafelymayresultinan

accident,tipoverofthesprayer,andseriousinjuryor

death.Drivecarefully .Topreventtippingorlossof

control:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,unfamiliarareas,oranyareasthathaveabrupt

changesingroundconditionsorelevation.

–Watchforholesorotherhiddenhazards.

–Useextracautionwhenoperatingthesprayeronwet

surfaces,inadverseweatherconditions,athigher

speeds,orwithafullload.Stoppingtimeanddistance

willincreasewithafullload.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithoutrst

comingtoacompletestop.

–Slowdownbeforeturning.Donotattemptsharp

turnsorabruptmaneuversorotherunsafedriving

actionsthatmaycausealossofsprayercontrol.

•Ifthemachineevervibratesabnormally,stopimmediately ,

waitforallmotiontostop,andinspectthesprayerfor

damage.Repairalldamagebeforeresumingoperation.

•Beforegettingoffoftheseat:

1.Stopthemovementofthemachine.

2.Removeyourfootfromthetractionpedalandset

theparkingbrake.

3.TurnthekeyforthestarterswitchtotheOff

position.

4.Removethekeyfromthestarterswitch.

Important:Donotparkthemachineonan

incline.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

Braking

•Slowdownbeforeyouapproachanobstacle.Thisgives

youextratimetostoporturnaway.Hittinganobstacle

candamagethesprayeranditscontents.Moreimportant,

itcaninjureyou.

•GrossVehicleWeight(GVW)hasamajorimpactonyour

abilitytostopand/orturn.Heavyloadsandattachments

makeasprayerhardertostoporturn.Theheavierthe

load,thelongerittakestostop.

•Turfandpavementaremuchmoreslipperywhenthey

arewet.Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.Ifyoudrivethroughstanding

waterdeepenoughtogetthebrakeswet,theywillnot

workwelluntiltheyaredry.Afterdrivingthroughwater,

youshouldtestthebrakestomakesuretheywork

properly.Iftheydonot,driveslowlywhileputtinglight

pressureonthebrakepedal.Thiswilldrythebrakesout.

–Beforebackingup,looktotherearandensurethat

nooneisbehindyou.Backupslowly.

6

OperatingonHillsandRoughTerrain

Operatingthesprayeronahillmaycausetippingorrolling

ofthesprayer,ortheenginemaystallandyoucouldlose

headwayonthehill.Thiscouldresultinpersonalinjury.

•Donotacceleratequicklyorslamonthebrakeswhen

backingdownahill,especiallywithaload.

•Neverdriveacrossasteephill;alwaysdrivestraightupor

downorgoaroundthehill.

•Iftheenginestallsoryoubegintoloseheadwaywhile

climbingahill,graduallyapplythebrakesandslowlyback

straightdownthehill.

•Turningwhiletravelingupordownhillscanbedangerous.

Ifyouhavetoturnwhileonahill,doitslowlyand

cautiously.Nevermakesharporfastturns.

•Heavyloadsaffectstability.Reducetheweightoftheload

andyourspeedwhenoperatingonhills.

•Avoidstoppingonhills,especiallywithaload.Stopping

whilegoingdownahillwilltakelongerthanstopping

onlevelground.Ifthesprayermustbestopped,avoid

suddenspeedchanges,whichmayinitiatetippingor

rollingofthesprayer.Donotslamonthebrakes

whenrollingbackward,asthismaycausethesprayerto

overturn.

•Usetheseatbeltwhenoperatingthemachineandbe

certainthatitcanbereleasedquicklyintheeventofan

emergency.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•Donotremovetherolloverprotectionsystem(ROPS).

•Reducespeedandloadwhenoperatingonroughterrain,

unevenground,andnearcurbs,holes,andothersudden

changesinterrain.Loadsmayshift,causingthesprayer

tobecomeunstable.

WARNING

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresultingin

handandarminjuries.

•Reduceyourspeedwhenoperatingonroughterrainand

nearcurbs.

•Gripthesteeringwheellooselyaroundtheperimeter.

Keepyourhandsclearofthesteeringwheelspokes.

Loading

Theweightofthecargocanchangethesprayercenterof

gravityandsprayerhandling.Toavoidlossofcontroland

personalinjury,followtheseguidelines:

•Reducetheweightoftheloadwhenoperatingonhills

androughterraintoavoidtippingoroverturningofthe

sprayer.

•Liquidloadscanshift.Thisshiftinghappensmostoften

whileturning,goingupordownhills,suddenlychanging

speeds,orwhiledrivingoverroughsurfaces.Shifting

loadscancausethesprayertotipover.

•Whenoperatingwithaheavyload,reduceyourspeedand

allowforsufcientbrakingdistance.Donotsuddenly

applythebrakes.Useextracautiononslopes.

•Beawarethatheavyloadsincreaseyourstoppingdistance

andreduceyourabilitytoturnquicklywithouttipping

over.

Maintenance

•Onlypermitqualiedandauthorizedpersonnelto

maintain,repair,adjust,orinspectthesprayer.

•Beforeperforminganymaintenance,ensurethatthe

systemhasbeenthoroughlyrinsedandcleaned.

•Beforeservicingormakingadjustmentstothemachine,

stoptheengine,settheparkingbrake,andremovethe

keyfromthestarterswitchtopreventsomeonefrom

accidentallystartingtheengine.

•Tomakesurethattheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

•Toreducethepotentialforre,keeptheengineareafree

ofexcessivegrease,grass,leaves,andaccumulationofdirt.

•Neveruseanopenametocheckthelevelorleakageof

fuelorbatteryelectrolyte.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keepyourhands,feet,clothing,andanyparts

ofyourbodyawayfromtheengineandanymovingparts.

Keepeveryoneaway.

•Donotuseopenpansoffuelorammablecleaning

uidswhencleaningparts.

•Donotadjustthetractioncontrolspeed.Toensure

safetyandaccuracy ,haveanAuthorizedToroDistributor

checkthegroundspeed.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthighpressureuid.Usecardboardor

papertondleaks.Fluidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

•Ifmajorrepairsareeverneededorassistanceisrequired,

contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety ,

alwayspurchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous.Alteringthis

sprayerinanymannerthatmayaffectsprayeroperation,

performance,durability ,oritsuse,mayresultininjuryor

death.Suchusecouldvoidtheproductwarranty.

7

SoundPower

Thisunithasaguaranteedsoundpowerlevelof101dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressure

Hand-ArmVibration

Measuredvibrationlevelforrighthand=0.2m/s

Measuredvibrationlevelforlefthand=0.3m/s

UncertaintyValue(K)=0.1m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

2

Thisunithasasoundpressurelevelattheoperator’searof90

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

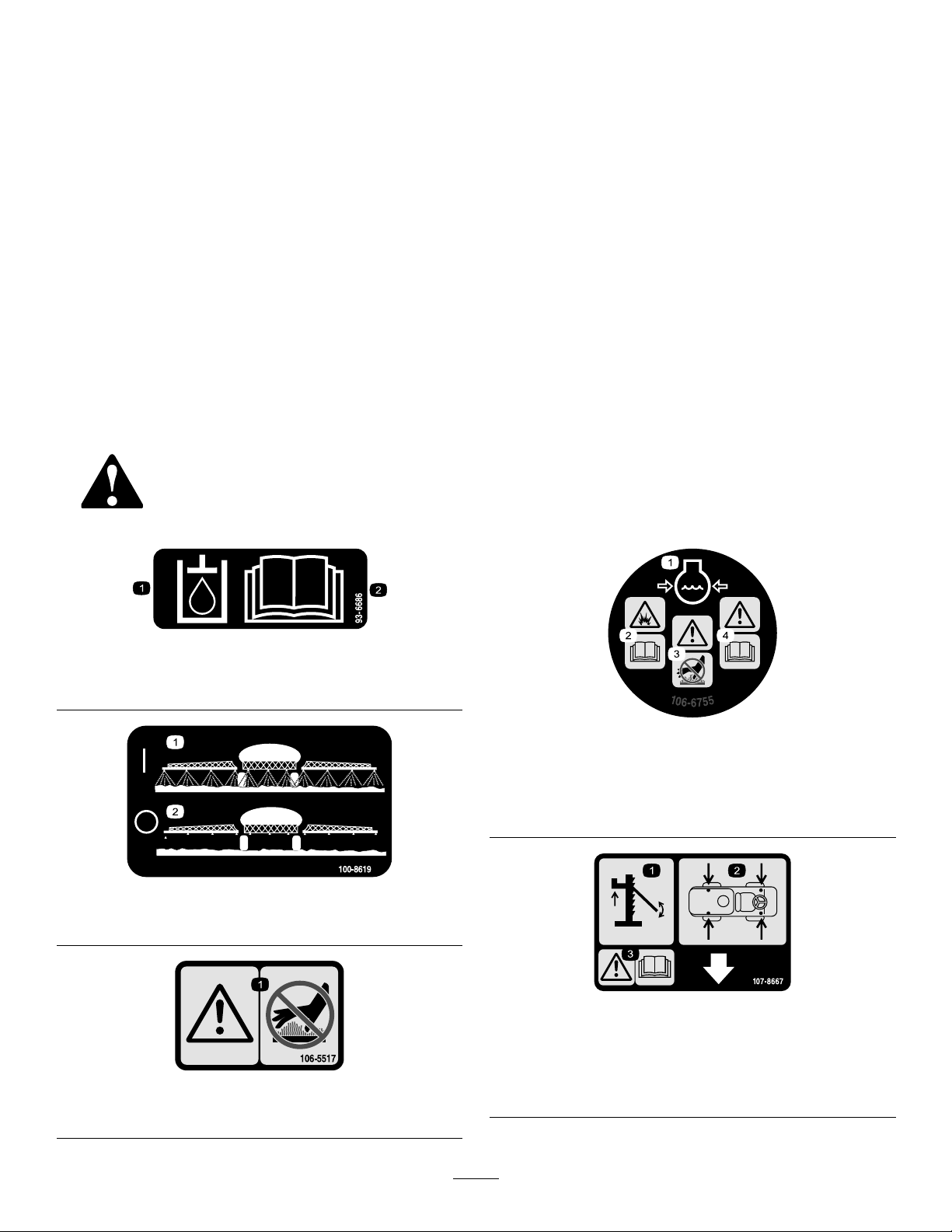

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93–6686

1.Hydraulicoil

2.ReadtheOperator's

Manual.

WholeBodyVibration

Measuredvibrationlevel=0.14m/s

UncertaintyValue(K)=0.07m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

100-8619

1.Sprayon2.Sprayoff

106-5517

1.Warning—donottouchthehotsurface.

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

1.Jacking

2.Jackpointlocations

3.Warning—ReadtheOperator'sManualformoreinformation

onjackingthevehicle

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

107-8667

8

107-8724

1.Tractiondrive3.Todriveinreverse,press

2.Todriveforward,pressthe

topofthetractionpedal

forwardanddown.

thebottomofthepedal

rearwardanddown.

4.Vehiclespeedincreases

withmorepedalpressure.

107-8731

1.Warning—readtheOperator'sManual.

2.Torquelugnutsto75to102N-m(55to75ft-lb).

107-8732

1.Warning—readtheOperator'sManual.

2.Torquelugnutsto95to122N-m(75to90ft-lb).

117-4955

1.Warning—readtheOperator'sManual;weartheseatbelt

whenseatedintheoperator'sposition;avoidtippingthe

machine.

2.Warning—wearhearingprotection.

120-0759

1.Decrease

2.Continuousvariable

setting,spraypressure

3.Increase

4.Rinsefromcleanwater

tank

5.Off

6.On

7.Mixeductor

8.Sonicboom

9.Hazardlights

117–2718

9

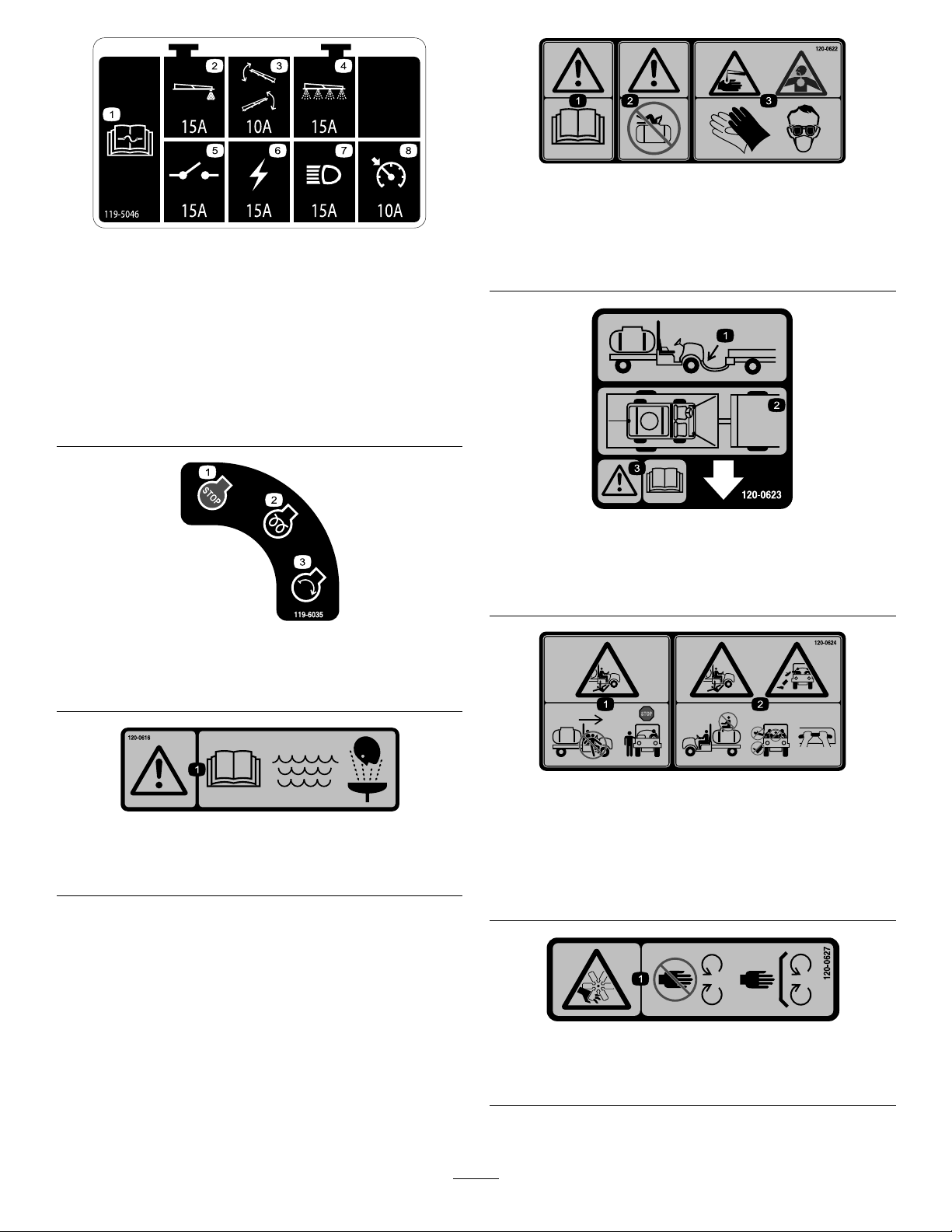

119-5046

1.ReadtheOperator'sManualforinformationonfuses.

2.Foammarker—15amp

3.Boomlift—10amp

4.Spraysystem—15amp

5.Breakerswitch—15amp

6.Ignition—15amp

7.Headlights—15amp

8.Ground-speedlockswitch—10amp

120-0622

1.Warning—readtheOperator'sManual.

2.Warning—donotenterthetank.

3.Causticliquid/chemicalburnandtoxicgasinhalation

hazards—wearhand,skin,eye,andrespiratoryprotection.

120-0623

1.Towhitchlocation

2.Tiedownlocations

3.Warning—ReadtheOperator'sManual.

119-6035

1.Engine—stop3.Engine—start

2.Engine—run,preheat

120–0616

1.Warning—readtheOperator'sManual;usefresh,clean

waterforrst-aidwashing.

120-0624

1.Crushing/dismembermenthazardofbystanders—donot

exitorenterthemachinewhileitismoving;stopthe

machinebeforeenteringorexiting.

2.Falling,crushinghazard—noridersontank;keeparms

andlegsinsideofthevehicleatalltimes,usepassenger

handholds.

120-0627

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

10

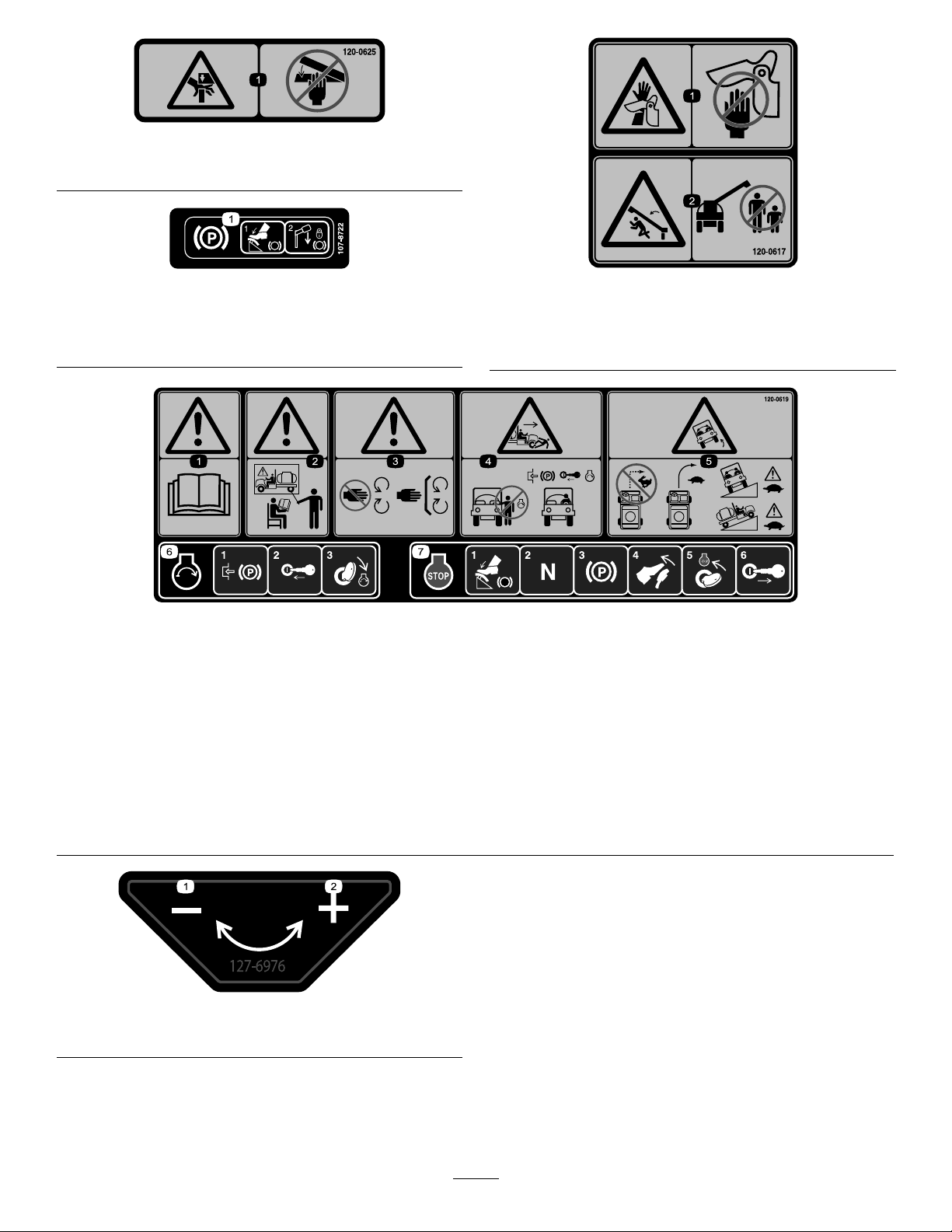

120-0625

1.Pinchpoint,hand—keephandsaway.

107-8722

1.Engagingtheparkingbrake—1)Pushdownontheparking

brakepedal;2)Pulldownontheparkingbrakelevertolock

theparkingbrake.

1.Pinchpoint,hand—keephandsawayfromhinge.

2.Crushinghazard,boom—keepbystandersasafedistance

fromthemachine.

120-0617

120-0619

1.Warning—readtheOperator'sManual.5.Tippinghazard—donotturnsharplywhiletravelingfast,drive

2.Warning—donotoperatethismachineunlessyouaretrained.6.T ostarttheengine,engagetheparkingbrake,insertthe

3.Warning—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

4.Crushing/dismembermenthazardofbystanders—donotstart

theenginewhileenteringorexitingthevehicle;engagethe

parkingbrake,insertthekey,andstarttheenginewhile

seatedinthedriver’sseat.

slowlywhenturning;usecautionanddriveslowlywhen

travelingacrossorupanddownslopes.

ignitionkeyandturnittothestartposition.

7.Tostoptheengine,pressthebrake,putthegearselectorin

neutral,settheparkingbrake,releasethebrake,stopthe

engine,andremovethekey.

127-6976

1.Decrease2.Increase

11

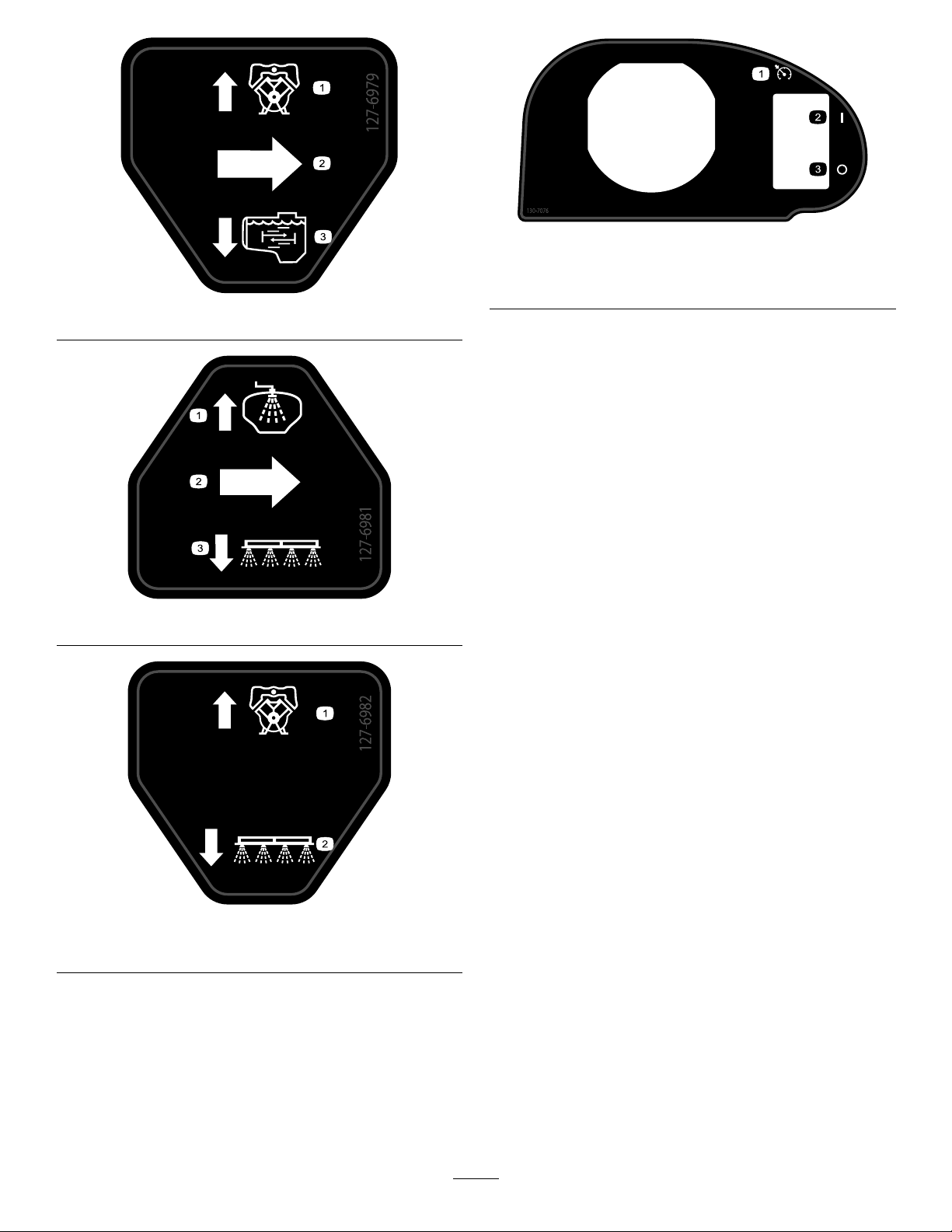

130-7076

1.Neutralenginespeedlock

2.On

3.Off

127-6979

127-6981

127-6982

1.Pump2.Boomspray

12

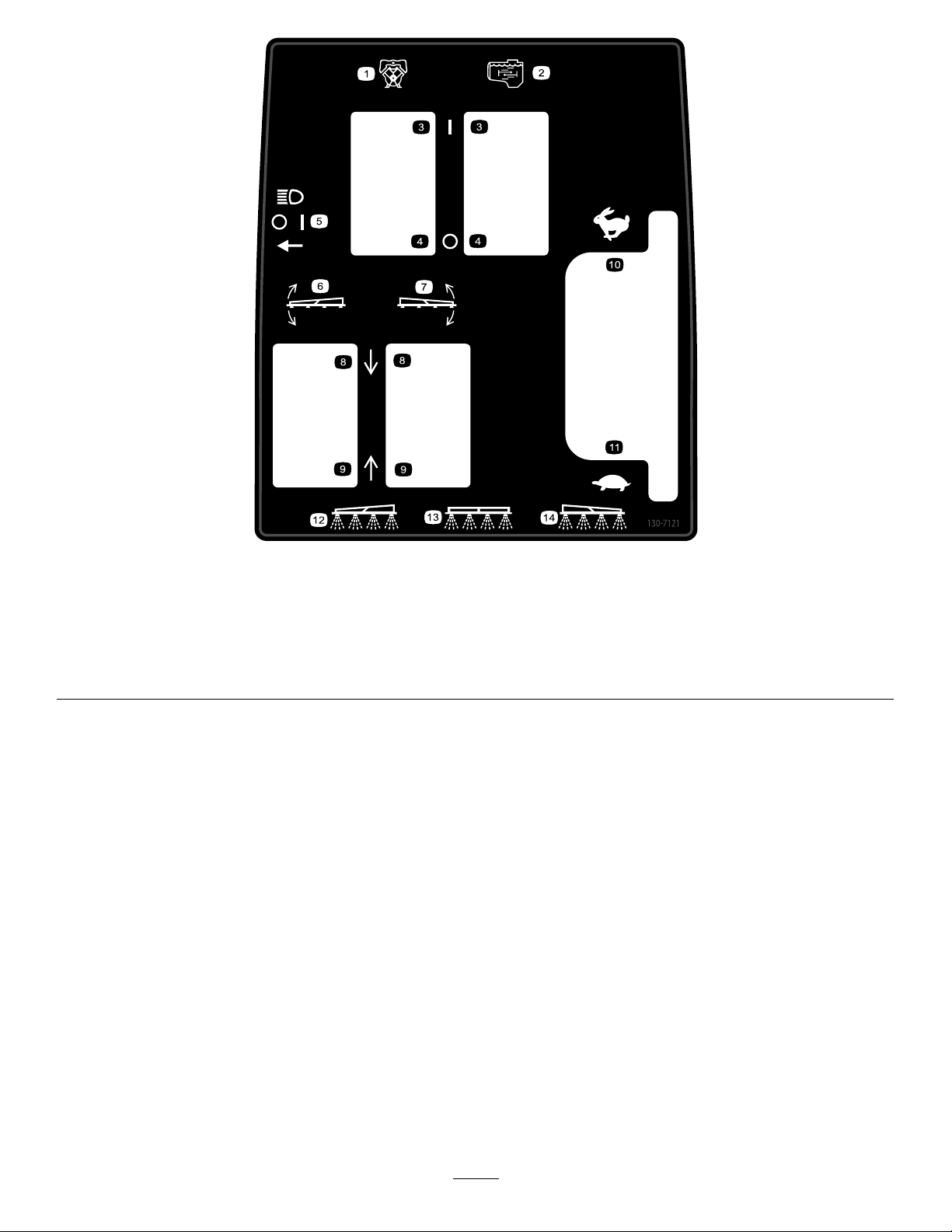

130-7121

1.Pump5.Lightswitchlocation9.Raiseboom

2.Agitation

3.On7.Rightboomraise/lower

4.Off

6.Leftboomraise/lower

8.Lowerboom

controls

controls

10.Fast14.Rightboomspray

11.Slow

12.Leftboomspray

13.Centerboomspray

13

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

Qty.

Nopartsrequired

Nopartsrequired

–

–

Checktheboomhingesprings.

Removetheshippingbumper.

Use

MediaandAdditionalParts

Description

Starterkey

Operator'sManual

Engineowner'sManual1

PartsCatalog

OperatorTrainingMaterials

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Ifyouhavequestionsorneedadditionalinformationregardingthespraycontrolsystem,refertotheOperator’sManual

suppliedwiththesystem.

Important:Thissprayerissoldwithoutnozzlesandaapplication-ratecontroller.Eithera

Kit

or

Pr oContr ol

Tousethesprayer,

ontheavailableboomkitandaccessories.

Afteryouinstallyournozzlesandbeforeusingthesprayerforthersttime(ifyou

System),adjusttheboombypassvalvessothatthepressureandapplicationrateremainsthesameforallbooms

whenyouturnoneormoreboomsoff.RefertoCalibratingtheBoomBypassV alvessectionintheOperationsection.

™

™ ™

XPKit

y ou must obtain and install nozzles

isnecessaryfortheproperfunctionofthemachine.

Qty.

2

1

1

1

Readthemanualsandwatchthetrainingmaterialsbefore

operatingthemachine.

.ContactyourAuthorizedToroDistributorforinformation

Use

Man ual Spray Operation

do not

useProControl™ ™™XPSpray

1

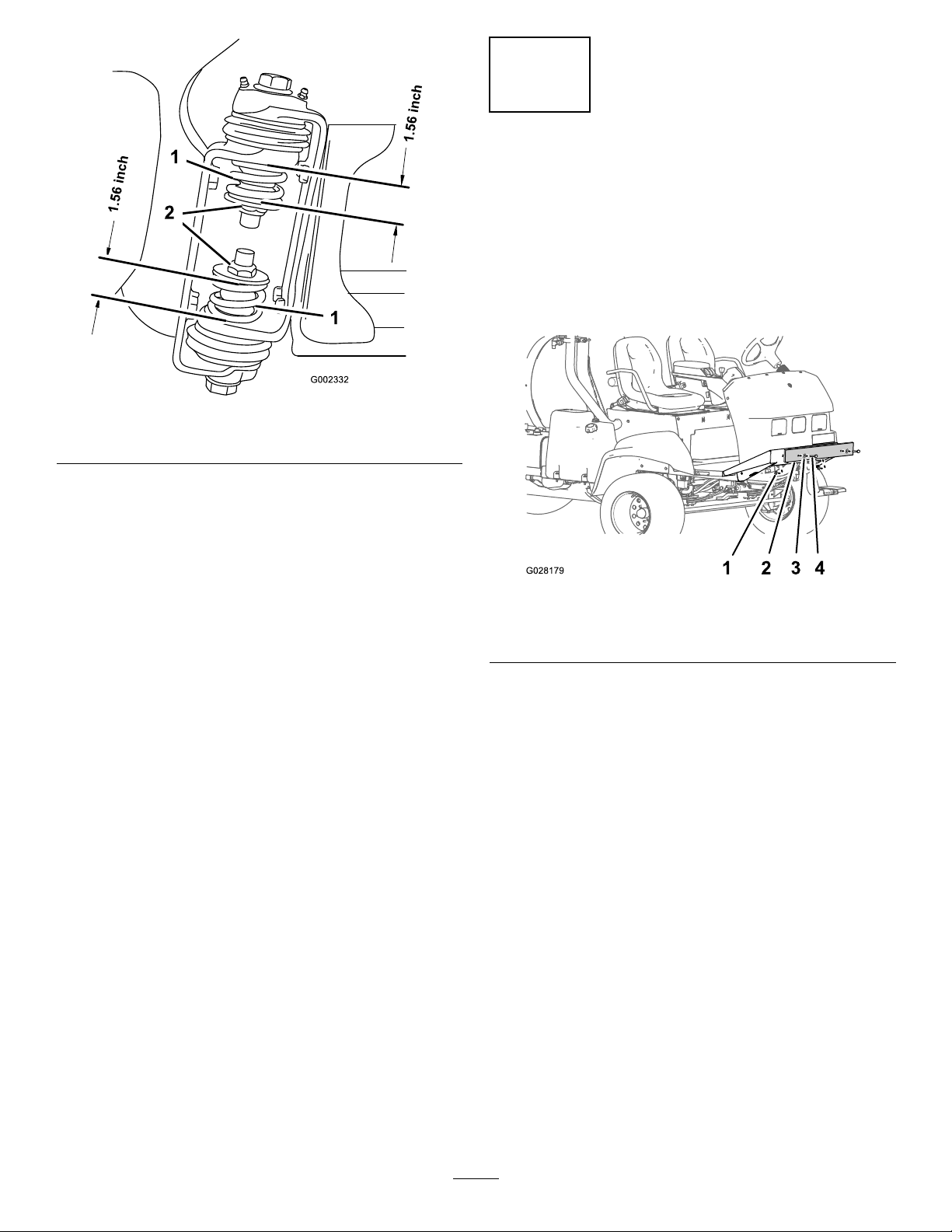

CheckingtheBoomHinge Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwiththeboom

hingespringsundertheincorrectcompressioncould

damagetheboomassembly.Measurethespringsand

usethejamnuttocompressthespringsto3.96cm(1.56

inches),ifnecessary.

Thesprayerisshippedwiththeboomextensionsswung

forwardtofacilitatepackagingofthemachine.Thesprings

arenotfullytightenedatthetimeofmanufacturetoallowthe

boomstobeinthispositionfortransit.Beforeoperatingthe

machine,adjustthespringstothecorrectcompression.

1.Ifnecessary,removethepackingcomponentsthat

securetherightandleftextensionboomsduring

shipping.

2.Supporttheboomswhiletheyareextendedtothe

sprayposition.

3.Attheboomhinge,measurethecompressionofthe

upperandlowerspringswhiletheboomsareintheir

extendedposition(Figure3).

A.Compressallspringsuntiltheymeasure3.96cm

(1.56inches).

B.Usethejamnuttocompressanyspringthat

measuregreaterthan3.96cm(1.56inches).

14

Figure3

1.Boomhingespring2.Jamnut

4.Repeattheprocedureforeachspringonbothboom

hinges.

5.Movetheboomsintothetransport“X”position;refer

toOperatingtheBooms(page32).

2

RemovingtheShipping Bumper

NoPartsRequired

Procedure

1.Removethebolts.washers,andnutsthatsecurethe

shippingbumpertothefrontchassisplate(Figure4).

Figure4

1.Nut3.Washer

2.Shippingbumper

2.Removetheshippingbumperfromthemachine

(Figure4).

Note:Discardthebolts.washers,nuts,andshipping

bumper.

4.Bolt

15

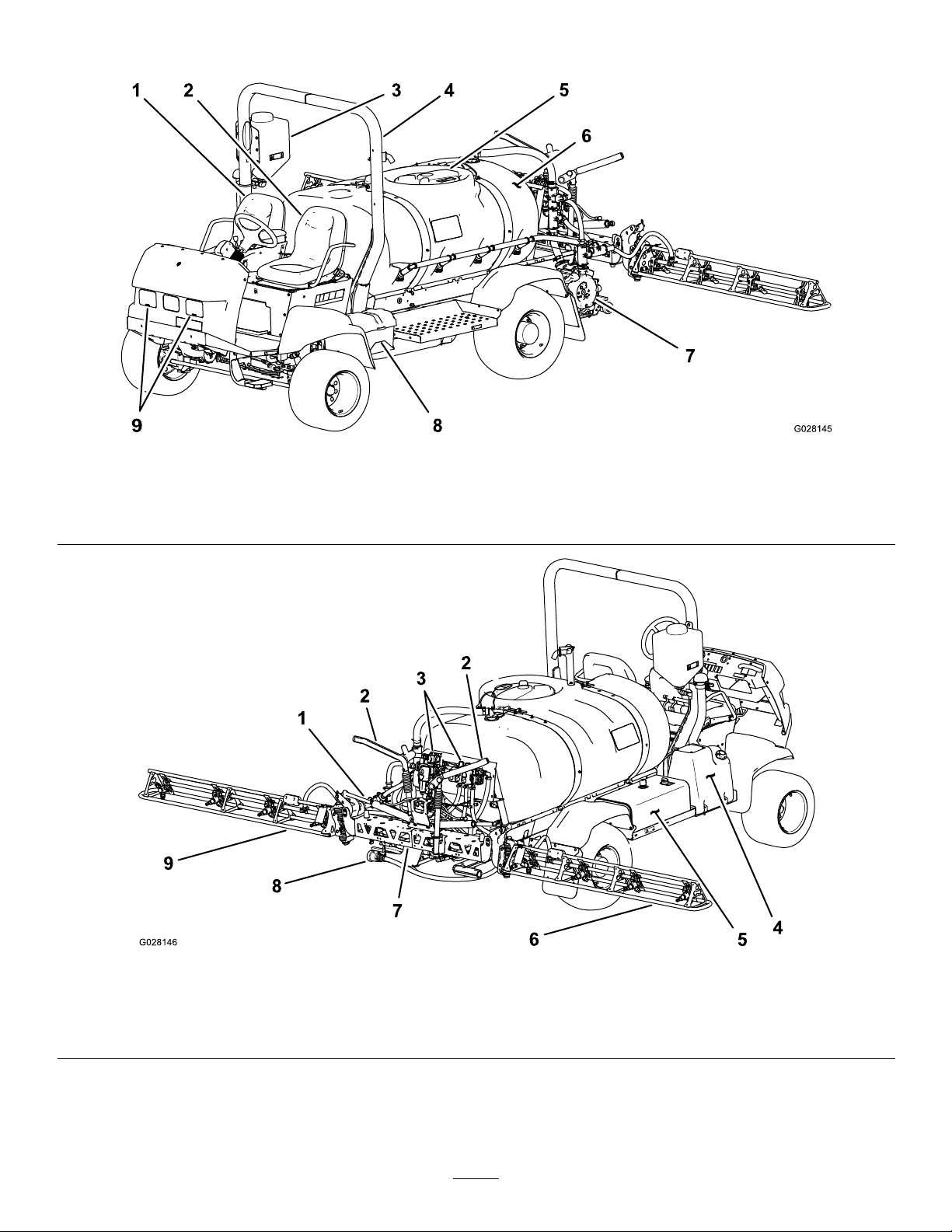

ProductOverview

Figure5

1.Passengerseat

2.Operator’sseat

3.Freshwatertank

4.RollOverProtectionSystem(ROPS)

5.Tanklid8.Battery

6.Chemicaltank

7.Pump

9.Headlights

Figure6

1.Boomcontrolcylinder4.Fueltank

2.Boomtransportcradle5.Hydraulictank8.Tankdrainvalve

3.Valvecluster6.Rightboomsection

16

7.Centerboomsection

9.Leftboomsection

Controls

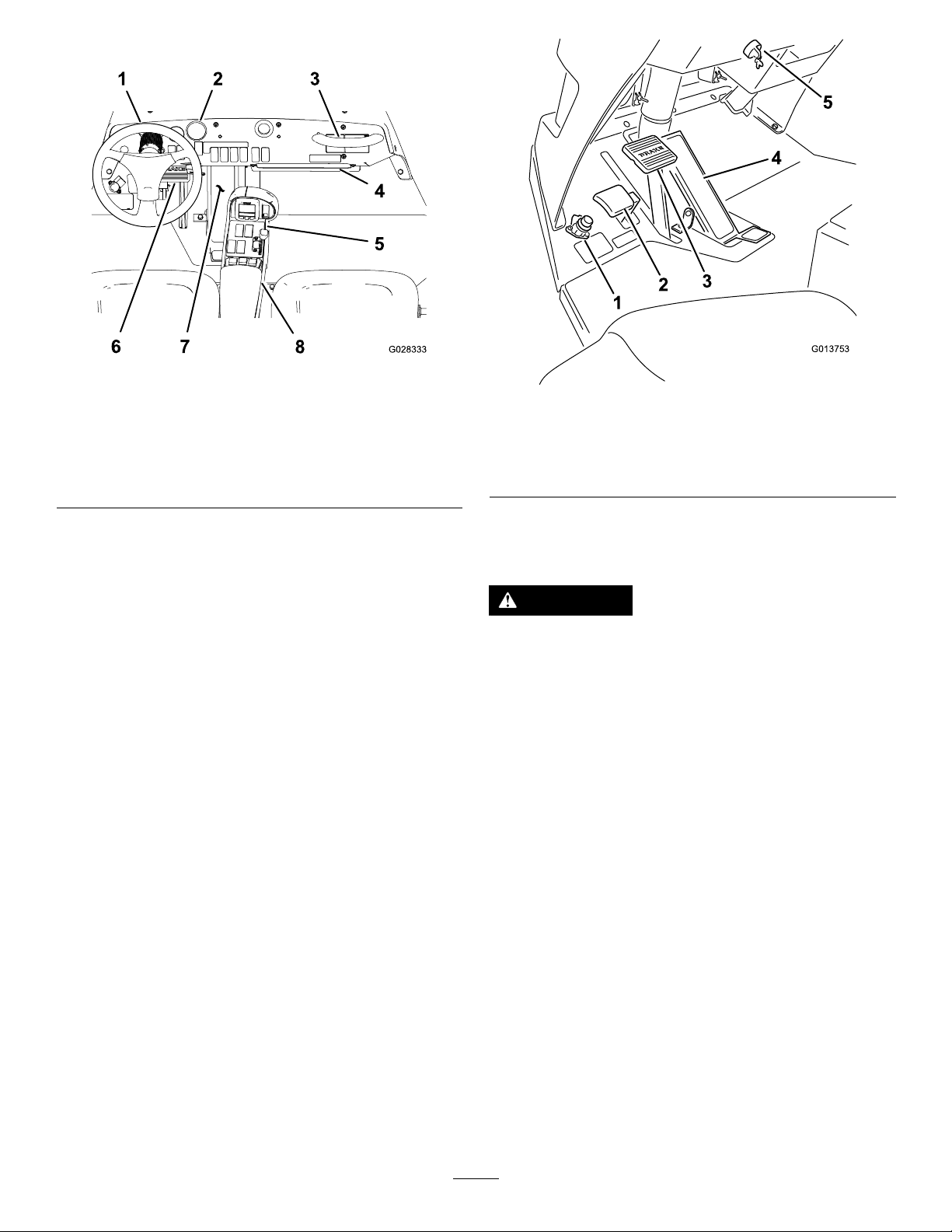

G013753

1

2

3

4

5

Figure7

1.Steeringwheel4.Storage

2.Pressure

gauge

3.Passenger

handhold

compartment

5.Centerconsole

6.Brake

7.Tractionpedal

8.Armrest

VehicleControls

TractionPedal

Thetractionpedal(Figure8)controlsthemovementofthe

machine,bothforwardandreverse.Usingtheheelandtoe

oftherightfoot,pressthetopofthepedaltomoveforward

orthebottomofthepedaltomoveinreverse.Releasethe

pedaltoslowandstop.

Important:Ensurethatyouallowthesprayertocome

toastopbeforeswitchingbetweentheForwardandthe

Reversepositions.

Note:Thefartheryoupressthepedalineitherdirection,the

fasterthesprayerwilltravel.Toobtainmaximumforward

speed,setthethrottlelevertotheFastpositionandpressthe

tractionpedalallthewayforward.

Note:Togetmaximumpowerunderheavyloadorwhen

ascendingahill,havethethrottleintheFastpositionwhile

pressingtractionpedalslightlytokeeptheenginespeedhigh.

Whentheenginespeedbeginstodecrease,releasethetraction

pedalslightlytoallowtheenginespeedtoincrease.

Figure8

1.Master-boomswitch4.Tractionpedal

2.Parking-brakepedal

3.Brakepedal

BrakePedal

5.Starterswitchandkey

Usethebrakepedaltostoporslowthesprayer(Figure8).

CAUTION

Ifyouoperatethesprayerwithpoorlyadjusted

orwornbrakes,youcouldlosecontrolofthe

sprayer,resultinginseriousinjuryordeathtoyou

orbystanders.

Alwayscheckthebrakesbeforeoperatingthe

sprayerandkeepthemproperlyadjustedand

repaired.

ParkingBrake

Theparkingbrakeisapedaltotheleftofthebrake(Figure

8).Engagetheparkingbrakewheneveryouplanonleaving

theseattopreventthesprayerfromaccidentlymoving.

Toengagetheparkingbrake,pressthebrakepedaland,

whileholdingthebrake,presstheparkingbrakepedal.T o

disengage,pressandreleasethebrakepedal.Ifthesprayeris

parkedonasteepgrade,applytheparkingbrakeandplace

blocksonthedownhillsideofthewheels.

StarterSwitch

Thestarterswitch(Figure8),usedtostartandstopthe

engine,has3positions:Off,On/PreheatandStart.

Ground-SpeedLockSwitch

Thegroundspeedlockswitchlocksthepositionofthe

tractionpedalatthetimetheswitchisset(Figure9).This

17

ensuresthesprayertravelsataconstantspeedwhiledriving

themachineonlevelground.

Figure9

1.Ground-speedlockswitch3.Centerconsole

2.Throttlelever4.Headlightswitch

ThrottleLever

Thethrottlelever,locatedonthecontrolpanelbetweenthe

seats(Figure9),controlsthespeedoftheengine.Pushthe

leverforwardtoincreasetheenginespeedandpullitrearward

todecreasetheenginespeed.

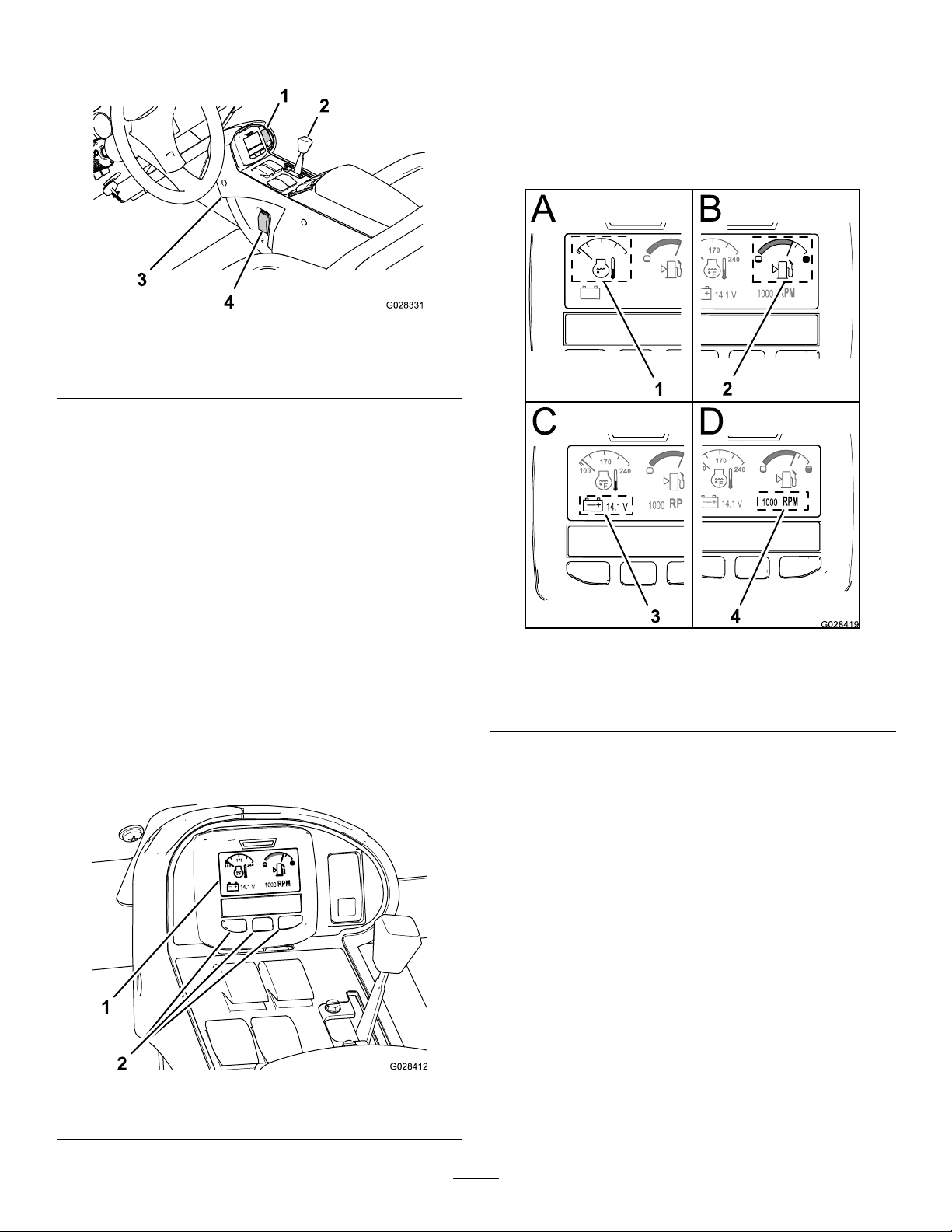

Engine-CoolantT emperatureIndicator

Usetheengine-coolantindicator(AofFigure11)toseethe

temperatureoftheenginecoolant.

Note:Youcanchangethetemperatureindicatorbetween

Englishandmetricunits;refertoChangingtheUnitsof

Measure(EnglishandMetric)(page27).

HeadlightSwitch

Toggletheswitchtooperatetheheadlights(Figure9).Pushit

forwardtoturnthelightsonandrearwardtoturnthemoff.

InfoCenter

UsetheInfoCentertoseethefollowinginformation.

•Coolanttemperatureindicator

•Fuellevelindicator

•Chargingsystemvoltage

•Enginespeed

Figure11

1.Engine-coolantindicator

2.Fuellevelindicator4.Enginespeedindicator

FuelLevelIndicator

3.Chargingsystemvoltage

indicator

Usethefuellevelindicator(BofFigure11)toseethelevel

offuelinthefueltank.

Note:Thefueltankcapacityisapproximately45L(12US

gallons).

Charging-SystemV oltageIndicator

Usethechargingsystemvoltageindicator(CofFigure11)to

seethevoltageofthebatterywhenthestarterswitchisinthe

Onpositionandtheengineisnotrunningorthealternator

voltagewhentheengineisrunning.

Figure10

1.Display(InfoCenter)2.Selectionbuttons

EngineSpeedIndicator

Usetheenginespeedindicator(DofFigure11)toseethe

enginespeedmeasuredinrevolutionsperminute(rpm).

18

HourMeter

Thehourmeter(Figure12)indicatesthetotalnumberof

hourstheenginehasrun.Thehourmeterstartstofunction

wheneverthekeyisturnedtotheRunposition.

Figure12

1.HourMeterlocation

SprayerControls

Figure14

1.Masterboomswitch

BoomLiftSwitches

Theboomliftswitchesarelocatedonthecontrolpaneltothe

rightoftheseatandusedtoraisetheleftandrightbooms

respectively(Figure15).

Figure13

1.Pressuregauge3.Keyandkeyswitch

2.Applicationrateswitch

ApplicationRateSwitch

Theapplicationrateswitchislocatedonthedashtotheright

ofthesteeringwheel(Figure13).Pressandholdtheswitch

forwardtoincreasethespraysystempressure,orpressand

holditrearwardtodecreasepressure.

PressureGauge

Thepressuregauge(Figure13)islocatedonthedash.This

gaugeshowsthepressureoftheuidinthesysteminpsi

andkPa.

MasterBoomSwitch

Themasterboomswitchislocatedontheoorboardofthe

machinecabandtotheleftoftheoperator.Itallowsyouto

startorstopthesprayoperation.Presstheswitchwithyour

foottoenableordisablethespraysystem(Figure14).

Figure15

1.InfoCenter6.Sectionliftswitch,left

2.Ground-speedlockswitch

3.Pumpswitch

4.Agitationswitch

5.Sectionliftswitch,right

boom

SectionSwitches

boom

7.Throttlelever

8.Sectionswitch,leftboom

9.Sectionswitch,center

boom

10.Sectionswitch,rightboom

Thesectionswitchesarelocatedonthecontrolpaneltothe

rightoftheseat(Figure15).Toggleeachswitchforwardto

turnthecorrespondingboomsectiononandrearwardto

turneachoff.WhentheswitchisintheOnposition,alight

willilluminateontheswitch.Theseswitcheswillonlyaffect

thespraysystemwhenthemasterboomswitchisintheOn

position.

PumpSwitch

Thepumpswitchislocatedonthecontrolpaneltotheright

oftheseat(Figure15).Togglethisswitchforwardtorun

thepumporrearwardtostopthepump.Whentheswitchis

turnedon,alightontheswitchilluminates.

19

Important:Onlyengagethepumpswitchwhenthe

G013787

1

2

engineisatlowidletoavoiddamagingthepumpdrive.

rotatetheknobonthevalveclockwisetoturnthevalveoffor

counterclockwisetoturniton.

AgitationSwitch

Theagitationswitchislocatedonthecontrolpaneltothe

rightoftheseat(Figure15).T ogglethisswitchforwardto

turnontheagitationinthetankorrearwardtostopthe

agitation.Whentheswitchisturnedon,alightontheswitch

illuminates.Tooperatetheagitationfunction,youmustrun

thesprayersystempumpandyoumustruntheengineabove

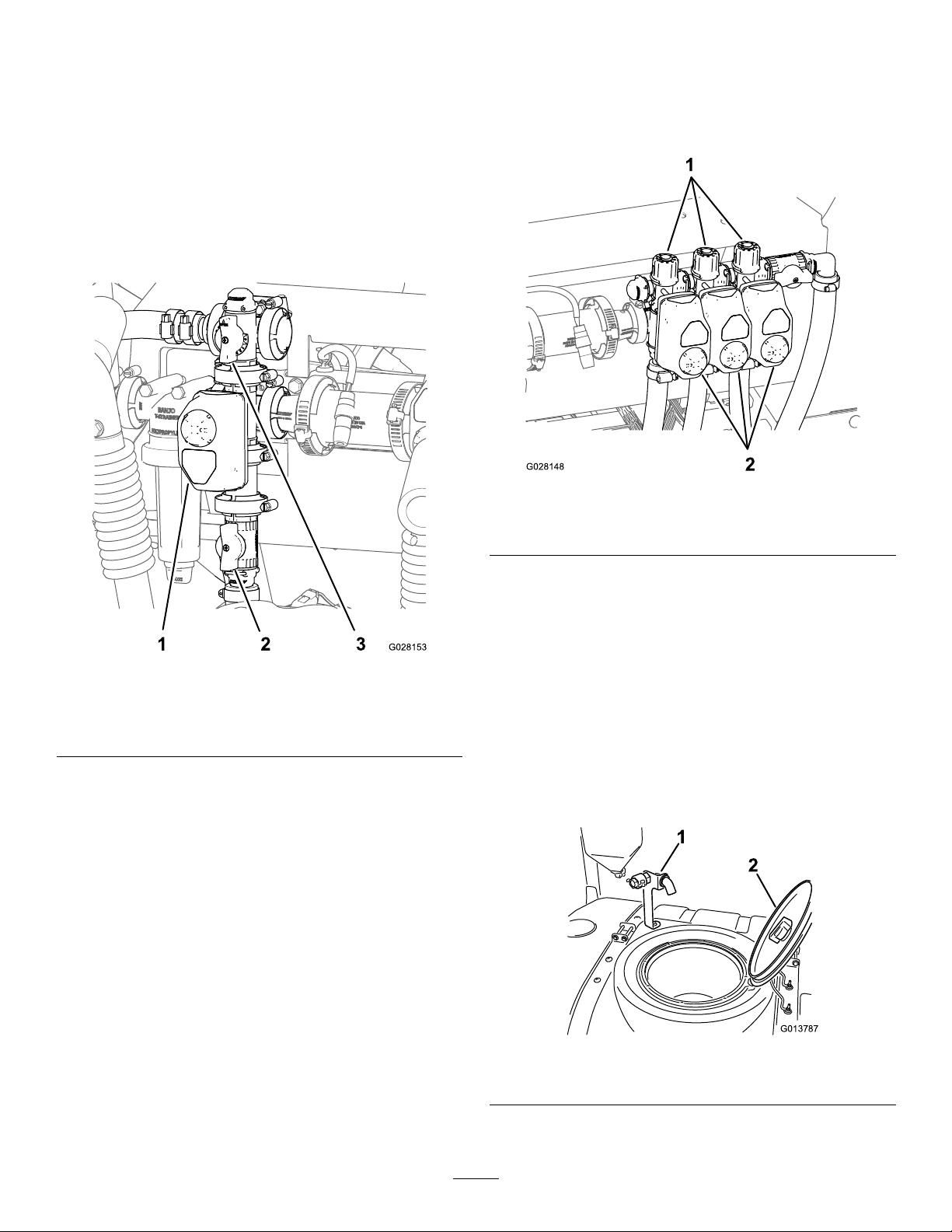

anidle.Theagitationvalveislocatedbehindthetank(Figure

16)

Note:Turningthesectionvalvemanuallycaninterferewith

thefunctionofthefuses.Thefusesshouldbecheckedafter

manuallyrotatingthevalve.

Figure17

1.Knob(sectionbypass

valve)

2.Actuators(sectionvalve)

Figure16

1.Actuator(agitationvalve)3.Handle(agitationbypass)

2.Handle(agitationthrottle

valve)

AgitationBypassValve

Theagitationbypassvalveredirectstheowofuidtothe

sprayersystempumpwhenyouturnofftheagitationfunction

(Figure16).Theagitationbypassvalveislocatedattheabove

oftheagitationvalve.Youcanadjustthebypassvalveto

ensurethatpressureremainsconstantduringagitation;refer

toCalibratingtheAgitationBypassValve(page35).

AgitationThrottleValve

Theagitationthrottlevalveisamanuallyoperatedballvalve

thatcontrolsowtotheagitationnozzlesinthemaintank

(Figure16).Usingthisvalveallowstheusertocontrolthe

sprayersystempressureattheagitationnozzlesofthemain

tankwhenlargerapplicationratesarerequired.

SectionValves

Anti-siphonFillReceptacle

Tothefrontofthetankcoverisahosereceptaclewitha

threadedtting,a90-degreebarbedtting,andashorthose

whichyoucandirecttowardthetankopening.Thisreceptacle

allowsyoutoconnectawaterhosetoitandllthetankwith

waterwithoutcontaminatingthehosewiththechemicalsin

thetank.

Important:Donotlengthenthehosetoallowcontact

withthetankuids.Thedistancefromtheendofthe

hosetotheuppermostwaterlevelshouldbewithinlocal

regulatorylimits.

Figure18

1.Anti-siphonllreceptacle

2.Tankcover

Thesectionvalvescontrolowtothe3boomsections

(Figure17).Ifyoueverneedtomanuallyturnoffasection,

20

TankCover

Thetankcoverislocatedinthecenterofthetopofthetank.

Toopenit,turnofftheengine,thenturnthefronthalfof

thecovertotheleftandswingitopen.Youcanremovethe

strainerinsideforcleaning.Tosealthetank,closethecover

androtatethefronthalftowardtheright.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Baseweight

Weightwithstandardspray

system,empty ,without

operator

Weightwithstandardspray

system,full,withoutoperator

Maximumgrossvehicleweight

(GVW)(onlevelground)

Tankcapacity

Overallwidthwithstandard

spraysystemboomsstoredin

theXposition

1135.6L(300USgallons)

1307kg(2,882lb)

1307kg(2,882lb)

2,499kg(5,510lb)

3,023kg(6,665lb)

189cm(74-3/4inches)

Overalllengthwithstandard

spraysystem

Overalllengthwithstandard

spraysystemtothetopofthe

boomsstoredintheXposition

Overallheightwithstandard

spraysystem

Overallheightwithstandard

spraysystemtothetopofthe

boomsstoredintheXposition

Groundclearance18.4cm(7.25inches)

Wheelbase

391cm(154inches)

442cm(174inches)

146cm(57.5inches)

231cm(91inches)

198cm(78inches)

OptionalEquipment

TheToroCompanyhasoptionalequipmentandaccessories

thatyoucanpurchaseseparatelyandinstallonyoursprayer.

ContactyourAuthorizedServiceDealerforacompletelistof

optionalequipmentthatiscurrentlyavailableforyoursprayer.

21

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

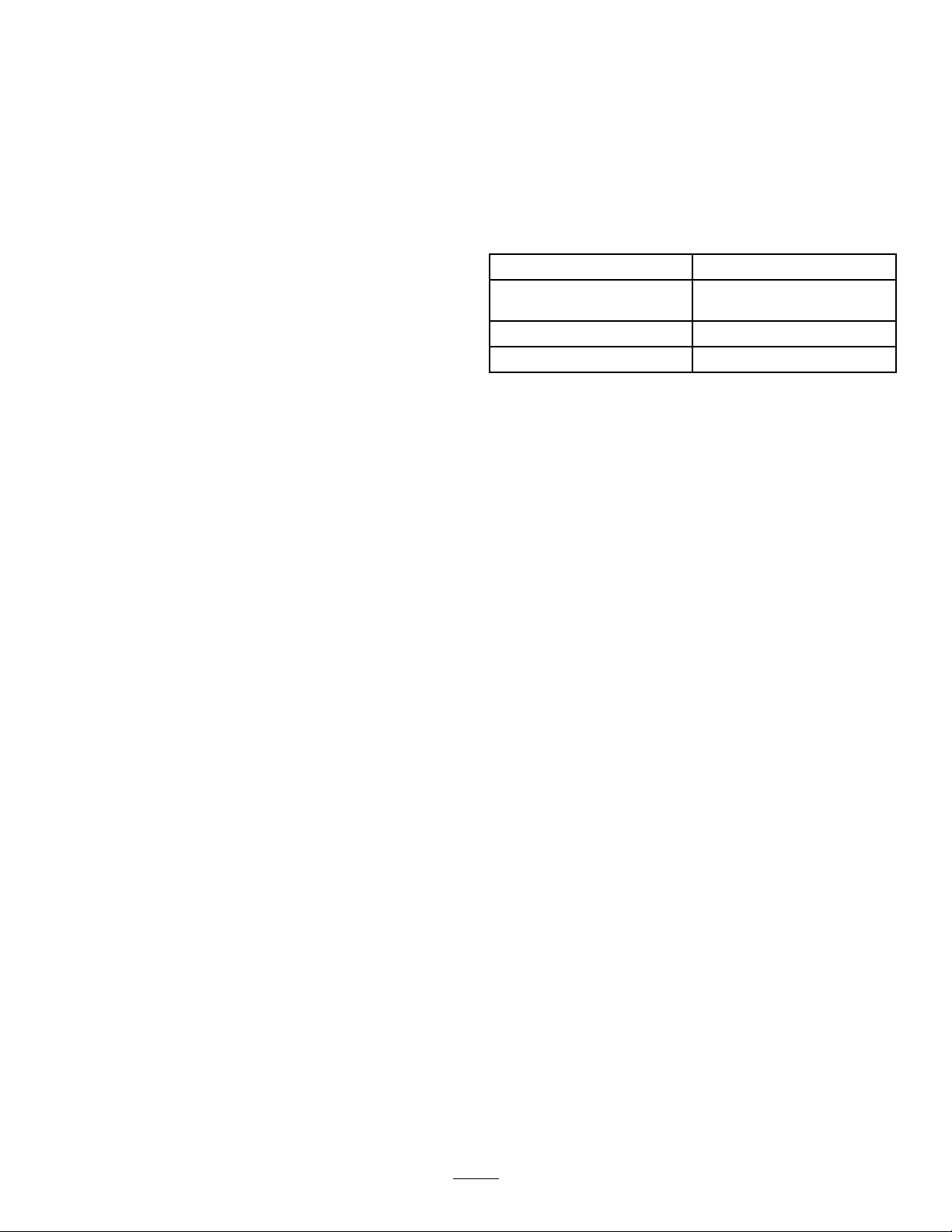

CheckingtheEngineOil

ServiceInterval:BeforeeachuseordailyChecktheengine

oillevelbeforeyoustarttheenginefor

thersttime.

Engineoilspecication:

•Oiltype:APIserviceclassicationSLorhigher.

•Oilviscosity:refertotheengineoilviscositytablebelow .

EngineOilViscosityTable

PerformingPre-Starting Checks

Checkthefollowingitemseachtimeyoubeginusingthe

sprayerfortheday:

•Checkthetirepressure.

Note:Thesetiresaredifferentthancartires;theyrequire

lesspressuretominimizeturfcompactionanddamage.

•Checkalluidlevelsandaddtheappropriateamountof

specieduids,ifanyarefoundtobelow .

•Checkthebrakepedaloperation.

•Checktoseethatthelightsareworking.

•Withtheengineoff,checkforoilleaks,looseparts,and

anyothernoticeablemalfunctions.

Ifanyoftheaboveitemsarenotcorrect,notifyyourmechanic

orcheckwithyoursupervisorbeforetakingthesprayerout

fortheday.Yoursupervisormaywantyoutocheckother

itemsonadailybasis,soaskwhatyourresponsibilitiesare.

PreparingtoDrivetheMachine

Ambienttemperaturerange

Above25C(77F)SAE30,SAE10W-30,or

0Cto25C(32Fto77F)SAE20orSAE10W-30

0Cto20C(32Fto-4F)SAE10WorSAE10W-30

ToroPremiumEngineOilisavailablefromyourdistributor

ineither15W40or10W30viscosity .RefertothePartsCatalog

forpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscool,beforeithasbeenstartedfortheday .Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.

Theengineisshippedwithoilinthecrankcase;however,the

levelofoilmustbecheckedbeforeyourststarttheengine

andafteryouhaverunit.

1.Positionthemachineonalevelsurface.

2.Removethedipstick,locatedunderthepassengerseat,

andwipeitwithacleanrag(Figure19).

Note:Insertthedipstickintothetubeandmakesure

itisseatedfully.Removethedipstickandcheckthe

oillevel.

Oilviscosity

SAE15W-40

CheckingtheTireAirPressure

ServiceInterval:Beforeeachuseordaily

Checkthetireairpressuretoensureproperlevels.Fillthe

tiresto124kPa(18psi).

Note:Also,checkthetiresforwearordamage.

22

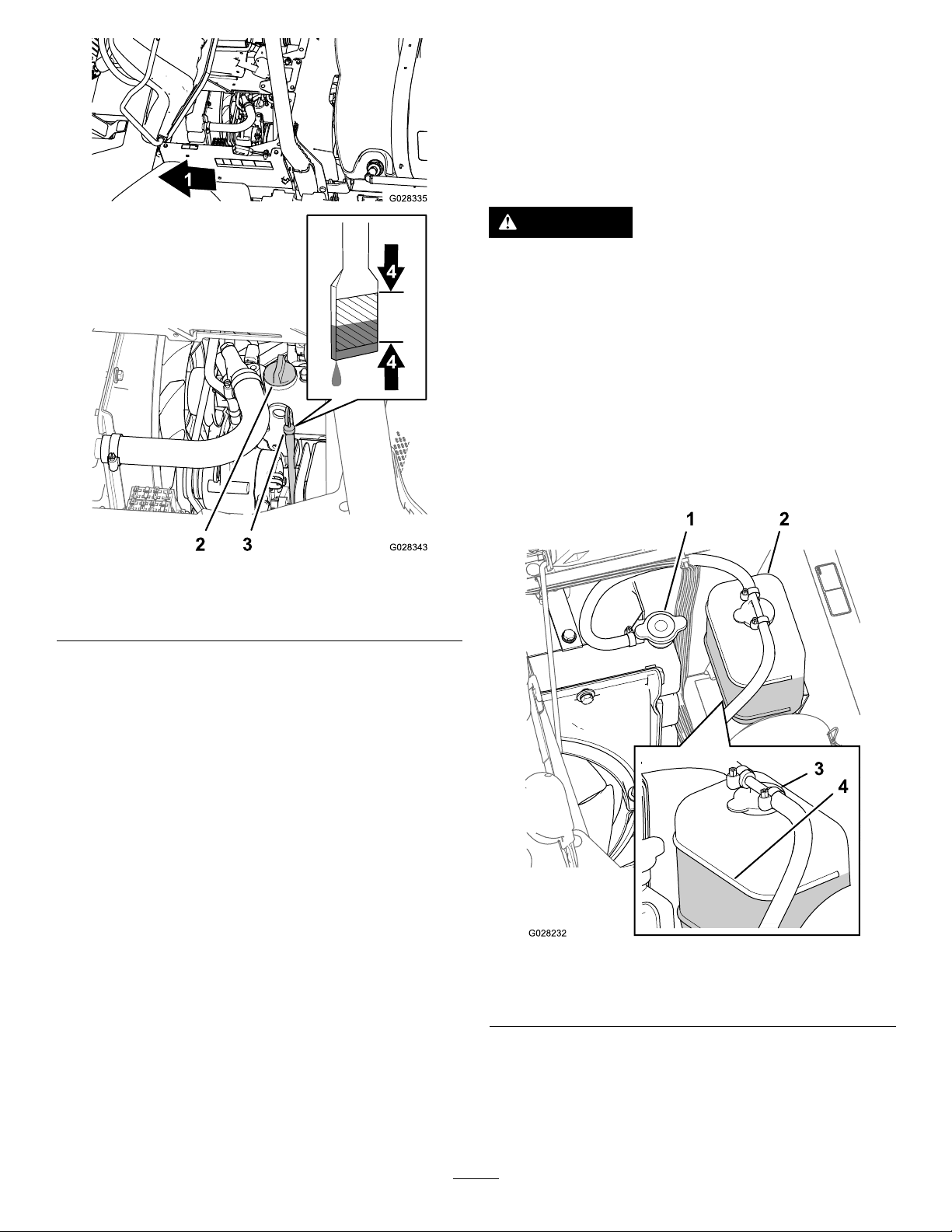

CheckingtheCoolantLevel

ServiceInterval:BeforeeachuseordailyCheckthelevelof

coolantintheradiatorandtheexpansion

tankatthebeginningofeachdaybefore

startingtheengine.

Coolanttype:asolutionof50%softwaterand50%long

lifeethyleneglycolantifreeze

CAUTION

Iftheenginehasbeenrunning,thecoolantmay

behotandpressurized.Ifyouopentheradiator

capwhenthecoolantishot,itcouldsprayoutand

severelyburnyouorbystanders.

Allowtheenginetocoolforatleast15minutes

beforeopeningtheradiatorcap.

1.Positionthesprayeronalevelsurface.

2.Settheparkingbrake,stopthepump,stoptheengine,

andremovethekeyfromthestarterswitch.

3.Carefullyremovetheradiatorcapandtheexpansion

tankcap(Figure20).

Figure19

1.Frontofthemachine

2.Oilllercap

3.Dipstick

3.Iftheoillevelislow,removethellercapfromthe

valvecover(Figure19)andpouroilintothellerneck

untiltheoillevelisuptotheFullmarkonthedipstick.

Note:Addtheoilslowlyandchecktheleveloften

duringthisprocess.Donotoverll.

4.Installthellercap(Figure19).

5.Installthedipstickrmlyinplace(Figure19).

Figure20

1.Radiatorcap3.Expansiontankcap

2.Expansiontank4.Fullline,expansiontank

4.Checkthecoolantlevelintheradiatorandinthe

expansiontank.

Note:Theradiatorshouldbelledtothetopofthe

llerneckandtheexpansiontanklledtotheFull

markonthetank(Figure20).

23

Loading...

Loading...